Page 1

Instruction Manual

8807-01

8808-01

8807-51

8808-51

MEMORY HiCORDER

January 2009 Revised edition 10 8807A981-10 09-01H

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes

iv

Notes on Use viii

Chapter Summary xii

Chapter 1 Product Overview 1

1.1 Major Features 1

1.2 Identification of Controls and Indicators

Chapter 2 Installation and Preparation 7

2.1 Installation of the Product 7

2.2 Power Supply and Ground Connection 8

2.2.1 Connecting the AC Adapter 8

2.2.2 Installing the Batteries/Battery Pack

2.3 Power On/Off 11

2.4 Connecting the Connection Cord 12

2.5 Connecting the 9322 DIFFERENTIAL

PROBE 13

2.6 Connecting the Logic Probe

2.7 Connecting the 9018-10, 9132-10 CLAMP

ON PROBE

2.8 Connecting the 8992 PRINTER UNIT

2.8.1 Loading Recoding Paper 19

2.8.2 Care of Recording Paper

2.9 Attaching the Strap 22

2.10 Notes on Measurement 23

16

17

18

21

3

9

Page 4

Chapter 3 Basic Button Operation 25

3.1 Screen Display Buttons 26

3.2 Printer Buttons

26

3.3 Item Setting Buttons 27

3.4 Waveform Scrolling Buttons

27

3.5 Input Operation 28

3.6 Measurement Start and Stop

29

3.7 Other Buttons Operation 29

3.8 Key Lock Function

3.9 Changing the Screen

30

31

Chapter 4 Memory Recorder Function 33

4.1 Overview of the Memory Recorder Function 33

4.2 Operation Sequence (MEM)

4.3 Setting Items 36

4.3.1 Setting the Function Mode 36

4.3.2 Setting the Time Axis Range

4.3.3 Setting the Recording Length

4.3.4 Setting the Display Layout

4.3.5 Setting the Auto Save Function

4.3.6 Setting the Print Mode

4.3.7 Setting the Auto Print Function

4.4 Using the X-Y Waveform Plots (MEM) 47

4.5 Waveform Screen Settings (MEM) 49

4.6 Auto Range Function

4.7 Start and Stop Operation (MEM) 51

4.8 Extended Status Screen Setup (MEM)

4.8.1 Channel Usage Settings 53

4.8.2 Setting the Roll Mode

4.8.3 Sequential Save Function

4.9 Numerical Calculation (Measurement) 64

34

37

38

40

42

45

46

50

52

54

55

Page 5

Chapter 5 Recorder Function 71

5.1 Overview of the Recorder Function 71

5.2 Operation Sequence (REC)

72

5.3 Setting Items 74

5.3.1 Setting the Function Mode 74

5.3.2 Setting the Time Axis Range

5.3.3 Setting the Recording Length

5.3.4 Setting the Display Layout

5.3.5 Setting the Auto Save Function

5.3.6 Setting the Print Mode

5.3.7 Setting the Printer Function

(Real Time Printing)

5.3.8 Setting the Display Clear Function

(X-Y only)

75

76

78

80

83

84

85

5.4 Using the X-Y CONT Recorder 86

5.5 Waveform Screen Settings (REC) 88

5.6 Start and Stop Operation (REC)

89

Chapter 6 RMS Recorder Function 91

6.1 Overview of the RMS Recorder Function 91

6.2 Operation Sequence (RMS) 92

6.3 Setting Items

6.3.1 Setting the Function Mode 94

6.3.2 Setting the Time Axis Range

6.3.3 Setting the Recording Length

6.3.4 Setting the Frequency

6.3.5 Setting the Display Layout

6.3.6 Setting the Auto Save Function

6.3.7 Setting the Print Mode

6.3.8 Setting the Printer Function (Real Time

Printing)

6.3.9 Instantaneous Waveform Recording

6.4 Waveform Screen Settings (RMS) 111

6.5 Settings on the Channel Screen (RMS) 112

94

95

96

98

99

101

104

105

106

Page 6

6.5.1 Selecting the Recorder Function or RMS

Function 112

6.6 Start and Stop Operation (RMS) 113

Chapter 7 Input Channel Settings 115

7.1 Overview 115

7.2 Operation Sequence (Input Channel

Setting)

7.3 Setting the Channel Screen

7.3.1 Setting the Waveform Display Color 118

7.3.2 Setting the Waveform Display Graph

7.3.3 Setting the Voltage Axis Range

7.3.4 Setting the Input Coupling

7.3.5 Setting the Magnification/Compression

Ratio Along the Voltage Axis

7.3.6 Setting the Zero Position

7.3.7 Setting the Low-Pass Filter

7.3.8 Setting the Logic Inputs

116

118

119

120

121

123

124

126

127

7.4 Waveform Screen Input Settings 129

7.5 Scaling Function 130

Chapter 8 Trigger Functions 137

8.1 Overview of the Trigger Function 137

8.2 Operation Sequence (Trigger mode setting)

138

8.3 Trigger Mode 140

8.4 Pre-trigger

141

8.5 Trigger Timing (REC only) 143

8.6 Trigger Source AND/OR Linking

144

8.7 Manual Trigger 145

8.8 Internal Trigger

8.8.1 Level Trigger 147

8.8.2 Window-In Trigger

8.8.3 Window-Out Trigger

8.8.4 Voltage Drop Trigger

8.8.5 Waveform Detection Trigger

(Memory Only)

146

150

152

154

156

Page 7

8.8.6 Logic Trigger 160

8.8.7 Trigger Settings from the Waveform

Screen

163

8.9 Timer Trigger Function 164

8.10 External Trigger Function

166

8.11 Trigger Output Terminal 168

8.12 Input Level Monitor Function

170

Chapter 9 Waveform Screen Operation 171

9.1 Using the A/B Cursors 172

9.1.1 Using the Line Cursors (Vertical) 174

9.1.2 Using the Line Cursors (Horizontal)

9.1.3 Using the Trace Cursors

9.1.4 Using the Cursors on the X-Y Screen

175

176

177

9.2 Scrolling the Waveform 178

9.3 Magnification /co mpr e ssion Rat io Along the

Time Axis 179

9.4 DMM Function

180

9.5 Setting the Waveform Display Area 183

Chapter 10 System Settings 185

10.1 Environment Screen (SYSTEM) 186

10.1.1 START Button Activation 186

10.1.2 Start Backup

10.1.3 Grid Type

10.1.4 Time Value

10.1.5 Logic Recording Width

10.1.6 Backlight Saver

10.1.7 Backlight Brightness

10.1.8 Display Color

10.1.9 Language

10.1.10 Printer

187

188

189

190

191

192

193

194

195

10.2 Comment Screen (SYSTEM) 196

10.3 RS© Screen (SYSTEM) 197

10.3.1 Screen Copy Output Destination 197

10.3.2 RS-232C Settings

199

Page 8

10.4 Setting Screen 200

10.5 Initialize Screen 202

10.5.1 Setting the Clock 202

10.5.2 Clearing the Waveform Data

10.5.3 System Reset

10.5.4 Self-check

203

204

205

Chapter 11 Printout of Measurement Data 207

11.1 Printout of Measurement Data Operating

Procedure

11.2 Environment Screen (Printer)

11.2.1 Grid Type 210

11.2.2 Time Value

11.2.3 List&Gauge

11.2.4 Channel Marker

11.2.5 Printer Density

11.3 Comment Screen (Printer) 215

11.3.1 Title Comment Entry 215

11.3.2 Analog and Logic Comment Entry

11.3.3 Text Entry Procedure

11.4 Setting the Status Screen (printout) 223

11.5 Setting the Channel Screen (printout)

11.6 Printing Procedure 225

11.6.1 Manual Print 225

11.6.2 Auto Print (MEM)

11.6.3 Real Time Print (REC, RMS)

11.6.4 Partial Print

11.6.5 Screen Copy

11.6.6 List Print

11.6.7 Report Print

11.7 Example of Printer Output 231

208

210

211

212

213

214

217

220

224

226

227

228

229

229

230

Chapter 12 Storing the Measurement Data 235

12.1 PC Card 236

12.2 Using the PC Card Slot 238

Page 9

12.3 Settings on the File Screen 240

12.3.1 Loading the Data 240

12.3.2 Saving Measurement and Setting Data

12.3.3 Deleting the Files and Directories

12.3.4 Creating the Directory

12.3.5 Initializing

12.3.6 Changing the Names of Fi les and

Directories

243

251

253

256

257

12.4 Settings on the File Configuration Screen

(Application Functions)

12.4.1 Sorting Files 259

12.4.2 Self-check

259

261

12.5 Text File Internal Format 262

Chapter 13 Communication Function 265

13.1 Connecting the RS-232C Cable 266

13.2 Setting the RS-232C Interface 267

Chapter 14 Specifications 269

14.1 General Specifications 269

14.2 Trigger

14.2.1 Harmonic Wave Trigger 274

14.3 Memory Recorder Function 275

14.4 Recorder Function

14.5 RMS Recorder Function 277

14.6 Harmonic Wave Analysis Function

14.6.1 General Specifications 278

14.6.2 Instantaneous Analysis Functions

14.6.3 Time Series Analysis Functions

14.6.4 Additional Functions

14.7 Communication Function 283

14.8 Others

273

276

278

279

280

282

284

Chapter 15 Logic and Analog Inputs 287

15.1 Logic Inputs 287

Page 10

15.2 Analog Inputs 290

Chapter 16 Maintenance and Service 293

16.1 Changing the Battery 293

16.2 9447 BATTERY PACK 295

16.2.1 Battery Charging with the MEMORY

16.2.2 Battery Charging with the 9643

HiCORDER 296

CHARGE STAND

297

16.3 Removing the Battery Before Discarding

the Product

16.4 Cleaning the Printer Head

298

299

16.5 Troubleshooting 300

16.6 Cleaning of the Product

302

Appendix APPENDIX 1

Appendix 1 Messages APPENDIX 1

Appendix 2 Reference APP ENDIX 4

Appendix 3 WaveViewer (Wv)

Appendix 3.1 Starting the Waveform

Viewer APPENDIX 11

Appendix 3.2 Waveform Viewer

Menus

Appendix 3.3 Using the Waveform

Viewer

Appendix 3.4 Conversion to CSV

Format

Appendix 3.5 Converting Multiple Waveform Files

into CSV Files

APPENDIX 10

APPENDIX 12

APPENDIX 14

APPENDIX 18

APPENDIX 20

Index INDEX 1

Page 11

_____________________________________________________________________

Introduction

Thank you for purchasing the HIOKI "8807-01, 8808-01,

8807-51, 8808-51 MEMORY HiCORDER." To obtain

maximum performance from the product, please read this

manual first, and keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully to ensure

that no damage occurred during sh ipping. In particular,

check the panel switches, and connectors. If damage is

evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Accessories

i

Instruction Manual

Measurement Guide

Application Disk (CD)

LR6 alkaline batteries

Alkaline battery box

Strap

NOTE

______________________________________________________________

The connector cable is not included with the product.

Use optional 9197, 9198, or 9217 CONNECTION CORD.

Maximum input voltage:

9197: 500 V AC/DC

9198: 300 V AC/DC

9217: 300 V AC/DC

1

1

1

6

1

1

Inspection

Page 12

ii

_____________________________________________________________________

Options

9418-15 AC ADAPTER

(SA145 A-1240V- 6, SI NO AM ERI CAN )

(universal 100 to 240 V AC, 12 V DC output)

9197 CONNECTION CORD

(maximum input voltage: 500 V AC/DC)

9198 CONNECTION CORD

(maximum input voltage: 300 V AC/DC)

9199 CONVERSION ADAPTOR (BNC-Banana female)

9217 CONNECTION CORD (BNC-BNC)

(maximum input voltage: 300 V AC/DC)

9322 DIFFERENTIAL PROBE

(maximum input voltage: CAT ll: 1000 V AC, 2000 V

DC, CAT lll:600VAC/DC)

9234 RECORDING PAPER (18 m/59.06feet, 112 mm/4.41"

width)

9447 BATTERY PACK (7.2 V/2450 mAh)

9643 CHARGE STAND (for Model 9447 BATTERY PACK)

8992 PRINTER UNIT (printing width 100 mm/3.94")

9320-01 LOGIC PROBE

(4-channel digital, contact signal on/off detection)

9321-01 LOGIC PROBE

(4 insulated channels, AC/DC voltage on/off detection)

*9323 CONVERSION CABLE (for connecting 9320, 9321)

9331 WAVE PROCESSOR (Operation software for

personal computer)

9335 WAVE PROCESSOR (Operation software for

personal computer)

9391 CARRYI NG CASE

9612 RS-232C CABLE (mini DIN 9-pin Dsub 9-pin)

*9270CLAMPONSENSOR(20A,5Hzto50kHz)

*9271 CLAMP ON SENSOR (200 A, 5 Hz to 50 kHz)

*9272 CLAMP ON SENSOR (20 A/200 A, 5 Hz to 10 kHz)

9277 UNIVERSAL CLAMP ON CT (20 A, DC to 100 kHz)

9278 UNIVERSAL CLAMP ON CT (200 A, DC to 100 kHz)

*9279UNIVERSALCLAMPONCT(500A,DCto20kHz)

*9555 SENSOR UNIT (used together with 9270 to 9272,

9277 to 9279)

9018-10 CLAMP ON PROBE (10 A to 500 A, 40 Hz to 3 kHz)

9132-10 CLAMP ON PROBE (20 A to 1000 A, 40 Hz to 1 kHz)

*9303 PT

*220H PAPER WINDER

______________________________________________________________

Inspection

Page 13

_____________________________________________________________________

iii

9626 PC CARD 32M

9627 PC CARD 64M

9726 PC CARD 128M

9727 PC CARD 256M

9728 PC CARD 512M

9729 PC CARD 1G

*: no CE marking

NOTE

The 9270 to 9272 CLAMP ON SENSORs and 9277 to 9279

UNIVERSAL CLAMP ON CTs are designed for use only with

the 9555 SENSOR UNIT, and cannot be used alone.

______________________________________________________________

Inspection

Page 14

iv

_____________________________________________________________________

Safety Notes

This product is designed to conform to IEC 61010

WARNING

Safety Symbols

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling during

use could result in injury or death, as well as damage

to the product. Be certain that you understand the

instructions and precautions in the manual before use.

We disclaim any responsibility for accidents or injuries

not resulting directly from product defects.

This manual contains information and warnings essential

for safe operation of the product and for maintaining it in

safe operating condition. Before using the product, be sure

to carefully read the following safety notes.

The symbol printed on the product indicates that the

user should refer to a corresponding topic in the

manual (marked with the

relevant function.

In the manual, the symbol indicates particularly

important information that the user should read before

using the product.

symbol) before using the

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates both DC (Direct Current) and AC (Alternating

Current).

Indicates DC (Direct Current).

______________________________________________________________

Safety Notes

Page 15

_____________________________________________________________________

R

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Indicates that incorrect operation presents an extreme

v

DANGE

WARNING

CAUTION

NOTE

hazard that could result in serious injury or death to

the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

product.

Advisory items related to performance or correct

operation of the product.

______________________________________________________________

Safety Notes

Page 16

vi

_____________________________________________________________________

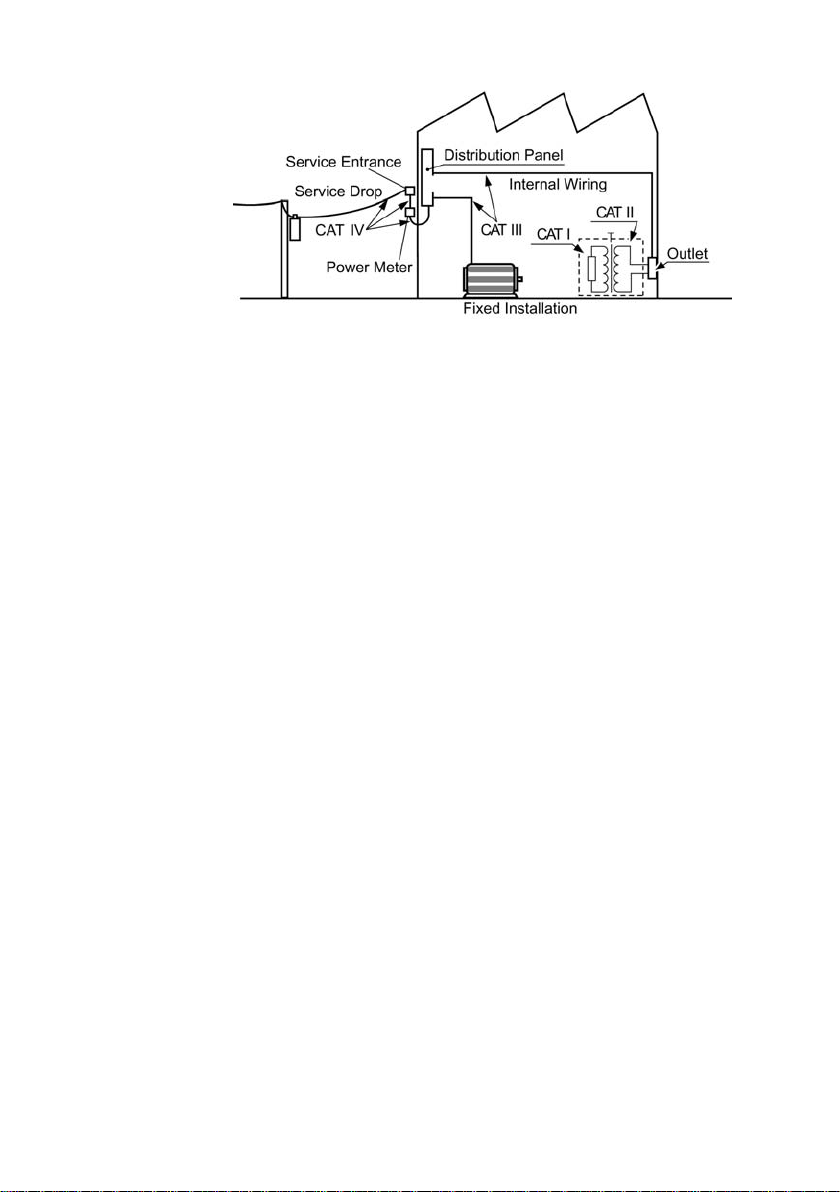

Measurement categories (Overvoltage categories)

This instrument complies with CAT II safety requirements.

To ensure safe operation of measurement instruments, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT I to CAT IV, and called

measurement categories. These are defined as follows.

CAT I

CAT II

CAT III

CAT IV

Secondary electrical circuits connected to an

AC electrical outlet through a transformer or

similar device.

Primary electrical circuits in equipment

connected to an AC electrical outlet by a power

cord (portable tools, household appliances, etc.)

Primary electrical circuits of heavy equipment

(fixed installations) connected directly to the

distribution panel, and feeders from the

distribution panel to outlets.

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution

panel).

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III environments can

endure greater momentary energy tha n a device designed for

CAT II.

Using a measurement instrument in an environment

designated with a higher-numbered category than that for

which the instrument is rated could result in a severe

accident, and must be carefully avoided.

Never use a CAT I measuring instrument in CAT II, III, or

IV environments.

The measurement categories comply with the Overvoltage

Categories of the IEC60664 Standards.

______________________________________________________________

Safety Notes

Page 17

_____________________________________________________________________

vii

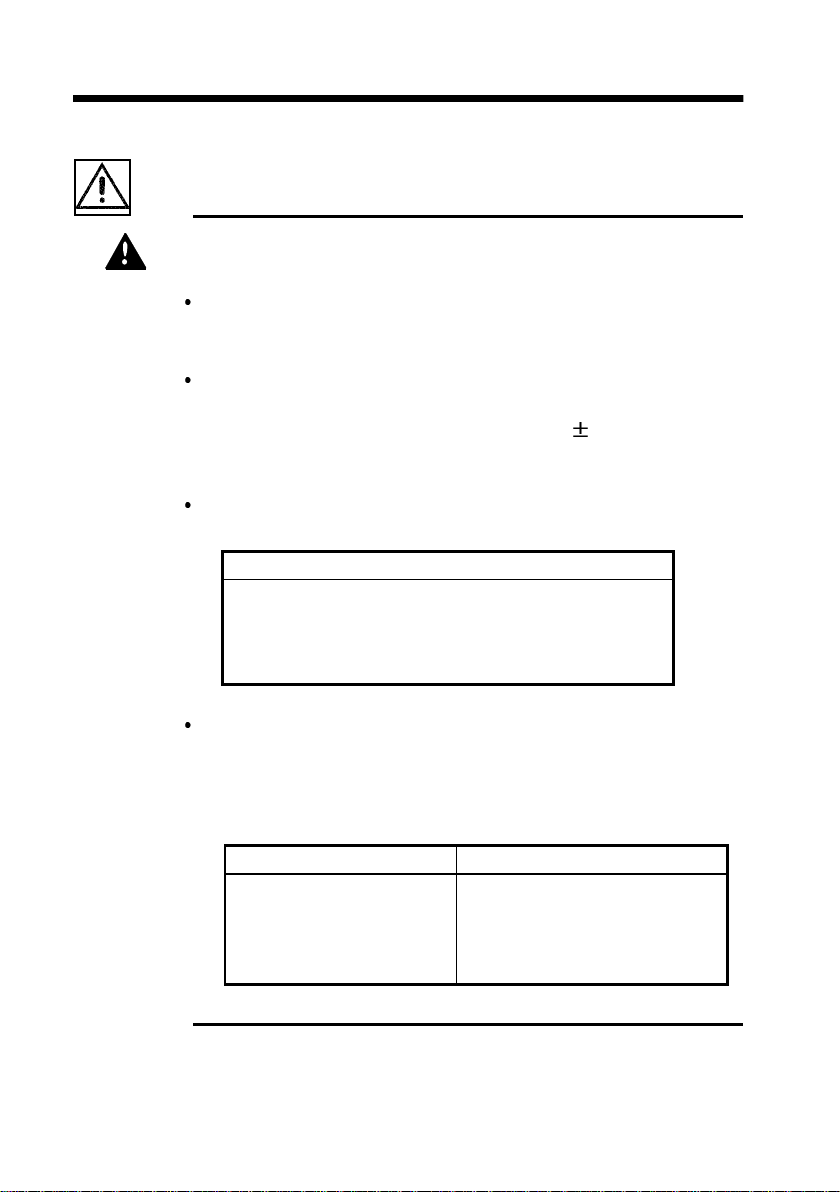

Accuracy

We define measurement tolerances in terms of f.s. (full

scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or the full length of the

scale.

This is usually the maximum value of the currently selected

range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the

measuring product.

dgt. (resolution)

The smallest displayable unit on a digital measuring

product, i.e., the input value that causes the digital display

to show a "1".

______________________________________________________________

Safety Notes

Page 18

viii

R

_____________________________________________________________________

Notes on Use

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

To avoid the risk of electric shock and damage to the

DANGE

product

Do not apply more than 450 V AC or DC between the

analog inputs and product, or between the analog

inputs.

Use only the specified Model 9418-15 AC ADAPTER

(SA145A-1240V-6, SINO AMERICAN). AC adapter input

voltage range is 100 to 240 V AC (with

10% stability)

at 50/60 Hz. To avoid electrical hazards and damage to

the product, do not apply voltage outside of this range.

Terminal inputs should never exceed the limits

indicated below.

Input/output terminals Maximum input voltage

Analog input 450 V AC/DC

EXT TRIG -5 V to +10 V

TRIG OUT

-20Vto+30V

500 mA max, 200 mW max

The maximum voltage applied to the probe and cables

connecting to the analog input of the product must

never exceed the limits in the following table.

Notwithstanding these limits, the voltage at the analog

input must not exceed 450V AC or DC.

Maximum input voltage

9197 CONNECTION CORD

9217 CONNECTION CORD

9322DIFFERENTIAL

PROBE

500 V AC/DC

300 V AC/DC

1000 V AC, 2000 V DC (CAT ll)

600 V AC/ DC (CAT lll)

______________________________________________________________

Notes on Use

Page 19

_____________________________________________________________________

W

When using the batteries, use LR6 alkaline batteries

ix

ARNING

or 9447 BATTERY PACK. In this case, do not use

new batteries with old ones. Also, do not mix

batteries of different types. We take no responsibility

for an accident using the batteries and battery packs

which are not specified.

The logic inputs are not floating. Although two sets

of logic probes can be connected, they all have a

common ground with the main product.

CAUTION

Use only the specified input cord. Using a non-specified

cable may result in incorrect measurements due to poor

connection or other reasons.

To avoid damage to the product, do not input a

voltage/current exceeding the rated maximum to the

external input terminals.

This product should be installed and operated indoors only,

between 5 and 40

Do not store or use the product where it could be exposed

to direct sunlight, high temperature or humidity, or

condensation. Under such conditions, the product may be

damaged and insulation may deteriorate so that it no longer

meets specifications.

Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged.

This product is not designed to be entirely water- or dustproof. To avoid damage, do not use it in a wet or dusty

environment.

Preliminary Checks

Before using the product the first time, verify that it

operates normally to ensure that the no damage occurred

during storage or shipping. If you find any damage, contact

your dealer or Hioki representative.

and 35 to 80%RH.

______________________________________________________________

Notes on Use

Page 20

x

_____________________________________________________________________

(1) Before Powering On

Check that the 9418-15 AC ADAPTER (SA145A-1240V-6,

SINO AMERICAN), 9447 BATTERY PACK, or LR6

alkaline batteries are correctly fitted.

When using an AC adapter and if properly grounded three-

pin outlet is available, then using the three-core power cord

provides automatic grounding.

(2) Using the Printer

Avoid using the printer in hot, h umid environments, as this

can greatly reduce printer life.

Printing is not possible if the recording paper is loaded

wrong-side up.

(3) Recording Paper

This product uses a thermal printer. The recording paper

supplied has characteristics finely tuned for use with the

printer.

Using recording paper of a different specification may not

only result in impaired printing quality, but even prevent

the printer from operating. Always use the 9234

RECORDING PAPER.

(4) Storage

Always place the product in the head-up condition when it

is stored for an extended period of time. If the product is

left idle for a long time with the head pressing on the roller,

the roller may be deformed, resulting in uneven prin ting.

(5) Shipment

Use the original packing materials when reshipping the

product, if possible.

______________________________________________________________

Notes on Use

Page 21

_____________________________________________________________________

Handling the CD

xi

CAUTION

Always hold the disc by the edges, so as not to make

fingerprints on the disc or scratch the printing.

Never touch the recorded side of the disc. Do not place the

disc directly on anything hard.

Do not wet the disc with volatile alcohol or water, as there

is a possibility of the label printing disappearing.

To write on the disc label surface, use a spirit-based felt

pen. Do not use a ball-point pen or hard-tipped pen,

because there is a danger of scratching the surface and

corrupting the data. Do not use adhesive labels.

Do not expose the disc directly to the sun's rays, or keep it

in conditions of high temperature or humidity, as there is a

danger of warping, with consequent loss of data.

To remove dirt, dust, or fingerprints from the disc, wipe with

a dry cloth, or use a CD cleaner. Always wipe radially from

the inside to the outside, and do no wipe with circular

movements. Never use abrasives or solvent cleaners.

Hioki shall not be held liable for any problems with a

computer system that arises from the use of this CD, or for

any problem related to the purchase of a Hioki product.

______________________________________________________________

Notes on Use

Page 22

xii

_____________________________________________________________________

Chapter Summary

This manual consists of the following chapters.

"Introduction", "Safety Notes", "Notes on Use" describe

precautions on use, overview, and features of this product.

Be sure to read them all. Next, check Chapter 1 to 3 and

the product to confirm your understanding of the function.

For details on the harmonic wave analysis function of the

8807-51, 8808 -51, refer to the supplement guide "Harmonic

Wave Analysis Function."

Chapter 1 Product Overview

Contains an overview of the product and its features.

Chapter 2 Installation and Preparation

Explains how to set the product up for measurement.

Chapter 3 Basic Button Operation

Explains how to operate the buttons for carrying out basic

measurement functions.

Chapter 4 Memory Recorder Function

Explains how to use the Memory Recorder functions of the

product.

Chapter 5 Recorder Function

Explains how to use the Recorder functions of the product.

Chapter 6 RMS Recorder Function

Explains how to use the RMS Recorder functions of the

product.

Chapter 7 Input Channel Settings

Explains how to make settings using the channel setting

screen.

Chapter 8 Trigger Functions

Explains how to use the Trigger functions of the product.

______________________________________________________________

Chapter Summary

Page 23

_____________________________________________________________________

xiii

Chapter 9 Waveform Screen Operation

Explains how to perform waveform scrolling, how to use

the A/B cursors and so.

Chapter 10 System Settings

Explains how to make settings using the system setting

screen.

Chapter 11 Printout of Measurement Data

Explains how to print out measurement data and how to

read printed charts.

Chapter 12 Storing the Measurement Data

Describes how to save, load and delete measurement data

and settings using a PC Card.

Chapter 13 RS-232C Interface

Describes RS-232C communications.

Chapter 14 Specifications

Contains general specifications and detailed function

specifications.

Chapter 15 Logic and Analog Inputs

Contains specifications and precautions for logic input and

analog inputs.

Chapter 16 Maintenance and Service

Describes maintenance procedures.

Appendix Contains important supplemental material such as error

messages and other information pertaining to product

operation.

______________________________________________________________

Chapter Summary

Page 24

xiv

_____________________________________________________________________

______________________________________________________________

Chapter Summary

Page 25

_____________________________________________________________________

1

Chapter 1

Product Overview

1

1

2

2

3

3

1.1 Major Features

(1) Easy-to-see color LCD

The 5.7-inch color LCD display has a resolution of 320 x

240 dots.

(2) Three functions support a variety of measurements

Memory recorder with up to 2.5 μs (all channels

simultaneously) sampling period (400 kS/s maximum

sampling rate).

Real-time recording capability to paper in Recorder function

RMS recorder function for recording rms values of AC

power supply lines and DC sources.

(3) Powerful trigger functions

Level trigger, window-in trigger, window-out trigger,

voltage drop trigger, waveform detection trigger, pattern

trigger (logic)

(4) Thermal printing with 8992 optional printer

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

(5) Scaling function

By setting the physical amount and the product to be used

for 1 V input, the measurement result can be converted into

any desired scale.

Two of the HIOKI CLAMP ON PROBEs, the 9018 and the

9132, feature a clamp mode that allows electric current

values to be read directly.

______________________________________________________________

1.1 Major Features

13

13

14

14

15

15

APP

APP

IND

IND

Page 26

2

_____________________________________________________________________

(6) Four isolated analog input channels (8807-01: 2

channels)

The analog inputs are floating, and so each input can be

connected to its own independent potentials.

(7) PC Card Slot provided

Measurement data and settings can be saved to a PC Card.

(8) Equipped with RS-232C standard interface

(9) Dual-language capability

Display language is switchable between Japanese and

English.

(10) Harmonic wave analysis function (8807-51, 8808-51

only)

Harmonic wave analysis function that is a powerful tool for

power supply analysis.

______________________________________________________________

1.1 Major Features

Page 27

_____________________________________________________________________

3

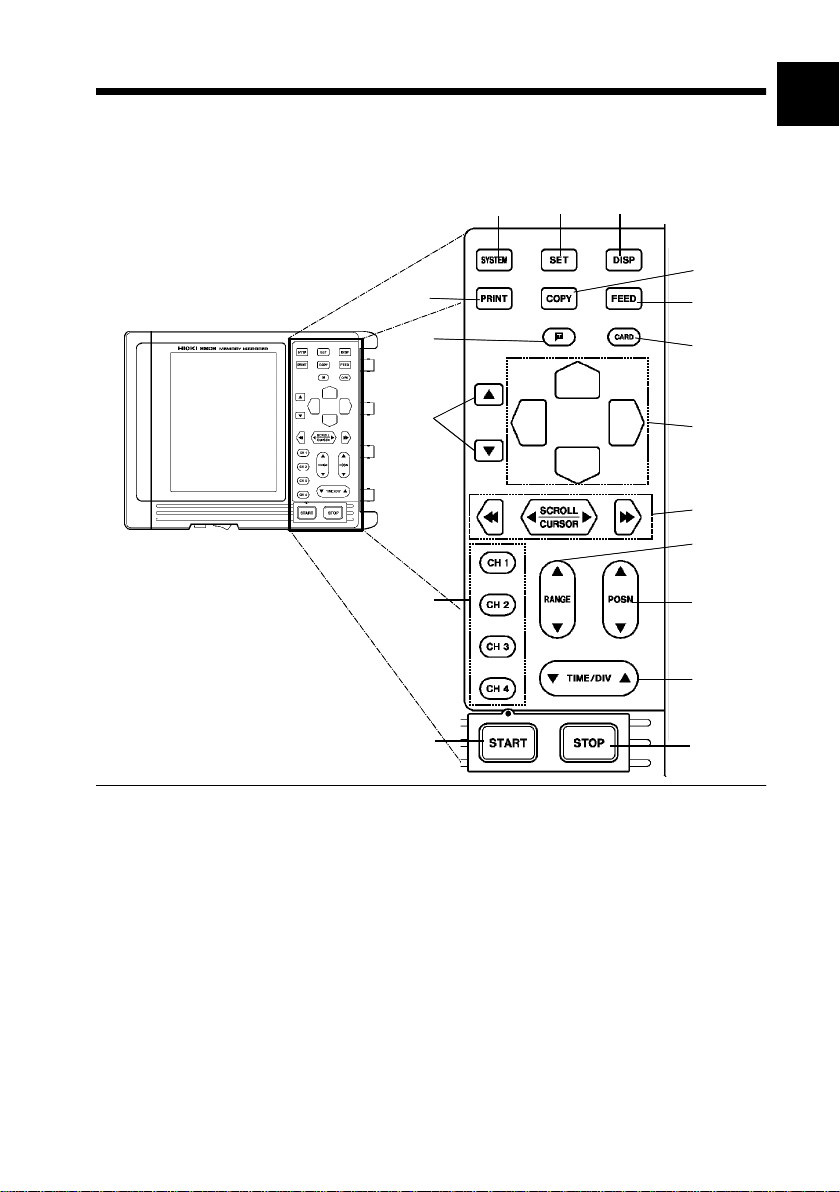

1.2 Identification of Controls and

1

Indicators

12

16

2

123

3

5

4

7

6

8

4

5

9

10

11

13

6

7

8

14

9

15

17

10

11

SYSTEM

1.

SET

2.

DISP

3.

(Waveform display)

PRINT

4.

COPY

5.

______________________________________________________________

button

button

button

button

button

Selects the Environment, Comment, RS©,

setting, and Initialization Screens.

Selects the Status, Channel and Trigger Screens.

Selects the Waveform Screen.

Pressing this button from the Waveform Screen

switches to the DMM Screen.

Serves to print out stored waveforms.

Serves to print out a copy of the current screen

display.

1.2 Identification of Controls and Indicators

12

13

14

15

APP

IND

Page 28

4

_____________________________________________________________________

FEED

6.

button

7. button

(Manual trigger)

CARD

8.

button

9. buttons

10. buttons

scroll/cursor

11.

,

CH1-CH4

12.

buttons

buttons

RANGE

13.

POSN

14.

TIME/DIV

15.

button

button

button

Causes the printer paper to advance for as long as

the button is pressed.

Press this button to activate a trigger event when

manual triggering is enabled.

Using PC card:

Causes the display to show the File Screen.

Using Fax/modem card:

Causes the display to show the FAX&Modem

Screen.

Select and accept settings here.

Moves the flashing cursor in the four directions.

Moves the A/B cursors and scrolls the waveforms.

Input and trigger settings can be made by

displaying the Settings window on the Waveform

Screen.

Sets the voltage axis range for the channel.

Sets the zero position for the channel.

Sets the input signal capture speed. On the

Waveform Screen, press both sides of the

TIME/DIV button for at least 2 seconds to activate

auto-ranging. (Memory recorder only)

16.

START

button

Initiates the measurement and analysis. During

measurement, the LED above the button is lit.

STOP

17.

______________________________________________________________

1.2 Identification of Controls and Indicators

button

Stops measurement and analysis.

Page 29

_____________________________________________________________________

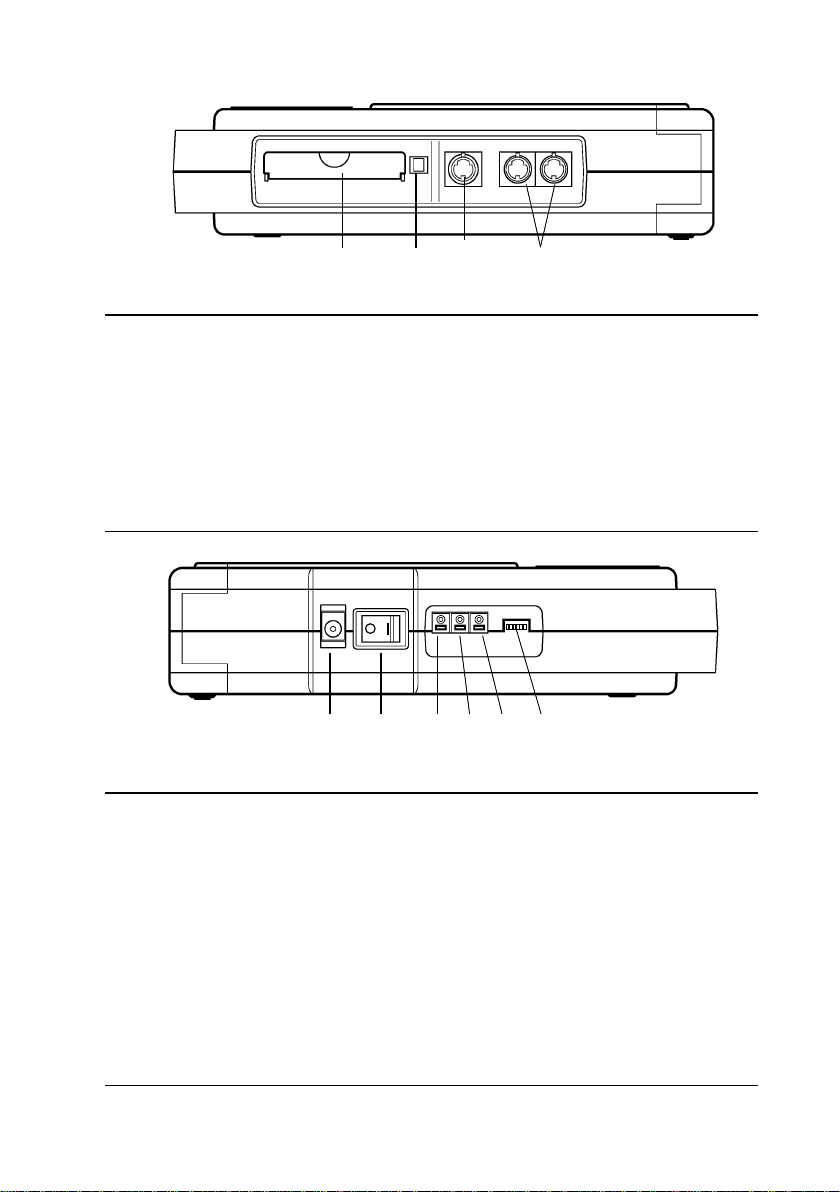

1234

Upper Side View

5

1. PC card slot

2. Eject button

3. RS-232C connecting

Insert the PC card.

Press this button to eject a PC card.

Connect the 9612 RS-232C CABLE.

terminal

4. Logic probe

connectors

Input connector for the logic input

section, designed for the optional 9320-01

and 9321-01 LOGIC PROBEs.

12 3456

Lower Side View

1. AC adapter connecting terminal

2. Power switch

3. External trigger

terminal

(EXT TRIG)

(POWER)

Switches on or off the power supply.

External trigger source input.

(for the AC adapter specified by Hioki)

4. Trigger output

terminal

5. Ground terminal

(TRIG OUT)

(GND)

6. Contrast adjustment

Trigger signals are output.

Used together with the trigger terminal.

Adjusts screen contrast.

knob

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 30

6

_____________________________________________________________________

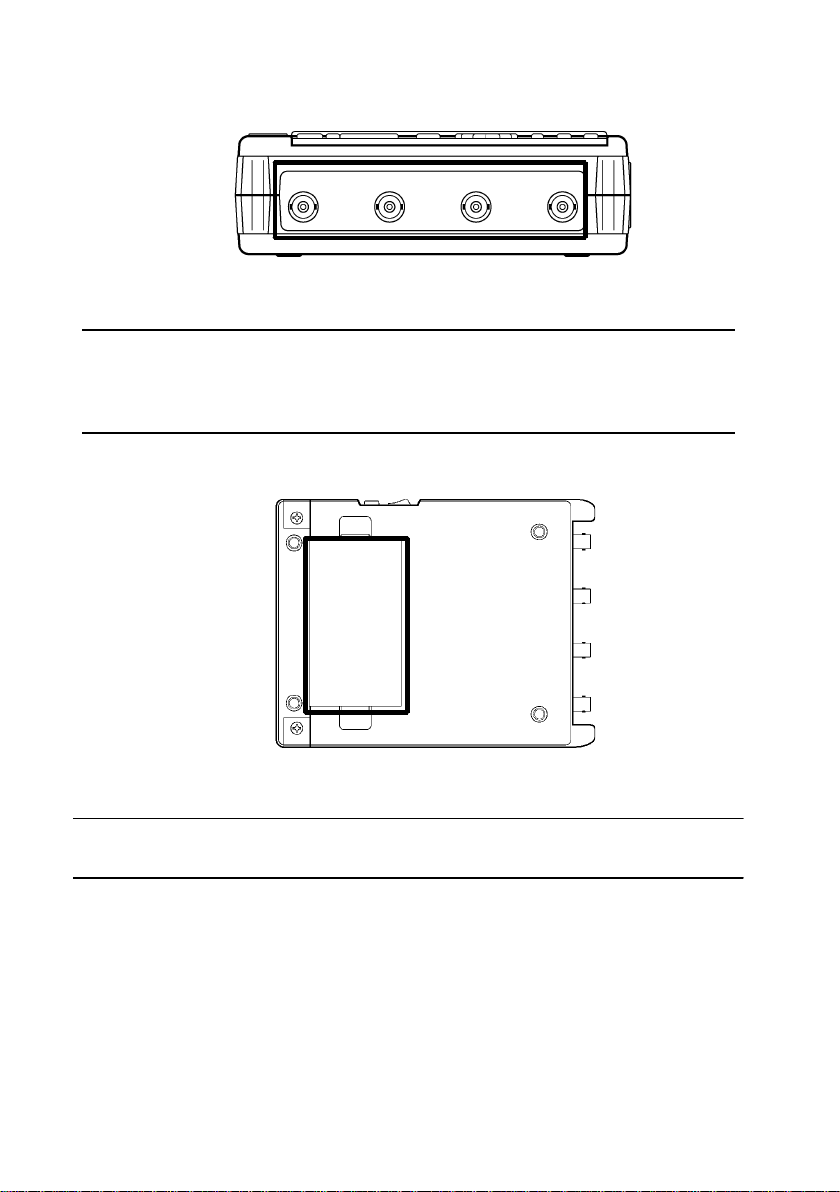

Analog input terminal

CH4 CH3 CH2

Right Side View

CH1

Input terminals for analog inputs, nonbalanced input type

(8808-01, 8808-51: 4-channel input, 880701, 8807-51: 2-channel input)

Bottom Side View

Battery compartment

Six LR6 alkaline batteries or the 9447

BATTERY PACK can be installed.

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 31

_____________________________________________________________________

7

Chapter 2

Installation and Preparation

1

2

3

2.1 Installation of the Product

Ambient conditions

Temperature

5to40

recommended for high-precision measurements.

Humidity

35 to 80%RH (no condensation); 5 0

(no condensation) recommended for high-precision

measurements.

Avoid the following locations:

Subject to direct sunlight.

Subject to high levels of dust, steam, or corrosive gases

(Avoid using the equipment in an environment containing

corrosive gases (e.g., H

that generate harmful gasses (e.g., organic silicones,

cyanides, and formalins).

Subject to vibrations.

In the vicinity of equipment generating strong

electromagnetic fields.

,23 5 (41 to 104 ,73 9 )

,NI2,andCI

S, SO

2

2

10%RH

) or substances

2

4

5

6

7

8

9

10

11

12

13

______________________________________________________________

2.1 Installation of the Product

14

15

APP

Page 32

8

R

_____________________________________________________________________

2.2 Power Supply and Ground Connection

2.2.1 Connecting the AC Adapter

Use only the specified/supplied Model 9418-15 AC

DANGE

ADAPTER (SA145A-1240V-6, SINO AMERICAN). AC

adapter input voltage range is 100 to 240 V AC (with

10% stability) at 50/60 Hz. To avoid electrical hazards

and damage to the product, do not apply voltage

outside of this range.

NOTE

______________________________________________________________

2.2 Power Supply and Ground Connection

The AC adapter is prior to the battery when using together.

Page 33

_____________________________________________________________________

9

2.2.2 Installing the Batteries/Battery Pack

1

2

WARNING

NOTE

Use the specified 9447 BATTERY PACK or LR6 alkaline

batteries. Do not use old and new batteries or batteries

of different types together.

The manufacturer disclaims all responsibility for any

accident or injury except that resulting due to defect in

its specified batteries or Battery packs.

Do not use old and new batteries or batteries of

different types together. If intend to, performance of

the product may suffer.

If not recharge, the 9447 can not be used.

For the details on charging batteries, refer to Section 16.2,

"9447 BATTERY PACK."

If the battery voltage drops while the product is running off of

battery power, the product will automatically switch off the

power supply. If the product is left in this state for an extended

period of time, the battery pack may be discharged too much.

Be sure to turn OFF the power switch on the product.

When the battery capacity is reduced, the power is automatically

turned off. Before turning on the power again with AC adapter

or new batteries, turn the power off and leave for about 30

seconds. If this time is shorter than 30 seconds, the power may

be immediately turned off even if powering on.

When not in use for a long time, to prevent possible corrosion

caused by battery leakage, remove the batteries before storage.

3

4

5

6

7

8

9

10

11

12

______________________________________________________________

2.2 Power Supply and Ground Connection

13

14

15

APP

IND

Page 34

10

_____________________________________________________________________

Installing the Batteries or Battery Pack

1. Turn the power OFF.

2. Take off the cover of the battery compartment.

3. Remove the old batteries and replace them with six new

LR6 alkaline batteries with the correct polarity.

4. Replace the battery cover.

Effective Battery-Powered Operating Time

(typical value at normal temperature)

Operating time is extended with the backlight brightness is

set to Dark.

For details, refer to Section 10.1.7

Not operating (waiting for trigger, etc.)

Alkaline battery: Approx. 60 min (dark)/ Approx. 40 min (bright)

9447 BATTERY PACK: Approx. 180 min (dark)/ Approx. 120

min (bright)

During operating (2 s/DIV 1 Hz sinewave (REC)

Alkaline battery: Impossible

9447 BATTERY PACK: Approx. 120 min (dark)

NOTE

______________________________________________________________

2.2 Power Supply and Ground Connection

Actual performance will change from values indicated in this table

according to the types of batteries, temperature , and printing rate.

The printer cannot be used with alkaline batteries: use either the

9418-15 AC ADAPTER (SA145A-1240V-6, SINO AMERICAN)

or 9447 BATTERY PACK when using the printer.

The backlight is automatically dimmed when the printer is in use.

Page 35

_____________________________________________________________________

11

2.3 Power On/Off

1

WARNING

Check the following points before the power switch is

turned on.

Power supply matches Rated supply voltage (100 to

240 V AC: Voltage fluctuations of

supply voltage are taken into account.) and rated

supply frequency (50/60 Hz).

The Product is correctly installed (See Section 2.1).

Depending on the type and status of power supply of the

product, one of the following messages appears on the

Waveform Screen.

Operating with the AC ADAPTER.

Operating with batteries.

10% from the rated

2

3

4

5

6

7

8

9

10

11

12

Battery capacity is low. Replace the batteries.

NOTE

______________________________________________________________

When the product is turned off, it memorizes the currently used

settings and reestablishes the same settings the next time the

product is turned on again. (Backup function)

2.3 Power On/Off

13

14

15

APP

IND

Page 36

12

f

_____________________________________________________________________

2.4 Connecting the Connection Cord

Never connect the cable to the product while the

WARNING

other end is connected to the measurement object,

as you could receive an electric shock.

Use only the specified connection cable.

To prevent electric shock, an insulated BNC

connector is used. There is the possibility of shock

if a metal BNC is used because the input L terminal

and the metal part of the BNC connector have the

same electric potential.

CAUTION

When disconnecting the BNC connector, be sure to release

the lock before pulling off the connector. Forcibly pulling the

connector without releasing the lock, or pulling on the

cable, can damage the connector.

Using a connection cable other than that specified may

result in damage to the BNC connector, poor contact, or

other symptoms preventing accurate measurement.

Use the optional 9197, 9198, or 9217

CONNECTION CORD

to connect to the analog input terminals.

CONNECTION CORDs

Maximum

input voltage:

9197 9198

500 V 300 V 300 V

9217

Connecting to the main product

1. Align the grooves in the BNC

Groove o

the BNC

connector with the guide pins on

the product input connector, then

turn clockwise while pressing in

to lock the connector.

2. To remove from the product, turn

Connectorguide

the BNC connector

counterclockwise to release the

lock, then pull it.

______________________________________________________________

2.4 Connecting the Connection Cord

Page 37

_____________________________________________________________________

R

13

2.5 Connecting the 9322 DIFFERENTIAL

PROBE

For the 9322, the maximum rated voltage to earth is as

DANGE

follows.

When using grabber clips: 1500 V AC or DC (CAT ll) /

600 V AC or DC (CAT lll)

When using alligator clips: 1000 V AC or DC (CAT lI) /

600 V AC or DC (CAT lll)

To avoid electrical shock and possible damage to the

product, never apply voltage exceeding these limits

between the input terminals and the chassis, or

between the inputs of two 9322s.

The maximum input voltage is 1000 V AC or 2000 V DC

(CAT ll) / 600 V AC or DC (CAT lll).

Do not attempt to measure voltage exceeding these

limits, as doing so may damage the equipment or

cause an accident that might result in injury or death.

High voltage can be present at the inputs to the 9322.

WARNING

______________________________________________________________

To avoid electrical hazard, be sure to turn off the

equipment to be measured before connecting the test

leads. Turn the power on only after the leads have been

securely connected.

Before using the product, make sure that the sheathing

on the probes is not damaged and that no bare wire is

exposed. If there is damage, using the product could

cause electric shock. Contact your dealer or HIOKI

representative.

2.5 Connecting the 9322 DIFFERENTIAL PROBE

Page 38

14

p

p

)

r

_____________________________________________________________________

The Model 9322 is a differential probe that connects to

input modules for the 8800 MEMORY HiCORDER series.

High voltage applied between the H and L terminals is

divided by 1/1000 and output as a voltage signal relative to

GND.

Power jack

(Connect the 9418-10

AC ADAPTER

BNC connecto

(Connect to the analog

input terminal

Grabber cli

Alligator cli

Connection Method

1. Connect the alligator or grabber clips to the 9322.

For the 9322, the maximum rated voltage to earth is as

follows.

When using grabber clips: 1500 V AC or DC (CAT ll) /

600 V AC or DC (CAT lll)

When using alligator clips: 1000 V AC or DC (CAT lI) /

600 V AC or DC (CAT lll)

2. Connect the AC ADAPTER to power jack of the 9322.

The indicator lights when power is applied.

______________________________________________________________

2.5 Connecting the 9322 DIFFERENTIAL PROBE

Page 39

_____________________________________________________________________

15

3. Connect the BNC connector of the 932 2 to the analog

input terminal of the product.

Grooves in the BNC

Connector guide

4. Connect the alligator clip or grabber clip to equipment to

be measured.

5. Select DC, AC or RMS output with the output selector

switch.

DC The voltage between H and L signals is divided

by 1/1000 and output as voltage relative to GND.

AC AC coupling for DC signals, and impulse voltage

is sampled on the carrier voltage.

RMS RMS conversion is applied to DC output signals

and output as a level variation.

NOTE

______________________________________________________________

One 9418-15 AC ADAPTER (SA145A-1240V-6, SINO

AMERICAN) is required for each 9322 to be used.

Refer to the 9322 DIFFERENTI AL PROBE Instruction Manual for

details.

2.5 Connecting the 9322 DIFFERENTIAL PROBE

Page 40

16

y

機

_____________________________________________________________________

2.6 Connecting the Logic Probe

The ground sides of the logic inputs are connected in

WARNING

common to the frame ground of the product. Therefore,

if the product is powered by the AC adapter and the

object to be measured is powered from a different

power source, the possibility exists for electric shock

or damage to the equipment. Furthermore, even when

power is supplied from the same source, a potential

difference can exist due to different ground-side wiring ,

resulting in current flow through the logic probes that

could result in electric shock or damage.

To avoid these hazards, before connecting a logic

probe to the product and the object to be measured,

confirm that power is sup plied from the same

grounded outlet using 3-wire grounded power cords.

Do not connect logic probes other than supplied by

HIOKI to the logic inputs.

Object to

be measured

Outlet

MEMORY

HiCORDER

Power suppl

Ground

The logic input is located on the

top side of the product. Since one

logic probe can record 4 channels,

the combined maximum recording

capability for logic waveforms is 8

channels.

NOTE

______________________________________________________________

2.6 Connecting the Logic Probe

If no logic probe is connected, the corresponding logic

waveform is displayed on the screen at high level.

Carefully read the instruction manual supplied with the 9320-01

or 9321-01 LOGIC PROBE.

Page 41

_____________________________________________________________________

R

17

2.7 Connecting the 9018-10, 9132-10

CLAMP ON PROBE

Always connect the clamp-on probe to the secondary

DANGE

side of a breaker. On the secondary side of a breaker,

even if the lines are shorted the breaker can trip and

prevent an accident. On the primary side, however, the

current capacity may be large, and in the event of a

short-circuit there may be a serious accident.

Before using the 9018-10, 9132-10 CLAMP ON PROBE,

be sure to carefully read its instruction manual and

familiarize yourself with the operation principles of this

product.

This product measures input voltage, so although current

cannot be measured directly, current can be measured by

the voltage output from the HIOKI 9018-10, 9132-10

CLAMP ON PROBEs.

Connect the BNC connector of the CLAMP ON PROBE to

the analog input terminal. For details, refer to Section 2.4.

9018-10

Load

9132-10

Source

Source

NOTE

______________________________________________________________

To measure current, set the input coupling of the product to

"CLAMP." For details, refer to Section 7.3.4.

When the clamp-on probe is used for measurement, the

measurement precision will be affected both by the product

precision and clamp-on probe precision ratings.

When using the 9199 CONVERSION ADAPTOR, the 9018,

9132 CLAMP ON PROBEs can be used.

When measuring electric current, make sure that the direction of

the CLAMP ON PROBE matches the direction of electric

current.The direction of connection for the 9132-10 is opposite

from the 9018-10. If the CLAMP ON PROBE is faced in the

opposite direction, the phase will shift 180 degrees from the

actual value.

2.7 Connecting the 9018-10, 9132-10 CLAMP ON PROBE

Load

Page 42

18

_____________________________________________________________________

2.8 Connecting the 8992 PRINTER UNIT

Before connecting or disconnecting the printer unit, make

sure that the power switch is off. When the printer is not

connected, be sure to install the cover.

1. Using a plastic screwdriver,

remove the two screws that secure

the product's rear cover and lift off

the cover.

2. Insert the 8992 PRINTER UNIT.

3. Secure with the two screws

provided.

If the connector does not mate easily,

rock the printer slightly as shown

while pressing the products together.

NOTE

______________________________________________________________

2.8 Connecting the 8992 PRINTER UNIT

The printer cannot be used with alkaline batteries: use either the

9418-15 AC ADAPTER (SA145A-1240V-6, SINO

AMERICAN) or 9447 BATTERY PACK when using the

printer.

Page 43

_____________________________________________________________________

19

2.8.1 Loading Recoding Paper

1. Lift the stock cover in the direction

of the arrows.

2. Raise the head up/down lever.

3. Insert the leading edge of the

recording paper from bottom into the

gap behind the printer roller, and

pull it out to the other side.

Pressing the

FEED

button feeds

paper.

4. Insert the attachments into the ends

of the roll of recording paper and set

the paper into its holder.

______________________________________________________________

2.8 Connecting the 8992 PRINTER UNIT

Page 44

20

_____________________________________________________________________

5. Pull the end of the recording paper

out at least 10 cm, and make sure

that it is positioned quite straight.

6. Put down the head up/down lever.

7. Pull the recording paper to the

outside through the printer exit slot

in the stock cover.

8. Close the stock cover, and finish by

tearing off the recording paper

against the edge of the printer exit

slot.

NOTE

______________________________________________________________

2.8 Connecting the 8992 PRINTER UNIT

When the stock cover is fully open, attempting to force it open

further may damage the cover.

The paper may jam if i t is not aligned with the roller.

Always place the product in the head-up condition when it is to

be transported or stored for an extended period of time. If the

product is left idle for a long time with the head pressing on the

roller, the roller may be deformed, resulting in uneven printing.

Be careful to correctly orient the recording paper. Nothing will

be printed if the recording paper is loaded with the wrong side

facing the print head.

We recommend using only the specified 9234 RECORDING

PAPER.

Page 45

_____________________________________________________________________

21

2.8.2 Care of Recording Paper

Care of recording paper

While unopened, thermal paper will not be affected by the

environment, provided that ambient temperature and

humidity do not exceed normal levels. For long-term

storage, temperature should be lower than 40

Low temperatures cause no problem.

After opening, protect the paper from strong light, to prevent

discoloration.

Storing data

The recording paper uses a thermochemical reaction.

Note the following points:

To avoid discoloration, do not leave recording paper in

direct sunlight.

Store at not more than 40 (104 ) and 90% RH.

To keep definitive data, make photocopies of the recordings.

Thermal paper will blacken when brought into contact with

alcohol, ester, ketone, or other volatile organic substances.

If the thermal paper absorbs an organic solvent such as

alcohols or ketones it may no longer develop properly, and

recorded information may fade. Soft PVC film and

transparent contact adhesive tape contain such solvents, so

avoid using them with recordings.

Avoid interleaving the thermal r ecordings with damp diazo

copies.

(104 ).

Direct sunlight

______________________________________________________________

2.8 Connecting the 8992 PRINTER UNIT

Organic solvent

Page 46

22

_____________________________________________________________________

2.9 Attaching the Strap

CAUTION

Attach the ends of the strap securely at both attachment

points. If the strap is not attached securely, the product

could drop while being carried.

1. Insert each end of the strap through an attachment point

on the product.

Attachment Point

2. Thread the end of the strap through the buckle twice as

shown below.

3. Finally, slide the stopper over the end of the strap.

Tighten the strap to remove slackness or twisting.

Stopper

______________________________________________________________

2.9 Attaching the Strap

Page 47

_____________________________________________________________________

R

2.10 Notes on Measurement

To avoid the risk of electric shock and damage to the

23

DANGE

product

Do not apply more than 450 V AC or DC between the

analog inputs and product, or between the analog

inputs.

Terminal inputs should never exceed the limits

indicated below.

Input/output terminals Maximum input voltage

Analog input 450 V AC rms, DC

EXT TRIG -5 V to +10 V

TRIG OUT -20Vto+30V

500 mA max, 200 mW max

The maximum voltage applied to the probe and cables

connecting to the analog input of the product must

never exceed the limits in the following table.

Notwithstanding these limits, the voltage at the analog

input must not exceed 450V AC or DC.

Maximum input voltage

9197

CONNECTION CORD

9217

CONNECTION CORD

9322

DIFFERENTIAL PROBE

500 V AC rms, DC

300 V AC rms, DC

1000 V AC, 2000 V DC (CAT ll)

600 V AC, DC (CAT lll)

______________________________________________________________

2.10 Notes on Measurement

Page 48

24

)

(

)

_____________________________________________________________________

Analog Input Zero Position

The zero position may be offset when the input coupling is

DC or GND and the input is open circuit in the highsensitivity (10 mV) range.

The accuracy specifications apply after 30-minute warm-up

following power on. During warm-up, the zero position

drifts as indicated below.

Error

%f.s.

2

1

0.5

0

-0.5

-1

-2

0 5 10 20 30 40 50 60

Time frompower on(minutes

______________________________________________________________

2.10 Notes on Measurement

Page 49

_____________________________________________________________________

25

Chapter 3

Basic Button Operation

Buttons for screen display setting

(Refer to Section 3.1)

Buttons for printer operation

(Refer to Section 3.2)

Buttons for item settings

(Refer to Section 3.3)

Buttons for waveform scrolling

and A/B cursor buttons

(Refer to Section 3.4)

1

2

3

4

5

6

7

8

Buttons for channels and input settings

(Refer to Section 3.5)

Start and stop buttons

(Refer to Section 3.6)

______________________________________________________________

9

10

11

12

13

14

15

APP

IND

Page 50

26

_____________________________________________________________________

3.1 Screen Display Buttons

These buttons switch between the display screens.

SYSTEM

SET

DISP

SYSTEM

button

SET button By pressing this button, you can select the

DISP button Calls up the Waveform Screen.

By pressing this button, you can select the

Environment, Comment, RS©, Setting,

and Initialization Screens.

Status, Channel, Trigger Screens.

Serves to display and observe waveforms.

Pressing this button from the Waveform

Screen switches to the DMM Screen.

3.2 Printer Buttons

These buttons are enabled when the 8992 PRINTER UNIT

is installed. For details, refer to Chapter 11.

PRINT

COPY

FEED

PRINT button Serves to print out the measured data.

COPY button Prints a copy of the displayed screen, or to

save it as a BMP file.

(For output destination, refer to Section 10.3.)

FEED button Forwards the paper while the button is held

down.

______________________________________________________________

3.1 Screen Display Buttons

Page 51

_____________________________________________________________________

27

3.3 Item Setting Buttons

Cursor buttons Serves to move the flashing cursor.

Use to select the Scroll or A/B cursors

and Key Lock ON/OFF functions.

1

2

3

buttons

(Select button)

Serves to set the items.

3.4 Waveform Scrolling Buttons

These buttons move the A/B cursors and scroll the

waveforms. For details, refer to Section 9.1 and 9.2.

Move the A and B cursors or scroll waveforms by these

buttons.

SCROLL

CURSOR

(1) Using the A/B cursors

(2) Scrolling the waveform

Pressing the

The A/B cursors can be used to read a time difference,

frequency, or potential difference on Waveform Screen.

The waveform on the display can be scrolled horizontally.

/ buttons moves quickly.

4

5

6

7

8

9

10

11

12

Press both cursor buttons (

switch the operation for using the A/B cursors or

scrolling the waveform.

______________________________________________________________

and ) simultaneously to

3.3 Item Setting Buttons

13

14

15

APP

IND

Page 52

28

_____________________________________________________________________

3.5 Input Operation

Press a channel select button (CH1 to CH4) on the

Waveform Screen to display the desired Settings window.

CH1

CH2

CH3

CH4

RANGE

POSN

TIME/DIV

CH1-CH4 buttons Display the Settings window for

voltage axis range, magnification, zero

position, filtering, trigger conditions

and more.

RANGE button Serves to set the voltage axis range for

the channel selected.

POSN button Serves to set the zero position for the

channel selected.

TIME/DIV button Serves to set the input signal capture

speed.

Other settings are made by moving the flashing cursor with

the Cursor buttons (

(

/ ) buttons.

) and pressing the Select

______________________________________________________________

3.5 Input Operation

Page 53

_____________________________________________________________________

29

3.6 Measurement Start and Stop

The measurement start/stop operation is separately

determined by each measurement function.

For details, refer to "Start and Stop Operation," which

explains each measurement function.

1

2

3

START

STOP

START

button

STOP button Pressing this button stops the measurement.

Pressing this button starts measurement.

The LED on the upper part of the switch

lights green during measurement.

3.7 Other Buttons Operation

CARD

button

Manual trigger

CARD button Using PC card:

When Manual Trigger is enabled (ON) on

the Trigger Screen, the trigger is activated

by pressing this button during the trigger

wait state.

Pressing the

cursor aligned with a setting item displays

the setting items.

Displays the File Screen.

Using Fax/modem card:

Displays the Fax&Modem Screen.

button with the flashing

4

5

6

7

8

9

10

11

12

______________________________________________________________

3.6 Measurement Start and Stop

13

14

15

APP

IND

Page 54

30

_____________________________________________________________________

3.8 Key Lock Function

This function disables all front-panel button controls of the

product. The function serves to prevent unintended changes

to settings during a measurement.

Press both cursor buttons (

) simultaneously for 3

seconds to switch the key lock on/off.

The key lock function will not be canceled by turning the

pow er off and on.

When the key lock function is active, the indication "

" is shown on the display.

LOCK

KEY

If the backlight saver function is used and the display

backlight turns off, it can be turned on again by touching

any button. The function assigned to the button will not be

activated.

______________________________________________________________

3.8 Key Lock Function

Page 55

_____________________________________________________________________

3.9 Changing the Screen

31

Waveform

display

SET

SET

Extended

status

DISP

MEM

STATUS

Numerical

calculation

CHANNEL

SYSTEM

DMM

DISP

DISP

Settings on the screen

STATUS

CHANNEL

REC

Initialize

SET

CommentEnvironmen

SYSTEM

RS©

SYSTEM

RMS

STATUS

CHANNEL

SCALING

TRIGGER

(MEM)

SCALING

TRIGGER

(REC)

SCALING

TRIGGER

(RMS)

(MEM): Memory recorder function/ (REC): Recorder function/

(RMS): RMS recorder function

______________________________________________________________

3.9 Changing the Screen

Page 56

32

_____________________________________________________________________

______________________________________________________________

3.9 Changing the Screen

Page 57

_____________________________________________________________________

33

Chapter 4

Memory Recorder Function

1

2

3

4.1 Overview of the Memory Recorder

Function

The memory recorder function has the following features.

(1) After being stored in the internal memory, input signal data

can be displayed and printed.

(2) All input channel data are recorded on the same time axis.

Since data for all channels can be superimposed, the

relative relationship between input signals can be observed

visually.

(3) Time axis setting

200 μs/DIV to 5 min/DIV

(4) Time axis resolution 80 points/DIV

(5) Storage capacity (DIV)

Model

8807-01, 8807-51

8808-01, 8808-51

(6) Waveform magnification/compression display and print

Time axis direction: x10 to x1/500

Voltage axis direction: x10 to x1/2

(7) Display layout

Time axis waveform: single, dual, quad displays

X-Y waveform: single display (dot, line)

(8) Logging function

Numeric printout of waveform data

(9) Memory segmentation (Sequential save) function helps to

reduce dead time of continuous recording.

(10) Numerical calculation functions

Eleven types of numerical calculation can be performed,

such as frequency and RMS measurements.

______________________________________________________________

4.1 Overview of the Memory Recorder Function

Number of channels

1 2 4

3200

3200

1600

1600

---

800

4

5

6

7

8

9

10

11

12

13

14

15

APP

IND

Page 58

34

_____________________________________________________________________

4.2 Operation Sequence (MEM)

Memory recorder operating procedures are described by the

following flowcharts.

Preparation

Settings on the Status Screen

Settings on the Status Screen

Function

Time axis range

Recording length

Display layout

Auto save

Printer recording format

Auto-print

Extended Status Screen

Extended Status Screen

Using channel

Refer to Chapter 2

Press the SET button to display the

Status Screen.

Select MEMORY (memory recorder

function).

Set the speed with which the input signal

waveform is captured.

Set the length of the data sample

for a single measurement.

Select the layout of the Waveform Screen

and for printing.

Select whether data is automatically saved.

Select whether measurement data is to be

printed as a waveform or numerically.

Select whether waveform data is to be

printed automatically.

Use this function, if necessary.

Configure memory allocation for

measurement data.

.

SET

Roll mode

Sequential save

Numerical Calculation Screen

Extended Status Screen

Requires connection of the optional 8992 PRINTER

UNIT.

Scrolls the waveform display if the time

axis is 10 ms/div to 5 min/div.

Segments memory into blocks, and records

a waveform in each block.

Refer to Section 4.8.3.

Input waveforms data is extrapolated and

displayed numerically. Refer to Section 4.9.

______________________________________________________________

4.2 Operation Sequence (MEM)

Page 59

_____________________________________________________________________

Settings on the Channel Screen

Settings on the Channel Screen

Channel Screen

Scaling Screen

Conversion ratio method

2-point method

Press the SET button to

display the Channel Screen.

Set the waveform display color,

voltage axis range, zero position,

etc. Refer to Chapter 7.

The scaling function can be used to

convert the output voltage

from a sensor, for example, to a

physical property of the measured

object.

Refer to Section 7.5.

35

SET

1

2

3

4

5

6

Settings on the Trigger Screen

Settings on the Trigger Screen

Start measurement

Press the START button to start measurement.

To avoid inadvertent measurements, the START button

activation condition can be selected. Refer to Section 10.1.1,

for details.

Zero adjustment is performed automatically for every

measurement.

Press the SET button to

display the Trigger Screen.

Set the trigger source, type and

condition, and pre-trigger condition.

Refer to Chapter 8.

SET

7

8

9

START

10

11

12

13

14

15

______________________________________________________________

4.2 Operation Sequence (MEM)

APP

IND

Page 60

36

A

y

_____________________________________________________________________

4.3 Setting Items

4.3.1 Setting the Function Mode

The 8807-01, 8808-01 has three function modes.

Additionally, the 8807-51, 8808-51 also offers a harmonic

wave analysis function. Select the Memory recorder

function.

Procedure

Status/ Channel/ Trigger Screen

1. Press the

SET

button to display the Status, Channel, or

Trigger Screen.

2. Move the flashing cursor to the position shown in the

figure below and select

Memory Recorder Function

Analog input signals are converted by the A/D converter to digital values

for display and storage in the internal memory.

X-Y combined plotting of multiple channels is possible.

nalog

input signal

Input voltage

A/D Converter

Digital

signal

MEMORY

Flashing cursor

RAM

using the buttons.

Digital processing

Display

Samplingperiod

Time

Screen displa

______________________________________________________________

4.3 Setting Items

Page 61

_____________________________________________________________________

37

4.3.2 Setting the Time Axis Range

1

Procedure 1

Procedure 2

Set the speed for inputting and storing the waveform of the

input signal. Time axis range setting expresses the time for

1 division.

Status Screen

1. Press the

2. Move the flashing cursor to

axis range using the

Pressing the

automatically to the Time Axis position for setting.

Waveform Screen

1. Press the

2. Move the flashing cursor to the position shown in the

figure below and use the

SET

button to display the Status Screen.

Time/DIV

buttons.

TIME/DIV

DISP

button to display the Waveform Screen.

button moves the flashing cursor

buttons to make a setting.

and select the time

The data interval for the

time axis range setting is

1/80 (1 DIV=80 data

points).

Flashing cursor

2

3

4

5

6

7

8

9

10

11

Flashing cursor

Pressing the

the flashing cursor position.

______________________________________________________________

TIME/DIV

button sets the time axis regardless of

4.3 Setting Items

12

13

14

15

APP

IND

Page 62

38

_____________________________________________________________________

4.3.3 Setting the Recording Length

The length of recording for one measurement operation

(number of divisions) can be set.

Constant recording length mode

Variable recording length mode

be selected by the user.

Status Screen

Procedure1 Constant recording length mode

1. Press the

SET

button to display the Status Screen.

2. Move the flashing cursor to

length using the

buttons.

: Select the recording length.

: Variable recording length can

Shot

and select the recording

Flashing cursor

Depending on the number of channels to be used, the

recording length is limited. (For setting the number of

channels, refer to

Using channels Constant recording length [DIV]

1 channel 20, 50, 100, 200, 400, 800, 1600, 3200

1 and 2 channels 20, 50, 100, 200, 400, 800, 1600

1 to 4 channels

(8808-01, 8808-51

only)

______________________________________________________________

4.3 Setting Items

Section 4.8.1

20, 50, 100, 200, 400, 800

.)

Page 63

_____________________________________________________________________

Procedure2 Variable recording length mode

39

1. Press the

2. Move the flashing cursor to

3. Press the

4. Using the

the digit to be set and use the

SET

button to display the Status Screen.

Shot

.

Flashing cursor

In variable recording-length

mode, the symbol "#" is

displayed before the

recording length.

button to set for variable recording length.

cursor buttons, move the flashing cursor to

buttons to make a

setting.

To return to the constant recording length mode, press the

button again.

______________________________________________________________

4.3 Setting Items

Page 64

40

.

_____________________________________________________________________

4.3.4 Setting the Display Layout

The display layout of input waveforms can be set for the

Waveform Screen and for printing.

The layouts Single, Dual, Quad, X-Y (Dot/Line) are

available.

Single Display

Display and record as one graph.

Quad Display

Display and record as four graph.

Display and record as two graph

(Dot) Linear interpolation

(smoothing) is not performed.

(Line) Linear interpolation is

performed.

Dual Display

X-Y Display

______________________________________________________________

4.3 Setting Items

Page 65

_____________________________________________________________________

41

Procedure

Status Screen

1. Press the

2. Move the flashing cursor to

display format using the

Single

Dual

Quad

X-Y (Dot)

X-Y (Line)

SET

button to display the Status Screen.

Display Format

and select the

buttons.

Flashing cursor

Display and record as one graph.

Display and record as two graphs.

Display and record as four graphs.

Display and record the waveform as an X-Y (Dot)

Screen.

Display and record the waveform as an X-Y (Line)

Screen.

When the Dual or Quad display is selected, the channel to

be displayed in each screen partition can be set.

For details, refer to Section 7.3.2, and for the settings on

the X-Y Screen, refer to Section 4.4.

______________________________________________________________

4.3 Setting Items

Page 66

42

_____________________________________________________________________

4.3.5 Setting the Auto Save Function

When the function is enabled, measurement data are

automatically stored on PC card after they are captured.

This function stores a file in the directory currently selected

on the File Screen.

Procedure

(1) Select the data format for Auto Save.

Status Screen

SET

1. Press the

button to display the Status Screen.

2. Move the flashing cursor to

saving using the

OFF

Binary

Text

Auto save is disabled.

Data are stored as binary data.

Data are stored as text data.

Data stored in the text format is not readable by

the product.

buttons.

Auto Save

and select the type of

Flashing cursor

______________________________________________________________

4.3 Setting Items

Page 67

_____________________________________________________________________

43

(2) If using the A/B cursors on the screen, specify the

area to save.

Flashing cursor

Move the flashing cursor to the position shown in the

figure below and use the

keys to make a setting.

ALL

A-B

Store data for all captured waveforms.