Page 1

9555-10

SENSOR UNIT

Instruction Manual

September 2013 Revised edition 6

Printed in Japan

9555B981-06 13-09H

Inspection and Maintenance

Never connect the tester as shown in the figure.

Initial Inspection

When you receive the device, inspect it carefully to ensure that

no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evident, or if it fails to operate according to the specifications, contact your dealer or Hioki representative.

Maintenance and Service

• To clean the device, wipe it gently with a soft cloth moistened

with water or mild detergent. Never use solvents such as

benzene, alcohol, acetone, ether, ketones, thinners or gasoline, as they can deform and discolor the case.

• If the device seems to be malfunctioning, confirm that the

batteries are not discharged, and that the test leads, probes

and fuse are not open circuited before contacting your dealer

or Hioki representative.

Pack the device so that it will not sustain damage during shipping, and include a description of existing damage. We cannot

accept responsibility for damage incurred during shipping.

Safety

Measurement categories

To ensure safe operation of measurement devices, IEC 61010

establishes safety standards for various electrical environments, categorized as CAT

ment categories.

CAT II: Primary electrical circuits in equipment connected to an AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

CAT III:Primary electrical circuits of heavy equipment (fixed installa-

tions) connected directly to the distribution panel, and feeders

from the distribution panel to outlets.

CAT IV:The circuit from the service drop to the service entrance, and

to the power meter and primary overcurrent protection device

(distribution panel).

Using a measurement device in an environment designated

with a higher-numbered category than that for which the device

is rated could result in a severe accident, an d must be carefully

avoided.

Use of a measurement instrument that is not CAT-rated in CAT

II to CAT IV measurement applications could result in a severe

accident, and must be carefully avoided.

II to CAT IV, and called measure-

Usage Notes

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

• Be sure to observe all operating precautions for the

waveform monitoring instrument (oscilloscope or

recorder) and other measurement instruments to

which the CURRENT SENSOR (refer to Specifications) is connected using with this device.

• When using a measurement instrument that does not

provide isolation between its input terminals and chassis or other input terminals, please pay attention to the

following points.

If a signal is applied to an input terminal other than that

to which the CURRENT SENSOR is connected, do not

connect the ground-side terminal to any non-ground

potential. Otherwise, short-circuit current will flow

through the CURRENT SENSOR or this device from

the ground terminal, which could cause an electrical

accident or damage.

Warranty

Warranty malfunctions occurr ing under conditions of normal u se

in conformity with the Instruction Manual and Product Precautionary Markings will be repaired free of charge. This warranty

is valid for a period of one (1) year from the date of purchase.

Please contact the distributor from which you purchased the

product for further information on warranty provisions.

Introduction

Thank you for purchasing the HIOKI Model 9555-10 SENSOR

UNIT. To obtain maximum performance from the device, please

read this manual first, and keep it handy for future reference.

This manual contains information and warnings essential for

safe operation of the device and for maintaining it in safe operating condition. Before using it, be sure to carefu lly read the fo llowing safety precautions.

This device is designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested

for safety prior to shipment. However, mishandling

during use could result in injury or death, as well as

damage to the device. Be certain that you understand the instructions and precautions in the manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from

device defects.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should read before using the

device.

The symbol printed on the device indicates that the

user should refer to a corresponding topic in the manual

(marked with the symbol) before using the relevant

function.

Indicates DC (Direct Current).

Instrument Installation

Operating temperature and humidity: 0 to 40°C, 80%RH or less (non-condensation)

Avoid the following locations that could cause an accident or damage to the device.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high humidity or condensation

Exposed to high levels

of particulate dust

In the presence of

corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

• Before turning the device on, make sure the supply

voltage matches that indicated on the its power connector. Connection to an improper supply voltage may

damage the device and present an electrical hazard.

• Use only the supplied Model 9418-15 AC ADAPTER.

AC adapter input voltage range is 100 to 240 VAC

(with ±10% stability) at 50/60 Hz. To avoid electrical

hazards and damage to the device, do not apply voltage outside of this range.

Overview

With this device, you can use the Model 9270, 9271, 9272,

9277, 9278, 9279, 9709, 9272-10, CT6862, CT6863 current

sensors as separate units. It is equipped with a high-performance sensor for easy current waveform measurement.

Use it as input unit for various current measurement applications combined with a recorder, oscilloscope, voltmeter, etc.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a significant

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a possibility

of injury to the user or damage to the device.

Indicates advisory items related to performance or correct operation of the device.

Other Symbol

Indicates a prohibited action.

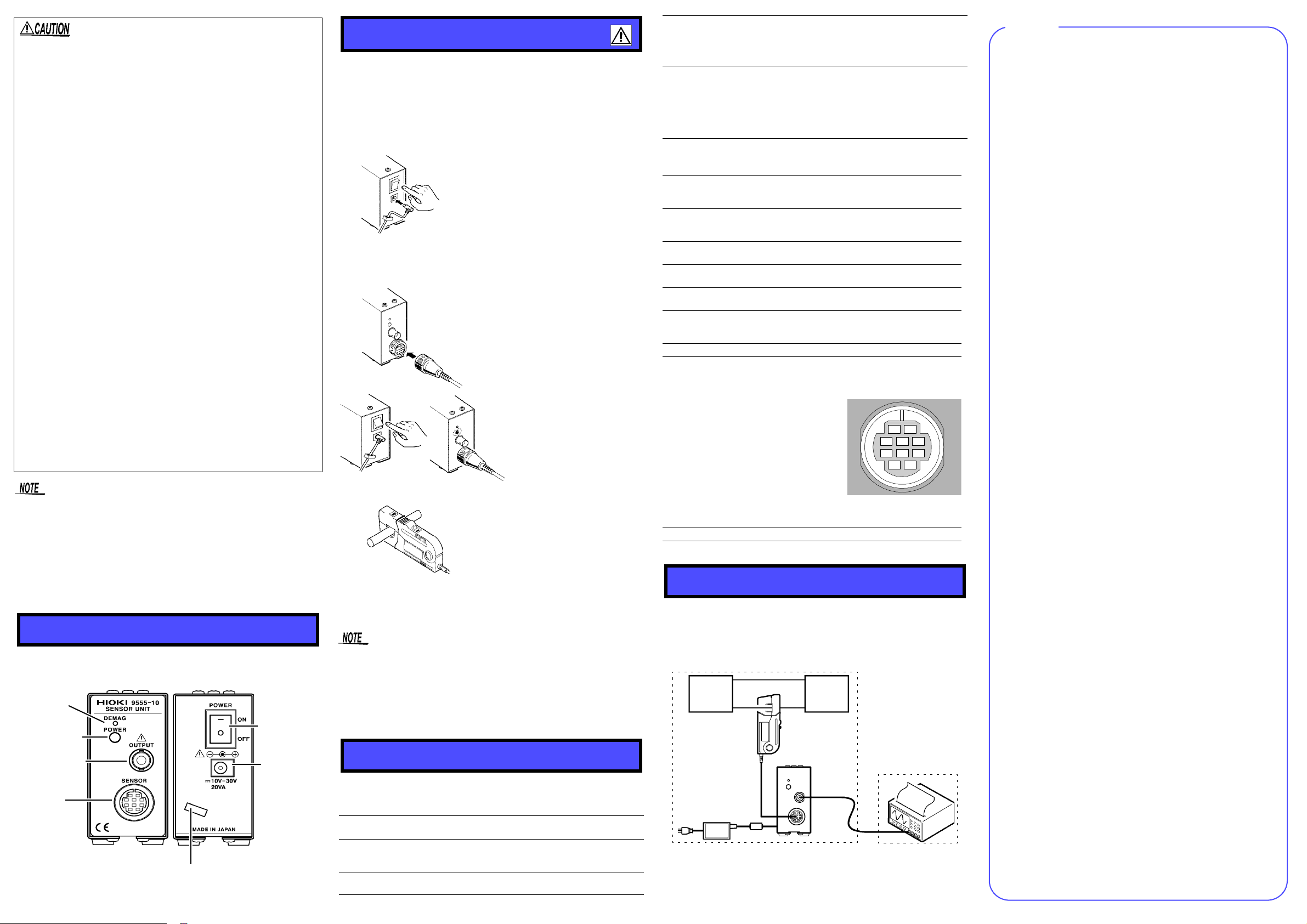

Page 2

• Be careful to avoid connecting voltage impro perly, as the in-

Locking clamp

(Prevents cord from disconnecting)

Front Panel Rear Panel

SENSOR

connector

Output terminal

(BNC terminal)

Power monitor

DEMAG SW

(Demagnetize

switch)

Power jack

Power switch

1. Confirm that the power

switch is OFF, then connect the AC ADAPTER

and the power cord.

Be sure to run the AC

ADAPTER cord through

the locking clamp as

shown in the diagram left

to prevent disconnection.

2. Connect the clamp sensor to the sensor connector.

3. Turn the power switch

ON and confirm that the

power monitor lights.

When using 9277, 9278 or

9279, you can enact

demagnetization by pressing

DEMAG SW.

4. Clamp the subject conductor and perform the

measurement.

1

2

3

45

6

7

8

9

10

9555-10

Power

source

Load

CURRENT

SENSOR

9418-15

AC ADAPTER

CURRENT SENSOR side

Measuring instrument side

Memo

ternal circuitry may be destroyed.

• Turn off the power before disconnecting the power cord.

• To avoid damage to the device, do not short the output terminal and do not input voltage to the output terminal.

• Because ± 12 V is output from the connector on the equipment to provide power to the sensor, do not plug anything

into this connector except for the sensor connector.

• To prevent damage to the connected instruments and the

sensor, never connect or disconnect a sensor while the power is on, or while the sensor is clamped around a conductor.

• To avoid damaging the power cord, grasp the plug, not the

cord, when unplugging it from the power outlet.

• When the power is turned off, do not ap ply voltage or current

to the clamp sensor. Doing so may damage the device.

• T o avoid d amage to the device, protect it from physical shock

when transporting and handling. Be especially careful to

avoid physical shock from dropping.

• Do not store or use the device where it could be exposed to

direct sunlight, high temperature or humidity, or condensation. Under such conditions, the device may be damaged

and insulation may deteriorate so that it no longer meets

specifications.

• Avoid stepping on or pinching cables, which could damage

the cable insulation.

• Keep the cables well away from heat sources, as bare conductors could be exposed if the insulation melts.

• Use the 9217 CONNECTION CORD (resin) when connecting to insulated BNC terminal, and the 9165 CONNECTION

CORD (metal) when connecting to metallic BNC terminal. If

you connect metal BNC cable to insulated BNC terminal, the

insulated BNC terminal can be damaged and the connection

equipment may be damaged.

• Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and highcurrent conductors, or in the presence of strong electromagnetic fields such as near radio transmitters.

• This device may cause interference if used in residential areas.

Such use must be avoided unless the user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of radio and television broadcasts.

Names of Parts

Measurement Procedure

Preliminary Checks

Before using the device the first time, verify that it operates normally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki

representative.

• Use a measuring instrument with an input resistance of 1 M

or more.

• If the power monitor does not light when the power switch is

turned on, it is likely the device has damaged.

• Also refer to the clamp sensor instruction manual.

Specifications

1. General Specifications

Operating

environment

Operating

temperature and

humidity

Storage temperature and humidity

Indoors, Up to 2000 m (6562ft) ASL

0°C to 40°C (32 to 104°F), 80%RH max.

(no condensation)

-10°C to 50°C (14 to 122°F), 80%RH max.

(no condensation)

Applicable Standards

Accessories Instruction manual

EN61010 Pollution degree 2

EN61326 Class A

EN61000-3-2

EN61000-3-3

Model 9418-15 AC ADAPTER (with a power cord)

Rated supply voltage: AC100 to 240 V

(Voltage fluctuations of ±10% from the rated

supply voltage are taken into account.)

Rated supply frequency: 50/60 Hz

Rated output voltage: DC 12 V

2. Specifications

Applicable current sensors

Output terminal BNC terminal

Output supply

voltage

Rated supply

voltage

Maximum rated

power

Dimensions

(Not including

protrusions)

Mass Approx. 600 g (21.2 oz.)

SENSOR

connector

SW for DEMAG Pressing SW shorts the circuit from 7-10.

Model 9270, 9271,9272, 9277, 9278, 9279, 9709,

9272-10,CT6862,CT6862-10,CT6863,CT6863-10,

CT6865

Accuracy and other characteristics depend on the

connected sensor.

±12 V ±0.5 V, 0.5 Amax

+10 V to +30 V

(The supplied AC ADAPTER supplies +12 V.)

20 VA

Approx. 42W×82H×132D mm

Approx. 1.65”W×3.24”H×5.20”D

RM515ERB-10SD(HIROSE ELECTRIC CO., LTD.)

Connector Pin Configuration

1.GND

2.+12 Vout

3.-12 Vout

4.GND

5.Signal input

6.GND

7.DEMAG

8.NC

9.NC

10.GND

Compatible Connector

RM515EPA-10PC(HIROSE ELECTRIC CO., LTD.)

Application Example

If the distance between the location of the current to be measured and the measuring instrument is greater than the length

of the CURRENT SENSOR cable, measurement is possible by

extending from the 9555-10 analog output. Note that there may

be effects such as noise.

Loading...

Loading...