Page 1

Instruction Manual

8715-01

POWER HiCORDER

January 2009 Revised edit ion 9 8714A981-09 09-01H

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes iv

Notes on Use viii

Chapter 1 Product Overview 1

1.1 Major Features 1

1.2 Identification of Controls and Indicators

Chapter 2 Installation and Preparation 7

2.1 Installation of the Unit 7

2.2 Power Supply and Ground Connection

2.2.1 Connecting the AC Adapter 8

2.2.2 Installing the 9447 BATTERY PACK

2.3 Power On/Off 11

2.4 Connection of the Connection Cord

2.5 Connecting the 9322 DIFFERENTIAL

PROBE

2.6 Connecting the Clamp on Probe

2.7 Loading Recording Paper

2.8 Care of Recording Paper

2.9 Attaching the Strap

12

14

16

20

22

23

2

8

9

Chapter 3 Waveform Measurement Mode 25

3.1 Outline of the Waveform Measurement

Mode

3.2 Operation Sequence (Waveform)

3.3 Setting Items (Waveform)

3.3.1 Setting the Measurement Mode 28

3.3.2 Setting the Time Axis Range

3.3.3 Setting the Recording Length

3.3.4 Setting the Auto Print Function

25

27

28

29

30

31

Page 4

3.4 Input Channel Setting (Waveform) 32

3.4.1 Setting the Input Mode 32

3.4.2 Setting the Measurement Range

3.4.3 Setting the Waveform Position

3.4.4 Setting the Low-Pass Filter

3.4.5 Setting the Waveform Display

3.4.6 Setting the Zoom

33

34

35

36

37

3.5 Trigger Functions 38

3.5.1 Level Trigger 40

3.5.2 Window-In/Out Trigger

3.5.3 Voltage Drop Trigger

3.5.4 Period Trigger

3.5.5 Waveform Detection Trigger

3.5.6 Setting the Pre-Trigger

3.5.7 Input Level Monitor Function

43

45

47

51

54

55

3.6 Waveform Display Screen Settings 56

3.7 Start and Stop Operation (Waveform)

3.8 Sequential Save Function

57

58

Chapter 4 RMS Trend Measurement Mode 59

4.1 Outline of the RMS Trend Measurement 59

4.2 Operation Sequence (Trend)

4.3 Setting Items (Trend)

4.3.1 Setting the Measurement Mode 61

4.3.2 Setting the Time Axis Range

4.3.3 Setting the Frequency

4.3.4 Setting the Printer (Real Time Printing)

4.4 Input Channel Setting (Trend) 66

4.4.1 Setting the Input Mode 66

4.4.2 Setting the Measurement Range

4.4.3 Setting the Waveform Position

4.4.4 Setting the Low-Pass Filter

4.4.5 Setting the Waveform Display

4.4.6 Setting the Print Value

4.4.7 Setting the Zoom

60

61

63

64

65

67

68

70

71

72

73

Page 5

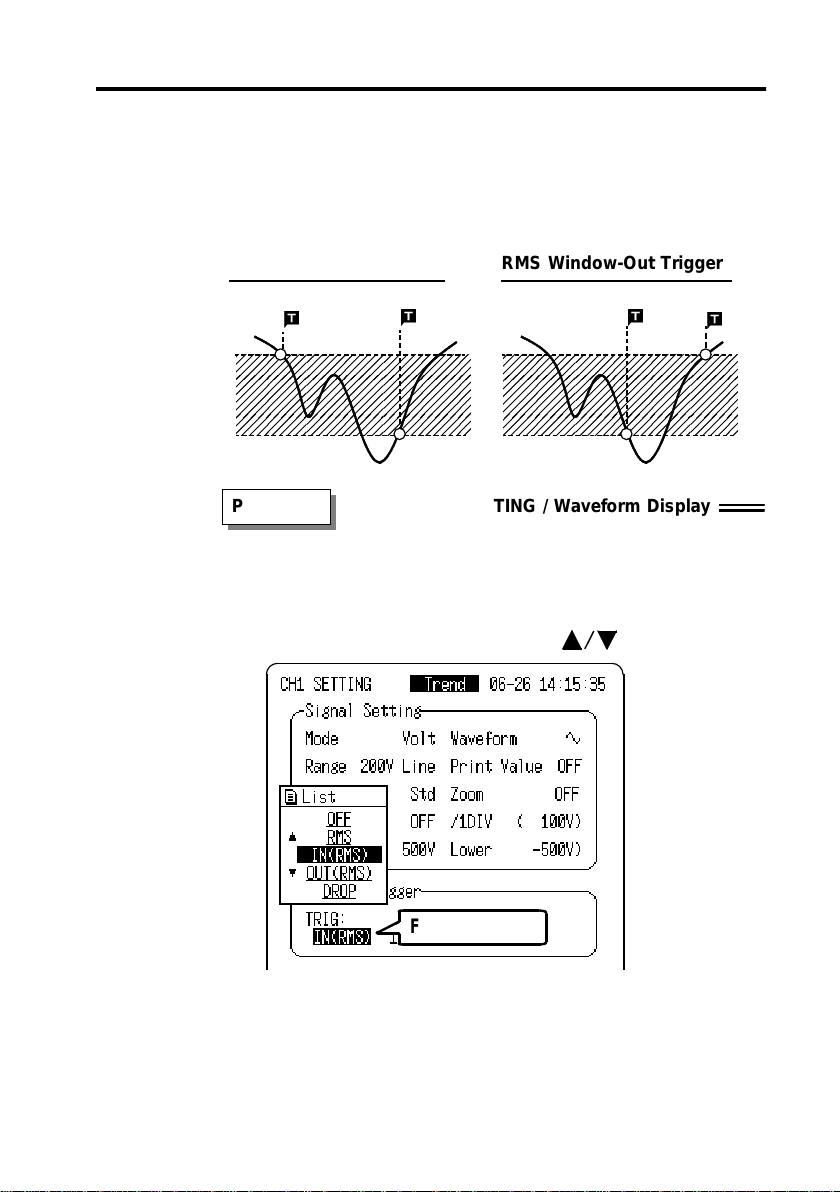

4.5 Instantaneous Waveform Recording

(Memory Record)

4.5.1 Setting the Instantaneous Waveform

Recording

4.5.2 Setting the Instaneous Waveform Trigger

4.5.3 RMS Level Trigger

4.5.4 RMS Window-In/Out Trigger

4.5.5 Voltage Drop Trigger

4.5.6 Setting the Pre-Trigger

4.5.7 Instantaneous Waveform Recording Display

Procedure

74

74

77

79

81

83

85

86

4.6 Waveform Display Screen Settings 88

4.7 Start and Stop Operation (Trend)

89

Chapter 5 Advanced Functions 91

5.1 Using the A/B Cursors 92

5.2 Scrolling the Waveform

5.3 Magnification/compression Ratio Along the

Time Axis

5.4 DMM Function

5.5 Key Lock Function

5.6 External Trigger Function

5.7 Trigger Output Terminal

95

96

97

98

99

101

Chapter 6 Advanced Settings 103

6.1 Environment Settings 104

6.1.1 Start Backup 104

6.1.2 Grid Type

6.1.3 LCD Saver

6.1.4 Display Color

6.1.5 Language

6.1.6 List & Gauge

6.1.7 Screen Copy Output Destination

105

106

107

108

109

110

Page 6

6.2 Using the Previous State Settings 112

6.2.1 Storing Settings 112

6.2.2 Loading Previously Saved State Settings

6.2.3 Deleting saved state settings

6.2.4 Auto Setting

114

115

116

6.3 Initialize Screen Settings 117

6.3.1 Setting the Clock 117

6.3.2 Clearing the Waveform Data

6.3.3 System Reset

6.3.4 Self-check

118

119

120

6.4 Extended Setting 122

6.4.1 Auto Save Settings 122

6.4.2 Sequential Save Function

125

Chapter 7 Printout of Measurement Data 127

7.1 Printing Procedure 128

7.1.1 Manual Print 128

7.1.2 Auto Print (Waveform)

7.1.3 Real Time Print (Trend RMS Recording)

7.1.4 Partial Print

7.1.5 Screen Copy

7.2 Example of Printer Output 134

129

130

132

133

Chapter 8 Storing the Measurement Data 135

8.1 PC Card 136

8.2 Using the PC Card Slot

8.3 Settings on the File Screen

8.3.1 Loading the Data 138

8.3.2 Saving Measurement and Setting Data

8.3.3 Entering the File Name

8.3.4 Deleting the Files and Directories

8.3.5 Creating the Directory

8.3.6 Initializing

8.3.7 Changing the Names of Files and

Directories

137

138

142

148

151

152

154

155

Page 7

Chapter 9 Specifications 157

9.1 General Specifications 157

9.2 Analog Inputs

9.3 Measurement Modes

9.4 Others

160

163

166

Chapter 10 Maintenance and Service 167

10.1 Changing the 9447 BATTERY PACK 168

10.2 Recharging the 9447 BATTERY PACK

170

10.3 Removing the Battery Before Discarding

the Instrument

10.4 Cleaning the Printer Head

10.5 Troubleshooting

10.6 Cleaning of the Instrument

171

172

173

174

Chapter 11 Appendix 175

11.1 Messages 175

11.2 RMS Value

11.3 Text File Internal Format

11.4 Waveform Viewer (Wv)

11.4.1 Starting the Waveform Viewer 181

11.4.2 Waveform Viewer Menus

11.4.3 Using the Waveform Viewer

11.4.4 Conversion to CSV Format

11.4.5 Converting Multiple Waveform Files into

CSV Files

177

178

180

182

184

188

190

Index INDEX 1

Page 8

Page 9

_____________________________________________________________________

Introduction

Thank you for purchasing the HIOKI "8715-01 POWER

HiCORDER." To obtain maximum performance from the

instrument, please read this manual first, and keep it handy

for future reference.

Inspection

When you receive the instrument, inspect it carefully to

ensure that no damage occurred during shipping. If damage

is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Accessories

i

Instruction Manual

Measurement Guide

Application Disk (CD)

Strap

9234 RECORDING PAPER

Attachment (for printer)

9418-15 AC ADAPTER

AMERICAN)

1

(SA145A -1240 V-6, SINO

9197 CONNECTION CORD

______________________________________________________________

1

1

1

1

1

1

4

Inspection

Page 10

ii

_____________________________________________________________________

Options

Cord, Adapter

9199 CONVERSION ADAPTOR (BNC-Banana female)

9217 CONNECTION CORD (BNC-BNC)

(maximum input voltage: 300 V AC/DC)

9322 DIFFERENTIAL PROBE

(maximum input voltage: CAT ll: 1000 VAC, 2000 VDC,

CAT lll: 600 VAC, DC)

9094 OUTPUT CORD

(for connecting with the 3283, 3284, and 3285)

Clamp

9010-10 CLAMP ON PROBE

(10 A to 500 A, 40 Hz to 1 kHz)

9018-10 CLAMP ON PROBE

(10 A to 500 A, 40 Hz to 3 kHz)

9132-10 CLAMP ON PROBE

(20Ato1000A,40Hzto1kHz)*1

3283 CLAMP ON LEAK HiTESTER

(10 mA to 200 A 40 Hz to 2 kHz)*2

3284 CLAMP ON AC/DC HiTESTER

(20Ato500A 40Hzto2kHz)*2

3285 CLAMP ON AC/DC HiTESTER

(20Ato500A 40Hzto3kHz)*2

PC Card

9626 PC CARD 32M

9627 PC CARD 64M

9726 PC CARD 128M

9727 PC CARD 256M

9728 PC CARD 512M

9729 PC CARD 1G

*1: This device is not approved for CE marking.

*2: This device requires the 9094 OUTPUT CORD (sold

separately).

______________________________________________________________

Inspection

Page 11

_____________________________________________________________________

iii

Others

9335 WAVE PROCESSOR

9418-15 AC ADAPTER (SA145A-1240V-6, SINO

AMERICAN)

9447 BATTERY PACK (7.2 V/2450 mAh)

9643 CHARGE STAND

9391 CARRYING CASE

9234 RECORDING PAPER

(18 m/59.06 feet, 112 mm width)

220H PAPER WINDER *1

*1: This device is not approved for CE marking.

______________________________________________________________

Inspection

Page 12

iv

R

_____________________________________________________________________

SafetyNotes

This instrument is designed to conform to IEC 61010

Safety Standards, and has been thoroughly tested for

DANGE

Safety Symbols

safety prior to shipment. However, mishandling

during use could result in injury or death, as well as

damage to the instrument. Be certain that you

understand the instructions and precautions in the

manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from

instrument defects.

This manual contains information and warnings essential

for safe operation of the instrument and for maintaining it

in safe operating condition. Before using the instrument,

be sure to carefully read the following safety notes.

The symbol printed on the instrument indicates that

the user should refer to a corresponding topic in the

manual (marked with the

relevant function.

symbol) before using the

In the manual, the symbol indicates particularly

important information that the user should read before

using the instrument.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates both DC (Direct Current) and AC (Alternating

Current).

Indicates DC (Direct Current).

______________________________________________________________

Safety Notes

Page 13

_____________________________________________________________________

R

The following symbols in this manual indicate the relative

importance of cautions a nd warnings.

Indicates that incorrect operation presents an extreme

v

DANGE

WARNING

CAUTION

NOTE

hazard that could result in serious injury or death to

the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

instrument.

Advisory items related to performance or correct

operation of the instrument.

______________________________________________________________

Safety Notes

Page 14

vi

_____________________________________________________________________

Measurement categories (Overvoltage categories)

This instrument complies with CAT II safety requirements.

To ensure safe operation of measurement instruments,

IEC61010 establishes safety standards for various electrical

environments, categorized as CAT I to CAT IV, and called

measurement categories. These are defined as follows.

CAT l

Secondary electrical circuits connected to an

AC electrical outlet through a transformer or

similar device.

CAT ll

CAT lll

CAT lV

Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distribution panel to

outlets.

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III environments can

endure greater momentary energy than a device designed

for CAT II.

Using a measurement instrument in an environment

designated with a higher-numbered category than that for

which the instrument is rated could result in a severe

accident, and must be carefully avoided.

Never use a CAT I measuring instrument in CAT II, III, or

IV environments.

The measurement categories comply with the Overvoltage

Categories of the IEC60664 Standards.

______________________________________________________________

Safety Notes

Page 15

_____________________________________________________________________

vii

Accuracy

We define measurement tolerances in terms of f.s. (full

scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

f.s.

(maximum display value or scale length)

The maximum displayable value or the full length of the

scale.

This is usually the maximum value of the currently

selected range.

rdg.

(reading or displayed value)

The value currently being measured and indicated on the

measuring instrument.

dgt.

(resolution)

The smallest displayable unit on a digital measuring

instrument, i.e., the input value that causes the digital

display to show a "1".

______________________________________________________________

Safety Notes

Page 16

viii

R

_____________________________________________________________________

Notes on Use

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

To avoid electric shock and damage to the instrument, do not

DANGE

apply more than 450 V AC or DC between the analog inputs

and instrument, or between the analog inputs.

Use only the supplied 9418-15 AC adapter (SA145A-1240V-6,

SINO AMERIC A N). AC adapter input voltage range is 100 to

240 VAC (with

10% stability) at 50/60 Hz. To avoid electrical

hazards and damage to the instrument, do not apply voltage

outside of this range.

To avoid damaging the instrument, do not apply voltage

exceeding the selected range to the input terminals, and never

exceed the maximum ratings for the analog input connection

cable or probe shown in the following table. In addition to

these limits, note that the absolute maximum analog input

voltage is 450V AC/DC.

Input/output terminal Maximum input voltage

Analog input 450 V AC, DC

EXT TRIG -5 V to +10 V

TRIG OUT -20Vto+30V

500 mA max, 200 mW max

Maximum input voltage

9197 CONNECTION CORD 500 V AC, DC

9217 CONNECTION CORD 300 V AC, DC

9448 CONSENT INPUT

CORD

9322 DIFFERENTIAL PROBE 1000 V AC, 2000 V DC (CAT ll)

125 V

600 V AC, DC (CAT lll)

For battery operation, use only the Hioki Model 9447

WARNING

BATTERY PACK. We cannot accept responsibility for

accidents or damage related to the use of any other

batteries.

NOTE

The 8715-01 POWER HiCO R DERs are not affected by a drop in

power lasting 40 ms or less. However, a drop in power lasting

more than 40 ms may interrupt the power supply. Check the

power supply conditions at the installation site in advance.

______________________________________________________________

Notes on Use

Page 17

_____________________________________________________________________

1

Chapter 1

Product Overview

1.1 Major Features

(1) Two Power Monitoring Modes

・ The Waveform Measurement Mode measures the

waveform level of commercial power lines.

・ The RMS Trend Measurement Mode records the trend in

the rms value of power line levels over a long term.

(2) Attached printer simultaneously prints measured waveforms

instantaneously on site.

(3) Current Measurement Capabilities

Current measurements capabilities are available when using

our clamp sensors, with which current values can be read

directly.

(4) Isolated Analog Inputs Satisfy Safety Concerns

・ The four channels of the 8715-01 are completely isolated

from the instrument's ground (GND), allowing worry-free

connections to points of independent potential.

・ Accepts direct connection to and measurement of 400V

lines.

______________________________________________________________

1.1 Major Features

Page 18

2

_____________________________________________________________________

1.2 Identification of Controls and

Indicators

2 31

4

5

6

9

10

11

12 13

14

15

16

17

7

8

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 19

_____________________________________________________________________

3

1. SET key

2. CH SET key

3. DISP key

4. PRINT key

5. COPY key

6. FEED key

7. DMM key

8. CARD key

9. / keys

10. Cursor keys

11. Scroll keys

12. CH1 - CH4

keys

13. RANGE key

14. POSN key

15. TIME/DIV

key

16. START key

17. STOP key

Selects the Basic Setting screen.

Selects the CH SETTING screen.

Selects the Waveform Display screen.

Serves to print out stored waveforms.

Serves to print out a copy of the current

screen display.

Causes the printer paper to advance for

as long as the key is pressed.

Selects the DMM screen.

Selects the File screen.

Select and accept settings here.

Moves the flashing cursor in the four

directions.

Moves the A/B cursors and scrolls the

waveforms.

Input and trigger settings can be made

by displaying the Settings window on

the Waveform Display screen.

Sets the voltage axis range for the

channel.

Sets the display position for the

channel.

Sets the input signal capture speed.

Initiates the measurement and analysis.

During measurement, the LED above

the key is lit.

Stops measurement.

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 20

4

_____________________________________________________________________

Upper Side View

21

1. PC card slot

2. Eject button

Insert the PC card.

Press this button to eject a PC card.

Lower Side View

4

5

132

6

1. AC adapter connecting terminal (for the AC adapter

specified by Hioki only)

2. Power switch

3. External trigger terminal

(EXT TRIG)

4. Trigger output terminal

(TRIG OUT)

5. Ground terminal

(GND)

6. Contrast adjustment knob

Switches on or off the power supply.

External trigger source input.

Trigger signals are output.

Used together with the trigger

terminal.

Adjusts screen contrast.

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 21

_____________________________________________________________________

5

Right Side View

CH4 CH3 CH2

1

1. Analog input terminal

Bottom Side View

CH1

Input terminals for analog inputs,

non-balanced input type

(8715-01: 4-channel input)

1

1. Battery compartment

9447 BATTERY PACK can be

installed.

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 22

6

_____________________________________________________________________

______________________________________________________________

1.2 Identification of Controls and Indicators

Page 23

_____________________________________________________________________

7

Chapter 2

Installation and Preparation

2.1 Installation of the Unit

Ambient conditions

Temperature

5to40

recommended for high-precision measurements.

Humidity

35 to 80%RH (no condensation); 50 10%RH

(no condensation) recommended for high-precision

measurements.

Avoid the following locations:

・ Subject to direct sunlight.

・ Subject to high levels of dust, steam, or corrosive gases

(Avoid using the equipment in an environment containing

corrosive gases (e.g., H

substances that generate harmful gasses (e.g., organic

silicones, cyanides, and formalins).

・ Subject to vibrations.

・ In the vicinity of equipment generating strong

electromagnetic fields.

,23 5 (41 to 104 ,73 9 )

,NI2,andCI

S, SO

2

2

)or

2

______________________________________________________________

2.1 Installation of the Unit

Page 24

8

R

_____________________________________________________________________

2.2 Power Supply and Ground Connection

2.2.1 Connecting the AC Adapter

Use only the supplied 9418-15 AC adapter (SA145A-

DANGE

1240V-6, SINO AMERICAN). AC adapter input voltage

range is 100 to 240 V AC (with

Hz. To avoid electrical hazards and damage to the

instrument, do not apply voltage outside of this range.

10% stability) at 50/60

The 8715-01 POWER HiCORDERs are not affected by a drop

NOTE

______________________________________________________________

2.2 Power Supply and Ground Connection

・

in power lasting 40 ms or less. However, a drop in power

lasting more than 40 ms may interrupt the power supply.

Check the power supply conditions at the installation site in

advance.

Page 25

_____________________________________________________________________

W

9

2.2.2 Installing the 9447 BATTERY PACK

For battery operation, use only the Hioki Model 9447

ARNING

BATTERY PACK. We cannot accept responsibility for

accidents or damage related to the use of any other

batteries.

Installing the 9447 BATTERY PACK

1. Turn the power OFF.

2. Take off the Blank box.

3. Install the 9447 BATTERY PACK.

Effective Battery-Powered Operating Time

(typical value at normal temperature)

When the LCD power save function is on, the maximum

operating time will be longer than listed in the table below.

For details, see 6.1.3, "LCD Saver".

Operating condition 9447 BATTERY PACK

Approx. 180 min

Not operating

(waiting for trigger, etc.)

(LCD power save ON)

Approx. 120 min.

(LCD power save OFF)

During operating

2s/DIV1Hzsinewave

______________________________________________________________

2.2 Power Supply and Ground Connection

Approx. 120 min

(LCD power save ON)

Page 26

10

_____________________________________________________________________

If not recharge, the 9447 can not be used. For the details on

NOTE

・

charging batteries, refer to Section 10.2, "Recharging the 9447

BATTERY PACK."

If the battery voltage drops while the instrument is running off

・

of battery power, the 8715-01 will automatically switch off the

power supply. If the instrument is left in this state for an

extended period of time, the battery pack may be discharged

too much. Be sure to turn OFF the power switch on the

instrument.

When the battery capacity is reduced, the power is

・

automatically turned off. Before turning on the power again

with AC adapter or new batteries, turn the power off and leave

for about 30 seconds. If this time is shorter than 30 seconds,

the power may be immediately turned off even if powering on.

The values listed in the table above may vary depending on

・

ambient temperature and the coverage rate in printing.

When the printer is printing, the 8715-01 automatically reduce

・

backlight brightness and enter LCD power save mode.

______________________________________________________________

2.2 Power Supply and Ground Connection

Page 27

_____________________________________________________________________

W

2.3 Power On/Off

Check the following points before the power switch is

turned on.

11

ARNING

Power supply matches Rated supply voltage (100 to

240 VAC: Voltage fluctuations of

10% from the

rated supply voltage are taken into account.) and

rated supply frequency (50/60 Hz).

The Unit is correctly installed (Section 2.1).

Depending on the type and status of power supply of the

8715-01, one of the following messages appears on the

Waveform Display screen.

Operating with the AC ADAPTER.

Operating with 9447 BATTERY PACK.

Battery capacity is low. Replace the batteries.

NOTE

______________________________________________________________

When the instrument is turned off, it memorizes the currently

used settings and reestablishes the same settings the next time

the instrument is turned on again. (Backup function)

2.3 Power On/Off

Page 28

12

_____________________________________________________________________

2.4 Connection of the Connection Cord

Never connect the cable to the 8715-01 while the cable

is already connected to the measurement object.

WARNING

Otherwise there is a risk of electric shock.

CAUTION

NOTE

When disconnecting the BNC connector, be sure to release

the lock before pulling off the connector. F orcibly pulling the

connector without releasing the lock, or pulling on the

cable, can damage the connector.

Use only the connection cord specified by Hioki. Using a nonspecified cable may result in incorrect measurements due to

poor connection or other reasons.

Use the supplied 9197 or optional connection cord for

analog input.

9197

Maximum input voltage: 500 V

9217

Maximum input voltage: 300 V

______________________________________________________________

2.4 Connection of the Connection Cord

Page 29

_____________________________________________________________________

r

13

Connecting to the main unit

Grooves in the BNC connecto

Connector guide

1. Align the grooves in the BNC connector with the guide

pins on the instrument input connector, then turn

clockwise while pressing in to lock the connector.

2. To remove from the instrument, turn the BNC connector

counterclockwise to release the lock, then pull it.

______________________________________________________________

2.4 Connection of the Connection Cord

Page 30

14

R

_____________________________________________________________________

2.5 Connecting the 9322 DIFFERENTIAL

PROBE

When using grabber clips, the 9322's maximum rated

DANGE

WARNING

voltage to earth is 1500 V AC or DC (CAT ll) / 600 V

AC or DC (CAT lll); when using alligator clips, it is

1000 V AC or DC (CAT ll) / 600 V AC or DC (CAT lll).

To avoid electrical shock and possible damage to the

instrument, never apply voltage greater than these

limits between the input channel terminals and

chassis, or across the input of two 9322s.

Maximum input voltage is 1000 VAC/2000 VDC (CAT

ll) / 600 V AC or DC (CAT lll). Do not measure voltage

in excess of these limitations, as doing so may

danger the instrument or cause an accident that

might result in injury or death.

9322 input part is applied with high voltage. To avoid

electric accident, be sure to turn off the power of

equipment to be measured before connecting. After

connection is properly handled, turn the power on.

Before using the instrument, make sure that the

insulation on the probes is undamaged and that no

bare conductors are improperly exposed. Using the

instrument in such conditions could cause an electric

shock, so contact your dealer or Hioki representative

for repair.

9322 is a differential probe that connects to analog input.

After high voltage is input to H and L terminal and divided

by 1/1000, the difference is output as signal to GND.

______________________________________________________________

2.5 Connecting the 9322 DIFFERENTIAL PROBE

Page 31

_____________________________________________________________________

p

A

p

p

ginp

15

Power jack

Connects o

tional AC adapter

BNC connector

connects to BNC connector on analo

ut.

Grabber cli

lligator cli

Connection Method

1. Connect the alligator or grabber clips to the 9322

DIFFERENTIAL PROBE.

2. Connect 9418-15 AC ADAPTER (SA145A-1240V-6,

SINO AMERICAN) to power jack. When power is

supplied, indicator turns on.

3. Connect 9322 BNC connector to analog input.

Grooves in the BNC

Connector guide

4. Connect alligator clip or grabber clip to equipment to be

measured.

5. Set the output selector switch to DC.

NOTE

______________________________________________________________

One 9418-15 AC ADAPTER (SA145A-1240V-6, SINO

AMERICAN) is required for each 9322 to be used.

Refer to the 9322 DIFFERENTI AL PROBE Instruction Manual for

details.

2.5 Connecting the 9322 DIFFERENTIAL PROBE

Page 32

16

R

φ

_____________________________________________________________________

2.6 Connecting the Clamp on Probe

Clamp-on probe should only be connected to the

DANGE

secondary side of a breaker, so the breaker can

prevent an accident if a short circuit occurs.

Connections should never be made to the primary side

of a breaker, because unrestricted current flow could

cause a serious accident if a short circuit occurs.

To avoid short circuits and accidents that could result

in injury or death, use clamp testers only with power

lines carrying 600 V rms or less.

The 8715-01 is fundamentally a voltage measuring device.

Although it does not measure current directly, current

measurement is possible using the voltage output of a

clamp sensor.

9010-10, 9018-10

Range: AC10/20/50/100/200 A

9010-10: 40 Hz to 1 kHz

9018-10: 40 Hz to 3 kHz

46 mm, 50 mm X 20 mm

9132-10

Range: 20/50/100/200/500/1000 A AC

40 Hz to 1 kHz

φ 55 mm, 80 mm X 55 mm

3283

Range: 10m/100m/1/10/200 A AC

40 Hz to 2 kHz

φ 40 mm max.

3284

Range: 20/200 A

DC, 10 Hz to 2 kHz

φ 33 mm max.

3285

Range: 200/2000 A

DC, 10 Hz to 1 kHz

φ 55 mm max.

______________________________________________________________

2.6 Connecting the Clamp on Probe

Page 33

_____________________________________________________________________

17

Using the 9010-10, 9018-10, and 9132-10

1. Align the grooves in the clamp sensor's BNC plug with

the connector guide pins on the analog input connector

on the 8715-01.

2. Push the BNC plug all the way in, and then turn it to the

right (clockwise). Confirm that the connectors are

securely mated.

3. To remove from the instrument, turn the BNC connector

counterclockwise to release the lock, then pull it.

Grooves in the BNC

Connector guide

CAUTION

______________________________________________________________

When disconnecting the BNC connector, be sure to release

the lock before pulling off the connector. F orcibly pulling the

connector without releasing the lock, or pulling on the

cable, can damage the connector.

2.6 Connecting the Clamp on Probe

Page 34

18

_____________________________________________________________________

Using the 3283, 3284, and 3285

Connection to the 8715-01 requires the 9199

CONVERSION ADAPTER and 9094 OUTPUT CORD.

1. Connect the 9199 to the 8715-01.

Refer to 2.4, for the connection procedure.

2. Connect the 9094 to the 9199.

(The connections are non-polarized, so red and black

may be reversed.)

3. Connect the 9094 to the OUTPUT terminal of the

CLAMP-ON HiTESTER.

9199

OUTPUT terminal

9094

______________________________________________________________

2.6 Connecting the Clamp on Probe

Page 35

_____________________________________________________________________

y

19

Setting the 3283, 3284, and 3285

LCD displa

Press the RANGE key on the clamp-on HiTESTER to set

the appropriate range.

Press the OUTPUT key to display [MON] (Waveform

output: AC).

Be sure to use the AC adapter when measuring over a long

period.

When the clamp-on probe is used for measurement, the

NOTE

・

measurement precision will be affected both by the instrument

precision and clamp-on precision ratings.

Set the range of the clamp sensor to match that of the 8715-

・

01. If set to different ranges, the display will show incorrect

values.

______________________________________________________________

2.6 Connecting the Clamp on Probe

Page 36

20

_____________________________________________________________________

2.7 Loading Recording Paper

1. Lift the stock cover in the

direction of the arrows.

2. Raise the head up/down lever.

3. Insert the leading edge of the

recording paper from bottom

into the gap behind the printer

roller, and pull it out to the

other side.

Pressing the FEED key feeds

paper.

4. Insert the attachments into the

ends of the roll of recording

paper and set the paper into

its holder.

______________________________________________________________

2.7 Loading Recording Paper

Page 37

_____________________________________________________________________

21

5. Pull the end of the recording

paper out at least 10 cm, and

make sure that it is positioned

quite straight.

6. Put down the head up/down

lever.

7. Pull the recording paper to the

outside through the printer exit

slot in the stock cover.

8. Close the stock cover, and

finish by tearing off the

recording paper against the

edge of the printer exit slot.

When the stock cover is fully open, attempting to force it open

NOTE

・

further may da mage the cover.

The paper may jam if it is not aligned with the roller.

・

For shipping or long-term storage, be certain that the recording

・

head is in the raised position. Otherwise the rollers could be

deformed and cause uneven printing.

Be careful to correctly orient the recording paper. Nothing will

・

be printed if the recording paper is loaded with the wrong side

facing the print head.

We recommend using only the specified 9234 RECORDING

・

PAPER.

______________________________________________________________

2.7 Loading Recording Paper

Page 38

22

_____________________________________________________________________

2.8 Care of Recording Paper

Care of recording paper

While unopened, thermal paper will not be affected by

the environment, provided that ambient temperature and

humidity do not exceed normal levels. For long-term

storage, temperature should be lower than 40

Low temperatures cause no problem.

After opening, protect the paper from strong light, to

prevent discoloration.

Storing data

As the recording paper is thermally sensitive, be aware of

the following points:

・ To avoid paper discoloration, do not expose it to direct

sunlight, and store at no more than 40

・ For permanent storage of important recorded data,

photocopy the recording paper.

・ If the thermal paper is exposed to an organic solvent such

as alcohol or ketone, it may no longer develop properly,

and recorded data may fade.

・ Also, the thermal recording paper is ruined by contact

with wet Daizo copy paper.

(104 ).

and 90%RH.

Direct sunlight

______________________________________________________________

2.8 Care of Recording Paper

Organic solvent

Page 39

_____________________________________________________________________

23

2.9 Attaching the Strap

CAUTION

Attach the ends of the strap securely at both attachment

points. If the strap is not attached securely, the instrument

could drop while being carried.

1. Insert each end of the strap through an attachment point

on the instrument.

Attachment Point

2. Thread the end of the strap through the buckle twice as

shown below.

3. Finally, slide the stopper over the end of the strap.

Tighten the strap to remove slackness or twisting.

Stopper

______________________________________________________________

2.9 Attaching the Strap

Page 40

24

_____________________________________________________________________

______________________________________________________________

2.9 Attaching the Strap

Page 41

_____________________________________________________________________

25

Chapter 3

Waveform Measurement Mode

3.1 Outline of the Waveform Measurement

Mode

The Waveform Measurement Mode provides a variety of

settable triggers that can be used to easily record waveform

anomalities associated with high-speed transient phenomena

such as instantaneous power dropouts and brownouts.

Features of the Waveform Measurement Mode are as

follows.

(1) Measures instantaneous commercial mains power

waveforms

・ Measures instantaneous, impulse and overvoltage

mains voltage waveforms

・ Measures peak load current when used with a clamp

sensor

(2) Powerful waveform judgment triggers

・ Judges waveforms in real time at 125-μsintervals

・ 2.5-μs sampling interval allows measuring nearly

instantaneous impulses

(3) Voltage-drop trigger effectively detects momentary

power dropouts

・ Detect momentary dropouts as small as one-half

cycle, or optionally set voltage drop detection

according to effective value (rms) level.

______________________________________________________________

3.1 Outline of the Waveform Measurement Mode

Page 42

26

_____________________________________________________________________

The Number of Waveform

The number of waveform anomalities that can be

sequentially recorded (the sequence limit) depends on the

selected recording length. When the number of sequentially

recorded waveforms has reached the sequence limit, the

earliest recorded waveform is overwritten.

Refer to 3.3.3 "Setting the Recording Length" for sequential

recording setup, and 3.8 "Sequential Save Function" for the

display procedure for sequentially saved waveforms.

______________________________________________________________

3.1 Outline of the Waveform Measurement Mode

Page 43

_____________________________________________________________________

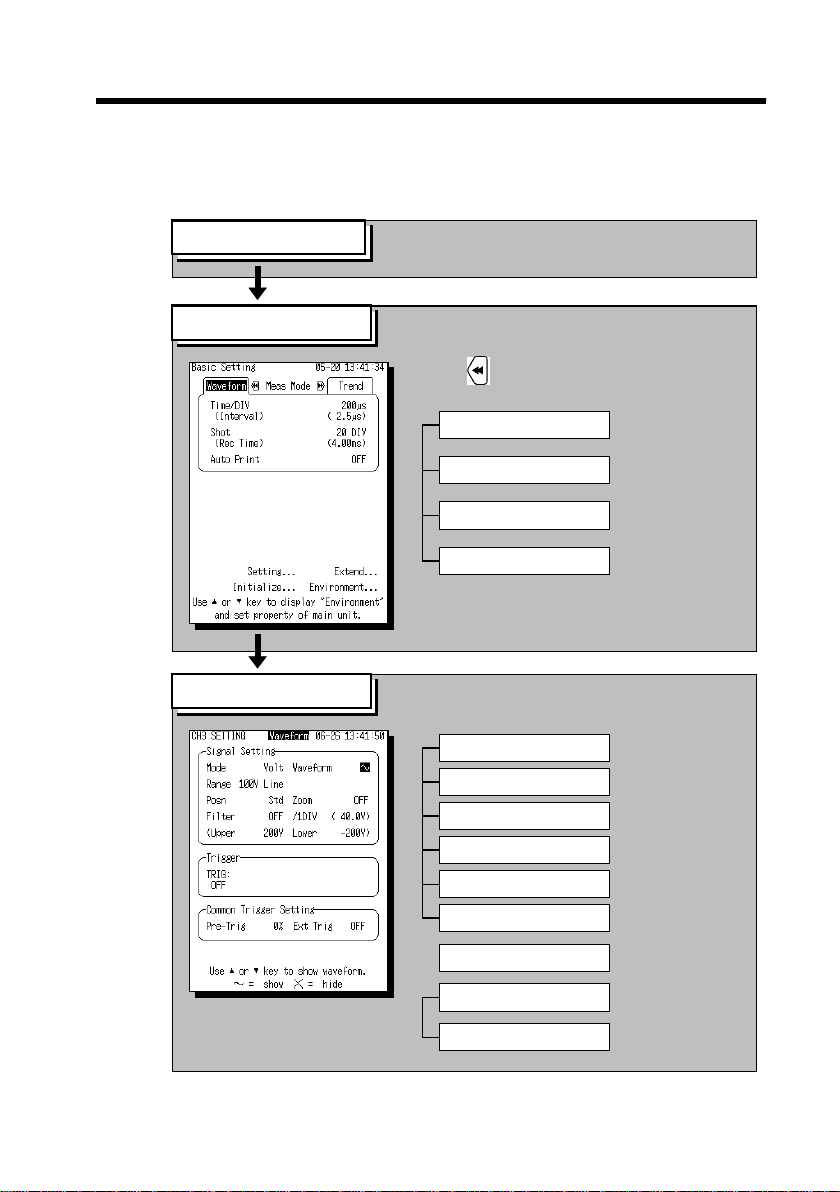

3.2 Operation Sequence (Waveform)

Waveform measurement mode operating procedures are

described by the following flowcharts.

27

Preparation

基本設定の

Basic Setting screen

CH SETTING screen

See Chapter 2.

Press the SET key to display the Basic

Setting screen.

Use the key to select the Waveform

measurement mode.

Measurement Mode

Time Axis Range

Recording Length

Auto Print

Press the CH SET key to display the desired

CH SETTING screen.

Input Mode

Measurement Range

Waveform Position

See 3.3.1.

See 3.3.2.

See 3.3.3.

See 3.3.4.

See 3.4.1.

See 3.4.2.

See 3.4.3.

Low-Pass Filter

Waveform Display

Zoom

Trigger

Pre-Trigger

Ext Trig

See 3.4.4.

See 3.4.5.

See 3.4.6.

See 3.5.

See 3.5.6.

See 5.6.

______________________________________________________________

3.2 Operation Sequence (Waveform)

Page 44

28

_____________________________________________________________________

3.3 Setting Items (Waveform)

3.3.1 Setting the Measurement Mode

The 8715-01 has two measurement modes. Select the

Waveform measurement mode.

Procedure Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Press the

key to select Waveform measurement mode.

______________________________________________________________

3.3 Setting Items (Waveform)

Page 45

_____________________________________________________________________

29

3.3.2 Setting the Time Axis Range

Set the speed for inputting and storing the waveform of the

input signal. Time axis range setting expresses the time for

1DIV.

Procedure-1 Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Move the flashing cursor to Time/DIV and select the

time axis range using the

keys.

Flashing cursor

The data interval for the

time axis range setting is

1/80 (1 DIV=80 data points).

Pressing the TIME/DIV key moves the flashing cursor

automatically to the Time Axis position for setting.

Procedure-2 Screen: Waveform Display

1. Press the DISP key to display the waveform display

screen.

2. Move the flashing cursor to the position shown in the

figure below and use the

Flashing cursor

keys to make a setting.

Pressing the TIME/DIV key sets the time axis regardless of

the flashing cursor position.

______________________________________________________________

3.3 Setting Items (Waveform)

Page 46

30

_____________________________________________________________________

3.3.3 Setting the Recording Length

The l ength of recording for one measurement operation

(number of divisions) can be set.

Procedure Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Move the flashing cursor to Shot and select the recording

length using the

Recording Length and Sequential Save

The maximum number of events that can be sequentially

recorded (the sequence limit) depends on the recording

length set for each event. For sequential save operation, the

internal memory is partitioned for storing multiple sets of

data.

In the Waveform Measurement Mode, when the number of

sequentially recorded waveforms has reached the sequence

limit and a trigger event occurs, the earliest recorded

waveform is overwritten.

Refer to 3.8 "Sequential Save Function" for more details.

keys.

Flashing cursor

Shot(DIV

Sequence Limit 32 16 8 4 2

______________________________________________________________

3.3 Setting Items (Waveform)

)

20 50 100 200 400

Number of waveforms that can currently

be displayed

Number of measurement events that

can be sequentially saved

Page 47

_____________________________________________________________________

31

3.3.4 Setting the Auto Print Function

Waveforms print out automatically after measurement starts

and each sequential save recording length (block size) has

been acquired.

Procedure Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Move the flashing cursor to Auto Print and set to ON or

OFF using the

keys.

Flashing cursor

OFF

ON

NOTE

______________________________________________________________

When cursor A and B are enabled, partial printing is executed.

For using the A/B cursors, see Section 5.1.

Disables the auto print.

Enables the auto print.

3.3 Setting Items (Waveform)

Page 48

32

_____________________________________________________________________

3.4 Input Channel Setting (Waveform)

3.4.1 Setting the Input Mode

Select the input mode (measurement object) for each

channel. The settable range is determined by the selected

input mode.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Mode position.

3. Use the

keys to make a setting.

Flashing cursor

Volt

9322

9010 to 3285

______________________________________________________________

3.4 Input Channel Setting (Waveform)

Measure voltage

Measure voltage using the

9322 DIFFERENTIAL PROBE

Measure cur rent using a clamp sensor

Page 49

_____________________________________________________________________

33

3.4.2 Setting the Measurement Range

Select the measurement range for each channel. The settable

range is determined by the selected input mode.

The vertical and horizontal dimensions of each frame

correspond to the set range, and the upper and lower limits

are displayed on the screen.

Procedure-1 Screen: CH SETTING

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Range position.

3. Use the

keys to make a setting.

Flashing cursor

Procedure-2 Screen: Waveform Display

1. Press the DISP key to display the waveform display

screen.

2. Press the CH1 - CH4 key to display the setting window.

3. Move the flashing cursor to the position shown in the

figure below and use the

Flashing cursor

keys to make a setting.

Pressing the RANGE key moves the flashing cursor

automatically to the Time Axis position for setting.

______________________________________________________________

3.4 Input Channel Setting (Waveform)

Page 50

34

_____________________________________________________________________

3.4.3 Setting the Waveform Position

Set the waveform display position.

The waveform display can be repositioned if it is obscured,

such as by an overlapping window.

Procedure-1 Screen: CH SETTING

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Posn position.

3. Use the

keys to make a setting.

Flashing cursor

Procedure-2 Screen: Waveform Display

1. Press the DISP key to display the waveform display

screen.

2. Press the CH1 - CH4 key to display the setting window.

3. Move the flashing cursor to the position shown in the

figure below and use the

Flashing cursor

keys to make a setting.

Pressing the POSN key moves the flashing cursor

automatically to the Time Axis position for setting.

______________________________________________________________

3.4 Input Channel Setting (Waveform)

Page 51

_____________________________________________________________________

35

3.4.4 Setting the Low-Pass Filter

Effective for removing unneeded high-frequency

components.

Procedure Screen: CH SETTING

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Filter position.

3. Use the

keys to make a setting.

Flashing cursor

OFF

500 Hz

5 kHz

______________________________________________________________

No low-pass filter is connected.

Connect a filter with a cutoff frequency of 500 Hz

Connect a filter with a cutoff frequency of 5 kHz

Filter: OFF Filter: 500 Hz

3.4 Input Channel Setting (Waveform)

Page 52

36

_____________________________________________________________________

3.4.5 Setting the Waveform Display

Enable/disable waveform measurement and display.

The 8715-01 can record and display up to four channels.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Waveform position.

3. Use the

keys to make a setting.

Flashing cursor

Colors on the Waveform Display screen are used to indicate

channels as follows, a nd are not changeable.

CH1 :Red CH3 : Yellow

CH2 :Green CH4 :Blue

______________________________________________________________

3.4 Input Channel Setting (Waveform)

Page 53

_____________________________________________________________________

37

3.4.6 Setting the Zoom

The voltage axis can be independently magnified or

compressed for display and recording of each channel.

Magnification and compression are applied relative to the

center of the display.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the Zoom position.

3. Use the

keys to make a setting.

Flashing cursor

OFF

ON

Display and record without magnification

Display and record with magnified voltage axis

OFF ON

______________________________________________________________

3.4 Input Channel Setting (Waveform)

Page 54

38

_____________________________________________________________________

3.5 Trigger Functions

・ The term "trigger" refers to a signal which is used to

control the timing for recording start. The term

"triggering has occurred" refers to the state when such a

signal has activated recording start.

・ Trigger settings can be made on each CH SETTING

screen or on the Waveform Display screen. This

document mainly describes the CH SETTING screen

settings.

Press the

CH1 - 4 key

Trigger conditions for the Waveform Measurement

Mode, with primary usage examples

・ Level Trigger

・ Window-In/Out Trigge r

In-rush current measurement

Overvoltage (or current)

・ Voltage Drop Trigger

・ Period Trigger

Momentary voltage dropouts and brownouts

Power frequency anomalities

・ Waveform Detection Trigger

______________________________________________________________

3.5 Trigger Functions

Surgeandnoisemeasurement

Page 55

_____________________________________________________________________

39

・ A trigger condition can be enabled by setting an OR

condition with other triggers. The OR condition causes a

trigger to occur when any of several trigger conditions are

satisfied.

・ Pre-trigger and external trigger settings can be made only

on the CH SETTING screen.

・ Refer to 5.6 "External Trigger Function" for external

trigger details.

______________________________________________________________

3.5 Trigger Functions

Page 56

40

_____________________________________________________________________

3.5.1 Level Trigger

Triggering occurs when the input signal crosses the preset

trigger level with the preset trigger slope (

, ).

Trigger point

Trigger level

Input signal

Upward trigger direction

(slope :

Procedure Screen: CH SETTING / Waveform Display

)

Downward trigger direction

(slope :

)

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the TRIG position and select

LVL (level) using the

keys.

Trigger point

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 57

_____________________________________________________________________

41

3. Move the flashing cursor to the position shown in the

figure below, and set the trigger level using the

keys.

Flashing cursor

4. Move the flashing cursor to the position shown in the

figure below, and set the trigger slope using the

keys.

Flashing cursor

Triggering occurs when the rising trigger slope

(

) crosses the trigger level.

Triggering occurs when the falling trigger slope

(

) crosses the trigger level.

5. Move the flashing cursor to the position shown in the

figure below, and set the trigger filter using the

keys.

Flashing cursor

OFF

ON

______________________________________________________________

Trigger filter is disabled.

Trigger filter is enabled. Filter width: 0.5 DIV

3.5 Trigger Functions

Page 58

42

_____________________________________________________________________

Trigger Filter

Triggering occurs when the trigger conditions are met

within the filter width (0.5 DIV). This is useful to prevent

spurious triggering by noise

Rising trigger slope :

Filter width (0.5 DIV)

Trigger point

Trigger level

Triggering does not occur here

To cause triggering at point A or point B with the sine

wave shown below, make the following settings.

Point A

Trigger level: 200 mV,

Trigger slope: rising ( )

200 mV

0V

A

Point B

Trigger level: -600 mV,

Trigger slope: falling ( )

0V

-600 mV

B

______________________________________________________________

3.5 Trigger Functions

Page 59

_____________________________________________________________________

3.5.2 Window-In/Out Trigger

Window-In Trigger

Set upper limit level and lower limit level and activated

when the input signal enters the range between these limits.

Window-Out Trigger

Set upper limit level and lower limit level and activated

when the input signal leaves this range.

43

Window-In Trigger

Window-Out Trigger

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the TRIG position and select

IN or OUT using the

keys.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 60

44

_____________________________________________________________________

3. Move the flashing cursor to the position shown in the

figure below, and set the lower limit of the trigger level

using the

keys.

Flashing cursor

4. Move the flashing cursor to the upper limit, and set the

upper limit of the trigger level using the

keys.

The upper limits must not be smaller than the lower

limits, or the lower limits must not be larger than the

upper limits.

5. Move the flashing cursor to the position shown in the

figure below, and set the trigger filter using the

keys.

Flashing cursor

OFF

ON

Trigger filter is disabled.

Trigger filter is enabled. Filter width: 0.5 DIV

If the trigger condition has already occurred before

measurement starts, the trigger is not activated. However,

after the trigger condition clears, the trigger is activated

when the condition next occurs.

______________________________________________________________

3.5 Trigger Functions

Page 61

_____________________________________________________________________

45

3.5.3 Voltage Drop Trigger

The 8715-01 is designed to measure commercial power

supplies (50/60 Hz), and detects momentary voltage drops

in commercial power supplies

Triggering occurs when peak voltage drops below the

specified level for morethan one-half cycle.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the TRIG position and select

DROP using the

keys.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 62

46

_____________________________________________________________________

3. Move the flashing cursor to the position shown in the

figure below, and set the frequency to be measured using

the

keys.

Flashing cursor

50 Hz

60 Hz

This measurement is made using a 50-Hz

commercial power supply.

This measurement is made using a 60-Hz

commercial power supply.

4. Move the flashing cursor to the position shown in the

figure below, and set the trigger level using the

keys.

The RMS value is displayed on the right side of the

trigger level.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 63

_____________________________________________________________________

47

3.5.4 Period Trigger

This function sets both the period reference voltage and the

period range, and measures the rise (fall) period of the

reference voltage. When the measured period deviates from

the specified range, triggering occurs.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the TRIG position and select

PRIOD using the

keys.

Flashing cursor

3. Move the flashing cursor to the position shown in the

figure below, and set the lower limit of the trigger level

(period range) using the

Flashing cursor

keys.

4. Move the flashing cursor to the upper limit, and set the

upper limit of the trigger level (period range) using the

keys.

______________________________________________________________

3.5 Trigger Functions

Page 64

48

_____________________________________________________________________

5. Move the flashing cursor to the position shown in the

figure below, and set the trigger slope using the

keys.

Flashing cursor

Triggering occurs when the rising trigger slope

(

) crosses the trigger level.

Triggering occurs when the falling trigger slope

(

) crosses the trigger level.

6. Move the flashing cursor to the position shown in the

figure below, and set the reference level using the

keys.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 65

_____________________________________________________________________

49

Triggering Position of the Period Trigger

The system monitors the period of the signal that crosses

the set reference level.

When the monitored period deviates from the set range,

triggering occurs. The trigger position is determined by the

set period range and the measurement signal period.

Signal with a period to be measured that is smaller than

lower limit of the period trigger (trigger slope:

Signal cycle

Reference level

Lower limit 1

Lower limit 2

):

When the signal crosses the reference level at the set trigger

slope before the lower limit of the set period range appears

on the screen, the intersection is always defined as the

triggering position.

Signal with a period to be measured that is larger th an the

upper limit of the period trigger (trigger slope:

Signal cycle

Reference level

Lower limit 1

Lower limit 2

):

When the upper limit of the set period range appears on the

screen before the signal crosses the reference level at the set

trigger slope, the upper limit is defined as the triggering

position. The triggering position is determined by the

position of the upper limit in the period range, as shown in

the figure above.

______________________________________________________________

3.5 Trigger Functions

Page 66

50

W

p

p

p

_____________________________________________________________________

Example for period Trigger

To measure a 50-Hz power trend waveform with period

deviation trigger conditions between 19 ms (about 52.6 Hz)

and 21 ms (about 47.6 Hz), set the following:

Lower limit: 19 ms Upper limit: 21 ms

Reference level: 0.000 V Slope:

Reference level

0.000 V

22 ms

20 ms 20 ms

21 ms

ithin the

eriod range

Within the

eriod range

Upper limit of

the

eriod range

______________________________________________________________

3.5 Trigger Functions

Page 67

_____________________________________________________________________

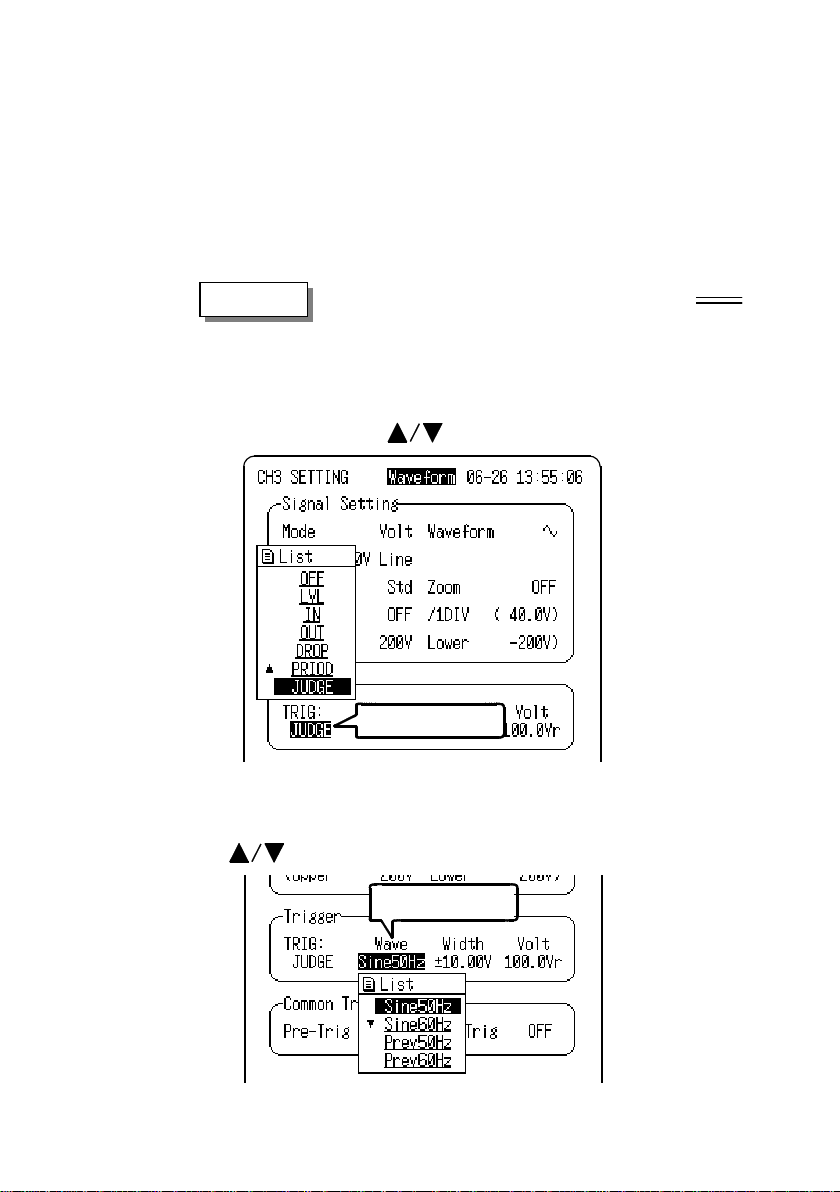

3.5.5 Waveform Detection Trigger

The waveform detection trigger function compares the

measured signal with a pre-defined control waveform range,

and triggers if the signal deviates from the control range

voltage. The control range consists of a positive and

negative amplitude offset from either a standard sine wave

or the previous input cycle.

51

Measurement data

Triggerpoint

0V

control

range

For purposes of creating a control range for a standard

waveform (either a sine wave or the previous cycle), one

cycle period is considered to begin at the positive-going 0volt crossing (positive 0 crossing).

(1) Sine Wave

The control range is based on a sine wave (with RMS

value voltage) at the mains frequency.

(2) Previous Cycle

The control range of each cycle is based on the previous

cycle of the input waveform. This selection is used

when gradual changes should not cause t riggering.

0V

Previous Cycle (one cycle)

The control range is applied to this

cycle's waveform

Input Waveform (one cycle)

This cycle is compared with

the previous cycle for

detection

______________________________________________________________

3.5 Trigger Functions

Page 68

52

_____________________________________________________________________

・ This function is not available in the 20-ms time axis

range.

・ The settable standard voltage and control range are

limited by the voltage range setting.

・ We recommend setting the standard voltage after

verifying the actual rms voltage with the DMM function.

Procedure Screen: CH SETTING / Waveform Display

1. Press the CH SET key to display the desired

CH SETTING screen.

2. Move the flashing cursor to the TRIG position and select

JUDGE using the

keys.

Flashing cursor

3. Move the flashing cursor to the position shown in the

figure below and select the reference waveform using the

keys.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 69

_____________________________________________________________________

53

4. Move the flashing cursor to the position shown in the

figure below and set the control range using the

keys.

Flashing cursor

5. When 50- or 60-Hz Sine Wave was selected in step 3, set

the Standard Voltage.

Move the flashing cursor to the position shown in the

figure below and set the standard voltage using the

keys.

When measuring 100-V commercial lines: Set the standard

voltage to 100 Vr.

When measuring 200-V commercial lines: Set the voltage

to 200 Vr.

Flashing cursor

______________________________________________________________

3.5 Trigger Functions

Page 70

54

_____________________________________________________________________

3.5.6 Setting the Pre-Trigger

The pre-trigger function serves to record the waveform not

only after but also before triggering has occurred.

In the Waveform measurement mode, using the recording

start point as 0% and the recording end point as 100%, the

trigger point can be specified in percent. When all trigger

sources are set to OFF, the pre-trigger setting is invalid.

Trigger point

Pre-trigger: OFF

Pre-trigger: 50%

Pre-trigger: 100%

Procedure Screen: CH SETTING

1. Press the CH SET key to display the CH SETTING

screen.

2. Move the flashing cursor to the Pre-Trig position and use

the

keys to make a setting.

Flashing cursor

・ In Waveform measurement mode, when the pre-trigger is

set, the trigger will not be registered for a certain period

after the start of measurement. (During this interval, Pretrig wait is shown on the Waveform display screen.)

・ When the trigger can be registered, the indication Wait

for trig is shown on the waveform display screen.

______________________________________________________________

3.5 Trigger Functions

Page 71

_____________________________________________________________________

play

3.5.7 Input Level Monitor Function

・ The in put signal is monitored in real time when waiting

for the trigger in Waveform measurement mode.

・ The input settings can be made for a particular channel

using the Channel Select keys (CH1 to CH4) while

monitoring on the Waveform Display screen.

Analogchannels

55

Input

level

CH1 to 4, left-to-right

When the input level is not displayed on the

screen displayrange

The input level exceeds the upper limit.

The input level exceeds the lower limit.

Waveform

dis

range

______________________________________________________________

3.5 Trigger Functions

Page 72

56

_____________________________________________________________________

3.6 Waveform Display Screen Settings

This section describes the settings on the Waveform

Display screen. Pressing CH1 to CH4 displays the input

channel and trigger settings. Press the same key again to

return to the previous screen.

2

1

3

4

5

6

Display item Selection Reference

1. Time axis range 200 μs to 20 ms /DIV 3.3.2

2. Magnification/

Compression of the

time axis

3. A/B cursor measurement or waveform scrolling 5.1, 5.2

4. Input channel setting Sets each channels 3.4

5. Trigger setting Sets each channels 3.5

6. Sequential save

______________________________________________________________

3.6 Waveform Display Screen Settings

X10 to X1/50 5.3

When multiple waveforms

have been stored, select

one to display.

3.8

Page 73

_____________________________________________________________________

3.7 Start and Stop Operation (Waveform)

Measurement start

57

測定開始

Trigger conditions

are met

Recording data

Pressing the START key causes a

confirmation window to appear.

Press the START key again to start

measurement.

The LED lights green when measurement

starts.

When pre-trigger is activated, the trigger is

not enabled until the specified pre-trigger data

has been read.("Pre-trig wait" is displayed.)

"Wait for trig" is displayed until the trigger

condition occurs.

Data recording starts when the trigger

conditions are met.

If no trigger conditions are enabled, data

acquisition starts when measurement starts.

During recording, "Storing" is displayed.

When automatic printing is selected, data is

printed after display.

Wait for trigger

Measurement end

測定終了

Measurement can be aborted by pressing the

STOP key twice.

Waveform data acquired before the Stop key

was pressed is displayed and saved.(automatic

printing will not execute)

・ If measurement is aborted before a trigger event has

occurred, no waveforms are stored. However, if a

waveform was acquired during a previous trigger event,

that waveform is displayed (unless it was the maximum

recording length).

・ When the number of recorded trigger events has reached

the sequence limit, the earliest recorded data is

overwritten.

______________________________________________________________

3.7 Start and Stop Operation (Waveform)

Page 74

58

_____________________________________________________________________

3.8 Sequential Save Function

When multiple trigger events occur during measurement

and several waveforms are acquired, the last-acquired

waveform is displayed by the Sequential Save function.

Waveform Display Procedure

Press CH1 to CH4 to display Sequential.

The selected number is d ispla yed in a reversed block in the

figure.

This block indicates the waveform currently displayed on the

Waveform Display screen.

To change the display, move the blinking cursor to the

position of the desired number or directly to the block

and press the keys to change

.

(

),

When measurement is restarted, all previous waveforms are

deleted and recording commences from the first block.

______________________________________________________________

3.8 Sequential Save Function

Page 75

_____________________________________________________________________

59

Chapter 4

RMS Trend Measurement

Mode

4.1 Outline of the RMS Trend

Measurement

The RMS Trend Measurement Mode records mains voltage

and changes in current levels as effective (rms) values.

This mode has the following features:

(1) Measures rms values of commercial power (50/60 Hz).

・ Mains voltage measurement

・ Load current measurement when used with clamp

sensor

・ Leakage current measurement when used with clamp

sensor (3283)

(2) Continuous real-time recording

・ Records rms value trends on the printer

・ Capability to print measured value at specified

intervals (1 frame) simultaneously with rms trend

waveform (hybrid recording)

Instantaneous waveform recording on the Basic Setting

screen must be enabled (ON) in order to set or change the

instantaneous waveform trigger for the time axis, recording

length and the channel screen for instantaneous waveform

recording.

______________________________________________________________

4.1 Outline of the RMS Trend Measurement

Page 76

60

_____________________________________________________________________

4.2 Operation Sequence (Trend)

RMS Trend Measurement Mode operating procedures are

described by the following flowcharts.

Preparation

基本設定の

Basic Setting screen

CH SETTING screen

See Chapter 2.

Press the SET key to display the Basic

Setting screen.

Use the key to select the Trend

measurement mode.

Measurement Mode

Time Axis Range

Frequency

Real Time Print

Memory Record

Press the CH SET key to display the desired

CH SETTING screen.

Input Mode

Measurement Range

Waveform Position

See 4.3.1.

See 4.3.2.

See 4.3.3.

See 4.3.4.

See 4.5.

See 4.4.1.

See 4.4.2.

See 4.4.3.

Low-Pass Filter

Waveform Display

Print Value

Zoom

Memory Trigger

Pre-Trigger

Ext Trigger

See 4.4.4.

See 4.4.5.

See 4.4.6.

See 4.4.6.

See 4.5.

See 4.5.6.

See 5.6.

______________________________________________________________

4.2 Operation Sequence (Trend)

Page 77

_____________________________________________________________________

61

4.3 Setting Items (Trend)

4.3.1 Setting the Measurement Mode

The 8715-01 has two measurement modes. Select the RMS

Trend Measurement Mode.

Procedure Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Press the

mode.

With the RMS Trend Mode (rms recording), the rms value

is continuously recorded in real time from the moment the

START key is pressed to start measuring until the STOP

key is pressed.

Up to 200 divisions of data are stored in internal memory,

after which data is overwritten.

After measurement, data stored in internal memory can be

viewed by reverse scrolling, or printed later.

The relationship between the time axis range and the

recording time storage capacity of the internal memory is

indicated in the following table. The maximum possible

recording time is the instrument of the time axis and 200

divisions.

Time/DIV Recording Time Time/DIV Recording Time

1s 3 min 20 s 1 min 3h20min

2s 6 min 40 s 2 min 6h40min

5s 16 min 40 s 5 min 16 h 40 min

10 s 33 min 40 s 10 min 1day9h20min

30 s 1h40min 30 min 4 day 4 h

key to select RMS Trend measurement

1h 8 day 8 h

______________________________________________________________

4.3 Setting Items (Trend)

Page 78

62

_____________________________________________________________________

When the time axis ranges from 1 to 5 s/DIV, simultaneous

NOTE

・

numerical data printing is unavailable.

If the instrument is used with battery pack 9447, simultaneous

・

printing is unavailable at 1 s/DIV of the time axis.

______________________________________________________________

4.3 Setting Items (Trend)

Page 79

_____________________________________________________________________

63

4.3.2 Setting the Time Axis Range

Set the speed for inputting and storing the waveform of the

input signal. Time axis range setting expresses the time for

1DIV.

Procedure-1 Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Move the flashing cursor to Time/DIV and select the

time axis range using the

keys.

Flashing cursor

The data interval for the

time axis range setting is

1/80 (1 DIV=80 data

points).

Pressing the TIME/DIV key moves the flashing cursor

automatically to the Time Axis position for setting.

Procedure-2 Screen: Waveform Display

1. Press the DISP key to display the waveform display

screen.

2. Move the flashing cursor to the position shown in the

figure below and use the

Flashing cursor

keys to make a setting.

Pressing the TIME/DIV key sets the time axis regardless of

the flashing cursor position.

______________________________________________________________

4.3 Setting Items (Trend)

Page 80

64

_____________________________________________________________________

4.3.3 Setting the Frequency

Serves to set the frequency of the signal to be measured.

Procedure Screen: Basic Setting

1. Press the SET key to display the Basic Setting screen.

2. Move the flashing cursor to Frequency and select the

frequency using the

keys.

Flashing cursor

50 Hz

60 Hz

______________________________________________________________

4.3 Setting Items (Trend)