Page 1

INSTRUCTION MANUAL

3664

OPTICAL POWER METER

www. .com

information@itm.com1.800.561.8187

Page 2

X

Contents

Introduction .................................................................. 1

Inspection ..................................................................... 1

Safety Information ........................................................2

Operating Precautions .................................................4

1Overview 7

i

Contents

1

2

1.1 Product Overview ...............................................7

1.2 Features ............................................................. 8

1.3 Names and Functions of Parts ........................... 9

2 Measurement Preparations 13

2.1 Attaching the Strap ...........................................13

2.2 Supplying Power ..............................................14

2.2.1 Using the AC Adapter ........................................14

2.2.2 Using the Batteries ............................................15

2.3 Connecting the Optical Sensor .........................16

2.4 Connecting the Analog Output Cord ................17

2.5 Turning the Power On and Off ......................... 18

3 Measurement 19

3.1 Setting the Measurement Mode ....................... 20

3.2 Setting the Range .............................................21

3.2.1 Auto Range .......................................................21

3.2.2 Manual Range ...................................................22

3.3 Setting the Wavelength .................................... 24

3.3.1 Setting an Arbitrary Measurement Wa v elength .24

3.3.2 Retrieving the Wavelength Setting from t he

Measurement-Wavelength Memory ..................26

3.4 Starting Measurement ......................................26

3.5 Setting Example ............................................... 28

3.5.1 Optical-Power Measurement .............................28

3.5.2 Relative Measurement (Measured -v alue basis) 29

3.5.3 Relative Measurement (Input-value basis) ........31

3

4

5

6

7

8

9

10

11

APP

IDX

www. .com

information@itm.com1.800.561.8187

Page 3

ii

Contents

4 Functions 33

4.1 Scalling Function .............................................. 33

4.1.1 Turning ON the Scaling Function ......................33

4.1.2 Turning OFF the Scaling Function .....................36

4.2 Maximum-Value Hold / Minimum-Value Hold

/ Averaging ....................................................... 37

5 Contr ol by Comp uter 39

5.1 Overview of Control ..........................................40

5.2 Installing the Driver ...........................................41

6 Specifications 51

6.1 Measurement Specifications ............................ 51

6.2 General Specifications .....................................53

7 Maintenance and Service 55

7.1 Cleaning ........................................................... 55

7.1.1 Cleaning of the 3664 .........................................55

7.1.2 Cleaning of the Optical Sensors ........................56

7.2 Service .............................................................56

7.3 Error Display ..................................................... 57

7.4 Reset ................................................................ 59

7.4.1 System Reset ....................................................59

7.4.2 Setting Data Reset ............................................59

7.4.3 Measurement-Wavelength Memory Reset ........60

7.5 Replacing the Batteries .................................... 61

Appendix 63

Explanations .............................................................. 63

Options .......................................................................64

www. .com

information@itm.com1.800.561.8187

Page 4

Introduction

Thank you for purchasing the HIOKI “Model 3664 OPTICAL

POWER METER.” To obtain maximum performance from the

instrument, please read this manual first, and keep it handy for

future reference.

1

1

Registered Trademarks:

• Windows is a registered trademark of Microsoft Corporation in

the United States and/or other countries.

• Adobe, the Adobe logo, Acrobat, the Acrobat logo are trademarks of Adobe Systems Incorporated.

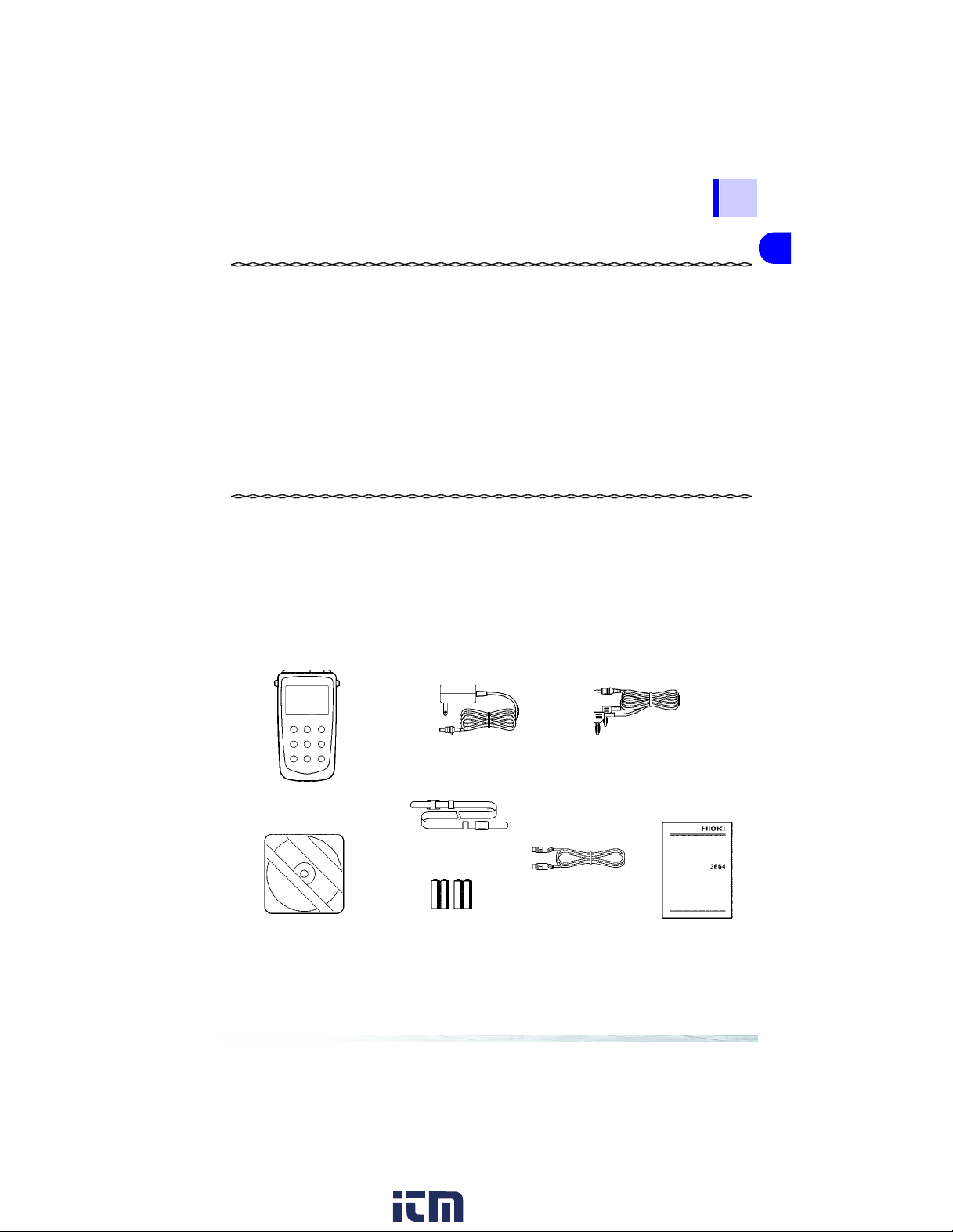

Inspection

• When you receive the instrument, inspect it carefully to ensure

that no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evident, or if it fails to operate according t o the specifications, contact your dealer or Hioki representative.

• Use the original packing materials when transporting the instrument, if possible.

Verifying Package Contents

Model 9445-02 AC ADAPTER or

Model 9445-03 AC ADAPTER (1)

Model 3664 OPTICAL

POWER METER (1)

2

3

4

5

6

7

8

Model 9094 OUTPUT CORD (1)

9

Driver CD-R (1)

Options

Strap (1)

USB Cable (1)

LR6 alkaline batteries (4)

Model 9246 CARRYING CASE............................................... .. ...1

Model 9742 OPTICAL SENSOR..................................................1

Model 9742-10 OPTICAL SENSOR.............................................1

www. .com

Instruction Manual (1)

information@itm.com1.800.561.8187

10

11

Page 5

2

Safety Information

This instrument is designed to comply with IEC 61010 Safety

Standards, and has been tho roughly tested for safety prior

to shipment. However, mishandling during use could result

in injury or death, as well as damage to the instrument. Be

certain that you understand the instructions and precautions

in the manual before use. We disclaim an y responsibility for

accidents or injuries not resulting direct ly from instrument

defects.

Safety Symbols

This manual contains information and warnings essential for safe

operation of the instrument and for maintaining it in safe operating

condition. Before using it, be sure to carefully read the following

safety precautions.

In the manual, the symbol indicates particularly

important information that the user should read before

using the instrument.

The symbol printed on the instrument indicates that

the user should refer to a corresponding topic in the

manual (marked with the symbol) before using the

relevant function.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instru ment.

Indicates advisory items related to performance or

correct operation of the instrument.

Other Symbols

Indicates the prohibited action.

❖

Indicates the location of reference information.

www. .com

information@itm.com1.800.561.8187

Page 6

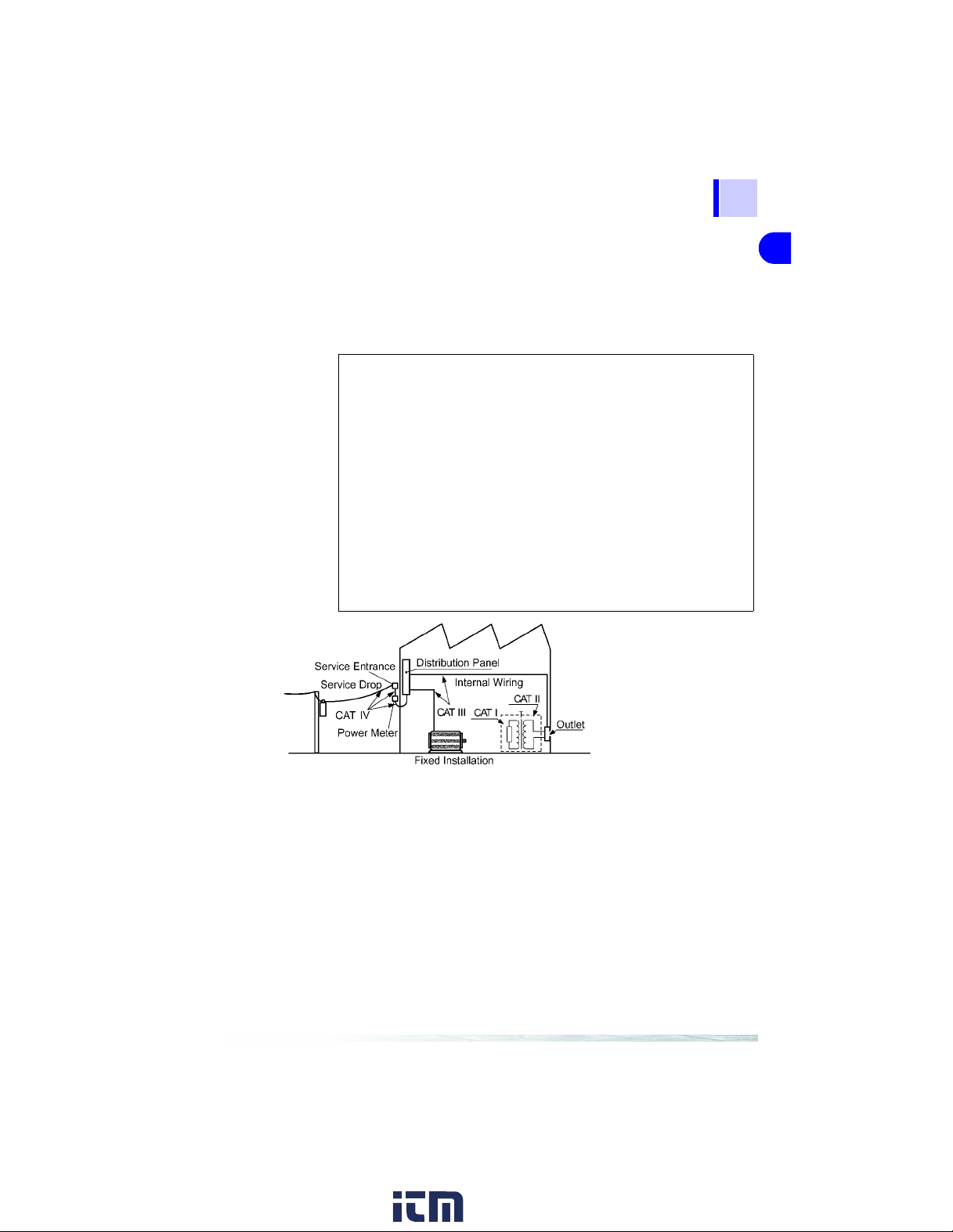

Overvoltage Categories (CAT )

To ensure safe operation of measurement instruments, IEC 60664

establishes safety standards for various electrical environments,

categorized as CAT I to CAT IV, and called overvoltage categories.

These are defined as follows.

3

1

CAT I Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar

device.

CAT II Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT III Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distribution panel to outlets.

CAT IV The circuit from the service drop to the service

entrance, and to the power meter and primary overcurrent protection device (distribution panel).

Higher-numbered categories correspond to electrical environments

with greater momentary energy. So a measurement device

designed for CAT III environments can endure greater momentary

energy than a device designed for CAT II.

Using a measurement instrument in an environment designated

with a higher-numbered category than that for which the instrument

is rated could result in a severe accident, and must be carefully

avoided.

2

3

4

5

6

7

8

9

10

11

www. .com

information@itm.com1.800.561.8187

Page 7

4

Operating Precautions

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Observe the following to avoid damage to the instrument.

• Do not allow the instrument to get wet, and do not take measurements with wet hands. This may cause an electric shock.

Avoid the following

Direct

Sunlight

High Temp erature

High Humidity

• Do not use the instrument where it may be exposed to corrosive

or combustible gases. The instrument may be damaged or

cause an explosion.

• To avoid damage to the instrument, protect it from physical

shock when transporting and handling. Be especially care ful to

avoid physical shock from dropping.

• Do not store or use the instrument wh ere it could b e exposed to

direct sunlight, high temperature or humidity, or condensation.

Under such conditions, the instrument may be damaged and

insulation may deteriorate so that it n o longer meets specifications.

• This instrument is designed for use indoors. It can be operated

at temperatures between 0 and 40°C without degrading safety.

• After use, always turn OFF the power.

• The “ ” indicator appears when batter y voltage becomes low.

Replace the batteries as soon as possible.

• Use the specified battery (AA alkaline battery) only. If a non-

specified battery such as a manganese battery is used, the

service hours may be shortened.

• When connecting the instrument to a PC with a USB cable,

use a cable of 2 m or shorter to prevent the influence of noise.

www. .com

information@itm.com1.800.561.8187

Page 8

Cords and Cables

5

• Avoid stepping on or pinching cables, which could dam age the

cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the output cable, grasp the connector, not

the cable, when unplugging the cable.

Optical Sensor

• Use only the specified optical sensor. Using a non-specified sensor may result in incorrect measurements due to poor connection or other reasons.

• To prevent damage to the instrument and sensor, never connect

or disconnect a sensor while the power is on, or while the sensor

is connected around a conductor.

• To avoid damaging the optical sensor and to ensure accurate

measurements, avoid dropping or applying any p hysical shock

to the optical sensor.

• Avoid touching the detector window with your bare hands. The

detector window must be clean for the sensor to meet the specified performance parameters.

• Avoid scratching the detector window with sharp or pointed

objects (e.g., the tips of tweezers) or against hard surfaces.

Damage to the detector window may prevent the sensor from

meeting specified performance parameters.

• Make sure no stress is applied to the repeater cable of the 974210 between the sensor main unit and its detector element.

1

2

3

4

5

6

7

8

9

To prevent dust accumulation, stains, and damage, cover the

detector window with the sensor cover when the sensor is not in

use.

www. .com

information@itm.com1.800.561.8187

10

11

Page 9

6

Care and Handling of CD-R

• Always hold the disc by the edges, so as not to make fingerprints on the disc or scratch the printing.

• Never touch the recorded side of the disc. Do not place the disc

directly on anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a

possibility of the label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do

not use a ball-point pen or hard-tippe d pen, because there is a

danger of scratching the surface and corrupting the data. Do not

use adhesive labels.

• Do not expose the disc directly to the sun's rays, or keep it in

conditions of high temperature or humidity, as there is a danger

of warping, with consequent loss of data.

• T o remove dirt, dust, or fi ngerprints from the disc, wipe with a dry

cloth, or use a CD cleaner. Always wipe radially from the inside

to the outside, and do no wipe with circular movements. Never

use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a com puter

system that arises from the use of this CD-R, or for any problem

related to the purchase of a Hioki product.

Preliminary Checks

• Before using the instrument, make sure that the insulation on the

optical sensor cable and USB cable is undamaged and that no

bare conductors are improperly exposed. Using the instrument

in such conditions could cause an electric shock, so contact your

dealer or Hioki representative for repair.

• Before using the instrument the first time, verify that it ope rates

normally to ensure that the no damage occur red during storage

or shipping. If you find any damage, contact your dealer or Hioki

representative.

www. .com

information@itm.com1.800.561.8187

Page 10

1.1 Product Overview

7

Overview

1.1 Product Overview

The 3664 OPTICAL POWER METER is an instrumen t for measuring the optical power of a spatial light. It is suitable for measurement of the optical power of a laser light source and an LED light

source. The 3664 is a hand-held meter equipped with various measurement functions and interfaces that meet diversified measurement needs. The optical sensors (optional) for the power meter are

interchangeable, as the sensitivity of each sensor is adjusted independently.

1

1

2

3

4

5

6

7

8

www. .com

9

10

11

information@itm.com1.800.561.8187

Page 11

8

1.2 Features

1.2 Features

Scaling function

The reading of the 3664 OPTICAL POWER METER can be converted to the reading of another optical power meter by a simple

operation.

Various measurement functions

In addition to the optical power measurement (absolute-value measurement), the 3664 power meter has relative-measurement, maximum-value-hold, minimum-value-hold, and averaging functions.

With all these functions, the display unit can be switched between

W and dBm (dB).

Automatic correction of sensitivity through input of

the measurement wavelength

When the measurement wavelength is entered, the wavelength

sensitivity of the sensor connected to the 3664 is automatically corrected for measurement display.

Interface with a computer

The USB interface is provided as standard equipment. The 3664

can be controlled on the PC, its settings can be edited on the PC ,

or its measurement data can be uploaded to the PC.

Analog output terminal

The 3664 has an analog output terminal. It outputs in the voltage

form the output signal of the optical sensor. Use this terminal, for

example, when performing monitoring using a DMM or reco rding

data for extended periods.

Auto-power-save funct ion

When the 3664 is running on the battery, if there is no key operation or USB communication for approximately 10 minutes, the

power to the 3664 will be automatically turned off to conserve battery power.

www. .com

information@itm.com1.800.561.8187

Page 12

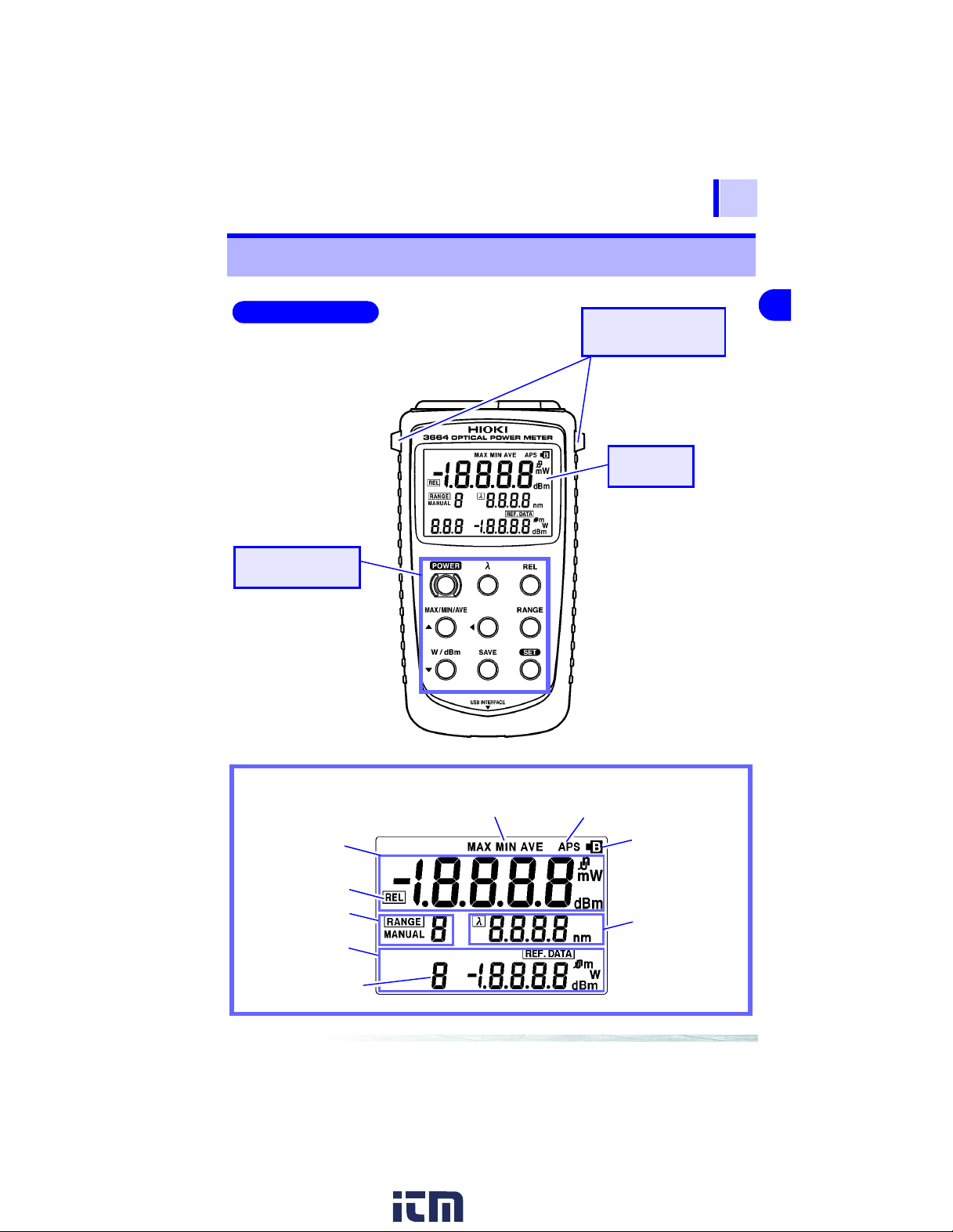

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

9

Front Panel

Operating Keys

Strap installation

Slot

Display

1

2

3

4

5

6

7

8

Display

Main display

Relative-measurement

indicator

Range

Sub display

Relative-measurement

mode

www. .com

Maximum, Minimum, Ave ra ge

Auto power save mark

Battery mark

Measurement

wavelength

information@itm.com1.800.561.8187

9

10

11

Page 13

10

1.3 Names and Functions of Parts

Operating Keys

POWER

λ

REL

RANGE

SET

SAVE

W/dBm

▼

MAX/MIN/AVE

▲

Turns ON/OFF power to the 3664.

Power ON: Hold down the key for approximately 2 seconds to

Power OFF: Hold down the key for approximate ly 1 second to turn

Sets the measurement wavelength to the preset wavelength.

Switches between optical-power measurement mode, relative-

measurement mode (measured-value basis) and relative-measurement mode (input-value basis).

Switches between auto range and manual range.

Moves to the setting edit screen. "

Moves the digit to edit the setting (the digit blinks) during setting

edit.

Confirms the setting during setting edit and returns the meter to

measurement mode.

Switches the unit of the reading between "W" and "dBm." In rela-

tive-measurement mode, the unit is switched between "W" and

"dB."

Decreases the number during setting edit.

Switches the value to be displayed between the measurement,

maximum, minimum, and average value.

Increases the number during setting edit.

turn the power ON (auto-power-save function ON).

Hold down the key for approximately 5 seconds to

turn the power ON and the auto-power-save function

is turned OFF.

the power OFF.

" appears on the screen.

SEt

www. .com

information@itm.com1.800.561.8187

Page 14

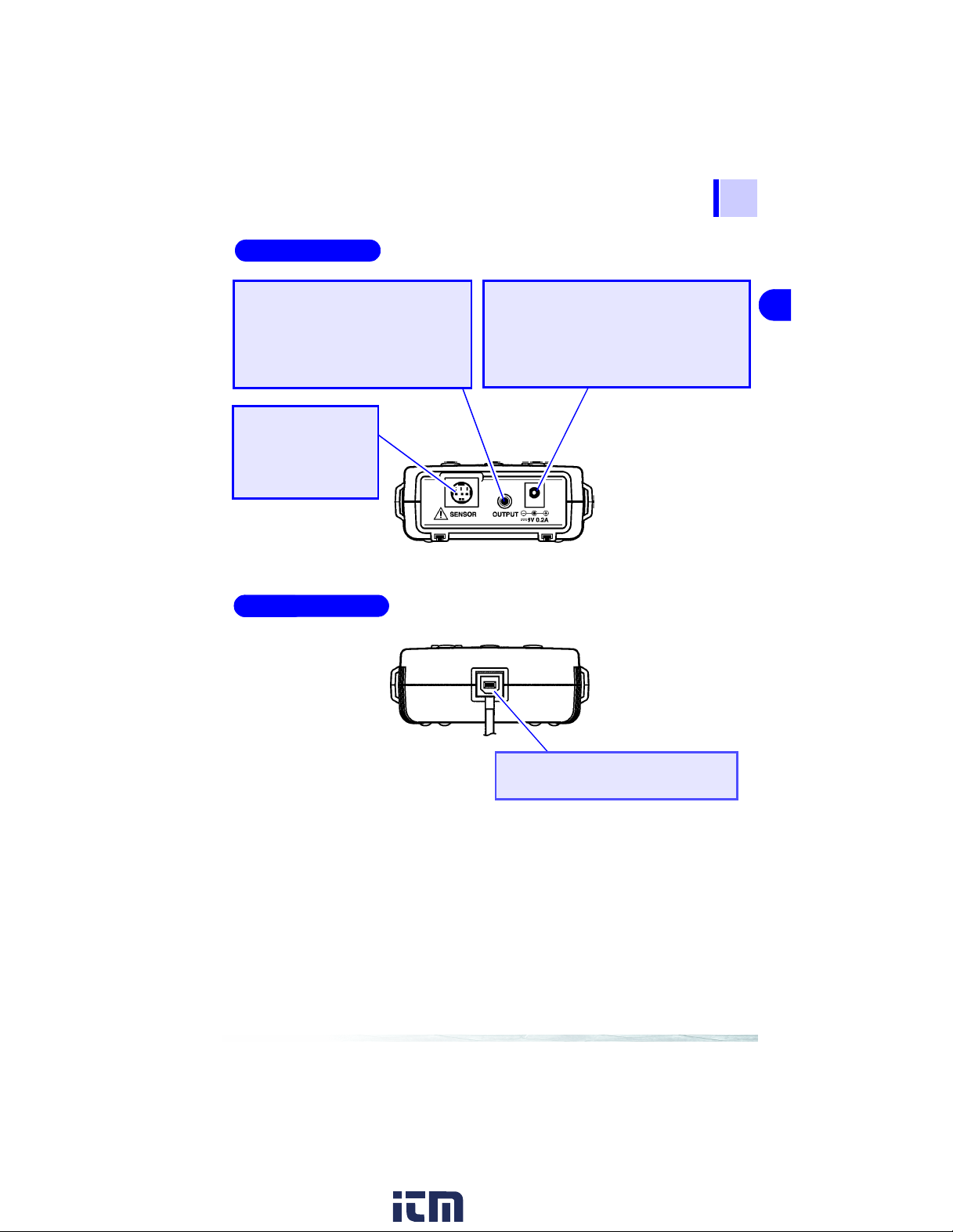

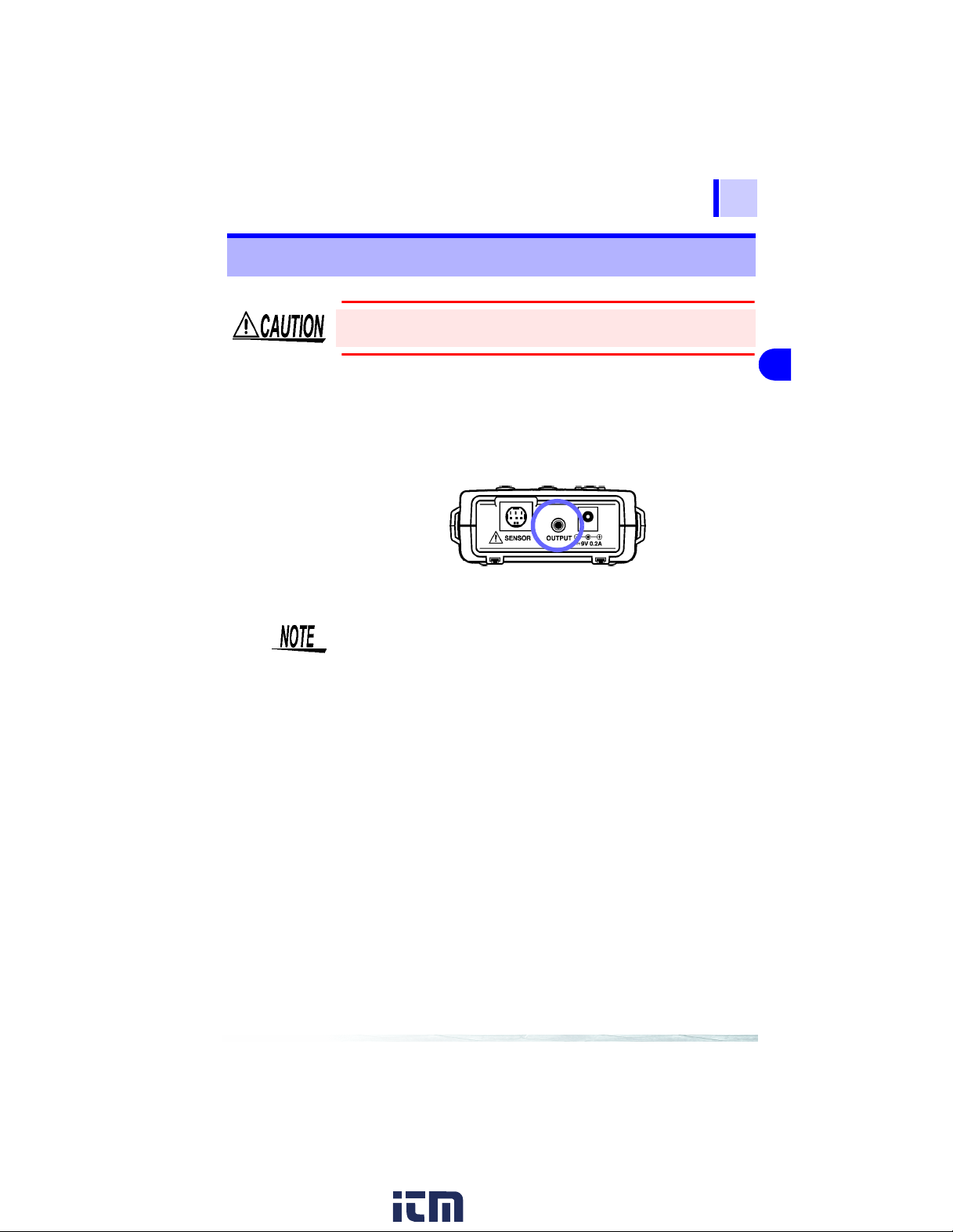

Upper Panel

11

1.3 Names and Functions of Parts

Analog output terminal

Connect the 9094 OUTPUT CORD included among the accessories to this

terminal. Output signals from the optical sensor are converted to a voltage

and output from this terminal.

Optical-sensor

terminal

Connect an optional

optical sensor to this

terminal.

Bottom Panel

AC-adapter terminal

Connect the 9445-02 or 9445-03 AC

ADAPTER included among the accessories to this terminal. When the AC adapter

is used, power is supplied to the 3664 from

a commercial power supply.

1

2

3

4

5

6

7

8

www. .com

USB terminal

Connect a USB cable to this terminal.

information@itm.com1.800.561.8187

9

10

11

Page 15

2.1 Attaching the Strap

13

Measurement Preparations

2.1 Attaching the Strap

Use the strap to carry the 3664 power meter or hang it on a hook.

Be sure to attach the strap to the 3664 power meter in place (2 locations) properly . If the strap is not properly attached, the meter m ay drop

and be broken.

Model 3664

Insert each end of the Strap through

1.

an installation slot on the instrument.

Feed each end of the Strap through its

2.

clasp.

Feed each end through its stopper.

3.

2

1

2

3

4

5

6

7

8

Confirm that the strap is not

slackened or twisted.

www. .com

9

10

information@itm.com1.800.561.8187

Page 16

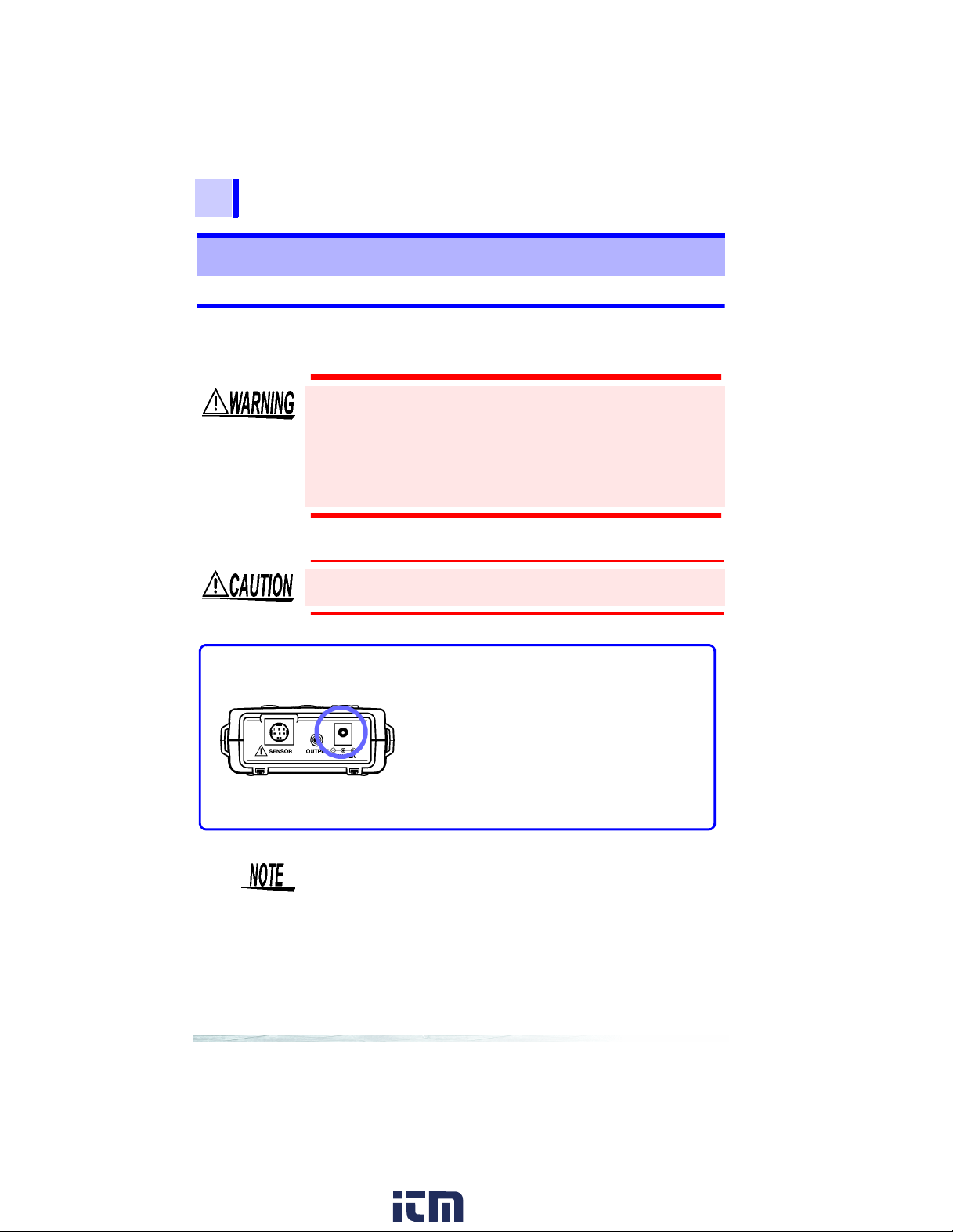

14

2.2 Supplying Power

2.2 Supplying Power

2.2.1 Using the AC Adapter

• Use only the specified Model 9445-02 ADAPTER (SA109010N,SINO-AMERICAN) or Model 9445-03 AC ADAPTER

(CEE, SA10-9010G, SINO-AMERICAN) AC adapter input

voltage range is 100 to 240 VAC (with ±10% stability) at 50/

60 Hz. To avoid electrical hazards and damage to the instrument, do not apply voltage outside of this range.

• Turn the instrument off before connecting the AC adap ter

to the instrument and to AC power.

To avoid damaging the cord, grasp the plug, not the cord, when unplugging it.

AC Adapter Connection Term i na l

• When the AC adapter is connected and the battery is installed,

the AC adapter is used. In case of power outage, the 3664 is

automatically switched to the battery drive.

• Make sure the power is turned off before connecting or discon-

necting the AC adapter.

Connect the output plug of the AC

1.

adapter to the AC-adapter terminal.

Connect the AC adapter to an AC

2.

outlet.

www. .com

information@itm.com1.800.561.8187

Page 17

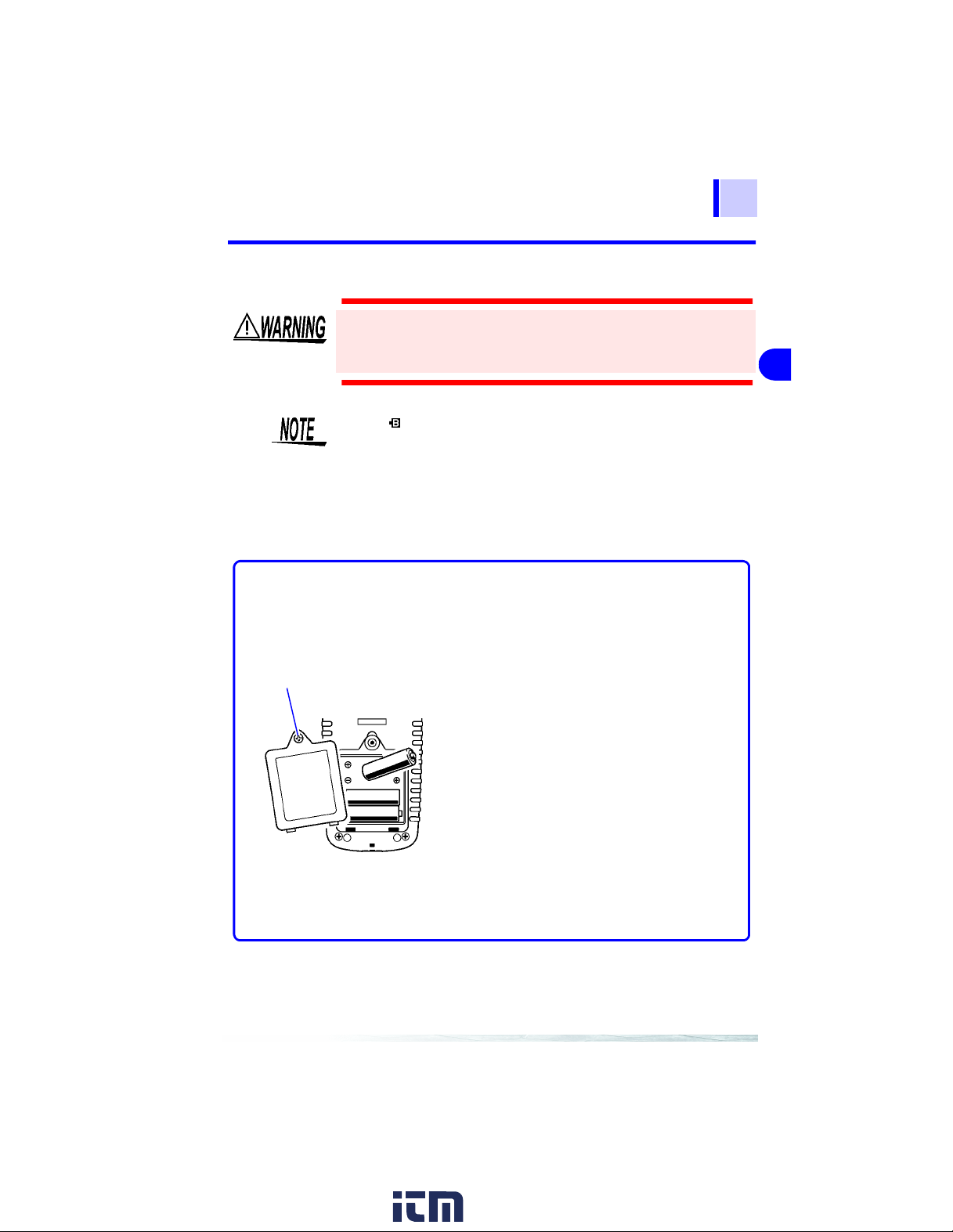

2.2.2 U sing the Batteri es

15

2.2 Supplying Power

Screw

Do not mix old and new batteries, or different types of batteries. Also, be careful to observe ba ttery polarity during installation. Otherwise, poor performance or da mage from battery

leakage could result.

• The “ ” indicator appears when battery voltage becomes low.

Replace the batteries as soon as possible.

• Do not use other than the specified type of batteries (LR6 alkaline batteries). Using manganese batteries will result in a

shorter operating time than when using alkaline batteries.

• The 3664 power meter runs on battery or AC power. When the

AC adapter is connected and the battery is installed, the AC

adapter is used.

Tools and materials:

Four AA alkaline batteries (LR6) and a Phillips screwdriver

Confirm that the power to the 3664 is

1.

turned OFF.

Disconnect all cables.

2.

Turn over the 3664 and loosen the

3.

screw on the battery cover.

1

2

3

4

5

6

7

8

Remove th e ba t te r y cover.

4.

Insert the four AA alkaline batteries

5.

(LR6) into the battery case, noting the

correct polarity. (When replacing the

batteries, replace all of them.)

Place the battery cover back on, and

6.

tighten the screw.

www. .com

9

10

information@itm.com1.800.561.8187

Page 18

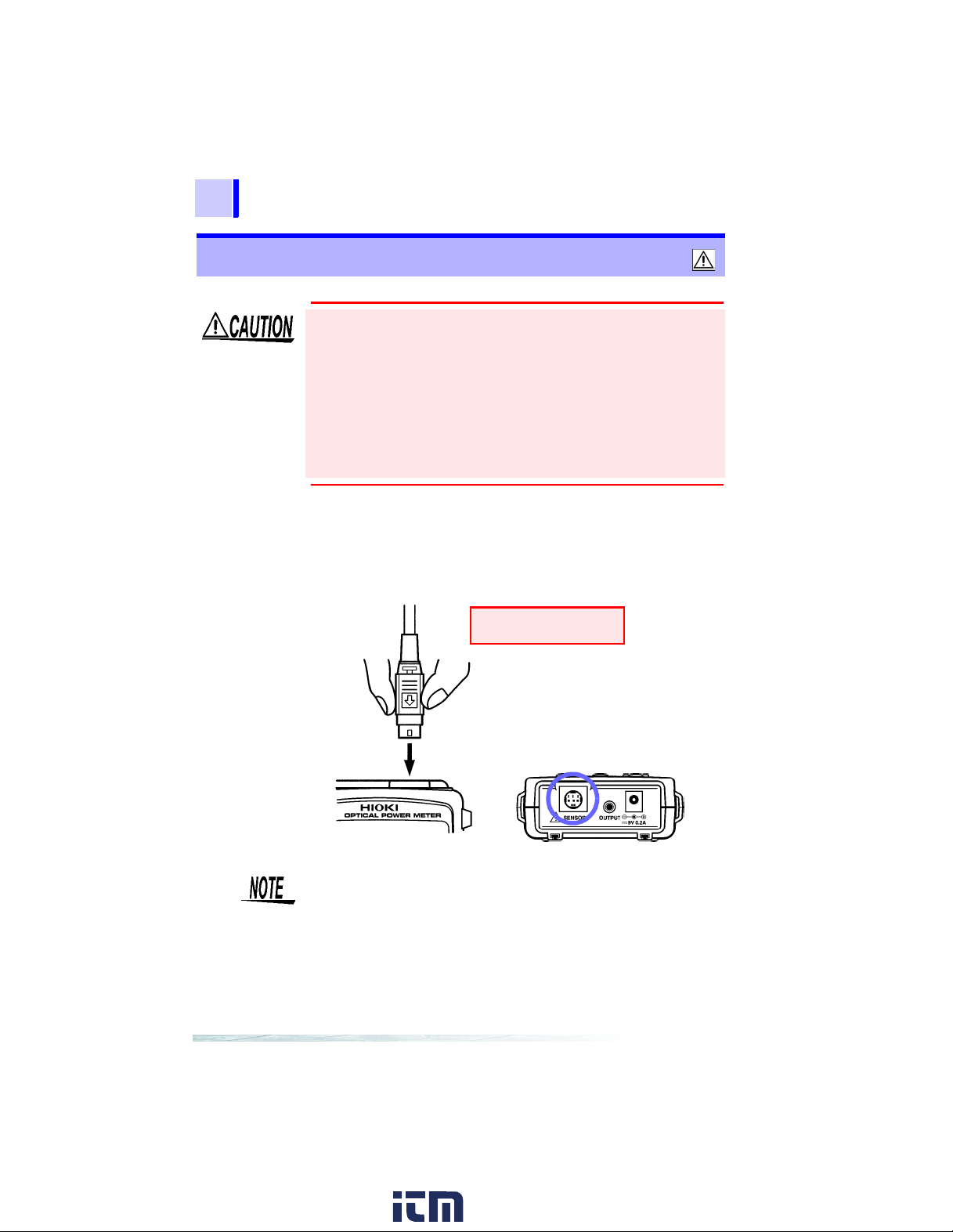

16

2.3 Connecting the Optical Sensor

2.3 Connecting the Optical Sensor

• Use only the specified optical sensor. Using a non-specified sensor may result in incorrect measurements due to poor connection or other reasons.

• To prevent damage to the instrument and sensor, never connect

or disconnect a sensor while the power is on, or while the sensor

is connected around a conductor.

• To avoid damaging the sensor cable, grasp the plug, not the

cable, when unplugging it.

• To avoid ensuring accurate measurements, avoid dropping or

applying any physical shock to the optical sensor.

Insert an optical sensor, with the surface marked with an arrow facing upward, into the optical-sensor terminal of the 3664.

Optical Sensor

Grasp the connector.

Optical Sensor Connection Te rmi na l

Always grasp the connector with the arrow to connect or disconnect the optical sensor. (You must grasp the connector to disconnect the sensor.)

www. .com

information@itm.com1.800.561.8187

Page 19

2.4 Connecting the Analog Output Cord

2.4 Connecting the An alog Output Cord

17

To avoid damage to the instrument, do not short-circuit the o utput terminal and do not input voltage to the output terminal.

By connecting the analog output cord to the analog output terminal,

the optical power detected by the optical sensor can be converted

to a voltage in order to monitor the signal.

Connect the analog output cord to the analog output terminal.

Analog Output Cord

Signals output from the analog output terminal are detected by

an optical sensor, with its wavelength sensitivity uncorrected.

This signal, therefore, is not proportional to the measurement

displayed on the screen.

1

2

3

4

5

6

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 20

18

2.5 Turning the Power On and Off

2.5 Turn in g the Power On and Off

Power On

Hold down the POWER key for approximately 2 seconds. The

screen lights up and the power is turned ON.

If the battery indicator appears (" " at the top right of the

screen) after the power has been turned ON, the battery is running down. Replace the battery (when the 3664 is running on the

battery).

❖See Section 7.5 "Replacing the Batteries" (61 page)

Power OFF

Hold down the POWER key for approximately 1 second. The

screen goes out and the power is turned OFF.

Auto-power-save funct ion

• This function automatically turns OFF the power to the 3664 if

there is no key operation or USB communication for approximately 10 minutes, when it is running on the battery. (The indication "

• To turn OFF the auto-power-save function, hold down the

POWER key for 5 seconds when turning ON the power. "

goes out and the auto-power-save function is turned OFF.

• When the 3664 is running on AC power, the auto-power-save

function is automatically turned OFF and the function is not available.

" lights up at the top right of the screen.)

APS

APS

"

• While power is supplied from the battery, when the power is

turned ON, the auto-power-save function is turned ON.

• When the USB is used, use the AC adapter for the power supply.

• After use, always turn OFF the power.

AC Adapter Connection Terminal

www. .com

information@itm.com1.800.561.8187

Page 21

19

Measurement

• Optical-power measurement and relative measurement of special light are performed using the 3664 power meter.

• The measurement wavelength may be set to an arbitrary wavelength.

• The measurement wavelength may also be set to a previously

set wavelength.

Connect an optional optical sensor to the 3664. To operate the

3664, an optical sensor must be connected to it.

Flow of measurement

Setting of the measurement

Setting of the range

Setting of the measurement wavelength

❖(2 0 page)

❖(21 page)

(24 page)

❖

3

1

2

3

4

5

6

7

8

Input of light to the sensor

❖(2 6 page)

9

10

www. .com

information@itm.com1.800.561.8187

Page 22

20

3.1 Setting the Measurement Mode

3.1 Setting the Measurement Mode

Each time the

changes as shown below.

Optical-power measurement

Relative measurement (measured-value basis)

Relative measurement (input-value basis)

key is pressed, the measurement mode

REL

The 3664 performs optical- po w er measurement.

The 3664 sets th e optical p ower

of the incident light to the optical

sensor as the reference value,

and measures th e difference between the set reference va lue

and the current incident o ptical

power.

The 3664 measures the difference between the refe re nce v alue arbitrarily set by key entry

and the current incident optical

power.

www. .com

information@itm.com1.800.561.8187

Page 23

3.2 Setting the Range

21

3.2 Setting the Range

Each time the

range alternate.

3.2.1 Auto Range

The appropriate range for the incident optical power is automatically selected. The range display area will appear as shown below.

RANGE

Auto Range

key is pressed, auto range and manual

Manual Range

1

2

3

4

5

6

7

8

When the RANGE key is pressed, "MANUAL" appears in the range

display area and the range is fixed to that displayed.

www. .com

information@itm.com1.800.561.8187

9

10

Page 24

22

3.2 Setting the Range

3.2.2 Manual Range

The range is set manually. "

area.

1.

Press the

2.

Press the

the manual range. The range display area will blink.

key to display the setting edit screen.

SET

RANGE

MANUAL

key to display the setting edit screen for

" appears in the range display

Blinking

3.

Use the ▲ and ▼ keys to change the range s et t ing.

▲

: Increases the sensitivit y range by one increment

▼

: Decreases the sensiti vity range by one increment

The range No. displayed on the screen is the range No. of the internal

circuit. The range is divided into seven levels, from 1 (lowest

sensitivity) to 7 (highest sensitivity).

www. .com

information@itm.com1.800.561.8187

Page 25

3.2 Setting the Range

4.

Press the

the 3664 will return to the meas urement scree n. The range

is now fixed.

key to save the setting. "

SAVE

" is displayed;

SAVE

23

1

2

3

4

Fixed range

When the range is fixed through manual range setting, the measurement display shows "

below the measurement range, and it shows "Hi" if the power

exceeds the range.

"Lo" Display

" if the incident optical power falls

Lo

"Hi" Display

5

6

7

8

9

10

www. .com

information@itm.com1.800.561.8187

Page 26

24

3.3 Setting the Wavelength

3.3 Setting the Wavelength

The following two methods can be used:

• Set an arbitrary measurement wavelength.

• Retrieve a wavelength from the measurement-wavelength memory, and set it as the measurement wavelength.

• The selectable wavelength range depends on the specification

of the optical sensor connected to the 3664.

• To ensure proper measurement, set the wavelength to the

wavelength of the light used.

3.3.1 Setting an Arbitrary Measurement Wavelength

1.

Press the

key to display the setting edit screen.

SET

2.

Press the λ key to display the setting edit screen for the

measurement wavelength.

Blinking

3.

Use the ▲ and ▼ keys to change the measurement wavelength.

▲

: Increases the number

▼

: Decreases the numbe r

www. .com

information@itm.com1.800.561.8187

Page 27

3.3 Setting the Wavelength

4.

Press the key to change the blinking digit.

Blinking

Repeat steps 3 and 4 above to set t he measurement w av elength.

5.

Press the

"SAVE" appears; the 3664 will then return to the measurement

screen. The measurement wavelength is now set.

key to complete setting.

SAVE

The measurement waveleng th set

25

1

2

3

4

5

6

• An arbitrarily set measurement wavelength is automatically

saved in the measurement-wavelength memory.

• The measurement-wavelength memory holds up to 10 wavelengths (including preset wavelengths for each optical sensor).

• Each optical sensor has preset wavelengths. These preset

wavelengths cannot be edited.

• Through the setting operation for the arbitrary measurement

wavelength, the setting data is automatically saved in the measurement-wavelength memory. When it is necessary to save a

new measurement wavelength to the measurement-wavelength memory when the memory already contains 10 wavelengths, the oldest data is deleted in order to make space for

the new data.

• To reset the data in the measurement-wavelength memory,

perform measurement-wavelength-memory reset. This will

return the memory to its default state for each sensor.

❖See Section 7.4.3 "Measurement-Wavelength Memory Reset" (60

page)

7

8

9

10

www. .com

information@itm.com1.800.561.8187

Page 28

26

3.4 Starting Measurement

3.3.2 Retrieving the Wavelength Setting from the Measurement-Wavelength Memory

Each time the λ key is pressed, the measurement wavelengths

stored in the memory are retrieved individually in order.

To reset the data in the measurement-wavelength memory, perform measurement-wavelength-memory reset. This will return

the memory to its default state for each sensor.

❖See Section 7.4.3 "Measurement-Wavelength Memory Reset" (60 page)

3.4 Starting Measurement

1.

When using the 9742 OPTICAL

Model 9742 OPTICAL SENSOR

Optical Sensor

Cover

SENSOR, slide the sensor cover

of the optical sensor until it clic ks

to lock the cover. When using the

9742-10 OPTICAL SENSOR,

remove the optical-sensor cover.

Model 9742-10 OPTICAL SENSOR

Optical Sensor

Cover

• Removed sensor cover (B e

• Mount the sensor cover as

careful to avoid misplacing.)

shown in the figure to the

left.

When using the 9742-10 OPTICAL SENSOR, remove the cover

of the optical sensor.

2.

Inject light.

3.

The 3664 displays the measured

optical power.

www. .com

information@itm.com1.800.561.8187

Page 29

27

3.4 Starting Measurement

• To ensure accurate measurements, make sure the detector

window is free of dust, stains, and any damage.

• Confirm that the light to be measured fits completely within the

detector window.

• If the optical power is too intense for the unit area, such as

when a condensed beam on the focus plane is measured, the

optical sensor may be saturated and the 3664 may not be able

to conduct accurate measurement. This problem can be

solved by changing the distance between the light source and

the detector window of the optical sensor.

• The operation of the light source may become unstable due to

the reflection of light from the detector window of the optical

sensor. This problem can be solved by angling the detector

window slightly to prevent the reflection from ret urning to the

light source.

• If background light, sunlight, illumination light, or any other light

than the light to be measured is overly intense, the 3664 may

not be able to conduct accurate measurement. Take appropriate light-shielding measures.

1

2

3

4

5

6

7

8

9

10

www. .com

information@itm.com1.800.561.8187

Page 30

28

3.5 Setting Example

3.5 Setting Example

3.5.1 Optical-Power Measurement

The 3664 performs optical-power measurement.

(1) Set the measurement mode.

Press the

(2) Set the measurement wavelength.

Set the measurement wavelength to an arbitrary wavelength or

one retrieved from the memory. The sensitivity is corrected by the

set measurement wavelength, and the 3664 displays the measured value adjusted in accordance with the corrected sensitivity.

Set the measurement wavelength to the wavelength of the light

used. If the wavelengths differ, the 3664 is not able to conduct

accurate measurement.

key to select the optical-power measurement mode.

REL

Optical-power

measurement

www. .com

information@itm.com1.800.561.8187

Page 31

3.5 Setting Example

3.5.2 R ela tive Mea surem ent (Meas ur ed-va lue basi s)

29

(1) Set the measurement mode.

(2) Set the measurement wavelength.

(3) Loading the reference value/relative measurement (when the optional

Model 9742 OPTICAL SENSOR

Model 9742-10 OPTICAL SENSOR

The 3664 sets the optical power of the incident light to the optical

sensor as the reference value, and measures the difference

between the set reference value and the current incident optical

power.

Press the

value basis) mode.

Set the measurement wavelength to an arbitrary wavelength or

one retrieved from the memory.

Set the measurement wavelength to the wavelength of the light

used. If the wavelengths differ, the 3664 is not able to conduct

accurate measurement.

9742 or 9742-10 OPTICAL SENSOR is used)

Optical Sensor

Cover

• Removed sensor cove r (Be

careful to avoid misplacing.)

• Mount the sensor cover as

shown in the figure to the

left.

key to select the relative-measurement (measured-

REL

1.

When using the 9742 OPTICAL

SENSOR, slide the sensor cover

of the optical sensor until it clicks

to lock the cover. When usi ng the

Optical Sensor

Cover

9742-10 OPTICAL SENSOR,

remove the optical-sensor cover.

When using the 97 42-10 OPTICAL

SENSOR, remove the cover of the

optical sensor.

2.

Inject light.

3.

In the relative-measure ment (measured-value basis) mode, hold

down the

mately 3 seconds.

key for approxi-

SAVE

1

2

3

4

5

6

7

8

9

10

www. .com

information@itm.com1.800.561.8187

Page 32

30

3.5 Setting Example

4.

"

" is displayed on the screen, and the relative-mea-

SAVE

surement result is then displayed.

The result is save d as the optical-pow er measuremen t reference valu e.

Mode

5.

"0" appears on the left side of t he sub-dis play are a, indicat -

Reference Value

ing the relative-measurement (measured-value basis)

mode, and the saved reference value is displayed on the

right side of the sub-display area.

The main display area shows the relative-measurement

value.

In the relative-mea surem ent (me asur ed- value basis ) mo de,

the value show n below is displayed.

(Current measurement) - (measurement set as the reference value)

• Only one reference value is saved, regardless of the wavelength setting. When a different measurement wavelength is

used, set a new reference value.

• When the maximum-value-hold, minimum-value-hold, or a veraging function is ON, "(calculation result) - (reference value)" is

displayed.

• When the scaling function is ON, "(value af ter scaling) - (refe rence value)" is displayed.

• When the reference value is input, if the main display area

shows "

The relative measurement is not calculated, and "

played on the screen.

" or "Hi," Lo or Hi is saved as the reference value.

Lo

- - - -

" is dis-

www. .com

information@itm.com1.800.561.8187

Page 33

3.5 Setting Example

3.5.3 Relative Measurement (Input-value basis)

31

The 3664 measures the difference between the reference value

arbitrarily set by key entry and the current incident optical power.

Entering the Reference Value Using the Keys/Relative

Measurement

1.

Press the

2.

Press the

screen.

3.

Use the ▲ and ▼ keys to change the position of the decimal

point and the unit.

▲

: Increases the number

▼

: Decreases the number

key to display the setting ed it screen.

SET

key to display the reference-value input

REL

Blinking

Blinking

1

2

3

4

5

6

7

8

9

4.

Press the key to change the blinking digit.

www. .com

information@itm.com1.800.561.8187

10

Blinking

Page 34

32

3.5 Setting Example

5.

Use the ▲ and ▼ keys to change the blink ing number.

▲

: Increases the number

▼

: Decreases the numbe r

Repeat steps 4 and 5 ab ov e t o s et the r ef erence value.

6.

Press the

"

" appears and then the 3664 returns to the measure -

SAVE

ment screen. The mea surem ent wa velen gth i s now se t an d

the relative-measurem ent result is dis played.

key to comp l ete setting.

SAVE

Blinking

Mode

The number "1" appears on the left side of the sub-display area,

indicating the relative-measurement (input-value basis) mode, and

the saved reference value is displayed on the right side of the subdisplay area.

The main display area displays the relative-measurement value.

In the relative-measurement (input-value basis) mode, the value

shown below is displayed.

(Current measurement) - (value entered using th e keys as the reference value)

• Only one reference value is saved regardless of the wavelength setting.

• When a different measurement wavelength is used, set a new

reference value.

• The values that can be entered using the keys as the reference

value range from 0.001 nW to 1.9999 W (-90.00 dBm to 33.0

dBm).

• When the maximum-value-hold, minimum-value-hold, or a veraging functions is ON, "(calculation result) - (reference value)"

is displayed.

• When the scaling function is ON, "(value af ter scaling) - (refe rence value)" is displayed.

Reference Value

www. .com

information@itm.com1.800.561.8187

Page 35

4.1 Scalling Function

33

Functions

• Using the scaling function, a measured value can be converted

to an arbitrary value and the converted value displayed.

• The maximum-value-hold, minimum-value-hold, and averaging

functions are available.

4.1 Scalling Function

• A measured value is converted by scaling to an arbitrary value

and displayed. When the scaling function is turned ON, "(measured value) x (internal coefficient)" is displayed.

• The internal scaling coefficient for each wavelength is saved in

the memory.

• When the display value after scaling is set, the internal coe fficient is automatically calculated and saved.

4.1.1 Turning ON the Scaling Function

Save the internal scaling coefficient, and turn ON the scaling function.

1.

Input the light to be measu red to the optical sensor.

2.

Press the

key to display the setting ed it screen.

SET

4

1

2

3

4

5

6

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 36

34

4.1 Scalling Function

3.

Press the λ key to display the setting edit screen for the

measurement wavelength.

Blinking

Scaling function

The value displaye d first in the sub-displa y area is the display value with the scaling OFF (internal coefficient of

1.000).

4.

Use the key to move the cursor to a digit in the s ub-display area.

5.

Use the ▲ and ▼ keys to change the blink ing number.

▲

: Increases the number

▼

: Decreases the numbe r

Repeat steps 4 and 5 above to set the display value after

scaling.

Measured value immediately before

the setting edit screen appears

Blinking

Sub Display

Blinking

www. .com

information@itm.com1.800.561.8187

Page 37

4.1 Scalling Function

6.

Press the

"

" is displayed, an d the 3664 then returns to the me a-

SAVE

surement screen. The scaling coefficient is automatically

calculated and saved as an i nt ern al setting.

7.

The indicator "λ" starts blinking and t he scaled value is displayed.

key to save the setting.

SAVE

35

1

Blinking

Scaled Value

• While the scaling function is ON, the indication "λ" blinks.

• The internal scaling coefficient ranges from 0.100 to 10.000.

The scaling function is not available under the following condi-

tions, and "

scaling (in the sub-display area).

• The measured value is displayed as "

range.

• The measured value is very large or very small in the auto

range.

" or "Lo" appears instead of the display value after

Hi

" or "Lo" in the manual

Hi

2

3

4

5

6

7

8

9

www. .com

10

information@itm.com1.800.561.8187

Page 38

36

4.1 Scalling Function

4.1.2 Turning OFF the Scaling Function

1.

Press the

2.

Press the λ key to display the setting edit screen for the

measurement wavelength.

key to display the setting edit screen.

SET

Blinking

Scalling Function

3.

Press the

before scaling.

"

" is displayed, and the 3664 then re turns to the mea-

SAVE

surement screen. A scaling coefficient of 1. 000 is set as an

internal s etting, and the s c aling functi on is turned OFF.

4.

The indication "λ" remains ON as a solid light, and the

measured value that is n ot scaled is displayed.

To return to the measurement screen with the scaling ON:

Do not press the

key twice.

SET

key without changing the display value

SAVE

key in step 4 above; instead, press the

SAVE

Display value before scaling

www. .com

information@itm.com1.800.561.8187

Page 39

4.2 Maximum-Value Hold / Minimum-Value Hold / Averaging

4.2 Maximum-Value Hold / Minimum-Value

Hold / Averaging

37

Each time the

changes as shown below.

No calculation

Maximum-value hold

Minimum-value hold

MAX/MIN/AVE

key is pressed, the calculation setting

The calculation functi on is

disabled.

The maximum value among

the current measurements

is displayed.

The minimum value among

the current measurements

is displayed.

1

2

3

4

5

6

7

8

Average-value hold

The moving average for the

set number of averaging

steps is displayed.

To reset the display value, press the

start calculation again.

www. .com

MAX/MIN/AVE

information@itm.com1.800.561.8187

9

10

key again and

Page 40

38

4.2 Maximum-Value Hold / Minimum-Value Hold / Averaging

Setting the Number of Averaging Steps

1.

Press the

2.

Press the

for the number of averaging steps.

3.

Use the ▲ and ▼ keys to change the blink ing number.

▲

: Increases the number

▼

: Decreases the numbe r

A digit may be chos en by moving the cursor using the

key.

key to display the setting edit screen.

SET

MAX/MIN/AVE

key to display the setting edit screen

Blinking

Blinking

4.

Press the

" is displayed, and the 3664 then re turns to the mea-

SAVE

"

key to save the setting.

SAVE

surement screen. The number of averaging steps is now

set.

• After returning to the measurement screen, "

blink until the number of averaging steps reaches the set number.

• The number of averaging steps is selectable between 2 and

100.

• If the

MAX/MIN/AVE

pressed during measurement with the calculation function ON,

the calculation is reset.

key, λ key,

RANGE

" continues to

AVE

key, or

SET

key is

www. .com

information@itm.com1.800.561.8187

Page 41

39

Control by Computer

By connecting the 3664 power meter to a PC, measurement s can

be read and the 3664 can be set up on the PC.

When connecting the 3664 to a PC with a USB cable, use a

cable of 2 m or shorter to prevent the influence of noise.

5

1

2

3

4

5

5

6

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 42

40

5.1 Overview of Control

5.1 Overview of Control

• By connecting the 3664 power meter to a PC with a USB interface and calling API functions stored in the DLL from the application, the 3664 can be remotely controlled, and data can be

exchanged between the 3664 and the PC.

• The table below shows a list of the API functions. For details, see

the "API Instructions Manual (3664api.pdf)" on the supplied CDR.

• To view the 3664api.pdf, Acrobat Reader must be installed on

your PC. If it is not installed, first install the Acrobat Reader from

the supplied CD-R.

API list

Name of function Description

RESET functions

ResetDeviceUSB() Resets the communications function

ResetAllData() Resets the setting dat a

ResetAllWave() Resets the measurement w avelength

SET functions

SET_Rel0() Sets the reference valu e for rel ative measur ement

SET_Rel1() Sets the reference valu e for rel ative measur ement

QUES functions

QUES_IDN() Queries the device data

QUES_Sensor() Queries the optical-sensor model No.

QUES_AllWave() Queries all measurement wavelengths stored in

QUES_MeasData() Queries the measurement data

QUES_Rel() Queries the reference value

SQ functions

SQ_Mode() Sets or queries the mode

SQ_Wave() Sets (arbitrary setting) or queries the measure-

SQ_Ave() Sets or que r ies the number of averaging steps

SQ_Range() Sets or queries the range

SQ_Aps() Sets or queries the APS (auto power save) func-

(measured-value basis)

(input-value basis)

the measurement-wavelength memory

ment wavelength

tion

An application for controlling the 3664 shall be created by the

user.

www. .com

information@itm.com1.800.561.8187

Page 43

5.2 Installing th e Driver

41

5.2 Installing the Driver

To connect the 3664 to a PC using the USB interface, the driver

must be installed.

System requirements

OS Windows 98SE, Windows Me, Windows 200 0,

Windows XP

Hardware requirements, such as those involving

the CPU, RAM, and display monitor, shall con-

form to the system requirements of the OS.

HDD space 10 MB or more of free disk space

Interface USB Ver. 1.1 or higher

(connectable to only one PC)

CD-R contents

HiUsbSgl.inf File for driver installation

HiUsbSgl.sys Device driver for the USB of the 3664

1

2

3

4

5

5

6

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 44

42

5.2 Installing the Driver

Do not plug in or unplug the USB cable while the instrument is operating.

• The PC and 3664 should be connected on a one-on-one basis.

Multiple 3664 units cannot be connected to the PC at a time.

• When a 3664 unit with a different serial No. is connected, the

instrument may indicate that a new device has been detected.

In such case, install the device driver by following the instructions appearing on the screen.

Turn on the power of the instrument.

1.

Connect the PC on which you intend to install the driver and the

2.

3664 by using the USB cable supplied with the instrument.

(PC side)

The 3664 will be recognized by the device name of "

OPTICAL POWER METER

After displaying "

the "

Found New Hardware Wizard

The "

Found New Hardware Wizard

depending on the OS.

Insert the CD-R into the PC according to instructions given in the

dialog box, then install the driver.

The following describes how to install the driver for each type of

OS.

❖See Section "For Windows XP" (page 43)

❖See Section "For Windows 2000" (page 45)

❖See Section "For Windows Me" (page 47)

❖See Section "For Windows 98SE" (page 48)

."

Found New Hardware

."

" requires different procedures

" on the screen, the PC starts

HIOKI 3664

www. .com

information@itm.com1.800.561.8187

Page 45

For Windows XP

Insert the CD-R supplied with the instrument into the CD-ROM

1.

drive. The "

5.2 Installing the Driver

Found New Hardware Wizard

" window appears.

43

1

2.

3.

Check "

Click the [

Install the software automatically

Continue Anyway

] button.

," then click the [

Next

] button.

2

3

4

5

5

6

7

8

9

Clicking the button initiates copying of the file. When this software

is recognized, the screen will display a message stating that the

software is not authorized by Microsoft. Ignore the message and

continue operation.

www. .com

information@itm.com1.800.561.8187

10

Page 46

44

5.2 Installing the Driver

Click the [

4.

When the "

5.

CD-R from the CD-ROM drive.

] button.

Finish

Found New Hardware Wizard

" window closes, remove the

www. .com

information@itm.com1.800.561.8187

Page 47

For Windows 2000

45

5.2 Installing the Driver

When the "

1.

[

Next

Insert the CD-R supplied with the instrument into the CD-ROM

2.

drive.

Check "

3.

button.

Found New Hardware Wizard

] button.

Search for a suitable driver fo r my device

" window appears, click the

," then click the [

Next

1

2

3

4

5

5

6

]

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 48

46

5.2 Installing the Driver

4.

5.

Check "

click the [

Click the [

CD-ROM drives

] button.

Next

] button.

Next

" (thus deselecting the other items), then

Click the [

6.

When the "

CD-R from the CD-ROM drive.

] button.

Finish

Add New Hardware Wizard

" window closes, remove the

www. .com

information@itm.com1.800.561.8187

Page 49

For Windows Me

Insert the CD-R supplied with the instrument into the CD-ROM

1.

drive.

The "

Add New Hardware Wizard

5.2 Installing the Driver

" window appears.

47

1

2.

3.

Check "

ton.

Click the [

Automatic search for a better driver

Finish

] button.

," then click the [

Next

] but-

2

3

4

5

5

6

7

8

9

When the "

4.

CD-R from the CD-ROM drive.

Add New Hardware Wizard

www. .com

10

" window closes, remove the

information@itm.com1.800.561.8187

Page 50

48

5.2 Installing the Driver

For Windows 98SE

1.

2.

When the "

[

] button.

Next

Check "

button.

Search for the best d riv er f or your device

Add New Hardware Wizard

" window appears, click the

," then click the [

Next

]

Insert the CD-R supplied with the instrument into the CD-ROM

3.

drive.

www. .com

information@itm.com1.800.561.8187

Page 51

5.2 Installing the Driver

49

4.

5.

Check "

the [

Click the [

CD-ROM drive

Next

] button.

] button.

Next

" (thus deselecting the other items), then click

1

2

3

4

5

5

6

7

Clicking the button initiates copying of the file.

8

9

10

www. .com

information@itm.com1.800.561.8187

Page 52

50

5.2 Installing the Driver

When the following window subsequently appears, click the [

6.

button.

When the "

7.

CD-R from the CD-ROM drive.

Add New Hardware Wizard

" window closes, remove the

Finish

]

www. .com

information@itm.com1.800.561.8187

Page 53

6.1 Measurement Specifications

51

Specifications

6

6.1 Measurement Specifications

Optical-power

measurement

Range selection Automatic and manual

Accuracy ± 0.7% (± 5% in combination with an optional optical sensor)

Maximum-value

hold

Minimum-value

hold

Average-value

display

Wavelength

sensitivity

correction

Scaling [Display value] = [Measured value] x [internal setting]

Unit: W/dBm

Displays the maximum value among the current measurements

Displays the minimum value among the current measurements

Displays the moving average for the set number of averaging

steps

The number of averaging steps is selectable between 2 and 100.

The setting is editable every 1 nm. The sensitivity of the sensor is

corrected automatically. Up to 10 wavelengths can be preset

(each sensor has unchangeable presets).

The internal setting is set for each wavelength and is selectable

between 0.1 and 10. The resolution is the same as that for opticalpower measurement.

1

2

3

4

5

6

7

8

Relative

measurement

Display update

rate

Analog output

Displays a relative value to a measured or set value

[Display value] = [Measured value] - [Reference value]

The reference value is set based on the measured value or

through key entry by the user. The selectable value ranges from

0.001 nW to 1.9999 W (-90.00 dBm to 33.00 dBm).

Approx. 330 ms

Output level: Approx. 1 V at the sensor calibration point

Output resistance: 50 Ω ± 5%

Connector: φ 3.5 Mini-jack

* The calibration point of the sensor is determined based on the

calibration wavelength and the calibration power specified in the

specification of the optional optical sensor.

www. .com

information@itm.com1.800.561.8187

*

9

10

Page 54

52

6.1 Measurement Specifications

Display monitor Monitor: LCD

Communications function

Functions • Auto power save

Measurement display: 4-1/2 digits in the unit of nW,

dBm, or dB

Wavelength display: 4 digits in the unit of nm

Communications data:

Output of measured values at the request of the

PC

Change in setting at the command of the PC

Interface: USB Ver. 1.1

Automatically turns OFF the power if there is no key operation or

USB communication for approximately 10 minutes. To turn OFF

the function, hold down the POWER key for 5 sec. when turning

ON the power. The auto-power-save function is available only

when the 3664 is running on the battery.

• Setting backup

Saves the settings when the power is turned OFF, and starts up

the 3664 with the saved settings when the power is turned ON

again.

• Battery check

Displays the battery indicator when the supply voltage falls

below 4.0 V

W, mW,

μ

www. .com

information@itm.com1.800.561.8187

Page 55

6.2 General Specifications

53

6.2 General Specifications

Rated supply

voltage

Maximum rated

power

Operating time • With maximum load

Dimensions Approx. 85W × 160H × 35D mm (3.35"W × 6.30"H × 1.38"D)

Mass Approx. 270 g (9.5 oz.) (without batteries)

Operating

temperature

and humidity

Storage

temperature

and humidity

Accuracy guarantee for temperature and

humidity

Guaranteed

accuracy period

Operating

environment

• 1.5 V DC × 4 (LR6 alkaline batteries × 4)

• AC Adapter 9 V DC, 0.2 A

Model 9445-02 AC ADAPTER or Model 9445-03 AC ADAPTER:

Rated supply voltage: 100 to 240 V AC (Voltage fluctuations of

±10% from the rated supply voltage are taken into account.), 50/

60 Hz, Maximum rated current 250 mA)

1.6 VA

Approx. 9 hours

(Ambient temperature 23°C(74°F) reference value)

• Specified measurement state

Approx. 60 hours

(Ambient temperature 23°C(74°F) reference value)

(excluding projections)

0 to 40°C (32 to 104°F), 80%RH or less (non-condensating)

-10 to 50°C (14 to 122°F), 80%RH or le ss (non-condensating)

23 ± 5°C (73 ± 9°F), 80%RH or less (non-con densating)

One year

Indoors, altitude up to 2000 m (6562-ft.)

1

2

3

4

5

6

7

8

9

10

Applicable

standards

Safety : EN61010-1:2001 Pollution degree II

EMC : EN61326:1997+A1:1998+A2:2001+A3:2003

www. .com

EN61000-3-2:2000

EN61000-3-3:1995+A1:2001

information@itm.com1.800.561.8187

Page 56

54

6.2 General Specifications

Accessories Model 9445-02 AC ADAPTER

Options Model 9246 CARRYING CASE ........................................... 1

or Model 9445-03 AC ADAPTER

CAN)

......................................................................................... 1

Model 9094 OUTPUT CORD................................................... 1

Driver CD-R ............................................................................. 1

LR6 alkaline batteries .............................................................. 4

USB cable................................................................................ 1

Strap ........................................................................................ 1

Instruction manual.................................................................... 1

Model 9742 OPTICAL SENSOR.......................................... 1

Model 9742-10 OPTICAL SENSOR .................................... 1

(UL, SA10-9010N, SINO-AMERICAN)

(CEE, SA10-9010G, SINO-AMERI-

www. .com

information@itm.com1.800.561.8187

Page 57

7.1 Cleaning

55

Maintenance and Service

Never modify the instrument. Only Hioki service engineers should disassemble or repair the instrument. Failure to observe t hese precautions

may result in fire, electric shock, or injury.

7.1 Cleaning

7.1.1 Cleaning of the 3664

To clean the instrument, wipe it gently with a soft cloth moistened

with water or mild detergent. Never use solvents such as benzene,

alcohol, acetone, ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

7

1

2

3

4

5

6

7

8

www. .com

9

10

information@itm.com1.800.561.8187

Page 58

56

7.2 Service

7.1.2 Cleaning of the Optical Sensors

• Avoid touching the detector window with your bare hands. The

detector window must be clean for the sensor to meet the specified performance parameters.

• With the exception of ethyl alcohol, avoid using organic solvents

to clean the detector window. These solvents can damage the

detector window.

• Avoid scratching the detector window with sharp or pointed

objects (e.g., the tips of tweezers) or against hard surfaces.

Damage to the detector window may prevent the sensor from

meeting specified performance parameters.

Ta ke the cleaning method of the 9742 OPTICAL SENSOR as an

example.

1.

Open the sensor cove r.

(When using the 9742-10 OPTICAL SENSOR , take care to

avoid misplacing the sensor cover.

2.

Wipe the detector w indow of the sensor usin g lens cleaning

paper or other lint-free ma t erial.

If lint remains on the detector wind ow, blow off with an optical lens airbrush.

If the detector window is soil ed, fl uf f th e tip of a cot ton swab.

Moisten the cotton tip in et hy l alcohol and wipe the surface .

7.2 Service

• If the instrument seems to be malfunctioning, confirm that the

batteries are not discharged, and that the USB cable is not open

circuited before contacting your dealer or Hioki representative.

• When sending the instrument for repair, remove the batteries and

pack carefully to prevent damage in transit. Include cushioning

material so the instrument cannot move within the package. B e

sure to include details of the problem. Hioki cannot be responsible for damage that occurs during shipment.

www. .com

information@itm.com1.800.561.8187

Page 59

7.3 Error Display

57

7.3 Error Display

In the event of an error, one of the following messages is displayed.

Err0 Reference-value save error

An improper value has been saved as the

reference value. If a reference value is

saved while the measured value is "Lo" or

"Hi" in the optical-power measurement

mode, "REL" and "SAVE" remain on the

screen and "Err0" is displayed. The reference value is then updated to Hi or Lo, and

the relative measurement display shows "

- -

".

Err1 Wavelength error

There is a problem with the measurementwavelength memory. Reset the measurement-wavelength memory.

❖See Secti on 7.4.3 Measu rement-Wavelength

Memory Reset (page 60)

If the measurement-wavelength-memory

reset does not solve the problem, conduct a

system reset.

❖See Section 7.4.1 System Reset (page 59)

If the system reset does not solve the problem, the 3664 may be malfunctioning.

Contact your dealer or Hioki representative.

Err2 Setting-data error

- -

1

2

3

4

5

6

7

8

9

There is a problem with the setting data.

Conduct a system reset.

❖See Section 7.4.1 System Reset (page 59)

If the system reset does not solve the problem, the 3664 may be malfunctioning.

Contact your dealer or Hioki representative.

www. .com

10

information@itm.com1.800.561.8187

Page 60

58

7.3 Error Display

Err3 Memory error

There is a problem with writing into the

memory. Conduct a system reset.

❖S ee Section 7.4.1 System Reset (page 59)

If the system reset does not solve the problem, the 3664 may be malfunctioning.

Contact your dealer or Hioki representative.

Err4 System error

The 3664 may be malfunctioning. Contact

your dealer or Hioki representative.

"1" Display over range

The value displayed after wavelength sensitivity correction or scaling exceeds the

upper limit that can be displayed by the

3664 (1.9999 W).

"no SEnS" Sensor disconnected

A sensor is not connected. Connect a sensor. The 3664 cannot be operated without a

sensor connected.

www. .com

information@itm.com1.800.561.8187

Page 61

7.4 Reset

59

7.4 Reset

There are three types of reset operations for the 3664.

•System reset

Returns all settings to their defaults

• Setting-data reset

Returns all settings except those for the wavelength data to their

defaults

• Measurement-wavelength memory reset

Returns the measurement-wavelength data stored in the measurement-wavelength memory to its default state.

7.4.1 System Reset

1.

While holding down the

power.

2.

"CLr" and "ALL" start blinking, and a ll settin gs ar e r eturn ed

to their defaults.

key and key, tu rn ON the

SET

Blinking

1

2

3

4

5

6

7

8

7.4.2 Setting Data Reset

1.

While holding down th e

power.

2.

"CLr" and "SEt" start blinking, and all setting d ata except

those for the wavelength is ret urned to its defaults.

www. .com

key and

SET

key, turn ON the

SAVE

Blinking

information@itm.com1.800.561.8187

9

10

Page 62

60

7.4 Reset

7.4.3 Measurement-Wavelength Memory Reset

1.

With an optional optical sensor connected to the 3664,

key and λ key, turn ON the

while holding down the

power.

2.

"CLr" and "λ" start blinking, and the measurement-wavelength data is returned to th e default wavelength setting of

the connected sensor.

The measurement-wavelength memory reset cannot be performed if a

sensor is not connected to the 3664.

SET

Blinking

www. .com

information@itm.com1.800.561.8187

Page 63

7.5 Replacing the Batteries

7.5 Replacing the Batteries

61

• To avoid electric shock, turn off the power switch and disconnect the USB cable before replacing the batteries.

• After replacing the batt eries, replace the cover and screws

before using the instrument.

• Do not mix old and new batteries, or diffe rent types of batteries. Also, be careful to observe battery polarity during

installation. Otherwise, poor perform ance or damage from

battery leakage could result.

• To avoid the possibility of explosion, do not short circu it,

disassemble or incinerate batteries.

• Handle and dispose of batteries in accordance with local

regulations.

• The “ ” indicator appears when battery voltage becomes low.

Replace the batteries as soon as possible.

• Use the specified battery (AA alkaline battery) only. If nonspecified battery such as a manganese battery is used, the

service hours may be shorter than when alkaline batteries are

used.

Tools and materials:

Four AA alkaline batteries (LR6) and a Phillips screwdriver

Make sure the power to the 3664 is

1.

OFF.

Disconnect all cables.

2.

1

2

3

4

5

6

7

8

9

Turn over the 3664 and loosen the

3.

screw on the battery cover.

Remove the battery cover.

4.

Insert the four AA alkaline batteries

5.

(LR6) into the battery case, noting the

correct polarity. (When replacing the

batteries, replace all of them.)

Place the battery cover back on, and

6.

tighten the screw.

www. .com

10

information@itm.com1.800.561.8187

Page 64

X

Appendix

63

Explanations

Optical-power measurement

Assuming that the energy of the input light measures E [mW], the

measured value P is expressed as follows.

P [dBm] = 10log

P: Measured value [dBm]

E: Energy of input light [mW]

10

E [mW]

1 [mW]

1

2

APP

4

5

6

7

8

9

10

11

APP

APP

www. .com

information@itm.com1.800.561.8187

Page 65

64

Options

Model 9742 OPTICAL SENSOR

Optical sensor for the 3664

Model 9742-10 OPTICAL SENSOR

Optical sensor for the 3664

Model 9246 CARRYING CASE

Carrying case holding the 3664, the complete accessory set, and

an optional optical sensor

www. .com

information@itm.com1.800.561.8187

Page 66

4

5

6

7

8

9

10

11

www. .com

information@itm.com1.800.561.8187

Loading...

Loading...