Page 1

8910

CAN ADAPTER

Instruction Manual

Aug. 2018 Revised edition 7

8910A981-07 18-08H

EN

Page 2

Page 3

Contents

Contents

Introduction.................................................................................1

Inspection...................................................................................1

Safety Notes............... .. ............................... ...............................4

Notes on Use.. .. .. ................................ ............................... .........7

Chapter 1

Product Overview __________________________ 11

1.1 Overview .....................................................................11

1.2 Major Feature s..... .. ... ............................... ...................12

1.3 Identification of Controls and Indicators......................13

i

Chapter 2

Preparation________________________________ 15

2.1 Installation o f th e In st r ument.......... ... .. ........................15

2.2 Power Supply Co n ne ct i o ns... .. .. ... ...............................16

2.2.1 Connecting the AC adapter ...........................................16

2.2.2 Connecting the DC Power Supply .................................17

2.3 Connection Procedure ................................................18

2.4 Power On/Of f .. .. ............................. ... .. ........................21

Chapter 3

Operation _________________________________ 23

3.1 Modes .........................................................................23

3.2 Conversion Mode........................................................23

3.3 Setting Mode...............................................................24

3.3.1 Activating setting mode .................................................25

3.3.2 Contents of display in setting mode ..............................26

3.3.3 Selecting a channel number ..........................................26

3.3.4 Selecting the CAN definition data to be output ..............27

3.3.5 Setting the D/A conversion format/logic bit position ......28

3.3.6 Returning to conversion mode ......................................29

8910A981-07

3.4 Calibration Mo de.. .. ... ..................................................30

3.4.1 Activating calibration mode ...........................................30

3.4.2 Selecting a channel number ..........................................31

3.4.3 Outputting a calibration signal .......................................31

3.4.4 Returning to conversion mode ......................................32

3.5 Operation Map ............................................................33

Page 4

ii

Contents

Chapter 4

Preparation of the CAN Set Program ___________37

4.1 Overview..................................................................... 37

4.2 Program Setup ........................................................... 38

4.2.1 System requirements ................................................. ...38

4.2.2 Installation .....................................................................38

4.2.3 Un-Installation ............................................................... 39

Chapter 5

Starting the CAN Set Program ________________41

5.1 Connecting the PC to the 8910 .................................. 41

5.2 Starting Up the Condition Setting Program ................42

5.3 Menu Items in the Setting Window.............................45

5.4 Operation Flowchart................................................... 46

Chapter 6

Setting the CAN Definition Data _______________49

6.1 Opening a CAN definition data file ............................. 49

6.1.1 Opening a CAN definition data file ................................49

6.1.2 Creating a new CAN definition data file ........................50

6.2 Editing the CAN Definitio n Data .......... .. ................. .. .. 52

6.2.1 Setting the message ID ............................................. ...53

6.2.2 Setting the data length ..................................................53

6.2.3 Setting the data start position .......................................54

6.2.4 Setting the data pattern .................................... .... ..... ...55

6.2.5 Setting the sign ..................... .... ..... ............................ ...56

6.2.6 Setting the signal name ................................................57

6.2.7 Setting the label name ..................................................57

6.2.8 Setting the unit .......................... ..... ..... ..........................57

6.2.9 Setting the scaling ............................................ .... ..... ...58

6.2.10 Error Massage ..............................................................60

6.3 Deletion of CAN Definition Data................................. 61

6.4 Closing the CAN Definition Data File

(Saving the File) ......................................................... 62

6.5 CAN Definition Data List Detail Display...................... 63

6.6 Editing in Another Window.........................................65

6.6.1 Opening a new window ................................ ..... ............65

6.6.2 Creating a new CAN definition data file ........................69

6.6.3 Opening a CAN definition data file ................................69

6.6.4 Editing CAN definition data ...........................................69

6.6.5 Saving CAN definition data ...........................................69

Page 5

Contents

Chapter 7

Settings___________________________________ 71

7.1 Registration List Operations........................................71

7.1.1 Opening a registration list ..............................................71

7.1.2 Creating a registration list (registering definition data

to a registration list) .......................................................72

7.1.3 Deleting data from the registration list ...........................74

7.2 Allocation to Output Channels.....................................75

7.2.1 Setting analog output channels .....................................75

7.2.2 Del eting registere d data from the analog output

allocation list ..................................................................76

7.2.3 Setting logic output channels ........................................77

7.2.4 Deleting data from the logic output allocation list ..........78

7.3 Massage ID Trigger.............................. ...................... .79

7.3.1 Setting the message ID trigger ......................................79

7.3.2 Setting output channels .................................................80

iii

7.4 Setting the ID Filter ... ............................... ...................81

Chapter 8

Transfer of Setting Data to the 8910 ___________ 83

8.1 Setting Communication Parameters ...........................83

8.2 Executing Data Transfer .............................................84

8.3 In Case of Errors....... .. ................. ................. ..............8 5

8.4 Duplicate Bit Check.....................................................86

Chapter 9

Functions of the Setting Program _____________ 87

9.1 Saving the Sett ing Da ta .................... ................ ..........87

9.1.1 Saving data with a new name .......................................87

9.1.2 Overwriting ....................................................................88

9.2 Setting Data Printout...................................................89

9.2.1 Printing ..........................................................................89

9.2.2 Print preview .................................................................89

9.2.3 Setting the printer ..........................................................90

9.2.4 Examples of printouts ....................................................90

9.3 Displaying Windows............................................ ........92

9.4 Password Setting ........................................................93

9.5 Version Chec k.............................. .. ... ..........................94

Page 6

iv

Contents

Chapter 10

Connection to Memory HiCorder ______________95

10.1 Using the 8910 with the 8826 MEMORY HiCORDER 96

10.1.1 Displaying the 8910 setting screen ...............................96

10.1.2 8910 setting screen ................................................... ...98

10.1.3 Setting the block no. .....................................................99

10.1.4 Setting analog channel output ....................................100

10.1.5 Setting logic channel output ........................................102

10.1.6 Displaying the registration list .....................................103

10.1.7 Communication between the 8826 and 8910 .............104

10.1.8 Downloading an setting data file .................................107

10.2 Using the 8910 with the 8841, 8842 MEMORY

HiCORDER............................................................... 109

10.2.1 Displaying the 8910 setting screen .............................109

10.2.2 8910 setting screen ................................................... .111

10.2.3 Setting the block no. ...................................................112

10.2.4 Setting analog channel output ....................................113

10.2.5 Setting logic channel output ........................................115

10.2.6 Displaying the registration list .....................................116

10.2.7 Communication between the 8841, 8842 and 8910 ...117

10.2.8 Downloading a setting data file ...................................120

Chapter 11

Specifications_____________________________123

11.1 General Specifications..............................................123

11.2 Specifications of Functions....................................... 125

11.3 Specifications of 8910 CAN Set Program

(PC Application)........... .. ............................... ............ 126

11.4 Specifications of CAN Setting Function

(for Memory HiCorder).............................................. 127

11.5 Accessories.............................................................. 128

11.6 Options..................................................................... 128

11.6.1 9713-01 CAN CABLE (one end unprocessed) ...........129

11.6.2 9713-02 CAN CABLE (For automotive connector) .....130

11.6.3 9714-01 LOGIC CABLE (one end unprocessed) ........131

11.6.4 9714-02 LOGIC CABLE (for Memory HiCorder) .........1 32

11.7 Specifications of Connectors....................................133

Page 7

Contents

Chapter 12

Maintenance and Service ___________________ 135

12.1 Service and Cleaning................................................135

12.2 Troubleshooting ........................................................135

v

Page 8

vi

Contents

Page 9

Introduction

Instruction manual.....................................1

CD-R ("8910 CAN set program" software

(Japanese/English 2 files) (for PC),

CAN

setting function (for Memory Hi Co rder)).... 1

RS-232C cable (D-sub 9-pin, male-female,

straight cable ) (Approx. 1.8 m ).... .............. 1

9418-15 AC ADAPTER ............................1

Inspection

1

Introduction

Thank you for purchasing the HIOKI “Model 8910 CAN ADAPTER”. To

obtain maximum performance from the instrument, please read this

manual first, and keep it handy for future reference.

When you receive the instrument, inspect it carefully to ensure that no

damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evident, or

if it fails to operate according to the specifications, contact your dealer

or Hioki representative.

Accessories

Page 10

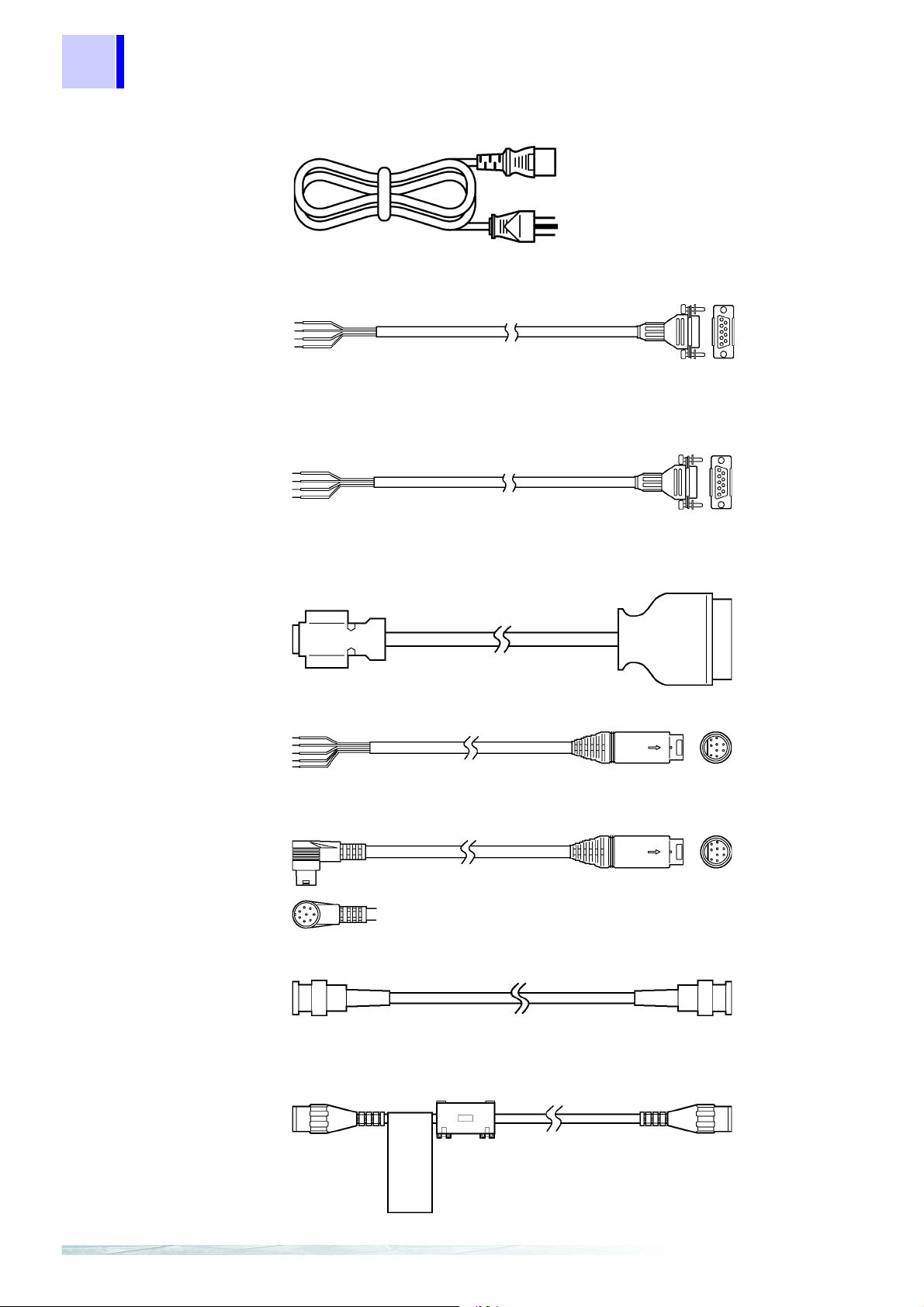

2

Power cord .... ............................................1

9713-01 CAN CABLE (one end

unprocesse d ) (A p p r ox. 2 m)....... ............. ..1

9713-01 CAN CABLE (one end unprocessed) (Approx. 2 m)

9713-02 CAN CABLE (For automotive connector) (Approx. 2 m)

(Since this part is made to order, check the specifications document

and delivery date.)

9714-01 LOGIC CABLE (one end unprocessed) (Approx. 1.5 m)

9714-02 LOGIC CABLE (for Memory HiCorder) (Approx. 1.5 m)

9165 CONNECTION CORD (Metal BNC - Metal BNC) (Approx. 1.5 m)

L9217 CONNECTION CORD (Metal BNC - Insulated BNC)

(Insulated BNC for Memory HiCorder) (Approx. 1.7 m)

Inspection

Options

Page 11

Inspection

9557 RS-232C CARD (for Memory HiCorder)

Preliminary Checks

Before using the instrument the first time, verify that it operates

normally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki

representative.

Before using the instrument, make sure that the insulation on the

cords and cables are undamaged and that no bare conductors

are improperly exposed. Using the product in such conditions

could cause an electric shock, so contact your dealer or Hioki

representative for repair.

3

Page 12

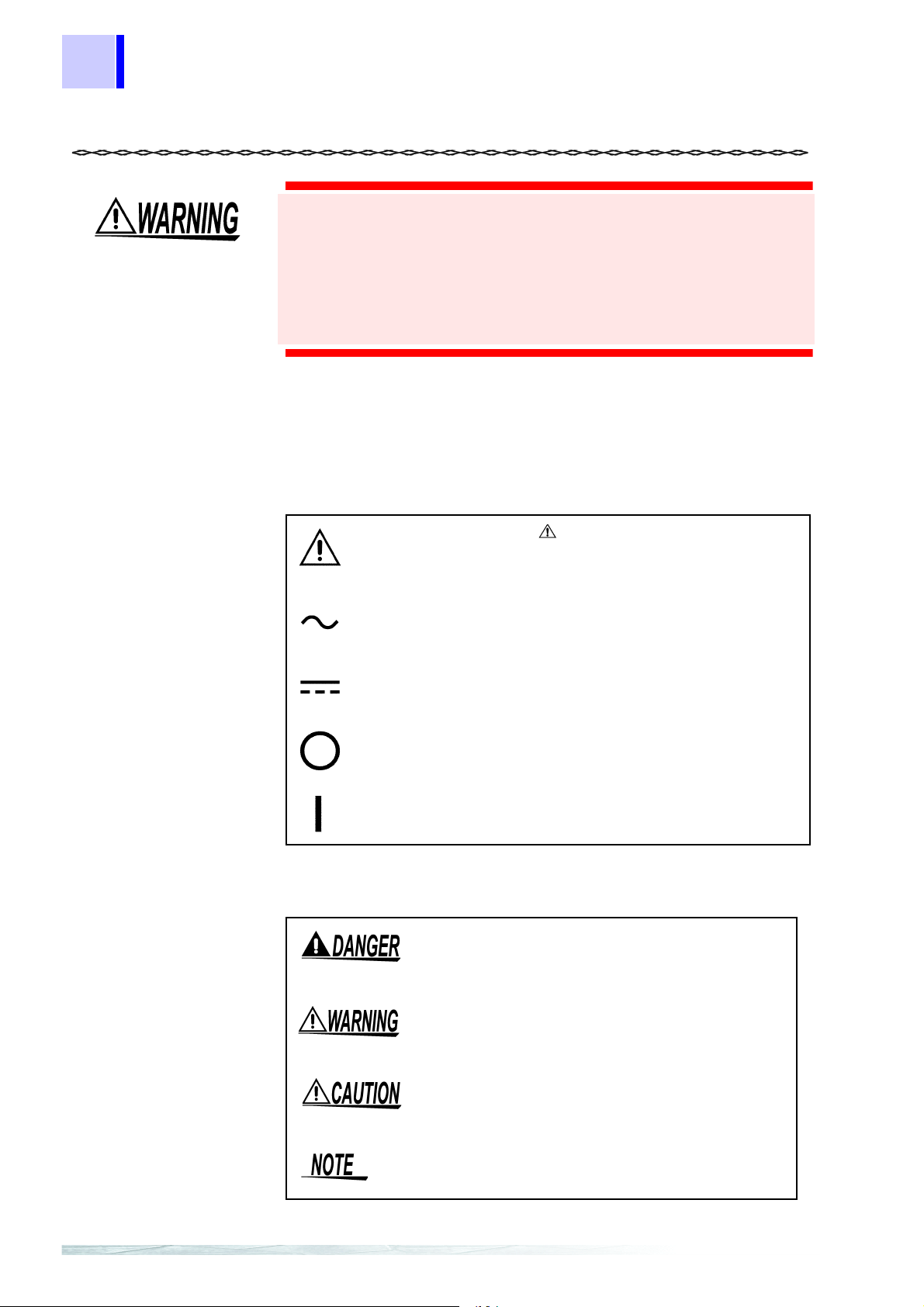

4

Safety Notes

Safety Notes

Safety symbols

This instrument is designed to comply with IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However , mishandli ng duri ng use could r esult in inj ury

or death, as well as damage t o the inst rument. Be ce rtain that you

understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or

injuries not resulting directly from instrument defects.

This manual contains information and warnings essential for safe

operation of the instrument and for maintaining it in safe operating

condition. Before using it, be sure to carefully read the following safety

precautions.

In the manual, the symbol indicates particularly

important information that the user should read before

using the instrument.

Indicates AC (Alternating Current) .

Indicates DC (Direct Current).

Indicates the OFF side of the power switch.

Indicates the ON side of the power switch.

The following symbols in this manual indicate the relative importance

of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

instrument.

Indicates advisory items related to performance

or correct operation of the instrument.

Page 13

Mouse Operation

5

Safety Notes

Indications

Click :

Right-click :

Double click :

Drag :

Activate :

Press and quickly release the left button of the mouse.

Press and quickly release the right button of the

mouse.

Quickly click the left button of the mouse twice.

While holding down the left button of the mouse, move

the mouse and then release the left button to deposit

the chosen item in the desired position.

Click on a window on the screen to activate that

window.

• Unless otherwise specified, “Windows” represents Windows 95, 98,

Me, Windows NT4.0, Windows 2000, or Windows XP.

• Dialogue box represents a Windows dialog box.

• Menus, commands, dialogs, buttons in a dialog, and other names

on the screen and the keys are indicated in brackets.

Page 14

6

Safety Notes

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT II to CAT IV, and called measurement categories.

These are defined as follows.

CAT II : Primary electrical circuits in equipment connected to an AC

CAT III : Primary electrical circuits of heavy equipment (fi xed

CAT IV: The circuit from the service drop t o the service entrance, and

Using a measurement instrument in an environment designated with a

higher-numbered category than that for which the instrument is rated

could result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to

CAT IV measurement applications could result in a severe accident,

and must be carefully avoided.

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electri cal outlet receptacles.

installations) connected directly to the distributi on panel, and

feeders from the distribution p anel to outlets.

to the power meter and primary overcurrent pr otection device

(distribution panel).

Page 15

Notes on Use

Notes on Use

Follow these precautions to ensure safe operation and to obtain the

full benefits of the various functions.

Connecting the Cables (RS-232C Cabl e, CAN Cable,

Connection Cord [Analog], Logic Cabl

The ground (GND) conductors of the connecting cables* connect

in common to the Model 8910 chassis ground (they are not

isolated). Care is therefore necessary to ensure that there is no

potential difference between the instrument chassis ground and

the ground of any connecting device. Otherwise, the instrument

or connecting device could be damaged. Refer to “Power

Sources” below.

Power Sources

The ground (GND) conductors of connecting cables* connect in

common to the Model 8910 chassis ground (they are not

isolated). Therefore, supplying power from different sources to

the instrument and a connecting device could cause electric

shock and equipment damage. To avoid these hazards, power

should always be supplied from the same source.

Even when power is supplied from the same source, as a result

of wiring, potential difference between grounds can result in

current flow through the connecting cables* that could damage

the equipment.

To avoid such hazards, we recommend observing the following

precautions for power connections:

) When poweri

(1

before connecting devices to the 8910, plug the (supplied)

grounded power cord of the AC adapter into the same outlet

as that used to power the devices to be connected.

ng the 8910 from the supplied AC adapter,

e)

❖ 2.2.1 Connecting the AC adapter (Page 16) and

2.3 Connection Procedure (Page 18)

) W

(2

hen powering the 8910 from a DC power source, before

making other connections, first connect the ground of the

8910 to the grounds of the devices to be connected. In this

case, always use the same power source.

❖ 2.2.2 Connecting the DC Power Supply (Page 17) and

2.3 Connection Procedure (Page 18)

) W

(3

hen powering the 8910 from the supplied AC adapter and

powering connecting devices from a DC source (or when

powering the 8910 from DC and connecting devices from

AC), before making other connections to the 8910, first

connect the ground of the 8910 to the grounds of the

devices to be connected. Refer to the following alternatives

regarding common ground connection methods.

) Connect

(a

the AC adapter’s ground.

) Conn

(b

the ground of the device to be connected.

the grounds of devices running on DC power to

ect pin 3 (CAN_GND) of the 9713-01 CAN Cable to

7

*Connecting cables: Cables and connection cords being connected to the 8910.

Page 16

8

Notes on Use

Note: In method (b) above, because of wire length and CAN cable

wiring conditions, some potential difference may remain

between grounding points, so we recommend (a) as the

preferred method.

❖ 2.2.1 Connecting the AC adapter (Page 16),

2.2.2 Connecting the DC Power Supply (Page 17) and

2.3 Connection Procedure (Page 18)

Power Supply Connections

Before turning the instrument on, make sure the supply voltage

matches that indicated on the its power connector. Connectio n to

an improper supply voltage may damage the instrument and

present an electrical hazard.

Grounding the Instrument

To avoid electrical accidents and to maintain the safety

specifications of this instrument, connect the power cord

provided only to a 3-contact (two- conductor + ground) outlet.

❖ 2.2 Power Supply Connections (Page 16)

Before Powering on

Check the power supply is correct for the rating of the unit.

Usage Precautions for the CD-R

• Always hold the disc by the edges, so as not to make fingerprints on

the disc or scratch the printing.

• Never touch the recorded side of the disc. Do not place the disc

directly on anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a

possibility of the label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not

use a ball-point pen or hard-tipped pen, because there is a danger of

scratching the surface and corrupting the data. Do not use adhesive

labels.

• Do not expose the disc directly to the sun's rays, or keep it in

conditions of high temperature or humidity, as there is a danger of

warping, with consequent loss of dat a.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry

cloth, or use a CD cleaner. Always wipe radially from the inside to

the outside, and do no wipe with circular movements. Never use

abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer

system that arises from the use of this CD-R, or for any problem

related to the purchase of a Hioki product.

Page 17

Notes on Use

Installation Environment

• Do not use the instrument where it may be exposed to corrosive or

combustible gases. The instrument may be damaged.

• The instrument should be installed and operated indoors only,

between -10 and 55°C and 30 to 80% RH.

• Do not store or use the instrument where it could be exposed to

direct sunlight, high temperature or humid ity, or condensation. Under

such conditions, the instrument may be damaged and in sulation may

deteriorate so that it no longer meets specifications.

Others

• To prevent an electric shock accident, confirm that the white or red

portion (insulation layer) inside the cable is not exposed. If a color

inside the cable is exposed, do not use the cable.

• Carefully read and observe all precautions in thi s manual.

9

• Using an connection cord other than that specified by HIOKI may

damage the BNC connector or result in measurement errors due to

contact failure.

• Even when using the 8910 within the permitted operating temperature

(-10 to 55°C) and humidity ranges, display on the LCD may become

difficult to read at very low o r high amb ient temperatures . (In such cas e,

alter the viewing angle.) Note that this change does no t affect instrume nt

operation.

•This

instrument may cause interference if used in residential areas.

Such use must be avoided unless the user takes special me asures to

reduce electromagnetic emissions to prevent interference to the

reception of radio and television broadcasts.

Page 18

10

Notes on Use

Page 19

roduct

P

Overview Chapter 1

1.1 Overview

• 8910 CAN ADAPTER is a signal converter that acquires necessary

• The type of data to be acquired is set by using a PC, with settings

• Internal memory can store up to 50 items of CAN definition data.

11

1.1 Overview

signals from CAN signals flowing on a CAN bus, converts the

signals to analog or logic signals, then genera tes out put.

transferred and saved in internal memory of the 8910 via the RS232C.

Since you can change allocated output channels by using the LCD

and operation keys on the f ront panel, the instr ument can be used i n

various applications without a PC.

Page 20

12

1.2 Major Features

1.2 Major Features

1. Compact size and lightweight

The main unit is compact and lightweight for easy portability.

2. Ample output channels

The 8910 is equipped with ample output channels - 12 channels for

analog signal output and 24 bits for logic signal output.

3. Two independent input ports

Since CAN1 and CAN2 are independent, two networks with different

baud rates can be connected.

4. Automatic baud rate setting

Because the 8910 monitors the CAN bus and automatically sets the

baud rate, there is no need to manually set the baud rate. (Supported

baud rates are 125 kbps, 250 kbps, 500 kbps, and 1 Mbps.)

5. Detailed settings using a PC

Easy-to-use PC application software enables the detailed settings of

data to be acquired from a CAN bus.

6. Observation with your existing recorder

The output signal level ranges from -5 to +5 V, and the value is held

until subsequent signal output. Therefor e, output from the 8910 can be

connected to an ordinary recorder. Thus, you can observe CAN

signals by connecting the 8910 to your existing recorder.

7. Real-time output

CAN signals are converted into analog/logic signals and output in real

time.

8. Mixed recording

By using the 8910 with a recorder such as the Memory HiCorder,

"sensor data or control signal on CAN" and "signal that cannot be

acquired on CAN" can be recorded together.

Page 21

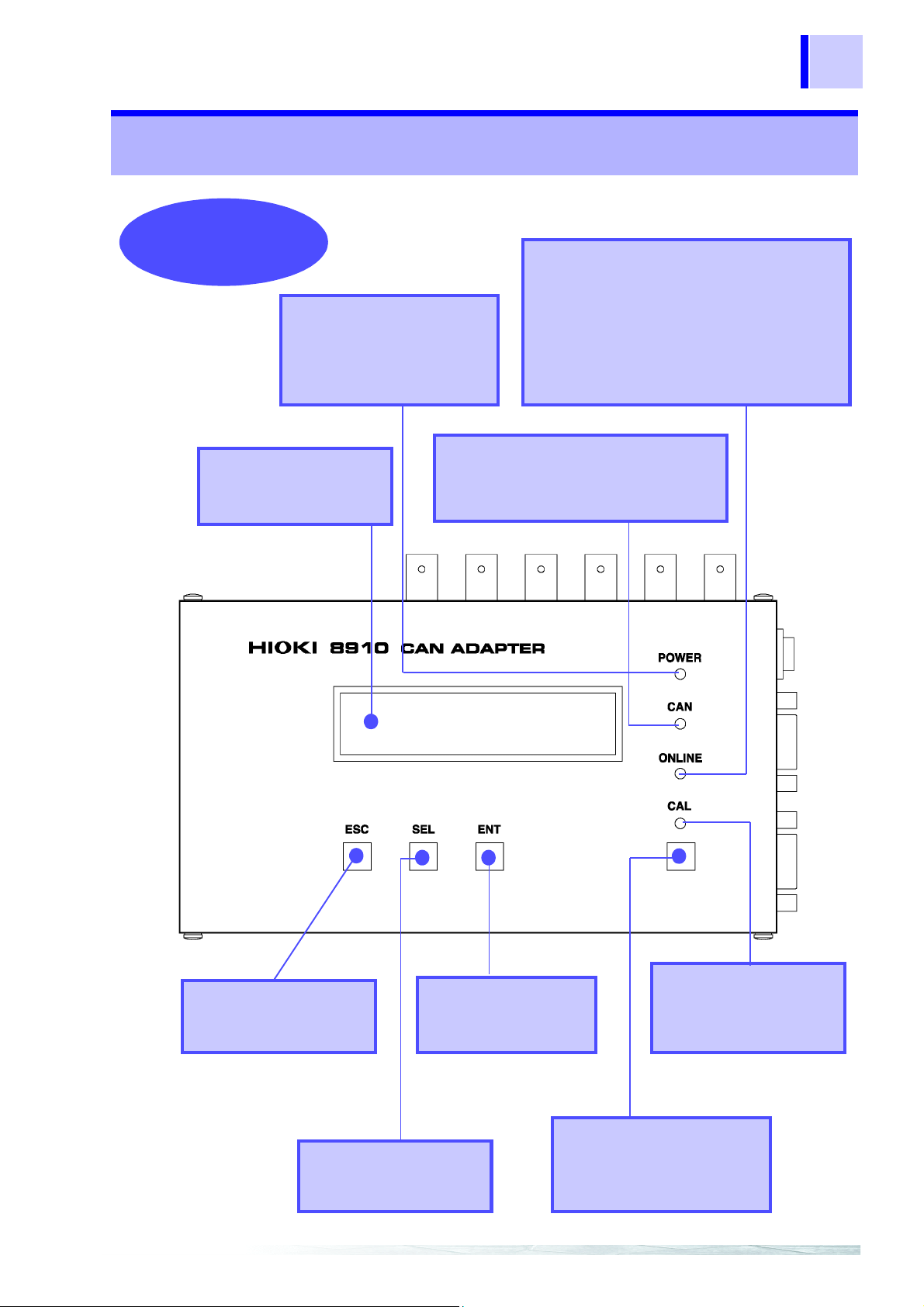

1.3 Identification of Controls and Indicators

Front Side

LCD display

20 characters x 2 lines,

with backlight

Power LED

The LED indicates the power

ON status of the instrument.

The LED goes on in red when

power is turned on.

CAN LED

The LED goes on in green when the

CAN message assigned to the 8910's

output channel is input.

Online LED

This LED indicates whether the 8910 and PC

can communicate via the RS-232C.

The LED goes on in green when the ONLINE/

OFFLINE switch is set to the ONLINE side for

enabling communication.

The LED goes on in orange when the 8910 is

engaged in communication.

ESC (escape) key

Key used for various

settings.

SEL (select) key

Key used for various

settings.

ENT (enter) key

Key used for various

settings.

CAL (calibration) key

In calibration mode, a

calibrat ion signal is output

only while this key is pressed.

CAL LED

The LED goes on in green

during calibration signal

output.

13

1.3 Identification of Controls and Indicators

Page 22

14

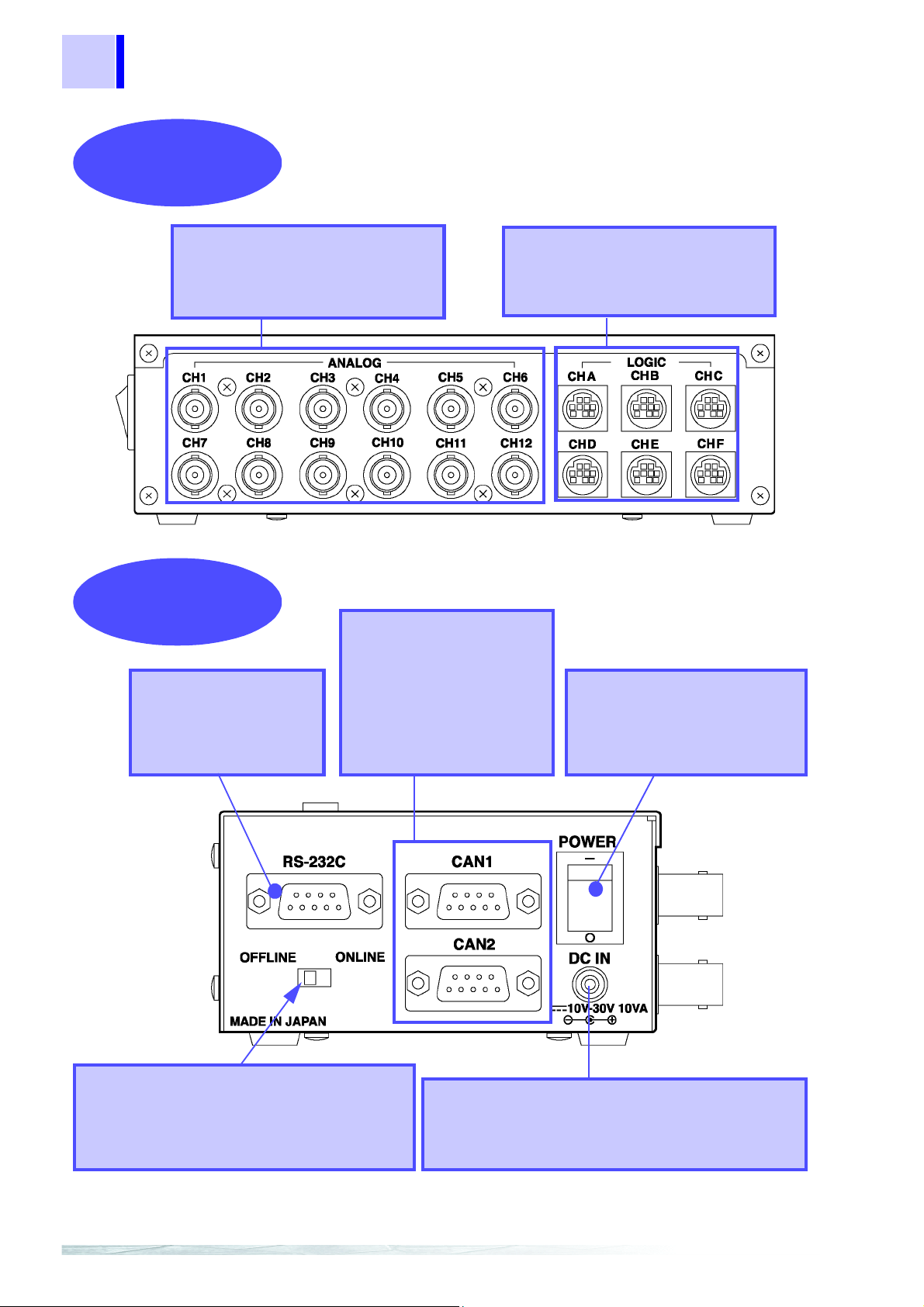

Back Side

Analog Output Terminals

These terminals output analog

signals. All 12 channels use BNC

connectors.

Logic Output Terminals

These terminals output logic signals.

Each terminal outputs 4 bits, for a

total of 24 bits.

Right Side

RS-232C Terminal

This is a communication

connector for connect ing

a host PC or Memory

HiCorder.

CAN Input Ports 1, 2

These ports are CAN signal

input terminals. Since CAN1

and CAN2 are independent,

two different networks can be

connected. These ports can

also be used to supply power

to the 8910.

Power Switch

This switch turns the power ON

and OFF. The switch is effective

for power supplied through

DCIN, CAN1, and CAN2.

AC adapter connection Terminal

This terminal is used to connect the AC ADAPTER.

(A DC power supply (10 to 30 V) can also be

connected.)

ONLINE/OFFLINE Switch

This switch is used to set the 8910 to ONLINE

or OFFLINE mode. Setting this switch to

ONLINE enables the 8910 to communicate

with the host PC or Memory HiCorder.

Key lock: Note that the 8910 accepts no key entry when the [

ONLINE/OFFLINE] switch is set to the

[

ONLINE] side.

1.3 Identification of Controls and Indicators

Page 23

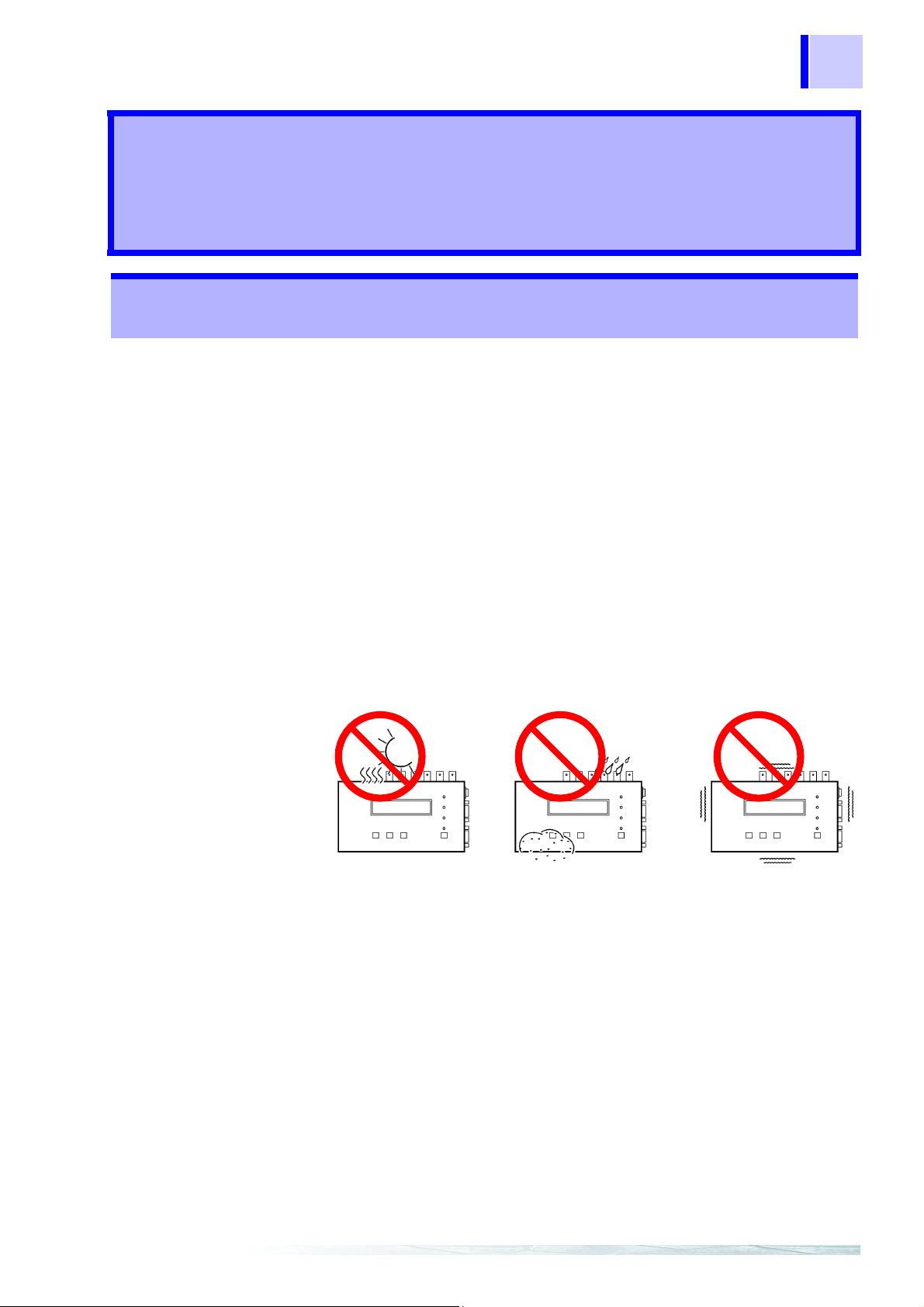

2.1 Installation of the Instrument

Preparation Chapter 2

2.1 Installation of the Instrument

1. Installation orientation

Install the instrument on a flat, level surface.

2. Ambient conditions

• Temperature : -10 to 55°C

• Humidity : 30 to 80%RH (with no condensation)

15

3. Do not us e the instrument in the following locations:

• Subject to direct sunlight.

• Subject to high levels of dust, steam, or corrosive gases (Avoid

using the equipment in an environment containing corrosive gases

(e.g., H

gasses (e.g., organic silicones, cyanides, and formalins).

• Subject to vibrations.

• In the vicinity of equipment generating strong electromagnetic fi elds.

2S, SO2, NI2, and CI2) or substances that generate harmful

Page 24

16

2.2 Power Supply Connections

2.2 Power Supply Connections

2.2.1 Connecting the AC adapter

• Use only the supplied Model 9418-15 AC ADAPTER . AC

adapter input voltage range is 100 to 240 VAC (with ±10%

stability) at 50/60 Hz. To avoid electrical hazards and damage to

the instrument, do not apply voltage outside of this range.

• To avoid electrical accidents and to maintain the safety

specifications of this instrument, connect the power cord only

to a 3-contact (two-conductor + ground) outlet.

Connect the A C adapter to the 8910 .

1

Connect the AC adapter plug to an outlet.

2

Page 25

2.2 Power Supply Connections

2.2.2 Connecting the DC Power Supply

In addition to the AC adapter, any of the following power sources can

be used:

• DC power supply (10 to 30 V) (Voltage fluctuations of ±10% from

the rated supply voltage are taken into account.)

• Power supplied from CAN input port (10 to 30 V) (Voltage fluctuations

of ±10% from the rated supply volt age are t ak en into account.)

17

Page 26

18

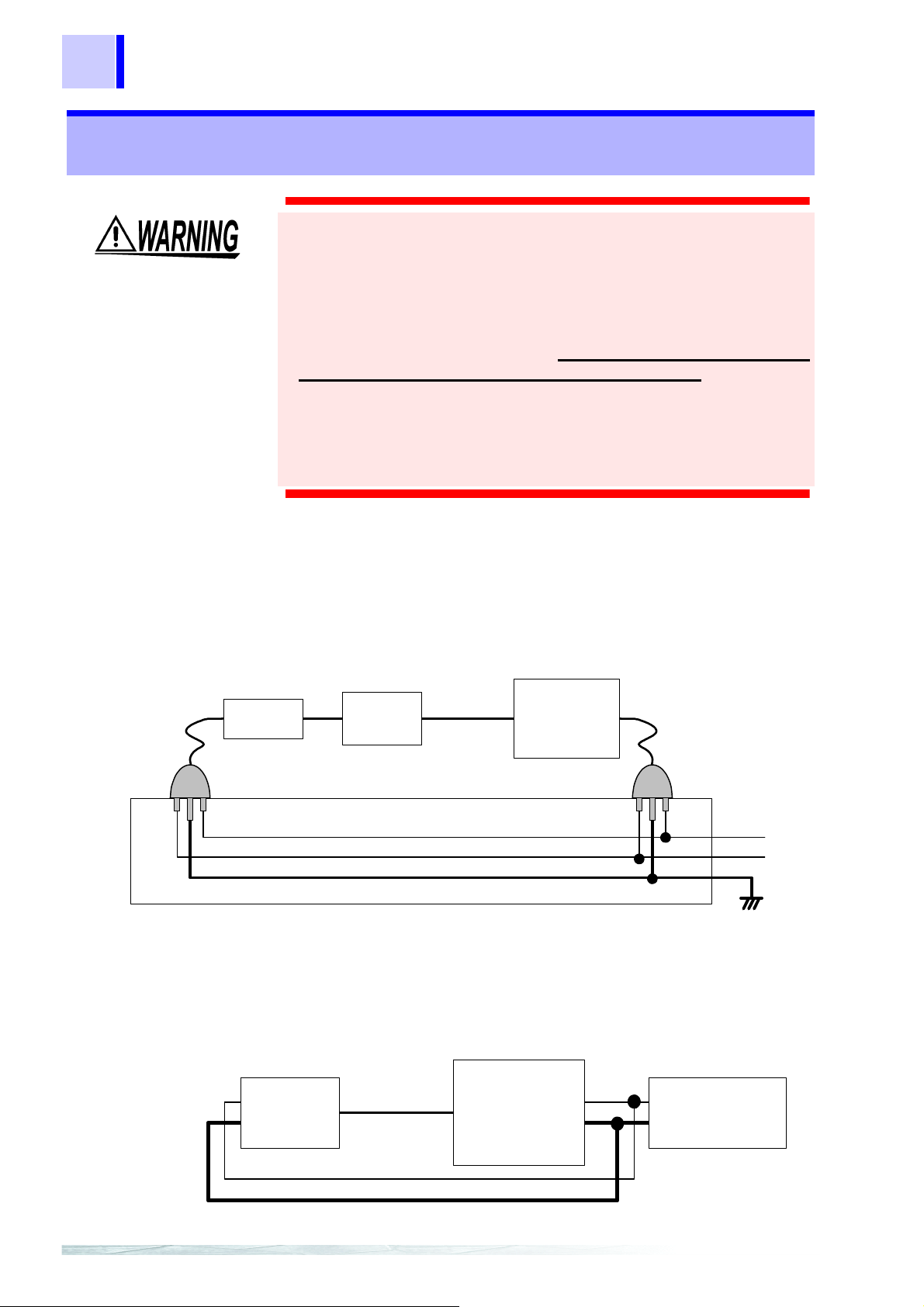

Earth

Power

Outlet

Connecting

cables

8910

AC

adapter

Device to be

coneected

GND

Connecting

Cables

DC pow er so urce

(Battery or equiv.)

+

-

Devic e to be

connected

+

-

8910

+

-

2.3 Connection Procedure

2.3 Connection Procedure

• To avoid the risk of electric shock, never connect the

connecting cables

• The ground (GND) conductors of connecting cables

in common to the Model 8910 chassis ground (they are not

isolated). Therefore, supplying power from different sources to

the instrument and a connecting device could cause electric

shock and equipment damage. To avoid these hazards, power

should always be supplied from the same source.

Even when power is supplied from the same source, as a result

of wiring, potential difference between grounds can result in

current flow through the connecting cable that could damage

the equipment. To avoid such hazards, we recommend

observing the following precautions for power connections:

*

of energized equipment to the 8910.

*

connect

*Connecting cables: Cables and connection cords being connected to the 8910.

Recommended Connection Procedures

(1) When powering the 8910 from the supplied AC adapter

Before connecting devices to the 8910, plug the (supplied) grounded

power cord of the AC adapter into the same outlet as that used to

power the devices to be connected.

(2) When powering the 8910 from a DC power source

Before making other connections, first connect the ground of the 8910

to the grounds of the devices to be connected. In this case, always

use the same power source.

Page 27

19

Earth

Power

Outlet

GND

9713-01

7 pin (CAN_H)

2 pin (CAN_L)

9 pin (CAN_V+)

3 pin (CAN_GND)

(b)

(a)

AC

adapter

DC power

(Battery or equiv.)

8910

+

-

Device to be

connected

+

-

2.3 Connection Procedure

(3) When powering the 8910 from the supplied AC adapter and

powering connecting devices from a DC source (or when

powering the 8910 from DC and connecting devices from AC)

Before making other connections to the 8910, first connect the ground

of the 8910 to the grounds of the devices to be conne cted. Refer to t he

following alternatives regarding common ground connection methods.

(a) Connect the grounds of devices running on DC power to the AC

adapter’s ground.

(b) Connect pin 3 (CAN_GND) of the 9713-01 CAN Cable to the

ground of the device to be connected.

Note: In method (b) above, because of wire length and CAN cable

wiring conditions, some potential difference may remain

between grounding points, so we recommend (a) as the

preferred method.

Page 28

20

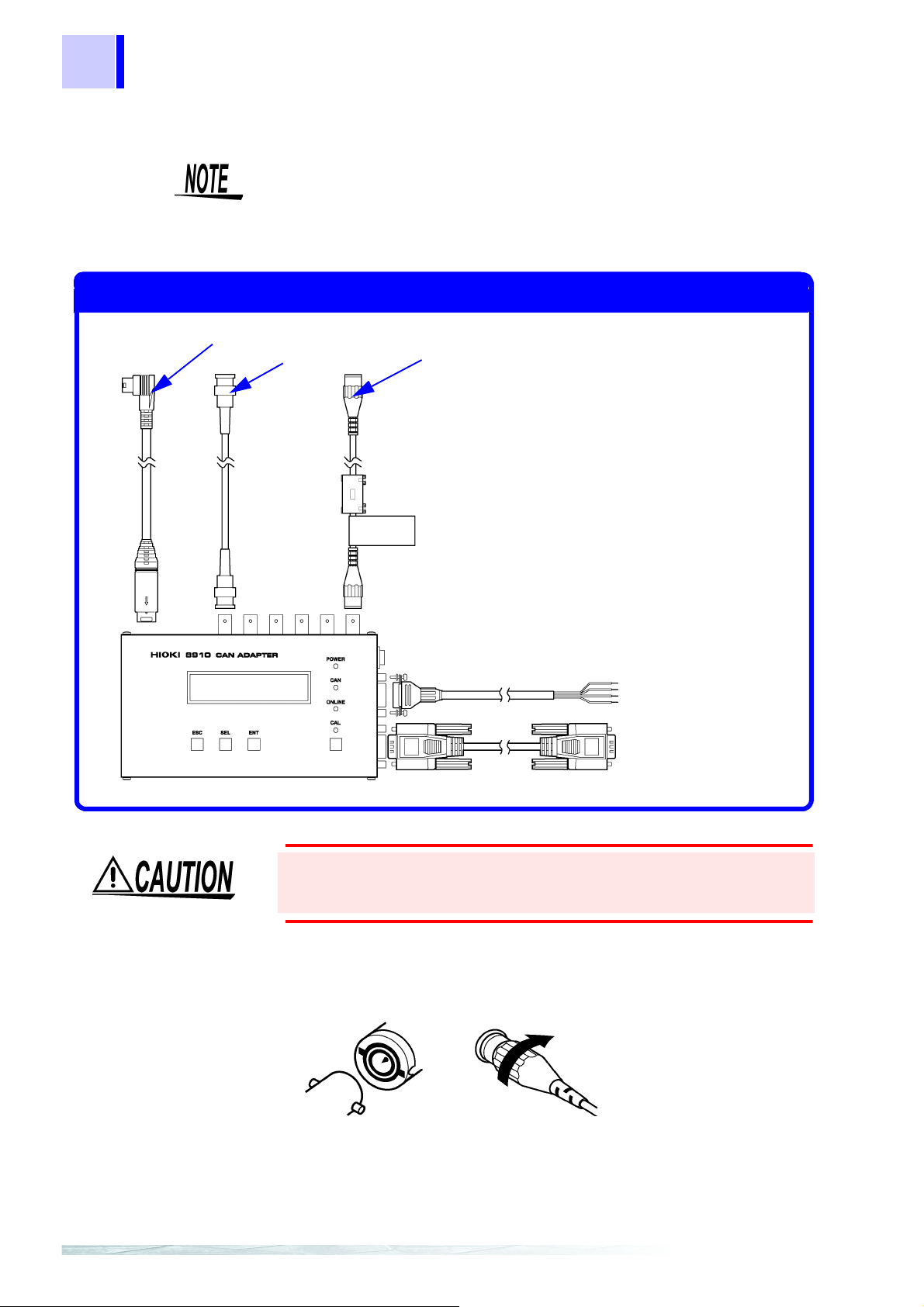

Connection Points

The 9714-01 or 9714-02 LOGIC CABLE (This is the 9714-02)

The 9165 or L9217 CONNECTION CORD

The 9713-01 or 9713-02 CAN CABLE

(This is the 9713-01)

RS-232C Cable

Lock

2.3 Connection Procedure

The following diagram shows the connection points of the cables and cords to

be connected to the 8910 CAN ADAPTER.

The instrument does not output signals (including response bits) to the CAN

bus. Therefore, when onl y one device connected to the bus in additio n to

the 8910, communication is not possible since response bits cannot be

exchanged. Therefore, be sure to connect the bus to which the 8910 is

connected with two or more devices to enable communication.

To prevent an electric shock accident, confirm that the white or

red portion (insulation layer) inside the cable is not exposed. If a

color inside the cable is exposed, do not use the cable.

Connecting to the Analog Output

1. Align the BNC connector with the guide groove of the unit output

connector, and turn clock wise while pressing in to lock the connector.

2. To remove from the instrument, turn the BNC connector

counterclockwise to release the lock, then pull it.

Page 29

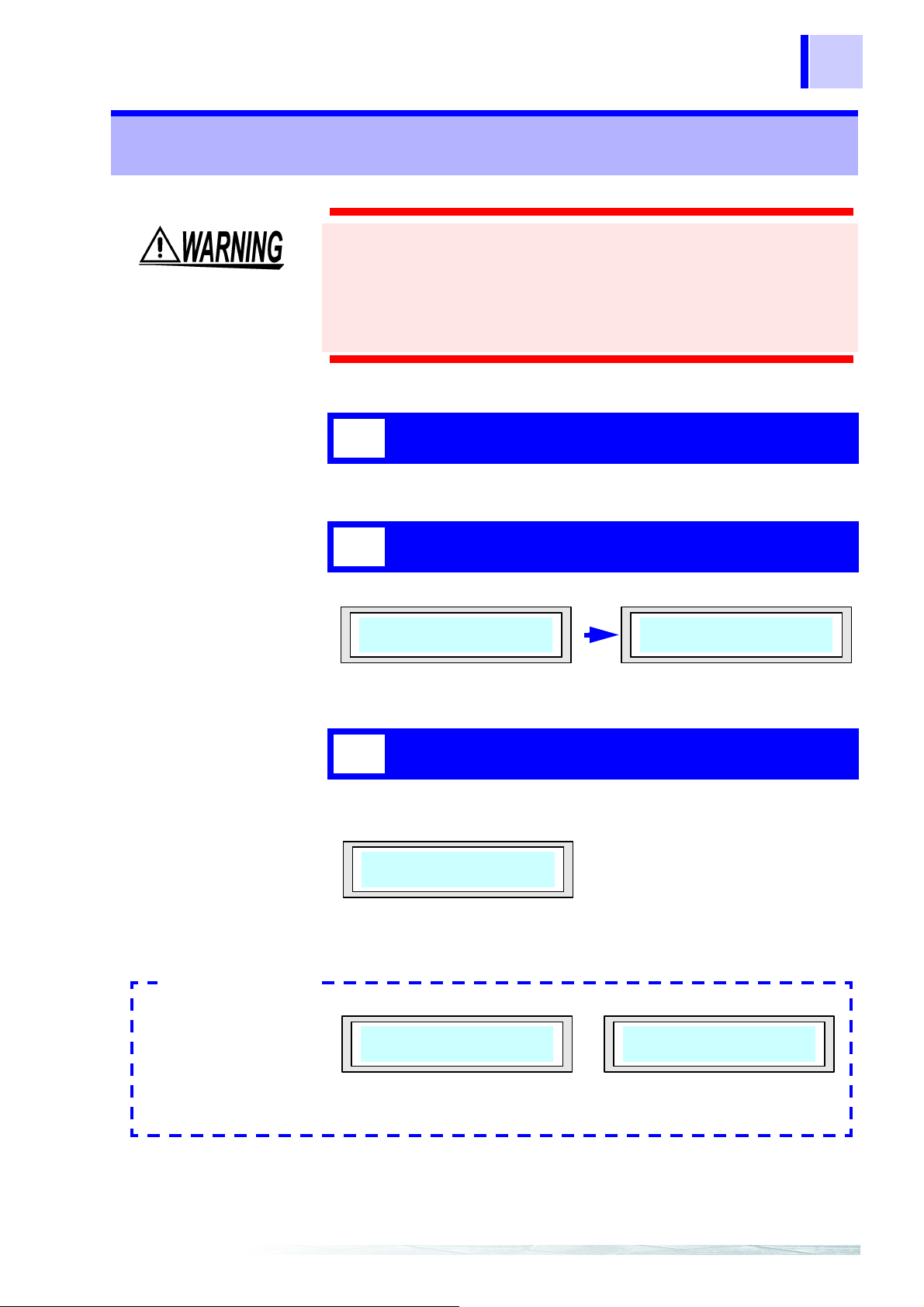

2.4 Power On/Off

HIOKI

8910CANADAPTER

8910CANADAPTER

VerX.XX

CONVMODE

Error Massages

Err:ASSIGNCH

NOTFOUND

Err:ASSIGNLIST

NOTFOUND

<When no CAN data is registered> <When no CAN data is assigned to

an output channel>

Check the following points before the power switch is turned on.

• When using the AC adapter, make sure that the power supply

complies with the rated voltage (100 - 240 VAC) and rated

frequency (50/60 Hz) of the 8910.

• The instrument is correctly connected.

❖ (Section 2.1, 15p.)

Connect the cables and cords.

1

Connect cables and cords before turning on the power.

21

2.4 Power On/Off

Turn on the power.

2

When the power switch is turned on, the POWER LED goes on.

Confirm that the above display appears. (X.XX is the version No.)

The 8910 then begins internal initialization.

3

When initialization is complete, the display bellow appears and the

instrument enters CAN signal conversion mode.

Note that if no CAN data has been registered or assigned to any

output channel, the following error message will flash on the display:

Page 30

22

2.4 Power On/Off

• The error message continues flashing unti l a key is pressed.

• While the error message is displayed, RS communication is

disabled. To conduct RS communication, press any key to place

the instrument in conversion mode.

Page 31

3.1 Modes

CONVMODE

Operation Chapter 3

3.1 Modes

The 8910 has the following three operation modes, which can be

switched by using keys on the front panel.

23

Conversion mode

Setting mode

Calibration mode

3.2 Conversion Mode

• Conversion mode is the first mode to become active after power is

turned on.

• This mode converts the CAN message supplied to CAN1 or CAN2

port according to internally set definition data, and outputs the

converted signal from a specified analog or logic output terminal.

This mode converts the CAN signal input from

the CAN 1 or 2 port according to the set

definition data, and outputs the converted

signal from the specified analog or l ogic outpu t

terminal.

This mode is used to select data to be

acquired from the CAN bus and set the

channel for acquired data output.

This mode outputs a calibration signal.

When conversion mode is active, the LCD indicates the following:

• The 8910 monitors the CAN bus and adjusts the baud rate

automatically. Therefore, the instrument has already begun to

receive signal input from CAN1 or CAN2 at this point.

• When the CAN message assigned to the output channel enters the

CAN port, the CAN LED goes on in green.

• The output voltage level is held until conversion of the next CAN

message.

• Four baud rates are supported: 125 kbps, 250 kbps, 500 kbps, and 1

Mbps.

Page 32

24

3.3 Setting Mode

3.3 Setting Mode

• This mode is used to set the data to be output from each analog/

logic output channel.

• The internal memory of the 8910 can store up to 50 items of CAN

definition data.

• The data in memory can be assigned to the 12 analog output

channels or six (24 bits) logic outpu t channels for output.

• CAN definition data must be set in advance using the PC application.

❖ Chapter 6, 49p

• The keys on the 8910 enable the following settings:

•Channel selection

•Label selection

•D/A conversion format/lo gic bit posi tion

But the setting bellow cannot be made solely by using the 8910.

•CAN input port selection

•ID trigger setting

•ID filter setting

Page 33

3.3.1 Activating setting mode

CONVMODE

CALMODE

SETMODE

[SEL] key

[

SEL] key

[

SEL] key

Conversion Mode

Calibration Mode

Setting Mode

Analog01

***OFF***

Position the [ONLINE/OFFLINE] switch to

1

the [OFFLINE] side.

To use the keys on the 8910 for entering settings, position the

[ONLINE/OFFLINE] switch to th e [ OFFLINE] side. Make sure that the

ONLINE LED is off

Press the [SEL] key.

2

When the instrument is in conversion mode, pressing the [SEL] key

changes the mode in the following sequence:

25

3.3 Setting Mode

In setting mode, press the [ENT] key.

3

In setting mode, pressing the [ENT] key displays the following

indication:

The instrument is now in setting mode. ([*** OFF ***] appears when

the channel is not assigned with data f or output.)

Page 34

26

<Example of disp lay for ana log channe l>

Analog01

labelnameM

LogicA0

labelname0

<Example of display for logic channel>

01→02→03…12→A0→A1→A2→A3→B0→B1→B2→B3→C0

→C1→C2→C3→D0→D1→D2→D3→E0→E1→E2→E3→F0

→F1→F2→F3→ (returns to the beginning)

CH

3.3 Setting Mode

3.3.2 Contents of display in setting mode

When the data to be output is assigned, the label name and D/A

conversion format ([B] or [M]) of CAN definition data are indicated for

an analog channel; the label name and bit position are indicated for a

logic channel.

3.3.3 Selecting a channel number

Activating setting mode (Section 3.3.1, 25p.)

1

When setting mode is activated, the channel number on the LCD

flashes, indicating that the channel selection can be changed.

Push the [SEL] key, and select a channel.

2

In this condition, each time the [SEL] key is pressed, the channel

indicated on the LCD changes sequentially from analog channel 1 to

12. After analog channel 12, logic channels are shown in order of [A0]

to [F3], then the indication returns to analog channel 1. Hold down the

[SEL] key until the desired channel is shown.

Push the [ENT] key.

3

After selecting a channel, press the [ENT] key. This enters the new

setting.

Since CAN data conversion and output are in process for all channels

during channel number selection, the setting can be changed while

observing the output.

Page 35

3.3 Setting Mode

3.3.4 Selecting the CAN definition data to be output

Enter the channel number.

1

(Section 3.3.3, 26p.)

When the [ENT] key is pressed to enter the channel number, the

channel number stops flashing. At the same time, the label name of

CAN definition data starts flashing, indicating that CAN definition data

assigned to the output channel can be changed.

Press the [SEL] key, and select a label name.

2

In this condition, pressing the [SEL] key changes the indication of the

label name. Hold down the [SEL] key until the label name of definition

data to be output is shown.

27

Press the [ENT] key.

3

After selecting the CAN definition data to be output, press the [ENT]

key. This enters the setting.

• To disable output, use the [SEL] key to select [*** OFF ***], t hen press

the [

ENT] key.

• CAN data conversi on an d outp ut ar e sto pped f or a ll chan nels wh ile C AN

definition data is being selected.

Page 36

28

3.3 Setting Mode

3.3.5 Setting the D/A conversion format/logic bit position

Enter the CAN definition data.

1

(Section 3.3.4, 27p.)

When CAN definition data is entered by pressing the [ENT] key, the

D/A conversion format ([B] or [M]) flashes for an analog channel; the

bit position flashes for a logic channel.

Press the [SEL] key, and set the value.

2

Hold down the [SEL] key until the flashing section shows the desired

value.

Press the [ENT] key.

3

To enter the D/A output format or bit position, press the [ENT] key.

This enters the new setting.

After the D/A output format or bit position is selected by pressing the

[ENT] key, the channel number indication starts flashing again.

CAN data conversion and output are s topped for all chan nels wh ile the D/A

conversion format/logic bit position is being set.

D/A conversion format

This format is used to select analog signal output

in a range from -5 to +5 V or 0 to +5 V. Selecting

Bipolar [B] sets the output range from -5 to +5 V;

selecting Monopolar [M] sets the output range

from 0 to +5 V.

The D/A resolution is 16 bits i n both cases. When

the data length is 16 bits, the relationship

between input data and output voltage is as

follows:(29p.)

(When the data length is N (bits), replace "16" in

the factorial of "2" shown in the diagram with "N"

in calculation.)

Page 37

3.3 Setting Mode

<Bipolar> <Monopolar>

0.0V

-5.0V

+32767

-32768

+65535

0

0

-32768

0

0+32767

+32767

+5.0V

+2.5V

0.0V

+32767 +65535

(-2 )

16-1

(+2 -1)

16

(+2 -1)

16

(+2 -1)

16-1

(-2 )

16-1

(+2 -1)

16-1

(+2 -1)

16-1

(+2 -1)

16-1

+5.0V

Relationship between input data and output voltage

(With sign) (Without sign)

(With sign) (Without sign)

29

Bit position

When the assigned CAN definition data is 2 bits

or more, this setting determines the type of bit

data that is output.

3.3.6 Returning to conversion mode

After settings are made, press the [ESC] key several times to return to

conversion mode.

When no key entry is made for about 30 seconds, the 8910 also

returns to conversion mode.

Page 38

30

CONVMODE

CALMODE

SETMODE

[SEL] key

[

SEL] key

[

SEL] key

Conversion Mode

Calibration Mode

Setting Mode

CalibrationA01

3.4 Calibration Mode

3.4 Calibration Mode

• This mode is used to select an analog/logic output channel and

output a calibration signal from the selected channel.

• This mode lets you check for proper connection of the analog

connection cords and logic cables.

3.4.1 Activating calibration mode

Position the [ONLINE/OFFLINE] switch to

1

the OFF LINE side.

To use the keys on the 8910 for entering settings, position the

[ONLINE/OFFLINE] switch to the [OFFLINE] side. Make sure that the

ONLINE LED is off.

Press the [SEL] key.

2

When the instrument is in calibration mode, pressing the [SEL] key

changes the mode in the following sequence:

In calibration mode, pressing the [ENT] key displays the following

indication:

In calibration mode, press the [ENT] key

3

Page 39

3.4.2 Selecting a channel number

CalibrationA01

A01→A02→A03....→A12→LA→LB→LC→LD→LE→LF→(returns to the beginning)

CH

<For analog channel> <For Logic Channel>

100ms 100ms

0 V

5 V

100ms

100ms

0

1

0

1

0

1

0

1

bit1

bit2

bit3

bit4

Activating calibration mode.

1

(Section 3.4.1, 30p.)

When calibration mode is activated, the channel number on the LCD

flashes, indicating that channel selection can be changed.

Push the [SEL] key, and select a channel.

2

31

3.4 Calibration Mode

In this condition, each time the [SEL] key is pressed, the channel

indicated on the LCD changes sequentially from analog channel 1 to

12. After analog channel 12, logic channels are shown in order of A to

F, then t he indication r eturns to an alog channel 1. Hold down th e [SEL]

key until the desired channel is shown.

3.4.3 Outputting a calibration signal

• After selecting a channel, press t he [CAL] key to ou tput a cali brati on

signal.The calibration signal is output from the selected channel

only while the [CAL] key is held down.

• CAN data conversion and output are st opped for al l channe ls duri ng

calibration signal output.

• For an analog channel, the output alternates between 0 V and 5 V

at 100-ms intervals.

• For a logic channel, the output bit pattern alternates between 0Ah

(1010) and 05h (0101) at 100-ms intervals.

Page 40

32

3.4 Calibration Mode

3.4.4 Returning to conversion mode

• Press the [ESC] key to exit from calibration mode and return to

conversion mode.

• When no key entry is made for about 30 seconds, the 8910 also

returns to conversion mode.

Page 41

3.5 Operation Map

ESC

SEL ENT CAL

HIOKI

8910CANADAPTER

Err:ASSIGNLIST

NOTFOUND

Err:ASSIGNCH

NOTFOUND

8910CANADAPTER

VerX.XX

CONVMODE

ESC

SEL ENT CAL

ESC

SEL ENT CAL

SEL

CALMODE

SEL

SETMODE

SEL

ESC

ESC

ENT

ENT

Analog01

SpeedB

CalibrationA01

SEL

ESC

ENT

SEL CAL

チャネル決定チャネル選択

Analog01

SpeedB

SEL

ESC

ENT

ラベル決定

ラベル選択

Analog01

SpeedB

SEL ENT

出力形式選択 出力形式決定

CAL出力チャネル選択

ESC ESC

設定モード

変換モード

CALモード

の部分は点滅表示です。

SYSTEMRESETモード

SYSTEMRESET

NO‑>ESCYES‑>ENT

Analog01

***OFF***

■出力OFFの設定

設定モードのラベル選択で下図の表示となるように

SELキーで選択し、ENTキーにて決定することでチャネル出力OFFとなります。

indicates a flashing display.

Conversion Mode

Calibration Mo de

Setting Mode

Output OFF setting

When label change is possible in setting mode, use the [

SEL

]

key to display the indication below, then press the [

ENT

] key.

This turns off channel output.

While pressing the [

ESC

] key, [

SEL

] key, and [

ENT

] key

simultaneously, turn on the power switch of the 8910.

Press the [

ENT

] key to

reset the system.

System Reset Mode

This will place the instrument in system reset mode.

Selection of channel

Entering the channe l

settings

Selection of label

Selection of output format

Entering the output

Entering the label

format

Selection of channel

Calibration signal output

:escape :selection :enter :calibration

33

3.5 Operation Map

Page 42

34

3.5 Operation Map

ONLINE mode/OFFLINE mode

Operate the switch to toggle between ONLINE mode and OFFLINE

mode.

In ONLINE mode, RS communication is enabled. The keys are not

operable in this mode (key lock).

In OFFLINE mode, the 8910 accepts oper ations . RS communic ation i s

not possible in this mode.

RS communication

Even when the instrument is in ONLINE mode, the ONLINE LED goes

off and RS communication is disabled in the following cases:

1. When an error message is displayed

2. When the instrument is in system reset mode

Key operation

Keys are not operable when the instrument is in ONLINE mode (key

lock).

Even in ONLINE mode (key lock), pressing a key turns on the

backlight for about 10 seconds.

Even in ONLINE mode (key lock), the keys are operable in the

following cases:

1. When an error message is displayed

2. When the instrument is in system reset mode

Display

The backlight turns off when no key entry is made for about 10

seconds.

The instrument returns to c onversi on mode when no k ey ent ry i s made

for about 30 seconds.

The display remains on until a key is pressed in the foll owing cases:

1. When an error message is displayed

2. When the instrument is in system reset mode

CAN conversion and output

CAN conversion and output are in process for all channels in the

following cases:

1. When the instrument is in conversion mode

2. While the [CAL] key is not pressed in CAL mode

3. When a channel is being selected in setting mode (with setting

changeable while observing the output)

Page 43

Setting change

35

3.5 Operation Map

CAN conversion and output are stopped for all channels in the

following cases:

1. When the [CAL] key is pressed in CAL mode during CAL signal

output

2. When the label, output format, or bit position is being selected in

setting mode

3. When the instrument is engaged in RS communication

4. When an error message is displayed

5. When the instrument is in system reset mode

When the [SEL] key is used in setting mode to change a setting,

pressing the [ENT] key enters the new setting.

A new setting will not be effective by simply changi ng a set ting with the

[SEL] key in setting mode.

The entered setting is written to backup memory immediately before

CAN conversion and output.

Operation tips

In setting mode, CAN conversion and output are conducted when

setting item selection returns to the channel selection. Therefore, the

setting is written to backup memory at this time.

If 8910 power is turned off before setting item selection returns to the

channel selection, the setting change made in setting mode will not be

written to backup memory.

In CAL mode, pressing the [SEL] key changes the channel indication

in the forward direction. Pressing the [SEL] key whil e holdi ng down the

[ENT] key changes the channel indication in the reverse direction.

In setting mode, pressing the [SEL] key changes the setting item

indication in the forward direct ion. Pr essing t he [CAL] key changes t he

setting item indication in the reverse direction.

Page 44

36

3.5 Operation Map

Page 45

4.1 Overview

Preparation of

the CAN Set

Program Chapter 4

4.1 Overview

The 8910 CAN set program is the software used to set recording

conditions for the 8910 CAN ADAPTER. The program mainly consists

of 8910 setting mode and CAN definition data editing mode.

37

8910 setting mode

This mode is used to set the 8910 CAN ADAPTER.

In this mode, up to 50 items of CAN definition data to be registered in

the 8910 can be selected, with data to be output from the 8910 output

channel selected from the data registered. After setting is completed,

the setting data is transferred to the 8910 via the RS-232C.

CAN definition data editing mode

This mode is used to create or edit a CAN definition data file.

Page 46

38

Assuming that your CD-ROM drive is drive R

(1) Click the [Start] button.

(2) Select [Run...] on the Windows Start Menu.

(3) Enter as following in the text box.

Using the English file : R:\8910SET\ENGLISH\SETUP.EXE

Using the Japanese file: R:\8910SET\JAPANESE\SETUP.EXE

(4) Click [OK].

(otherwise, substitute the appr opriate drive letter for R)

4.2 Program Setup

4.2 Program Setup

4.2.1 System requirements

To use the pr ogram, the f ollowi ng hardware and sof tware are requi red:

Personal computer

IBM PC/AT compatible

Pentium 133 MHz or higher (recommended)

Min. 64 MB RAM (recommended)

Free hard disk space: 5 MB

RS-232C capability

CD-ROM drive (to install software)

OS

4.2.2 Installation

Follow the procedure below to instal l the program.

1. Close all active applications.

2. Insert the CD-R provided into the CD-ROM drive.

3. Execute the Setup file on the CD-R.

Microsoft Windows 95 (OSR2 or later)

Windows 98

Windows NT4.0 (SP3 or later)

Windows Me

Windows 20 00

Windows XP

4. The installer starts up. Follow the instructions displayed on the screen

to install the program.

Page 47

4.2.3 Un-Installation

The program can be uninstalled by using one of the following

methods:

<Method 1>

1. Click the [Start] button to open the Windows Start Menu.

2. Select [Programs] - [HIOKI] − [8910 CanSet Program] - [Uninstall

8910 CanSet Program].

3. When a dialog box appears asking about file deletion, select [Yes].

<Method 2>

1. Click the [Start] button to open the Windows Start Menu.

39

4.2 Program Setup

2. Select [Settings] - [Control Panel].

3. Click the [Add/Remove Programs] icon to open the [Add/Remove

Programs Properties] dialog box.

4. Select [8910 CanSet Program] in the list shown in the [Add/Remove

Programs Properties] dialog box, then click the [Add/Remove].

The uninstaller starts up and deletes the program. Note that setting

files remain on the PC. Manually delete any unnecessary files.

Page 48

40

4.2 Program Setup

Page 49

5.1 Connecting the PC to the 8910

Starting the CAN

Set Program Chapter 5

Before initiating the setting procedure, connect the PC to the 8910.

After connection is made, start up the setting application software.

5.1 Connecting the PC to the 8910

Follow the procedure below to connect the PC to the 8910.

1. Turn off the power of the 8910.

41

2. Make sure that no cable is connected to the CAN1 or CAN2 port of the

8910.

3. Connect the RS cable to the RS-232C terminal on the 8910.

4. Connect the other end of the RS cable to the RS-232C terminal on the

PC.

5. Turn on the power of the 8910.

6. Position the [ONLINE/OFFLINE] switch to [ONLINE] si d e.

Page 50

42

2. 3. 8. 9. 10. 11. 13.

1.

4.

5.

6.

7.

14.

12.

5.2 Starting Up the Condition Setting Program

5.2 Starting Up the Condition Setting

Program

1. Click the [Start] button to open the Windows Start Menu, then select

[Programs] - [HIOKI] - [8910 CanSet Program] - [8910 CanSet

Program].

2. The program starts up and the following 8910 setting window appears

on the display.

<To end the program>

Select [Close] or [Exit] on the [File] pull-down menu. Selecting

[Close] only closes the 8910 setting window. Selecting [Exit] closes

the 8910 setting window and CAN definition data editing window

(Section 6.6, 65p.) at the same time.

Page 51

5.2 Starting Up the Condition Setting Program

43

1. Toolbar

2. ID trigger setting

3. CAN definition data file selection

4. CAN definition data edit button

Various operations can be conducted by clicking

appropriate icons on the toolbar.

The colored icons effective in this window (from the

left) are:

•[New] for the 8910 setting file

•[Open] for the 8910 setting file

•[New] for the CAN definition data file

•[Open] for the CAN definition data file

•[Save] for the currently open file

•[Save as] for the currently open file

•[Print] for setting data

Checking [Toolbar] on the [View] pull-down menu

displays the toolbar.

The ID trigger is a function that outputs a pulse wave

from a selected logic channel at ID message input.

This section is used to enter the ID trigger setting.

This shows the name of the CAN definition data list file

currently selected. To change the file, click the [...]

button on the right side.

This button is used to edit CAN definition data. It

allows the editing of existing data and creation of new

data.

5. CAN port selection

6. CAN definition data list detail display

7. CAN definition data list

8. ID filter setting

9. 8910 registration list edit button

10. 8910 registration list content

11. Analog output allocation list

This is used to select CAN1 or CAN2 input port of the

8910 for data input.

Checking this item displays all setting items of

definition data in list format. When this setting is off,

only the necessary items are displayed.

This section displays the content of the downloaded

CAN definition data file. In the initial state, the content

of the previously used file is displayed.

Each input port can be set with a filter to prevent the

reception of messages in s t andard or extended f ormat.

This button is used for editing an 8910 registration list.

It allows the editing of an existing list and creation of a

new list.

This section displays the CAN definition data to be

registered on the 8910 CAN ADAPTER. Up to 50

items of definition data can be registered on the 8910.

This list displays the data to be output through analog

output channels 1 through 12 of the 8910 CAN

ADAPTER.

12. Logic output allocation list

13. Send button

This list displays the data to be output through logic

output channels A through F of the 8910 CAN

ADAPTER. Each line on the display represents one bit.

This button transmits the settings made in this window

to the 8910 CAN ADAPTER.

Page 52

44

5.2 Starting Up the Condition Setting Program

14. Status bar

This section indicates the current status. Checking

[Status bar] on the [View] pull-down menu displays

the status bar.

Page 53

5.3 Menu Items in the Setting Window

[New]

[Open]

[Close]

[Save]

[Save as]

[Can Define Data File]

[Print]

[Print Preview]

[Print Setup]

[Exit]

❖(Section 7.1.2, 72p.)

❖(Section 7.1.1, 71p.)

❖(Section 5.2, 42p.)

❖(Section 9.1.2, 88p.)

❖(Section 9.1.1, 87p.)

❖(Section 9.2.1, 89p.)

❖(Section 9.2.2, 89p.)

❖(Section 9.2.3, 90p.)

❖(Section 5.2, 42p.)

[New]

[Open]

❖(Section

6.6.2, 69p.)

❖(Section

6.6.3, 69p.)

[Modify Password]

❖(Section 9.4, 93p.)

[Send]

[Settings]

❖(Section 8.2, 84p.)

❖(Section 8.1, 83p.)

[Toolbar]

[Status bar]

❖(Section 5.2, 42p.)

❖(Section 5.2, 42p.)

[Cascade]

[Tailed]

❖(Section 9.3, 92p.)

❖(Section 9.3, 92p.)

[About 8910 Can Set]

❖(Section 9.5, 94p.)

5.3 Menu Items in the Setting Window

45

Page 54

46

1. Prepare for setting.

2. S

et the CAN definition data.

• Connecting the PC to the 8910

Connect the PC to the 8910 via the

RS

-232C.

• Starting up the 8910 CAN set

program

• Setting the message ID

Set the message ID.

• Setting the data length

Set the data size.

• Setting the data start position

Set the data location.

• Setting the data pattern

Set the data pattern

(byte arrangement).

• Setting the sign

Set whether the data has a sign.

• Setting the signal name/label

name

Set the name of the data.

• Setting the scaling

Set the physical quantity of data.

3. Register the definition data

in the registration list.

4. Set the ID filter.

• Loading CAN definition data

Read the data from the file.

• Registration of definition data in

the registration list

Select the data from the definition list

and register it.

• Setting the ID filter

Set the filter ON/OFF for each input

po

rt.

5. Assign data to output channels.

• Allocation of data to analog

channels

Set the output analog channels.

• Allocation of data to logic

channels

Set the output logic channels.

<Go to the next page>

• Selection of a message ID

Select an applicable message ID.

• Selection of output channels

Select a pulse output channel.

6. Set the ID trigger.

5.4 Operation Flowchart

5.4 Operation Flowchart

Page 55

5.4 Operation Flowchart

7. Send the set data to the 8910. • Setting of communication

parameters

Set the communication parameters on

the PC.

• Transmission of data

Transfer the data to the 8910.

8. Record the setting data.

• Storage of set data

Save the set data.

• Printing of set data

Print the setting data.

9. End the setting procedure.

• Ending the 8910 CAN set

program

Close the application software.

47

Page 56

48

5.4 Operation Flowchart

Page 57

6.1 Opening a CAN definition data file

Setting the CAN

Definition Data Chapter 6

• Parameters must be edited or created to acquire data f rom t he CAN

bus.

• CAN definition data can be set using the 8910 setting window or by

opening the CAN definition data editing window. The following

describes how to set data in the 8910 setting window

❖How to use the editing window → (Section 6.6, 65p.)

6.1 Opening a CAN definition data file

.

49

6.1.1 Opening a CAN definition data file

The stored CAN definition data file can be read.

Click the [...] button.

1

Click the [...] button located to the right of the CAN definition data file

name box to show the file loading dialog box.

Select a file.

2

From the list of CAN definition data files shown in the file loading

dialog box, select a file (with extension "c df") to read.

Click the [Start] button.

3

Clicking the [Start] button on the dialog box updates the CAN

definition data list.

Page 58

50

6.1 Opening a CAN definition data file

6.1.2 Creating a new CAN definition data file

Click [Edit] button.

1

Click the button located above the CAN definition data list to create a

new CAN definition data file. To prevent operation errors, only the

[Edit] button is operable under normal conditions. First, click this

button.

Enter the password.

2

When the password protec tion function is enabled, the password input

dialog box opens. Enter the password.

❖Details of the password setting →(Section 9.4, 93p.)

The [Edit] button remains depressed and the [New] button, [Add]

button become operable. (The Memo (comment) display (66 p.) also

becomes available for use.)

Page 59

51

6.1 Opening a CAN definition data file

Click the [New] button.

3

Clicking the [New] button opens a confirmation dialog box that asks

whether to initialize the CAN definition data fil e.

OK

Cancel

Clicking [OK] deletes the content of the currently displayed CAN

definition data list and executes i nitialization.

Creates a CAN definition data file.

Cancels creation of a CAN definition data file.

Page 60

52

CAN definition data setting window

Setting of message ID

Setting of data start position

Setting of data length

Setting of data type

Setting of sign

Setting of signal name Setting of label name Setting of unit

Setting of scaling

6.2 Editing the CAN Definition Data

6.2 Editing the CAN Definition Data

New definition data can be added to the currently open CAN definition

data file.

Click the [Add] button.

1

Click the [Add] button located above the CAN definition data list to

open the CAN definition data setting window.

Set items.

2

This window is used to set items such as the message ID and start bit.

Page 61

6.2.1 Setting the message ID

• Set the message ID of the message in which data to be acquired is

stored.

• Since this instrument supports extended format, a value of up to 29

bits can be set in the message ID section. Enter numeric values in

hexadecimal notation.

ID

Example: When 64 is entered in the input box, this input is

0 to 1FFFFFFF

interpreted as 100 in decimal notation since 64 in

hexadecimal notation is 100.

53

6.2 Editing the CAN Definition Data

6.2.2 Setting the data length

Enter the size (bits) of dat a to be acquired.

• Since the maximum size of data that can be captured by the 8910 is

2 bytes (16 bits), a value from 1 to 16 can be entered in the input

box.

• The data length set here, together with the data start position and

data pattern system settings, determines the location of acquisition

data in the CAN data frame.

Length [bit]

1 to 16 (bits)

Page 62

54

7 6 5 4 3 2 1 0

15 14 13 12 11 10 9 8

7 6 5 4

23 22 21 20 19 18 17 16

31 30 29 28 27 26 25 24

39 38 37 36 35 34 33 32

47 46 45 44 43 42 41 40

55 54 53 52 51 50 49 48

63 62 61 60 59 58 57 56

3 2 1 0

0

1

2

3

4

5

6

7

bit

byte

←MSB LSB→

↑

Beginning

End

↓

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4

・・・

Massage beginning

Massage end →

Most significant bit Least significant bit

byte 0 byte 1 byte 2 byte 3

6.2 Editing the CAN Definition Data

6.2.3 Setting the data start position

The least significant bit (LSB) position of acquisition data is used to

specify its location in the CAN data frame.

The bit positions are numbered as follows:

1. As the reference position, the least significant bit (LSB) position of the

first byte of data in t he data f rame is given a value of 0. From there, t he

number is increased by one towards the most significant bit (MSB)

position.

2. From the MSB position, it moves to the next byte data, and the

number is incremented by one from the LSB toward the MSB.

3. Since the maximum size of the data frame section is 8 bytes (64 bits),

the MSB position in the 8th byte from the beginning is numbered 63.

Therefore, the bit positions can be expressed with numbers from 0 to

63, as shown below .

Example: 8-bit data in the second byte from the beginning is specified.

Since its least significant bit (LSB) position is Bit 0 in Byte 1, the bit positi on is 8.

Page 63

6.2 Editing the CAN Definition Data

<Motorola format> <Intel format>

7 6 5 4 3 2 1 0

15 14 13 12 11 10 9 8

bit

byte

7 6 5 4 3 2 1 0

0

1

23 22 21 20 19 18 17 16

2

31 30 29 28 27 26 25 24

3

7 6 5 4 3 2 1 0

15 14 13 12 11 10 9 8

bit

byte

7 6 5 4 3 2 1 0

0

1

23 22 21 20 19 18 17 16

2

31 30 29 28 27 26 25 24

3

23 22 21 20 19 18 17 169 8

23 22 21 20 19 18 17 1625 24

(MSB) (LSB) (MSB) (LSB)

The position of Bit 9 is the MSB

(most significant bit) position.

The position of Bit 25 is the MSB

(most significant bit) position.

6.2.4 Setting the data pattern

Here, the data pattern is set. Even if the data start position and data

length are the same, the data position (method of data acquisition)

varies depending on whether the data pattern is Motorola format or

Intel format.

Example: A data whose bit length is 10 bits and data start position (LSB position) is Bit 1 6.

55

The data pattern (method of data acquisition) is selected from the

following three systems:

U/L (Motorola)

L/U (Motorola)

Data is extracted according to Motorola format.

Data is extracted according to Motorola format,

then the high-byte and low-byte positions are

switched. This setting is effective when the data

length is from 9 to 16 bits. When the data length

is 8 bits or shorter, this setting function is the

same way as U/L (Motorola).

L/U (Intel)

Data is extracted according to Intel format.

Page 64

56

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4

・・・

byte 0 byte 1 byte 2 byte 3

Data frame beginning

Data frame end

→

6.2 Editing the CAN Definition Data

Example: In the 16-bit data shown in the diagram, when the value of Byte 0 is FF and the

value of Byte 1 is 00, the following value results according to the method used:

Value based on U/L (Motorola): FF00

Value based on L/U (Motorola): 00FF

Value based on L/U (Intel) : 00FF

(The data start position is 8 in Motorola format, and 0 in Intel for mat.)

6.2.5 Setting the sign

This is used to set whether the pertinent data has a sign.

Unsigned

1-Signed

2-Signed

When "with sign" is set in “positive

complement only interchanges 0 and 1 in binary notation, whereas

two's complement adds 1 after 0 and 1 are interchanged.

Example: Data with a data length of one byte

Without sign

With sign

(with negative number being one's complement)

With sign

(with negative number being two's complement)

→ negative" sign conversion, one's

Unsigned: 0 to +255 (00h to FFh)

1-Signed : -127 to +127 (80h to 7Fh)

2-Signed : -128 to +127 (80h to 7Fh)

-1 in 2-Signed is FFh, but -1 in 1-Signed results in FEh.

When the data length is 1 bit, only Unsigned can be selected.

Page 65

6.2 Editing the CAN Definition Data

6.2.6 Setting the signal name

A signal name with up to 40 characters can be assigned to data.

• Click the signal name input box, then enter a signal name.

• The signal name is useful for identifying data among other data

used in the condition setting program. A comment can be entered

as the signal name.

• When the 8910 CAN ADAPTER is used with the HIOKI 8826, 8841,

8842 MEMORY HiCORDER, the signal name can be transferred to

the 8826, 8841, 8842 MEMORY HiCORDER as comment data.

Spaces or commas cannot be used in a signal name.

57

6.2.7 Setting the label name

The label name must be set for each item of data since data is

distinguished by the label name on the 8910.

• Make sure that the same label name is not used twice.

• Up to 16 characters can be used in the label name. To enter a label

name, click the label name input box, then enter a name.

Spaces or commas cannot be used in a label name.

6.2.8 Setting the unit

Data can be attached with a unit of physical quantity with up to 8

characters.

• Click the unit input box, then enter a unit.

Spaces or commas cannot be used in an unit.

Page 66

58

Physical quantity = BitRate X Data value (Bit) + Offset

6.2 Editing the CAN Definition Data

6.2.9 Setting the scaling

• Data can be set with a physical quantity.

• Since the output voltage from the 8910 CAN ADAPTER is

determined by the data length setting, sign setting, and D/A output

setting, the setting value entered here is not reflected in the actual

output value.

• However, this setting is useful for understanding the possible range

of physical quantity of actual data.

• When the 8910 CAN ADAPTER is used with the HIOKI 8826, 8841,

8842 MEMORY HiCORDER, the scaling setting on the 8826, 8841,

8842 MEMORY HiCORDER side can be automatically adjusted

according to the value set here.

The conversion bit rate/of fset value or maximum value/minimum value

can be used to specify scaling. Select one of the two methods.

Specifying with conversion bit rate/offset value

Select the radio button next to [BitRate].

1

Select the radio button next to [BitRate] when using the conversion bit

rate/offset value to speci fy the scaling.

BitRate

Offset

Set the [BitRate] and [Offset] value.

2

Based on the physical quantity per bit of ac quisiti on data and the offset

value, the physical quantit y can be expressed by the foll owing for mula:

Physical quantity per 1 bit of acquisition data

Offset value

Example: When the [BitRate] is set to 0.1 and [Offset] to 100 as

shown above, and the acquired data value is 500, the

physical quantity

Physical quantity = 500 x 0.1 + 100 = 150

Page 67

59

6.2 Editing the CAN Definition Data

When the [BitRate] or [Offset] is set, the [Maximum] and [Minimum]

values are automatically set based on the set values, data length

setting, and sign setting.

Specifying with maximum and minimum values

Select the radio button next to [Minimum].

1

Select the radio button next to [Minimum] when using the maximum

and minimum values to specify the scaling

Set the [Maximum] and [Minimum] value.

2

Set the [Maximum] and [Minimum] possible values of the data.

When the [Maximum] and [Minimum] value is set, the physical

conversion bit rate and offset value are automatically set based on the

set values, data length setting, and sign setting.

Page 68

60

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4

9 8 7 6 5 4 3 2 1 0

byte 0 byte 1

Two high-order bits extend from the frame

6.2 Editing the CAN Definition Data

6.2.10 Error Massage

If the CAN definition data settings are incorrect or conflicting, an error

message appears when the [OK] button is clicked.

If an error message appears, take the following corrective action:

If error message "Input please " appears

The message ID or label name input box (or both) i s b lank. Nei ther t he

message ID input box nor label name input box can be left blank. Be

sure to enter a setting in both boxes.

If error message "Bad Can define data!" appears

The data length, data start position, and data pattern settings