Page 1

CT6710

HIOKI CT6710A961-01

CT6711

CURRENT PROBE

Instruction Manual

Aug. 2020 Revised edition 1

CT6710A961-01 20-08H

EN

Page 2

HIOKI CT6710A961-01

Page 3

Measurement Procedure

HIOKI CT6710A961-01

Be sure to familiarize yourself with the “Usage Notes”

section (p. 8), each instruction of use, and safety notes

presented at the beginning of each instruction of use.

Inspecting the Device Before Use

Preparing for Measurement

• Provide power to the device.

• Connect the termination unit to your waveform

measuring instrument.

• Execute demagnetization and automatic zero-

adjustment.

Measuring Currents

• Clamp the sensor around a conductor to be

measured.

• Measure a current.

Finishing Measurement

CT6710A961-01

(p. 26)

(p. 28)

(p. 41)

(p. 65)

Page 4

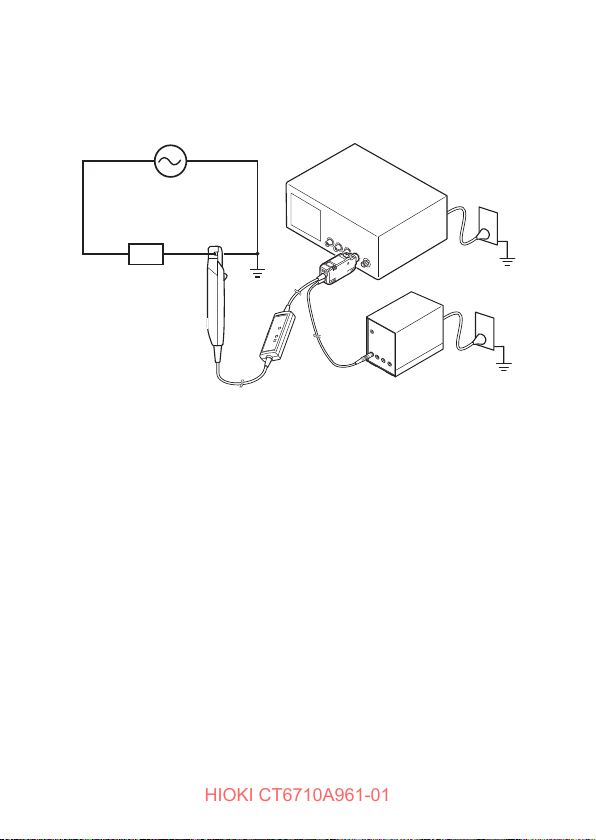

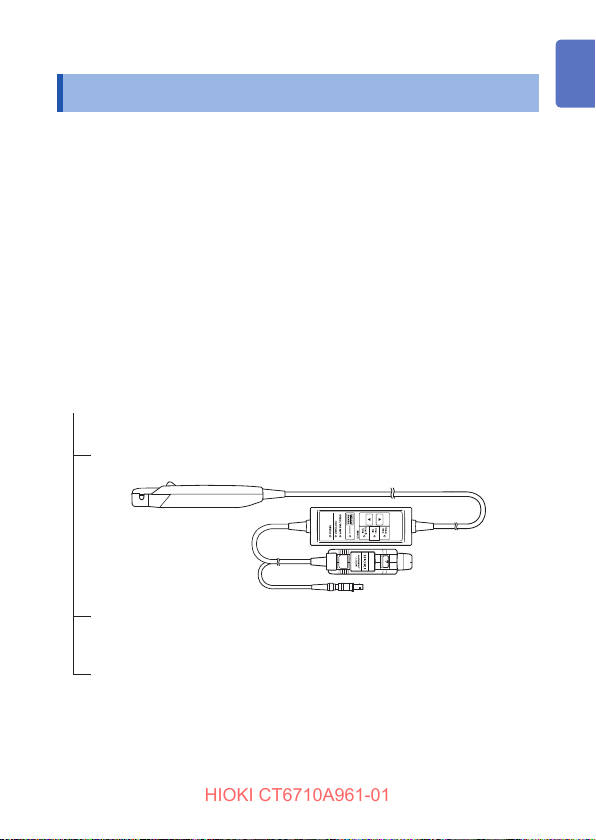

Connection Example

HIOKI CT6710A961-01

Waveform measuring instrument

H

Power source

Load

See “Example of connection to the circuit to be measured”

(p. 49).

L

Model 3269 Power Supply

Page 5

Contents

HIOKI CT6710A961-01

Introduction .....................................................................................1

Notations ......................................................................................... 2

Checking Package Contents ......................................................... 5

Safety Notes .................................................................................... 7

Usage Notes .................................................................................... 8

1 Overview 13

1.1 Product Overview ...................................................13

1.2 Product Features ....................................................14

1.3 Name and Function of Each Part ..........................16

Termination unit .................................................................... 16

Junction box (keys, LEDs) .................................................... 18

Sensor .................................................................................. 20

1.4 Specications of Lighting Up / Blinking LEDs ..... 22

2 Current Measurement 25

2.1 Inspecting the Device Before Use ......................... 26

2.2 Preparing for Measurement ................................... 28

Providing power to the CT6710/CT6711 ............................... 29

Executing demagnetization and automatic

zero-adjustment .................................................................... 33

2.3 Measuring Currents ................................................ 41

How to measure a current .................................................... 50

To measure a low current ..................................................... 58

To measure a current accurately .......................................... 60

When the device has entered protection mode .................... 62

2.4 Finishing Measurement .......................................... 65

1

2

3

4

Index

i

Page 6

Contents

HIOKI CT6710A961-01

3 Specications 69

3.1 General Specications ........................................... 69

3.2 Specications of Input, Output, and

Measurement ........................................................... 71

Basic specications .............................................................. 71

Specications of accuracy .................................................... 73

3.3 Specications of Functionality .............................. 75

3.4 Typical Characteristics ...........................................77

Frequency characteristics ..................................................... 77

Frequency derating curve ..................................................... 78

Input impedance ................................................................... 80

Consumption current ............................................................ 81

Inuence of common-mode voltage ...................................... 82

4 Maintenance and Service 83

4.1 Troubleshooting ......................................................84

Before sending back your device for repair .......................... 85

4.2 Errors ....................................................................... 88

Types of errors ...................................................................... 89

4.3 Cleaning ................................................................... 96

4.4 Disposal ................................................................... 97

Index 99

Warranty

ii

Page 7

Introduction

HIOKI CT6710A961-01

Introduction

Thank you for choosing the Hioki CT6710, CT6710 Current

Probe. To ensure your ability to get the most out of this

device over the long term, please read this manual carefully

and keep it available for future reference.

Each model oers a dierent frequency band listed below:

Model CT6710: DC to 50 MHz

Model CT6711: DC to 120 MHz

The following manuals are provided along with these

models. Refer to manuals relevant to your purpose.

• Current Sensor Operating Precautions

Information on the device for safe operation

• Instruction Manual (this document)

Basic instructions and specications of the device

Please review the separate “Current Sensor Operating

Precautions” before using the device.

Target audience

This manual has been written for use by individuals who use

the product in question or who teach others to do so.

It is assumed that the reader possesses basic electrical

knowledge (equivalent to that of someone who graduated

from the electrical program at a technical high school).

1

Page 8

Notations

HIOKI CT6710A961-01

Notations

Safety notations

This manual classies seriousness of risks and hazard

levels as described below.

Indicates an imminently hazardous situation

DANGER

WARNING

CAUTION

that, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

that, if not avoided, could result in minor or

moderate injury.

NOTICE

IMPORTANT

NOTE

Indicates a high-voltage hazard.

Failure to verify safety or improper handling of the device

could lead to electric shock, burn injury, or death.

2

Indicates potential risks of damage to the

supported product (or to other property).

Indicates information or content that is

particularly important from the standpoint of

operating or maintaining the device.

Indicates useful advice concerning device

performance and operation.

Page 9

Indicates an action that must not be performed.

HIOKI CT6710A961-01

Indicates an action that must be performed.

Symbols shown on the device

Indicates the presence of a potential hazard. For more

information about locations where this symbol appears

on device components, see the “Usage Notes” section

(p. 8), warning messages listed at the beginning of

operating instructions, and the accompanying document

entitled “Current Sensor Operating Precautions.”

Indicates that the device can only be used at a location

on an insulated wire with sucient insulation for the

circuit voltage.

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Indicates that the product complies with standards

imposed by EU directives.

Notations

3

Page 10

Notations

HIOKI CT6710A961-01

Others

*

Indicates additional information is described below.

Bold

Indicates the names of the control keys.

Accuracy

Hioki denes tolerances for measured values in terms of

percentage of reading, as indicated below.

Reading (Displayed value)

Indicates the value the measuring instrument

rdg.

displays. Tolerances for reading errors are

expressed in percent of reading (% of reading,

% rdg).

4

Page 11

Checking Package Contents

HIOKI CT6710A961-01

Checking Package Contents

When you receive the device, inspect it to ensure that

no damage occurred during shipment. Pay particular

attention to keys and connectors. If you nd any damage

or discover that the device does not perform as indicated

in its specications, please contact your authorized Hioki

distributor or reseller.

Check that the package contents are correct.

The carrying case contains the current probe, Instruction

Manual, and Current Sensor Operating Precautions.

Carrying case

(Accessory)

Model CT6710/CT6711 Current Probe

Instruction Manual

(Accessory)

Current Sensor Operating Precautions

(0990A901)

(Accessory)

5

Page 12

Checking Package Contents

HIOKI CT6710A961-01

Option

The option below is available for the device. To order an

option, please contact your authorized Hioki distributor or

reseller.

Options are subject to change. Check Hioki’s website for the

latest information.

Model 3269 Power Supply

The 3269 Power Supply can provide the power to up to

two probes of the CT6710/CT6711.

(The 3272 Power Supply cannot be used as a power

supplying unit for the CT6710/CT6711.)

Precautions for transportation

• Store packaging materials for future use. You will need the

packaging materials when shipping the device.

• Transport the device in its carrying case.

6

Page 13

Safety Notes

HIOKI CT6710A961-01

Safety Notes

The device has been designed in accordance with the IEC

61010 safety standard, and its safety has been veried by

means of testing prior to shipment. However, failure to follow

the information in this manual could render safety-related

functionality provided by the device ineective.

Please review the safety information below before using the

device.

DANGER

Read this manual carefully and ensure you

understand its contents before using the

device.

Improper use of the device could result in serious bodily

injury or damage to the device.

WARNING

If using an electrical measuring instrument

for the rst time, seek instruction from an

individual with electrical measurement

experience rst.

Failure to do so may lead to electric shock, overheating,

re, arcing due to a short-circuit, or other hazards.

7

Page 14

Usage Notes

HIOKI CT6710A961-01

Usage Notes

Be sure to follow the precautions listed below in order to use

the device safely and in a manner that allows it to function

eectively.

Use of the device should conform not only to its

specications, but also to the specications of all

accessories, options, and other equipment in use.

DANGER

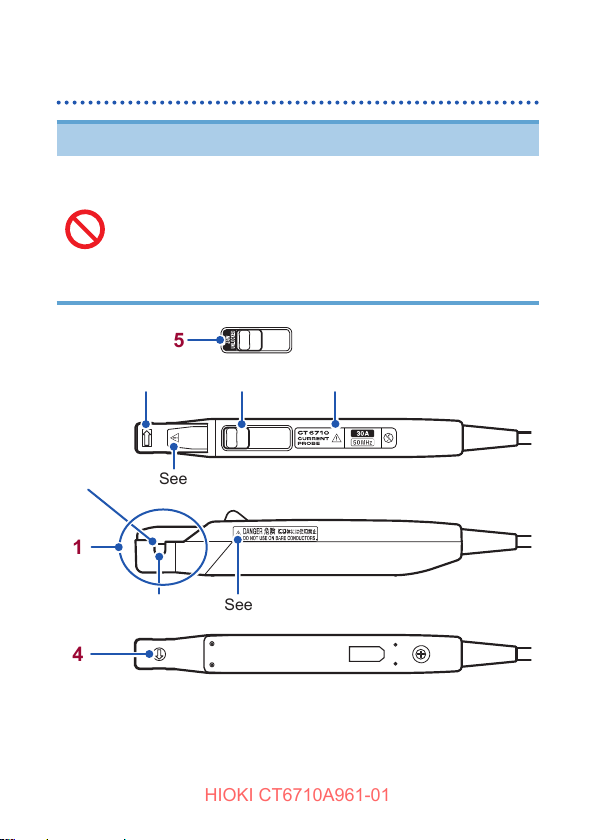

Do not use the device for measuring bare

conductors.

Take measurements at a location on an

insulated wire with sucient insulation for the

circuit voltage.

Doing so may result in electric shock or a short-circuit.

8

Page 15

Usage Notes

HIOKI CT6710A961-01

DANGER

Do not remove any covers of the sensor,

junction box, and termination unit.

The internal components of the device carry high

voltages and may become very hot during operation.

Touching them could cause electric shock or burns.

Do not connect the device to the primary side

of a distribution panel.

If a short-circuit occurs on the primary side, an

unrestricted current ow can damage the device

and facilities, resulting in serious bodily injury. Even

if a short-circuit occurs on the secondary side of the

distribution panel, the panel will interrupt the short-

circuit current.

Do not use the device in powerful magnetic

elds.

Doing so could cause the sensor to become abnormally

hot, resulting in bodily injury, damage to the device, or

re.

Follow all operating precautions for a

waveform measuring instrument or any other

measuring instruments to which this device is

connected.

Failure to observe this could cause serious bodily injury

or damage to these instruments.

9

Page 16

Usage Notes

HIOKI CT6710A961-01

Do not use the device to measure circuits that

Do not install the instrument in locations such

WARNING

exceed the ratings or specications of the

device.

Doing so could cause damage to the device or

overheating, resulting in bodily injury.

as the following:

• In locations where it would be subject to direct

sunlight

• In locations where it would be subject to high

temperatures

• In locations where it would be exposed to corrosive

or explosive gases

• In locations where it would be exposed to water, oil,

chemicals, or solvents

• In locations where it would be exposed to high

humidity or condensation

• In locations where it would be exposed to powerful

electromagnetic radiation

• Close to objects carrying an electric charge

• In locations with an excessive amount of dust

• Close to inductive heating devices (high-frequency

inductive heating devices, IH cooktops, etc.)

• In locations characterized by a large amount of

mechanical vibration

• Close to HF power supply units

Doing so could cause damage to the device or cause it

to malfucntion, resulting in bodily injury.

10

Page 17

Usage Notes

HIOKI CT6710A961-01

WARNING

Ensure that the insulation on the cords is

undamaged and that no bare conductors are

improperly exposed before using the device.

Any damage to the cords leads to electric shock.

Contact your authorized Hioki distributor or reseller for

repair.

CAUTION

Do not place the device on an unstable stand

or angled surface.

Doing so could cause the device to fall or overturn,

resulting in bodily injury or damage to the device.

Properly connect the device to a circuit to

be measured and your waveform measuring

instrument.

Improperly connecting them could cause electric shock

or damage to the circuit, device, or your instrument.

11

Page 18

Usage Notes

HIOKI CT6710A961-01

Do not store or use the device in locations

Do not apply force in the directions shown in

Do not

apply force.

Keep the upper jaw locked in place when the

NOTICE

subject to abrupt temperature changes.

Doing so could damage the sensor heads.

the gure below while the upper jaw is locked

in place.

Opening lever position

when the upper jaw is

locked in place

Doing so may damage the retracting/extending

mechanism.

device is not in use.

Leaving the upper jaw unlocked will cause dust or dirt to

settle on the facing core surfaces, resulting in damage

to the device.

12

Page 19

1

HIOKI CT6710A961-01

Overview

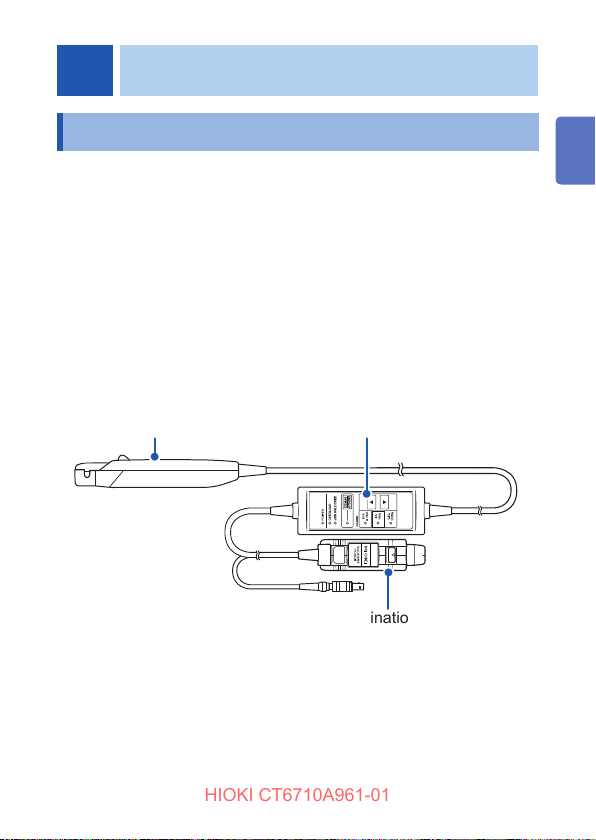

1.1 Product Overview

Model CT6710/CT6711 is a clamp-on current probe that

features high current-detection sensitivity and broad

frequency band. The probe uses three current ranges to

detect current waveforms from 1 mA to 50 A.

You can directly connect the termination unit to a BNC input

terminal of your waveform measuring instrument such as

an oscilloscope and recorder, and then clamp the sensor

around a conductor to be measured to observe current

waveforms easily.

Sensor (p. 20)

Junction box (p. 18)

Termination unit (p. 16)

1

13

Page 20

Product Features

HIOKI CT6710A961-01

1.2 Product Features

Clamp-on sensor heads (p. 21)

The clamp-on sensor heads allow current measurement

without the need to make physical contact with a

conductor to be measured or to disconnect it. You can

observe current waveforms while maintaining the ow of

electric current.

Sliding jaw retracting/extending mechanism

(p. 21)

This feature lets you easily retract, extend, and lock the

upper jaw in place to clamp the sensor around a conductor

to be measured.

Easy-to-connect output terminal (p. 17, p. 38)

Insert the output terminal into a BNC input terminal on

your waveform measuring instrument to connect the

termination unit.

Warning LED lights (p. 18)

The warning LEDs alert you to an overload (indicating

that an input current value exceeds the rated current of

the device) or jaw-unlocked condition (indicating that the

upper jaw has not been locked in place).

14

Page 21

Product Features

HIOKI CT6710A961-01

Three current measurement ranges (p. 53)

You can choose from the three ranges according to the

magnitude of the current to be measured. This feature lets

you observe a wide range of currents, from 1 mA to 50 A.

Broad frequency band (p. 71)

Model CT6710: DC to 50 MHz

Model CT6711: DC to 120 MHz

Demagnetizing and automatic zero-adjustment

functions (p. 33)

You can use a single key to demagnetize the magnetic

cores and correct variations in oset voltage, both of

which are required before measuring.

Protection mode (p. 62)

The device automatically enters protection mode to

prevent damaging itself when overheating.

1

15

Page 22

Name and Function of Each Part

HIOKI CT6710A961-01

1.3 Name and Function of Each Part

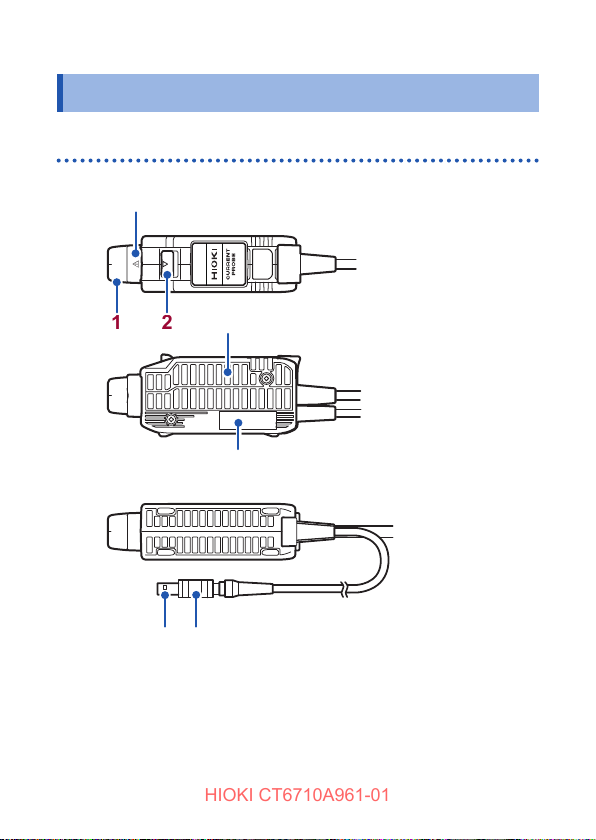

Termination unit

See p. 34 and p. 35.

Top view

1 2

5

16

3

4

6

Page 23

Name and Function of Each Part

HIOKI CT6710A961-01

Output terminal

1

The device converts a captured current waveform into a

voltage waveform by multiplying a particular rate according

to a specied current range and outputs the voltage

waveform from this terminal. Connect this terminal to a BNC

input terminal of your waveform measuring instrument.

Unlock lever

2

To disconnect the output terminal, pull on the termination unit

while simultaneously pulling this lever.

Vents

3

The unit has the vents on the sides and bottom. Do not clog

them.

Serial number

4

The serial number consists of nine digits. The rst two digits

indicate the year of manufacture, while the second two

digits indicate the month of manufacture. Do not remove this

sticker as the number is important.

Power plug

5

Power is provided to the CT6710/CT6711 through this plug.

Connect this plug with the 3269 Power Supply.

Shell

6

Pull on the power plug while simultaneously pulling this shell

to disconnect the plug.

1

You can easily connect and disconnect

the termination unit with two ngers

even when multiple termination units

are connected to a waveform measuring

instrument.

17

Page 24

Name and Function of Each Part

HIOKI CT6710A961-01

Junction box (keys, LEDs)

4

5

6

7

1

8

DEMAG / AUTO ZERO key

1

Hold down

(about 1 s)

Press momentarily

(less than 0.5 s)

(Higher range) key (p. 53)

2

Switch over to a next higher current range.

(Does not switch from the 30 A range to the 0.5 A range)

(Lower range) key (p. 53)

3

Switch over to a next lower current range.

(Does not switch from the 0.5 A range to the 30 A range)

18

2

3

Top view

Performs demagnetization followed by

automatic zero-adjustment. (p. 33)

Performs automatic zero-adjustment

alone. (p. 40)

Page 25

Name and Function of Each Part

HIOKI CT6710A961-01

POWER LED (green light)

4

• Lights up when the power is on (p. 31). (Normal operation)

• Rapidly blinks when a checksum error has occurred (p. 95).

OVERLOAD LED (red light)

5

• Flashes three times when demagnetizing or automatic zeroadjustment cannot be performed (p. 91).

• Rapidly blinks when an overload state is detected (p. 90),

the device has entered protection mode (p. 62), or a

checksum error has occurred (p. 95).

JAW UNLOCKED LED (red light)

6

• Lights up when the upper jaw is unlocked.

• Flashes three times when demagnetizing or automatic zero-

adjustment cannot be performed (p. 91).

• Rapidly blinks when the device has entered protection mode

(p. 62) or a checksum error has occurred (p. 95).

DEMAG / AUTO ZERO LED (orange light)

7

• Slowly blinks when demagnetization or automatic zeroadjustment has not yet been performed (p. 33).

• Lights up when demagnetization and automatic zeroadjustment are

• Goes out when demagnetization and automatic zeroadjustment have been completed (p. 39).

• Flashes three times when demagnetization and automatic

zero-adjustment cannot be performed (p. 91).

• Rapidly blinks when the device has entered protection mode

(p. 62) or a checksum error has occurred (p. 95).

RANGE LEDs (green lights)

8

• Lights up when its current range is chosen (p. 53). (Normal

operation)

• Blinks rapidly when the device has entered protection mode

(p. 62) or a checksum error has occurred (p. 95).

in execution

(p. 39).

1

19

Page 26

Name and Function of Each Part

HIOKI CT6710A961-01

Sensor

NOTICE

Do not store or use the device in locations

subject to abrupt temperature changes.

Do not apply force or mechanical shock to the

device.

Do not subject the device to static electricity.

Doing so could damage the device.

4

2

See p. 41.

1

3

4

20

5

6

See p. 41.

When the upper jaw is unlocked

See p. 41.

Top view

Page 27

Name and Function of Each Part

HIOKI CT6710A961-01

Jaws

1

Clamp this part around a conductor to be measured by

operating the opening lever, which allows the upper jaw to

slide (retract/extend).

Sensor aperture

2

A conductor to be measured must pass through this

aperture.

Sensor heads

3

The sensor heads, located inside the jaws, detects currents.

Current direction indicator

4

Clamp the sensor around the conductor such that the

direction this arrow indicates matches the current direction of

a conductor to be measured.

JAW UNLOCKED indicator

5

If this indicator appears, the upper jaw is not locked in place.

Opening lever

6

To retract and extend the upper jaw, always operate this

lever. This lever allows you to retract and lock the upper jaw

in place.

1

21

Page 28

Specications of Lighting Up / Blinking LEDs

HIOKI CT6710A961-01

1.4 Specications of Lighting Up /

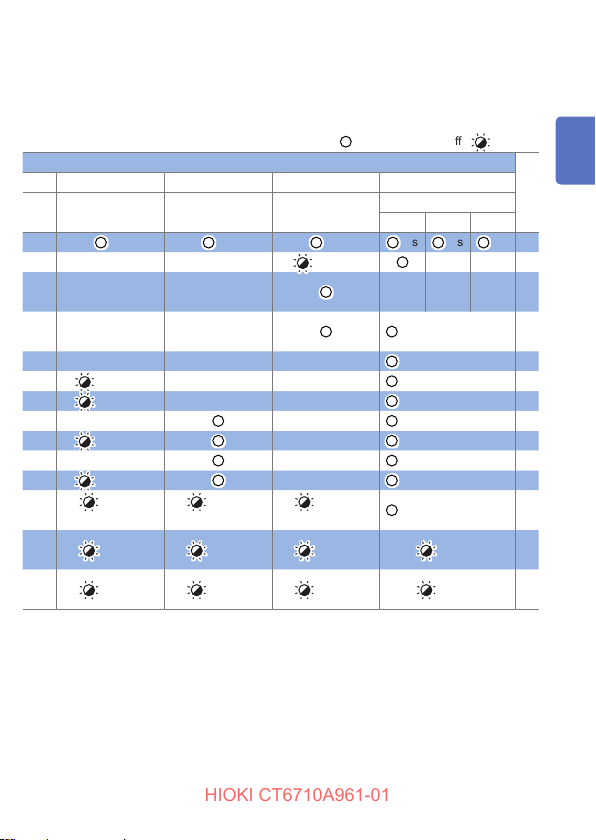

Blinking LEDs

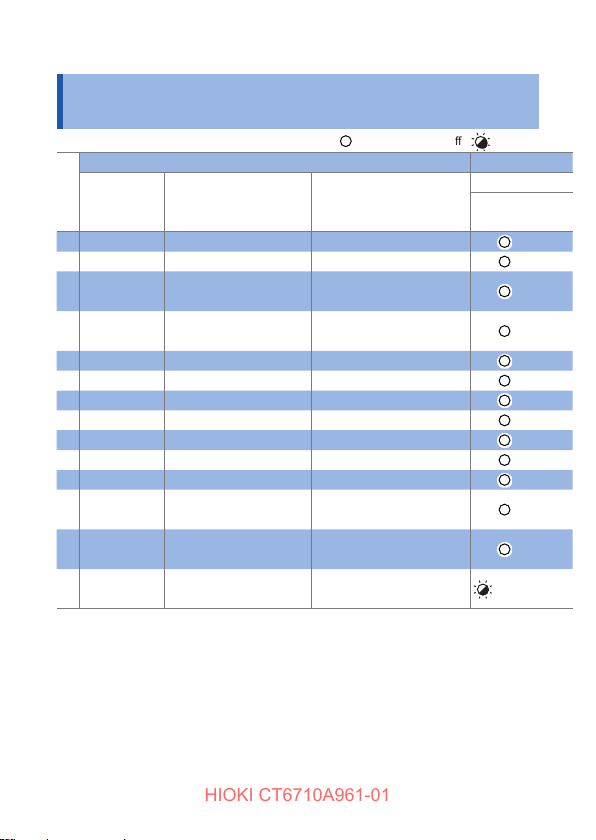

: Lighting up : O : Blinking

Device state LED

Automatic

zero-

adjustment

1 − − (On start-up)

2 Not performed Not detected (Initial state)

In execution

3

(Incl. demag.)

In execution

4

(excl. demag.)

5 Completed Not detected (Before use, normal state )

6 Completed Exceeds prescribed level −

7 Not performed Exceeds prescribed level −

8 Completed Not detected Upper jaw unlocked

9 Completed Exceeds prescribed level Upper jaw unlocked

10 Not performed Not detected Upper jaw unlocked

11 Not performed Exceeds prescribed level Upper jaw unlocked

12 − *1 *1

13 − −

14 − −

Overload Others

− (No range keys available)

− (No range keys available)

Excess heat detected in

junction box*

ROM checksum error at

power-on (CPU failure)

2

*1. When the DEMAG / AUTO ZERO key is pressed under any one of the

following conditions (p. 91):

• The upper jaw is unlocked.

• An overload has been detected whether or not the upper jaw is locked

in place.

• A current exceeding 0.5 A rms has been detected whether or not the

upper jaw is locked in place.

*2. Press any key to restore the device. The ranges cannot be switched until

the device is restored.

See “When the device has entered protection mode” (p. 62).

Green

POWER

Rapidly

22

Page 29

Specications of Lighting Up / Blinking LEDs

HIOKI CT6710A961-01

: Lighting up : O : Blinking

Red Red Orange Green

OVERLOAD JAW UNLOCKED

1 s 1 s 1 s 1 s 1 s 1 s 1

LED

DEMAG / AUTO

ZERO

Slowly*

30 A 5 A 0.5 A

4

RANGE

3

Rapidly*

3

Rapidly*

3

Rapidly*

3

Rapidly*

Rapidly

ashes 3 times

Rapidly

Rapidly

*3. Blinks at 250-ms intervals. (duty ratio: 50%)

*4. After the device is turned on and then all LEDs light up for 1 second, the

DEMAG / AUTO ZERO LED blinks, which indicates that demagnetization

or automatic zero-adjustment has not yet been performed.

*5. Even when demagnetization or automatic zero-adjustment has not yet

been performed, the device that has detected an overload and that with

the upper jaw unlocked leave the DEMAG / AUTO ZERO LED unlit.

Rapidly

ashes 3 times

Rapidly

Rapidly

5

*

5

*

Rapidly

ashes 3 times

Rapidly

Rapidly

Specied range only 4

Specied range only 5

Specied range only 6

Specied range only 7

Specied range only 8

Specied range only 9

Specied range only 10

Specied range only 11

Specied range only 12

Rapidly 13

Rapidly 14

1

2

3

23

Page 30

Specications of Lighting Up / Blinking LEDs

HIOKI CT6710A961-01

24

Page 31

Current Measurement

HIOKI CT6710A961-01

2

Do not clog the vents on the sides and bottom

of the termination unit (p. 16).

Doing so could cause internal overheating of the

termination unit, resulting in bodily injury, re, or

damage to the device.

Do not pile the junction box (p. 18) on

another.

Do not cover the junction box with a cloth.

Doing so could cause internal overheating of the

junction box, resulting in bodily injury, re, or damage to

the device.

IMPORTANT

Do not drop the device.

Do not subject the device to an impact.

Do not place any foreign object between the facing

core surfaces of the sensor heads.

Do not scratch the facing core surfaces between the

sensor heads.

Do not touch the facing core surfaces.

Do not insert any foreign object into the gap around

the sensor heads.

Doing so could adversely aect the measurement

accuracy and the retracting/extending mechanism.

WARNING

2

25

Page 32

Inspecting the Device Before Use

HIOKI CT6710A961-01

2.1 Inspecting the Device Before Use

Check the device for any damage that may have occurred

during storage or shipping, and verify proper operation

before use. If you nd any damage or failure, contact your

authorized Hioki distributor or reseller.

See “Before sending back your device for repair” (p. 85).

Items to prepare

• Model CT6710/CT6711 Current Probe

• Model 3269 Power Supply (available as an option)

• Waveform measuring instrument (such as oscilloscope

and recorder)

Connecting the CT6710/CT6711 to a Hioki Memory HiCorder

with a power supply module for current probes (option)

installed allows the CT6710/CT6711 to operate without the

3269 Power Supply. For more information, contact your

authorized Hioki distributor or reseller.

IMPORTANT

Use a waveform measuring instrument (such as

oscilloscope and recorder) with an input impedance of

1 MΩ or more.

The output of the device is internally terminated.

Accurate measurement is not possible with waveform

measuring instruments with an input resistance of

50

.

Ω

26

Page 33

Inspecting the Device Before Use

HIOKI CT6710A961-01

Inspecting appearance and functionality of

the device and condition of conductors to be

measured

Are the sensor, junction

box, and termination

unit damaged?

No

Yes

ZHave the device repaired.

Damage can cause

electric shock.

2

Is the insulation of each

cord damaged?

No

Provide power to the device. (p. 29)

Do the seven LEDs

light up for about one

second after the device

is turned on?

Yes

Is the insulation of

each conductor to be

measured damaged?

No

The inspection is

completed.

Yes

O or

blinking

Yes

ZHave the device repaired.

Damage can cause

electric shock.

ZHave the device repaired.

The device is damaged.

Do not clamp the sensor

around any damaged

conductor.

27

Page 34

Preparing for Measurement

HIOKI CT6710A961-01

2.2 Preparing for Measurement

WARNING

Turn o all equipment before connecting the

device.

Failure to do so can cause electric shock or a short-

circuit.

CAUTION

Before connecting the power cord to the inlet

on the rear panel of the 3269 Power Supply,

verify that the supply voltage you plan to use

falls within the supply voltage range noted on

the 3269.

Supplying a voltage that falls outside the specied

range to the 3269 could damage the CT6710/CT6711 or

the 3269, causing bodily injury.

NOTICE

Always operate the opening lever to retract,

extend, and lock the upper jaw.

If you retract, extend, or lock the upper jaw directly by

hand, the sensor may be damaged.

28

Page 35

Preparing for Measurement

HIOKI CT6710A961-01

Providing power to the CT6710/CT6711

IMPORTANT

Do not allow the total consumption current of the

current sensors connected with the 3269 Power

Supply to exceed the rated output current of the 3269.

The consumption current of the CT6710/CT6711

depends on current under measurement. One unit

of the 3269 can simultaneously provide power to up

to two current probes (the CT6710/CT6711) each of

which measures a current with the maximum rated

current value. For information about the consumption

current, see “Consumption current” (p. 81) in “Typical

Characteristics.”

The 3272 Power Supply, which does not have sucient

current capacity, cannot activate the CT6710/CT6711.

2

29

Page 36

Preparing for Measurement

HIOKI CT6710A961-01

How to provide the power to the CT6710/CT6711

Ensure that the POWER switch of the 3269

1

Power Supply is set to OFF.

Connect the power cord to the power inlet on the

2

back of the 3269 Power Supply.

Slide the opening lever

3

of the sensor toward the

lower jaw until the JAW

UNLOCKED indicator is

hidden.

The upper jaw will be locked

in place.

Do not clamp the sensor around any

conductor.

Connect the power plug

4

of the CT6710/CT6711 to

the power receptacle of

the 3269 Power Supply.

30

Power receptacle

Page 37

Preparing for Measurement

HIOKI CT6710A961-01

Set the POWER switch of the 3269 Power Supply

5

to the ON position.

The LEDs of the CT6710/CT6711 and the 3269 will light up

or blink as follows:

Model 3269

The POWER indicator will light up.

Model CT6710/CT6711

All LEDs will light up for 1 s, and then the CT6710/

CT6711 will operate as follows:

• The POWER LED will light up.

• The DEMAG / AUTO ZERO LED will blink slowly.

Green will light up

Orange will blink slowly

Keep the upper jaw locked in place while the

POWER LED lights up.

2

31

Page 38

Preparing for Measurement

HIOKI CT6710A961-01

Wait for 30 minutes or more.

6

Wait at least 30 minutes after starting to supply power

to the CT6710/CT6711 to accurately measure a current

before executing demagnetization and automatic zeroadjustment. See “Executing demagnetization and automatic

zero-adjustment” (p. 33).

Do not execute demagnetization and

automatic zero-adjustment or measure current

immediately after starting to supply power to

the CT6710/CT6711.

An oset voltage may increase due to the heat

generation of the CT6710/CT6711.

32

Page 39

Preparing for Measurement

HIOKI CT6710A961-01

Executing demagnetization and automatic zeroadjustment

WARNING

Do not hold down the DEMAG / AUTO ZERO

key when the sensor is clamped around a

conductor under measurement.

Conductor

under measurement

Do not hold down the key.

Doing so will start magnetization, causing bodily injury

or damage to the circuit under measurement.

2

33

Page 40

Preparing for Measurement

HIOKI CT6710A961-01

Do not subject the connection to force.

Do not rotate the output terminal while the

termination unit is connected with a waveform

measuring instrument.

Doing so could damage the output terminal on the

termination unit or the BNC input terminal on the

waveform measuring instrument.

Do not short-circuit the output terminal

Do not apply voltage to the output terminal.

Doing so could damage the device.

NOTICE

34

Page 41

Preparing for Measurement

HIOKI CT6710A961-01

NOTICE

Arrange the termination unit and a BNC

input terminal of your waveform measuring

instrument in a straight line when connecting

the termination unit.

Failure to do so may damage the output terminal.

When connecting the output terminal to an

input terminal that is not a BNC terminal

through a conversion plug, make sure that the

polarity is as follows:

BNC center contact: Positive

Outer conductor: Ground potential

(or negative)

Failure to do so may damage the device and your

waveform measuring instrument.

2

35

Page 42

Preparing for Measurement

HIOKI CT6710A961-01

What is demagnetization?

The magnetic core can be magnetized, which results

from turning power on and o, inputting an excessively

large current, or other factors. Executing demagnetization

eliminates magnetic charges.

What is automatic zero-adjustment?

Automatic zero-adjustment corrects variations in the oset

voltage caused by factors such as the device-specic

oset voltage and variations in temperature.

When the DEMAG / AUTO ZERO LED blinks slowly,

execute demagnetization and automatic zero-adjustment.

The DEMAG / AUTO ZERO LED blinks slowly in the

following states:

• The power supply to the CT6710/CT6711 just started.

• A current exceeding the rated current was inputted to

the device, but this condition was resolved. (The current

value fell below the rated value or stopped. Otherwise,

the sensor was removed from the conductor under

measurement.)

During demagnetization (with the DEMAG / AUTO ZERO

LED lit), the device outputs a demagnetization waveform

(which attenuates over time) from its output terminal.

This waveform, which appears on a waveform measuring

instrument, may be asymmetric along the horizontal axis;

however, this does not represent a device malfunction.

36

Page 43

Preparing for Measurement

HIOKI CT6710A961-01

How to execute demagnetizing and automatic

zero-adjustment

IMPORTANT

Do not move the sensor during demagnetization or

automatic zero-adjustment.

Disturbance (such as external magnetic elds and

temperature changes) may prevent demagnetization

or automatic zero-adjustment from being completed

normally.

Slide the opening lever

1

of the sensor toward the

lower jaw until the JAW

UNLOCKED indicator is

hidden.

The upper jaw will be locked

in place.

The JAW UNLOCKED LED

will go out.

2

Set the input coupling of your waveform

2

measuring instrument to GND, then adjust the

zero position of the display.

Do not clamp the sensor around any

conductor.

37

Page 44

Preparing for Measurement

HIOKI CT6710A961-01

Set the input coupling of the waveform

3

measuring instrument to DC.

Connect the output

4

terminal of the

termination unit to a

BNC input terminal of

the waveform measuring

instrument.

• Insert the output terminal

straight.

• Insert the output terminal

until it clicks so that it is

securely locked in position.

The connection can be established with the unlock lever of

the termination unit pointing up, regardless of whether the

pair of the locking studs in the BNC input terminal on the

waveform measuring instrument is xed in the horizontal or

vertical orientation.

38

Vertical Horizontal

Page 45

Hold down the DEMAG /

HIOKI CT6710A961-01

5

AUTO ZERO key on the

junction box for about 1

second.

Preparing for Measurement

The DEMAG / AUTO ZERO LED will light up.

Demagnetization and automatic zero-adjustment will

start.

After the completion, the DEMAG / AUTO ZERO LED

will go out.

Green will light up

Orange will light up

Green will light up

Orange will go out

Hold down

2

39

Page 46

Preparing for Measurement

HIOKI CT6710A961-01

If the DEMAG / AUTO ZERO LED ashes three times, the

device cannot perform demagnetization or automatic zeroadjustment.

ZImplement the remedy described on the following page.

“Demagnetizing / automatic zero-adjustment

unavailable” (p. 92)

To halt demagnetization or automatic zero-adjustment

on the middle of its execution

ZPull the unlock lever toward you to unlock the upper

jaw.

When you halt demagnetization or automatic zeroadjustment, re-execute demagnetization and automatic

zero-adjustment before taking a measurement.

To execute automatic zero-adjustment alone (without

executing demagnetization)

ZPress the DEMAG / AUTO ZERO key momentarily (Do

not hold down the key). (p. 18)

40

Page 47

Measuring Currents

HIOKI CT6710A961-01

2.3 Measuring Currents

Be sure to read the following sections and perform the steps

described there before taking measurements:

“2.1 Inspecting the Device Before Use” (p. 26)

“2.2 Preparing for Measurement” (p. 28)

Follow all operating precautions for your waveform

measuring instrument or any other measuring instrument.

DANGER

Do not cause a short-circuit between the wire

to be measured and another wire with the

metallic parts of the tips of the sensor.

Doing so can cause arc ash, resulting in serious bodily

injury or damage to the device or other equipment.

Do not measure any current in excess of the

derating curve.

Doing so can cause overheating of the device, resulting

in bodily injury, re, or damage to the device.

See “Frequency derating curve” (p. 78).

The maximum measurement current varies with the

frequency, and the current that can be measured

continuously is limited. Operating the device at less than

this limitation is referred to as derating.

2

41

Page 48

Measuring Currents

HIOKI CT6710A961-01

Do not subject the ground side of other input

terminals to a dierent potential when you

use one of the following waveform measuring

instruments:

• an instrument that does not provide

electrical insulation between its input

terminals and chassis

• an instrument that does not provide

electrical insulation among its input

terminals

H

Power source

Load

DANGER

L

Waveform measuring

instrument

Load

Model 3269

Power Supply

If you do so, a short-circuit current will ow through the

3269 Power Supply and the CT6710/CT6711 from the

ground terminal, causing electric shock or damage to

the CT6710/CT6711 and the 3296.

See the gure in “Example of connection to the circuit to be

measured” (p. 49) for a proper connection.

42

Page 49

Measuring Currents

HIOKI CT6710A961-01

DANGER

Ensure that the insulation on a conductor is

not worn or damaged before clamping the

sensor around the conductor to be measured.

Take care not to damage the insulation when

clamping the sensor around the conductor.

Damage to the conductor insulation can cause electric

shock.

Connect the CT6710/CT6711 to the 3269 Power

Supply and a waveform measuring instrument

(oscilloscope or recorder) before clamping the

device around a live line to be measured.

Failure to do so may cause electric shock or a short-

circuit.

2

43

Page 50

Measuring Currents

HIOKI CT6710A961-01

While measuring a high-frequency current

or a current that includes high-frequency

components, keep hands and other body

parts away from the jaws.

Eddy current loss may cause heating of the sensor

heads. Failure to do so could re or damage to the

measurement target and device, resulting in burns.

Keep away any cords and other parts, which

include the cords of the device, from the

conductor under measurement.

Dielectric heating may cause heating of cords and other

parts, resulting in burns.

WARNING

44

Page 51

Measuring Currents

HIOKI CT6710A961-01

CAUTION

Do not place any conductor carrying a current

with a frequency of 10 kHz or more close to

the jaws even when the sensor is not clamped

around a conductor.

A current owing through conductors near the sensor

may heat up the sensor heads, leading to damage to

the device, resulting burns.

When the device is clamped around one of the goand-return conductors and the other conductor is

placed close to the jaws, self-heating of both currents

will synergistically heat up the sensor heads even if

the electric current is lower than the maximum rated

current.

Do not place conductors

not to be measured close

to the jaws.

2

45

Page 52

Measuring Currents

HIOKI CT6710A961-01

Do not prevent heat radiation from the device.

Do not input a current that exceeds the

maximum rated current value*.

An temperature increase in the device cause burns,

damage to the device, or a short-circuit.

Never input a current that exceeds ±50 A even

momentarily.

Doing so can damage the device, resulting in bodily

injury.

See “Maximum peak current” (p. 72).

Do not exceed the maximum rated current,

regardless of the blinking state of the

OVERLOAD LED.

Doing so can damage the device, resulting in bodily

injury.

Overload warnings are detectable in a frequency band

of DC and 45 Hz to 66 Hz (sine wave). When measuring

a current with a frequency outside the frequency

detection band, the overload warning function may not

work properly.

See “Frequency characteristics” (p. 77).

CAUTION

* The maximum rated current has been specied in

light of a temperature increase caused by self-heating

during measurement. The maximum rated current

varies depending on the frequency of the current under

measurement.

See the gures in “Frequency derating curve” (p. 78).”

46

Page 53

Measuring Currents

HIOKI CT6710A961-01

CAUTION

Use the device for measuring currents much

lower than the maximum rated current value if

an ambient temperature is relatively high or a

current to be measured can contain frequency

components other than the fundamental.

Self-heating could cause burns or damage to the device

even if the current under measurement is lower than the

maximum rated current.

The maximum rated current is dened as a

recommended value for when a sine-wave current is

inputted to the device at the temperatures and humidity

specied for the guaranteed accuracy.

See “Frequency derating curve” (p. 78).

Connect the device and other probes properly

to a circuit to be measured and your waveform

measuring instrument.

Improperly connecting them could cause electric shock

or damage to the device, other probes, and instrument.

2

47

Page 54

Measuring Currents

HIOKI CT6710A961-01

Do not subject the sensor to high voltage,

including static electricity.

Doing so may damage the device.

Do not pass a current through a conductor

under measurement when the 3269 Power

Supply or your waveform measuring

instrument is o.

Doing so may damage the device and instrument.

Keep the upper jaw locked in place except the

following occasions:

• When clamping the sensor around a

conductor to be measured

• When removing the sensor from the

conductor.

Leaving the upper jaw unlocked can damage the device.

NOTICE

48

Page 55

Measuring Currents

HIOKI CT6710A961-01

Example of connection to the circuit to be

measured

The gure below illustrates a connection between the device and a

measuring instrument with non-isolated input terminals equipped,

such as a general oscilloscope.

Waveform measuring instrument

H

Power source

Load Load

L

Model 3269 Power Supply

The 3269 Power Supply can provide the power to up to two

probes of the CT6710/CT6711.

Connecting the CT6710/CT6711 to a Hioki Memory HiCorder

with a power supply module for current probes (option)

installed allows the CT6710/CT6711 to operate without the

3269 Power Supply. For more information, contact your

authorized Hioki distributor or reseller.

2

49

Page 56

Measuring Currents

HIOKI CT6710A961-01

How to measure a current

IMPORTANT

Do not place the sensor close to a heat source.

Do not roughly operate the opening lever to lock the

upper jaw.

Do not subject the jaws and opening lever to force.

Do not subject the sensor aperture to force while the

sensor is clamped around the conductor.

Changes in ambient temperature and an impact

on the sensor head can cause uctuations in the

oset voltage, resulting in an adverse eect on the

measurement accuracy.

Be sure to execute demagnetization and automatic

zero-adjustment before taking measurements.

Failure to do so can adversely aect the measurement

accuracy.

See “Executing demagnetization and automatic zeroadjustment” (p. 33).

50

Page 57

Pull the opening lever of

HIOKI CT6710A961-01

1

the sensor toward you to

retract the upper jaw.

Clamp the sensor

2

around a conductor to be

measured.

• Have the current direction

indicator match the

direction of the current to be

measured.

• Place the conductor at

the center of the sensor

aperture.

Slide the opening lever

3

toward the lower jaw until

the JAW UNLOCKED

indicator is hidden.

The upper jaw will be locked

in place.

The JAW UNLOCKED LED

will go out.

Measuring Currents

2

Low-potential side

(Ground potential

side)

High-

potential side

51

Page 58

Measuring Currents

HIOKI CT6710A961-01

Check the LEDs on the junction box.

4

The POWER LED

and one of

light up.

There is no error.

Go on to step

Z

.

5

The OVERLOAD LED blinks rapidly.

The device has detected a measurement current in excess

of the level dened for the current range.

See “Overload” (p. 90).

When you use the 30 A range

Immediately remove the sensor from the conductor

Z

under measurement.

When you use the 0.5 A range or 5 A range

Switch a higher current range.

Z

IMPORTANT

• The instrument may be unable to properly detect

overload states immediately after the current range has

changed.

• The currents for which an overload state can be detected

are DC and sine waves with frequencies of 45 Hz to

66 Hz. The device is unable to detect the currents listed

below as an overload state.

- Currents that exceed the dened level on a

momentary basis

- High-frequency currents that exceed the dened level

the RANGE LEDs

Any other LEDs lights up or blinks.

A dierent error is occurring.

See “4.2 Errors” (p. 88) to identify a reason and take

Z

necessary measures.

52

Page 59

Measuring Currents

HIOKI CT6710A961-01

Press the (higher range) key or (lower range)

5

key to choose a current range.

• Choose a current range with a maximum peak

current higher than the peak value of a current under

measurement.

See “Maximum peak current” (p. 72).

If the peak value of the current under measurement

exceeds the maximum peak current of the chosen current

range, the output waveform will be saturated or distorted,

preventing you from correctly observing the current

waveform.

• You need to choose a current range according to the level

of the current under measurement to minimize an adverse

eect of noise on observation of the current waveform. The

following table shows the recommended current ranges for

each of the levels of currents under measurement.

Electric current level

Recommended current

±5 A to ±50 A 30 A (0.1 V/A)

±0.5 A to ±5 A 5 A (1 V/A)

±1 mA to ±0.5 A 0.5 A (10 V/A)

range

(Output rate)

2

53

Page 60

Measuring Currents

HIOKI CT6710A961-01

Convert a voltage sensitivity of the waveform

6

measuring instrument into a current sensitivity.

Using the following formula can convert a voltage sensitivity

(unit: V/div) specied on the waveform measuring instrument

into a current sensitivity (unit: A/div).

S

=

S

/

R

I

V

O

S

: Current sensitivity (A/div)

I

S

: Voltage sensitivity (V/div)

V

R

: Output rate (V/A)

O

Example

When your waveform measuring instrument with its voltage

sensitivity set at 10 mV/div measures a current that has an

RMS value of 1 mA

1 mA/div

0.5 A range (10 V/A) 5 A range (1 V/A)

S

= (10 ×10-3) / 10

I

= 1 × 10

-3

(A/div) = 10 ×10-3 (A/div)

S

I

54

10 mA/div

= (10 × 10-3) / 1

Page 61

Measuring Currents

HIOKI CT6710A961-01

IMPORTANT

After you measured a current that exceeds the

maximum rated current value of each current range,

re-execute the demagnetization and automatic zeroadjustment.

The sensor heads have been magnetized, causing

incorrect current measurements.

See “Executing demagnetization and automatic zeroadjustment” (p. 33).

IMPORTANT

When you measure high-frequency currents, the position of the

conductor under measurement in the sensor aperture may vary

the magnitude of load applied to the circuit under measurement,

adversely aecting the measurement accuracy.

See “Input impedance” (p. 80).

The following methods can minimize the adverse eect:

• Straighten the conductor under measurement as long as

possible.

• Clamp the sensor at the center of the straight portion of the

conductor as close as possible.

• Arrange the conductor at the center of the sensor aperture as

close as possible.

• Do not wind the conductor around a jaw.

2

55

Page 62

Measuring Currents

HIOKI CT6710A961-01

IMPORTANT

When you measure high-frequency currents, Clamping the

sensor around the high-potential side of a circuit may cause

common-mode noise to aect the measurement accuracy

adversely.

See “Inuence of common-mode voltage” (p. 82).

As needed, reduce the frequency band of the waveform

measuring instrument, or clamp the sensor around the lowpotential side conductor.

H

NO

Power

source

Load

L

Displayed values can frequently uctuate due to induction

potential even when no voltage is applied. This, however, is

not a malfunction.

56

OK

Page 63

Measuring Currents

HIOKI CT6710A961-01

NOTE

• Depending on the amplitude and frequency of a current

under measurement, the sensor heads may emit a

resonant sound. Such a sound may also be emitted during

demagnetization. This, however, does not represent a

device malfunction.

• If foreign matter adheres to the facing core surfaces on

the sensor heads and thus creates a slight gap between

the upper and lower sensor heads, the sensor heads may

emit a resonant sound.

ZRemove any foreign matter by following the cleaning

method.

See “4.3 Cleaning” (p. 96).

• An increase in the resonant sound while the device is in

use may indicate that the gap between the upper and

lower heads has widened. The gap may adversely aect

the measurement accuracy. Calibrating the device is

recommended.

See “Maintenance and Service” (p. 83).

2

57

Page 64

Measuring Currents

HIOKI CT6710A961-01

To measure a low current

When measuring low DC or low-frequency low AC, you can

increase the current-detection sensitivity of the device in the

following way.

How to measure a low current

Coil a single conductor to be measured into

1

several loops with a diameter of 200 mm or

more.

Clamp the sensor around the loops in a bundle.

2

This will make the conductor pass through the sensor

aperture one time more than the loop count consecutively

in one direction.

Arrange the loops radially as shown on the

3

following page.

Measure the current.

4

58

Page 65

Measuring Currents

HIOKI CT6710A961-01

As shown in the gure below, clamping the sensor around

the seven loops in a bundle allows the conductor to pass

through the sensor aperture eight times, which increases the

voltage of the output signal by a factor of eight.

200 mm or more

Arrange loops radially.

φ

2

High-potential

side

Low-potential

side

(Grounded side)

59

Page 66

Measuring Currents

HIOKI CT6710A961-01

To measure a current accurately

Retracting and extending the upper jaw can cause an oset

voltage of several millivolts. Perform the steps described

below before measuring a current to measure it accurately.

How to measure a current accurately

Hold down the DEMAG /

1

AUTO ZERO key on the

junction box for about 1

second.

The DEMAG / AUTO ZERO

LED will light up.

Demagnetization and

automatic zero-adjustment will

start.

After the completion, the

DEMAG / AUTO ZERO LED

will go out.

Wait for about 5 minutes.

2

The uctuation in the oset voltage will stabilize.

Operate the opening

3

lever of the sensor back

and forth to retract and

extend the upper jaw 4

or 5 times.

60

Hold down

Before execution,

orange blinks or

goes out.

Page 67

Slide the opening

HIOKI CT6710A961-01

4

lever toward the lower

jaw until the JAW

UNLOCKED indicator is

hidden.

The upper jaw will be locked

with the upper and lower

sensor heads arranged in

position relative to each other.

The JAW UNLOCKED LED

will go out.

Momentarily press the

5

DEMAG / AUTO ZERO

key on the junction box.

(Do not hold down the

key.)

Measuring Currents

2

The DEMAG / AUTO ZERO

LED will light up.

Automatic zero-adjustment

will be performed alone.

After the completion, the

DEMAG / AUTO ZERO LED

will go out.

Measure a current.

6

See “How to measure a current” (p. 50).

Press

(Do not hold down)

61

Page 68

Measuring Currents

HIOKI CT6710A961-01

When the device has entered protection mode

To protect the device against self-generated heat, it enters

protection mode when the temperature of the junction box

exceeds a specied level.

Green lights up

Reds blink rapidly

Orange blinks rapidly

Greens blink rapidly

In protection mode, the device cannot correctly measure any

current. Moreover, you cannot switch the current ranges.

When the device has entered protection mode, follow the

procedure presented on the following pages to restore it to

normal operation.

If the device has entered protection mode, it is

recommended to re-calibrate it because internal components

may have been subjected to thermal stress.

62

Page 69

How to restore the device

HIOKI CT6710A961-01

Pull the opening lever of

1

the sensor toward you

to retract the upper jaw,

and remove the sensor

from the conductor

under measurement.

Slide the opening

2

lever toward the lower

jaw until the JAW

UNLOCKED indicator is

hidden.

The upper jaw will be locked

in place.

Wait for a while to let the junction box cool down

3

to a normal temperature.

Measuring Currents

2

63

Page 70

Measuring Currents

HIOKI CT6710A961-01

Press any key.

4

One of the RANGE LEDs (of

the range used before the

device entered protection

mode) will light up, and the

device will get back to normal.

The DEMAG / AUTO ZERO

LED will blink slowly.

Perform demagnetization

5

and automatic zeroadjustment.

See “Executing

demagnetization and

automatic zero-adjustment”

(p. 33).

Press

any key

64

Page 71

Finishing Measurement

HIOKI CT6710A961-01

2.4 Finishing Measurement

NOTICE

Do not pull the cord to unplug the output

terminal.

Doing so can damage the cord and output terminal.

Hold the termination unit and disconnect the

output terminal while pulling the unlock lever

toward you.

2

65

Page 72

Finishing Measurement

HIOKI CT6710A961-01

To disconnect the power plug of the device,

do not pull the cord.

Do not twist the power plug.

Doing so could damage the cord and the power

receptacle of the 3269 Power Supply.

While holding the shell (p. 17), pull the

power plug out.

Pulling the shell lets the plug be unlocked, so you can

disconnect the plug from the power receptacle.

NOTICE

66

Page 73

How to nish measurement

HIOKI CT6710A961-01

Pull the opening lever of

1

the sensor toward you

to retract the upper jaw,

and remove the sensor

from the conductor

under measurement.

Slide the opening

2

lever toward the lower

jaw until the JAW

UNLOCKED indicator is

hidden.

The upper jaw will be locked

in place.

The JAW UNLOCKED LED

will go out.

Disconnect the

3

termination unit from the

BNC input terminal on

the waveform measuring

instrument.

Finishing Measurement

2

While pulling the unlock lever,

pull out the termination unit

straight.

67

Page 74

Finishing Measurement

HIOKI CT6710A961-01

Set the POWER switch of the 3269 Power Supply

4

in the OFF position.

Disconnect the power

5

plug of the CT6710/

CT6711 from the 3269

Power Supply.

Hold the shell (p. 17) of

the power plug when you

disconnect it.

Do not pull the cord.

Do not twist the power plug.

Unplug the power cord of the 3269 Power Supply

6

from the outlet.

68

Page 75

Specications

HIOKI CT6710A961-01

3

Unless otherwise specied, each specication item is applied to

both Model CT6710 and Model CT6711.

Items with a model number, “(Model CT6710)” or “(Model CT6711),”

indicated are applicable to each model.

Each item is specied for the device operated at 23°C±5°C

(73°F±9°F) and 80% RH (no condensation), 30 minutes elapses

after the device is turned on before use.

3.1 General Specications

Operating environment

Indoor, Pollution Degree 2, Operating altitude

up to 2000 m (6562 ft.)

Operating temperature and humidity

0°C to 40°C (32°F to 104°F), 80% RH or less

(no condensation)

Storage temperature and humidity range

−10°C to 50°C (14°F to 122°F), 80% RH or less

(no condensation)

Standards Safety: EN61010

EMC: EN61326

Measurable conductors

Insulated conductors

Measurable diameter of conductors

5 mm or less in diameter

3

69

Page 76

General Specications

HIOKI CT6710A961-01

Power supply External power supply (Model 3269)

Rated supply voltage: ±12 V DC ±0.5 V

Maximum rated power: 7.8 VA

(For current probe only, when measuring

30 A rms continuously)

Consumption current

See “Consumption current” (p. 81) in “3.4

Typical Characteristics.”

Dimensions • Sensor

Approx. 155W × 18H × 26D mm

(6.10″W × 0.71″H × 1.02″D)

• Junction box

Approx. 45W × 120H × 25D mm

(1.77″W × 4.72″H × 0.98″D)

• Termination unit

Approx. 29W × 83H × 40D mm

(1.14″W × 3.27″H × 1.57″D)

Excluding BNC connector or protrusions

Mass Approx. 370 g (13.1 oz.)

Cord lengths • Between sensor and junction box

Approx. 1500 mm (59.06″)

• Between junction box and termination unit

Approx. 150 mm (5.91″)

• Power cord

Approx. 1000 mm (39.37″)

Product warranty period

1 year

Accessories

Option

See “(Accessory)” (p. 5) and “Option”

(p. 6).

70

Page 77

Specications of Input, Output, and Measurement

HIOKI CT6710A961-01

3.2 Specications of Input, Output, and

Measurement

Basic specications

Frequency band

DC to 50 MHz (−3 dB) (Model CT6710)

DC to 120 MHz (−3 dB) (Model CT6711)

See “Frequency characteristics” (p. 77) in “3.4

Typical Characteristics.”

Rise time (10% to 90%)

7.0 ns or less (Model CT6710)

2.9 ns or less (Model CT6711)

Delay time (the time lag between the input signal with a rise

time of 1 ns and the output signal)

30 A range: 12 ns (typical)

5 A range: 12 ns (typical)

0.5 A range: 13 ns (typical)

Current range (output rate)

30 A range (Rate: 0.1 V/A)

5 A range (Rate: 1 V/A)

0.5 A range (Rate: 10 V/A)

3

71

Page 78

Specications of Input, Output, and Measurement

HIOKI CT6710A961-01

Maximum rated current*

Maximum peak current

Noise 75 µA rms or less (Typical: 60 µA rms)

Input impedance

*1. Depending on the ambient temperature and measurement

conditions, internal overheating can result in an overload

condition, limiting the maximum rated current lower than those

specied here.

*2. The device requires to cool down for 10 times the length of time

the current was inputted.

1

30 A range: 30 A rms

5 A range: 5 A rms

0.5 A range: 0.5 A rms

Derating is needed as input frequency

increases.

See “Frequency derating curve” (p. 78) in “3.4

Typical characteristics.”

Specied for currents of DC and sine wave

30 A range: ±50 A peak

(maximum duration of input: 2 s*2)

5 A range: ±7.5 A peak

0.5 A range: ±0.75 A peak (less than 10 MHz)

±0.3 A peak (10 MHz or more)

(For only the probe with the 0.5 A range,

connected with a measuring instrument that has

a frequency band of 20 MHz)

See “Input impedance” (p. 80) in “3.4 Typical

characteristics.”

72

Page 79

Specications of Input, Output, and Measurement

HIOKI CT6710A961-01

Specications of accuracy

Accuracy warranty conditions

• Accuracy warranty period

1 year (until the upper jaw has been retracted

and locked up to 10,000 cycles)

• Guaranteed accuracy period after adjustment

made by Hioki

0.5 year

• Temperature and humidity for guaranteed

accuracy

23°C±5°C (73°F±9°F), 80% RH or less

• Warm-up time

At least 30 minutes

• Power voltage range

±12 V DC ±0.5 V

Amplitude accuracy*

*3. Unless there is any change in the state of the facing core

surfaces, which includes scratches, adhesion of foreign objects,

or any change in the operating environment.

3

30 A range: ±3.0% rdg. ±1 mV

(Typical: ±1.0% rdg. ±1 mV

[for 10 A rms or less])

5 A range: ±3.0% rdg. ±1 mV

(Typical: ±1.0% rdg. ±1 mV)

0.5 A range: ±3.0% rdg. ±10 mV

(Typical: ±1.0% rdg. ±10 mV)

For a direct current and a sine-wave current

with frequencies of 45 Hz to 66 Hz within the

maximum peak current value of each current

range

3

73

Page 80

Specications of Input, Output, and Measurement

HIOKI CT6710A961-01

Temperature characteristics of sensitivity*

±2.0% rdg. or less

After automatic zero-adjustment was executed,

in the temperature range except 23°C±5°C,

under the following input conditions:

30 A range: AC with 50 Hz, 30 A

5 A range: AC with 50 Hz, 5 A

0.5 A range: AC with 50 Hz, 0.5 A

Eect of radiated radio-frequency electro-magnetic eld

±10 mA or less at 3 V/m

Eect of conducted radio-frequency electro-magnetic eld

±10 mA or less at 3 V

Eect of external magnetic eld

20 mA or less (Model CT6710)

(DC and 60 Hz, in a magnetic eld of

400 A/m)

5 mA or less (Model CT6711)

(DC and 60 Hz, in a magnetic eld of

400 A/m)

*3. Unless there is any change in the state of the facing core

surfaces, which includes scratches, adhesion of foreign objects,

or any change in the operating environment.

*4. The values of the temperature characteristics of sensitivity are

added to the amplitude accuracy.

3, *4

74

Page 81

Specications of Functionality

HIOKI CT6710A961-01

3.3 Specications of Functionality

Demagnetizing and automatic zero-adjustment functions

When the upper jaw is not locked in place, an

overload is detected, or an inputted current

exceeds the values listed below, the functions

are not available.

0.50 ±0.25 A rms

(DC and sine wave with frequencies of 45 Hz

to 66 Hz)

• Demagnetizing and automatic zero-adjustment

Operation: Executes demagnetization and

automatic zero-adjustment.

Means: Hold down the DEMAG / AUTO

ZERO key (1 s).

• Automatic zero-adjustment

Operation: Executes automatic zero-

adjustment alone.

Means: Press the DEMAG / AUTO ZERO

key.

Jaw-unlocked detection

When the upper jaw is not locked in place, the

JAW UNLOCKED LED lights up.

3

75

Page 82

Specications of Functionality

HIOKI CT6710A961-01

Overload detection

• Typical sampling frequency: 7.8125 kHz

• Typical checking cycle: 500 ms

Breakdown

Typical sampling period: 400 ms

Typical computing-and-judging period:

100 ms

(1) Excess of rated current level

When the input current exceeds the following

level, the OVERLOAD LED blinks rapidly.

30 A range: 32.5 ±2.5 A rms

5 A range: 5.25 ±0.25 A rms

0.5 A range: 0.525 ±0.025 A rms

(For all the ranges, the target currents are of

DC and sine wave with frequencies of 45 Hz

to 66 Hz)

(2) Excess of specied temperature

Detects an internal temperature anomaly and

issues an alert by blinking all of the LEDs

except the POWER LED.

Typical specied-temperature: 80°C

Typical hysteresis: 10°C

Recovery means: Press any key. Then,

the device requires

demagnetization and

automatic zero-adjustment.

Specications of lighting up / blinking LEDs

See “1.4 Specications of Lighting Up / Blinking

LEDs” (p. 22).

76

Page 83

Typical Characteristics

0.5 A range (10 V/A)

Gain (dB)

Frequency

(Hz)

0.5 A range (10 V/A)

HIOKI CT6710A961-01

3.4 Typical Characteristics

All of the characteristics shown in this section are typical.

Frequency characteristics

30

20

10

5 A range (1 V/A)

0

−10

Gain (dB)

30 A range (0.1 V/A)

−20

−30

−40

1 10 100 1 k 10 k 100 k 1 M 10 M 100 M

Fig. 1 Frequency characteristics (Model CT6710)

30

20

10

5 A range (1 V/A)

0

−10

30 A range (0.1 V/A)

−20

−30

−40

1 10 100 1 k 10 k 100 k 1 M 10 M 100 M

Fig. 2 Frequency characteristics (Model CT6711)

Frequency (Hz)

3

77

Page 84

Typical Characteristics

HIOKI CT6710A961-01

Frequency derating curve

Figures 3 and 4 show the derating curves with a sine-wave

current inputted in the temperature and humidity range for

the guaranteed accuracy. If the ambient temperature (T

rises or the current under measurement contains highfrequency components, the device temperature will rise, and

thus its continuously inputtable current value and frequency

will lower.

)

A

78

Page 85

Typical Characteristics

35

Maximum input current (A)

TA = 23°C, Sine wave

35

Maximum input current (A)

HIOKI CT6710A961-01

30

25

20

15

10

5

0

100 1 k 10 k 100 k 1 M 10 M 100 M 1 G

Frequency (Hz)

Fig. 3 Derating curve according to frequency (Model CT6710)

30

25

20

15

10

5

0

100 1 k 10 k 100 k 1 M 10 M 100 M 1 G

Frequency (Hz)

30 A range

5 A range

3

30 A range

5 A range

TA = 23°C, Sine wave

Fig. 4 Derating curve according to frequency (Model CT6711)

79

Page 86

Typical Characteristics

HIOKI CT6710A961-01

Input impedance

The location where the sensor is clamped will exhibit

impedance as shown in Figs. 5 and 6, which inserts a load

in a circuit under measurement. In particular, take this

characteristic into account when measuring a high-frequency

current.

1

0.1

0.01

Input impedance (Ω)

0.001

100 1 k 10 k 100 k 1 M 10 M 100 M 1 G

Fig. 5 Input impedance (Model CT6710)

1

Frequency (Hz)

0.1

0.01

Input impedance (Ω)

0.001

100 1 k 10 k 100 k 1 M 10 M 100 M 1 G

Fig. 6 Input impedance (Model CT6711)

80

Frequency (Hz)

Page 87

Consumption current

1.2

Input current (A)

HIOKI CT6710A961-01

Consumption current (A)

Fig. 7 Consumption current (with the 30 A range specied)

Typical Characteristics

1

0.8

0.6

0.4

0.2

0

0 10 20 30 40 50

DC

AC

3

81

Page 88

Typical Characteristics

V

/ V

(dB)

Frequency (Hz)

HIOKI CT6710A961-01

Inuence of common-mode voltage

The gure below indicates the ratio of common-mode

voltage (external noise voltage) applied to a conductor under

measurement positioned in the sensor aperture and the

resulting output voltage.

−40

−60

−80

−100

c

−120

O

−140

−160

−180

10 100 1 k 10 k 100 k 1 M 10 M

VO: Output voltage (V)

VC: Common-mode voltage (V)

Fig. 8 Inuence of common-mode voltage

82

0.5 A range

5 A range

30 A range

30 A range

Page 89

Maintenance and Service

HIOKI CT6710A961-01

4

WARNING

Do not attempt to modify, disassemble, or

repair the device yourself.

Attempting the above may cause bodily injury or re.

Calibration

The calibration interval depends on factors such as

operating conditions and environment.

Please determine the appropriate calibration interval based

on your operating conditions and environment and have

Hioki calibrate it accordingly on a regular basis.

4

83

Page 90

Troubleshooting

HIOKI CT6710A961-01

4.1 Troubleshooting

If damage is suspected, read “Before sending back your

device for repair” (p. 85) and check the device as

described. If this cannot resolve problems, contact your

authorized Hioki distributor or reseller.

When transporting the device, be sure to observe the

following precautions:

• Remove the CT6710/CT6711 from the 3269 Power

Supply.

• Include a memo that describes the problem in detail.

• Pack the device in the packaging in which it was initially

delivered and double-pack it.

Damage that occurs during transportation is not covered by

the warranty.

84

Page 91

Troubleshooting

HIOKI CT6710A961-01

Before sending back your device for repair

Symptom

No waveform is displayed on the waveform measuring

instrument.

Z

Z

If the issue has not been resolved, the device may be

malfunctioning.

Z

A resonant sound is emitted from the sensor heads.

This does not aect the measurement accuracy.

The sensor head may emit a resonant sound depending

on the amplitude and frequency of the current under

measurement.

The resonant sound emitted from the sensor heads

becomes louder.

Calibration of the device is recommended because the

gap may adversely aect the measurement accuracy.

The gap between the upper and lower sensor heads may

have increased.

Cause, remedy

/

Re-execute demagnetization and automatic zeroadjustment. (p. 33)

Make sure that the input coupling of the waveform

measuring instrument is set to DC. (p. 38)

Have the device repaired.

4

85

Page 92

Troubleshooting

HIOKI CT6710A961-01

Symptom

Cause, remedy

/

Demagnetization and automatic zero-adjustment

cannot be performed.

Demagnetization or automatic zero-adjustment has not

been completed normally.