Page 1

INSTRUCTION MANUAL

8807-51

8808-51

MEMORY HiCORDER

HARMONIC WAVE

ANALYSIS FUNCTION

Page 2

Page 3

Contents

1. General Description 1

2. Setup Procedures 2

3. Basic Setting Items 3

3.1 Function Setting 3

3.2 Measurement Target Setting

4. Analog Input Channel Setting 5

4.1 Waveform Display Color Setting 5

4.2 Input Type Setting

4.3 Vertical Axis Range Setting

4.4 Scaling Setting

4.5 Scale Conversion Rate Setting

4.6 Line Connection & Level Check

4.7 DMM Function

11

13

5. Instantaneous Analysis Mode 15

5.1 Analyses and Display Screens 15

5.2 Basic Item Setting

5.3 Cursor Operation

5.4 Analysis Example 1: Simultaneous Instantaneous

Analysis of Two 100-VAC Single-Phase 2-Wire Lines

21

27

28

3

6

7

8

9

5.5 Analysis Example 2: Instantaneous Analysis of 200-VAC

3-Phase 3-Wire Line

33

6. Time-Series Analysis Mode 35

6.1 Basic Item Setting 35

6.2 Analysis Item Setting

6.3 Cursor Operations

6.4 Waveform Scrolling

6.5 Input Setting in Waveform Display Screen

6.6 Over-Range Check Function

6.7 Analysis Example: Time-Series Analysis of 100-VAC

Single-Phase 3-Wire Line

41

45

46

47

48

49

7. Triggers for Harmonic Wave Analysis Function 52

7.1 Basic Trigger Setting Items and Setting Methods 52

7.2 Harmonic Wave Trigger

55

Page 4

8. Printer Operations 59

8.1 Recording on Printer 59

9. PC Card 62

9.1 Input of File Name 62

9.2 Text File Internal Format

9.3 Examples of Stored Files

63

64

10. Characteristics of CLAMP ON PROBES

(Reference Information) 66

Index INDEX 1

Page 5

_____________________________________________________________________________________________

1

1. General Description

The harmonic wave analysis function is designed exclusively for use with the

8807-51/8808-51 MEMORY HiCORDER.

For detailed information on the product and product functions, please refer

to the manual for the main unit.

Features

(1) A range of harmonic wave analysis functions for commercial

power supplies

The 8807-51 is designed for analysis of single-phase 2-wire lines, while the

8808-51 is intended for analysis of single-phase 2-wire lines, single-phase 2wire lines of two different systems, single-phase 3-wire lines, and 3-phase 3wire lines.

The function measures power supplies with a fundamental frequency ranging

from 45 to 65 Hz.

(2) Fast Fourier transform in accordance with frequency

512 data points sampled at a rate of 400 kS/s are extracted for calculations.

(3) Two analysis modes to match specific applications

Instantaneous analysis mode for analysis of instantaneous waveforms during

measurement.

Time-series analysis mode for recording and analyzing analysis data as timeseries data.

(4) Extensive analysis items

Six types of analysis of harmonic waves of all degrees rms value, content

ratio, phase angle, active power, power content ratio, and power phase angle

and calculations of total rms value, total distortion, active power, reactive

power, apparent power, and power factor are available.

(5) Instantaneous analysis mode

Displays analysis results as spectral graphs or with numeric values, and

stores result data.

Displays all harmonic wave components from 1st degree to 40th degree on a

single screen.

(6) Time-series analysis mode

Data on 20 phenomena over a period of up to 30 days, or data on four

phenomena over a maximum of 150 days, can be stored in memory.

Four phenomena can be recorded in an overlapping manner on a single time

axis to allow an easy grasp of the interrelationships among phenomena.

The time axis can be set in seven levels from 5 min/DIV to 12 h/DIV.

Smoothing function for cancellation of unexpected phenomena

Pre-trigger function for observation of the signal prior to a trigger

(7) Harmonic wave trigger function

The trigger can be tripped for rms value, content ratio, all degrees power,

power content ratio, power phase angle, total rms value, and any type of

distortion of a selected harmonic wave component.

______________________________________________________________________________________________

Page 6

2

_____________________________________________________________________________________________

(8) Scaling function

Easy input setting for measurement using a clamp ammeter

(9) Equipped with anti-aliasing filter

Built-in low-pass filter prevents return distortion by eliminating all

frequencies other than measurement targets.

(10) Over-range check function

Automatically switches to a lower sensitivity range when an input waveform

exceeds the maximum input voltage.

2. Setup Procedures

1 Basic Settings (Page)

1. Selecting the Harmonic Wave Function 3

2. Selecting the Power Supply Line

2 Detailed Input Settings

1. Waveform Display Color Setting 5

2. Input Type Setting

3. Vertical Axis Range Setting

4. Scaling Setting

5. Line Connection & Level Check Setting

Application: Trigger Setting

3 Instantaneous Analysis

1. Basic Settings 21

2. Reading Display with Cursor

Analysis Example 1:

Instantaneous Analysis of 100-VAC Single-Phase

2-Wire Line

Analysis Example 2:

Instantaneous Analysis of 200-VAC 3-Phase

3-Wire Line

Time-Series Analysis

1. Basic Settings 35

2. Analysis Item Setting

3. Reading Display with Cursor, and Waveform

Scrolling

Analysis Example 1:

Time-Series Analysis of 100-VAC Single-Phase

3-Wire Line

11

52

27

28

33

41

45

49

Setting examples

Q&A

3

6

7

8

Method of selecting the range

when measuring commercial

power supplies 7

Q&A

Method of selecting the range

when using the 9018-10 CLAMP

ON PROBE 7

Q&A

Method of scaling with a

combination of the 9020 CLAMP

ON ADAPTER and 9018-10

CLAM ON PROBE 9

Q&A

Current measurement using a

combination of the 9277

UNIVERSAL CLAMP ON CT

and 9555 SENSOR UNIT 10

4 Data Printing and Saving

Printer Recording Setting 59

Using a PC Card

Entering a File Name

______________________________________________________________________________________________

62

62

Page 7

_____________________________________________________________________________________________

3

3. Basic Setting Items

3.1 Function Setting

The 8807-51 and 8808-51 each provide a total of four functions.

To use the harmonic wave analysis function, follow the procedures given

below.

Setting Screen SET >>

STATUS(1/4)/ CHANNEL(2/4)/ TRIGGER(3/4)/ ANALYZE(4/4)

1. Move the flashing cursor to the location shown

in the diagram.

2. Using the buttons, select

HARM

3.2 Measurement Target Setting

This screen is used to select the power supply type to be measured.

Setting Screen SET >>

1. Move the flashing cursor to

2. Make a setting using the buttons.

UNIQUE

(Independent

channels)

Conducts power analysis only when

odd-number channel receives

voltage input and even-number

channel receives current input

(clamp). (Any input type can be

set.)

Wiring

.

CHANNEL(2/4)

.

1P2W

Single-phase

2-wire

1P3W

(Single-phase

3-wire)

3P3W

(3-phase 3wire)

______________________________________________________________________________________________

Analyzes single-phase 2-wire line.

Perform the setting so that oddnumber channels receive voltage

input and even-number channels

receive current input (clamp). (The

8808-51 can analyze two singlephase 2-wire lines simultaneously.)

Analyzes single-phase 3-wire line.

(8808-51 only)

Analyzes 3-phase 3-wire line.

(8808-51 only)

3.2 Measurement Target Setting

Page 8

4

_____________________________________________________________________________________________

Single-phase 2-wire

Single-phase 3-wire

8808-51 only

Source

1

HL

CH1 CH2

8807-51

Load

Position the clamp with the current direction

indicator pointing toward the load side.

LoadSource

Source

1

N

Load

HL

CH1 CH2 CH3 CH4

Source

1

N

HL

Load

8808-51

3-phase 3-wire

8808-51 only (3-phase 3-wire, 2-power meter method)

Source

R

Load

N

2

L

H

CH1 CH2 CH3 CH4

L

H

8808-51

For example, when using a HIOKI clamp on probe, the clamping method should be as shown below.

If the clamp on probe is faced in the opposite direction, the phase will shift 180 degrees from the actual

value.

NOTE

The direction of connection for the 9132-10 is opposite from the 9018-10.

9018-10

Load

S

T

L

H

CH1 CH2 CH3 CH4

H

8808-51

9132-10

Source

L

Source

______________________________________________________________________________________________

3.2 Measurement Target Setting

Load

Page 9

_____________________________________________________________________________________________

5

4. Analog Input Channel Setting

4.1 Waveform Display Color Setting

In instantaneous analysis mode, you can select the color of the displayed

waveform.

Setting Screen SET >>

1. Move the flashing cursor to the location next to

the channel to be set, as shown in the diagram.

2. Make a setting using the buttons.

List

OFF

Red/Green

Yellow/Light

Blue

Blue/Gray

Does not display

waveform.

Prints waveform at

standard print density.

Prints waveform at low

print density.

Prints waveform at high

print density.

When the 8992 PRINTER UNIT is used to print a

waveform, the three print densities are used to

represent the selected waveform display color (6

colors).

Print density has no effect in real-time printing.

CHANNEL(2/4)

______________________________________________________________________________________________

4.1 Waveform Display Color Setting

Page 10

6

(

_____________________________________________________________________________________________

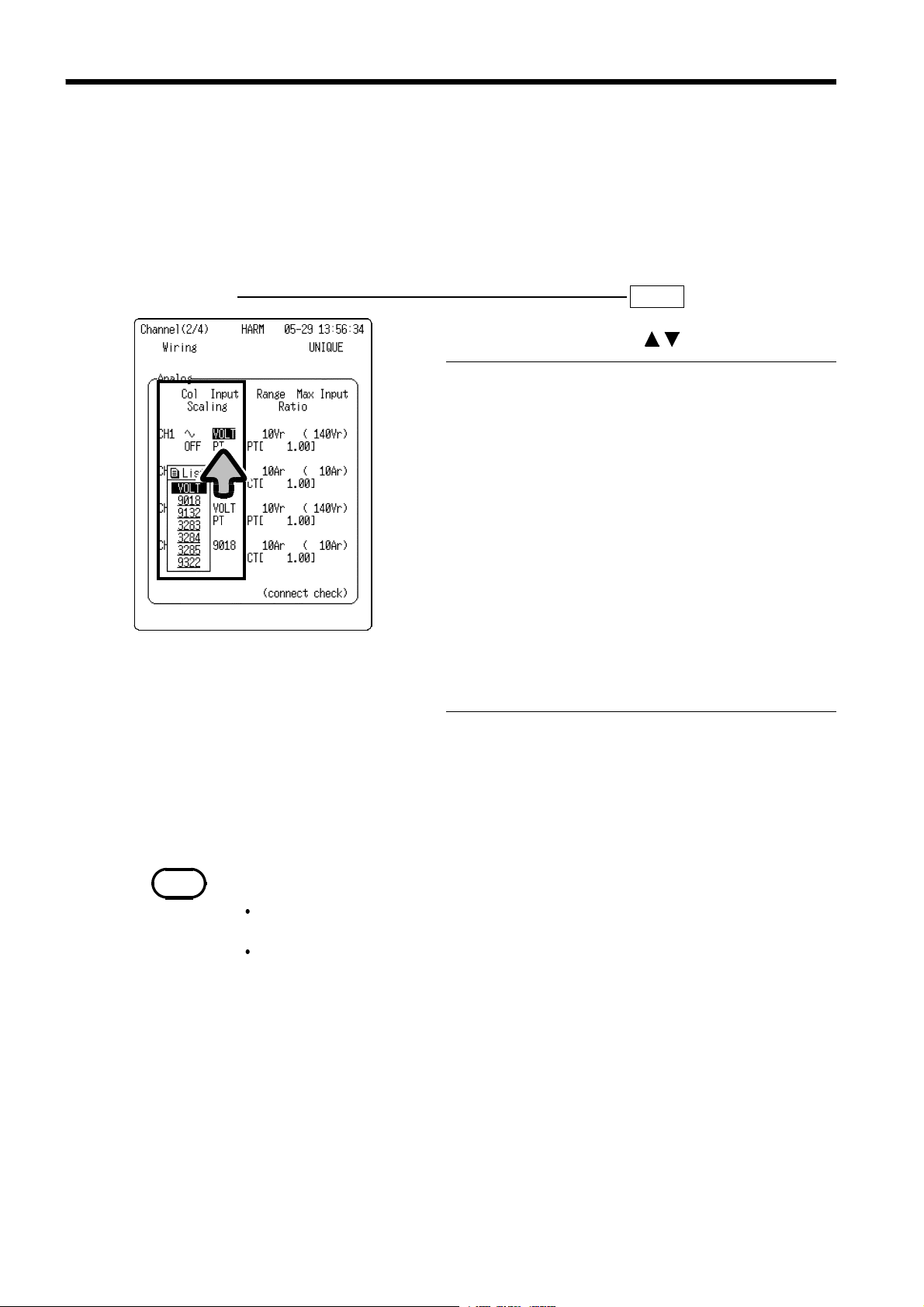

4.2 Input Type Setting

The input type must be set for each analog input channel.

Voltage and current in combination with the HIOKI Clamp Sensor can be

measured.

When the name of clamp is selected, measurements are automatically

converted to current values and displayed.

Setting Screen SET >>

1. Move the flashing cursor to

INPUT

2. Make a setting using the buttons.

For direct input of voltage or when using a

general-purpose clamp probe

(Current measurement)

When using a 9018-10 CLAMP ON PROBE

(Current measurement)

When using a 9132-10 CLAMP ON PROBE

(Leakage current measurement)

When using a 3283 CLAMP ON LEAK

HiTESTER

(Current measurement)

When using a 3284 CLAMP ON AC/DC

HiTESTER

(Current measurement)

When using a 3285 CLAMP ON AC/DC

HiTESTER

(High voltage measurement)

When using a 9322 DIFFERENTIAL PROBE

(*)When a 3283, 3284, or 3285 CLAMP ON

HiTESTER is selected, power analysis

(harmonic wave active power, harmonic wave

power content ratio, harmonic wave power

phase angle, active power, apparent power,

reactive power, power factor) cannot be

performed due to the phase characteristics.

If the 3283, 3284, or 3285 is selected, the

following warning message is displayed when

power analysis begins.

"Warning 635: 3283,3284,3285 can't analyze

power."

VOLT

9018

9132

3283(*)

3284(*)

3285(*)

9322

CHANNEL(2/4)

.

NOTE

Precautions for measuring current using a HIOKI CLAMP ON PROBE/CLAMP ON

HiTESTER

Set the same measurement range for the 8807-51/8808-51 and the clamp.

Accurate measurements are not possible if improper ranges are set.

When using the 3283, 3284 or 3295 CLAMP ON HiTESTER for current

measurement, press the OUTPUT button on the 3283/3284/3285 unit and set to

MON

______________________________________________________________________________________________

4.2 Input Type Setting

waveform output: AC).

Page 11

_____________________________________________________________________________________________

7

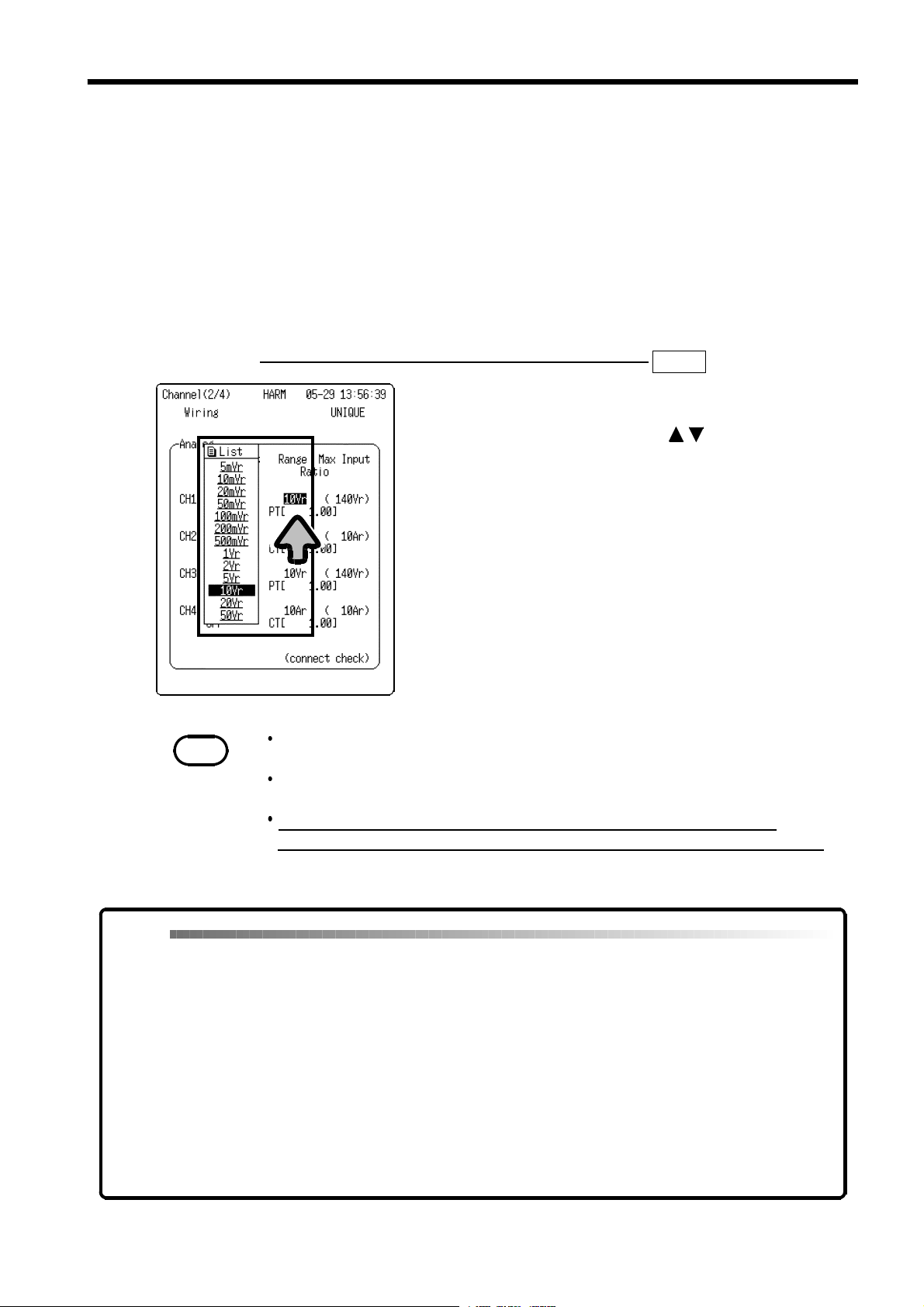

4.3 Vertical Axis Range Setting

The vertical axis range must be set for each channel.

When VOLTAGE is set as the input type:

Indicates rms voltage value per division when vertical axis magnification is

setto"x1."

When CLAMP is set as the input type:

Indicates rms current value on full vertical axis scale.

Setting Screen SET >>

1. Move the flashing cursor to

RANGE

2. Make a setting using the buttons.

NOTE

The input range for the harmonic wave analysis function is indicated as an rms

value.

In instantaneous analysis, the voltage value read by the cursor on the input

waveform screen is indicated as an instantaneous value.

Note that when VOLTAGE is selected as the input type, the maximum

measurement voltage displayed on the channel screen becomes the guaranteed

accuracyrange.

CHANNEL(2/4)

.

Q&A

Q1

What range should I select

when measuring a

commercial 110-Vrms

power supply?

Q2

What range should I select

when using the 9018 for 15Arms measurement?

______________________________________________________________________________________________

A1

Since commercial power supplies can fluctuate in the range of 10%,

select a range that covers 121 Vrms (110 Vrms x 1.1).

Maximum measurement voltage in 5-Vr range: 70 Vrms

70 Vrms < 121 Vrms X (over range)

Maximum measurement voltage in 10-Vr range: 140 Vrms

140 Vrms > 121 Vrms O (appropriate range)

A2

The clamp probe range indicates the maximum full-scale input as an

rms value. Select a range larger than the value of current to be

measured.

Be sure to set the same range in the clamp probe and the main unit.

10-Ar range setting: 10 Arms < 15 Arms X (over range)

20-Ar range setting: 20 Arms > 15 Arm s O (appropriate range)

4.3 Vertical Axis Range Setting

Page 12

8

_____________________________________________________________________________________________

4.4 Scaling Setting

The scaling function can be turned On or Off when using a CT/PT or

generic clamp probe.

Setting Screen SET >>

1. Move the flashing cursor to the location next to

the channel to be set, as shown in the diagram.

2. Make a setting using the buttons.

OFF

ON

No scaling

Scaling provided

3. When VOLTAGE is set as the input type:

Select the type of scaling.

PT

For PT rate setting

CHANNEL(2/4)

A

When a clamp probe other than HIOKI unit

is used

______________________________________________________________________________________________

4.4 Scaling Setting

Page 13

_____________________________________________________________________________________________

9

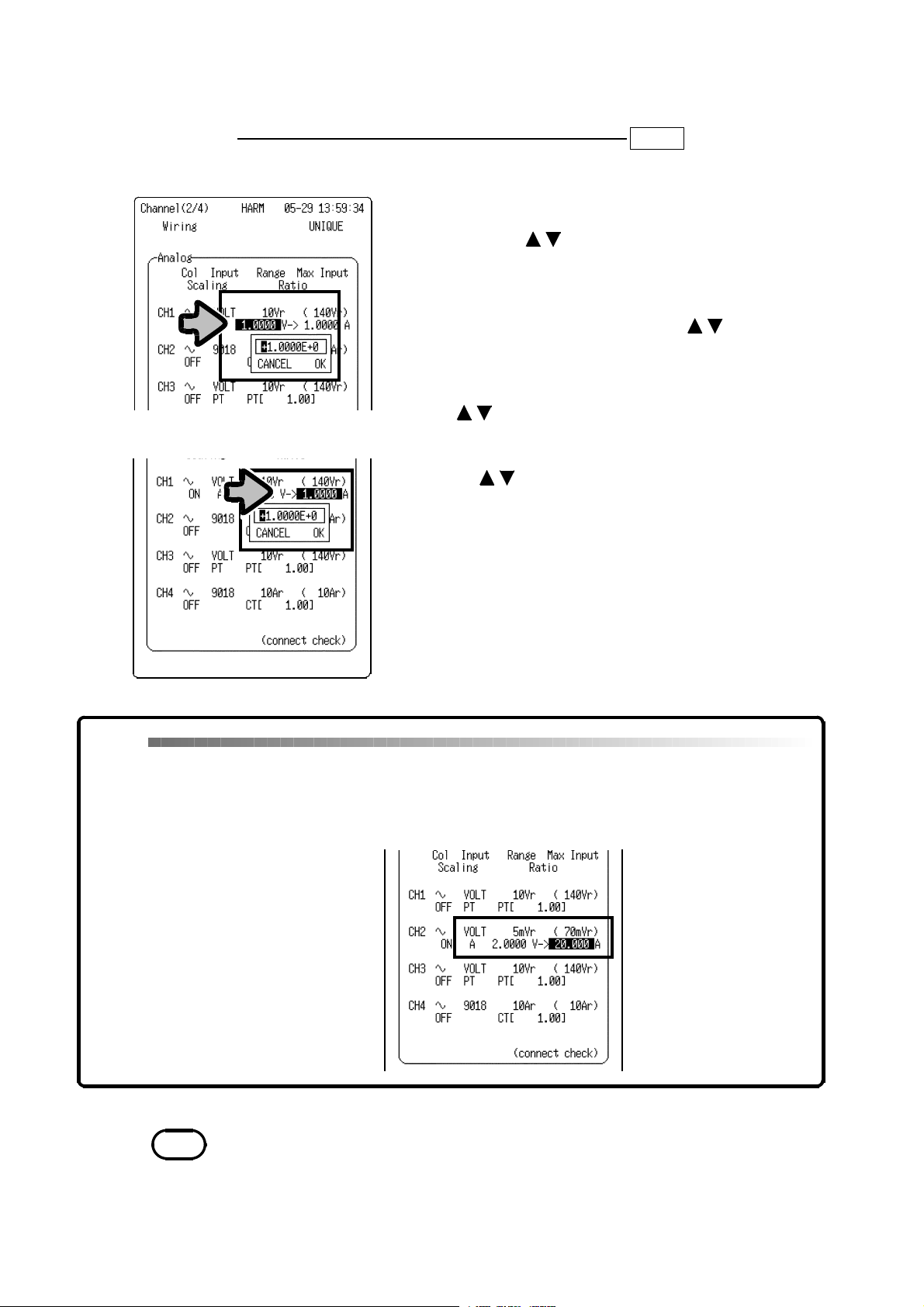

4.5 Scale Conversion Rate Setting

This screen is used to set the scaling conversion rate when using a CT/PT or

other clamp probe.

Setting of CT/PT rate

Setting Screen SET >>

1. Move the flashing cursor to the location next to

the channel to be set, as shown in the diagram.

2. Press the buttons to open the numerical

value setting window.

3. Move the cursor to a selected digit in the

numerical value setting window and enter a value

using the buttons. (exponential notation)

4. To confirm the setting:

Move the flashing cursor toOK, and press the

buttons or the

START

button.

To cancel the setting:

Move the flashing cursor to

the buttons or the

CANCEL

STOP

button.

Q&A

Q1

How can I measure 1500

Arms using a combination

of the 9020 CLAMP ON

ADAPTER (10:1) and the

9018?

A1

When the 10:1 9020 is used to measure 1500 Arms, the 9020 unit

outputs 150 Arms (1500 Arms x 1/10).

To measure 150 Arms, the 9018 should be set to the 200 Arms range.

With this setting, when scaling is turned ON and the conversion rate is

set to "10.00," the screen will display "1500 Arms" as the measured

value.

CHANNEL(2/4)

and press

______________________________________________________________________________________________

4.5 Scale Conversion Rate Setting

Page 14

10

g

_____________________________________________________________________________________________

Settings for use of other clamp products

Setting Screen SET >>

1. Move the flashing cursor to the location next to

the channel to be set, as shown in the diagram.

2. Press the buttons to open the numerical

value setting window.

3. Move the cursor to a selected digit in the

numerical value setting window and enter an

output voltage value using the buttons.

(exponential notation)

4. To confirm the setting:

Move the flashing cursor toOK, and press the

buttons or the

START

button.

To cancel the setting:

Move the flashing cursor to

the buttons or the

CANCEL

STOP

button.

5. Move the flashing cursor toAand enter the

measurement range of the clamp to be used.

(Repeat steps 3 and 4.)

CHANNEL(2/4)

and press

Q&A

Q1

How can I make high

accuracy current

measurements using a

combination of the 9277

UNIVERSAL CLAMP ON

CT and the 9555?

NOTE

The scaling in the harmonic wave analysis function is effective only for harmonic

wave analyses.

The scaling setting in other functions is not valid in harmonic wave analyses.

You can enter a conversion rate even if scalin

A1

When the 9277 and 9555 are used together, the voltage output

becomes 2 Vf.s. with an input of 20 Af.s. In such cases, enter "2.00" in

"VOLTAGE" and "20.00" in "A" for automatic conversion of

measurement values to current values.

is set to OFF.

______________________________________________________________________________________________

4.5 Scale Conversion Rate Setting

Page 15

_____________________________________________________________________________________________

11

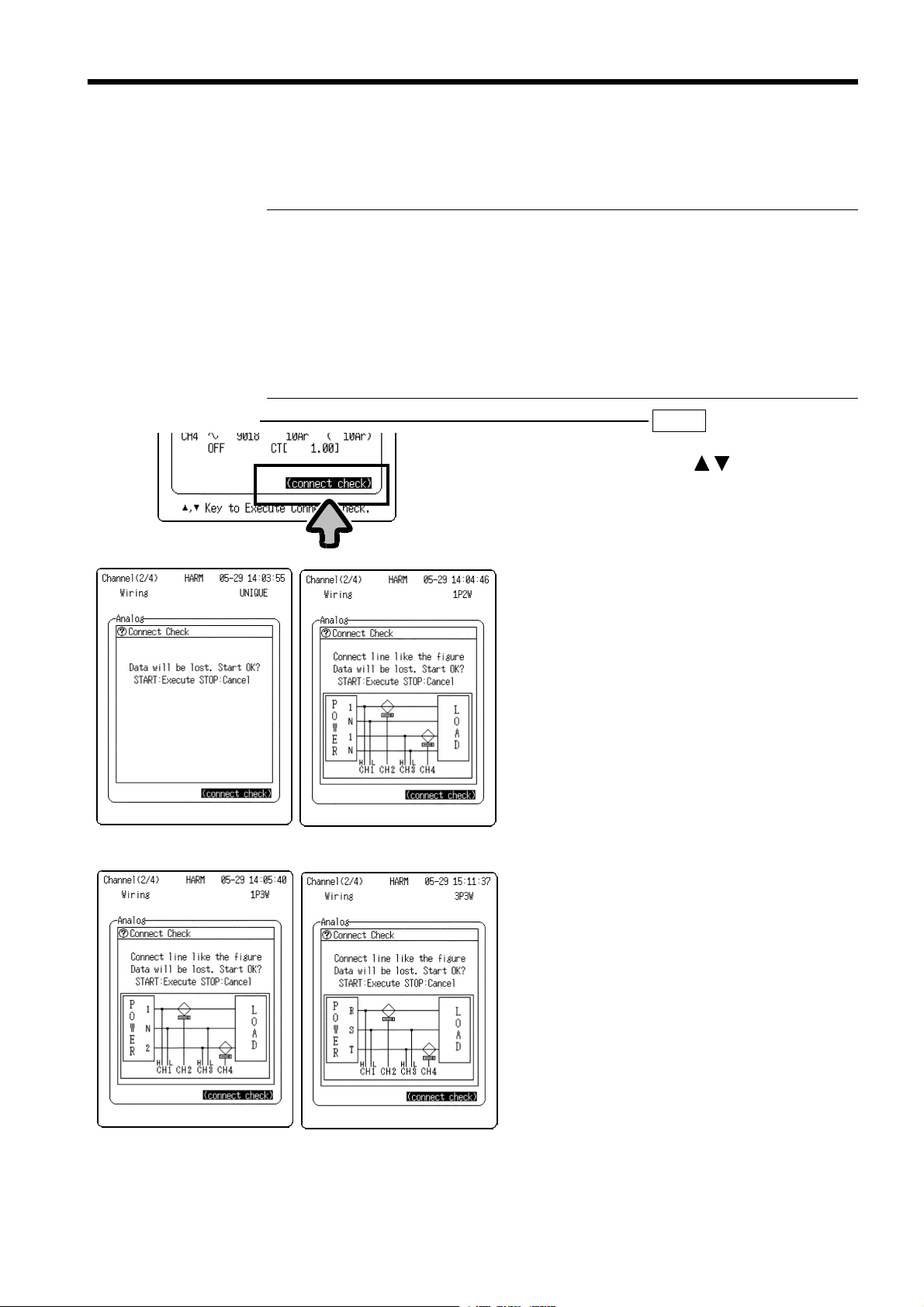

4.6 Line Connection & Level Check

This function is used to set an appropriate range for the input signal prior to

measurement. When a clamp probe is used, this function checks the

orientation of the probe. The check items vary by measurement target.

UNIQUE

Range check, voltage, and current phase check (when power analysis

is valid)

1P2W

1P3W

3P3W

Input type check, range check, voltage, and current phase check

Input type check, range check, voltage, and current phase check,

voltage level imbalance check, single-phase 3-wire and 3-phase 3-wire

detection

Input type check, range check, voltage, and current phase check,

voltage level imbalance check, single-phase 3-wire and 3-phase 3-wire

detection, phase sequence check

Setting Screen SET >>

1. Move the flashing cursor to

check)

, and press the buttons to

open the connection diagram and check

start window (diagrams at lower left).

(The displayed window corresponds to the

measurement target.)

2. Make connections according to the

connection diagram.

3. To run the check after completing the

connections:

Press the

START

button.

(The line connection & level check begins

automatically.)

To cancel:

Press the

STOP

button.

CHANNEL(2/4)

(connect

Independent channels

Single-phase 3-wire

______________________________________________________________________________________________

Single-phase 2-wire

3-phase 3-wire

4.6 Line Connection & Level Check

Page 16

12

_____________________________________________________________________________________________

4. Check the results of the line connection &

level check.

(The check items are automatically

selected from the items listed below,

according to measurement target.)

Range Over

Checks whether the range is appropriate for

the waveform to be measured.

For voltage measurement, the range switches

automatically to prevent input overshoot.

When the range switches, the following

message appears: "Range changed. (Out of

range) " (at the bottom of the screen)

Input type

Independent channels

Single-phase 2-wire

(modes except "UNIQUE")

Checks that the settings are appropriate for

power measurement.

Checks whether an appropriate clamp probe is

connected.

Sensor Direction

Checks the orientation of the clamp probe.

If the level of voltage/current input signal is

low, the screen indicates that a determination

cannot be made.

Single-phase 3-wire

The result of each check is indicated by "OK" or

"NG" (no good). When a check results in a

"NG" result, the line connection & level check

function halts, and details of the connection

error are displayed.

NOTE

If the input waveform phase is reversed, an accurate active power will not be

displayed. Be sure to perform the line connection & level check before

3-phase 3-wire

measurement.

Note that the waveform data stored in memory is deleted when the line

connection & level check is executed.

If the voltage/current level is low, a reversed clamp connection may not be

detected. In this case, the result of the clamp reversal connection check is

displayed as "?."

Connection errors may not be detected under the following conditions.

1) When there are two or more connection errors.

2) When the voltage/current level is low.

3) When the power factor is low.

In addition to the line connection & level check, we recommend checking the

DMM screen for abnormal measured values.

Voltage RMS line

(when set for 1P3W or 3P3W)

Checks voltage level imbalance

Select Measure Line

(when set for 1P3W or 3P3W)

Checks whether measurement is for a singlephase 3-wire line or 3-phase 3-wire line.

Voltage Phase Sequence

(when set for 3P3W)

Checks the phase sequence when measuring

a 3-phase 3-wire line.

5. When a check results in "NG":

Check and correct connections and restart

the line connection & level check.

Repeat the check until all items show

"OK."

______________________________________________________________________________________________

4.6 Line Connection & Level Check

Page 17

_____________________________________________________________________________________________

13

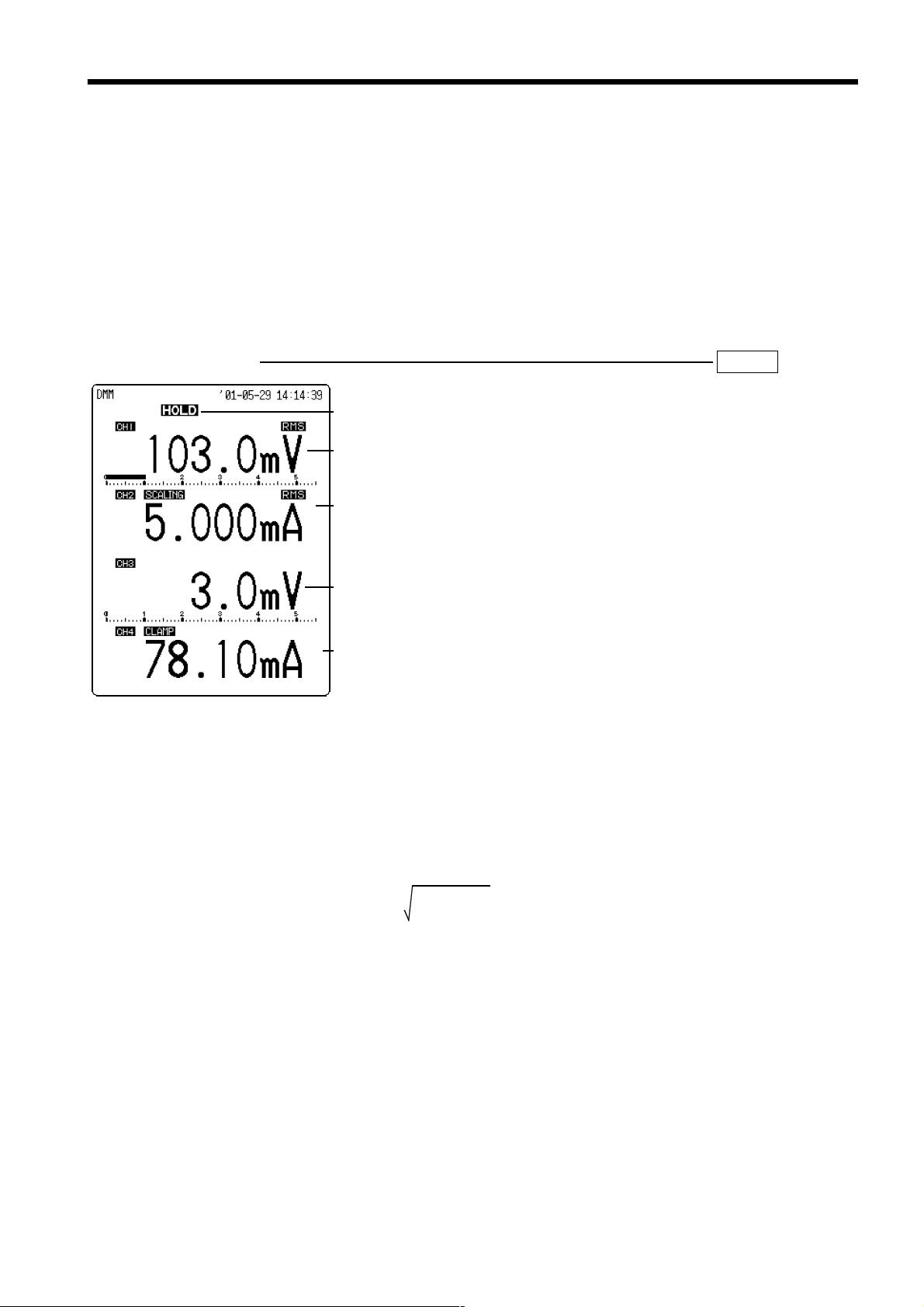

4.7 DMM Function

The DMM function provides a numeric display of the input voltage of a

commercial power supply (50/60 Hz) and DC signal on the screen.

The digital display can be switched between instantaneous value and rms

value.

This function will not display accurate values if the input voltage is not of a

commercial power supply (50/60 Hz) or a DC signal.

When the DMM screen is used with the harmonic wave analysis function,

the range set in the harmonic wave analysis function is reflected in the

display values.

Setting Screen DISP >>DMM

Hold

indication

rms value

(voltage)

rms value

(clamp)

1. Press the

screen.

2. Press the

open the DMM screen.

To return to the waveform screen, press the

button on the DMM screen.

button to open the waveform

DISP

button on the waveform screen to

DISP

DISP

Instantaneous

value

(voltage)

Instantaneous

value

(clamp)

Display contents

Instantaneous value display: The indications show the instantaneous values

of the input voltage of a commercial power supply (50/60 Hz) and DC

signal.

RMS value display: The displayed value is an rms value calculated on the

basis of the input voltage. The calculation is based on the following

equation:

RMS =

"A" indication when clamp is used

This indication shows the channel that measures the current using the 901810/9132-10 CLAMP ON PROBE, 3283 CLAMP ON LEAK HiTESTER, or

3284/3285 CLAMP ON AC/DC HiTESTER, or with scaling applied by a

generic clamp.

n

(

di2/n)

Σ

i=1

RMS: Rms value

n: Data number source

di: ith data in channel

______________________________________________________________________________________________

4.7 DMM Function

Page 18

14

play

_____________________________________________________________________________________________

Switching between instantaneous value display and rms value display

Channels with rms value display are indicated with an "RMS" displayed on

the DMM screen. You can toggle the display between instantaneous value

and rms value in the following ways:

Change to all-channel rms value display: button

Change to all-channel instantaneous value display: button

Change the specified channel:

CH1, CH2, CH3, CH4

(channel to be changed)

Display hold/cancellation of hold

Display hold:

STOP

(The screen shows

. The values displayed at the

HOLD

time that the button is pressed remain on screen.)

Canceling hold:

START

Printing the DMM screen

Printing the displayed values:

Screen copy:

COPY

PRINT

DMM function specifications in harmonic wave analysis function

Measurement target: Commercial power supply (50/60 Hz) (automatic

frequency setting)

Displayed information: Rms value or instantaneous value

Update rate: 1 s

Sampling speed: 4 kS/s

The number of displayed digits: 4 digits (the lowest digit indicates "0" when

the actual value is between 0 and 4, and "5" when the actual value is

between 5 and 9.). When scaling turned ON, exponential notation is used.

Accuracy: 3% rdg. 5 dgt.

NOTE

With scaling turned OFF, the maximum voltage value that can be displayed is

5499. The auto range function switches to a lower range when the count falls

below 500. The lowest digit indicates either "0" or "5."

The color of the digital indication for each channel corresponds to the waveform

dis

color set in instantaneous analysis mode.

______________________________________________________________________________________________

4.7 DMM Function

Page 19

_____________________________________________________________________________________________

15

5. Instantaneous Analysis Mode

This mode is used to perform various analyses on one cycle of an input

waveform.

5.1 Analyses and Display Screens

The analyses that can be performed in instantaneous analysis mode and

analysis result screens are described below.

The instantaneous analysis mode supports six analyses (items), each with its

own analysis screen, and seven analyses (parameter values) with numeric

indications only.

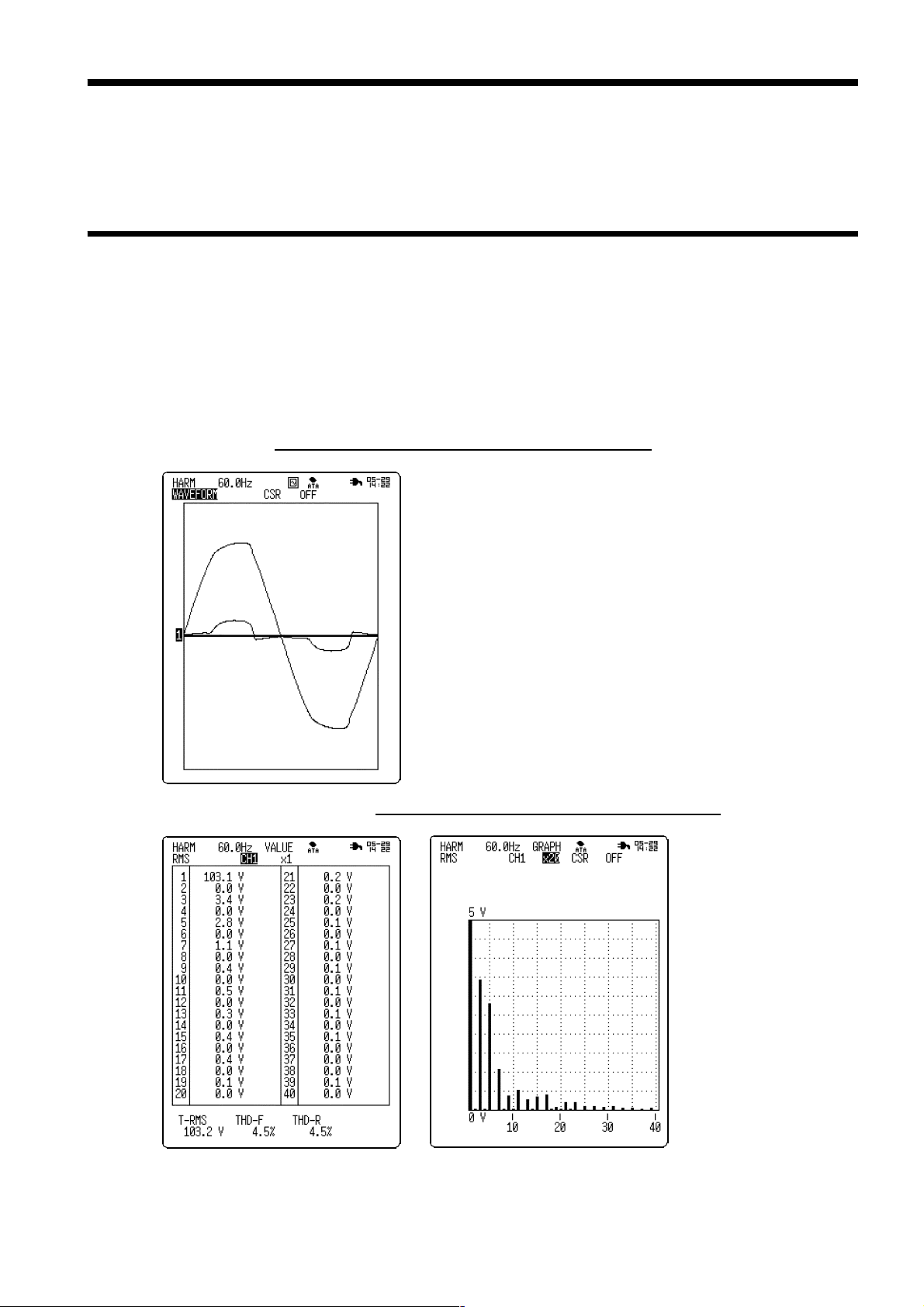

(1) Input waveform

(2) Harmonic wave rms value

(WAVEFORM screen)

512 sample points are extracted from the data,

which is sampled at a frequency of 400 kS/s.

(RMS screen)

The screen displays

the rms values of

harmonic wave

components of each

input signal, ranging

from the fundamental

wave to the 40th

degree.

Numeric screen

______________________________________________________________________________________________

Graph screen

5.1 Analyses and Display Screens

Page 20

16

_____________________________________________________________________________________________

(3) Harmonic wave content ratio

Numeric screen

The fundamental wave content ratio is assigned a value of 100% for the calculations.

Content ratio =

___________________________

Graph screen

(nth-degree harmonic wave)

(Fundamental wave)

2

2

x 100 (%)

(RMS-RATIO screen)

The screen displays

the content ratios (%)

of harmonic wave

components of all

degrees to the input

signal.

(n = degree of

harmonic wave)

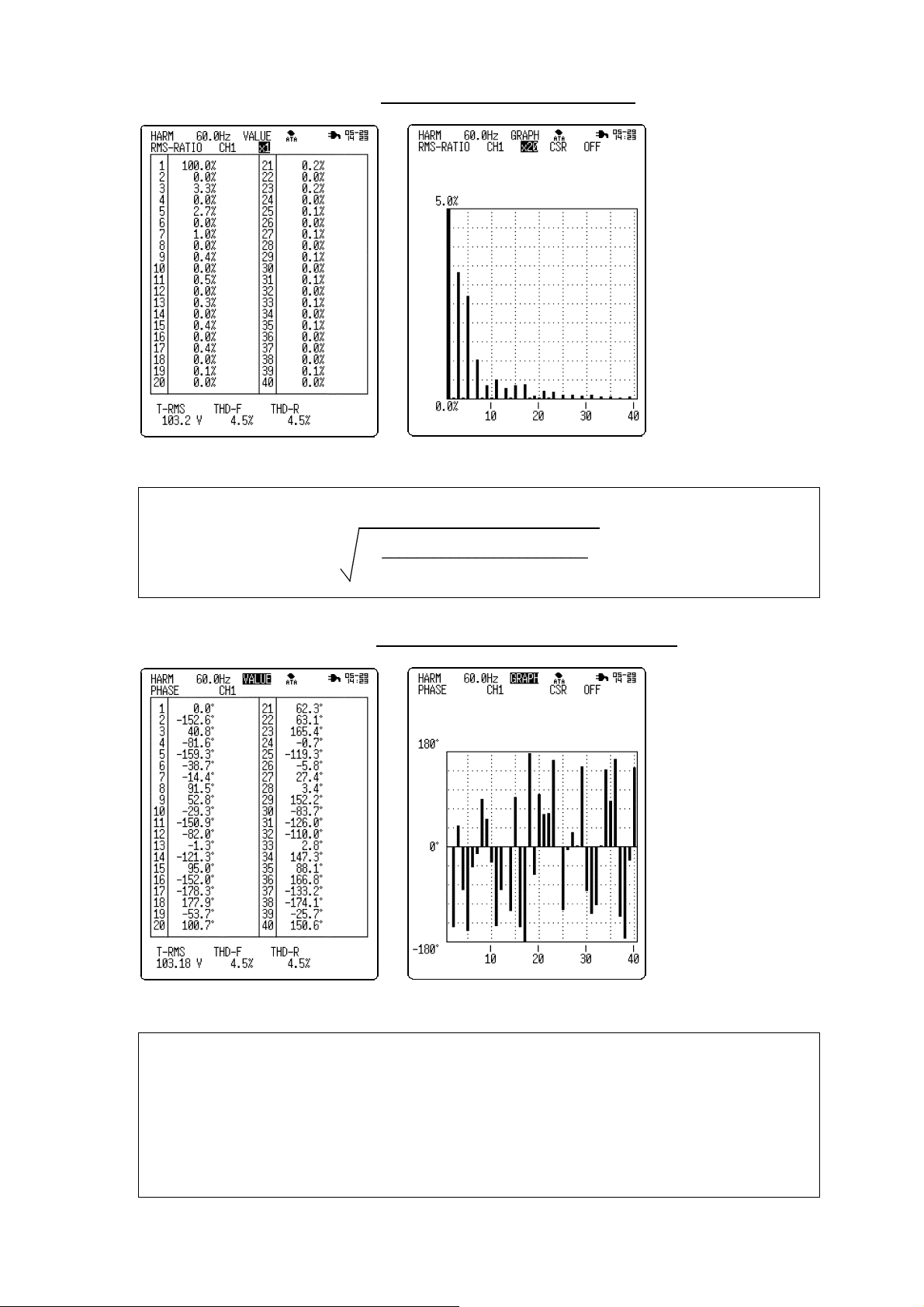

(4) Harmonic wave phase angle

Numeric screen

The input signal V can be expressed by the following equation:

sin(ωt)+V

V=V

1

.... +V

sin(2ωt+θ

2

sin{(n-1)ωt+θ

(n-1)

)+V

2

(n-1)

Graph screen

sin(3ωt+θ

3

sin(nωt+θ

}+V

n

)+ ...

3

ω =2π/T

t: Fundamental wave

)

n

frequency

: Rms value of nth degree

V

n

: Phase deviation of nth-

θ

n

degree harmonic wave from

fundamental wave

(PHASE screen)

The screen displays

the phase deviation of

the harmonic wave

components of all

degrees from the

fundamental input

signal wave.

______________________________________________________________________________________________

5.1 Analyses and Display Screens

Page 21

_____________________________________________________________________________________________

17

(5) Harmonic wave active power

Numeric screen

Active power = (Rms voltage value)

Graph screen

x (Rms current value)

n

(POWER screen)

The screen displays

the active power

values (W) of the input

signal harmonic wave

components, ranging

from the fundamental

wave to the 40th

degree.

x cos(Power phase angle)

n

(n = 1 to 40)

n

(6) Harmonic wave active power content ratio

Numeric screen

Active power content ratio=

Active power of nth-degree harmonic wave

____________________________________

Active power of fundamental wave

Graph screen

(P-RATIO screen)

The screen displays

the percentage of

active power value of

the harmonic wave

component of each

degree in the active

power value (given a

value of 100%) of the

fundamental wave of

input signal.

x100(%)

(n = degree of harmonic wave)

______________________________________________________________________________________________

5.1 Analyses and Display Screens

Page 22

18

_____________________________________________________________________________________________

(7) Harmonic wave power phase angle

Numeric screen

NOTE

In the graph, the horizontal axis and vertical axis show active power and reactive

power, respectively, while vector length indicates the magnitude of rms value

(apparent power).

The power phase angle vector diagram shows the harmonic wave components of

all degrees from the fundamental wave to the 40th degree.

Specifying a desired harmonic wave component displays the component in the

vector diagram as a solid line.

Harmonic wave inflow and outflow can be determined as shown below.

(P-PHASE screen)

By measuring the

phase angle of

harmonic wave current

of each degree relative

to the voltage

waveform, the screen

indicates the direction

of drift in the harmonic

wave of each degree.

Graph screen

Harmonic wave outflow

(8) Parameters

The numeric screen displays the following parameters:

90

180

-90

Harmonic wave inflow

0

Analysis screen Displayed parameters

RMS, RMS-RATIO, PHASE Total rms, total distortion-F, total

distortion-R

POWER, P-RATIO, P-PHASE Active power, apparent power, reactive

power, power factor

______________________________________________________________________________________________

5.1 Analyses and Display Screens

Page 23

_____________________________________________________________________________________________

19

Total rms value

Sum of rms values of all harmonic wave components.

Total rms value=

40

(nth-degree harmonic wave)

Σ

i=1

2

[V] or [A]

(n = degree of harmonic wave)

Total distortion-F

Percentage of all harmonic waves in fundamental wave.

"F" refers to "fundamental."

Total distortion-F =

40

(nth-degree harmonic wave)

Σ

i=2

(Fundamental wave)

2

2

[%]

(n = degree of harmonic wave)

Total distortion-R

Percentage of all harmonic waves in total rms value.

"R" refers to "rms."

Total distortion- R =

40

(nth-degree harmonic wave)

Σ

i=2

Total rms value

2

[%]

(n = degree of harmonic wave)

Active power

Mean value of the amount of work performed by one cycle of AC

instantaneous power

Active power =

40

{(Rms voltage value)

Σ

i=1

cos(Power phase angle)

x (Rms current value)

n

}[W]

n

(n = degree of harmonic wave)

x

n

Apparent power

Product of rms values of voltage and current

Apparent power = (Total rms voltage value) x (Total rms current value) (VA)

Reactive power

Value obtained by multiplying the product of rms values of voltage and

current by sin.

Reactive power =

40

{(Rms voltage value)

Σ

i=1

sin(Power phase angle)

x (Rms current value)

n

} [var]

n

(n = degree of harmonic wave)

x

n

Power factor

Cos of the phase difference between voltage and current.

Power factor = (Active power)/(Apparent power)

______________________________________________________________________________________________

5.1 Analyses and Display Screens

Page 24

20

p

_____________________________________________________________________________________________

NOTE

Harmonic wave analysis shows the results of analysis performed on sample data.

Based on analysis results, the rms value and content ratio are calculated

independently with a greater number of decimal places than are actually displayed

on screen. Therefore, the results calculated for rms value and content ratio may

differ slightly from the results obtained by calculating with the values displayed

on the screen.

If any of the following conditions is met, power measurement cannot be

erformed.

Condition 1 When CH1 and CH3 are set for current measurement

(input type: voltage/ 9322, scaling: A) or

(input type: 9018/ 9132/ 3283/ 3284/ 3285)

Condition 2 When CH2 and CH4 are set for voltage measurement

(input type: voltage/ 9322, scaling: OFF/ PT)

Condition 3 When the input types of CH2 and CH4 are set to 3283/ 3284/

3285

If one of conditions 1 through 3 is met at the start of measurement and

the following conditions apply, a warning message is displayed.

Condition

Setting

1 2 3

a (Harmonic wave trigger)

When the harmonic wave trigger source is set

to "power of each degree," "power content

ratio," or "power phase"

*1

Warning

633 (in 8807-51)

634 (in 8808-51)

*1

Warning

635

b (Instantaneous analysis)

When the analysis type is set to "active

power," "power content ratio," or "power

phase angle"

c (Time-series analysis)

When the analysis item is set to "active power

of each degree," "power content ratio," "power

phase angle," "active power," "reactive power,"

or "power factor"

d (Instantaneous analysis)

With the measurement target set to

*2

Warning 636

"independent channels" and the analysis type

set to "waveform," "rms value," "content

ratio," or "phase angle," when the analysis

type is changed to "active power," "power

content ratio," or "power phase angle" after

measurement

*1: Measurement halts if one of the following warning messages is

displayed:

Warning 633: Set CH1=Volt, CH2=Current (for 8807-51).

Warning 634: Set CH1,CH3=Volt, CH2,CH4= Current (for 8808-51).

Warning 635: 3283,3284,3285 can't analyze power.

*2: When the following warning message is displayed, the screen displays a

table with no numeric values.

Warning 636: Don't analyze power.

______________________________________________________________________________________________

5.1 Analyses and Display Screens

Page 25

_____________________________________________________________________________________________

21

5.2 Basic Item Setting

The following describes various setting items and setting methods.

1. Settings on Status Screen

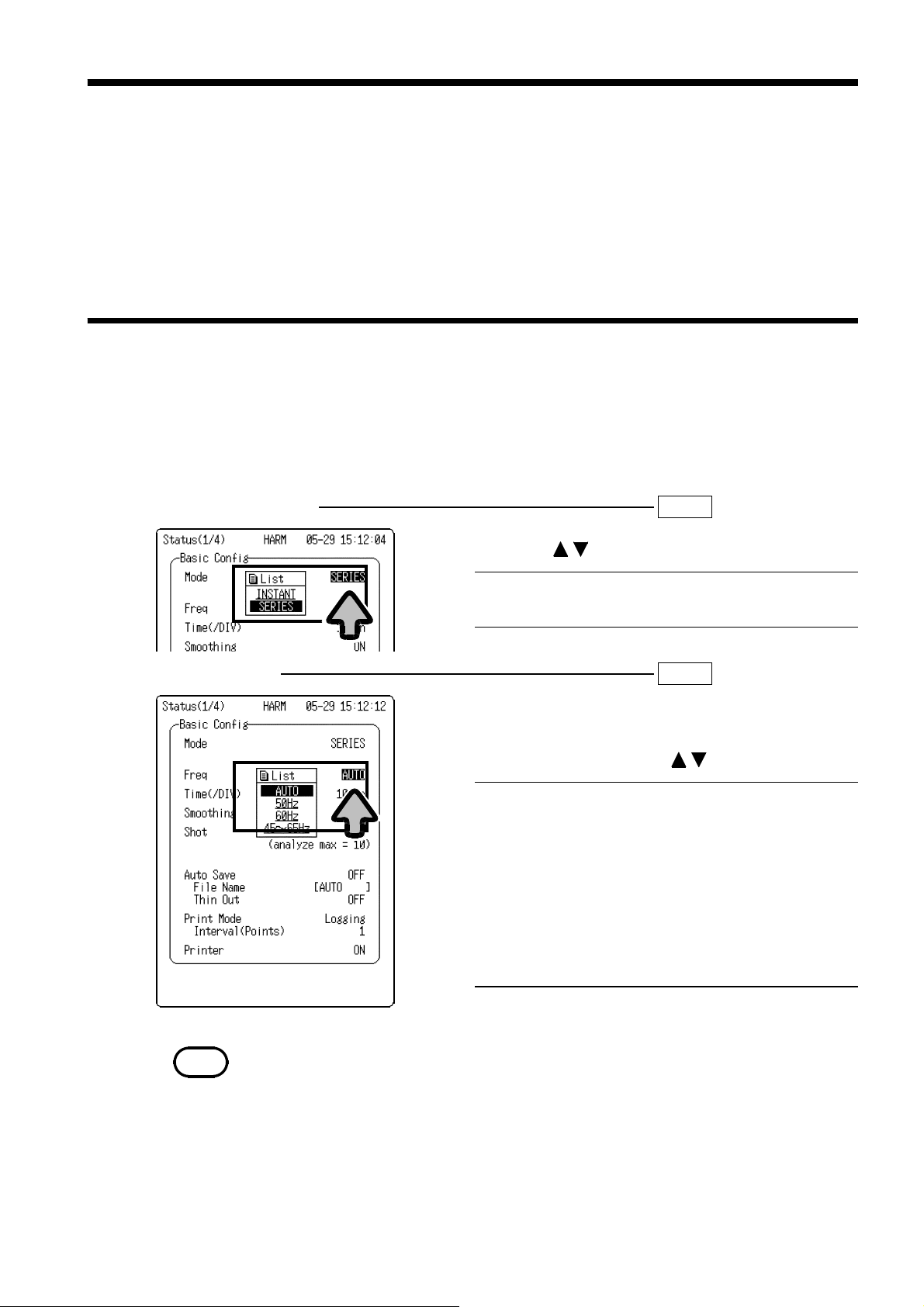

(1) Analysis mode setting SET >>STATUS(1/4)

1. Move the flashing cursor to

MODE

2. Using the buttons, select

.

INSTANT

.

INSTANT

SERIES

Conducts instantaneous analysis.

Conducts time-series analysis.

(2) Frequency setting SET >>STATUS(1/4)

This item is used to set the power supply frequency

of the analysis target.

1. Move the flashing cursor to

Freq

.

2. Select the setting using the buttons.

Auto

50Hz

60Hz

45Hz65Hz

The frequency of the measurement

target is automatically calculated (in 0.1Hz steps) based on the input waveform.

The frequency of the measurement

target is set to 50 Hz.

The frequency of the measurement

target is set to 60 Hz.

For manual frequency settings (in 0.1-Hz

steps).

NOTE

The frequency estimate may fail if the waveform contains a significant amount of

noise, or with square waves. If this happens, set the basic frequency manually.

(3) Multi-screen setting SET >>STATUS(1/4)

The input waveform screen can be divided into subscreens, each displaying one channel.

1. Move the flashing cursor to

Display format

.

2. Using the buttons, select the number of

sub-screens to display.

Single

Dual

Quad

One graph for display and recording

Two graphs for display and recording

Four graphs for display and recording

The setting is valid only when the analysis type is

setto"WAVEFORM."

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 26

22

_____________________________________________________________________________________________

(4) Auto save setting SET >>STATUS(1/4)

You can have data saved automatically to a PC card

when waveform analysis is complete. Data files are

stored in the directory selected in the file screen.

Selecting the data format for auto save

1. Move the flashing cursor to

Auto Save

.

2. Using the buttons, select the data format for

data to be saved by the auto save function.

OFF

Binary

Text

The auto save function is turned off.

Data is saved in binary format (for use in

8807-51/8808-51 only).

Data is saved in text format (for used in

PC). (Data saved in text format cannot be

loaded on the 8807-51 or 8808-51.)

Entering a file name for auto save

When a file name is entered, the auto save function

stores the file with that name. When several files

are saved in succession, they are assigned individual

numbers.

If no file name is entered, files are named

"AUTO.***", "AUTO0001.***", and so on.

For information on the file input method, see

Section 9.1 "Input of File Name."

(5) Print channel setting SET >>STATUS(1/4)

Select a channel from which results of measured

data analysis are printed.

1. Move the flashing cursor to the location of each

channel position, as shown in the diagram.

2. Using the buttons, select to print or not

print analysis results for each channel.

Print analysis results.

O

Do not print analysis results.

x

The setting is valid only when analysis results are

displayed as numerical values.

For active power, power content ratio, and power

phase angle, the power analysis results of the

systems containing the channels set for printout are

printed.

(6) Auto print setting SET >>STATUS(1/4)

You can have data printed automatically when

waveform analysis is complete.

1. Move the flashing cursor to

Auto Print

.

2. Using the buttons, select ON/OFF for the

auto print function.

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 27

_____________________________________________________________________________________________

23

2. Settings in the Analysis Item Screen

(1) Analysis type setting SET >>ANALYZE (4/4)

Select the analysis result to be displayed.

1. Move the flashing cursor to

Analyze

2. Select the setting using the buttons.

.

Displays waveform data based on

512 points extracted from data

sampled at a rate of 400 kS/s.

Displays the harmonic wave rms

value component of an input signal.

Displays the content ratio of the

harmonic wave component of any

degree for the input signal.

Displays deviations in harmonic

wave component of any degree from

fundamental wave of the input signal.

Displays active power value (W) of

harmonic wave component of any

degree in input signal.

Displays active power content ratio

of the harmonic wave component of

any degree in active power (given a

value of 100%) of fundamental wave

of the input signal.

Displays the phase angle of the

harmonic wave current of any degree

relative to voltage waveform.

(*) Measurement is possible only when oddnumber channels are set for voltage and evennumber channels set for current. With HIOKI

CLAMP ON SENSORS 3283, 3284, or 3285,

power measurement cannot be performed, due

to inadequate phase accuracy.

WAVEFORM

RMS

RMS-RATIO

PHASE

POWER (*)

P-RATIO(*)

P-PHASE(*)

(2) Analysis channel setting SET >>ANALYZE (4/4)

Select the channel to be analyzed.

Selection options vary depending on the analysis

item.

vary depending on the analysis item.

1. Move the flashing cursor to

Channel

.

2. Select the setting using the buttons.

8807-51

8808-51

CH1/CH2

CH1/CH2/CH3/CH4

(3) Analysis result display setting SET >>ANALYZE (4/4)

Select the method for displaying analysis results.

1. Move the flashing cursor to

Disp Kind

.

2. Select the setting using the buttons.

VALUE

GRAPH

Displays analysis results numerically.

Displays analysis results in graph.

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 28

24

_____________________________________________________________________________________________

3. Settings on Measurement Screen

(1) Analysis type setting DISP >>Waveform display

Select the analysis results to be displayed.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

(*) Measurement is possible only when oddnumber channels are set for voltage and evennumber channels are set for current. With

HIOKI CLAMP ON SENSORS 3283, 3284, or

3285, power measurements cannot be

performed due to inadequate phase accuracy.

WAVEFORM

RMS

RMS-RATIO

PHASE

POWER(*)

P-RATIO(*)

P-PHASE(*)

Displays waveform data based on 512

points extracted from data sampled at

a rate of 400 kS/s.

Displays the harmonic wave rms value

component of the input signal.

Displays the content ratio of the

harmonic wave component of any

degree for the input signal.

Displays deviations in the harmonic

wave component of any degree from

the fundamental wave of the input

signal.

Displays active power value (W) of

harmonic wave component of any

degree in the input signal.

Displays active power content ratio of

the harmonic wave component of any

degree in active power (given a value

of 100%) of the fundamental wave of

the input signal.

Displays phase angle of harmonic

wave current of any degree relative to

voltage waveform.

(2) Analysis result display setting DISP >>Waveform display

Select the method for displaying analysis results.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

(not displayed on the input waveform screen)

VALUE

GRAPH

Displays analysis results numerically.

Displays analysis results in graph.

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 29

_____________________________________________________________________________________________

25

(3) Analysis channel setting DISP >>Waveform display

Select the channel to be analyzed.

1. Move the flashing cursor to the location

indicated in the diagram

2. Select the setting using the buttons.

Selection options vary depending on the analysis

item.

8807-51

8808-51

CH1/CH2

CH1/CH2/CH3/CH4

For POWER, P-RATIO, P-PHASE, the analysis

results of the system containing the selected channel

are displayed.

(4) Analysis result magnification/compression DISP >>Waveform display

You can magnify or compress the displayed

analysis results.

Magnified graph allows detailed examination of the

results.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

LOG, x1/2, x1, x2, x5, x10, x20, x50, x100

NOTE

1/10 f.s.

1/100 f.s.

1/1000 f.s.

1/10000 f.s.

When the analysis result is magnified by x10 or more, the display resolution

increases order of magnitude. Note that the measurement accuracy is based on a

display of x1 magnification.

The vertical axis of the LOG displayis as follows:

When the magnification is set to

the LOG display on the POWER

f.s.

screen, the center value of the

graph indicates the following:

When POWER (W) is selected:

(1/100,000 of f.s.)

When P-RATIO (%) is selected:

0.01%

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 30

26

_____________________________________________________________________________________________

(5) Cursor ON/OFF setting (for graph screen only) DISP >>Waveform display

You can choose to hide or display detailed data for

each harmonic wave on the screen.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

OFF

+

Cursor is not used.

Cursor is used.

(6) Analysis degree setting (for graph screen only) DISP >>Waveform display

Use the cursor to select the analysis degree to read.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

From first degree to 40th degree

(7) Waveform display range setting

(for waveform input screen only) DISP >>Waveform display

You can select the display size of the waveform

input screen. Selecting the multi-screen setting

displays the input range for the instantaneous

waveform used for harmonic wave analysis.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select the setting using the buttons.

Displays the input instantaneous waveform in a

full screen.

Displays the input instantaneous waveform in a

sub-screen.

Upper and lower limit values for four channels (two

channels with 8807-51) are displayed on the screen.

______________________________________________________________________________________________

5.2 Basic Item Setting

Page 31

_____________________________________________________________________________________________

27

(8) Input setting (for waveform input screen only) DISP >>Waveform display

Input can be set for each channel on the waveform

input screen.

Setting

of

channel

1

2

3

4

1. Using the

CH1,CH2,CH3,CH4

buttons, display

the setting window for a selected channel.

2. Move the flashing cursor to the position of the

channel to set and press the buttons.

(You can change the setting window to input

channels CH1 through CH4 (CH2 for the 8807-

51).)

3. Move the flashing cursor to the item to be set.

4. Press the buttons.

5. To close the setting window, press the channel

button again.

Setting details

1. Waveform display color Used to select waveform display color

2. Input type Used to select the input type for the analog input

channel

3. Vertical axis range Used to set the vertical axis range for each channel

4. Maximum input (display

only)

Displays the maximum input that can be measured

in the set vertical axis range.

5.3 Cursor Operation

In the input waveform screen, you can use the cursor to simultaneously read

the phase relative to the zero crossing point and the voltage value.

Setting Screen DISP >>Waveform display

1. Using the buttons, set the analysis type to

.

Do not use cursors A/B.

Use only cursor A.

Setting of analysis type

WAVEFORM

2. Move the flashing cursor to the location

indicated in the diagram and select the cursor

type using the buttons.

OFF

A

A-B

A-B Use cursors A and B and move cursor B.

A-B

Value of A or B Value of B-A

t Phase difference from

zero crossing point

v Instantaneous voltage

(current) value of

selected channel

______________________________________________________________________________________________

Phase difference

between cursors

Potential difference

between cursors

3. Move the cursor using the

and read an indication.

Use the buttons to move the cursor

quickly.

Use cursors A and B and move cursor A.

Use cursors A and B and move both

simultaneously.

SCROLL/CURSOR

5.3 Cursor Operation

button

Page 32

28

p

)

_____________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis

of Two 100-VAC Single-Phase 2-Wire Lines

NOTE

Described below is a method for performing instantaneous analysis of two

100-VAC single-phase 2-wire lines simultaneously using the 8808-51.

In the example, the HIOKI 9018-10 CLAMP ON PROBE is used for current

measurement.

(1) Power supply on

Turn on the power switch for the 8808-51.

(2) Input connection

This equipment is designed to measure input voltage. To measure current, use a

voltage-output-type clamp ammeter. We recommend our CLAMP ON PROBE

and CLAMP ON HiTESTER for current measurements.

If a clamp ammeter is used to take measurements, the accuracy of both the 880751/8808-51 and the clamp affects the accuracy of measurements. Carefully check

the specifications for the CLAMP ON PROBEs and select the unit most

appropriate for the specific application. (Refer to Section 10 "Characteristics of

Clam

-on Probes."

Connect the 8808-51, as shown in the diagram below.

Source

1

N

Load

HL

CH1 CH2 CH3 CH4

Source

1

N

HL

8808-51

Load

To ensure that the phases of

measured current and the output

voltage match, check that the

current flow direction arrow

displayed on the clamp part points

toward the load.

Refer to P4 clamp on probe

connection method.

______________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis of Two 100-VAC Single-Phase 2-Wire Lines

Page 33

_____________________________________________________________________________________________

29

(3) Preparing for measurement

1. Using the

to the screen in which settings

are to be made.

2. Using the cursor and

buttons, make the settings as

shown in the diagrams on the

left.

button, proceed

SET

(4) Line connection & level check

This item is used to check the connections.

1. Move the flashing cursor to

(connect check)

the channel screen (2/4).

2. Press the buttons to open the confirmation

window.

3. To start the line connection & level check:

Press the

START

button.

4. To cancel the line connection & level check:

Press the

NOTE

______________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis of Two 100-VAC Single-Phase 2-Wire Lines

When a line connection & level check is executed, measurement data stored in

memory is deleted.

We recommend saving any required data to a PC card before running a line

connection & level check.

STOP

button.

on

Page 34

30

_____________________________________________________________________________________________

Line connection & level check start

The voltage range automatically switches to prevent

input overshoot. When the range changes, the

following message appears at the bottom of the

screen:

"Range changed. (Out of range)."

1) After the line connection & level check, check

the window.

2) When the line connection check result is "NG"

(no good):

Cause: Reverse probe connection

Remedy: Check the direction of the arrow on the

probe and correct the probe orientation. Restart

the line connection & level check.

Make sure that the check result shows "OK."

For details, see Section 4.6, "Line Connection &

Level Check."

(5) Measurement start

Press the

START

(6) Measurement complete

When one cycle of data is input, the LED turns off and measurement halts.

The screen displays a waveform.

(7) Other analyses

Proceed to the analysis type item and select the analysis screen by pressing

the buttons.

button to execute the measurement. (Green LED lights.)

Waveform input screen

This example indicates that the

analysis target is a waveform

with a frequency of 60 Hz.

______________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis of Two 100-VAC Single-Phase 2-Wire Lines

Rms value graph screen

This example shows that the

third-degree, fifth-degree and

seventh-degree harmonic wave

Content ratio graph screen

Indicates harmonic wave

components by content ratios.

This example indicates that oddnumbered harmonic wave

components are high in content.

Page 35

_____________________________________________________________________________________________

31

Phase angle numeric screen Active power graph screen

Shows the harmonic wave active

power of any degree with a bar

graph.

Power content ratio screen

Indicates the percentage of the

active power of harmonic wave

component of any degree in

active power (given a value of

"100%") of the fundamental

wave.

Power phase angle vector graph

screen

The vector graph shows the inflow

and outflow of harmonic waves.

______________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis of Two 100-VAC Single-Phase 2-Wire Lines

Page 36

32

_____________________________________________________________________________________________

(8) Printout

Press the

PRINT

button.

When the numeric screen is displayed, the numeric data is printed. When

the graph screen is displayed, a hard copy of the screen is printed. For more

information, refer to Section 8.1 "Recording on Printer."

Numeric data

Example of printout of RMS, RATIO, PHASE screen

Numeric data

Example of printout of POWER, P-RATIO, P-PHASE

screen

______________________________________________________________________________________________

5.4 Analysis Example 1: Simultaneous Instantaneous Analysis of Two 100-VAC Single-Phase 2-Wire Lines

Page 37

_____________________________________________________________________________________________

33

5.5 Analysis Example 2: Instantaneous Analysis of 200-VAC 3Phase 3-Wire Line

Describes below is a method for performing an instantaneous analysis of a

200-VAC 3-phase 3-wire line using the 8808-51.

The 8808-51 uses a 2-wattmeter method for power analysis of 3-phase lines.

(1) Input connection

Connect the 8808-51, as shown in the diagram below.

Source Load

R

S

T

H

CH1 CH2 CH3 CH4

(2) Preparation for measurement

L

L

H

8808-51

To ensure that the phases of

measured current and the output

voltage match, check that the

current flow direction arrow

displayed on the clamp part points

toward the load.

Refer to P4 clamp on probe

connection method.

1. Using the

button, proceed

SET

to the screen in which settings

are to be made.

2. Using the cursor and

buttons, make the settings as

shown in the diagrams on the

left.

______________________________________________________________________________________________

5.5 Analysis Example 2: Instantaneous Analysis of 200-VAC 3-Phase 3-Wire Line

Page 38

34

_____________________________________________________________________________________________

(4) Line connection & level check

This item is used to check

connections.

For detailed information, refer to

Measurement Example 1(4).

(5) Measurement start/end

Press the

When one cycle of data is input, the LED goes out and measurement stops.

The screen displays a waveform.

START

button to perform the measurement. (Green LED lights.)

______________________________________________________________________________________________

5.5 Analysis Example 2: Instantaneous Analysis of 200-VAC 3-Phase 3-Wire Line

Page 39

_____________________________________________________________________________________________

y

35

6. Time-Series Analysis Mode

The time-series analysis mode is used to perform data analysis for a specific

time interval for any of the 13 types of analysis available in instantaneous

analysis mode, and then to record changes in data over time.

The following section describes how to use the time-series analysis mode

and provides examples of analysis.

6.1 Basic Item Setting

Described below are selection options and setting methods for various setting

items:

1. Settings in the Status Screen

(1) Analysis mode setting SET >>STATUS(1/4)

1. Move the flashing cursor to

2. Using the buttons, select

INSTANT

SERIES

Conducts instantaneous analysis.

Conducts time-series analysis.

Mode

SERIES

.

.

(2) Frequency setting SET >>STATUS(1/4)

This screen is used to set the frequency of the

analysis target.

1. Move the flashing cursor to

Freq

.

2. Select a setting using the buttons.

Auto

50Hz

60Hz

45Hz-65Hz

The frequency of the measurement

target is automatically calculated (in

0.1-Hz steps) based on the input

waveform.

Sets 50 Hz as the frequency of the

measurement target.

Sets 60 Hz as the frequency of the

measurement target.

Used to set the frequency manually (in

0.1-Hz steps).

NOTE

______________________________________________________________________________________________

Frequency estimations may fail if the waveform contains significant amounts of

noise or consists of square waves. If this happens, set the basic frequency

manuall

.

6.1 Basic Item Setting

Page 40

36

_____________________________________________________________________________________________

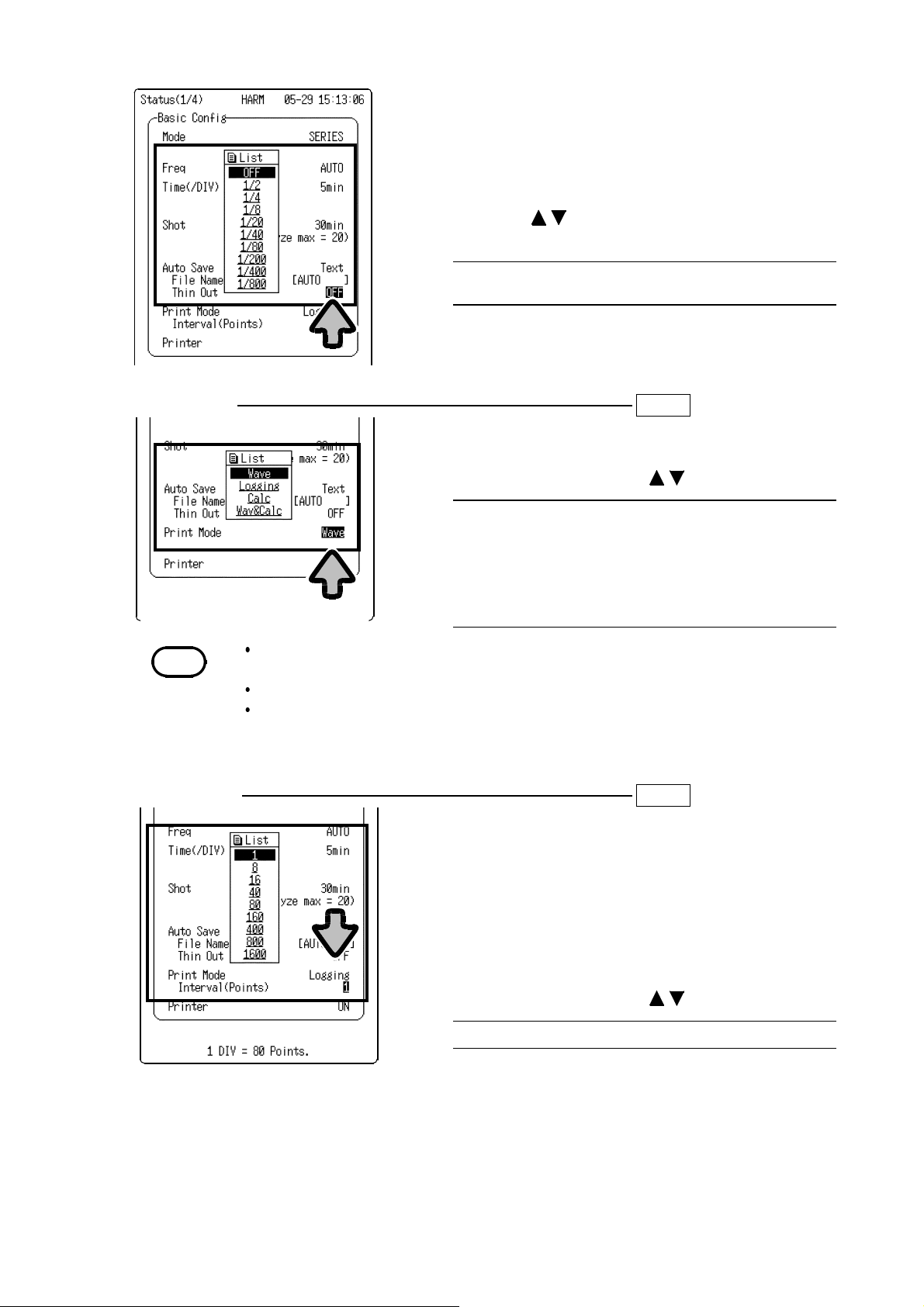

(3) Time-axis range SET >>STATUS(1/4)

This item is used to set the time per division on the

time axis (one grid on recording paper).

1. Move the flashing cursor to

Time (/DIV)

.

2. Select a setting using the buttons.

5, 10, 30 min/DIV, 1, 3, 6, 12 h/DIV

NOTE

The data interval is 1/80 of the time-axis range setting.

(4) Average processing SET >>STATUS(1/4)

This function cancels out unexpected phenomena by

obtaining an average of the analysis data.

A simple average of all data measured in a data

interval is recorded for each data interval.

1. Move the flashing cursor to

Smoothing

.

2. Select a setting using the buttons.

OFF, ON

NOTE

The number of data used to calculate the average depends on the time-axis range.

Time-axis range 5min 10 min 30 min 1h 3h 6h 12 h

No. of data Not

available

2 6 12 24 48 96

(5) Recording length SET >>STATUS(1/4)

This item is used to set the recording length

(recording time) of one measurement input

operation.

1. Move the flashing cursor to

Shot

.

2. Select a setting using the buttons.

______________________________________________________________________________________________

6.1 Basic Item Setting

Page 41

_____________________________________________________________________________________________

(

37

Relationship between time-axis range and recording length

(min: minutes/ h: hours/ d: days)

Time axis

No. of

analysis items

20 30

20 1 hour 3 hours 6 hours 12 hours 1day 3days 7days

20 3 hours 6 hours 12 hours 1 day 3days 7days 14 days

20 5 hours 10 hours 1 day 2days 7days 14 days 30 days

10 10 hours 20 hours 2days 4days 14 days 30 days 60 days

4 1 day 2days 6days 12 days 37 days 75 days 150 days

20 CONT*

5min 10 min 30 min 1h 3h 6h 12 h

1 hour 3 hours 6 hours 12 hours 1 day 3days

minutes

(5 hours)

CONT*

(10 hours)

CONT*

(30 hours)

CONT*

(2.5 days)

CONT*

(7.5 days)

CONT*

(15 days)

CONT*

(30 days)

(*) The last 60 divisions of analysis data are stored in memory. Figures in ( ) indicate recording time

lengths.

NOTE

When the recording length is set to "CONT," measurement continues until the

STOP button is pressed.

When the recording length is set to "CONT," waveforms for the last 60 divisions

includingthe screen currentlydisplayed)are saved to memory.

(6) Auto save setting SET >>STATUS(1/4)

As soon as waveform analysis is complete, data can

be saved automatically to a PC card. Data files are

stored in the current directory set in the file screen.

Selection of data format for auto save

1. Move the flashing cursor to

Auto Save

.

2. Using the buttons, select the format for data

to be stored by the auto save function.

OFF

Binary

Text

Auto save function is turned off.

Data is saved in binary format (for use in

8807-51/8808-51 only).

Data is saved in text format (for use on a

PC).(Data saved in text format cannot be

loaded by the 8807-51 or 8808-51. Data

for all set analysis items (max. 20 items) is

saved.)

Entering name of file to be auto-saved

If a file name is entered, the auto save function

stores the file under that name. If files are saved in

succession, they are assigned individual numbers.

If no file name is entered, files are named

"AUTO.***," "AUTO0001.***", and so forth.

For information on the file input method, refer to

Section 9.1 "Input of File Name."

______________________________________________________________________________________________

6.1 Basic Item Setting

Page 42

38

_____________________________________________________________________________________________

Selective save setting

When "Text" is set for the data saving format, data

can be saved at selected intervals.

The selective save function stores data at selected

intervals. No other data is included in the data file.

1. Move the flashing cursor to

Thin out

.

2. Using the buttons, select the interval for

saving data.

OFF, x1/2, x1/4, x1/8, x1/20, x1/40, x1/80, x1/200,

x1/400, x1/800

(7) Printing types SET >>STATUS(1/4)

This item is used to select the printer output type.

1. Move the flashing cursor to

Print Mode

.

2. Select a setting using the buttons.

Outputs waveform.

Outputs numeric values.

Outputs calculation values.

Outputs waveform and

calculation values.

NOTE

Wave

Logging

Calc

Wav & Calc

The calculation operation determines the maximum value and average value of

measurement data collected over the entire recording length.

The calculation operation is performed only for analysis displayed on the screen.

When cursors are used, calculations are performed for the section located between

the cursors.

(8) Printing interval SET >>STATUS(1/4)

When "Logging" is selected as the print type in step

7, this item allows the setting of the interval of data

to be printed.

The selective printing function prints data at

selected intervals.

The number of points per one division of the record

is 80.

1. Move the flashing cursor to

Interval (Points)

.

2. Select a setting using the buttons.

1, 8, 16, 40, 80, 160, 400, 800, 1600

______________________________________________________________________________________________

6.1 Basic Item Setting

Page 43

_____________________________________________________________________________________________

39

(9) Printer setting SET >>STATUS(1/4)

Measurements can be printed simultaneously as

analysis is being carried out.

1. Move the flashing cursor to

Printer

.

2. Select a setting using the buttons.

OFF

ON

Does not print measurements in real time.

Prints measurements as data is input.

2. Settings on Measurement Screen

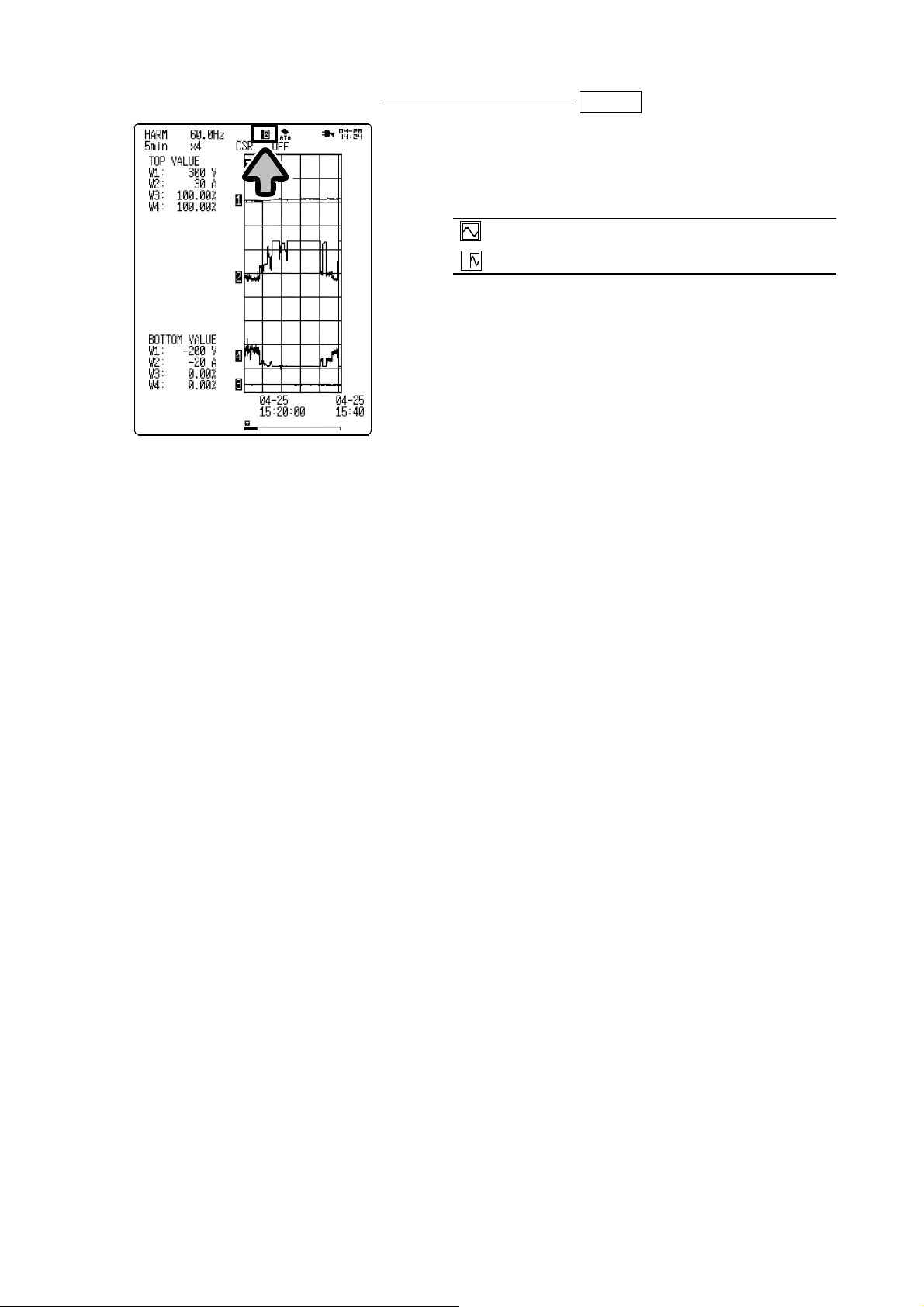

(1) Time-axis range magnification/compression DISP >>Waveform display

The magnification/compression rate can be set for

the time axis in the waveform screen.

A magnified display of waveforms allows detailed

examination of results.

A compressed display of waveforms makes it easier

to see overall changes.

Waveform magnification/compression uses the left

edge of the screen as the stationary point.

1. Move the flashing cursor to the location

indicated in the diagram.

2. Select a setting using the buttons.

x4, x2, x1, x1/2, x1/4, x1/6, x1/12, x1/24, x1/48

x4

x1/4

______________________________________________________________________________________________

6.1 Basic Item Setting

Page 44

40

_____________________________________________________________________________________________

(2) Waveform display range setting DISP >>Waveform display

You can select the display size of the waveform

input screen. When the multi-screen setting is

selected, the upper and lower limit values for the

display of the selected analysis item are indicated.

Displays measurement screen on full screen.

Displays measurement screen on sub-screen.

Upper and lower limit values for four channels (two

channels with 8807-51) are displayed on the screen.

______________________________________________________________________________________________

6.1 Basic Item Setting

Page 45

_____________________________________________________________________________________________

41

6.2 Analysis Item Setting

In time-series analysis mode, a maximum of 20 items from the following 13

types can be analyzed for harmonic waves of all degrees simultaneously.

Harmonic wave rms value, harmonic wave content ratio, harmonic wave

phase angle, total rms value, total distortion-F, total distortion-R, active

power of each degree, power content ratio, power phase angle, active power,

apparent power, reactive power, and power factor

(For calculation methods, refer to Section 5.1.)

1. Settings in Analysis Item Screen

(1) Analysis type setting SET >>Analyze

This screen is used to select the analysis to be

performed.

1. Move the flashing cursor to an analysis item.

2. Select a setting using the buttons.

NOTE

The following conditions must be met to

measure active power of each degree, power

content ratio of each degree, power phase angle

of each degree, active power, apparent power,

reactive power, and power factor.

1. Odd-numbered channels are set to receive

voltage waveforms, while even-numbered

channels are set for current waveforms.

2. The 9018, 9132, or general-purpose clamp is

selected for current measurement.

If the above conditions are not met for the

measurement of power values, one of the

following warning messages is displayed when

measurement starts, and measurement then stops.

Warning 633: Set CH1=Volt, CH2=Current.

(for

8807-51).

Warning 634: Set CH1,CH3=Volt, CH2,CH4=

Current.

Warning 635: 3283,3284,3285 can't analyze

power.

(for 8808-51).

(for both 8807-51 and 8808-51).

RMS

RATIO

PHASE

T-RMS

THD-F

THD-R

POWER

P-RATIO

P-PHASE

WATT

VA

var

P-FACTOR

Rms value of harmonic wave component

of each degree

Content ratio of harmonic wave

component of each degree in the

fundamental wave

Phase deviation of harmonic wave

component of each degree relative to the

fundamental wave

Sum of rms values of all harmonic wave

components (overall rms value)

Percentage of all harmonic waves in

fundamental wave

Percentage of all harmonic waves in total

rms value

Active power value of harmonic wave

component of each degree

Active power content ratio of harmonic

wave component of each degree in active

power of the fundamental wave

Phase angle of harmonic wave current of

each degree relative to the voltage

waveform

Active power containing all harmonic wave

components

Apparent power

Reactive power

Power factor

______________________________________________________________________________________________

6.2 Analysis Item Setting

Page 46

42

_____________________________________________________________________________________________

(2) Analysis channel setting SET >>Analyze

You can select the channel to be analyzed.

1. Move the flashing cursor toCH.

2. Select a setting using the buttons.

8807-51

8808-51

CH1/CH2

CH1/CH2/CH3/CH4

For POWER, P-RATIO, P-PHASE, WATT, VA,

var, and P-FACTOR, data for the system containing

the selected channel is analyzed.

(3) Setting Degree of analysis SET >>Analyze

When harmonic wave rms value, harmonic wave

content ratio, harmonic wave phase angle, active

power of each degree, power content ratio of each

degree, and power phase angle of each degree are

selected, this item is used to select the degree of

harmonic wave to be analyzed.

1. Move the flashing cursor to theNsection of an

analysis item.

2. Select a setting using the buttons.

1to40

(4) Result screen display setting SET >>Analyze

A maximum of four analysis result phenomena can

be displayed on the screen and printed. Waveforms

to be displayed are set in W1 through W4.

1. Move the flashing cursor to

in the display

No

item section.

2. Select a setting using the buttons.

OFF

1-20

______________________________________________________________________________________________

6.2 Analysis Item Setting

Hides analysis results.

Used to select analysis result to be

displayed.

Page 47

_____________________________________________________________________________________________

43

(5) Waveform display color setting SET >>Analyze

Select the color of the displayed waveforms.

1. Move the flashing cursor to

in the display

Col

item section.

2. Select a setting using the buttons.

NOTE

When the 8992 PRINTER UNIT is used to print a waveform, the three print

densities are used to represent the 6 selected waveform display colors.

Theprint densitysettinghas no effect for real-timeprinting.

(6) Analysis result magnification/compression

Magnify or compress the display of analysis results.

A magnified display allows detailed examination of

the results.

1. Move the flashing cursor to

item section.

2. Select a setting using the buttons.

LOG, x1/2, x1, x2, x5, x10, x20, x50, x100

List

OFF

Red/Green

Yellow/Light

Blue

Blue/Gray

Hides waveform.

Prints waveform at

standard print density.

Prints waveform in low

print density.

Prints waveform in high

print density.

Zoom

in the display

x1 xLOG

______________________________________________________________________________________________

6.2 Analysis Item Setting

Page 48

44

_____________________________________________________________________________________________

(7) Zero position

This item is used to set the zero position of an

analysis result.

1. Move the flashing cursor to

in the display

Posn

item section.

2. Select a setting using the buttons.