Hioki 9675 Instruction Manual

Warranty

9675

CLAMP ON LEAK SENSOR

Instruction Manual

July 2015 Revised edition 8

Printed in Japan

9675A981-08 15-07H

Warranty malfunctions occurring under conditions of normal

use in conformity with the Instruction Manual and Product Precautionary Markings will be repaired free of charge. This warranty is valid for a period of one (1) year from the date of

purchase. Please contact the distributor from which you purchased the product for further information on warranty provisions.

Introduction

Thank you for purchasing the HIOKI Model 9675 CLAMP ON

LEAK SENSOR. To obtain maximum performance from the

product, please read this manual first, and keep it handy for future reference.

Inspection and Maintenance

Initial Inspection

When you receive the product, inspect it carefully to ensure that

no damage occurred during shipping. If damage is e vident, o r if

it fails to operate according to the specifications, contact your

dealer or Hioki representative.

Maintenance and Service

• To clean the product, wipe it gently with a soft cloth moistened with water or mild detergent. Never use solvents such

as benzene, alcohol, acetone, ether, ketones, thinners or

gasoline, as they can deform and discolor the case.

• If the product seems to be malfunctioning, contact your

dealer or Hioki representative. Pack the product so that it will

not sustain damage during shipping, and include a description of existing damage. We cannot accept responsibility for

damage incurred during shipping.

• Use the original packing materials when transporting the

product, if possible.

Safety

This manual contains information and warnings essential for

safe operation of the product and for mainta ining it in safe o perating condition. Before using it, be sure to carefu lly read the fo llowing safety precautions.

This product is designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling during

use could result in injury or death, as well as damage to

the product. Be certain that you understand the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not

resulting directly from product defects.

Safety Symbol

Indicates cautions and hazards. When the symbol is

printed on the product, refer to a corresponding topic in the

Instruction Manual.

Indicates AC (Alternating Current).

Indicates that only insulated conductors suited to the volt-

age of the circuit under test can be measured.

Symbols for various standards

This symbol indicates that the product conforms to regulations set out by the EC Directive.

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Usage Notes

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

• Do not measure around a bare conductor. Doing so

may result in short-circuit or electric shock. Take measurements at a location on an insulated wire where

there is sufficient insulation for the circuit voltage.

• This product should only be connected to the secondary side of a breaker, so the breaker can prevent an

accident if a short circuit occurs. Connections should

never be made to the primary side of a breaker,

because unrestricted current flow could cause a serious accident if a short circuit occurs.

• When the clamp sensor is opened, do not allow the

metal part of the clamp to touch any exposed metal, or

to short between two lines.

• To avoid electric shock, do not allow the product to get

wet, and do not use it when your hands are wet.

• To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

• To avoid electric shock when measuring the ground

conductor on an E (PE) transformer connection site,

be careful not to approach high voltage devices or

conductors. Also, if close to high voltage charging

devices or if measurement is otherwise difficult, first

change the route of the grounding wire.

• Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged or cause an explosion.

• Do not store or use the product where it could be exposed to

direct sunlight, high temperature or humidity, or condensation. Under such conditions, the product may be damaged

and insulation may deteriorate so that it no longer meets

specifications.

• To avoid damage to the product, protect it from vibration or

shock during transport and handling, a nd be especially careful to avoid dropping.

• Be careful to avoid dropping the product or otherwise subjecting them to mechanical shock, which could damage the

mating surfaces of the core and adversely affect measurement.

• Keep the clamp jaws and core slits free from foreign objects,

which could interfere with clamping action.

• Keep the clamp closed when not in use, to avoid accumulating dust or dirt on the mating core surfaces, which could interfere with clamp performance.

• Measurements are degraded by dirt on the mating surfaces

of the clamp-on sensor , so keep the surfaces clean by g ently

wiping with a soft cloth.

• This product is not designed to be entirely water- or dustproof. To avoid damage, do not use it in a wet or dusty environment.

• This product is designed for indoor use, and operates reliably from 0°C to 50°C.

• This product should be installed an d operated in doors only,

between 0°C and 50°C and 80% RH or less

• Avoid stepping on or pinching the cable, which could damage the cable insulation.

• Keep the cables well away from heat sources, as bare conductors could be exposed if the insulation melts.

• To avoid damaging the sensor cable, do not bend or pull the

cable.

• Note that the product may be damaged if current exceeding

the selected measurement range is applied for a long time.

Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and high-current conductors, or in the presence of strong electromagnetic

fields such as near radio transmitters.

Overview

The Model 9675 CLAMP ON LEAK SENSOR provides voltage

output corresponding to sensed currents up to 10A AC. The

high-permeability magnetic material of the sensor’s core and

magnetic shield enables high-precision measurement of very

weak currents.

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Indicates that incorrect operation presents an extreme

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a significant

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a possibility

of injury to the user or damage to the device.

Advisory items related to performance or correct operation of the product.

Specifications

Jaws

Cable

BNC connector

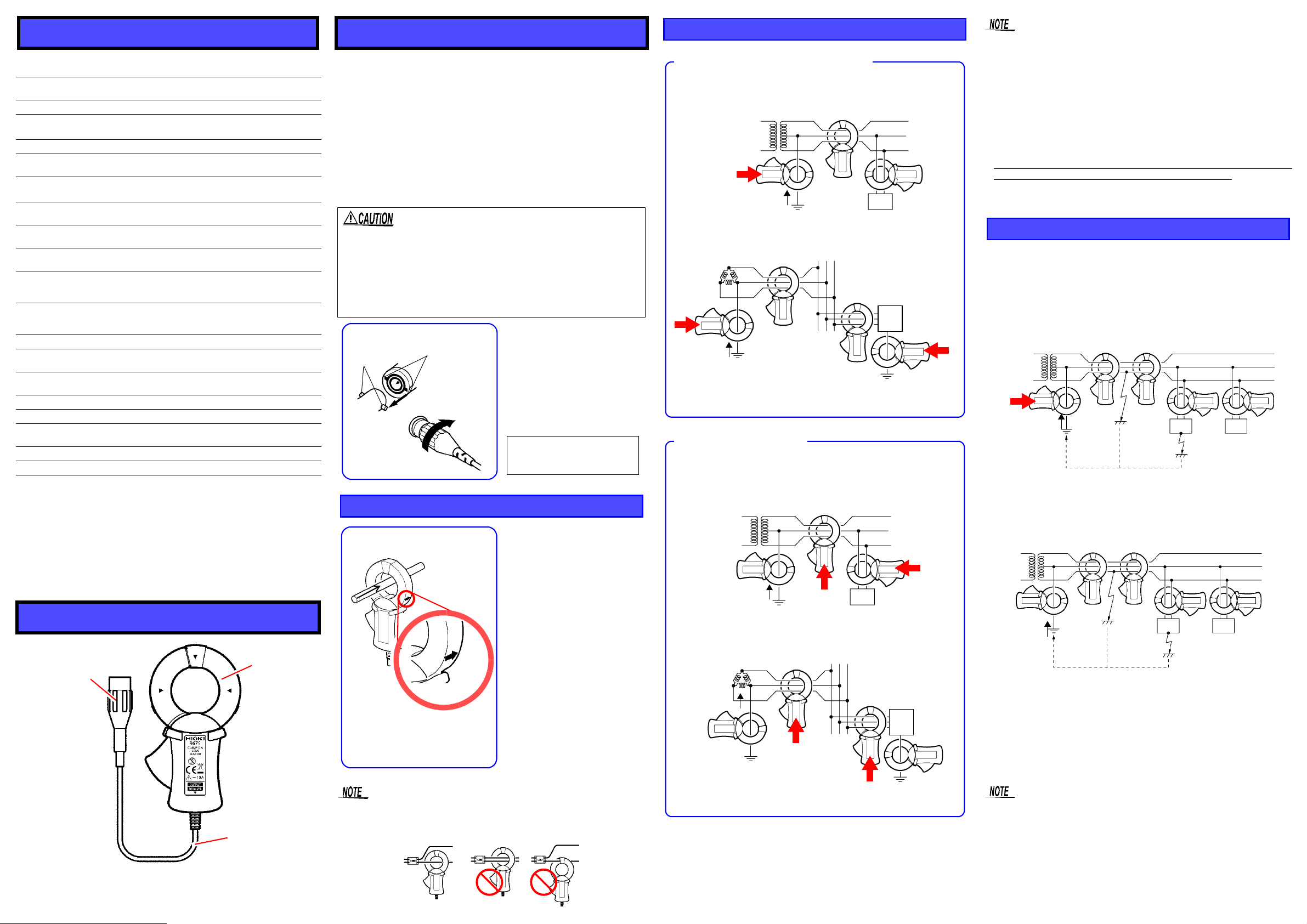

To remove the BNC connector,turn the connector counterclockwise and pull it out.

1. Engage the BNC connec-

tor grooves with the connectorguide projections,

and turn the connector

clockwise to lock the components.

2. Clockwise to lock the

components.

Lock

Connect the BNC connector.

Connector

Guide

BNC connector

grooves

1

2

Load Current Measurement

1. Open the jaws. Orient the

current direction indicator

to the load side and

clamp one conductor at

the center of the clamp.

2. Confirm that the jaws is

fully closed.

Position the clamp with the current direction indicator pointing

toward the load side. (If installed

in the opposite direction,the

phase deviates 180 degrees.)

L

O

A

D

S

O

U

RC

E

Clamp the conductor.

Current direction

indicator

Conductor

OK

Leak Current Measurement

lg

Attach the clamp around only one conductor.

Ground Conductor Measurement

Single-phase 3-lead circuits

Three-phase 3-lead circuits

Transformer

Load

Device

Load

Device

Leak Current

Clamp

here

Clamp

here

Clamp

here

PE

E (PE)

lg

Leak Current

E (PE)

負荷

機器

Circuit conductors are bundled and clamped in the middle.

See ”Load Current Measurement”.

Bundle Measurement

Load

Device

Load

Device

Transformer

PE

E (PE)

lg

Leak Current

Clamp all three leads

of the circuit.

Clamp all three leads

of the circuit.

Single-phase 3-lead circuits

Three-phase 3-lead circuits

Clamp

here

Clamp

here

Clamp

here

Clamp

here

E (PE)

lg

Leak Current

Checking for insulation faults

1. Measure overall circuit leakage current and determine leak-

age conditions based upon measurement discrepancies.

Normally measured on the ground line of an E (PE) transformer.

Single-phase 3-lead circuits

Load

Device

Load

Device

lg

Leak Current

Clamp

here

E (PE)

2. If current leakage is detected, further bundled measurements

(clamping around bundled conductors) is employed to search

from the source to the load side.

Location A

a

a'

b

b’

Load

Device

Load

Device

lg

Leak Current

E (PE)

of isolation

fault

Location B

of isolation

fault

Accuracy guaranteed for one year at 23 ± 5°C (73 ± 9°F), 80%RH or

less (Opening and Closing of the Sensor: Maximum 10000 times).

Rated primary

10 A AC

current

Output voltage 100 mV AC/A

Amplitude

accuracy

±

1.0% rdg. ± 0.005% f.s. (f.s.: 10 A at the clamp

core center, 45 Hz to 66 Hz)

Phase accuracy within ± 5° (at 50 Hz or 60 Hz)

Amplitude frequency

characteristics

Maximum

input current

Effect of

conductor position

Effect of external

magnetic fields

Remaining electric

current character

Operating

temperature and

humidity range

Storage

temperature and

Within ± 5% at 40 Hz to 5 kHz

(deviation from accuracy)

10 A continuous at 45 Hz to 66 Hz

(Ambient temperature: 50°C

)

within ± 0.1%

(deviation from center)

Max. 7.5 mA

(400 A AC/m corresponds)

1 mA or less (10 A AC, 50/60 Hz on forward and

return lines with 10 mm or less line spacing)

0°C to 50°C (32°F to 122°F)

80%RH or less (no condensation)

-10°C to 60°C (14°F to 140°F)

80%RH or less (no condensation)

humidity range

Location for use Altitude up to 2000 m (6562 feet), Indoors

Standards

applying

Diameter of

able conductor

measur-

(Safety) EN61010

(EMC) EN61326

30 mm (1.18") or less

Me as u r a b l e co n d u c t or Insulated conductor

Cable length Isolated BNC, Approx. 3 m (118.11")

External

dimensions

Approx. 60W x 112.5H x 23.6D mm (2.36"W x

4.43"H x 0.93"D, excluding protrusions)

Mass Approx. 160 g (5.6 oz.)

Accessories Instruction manual (1)

We define measurement tolerances in terms of f.s. (full scale)

and rdg.(reading) values, with the following meanings:

f.s.

(maximum display value or scale length)

The maximum displayable value or the full length of the scale.

This is usually the maximum value of the currently selected

range.

(reading or displayed value)

rdg.

The value currently being measured and indicated on the measuring product.

Parts Names

Measurement Procedure

Preliminary Checks

• Before using the product the first time, verify that it operates

normally to ensure that the no damage occurred during storage or shipping. If you find any damage, contact your dealer

or Hioki representative.

• Before using the product, make sure that the insulation on

the cables is undamaged and that no bare conductors are

improperly exposed. Using the product in such conditions

could cause an electric shock, so contact you r dealer or Hio ki

representative for repair.

Connecting the BNC Connector

• When disconnecting the BNC connector, be sure to release the lock before pulling off the connector . Forcibly

pulling the connector without releasing the lock, or pulling on the cable, can damage the connector.

• To prevent damage to the product and sensor, never

connect or disconnect a sensor while the power is on,

or while the sensor is clamped around a conductor.

• For measurement of single-phase 2-lead circuits, clamp both

leads of the circuit.

• For measurement of three-phase 4-lead circuits, clamp all

four leads of the circuit. If this is not possible, the measurement can also be carried out on the ground lead of the equipment.

• If a strong current (on the order of 100 A) is flowing in an adjacent circuit, accurate measurement may not be possible. Perform the measurement at a sufficient distance from other

current-carrying conductors.

• The frequency of special waveforms such as at the secondary

side of an inverter may not be indicated correctly.

• Do not input a current which exceeds the rated current.

Attach the clamp around only one conductor. Single-phase (2wire) or three-phase (3-wire) c ables clamped together will not

produce any reading.

• If an insulation fault in the wiring has occurred at position “A”

in the illustration, leak current will be detected at position “a”

using overall measurement, but not at position “a'”.

• If an insulation fault in the load equipment has occurred at

position “B” in the illustration, leak current will be detected at

position “b” using overall measurement, but not at position

“b'”.

For detection of intermittent leak current conditions (such as on ly

when a certain piece of equipment is operating), the use of a level recorder will be helpful.

Loading...

Loading...