Page 1

INSTRUCTION MANUAL

8846

MEMORY HiCORDER

Page 2

Page 3

Contents

Introduction i

Inspection ii

Safety Notes iii

Notes on Use v

Chapter Summary ix

Chapter 1 Product Overview 1

1.1 Major Features 1

1.2 Identification of Controls and Indicators 3

Chapter 2 Specifications 11

2.1 General Specifications 11

1

2

3

4

5

6

2.2 Trigger Unit Specifications 14

2.3 Memory Recorder Function Specifications 15

2.4 Recorder Function Specifications 16

2.5 FFT Function Specifications 17

2.6 Auxiliary Functions Specifications 18

2.7 Accessories and Options 21

2.8 System Operation 22

Chapter 3 Logic and Analog Inputs 23

3.1 Logic Inputs 23

3.1.1 Logic Probes

3.2 8916 ANALOG UNIT 25

3.2.1 Specifications

3.2.2 Safety Requirements

3.3 8917 DC/RMS UNIT 27

3.3.1 Specifications

24

25

26

27

7

8

9

10

11

12

13

3.3.2 Safety Requirements

3.4 8918 TEMPERATURE UNIT 29

3.4.1 Specifications

3.4.2 Safety Requirements

3.4.3 Notes on Installation Site

28

29

30

31

14

A

Page 4

3.5 8919 FFT ANALOG UNIT 32

3.5.1 Specifications

3.5.2 Safety Requirements

32

33

3.6 8927 ANALOG UNIT 34

3.6.1 Specifications

3.6.2 Safety Requirements

34

35

3.7 8928 STRAIN UNIT 36

3.7.1 Specifications

3.7.2 Safety Requirements

3.7.3 Strain Unit Settings

36

37

37

3.8 Replacement Procedure 38

3.9 Input Cables 39

3.10 Measurement Errors Caused by Signal Source Internal

Resistance 40

Chapter 4 Installation and Preparation 41

4.1 Installation of the Unit 41

4.2 Power Supply and Ground Connection 44

4.3 Power On/Off 47

4.4 Probe and Thermocouple Connection 48

4.5 Connection to a Strain Gauge Adapter 51

4.6 Connecting the Voltage Transformer 52

4.7 Loading Recoding Paper 54

4.8 Storage and Handling Precautions 56

4.9 Notes on Measurement 57

Chapter 5 Basic Operation and Measurement 59

5.1 Basic Operation 59

5.1.1 Basic Display Operation

5.1.2 JOG/SHUTTLE Control and Select Key

5.1.3 Setting Items

5.1.4 Measurement Start and End

5.2 Basic Measurement and Setting Procedures 63

59

60

62

62

5.2.1 Measuring and Recording a Voltage

(Memory Recorder, Recorder)

5.2.2 Frequency Analysis of Measured Voltage (FFT)

63

74

Page 5

Chapter 6 Memory Recorder Function 81

6.1 Outline 81

1

6.2 Making Settings 83

6.2.1 Setting the Function Mode

6.2.2 Setting the Time Axis Range

6.2.3 Setting the Recording Length

6.2.4 Setting the Format

6.2.5 Using the X-Y Waveform Plots

6.2.6 Setting the Interpolation Function

6.2.7 Setting the Roll Mode

6.2.8 Superimpose

6.2.9 Other Settings (STATUS Screen)

6.3 Settings on the Display Screen and Auto Settings 98

6.3.1 Setting Magnification/Compression Along the Time Axis

6.3.2 Making Channel Settings

6.3.3 Automatic Setting of Time Axis and Voltage Axis

6.4 Start and Stop Measurement Operation 102

83

84

85

86

90

93

94

95

96

98

99

100

2

3

4

5

6

7

Chapter 7 Recorder Function 105

7.1 Outline 105

7.2 Making Settings 106

7.2.1 Setting the Function Mode

7.2.2 Setting the Time Axis Range

7.2.3 Setting the Magnification Along the Time Axis

7.2.4 Setting the Recording Time

7.2.5 Setting the Format

7.2.6 Setting the Interpolation Function

7.2.7 Setting the Recording Medium

7.2.8 Recording a Voice Memo

7.2.9 Transferring Data to the Memory Recorder Function

7.2.10 Other Settings

7.3 Settings on the Display Screen and Auto Settings 123

7.3.1 Making Channel Settings

7.3.2 Automatic Setting of Time Axis and Voltage Axis

106

107

109

112

113

116

117

118

119

121

123

123

8

9

10

11

12

13

14

7.4 Start and Stop Measurement Operation 125

A

Page 6

Chapter 8 FFT Function 127

8.1 Outline 127

8.2 Item Settings 128

8.2.1 Setting the FFT Function

8.2.2 Setting the FFT Channel Mode

8.2.3 Setting the Frequency Range

8.2.4 Setting the Window Function

8.2.5 Setting the Display Format

8.2.6 Selecting Reference Data

8.2.7 Setting the Peak Display

8.2.8 Setting the FFT Analysis Mode

8.2.9 Setting the Analysis Channel

8.2.10 Setting the X-axis and Y-axis Displays

8.2.11 Setting the Display Scale

8.2.12 Octave Filter Setting

8.2.13 Setting the Interpolation Function

8.2.14 Other Settings

128

129

130

132

134

136

138

140

141

142

144

146

147

148

8.3 Analysis Function 150

8.3.1 Storage Waveform [STR]

151

8.3.2 Linear Spectrum [LIN]

8.3.3 RMS Spectrum [RMS]

8.3.4 Power Spectrum [PSP]

8.3.5 Auto Correlation [ACR]

8.3.6 Histogram [HIS]

8.3.7 Transfer Function [TRF]

8.3.8 Cross Power Spectrum [CSP]

8.3.9 Cross Correlation [CCR]

8.3.10 Unit Impulse Response [IMP]

8.3.11 Coherence [COH]

8.3.12 Octave Analysis [OCT]

152

154

156

158

159

160

162

164

166

168

170

Page 7

1

Chapter 9 Input Channel Settings 175

9.1 Overview 175

1

9.2 Selecting Units (SYSTEM Screen) 176

9.3 Selecting Functions 177

9.4 Selecting the Input Type 178

9.5 Making Logic Input Settings (FFT Excluded) 180

9.6 Making Analog Input Settings 181

9.6.1 Waveform Display Color (FFT Excluded)

9.6.2 Display Graph Type (FFT Excluded)

9.6.3 Setting the Voltage Axis, Temperature Axis, Strain Axis

Ranges

9.6.4 Setting the Input Coupling (Not Required for 8918, 8928)

9.6.5 Setting Voltage Axis, Temperature Axis, and Strain Axis

Magnification/ Compression

9.6.6 Setting the Zero Position

9.6.7 Setting the Low-Pass Filter

9.6.8 Setting the Thermocouple Type (8918 Only)

9.6.9 Setting the Antialiasing Filter (8919 Only)

9.6.10 Arbitrary Setting if Voltage Axis Magnification/

181

183

184

187

188

189

191

192

193

2

3

4

5

6

7

8

Compression and Display Range

9.6.11 Copying Channel Settings

9.6.12 Making Channel Settings on Display Screen

195

197

198

Chapter 10 Trigger Functions 199

10.1 Overview 199

10.2 Setting the Trigger Mode 200

10.3 Setting Trigger Source AND/OR Linking 201

10.4 Setting the Pretrigger (Memory recorder, FFT) 202

10.5 Using the Analog Trigger Function 204

10.5.1 Level Trigger

10.5.2 Window-In, Window-Out Trigger

10.6 Using the Logic Trigger Function 210

10.7 Using the External Trigger Function 214

10.8 Using the Timer Trigger Function 215

10.9 Trigger Output Connector 218

205

208

9

0

11

12

13

14

15

Page 8

Chapter 11 SYSTEM Screen Settings 219

11.1 Overview 219

11.2 How to Use the SYSTEM Screen 220

11.3 Initialization [ INITIALIZE ] 221

11.3.1 Setting the Clock

11.3.2 Clear Waveform Data

11.3.3 System Reset

[ TIME SET ] 221

[ DATA CLEAR ] 222

[ SYSTEM RESET ] 223

11.4 Special Function Settings [ SETUP ] 226

11.4.1 Channel Selection

11.4.2 Start Key Backup

11.4.3 Setting the Grid

11.4.4 Channel Marker Function

11.4.5 Time Axis Display

11.4.6 List and Gauge Functions

11.4.7 Backlight Saver Function

11.4.8 Setting Screen Colors

11.4.9 Setting the Volume

11.4.10 Intermittent Printing [ intermittent print ]

11.4.11 Selecting the Hard Copy Destination

11.4.12 Setting the Display Language

[ using unit ] 227

[ start backup ] 228

[ grid type ] 229

[ channel marker ] 231

[ time axis ] 232

[ list & gauge ] 233

[ backlight saver ] 234

[ LCD color type ] 235

[ volume ] 236

237

238

239

11.5 Scaling Function [ SCALING ] 240

11.5.1 Conversion Ratio Scaling

11.5.2 2-Point Scaling

11.5.3 Scaling Setting Example

241

242

245

11.6 Adding Comments to a Graph [ COMMENT ] 247

11.6.1 Comment and File Name Entry Procedure

248

11.7 Self Check 249

11.7.1 ROM/RAM Check

11.7.2 LED Check

11.7.3 Printer Check

11.7.4 Key Check

11.7.5 Display Check

11.7.6 MO Check

11.7.7 D/A Unit Output Check

250

251

252

253

254

255

256

11.8 Interface Settings 257

Page 9

11121

Chapter 12 Printout of Waveform Data and Processing

1

Data

12.1 Overview 259

12.2 Selecting Waveform or Numeric Print 260

12.3 Using the Smooth Print Function 262

12.4 Print Settings on SYSTEM Screen 263

12.5 Printing Procedure 264

12.5.1 Normal Print

12.5.2 Normal Print

12.5.3 Real-Time Print

12.5.4 Partial Print

12.5.5 Screen Hard Copy

12.5.6 A4 Print

12.5.7 List Print

12.5.8 Paper Change During Printing

12.6 Reading the Display and Printout 275

(Manual) (All Functions) 264

(Auto) (Memory Recorder, FFT) 266

(Recorder Function) 267

(Memory Recorder, Recorder) 269

(All Functions) 271

(Memory Recorder, Recorder) 272

(All Functions) 273

259

274

2

3

4

5

6

7

Chapter 13 Storing Data on DDS Tape/Reading Data

From DDS Tape

13.1 Overview 283

13.2 About the MO Disk 284

13.3 MO Drive Operation 285

13.4 Displaying File List and File Information 287

13.4.1 Displaying a File List

13.4.2 Displaying File Information

13.5 Storing Data on a MO Disk 289

13.5.1 Storing Memory Recorder and FFT Data

13.5.2 Storing Recorder Data

13.5.3 Automatic File Name Assignment

13.5.4 File Contents and Size

13.6 Reading Data From MO Disk 302

13.6.1 Reading Stored Data

8

283

9

10

287

288

289

295

297

298

3

302

13.6.2 Playback of Stored Data

13.7 Recording the Recorder Waveform Data Stored on MO

in Memory Recorder Function/FFT Function

(FILEtoMEM/FFTT)

13.8 Deleting Stored Data (directory and file deleting) 311

304

309

14

15

Page 10

13.9 Renaming File (file name and directory name) 313

13.10 Operating the Disk/ Deleting the Window (HELP key) 314

13.10.1 Creating a Directory

13.10.2 Searching file

13.10.3 Sorting files

13.10.4 Formatting a MO Disk

13.10.5 Formatting a MO Disk Physically (Physical Format)

316

317

319

320

321

Chapter 14 Calculating Waveform Data 323

14.1 Overview 323

14.2 Preparing for Waveform Processing 324

14.3 Defining the Processing Equation 326

14.3.1 Entering the Equation

14.3.2 Deleting an Equation

14.3.3 Copying an Equation

14.4 Setting the Channel for Recording Processing Results 331

14.5 Setting the Display Scale 332

14.6 Specifying the Waveform Processing Range 333

326

329

330

14.7 Setting Example for Waveform Processing 334

14.8 Details on Operators 337

Chapter 15 Determining Waveform

Parameters / Evaluating

15.1 Overview 343

15.2 Making Settings for Waveform Parameter Calculation 344

15.3 Making Settings for Waveform Parameter Evaluation 348

15.4 Using the NG Output 351

15.5 Specifying a Range for Waveform Parameter Calculation 352

15.6 Printing Out Waveform Parameter Calculation Results 353

15.7 Waveform Parameter Calculation and Waveform

Parameter Evaluation Examples 354

15.8 Parameter Calculation Details 357

Parameter Values 343

Page 11

1

1

1819202122232

141

Chapter 16 Waveform GO/NG Evaluation 361

16.1 Overview 361

6

16.2 Waveform Evaluation Settings 362

16.3 Creating the Evaluation Area 366

16.4 Editor Command Details 368

16.5 Using the NG Output 378

16.6 Setting Example for Waveform Evaluation 379

Chapter 17 Memory Segmentation Function 383

17.1 Overview 383

17.2 Using the Sequential Save Function 384

17.3 Using the Multi-Block Function 389

Chapter 18 Waveform Averaging 393

18.1 Overview 393

18.2 Setting the Averaging Function 395

18.2.1 When Using Memory Recorder Function

18.2.2 When Using FFT Function

395

398

7

18.3 Averaging Equations 403

Chapter 19 Using the A/B Cursors / Waveform

Scrolling

19.1 Overview 405

19.2 Using the A/B Cursors 406

19.3 Scrolling the Waveform 414

Chapter 20 LEVEL MON. / CH.SET / HELP Keys 419

20.1 Overview 419

20.2 Checking the Input Level (LEVEL MON. Key) 420

20.3 Selecting the Input Channel on the Display Screen and

L.evel Monitor Screen

20.4 Checking the Waveform Display Position (HELP Key) 425

(CH.SET Key) 422

405

4

10

11

12

13

5

APP

IND

Page 12

Chapter 21 External Input/Output Connectors / Key Lock

Function

21.1 Overview 433

21.2 Using the External Start, Stop, and Print Terminals 434

21.3 Using the External Trigger Input (EXT TRIG) 436

21.4 Using the External Trigger Output (TRIG OUT) 437

21.5 Using the External Sampling Input (EXT SMPL) 438

21.6 Using the NG Evaluation Output (NG) 439

21.7 Using the Microphone Input (MIC) 441

21.8 Using the Key Lock Function 442

433

Chapter 22 Using the D/A Output Unit 9539 (Option) 443

22.1 Overview 443

22.2 Specifications 444

22.3 Usage Precautions 446

22.4 Replacing Units 447

22.5 Output of a Waveform Recorded With the Memory

Recorder or Recorder Function 448

Chapter 23 Maintenance 451

23.1 Cleaning of the Unit and Parts 451

23.2 Replacing the DC Power Supply Fuse 454

23.3 Removing the Battery Before Discarding the 8846 455

23.4 Troubleshooting 457

Chapter 24 Error and Warning Messages 459

24.1 Overview 459

24.2 Error Messages 460

24.3 Warning Messages 461

Appendix APPENDIX 1

Appendix 1 Glossary APPENDIX 1

Appendix 2 Reference APPENDIX 5

Appendix 2.1 Memory Recorder Function,

Recorder Function

Appendix 2.2 FFT Function

Appendix 3 Reference Table APPENDIX 18

APPENDIX 5

APPENDIX 8

Page 13

────────────────────────────────────────────────────

I

ntroduction

Thank you for purchasing this HIOKI "8846 MEMORY HiCORDER."

To get the maximum performance from the unit, please read this manual first,

and keep this at hand.

i

────────────────────────────────────────────────────

Introduction

Page 14

ii

I

────────────────────────────────────────────────────

nspection

・When the unit is delivered, check and make sure that it has not been

damaged in transit. In particular, check the accessories, panel switches, and

connectors.

・If the unit is damaged, or fails to operate according to the specifications,

contact your dealer or HIOKI representative.

Accessories

□ Power cord 1

□ DC power cord 1

□ Recording paper (roll paper) 1

□ Spare fuse 1

(DC supply 10 - 30 V: class A melting fuse (NM) 12 A/250 V,

6.4 dia.×31.8 mm)

□ Instruction Manual 1

□ Protect cover 1

□ MO disk (230MB) 1

□ Recording paper attachment 2

□ Eject pin 1

────────────────────────────────────────────────────

Inspection

Page 15

iii

R

S

────────────────────────────────────────────────────

afety Notes

This Instruction Manual provides information and warnings essential for

operating this equipment in a safe manner and for maintaining it in safe

operating condition. Before using this equipment, be sure to carefully read the

following safety notes.

DANGE

During high voltage measurement, incorrect measurement procedures

could result in injury or death, as well as damage to the equipment.

Please read this manual carefully and be sure that you understand its

contents before using the equipment. The manufacturer disclaims all

responsibility for any accident or injury except that resulting due to

defect in its product.

Safety symbols

・This symbol is affixed to locations on the equipment where the

operator should consult corresponding topics in this manual

(which are also marked with the

functions of the equipment.

・In the manual, this mark indicates explanations which it is

particularly important that the user read before using the

equipment.

Indicates a grounding terminal.

symbol) before using relevant

Indicates a grounding terminal for measurement.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

PEAK

────────────────────────────────────────────────────

Indicates a peak value.

Safety Notes

Page 16

iv

R

G

N

e

e

(

I

s.

I

I

I

────────────────────────────────────────────────────

Conventions used in this manual

The following symbols are used in this Instruction Manual to indicate the

relative importance of cautions and warnings.

DANGE

WARNIN

CAUTIO

NOTE

Method

Operation

Indicates that incorrect operation presents extreme danger of

accident resulting in death or serious injury to the user.

Indicates that incorrect operation presents significant danger of

accident resulting in death or serious injury to the user.

Indicates that incorrect operation presents possibility of injury to the

user or damage to the equipment.

Denotes items of advice related to performance of the equipment or

to its correct operation.

Symbols used for setting and operating steps

Indicates a setting or operating procedure. Follow the numbered

sequence and perform the indicated steps.

Step

Referenc

Exampl

Bold character)

[]

Additional information about setting and operating procedures.

Indicate practical examples for setting and operating procedures.

Example

Set to FFT

( Section ..)

F1

[ FFT ]

ndicates display items or selection item

ndicates sections for reference.

ndicates operation keys.

ndicates function key displays.

────────────────────────────────────────────────────

Safety Notes

Page 17

v

G

R

N

────────────────────────────────────────────────────

otes on Use

In order to ensure safe operation and to obtain maximum performance from

the unit, observe the cautions listed below.

(1) Installation environment

WARNIN

DANGE

The unit should always be operated in a range from 5℃ to 40℃ and 35%

to 80% RH or less. Do not use the unit in direct sunlight, dusty

conditions, or in the presence of corrosive gases.

(2) Power supply connections

Before connecting the unit, make sure that the power supply voltage

matches the rated power supply voltage of the 8846 (

"Power Supply and Ground Connection".

Before connecting the unit to a battery or other DC source, make sure

that the intermediate switch is set to OFF. If the switch is ON, there is a

risk of sparks.

Section 4.2,

(3) Protective grounding

・Be sure to connect the ground terminal to a good ground ( Section 4.2,

"Power Supply and Ground Connection"). If the AC outlet is grounded, using

the supplied power cord with 3-prong plug will establish the ground

connection.

・Also when powering the unit from a battery or other DC source, connect the

ground terminal to a good ground.

(4) Before powering on

・Check that the power supply is correct for the rating of the unit. Also check

that the correct fuse is fitted. (

Connection". (The AC fuse is integrated in the unit.)

・The power switches of this unit are separate for AC power (power switch on

8846) and DC power (intermediate switch on DC power supply cable). If DC

power is being supplied and the intermediate switch is set to ON, the 8846

will operate also if the power switch is set to OFF.

────────────────────────────────────────────────────

Section 4.2, "Power Supply and Ground

Notes on Use

Page 18

vi

R

shock.

e

────────────────────────────────────────────────────

(5) Probe Connection, Measurement Voltage Input

DANGE

Maximum input ratings for the analog units 8916 - 8919, 8927, and 8928

and the input terminals of the 8846 are shown below. To avoid the risk

of electric shock and damage to the unit, take care not to exceed these

ratings.

The 8918 TEMPERATURE UNIT is designed specifically for

thermocouples. Do not use it with any other components. (Circuit

protection is provided for up to 100 V DC or AC, but any voltage above

this value will destroy the unit.)

The maximum floating voltage of 8916 to 8919, 8928 (voltage between

input and 8846 frame ground, and between inputs of other analog units)

is shown below. To avoid the risk of electric shock and damage to the

unit, take care that voltage between channels and between a channel

and ground does not exceed these ratings.

The maximum floating voltage rating applies also if an input attenuator

or similar is used.

The 8927 ANALOG UNIT is not isolated from the ground of the 8846

(common ground). To avoid the risk of electric shock and damage to the

unit, make sure that the ground connection and input connections are

correctly established. (

Section 4.4)

When measuring power line voltages with the 8916, 8917, or 8919,

always connect the probe to the secondary side of the circuit breaker.

Connection to the primary side involves the risk of electric shock and

damage to the unit.

Always use the supplied input cables (units 8916, 8917, and 8919 use

the input cable 9574, and unit 8927 uses the connecting cable 9437).

Any exposed metal sections in an input cable consist a risk of electric

Input/output terminalMaximum input rating Maximum floating voltag

8916 inputs

8917 inputs

500 V DC+AC peak 450 V AC/DC

8919 inputs

8918 inputs

8927 inputs

8928 inputs

100 V AC/DC 250 V AC/DC

50 V DC+AC peak No floating

10 V DC+AC peak 40 V DC+AC peak

EXT TRIG

START

STOP

-5 V to 10 V No floating

PRINT

EXT SMPL

MIC

TRIG OUT

NG

0 V to 5 V DC+AC peak No floating

-20 V to +30 V

500 mA max

200 mW max

No floating

────────────────────────────────────────────────────

Notes on Use

Page 19

vii

G

R

N

N

────────────────────────────────────────────────────

WARNIN

DANGE

CAUTIO

The logic units all have and the 8846 have a common ground.

(6) Replacing the fuse and input units

Use a DC power supply fuse of the proper rating (12 A/250 V).

In order to avoid accidents from electric shock, before removing or

replacing an input unit or changing a fuse, check that the input cables

are disconnected, turn off the power, and remove the power cable.

Normally keep all eight input units installed permanently. If a unit is not

fitted, it must be replaced by a blanking panel. If the unit is operated

with an input unit not in place it poses a shock hazard.

(7) Recording paper

・This unit uses a thermal printer. The recording paper supplied has

characteristics finely tuned for use with the printer.

Using recording paper of a different specification may not only result in

impaired printing quality, but even prevent the printer from operating. Always

use the HIOKI specified product.

・Insert the paper with correct orientation (

Paper").

Section 4.6, "Loading Recording

CAUTIO

NOTE

(8) Using a printer

Using the printer in a high-temperature or high-humidity environment should be

avoided at all costs. This can seriously reduce the printer life.

(9) Storing

When the unit is not to be used for an extended period, set the head up/down

lever to the "head up" position. This will protect the printer head and prevent

deformation of the rubber roller.

────────────────────────────────────────────────────

Notes on Use

Page 20

viii

N

────────────────────────────────────────────────────

(10) Shipping

CAUTIO

NOTE

NOTE

Remove the printer paper from the unit. If the paper is left in the unit, paper

support parts may be damaged due to vibrations.

Remove the tape from the unit.

If reshipping the unit, preferable use the original packing.

(11) Others

・ In the event of problems with operation, first refer to Section 23.4, "Trouble

shooting".

・ Carefully read and observe all precautions in this manual.

────────────────────────────────────────────────────

Notes on Use

Page 21

ix

C

────────────────────────────────────────────────────

hapter Summary

Chapter 1 Product Overview

Contains an overview of the unit and its features.

Chapter 2 Specifications

Contains general specifications and detailed function specifications.

Chapter 3 Logic Input Section and Analog Input Unit

Contains specifications and precautions for logic input section and input

amplifier units.

Chapter 4 Setup and Preparations

Explains how to set the unit up for measurement.

Chapter 5 Operation Steps for Basic Measurement

Explains how to operate the keys and JOG/SHUTTLE control for carrying out

basic measurement functions.

Chapter 6 Memory Recorder Function Settings

Explains how to use the memory recorder functions of the unit.

Chapter 7 Recorder Function Settings

Explains how to use the recorder functions of the unit.

Chapter 8 FFT Function Settings

Explains how to use the FFT analysis functions of the unit.

Chapter 9 Input Channel Settings

Explains how to make settings using the channel setting screen.

Chapter 10 Trigger Functions

Explains how to use the trigger functions of the unit.

Chapter 11 System Screen Settings

Explains how to make settings using the system setting screen.

Chapter 12 Printout of Waveform Data and Processing Data

Explains how to print out data and how to read printed charts.

Chapter 13 Storing Data On MO Disk

Explains how to store data on MO disk and how to read stored data.

────────────────────────────────────────────────────

Chapter Summary

Page 22

x

────────────────────────────────────────────────────

Chapter 14 Calculating Waveform Data

Explains the waveform processing functions of the unit and how to input

processing equations.

Chapter 15 Determining Waveform Parameters / Evaluating Parameter Values

Explains waveform parameter processing functions and waveform parameter

evaluation. 14 parameters of the input waveform are determined and used for

GO/NG evaluation.

Chapter 16 Waveform GO/NG Evaluation

Explains the waveform evaluation function which uses an evaluation area

created by the user for GO/NG evaluation.

Chapter 17 Memory Segmentation Function

Explains the memory segmentation function which splits the internal memory

into blocks for storing waveform data.

Chapter 18 Waveform Averaging

Explains the waveform averaging function which serves to remove noise

components from the waveform.

Chapter 19 Using the A/B Cursors / Waveform Scrolling

Explains how to use the A/B cursors and how to perform waveform scrolling.

Chapter 20 LEVEL MON. Key, CH.SET Key, HELP Key

Explains how to use the LEVEL MON., CH.SET, and HELP keys.

Chapter 21 External Input/Output Connectors / Key Lock Function

Gives specifications and usage details of the external input/output connectors.

Chapter 22 Using the D/A Output Unit 9539 (Option)

Gives specifications and usage details of the optional D/A output unit 9539.

Chapter 23 Maintenance

Describes maintenance and fuse replacement procedures.

Chapter 24 Error and Warning Messages

Describes error and warning messages and lists reference sections in the

manual.

Appendix Contains a glossary of terms used in this manual and gives some basic

reference information.

────────────────────────────────────────────────────

Chapter Summary

Page 23

1

1

w

1

────────────────────────────────────────────────────

Chapter

1

2

.1 Major Features

(1) Storage capability using MO disk

Waveform data and parameter information can be recorded on MO disk.

(2) Easy to read, large color display

The 9.5-inch TFT color screen with a resolution of 640 × 480 dots shows all

information at a glance.

(3) Built-in thermal printer for A4-size printouts

・The built-in printer delivers waveform printouts on the spot.

・The printer can also be used to print screen shots and parameter information.

Product Overvie

3

4

5

6

7

8

9

(4) 16-channel, 14-bit high-resolution recording capability

Using the analog unit 8927 (designed specifically for the 8845 and 8846, not

isolated from ground), waveform recording can be performed in up to 16

channels with 14-bit resolution.

(5) Expansion units designed for 8840 can be used

・The 8916 ANALOG UNIT, 8917 DC/RMS UNIT, 8918 TEMPERATURE UNIT,

and 8919 FFT UNIT can be used in the 8846.

・Units designed for 8840 are connected in a floating configuration (isolated

from ground).

(6) Playback of recorded waveform data

The optional 9539 D/A OUTPUT UNIT allows output of recorded waveform

data (2 channels) as an analog waveform with a +6.4 to -6.4 V range.

(7) Voice memo capability

Simply by connecting a microphone to the unit, the user can record a voice

memo along with waveform data.

10

11

12

13

14

A

────────────────────────────────────────────────────

1.1 Major Features

Page 24

2

────────────────────────────────────────────────────

(8) Simple function key interface

Thanks to its GUI-inspired design using large function key graphics, the unit

is easy to set up and operate.

(9) 3 incorporated functions

・Memory recorder with up to 200 kS/s and 2 M word capacity (using 1 unit/1

channel); X-Y plotting also possible.

・Continuous real-time recording capability to tape or paper in recorder function

・FFT function with 12 analysis patterns

(10) Trigger function

・Digital trigger circuit

・4 trigger types: level trigger, window-in trigger, window-out trigger, logic

trigger

(11) Waveform data processing

Absolute waveform values, integral values, and differential values can be

calculated, and arithmetic processing of multiple waveform data is also

possible.

(12) Waveform parameter calculation

14 waveform values including maximum, minimum, and effective values can

be determined.

(13) Waveform evaluation

A good/no-good decision (GO/NG) can be performed depending on whether the

waveform is in a standard area or not. The standard area can be easily set up

using the graphics editor.

(14) Scaling function

By setting the physical amount and the unit to be used for 1 V input, the

measurement result can be converted into any desired scale.

(15) Strain gauge adapter

The measurement with a strain gauge adapter is possible by using the 8928

STRAIN UNIT.

(16) GP-IB interface

The optional 9537 GP-IB INTERFACE applied to IEEE-488.2 can be used.

It is possible to input and output data and remotely control.

(17) SCSI interface

The optional 9538 SCSI INTERFACE applied to ANSI-X3.131-1986, JIS-X6051

can be used. The waveform data recorded on a MO disk can be transferred to

a personal computer with using the 9606 DATA CONVERSION UTILITY.

────────────────────────────────────────────────────

1.1 Major Features

Page 25

3

1

────────────────────────────────────────────────────

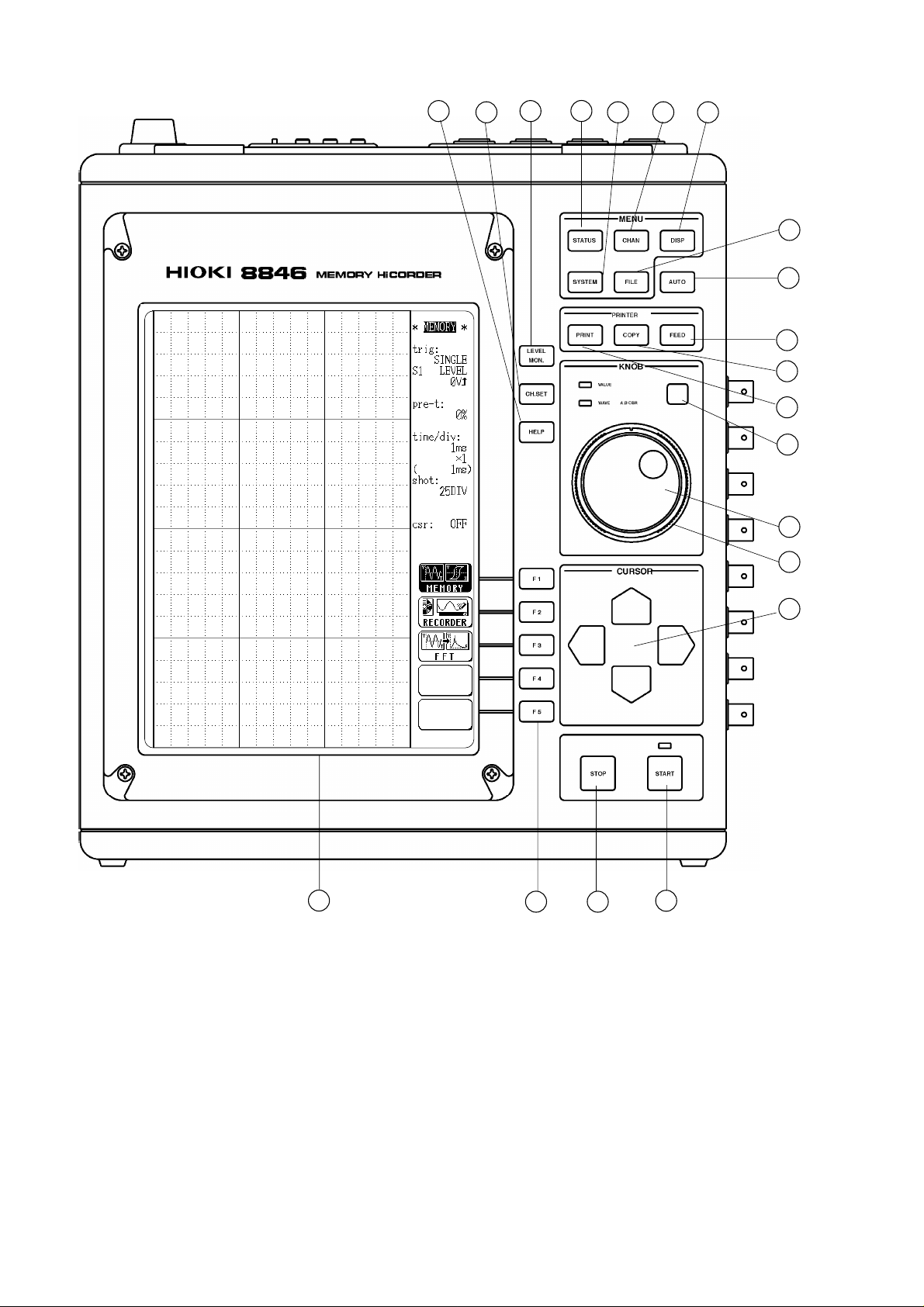

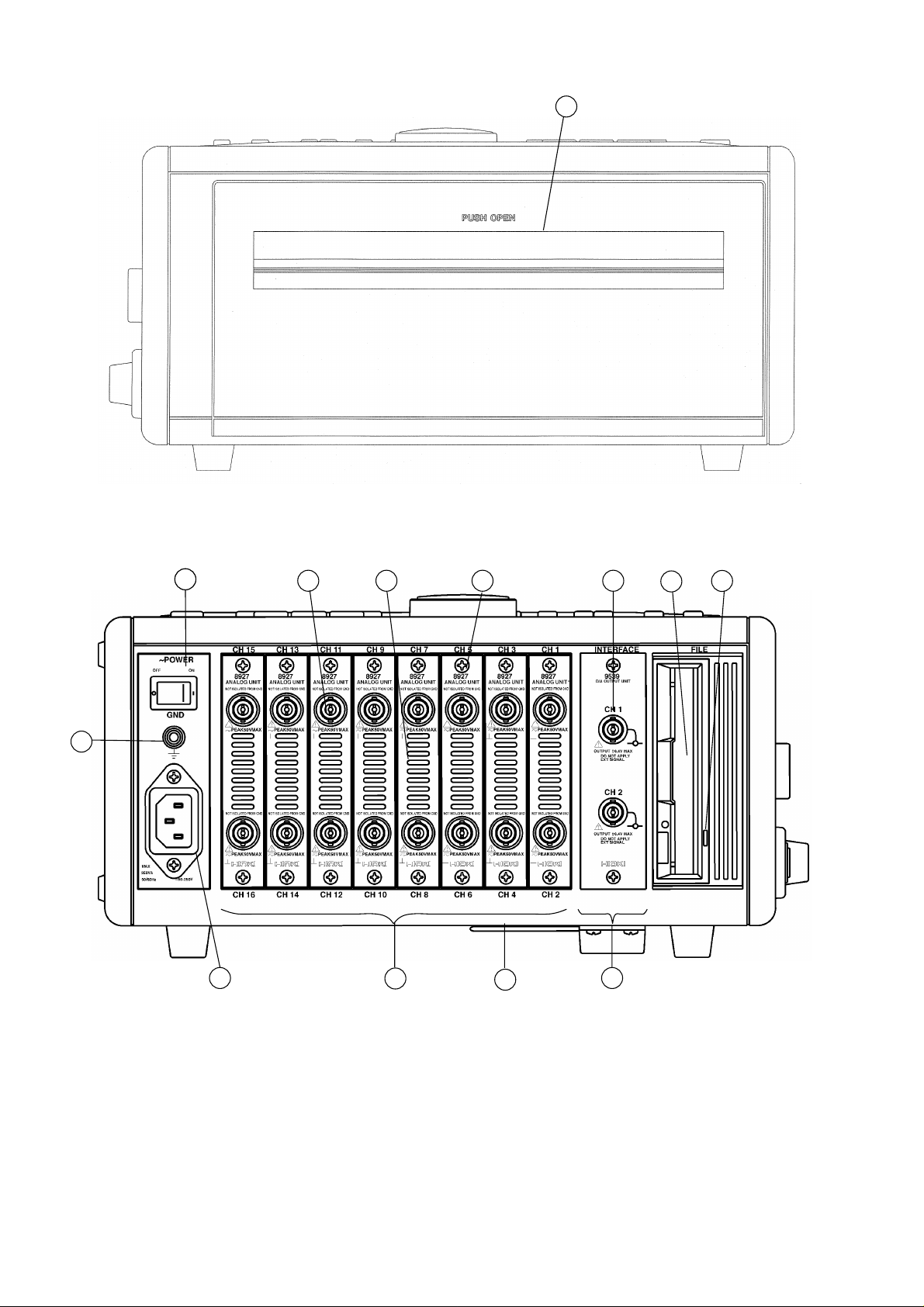

.2 Identification of Controls and Indicators

1

Controls and indicators of the unit are listed on the following pages, along

with a simple explanation of their function.

2

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 26

4

18171674123568

91011

1213191415

20

────────────────────────────────────────────────────

Front Panel

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 27

5

0

1

2

314151617181920

────────────────────────────────────────────────────

1

STATUS key Causes the display to show the STATUS screen which

serves for setting most measurement parameters.

2

CHAN key Causes the display to show the CHANNEL screen which

serves for making input channel settings.

3

DISP key Causes the display to show measurement and analysis

results.

1

2

4

SYSTEM key Causes the display to show the SYSTEM screen which

serves for making system-wide settings such as for the

scaling function (

5

FILE key Causes the display to show the MO screen which serves

for making MO disk settings (

6

AUTO key Pressing this key activates automatic setting of X and Y

axis range values for easy reading (

7

PRINT key Serves to print out stored waveforms ( Chapter 12).

8

COPY key Serves to print out a hard copy of the current screen

display (

9

FEED key Causes the printer paper to advance for as long as the

key is pressed (

1

Select key Selects the function that is controlled by the

JOG/SHUTTLE knob. With each push of the key, the

functions is toggled between VALUE and WAVE A B

CSR. The respective LED lights up (

1

JOG key Rotary control knob that serves to change values, move

the A/B cursors, and scroll the waveform.

Chapter 12).

Chapter 11).

Chapter 13).

Sections 6.3, 7.3).

Chapter 12).

Chapter 19).

3

4

5

6

7

8

9

1

SHUTTLE key Concentric ring that serves to move the flashing cursor,

A/B cursors, and to scroll the waveform. The speed of

movement is proportional to the rotation angle

(

Chapter 19).

1

CURSOR keys These keys serve to move the flashing cursor in the four

directions.

START key Initiates the measurement and analysis. During

measurement, the LED above the key is lit.

STOP key Stops measurement and analysis.

LEVEL MON. key Serves to check the input signal level ( Chapter 20).

CH. SET key Serves to display and change measurement parameters

for the various channels (

HELP key Serves to indicate the position of the currently displayed

screen information in relation to the entire recording

length (

F1 - F5 keys Serve to select setting items.

LCD screen

Chapter 20).

Chapter 20).

10

11

12

13

14

A

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 28

6

21

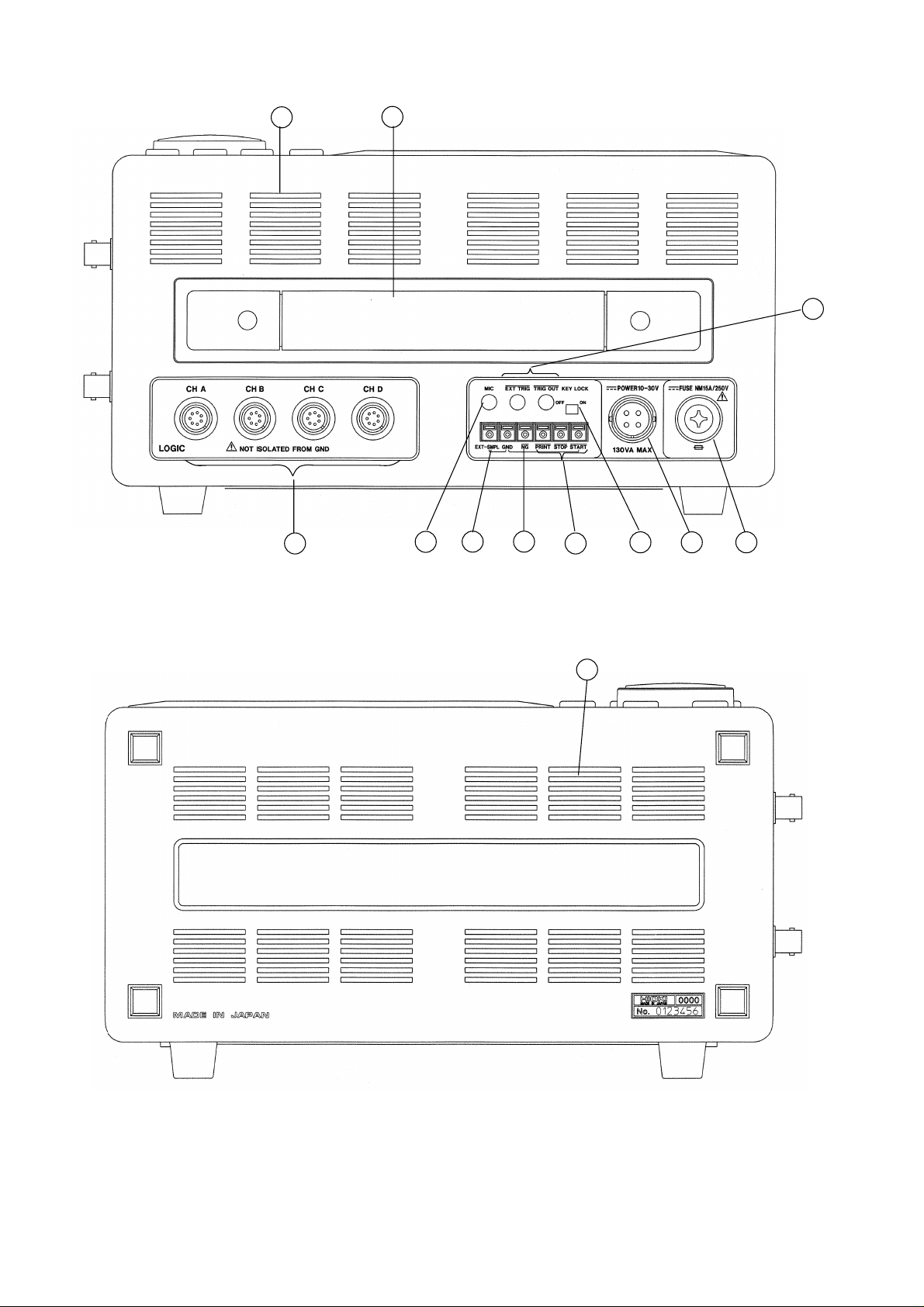

212223262728313325292432

30

────────────────────────────────────────────────────

Left Side View

Right Side View

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 29

7

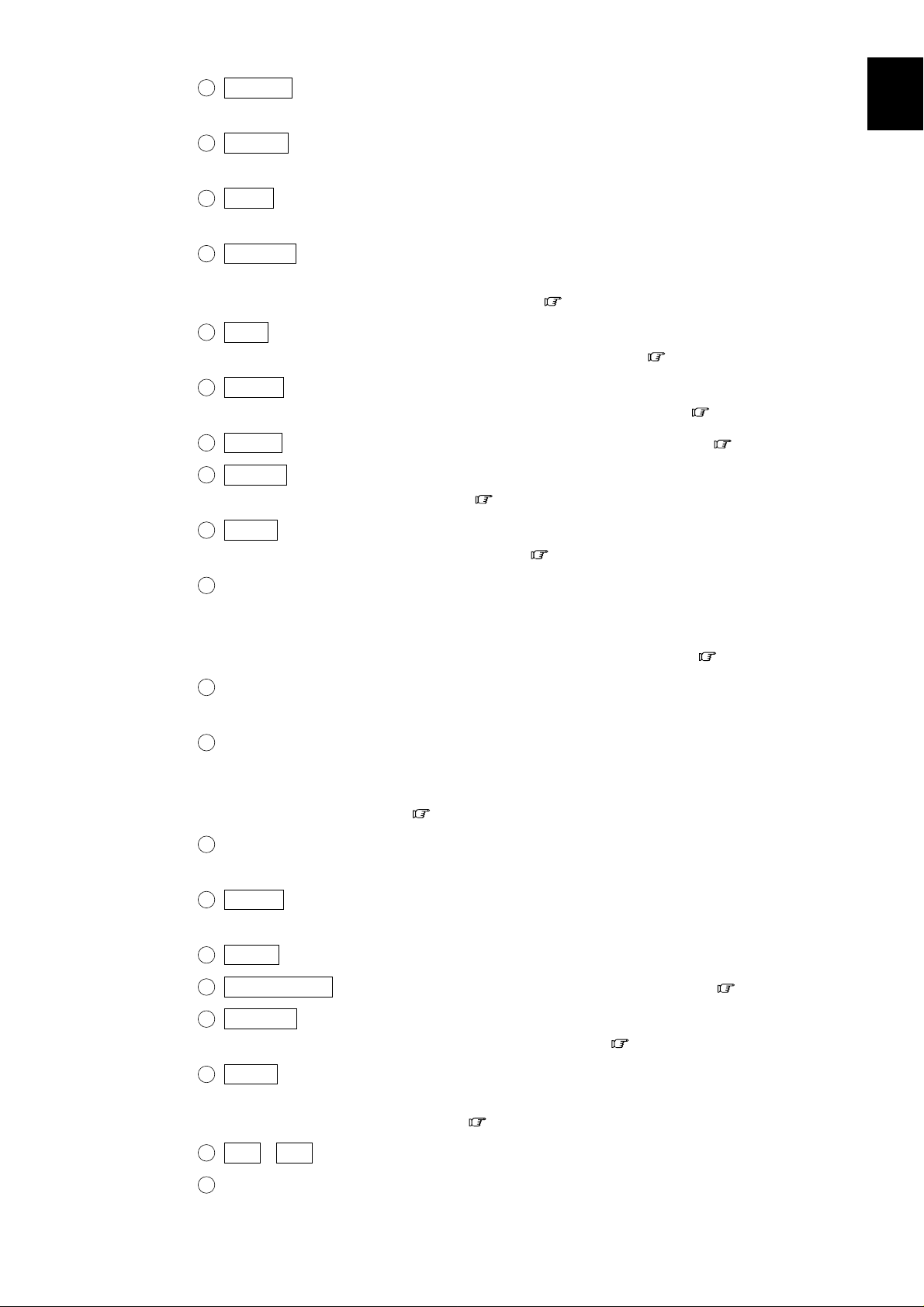

1222324

5

62728

9

0313233

────────────────────────────────────────────────────

2

Printer

AC POWER switch Serves to turn the unit on and off.

1

Protective ground terminal (GND)

AC connector The supplied power cord must be plugged in here.

2

Input unit slots These slots accept various input units, such as

the 8916

8918

8927

2

Analog input connector (on 8927 ANALOG UNIT) Unbalanced analog input

Ventilation slots

Fastening screw Secures the plug-in unit.

2

Expansion slot Accepts the optional unit.

The 9537 GP-IB INTERFACE, 9538 SCSI INTERFACE,

and 9539 D/A OUTPUT UNIT can be used.

3

Analog output connector (of the 9539 D/A OUTPUT UNIT)

BUSY lamp MO drive activity indicator. Indicates during drive

operation.

Disk insertion slot The MO disk is inserted here.

ANALOG UNIT, 8917 DC/RMS UNIT,

TEMPERATURE UNIT, 8919 FFT ANALOG UNIT,

ANALOG UNIT, and 8928 STRAIN UNIT.

2

3

4

5

6

7

Tilt support Serves to tilt the unit upwards.

8

9

10

11

12

13

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

14

A

Page 30

8

3538373641424044343943

45

────────────────────────────────────────────────────

Top View

Bottom View

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 31

9

435363738394041

2

3

4

5

────────────────────────────────────────────────────

3

Ventilation slots

Handle Serves for transporting the 8846.

Logic probe connectors Input connector for the logic input section, designed for

the dedicate logic probes (CH A, CH B, CH C, CH D)

(

Chapter 3).

MIC (microphone) For connection of a microphone (

Chapter 21).

connector

Trigger connectors Can be used to synchronize multiple units, using the

EXT TRIG input and TRIG OUT output

(

Chapter 21).

KEY LOCK switch When this switch is set to ON, all keys of the 8846 are

inactive. The key lock condition is maintained also when

the power is switched off and on again (

Chapter 21).

Remote terminals Start, stop, and print operation can be controlled via

external signals (

Chapter 21).

NG evaluation output When the waveform evaluation based on waveform

terminal parameters has resulted in NG, a signal is output from

this terminal (

4

External sampling Allows input of an external sampling signal

terminal (

4

DC power supply Allows use of an external DC source to power the unit

Chapter 21).

Chapter 21).

connector (with dedicated DC cable).

4

Fuse holder Contains a DC power supply fuse.

4

Ventilation slots

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 32

10

────────────────────────────────────────────────────

────────────────────────────────────────────────────

1.2 Identification of Controls and Indicators

Page 33

11

Basic specifications

2

s

2

────────────────────────────────────────────────────

Chapter

1

2

.1 General Specifications

■

Number of units

(maximum)

Memory capacity

When 1 unit is in use

When 2 units are in use

When 4 units are in use

When 8 units are in use

Maximum sampling speed

Specification

Analog 8 units

8 channels when using with only the 8916, 8917, 8918, 8919, 8928

16 channels when using with only the 8927

(The logic channels are standard equipment for the 8846, common

ground with main unit)

2 M words

8916, 8917, 8918, 8919, 8928 8927

12 bits×2 M words /channel 14 bits×1 M words /channel

12 bits×1 M words /channel 14 bits×500 K words /channel

12 bits×500 K words /channel 14 bits×200 K words /channel

12 bits×200 K words /channel 14 bits×100 K words /channel

one unit of the 8928 equals two units of the 8916 to 8919

Memory recorder, FFT 200 kS/s (8927 is not in use)

100 kS/s (8927 is in use)

Recorder 80 kS/s

3

4

5

6

7

8

9

10

Input method

Time measurement

functions

Time measurement

precision (maximum)

Backup battery and

lifetime

Operational ranges for

temperature and humidity

Temperature and humidity

ranges for assured

accuracy

Temperature and humidity

ranges for storage

────────────────────────────────────────────────────

Plug-in analog input units

floating input 8916, 8917, 8918, 8919, 8928

no floating 8927

Auto calendar with automatic leap year, 24 hour clock

20 ppm (25℃)

Used for clock and to preserve settings, 8 years (reference value at

25℃)

Temperature: 5℃ to 40℃

Relative humidity: 35% to 80% RH (with no condensation)

Temperature: 23℃±5℃

Relative humidity: 35% to 80% RH (with no condensation)

Temperature: -10℃±50℃

Relative humidity: 35% to 80% RH (with no condensation)

2.1 General Specifications

11

12

13

14

A

Page 34

12

Display

────────────────────────────────────────────────────

Insulation resistance and

dielectric strength

Power supply

Fuse

Maximum rated power

Dimensions

Mass

At least 10 MΩ/500 VDC, one minute at 1.5 kVAC

(between the frame and the AC power supply)

At least 10 MΩ/500 VDC, one minute at 700 VDC

(between the frame and the DC power supply)

At least 100 MΩ/500 VDC, one minute at 2 kVAC

(between the input units (excluding 8918, 8927, 8928) and the frame)

At least 100 MΩ/500 VDC, one minute at 1.5 kVAC

(between the input unit (8918) and the frame)

At least 100 MΩ/500 VDC, one minute at 500 VAC

(between the input unit (8928) and the frame)

At least 100 MΩ/500 VDC, one minute at 2 kVAC

(between the input units (excluding 8918, 8927, 8928))

At least 100 MΩ/500 VDC, one minute at 500 VAC

(between the input units (8928))

90 to 250 VAC (50/60 Hz)

10 to 30 VDC

10 to 30 VDC class A melting fuse (NM) 12 A/250 V

6.4 dia.×31.8 mm (DC power supply)

AC: 350 VA (when printer off, 130 VA)

DC: 130 VA (when printer off, 70 VA)

Approx. 280 (W)×306 (H)×140 (D) mm (excluding projections)

Approx. 7 kg

■

Screen

Display resolution

Dots spacing

Maximum display defect

ratio

■ Recorder

Method of recording

Recording paper

Width of recording

Recording speed

Paper feed accuracy

9.5 inch LCD display (TFT color LCD, 640×480 dots)

Waveform: 20 DIV f.s. × 15 DIV f.s.

Text: 60 characters × 40 characters

(1 DIV= 32 dots (vertically) × 32 dots (horizontally)

0.30 mm × 0.30 mm

Always-on dots + always-off dots = max. 15

Thermosensitive recording method using a thermal line head

Roll type thermosensitive recording paper, 216 mm × 30 m (long)

Total recording width: 212 mm±1mm (1696 dots)

Waveform portion: 200 mm±1mm f.s. (1 DIV=10 mm)

Approx. 25 mm/s max

±1% (25℃, 60% RH)

────────────────────────────────────────────────────

2.1 General Specifications

Page 35

13

────────────────────────────────────────────────────

■ External data storage

Device

Capacity

Data format

Recorded data

■ External input /output terminals

START

STOP

PRINT

EXT TRIG

EXT SMPL

Input signal active LOW

HIGH level 2.5 to 5.0 V LOW level 0 to 1.0 V

Pulse width HIGH level 20 ms at least LOW level 10 ms at least

Maximum allowable input -5 to 10 V

Input signal active LOW

HIGH level 2.5 to 5.0 V LOW level 0 to 1.0 V

Pulse width LOW level 5 μs at least

Maximum allowable input -5 to 10 V

Input terminal mini-jack connector, 3.5 mm diameter

Input signal active LOW

HIGH level 2.5 to 5.0 V LOW level 0 to 1.0 V

Pulse width LOW level 1 μs at least

Frequency 180 kHz max (90 kHz max when using the 8927)

Maximum allowable input -5 to 10 V

3.5-inch MO drive

640 MB (540, 230, 128 MB)

Accordance with ISO standard , overwrite object supported

Binary format and text format of the waveform data (memory

recorder, recorder, FFT), settings, waveform decision area, screen copy

(BMP file)

1

2

3

4

5

6

7

8

MIC

TRIG OUT

NG

Maximum allowable input 0 to 5.0 V DC+AC peak

Input terminal mini-jack connector, 3.5 mm diameter

Output signal active LOW

HIGH level 4.5 to 5.0 V LOW level 0 to 0.5 V

Pulse width LOW level 1.5±0.5 ms

Maximum allowable input -20 to 30 V, 500 mA max, 200 mW max

Output terminal mini-jack connector, 3.5 mm diameter

Output signal active LOW

HIGH level 4.5 to 5.0 V LOW level 0 to 0.5 V

Pulse width HIGH level 20 ms at least LOW level 70 ms approx.

Maximum allowable input -20 to 30 V, 500 mA max, 200 mW max

9

10

11

12

13

14

────────────────────────────────────────────────────

2.1 General Specifications

A

Page 36

14

y

2

────────────────────────────────────────────────────

.2 Trigger Unit Specifications

Trigger Method

Trigger modes

Trigger source

Analog trigger

Logic trigger

Digital comparison

Memory recorder, FFT Single, repeat, auto, auto-stop

functions

Recorder function Single repeat

CH1 - CH16 Analog waveform to input for each channel

CHA - CHD Logic waveform to input for each channel

External trigger Input signal to EXT TRIG terminal

Timer trigger Start, stop, interval selectable

Sources can be set on or off. When all sources are off, the unit is in

the free-run state.

Trigger conditions can be set for each source individually.

Uses analog input waveform (channel 1 - 16) as trigger source.

Level trigger Trigger level is set as voltage. Triggering occurs

when the signal passes the trigger level with the

selected slope (rising edge, falling edge).

Window-in trigger Upper and lower trigger levels can be set.

Triggering occurs when the waveform enters the

defined area.

Window-out trigger Upper and lower trigger levels can be set.

Triggering occurs when the waveform leaves the

defined area.

Uses the logic input waveform (CH A - CH D) as trigger source.

Triggering occurs when the set pattern is matched.

Trigger source AND, OR

Trigger filter

Trigger level resolution

Pre-trigger

Trigger output

AND, OR logic can be used to link trigger sources.

AND Triggering occurs when all sources have been triggered.

OR Triggering occurs when one trigger source has been

triggered.

Trigger width can be set by number of sampling points.

OFF, 10, 20, 50, 100, 150, 200, 250, 500, 1000

0.25 % f.s. (f.s. = 20 DIV)

0, 2, 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 95, 100, -95 % (in the memor

recorder function,) unsettable at external sampling

Signal is output from TRIG OUT terminal when triggering occurs.

────────────────────────────────────────────────────

2.2 Trigger Unit Specifications

Page 37

15

2

────────────────────────────────────────────────────

.3 Memory Recorder Function Specifications

Time axis

500 μs/DIV (not available when 8927 is used)

1, 1.25, 2, 2.5, 5, 10, 20, 50, 100, 200, 500 ms/DIV

1, 2, 5, 10, 20 s/DIV

1, 2, 5 min/DIV

1

2

3

Time axis resolution

Time axis precision

Sampling period

Recording length

Display format

Recording line display

Interpolation function

Waveform magnification/

compression

Variable display function

Automatic store function

100 points/DIV (time axis magnification × 1)

±0.001% (relative scale vs. time error)

1/100 of the time axis

, 2000

(*2)

25, 50, 100, 200, 500, 1000

*1: when 16 channels are in use

*2: when 8 channels are in use

*3: when 4 channels are in use

*4: when 2 channels are in use

*5: when 1 channel is in use (when using the 8927, not selectable)

Single, dual, quad, oct screen display, X-Y single, X-Y dual display

16-color (LCD)

dark, medium dark, normal, light (printer)

dot (no interpolation), line (linear interpolation)

Time axis ×10, ×5, ×2, ×1, ×1/2, ×1/5, ×1/10, ×1/20, ×1/50,

×1/100, ×1/200, ×1/500, ×1/1000

Voltage axis ×20, ×10, ×5, ×2, ×1, ×1/2, ×1/5, ×1/10

Settable upper and lower limit (-9.9999E+29 to 9.9999E+29)

0 V (position) fixed; magnification/compression from

0.0001E-29V/DIV to 9.9999E+28V/DIV

ON/OFF switchable. Automatic recording of waveform data on MO

disk after completion of measurement.

(*1)

, 5000

(*3)

, 10000

(*4)

, 20000

(*5)

DIV

4

5

6

7

8

9

Auto-print

Manual print

Partial print

Print smoothing function

Logging function

Memory segmentation

function

Superimposition function

Waveform scrolling

ON/OFF switchable. Automatically prints the memorized waveform

Prints by pressing the PRINT key

Prints between the A and the B cursors

ON/OFF switchable. Doubles density along time axis for smooth

printout (at lower speed).

Numeric printout of waveform data

Memory area of each channel can be divided into max. 63 blocks.

Multi-block memory (memory segmentation)

Sequential save

ON/OFF switchable

Available in both the left/right and the up/down directions

10

11

12

13

14

A

────────────────────────────────────────────────────

2.3 Memory Recorder Function Specifications

Page 38

16

2

────────────────────────────────────────────────────

.4 Recorder Function Specifications

(*5)

(*4)

(*3)

Time axis

(*1)

1.25, 2,

1, 2, 5, 10, 20 s/DIV

1, 2, 5, 10, 20 min/DIV

1 h/DIV

*1: when 1 channel is in use

*2: when 2 channels are in use

*3: when 4 channels are in use

*4: when 8 channels are in use

*5: when 16 channels are in use

(*2)

2.5,

5,

20, 50, 100, 200, 500 ms/DIV

10,

Time axis resolution

Time axis precision

Recording time

Display format

Recording line display

Interpolation function

Waveform magnification/

compression

Variable display function

Data storage medium

Data transferring

100 points/DIV (time axis magnification × 1)

±0.001% (relative scale vs. time error)

Continuous or settable from 1 second to 366 days 23 h 59 min 59 s in

1-second intervals

Single, dual, quad, oct screen display

16-color (LCD)

dark, medium dark, normal, light (printer)

dot (no interpolation), line (linear interpolation) line only when

measurement

Time axis ×10, ×5, ×2, ×1, ×1/2, ×1/5, ×1/10, ×1/20, ×1/50,

×1/100, ×1/200, ×1/400, ×1/500, ×1/800, ×1/1000,

×1/2000, ×1/5000, ×1/10000, ×1/20000, ×1/50000,

×1/100000

Voltage axis ×20, ×10, ×5, ×2, ×1, ×1/2, ×1/5, ×1/10

Settable upper and lower limit (-9.9999E+29 to 9.9999E+29)

0 V (position) fixed; magnification/compression from

0.0001E-29 V/DIV to 9.9999E+28 V/DIV

OFF, printer, MO

Transfer the recorded data in memory recorder function to memory

recorder function.

Manual printing

Partial print

Waveform scrolling

Logging function

────────────────────────────────────────────────────

2.4 Recorder Function Specifications

Activated by pressing the PRINT key

Printout of data in memory at completion of recording

Printout of all recording data when data are read

Prints between the A and the B cursors

Available in both the left/right and the up/down directions

Numeric printout of waveform data

Page 39

17

s

2

────────────────────────────────────────────────────

.5 FFT Function Specifications

FFT range setting

Frequency resolution

133, 333, 667 mHz

2, 4, 8, 20, 40, 80, 200, 400, 800 Hz

2, 4, 8, 16, 20, 32, 40, 80* kHz (*:not available when 8927 is used)

1/400

1

2

3

Number of sampling point

Dynamic range

Antialiasing filter

Window functions

FFT analysis modes

X-axis setting

Y-axis setting

FFT channel mode

Analysis channels

Reference data

Display format

Recording line display

1000 (storage waveform)

72 dB (logical value for 8916, 8917, 8918, 8919, 8928)

84 dB (logical value for 8927)

ON/OFF switchable. Automatic cutoff frequency selection linked to

frequency range (for channels using 8919 FFT unit)

Rectangular, Hanning, Exponential

Storage waveform, linear spectrum, RMS spectrum, power spectrum,

auto-correlation function, histogram, transfer function, cross-power

spectrum, cross-correlation function, unit-impulse response, coherence

function, octave analysis

Time, frequency (linear, logarithmic), real-number voltage (Nyquist

only)

Voltage (real-number, imaginary number, absolute value, logarithmic)

1 channel FFT, 2 channel FFT

2 channels selectable from all analog channels

Newly read waveform, waveform stored with memory recorder

function

Single, dual screen display, Nyquist display

Identical fixed color for g1, g2 (display), Dark (printer)

4

5

6

7

8

9

Interpolation function

Waveform magnification/

compression

Automatic store function

Auto-print

Manual print

Logging function

dot (no interpolation), line (linear interpolation)

Selectable upper and lower limit (only voltage values set with

STATUS screen; settings made with CHANNEL screen are valid only

for histogram of X-axis)

ON/OFF switchable. Automatic recording of waveform data on MO

disk after completion of measurement.

ON/OFF switchable. Automatically prints the memorized waveform

Prints by pressing the PRINT key

Numeric printout of waveform data

10

11

12

13

14

A

────────────────────────────────────────────────────

2.5 FFT Function Specifications

Page 40

18

2

────────────────────────────────────────────────────

.6 Auxiliary Functions Specifications

■ Averaging function

Memory recorder

FFT

Averaging count (OFF, 2 - 256, summing averaging up to specified

count, then exponent averaging)

Averaging count (OFF, 2 - 4096)

Selectable functions: summing averaging, exponent averaging (each on

time axis or frequency axis), peak hold (frequency axis)

■ Waveform decision function

Waveform area evaluation

Decision modes

Stop modes

Decision time

Decision period

Comparison to reference area

Memory recorder (single, X-Y single display)

FFT (single, Nyquist display)

Out NG (fail) if any part of the waveform goes out of the decision

All out NG (fail) if the waveform is entirely outside the decision

Go stop, NGstop, GO&NG stop

On stop, printer output and waveform save can be selected.

20 ms approx.

1.75 s approx. (1 ch, 1 mS/DIV, 25 DIV, ×1, line display during

compressed display or when the recoding length is long, this becomes

slower.

area.

area.

Reference area editor

Editor commands

Waveform parameter

evaluation

(memory recorder, recorder)

Evaluation modes

Evaluation output

Graphic editor

Line (dotted line), Paint, Read Waveform, Erase, Parallel Move (with

overwrite), Reverse, Clear (partial deletion), All Clear (screen

deletion), Undo, Save

Upper and lower trigger limits for waveform parameter processing can

be set

Out NG when parameter leaves specified range

In NG when parameter enters specified range

Signal is output from NG terminal when NG occurs.

────────────────────────────────────────────────────

2.6 Auxiliary Functions Specifications

Page 41

19

t

────────────────────────────────────────────────────

■ Calculation processing

Waveform processing

(Memory recorder)

Waveform parameter

(Memory recorder, recorder)

■ Other function

(1) System screen

Start condition backup

Grid settings

Channel marker

List/gauge print function

Arithmetic calculation, absolute value, exponent, common logarithm,

square root, displacement average, 1st and 2nd differential, 1st and

2nd integral, parallel displacement on time axis, trigonometric

functions (sin, cos, tan), reverse trigonometric functions (asin, acos,

atan)

Average value, effective value, peak-to-peak value, maximum value,

time to maximum value, minimum value, time to minimum value,

period, frequency, rise time, fall time, area, standard deviation, area

value, XY area value,

ON/OFF switchable. (Retains measurement status.)

OFF, standard, fine, standard (dark), fine (dark), standard (shaded),

fine (shaded) (only OFF and standard for display)

ON/OFF switchable. Waveform numbered with channel number.

Always used (regardless of ON/OFF setting) for logic waveforms. Not

valid for FFT.

ON/OFF switchable. Together with measurement waveform,

measurement settings (list) and Y-axis scale (gauge) information is

printed.

LCD backlight saver

function

Comment input function

Scaling function

Subsampling print function

(2) Key operation

A4 print function

Display copy function

List print function

Auto-range function

Level monitor function

ON/OFF switchable. Turns LCD backlight off automatically after 10

minutes of key inactivity.

Input and printout of comments possible.

ON/OFF switchable. Converts voltage values into any unit. Can be se

separately for each channel.

ON/OFF switchable. Omits interpolation in envelope display.

Activated by pressing FEED key and COPY key simultaneously.

Displayed waveform is printed out in A4 size.

Activated by pressing COPY key. Produces a hard copy of display

contents.

Activated by pressing PRINT key when display shows setting

information. Produces a list of parameter settings.

Activated by pressing AUTO key (not valid in FFT mode). Selects

optimum time axis and voltage axis for input waveform.

Activated by pressing LEVEL MON. key. Serves to verify voltage

range position for input waveform in each channel.

Help function

────────────────────────────────────────────────────

Activated by pressing HELP key. Shows relative position of

displayed data within entire recorded data. When voltage axis is

enlarged, relative position of displayed data to full-scale point for each

channel is shown (memory recorder, recorder).

When memory segmentation is used, usage condition of each block is

shown (memory recorder).

2.6 Auxiliary Functions Specifications

Page 42

20

────────────────────────────────────────────────────

(3) External terminal and switches

Remote control

External sampling

Voice memo function

Key lock

(4) Others

Comment printing

Cursor measurement

function

Measurement start, stop, and print control via rear- panel connectors.

Signal input to EXT SMPL connector (max. 180 kHz) can be used for

sampling (limited by number of recording channels and input units).

Microphone connected to MIC connector can be used to record a voice

memo for any unit.

ON/OFF switchable

Function, channel, input range, 0 V position, trigger time, DIV and

other information can be printed.

Time, potential, temperature, frequency difference between A and B

cursor can be measured.

Potential, time from trigger, frequency at A or B cursor can be

measured.

────────────────────────────────────────────────────

2.6 Auxiliary Functions Specifications

Page 43

21

2

────────────────────────────────────────────────────

.7 Accessories and Options

Accessories

Power cord 1

Cord for DC power supply 1

Recording paper (roll) 1

Recording paper attachment 2

Instruction Manual 1

Protect cover 1

Spare fuse 1 (DC power supply 10 to 30 V: class A melting

fuse (NM) , 12 A/250 V, 6.4 dia. ×31.8 mm)

MO disk (230 MB) 1

Eject pin 1

Options

8916 ANALOG UNIT

8917 DC/RMS UNIT

8918 TEMPERATURE UNIT

8919 FFT ANALOG UNIT

8927 ANALOG UNIT (2 channel/one unit)

8928 STRAIN UNIT

9537 GP-IB INTERFACE

9538 SCSI INTERFACE

9539 D/A OUTPUT UNIT (for output of data recorded with recorder function)

9606 DATA CONVERSION UTILITY

Optional accessories

9231 RECORDING PAPER (6 rolls)

9303 PT

9305 TRIGGER CORD

9306 LOGIC PROBE

9307 LINE LOGIC PROBE

9308 LINE DIP DETECTOR??

9369 CARRYING CASE

9370 CARRYING CASE

220H PAPER WINDER

────────────────────────────────────────────────────

2.7 Accessories and Options

Page 44

22

it

Pre-

amplifier

Pre-

amplifier

)

Pre-

r

amplifier

Block Diagram

2

────────────────────────────────────────────────────

.8 System Operation

System operation is explained according to the block diagram.

(1) All system operations are controlled by a 32-bit CPU.

(2) The input units 8916, 8917, 8918, and 8919 incorporate high-speed 12-bit A/D

converters which are connected to the main unit via a photocoupler integrated

in each input unit. Each channel has its own power supply, to assure electrical

isolation from the main unit.

(3) The analog unit 8927 incorporates a 14-bit A/D converter and uses a common

ground with the main unit.

(4) The input signals for each channel are converted into digital form by the A/D

converter, and the resulting data are stored in the memory by the memory

control circuit.

(5) Measurement data stored in memory are processed by the CPU and displayed

on the LCD screen. The waveform displayed on the screen can be printed out.

(6) Waveforms can be recorded on MO disk and redisplayed using the D/A output

unit (option).

Analog input unit

8927 (1 unit 2 channels)

A/D

A/D

8916 to 8919, 8928

Logic input

(4 probes, corresponding to 1 unit)

Logic

probe

Logic

probe

A/D

Photo

couple

Memory

control and

trigger

circuit

Stored

memory

(2 M words

Main un

32 bit CPU

LCD display

Printer

Control

MO drive

Option

Logic

probe

Logic

probe

────────────────────────────────────────────────────

2.8 System Operation

9537

9538

9539

Page 45

23

G

t

8846 main unit

it

d

s

g

3

ts

3

────────────────────────────────────────────────────

Chapter

1

2

.1 Logic Inputs

・The logic input is located on the top side of the unit. Up to four probes can be

connected.

・Since one logic probe can record 4 channels, the combined maximum recording

capability for logic waveforms is 16 channels.

WARNIN

The 8846 has separate inputs for four probes, but the ground lines of

these inputs are not isolated from each other and from the frame ground

of the unit (common ground).

Do not connect logic probes other than supplied by HIOKI to the logic

inputs.

Logic and Analog Inpu

3

4

5

6

7

8

9

NOTE

Logic inpu

GND

Logic input un

Common groun

Logic

probe

Not floatin

If no logic probe is connected, the corresponding logic waveform is displayed

on the screen ad high level.

10

11

12

13

14

A

────────────────────────────────────────────────────

3.1 Logic Inputs

Page 46

24

3

R

R

R

────────────────────────────────────────────────────

.1.1 Logic Probes

NOTE

DANGE

Carefully read the documentation supplied with the probe.

■

9306 LOGIC PROBE

Input can be switched between voltage input and contact input. Suitable for a

wide range of applications, from checking electronic circuits to measuring

relay timing.

The 8846 has separate inputs for four probes, but the ground lines of

these inputs are not isolated from each other and from the frame ground

of the unit (common ground). If voltages with different ground levels are

input, probe short-circuiting may occur and lead to accidents.

■

9307 LINE LOGIC PROBE

・Can be used to detect the on/off status of AC line voltage. Maximum input

voltage is 250 V. The probe is suitable for timing measurements of relay

sequencers or similar.

DANGE

DANGE

・The probe provides internal isolation between channels and between input and

output.

The maximum floating (insulation) voltage between channels and between

input and output is 250 V AC. To avoid the risk of electric shock and

damage to the unit, make sure that the voltage in each channel and

between input and output does not exceed this value.

■

9308 LINE DIP DETECTOR

・Serves to detect momentary voltage drops in commercial power supply lines

(100, 120 V AC).

・Dip level switchable between 80% and 90%.

・Requires 8916 ANALOG UNIT, 8917 DC/RMS UNIT or 8919 FFT UNIT .

The banana plug on the LOW side (black) is directly connected to the

input clip (black). Take suitable precautions against the risk of electric

shock.

────────────────────────────────────────────────────

3.1 Logic Inputs

Page 47

25

3

3

────────────────────────────────────────────────────

.2 8916 ANALOG UNIT

1

・The 8916 is the analog unit for the 8840 and 8846 MEMORY HiCORDER.

・Follow carefully the advice of Section 3.2.2, "Safety Requirements."

.2.1 Specifications

Accuracy at 23℃±5℃, after 1 hour warming-up time

Accuracy guaranteed for six months.

Measurement ranges

DC amplitude accuracy

Zero position accuracy

Temperature characteristic

Frequency characteristic

Noise

Common mode rejection

ratio

Low-pass filter

5, 10, 20, 50, 100, 200, 500 mV/DIV

1, 2, 5, 10, 20 V/DIV

±0.25% f.s.

±0.1% f.s.(after zero adjustment)

Gain: ±0.02%f.s./℃

Zero position: ±0.015%f.s./℃

DC to 100 kHz, -3 dB

180 μVp-p (typical) maximum sensitivity range, with input shorted

100 dB minimum (at 50/60 Hz and with signal source resistance

100 Ω maximum)

Cutoff frequency 5, 50, 500 Hz, 5 kHz approx.

Can be turned on and off

2

3

4

5

6

7

8

Input type

Input resistance and

capacitance

A/D resolution

Maximum sampling speed

Input terminals

Maximum allowable input

voltage

Maximum floating voltage

Dimensions and mass

Accessories

Unbalanced (floating)

1MΩ±1% (at power supply off, 500 kΩ)

approx. 20 pF (at 100 kHz)

12 bits

200 kS/s

2 terminals (for banana plugs)

500 V (DC+AC peak)

450 V AC/DC (between input unit and frame, and between input

units)

110 (W) × 20 (H) × 88 (D) mm (excluding projections), 110 g approx.

9574 INPUT CABLE (1)

9

10

11

12

13

14

A

────────────────────────────────────────────────────

3.2 8916 ANALOG UNIT

Page 48

26

3

R

r

G

N

t

8846 main unit

x

x

────────────────────────────────────────────────────

.2.2 Safety Requirements

DANGE

WARNIN

CAUTIO

The maximum floating voltage (voltage between 8916 input and 8846

frame, and between inputs of other analog units) is 450 V AC/DC. To

avoid the risk of electric shock and damage to the unit, take care that

voltage between 8916 input and 8846 frame, and between inputs of othe

analog units does not exceed these ratings.

The maximum allowable input to the 8916 is 500 V (DC+AC peak). To

avoid the danger of electric shock or damage to the equipment, ensure

that the applied voltage never exceeds this level.

The maximum floating voltage rating applies also if an input attenuator

or similar is used.

When measuring voltages in power lines with high current capability,

always connect the probe to the secondary side of the circuit breaker, to

avoid the risk of electric shock and damage to the unit.

・For safety reasons, only use the 9574 INPUT CABLE provided with the unit

for measurement.

・Before using the unit, make sure that the sheathing on the input cables is no

damaged and that no bare wire is exposed. If there is damage, using the

unit could cause electric shock. Replace with the specified 9574 INPUT

CABLE.

────────────────────────────────────────────────────

3.2 8916 ANALOG UNIT

8916

ANALOG UNIT

GND

H

L

500 V DC+AC peak ma

450 V AC, DC ma

Page 49

27

3

3

────────────────────────────────────────────────────

.3 8917 DC/RMS UNIT

・The 8917 DC/RMS UNIT is the analog unit for the 8840, 8845, and 8846

MEMORY HiCORDERs.

・Records the voltage level converted into RMS values.

・Follow carefully the advice of Section 3.3.2, Safety Requirements."

.3.1 Specifications

Accuracy at 23℃±5℃, after 1 hour warming-up time

Accuracy guaranteed for six months.

Measurement ranges

5, 10, 20, 50, 100, 200, 500 mV/DIV

1, 2, 5, 10, 20 V/DIV

1

1

2

2

3

3

4

4

5

5

DC amplitude accuracy

Zero position accuracy

RMS accuracy

Temperature characteristic

Frequency characteristic

RMS response rate

Crest factor

Noise

Common mode rejection

ratio

Low-pass filter

Input type

Input resistance and

capacitance

A/D resolution

Maximum sampling speed

±0.3% f.s.

±0.1% f.s. (after zero adjustment)

±1% f.s. (DC, 40 to 1 kHz), ±8% f.s. (1 to 100 kHz),

Gain: ±0.02%f.s./℃

Zero position: ±0.05%f.s./℃

DC to 100 kHz, -3dB

100 ms typical (0→90%f.s.)

200 ms typical (100→10%f.s.)

2

250 μVp-p (typical) maximum sensitivity range, with input shorted

100 dB minimum (at 50/60 Hz and with signal source resistance

100 Ω maximum)

Cutoff frequency 5, 500 Hz, approx.

Can be turned on and off

Unbalanced (floating)

1MΩ±1% (at power supply off, 500 kΩ)

approx. 20 pF (at 100 kHz)

12 bits

200 kS/s

6

6

7

7

8

8

9

9

10

10

11

11

12

12

Input terminals

Maximum allowable input

voltage

Maximum floating voltage

Dimensions and mass

Accessories

────────────────────────────────────────────────────

2 terminals (for banana plugs)

500 V (DC+AC peak)

450 V AC/DC (between input unit and frame, and between input

units)

110 (W) × 20 (H) × 88 (D) mm (excluding projections), 110 g approx.

9574 INPUT CABLE (1)

3.3 8917 DC/RMS UNIT

13

13

14

14

A

A

Page 50

28

3

R

t

r

G

N

t

x

x

8846 main unit

────────────────────────────────────────────────────

.3.2 Safety Requirements

DANGE

WARNIN

CAUTIO

The maximum floating voltage (voltage between 8917 input and 8846

frame, and between inputs of other analog units) is 450 V AC/DC.

To avoid the risk of electric shock and damage to the unit, take care tha

voltage between 8917 input and 8846 frame, and between inputs of othe

analog units does not exceed these ratings.

The maximum allowable input voltage to the 8917 is 500 V (DC+AC

peak). To avoid the danger of electric shock or damage to the

equipment, ensure that the applied voltage never exceeds this level.

The maximum floating voltage rating applies also if an input attenuator

or similar is used.

When measuring voltages in power lines with high current capability,

always connect the probe to the secondary side of the circuit breaker

,

to avoid the risk of electric shock and damage to the unit.

・For safety reasons, only use the 9574 INPUT CABLE provided with the unit

for measurement.

・Before using the unit, make sure that the sheathing on the input cables is no

damaged and that no bare wire is exposed. If there is damage, using the

unit could cause electric shock. Replace with the specified 9574 INPUT

CABLE.

────────────────────────────────────────────────────

3.3 8917 DC/RMS UNIT

8917

DC/RMS UNIT

GND

H

L

500 V DC+AC peak ma

450 V AC, DC ma

Page 51

29

3

3

────────────────────────────────────────────────────

.4 8918 TEMPERATURE UNIT

・The 8918 TEMPERATURE UNIT is a thermocouple unit that is used the

8840, 8845, and 8846 MEMORY HiCORDERs for measuring temperature.

・Using the 8918, temperature can be measured by any of three types of

thermocouples: K, J, T.

・Follow carefully the advice of Section 3.4.2, Safety Requirements."

.4.1 Specifications

Accuracy at 23℃±5℃, after 1 hour warming-up time

Accuracy guaranteed for six months.

Measurement ranges

Measurement input range

Zero position

Reference contact

compensation

Accuracy

Temperature characteristic

Frequency characteristic

Response time

Normal mode rejection

ratio

Common mode rejection

ratio

10 (0.125), 20 (0.25), 50 (0.625)℃/DIV ( ): minimum resolution

K (CA) -90 to 1200℃

J (IC) -90 to 800℃

T (CC) -90 to 400℃

-110 to 110% of recording width in 1% steps (no zero adjustment)

Automatic compensation

±0.25%f.s.±2℃

±0.05%f.s./℃

DC to 500 Hz, -3dB typical

1 ms typical (0→90%f.s.), (100→10%f.s.)