Page 1

March 2006 Edition 1 Printed in Japan

9772A980-00 06-03H

9772

PIN TYPE LEAD

INSTRUCTION MANUAL

Safety

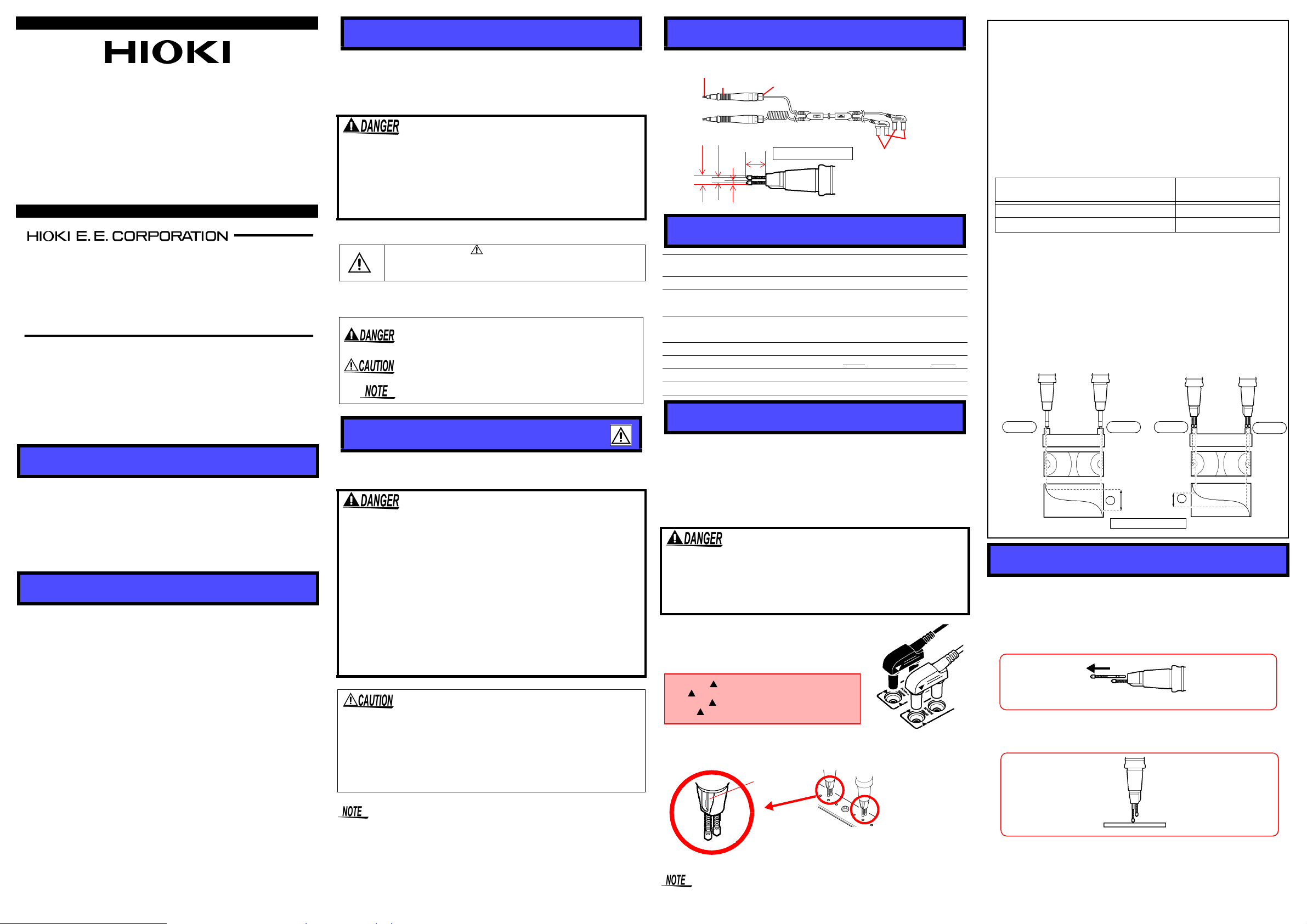

Conductive contact pin (Parallel pins)

9.15

4.3

2.5

Unit: mm

SOURCE connector

SENSE connector

Enlarged view of pin

Grip

Cable lock

φ1.8

1.

2

e

Important

Measurement values when using four-terminal measurement

(Differences in measurement values due to measurement leads used)

Depending on the subject of measurement, such as a lead-acid battery,

measurement values may vary due to the measurement lead used. Since

these differences in measurement values are due to the shapes and

dimensions of the pr obes used in four-term inal measur ement, measu rement

values taken using any probe represent the true values for that probe only.

When judging batter y wear using cha nges in resistance v alues with time, be

sure to use measurement leads having the same dimensions.

Reference example:(measurement of an MSE-200 valve-regulated stationary

lead-acid battery)

Note:Resistanc e values vary acco rding to the materia ls and structure of th e

terminals of the subject of measurement.

See the 3554 Battery HiTESTER manual for detailed technical descriptions.

- Explanation -

Differences in measurement values are physical phenomena resulting from

differences in the distances (dimensions) between current-impression pins and

voltage-measurement pins. The greater the battery terminal resistance in

comparison to the battery's internal resistance, the more marked these

differences become. The following diagram shows how differences in voltage

detected result from dif ferences in d istance whe n measuring a l ead-acid batte ry .

measurement lead

(Distance between the current-

impression pin and the voltage-measurement pin

)

Measuremen t values using

the 3554 Battery HiTESTER

9465-10 PIN TYPE LEAD (0.65 mm)

0.538 mΩ

9772 PIN TYPE LEAD (2.5 mm)

0.490 mΩ

(

Pin distance

: 2.5 mm)

+Terminal

-Terminal

+Terminal

-T erminal

A

B

Lead-acid battery

Lead-acid battery

Equipotential line

Equipote ntia l li ne

Potential gradient Potential gradient

V (voltage detected):A>

B

The model 9465-10

(Pin distance

: 0.65 mm)

The model 9772

Parts Names

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

Introduction

Thank you for purchasi ng the HIOKI “Model 9772 PIN TYPE

LEAD.” To obtain maximum performance from the product,

please read this manual first, and keep it handy for future reference.

Overview

The 9772 PIN TYPE LEAD is a four-terminal pin lead designed

to be usable in nar row spaces w here it is difficult to ma ke contact with the subject of measurement, such as when maintaining

emergency batteries. Its two parallel 1.88-millimeter extendable

coil pins make it possible to achieve stable connections with the

subjects of measurement, as well as measurement using the

testing holes in battery terminal covers.

Inspection and Maintenance

Initial Inspection

When you receive the product, inspect it carefully to ensure that

no damage occurred during shipping. If damage is evident, or if

it fails to operate according to the specifications, contact your

dealer or Hioki representative.

Maintenance and Service

• To clean the product, wipe i t gently with a soft cloth moistened with water or mild det ergent. Never use solvents such

as benzene, alcohol, acetone, ether, ketones, thinners or

gasoline, as they can deform and discolor the case.

• If the product seems to be malfunctioning, contact your

dealer or Hioki representative.

• Pack the product so that it will not sustain damage during

shipping, and in clude a description of existing damage. We

cannot accept responsibility for damage incurred during shipping.

This manual contains information and warnings essential for

The model 9772 PIN TYPE LEAD

safe operation of the product and for maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety precautions.

Mishandling this product during use could result in injury

or death, as well as damage to the product. Be certain

that you understand the instructions and precautions in

the manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from product

defects.

Safety Symbol

In the manual, the symbol indicates particularly important information that the user should read before using the

product.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operati on pres en ts an extreme

hazard that could resul t in s erious injur y or de ath to the

user.

Indicates that incorrect operation presents a possibility

of injury to the user or damage to the product.

Indicates advisory items related to performance or correct operation of the product.

Specific ations

Maximum rated voltage to

earth

Maximum input current AC/DC 2 A continuous

Operating temperature

and humidity

Storage temperature

and humidity

Operating Environment Altitude up to 2000 m (6562 feet), Indoors

Size&Weight Approx. 1900 mm (33.86

Accessories Instruction manual

Option The model 9772-90’s pin

33 Vrms or less, 46.7 Vp AC or less and 70 V DC

or less

°C to 40°C (32°F to 104°F), 80%RH or less

0

(no condensation)

°C to 50°C (14°C to 122°C), 80%RH or less

-10

(no condensation)

”)/ Aprrox. 180g (3.9 oz.)

Procedure

Usage Notes

Preliminary Checks

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

• To avoid electrical sh ock, be careful to avoid shorting

live lines with the Pin type leads.

• The maximum rated voltage between input terminals

and ground is 33 Vrms, 46.7 Vp AC and 70 V DC.

Attempting to measure voltages ex ceeding these limits

with respect to ground could damage the product and

result in personal injury.

• The maximum input current is is as follows;

2 A AC/DC

Never exceed this limit, as doing so could result in

destruction of the instrument and personal injury or

death.

• To avoid shock and short circuits, turn off all power

before connecting leads.

• To avoid damage to the product, protect it from physical

shock when transporting and handling. Be especially careful

to avoid physical shock from dropping.

• To avoid breaking the leads, do not bend or pull them.

• The ends of the leads are sharp. Be careful to avoid injury. Fit the

protective pin cap when the product is not in use.

A cap are placed on pin for protection during transport. Remove

the cap before use.

Before using the product the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. Points

to check include the pin operation and whether the pin and cable lock

are loose. As loose screwi ng o f the c able lock and o th er comp onents

can result in damage, be sure to tighten them securely before use.

If you find any damage, contact your dealer or Hioki representative.

Before using the pr oduct, make sure that the insu lation

on the test leads is undamaged and that no bare conductors are improperly exposed. Using the product in such

conditions could cause an electric shock, so conta ct your

dealer or Hioki representative for repair.

Make sure that power of the device to connect the

pin type lead to is off.

. Connect the pin type lead to the input terminal of

the device.

Plug the mark on the red lead into the

red marked jack on the instrument, and

plug the mark on the black lead into the

black marked jack on the instrument.

3.

Perform zero adjustment.

Be sure to use a 9454 zero-adjust board.

See the instruction manual for details of connectable devices.

line

Each sensor pi n has a line af fixed to it s base. When usi ng th

zero-adjust feature, align these lines in the same direction.

4. Connect the model 9772 to a sample.

• Please cap it when you do not using.

Replacing the Pin

The conductive-tip contact pin is replaceable. Replace the pin with a new one

if it is broken or worn. One-piece condu ctive-tip contact pins with a plastic pin

base are available separately.

1. Turn off power of the device, and disconnect the cable.

2. Pull out the pin tip to be replaced, using pliers or a similar tool.

The model

9770’s pin

3. Replace the 9772-90 pin tip by inserting a new pin into the socket and

pressing against a hard board or other surface to fix the pin firmly in place.

The model

9770’s pin

4. Check the performance. Measure an object with a known resistance.

Make sure that the measured resistance is correct before using the pin type

lead.

Loading...

Loading...