Page 1

BT4560

BATTERY

IMPEDANCE METER

Instruction Manual

Aug. 2018 Revised edition 1

BT4560A981-01 18-08H

EN

Page 2

Page 3

Contents

Introduction ................................................ 1

Registered trademark ...................................1

Verifying Package Contents ..................... 1

Safety Information ..................................... 3

Operating Precautions .............................. 6

1 Overview 11

1.1 Product Overview and Features ....11

1.2 Names and Functions of Parts ..... 12

1.3 ScreenCongurationand

Operation ........................................ 15

Measurement screen ..................................15

Settings screen ...........................................15

1.4 Measurement Flow ......................... 16

2 Preparation 17

2.1 Connecting the Power Cord .......... 17

2.2 Connecting the Measurement

Probe and Temperature Sensor

(Optional) ........................................ 18

Connect the four-terminal cable to the

instrument ...................................................18

Connect the temperature sensor to the

instrument ...................................................18

2.3 Turning the Power ON or OFF ....... 19

2.4 Inspection Before Use ................... 19

3 Basic Measurement 21

4 Customization

of Measurement

Conditions 37

4.1 Setting the Measurement

Starting Conditions (Trigger

Functions) ....................................... 37

Setting the trigger .......................................37

Inputting the external trigger .......................38

4.2 Starting the Measurement After

the Response of the Measuring

Object is Stable (Sample Delay

Function) ......................................... 38

4.3 Maintaining Voltage

Measurement Accuracy (Self-

Calibration Function) ..................... 41

4.4 Stabilizing the Measurement

Values (Average Function) ............ 42

4.5 Compensating the Potential

Slope Due to Electric Discharge

(Slope Correction Function) .......... 43

4.6 Preventing the Overcharge due

to Measurement Signal (Voltage

Limit Function) ............................... 45

4.7 Prevents Charging and

Discharging due to the

Measurement Signal

(Measurement Signal Zero

Cross Stop Function) ..................... 47

1

2

3

4

5

6

7

3.1 Selecting the Measurement

Functions ........................................ 21

3.2 Selecting the Measurement Range 22

3.3 Setting the Measurement Speed ... 23

3.4 Setting the Measurement

Frequency ....................................... 24

When the measurement time is long

(Display of the Progress Bar) ......................25

3.5 Performing the Zero Adjustment .. 26

Performing the zero adjustment ..................26

Connection when performing the zero

adjustment ..................................................29

3.6 Checking the Measurement

Results ............................................ 30

Detecting the measurement abnormality ....30

Temperature measurement indication ........32

Overrange indication ...................................32

3.7 Basic Measurement Examples ...... 33

BT4560A981-01

5 Judging Measurement

Results (Comparator

Function) 49

5.1 Turning the Comparator

Function ON and OFF .................... 50

5.2 Setting the Upper and Lower

Limit Value ...................................... 51

5.3 Voltage is Judged with the

Absolute Value ............................... 54

5.4 Checking the Judgment with

Sound .............................................. 55

5.5 Checking the Judgment Result .... 56

8

9

10

Appx. Index

i

Page 4

Contents

6 Saving and Reading

Measurement

Conditions 57

6.1 Saving the Setting Conditions

(Panel Saving Function) ................ 58

6.2 Reading the Setting Conditions

(Panel Loading Function) .............. 60

6.3 Deleting the Contents of the Panel 61

7 System Setting 63

7.1 Making the Key Operation

Effective or Ineffective ................... 63

7.2 Setting the Sound of the Key

Operation Effective or Ineffective . 65

7.3 Adjusting the Contrast of the

Screen ............................................. 66

7.4 Adjusting the Backlight ................. 67

7.5 System Testing ............................... 68

7.6 ConrmInstrumentInformation ... 73

7.7 Initializing (Reset) .......................... 74

Initial setting table .......................................76

8 External control (EXT.I/

O) 79

8.1 External Input/output Terminals

and Signals ..................................... 80

Switching the current sink (NPN) /the

current source (PNP) ..................................80

Arranging the usage connector and the

signals .........................................................80

Functions of each signal .............................82

8.2 Timing Chart ................................... 84

Acquiring the judgment results after

starting measurement .................................84

Timing of the zero adjustment.....................87

Timing of the self-calibration .......................87

Timing of the panel loading .........................89

Output signal status when turning ON

the power supply .........................................89

Taking-in ow with the external trigger ........90

8.3 Internal Circuitry ............................ 91

Electrical Specications ..............................92

Examples of connection ..............................93

8.4 Checking the External Control ...... 94

Testing the inputs/outputs (EXT.I/O

testing functions) .........................................94

9 Communication

(RS-232C, USB) 95

9.1 Features of Interface ...................... 95

Specications ..............................................95

9.2 Connecting and Setting Method ... 96

Using the USB interface .............................96

Using the RS-232C cable ...........................98

Setting the transmission speed

(Common for USB, RS-232C) ....................99

9.3 Controlling the Communication

and Acquiring the Data ................ 100

Remote state/Local state ..........................100

10 Specications 101

10.1 SpecicationsofMeasurement

Functions ...................................... 101

10.2 Additional Function ..................... 104

10.3 User Interface ................................110

10.4 External Interface ..........................110

10.5 Accuracy ........................................112

10.6 GeneralSpecications .................115

Standards ................................................. 116

Accessories .............................................. 116

Options ..................................................... 116

11 Maintenance and

Service 117

11.1 Troubleshooting ............................117

Q&A (Frequent inquiries) ..........................117

Error display and remedy ..........................121

11.2 Inspection, Repair and Cleaning 123

11.3 Discarding the Instrument ........... 124

Lithium battery removal ............................124

ii

Page 5

Contents

Appendix A1

Appx. 1 Measurement

Parameters and

Calculation Formula ................A1

Appx. 2 Four-terminal Pair Method ...... A2

Appx. 3 Cautions When Making

Your Own Measurement

Probe .........................................A4

Appx. 4 Measurement Probe

Structure and Extension .........A6

Appx. 5 Measurement Value

in the Four-terminal

Measurement

(Difference in

Measurement Value Due

to the Measurement Probe) ....A7

Appx.6 InuenceoftheEddyCurrent A8

Appx. 7 Zero Adjustment ......................A8

Appx. 8 Measurement Probe (Option) A12

Appx. 9 Precautions When

Making the Switching Unit .... A13

Appx. 10 Precautions When

Measuring the Battery ........... A15

Appx. 11 Calibrating the Instrument .... A18

Appx. 12 Rack Mounting ....................... A20

Appx. 13 Dimensional Diagram ............ A22

1

2

3

4

5

6

Index Index1

7

8

9

10

Appx. Index

iii

Page 6

Contents

iv

Page 7

Introduction

Thank you for purchasing the HIOKI BT4560 Battery Impedance Meter. To obtain maximum

performance from the instrument, please read this manual rst, and keep it handy for future

reference.

Registered trademark

Introduction

1

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in

the United States and other countries.

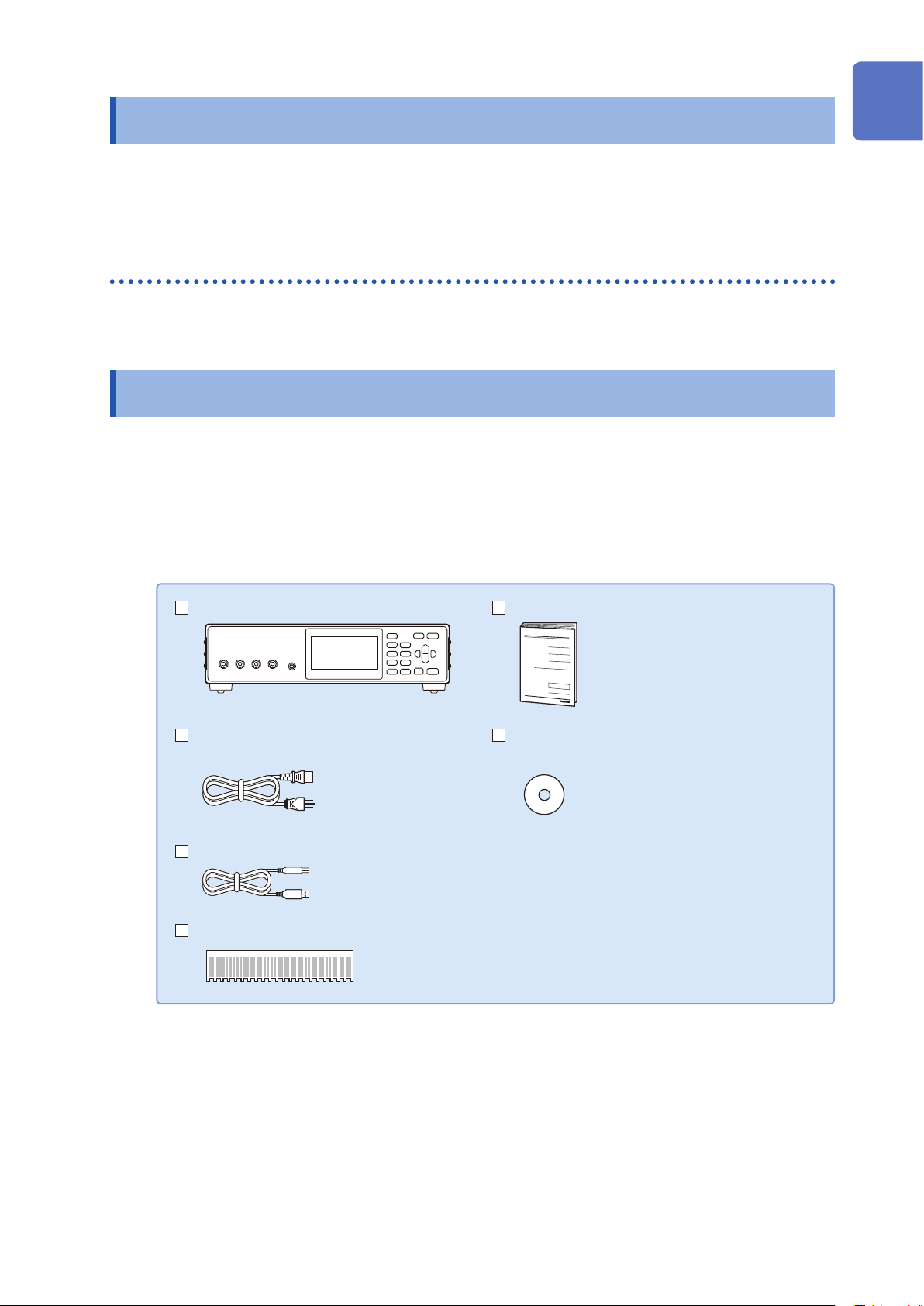

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it

fails to operate according to the specications, contact your authorized Hioki distributor or reseller.

Conrm that these contents are provided.

BT4560 Battery Impedance Meter Instruction Manual

Power Cord CD (Communications Command Instruction

Manual, Application Software*, USB Driver)

2

3

4

5

6

7

USB Cable (A-B type)

Zero Adjustment Board

*The latest version can be downloaded

from our website.

8

9

10

Appx. Ind.

1

Page 8

Verifying Package Contents

Options (p. A12)

The following options are available for the instrument. Contact your authorized Hioki distributor or

reseller when ordering.

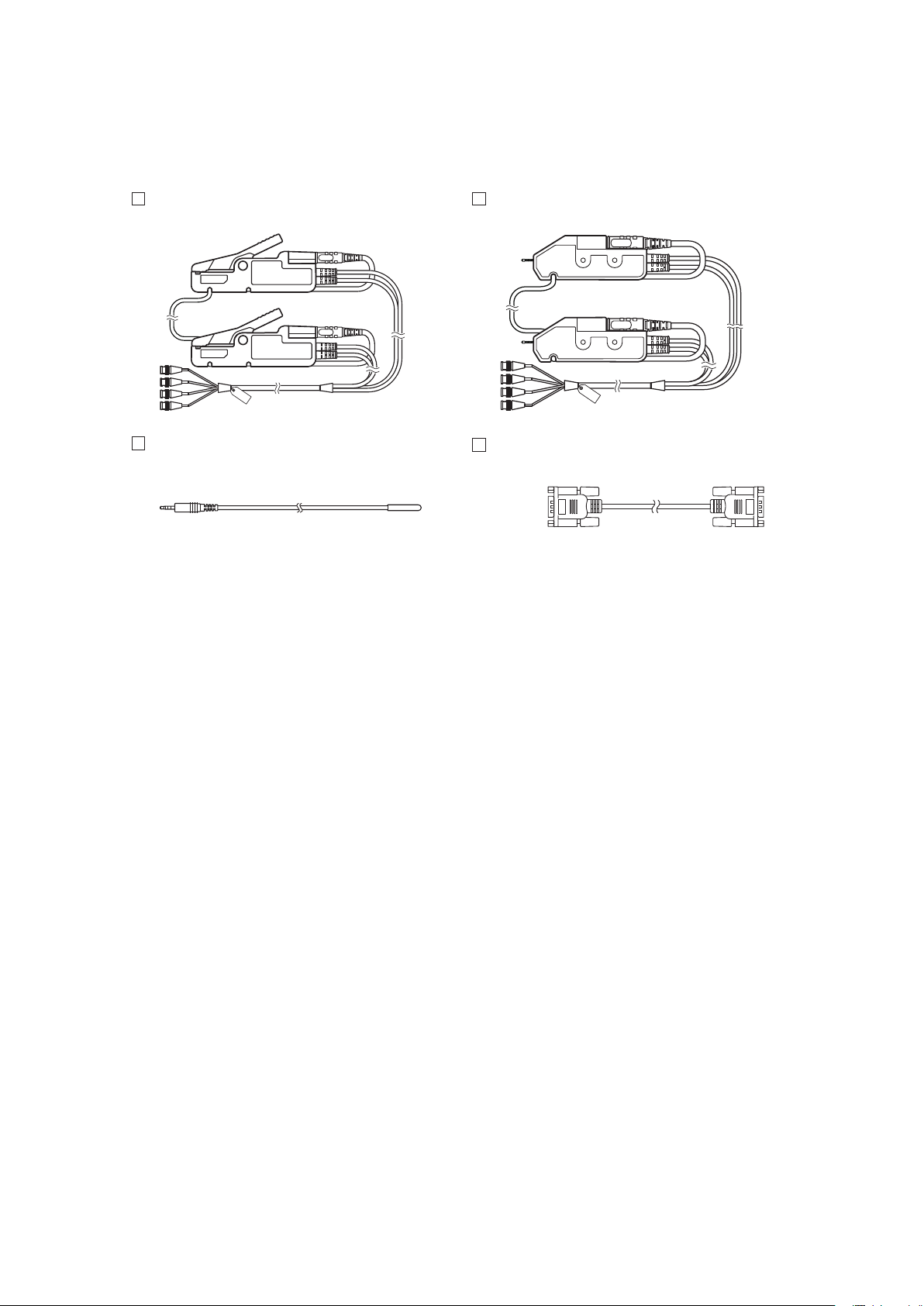

L2002 Clip Type Probe L2003 Pin Type Probe

Z2005 Temperature Sensor

9637 RS-232C Cable (9pin-9pin/1.8 m)

2

Page 9

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

1

2

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc discharge due to short circuits. If persons unfamiliar

with electricity measuring instrument are to use the instrument, another person

familiar with such instruments must supervise operations.

Notation

In this manual, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may

give rise to a hazardous situation; the operator may receive an electric shock, may get

burnt or may even be fatally injured.

3

4

5

6

7

8

*

[ ]

SET

(Bold character)

Indicates prohibited actions.

Indicates the action which must be performed.

Additional information is presented below.

Setting items and names on the screen are indicated in brackets [ ].

Bold characters within the text indicate operating key labels.

9

10

Appx. Ind.

3

Page 10

Safety Information

Symbols on the instrument

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to a

corresponding topic in the Instruction Manual.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

This symbol indicates that the product conforms to regulations set out by the EC Directive.

Accuracy

We dene measurement tolerances in terms of rdg. (reading) and dgt. (digit) values, with the

following meanings:

rdg.

dgt.

(Reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

4

Page 11

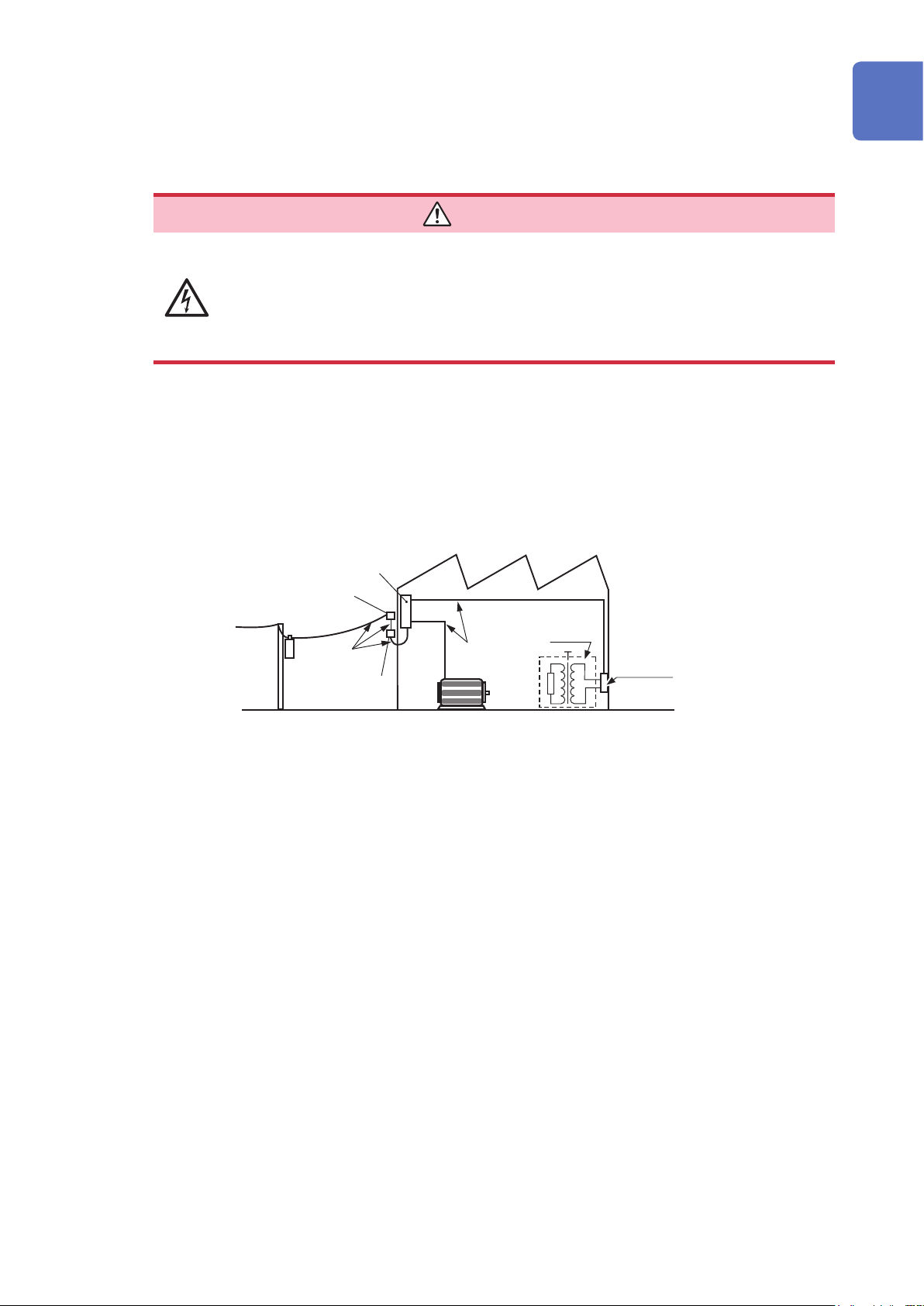

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

Safety Information

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Using a measuring instrument without categories in an environment designated

with the CAT II to CAT IV category could result in a severe accident, and must

be carefully avoided.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical

circuits in equipment connected to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.).

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets.

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

Distribution Panel

Service Entrance

Service Drop

CAT IV

Power Meter

Internal Wiring

CAT II

CAT III

Outlet

1

2

3

4

5

6

Fixed Installation

7

8

9

10

Appx. Ind.

5

Page 12

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

DANGER

This instrument carries a maximum electric current up to 1.5 A to the measuring

object. Do not measure the primary battery. Doing so may cause damage to the

measuring object.

Battery may cause ignition and damage due to overcharge/over discharge. Be

certain in managing battery voltage when measuring.

WARNING

If the measurement probe or the instrument is damaged, there is a risk of electric

shock. Before using the instrument, perform the following inspection.

• Before using the instrument, check that the coating of the measurement

probes are neither ripped nor torn and that no metal parts of connection cord

are exposed. Using the instrument under such conditions could result in

electrocution. Replace the measurement probes with those specied by our

company.

• Before using the instrument for the rst time, verify that it operates normally

to ensure that no damage occurred during storage or shipping. If you nd any

damage, contact your authorized Hioki distributor or reseller.

Instrument installation

Installing the instrument in inappropriate locations may cause a malfunction of instrument or may

give rise to an accident. Avoid the following locations.

For details on the operating temperature and humidity, see the specications p. 115.

WARNING

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic eld or electrostatic charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency induction heating systems

and IH cooking equipment)

• Susceptible to vibration

6

Page 13

Operating Precautions

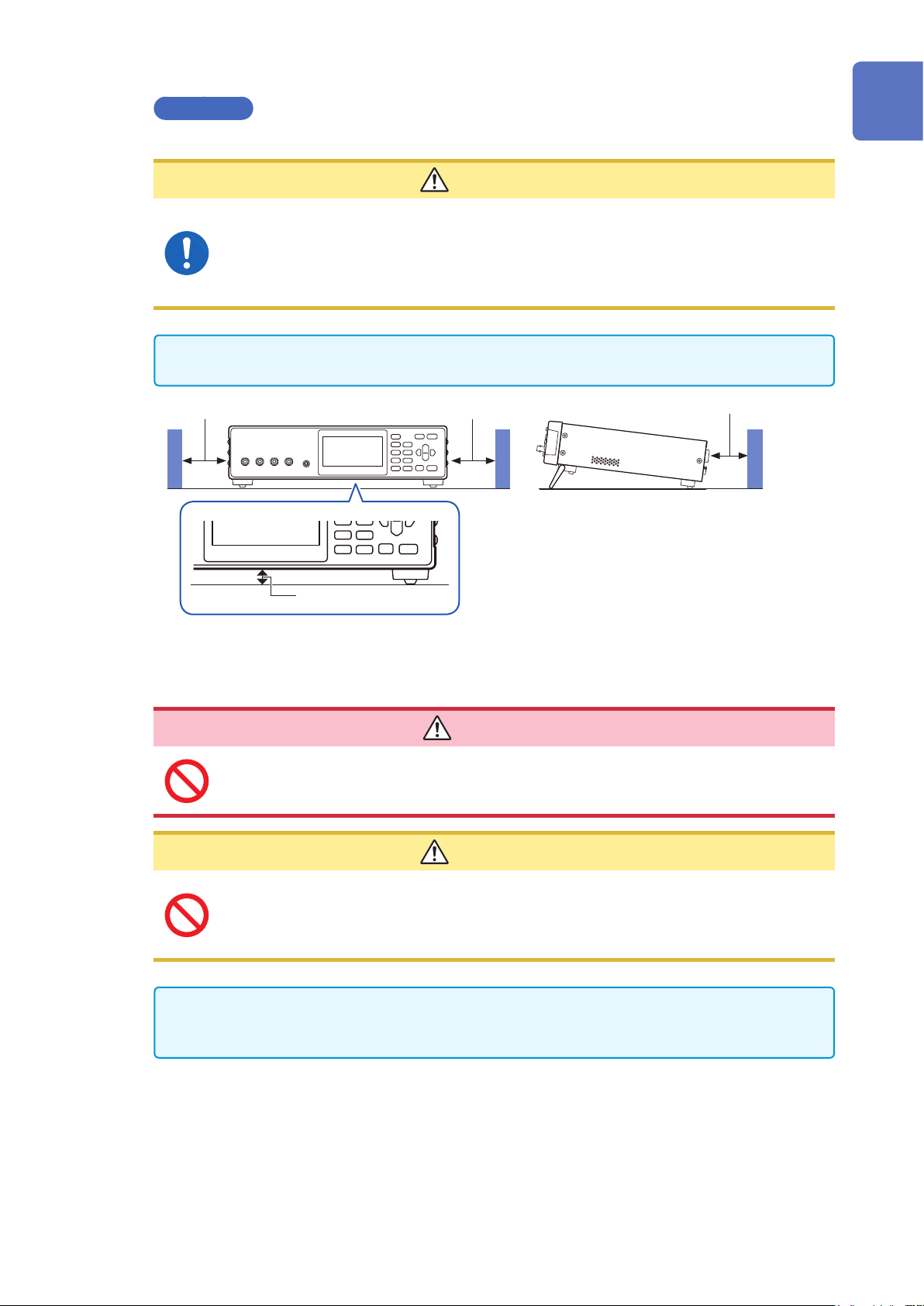

Installation

To prevent overheating, be sure to leave the specied clearances around the instrument.

CAUTION

• Do not install the instrument with any side except the bottom facing down.

• Ventilation holes for heat radiation are provided on the side, bottom and rear panels

of the instrument. Leave sufcient space around the ventilation holes and install

the instrument with the holes unobstructed. Installation of the instrument with the

ventilation holes obstructed may cause a malfunction or re.

Unplugging the power cord kills power to the instrument. Be sure to provide enough unobstructed

space to unplug the power cord immediately in an emergency.

Greater than 50 mmGreater than 50 mm

Greater than 10 mm

Rear

1

2

3

4

Greater than 15 mm

“Raising/closing the stand” (p. 13)

Handling the instrument

To avoid electric shock, do not remove the instrument’s case. The internal

components of the instrument carry high voltages and may become very hot

during operation.

• Do not place the instrument on an unstable table or an inclined place. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

DANGER

CAUTION

5

6

7

8

9

10

Appx. Ind.

7

Page 14

Operating Precautions

Before connecting the power cord

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specications of this

instrument, connect the power cord provided only to a 3-contact (two-conductor

+ ground) outlet.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the power outlet.

• Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

WARNING

CAUTION

IMPORTANT

• Turn off the power before disconnecting the power cord.

• Use only the specied power cord. Using a non-specied cord may result in incorrect

measurements due to poor connection or other reasons.

Before connecting measurement probe/temperature sensor

DANGER

• To avoid electrical hazards and damage to the instrument, do not apply voltage

exceeding the rated maximum to the input terminals.

• The maximum rated voltage to earth of the SOURCE-H terminal and the

SENSE-H terminal is ±5 V DC. The maximum rated voltage to earth of the

SOURCE-L terminal and the SENSE-L terminal is 0 V DC. Attempting to measure

voltages exceeding this level with respect to ground could damage the

instrument and result in personal injury. (Do not apply voltage to earth since the

SOURCE-L terminal and SENSE-L terminal where pseudo earthing is provided

in the internal circuit.)

• To avoid electrical shock, be careful to avoid shorting live lines with the

measurement probe.

WARNING

To avoid injury or damage to the instrument, do not attempt to measure AC

voltage, or DC voltage exceeding 5 V DC.

8

Page 15

Operating Precautions

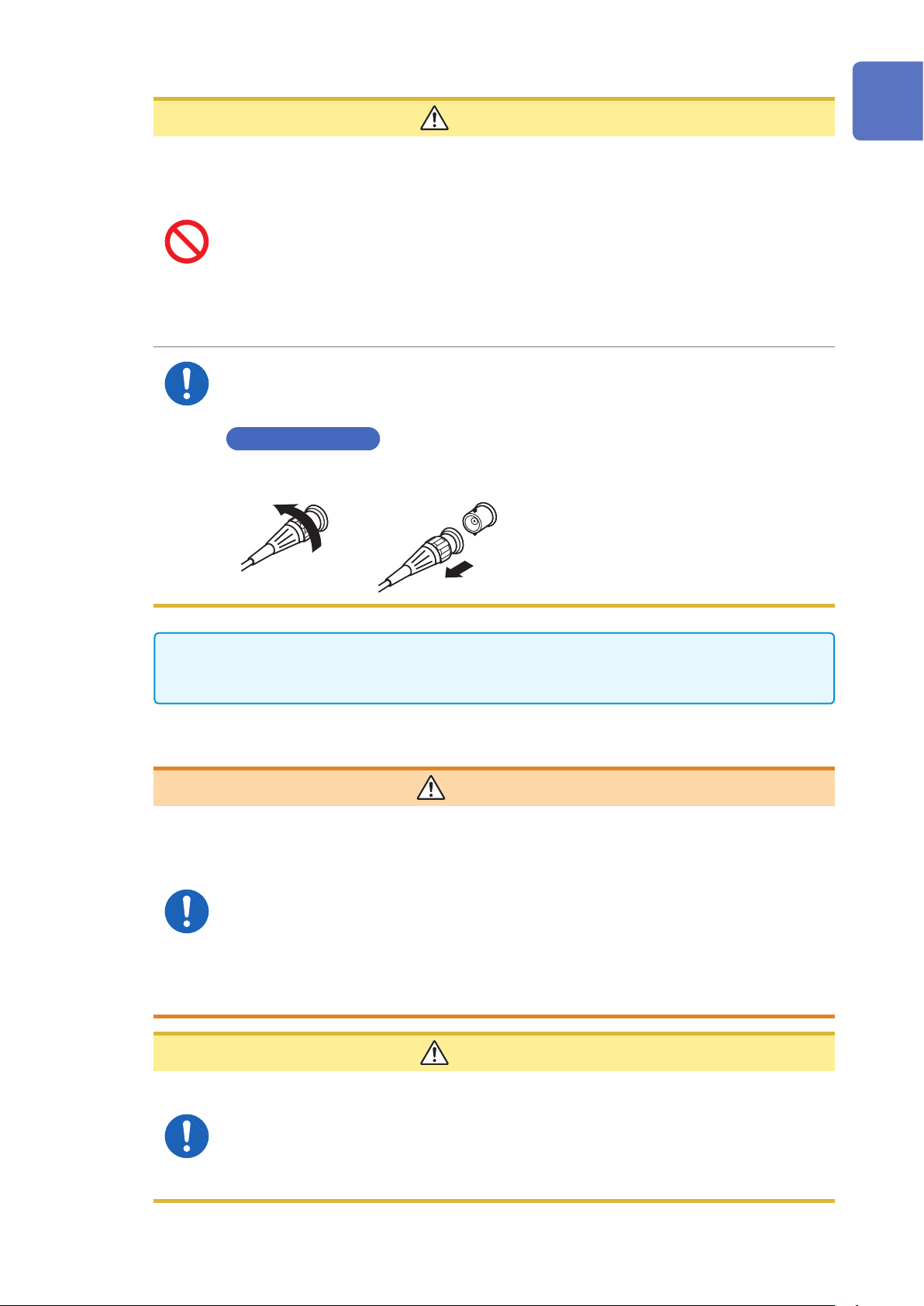

CAUTION

• To avoid damage to the instrument, do not apply voltage or current to temperature

sensor terminal.

• To prevent cable damage, do not step on cables or pinch them between other objects.

Do not bend or pull on cables at their base.

• The sensor used in the temperature sensor is a thin, precision platinum lm. Be aware

that excessive voltage pulses or static discharges can destroy the lm.

• Avoid subjecting the temperature sensor tip to physical shock, and avoid sharp bends

in the sensor. These may damage the probe or break a wire.

• When measuring high temperatures, do not let the temperature sensor exceed the

specied temperature range.

• When disconnecting the BNC connector, be sure to release the lock before pulling off

the connector. Forcibly pulling the connector without releasing the lock, or pulling on

the cable, can damage the connector.

Releasing the lock

1

2

3

1 2

Use only the specied measurement probe and the temperature sensor. Using a non-specied

one when measuring may result in incorrect measurements due to poor connection or other

reasons.

Before connecting the communication cable

WARNING

• Always turn both devices OFF when connecting and disconnecting an interface

connector. Otherwise, an electric shock accident may occur.

• After connecting, be sure to tighten the screws. When the mounting screws

are not rmly tightened, the input module may not perform to specications, or

may even fail.

• To avoid electric shock or damage to the equipment, always observe the

following precautions when connecting to connectors.

• Be careful to avoid exceeding the ratings of connectors .

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure RS-232C.

4

5

6

7

8

9

CAUTION

The USB and RS-232C are not insulated to the ground (earth). Grounding (earthing) for

the instrument and the controller must be wired as the common earth. Different earthing

may cause a voltage potential difference between the GNDs of the instrument and the

controller. Connecting the communication cable under condition that there is a voltage

potential difference may cause a malfunction and/or a failure. When different earthing is

required, connecting instruments and devices must be isolated.

10

Appx. Ind.

9

Page 16

Operating Precautions

Before switching the current sink (NPN) and the current source (PNP)

CAUTION

You must not operate the EXT.I/O MODE changing over switch (NPN/PNP) during

Power-ON status of the instrument.

Set the NPN/PNP based on devices that are externally connected.

Before connecting the EXT.I/O terminals

WARNING

• The EXT.I/O of the instrument cannot be applied to from an external power. Do

not apply external power to the instrument. (The ISO_5V terminal of the EXT I/O

connector is a 5 V (NPN)/-5 V (PNP) power output.)

To avoid electric shock or damage to the instrument, always observe the

following precautions when connecting to the connector.

• Always turn off the main power switch to the instrument and to any device to be

connected before making connections.

• Be careful to avoid exceeding the ratings of the signal of the EXT.I/O terminals.

(p. 111)

During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the external

connectors.

Precautions during shipment

When shipping the instrument, observe the following.

Hioki cannot be responsible for damage that occurs during shipment.

CAUTION

During shipment of the instrument, handle it carefully so that it is not damaged due to a

vibration or shock.

CD disc precautions

IMPORTANT

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text

on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

10

Page 17

1

Overview

1.1 Product Overview and Features

The BT4560 is a variable-frequency impedance meter.

This instrument is equipped with a highly accurate voltmeter and a temperature measurement function,

and optimal for quality control of batteries.

This instrument has the circuit conguration with high noise immunity, and thus, can provide stable

measurement even at production sites.

• The instrument can measure the internal impedance of a battery using

the AC four-terminal method.

What can the instrument

BT4560 measure?

What is the difference

between the instrument BT4560

and the existing battery impedance

instruments?

(Frequency: 0.1 Hz to 1050 Hz, Minimum resolution: 0.1 µ

• This instrument can also measure the DC voltage (the electromotive

force of the battery) simultaneously.

(Resolution: 10 µV, Measurement accuracy: ±0.0035% rdg.±5 dgt.)

• In addition, temperature measurement, which is important for battery

control, can be performed. (Temperature measurement accuracy:

±0.5°C)

• The instrument has a simple structure, which does not need a loading

device. It is not necessary to congure a system.

• This is a compact instrument and measurement can be performed

without other instruments or devices.

)

Ω

1

Overview

Can the instrument BT4560 be

used at production lines or sites?

Can the instrument BT4560

analyze the internal resistance of

batteries?

• Optional measurement probes can be extended up to a maximum of

4 m, corresponding to an operating environment.

• This can provide highly accurate measurement with a measurement

conguration that resists the inuences of external noise and contact

resistance.

• The built-in comparator function can perform quality judgment of

batteries.

• PLC control using the EXT. I/O is possible.

• A personal computer with application software connected to the

instrument can continuously measure any frequency in the range of

0.01 Hz to 1050 Hz and necessary points.

• This instrument is able to draw Cole-Cole plots*.

* The Cole-Cole plot is a plot of the frequency characteristics of battery

impedance in which the horizontal axis represents the real part of

impedance and the vertical axis represents the imaginary part of

impedance. This plot is used to evaluate the internal resistance of the

battery.

11

Page 18

Names and Functions of Parts

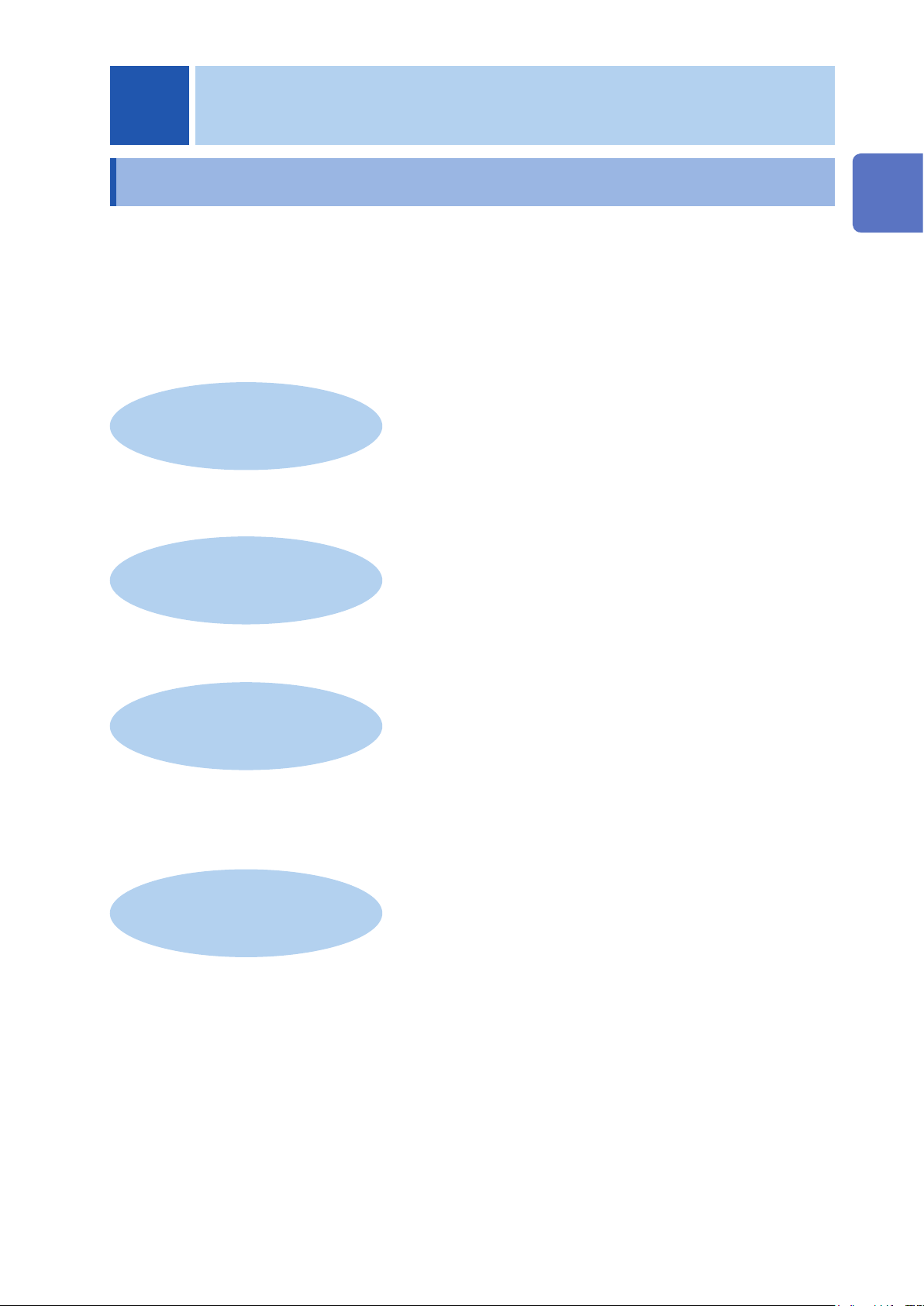

1.2 Names and Functions of Parts

Front

Measurement terminal

Connect the measurement probe.

Refer to p. 8.

Voltage detection terminal

(SENSE-L, SENSE-H)

Current generation terminal

(SOURCE-H)

Temperature sensor terminal

Connects the Z2005

temperature sensor.

Rear

Power inlet

Connects the power

cord (accessory).

(p. 17)

Refer to p. 8.

RS-232C interface

Connects to the

computer. (p. 95)

Current detection terminal

(SOURCE-L)

Display

Monochrome graphic LCD

USB interface

Connects to the

computer. (p. 95)

Operating keys (p. 14)

EXT.I/O terminal

Connects to an

external controller.

(p. 79)

Refer to p. 10.

Vents

Keep clear of

obstructions .

Power

switch

(p. 19)

12

Manufacturer’s serial number

Indicates the serial number.

Do not remove this label, as it is required for product

support.

EXT.I/O NPN/PNP switch

Left: Current sink (NPN)

Right: Current source (PNP)

(p. 80)

Page 19

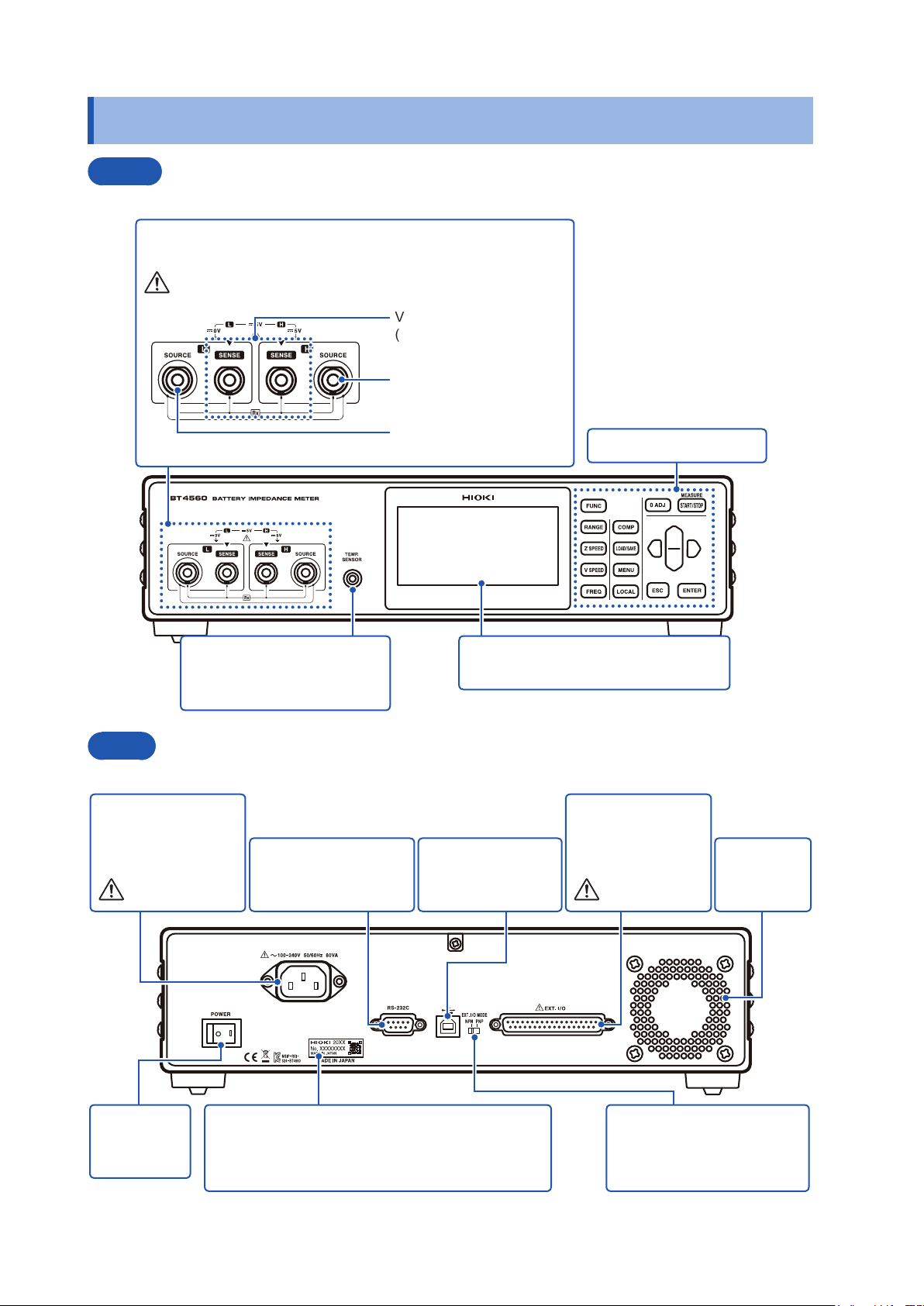

Bottom panel

Names and Functions of Parts

Stands

1

Overview

Vents

Side

Raising/closing the stand

Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

CAUTION

13

Page 20

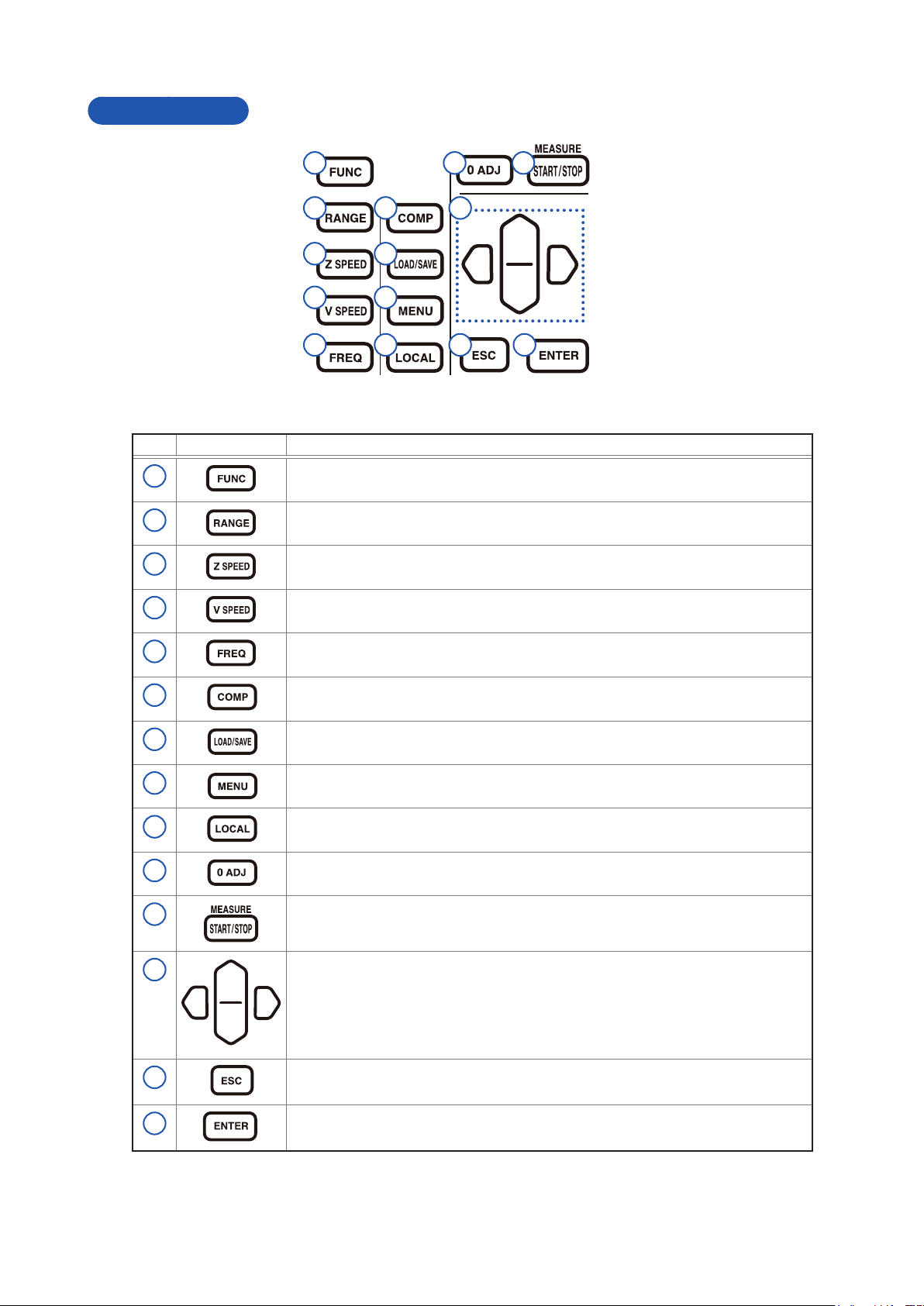

Names and Functions of Parts

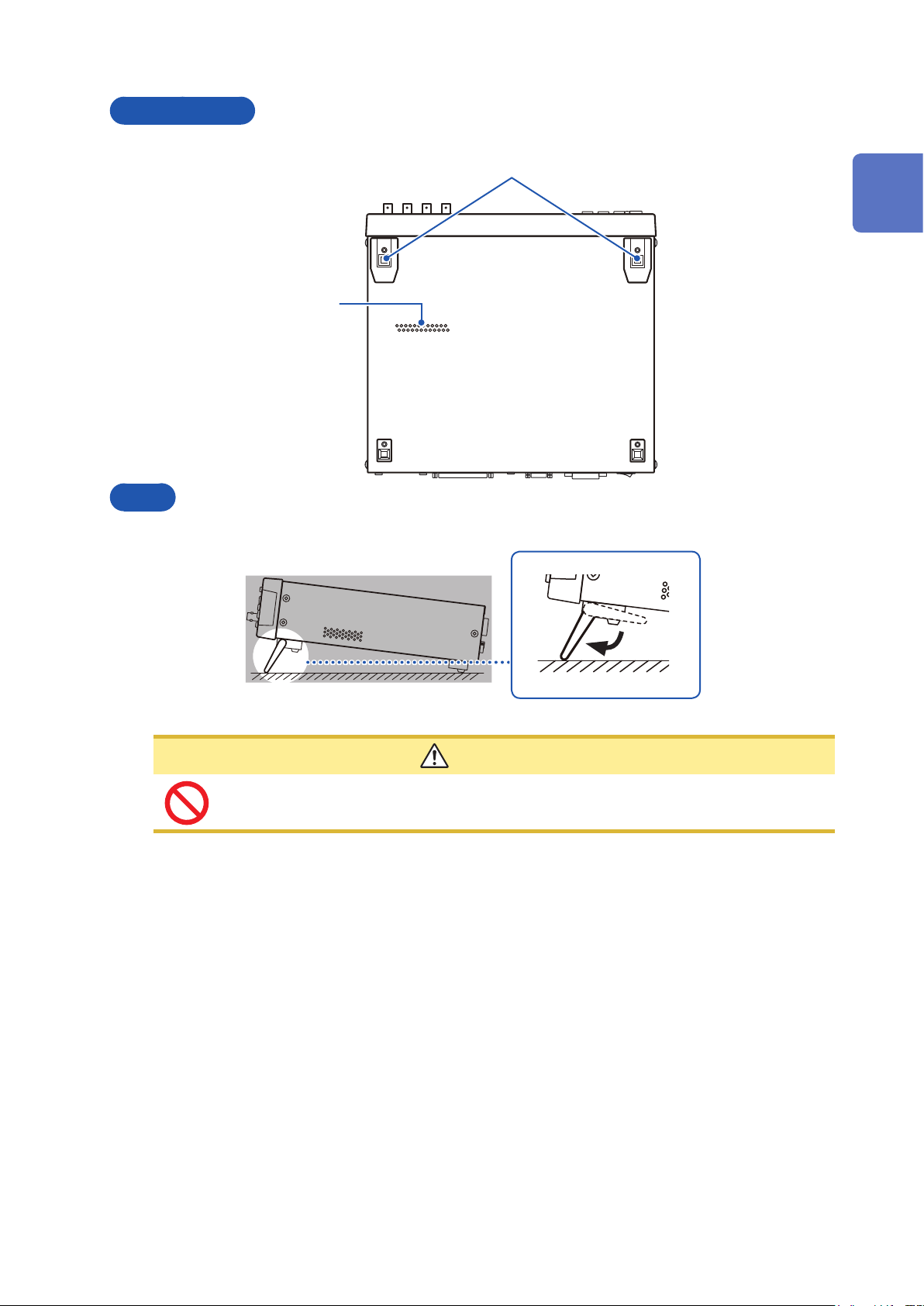

Operating keys

1

2

3

4

5

Key Description

1

2

3

4

Selects the measurement function (combination of the voltage measurement and

the impedance measurement).

Sets the measurement range.

Sets the measurement speed of impedance.

Sets the measurement speed of voltage.

6

7

8

9

10 11

12

13 14

10

11

12

13

5

6

7

8

9

Sets the measurement frequency of impedance.

Sets the power switch of ON-OFF and the upper and lower limit values ,etc. of the

comparator.

Saves and reads the measurement conditions.

Sets each of the functions (Trigger, Sample delay, Self-calibration, etc.).

Releases the remote state and enables key operation.

Performs the zero adjustment.

Starts and stops the measurement.

• Moves setting items and digits.

• Changes numerical values.

• Cancels the settings being set.

• Erases a display message.

14

14

Conrms the setting.

Page 21

Screen Conguration and Operation

1.3 Screen Conguration and Operation

The instrument is congured with the measurement screen and each setting screen.

Measurement screen

Settings screen

Measurement frequency setting screen

Comparator setting screen

1

Overview

When [EXIT] is selected, display returns to the

measurement screen.

Panel load/panel save screen

Menu settings screen

Zero adjustment setting screen

When [EXIT] is selected, display returns to the

measurement screen.

When [EXIT] is selected, display returns to the

measurement screen.

15

Page 22

Measurement Flow

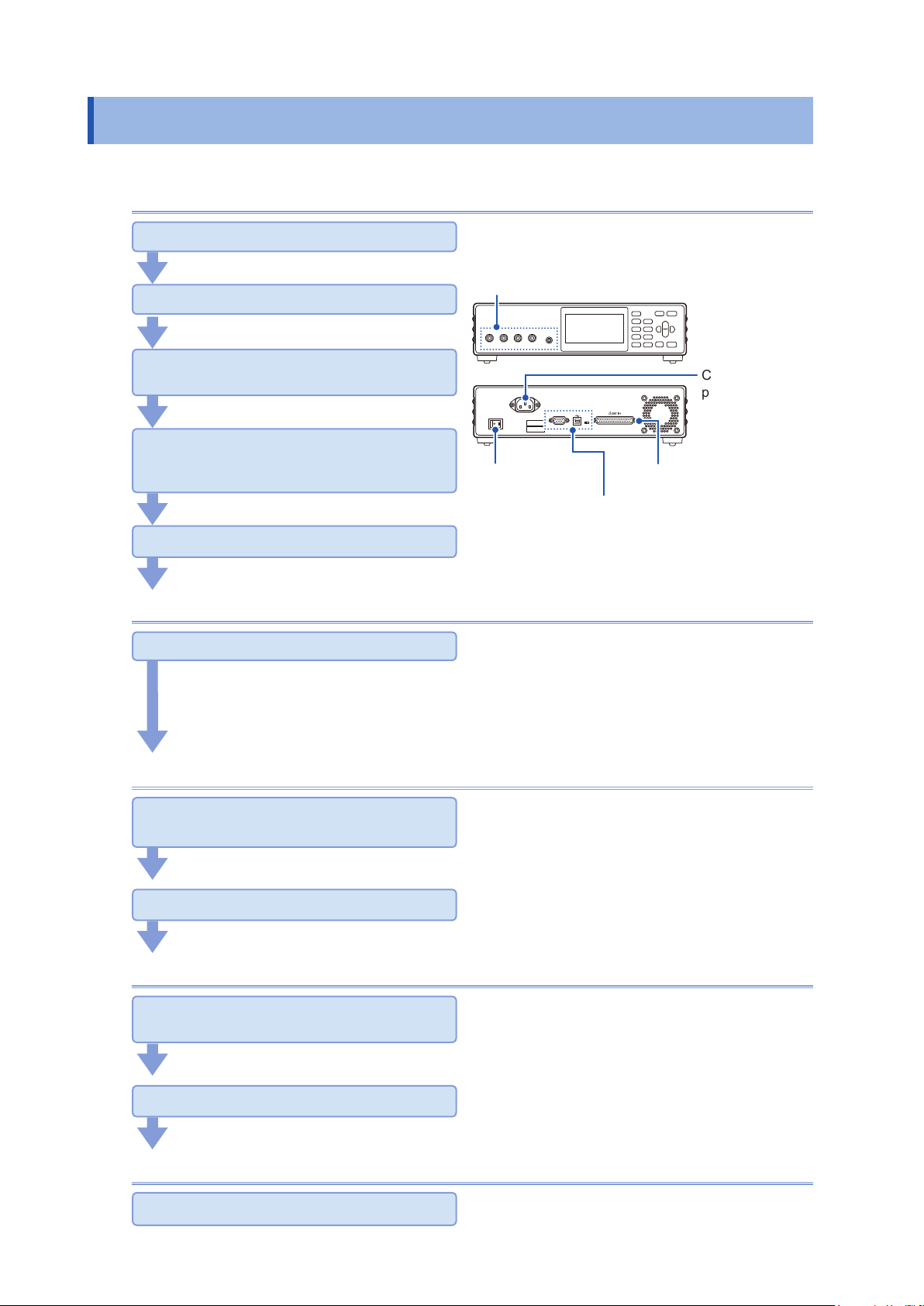

1.4 Measurement Flow

Be sure to refer to “Operating Precautions” (p. 6) before using the instrument.

Installing, connecting, and turning power on

Install (p. 7).

Connect the measurement probe and the temperature

sensor (p. 18).

Connect the power cord (p. 17).

Connect the measurement probe and the

temperature sensor (p. 18).

Connect the external interface (as needed).

• Use the EXT. I/O (p. 80).

• Communicate computer with USB or RS-232C (p. 95).

Turn Power On (p. 19).

Setting the instrument (p. 21)

Set the measurement conditions (as needed).

• Basic setting (p. 21)

• Setting basic conditions for customization (p. 37)

• Setting system related items (p. 63)

• Initial setting table (p. 76)

Performing the zero adjustment

Make the measurement probes short-circuit

with the zero adjustment board (p. 26).

Turn Power On

(p. 19).

Communicate computer with

USB or RS-232C (p. 95).

Connect the

power cord

(p. 17).

Use the EXT. I/O (p. 79).

Perform zero adjustment (p. 26).

Starting the measurement

Connect the measurement probe to the

object being measured.

(For EXT trigger, start the measurement by pressing the START/STOP key.)

Check the measurement values.

Ending

Turn Power Off (p. 19).

16

Page 23

2

Preparation

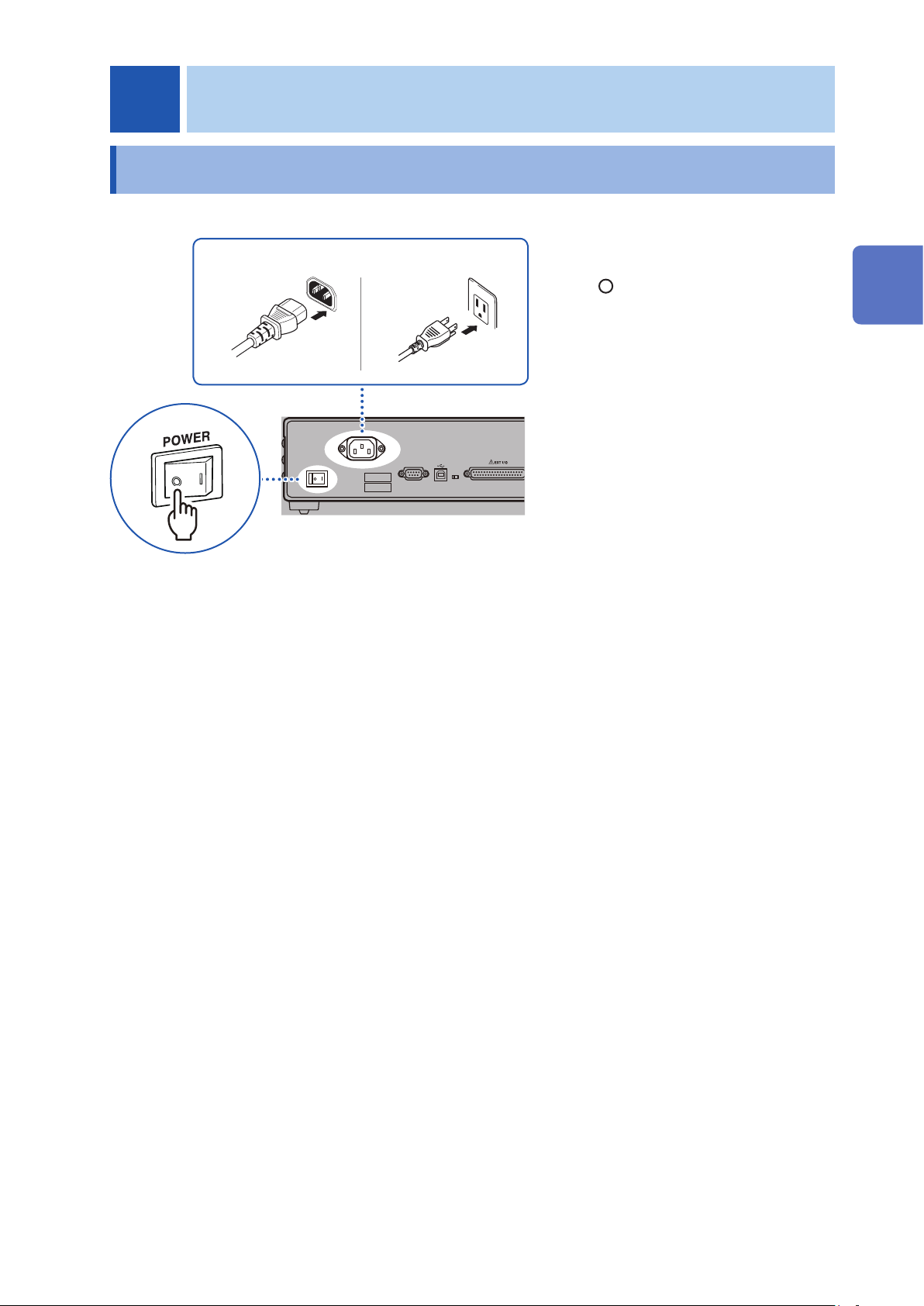

2.1 Connecting the Power Cord

Power inlet Outlet

2 3

1

Check that the power switch

1

(rear) of the instrument is OFF

( ).

Check that the power voltage

2

is in the range indicated on the

rear, and then connect the power

cord to the power inlet.

Connect the plug of the power

3

cord into an outlet.

2

Preparation

17

Page 24

Connecting the Measurement Probe and Temperature Sensor (Optional)

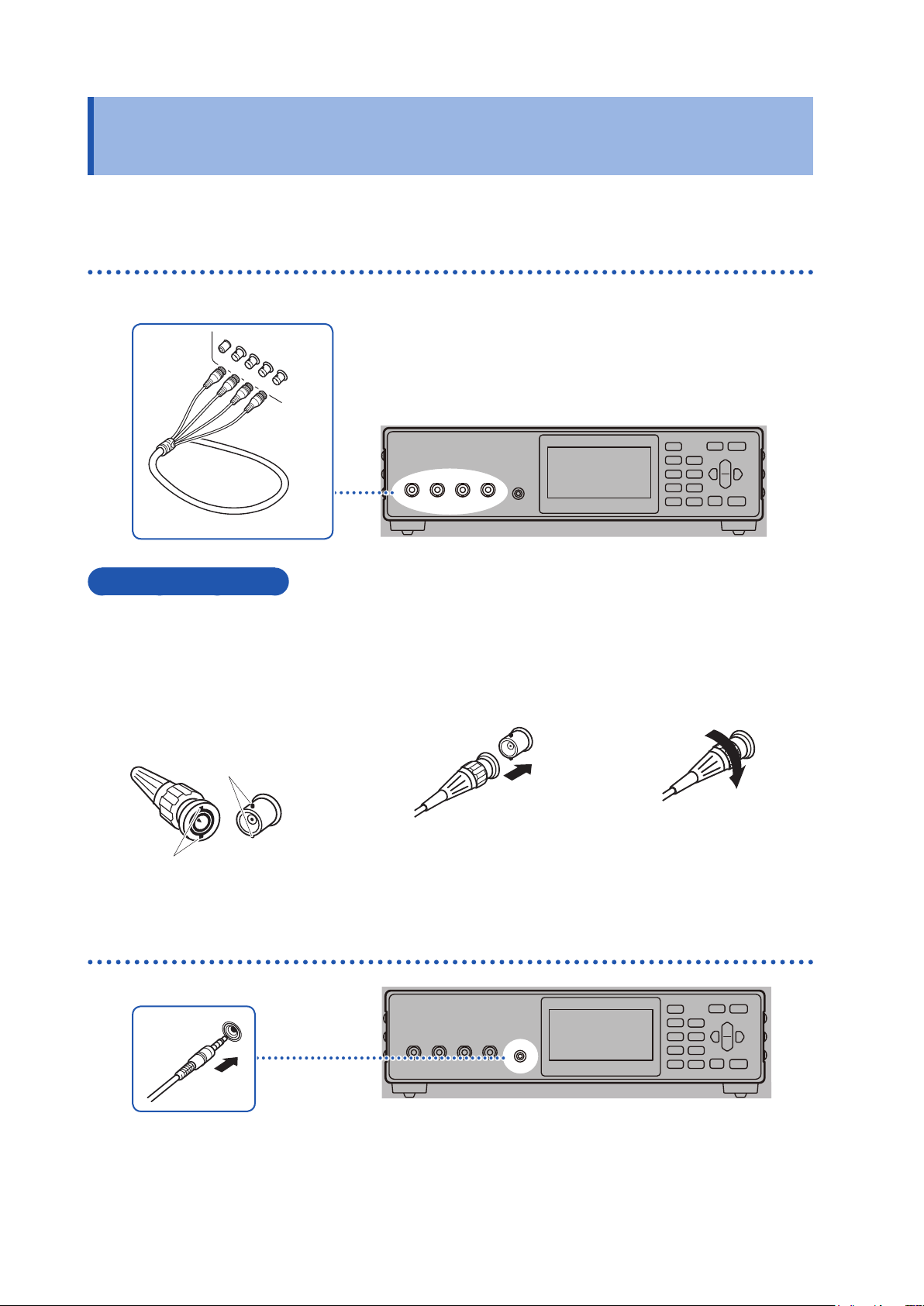

2.2 Connecting the Measurement Probe and Temperature Sensor (Optional)

The measurement probe and the temperature sensor are optional. (p. A12)

Connect the four-terminal cable to the instrument

Connection method

Check the orientation of the groove

1

in the BNC connector and ensure

that it ts into the connector guide

of the instrument side.

Connector guide of the

instrument’s current

input terminal

BNC connector groove of

measurement probe

Align the groove in the BNC

2

connector along the connector

guide of the instrument, and

insert the BNC connector into the

instrument connector.

3

Connect the temperature sensor to the instrument

Turn the BNC connector to the

right and lock it.

18

Page 25

Turning the Power ON or OFF

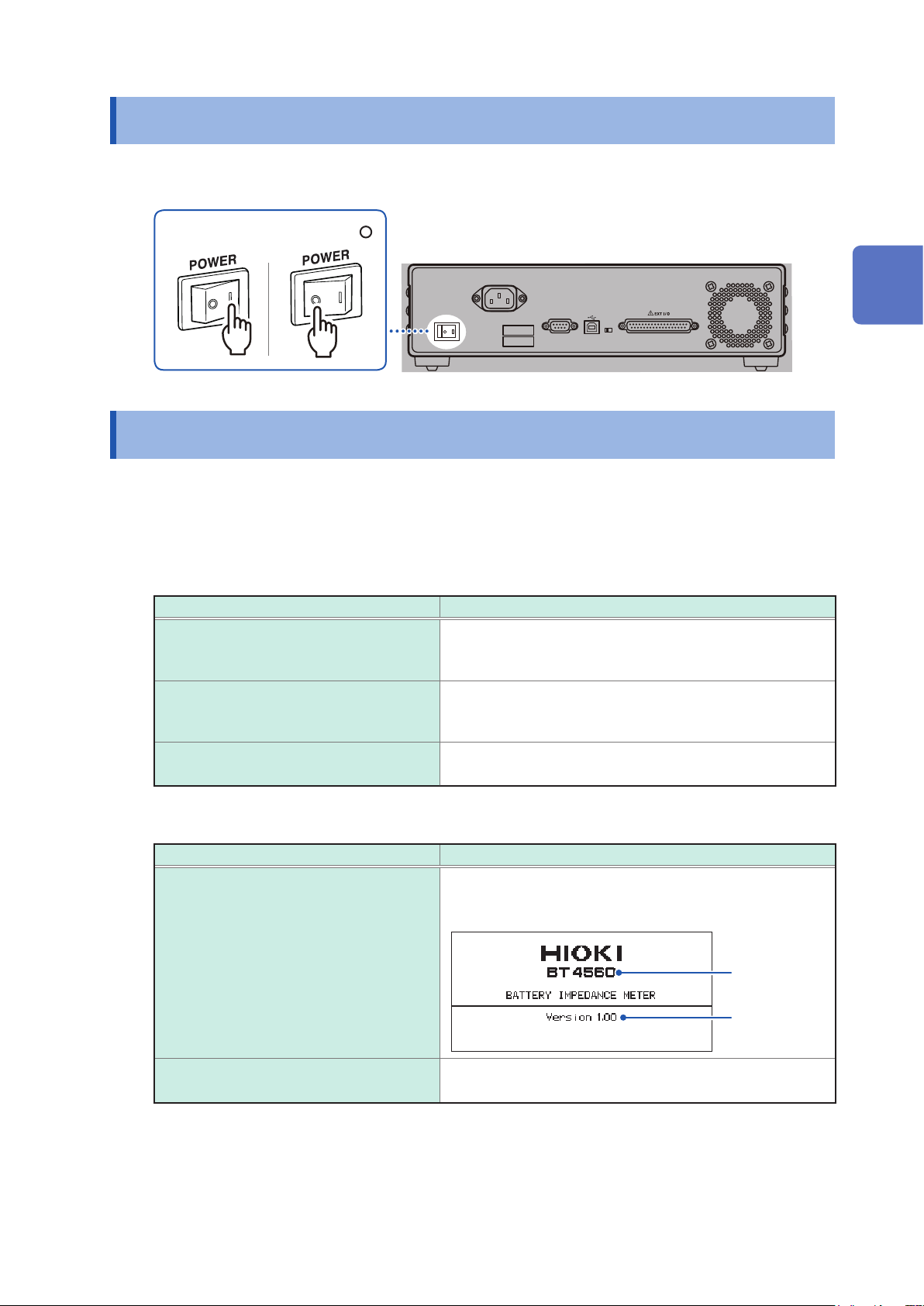

2.3 Turning the Power ON or OFF

Turn the power on or off using the power switch on the rear.

Power OFF ( )Power ON (I)

2.4 Inspection Before Use

Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

2

Preparation

Verifying the instrument and the peripheral devices

Inspection items Countermeasures

Is the power cord insulation torn, or is any

metal exposed?

Is the insulation of the measurement probe

or the connection cords torn, or is any metal

exposed?

Is the instrument damaged? When any damage is found, it may cause electrical shock. Do

Verifying when turning the power on

Inspection items Countermeasures

Does the fan rotate when the power is

turned on? Are there the indications of

“BT4560” and “Version number” on the

display?

Do not use the instrument if damage is found, as electric

shock or short-circuit accidents could result.

Contact your authorized Hioki distributor or reseller.

When any damage is found, it may cause electrical shock. If

this happens, replace the measurement probe or connection

cords with ones specied by Hioki.

not use the instrument, and then request repair.

If the fan does not rotate, or if “BT4560” and “Version number”

are not displayed, the instrument may be malfunctioning.

Request repairs.

BT4560

After the self-test, is the measurement

screen displayed?

Version

If the screen does not display, the instrument may have be

malfunctioning internally. Request repairs.

19

Page 26

Inspection Before Use

20

Page 27

3

Basic Measurement

3.1 Selecting the Measurement Functions

Set the measurement functions.

Parameters

Z

θ

R

By pressing

For the selectable functions, refer to Table below.

Measurement functions

R, X, V, T

Measurement items

Impedance

Phase angle

Resistance

(FUNC) the measurement functions are switched.

Resistance

measurement value

Reactance

measurement value

Voltage

measurement value

Parameters

X

V

T

Screen

Measurement items

Reactance

Voltage

Temperature

RXVT

ZθVT

RXT

Measurement

functions switches.

VT

ZθT

Temperature

3

Basic Measurement

Z, θ, V, T

R, X, T

Z, θ, T

V, T

measurement value

Impedance

Phase angle

measurement value

Voltage

measurement value

Resistance

measurement value

Reactance

measurement value

Impedance

measurement value

Phase angle

measurement value

Voltage measurement

value

Temperature

Temperature

Temperature

Temperature

21

Page 28

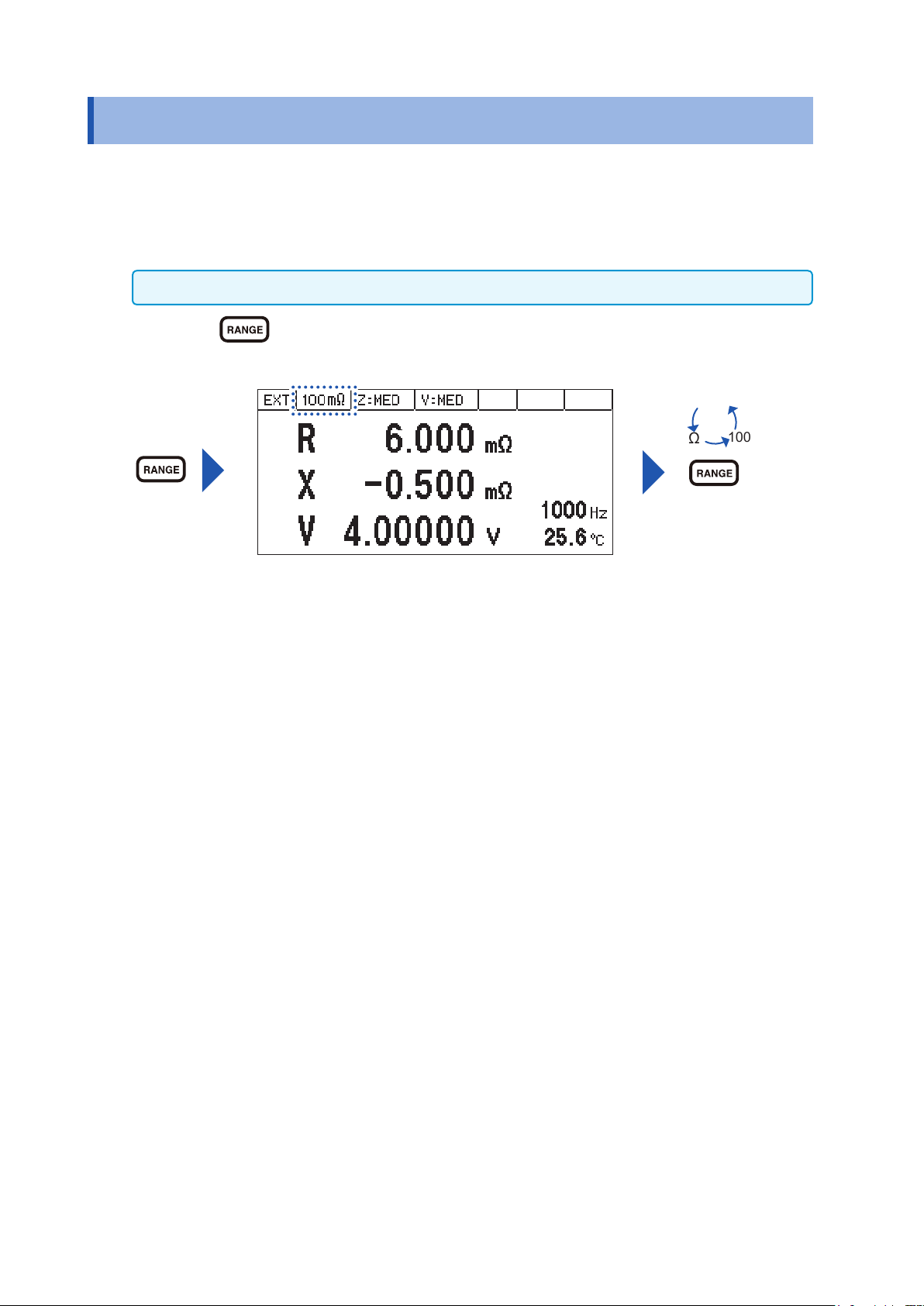

Selecting the Measurement Range

3.2 Selecting the Measurement Range

Set the measurement range of impedance (3 mΩ, 10 mΩ, 100 mΩ).

The voltage and the temperature have a single range respectively. Thus, setting is not necessary.

Use the measurement range of impedance when the impedance measurement value exceeds the

present range or when changing the measurement accuracy.

When the functions (V, T) are selected, setting cannot be performed.

By pressing (RANGE) the measurement ranges are switched.

3 m

10 m

Ω

Ω

100 m

Ω

Measurement ranges

switches.

22

Page 29

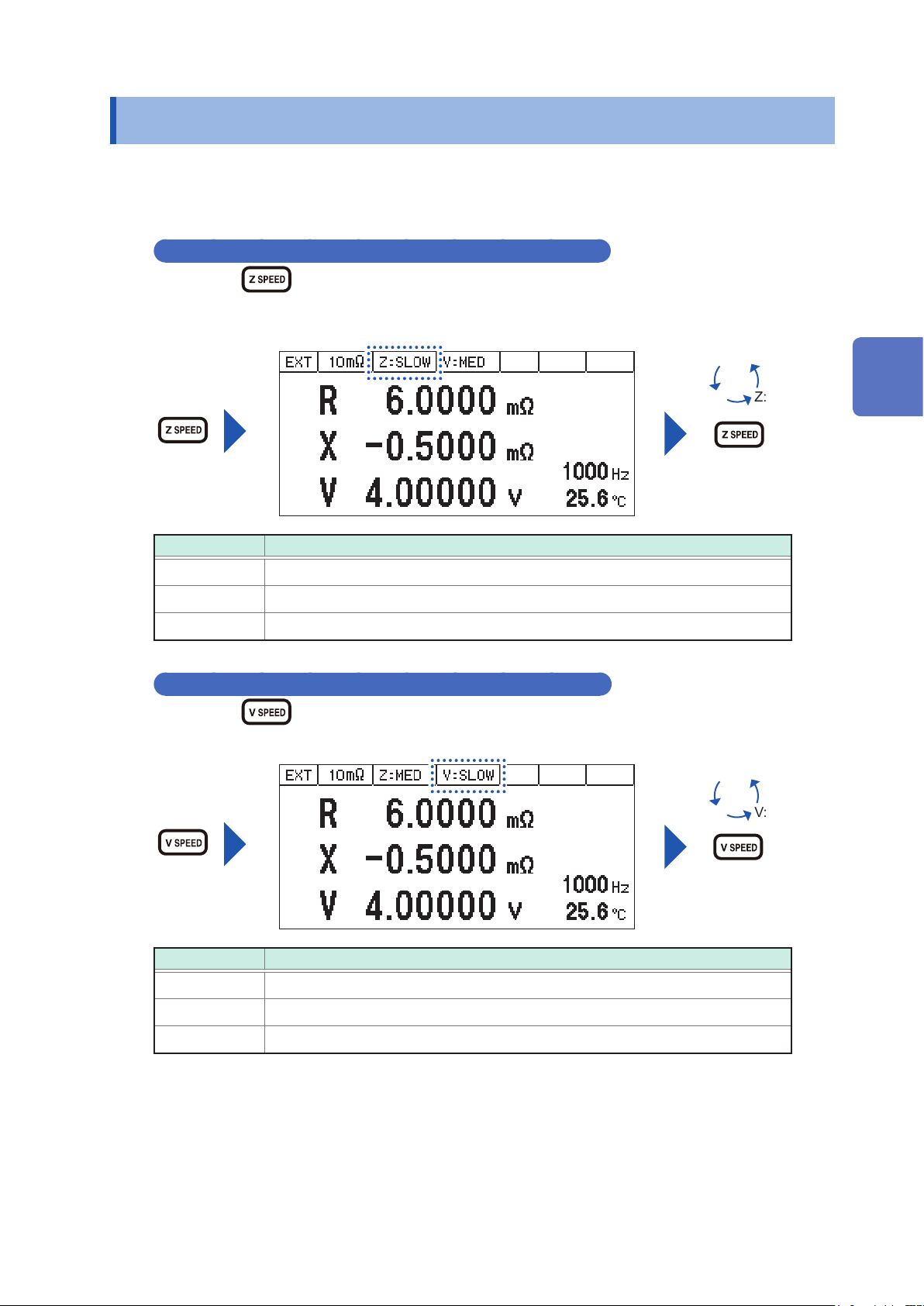

Setting the Measurement Speed

3.3 Setting the Measurement Speed

Set the measurement speed (FAST, MED, SLOW) in the impedance measurement and the voltage

measurement.

The slower the measurement speed is, the more accurate are the results.

Set the measurement speed of impedance measurement (Z)

By pressing

switched.

Setting Items Contents

Z:FAST When the high speed measurement is performed, set this item.

Z:MED When the normal speed measurement is performed, set this item.

Z:SLOW When the high accurate measurement is performed, set this item.

Set the measurement speed in the voltage measurement (V)

By pressing

(Z SPEED) the measurement speed in the impedance measurement is

(V SPEED) the measurement speed in the voltage measurement is switched.

Z:FAST

Z:MED

Measurement speed

Z:SLOW

switches.

3

Basic Measurement

V:MED

Measurement speed

Setting Items Contents

V:FAST When the high speed measurement is performed, set this item.

V:MED When the normal speed measurement is performed, set this item.

V:SLOW When the high accurate measurement is performed, set this item.

V:FAST

V:SLOW

switches.

23

Page 30

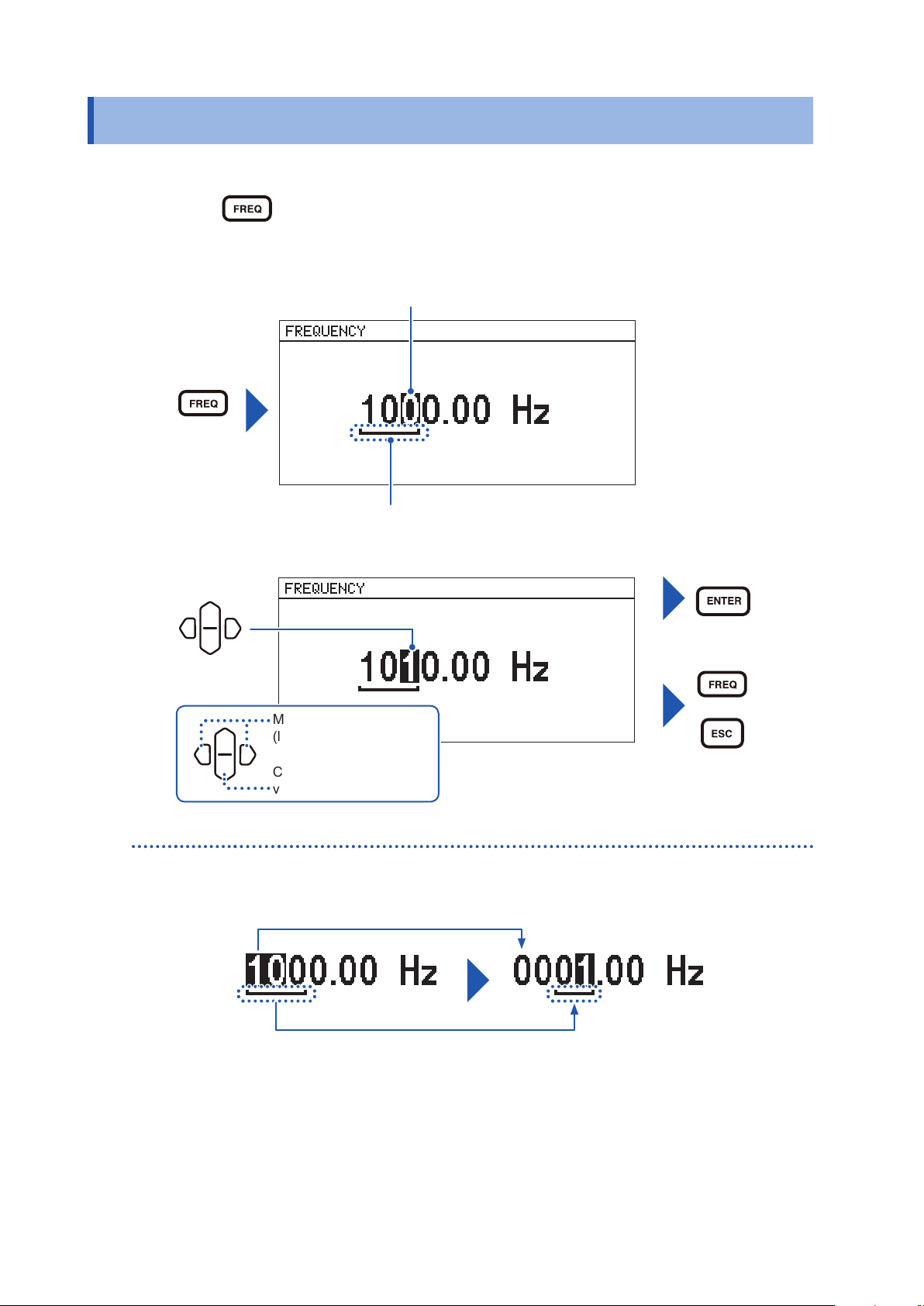

Setting the Measurement Frequency

3.4 Setting the Measurement Frequency

Setting the measurement frequency. (0.1 Hz to 1050 Hz)

Press (FREQ). (Measurement frequency setting screen appears.)

1

The selected digit is displayed in reverse black and white, with a bar under the digit enabled

to be set.

Portion selected (reverse black and white)

Digits enabled to be set

Set the measurement frequency.

2

Setting

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Disabled digits will be set to zero automatically.

Conrm

(or)

Cancel

The display will automatically change

to zero as setting the digits is disabled.

24

Page 31

Setting the Measurement Frequency

When the measurement time is long (Display of the Progress Bar)

When the impedance measurement time is long (more than approx. 1 second), the progress bar is

displayed on the right side of the measuring screen which is in operation.

During sample delay (p. 38)

[D] is displayed at the center of the progress bar.

Progress bar

([D] is displayed at the center.)

During impedance measurement

Percentage of measurement progress is displayed at the center of the progress bar.

3

Basic Measurement

Progress bar

(Progress percentage is displayed at the

center.)

Transition of the progress percentage

Progress

percentage

0%

During the detection of zero cross stop (When zero cross stop is ON) (p. 47)

[Z] is displayed at the center of the progress bar.

Progress

percentage

20%

Progress

percentage

80%

Measurement complete (The

progress percentage is 100%.)

The measurement is nished and the

measurement value is displayed.

Progress bar

([Z] is displayed at the center.)

25

Page 32

Performing the Zero Adjustment

3.5 Performing the Zero Adjustment

Remove the residual components due to offset and the measurement environment.

Be sure to perform the zero adjustment before the impedance measurement and the voltage

measurement.

Performing the zero adjustment

Placing the measurement probe (Example: L2002)

Place the measurement probe in the same condition as the measurement is performed.

1

The zero residual volume differs due to the condition of the measurement probe (length, shape, and location).

Thus, place the measurement probe in the same condition as the actual measurement is performed, before

performing the zero adjustment.

Prepare the zero adjustment board (accessory).

2

Place the probes with a space the same length as the width of the actual measuring object.

3

Clip a pattern on the zero adjustment board, with the same number of divisions for both HIGH and LOW.

L2002

Clip Type Probe

Zero adjustment board

Measuring object

Divisions

Setting the zero adjustment

There are two methods of the zero adjustment, the spot zero adjustment (SPOT) and the all zero

adjustment (ALL).

The zero adjustments for the range and the frequency that are presently set, and

the voltage measurement are performed. The time required differs according to

Spot zero adjustment

(SPOT)

All zero adjustment

(ALL)

the frequency. The lower the frequency, the longer it takes to set (Reference:

approx. 350 s for 0.1 Hz, approx. 45 s for 1 Hz).

When setting at a different range and/or frequency, zero adjustment will be

invalid.

The zero adjustments for the range that is presently set, and the full range

of the frequency, and the voltage measurement are performed. Even if the

measurement frequency is changed, the zero adjustment is effective. However,

when the range is changed, the zero adjustment is not effective.

26

• When the zero adjustment is effective, the indicator of 0 ADJ appears on the measurement

screen.

• After performing the zero adjustment, even if the zero adjustment becomes ineffective, the zero

adjustment will become effective when returning to the conditions that the zero adjustment was

performed.

• With the 0ADJ_SPOT of the EXT.I/O and 0ADJ_ALL terminals, performing can be done.

Page 33

Press (0 ADJ). (The zero adjustment screen appears.)

1

Select [ON].

2

Performing the Zero Adjustment

3

Selection

Select [SPOT] or [ALL].

3

Selection

When selecting [ALL], the conrmation window opens.

OK: Performing all zero adjustment

CANCEL: Returns to the measurement screen without execution.

To the SPOT and ALL

selection screen

(or)

Cancel

Performing zero

adjustment

(or)

Cancel

Basic Measurement

Conrm

Selection

After the zero adjustment is normally performed, the screen will go back to the measurement

4

screen.

(When the zero adjustment is effective, 0 ADJ appears at the upper right on the measurement

screen.)

27

Page 34

Performing the Zero Adjustment

When the zero adjustment is not normally performed

When [0 ADJUST ERROR] appears, the proper adjustment is not performed.

Check the short-circuit method of the measurement probe and perform the zero adjustment with a proper

method so that the zero adjustment data values come within the range given in the table below.

Return

Impedance

measurement

range -0.1000 mΩ to 0.1000 m

3 m

Ω

10 mΩ range -0.3000 mΩ to 0.3000 m

100 mΩ range -3.000 mΩ to 3.000 m

Voltage measurement

-0.10000 V to 0.10000 V

R X

-1.5000 mΩ to 1.5000 m

Ω

-1.5000 mΩ to 1.5000 m

Ω

Ω

-1.500 mΩ to 1.500 m

Ω

Ω

Ω

Disabling zero adjustment

Select [OFF] on the zero adjustment screen.

(When [OFF] is selected, zero adjustment will be disabled. To enable, perform zero adjustment again.)

Conrm

28

Selection

(or)

Cancel

Page 35

When measuring while changing the measurement range

If measured as below, zero adjustment will not be necessary every time the range is changed.

1. Perform zero adjustment at 3 mΩ range.

2. Save the current condition by panel saving function (p. 58).

(Zero adjustment data of the current range will be saved.)

3. Change the range to 10 m

4. Save the current condition by panel saving function (p. 58).

5. Change the range to 100 m

6. Save the current condition by panel saving function (p. 58).

7. Read the condition of the range used by panel saving function (p. 58), and then measure.

and perform zero adjustment.

Ω

and perform zero adjustment.

Ω

Connection when performing the zero adjustment

Performing the Zero Adjustment

If the zero adjustment board is used, the connection will be as below.

Perform zero adjustment with the same connection when making your own measurement probe (refer to

“Appx. 3 Cautions When Making Your Own Measurement Probe” (p. A4)).

Connect the shields of SOURCE-H and SOURCE-L.

1

(Connected by the return cable)

Connect SENSE-H and SENSE-L.

2

Connect SOURCE-H and SOURCE-L.

3

Connect the above 2 and 3 lines at one point.

4

SENSE-HSENSE-L SOURCE-HSOURCE-L

3

Basic Measurement

Connection to the SOURCE shield Connect the above 2 and 3 at one point.

Connection to the

SOURCE shield

29

Page 36

Checking the Measurement Results

3.6 Checking the Measurement Results

Detecting the measurement abnormality

When the measurement is not normally performed, the indication expressing the measurement

abnormality appears on the screen, and the ERR signal from the EXT.I/O is output.

Contact error

When the resistance value is greater between SOURCE-H and SENSE-H, or between SENSE-L

and SOURCE-L, the contact error appears. The possible causes are listed below.

• The measurement probe is not connected to the measuring object.

• The probe is broken.

• The contact resistance or the wiring resistance are large due to frictional wear and dirt of the probe.

• The circuit protection fuse is broken.

The guideline in the contact error detection

Target resistance value for

Place for abnormality

detection

SOURCE-H and SENSE-H 10

SOURCE-H and SOURCE-L 10

• The resistance values indicate the guideline, which are not strictly dened.

• The capacitance of the measurement probe is greater than 20 nF, the measurement abnormality may not

be detected.

• For functions V and T, target resistance value for abnormality detection will be the same resistance value

as 100 m

range.

Ω

abnormality detection

3 m

10 mΩ

Ω

range

range

Ω

Ω

15

15

Ω

Ω

100 mΩ

range

50

Ω

50

Ω

Measurement

abnormality type

H Contact error

L Contact error CONTACT ERROR L

Error indication

CONTACT ERROR H

Over-voltage input error (indication: OVER VOLTAGE)

When the voltage of the measuring object exceeds the measurable range, OVER VOLTAGE

appears.

The measurable voltage range is -5.10000 V to 5.10000 V.

It may be displayed SENSE-H and SOURCE-H short-circuit, and SENSE-L and SOURCE-L shortcircuit state.

Voltage limit error (Indication: OVER V LIMIT)

When the voltage of the measuring object exceeds the voltage limit setting range, LIMIT VOLTAGE

appears.

For the setting method of the voltage limit, refer to “4.6 Preventing the Overcharge due to

Measurement Signal (Voltage Limit Function)” (p. 45).

It may be displayed SENSE-H and SOURCE-H short-circuit, and SENSE-L and SOURCE-L shortcircuit state.

Measurement current abnormality (Indication: ------)

This indication appears when the measurement current does not ow normally. The possible

causes are listed below.

• The contact resistance or the wiring resistance are large due to frictional wear and dirt of the

probe.

• The resistance of the measuring object is remarkably large to the range (Example: when 1 k

Ω

is

selected).

• When wiring is wrongly connected to a battery.

• When wiring is connected to a battery that is grounded.

30

Page 37

Checking the Measurement Results

The guide line in the abnormality detection of the measurement current

Place for abnormality

detection

SOURCE-H 1.5

SOURCE-L 1.5

The resistance values indicate the guideline, which are not strictly dened. The detected value of

SOURCE-H changes based on the voltage of the measuring object.

Target resistance value for abnormality

detection

3 mΩ range 10 mΩ range 100 mΩ range

to 4.0

Ω

Ω

Ω

5 Ω to 12

4

Ω

Ω

50 Ω to 55

45

Ω

Measurement

abnormality

Measurement

Ω

abnormality

Measurement

abnormality

type

current

current

Indi-

cation

------

------

Impedance measurement error due to voltage drift (Indication: VOLTAGE DRIFT)

The voltage of the measuring object considerably uctuates during the measurement.

When the difference between voltage values at the start and at the end of measurement is 10 mV

or more, the difference is detected as an error.

Return cable unconnected error (Indication: RETURN CABLE ERROR)

The probe’s return cable is not properly connected. It may be disconnected or the wire connection

may be wrong.

To reduce noise due to the electromagnetic induction, it needs the return cable where the current

ows opposed to the measurement current. The return cable has a structure that short-circuits

between the shield wire of the SOURCE-H and the shield wire of the SOURCE-L. (In the optional

probe, the return cable short-circuits between the shield wire of the SOURCE-H and the shield wire

of the SOURCE-L.)

3

Basic Measurement

31

Page 38

Checking the Measurement Results

Detection sequence of measurement abnormality

Error indication judgment Indication

Contact error between the SOURCE-H and the SENSE-H

No

Contact error between the SOURCE-L and the SENSE-L

No

Over-voltage input error

No

Voltage limit error

No

Voltage drift error

No

Return cable error

No

Contact error between the SOURCE-H and the SENSE-H

Yes

Yes

Yes

Yes

Yes

Yes

Yes

CONTACT

ERROR H

CONTACT

ERROR L

OVER

VOLTAGE

OVER

V LIMIT

VOLTAGE

DRIFT

RETURN CABLE

ERROR

CONTACT

ERROR H

No

Contact error between the SOURCE-L and the SENSE-L

Yes

Measurement errors are judged in the order of the above gure and the error detected initially is

displayed.

Abnormal measurement current is monitored during the following:

• When trigger has been accepted until voltage measurement is executed

• During impedance measurement

CONTACT

ERROR L

Temperature measurement indication

Temperature sensor unconnected (Indication: --.-°C)

The temperature sensor is not connected. Thus, the temperature measurement cannot be performed.

When the temperature measurement is not necessary, there is no need for connection.

Overrange indication

Each parameter over-indicates due to causes listed below.

Parameters Over indication Cause

R

32

X

Z

OverRange

The measurement value of Z exceeds the indication range of the

present range.

θ

T

+Over°C The measurement value is greater than 60.0°C.

-Under°C The measurement value is smaller than -10.0°C.

Page 39

3.7 Basic Measurement Examples

In this section, setting the battery cell is explained as an example.

Examples of setting contents

Measurement functions R, X, V, T

Measurement Range 100 m

Measurement

speed

Impedance measurement frequency 1 Hz

Zero adjustment ALL

Impedance

measurement

Voltage measurement SLOW

FAST

Basic Measurement Examples

Ω

3

Set the measurement functions (R, X, V, T). (p. 21)

1

Set the measurement range at 100 mΩ. (p. 22)

2

Set the measurement speed of impedance measurement (Z) at [FAST]. (p. 23)

3

Basic Measurement

33

Page 40

Basic Measurement Examples

Set the speed of the voltage measurement (V) at [SLOW]. (p. 23)

4

Set the measurement frequency of impedance at 1 Hz. (p. 24)

5

Connect the zero adjustment connection and then perform the all zero adjustment. (p. 26)

6

Connect the battery cell.

7

Battery cell

34

8

Press START/STOP to measure.

Page 41

Check the measurement results.

9

Basic Measurement Examples

3

Basic Measurement

35

Page 42

Basic Measurement Examples

36

Page 43

Customization of Measurement

4

Conditions

4.1 Setting the Measurement Starting Conditions (Trigger Functions)

There are two methods to set the measurement starting conditions, which are described below.

External trigger

Internal trigger

Setting the trigger

Press (MENU). (The setting screen appears.)

1

Select [MEAS] tab.

2

When (START/STOP)

measurement starts.

Trigger signals are automatically generated internally to perform the automaticmeasurement.

is pressed or the external trigger signal is input, the

4

Customization of Measurement Conditions

Selection

Select [EXT] (external trigger) or [INT] (internal trigger).

3

Selection

Conrm

(or)

Cancel

37

Page 44

Starting the Measurement After the Response of the Measuring Object is Stable (Sample Delay Function)

Inputting the external trigger

• When inputting from the key

On the measurement screen, press

• When inputting from the EXT.I/O

If the TRIG terminal of the EXT.I/O terminal is short-circuited to ISO_COM, the measurement is

performed once. (p. 80)

• When inputting from the communication interface

When the

IMPORTANT

• When the function is set in the internal trigger, the input from the EXT.I/O and

are ignored, and the voltage limit function is enabled. If the measuring object continues to

be connected with an internal trigger set, may cause continuous charging or discharging.

Therefore, remove the measuring object from the instrument after measurement.

• Measurement will stop if

*TRIG

command is received, measurement is performed once.

(START/STOP) is pressed during measurement.

(START/STOP) to perform measurement once.

*TRG

command

4.2 Starting the Measurement After the Response of the Measuring Object is Stable (Sample Delay Function)

When measuring impedance, set the delay (delayed time) from applying AC to the start of the

sampling. There are two methods to set the delay, one is to use the frequency of the Alternating

Current signal for setting and the other is to use the deviation of the offset voltage uctuation for

setting.

Settings based on waveform (WAVE)

Alternating Current response of the battery

Set the delay with the frequency of the Alternating Current signal.

(This is an example for delay of frequency 4.)

38

Sample delay

Application of Alternating Current

Sampling

Page 45

Starting the Measurement After the Response of the Measuring Object is Stable (Sample Delay Function)

Setting with the deviation of voltage uctuation (∆VOLT)

Alternating Current response of the battery

VOLT

∆

VOLT

∆

Sampling

The slope of Alternating Current response is monitored and sampling is started

when the slope of deviation (∆VOLT) drops below the set value.

Press (MENU). (The setting screen appears.)

1

4

Select [MEAS] tab.

2

Selection

Select [WAVE] or [∆VOLT].

3

Customization of Measurement Conditions

Selection

Conrm

(or)

Cancel

39

Page 46

Starting the Measurement After the Response of the Measuring Object is Stable (Sample Delay Function)

When selecting [WAVE], set the wavenumber of delay. (0.0 waves to 9.0 waves)

Conrm

Setting

Move to the next digit

(left or right)

(or)

Changing the numerical

value (up and down)

When selecting [∆VOLT], set the voltage. (00.001 mV to 10.000 mV)

Setting

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Cancel

Conrm

(or)

Cancel

40

Page 47

Maintaining Voltage Measurement Accuracy (Self-Calibration Function)

4.3 Maintaining Voltage Measurement Accuracy (Self-Calibration Function)

This function compensates the offset voltage and the gain drift in the internal part of the circuit, to

improve the voltage measurement accuracy.

To satisfy the instrument’s measurement accuracy, the self-calibration is required. Be sure to

perform it. Be sure to perform the self-calibration especially after warming-up or when the ambient

temperature has changed more than 2°C.

The methods for conguring self-calibration to run are as follows:

Self calibration of 0.2 s is automatically executed before measuring the voltage.

AUTO

MANUAL

In the functions (R, X, T) and (Z, θ, T) where the voltage measurement is not

performed, the self-calibration is not performed.

The self-calibration is performed from the input signal CAL of the EXT.I/O, or from

the command.

(Perform it under the TRIG waiting condition. When the signal is input, perform it

after the measurement.)

4

Press (MENU). (The setting screen appears.)

1

Select [MEAS] tab.

2

Selection

Customization of Measurement Conditions

Select [AUTO] or [MANUAL].

3

Selection

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Conrm

(or)

Cancel

41

Page 48

Stabilizing the Measurement Values (Average Function)

4.4 Stabilizing the Measurement Values (Average Function)

The arithmetic mean for the set number of measurement values will be displayed as the result. This

function can reduce the uctuation of the measurement values. This function can apply only to the

impedance measurement.

Press (MENU). (The setting screen appears.)

1

Select [MEAS] tab.

2

Selection

Sets the number of measured values to be used for averaging. (1 to 99)

3

Selection

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Conrm

(or)

Cancel

42

Page 49

Compensating the Potential Slope Due to Electric Discharge (Slope Correction Function)

4.5 Compensating the Potential Slope Due to Electric Discharge (Slope Correction Function)

During impedance measurement, the measurement signal may drift due to characteristics of the

battery and input impedance of the measuring instrument. This function performs compensation for

linear drift.

Before compensation

V V

IMPORTANT

Compensation will be performed for linear drift.

Proper compensation cannot be performed for uctuations that are not linear as shown below.

“Starting the Measurement After the Response of the Measuring Object is Stable (Sample Delay

Function)” (p. 38) is used, and wait to measure until the measuring object’s response time

becomes stable.

Proper compensation cannot be performed

for drifts that are not linear.

V

After compensation

4

Customization of Measurement Conditions

Compensation is enabled for

linear drift.

43

Page 50

Compensating the Potential Slope Due to Electric Discharge (Slope Correction Function)

Press (MENU). (Settings screen is displayed.)

1

Select [MEAS] tab.

2

Selection

Select [ON] or [OFF].

3

Selection

Conrm

(or)

Cancel

44

Page 51

Preventing the Overcharge due to Measurement Signal (Voltage Limit Function)

4.6 Preventing the Overcharge due to Measurement Signal (Voltage Limit Function)

This function prevents the battery from getting overcharged due to the applied signal when

measuring impedance. If the voltage of the object to be measured is higher compared to the set

voltage, impedance will not be measured and the message [OVER V LIMIT] will be displayed.

CAUTION

Set the voltage limit value lower than the voltage value of the measuring object’s battery

which will become overcharged. The battery may be overcharged, if the measurement

is repeated at a high voltage value setting.

Press (MENU). (Settings screen is displayed.)

1

4

Select [MEAS] tab.

2

Selection

Select [ON] or [OFF].

3

Customization of Measurement Conditions

Conrm

Selection

(or)

Cancel

45

Page 52

Preventing the Overcharge due to Measurement Signal (Voltage Limit Function)

When selecting [ON], set the voltage. (0.01 V to 5.00 V)

Selection

Conrm

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

(or)

Cancel

46

Page 53

Prevents Charging and Discharging due to the Measurement Signal (Measurement Signal Zero Cross Stop Function)

4.7 Prevents Charging and Discharging due to the Measurement Signal (Measurement Signal Zero Cross Stop Function)

This function performs the process of stopping the applied measurement signal at zero cross during

impedance measurement to prevent charging and discharging of the object to be measured. When

the measurement signal zero cross stop function is enabled, the measurement time increases by

approximately one cycle of measurement frequency.

The charging and discharging of the battery is prevented

I

by stopping the measurement current at zero cross.

Charging

0

Press (MENU). (Settings screen is displayed.)

1

Select [MEAS] tab.

2

4

Customization of Measurement Conditions

Discharging

Selection

47

Page 54

Prevents Charging and Discharging due to the Measurement Signal (Measurement Signal Zero Cross Stop Function)

Select [ON] or [OFF].

3

Conrm

Selection

(or)

Cancel

48

Page 55

Judging Measurement Results

5

(Comparator Function)

The function judges that the measured value is in the range of Hi (upper limit value < measured

value), or IN (lower limit value ≤ measured value ≤ upper limit value), or Lo (measured value <

lower limit value) compared to the preset upper and lower limit value.

Upper and lower limit values and absolute values (absolute values setting is for voltages [V] only)

Upper and lower limit values

The function judges whether the measurement value is in the Hi, IN, or Lo range for the upper and

lower limit values set previously.

(Example: If the upper limit is 3 V, Lower limit is 2 V, and the measurement value is 1.5 V)

Measurement value

Lower limit value Upper limit value

Judgment

1.5 V

(Lo Judgment)

Absolute value

The function judges whether the absolute value of the measurement value is in the Hi, IN, or Lo

range for the upper and lower limit values set previously.

Even if wiring is connected in reversed polarity, judgment can be performed correctly.

(Example: If the upper limit 3 V, Lower limit is -1 V, and the measurement value is -2 V)

Measurement value

Lower limit value Upper limit value

Judgment

-1 V

2 V 3 V

INLo

Absolute value

INLo

Hi

Hi

3 V

5

Judging Measurement Results (Comparator Function)

-2 V

2 V

(IN judgment)

49

Page 56

Turning the Comparator Function ON and OFF

5.1 Turning the Comparator Function ON and OFF

Press (COMP). (The setting screen appears.)

1

Select [SYST] tab.

2

Selection

Select [ON] or [OFF].

3

Selection

Conrm

(or)

Cancel

50

Page 57

Setting the Upper and Lower Limit Value

5.2 Setting the Upper and Lower Limit Value

When making the comparator function effective, set the upper and lower limit value, which are used

for the judgment. The following describes the setting method, taking R, X, V as the examples.

Setting examples

R Upper limit value: 7.5 mΩLower limit value: 7 m

X No judgment

V Upper limit value: 5 V Lower limit value: 4 V

Press (COMP). (The setting screen appears.)

1

Select [COMP] tab.

2

Selection

Ω

5

Judging Measurement Results (Comparator Function)

Select parameter [R].

3

Setting

Conrm

(or)

Cancel

51

Page 58

Setting the Upper and Lower Limit Value

Set the upper limit value of [R] at 7.5000 mΩ, and the lower limit value at 7.0000 mΩ.

4

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Since the parameter [X] is not used, the value is not set. ([---.----] display indicates disabled.)

5

Upper limit value Lower limit value

Conrm

(or)

Cancel

Select parameter [V].

6

Selection

Set the upper limit value of [V] at 5.00000 V, and the lower limit value at 4.00000 V.

7

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Conrm

(or)

Cancel

Conrm

(or)

52

Upper limit value Lower limit value

Cancel

Page 59

Setting the Upper and Lower Limit Value

When [CLR] is selected and conrmed, the set value is displayed as [-.----] and is disabled.

Disabled parameters are not judged.

Conrm

Selection

(or)

Cancel

When set to 100 mΩ range (Minimum resolution 0.001 mΩ)

Rounded off to the minimum digits set.

After rounding, the upper limit will be 7.500 mΩ, and the lower limit will be 7.001 mΩ.

Settable range

R -003.0000 mΩ to +120.0000 m

X -120.0000 mΩ to +120.0000 m

Z +000.0000 mΩ to +120.0000 m

θ

V -5.10000 V to +5.10000 V

IMPORTANT

When the value of Hi is set smaller than the value of Lo, the value of Hi set is corrected to the

value of Lo.

-180.000° to +180.000°

Common in all ranges

Ω

Ω

Ω

5

Judging Measurement Results (Comparator Function)

53

Page 60

Voltage is Judged with the Absolute Value

5.3 Voltage is Judged with the Absolute Value

The upper and lower limit of voltage is judged with the absolute values.

(R, X, Z and

Press (COMP). (Settings screen is displayed.)

1

Sets the upper and lower limit values for [V]. (p. 51)

2

cannot be set to be judged with absolute values.)

θ

Select [SYST] tab.

3

Selection

Select [ON] or [OFF].

4

Move to the next digit

(left or right)

Changing the numerical

value (up and down)

Upper limit value Lower limit value

Conrm

(or)

Cancel

54

Conrm

Setting

(or)

Cancel

Page 61

Checking the Judgment with Sound

5.4 Checking the Judgment with Sound

Select whether to use a judgment sound of the measurement results.

OFF : The buzzer does not sound.

Hi • Lo : When the judgment result is Hi • Lo, the buzzer sounds (three short sounds).

IN : When the judgment result is IN, the buzzer sounds (long sound).

ALL : When the judgment result is Hi • Lo, the buzzer sounds (three short sounds).

When the judgment result is IN, the buzzer sounds (long sound).

Setting the sound

Judgment result in

measurement

HI —

OFF Hi • Lo IN ALL

(three short sounds) —

(three short sounds)

IN — —

Lo —

—: No buzzer sound, (long sound): Long buzzer sound, (three short sounds): Three short buzzer sounds.

Press (COMP). (The setting screen appears.)

1

Select [SYST] tab.

2

(three short sounds) —

(long sound)

(long sound)

(three short sounds)

5

Judging Measurement Results (Comparator Function)

Selection

Select the buzzer sound from among [OFF], [IN], [Hi • Lo], [ALL].

3

Selection

Conrm

(or)

Cancel

55

Page 62

Checking the Judgment Result

5.5 Checking the Judgment Result

The indicator appears at the left of the parameters on the measurement screen depending on the

judgment result.

Each judgment result, and the comprehensive judgment result of all the parameters are output to

the EXT.I/O.

PASS of the comprehensive judgment result is ON (FAIL is OFF) only when all the enabled

parameters judged by the comparator are IN.

When the measured value is smaller than the upper limit value and greater than the

lower limit value.

When the measured value is greater than the upper limit value that is set.

When the measured value is smaller than the lower limit value that is set.

Judgment

result

Measurement result

Hi Set value < Measured value Hi ON OFF OFF OFF OFF ON

Lo Set value ≤ Measured value ≤

Hi Set value

Measured value < Lo Set value Lo OFF OFF ON OFF OFF ON

OverRange Hi ON OFF OFF OFF OFF ON

Measurement Error

During interruption of

measurement

Judgment

result

IN OFF ON OFF OFF ON OFF

No

judgment

No

judgment

Hi IN Lo ERR PASS FAIL

OFF OFF OFF ON OFF OFF

OFF OFF OFF OFF OFF OFF

Output of EXT. I/O

56

Page 63

Saving and Reading

6

Measurement Conditions

(Panel Saving and Loading)

The present measurement conditions are saved to the memory of the instrument (panel saving

function), and the measurement conditions are read from the memory by the key operation,

communication command transmission, and external control. (Panel loading function)

The instrument can save 126 panels of measurement conditions at a maximum. The measurement

conditions that are saved are retained even if the power is turned off, which can be read by the

panel loading function.

Items that can be saved by the panel saving

• Measurement functions • Measurement range • Measurement frequency

Saving

contents

• Measurement speed of

impedance

• Zero adjustment data • Sample delay setting • Comparator setting

• Average • Slope correction setting • Voltage limit

• Self -Calibration settings • Measurement signal zero

• Measurement speed of

voltage

cross stop function

• Zero adjustment setting

• Trigger source

Numbers

of panel

126

6

Saving and Reading Measurement Conditions

57

Page 64

Saving the Setting Conditions (Panel Saving Function)

6.1 Saving the Setting Conditions (Panel Saving Function)

Saves the measurement conditions that are currently set.

Press (LOAD/SAVE). (The panel screen appears.)

1

Select the number of the panel that will be saved.

2

Conrm

Selection

Select [SAVE].

3

Selection

(When selecting the number of the panel that has been saved, the conrmation window will

appear.)

OK: Overwriting

CANCEL: Cancel

(or)

Cancel

Conrm

(or)

Cancel

58

Conrm

Selection

Page 65

Saving the Setting Conditions (Panel Saving Function)

When [+5] is selected, the next 5 panel numbers are displayed. When [-5] is selected, the

previous 5 panel numbers are displayed.

6

(Panel Saving and Loading)

59

Page 66

Reading the Setting Conditions (Panel Loading Function)

6.2 Reading the Setting Conditions (Panel Loading Function)

Reads the measurement conditions that are saved.

Press (LOAD/SAVE). (The panel screen appears.)

1

Select the number of the panel that will be read.

2

Conrm

Selection

Select [LOAD].

3

Selection

When [+5] is selected, the next 5 panel numbers are displayed. When [-5] is selected, the

previous 5 panel numbers are displayed.

(or)

Cancel

Conrm

(or)

Cancel

60

Page 67

Deleting the Contents of the Panel

6.3 Deleting the Contents of the Panel

Deletes saved measurement conditions.

Press (LOAD/SAVE). (Panel screen is displayed.)

1

Select a panel number to be deleted.

2

Selection

Select [CLEAR].

3

Selection

Opens conrmation window.

OK: Clear

4

CANCEL: Cancel

Conrm

(or)

Cancel

Conrm

(or)

Cancel

6

(Panel Saving and Loading)

Selection

Conrm

61

Page 68

Deleting the Contents of the Panel

62

Page 69

7

System Setting

7.1 Making the Key Operation Effective or Ineffective

Makes the key operation except for (START/STOP) ineffective.

Ineffective

Press (MENU). (The setting screen appears.)

1

Select [SYST] tab.

2

Selection

Select [ON].

3

Selection

7

System Setting

Conrm

(or)

Cancel

[LOCK] appears on the measurement screen, and the key operation becomes ineffective.

4

63

Page 70

Making the Key Operation Effective or Ineffective

Effective

Press (LOCAL) and hold for at least 5 seconds.

1

[LOCK] disappears on the measurement screen, and the key operation becomes effective.

2

64

Page 71

Setting the Sound of the Key Operation Effective or Ineffective

7.2 Setting the Sound of the Key Operation Effective or Ineffective

Make the sound of the key operation effective or ineffective.

Press (MENU). (The setting screen appears.)

1

Select [SYST] tab.

2

Selection

Select [ON] or [OFF].

3

ON : The operation sound is beeped.

OFF : The operation sound is not beeped.

Selection

7

System Setting

Conrm

(or)

Cancel

65

Page 72

Adjusting the Contrast of the Screen

7.3 Adjusting the Contrast of the Screen

The visibility of the screen may not be clear at some ambient temperatures. The visibility of the

screen can be adjusted by adjusting the screen contrast.

Press (MENU). (The setting screen appears.)

1