Page 1

Instruction Manual

8206-10

MICRO HiCORDER

July 2013 Revised edition 8 8206B981-08 13-07H

Page 2

Page 3

Contents

Introduction i

Inspection ii

Safety Notes iii

Notes on Use vi

Chapter Summary viii

Chapter 1 Product Overview 1

1.1 Product Overview 2

1.2 Features 3

1.3 Front Panel

1.4 LCD (Display) 6

1.5 Printout Information

Chapter 2 Measurement Procedures 9

2.1 Preparations 9

2.2 AC Voltage Measurement

2.3 AC Current Measurement 17

2.4 AC Voltage and Current Measurement

2.5 Common Measurement Operations 26

13

21

4

7

Chapter 3 Changing the Recording Paper 31

3.1 Opening and Closing the Printer Cover 31

3.2 Installing Recording Paper 32

Page 4

Chapter 4 Specifications 33

4.1 General Specifications 33

4.2 Voltage Measurement Input Specifications

4.3 Current Measurement Input Specifications 36

4.4 Display Specifications

4.5 Recorded Information 38

4.6 Recording Time

35

37

38

Chapter 5 Maintenance and Service 39

5.1 Storage Precautions 39

5.2 Cleaning

5.3 Cleaning the Printer Head 41

5.4 Service

40

42

Page 5

_____________________________________________________________________

Introduction

Thank you for purchasing the Hioki 8206-10 MICRO

HiCORDER. To obtain maximum performance from the

instrument, please read this manual first, and keep it handy

for future reference.

i

______________________________________________________________

Introduction

Page 6

ii

_____________________________________________________________________

Inspection

When you receive the instrument, inspect it carefully to

ensure that no damage occurred during shipping. In

particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki

representative.

Accessories

9344 CARRYING CASE 1

L9257 CONNECTOR CORD 1

9235 RECORDING PAPER (15 m) 1

Roll Paper Spools 2

AC Power Cord 1

Instruction Manual 1

Options

9235 RECORDING PAPER (15 m, 10 rolls) 1

9236-01 RECORDING PAPER

(15 m, Climate-resistant; 10 rolls) 1

9650 CLAMP ON SENSOR 1

9651 CLAMP ON SENSOR 1

9668 CLAMP ON SENSOR 1

Before using the instrument the first time, verify that it

operates normally to ensure that the no damage occurred

during storage or shipping. If you find any damage, contact

your dealer or Hioki representative.

NOTE

Before using the instrument, make sure that the insulation on the

connection cords is undamaged and that no bare conductors are

improperly exposed. Using the instrument in such conditions

could cause an electric shock, so contact your dealer or Hioki

representative for repair.

______________________________________________________________

Inspection

Page 7

_____________________________________________________________________

R

iii

SafetyNotes

This instrument is designed to conform to IEC 61010

Safety Standards, and has been thoroughly tested for

DANGE

Safety Symbols

safety prior to shipment. However, mishandling

during use could result in injury or death, as well as

damage to the instrument. Be certain that you

understand the instructions and precautions in the

manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from

product defects.

This manual contains information and warnings essential

for safe operation of the instrument and for maintaining it

in safe operating condition. Before using the instrument,

be sure to carefully read the following safety notes.

The symbol printed on the instrument indicates that

the user should refer to a corresponding topic in the

manual (marked with the

relevant function.

In the manual, the symbol indicates particularly

important information that the user should read before

using the instrument.

symbol) before using the

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating

Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

______________________________________________________________

Safety Notes

Page 8

iv

R

W

_____________________________________________________________________

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Indicates that incorrect operation presents an extreme

DANGE

hazard that could result in serious injury or death to

the user.

Indicates that incorrect operation presents a

ARNING

CAUTION

significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

instrument.

NOTE

Advisory items related to performance or correct

operation of the instrument.

Accuracy

We define measurement tolerances in terms of f.s. (full

scale) values, with the following meanings:

f.s.

(maximum display or scale value, or length of scale)

Signifies the maximum display (scale) value or the length

of the scale (in cases where the scale consists of unequal

increments or where the maximum value cannot be

defined).

In general, this is the range value (the value written on

the range selector or equivalent) currently in use.

______________________________________________________________

Safety Notes

Page 9

_____________________________________________________________________

v

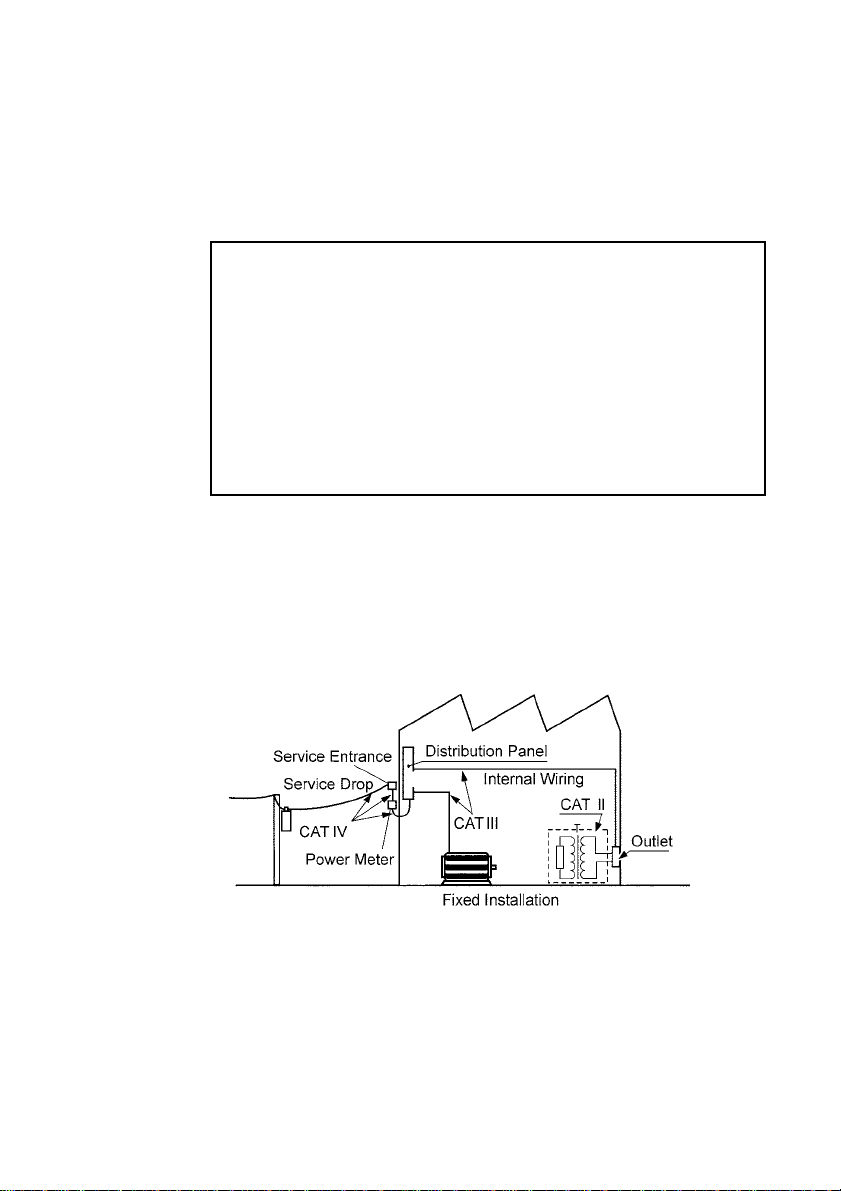

Measurement categories

This instrument complies with CAT III safety requirements.

To ensure safe operation of measurement instruments, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT II to CAT IV, and called

measurement categories. These are defined as follows.

CATII

CATIII

CATIV

Primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT II covers directly measuring electrical outlet

receptacles.

Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent

protection device (distribution panel).

Using a measurement instrument in an environment

designated with a higher-numbered category than that for

which the instrument is rated could result in a severe

accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in

CAT II to CAT IV measurement applications could result in

a severe accident, and must be carefully avoided.

______________________________________________________________

Safety Notes

Page 10

vi

R

_____________________________________________________________________

Notes on Use

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

The maximum input voltage is 600 V DC/AC. Attempting

DANGE

to measure voltage in excess of the maximum input

voltage could destroy the instrument and result in

personal injure or death.

The maximum rated voltage between input terminals

and ground is 600 Vrms. Attempting to measure

voltages exceeding 600 V with respect to ground could

damage the instrument and result in personal injury.

Connection cords or clamp-on sensor should be made

only at the secondary side of a breaker, so the breaker

can prevent an accident if a short circuit occurs.

Connections should never be made to the primary side

of a breaker, because unrestricted current flow could

cause a serious accident if a short circuit occurs.

To avoid short circuits and potentially life-threatening

hazards, never attach the clamp to a circuit that

operates at more than the maximum rated voltage, or

over bare conductors.

To avoid electric shock, do not allow the instrument to

WARNING

get wet, and do not use it when your hands are wet.

To avoid electric accidents and to maintain the safety

specifications of this instrument, connect the power

cord provided only to a 3-contact (two-conductor +

ground) outlet.

To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged or cause an explosion.

______________________________________________________________

Notes on Use

Page 11

_____________________________________________________________________

vii

CAUTION

This instrument is designed for indoor use, and operates

reliably from 5 to 40℃.

Do not store or use the instrument where it could be

exposed to direct sunlight, high temperature or humidity, or

condensation. Under such conditions, the instrument may

be damaged and insulation may deteriorate so that it no

longer meets specifications.

This instrument is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a wet or

dusty environment.

To operate from DC power, pay careful attention to polarity

when making power connections, and set the power source

switch to the DC position (

changing the power source, unplug the (

) before use. Also, before

) power cord

from the outlet to prevent hazards, and remove the

connection cord from any object under test.

Avoid stepping on or pinching the cable, which could

damage the cable insulation.

Keep the cables well away from heat sources, as bare

conductors could be exposed if the insulation melts.

To prevent an electric shock accident, confirm that the

white or red portion (insulation layer) inside the cable is not

exposed. If a color inside the cable is exposed, do not use

the cable.

Be careful to avoid dropping the clamps or otherwise

subjecting them to mechanical shock, which could damage

the mating surfaces of the core and adversely affect

measurement.

Keep the clamp jaws and core slits free from foreign

objects, which could interfere with clamping action.

For shipping or long-term storage, be certain that the

recording head is in the raised position. Otherwise the

rollers could be deformed and cause uneven printing.

NOTE

Use only recording paper specified by Hioki. Non-specified

recording paper may result in poor-quality or blank printouts.

Avoid using the printer in hot, humid environments, as this can

greatly reduce printer life.

Accurate measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and highcurrent conductors, or in the presence of strong electromagnetic

fields such as near radio transmitters.

This instrument may cause interference if used in residential

areas. Such use must be avoided unless the user takes special

measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

______________________________________________________________

Notes on Use

Page 12

viii

y

_____________________________________________________________________

Chapter Summar

This manual consists of the following chapters.

"Introduction", "Safety Notes", "Notes on Use" describe

precautions on use, overview, and features of this unit.

Be sure to read them all. Next, check Chapter 1 to 5 and

the unit to confirm your understanding of the function.

Chapter 1 Product Overview

Outlines the product and explains the names and functions

of its parts.

Chapter 2 Measurement Procedures

Explains procedures for measurement using the product.

Chapter 3 Changing the Recording Paper

Explains how to replace the recording paper.

Chapter 4 Specifications

Sets forth specifications of the product.

Chapter 5 Maintenance and Service

Provides information maintenance and service information

for the product.

______________________________________________________________

Chapter Summary

Page 13

_____________________________________________________________________

1

Chapter 1

Product Overview

______________________________________________________________

Product Overview

Page 14

2

_____________________________________________________________________

1.1 Product Overview

The multi-functional recording Model 8206-10 MICRO

HiCORDER is almost as easy to use as a simple DMM.

This instrument features the capability to simultaneously

record voltage and current (When using the optional clamp-

on sensor), such as is often required for AC power

management, as well as providing input voltage ranges

corresponding to standard commercial mains voltages.

Voltage can be measured and recorded with magnified

display resolution (approximately doubled) around the

centered standard voltage. This feature is ideally suited to

AC power systems management and inspection.

______________________________________________________________

Product Overview

Page 15

_____________________________________________________________________

3

1.2 Features

(1) Easy operation

The large single-function controls allow operation without

requiring repeated reference to the manual.

(2) Graduated analog-style amplitude display

The high-resolution graduated display and data display

matching the selected range allow input signal levels to be

viewed like an analog meter.

(3) Recording paper printout

Setup conditions for recorded data and elapsed time are

printed out with recorded measurements, eliminating the

need for complex multiple printouts for record storage and

reporting.

(4) Simultaneous Voltage and Current Recording

Voltage and current can be recorded either simultaneously

or independently.

(5) Ranges Correspond to Standard Mains Voltages

The ranges are designed to correspond to standard

commercial mains ratings. Also, to aid in measuring

voltages that deviate considerably from standard ratings, a

POSITIO N control allows offsetting the display area,

facilitating applicability in a wide variety of circuits.

(6) Dual power supply system

Power can be supplied from either the AC mains or a 12-V

DC source. AC mains supply voltages between 100 to 240

V AC are automatically selected.

(7) Handy carrying case

The supplied carrying case includes storage for the power

cord and recording paper.

______________________________________________________________

Product Overview

Page 16

4

_____________________________________________________________________

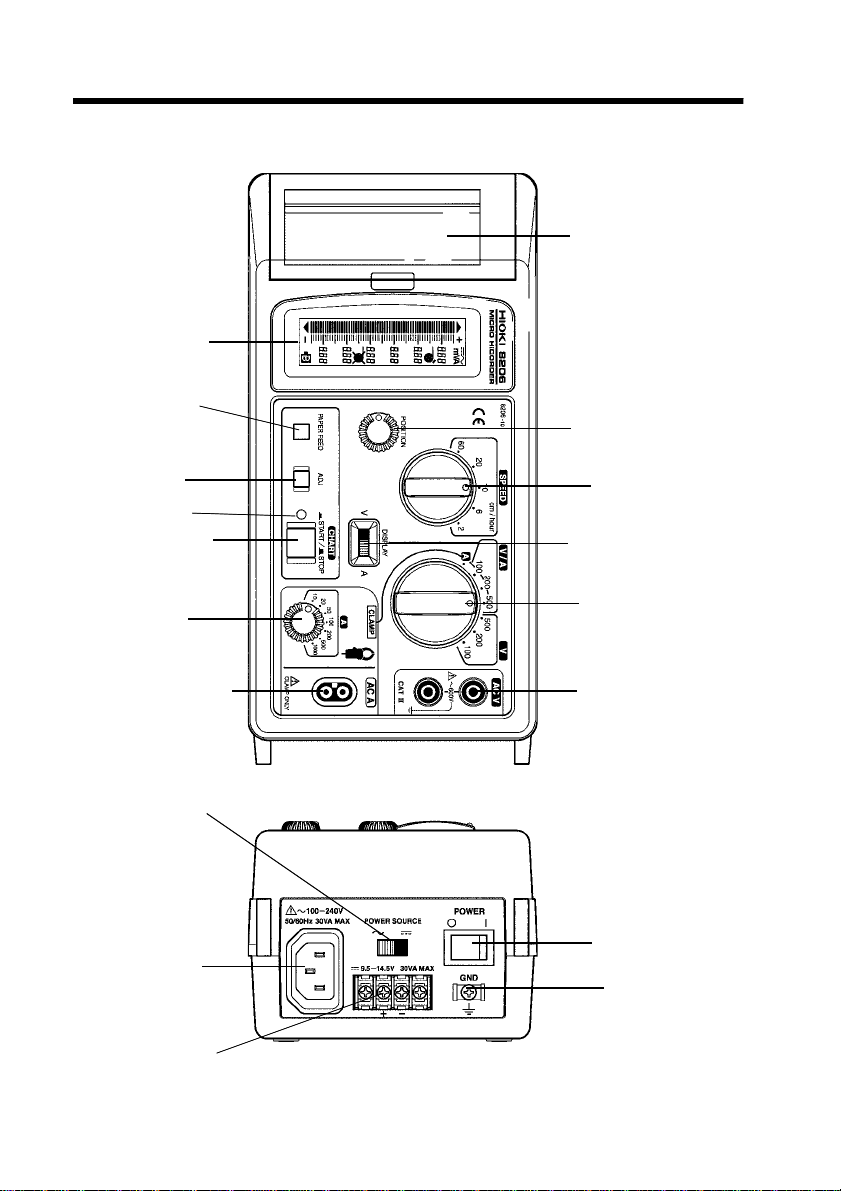

1.3 Front Panel

Printer Cover

LCD (display)

PAPER FEED

Button

POSITION Control

ADJ Button

Indicator

CHART Button

A (CLAMP)

Selector

Clamp Terminals

POWER SOURCE Switch

AC Connector

SPEED Selector

DISPLAY Switch

RANGE Selector

Test Voltage Input

Terminals

POWER Switch

GND Terminal

DC Terminals (DC Power Source)

______________________________________________________________

Product Overview

Page 17

_____________________________________________________________________

5

LCD (display) Displays the signal level and device status, including

selected mode and range, numeric scale values, and

indicators. States such as print head up, out of paper and

low supply voltage are also displayed.

PAPER FEED

Button

ADJ Button Adjusts the zero-reference point for measurements

Indicator This indicator l ights when the

CHART Button Starts and stops recording

A (CLAMP)

Selector

Clamp Terminals Connect a clamp-on sensor to these terminals to measure current

Test Voltage

Input Terminals

RANGE Selector Selects the measurement signal type and amplitude range

DISPLAY Switch When you are recording voltage and current simultaneously

SPEED Selector Sets the transport speed of the recording paper

POSITION

Control

Printer Cover Covers the printer mechanism and recording paper storage

POWER

SOURCE Switch

AC Connector Connect the AC cord here to operate the recorder from

DC Terminals (DC

Power Source)

GND Terminal This is a signal reference ground to establish a reference

POWER Switch Turns the recorder on an off

Manually advances the recording paper

Pressing this button momentarily advances the paper about

30 mm. Holding this button advances the paper

continuously.

CHART

START state, and blinks when the print head is up and at

paper end (in the START state).

Selects input sensitivity to match a connected clamp-on

sensor (when used), and applies that sensitivity internally

so that the range setting prints appropriately on the

recording paper

Apply the test voltage across these terminals for

measurement

(V/A range selected), you can set this switch to either A or

V, according whether you wish the LCD to display current

or voltage.

When voltage measurement is selected, this switch

moves the center value for enlarged display.

Selects whether the recorder is to be powered from AC

mains, or DC

commercial power (100 to 240 V AC)

Connect a 12-V (nominal) DC supply to these terminals to

operate the recorder from DC power

for eliminating stray effects such as noise from

measurements

button is in the

______________________________________________________________

Product Overview

Page 18

6

.

_____________________________________________________________________

1.4 LCD (Display)

*Subunits (m)

*Positive

Over-range Indicator

Pointer

Under-range Indicator

*Negative

Pointer The input signal level is indicated by the lit segment

(pointer) in the graduated bar-type scale

Over-range Indicator This arrow lights when the input signal exceeds the

upper limit of the selected range (the highest level

segment lights at the same time).

Under-range Indicator This arrow lights when the input is below the lower

limit of the selected range (the lowest level segment

lights at the same time).

Low (DC) Supply

Voltage Indicator

Numeric Display These numeric values are the amplitude values of the

Paper End Indicator Lights when no recording paper is present.

Scale This graduated scale contains the pointer (lit

Print Head Up

Indicator

Lights when the DC supply voltage is low.

gradations on the meter scale, according to the

selected range (six 3-digit, 7-segment numerals plus

decimal point)

segment) that indicates the input signal level.

Lights when the print head is raised.

*Not used for the 8206-10

*Indicates Direct Current( )

*Indicates Alternating

Current( )

Print Head Up Indicator

Scale

Paper End Indicator

Numeric Display

Low (DC) Supply Voltage

Indicator

______________________________________________________________

Product Overview

Page 19

_____________________________________________________________________

1.5 Printout Information

Example of D/A-100 V range case

7

Setup Range Data 1

Model

Trademark

Setup Range Data 1 The print setup signal type, numeric value of the

Model Prints when the

Trademark Prints when the

Scale Prints when the

Elapsed Time Display Prints at 5-division intervals

Setup Range Data 2 Prints at 10-division intervals, and when the range

Interval Printing

(numeric amplitude)

Printing Waveform Prints when the average mode is selected.

ADJ Data See Section 2.5, Item 9 regarding ADJ button

Printing Waveform

Scale

range and display units are printed once when the

CHART

setting or position control is changed.

The input signal amplitude is printed numerically at

specific intervals.

If the measurable range is widely over range, the

following indications will appear.

OVER(V): Voltage

OVER(A): Current

Unaverage mode: AC, Average mode:

Interval Printing

Elapsed Time Display

button is pushed (ON).

CHART

CHART

CHART

button is pushed (ON)

button is pushed (ON)

button is pushed (ON)

Setup Range Data 2

AC

Recording

Waveform

______________________________________________________________

Product Overview

Page 20

8

_____________________________________________________________________

NOTE

When the V/A range is selected, the recording waveform prints

in two lines. The uppermost signal printed at intervals indicates

the higher recording waveform.

______________________________________________________________

Product Overview

Page 21

_____________________________________________________________________

9

Chapter 2

Measurement Procedures

2.1 Preparations

To avoid electric accidents and to maintain the safety

WARNING

specifications of this instrument, connect the power

cord provided only to a 3-contact (two-conductor +

ground) outlet.

To avoid ele ctrical accidents, turn the power switch off

and unplug the power cords from the outlet after use.

(1) Check the paper

Check the installation condition and amount of paper

remaining before starting a measurement. Refer to Chapter

3 for the paper installation procedure, if necessary.

(2) Connect the power

This product can be operated from either AC mains or 12

V DC.

______________________________________________________________

Measurement Procedures

Page 22

10

_____________________________________________________________________

AC Operation

Set the POWER SOURCE switch to

1.

the

(AC) position.

2. Connect the supplied power cord to the

socket on the recorder.

3. Plug in the power cord. Insert the plug

directly into the outlet.

NOTE

______________________________________________________________

Measurement Procedures

Although the product can operate from 100 to 240 V AC, the

power cord should be selected to conform to the requirements of

the mains voltage used.

To avoid electrical accidents, unplug the power cord from the

outlet after use, and turn the power switch off.

Page 23

_____________________________________________________________________

11

DC Operation

Positive

Negative

1. Set the

the

POWER SOURCE

(DC) position.

switch to

2. Connect the GND terminal to earth

ground.

3. Connect a source of 9.5 to 14-V DC to

the terminals.

From 9.5 to 14-V DCpower source

NOTE

______________________________________________________________

A proper ground connection is important for safety and to

ensure stable operation.

The power wiring should be of sufficient current capability to

handle the power consumption (30 VA maximum) of the

product, with a margin for safety.

Measurement Procedures

Page 24

12

_____________________________________________________________________

NOTE

We recommend the following wiring for power connections.

PVC-insulated ring-type crimp-on terminals

(3.2-mm ID, less than 6-mm OD)

Vinyl-insulated wire, at least 1.25 mm2(#14 AWG)

(3) Powering on

Slide the PO WER switch to the on

1.

position (

The LCD should light. Confirm that no

2.

).

error indicators appear.

(4) Make the appropriate settings for the intended type of

measurement:

To measure AC voltage, see Section 2.2, AC Voltage

Measurement.

To measure AC current, see Section 2.3, AC Current

Measurement.

To measure AC current, see Section 2.4, AC Voltage and

Current Measurement.

______________________________________________________________

Measurement Procedures

Page 25

_____________________________________________________________________

R

W

2.2 AC Voltage Measurement

To avoid electric shock, short circuits and damage to

13

DANGE

the instrument, observe the following precautions:

The maximum input voltage is 600 V DC/AC.

Attempting to measure voltage in excess of the

maximum input voltage could destroy the instrument

and result in personal injure or death.

The maximum rated voltage between input terminals

and ground is 600 Vrms. Attempting to measure

voltages exceeding 600 V with respect to ground

could damage the instrument and result in personal

injury.

When connecting clip-type connection cords to live

terminals, be very careful to avoid accidentally

shorting conductors together and causing a serious

accident.

Connection cords should be made only at the

secondary side of a breaker, so the breaker can

prevent an accident if a short circuit occurs.

Connections should never be made to the primary

side of a breaker, because unrestricted current flow

could cause a serious accident if a short circuit

occurs.

If the input signal level is unknown, begin measuring

with the highest range to determine the approximate

signal level, then select the appropriate range for

actual measurement.

Disconnect the connection cords from the

measurement object before switching ranges.

To avoid electrical shock, be careful to avoid shorting

ARNING

CAUTION

live lines with the connection cords.

For safety reasons, use only the supplied connection cords

to connect the instrument input terminals to the circuit to

be tested.

______________________________________________________________

Measurement Procedures

Page 26

14

_____________________________________________________________________

Example 1

Recording voltage changes at a breaker.

Estimated test voltage: 200 V AC

Recording period: 24 hours

1. The supplied connection cord

connect to the Test voltage input

terminals.

2. Set the Range selector to

200 V

,

corresponding to the input signal level.

(Select the voltage of the part to divide

by V.)

______________________________________________________________

Measurement Procedures

Page 27

_____________________________________________________________________

Adjust the POSITION control to display

3.

15

140 to 240 V (see Section 2.5, Item 3

regarding POSITION control

adjustment).

Set the SPEED selector to 10 cm/hour

4.

(according to particular application).

5. Press the

ADJ

button to reset the zero

position. (see Section 2.5, Item 9

regarding ADJ button).

6. Connect the connection cord in parallel

with the device under test.

7. Press the

CHART

button to begin

measuring.

8. Record for 24 hours.

9. Press the

recording.

______________________________________________________________

CHART

button again to stop

Measurement Procedures

Page 28

16

_____________________________________________________________________

10.Disconnect the connection cord from the circuit under

test.

11.Press the

PAPER FEED

button to feed out the recording

paper, and cut it off.

12.Turn the POWER switch off ( ).

Inspect the results. In this example, the elapsed time

13.

until the battery voltage decreases to the warning level

can be read from the printout and the scale.

______________________________________________________________

Measurement Procedures

Page 29

_____________________________________________________________________

R

17

2.3 AC Current Measurement

To avoid electric shock, short circuits and damage to

DANGE

the instrument, observe the following precautions:

Clamp-on sensor should be made only at the

secondary side of a breaker, so the breaker can

prevent an accident if a short circuit occurs.

Connections should never be made to the primary

side of a breaker, because unrestricted current flow

could cause a serious accident if a short circuit

occurs.

To avoid short circuits and potentially life-threatening

hazards, never attach the clamp to a circuit that

operates at more than the maximum rated voltage or

over bare conductors.

If the input signal level is unknown, begin measuring

with the highest range to determine the approximate

signal level, then select the appropriate range for

actual measurement.

Disconnect the clamp-on sensor from the

measurement object before switching ranges.

CAUTION

Note that the clamp-on sensor may be damaged if current

exceeding the selected measurement range is applied for a

long time.

To prevent damage to the clamp-on sensor, never connect

or disconnect a sensor while the power is on.

Example 2

Recording current flow through a breaker.

Estimated test current: 30 A

Recording period: 1 hour

______________________________________________________________

Measurement Procedures

Page 30

18

_____________________________________________________________________

Connect the optional clamp-on

1.

sensor to the Clamp terminals.

Set the Range selector to the A position.

2.

3. Set the

A

(CLAMP) selector to

50 A

sensitivity.

4. Set the

SPEED

selector to

60 cm/hour

(according to particular application).

______________________________________________________________

Measurement Procedures

Page 31

_____________________________________________________________________

Press the ADJ button to reset the zero

5.

19

position. (see Section 2.5, Item 9

regarding ADJ button).

6. Clip the clamp on sensor.

OK

NOTE

Attach the clamp around only one conductor. Single-phase (2-

wire) or three-phase (3-wire) cables clamped together will not

produce any reading.

Position the conductor so that it is as nearly centered in the

clamp core as possible.

Non-sinusoidal waveforms such as the secondary side of

inverters may not be measurable.

Depending on the size and frequency of the measured current,

the core of the clamp may hum as a result of resonance. This

does not affect measurement performance.

Do not attempt to measure current levels that are likely to

exceed the specified maximum r ating of the clamp-on sensor.

7. Press the

CHART

button to begin

measuring.

8. Record for 1 hour.

9. Press the

recording.

CHART

button again to stop

______________________________________________________________

Measurement Procedures

Page 32

20

_____________________________________________________________________

10.Remove the clamp from the conductor being measured.

Press the PAPER FEED button to feed out the recording

11.

paper, and cut it off.

Turn the POWER switch off ( ).

12.

13.Inspect the results. In this example, the current flow

through the breaker over ten minutes can be read from

the printout and the scale.

______________________________________________________________

Measurement Procedures

Page 33

_____________________________________________________________________

R

2.4 AC Voltage and Current Measurement

To avoid electric shock, short circuits and damage to

21

DANGE

the instrument, observe the following precautions:

The maximum input voltage is 600 V DC/AC.

Attempting to measure voltage in excess of the

maximum input voltage could destroy the instrument

and result in personal injure or death.

The maximum rated voltage between input terminals

and ground is 600 Vrms. Attempting to measure

voltages exceeding 600 V with respect to ground could

damage the instrument and result in personal injury.

When connecting clip-type connection cords to live

terminals, be very careful to avoid accidentally shorting

conductors together and causing a serious accident.

Connection cords or clamp-on sensor should be

made only at the secondary side of a breaker, so the

breaker can prevent an accident if a short circuit

occurs. Connections should never be made to the

primary side of a breaker, because unrestricted

current flow could cause a serious accident if a short

circuit occurs.

To avoid short circuits and potentially life-threatening

hazards, never attach the clamp to a circuit that

operates at more than the maximum rated voltage or

over bare conductors.

If the input signal level is unknown, begin measuring

with the highest range to determine the approximate

signal level, then select the appropriate range for

actual measurement.

Disconnect the connection cords from the

measurement object before switching ranges.

To avoid electric shock and short-circuit accidents, use

only the supplied connection cords to connect the

instrument input terminals to the circuit to be tested.

To avoid electrical shock, be careful to avoid shorting

WARNING

CAUTION

live lines with the connection cords.

Note that the clamp-on sensor may be damaged if

current exceeding the selected measurement range is

applied for a long time.

To prevent damage to the clamp-on sensor, never

connect or disconnect a sensor while the power is on.

______________________________________________________________

Measurement Procedures

Page 34

22

_____________________________________________________________________

Example 3

Recording current flow through a breaker.

Estimated test voltage: 200 V AC

Estimated test current: 30 A

Recording period: 5 hours

1. The supplied connection cord

connect to the Test voltage input

terminals.

2. Connect the optional clamp-on

sensor to the Clamp terminals.

______________________________________________________________

Measurement Procedures

Page 35

_____________________________________________________________________

23

3. Set the Range selector to

200 V

,

corresponding to the input signal level.

(Select the voltage of the part to divide

by V/A.)

Adjust the POSITION control to display

4.

160 to 260 V (see Section 2.5, Item 3

regarding POSITION control

adjustment).

5. Set the

V

DISPLAY

switch to eitherAor

, according whether you wish the

LCD to display current or voltage,

respectively.

Displays current

______________________________________________________________

Displays voltage

Measurement Procedures

Page 36

24

_____________________________________________________________________

Set the SPEED selector to 10 cm/hour

6.

(according to particular application).

NOTE

7. Press the

ADJ

button to reset the zero

position. (see Section 2.5, Item 9

regarding ADJ button).

Connect the connection cord in parallel

8.

with the device under test.

Clip the clamp on sensor.

9.

OK

Attach the clamp around only one conductor. Single-phase (2wire) or three-phase (3-wire) cables clamped together will not

produce any reading.

Position the conductor so that it is as nearly centered in the

clamp core as possible.

Non-sinusoidal waveforms such as the secondary side of

inverters may not be measurable.

Depending on the size and frequency of the measured current,

the core of the clamp may hum as a result of resonance. This

does not affect measurement performance.

Do not attempt to measure current levels that are likely to

exceed the specified maximum r ating of the clamp-on sensor.

______________________________________________________________

Measurement Procedures

Page 37

_____________________________________________________________________

Press the CHART button to begin

10.

25

measuring.

11.Record for 5 hours.

12.Press the

CHART

button again to stop

recording.

13.Disconnect the connection cord from the circuit under

test.

Remove the clamp from the conductor being measured.

14.

15.Press the

PAPER FEED

button to feed out the recording

paper, and cut it off.

16.Turn the POWER switch off ( ).

Inspect the results. In this example, changes in voltage

17.

and current through the breaker for five hours can be

read from the printout and the scale.

______________________________________________________________

Measurement Procedures

Page 38

26

_____________________________________________________________________

2.5 Common Measurement Operations

(1) Starting and ending recording

Pressing the

pressing it again (to return it to the undepressed STOP

position) ends recording.

NOTE

The PAPER FEED button and ADJ button are disabled while

the CHART button is depressed (ON).

Changing the range during recording, the new scale is printed.

(2) Paper transport speed

Use the

NOTE

Settings can be changed during recording, but the setting

information cannot be printed. Check the elapsed time printed

on the paper.

(3) POSITION control

For voltage measurement (Range selector set to V/A or V),

the central value on the magnified display can be offset in

steps equal to 10% of the range limit. This function is

useful in cases where the actual voltage of a circuit under

test differs from standard voltage ratings.

Display Example of 200-V DC Range Case

CHART button down starts recording, and

SPEED

selector to set the paper transport speed.

g

n

i

t

t

e

S

N

O

I

T

I

S

O

P

m

u

m

i

n

i

M

______________________________________________________________

Measurement Procedures

g

n

i

t

t

e

S

N

O

I

T

I

S

O

P

r

e

t

n

e

C

g

n

i

t

t

e

S

N

O

I

T

I

S

O

P

m

u

m

i

x

a

M

Page 39

_____________________________________________________________________

27

(4) PAPER FEED button

Use this button for manual paper recording.

Pressing this button momentarily advances the paper about

30 mm. Holding this button advances the paper

continuously.

NOTE

The button is disabled during automatic recording.

(5) DISPLAY Switch

When you are recording voltage and current simultaneously

(V/A range selected), you can set this switch to either A or

V, according whether you wish the LCD to display current

or voltage, respectively.

(6) Range selector

Set according to the expected maximum amplitude of the

measured signal.

(7) AC current measurement

To measure AC current using an optional clamp-on sensor,

connect the clamp-on sensor to the clamp terminals and set

the range selector to A. (Set the Range selector to V/A to

record voltage and current simultaneously, or set to the A

position to record only current.) Also, set the A (CLAMP)

selector to match the input sensitivity of the clamp with the

expected maximum current to be measured.

(8) Printing waveforms

Either average or peak values can be selected for waveform

printing. The selection is made when turning the power on

(when the power is off, the standard condition is selected).

Unaveraged mode (standard setting)

The printed waveform consists of the minima and maxima

points of the data sampled between printing intervals. This

mode is useful for recording rapid changes in input signals,

such as instantaneous electrical faults.

______________________________________________________________

Measurement Procedures

Page 40

28

_____________________________________________________________________

Average mode

The printed waveform consists of the average of the data

points between printing intervals.

The printing waveform mode is displayed as AC

_

.

The following shows the relation between the paper

transport speeds and intervals.

Papertransport speed Intervals

60 cm/hour 750 ms

20 cm/hour 2.25 s

10 cm/hour 4.5 s

6 cm/hour 7.5 s

2 cm/hour 22.5 s

Average mode

Hold the PAPER FEED button

while turning the POWER switch on.

NOTE

Standard Condition

Continuing to hold the switch causes the paper to feed.

______________________________________________________________

Measurement Procedures

Page 41

_____________________________________________________________________

29

(9) ADJ button

Press this button to adjust the fine offset of the zero

position during measurement. While shorting the connection

cord together, press this button to reset the zero position.

After adjusting the zero position, the "0" in the numeric

display of the LCD changes to "0.0", the "0" in the range

setting information for the recording paper changes to

"0.0", and "_" appears under the unit display.

Before adjusting

NOTE

______________________________________________________________

This button is intended only for fine adjustment of the zero

position. It cannot compensate for a large offset.

The zero adj ustment is lost when power is turned off or range

selector setting is changed, so reset the zero position again if

necessary when power is turned on.

The button is disabled during automatic recording.

After verifying that input is 0, press the ADJ button. To ensure

zero input, either short the tips of the connection cords or short

the test voltage input terminals. Measurement error will be larger

in any input is present when the ADJ button is pressed.

・For accurate measurements, press the ADJ button only when the

conductor is not clamped and the core junction is closed (when

the input value is 0).

・After changing the range, press the ADJ button to reset the zero

position.

After adjusting

Measurement Procedures

Page 42

30

_____________________________________________________________________

______________________________________________________________

Measurement Procedures

Page 43

_____________________________________________________________________

31

Chapter 3

Changing the Recording Paper

3.1 Opening and Closing the Printer Cover

CAUTION

Avoid forcing the printer cover, as the hinge could break.

Opening the Printer Cover

Hook your fingertip under the projecting part

1.

of the printer cover, and pull it up slightly to

disengage the catch.

2. Open the cover when the catch is disengaged.

Closing the Printer Cover

1. Confirm that some paper is sti cking out

before closing the printer cover.

2. Align the hook in the cover with the catch on

the unit, and press the cover lightly until the

catch engages.

______________________________________________________________

Changing the Recording Paper

Page 44

32

_____________________________________________________________________

3.2 Installing Recording Paper

Head up/down lever

Recording paper

Recording paper

Platen

Roll paper spool

Print head

Guide shaft

Raise the print head. Move the

1.

head up/down lever up to raise

the print head.

2. Insert the spool into the

recording paper roll.

Install the spool and paper roll

3.

into the holder.

Feed the paper over the guide

4.

shaft.

5. Feed the paper over the platen

and out through the printer

frame.

6. Confirm that the paper is

centered on the platen, and move

the lever down to lower the print

head.

NOTE

______________________________________________________________

Changing the Recording Paper

Printing is not possible if the recording paper is loaded wrongside up.

The paper may jam if it is not aligned with the roller.

Page 45

_____________________________________________________________________

Chapter 4

Specifications

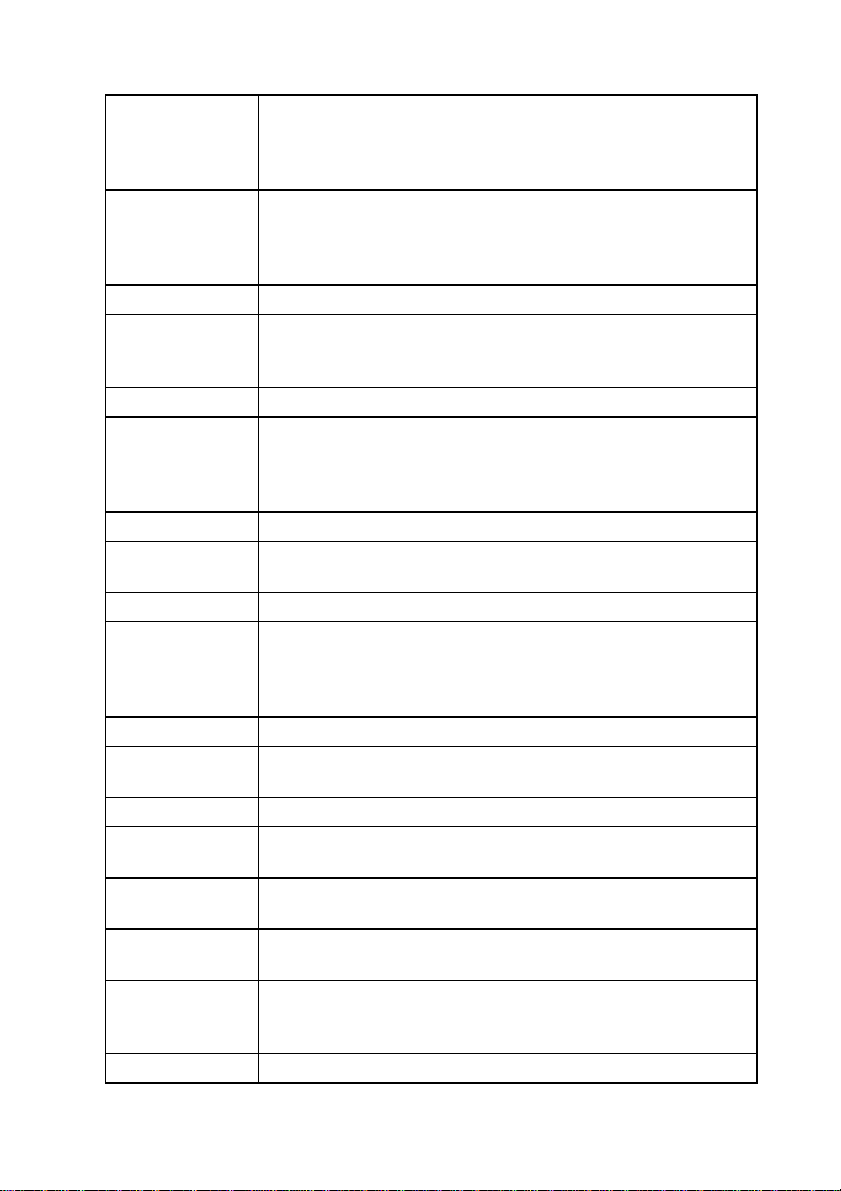

4.1 General Specifications

Recording system Thermal recording paper

Input channels 2 (Each channel sampled alternately)

Sampling period 10 ms

Valid recording width Waveform recording width: 60 mm

33

Paper transport

speeds

2, 6, 10, 20 or 60 cm/hour

Recording axis

precision

Operating

temp./humidity

Storage

temp./humidity

Guaranteed accuracy

signal frequency

Operating temperature

and humidity for

guaranteed accuracy

Period of guaranteed

accuracy

Operating

environment

Withstand voltage 4.29 kVrms (50/60 Hz, 1 min)

Power requirements AC: 100 to 240 V, 50/60 Hz, 30 VA

Within 0.5%

5to40oC (41 to 104 ), 35 to 80% RH (noncondensating)

-10to50oC (14 to 122 ), 80% RH or less (noncondensating)

45 to 66 Hz

23 5oC(73 41 ), 35 to 80% RH (non-condensating)

1 year

Indoors, below 2000 m (6562 feet) altitude

between GND and input terminals

DC: 9.5 to 14 V, 30 VA

(Voltage fluctions of 10% from the rated supply

voltage are taken into account. )

______________________________________________________________

Specifications

Page 46

34

_____________________________________________________________________

External dimensions

and mass

Accessories 9344 CARRYING CASE 1

Options 9235 RECORDING PAPER (15 m, 10 rolls) 1

Applicable Safety:

Standards

EMC:

Approx. 250W 122H 93.5D mm

(9.84"W

Approx. 1200 g (42.3 oz.)

L9257 CONNECTOR CORD 1

9235 RECORDING PAPER (15 m) 1

Roll Paper Spools 2

AC Power Cord 1

Instruction Manual 1

9236-01 RECORDING PAPER

9650 CLAMP ON SENSOR 1

9651 CLAMP ON SENSOR 1

9668 CLAMP ON SENSOR 1

EN61010

Pollution Degree 2, Measurement category III

(6000 V expected transient Overvoltage)

EN61326 Class A

EN61000-3-2

EN61000-3-3

4.8"H 3.68"D)

(15 m, Climate-resistant; 10 rolls) 1

______________________________________________________________

Specifications

Page 47

_____________________________________________________________________

4.2 Voltage Measurement Input Specifications

35

Measurement ranges

(based on standard

ratings)

Maximum input voltage 600 Vrms

Maximum rated voltage

between input

terminals and ground

Input impedance 1MΩ 5%

Accuracy Within 2% of the maximum graduated value (the

Rectification system Effective value rectification

Common mode

rejection ratio

Frequency

characteristics

Effect of electromagnetic

interference

100, 200 and 500 V AC (rated value of the range can

be adjusted within

steps) The display can be magnified to show the area

between +25 and -35% of the measurement range.

600 Vrms

maximum graduated value is 25% above the rated

value of the range)

Better than 50 dB (50/60 Hz, less than 100Ω unbalance)

Within +0.5, -3 dB for the range between 30 Hz to 30

kHz, using 50/60 Hz as the standard reference point.

Within +5, -0.5%f.s. at 3 V/m

20% of standard ratings in 10%

______________________________________________________________

Specifications

Page 48

36

_____________________________________________________________________

4.3 Current Measurement Input Specifications

Measurement ranges

(max. ratings)

Input sensitivity 10, 20, 50, 100, 200, 500, 1000 mA f.s.

Input impedance 1 Ω 10%

Accuracy Within 2% of max. rating

Rectification system Effective value rectification

Frequency

characteristics

Range information Sensitivity and display range are determined by the

Effect of

electromagnetic

interference

10, 20, 50, 100, 200, 500, 1000 AAC (depending on

clamp-on sensor used). Maximum display range is

110% of measurement range.

(f.s. = max. rating)

(10, 20, 50, 100, 200, 500 A range)

Within 3% of max. rating (1000 A range)

Within +0.5, -3 dB for the range between 20 Hz to 20

kHz, using 50/60 Hz as the standard reference point

(independent of clamp-on sensor characteristics).

Clamp Range input selector setting.

Within +10, -1%f.s. at 3 V/m

The full-scale accuracy of the ranges of each clamp-on sensor is as

follows.

Range

model

9650 1.8% 1.65% 1.56% 1.53%

9651 3.0% 2.25% 1.8% 1.65% 1.58% 1.53%

9668 6.0% 4.5% 3.6% 3.3% 3.15% 3.06% 3.03%

10 A 20 A 50 A 100 A 200 A 500 A 1000 A

______________________________________________________________

Specifications

Page 49

_____________________________________________________________________

37

Overall accuracy is the cumulative accuracy of the recorder and the

probe, as indicated in the following examples.

(Examples)

1. For the 100-A range, combining the accuracy of the recorder and the

9650 yields an overall accuracy of

range,

3.56% f.s.

3.53% f.s., and for the 50-A

2. For the 500-A range, combining the accuracy of the recorder and the

9651 yields an overall accuracy of

range,

3.65% f.s.

3.53% f.s., and for the 100-A

3. For the 1000-A range, combining the accuracy of the recorder and the

9668 yields an overall accuracy of

range,

5.3% f.s.

6.03% f.s., and for the 100-A

NOTE

When using the 9668 CLAMP ON SENSOR in conjunction with

the 8205-10 to measure current, we do not recommend t a king

measurements at high sensitivities. We do recommend using a

clamp that is suited to the current to be measured.

4.4 Display Specifications

Display method Signal level and setting data displayed by LCD bar

Display contents Signal input level (V):

The display can be magnified to show the area between

+25 and -35% of the measurement range. (rated value of

the range can be adjusted within

atings in 10% steps)

Maximum displayable voltage = 725 V AC

Minimum resolvable voltage =

Voltage: 1% of the rated value of the range

Current: 2% of the rated value of the range

Signal input level (A):

0 to 110% of range rating

Minimum resolution = 2% of range rating

Low Supply Voltage (when operating on DC)

Print Head Up

Paper End

Type of Signal Measurement

Measured signal units and subunits

20% of standard

______________________________________________________________

Specifications

Page 50

38

_____________________________________________________________________

4.5 Recorded Information

Waveform data Voltage or current amplitude. Waveform data may be

either average or unaveraged values (set at power on)

Settings Range, mode, etc. print at start and stop, and at each

10 DIV (format differs when printed at intervals)

Elapsed time Elapsed time from starting to record are printed at

each 5 DIV

Interval printing Measured values print along grid at each 2 DIV

Printing when setting

change

Changes in various settings during recording are

printed after the changes are made

4.6 Recording Time

The following table shows the recording capacity of one

roll of recording paper.

Papertransport speed Recording time

2 cm/hour 31.25 days

6 cm/hour 10.43 days

10 cm/hour 6.25 days

20 cm/min 75 hours

60 cm/min 25 hours

______________________________________________________________

Specifications

Page 51

_____________________________________________________________________

39

Chapter 5

Maintenance and Service

5.1 Storage Precautions

(1) Recorder

Avoid storing the product in conditions of high temperature

and humidity, as damage may result from condensation and

corrosion.

During long-term storage and during transportation, the

print head should be in the raised position. Leaving the

print head in the lowered position for an extended period

can dent the platen (rubber roller) that transports the paper,

resulting in uneven printing.

(2) Storing recording paper

o

Store rolls of thermal paper at no more than 4 0

The paper will change color if exposed to light over a long

period, so do not unwrap a roll of paper until you are ready

to use it.

______________________________________________________________

Maintenance and Service

C.

Page 52

40

_____________________________________________________________________

(3) Storing recordings

As the recording paper is thermally sensitive, be aware of

the following points:

To avoid paper discoloration, do not expose it to direct

o

sunlight, and store at no more than 40

C and 90% RH.

For permanent storage of important recorded data,

photocopy the recording paper.

If the thermal paper is exposed to an organic solvent such

as alcohol or ketone, it may no longer develop properly,

and recorded data may fade.

Also, the thermal recording paper is ruined by contact with

wet Daizo copy paper.

5.2 Cleaning

To clean the instrument, wipe it gently with a soft cloth

moistened with water or mild detergent. Never use solvents

such as benzene, alcohol, acetone, ether, ketones, thinners

or gasoline, as they can deform and discolor the case.

______________________________________________________________

Maintenance and Service

Page 53

_____________________________________________________________________

41

5.3 Cleaning the Printer Head

To maintain print quality, use the following method to

clean the print head whenever recording paper is replaced.

Method 1

ADJ

NOTE

1. Turn on the printer's power while holding down the

button.

2. Print solid black for about 50 cm, and the printer should

turn on as usual. (Press the PAPER FEED button to stop

at any time.)

Print solid black several times to confirm whether

3.

printing has improved. If it does not improve, perform

Method 2.

Method 2

1. Apply a solvent such as a non-water alcohol or normal

hexane, to the recording paper and insert it into the

printer. The recording paper may change color depending

on the solvent you use, so use the reverse side.

2. Move the head up/down lever to the down position.

3. Move the recording paper back and forth with your hand

to clean the head.

Do not use organic solvents such as thinner or benzene, which

could discolor or deform the printer.

After applying a solvent, be certain that the printer is completely

dry before use to avoid discoloring or deforming the printer.

After prolonged use, white paper dust may build up on the

surface of the paper roller. Small amounts of paper dust will not

affect printer operation. However, you may remove it using a

blower brush, such as those used for cameras.

Cut the recording paper with the cutter attached to the printer's

cover. If you cut the recording paper against the side of the

printer head, large amounts of paper dust will stick to the paper

rolle.

______________________________________________________________

Maintenance and Service

Page 54

42

_____________________________________________________________________

5.4 Service

If damage is suspected, check the "Troubleshooting" section

before contacting your dealer or Hioki representative. Pack

the instrument carefully so that it will not be damaged

during shipment, and include a detailed written description

of the problem. Hioki cannot be responsible for damage

that occurs during shipment.

Troubleshooting

Symptom Cause Remedy

Does not turn on POWER SOURCE switch

may be set incorrectly

Power cord may be broken Check and replace cord.

Does not print Paper may be installed

upside down

Set to match power source.

Reinstall the paper

Measured values

unstable

Input signals do not

display

Ground not connected Connect the GND terminal

to earth ground

A connection cord may be

open

Check and replace

connection cord

______________________________________________________________

Maintenance and Service

Page 55

Page 56

Loading...

Loading...