Page 1

3805

DIGITAL HiTESTER

INSTRUCTION MANUAL

Page 2

Page 3

Contents

Introduction

i

Inspection

i

Safety Notes

ii

Notes on Use

viii

Chapter 1 Overview

1

1.1 Product Overview 1

1.2 Features

2

Chapter 2 Names and Functions of Parts 3

2.1 Push Buttons 4

2.2 Rotary Switch

7

2.3 Input Terminal

8

2.4 LCD Display Illustration

9

Chapter 3 Measurement Procedures 11

3.1 Voltage Measurement 13

3.1.1 AC Voltage Measurement 14

3.1.2 Frequency Measurement

15

3.1.3 DC Voltage Measurement

16

3.2 Diode Check 17

3.3 Resistance Measurement

19

3.4 Current Measurement

21

3.4.1 AC Current Measurement 22

3.4.2 Frequency Measurement

23

3.4.3 DC Current Measurement

24

3.5 Capacitance Measurement 25

3.6 Temperature Measurement

27

Page 4

Chapter 4 Special Functions Instructions 31

4.1 Data Hold 32

4.2 Refresh Hold

33

4.3 Dynamic Recording

34

4.4 Harmonic Ratio Measurement

37

4.5 Relative (Zero)

38

4.6 % of mA Measurement (4-20mA)

39

4.7 Beeper On/Off

40

4.8 Set Up

41

4.8.1 Timer Setting for Auto-power Save 42

4.8.2 Selecting % Display for 4 to 20 mA

43

4.8.3 Selecting J/ k Types and

/ Display 44

4.9 Communication (RS-232C) 45

Chapter 5 Specifications 47

5.1 General Specifications 47

5.2 Accuracy Chart

51

Chapter 6 Maintenance and Service 57

6.1 Changing the Battery and Fuses 57

6.2 Cleaning

60

6.3 Service

60

Page 5

i

_______________________________________________

Introduction

_______________________________________________

Introduction

Inspection

Thank you for purchasing the HIOKI "3805

DIGITAL HiTESTER". To obtain maximum

performance from the product, please read this

manual first, and keep it handy for future reference.

When you receive the product, inspect it carefully to

ensure that no damage occurred during shipping. If

damage is evident, or if it fails to operate according

to the specifications, contact your dealer or Hioki

representative.

Accessories

3851-10 TEST LEAD (a pair) 1

Protective holster 1

Instruction Manual 1

6F22 manganese battery 1

(built into this unit, for monitor)

Page 6

ii

_______________________________________________

Safety Notes

_______________________________________________

WARNING

This product is designed to conform to IEC 61010

Safety Standards, and has been thoroughly tested

for safety prior to shipment. However,

mishandling during use could result in injury or

death, as well as damage to the product. Be

certain that you understand the instructions and

precautions in the manual before use. We

disclaim any responsibility for accidents or

injuries not resulting directly from product

defects.

Safety Notes

Page 7

iii

_______________________________________________

Safety Notes

_______________________________________________

The symbol printed on the product

indicates that the user should refer to a

corresponding topic in the manual

(marked with the

symbol) before

using the relevant function.

In the manual, the symbol indicates

particularly important information that

the user should read before using the

product.

Indicates a double-insulated device.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates both DC and AC.

Indicates grounding terminal.

Indicates that dangerous voltage may be

present at this terminal.

This manual contains information and warnings

essential for safe operation of the product and for

maintaining it in safe operating condition. Before

using the product, be sure to carefully read the

following safety notes.

Safety symbols

Page 8

iv

_______________________________________________

Safety Notes

_______________________________________________

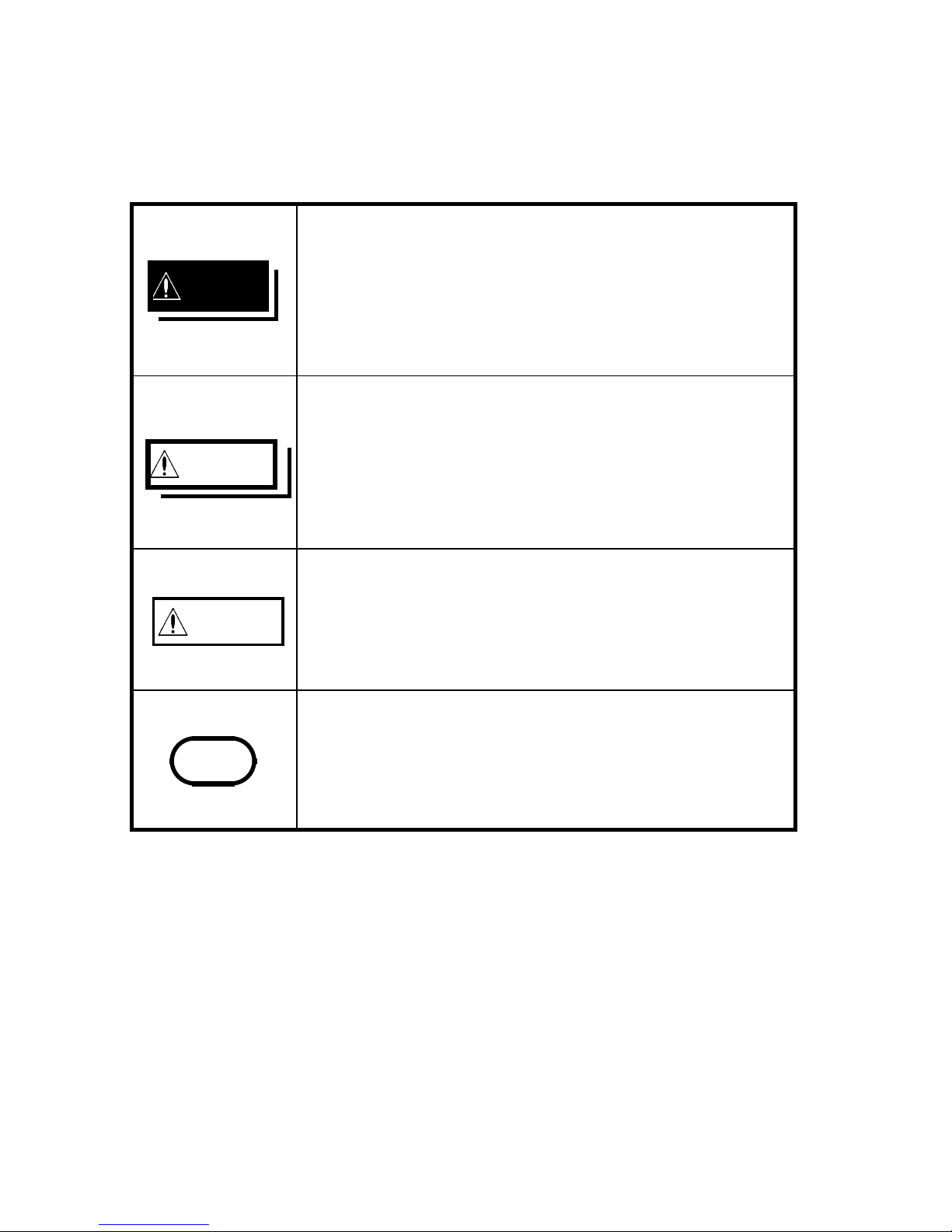

DANGER

Indicates that incorrect operation

presents an extreme hazard that could

result in serious injury or death to the

user.

WA R NING

Indicates that incorrect operation

presents a significant hazard that could

result in serious injury or death to the

user.

CAUTION

Indicates that incorrect operation

presents a possibility of injury to the

user or damage to the product.

NOTE

Advisory items related to performance

or correct operation of the product.

The following symbols in this manual indicate the

relative importance of cautions and warnings.

Page 9

v

_______________________________________________

Safety Notes

_______________________________________________

We define measurement tolerances in terms of f.s.

(full scale), rdg. (reading) and dgt. (digit) values,

with the following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or the full length of

the scale. This is usually the maximum value of the

currently selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated

on the measuring product.

dgt. (resolution)

The smallest displayable unit on a digital measuring

product, i.e., the input value that causes the digital

display to show a "1".

Page 10

vi

_______________________________________________

Safety Notes

_______________________________________________

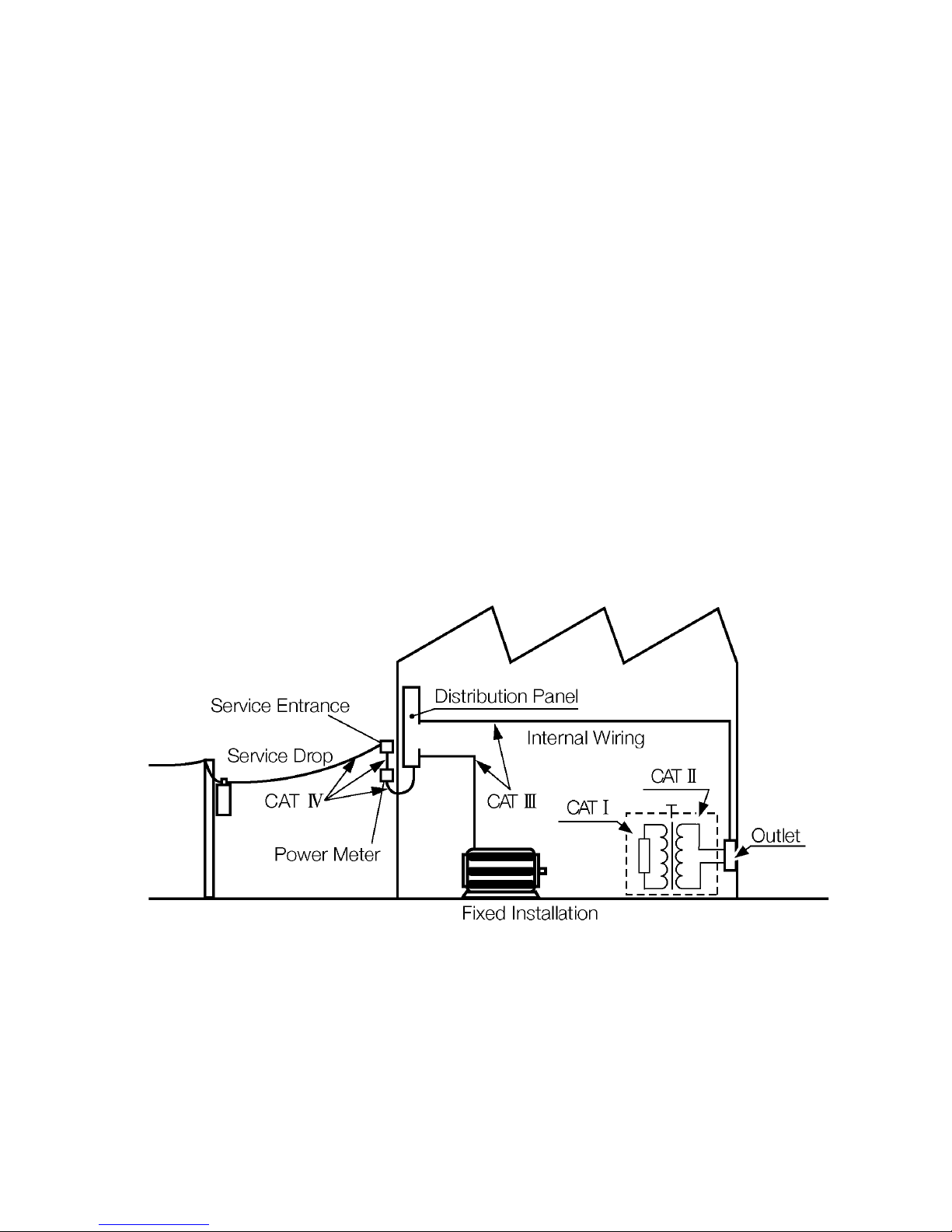

Measurement categories (Overvoltage

categories)

This product conforms to the safety requirements for

CAT II (1000V), CATIII (600V) measurement

products.

To ensure safe operation of measurement product,

IEC 61010 establishes safety standards for various

electrical environments, categorized as CAT I to

CAT IV, and called measurement categories. These

are defined as follows.

CAT I : Secondary electrical circuits connected to

an AC electrical outlet through a

transformer or similar device.

CAT II : Primary electrical circuits in equipment

connected to an AC electrical outlet by a

power cord (portable tools, household

appliances, etc.)

CAT III : Primary electrical circuits of heavy

equipment (fixed installations) connected

directly to the distribution panel, and

feeders from the distribution panel to

outlets.

CAT IV : The circuit from the service drop to the

service entrance, and to the power meter

and primary overcurrent protection device

(distribution panel).

Page 11

vii

_______________________________________________

Safety Notes

_______________________________________________

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III

environments can endure greater momentary energy

thanadevicedesignedforCATII.

Using a measurement product in an environment

designated with a higher-numbered category than

that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Never use a CAT I measuring product in CAT II,

III, or IV environments.

The measurement categories comply with the

Overvoltage Categories of the IEC60664 Standards.

Page 12

viii

_______________________________________________

Notes on Use

_______________________________________________

WARNING

Do not use the p roduct where it may be

exposed to corrosive or combustible gases.

The product may be damaged or cause an

explosion.

Before using the product, make sure that the

insulation on the test leads is undamaged and

that no bare conductors are improperly

exposed. Using the product under such

conditions could result in electrocution.

Replace the test leads with the specified Hioki

Model 3851-10.

Notes on Use

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various

functions.

Preliminary Check

Before using the product the first time, verify that it

operates normally to ensure that the no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

Page 13

ix

_______________________________________________

Notes on Use

_______________________________________________

CAUTION

To avoid damage to the product, do not allow the

product to get wet, and do not use it when your

hands are wet.

Adjustments and repairs should be made only by

technically qualified personnel.

This product should be installed and operated indoors

only, between 0 and 40

and 80% RH or less.

However, it can be safely operated down to -10

.

Do not store or use the product where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions, the

product may be damaged and insulation may

deteriorate so that it no longer meets specifications.

This product is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a wet or

dusty environment.

Do not use the product near a device that generates

a strong electromagnetic field or electrostatic charge,

as these may cause erroneous measurements.

To avoid damage to the product, protect it from

vibration or shock during transport and handling, and

be especially careful to avoid dropping.

If the protective functions of the product are damaged,

either remove it from service or mark it clearly so that

others do not use it inadvertently.

Page 14

x

_______________________________________________

Notes on Use

_______________________________________________

NOTE

To avoid corrosion from battery leakage, remove the

batteries from the product if it is to be stored for a

long time.

Page 15

1

_______________________________________________

Chapter 1 Overview

_______________________________________________

Chapter 1

Overview

1.1 Product Overview

This multimeter has DCV, ACV, DCA, ACA,

OHM, Diode check, Audible continuity, Capacitor,

Temperature and % of 4-20 mA tests. It also built-in

TRUE-RMS for non-linear and traditional loads, and

frequency measurement helps detect the presence of

harmonics in neutral conductors and determine

whether they are the result of unbalanced phases or

non-linear loads. The display of Harmonic Ratio will

be helpful for quickly to know the presence of

harmonic. Smart scanning display lets you can see

the T1, T2 and

T values for temperature

measurements periodical. The built-in optical RS232C will assist you to capture the data without

hazardous as the high voltage has been measured.

Page 16

2

_______________________________________________

Chapter 1 Overview

_______________________________________________

1.2 Features

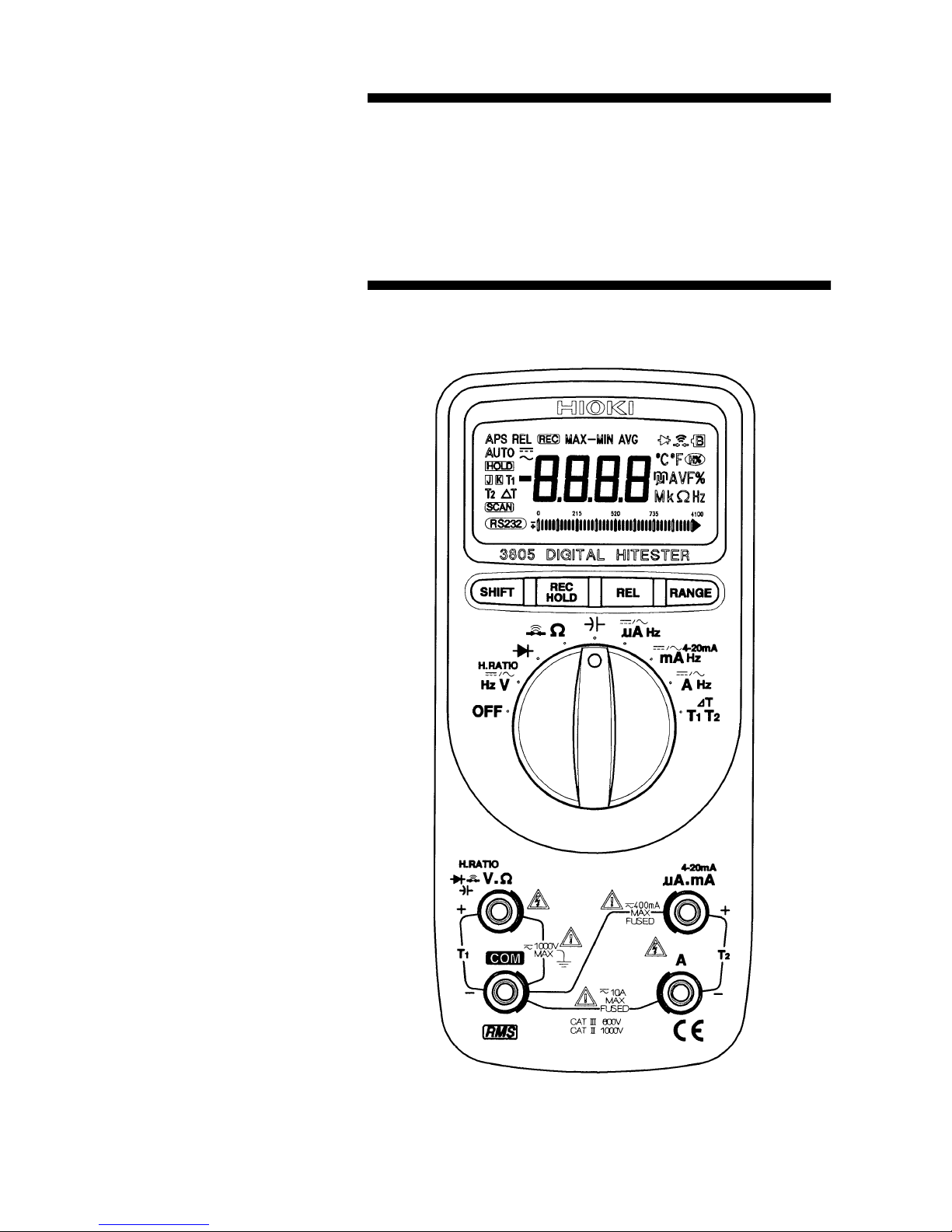

The multimeter is shown in the following Figure.

This meter has a lot of functions can be used in

HVAC, Power, Process fields, Electronic/Electrical

system diagnostics and troubleshooting. It will be

the best one of your need. See below detail:

Resolution of display: 9,999 counts for Voltage

and frequency and 3,999 counts for other

measurements.

TRUE RMS measurement for non-linear and

traditional loads.

Both paths of Current and Voltage can do

frequency measurement.

The thermocouple types of temperature

measurement can be selected K and J.

Scan T1, T2 and T1-T2 displays.

% of mA display can be selected for 4-20 mA or

0-20 mA.

The timer of auto power save can be adjusted

from 1 to 99 minutes even disable this function.

Dynamic Recording helps to record the variation

of tests.

Data Hold to freeze displayed digital value.

Refresh Hold to freeze the digital value for

difficult measuring place.

Relative function

Auto and Manual Ranging

Communication with RS-232C

Page 17

3

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

Chapter 2

Names and

Functions of Parts

Page 18

4

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

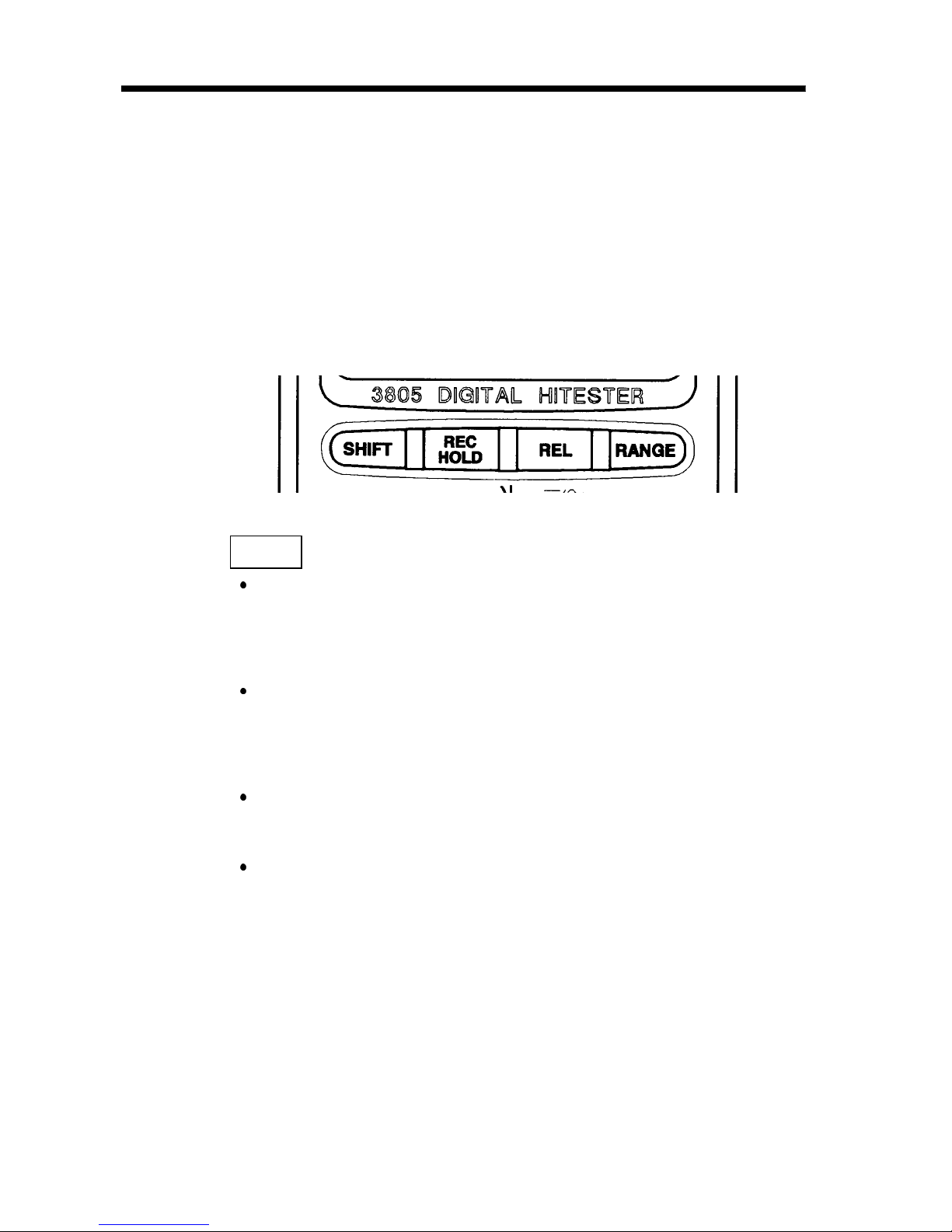

2.1 Push Buttons

The operation of push-button is shown as below.

When push the button, a display symbol will light,

and the beeper will sound. Turning the rotary switch

to another switch setting resets all push buttons to

their default state.

SHIFT

button

For voltage and current measurements, press this

button momentarily to cycle through DC,

frequency and AC tests.

For voltage measurement, press this button for

more than 1 second to set Harmonic ratio

measurement.

For mA measurement, press this button for more

than 1 second to set % of 4-20mA display.

For temperature test, press this button

momentarily to cycle through T2, ∆TandT1

tests. Press this button for more than 1 second to

set scanning the T1, T2 and ∆Tdisplays.

Page 19

5

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

For Ohm test, press button momentarily to toggle

"Audible continuity mode" ON/OFF. Pushing this

button for more than 1 second will exit the

continuity function and returns to the autoranging ohm measurement.

HOLD

button (Data Hold or Refresh Hold)

Press this button momentarily to toggle data hold

on or off. The display shows

HOLD

to indicate

the hold function.

The data hold function allows operator to hold the

displayed digital value, if you select " Refresh

Hold " by Power-ON Options, the reading is

updated to the display automatically when the

reading changes. The beeper sounds a tone to

remind user, that an update has occurred.

REC

button (Dynamic Recording)

Records maximum, minimum, and calculates true

average. Press this button for more than 1 second

to toggle recording mode on or off.

Press this button momentarily to cycle through

MAX, MIN, MAX-MIN, AVG and present (

REC

) readings.

The beeper sounds when a new maximum or

minimum value is recorded.

Page 20

6

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

REL

button

Press this button momentarily to toggle the relative

mode ON or OFF.

RANGE

button

In auto-range press this button momentarily to

select manual range and turn off the "AUTO"

annunciator.

In manual range, press this button momentarily to

step up 1 range at one time, press this button for

more than 1 second to select auto-range.

In auto-range, the "AUTO" annunciator is lit and

the meter will select an appropriate range for

measurement being made. If a reading is greater

than maximum available range, "OL"(overload) is

displayed on the screen. The meter selects a lower

range when reading is less than about 9% of full

scale.

For temperature measurement, press this button

momentarily to cycle throughK/ ,K/ ,J/

andJ/ , then come backK/ .Thesesetswill

disappear after power save. It will be set to

original setup condition when power ON.

Page 21

7

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

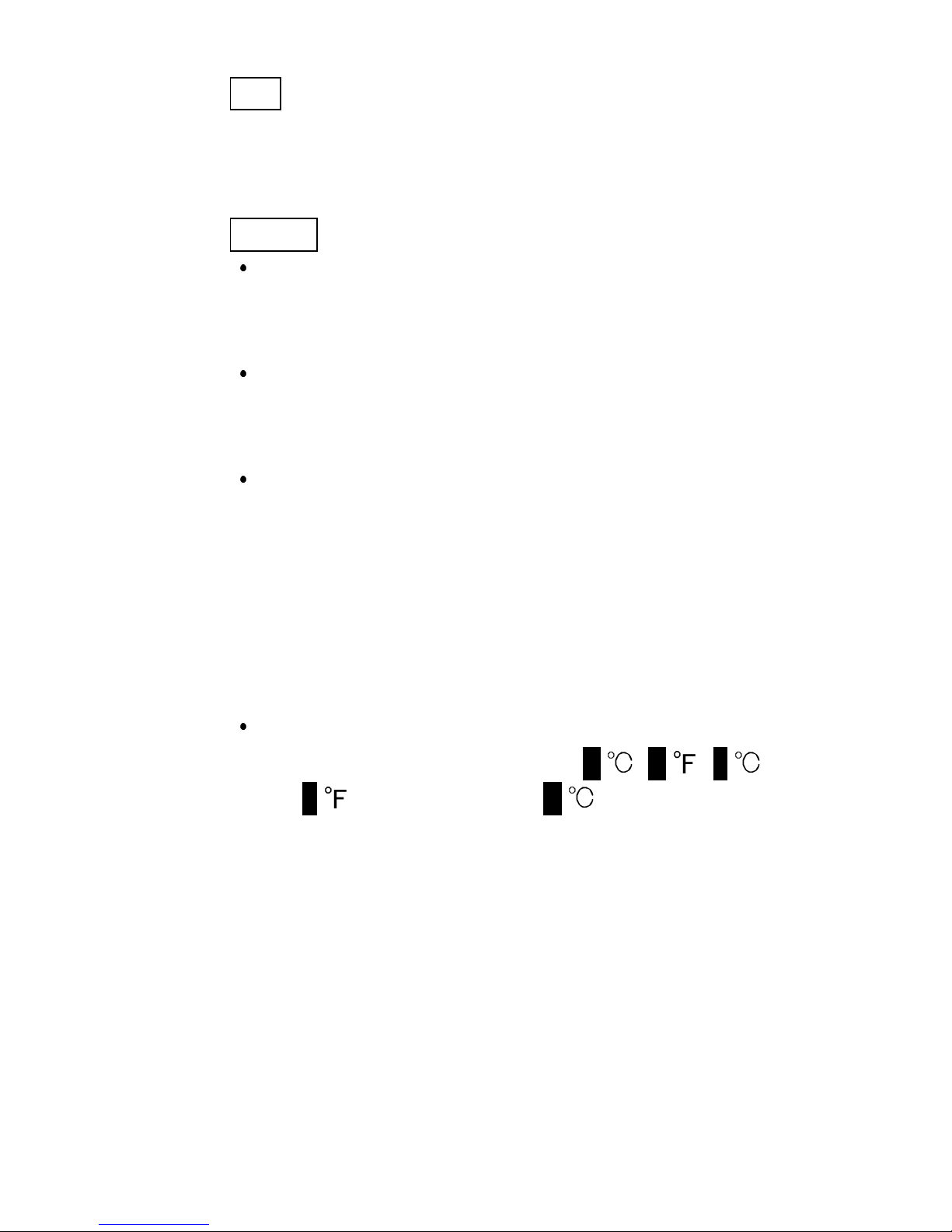

Power off position.

AC or DC voltage measurements.

Initial test is defined to AC.

Diode Check

Ohm and Continuity measurements

Capacitance measurement.

AC or DC Current measurements

AC or DC Current measurements.

A

AC or DC Current measurements.

T

1

T

2

Temperature measurement

2.2 Rotary Switch

To select function, turn the rotary switch to a switch

setting. Then the meter is ready for use. (If you

press and hold any push button while pushing the

meter from OFF to ON, the display will remain lit

until the push button is released.)

Page 22

8

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

2

3

4

1

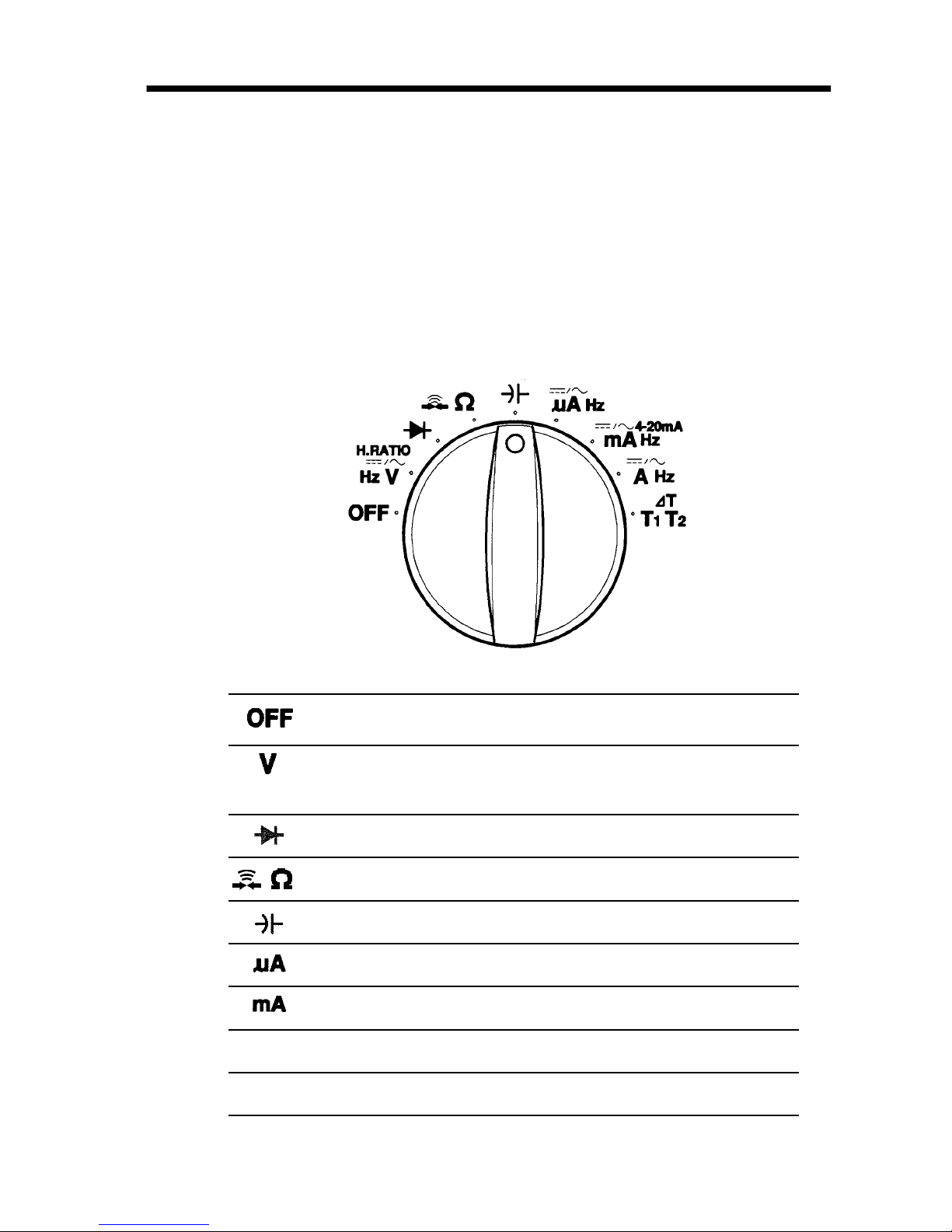

2.3 Input Terminal

1. Volts, Ohms, Diode, T1, Capacitance and

Frequency of Voltage measurements.

2. Common terminal for all measurements except

temperature of T1 test.

3. Current (maximum 400 mA) and temperature of

T2 measurements.

4. Current (maximum 10 A continuous) and

temperature of T2 measurements.

Page 23

9

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

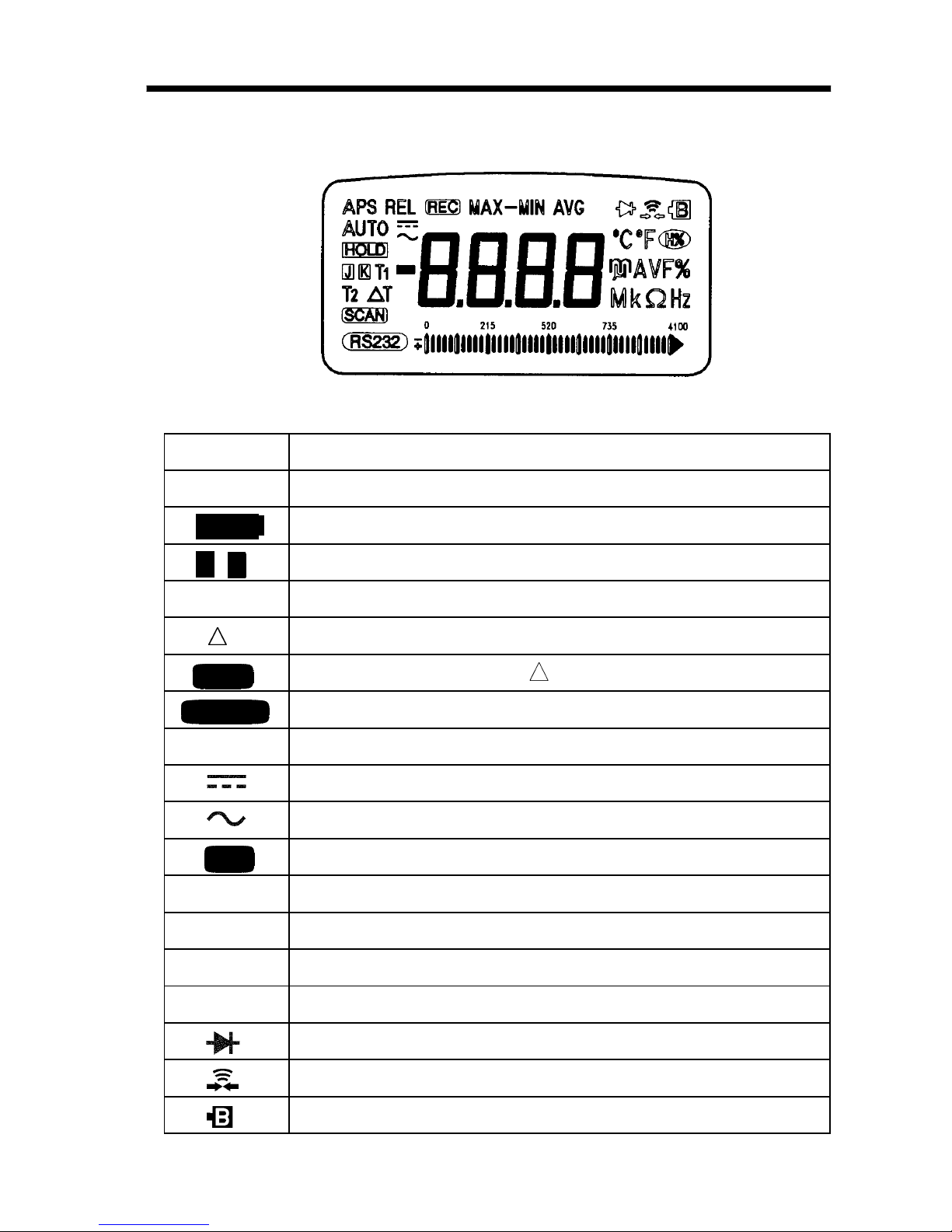

APS

Enable Auto power save

A

UTO

Indicates AUTO range Mode

HOLD

Data hold annunciator

J

K

Thermocouple type display

T1T

2

T1 or T2 temperature measurement

T

T1-T2 temperature measurement

SCAN

Scan the T1, T2 and T measurements

RS232C

Enable RS-232C

REL

Relative mode annunciator

Direct Current or Voltage

Alternating Current or Voltage

REC

Dynamic recording mode, Present reading

MAX-MIN

Different reading for MAX-MIN

MAX

Maximum reading

MIN

Minimum reading

AVG

Average reading

Diode measurement

Continuity function annunciator

Low battery indicator

2.4 LCD Display Illustration

Page 24

10

_______________________________________________

Chapter 2 Names and Functions of Parts

_______________________________________________

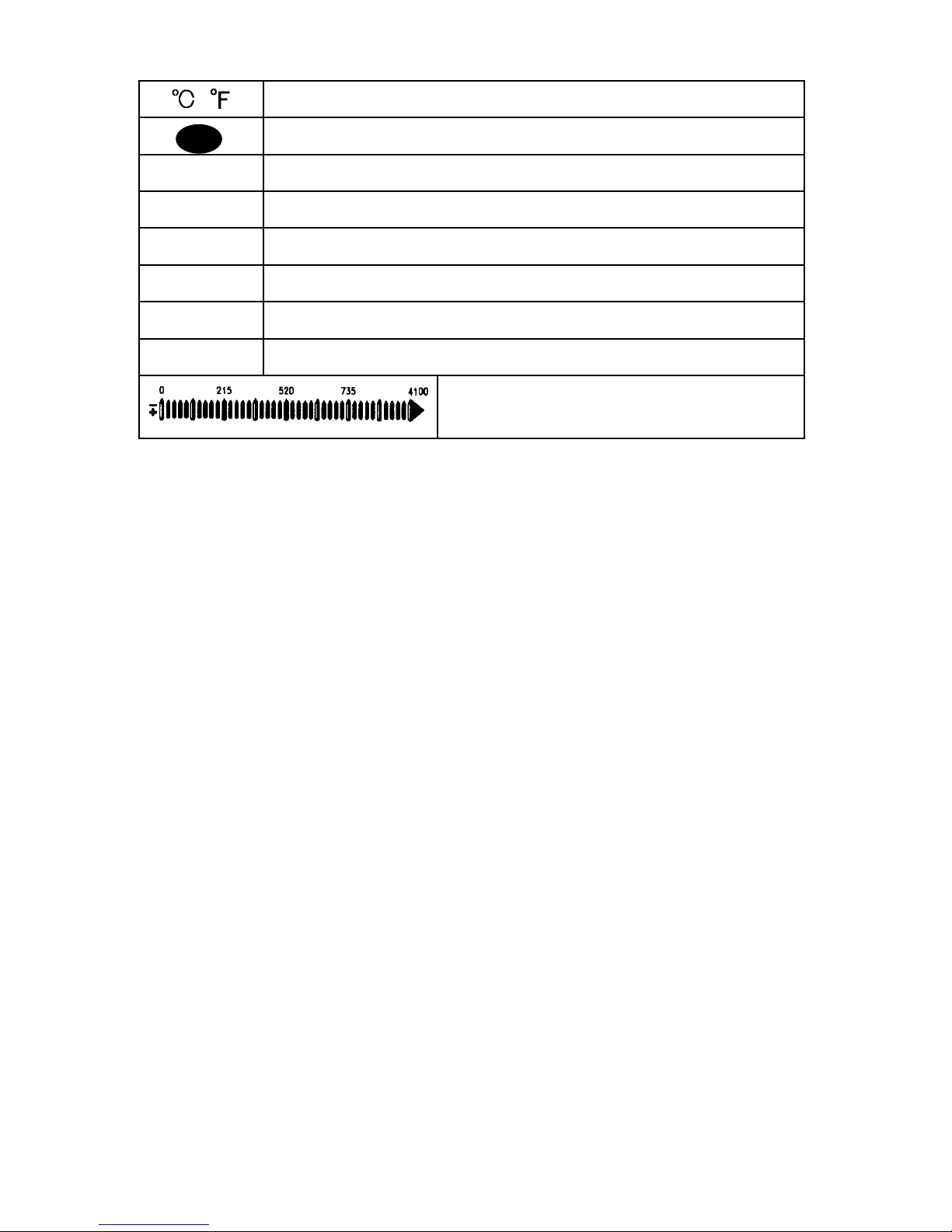

,

Units of Temperature

H%

Harmonics ratio

%

% display for 4-20mA measurement

mV

Units of Voltage measurement

µ

m

A

Units of Current measurement

µ

mF

Units of Capacitance measurement

Mk Ω

Units of Resistance (ohm) measurement

kHz

Units of frequency measurement

Bar-graph indicator

Page 25

11

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Observe the following precautions to avoid

electric shock.

Al ways verify the appropriate setting of the

function selector before connecting the test

leads.

Disconnect the test leads from the

measurement object before switching the

function selector.

NOTE

Chapter 3

Measurement

Procedures

When measuring voltage which includes harmonic

waves

(ex. horizontal output of TV), there is the possibility

that a setting error may occur.

Page 26

12

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

Preparation for Measurement

The safety caps are attached to the test leads.

Remove these caps before connecting to the unit.

Page 27

13

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

The maximum input voltage is 1000 VDC, 1000

Vrms or 10

6

V Hz. Attempting to measure

voltage in excess of the maxi mum input could

destroy the product and result in personal

injury or death.

To avoid electrical shock, be careful to avoid

shorting live lines with the test leads.

For safety, test lead connections must always

be made at the secondary side of a circuit

breaker.

3.1 Voltage Measurement

Page 28

14

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

3.1.1 AC Voltage Measurement

(1) Set the rotary switch to "Hz

/ V ".

(2) Connect the black test lead to "COM" terminal

and red test lead to " " terminal.

(3) Touch the test leads to the test points and read

the display.

Page 29

15

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

3.1.2 Frequency Measurement

(1) Set the rotary switch to "Hz

/ V ".

(2) Press

SHIFT

button momentarily two times to

set frequency measurement.

(3) Connect the black test lead to "COM" terminal

and red test lead to "

" terminal.

(4) Touch the test leads to the test points and read

the display.

The bar graph is used to indicate the value of AC

voltage.

Page 30

16

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

3.1.3 DC Voltage Measurement

(1) Set the rotary switch to "Hz

/ V ".

(2) Push

SHIFT

button momentarily to set DC test.

(3) Connect the black test lead to "COM" terminal

and red test lead to "

" terminal.

(4) Touch the test leads to the test points and read

the display.

Page 31

17

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Never apply voltage to the test leads when the

Diode Check functions is selected. Doing so

may damage the product and result in personal

injury.

To avoid electrical accidents, remove power

from the circuit before measuring.

3.2 Diode Check

A good diode allows current to flow in one direction

only. To test a diode, turn the power off, remove the

diode from the circuit, and proceed as follows:

(1) Set the rotary switch to "

" position.

(2) Connect the black test lead to "COM" terminal

and red test lead to "

" terminal.

(3) Touch the test leads to diode and read the

display.

(4) Touch the red lead to the positive side of the

diode and the black lead to the negative side.

The meter can display diode voltage drops to

approximately 2.5 V. A typical voltage drop is

0.3 to 0.8 V, and the meter will sound a beep to

remind user.

Page 32

18

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

Reverse the test leads and measure the voltage

across the diode again. If the diode is:

Good : "OL" is displayed.

Shorted : Near 0 V drop is displayed in both

directions, and the beeper sounds

continuously.

Open : "OL" is displayed in both directions.

Repeat step (3) and (4) for other diodes.

Page 33

19

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Never apply voltage to the test leads when the

Resistance, Continuity Check functions are

selected. Doing so may damage the product

and result in personal injury.

To avoid electrical accidents, remove power

from the circuit before measuring.

3.3 Resistance Measurement

(1) Set the rotary switch to " ".

(2) Connect the black test lead to "COM" terminal

and red test lead to "

" terminal.

(3) Touch the test leads to resistor and read the

display.

(4) Press

SHIFT

button momentarily to toggle

CONTINUITY function ON/OFF. The continuity

range is 0 to 400.0 Ω.

(5) Momentarily pushing this button will only turn

the beeper off. While testing continuity, the

beeper will sound if the resistance falls below

100 counts.

Page 34

20

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

Page 35

21

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Never apply voltage to the test leads when a

current measurement function is selected.

Doing so may damage the product and result in

personal injury.

To avoid electrical accidents, remove power

from the circuit before connecting the test

leads.

WARNING

To prevent electrical accidents, do not use the

tester to measure current when the electric

potential is 600 V or greater. The current

function overload protection trips at either 600

V DC, 600 V rms.

3.4 Current Measurement

Page 36

22

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

Instrument operated by

alternating current

3.4.1 AC Current Measurement

(1) Set the rotary switch to "Hz

/ A ".

(2) Connect the black test lead to "COM" terminal

and red test lead to "A" terminal.

(3) Touch the test leads to the test points and read

the display.

If the reading is lower than 400 mA, to get better

resolution of display, please turn the rotary switch to

mA or µA position and remove the red test lead to

"µAmA" terminal.

Page 37

23

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

Instrument operated by

alternating current

3.4.2 Frequency Measurement

(1) Set the rotary switch to "Hz

/ A ".

(2) Press

SHIFT

button momentarily two times to

set frequency measurement.

(3) Connect the black test lead to "COM" terminal

and red test lead to "A" terminal.

(4) Touch the test leads to the test points and read

the display.

The bar graph is used to indicate the value of AC

current.

Page 38

24

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

3.4.3 DC Current Measurement

(1) Set the rotary switch to "Hz

/ A ".

(2) Push

SHIFT

button momentarily to set DC test.

(3) Connect the black test lead to "COM" terminal

and red test lead to "A" terminal.

(4) Touch the test leads to the test points and read

the display.

If the reading is lower than 400 mA, to get better

resolution of display, please turn the rotary switch to

mA or µA position and remove the red test lead to

"µAmA" terminal.

Page 39

25

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Never apply voltage to the test leads when the

Capacitance functions are selected. Doing so

may damage the product and result in personal

injury.

To avoid electrical accidents, remove power

from the circuit before measuring.

3.5 Capacitance Measurement

(1) Set the rotary switch to " " position

(2) Connect the red lead to "

" terminal, and black

lead in "COM" terminal.

(3) Open test leads, then push

REL

button

momentarily to zero the residual.

(4) Remove the capacitor from circuit board or

device.

(5) Connect the test lead across the capacitor and

read the display.

Page 40

26

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

Observe polarity when measuring the polarized

capacitors.

Discharge capacitor before measurement.

When testing low-capacitance devices, noise

introduced into the test leads from the human

body may prevent the measured value from

stabilizing. If this occurs, use the optional 9617

CLIP ON BASE or the optional 9618 CLIP-TYPE

LEAD and keep hands away from the leads

during measurement.

Page 41

27

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

DANGER

Do not apply a voltage while a temperature

range is selected. Applying a voltage may result

in damage to the unit, or a serious accident.

Do not input a voltage exceeding 30 Vrms or 60

VDC to the temperature probe.

3.6 Temperature Measurement

(1) Turn the rotary switch to the "T1 T2" position.

(2) Press

SHIFT

button momentarily to cycle

through T2, T1 and

T tests. Press this button

for more than 1 second to set scanning the T1,

T2 and

Tdisplays.

(3) Press

RANGE

button momentarily to cycle

through K/

,K/ ,J/ and J/ , then come

back K/

. These sets will disappear after power

off. It will be set to original setup condition

when power ON.

(4) Plug the thermocouple probe into T1 or T2 for

the plus side and the minus side terminal.

(5) Attach the thermocouple to the heated source.

(6) Read the display.

Page 42

28

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

NOTE

Do not sharply bend the thermocouple leads.

Repeatedly bending the leads can break them.

The optional temperature probes are all the K type

probe. Please use it in accordance with the

instruction manual of the temperature probe. For J

type temperature probes , please read its manual

prior to use.

The temperature range of the 3805 is different

from the range of temperature probes. Please

measure within the common temperature range.

Page 43

29

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

T

1

-

T

2

T2

T

1

SCAN MODE

This function will assist you to see the T1, T2 and

T (T1-T2) display, quickly. Press and hold

SHIFT

button for more than 1 second to toggle SCAN

mode ON or OFF. When SCAN mode is selected,

the display continuously cycles between T1, T2 and

T temperature readings, and the annunciator of

will be lit. The cycling time is around 3 to 4

seconds, and the T1, T2 and

T will be lit to

indicate which reading has been display,

respectively. For bar graph, it is using to indicate

the environment temperature. For scale

, each bar

is equal 1

.Forscale , each bar is equal 2.5 .

Page 44

30

_______________________________________________

Chapter 3 Measurement Procedures

_______________________________________________

Page 45

31

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

Chapter 4

Special Functions

Instructions

This multi-meter provides the operator with various

functions including:

(1) Data Hold

(2) Refresh Hold

(3) Dynamic Recording

(4) Harmonic Ratio Measurement

(5) Relative (Zero)

(6) % of mA Measurement (4-20 mA)

(7) Beeper On/Off

(8) Set Up

(9) Communication (RS-232C)

Page 46

32

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.1 Data Hold

The data hold function allows operators to hold the

displayed digital value, while the analog bar graph

continues showing the present readings. Press

HOLD

button to enter the data hold mode, and the "

HOLD

"

will be displayed. Press the button again to exit. The

present reading is now shown.

The range is held in the case of auto range.

Page 47

33

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.2 Refresh Hold

The reading is updated the value automatically and

the beeper sounds when the measurement value

changes 30 counts at least.

The refresh hold mode is effective until the power

supply is turned off.

(1) To active the refresh hold mode, turn on the

power supply while pressing the

HOLD

button.

(2) Release the button after all the LCD segments

are lit. Press any button for the measurement

modes

(3) Press

HOLD

button to select ON/OFF of the

refresh hold. While the refresh hold mode is

effective ,

HOLD

is displayed.

When the reading value is unstable, the 3805 may

not update the display.

In the voltage, current, and capacitance function,

the reading is not updated when the measurement

value is less than 50 counts.

In the resistance and diode function, the reading

is not updated when the reading is "OL" or the

test leads are open.

The hold mode and the refresh hold mode use the

same display, so please pay attention when

measuring to make sure you are in the correct

mode.

Page 48

34

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

4.3 Dynamic Recording

The dynamic recording mode can be used to catch

intermittent and turn on or turn off surges, verify

performance, measure while you are away, or take

readings while you are operating the equipment

under test and can not watch the meter.

The average reading is useful for smoothing out

unstable or changing inputs, estimating the percent

of time a circuit is operational, or verifying circuit

performance.

The operational procedures are described below:

(1) Press

REC

button for more than 1 second to

enter the dynamic recording. The present value

is stored to memories of maximum, minimum

and average, and the annunciator turns on.

(2) Press

REC

button for more than 1 second to

toggle recording mode on or off.

(3) Press

REC

button momentarily to cycle through

maximum, minimum, maximum - minimum,

average and present readings. The MAX, MIN,

MAX-MIN, AVG or annunciator will turn on

respectively to indicate what value is being

displayed.

Page 49

35

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

(4) The beeper sounds when a new maximum or

minimum value is recorded.

(5) If an overload is recorded the averaging function

is stopped. An average value becomes

"OL"(overload).

In dynamic recording, the auto power save feature

is disabled, after disabled and the "APS" turns

off.

Select dynamic recording in auto range, it will

record the values of MAX, MIN or AVG for

different ranges.

The record speed of dynamic recording is about

100 ms (0.1 s).

The average value is the true average of all

measured values taken since the recording mode

was entered.

If the range is changed in the manual range mode

or the function is changed, the dynamic recording

function is canceled.

Page 50

36

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

Press REC button for

more than 1 second

Current value

Maximum value

Minimum value

Max. - Min. value

Average value

Page 51

37

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.4 Harmonic Ratio Measurement

The harmonic ratio measurement function shows

how much the wave is distorted.

The distortion rate of the wave is shown in

accordance with the following formula.

The harmonic ratio = (the conversion value from the

mean value - the true RMS value) X

100/the true RMS value.

In order to convert from the mean value to the RMS

value, the mean value is multiplied by 1.11.

Although the harmonic ratio becomes 0% when a

sine wave is measured, the harmonic ratio becomes

11.1% in the case of a square wave.

(1) Set the rotary switch to "Hz

/ V ".

(2) Push and hold

SHIFT

button for more than 1

second to enter Harmonic Ratio mode.

(3) Connect the black test lead to "COM" terminal

and red test lead to "

" terminal.

(4) Touch the test leads to the test points and read

the display.

The bar graph is used to indicate the value of AC

voltage, however if you push

RANGE

button

momentarily, the digits will indicate the value of

AC voltage. The meter will return to indicate the

value of Harmonic Ratio after 3 seconds

automatically.

Page 52

38

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.5 Relative (Zero)

The relative function subtracts a stored value from

the present measurement and displays the result.

(1) Press

REL

button momentarily to set the relative

mode.Itwillsetthedisplaytozeroandstores

the displayed reading as a reference value, also

"REL" is displayed.

(2) Press this button again to exit the relative mode.

Both auto-range or manual range can set relative

mode.

The relative mode can't be set when an overload

has occurred.

Page 53

39

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.6 % of mA Measurement (4-20mA)

The 4-20 mA (0-20 mA) function converts 4 mA (0

mA) as 0% and 20 mA as 100%.

It is used in instrumentation.

(1) Set the rotary switch to "Hz

/ mA ".

(2) Push and hold

SHIFT

button for more than 1 sec

to set % of mA test.

(3) Connect the black test lead to "COM" terminal

and red test lead to "µAmA" terminal.

(4) Touch the test leads to the test points and read

the display.

The 0-20mA mode and the 4-20mA mode use the

same display, so please confirm the correct display

at the set up mode.(Refer to Section 4.8.2 )

Page 54

40

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

4.7 Beeper On/Off

Press and hold

REL

button while turning the rotary

switch to any on position. Turns off all beeper

functions. Beeper off function remains selected until

the meter is turned off.

Page 55

41

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

SHIFT

Press button momentarily to select

other setup modes. The existing value

will be indicated on the display.

HOLD

Push this button momentarily to adjust

value.

REL

Press this button momentarily to save

the settling value into the memory.

RANGE

Press this button momentarily to exit

setup mode, it will come to the normal

measurement.

4.8 Set Up

This multi-meter provides the operator with set up

procedures below:

(1) Timer setting for auto-power save

(2) Selecting % display for 4-20 mA, or 0-20 mA

(3) Selecting J/k types and

/ display

How to entry setup mode

Press and hold

SHIFT

button then turns the rotary

switch to any ON positions. Release pressing button

after the LCD lit all signs. It will enter setup mode,

first mode is time setting for auto power save. In the

setup mode, the button will be operated, see

following explanation:

Page 56

42

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.8.1 Timer Setting for Auto-power Save

Between the auto power save setting screen and the

screen for selecting 4-20mA or 0-20mA

measurement, the setting screen for the back light

appears. Although this screen appears, the 3805 can

not perform this function. Because the 3805 does

not include a back light, please ignore this display.

When the meter is to be used for long periods of

time, the operator might want to disable the auto

power save. Once the auto power save function is

disabled, the meter will stay on continuously. The

meter will shut off by turning the rotary switch to

the off position.

In general, the auto power save function will turn

the meter off if neither rotary switch nor push

button is activated for existing setting. The LCD

will indicate existing time setting, and the APS will

light. You can set the timer from 0 to 99 minutes.

Each step is 1 minute by pushing

HOLD

button.

When you set the timer to zero, the auto power save

will be disabled, the meter will stay on

continuously. Press

REL

button momentarily to save

your setting after you finished. Press

RANGE

button

momentarily to exit set up procedures.

Page 57

43

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.8.2 Selecting % Display for 4 to 20 mA

The instrument will auto-power save, if none of the

following happens. You can push any buttons to

wake-up the meter after auto power save.

Push buttons used.

Measurement function changed.

Set dynamic recording.

Disable auto power save with power-on option.

In this mode, you can set % display for other

ranges. The LCD will indicate existing setting, and

the % and mA will light. The digit will indicate

existing setting. For example of 4 to 20 mA, the

digits will show "0420". You can press the

HOLD

button to toggle 04 to 20mA and 00 to 20mA.

Press

REL

button momentarily to save your setting

after you finished. Press

RANGE

button

momentarily to exit set up procedures.

Page 58

44

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.8.3 Selecting J/ k Types and / Display

The display will indicate existing setting. Press

HOLD

button momentarily to change the setting. It

will cycle through K/

,K/ ,J/ and J/ , then

come back K/

.Press

REL

button momentarily to

save your setting after you finished. Press

RANGE

button momentarily to exit set up procedures.

The following expression converts degrees

Fahrenheit into degree Celsius

=1.8 +32

Page 59

45

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

NOTE

4.9 Communication (RS-232C)

This meter has a communication capability. This

function will assist user to recording and keeping

data easy.

We offer the 3854 RS-232C PACKAGE to optional

accessories. This package includes a cable with

optical receiver, positional connector and a software

disc.

Please refer following procedures if you want to

communicate with personal computer.

(1) Fixed the connector to the holster.

(2) Fixes one side of cable to the positional

connector, and connect the 9 pin's terminal of

cable to communication port 1 or 2 of personal

computer.

(3) Push and hold the

RANGE

button then turn the

rotary switch from off position to any function,

wait 1 second, then release the push button. You

will find that the annunciator of

RS232

is light

on the display.

(4) Execute the software to take the data for your

necessary

Please refer to manual that the use method of

software belonged to 3854 RS-232C PACKAGE .

The RS-232C function remains selected until the

meter is turned off.

Page 60

46

_______________________________________________

Chapter 4 Special Functions Instructions

_______________________________________________

Please fix the connector so that

the label becomes downward.

Page 61

47

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Measurement

Mode

Dual integration

AC measurement

Mode

True RMS measurement

Function

DCV, ACV, DCA, ACA, OHM, Diode

check, Audible continuity, Capacitor,

Temperature, % of 4-20 mA and

Frequency tests.

Harmonics ratio measurement.

The thermocouple types can be selected

for K and J.

Additional

Function

Auto Range function

Dynamic Recording function

Data Hold

Refresh Hold

Harmonic Ratio Measurement

% of mA Measurement (4-20mA)

Relative function

Auto Power Save function

Low Battery Indicate function

RS-232C Interface

Type of Display

LCD

Chapter 5

Specifications

5.1 General Specifications

Page 62

48

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Display

The liquid crystal display (LCD) is 4 digits with

maximum reading 3,999/9,999 counts.

41 segments analog bar graph and full

annunciator

Automatic polarity indication.

Range

Selection

Automatic or Manual

Measuring Rate

3 times per second.

1 time per second for frequency

measurement.

Constituent

Inputs

V, Hz,Ω, C, Audible continuity, Diode,

H.RATIO, T1 Terminal

µ

A, mA, 4-20mA, T2 Terminal

A Terminal

COM Terminal

4 Terminal components

Power Supply

6F22 manganese battery X1 (9V)

Low Battery

Indicator

The " " appears when the battery

voltage drops below 6.3 to 7.5V

(approx.).

Dimension

Approx. 76W X 167H X 33D mm

Approx. 2.99"W X 6.54"H X 1.30"D

Mass

Approx. 300 g (with a battery included)

Approx. 10.6 oz.

Approx. 400 g (with protective holster and

a battery)

Approx. 14.1 oz.

Dielectric Strength

6 kVrms sin (1 minute at 50/60 Hz)

Electrical

Specifications

Accuracy: See "5.2 Accuracy Chart"

Accuracy Guarantee: 23

5 (73 5

), less than 80% RH (no condensation)

Supply Voltage: 9 V to Low Battery

Indicator appears

Page 63

49

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Temperature

Coefficient

specified accuracy X 0.15/

(from 0 to 18 or 28 to 40 )

(from 32 to 64

or 82 to 104 )

Noise

Rejection

NMRR DCV: more than -60 dB (50/60 Hz)

CMRR DCV: more than -120 dB (50/60 Hz)

ACV: more than -60 dB (50/60 Hz)

(1 kΩUnbalance)

Rated Supply

Voltage

9.0VDC X 1 (6F22 manganese battery)

Rated Power

35 mVA (Typ.)

(DCV Supply Voltage=9.0 V )

50 mVA (Max.)

(Diode (RS232-C) Supply Voltage=9.0 V)

Continuous

Operating

Time

Approx. 100 hours (DCV Function at 6F22

manganese battery)

Operating

Temperature

0to40 (32 to 104 ) less than 80% RH

(no condensation)

Storage

Temperature

-20 to 60 (-4 to 140 ) less than 80% RH

(no condensation)

Location for

Use

Indoors, altitude up to 2000 m

Accessories

3851-10 TEST LEAD (a pair)

Protective holster

Manual

6F22 manganese battery (built in)

Page 64

50

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Option

3851-10 TEST LEAD (a pair)

Protective holster

3853 CARRYING CASE

3854 RS-232C PACKAGE

9180, 9182, 9183, 9472 to 9475

SHEATH TYPE TEMPERATURE PROBE

9181 SURFACE TEMPERATURE PROBE

9476 SURFACE TYPE TEMPERATURE

PROBE

9617 CLIP ON BASE

9618 CLIP-TYPE LEAD

Protective

Fuse

µA µA

D086483P (Made by FERRAZ Inc.)

0.5 A/660 V,φ6.35-32 mm, Breaking Capacity

30 kA

or 70125(Made by SIBA Inc.)

0.5 A/700 V,φ6.35-32 mm, Breaking Capacity

50 kA

A

TDC600 ( Made by Cooper Bussmann Inc. )

10 A/600 V,φ6.35-25.35 mm, Breaking

Capacity 10 kA

Applicable

Standards

Safety

EMC

EN 61010-1:2001

EN 61010-2-031:1994

Pollution 2, Measurement Category II

(1000 V), Measurement Category III

(600 V)

(anticipated transient overvoltage

6000 V)

UL 3111-1:1994

CAN/CSA-C22.2 No.1010-1-92+B-97

CAN/CSA-C22.2 No.1010.2.031-94

EN61326:1997+A1:1998+A2:2001

+A3:2003

Page 65

51

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range Resolution Accuracy

Overload

Protection

999.9 mV 0.1 mV 0.2%rdg. 5dgt.

1000 V DC/

1000 V rms

or 10

6

V Hz

9.999 V 1mV

0.1%rdg. 2dgt.

99.99 V 10 mV

999.9 V 0.1 V 0.4%rdg. 5dgt.

Range Resolution Accuracy

Overload

Protection

999.9 mV 0.1 mV 2.5%rdg. 5dgt.

1000 V DC/

1000 V rms

or 10

6

V Hz

9.999 V 1mV 1.1%rdg. 6dgt.

99.99 V 10 mV

1.1%rdg. 5dgt.

999.9 V 0.1 V

Range Resolution Accuracy

Overload

Protection

999.9 mV 0.1 mV -

1000 VDC/

1000 Vrms

or 10

6

V Hz

9.999 V 1mV 1.1%rdg. 6dgt.

99.99 V 10 mV

1.1%rdg. 5dgt.

999.9 V 0.1 V

5.2 Accuracy Chart

Temperature and humidity for guaranteed accuracy

23 5 (73 9 ), 80% RH or less, no condensation

Guaranteed accuracy period

1 year

(1) DC VOLTAGE

Input Impedance: 10 MΩ (15 MΩ nominal for 999.9 mV range)

(2) AC VOLTAGE

1. 40 Hz to 200 Hz

2. 200 Hz to 500 Hz

Page 66

52

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range Resolution Accuracy

Overload

Protection

999.9 mV 0.1 mV 1000 V DC/

1000 V rms

or 10

6

V Hz

9.999 V 1mV 2.0%rdg. 6dgt.

99.99 V 10 mV 2.0%rdg. 6dgt.

999.9 V 0.1 V -

Range

Resolu-

tion

Accuracy

Internal

Resistance

(approx)

Overload

Protection

400.0 µA 0.1 µA 0.2%rdg. 3dgt. 100 Ω

0.5 A/600 V

Quick

Acting Fuse

4000 µA 1 µA 0.1%rdg. 3dgt. 100 Ω

40.00 mA 10 µA 0.2%rdg. 3dgt. 1 Ω

400.0 mA 0.1 mA 0.1%rdg. 3dgt. 1 Ω

4.000 A 1mA 0.3%rdg. 3dgt. 0.01 Ω 10 A/600 V

Quick

Acting Fuse

10.00 A 10 mA 0.3%rdg. 3dgt. 0.01 Ω

3. 500 Hz to 2 kHz

Measurement accuracy is prescribed from 5% to 100% of the range

For lower than 5.0mV,the specification will add 45dgt to specified

accuracy.

Input Impedance: 10 MΩ (999.9 mV range 15 MΩ)

Crest factor: 3

(3) DC CURRENT

10 A continuous, 10 to 20 A for 30 seconds maximum with 5

minutes cool down interval.

Page 67

53

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range

Resolut

-ion

Accuracy

Internal

Resistance

(approx)

Overload

Protection

400.0 µA 0.1 µA

1.0%rdg. 5dgt.

(40 Hz to 500 Hz)

1.5%rdg. 5dgt.

(500 Hz to 2 kHz)

100 Ω

0.5 A/600 V

Quick

Acting Fuse

4000 µA 1 µA 100 Ω

40.00 mA 10 µA 1 Ω

400.0 mA 0.1 mA 1 Ω

4.000 A 1mA 0.01 Ω 10 A/600 V

Quick

Acting Fuse

10.00 A 10 mA 0.01 Ω

Range Voltage

0.0% to 99.9% 100 mV AC to 1000 V AC

(4) AC CURRENT

Measurement accuracy is prescribed from 5% to 100% of the range

10 A continuous, 10 to 20 A for 15 seconds maximum with 5

minutes cool down interval.

Crest factor: 3

(5) HARMONIC RATIO

Harmonics Ratio function generates a value between 0% to 100% to

indicate the deviation of non-sinusoidal to a sinusoidal waveform,

which is a good indication of the presence of harmonics. Pure

sinusoidal waveforms without harmonics have a Harmonics Ratio of

0%. The higher Harmonics Ratio, the more harmonics are present.

Page 68

54

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range

Resolut

-ion

Accuracy

Maximum

Test

Voltage

Overload

Protection

400.0 Ω 0.1 Ω

0.5%rdg. 3dgt.

3.3 V

max.

600 V DC/

600 V rms

4.000 kΩ 1 Ω

40.00 kΩ 10 Ω

1.28 V

max.

400.0 kΩ 100 Ω

4.000 MΩ 1kΩ 0.8%rdg. 3dgt.

40.00 MΩ 10 kΩ 1.2%rdg. 3dgt.

Range Threshold level

Overload

Protection

CONTINUITY

The beeper will sound if the resistance

falls below 100 counts.

600 V DC/

600 V rms

Range Resolution Accuracy

Overload

Protection

4.000 µF 1nF

2.0%rdg. 4dgt.

600 V DC/

600 V rms

40.00 µF 0.01 µF

400.0 µF 0.1 µF 3.5%rdg. 4dgt.

9999 µF 1 µF

3.5%rdg. 5dgt.

>2mF, NO Spec

(6) RESISTANCE

(7) AUDIBLE CONTINUITY TEST

Relative mode is used in Audible continuity test function. Using

Relative mode to zero residual.

The measurement accuracy and open terminal voltage (test voltage)

are the same as these of Ω function.

(8) CAPACITANCE

The accuracy is based on the film capacitor or better. Using Relative

mode to zero residual.

Page 69

55

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range

Resolution

Accuracy

Test Current

Voltage

Overload

Protection

Diode

1mV

1.0%rdg. 2dgt.

approx. 0.7 mA

Less than 3.3 V

600 V DC/

600 V rms

Range Resolution Accuracy

Min. Input

Freq.

Overload

protection

9.999 Hz 0.001 Hz

0.05%rdg.

4dgt.

1Hz

1000 V DC/

1000 V rms

or

10

6

V Hz

99.99 Hz 0.01 Hz

999.9 Hz 0.1 Hz

9.999 kHz 1Hz

50.00 kHz 10 Hz

INPUT

RANGE

MINIMUM SENSITIVITY (rms sinwave)

40 Hz - 5 kHz 20 Hz

*

-15kHz

15 kHz - 50 kHz

999.9 mV 0.4 V 0.7 V -

9.999 V 0.8 V 0.8 V 3V

99.99 V 8V 8V 30 V

999.9 V 80 V 100 V 20 Hz

*

-10kHz

400.0 µA 50 µA

4000 µA 300 µA

40.00 mA 5mA

400.0 mA 30 mA

4.000 A 0.5 A

10.00 A 3A

(9) DIODE CHECK

In Audible continuity function if measurement voltage is about less

than 100 mV, the beeper sounds.

(10) FREQUENCY MEASUREMENT FOR VOLTAGE

FREQUENCY SENSITIVITY

Maximum input for specified accuracy = 10 x Range or 1000 V

*:

In the case of a square wave : from 10 Hz to 20 kHz.

Page 70

56

_______________________________________________

Chapter 5 Specifications

_______________________________________________

Range Resolution Accuracy

Overload

protection

-40 to 850 (K)

1 0.3%rdg. 3

600 V DC

/600 V rms

-40 to 650 (J)

-40 to 1562 (K)

1 0.3%rdg. 6

-40 to 1202 (J)

(11) K -TYPE TEMPERATURE TEST

Do not allow the temperature sensor to contact a surface that is

energized above 30 V RMS or 60 V DC, such voltages pose a

shock hazard.

The accuracy does not include the tolerance of thermocouple probe.

Page 71

57

_______________________________________________

Chapter 6 Maintenance and Service

_______________________________________________

WARNING

To avoid electric shock when replacing the

battery and fuse, first disconnect the test leads

from the object to be measured, then open the

cover.

After replacing the battery or fuse, replace the

cover and screws before using the product.

When replacing the battery, Be sure to insert

them with the correct polarity. Otherwise, poor

performance or damage from battery leakage

could result. Replace batter y only with the

specified type.

To avoid the possibility of explosion, do not short

circuit, disassemble or incinerate battery.

Handle and dispose of battery in accordance with

local regulations.

Replace the fuse only with one of the specified

characteristics and voltage and current ratings.

Using a non-specified fuse or shorting the fuse

holder may cause a life-threatening hazard.

Chapter 6

Maintenance and

Service

6.1 Changing the Battery and Fuses

Page 72

58

_______________________________________________

Chapter 6 Maintenance and Service

_______________________________________________

Use the following procedures to replace the battery,

or fuse.

(1) Using the rotary switch to turn the meter off,

and remove the test leads from terminals.

(2) Loosen 3 screws on bottom cover, pull up and

move the cover.

(3) Replace the defective battery.

The meter is powered by a 6F22 battery. Replace

battery if the low battery sign (

) is displayed

and flashes.

(4) Remove the defective fuse by gently prying one

end of the fuse loose and sliding the fuse out of

the fuse bracket.

Install a new fuse of the same size and rating.

Make sure the new fuse is centered in the fuse

holder. There are 2 types of fuses, one for the

µA , mA terminal and one for the A terminal.

Be sure to set the correct fuse.

(5) Reverse the procedure of opening cover to close

the bottom cover.

Page 73

59

_______________________________________________

Chapter 6 Maintenance and Service

_______________________________________________

For A terminal fuse :

TDC600 (Made by Cooper

Bussmann Inc.)

10A/600V, 6.35 mm-25.35

mm dia.

6F22 manganese batter

y

For µA mA terminal fuse :

D086483P

(Made by FERRAZ Inc.)

F0.5A/660V, 6.35mm32mm dia.

or 70125

(Made bySIBA Inc.)

0.5 A/700 V, 6.35-32 mm

dia.

Page 74

60

_______________________________________________

Chapter 6 Maintenance and Service

_______________________________________________

6.2 Cleaning

6.3 Service

To clean the product, wipe it gently with a soft

cloth moistened with water or mild detergent. Never

use solvents such as benzene, alcohol, acetone,

ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

If the product seems to be malfunctioning, confirm

that the battery are not discharged, and that the test

leads, and fuse are not open circuited before

contacting your dealer or Hioki representative.

When sending the product for repair, pack the

product carefully so that it will not be damaged

during shipment, and include a detailed written

description of the problem. Hioki cannot be

responsible for damage that occurs during shipment.

Page 75

Page 76

Page 77

HIOKI 3805 DIGITAL HiTESTER

Instruction Manual

Publication date: September 2006 Revised edition 8

Edited and published by HIOKI E.E. CORPORATION

Technical Sales Support Section

All inquiries to International Sales and Marketing

Department

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3805A980-08

All reasonable care has been taken in the production

of this manual, but if you find any points which are

unclear or in error, please contact your supplier or

the International Sales and Marketing Department

at HIOKI headquarters.

In the interests of product development, the contents

of this manual are subject to revision without prior

notice.

Unauthorized reproduction or copying of this manual

is prohibited.

Page 78

Printed on recycled paper

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp URL http: //www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3805A980-08 06-09H

Loading...

Loading...