INSTRUCTION MANUAL

For...は専用機種。複数の場合は「,」で区切る。不要の場合はとる。

形名を入力。 複数の場合は改行

8826

品名を入力。

MEMORY HiCORDER

Contents

Introduction i

Inspection

i

Safety Notes

iii

Notes on Use

v

Chapter Summary

x

Chapter 1 Product Overview

1

1.1 Major Features 2

1.2 Names and Function of Parts 4

Chapter 2 Installation and Preparation 9

2.1 Installation of the Unit 9

2.2 Power Supply and Ground Connection 11

2.3 Power On/Off 13

2.4 Connection of the Input Unit 14

2.4.1 8936 ANALOG UNIT / 8938 FFT ANALOG UNIT 14

2.4.2 8937 VOLTAGE/TEMP UNIT

15

2.4.3 8939 STRAIN UNIT

16

2.4.4 8940 F/V UNIT

17

2.4.5 8947 CHARGE UNIT

20

2.5 Logic Probe Connection 22

2.6 9018-10, 9132-10 CLAMP ON PROBE Connection

23

2.7 9322 DIFFERENTIAL PROBE Connection

23

2.8 Loading Recording Paper 24

2.9 Care of Recording Paper 26

2.10 Notes on Measurement 27

2.10.1 Maximum Input Voltage 30

2.10.2 Using a Voltage Transformer

31

Chapter 3 Basic Key Operation 33

3.1 Basic Key Operation 33

3.1.1 Basic Display Operation ( MENU ) 33

3.1.2 Printer Key Operation

34

3.1.3 Setting Items

34

3.1.4 JOG/SHUTTLE Control and Select Key

34

3.1.5 Basic Input Operation

35

3.2 Measurement Start and Stop 35

3.3 Other Keys Operation 36

3.4 Screen Configuration 37

3.5 Using the Key Lock Function 38

Chapter 4 Memory Recorder Function 39

4.1 Outline of the Memory Recorder Function 40

4.2 Operation Sequence (MEM)

42

4.3 STATUS Settings (MEM)

44

4.3.1 Setting the Function Mode 44

4.3.2 Setting the Time Axis Range

45

4.3.3 Setting the Recording Length

46

4.3.4 Setting the Format

48

4.3.5 Setting the Display Size

51

4.3.6 Setting the Interpolation (dot-line)

51

4.3.7 Setting the Print Mode

52

4.3.8 Setting the Roll Mode

54

4.3.9 Setting the Auto Print Function

55

4.3.10 Setting the Auto Save Function

56

4.3.11 Setting the Overlay Function

58

4.3.12 Setting the Averaging Function

59

4.3.13 Setting the Waveform Evaluation

61

4.4 Using the X-Y Waveform Plots (MEM) 62

4.5 Settings on the Display Screen (MEM) 65

4.6 Auto Range Function

66

4.7 Other Screen Settings (MEM)

67

4.8 Start and Stop Operation (MEM) 68

Chapter 5 Recorder Function 69

5.1 Outline of the Recorder Function 70

5.2 Operation Sequence (REC) 72

5.3 STATUS Settings (REC) 74

5.3.1 Setting the Function Mode 74

5.3.2 Setting the Time Axis Range

75

5.3.3 Setting the Sampling Period

76

5.3.4 Setting the Recording Length

77

5.3.5 Setting the Format

79

5.3.6 Setting the Display Size

81

5.3.7 Setting the Print Mode

82

5.3.8 Setting the Additional Recording Function

84

5.3.9 Setting the Printer Function (Real Time Printing) 86

5.3.10 Setting the Auto Save Function

87

5.3.11 Setting the Interpolation (dot-line, X-Y only)

89

5.3.12 Setting the Display Clear Function (X-Y only)

89

5.4 Using the X-Y CONT Recorder 90

5.5 Settings on the Display Screen (REC) 93

5.6 Start and Stop Operation (REC) 94

Chapter 6 RMS Recorder Function 95

6.1 Outline of the RMS Recorder Function 96

6.2 Operation Sequence (RMS) 98

6.3 STATUS Settings (RMS) 100

6.3.1 Setting the Function Mode 100

6.3.2 Setting the Time Axis Range

101

6.3.3 Setting the Frequency

101

6.3.4 Setting the Recording Length

102

6.3.5 Setting the Format

104

6.3.6 Setting the Display Size

106

6.3.7 Setting the Print Mode

107

6.3.8 Setting the Additional Recording Function

109

6.3.9 Setting the Printer Function (Real Time Printing)

111

6.3.10 Setting the Auto Save Function

112

6.4 Settings on the Display Screen (RMS) 114

6.5 Start and Stop Operation (RMS)

115

Chapter 7 Recorder & Memory Function 117

7.1 Outline of the Recorder & Memory Function 117

7.2 Operation Sequence (REC&MEM)

118

7.3 STATUS1 Settings (REC&MEM) 120

7.3.1 Setting the Function Mode 120

7.3.2 Setting the Time Axis Range

121

7.3.3 Setting the Recording Length

122

7.3.4 Setting the Display function

124

7.3.5 Setting the Display Size

125

7.3.6 Setting the Format

126

7.3.7 Setting the Print Mode

127

7.3.8 Setting the Additional Recording Function

129

7.3.9 Setting the Printer Function (Real Time Printing)

131

7.3.10 Setting the Auto Save Function

132

7.3.11 Setting the Real-Time Save 135

7.4 STATUS2 Settings (REC&MEM) 140

7.4.1 Using the Sequential Save Function 140

7.5 Settings on the Display Screen (REC&MEM) 141

7.6 Start and Stop Operation (REC&MEM)

142

Chapter 8 FFT Function 143

8.1 Outline of the FFT Function 143

8.2 Operation Sequence (FFT) 144

8.3 STATUS1 Settings (FFT) 146

8.3.1 Setting the Function Mode 146

8.3.2 Setting the FFT Channel Mode

147

8.3.3 Setting the Frequency Range

148

8.3.4 Setting the Sampling Point

149

8.3.5 Setting the Window Processing

150

8.3.6 Setting the Format

151

8.3.7 Selecting Reference Data

153

8.3.8 Setting the FFT Analysis Mode

154

8.3.9 Setting the Analysis Channel

154

8.3.10 Setting the X-axis and Y-axis Displays

155

8.3.11 Setting the Display Scale

157

8.3.12 Octave Filter Setting

159

8.4 STATUS2 Settings (FFT) 160

8.4.1 Setting the Averaging Function 160

8.4.2 Setting the Interpolation

165

8.4.3 Setting the Print Mode

166

8.4.4 Setting the Auto Print Function

167

8.4.5 Setting the Auto Save Function

168

8.4.6 Setting the Waveform Evaluation

170

8.5 Settings on the Display Screen (FFT) 171

8.6 Start and Stop Operation (FFT) 172

8.7 Analysis Function 173

8.7.1 Storage Waveform [STR] 173

8.7.2 Linear Spectrum [LIN]

174

8.7.3 RMS Spectrum [RMS]

176

8.7.4 Power Spectrum [PSP]

178

8.7.5 Auto Correlation [ACR]

180

8.7.6 Histogram [HIS]

181

8.7.7 Transfer Function [TRF] 182

8.7.8 Cross Power Spectrum [CSP]

184

8.7.9 Cross Correlation [CCR]

186

8.7.10 Unit Impulse Response [IMP]

187

8.7.11 Coherence [COH]

188

8.7.12 Octave Analysis [OCT]

190

Chapter 9 Input Channel Settings 193

9.1 Setting Items for Input Channel 193

9.2 Input Channel Setting Procedure 194

9.3 Setting the CHANNEL1 Screen 196

9.3.1 Setting the Waveform Display Color 197

9.3.2 Setting the Waveform Display Graph Position

198

9.3.3 Setting the Measurement Range

199

9.3.4 Setting the Input Coupling

200

9.3.5 Setting the Magnification/Compression Ratio Along the

Voltage Axis

201

9.3.6 Setting the Zero Position

202

9.3.7 Setting the Low-Pass Filter

204

9.3.8 Setting the Logic Inputs

205

9.4 Copying Channel Settings 207

9.5 Zero Setting

208

9.5.1 Zero Adjustment 208

9.5.2 Zero Offset

209

9.6 Setting the CHANNEL2 Screen 212

9.6.1 Setting the Variable Function 212

9.7 Scaling Function (SYSTEM2) 215

9.7.1 Setting the Scaling Function 216

9.7.2 Scaling Setting Example

220

9.8 Comment Function (SYSTEM 3) 221

9.8.1 Title Comment Input 221

9.8.2 Analog Channel Comment Input

222

9.8.3 Logic Channel Comment Input

224

9.8.4 Character Entry Procedure

226

9.9 Setting the Display Screen 228

9.9.1 Entering by CH.SET key 228

9.9.2 Vernier Function

229

9.9.3 Direct Channel Setting

230

9.10 Setting the 8937 VOLTAGE/TEMP UNIT 231

9.10.1 Making the Settings of Voltage Measurement 232

9.10.2 Making the Settings of Temperature Measurement

234

9.11 Setting the 8938 FFT ANALOG UNIT 237

9.12 Setting the 8939 STRAIN UNIT

238

9.13 Setting the 8940 F/V UNIT 240

9.13.1 Setting Frequency Mode 241

9.13.2 Setting the Count Mode

245

9.13.3 Setting the Pulse Duty Ratio Mode

247

9.13.4 Setting the Voltage Mode

249

9.13.5 Setting the Current Mode

251

9.14 Setting the 8947 CHARGE UNIT 253

9.14.1 Setting the Acceleration Measurement

(Charge/Preamp)

254

9.14.2 Setting the Sensor Sensitivity

257

9.14.3 Setting the Voltage Mode

259

Chapter 10 Trigger Functions 261

10.1 Outline of the Trigger Function 261

10.2 Operation Sequence ( Trigger mode setting ) 262

10.3 Trigger Screen Organization 264

10.4 Trigger Mode 265

10.5 Pre-trigger

266

10.6 Trigger Timing ( REC only )

269

10.7 Trigger Source AND/OR Linking 270

10.8 Analog Trigger

271

10.8.1 Level Trigger ( MEM and REC only ) 272

10.8.2 Window-In, Window-Out Trigger

275

10.8.3 Voltage Drop Trigger ( MEM Only )

277

10.8.4 Period Trigger

279

10.8.5 RMS Level Trigger

283

10.9 Logic Trigger 285

10.10 External Trigger Function 287

10.11 Timer Trigger Function 288

10.12 Manual Trigger 291

10.13 Trigger Output Terminal

291

Chapter 11 Display Screen Operation 293

11.1 Scrolling the Waveform 294

11.2 Using the A/B Cursors 295

11.2.1 Using the Line Cursors (Vertical) 296

11.2.2 Using the Line Cursors (Horizontal)

298

11.2.3 Using the Trace Cursors

300

11.2.4 Using the A/B Cursors (X-Y Screen)

302

11.3 TheMagnification/Compression Ratio Along the Time Axis 303

11.4 Zoom Function

304

11.5 Input Level Monitor Function 306

11.6 View Function (VIEW key) 307

Chapter 12 SYSTEM Screen Settings 311

12.1 Overview 311

12.2 SET UP Screen (SYSTEM 1) 312

12.2.1 Use Channel ( MEM only) 312

12.2.2 Start Backup

313

12.2.3 Back Light Saver

313

12.2.4 Display Color

313

12.2.5 Beep Sound

314

12.2.6 Language

314

12.2.7 Grid Type

315

12.2.8 Channel Marker

315

12.2.9 Time Value

315

12.2.10 List & Gauge

316

12.2.11 Printer Density

316

12.2.12 Upper-lower Print

316

12.2.13 0 Position Comment

316

12.2.14 Counter Print

317

12.3 SCALING Screen (SYSTEM 2) 318

12.4 COMMENT Screen (SYSTEM 3) 318

12.5 INTERFACE Screen (SYSTEM 4) 319

12.5.1 Output Destination by the COPY key 319

12.5.2 Output Destination by the PRINT key

320

12.5.3 Setting the Interface

321

12.5.4 Setting the SCSI ID and Target ID

322

12.5.5 Setting the MO Drive

322

12.5.6 Setting the LAN Interface

322

12.6 INITIALIZE Screen 328

12.6.1 TIME SET (Setting the Clock) 328

12.6.2 WAVE DATA CLEAR (DATA INITIALIZE)

329

12.6.3 SYSTEM RESET

329

12.6.4 System Information

329

12.7 SELF CHECK 330

12.7.1 ROM/RAM CHECK 330

12.7.2 PRINTER CHECK

330

12.7.3 DISPLAY CHECK

331

12.7.4 KEY CHECK

331

12.7.5 PC CARD CHECK

332

Chapter 13 Printout of Measurement Data 333

13.1 Printout of Measurement Data Operating Procedure 334

13.2 Setting the STATUS Screen (printout)

336

13.2.1 Setting the Format 336

13.2.2 Setting the Print Mode

337

13.3 Setting the CHANNEL Screen (printout) 339

13.3.1 Setting the Print Density 339

13.3.2 Setting the Waveform Display Graph Position

340

13.4 Setting the SYSTEM Screen (printout) 342

13.4.1 SET UP Screen (SYSTEM 1) 342

13.4.2 SCALING Screen

345

13.4.3 COMMENT Screen

345

13.4.4 INTERFACE Screen

346

13.5 Example of Printer Output 347

13.6 Printing Procedure 354

13.6.1 Manual Print 355

13.6.2 Auto Print

356

13.6.3 Real-Time Print

357

13.6.4 Partial Print

358

13.6.5 Screen Hard Copy

359

13.6.6 List Print

360

13.6.7 Report Print

360

13.7 External Printer (Color Print) 361

Chapter 14 Storing Measurement Data 363

14.1 Floppy Disk 364

14.2 MO Disk (Option)

365

14.2.1 Setting the MO Drive 366

14.3 PC Card 367

14.3.1 Using the PC Card Slot (PC Card with a Cable Only) 368

14.4 SCSI Interface 369

14.4.1 SCSI Interface Specifications 369

14.4.2 Setting the MO Drive

370

14.4.3 Setting the SCSI Number

371

14.5 Selecting the Media Type 372

14.6 FORMAT (Initializing) 373

14.7 SAVE 375

14.7.1 Setting the Saving Items 377

14.7.2 Text data store example

382

14.8 LOAD 384

14.9 INFO 388

14.10 DELETE

389

14.11 Sorting File (SORT)

391

14.12 Operating the Directory 392

14.12.1 MK DIR (Making a Subdirectory) 392

14.12.2 CH DIR (Changing a Directory)

393

14.12.3 RM DIR (Deleting a Directory)

394

14.13 Printing the File List 395

Chapter 15 Memory Segmentation Function 397

15.1 Using the Sequential Save Function (MEM) 398

15.2 Using the Multi-Block Function

403

Chapter 16 Waveform Operation Function 409

16.1 Waveform Parameter Calculation 409

16.1.1 Making Settings for Waveform Parameter Calculation 411

16.1.2 Making Settings for Waveform Parameter Evaluation

414

16.1.3 Setting Waveform Parameter Evaluation GO/NG

Stop Mode

415

16.1.4 Executing Waveform Parameter Calculation

415

16.2 Calculating Waveform Data 418

16.2.1 Preparing for Waveform Processing 420

16.2.2 Defining the Processing Equation

421

16.2.3 Copying an Equation

424

16.2.4 Setting the Channel for Recording Processing Results

425

16.2.5 Setting the Display Scale and Floating Decimal Point

426

16.2.6 Perform Waveform Processing 428

16.3 Waveform GO/NG Evaluation 430

16.3.1 Setting the Evaluation Area 432

16.3.2 Setting the Waveform Evaluation Mode

434

16.3.3 Setting the GO/NG Stop Mode

435

16.3.4 Creating the Evaluation Area

436

16.3.5 Editor Command Details

437

Chapter 17 External Input/Output Terminals 445

17.1 Connecting the Terminals 445

17.2 External Trigger Input Terminal [EXT TRIG] 447

17.3 External Trigger Output Terminal [TRIG OUT] 448

17.4 External Sampling Terminal [EXT SMPL] 449

17.5 External Print / Start / Stop Terminal 450

17.6 GO/NG Evaluation Output Terminal 451

Chapter 18 Specifications 453

18.1 General Specifications 453

18.2 External Data Storage and Interface

456

18.3 Trigger Unit 458

18.4 Memory Recorder Function

459

18.5 Recorder Function

460

18.6 RMS Recorder Function 461

18.7 Recorder & Memory Function

462

18.8 FFT Function

463

18.9 Auxiliary Functions 464

18.10 Others 465

18.11 System Operation 466

18.12 Maximum Recording Length for Time Axis Settings

467

18.13 Memory Capacity and Recording Length

469

Chapter 19 Logic and Analog Inputs 471

19.1 Logic Inputs 471

19.1.1 9320 LOGIC PROBE 472

19.1.2 9321 LOGIC PROBE

473

19.2 Analog Inputs 474

19.2.1 8936 ANALOG UNIT 475

19.2.2 8937 VOLTAGE/TEMP UNIT

476

19.2.3 8938 FFT ANALOG UNIT

478

19.2.4 8939 STRAIN UNIT 479

19.2.5 8940 F/V UNIT

480

19.2.6 8947 CHARGE UNIT

482

Chapter 20 Maintenance and Service 485

20.1 Maintenance and Inspection 485

20.2 Unit Replacement Procedure 487

20.3 Adding the 9599 MEMORY BOARD 488

20.4 Removing the Battery Before Discarding the Unit 489

20.5 Troubleshooting

490

Chapter 21 Appendix 491

21.1 Error Messages 491

21.2 Glossary 496

21.3 Reference 498

21.3.1 Sampling 498

21.3.2 Aliasing

498

21.3.3 Measurement Limit Frequency

499

21.3.4 Recorder Function

500

21.3.5 RMS Recorder Function

501

21.3.6 Averaging Equations

502

21.3.7 2-point Method Scaling Equation

503

21.3.8 Parameter Calculation Details

504

21.3.9 Details on Operators

507

21.3.10 FFT Function

510

21.4 File Size 519

21.4.1 Size of a Waveform File (Binary data) 519

21.4.2 Size of a Waveform File (Text data (Reference value))

521

21.4.3 Size of a FFT File (Reference value)

522

21.4.4 Real-Time Save Files Size (Memory data)

523

21.5 Waveform Viewer (Wv) 524

21.5.1 Starting the Waveform Viewer 525

21.5.2 Waveform Viewer Menus

526

21.5.3 Using the Waveform Viewer

528

21.5.4 Conversion to CSV Format

531

21.5.5 Batch Conversion

533

i

────────────────────────────────────────────────────

Introduction

────────────────────────────────────────────────────

I

ntroduction

I

nspection

Thank you for purchasing the HIOKI "8826 MEMORY HiCORDER". To obtain

maximum performance from the instrument, please read this manual first,

and keep it handy for future reference.

・When you receive the instrument, inspect it carefully to ensure that no

damage occurred during shipping. In particular, check the accessories, panel

switches, and connectors.

・If damage is evident, or if it fails to operate according to the specifications,

contact your dealer or Hioki representative.

Accessories

Power cord

1

9229 RECORDING PAPER

1

Protective cover

1

Roll paper attachment

2

PC card protector

1

Connector cable label

1

Instruction Manual

1

Application Disk (CD-R)

1

ii

────────────────────────────────────────────────────

Inspection

────────────────────────────────────────────────────

NOTE

Options

8936 ANALOG UNIT

8937 VOLTAGE/TEMP UNIT

8938 FFT ANALOG UNIT

8939 STRAIN UNIT

8940 F/V UNIT

8947 CHARGE UNIT

9557 RS-232C CARD

9558 GP-IB CARD

9559 PRINTER CARD

9578 10BASE-T LAN CARD

9626 PC CARD 32M

9627 PC CARD 64M

9726 PC CARD 128M

9727 PC CARD 256M

9728 PC CARD 512M

9729 PC CARD 1G

9598 MO UNIT

9599 MEMORY BOARD(48 M words)

9229 RECORDING PAPER (6 rolls)

9229-01 RECORDING PAPER(PERFORATED)(6 rolls)

9197 CONNECTION CORD (for high voltage, maximum input voltage 500 V)

9198 CONNECTION CORD (for low voltage, maximum input voltage 300 V)

9199 CONVERSION ADAPTOR (BNC-BANANA)

9217 CONNECTION CORD(BNC - BNC)

9320 LOGIC PROBE (maximum input voltage 50 V)

9321 LOGIC PROBE (maximum input voltage 250 V)

*9303 PT

9318 CONVERSION CABLE(For 9270 to 72, 9277 to 79)

9319 CONVERSION CABLE(For 3273)

9322 DIFFERENTIAL PROBE

9324 POWER CORD (for logic connector)

9325 POWER CORD (for the 8940 F/V UNIT sensor connector)

3273 CLAMP ON PROBE(15 A, DC to 50 MHz)

3273-50 CLAMP ON PROBE(30 A, DC to 50 MHz)

*9018-10 CLAMP ON PROBE (10 to 500 A, 40 Hz to 3 kHz)

*9132-10 CLAMP ON PROBE * (20 to 1000 A, 40 Hz to 1 kHz)

*9270 CLAMP ON SENSOR * (20 A, 5 Hz to 5 kHz)

*9271 CLAMP ON SENSOR * (200 A, 5 Hz to 50 kHz)

*9272 CLAMP ON SENSOR * (20/200 A

, 5 Hz to 10 kHz)

9277 UNIVERSAL CLAMP ON CT * (20 A, DC to 100 kHz)

9278 UNIVERSAL CLAMP ON CT * (200 A, DC to 100 kHz)

*9279 UNIVERSAL CLAMP ON CT * (500 A, DC to 20 kHz)

*9555 SENSOR UNIT * (used with the 9270 to 9272, and the 9277 to 9279)

8910 CAN ADAPER

9333 LAN COMMUNICATOR

9555 WAVE PROCESSOR

・*: Not complied with the CE marking

・The 9270 to 9272 CLAMP ON SENSORs and the 9277 to 9279 UNIVERSAL

CLAMP ON CTs are used with the 9555 SENSOR UNIT. They cannot be

used by themselves.

iii

────────────────────────────────────────────────────

Safety Notes

────────────────────────────────────────────────────

WARNIN

G

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as damage

to the instrument Be certain that you understand the instructions and

precautions in the manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from instrument defects.

・The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual (marked with

the

symbol) before using the relevant function.

・In the manual, the

symbol indicates particularly important

information that the user should read before using the instrument.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

S

afety Notes

Safety symbols

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before

using the instrument, be sure to carefully read the following safety notes.

Accuracy

We define measurement tolerances in terms of f.s. (full scale) with the

following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or scale length. This is usually the name of

the currently selected range.

iv

────────────────────────────────────────────────────

Safety Notes

────────────────────────────────────────────────────

DANGE

R

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

WARNIN

G

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

CAUTIO

N

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the instrument.

NOTE

Advisory items related to performance or correct operation of the

instrument.

Conventions used in this manual

The following symbols in this manual indicate the relative importance of

cautions and warnings.

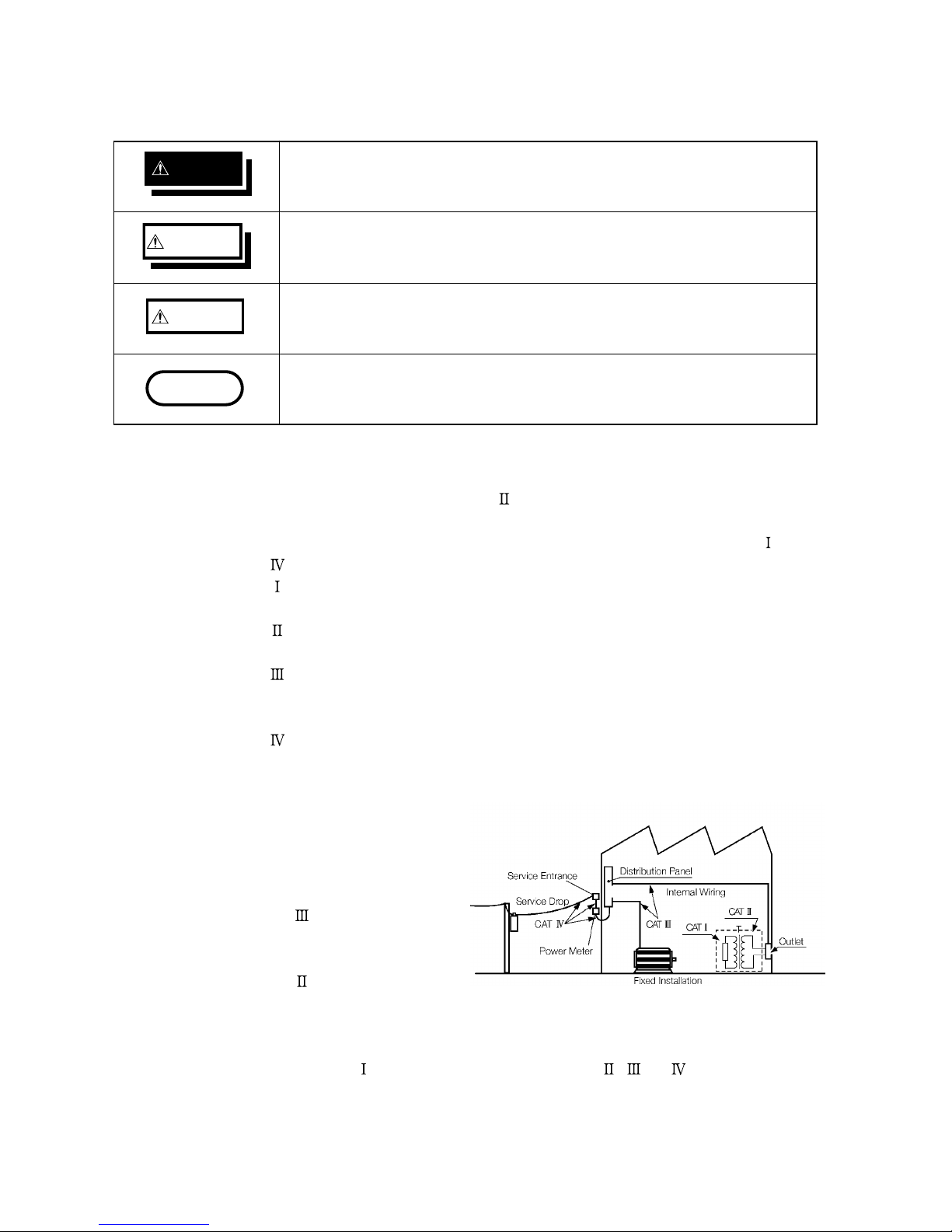

Measurement categories (Overvoltage categories)

This instrument complies with CAT safety requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT

to

CAT

, and called measurement categories. These are defined as follows.

CAT

: Secondary electrical circuits connected to an AC electrical outlet through

a transformer or similar device.

CAT

: Primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.)

CAT

: Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT

: The circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution

panel).

Higher-numbered categories

correspond to electrical

environments with greater

momentary energy. So a

measurement device designed

for CAT

environments can

endure greater momentary

energy than a device designed

for CAT

.

Using a measurement instrument in an environment designated with a highernumbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

Never use a CAT

measuring instrument in CAT , ,or environments.

The measurement categories comply with the Overvoltage Categories of the

IEC60664 Standards.

v

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

DANGE

R

■ Probe Connection, Measurement Voltage Input

Maximum input voltage ratings for the input units and the input

terminals of the 8826 are shown below. To avoid the risk of electric

shock and damage to the units, take care not to exceed these ratings.

The maximum rated voltage to earth of the input units (voltage between

input terminals and 8826 frame ground, and between inputs of other

analog units) is shown below. To avoid the risk of electric shock and

damage to the units, take care that voltage between channels and

between a channel and ground does not exceed these ratings.

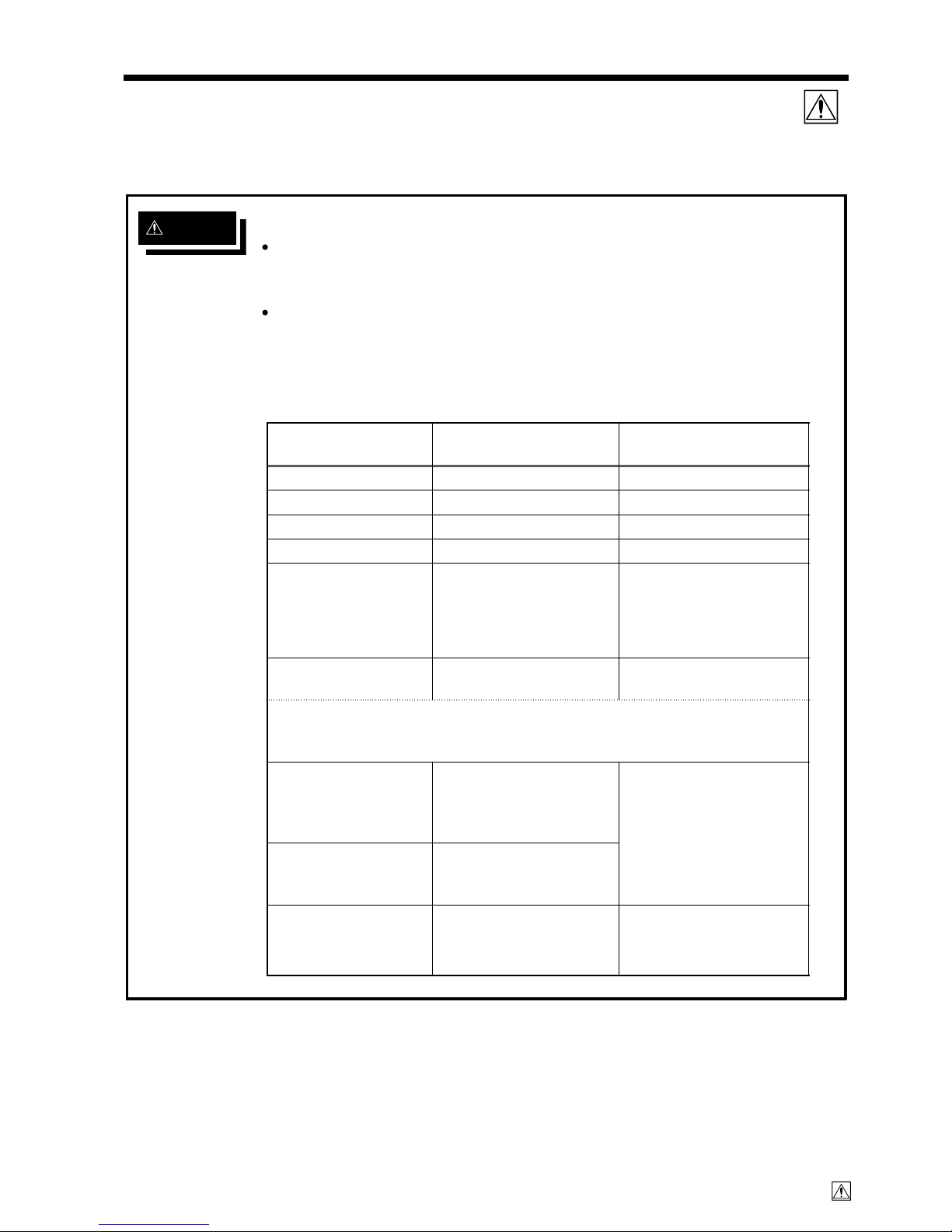

Input/output terminalMaximum input voltage

Maximum rated voltage

to earth

8936 inputs 400 V DC max. 370 V AC/DC

8937 inputs 30 V rms or 60 V DC 30 V rms or 60 V DC

8938 inputs 400 V DC max. 370 V AC/DC

8939 inputs 10 V DC max. 30 V rms or 60 V DC

8940 inputs

30 V rms or 60 V DC

(BNC/Sensor

connector terminal)

・ 30 V rms or 60 V DC

(BNC terminal)

・ Not insulated

(Sensor connector

terminal)

8947 inputs 30 V rms or 60 V DC

(BNC terminal)

30 V rms or 60 V DC

(BNC terminal)

The maximum allowable charge that can be applied to the miniature

connection terminals is 500 pC at the most sensitive of the six ranges,

and 50,000 pC at the least sensitive range.

EXT TRIG

START・STOP

PRINT

EXT SMPL

-5 to +10 V DC

Not insulated

TRIG OUT

GO

NG

-20 V to +30 V DC

500 mA max.

200 mW max.

9322

DIFFERENTIAL

PROBE

2000 V DCmax.

1000 V ACmax.

1500 V AC/DC

(when using grabber clips)

1000 V AC/DC

(when using alligator clips)

N

otes on Use

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

vi

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

DANGE

R

The external I/O terminal and the unit have a common GND.

The maximum rated voltage to earth rating applies also if an input

attenuator or similar is used. Ensure that voltage does not exceed these

ratings.

When measuring power line voltages with the 8936 or 8938, always

connect the probe to the secondary side of the circuit breaker.

Connection to the primary side involves the risk of electric shock and

damage to the units.

Before using the instrument, make sure that the insulation on the

connection cords is undamaged and that no bare conductors are

improperly exposed. Using the instrument under such conditions could

result in electrocution. Replace the connection cords specified by Hioki.

■Logic Probe Connection

The logic input and 8826 Unit share a common ground. Therefore, if powe

r

is supplied to the measurement object of the logic probe and to the 8826

from different sources, an electric shock or damage to the equipment may

result. Even if power is supplied from the same system, if the wiring is such

that a potential difference is present between the grounds, current will flow

through the logic probe so that the measurement object and 8826 could be

damaged. We therefore recommend the following connection method to

avoid this kind of result. Refer to Section 2.5 for details.

(1) Before connecting the logic probe to the measurement object, be sure

that power is supplied from the same outlet box to the measuremen

t

object and the 8826 using the supplied grounded 2-wire power cord.

(2) Before connecting the logic probe to the measurement object, connec

t

the ground of the measurement object to the 8826 ground terminal. Also

in this case, power should be supplied from the same source. Refer to

Section 2.2 for grounding terminal details.

vii

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

WARNIN

G

■ Replacing the input units

・ To avoid electric shock accident, before removing or replacing an input

module, confirm that the instrument is turned off and that the power

cord, connection cords, and thermocouples are disconnected.

・ To avoid the danger of electric shock, never operate the instrument with

an input module removed. To use the instrument after removing an

input module, install a blank panel over the opening of the removed

module.

■ Preliminary Checks

・ Before using the instrument the first time, verify that it operates

normally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki

representative.

・ Before using the instrument, make sure that the insulation on the

connection cords is undamaged and that no bare conductors are

improperly exposed. Using the instrument under such conditions could

result in electrocution. Replace the connection cords specified by Hioki

.

■ Power supply connections

・ Before turning the instrument on, make sure the source voltage

matches that indicated on the instrument’s power connector.

Connection to an improper supply voltage may damage the instrument

and present an electrical hazard.

■ Grounding the unit

・ To avoid electric shock and ensure safe operation, connect the power

cable to a grounded (3-contact) outlet. (refer to Section 2.2).

■ Usage Precautions for the Internal MO Drive (option)

・ Please do not attempt to disassemble the MO drive.

・ Laser radiation can be emitted when the MO drive is open. Avoid

looking directly into the laser when the MO drive is open. Maximum

laser output is 50 mW (at 685 nm, pulsed).

A

laser warning label is attached to the bottom of the 8826 Uni

t.

R

efer to Section 1.2 for the label location.

viii

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

CAUTIO

N

■ Installation environment

・ This instrument should be installed and operated indoors only, between 5 and

40℃ and 35 to 80% RH.

・ Do not store or use the instrument where it could be exposed to direct

sunlight, high temperature or humidity, or condensation. Under such

conditions, the instrument may be damaged and insulation may deteriorate

so that it no longer meets specifications.

・ To avoid electric shock, do not allow the instrument to get wet, and do not

use it when your hands are wet.

・ Do not use the instrument where it may be exposed to corrosive or

combustible gases. The instrument may be damaged or cause an explosion.

■ Before powering on

・ The microgap power switch construction necessitates that the instrument be

used near a power outlet. When not in use and while making connections to

the circuit to be tested, disconnect the instrument from the power source by

unplugging it from the outlet.

■

Using a connection cable

・ Use only the specified connection cord. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

■

Storing

・ When the unit is not to be used for an extended period, set the head

up/down lever to the "head up" position. This will protect the printer head

and prevent deformation of the rubber roller.

■ Precautions on carrying this equipment

・ The terminal guard of the equipment protects the inputs. Do not hold this

guard when carrying the equipment. To carry this equipment, use the

handle. See section 1.2.

■

Shipping

・ Remove the printer paper from the unit. If the paper is left in the unit, paper

support parts may be damaged due to vibrations.

・ To avoid damage to the instrument, be sure to remove the floppy disk, MO

disk, PC card, and SCSI cable before shipping.

ix

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

NOTE

■ Using a printer

・ Avoid using the printer in hot, humid environments, as this can greatly reduce

printer life.

■

Recording paper

・ This unit uses a thermal printer. The recording paper supplied has

characteristics finely tuned for use with the printer.

Using recording paper of a different specification may not only result in

impaired printing quality, but even prevent the printer from operating. Always

use the HIOKI specified instrument.

・ Printing is not possible if the recording paper is loaded wrong-side up. (See

Section 2.8)

x

────────────────────────────────────────────────────

Chapter Summary

────────────────────────────────────────────────────

Chapter 1

Product Overview

Contains an overview of the unit and its features.

Chapter 2

Installation and Preparation

Explains how to set the unit up for measurement.

Chapter 3

Basic Key Operation

Explains how to operate the keys and the JOG/SHUTTLE

control for carrying out basic measurement functions.

Chapter 4

Memory Recorder Function

Explains how to use the memory recorder functions of the unit.

Chapter 5

Recorder Function

Explains how to use the recorder functions of the unit.

Chapter 6

RMS Recorder Function

Explains how to use the RMS recorder functions of the unit.

Chapter 7

Recorder & Memory Function

Explains how to use the Recorder & Memory Functions of th

e

unit.

Chapter 8

FFT Function

Explains how to use the FFT recorder functions of the unit.

Chapter 9

Input Channel Settings

Explains how to make settings using the channel setting screen

.

Chapter 10

Trigger Functions

Explains how to use the trigger functions of the unit.

Chapter 11

Display Screen Operation

Explains how to perform waveform scrolling, how to use the

A/B cursors and so.

Chapter 12

System Screen Settings

Explains how to make settings using the system setting screen.

Chapter 13

Printout of Measurement Data

Explains how to print out measurement data and how to rea

d

printed charts.

Chapter 14

Storing Measurement Data

Explains how to store, recall, and delete measurement data an

d

measurement settings.

Chapter 15

Memory Segmentation Function

Explains how to use the Memory Segmentation Function.

C

hapter Summary

xi

────────────────────────────────────────────────────

Chapter Summary

────────────────────────────────────────────────────

Chapter 16

Waveform Operation Function

Explains how to use the Calculating, Waveform

Parameters/Evaluating Parameter value and Waveform GO/NG

Evaluation.

Chapter 17

External Input/Output Terminals

Gives specifications and usage details of the external

input/output terminals, and explains how to use the key lock

function.

Chapter 18

Specifications

Contains general specifications and detailed function

specifications.

Chapter 19

Logic and Analog Inputs

Contains specifications and precautions for logic input section

and input amplifier units.

Chapter 20

Maintenance and Service

Describes maintenance procedures.

Chapter 21

Appendix

Contains information that is necessary for using this unit,

including a description of error messages, a glossary, and an

explanation how to increase memory.

xii

────────────────────────────────────────────────────

Chapter Summary

────────────────────────────────────────────────────

1

────────────────────────────────────────────────────

────────────────────────────────────────────────────

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

Chapter

1

Product Overvie

w

2

────────────────────────────────────────────────────

1.1 Major Features

────────────────────────────────────────────────────

1

.1 Major Features

(1) Powerful waveform capture capability

・Using the analog unit 8936 (unbalanced), waveform recording can be

performed in up to 32 channels with 12-bit resolution.

(2) Easy to read, TFT color display

・The 10.4-inch TFT color screen with a resolution of 640 × 480 dots shows

all information at a glance.

(3) Five functions to meet a huge range of applications

・Memory recorder with up to 1 μs (all channels simultaneously) (1 MS/s)

・Real-time recording capability to paper in recorder function

・RMS recorder function for recording rms values of AC power supply lines

and DC sources.

・Recorder & Memory Recorder function provides combined recorder and

memory recorder functions

・FFT function offers 12 types of analysis functions

(4) Large capacity memory of max. 16 M words

・The memory is expandable up to 64 M words. (option)

(5) Flexible trigger function

・Digital trigger circuit

・Trigger types: level trigger, window-in trigger, window-out trigger, voltage

drop trigger, RMS level trigger, logic trigger

(6) Simple function key interface (GUI)

・Thanks to its GUI-inspired design using large function key graphics, the

unit is easy to set up and operate.

(7) On-line help

・On-line help guides the user through operation steps and various functions.

(8) Scaling function

・By setting the physical amount and the unit to be used for 1 V input, the

measurement result can be converted into any desired scale.

(9) Additional recording function

・When enabled, the memory is regarded as printer paper.

(10) Floating input units

・The analog inputs are floating, and so each input can be connected to its

own independent potentials.

(11) Built-in thermal printer

・Thermal line head

・The built-in printer delivers waveform printouts on the spot.

・The printer can also be used to print screen shots and parameter

information.

・Report print (B4 size) can be printed.

3

────────────────────────────────────────────────────

1.1 Major Features

────────────────────────────────────────────────────

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

(12) The floppy-disk drive, MO drive (option), and PC card can be used as external

storage means.

・The waveform data and/or setup conditions can be stored on a floppy disk,

MO disk, or PC card (SRAM, flash ATA, or HDD card).

(13) SCSI and PC card slots are originally equipped as external interfaces.

・If a MO drive is connected to the SCSI interface, the waveform data and/or

setup conditions can be stored on a MO disk.

・A GP-IB card, RS-232C card, 10BASE-T LAN card, and printer card can be

inserted into the PC card slot.

(14) GP-IB and RS-232C interface

・Remote control including input unit is possible.

(15) Color print

・If a color printer is connected to the printer card, the data can be printed in

color.

(16) Dual-language capability

・Display language is switchable between Japanese and English.

4

────────────────────────────────────────────────────

1.2 Names and Function of Parts

────────────────────────────────────────────────────

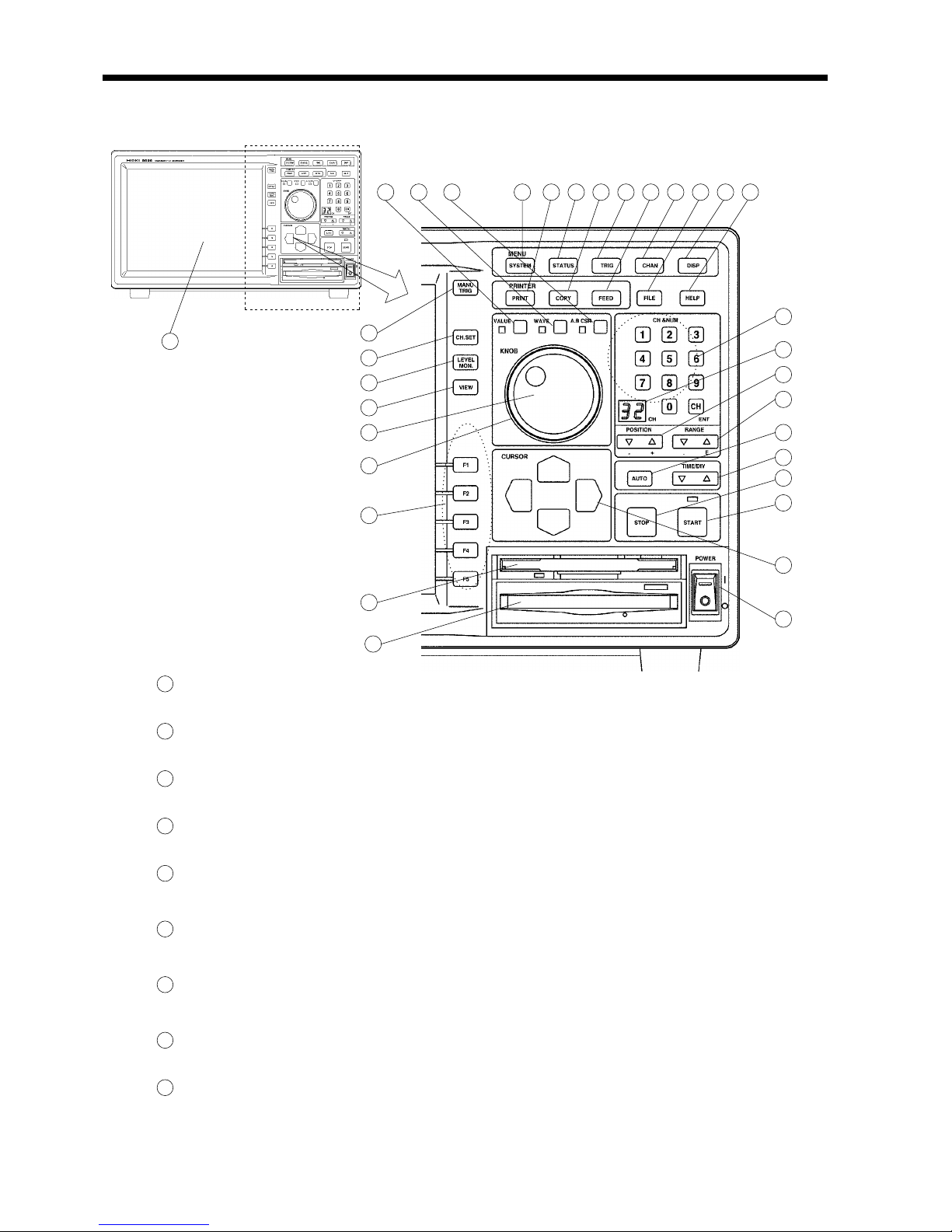

1 2 3 4 56 7 8 9 1

0111213141516181920

2

1

2

22324252627282930

3

13317

3

2

1

SYSTEM key

・ Causes the display to show the SYSTEM screen which serves for

making system-wide settings such as for the scaling function.

2

STATUS key

・ Causes the display to show the STATUS screen which serves for

setting most measurement parameters.

3

TRIG key

・ Causes the display to show the TRIGGER screen. Setting the

trigger functions.

4

CHAN key

・ Causes the display to show the CHANNEL screen which serves

for making input channel settings.

5

DISP key

・ Causes the display to show measurement and analysis results.

・ The display size can be change the normal size or wide size.

6

PRINT key

・ Serves to print out stored waveforms.

・ Output destination by the PRINT key set the SYSTEM4 screen.

7

COPY key

・ Serves to print out a hard copy of the current screen display.

・ Copy destination by the COPY key set the SYSTEM4 screen

8

FEED key

・ Causes the printer paper to advance for as long as the key is

pressed.

9

FILE key

・ Causes the display to show the FILE screen which serves for

reading, storing, etc. the waveform data etc.

1

.2 Names and Function of Parts

Loading...

Loading...