Page 1

8423

Instruction Manual

MEMORY HiLOGGER

Mar. 2019 Revised edition 9

8423A981-09 19-03H

This manual describes the

Memory HiLogger's functions

and operation in detail, and its

specications.

EN

Page 2

Page 3

Contents

Introduction.................................................................................1

i

Contents

1

Verifying Package Contents .......................................................2

Safety Information ......................................................................4

Operating Precautions................................................................6

Chapter 1 Overview ________________________ 9

1.1 Product Overview ................................................................9

1.2 Features ............................................................................10

1.3 Names and Functions of Parts ..........................................12

1.4 System Configuration ........................................................ 15

1.5 Measurement Flowchart ...................................................16

Chapter 2 Installing the Software ____________ 17

2.1 Installing Logger Utility ......................................................18

2.2 Installing the USB Driver ...................................................21

2.3 Connect the instrument and computer with the USB

cable provided ...................................................................25

2

3

2.4 Starting and Ending Logger Utility ....................................28

2.5 Uninstalling the Logger Utility ...........................................30

Chapter 3 Setting Up the Instrument _________ 31

3.1 Attaching Units ..................................................................32

3.1.1 Unit Types ..............................................................................32

3.1.2 Attaching a Unit ......................................................................33

3.2 Connecting a Cable to the Terminal Block ........................ 35

3.2.1 Removing and Attaching a Terminal Block .............................35

3.2.2 Connecting a Cable ................................................................37

3.3 Installing the Memory HiLogger ........................................40

3.3.1 Mounting to a Wall Surface with Screws ................................40

3.3.2 Securing with a DIN Rail .........................................................41

3.4 Connecting the AC Adapter ..............................................42

3.5 Connecting a Communication Cable ................................43

3.5.1 Connecting the USB Cable .....................................................43

3.5.2 Connecting the LAN Cable .....................................................44

8423A981-09

3.6 Using a CF Card ............................................................... 45

Page 4

ii

Contents

3.6.1 Formatting a CF Card ............................................................ 45

3.6.2 Inserting and Ejecting a CF Card ........................................... 46

3.6.3 Replacing a CF Card during Measurement ........................... 47

3.6.4 File Protection during Power Outage ..................................... 47

3.7 Connecting Synchronization Cables ................................. 48

3.8 Connection Method for External Control Input Terminals . 50

3.9 Turning the Power On and Off .......................................... 52

Chapter 4 Software Screen _________________ 53

4.1 Main Screen ...................................................................... 53

4.2 Settings Screens ............................................................... 56

4.3 Display Settings Windows ................................................ 60

4.4 Channel Indication on Screens ......................................... 61

Chapter 5 Setting Measurement Conditions ___ 63

5.1 Registering Loggers in Logger Utility ................................ 64

5.1.1 Searching and Registering ..................................................... 64

5.1.2 Registering Manually ............................................................. 68

5.1.3 Settings for Synchronized Measurement ............................... 74

5.2 Confirming the Unit Configuration (Digital Filter Setting) .. 75

5.3 Configuring Basic Settings for Measurement ................... 77

5.3.1 Setting Function and Recording Interval ................................ 77

5.3.2 File Save Settings .................................................................. 82

5.3.3 Comment Input ...................................................................... 84

5.3.4 Recording Settings ................................................................ 85

5.4 Advanced Settings for Each Channel ............................... 89

5.4.1 Setting Measurement Conditions ........................................... 89

5.4.2 Waveform Calculation Settings .............................................. 96

5.4.3 Setting the Display Method .................................................... 98

5.4.4 Assigning Channels to Sheets ............................................. 103

5.5 Setting the Trigger Function ........................................... 105

5.5.1 Recording Operation during Simultaneous Use of Timer

Measurement and Triggers .................................................. 105

5.5.2 Pre-trigger ............................................................................ 109

5.5.3 Trigger Timing ...................................................................... 111

5.5.4 Trigger Sources ................................................................... 112

5.5.5 External Triggers .................................................................. 113

5.5.6 Analog Triggers ................................................................... 114

5.5.7 Logic Triggers ...................................................................... 117

5.6 Setting the Alarm Function ............................................. 118

Page 5

5.7 Setting Environment Conditions ......................................121

5.7.1 Setting External Control Input Terminals ..............................121

5.7.2 CF Card Save Settings .........................................................123

5.7.3 Time Value Display ...............................................................125

5.7.4 Start Backup .........................................................................126

5.8 Send Settings ..................................................................127

5.9 Process All ......................................................................128

iii

Contents

5.10 Narrowing Down of Display Channels ............................129

Chapter 6 Starting and Stopping Measurement131

6.1 Pre-Operation Inspection ................................................134

6.2 Starting and Ending Measurement .................................135

6.2.1 Computer Based Measurement ............................................135

6.2.2 Standalone Measurement ....................................................137

Chapter 7 Analyzing Measurement Data _____ 139

7.1 Changing the Waveform Display Range ......................... 140

7.2 Checking Cursor Values .................................................141

7.3 Changing Display Settings ..............................................142

7.3.1 Switching between Waveform Display and List Display .......142

7.3.2 Waveform Display Settings ..................................................143

7.3.3 List Display Settings .............................................................148

7.3.4 Common Settings and Auto Update Settings .......................149

3

4

5

6

7

8

7.4 Calculations ....................................................................150

7.4.1 Calculation Settings ..............................................................150

7.4.2 Numerical Calculation Expressions ......................................152

7.5 Event Mark Function .......................................................153

7.5.1 Adding a Mark (Event Mark) to a Waveform ........................153

7.5.2 Searching for and Editing Event Marks ................................154

7.6 Searching for the Maximum Value, Minimum Value,

and Variation ...................................................................155

7.7 Displaying the Channel List ............................................159

7.8 Confirming Measurement Conditions ..............................160

7.9 Monitor Display ...............................................................161

Chapter 8 Saving and Reading Data ________ 163

8.1 Saving and Reading Measurement Data ........................164

8.1.1 Saving Measurement Data as Text ......................................164

8.1.2 Converting Measurement Data to an Excel File ...................167

Page 6

iv

Contents

8.1.3 Reading Measurement Data ................................................ 169

8.2 Saving and Reading Setting Data ................................... 170

8.2.1 Saving Setting Data ............................................................. 170

8.2.2 Reading Setting Data ........................................................... 170

8.3 Automatically Transferring Measurement Data to Excel . 171

8.3.1 Real-Time Transfer Settings ................................................ 171

8.3.2 Real-Time Transfer Example ............................................... 172

8.4 Notes in Windows Vista /7 .............................................. 173

Chapter 9 Printing _______________________175

9.1 Setting the Printing Range .............................................. 176

9.2 Settings for Waveform Print Options .............................. 177

9.3 Settings for the Appendix ................................................ 179

9.4 Printer Settings/Printing .................................................. 179

9.5 Copy to Clipboard ........................................................... 180

9.6 Print Example .................................................................181

Chapter 10 Setting Method for Logger ______185

10.1 Setting Method ................................................................ 186

10.2 Synchronized Measurement ........................................... 187

10.3 Date ................................................................................ 188

10.4 Time ................................................................................ 189

10.5 DHCP .............................................................................. 190

10.6 IP Address ...................................................................... 191

10.7 Subnet Mask ................................................................... 192

10.8 Port Number ................................................................... 193

10.9 Gateway .......................................................................... 194

10.10 Display Language ........................................................... 196

10.11 Self Check ...................................................................... 197

10.11.1 ROM Check ........................................................................ 197

10.11.2 RAM Check ......................................................................... 198

10.11.3 BUS Check ......................................................................... 199

10.11.4 Key Check .......................................................................... 200

10.11.5 LED Check .......................................................................... 201

10.11.6 LCD Check ......................................................................... 202

10.12 Displaying Individual Version Information ...................... 203

10.12.1 ROM Version ...................................................................... 203

10.12.2 FPGA Version ..................................................................... 204

Page 7

10.12.3 MAC Address ......................................................................205

10.12.4 Serial No. .............................................................................206

10.13 Reading and Writing a Setting File ................................ 207

10.13.1 Writing a Setting File ...........................................................207

10.13.2 Reading a Setting File .........................................................208

Chapter 11 Communications (HTTP/FTP) ____ 209

11.1 Displaying the Main Page ...............................................209

11.2 Starting and Stopping Measurement ..............................210

11.3 Current Value Display .....................................................211

11.4 Acquiring Data from Memory ..........................................212

11.5 Data Acquisition using FTP .............................................213

v

Contents

Index

Chapter 12 Specifications_________________ 215

12.1 General Specifications ....................................................215

12.2 Application Software .......................................................219

12.3 Unit Specification ............................................................221

12.3.1 Model 8948 Voltage/Temp Unit ............................................221

12.3.2 Model 8949 Universal Unit ...................................................223

12.3.3 Model 8996 Digital/Pulse Unit ..............................................226

12.3.4 Model 8997 Alarm Unit .........................................................227

12.4 Dimension Diagrams ....................................................... 228

Chapter 13 Maintenance and Service _______ 231

13.1 Cleaning ..........................................................................231

13.2 Troubleshooting ..............................................................232

13.3 Initializing Settings (System Reset) ................................233

13.4 Zero-position Calibration (Zero Adjustment) ...................234

8

9

10

13.5 Industrial Waste ..............................................................235

Appendix________________________________ A 1

Appendix 1 Scan Timing ............................................................... A 1

Appendix 2 Version Update........................................................... A 2

Appendix 3 Error Display............................................................... A 3

Appendix 3.1 Application Software .................................................................. A 3

Appendix 3.2 8423 Memory HiLogger Main Unit ............................................. A 5

Appendix 4 Recording Intervals and Maximum Times for

Recording to CF Cards............................................... A 7

11

12

13

Appendix

Page 8

vi

Contents

Appendix 4.1 Model 9726 PC Card 128M ........................................................A 8

Appendix 4.2 Model 9727 PC Card 256M ......................................................A 10

Appendix 4.3 Model 9728 PC Card 512M ......................................................A 12

Appendix 4.4 Model 9729 PC Card 1G ..........................................................A 14

Index ________________________________Index 1

Page 9

Introduction

The 8423 Memory HiLogger is a data collection instrument for use connected to a computer. This method of measurement is referred to as “computer based” within this manual. The supplied software Logger Utility is

used to set measurement conditions, start measurement, and otherwise

control the instrument. Install the software while referring to "Chapter 2

Installing the Software" (p. 17). You can also attach units to the instrument

in accordance with the measurement object. For details, refer to the manuals supplied with the units.

Measurement Data

USB or LAN

1

Introduction

Thank you for purchasing the HIOKI "Model 8423 Memory HiLogger." To obtain

maximum performance from the instrument, please read this manual first, and

keep it handy for future reference.

The following instruction manuals are included with the 8423 Memory HiLogger.

Refer to them as they pertain to your usage of the instrument.

Manuals Contents

Read first.

Quick Start Manual

1

Instruction Manual

2

(this manual)

Registered

Trademarks

• Windows, MS-DOS, and Excel is a registered trademark of Microsoft Corporation in the United States and/or other countries.

• Pentium is a registered trademark of Intel Corporation.

Offers an introduction to the 8423's basic measuring

method for first time users.

Contains explanation and instructions regarding the instrument's operating method and functions.

Page 10

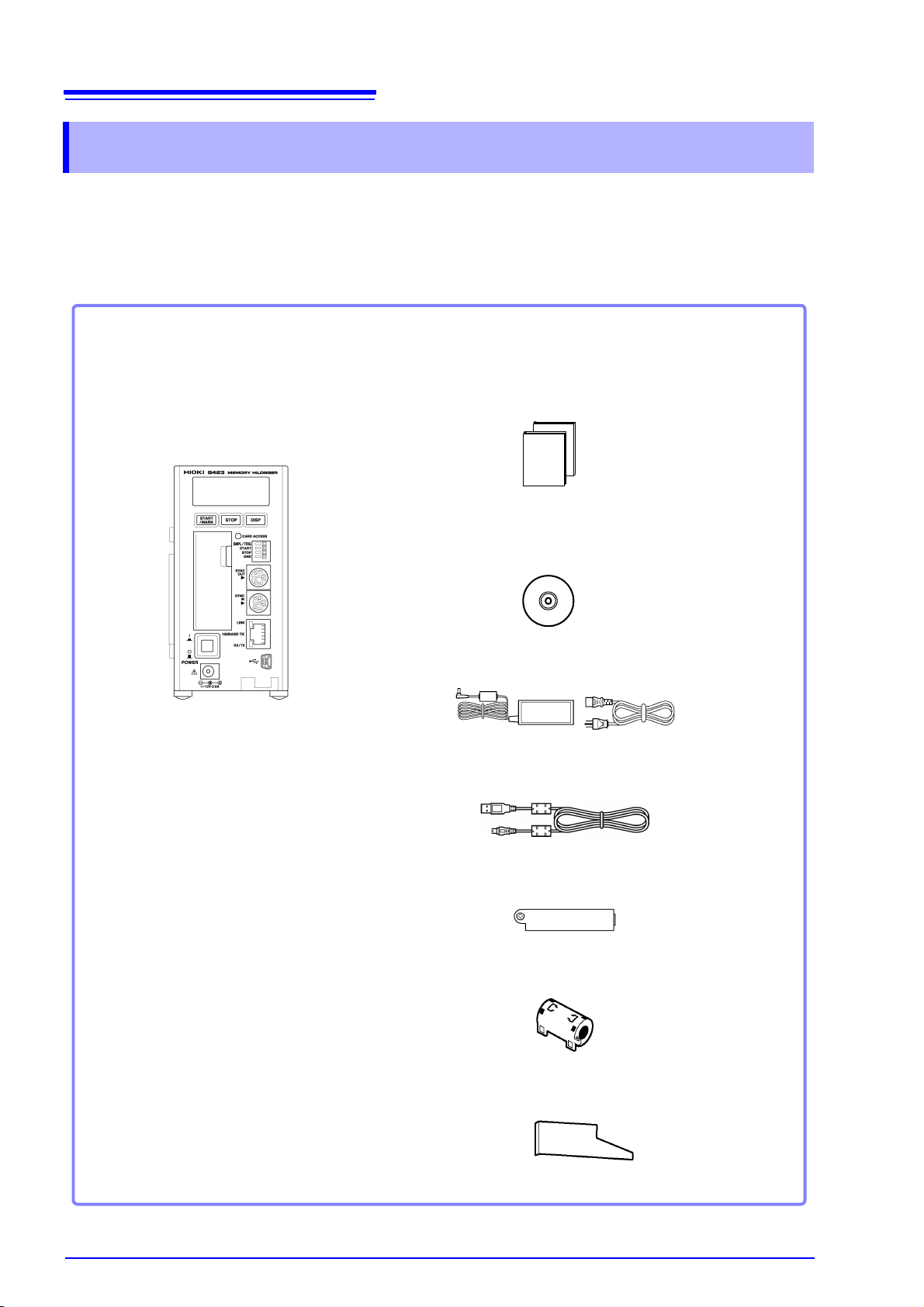

2

Model 8423 Memory HiLogger

.................................................. 1

Please check to make sure that no items are missing from your package.

Quick Start Manual ..................................1

Instruction Manual ...................................1

Logger Utility CD (data collection software)

.................................................................1

(The latest version can be downloaded from our web site.)

Model 9418-15 AC Adapter .....................1

USB Cable...............................................1

Connector Cover .....................................1

Ferrite Clamp...........................................1

Connection Plate .....................................1

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Page 11

Verifying Package Contents

Options

The following options are available.

Model 8948 Voltage/Temp Unit Model 8949 Universal Unit Model 8996 Digital/Pulse Unit

3

Model 8997 Alarm Unit Model 9418-15 AC Adapter Model 9642 LAN Cable

Model 9683 Connection Cable (for

synchronization)

Model 9701 Humidity Sensor Model 9726 PC Card 128M

Model 9727 PC Card 256M

Model 9728 PC Card 512M

Model 9729 PC Card 1G

Page 12

4

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to

the instrument. Be certain that you understand the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using it,

be sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual (marked with

the symbol) before using the relevant function.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates a ground.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Page 13

Notation

5

Safety Information

Indicates a prohibited action.

Indicates quick references for operation and remedies for troubleshooting.

*

Accuracy

We define measurement tolerances in terms of f.s. (full scale) with the following

meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or scale length. This is usually the name of the

currently selected range.

Measurement Categories

This 8423's unit complies with CAT II safety requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories. These are defined as follows.

CAT II Primary electrical circuits in equipment connected to an AC elec-

CAT III Primary electrical circuits of heavy equipment (fixed installations)

Indicates that descriptive information is provided below.

trical outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance, and to

the power meter and primary overcurrent protection device (distribution panel).

Using a measurement instrument in an environment designated with a highernumbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must be carefully avoided.

Page 14

6

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits

of the various functions.

Preliminary Checks

Before using the instrument the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the cables is

undamaged and that no bare conductors are improperly exposed. Using

the instrument in such conditions could cause an electric shock, so contact your dealer or Hioki representative for replacements.

Installing the Instrument

Operating temperature & humidity:

0 to 40°C (32 to 104°F), 30 to 80%RH (non-condensating)

Operating temperature & humidity for guaranteed accuracy:

23 ± 5°C (73 ± 9°F), 30 to 80%RH

Avoid the following locations that could cause an accident or damage to the

instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels

of particulate dust

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

Installing the

instrument

In addition to placing this instrument on a flat surface, you can also mount it on a

DIN rail or a wall surface.See "3.3 Installing the Memory HiLogger" (p. 40).

Page 15

Handling the Instrument

To avoid electric shock, do not remove the instrument's case. The internal

components of the instrument carry high voltages and may become very

hot during operation.

Never modify the instrument. Only Hioki service engineers should disassemble or repair the instrument. Failure to observe these precautions may

result in fire, electric shock, or injury.

To avoid damage to the instrument, protect it from physical shock when transporting and handling. Be especially careful to avoid physical shock from dropping.

7

Operating Precautions

Handling the Cables

Handling the CD

This instrument may cause interference if used in residential areas. Such use

must be avoided unless the user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of radio and television

broadcasts.

• Avoid stepping on or pinching cables, which could damage the cable insula-

tion.

• To avoid breaking the cables, do not bend or pull them.

Use only the specified cables. Using a non-specified cable may result in incorrect measurements due to poor connection or other reasons.

Page 16

8

Operating Precautions

• Always hold the disc by the edges, so as not to make fingerprints on the disc or

scratch the printing.

• Never touch the recorded side of the disc. Do not place the disc directly on

anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the

label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not use a ballpoint pen or hard-tipped pen, because there is a danger of scratching the surface and corrupting the data. Do not use adhesive labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high

temperature or humidity, as there is a danger of warping, with consequent loss

of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry cloth, or use

a CD cleaner. Always wipe radially from the inside to the outside, and do no

wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system that

arises from the use of this CD, or for any problem related to the purchase of a

Hioki product.

Page 17

9

Data is transferred

in real time

USB or LAN

Computer Based Standalone

Data is saved to

a CF card

Start measurement

Stop measurement

Measurement is started and

stopped with the keys on

the instrument.

Optional 9683 Connection Cable

(for synchronization)

Maximum of

five loggers

Example of Connecting Multiple Memory HiLoggers

USB or LAN

HUB

1.1 Product Overview

1

Overview Chapter 1

1.1 Product Overview

The 8423 Memory HiLogger is a computer based data collection instrument. A

combination of four types of unit can be connected to enable the measurement

of up to 120 channels with one Memory HiLogger. Furthermore, the synchronous

operation of a maximum of five Memory HiLoggers enables you to build a system with up to 600 channels. The instrument transfers the measurement data to

the computer in real time. The instrument can also be used not just for computer

based data collection but also as a standalone instrument. (Measurement with

just this instrument is referred to as “standalone” within this manual.) In either

case, set the measurement conditions with the supplied software Logger Utility.

See "2.1 Installing Logger Utility" (p. 18).

Chapter 1 Overview

Page 18

10

1.2 Features

1.2 Features

10 ms Recording Intervals*

The fastest recording interval is 10 ms, during which the input data of all channels is scanned. The recording intervals can be set in 19 steps from 10 ms to 1

hour.

* The recording interval is 5 seconds or longer when one or more channels are

set to humidity measurement.

Multiple Channels (Up to 600 Channels)

A maximum of eight units can be connected to one 8423 Memory HiLogger to

enable the measurement of up to 120 channels. Furthermore, the synchronous

operation of five Memory HiLoggers facilitates the synchronized measurement of

600 channels.

Isolated Input Circuits

The input circuits of all of the channels are isolated*. The maximum rated voltage

to earth is 600 VAC/DC, so voltage can be measurement safely.

* 8948 Voltage/Temp Unit and 8949 Universal Unit only.

For the 8996 Digital/Pulse Unit, each 3 blocks of 5 channels are isolated within

the unit.

Dual Sampling

A combination of 2 types of recording interval can be set within the system. The

recording intervals can be set individually by unit. Measuring with a recording

interval suitable for each measurement object allows for efficient use of space in

the internal memory or CF card.

See "5.3.1 Setting Function and Recording Interval" (p. 77).

Flexible System Configuration

The following four types of unit can be used in accordance with the purpose of

use. The input terminal block is removable to enable connections to be made

easily.

• Model 8948 Voltage/Temp Unit and 8949 Universal Unit

There are 15 channel inputs per unit. Measurement is possible for voltage,

nine types of thermocouple, two types of resistance temperature detector*,

and humidity* (an optional sensor is required).

* Model 8949 Universal Unit only

• Model 8996 Digital/Pulse Unit

There are 15 channel inputs per unit. Logic input and pulse input can be set

for each channel. Logic signal, totalization, and rotation rate measurement are

possible.

• Model 8997 Alarm Unit

There are 15 channel outputs per unit. Alarm output (open collector output)

allows for controlling external devices.

Page 19

11

1.2 Features

Synchronized Measurement

Connecting multiple Memory HiLoggers with optional 9683 Connection Cable

(for synchronization) allows for synchronized measurement. See "3.7 Connecting Synchronization Cables" (p. 48).

Equipped with LAN & USB Interfaces

The instrument is compatible with LAN 100BASE-TX and USB2.0. A computer

and Memory HiLogger can be connected to enable the supplied software Logger

Utility to be used to control the Memory HiLogger and collect data.

Equipped with CF Card Slot

This allows you to save the setting conditions and the measurement data in real

time to a CF card. While data is being saved to the CF card in real time, you can

replace the CF card without stopping measurement. Furthermore, the risk of files

being damaged as a result of, for instance, an unexpected power outage is

greatly reduced because internal backup circuitry is used to process the ending

of files when there is a power outage.

Equipped with External Control Input Terminals

The Memory HiLogger can be controlled by inputting a signal from an external

device. This allows for the starting and stopping of measurement, external sampling, and external triggers.

1

Chapter 1 Overview

Standalone Measurement

After settings such as the measurement conditions have been configured from

Logger Utility, you can disconnect the computer and then start/stop measure-

ment with or on the instrument.

Page 20

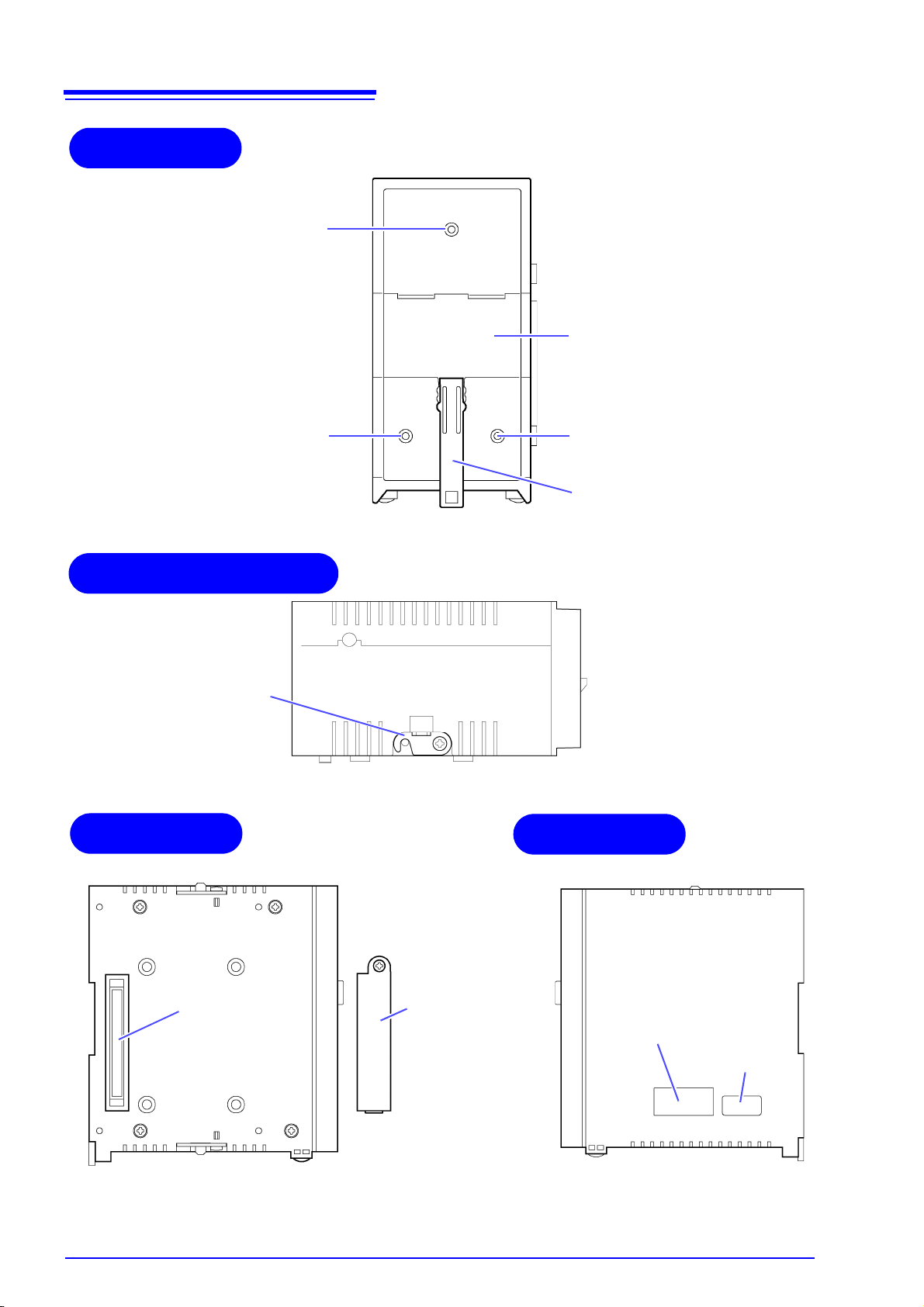

12

CF card slot

Power switch

Front Panel

AC adapter connector

CF card access LED

External control input terminals

Synchronization cable connectors

100BASE-TX connector

USB connector

Display

Key operations

(See the next page)

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

Names of Parts Explanations

Display

CF card access LED

CF card slot Allows for a CF card to be inserted for saving measurement data.

Power switch Turns the power ON/OFF.

AC adapter connector Allows for a 9418-15 AC Adapter to be connected.

USB connector Allows for a USB cable to be connected.

100BASE-TX connector Allows for a 9642 LAN Cable to be connected.

Synchronization cable

connectors

External control input

terminals

Displays setting values, measurement values, error messages, warning

messages, and other information.

• When the cover is open:

Off: The CF card can be ejected.

Lit red: The CF card cannot be ejected because data is being written.

• When the cover is closed:

Off: A CF card is not inserted or recording is not possible because the

CF card cannot be recognized.

Lit green: A CF card is inserted and recording is possible.

Lit red: The CF card is being read or written.

Allows for connecting optional 9683 Connection Cable (for synchronization) when you want to perform synchronized measurement with multiple

Memory HiLoggers.

Allows for controlling the instrument by inputting a signal from an external

device.

Page 21

13

1.3 Names and Functions of Parts

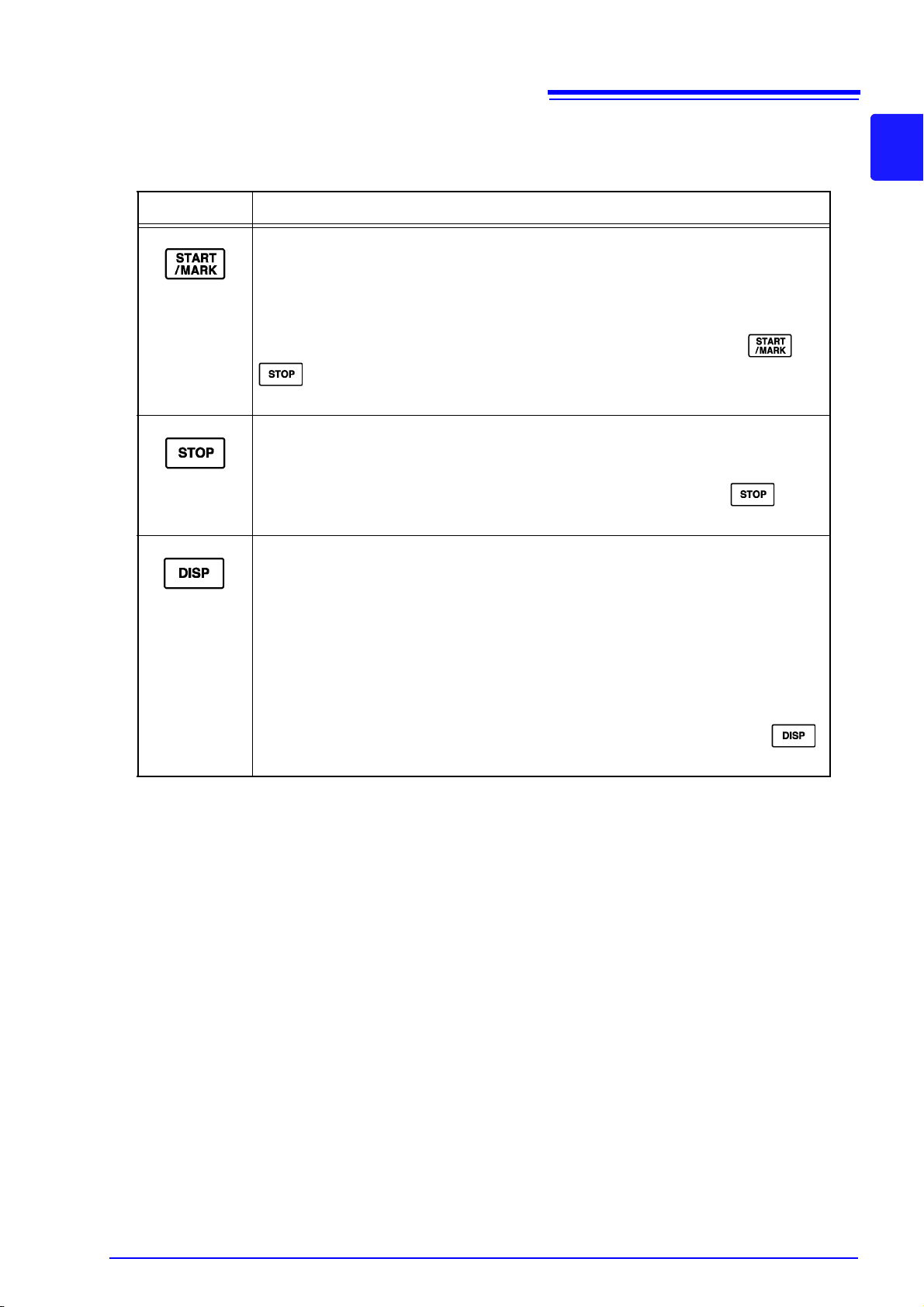

Key Operations

Keys Explanations

• The key lights during measurement.

• Press the key once during standby to start measurement.

• Press the key during measurement to input an event mark.

When the power is on:

You can initialize the settings by turning the power on while pressing and

See "13.3 Initializing Settings (System Reset)" (p. 233).

• Press the key twice in succession during measurement to stop measurement.

When the power is on:

You can initialize the settings by turning the power on while pressing .

See "13.3 Initializing Settings (System Reset)" (p. 233).

• Switches the display content.

• The key flashes while an error message or warning message is displayed. Press

• If the key is pressed for at least one second and then released while measure-

1

Chapter 1 Overview

.

the key once to clear the display.

ment values are displayed during measurement, the display channels are fixed

to those displayed the instant the key was released. Press the key for at least

one second again to cancel fixing of the display channels.

When the power is on:

The instrument enters setting mode if you turn on the power while pressing .

See "Chapter 10 Setting Method for Logger" (p. 185).

Page 22

14

Rear Panel

Wall surface

mounting nut

Lever

DIN Rail Mounting Groove

Wall surface

mounting nut

Wall surface

mounting nut

Upper/Bottom Panel

Connection

fittings

Left Panel

Right Panel

Connector

Connector cover

Be sure to attach this to

the unit at the very end.

Serial No.

When controlling this instrument

with Logger Utility, use the serial

No. to differentiate it from other instruments.

MAC address

1.3 Names and Functions of Parts

Page 23

15

Model 9418-15 AC Adapter

Model 8423 Memory HiLogger

USB cable

Model 9683 Connection Cable (for

synchronization)

External control input

Model 8948 Voltage/Temp Unit

Model 8996 Digital/Pulse Unit

Model 8997 Alarm Unit

Model 8949 Universal Unit

Connection Example:

Model 9642 LAN

Cable

1.4 System Configuration

1.4 System Configuration

The system configuration is as follows.

1

Chapter 1 Overview

Page 24

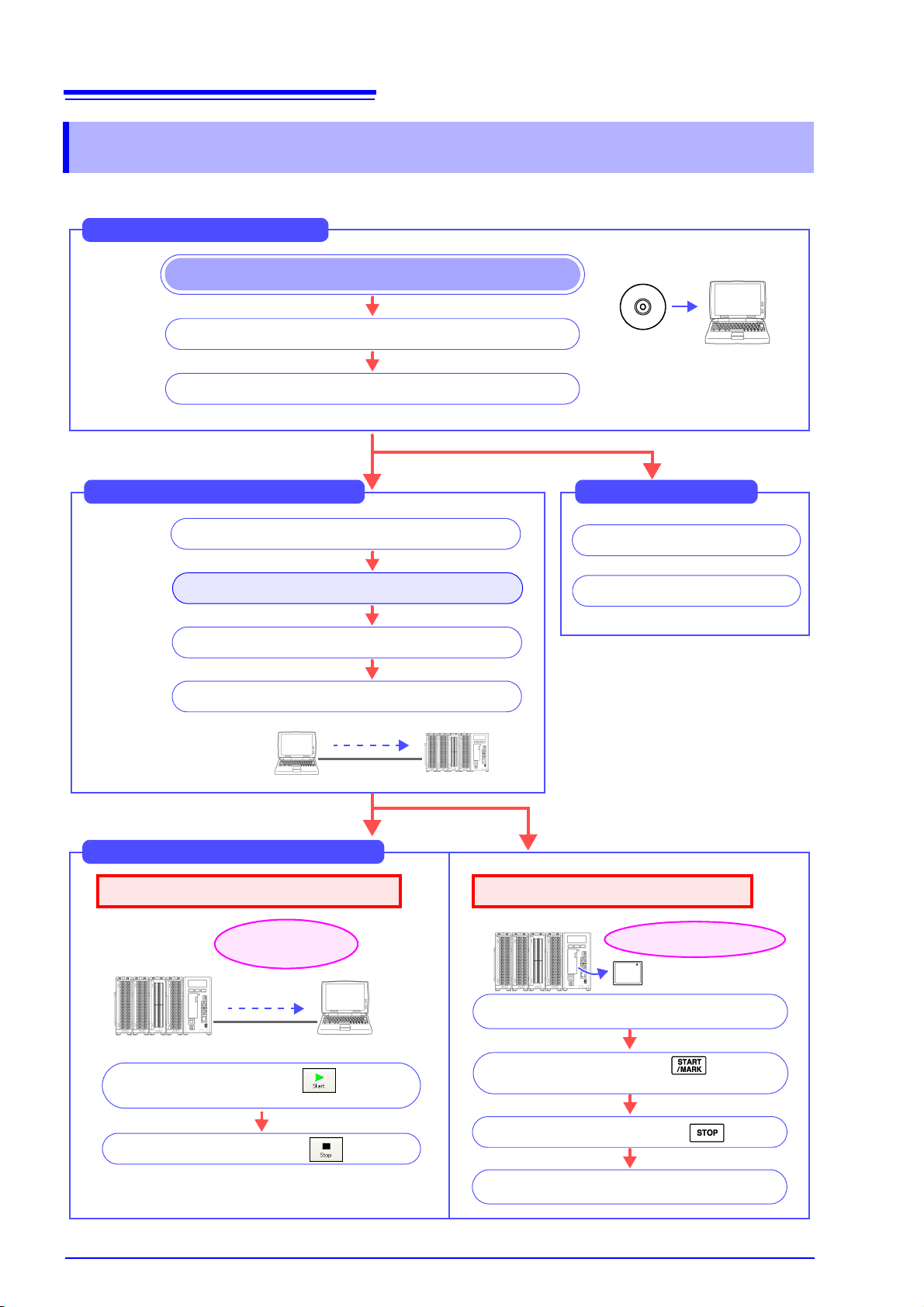

16

Save data to the CF card

Viewing Saved Data

Read the measurement data (p. 169)

Read the setting data (p. 170)

From Start to End of Measurement

At the time

of purchase

Preparing for Measurement

Start the software Logger Utility

Install and connect the instrument (p. 31)

Install the software on the PC (p. 18)

Disconnect the communication cable from the

instrument

Start measurement with the button of

Logger Utility

Start measurement with of the

Memory HiLogger

Stop measurement with the button

Stop measurement with

Setting Measurement Conditions

Register the logger in Logger Utility (p. 64)

Set the IP address and other communication settings

Set the measurement conditions (p.74 to p.126)

Send the settings to the instrument (p. 127)

For LAN

communication only

Load and display the measurement data

on the computer

Obtain and save data

in real time

Computer Based Measurement (p. 135)

Standalone Measurement (p. 137)

1.5 Measurement Flowchart

1.5 Measurement Flowchart

Proceed with measurement while referring to the following measurement flowchart.

Page 25

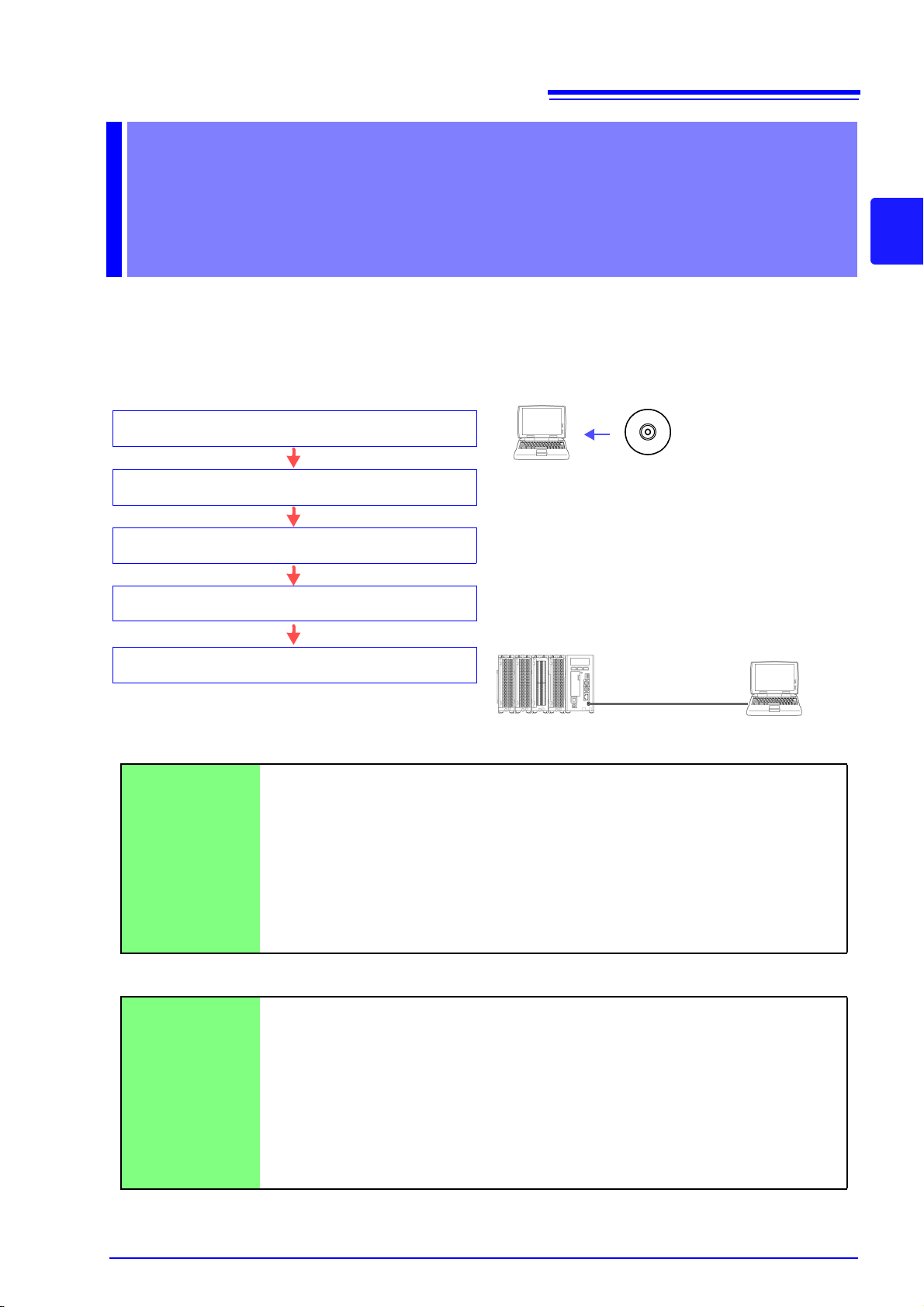

Installing the

(1) Set the CD into the drive of the computer

(2) Install Logger Utility (p. 18)

(5) Connect the instrument and computer with the USB

cable

Operating Environment

OS : Windows 2000 (with SP4 or later)

Windows XP (with SP2 or later)

Windows Vista

Windows 7

CPU : Pentium III (500 MHz) or better

Monitor Resolution : 1024 x 768 dots or better

Internet Explorer : 6.0 or better

Memory : At least 512 MB

Interface : Ethernet or USB

USB cable

Supplied CD

(4) Connect the AC adapter to the instrument and turn on

the power

(3) Install the USB driver (p. 21)

Software Chapter 2

Install the supplied software Logger Utility on the computer the first time you use

the instrument after purchase. Before starting the installation, check the operating environment.

Installation Procedure

17

2

Chapter 2 Installing the Software

Mouse Operation

Click Press and quickly release the left button of the mouse.

Right-click Press and quickly release the right button of the mouse.

Double click Quickly click the left button of the mouse twice.

Drag While holding down the left button of the mouse, move the mouse and then release

the left button to deposit the chosen item in the desired position.

Activate Click on a window on the screen to activate that window.

Notation

[ ]

CURSOR

(Bold characters)

Windows Unless otherwise specified, "Windows" represents Windows 2000, Windows XP,

Dialog Dialog box represents a Windows dialog box.

Menus, pages, setting items, dialogs, buttons in a dialog, and other names on the

screen and the keys are indicated in brackets.

Bold characters within the text indicate operating key labels.

Windows Vista or Windows 7.

Page 26

18

Important

If you are running software such as antivirus software, be sure to end

the software before you start the installation. The installation may not

be performed properly if antivirus software is running.

Click

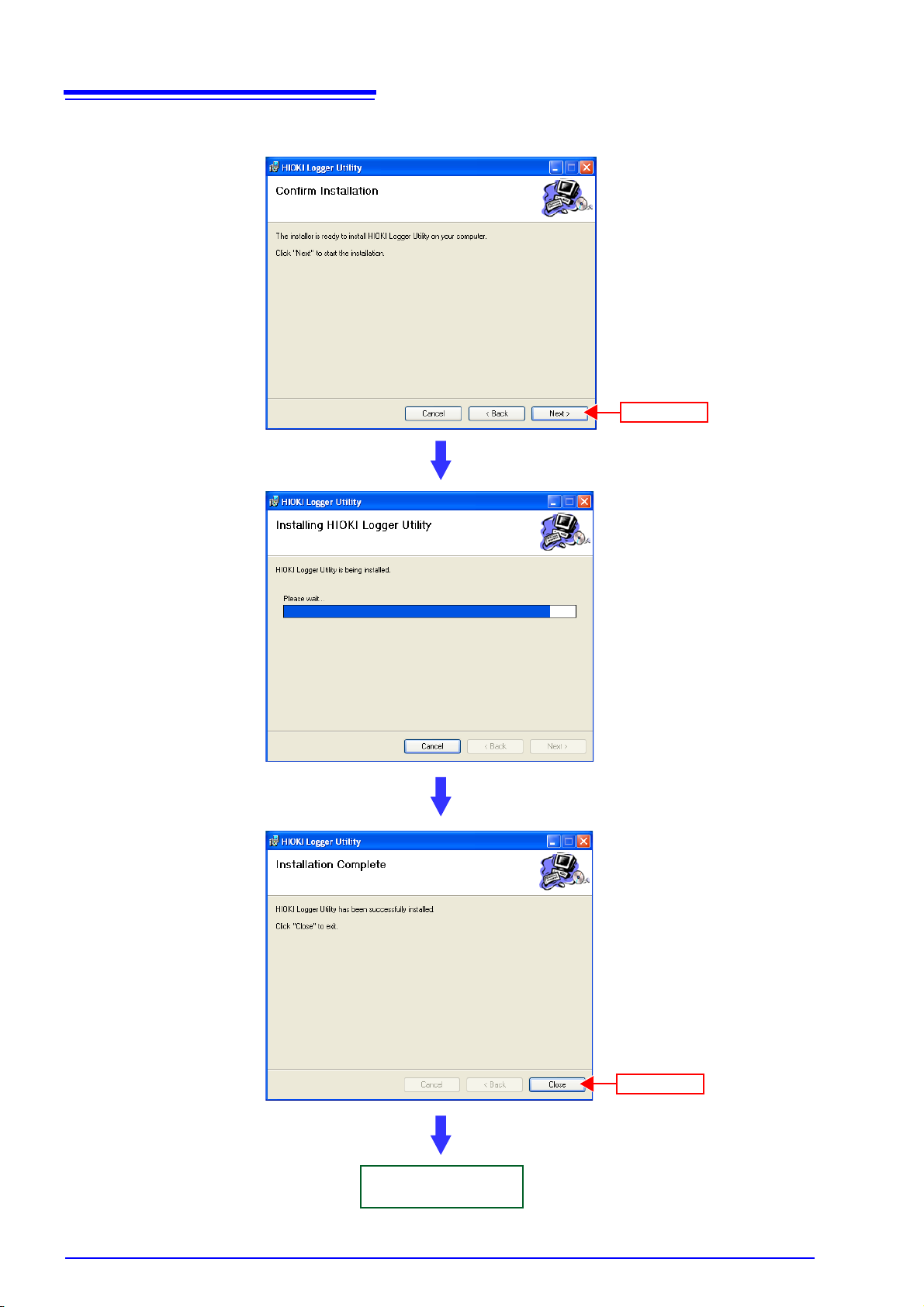

2.1 Installing Logger Utility

2.1 Installing Logger Utility

Follow the procedure below to install Logger Utility. This explanation is for installing the software on Windows XP. The messages displayed may differ slightly

depending on other operation system or settings you are using.

1. Start up Windows.

Exit all running applications.

2. Insert the included CD into the computer's CD-ROM drive, the installer run

automatically.

If the installer do not start, execute “Setup.exe” from the CD-ROM drive.

In Vista, Although the dialog which ask for installation permission of application,

click

[Allow].

Page 27

19

(2) Click

(3) Click

(1) Click

(1) Click

(2) Click

To change the

installation destination

Click [Browse] to select another folder.

There is normally no need to

change it.

2.1 Installing Logger Utility

3. Click the [Next] button of the installer, then read and agree with the con-

tents in the License Agreement before clicking the [Next] button.

2

Chapter 2 Installing the Software

4. Click [Everyone] before clicking the [Next] button.

Page 28

20

Installation starts.

Progress is displayed during

installation.

To interrupt installation in

progress,

click

[Cancel].

Installation finished

(1) Click

(2) Click

2.1 Installing Logger Utility

5. Click [Next] to start installing.

Page 29

2.2 Installing the USB Driver

Click

Install the USB driver before you use the instrument with a USB connection.

1. Install the driver.

Run [SetupDriver32.msi] in the CD-R.

If [Logger Utility] is already installed, run the CD from the following location.

[c:\Program Files\HIOKI\LoggerUtility\Driver\SetupDriver32.msi]

If you are using the WindowsVista/7 64bit version:

[c:\Program Files(x86)\HIOKI\LoggerUtility\Driver\SetupDriver64.msi]

Run [SetupDriver64.msi] in the CD-R.

If [Logger Utility] is already installed, run the CD from the following location.

[c:\Program Files\HIOKI\LoggerUtility\Driver\SetupDriver64.msi]

21

2.2 Installing the USB Driver

2

Chapter 2 Installing the Software

Depending on the environment, the dialog box may take some time to appear so

please wait till it does so.

2. Click [Next].

Page 30

22

(2) Click

(1) Check

Click

2.2 Installing the USB Driver

3. Check [Everyone] and click [Next].

When you want to change the installation destination, click [Browse…] to change

the folder to install into. Normally, there is no need to change.

4. Click [Next] to start installing.

Installing.

Page 31

For WindowsXP

Click

Click

(1) Check

(2) Click

For Windows Vista/7

23

2.2 Installing the USB Driver

During the installation, a message saying that the software has not passed

Windows Logo testing will appear a few times, click [Continue Anyway]

continue installing.

When a dialog box requesting your permission to continue the program

appears, click [Continue].

to

2

Chapter 2 Installing the Software

Sometimes another dialog box requesting your permission to install the

software may appear. When it does, check [Always trust software from

“HIOKI E.E. CORPORATION”] and click [Install] to continue.

Page 32

24

Click

2.2 Installing the USB Driver

5. When installation is completed and the dialog box appears, click [Close] to

exit.

This completes the driver installation.

Page 33

25

(2) Click

(1) Check

2.3 Connect the instrument and computer with the USB cable provided

2.3 Connect the instrument and computer with

the USB cable provided

Please connect the instrument after installing the USB driver.

Do not plug in or unplug the USB cable while the instrument is operating.

For Windows 2000/Vista/7

1. Connect the AC adapter to the instrument and switch on the power.

2. Connect the instrument and computer with the USB cable provided.

The HiLogger is automatically recognized, and preparations to use the

device are complete.

For Windows XP

2

Chapter 2 Installing the Software

1. Connect the AC adapter to the instrument and switch on the power.

2. Connect the instrument and computer with the USB cable provided.

A [Found New Hardware Wizard] dialog box will appear and the new hardware detection wizard will begin.

3. Check [No, not this time] and click [Next].

Page 34

26

(2) Click

(1) Check

Click

2.3 Connect the instrument and computer with the USB cable provided

4. Check [Install the software automatically (Recommended)] and click

[Next].

Please wait while the driver is being installed.

5. A message saying that the software has not passed Windows Logo testing

will appear a few times, click [Continue Anyway] to continue installing.

Page 35

27

Click

2.3 Connect the instrument and computer with the USB cable provided

6. When installation is completed and the dialog box appears, click [Finish]

to exit.

2

Chapter 2 Installing the Software

This completes the driver installation.

Page 36

28

(1) Click

(2) Click

Click

2.4 Starting and Ending Logger Utility

2.4 Starting and Ending Logger Utility

Starting Logger Utility

From the Start Menu of Windows, click [All Programs] - [HIOKI] - [Logger Utility] -

[Logger Utility]

.

Logger Utility starts with the settings in the same state as when the software was

last ended. When you want to initialize the settings, click

from the File menu.

[Initialize All Settings]

Page 37

Ending Logger Utility

Click

Minimizes the

window.

Closes the

window.

Maximizes the

window size.

Close button

Click

Click [Exit Application] from the File menu of the main screen.

29

2.4 Starting and Ending Logger Utility

2

Chapter 2 Installing the Software

Alternatively, you can click the

screen.

[x] close button at the top right of the main

Page 38

30

The [Add or Remove Programs] screen

appears.

(1) Click

(3) Click

(2) Click

A confirmation dialog appears when

you click [Remove].

The uninstall process begins.

The uninstall progress status is displayed.

Uninstall is finished

(2) Click

(1) Click

2.5 Uninstalling the Logger Utility

2.5 Uninstalling the Logger Utility

Use the following procedure to uninstall the program.

1. From the Windows Start menu, select the [Control Panel], and double click

[Add or Remove Programs].

2. From the list of installed programs, select [HIOKI Logger Utility], and

remove it.

You are returned to the

Settings files are not deleted during uninstall, so if no longer needed, delete

them manually.

[Add or Remove Programs] screen.

Page 39

Setting Up

(1) Attaching units (p. 32)

(2) Connect the input cables to the units (p. 35)

(3) Installing the Memory HiLogger (p. 40)

(4) Connecting the AC adapter (p. 42)

(5) Connecting a communication cable (p. 43)

(6) Inserting a CF card (p. 46)

(7) Connecting synchronization cables (p. 48)

(8) Connect the cables to the external control input terminals (p. 50)

(9) Turning the power on (p. 52)

When performing

synchronized

measurement

When performing

external control

the Instrument Chapter 3

This section describes preparations for starting measurement.

Before connecting the instrument to a computer or network, install Logger Utility

while referring to "Chapter 2 Installing the Software" (p. 17).

Installation and Connection Procedure

31

3

Chapter 3 Setting Up the Instrument

7

Page 40

32

Measurement object

•Voltage

• Temperature (Thermocouple)

M3 screw terminal block

15 input channels

CH1

CH15

Measurement object

•Voltage

• Temperature

(Thermocouple/resistance

temperature detector)

• Humidity (use the 9701

Humidity Sensor)

Push-type terminal block

15 input channels

CH1

CH15

Measurement object

• Logic signal

• Pulse signal

• Rotation rate

M3 screw terminal block

15 input channels

CH1

CH15

Alarm output function

M3 screw terminal block

15 output channels

CH1

CH15

3.1 Attaching Units

3.1 Attaching Units

You can attach optional units to the instrument in accordance with the measurement object. A maximum of eight units (total of 120 channels) can be connected

to one instrument.

3.1.1 Unit Types

The following four types of unit are available. Select a unit in accordance with the

measuring object. For detailed specifications of the units, see "12.3 Unit Specification" (p. 221).

Unit List

Model 8948 Voltage/Temp Unit Model 8949 Universal Unit

This unit is capable of measuring voltage and temperature.

Model 8996 Digital/Pulse Unit Model 8997 Alarm Unit

This unit is capable of measuring pulse signals and

logic signals. It allows you to totalize the number of

pulses of, for instance, an integrating wattmeter or

flowmeter, and count the number of pulses of, for

instance, a rotation meter to obtain the rotation rate.

This unit is capable of measuring voltage, temperature, and humidity.

This unit outputs an alarm when the measurement

value satisfies the set alarm condition (output format:

open collector). This enables control of an external

device in accordance with an alarm.

Page 41

3.1.2 Attaching a Unit

Align

Left side of Memory

HiLogger

Right side of

unit

Press

Press

Maximum of eight units

(2) Press and turn

Top of the 8423

(1) Loosen the screw

(3) Tighten the screw

Connection

Fittings

This section describes attaching a unit to the instrument. Units are coupled

together with connectors on the left and right sides.

• To avoid electric shock accident, before removing or replacing a unit, confirm

that the instrument is turned off and that the cables are disconnected.

• If the units are not securely attached with the connection fittings, the specifications may not be satisfied, resulting in a malfunction.

• Failure to fasten the connectors properly may result is sub-specification performance or damage to the equipment

• Be sure to attach the supplied connector cover to the unit at the very end.

Up to eight units can be connected to the instrument. If nine or more units are

connected, measurement will not be possible.

33

3.1 Attaching Units

3

Chapter 3 Setting Up the Instrument

Required tools: Phillips screwdriver ................... 1

1. Turn off the power of the unit.

Disconnect any connected cables.

2. Attach the unit to the 8423 Memory HiLogger. To attach multiple units.

repeat the same procedure.

3. Secure the unit in place with the connection fittings at the top and bottom

of the unit.

Use the Phillips screwdriver to tighten the screws to no more than 0.6 Nm.

7

Page 42

34

Connector cover

DIN Rail Mounting Groove

Lever

3.1 Attaching Units

4. Attach the supplied connector cover to the unit on the very left side when

looking from the front.

Insert the protruding part of the connector cover into the connector opening of

the unit, close the cover, and then secure it in place with the screw. Tighten the

screw to no more than 0.6 Nm.

5. Pull down the levers on the rear of the instrument and unit, and hook the

connection plate on to the hooks at the top of the DIN rail mounting

groove.

6. Push up the levers until they click into place.

• When you remove the connection plate from the instrument, perform the

attachment procedure in the reverse order.

• When you secure the instrument to a wall surface or DIN rail, the connection

plate does not need to be attached.

Page 43

3.2 Connecting a Cable to the Terminal Block

Phillips screwdriver

Terminal block

3.2 Connecting a Cable to the Terminal Block

Connect cables to the terminal block of a unit in accordance with the purpose of

use.

3.2.1 Removing and Attaching a Terminal Block

A terminal block can be removed to enable the cable to be easily connected.

(You can also connect the cable while the terminal block is attached.)

To avoid an electric shock or short-circuit accident:

• Turn off the power of the instrument before removing and attaching the terminal block.

• Never attach or remove the terminal block while the power of a measurement

object to which a cable is connected is on.

35

3

Chapter 3 Setting Up the Instrument

1. Turn off the power of the unit.

Disconnect any connected cables.

2. Loosen the screws at the top and bottom of the unit with the Phillips

screwdriver, and pull the front to remove the terminal block.

3. Connect the cable, and then attach the terminal block by performing the

procedure up to now in the reverse order.

Tighten the screws to no more than 0.6 Nm.

7

Page 44

36

Mark area

Serial No.

Mark area

Front of unit

Front of terminal

block

3.2 Connecting a Cable to the Terminal Block

• Be sure to attach the removed terminal block to the unit to which it was originally attached.

• Since the structure of a terminal block is designed so that it cannot be attached

to a unit of a different type, using excessive force to try to attach a terminal

block to the wrong unit will damage the connector.

When you want to mark a terminal block and unit:

Use the mark area on the front of the unit for writing a number, comment, or

other information. If you use a pencil, you can erase the writing by just gently

wiping it off. It is convenient to mark the removed terminal blocks and the units

to help you remember which block to attach to which unit.

Page 45

3.2.2 Connecting a Cable

Lift up

Phillips screwdriver

+

-

Example:

Model 8948 Voltage/Temp Unit

CH1

CH15

To connect a cable to a terminal block, lift up the cover at the front and then connect the cable to the terminal block.

• In order to prevent electric shock and short-circuit accidents, shut off the power

to the line to be measured before connecting the input cable.

• To avoid electrical accidents, confirm that all connections are secure. The

increased resistance of loose connections can lead to overheating and fire.

• Channels are isolated by semiconductor relays. Never apply a voltage in

excess of the specifications between channels as doing so could damage the

semiconductor relays by causing them to short out. Exercise particular care

concerning surge protection against lightning and other threats. If the instrument yields erroneous measured values, have it inspected.

Be sure to pull out an input cable after you loosen the screws of the terminal

block. The input cable will be damaged if the screws are not loosened and

excessive force is used to pull out the input cable.

37

3.2 Connecting a Cable to the Terminal Block

3

Chapter 3 Setting Up the Instrument

1. Loosen the screw at the bottom of the cover with the Phillips screwdriver

and lift up the cover.

2. Loosen the screws of the terminal block, connect the input cable, and then

tighten the screws.

The connection method differs depending on the measurement object. See the

next page.

7

3. Reattach the cover, and tighten the screw.

Tighten the screw to no more than 0.6 Nm.

Page 46

38

+

-

Not connected

Model 8948 Voltage/Temp Unit

Model 8949 Universal Unit

Voltage Measurement and Temperature Measurement with Thermocouple

+

-

Not connected

Model 8948 Voltage/Temp Unit

Model 8949 Universal Unit

250 Ω shunt

resistance

250 Ω shunt

resistance

4-20 mA Input

Model 8949 Universal Unit

Black

Green

Yellow

Red

Model 9701 Humidity Sensor

Humidity Measurement

(3-wire)

Model 8949 Universal Unit

B

B

A

Not connected

(4-wire)

Model 8949 Universal Unit

B

B

A

A

Temperature Measurement with Resistance Temperature Detector

Model 8996 Digital/Pulse Unit

Model 8997 Alarm Unit

+

-

+

-

Logic Signal, Pulse, and Rotation Rate Measurement

Alarm Output

3.2 Connecting a Cable to the Terminal Block

See For more information about individual units' circuit architecture, see the circuit schematic for the unit in question.

(p. 133)

Page 47

39

6 mm

or less

6 mm

or less

Single strand

Multi-strand

5 mm

3.2 Connecting a Cable to the Terminal Block

• If an input cable of 3 m or longer is connected, measurement may be affected

by external noise and other electromagnetic interference.

• The general guidelines for resistance temperature detector terminations are pro-

vided in JIS Z 8704, in which A and B signals are designated by red and white

wires, respectively. However, the three-wire IEC guidelines define the connections differently (red and white are reversed), so special attention is required.

• The measurement current for a resistance temperature detector is 1 mA.

• Connect the cable while it is disconnected from the power line and ground wire.

• Be sure to close the terminal block cover, and tighten the screw.

• If the cable is connected in parallel with another device, there may be variations in the measurement values. When connecting in parallel, confirm operation before use.

• In the case of the SoL terminal (8949 Universal Unit only) for connecting a

resistance temperature detector or 9701 Humidity Sensor, all channels are

common internally and not insulated.

• Make sure the ambient temperature around the terminal block does not

change. In particular, make sure there is no ventilation fan, air conditioner, or

the like blowing air directly onto the terminal block.

• When using crimp-type terminals for connecting to the terminal block of the

8948 Voltage/Temp Unit, 8996 Digital/Pulse Unit, or 8997 Alarm Unit, use terminals with insulating coating that are for M3 screws and of the size shown in

the figure below.

3

Chapter 3 Setting Up the Instrument

7

• The following cable is recommended for connecting to the terminal block of the

8949 Universal Unit.

Single strand: 0.14 to 1.5 mm

Multi-strand: 0.14 to 1.0 mm

AWS: AWG26 to AWG16

Standard insulation stripping length: 5 mm

• The waveform for an open channel may sometimes appear to be influenced by

the signals of the other channels being measured. If you do not like this,

please set the waveform display of the open channel to OFF or short-circuit the

input terminals of the open channel by connecting the positive and negative

terminal.

2

2

Page 48

40

(1) Place on a flat surface

(2) Mount to a DIN rail

(3) Mount to a wall surface with

screws

3-φ4

2-φ4

2-φ4

88

23.5

21.5

39

26.4

18.8

17.217.2

9.4 9.4

19.5

14

Unit: mm

Model 8423

Unit

Unit

3.3 Installing the Memory HiLogger

3.3 Installing the Memory HiLogger

The following three installation methods are possible.

3.3.1 Mounting to a Wall Surface with Screws

When mounting to a wall surface, use screws to secure the instrument. Secure it

to a wall surface of sufficient strength.

1. Turn off the power of the unit.

Disconnect any connected cables.

2. Refer to the figure below and create mounting holes in the wall surface.

3. Insert the screws from the back side of the wall surface and secure the

instrument with the nuts on the rear of the instrument.

Use M3 screws of a length equivalent to the thickness of the board plus no more

than 5 mm.

Tighten the screws to no more than 0.6 Nm.

Page 49

3.3.2 Securing with a DIN Rail

Lever

DIN Rail Mounting Groove

(The figure shows the 8423 Memory HiLogger

main unit.)

DIN rail

You can use the DIN rail mounting groove on the rear of the instrument to secure

the instrument to a 35 mm wide DIN rail.

To avoid damage to the instrument as a result of it falling, do not apply excessive

force on the instrument from above.

41

3.3 Installing the Memory HiLogger

3

1. Secure the DIN rail to a wall or other surface.

2. Turn off the power of the unit.

Disconnect any connected cables.

3. Pull up the levers on the rear of the instrument and unit.

4. Hook the hooks at the top of the DIN rail mounting groove on to the DIN rail

and push in the bottom.

Chapter 3 Setting Up the Instrument

7

5. Push up the levers until they click into place.

When you want to unmount the instrument from the DIN rail, perform the mounting procedure in the reverse order.

Page 50

42

Insert the plug

Hook

3.4 Connecting the AC Adapter

3.4 Connecting the AC Adapter

This section describes connecting the 9418-15 AC Adapter to the instrument in

order to supply power.

• Turn the instrument off before connecting the AC adapter to the instrument and

to AC power.

• Use only the supplied Model 9418-15 AC Adapter. AC adapter input voltage

range is 100 to 240 VAC (with

hazards and damage to the instrument, do not apply voltage outside of this

range.

• To avoid electrical accidents and to maintain the safety specifications of this

instrument, connect the power cord provided only to a 3-contact (two-conductor + ground) outlet.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

±10% stability) at 50/60 Hz. To avoid electrical

• Make sure the power is turned off before connecting or disconnecting the AC

adapter.

• The instrument will run erratically under a momentary power outage lasting

less than 40 ms. However, if a momentary power outage lasting 40 ms or more

occurs, the instrument may turn off temporarily, so the state of the power supply at the installation location should be considered beforehand.

• If a power outage occurs, the measurement data is lost.

• If the instrument is run on a 12 V battery without using the AC adapter and is

connected to the battery with a cable of 3 m or longer, measurement may be

affected by external noise and other electromagnetic interference.

1. Make sure the instrument is OFF.

2. Connect the connector of the AC adapter to the connector of the instru-

ment, and insert the plug into a power outlet with a ground.

Page 51

3.5 Connecting a Communication Cable

USB cable

USB connector

When connecting the instrument and computer directly on a one-to-one-basis:

When connecting multiple Memory HiLoggers to a computer:

HUB

USB cable

Use a USB hub or connect the Memory

HiLoggers to available USB ports.

3.5 Connecting a Communication Cable

A computer is used to set the instrument, record measurement data, and analyze recorded data. Use the USB cable or 9642 LAN Cable to connect the instrument and computer.

• To avoid a malfunction, do not connect or disconnect the USB cable or LAN

cable during operation.

• To ensure stable communication, connect either just the USB cable or just the

LAN cable and then take measurements.

Be sure to install the supplied software Logger Utility on the computer

before connecting the USB cable to the computer for the first time.

43

3

Chapter 3 Setting Up the Instrument

3.5.1 Connecting the USB Cable

When you want to measure via USB, connect the instrument and computer with

the supplied USB cable. To ensure stable communication, do not connect the

LAN cable when measuring via USB.

7

Page 52

44

Adapter connector +

Model 9642 LAN Cable (straight)

100BASE-TX

connector

Lights when communication with the connected

device is possible.

Flashes when data is being exchanged.

When connecting via a hub:

HUB

Model 9642 LAN

Cable (straight)

When connecting the instrument and computer directly on a one-to-one-basis:

The 9642 LAN Cable is straight cable, so use the supplied adapter connector when

connecting the instrument and computer directly on a one-to-one basis.

Model 9642 LAN

Cable (straight)

3.5 Connecting a Communication Cable

3.5.2 Connecting the LAN Cable

When you want to measure via LAN, connect the instrument and computer with

the LAN cable. To ensure stable communication, do not connect the USB cable

when measuring via LAN.

• When you want to communicate between the instrument and computer via

LAN, configure the network settings of the instrument.

• When connecting to an existing LAN network, obtain the settings from the network administrator.

• When the instrument will be affected by external noise, attach the supplied ferrite clamp as shown in the figure below.

Attaching the Ferrite Clamp

1. Wrap the LAN cable around the ferrite clamp once.

Attach the ferrite clamp at a position that is 2 to 4 cm away from the connector to

be connected to the instrument.

2. Close the ferrite clamp until a click is heard.

Page 53

3.6 Using a CF Card

(1) Right click

(3) Select

(4) Click

(2) Click

If you insert a CF card in the instrument and set real-time saving, data can be

saved to the hard disk of the computer and the CF card simultaneously during

measurement. Furthermore, standalone measurement in which the instrument

measures when not connected to the computer is made possible by saving the

measurement data to a CF card.

45

3.6 Using a CF Card

Important

Use only PC Cards sold by Hioki.

Compatibility and performance are not guaranteed for PC cards (use a CF

card only; do not use an adapter) made by other manufacturers. You may

be unable to read from or save data to such cards.

Hioki options

PC cards (includes adapter)

• Model 9726 PC Card 128M

• Model 9727 PC Card 256M

• Model 9728 PC Card 512M

• Model 9729 PC Card 1G

3.6.1 Formatting a CF Card

Format a CF card on a computer the first time you use it or before you begin

measurement. If the CF card has been used for another purpose, saving may

take a while or the file information may be damaged. Formatting will prevent

these problems from occurring.

1. Right-click the removable disk containing the CF card in My Computer, and

then click [Format] from the menu.

3

Chapter 3 Setting Up the Instrument

7

2. Select [FAT] or [FAT32] as the file system in the dialog box, and then click

[Start].

Formatting of the CF card starts.

Page 54

46

CF card

Cover

Eject button

Inserting a CFcard upside down, backwards

or in the wrong direction may damage the instrument.

Eject button

Do not remove the CF card while the CF card access LED

is lit. The files of the CF card will become unreadable, and

recording will no longer be able to be performed properly.

CF Card Access LED

• When the cover is open:

Off: The CF card can be ejected.

Lit red: The CF card cannot be ejected because data is being

written.

• When the cover is closed:

Off: A CF card is not inserted or recording is not possible

because the CF card cannot be recognized.

Lit green: A CF card is inserted and recording is possible.

Lit red: The CF card is being read.

3.6 Using a CF Card

3.6.2 Inserting and Ejecting a CF Card

Inserting a CF Card

1. Open the cover of the CF card slot.

2. When the eject button comes out, fully press it all the way in.

3. Fully insert the CF card from the front with the top surface facing left

(cover side), and then close the cover.

Confirm that the CF card access LED lights. The cover cannot be closed unless

the eject button is pushed in.

Ejecting a CF Card

1. Fully press the eject button, and then remove your finger from the button.

2. When the eject button pops out, press it in again to eject the CF card.

• Be sure to close the cover after inserting a CF card. Measurement data will

not be saved to the CF card if the cover is not closed.

• When measurement will be performed for a long period of time, first, back up

all files on the CF card by copying them to a drive on the computer. Then, format the CF card so that there are no unnecessary files. It is recommended to

perform a backup and format each time you measure.

• If the cover of the CF card slot cannot be closed properly, submit the instrument for repair. Recording to the CF card may stop if, for instance, vibration

causes the cover to open during measurement.

Page 55

3.6 Using a CF Card

3.6.3 Replacing a CF Card during Measurement

While data is being saved to a CF card in real time, you can replace the CF card

without stopping measurement.

1. Open the CF card slot cover.

47

2. Confirm that the CF card access LED is off, and then eject the CF card.

3. Insert a CF card with sufficient available space, and then close the cover.

As the CF card is sensitive to static electricity, damage to the CF card or wrong

operations by the HiLogger may occur due to static electricity. Please be careful

when handling it.

• The CF card access LED may sometimes be lit red immediately after you open

the cover, because the CF card is being processed. Ejecting the card in such a

state will result in the files of the CF card being damaged. Always make sure

the LED is off before ejecting a CF card.

• Be sure to close the cover after inserting a CF card. Measurement data will not

be saved if the cover is not closed.

• If the CF card is not replaced within 5 minutes, the data of the internal memory

may overflow and the measurement data may not be saved.

• If measurement ends while no CF card is inserted, the data up until the end of

measurement will not be saved even if you insert a CF card afterwards. In

such a case, you can use the HTTP function to extract the data in the instrument while the instrument is connected to the LAN. See "Chapter 11 Communications (HTTP/FTP)" (p. 209).

3

Chapter 3 Setting Up the Instrument

7

3.6.4 File Protection during Power Outage

The instrument has a large built-in capacitor that processes the ending of files

when the power is switched off or there is a power outage. This greatly reduces

the risk of files being damage by an unexpected power outage.

A CF card cannot be accessed for 30 seconds immediately after the power is

turned on because the large capacitor is being charged.

Page 56

48

Instrument 1

Instrument 2

Instrument 5

Model 9683 Connection Cable

(for synchronization)

Unit

1

8

OUT

IN

Master*

Slave 1

Slave 4

HUB

USB or LAN

3.7 Connecting Synchronization Cables

3.7 Connecting Synchronization Cables

Connecting multiple Memory HiLoggers with optional 9683 Connection Cables

(for synchronization) and using the supplied software Logger Utility to set synchronized measurement allows you to synchronize the sampling of the loggers

and perform synchronized measurement with up to 600 channels. In such a

case, you can share trigger function and event mark information, as well as perform an external start, external stop, and synchronization by external sampling.

For external sampling, input a sampling signal to the master Memory HiLogger.

It is possible for multiple loggers connected by the 9683 Connection Cables (for

synchronization) to measure at the same timing.

* Master:

Generates a synchronization clock to adjust the sampling of slaves 1 to 4.

Page 57

49

Model 9683 Connection Cable (for

synchronization)

IN

OUT

OUT

IN

3.7 Connecting Synchronization Cables

1. Connect the 9683 Connection Cables (for synchronization) to the IN and

OUT synchronization cable connectors of the Memory HiLoggers so that

loops are created.

Connect the connector of the end with the ferrite clamp attached to the IN terminal. Align the arrows ( ) on the front of the instrument and on the 9683 Connec-

tion Cables when you connect the cables.

3

Chapter 3 Setting Up the Instrument

2. Connect all of the Memory HiLoggers to be used for synchronized mea-

surement to the computer with LAN or USB cables.

3. Register the loggers in Logger Utility, and then set synchronized measure-

ment.

See "Chapter 5 Setting Measurement Conditions" (p. 63).

• The synchronization settings can also be set on the instrument.

• Synchronized measurement is possible with two to five loggers. Synchronized

measurement is not possible with one or six or more loggers.

• Multiple masters cannot be assigned to one measurement system.

• The sampling clock is transferred via the 9683 Connection Cables during synchronized measurement. Never disconnect the 9683 Connection Cables during measurement, because the supply of the clock will stop.

• The IN and OUT connectors of a 9683 Connection Cable differ. Do not use

excessive force to insert a connector.

• Turn on the power of all 8423 Memory HiLoggers connected with the 9683

Connection Cables.

7

Page 58

50

This allows a sampling trigger to be input. (p. 81)

This allows a measurement start signal to be input.

This allows a measurement stop signal to be input.

This is the GND terminal.

Single strand

Multi-strand

10 mm

3.8 Connection Method for External Control Input Terminals

3.8 Connection Method for External Control

Input Terminals

Inputting a signal from an external device enables the input signal to be a trigger

source, and measurement to be started and stopped. Furthermore, you can collect data (external sampling) at any timing with which you want to measure.

To avoid electrical hazards and damage to the instrument, do not apply voltage

outside of the range (DC -5 to 10 V) to the External control input terminals.

To avoid electric shock or damage to the equipment, always observe the following precautions when connecting to External control input terminals

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of external terminals and connectors.

• Ensure that devices and systems to be connected to the External control input

terminals are properly isolated.

• The GND of the external control input terminals and the GND of the Memory

HiLogger main unit are not commonly insulated. To avoid damaging the instrument, make sure wiring is done in such a manner that no potential difference

can result between the GND of the external control input terminals and the

GND of the equipment or device to be connected.

• To avoid electric shock, use the recommended

wire type to connect to the current input terminals, or otherwise ensure that the wire used has

sufficient current handling capacity and insulation.

Recommended wire

Single strand: 1.0 mm dia. (AWG 18)

Multi-strand: 0.75 mm

Acceptable limits

Single strand: 0.4 to 1.0 mm dia.

(AWG 26 to 18)

Multi-strand: 0.3 to 0.75 mm

Strand diameter: minimum 0.18 mm

Standard insulation stripping length: 10 mm

Button pressing tool: Blade screwdriver (tip width 2.6 mm)

2

(AWG 20)

2

(AWG 22 to 20)

.

Page 59

3.8 Connection Method for External Control Input Terminals

(1)

(2)

(3)

* 10 μF when the chattering prevention filter is on.

*

Required tools: Flat blade screwdriver............... 1

1. Press the button of the terminal with a flat blade screwdriver (or other

tool).

2. While keeping the button pressed in, insert the wire into the hole of the ter-

minal.

51

3

Chapter 3 Setting Up the Instrument

3. Release the button to lock the wire into place.

<Circuit Diagram of External Control Input Terminals>