Page 1

INSTRUCTION MANUAL

For...は専用機種。複数の場合は「/」で区切る。

不要の場合はとる。

形名を入力。 複数の場合は「/」で区切る。

3636-20

品名を入力。

CLAMP LOGGER

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use v

Measurement Flow Chart and Reference Guide vi

Chapter 1 Product Outline 1

1.1 Name and Functions of Parts 2

1.2 Interval and Maximum Recording Time

3

1.3 Measurement Value Recording Modes

5

Chapter 2 Set Up 7

2.1 Installing or Replacing the Batteries 7

2.2 Power Save Function

9

2.3 Setting Current Time

10

2.4 Connecting Sensor/Cable

11

Chapter 3 Settings 13

3.1 Setting Items 13

3.2 Manual Setting

18

3.3 Setting by COMMUNICATION BASE

20

Chapter 4 Specifications 23

Chapter 5 Maintenance and Service 25

Page 4

Page 5

i

_____________________________________________________________________

Inspection

______________________________________________________________

Testing monitor batteries installed in the

unit may possibly be weak. Replace

batteries before extended measurement

usage.

Introduction

Inspection

Thank you for purchasing the HIOKI "3636-20 CLAMP

LOGGER." To obtain maximum performance from the

product, please read this manual first, and keep it handy for

future reference.

When you receive the product, inspect it carefully to ensure

that no damage occurred during shipping. If damage is

evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Accessories

9632 CONNECTION CABLE

Instruction Manual

LR03 alkaline battery X 4

(built into this unit, for monitor)

Before using the product the first time, verify that it

operates normally to ensure that the no damage occurred

during storage or shipping. If you find any damage, contact

your dealer or Hioki representative.

Before using the product, make sure that the insulation on

the probes is undamaged and that no bare conductors are

improperly exposed. Using the product in such conditions

could cause an electric shock, so contact your dealer or

Hioki representative for repair.

Page 6

ii

_____________________________________________________________________

Safety Notes

______________________________________________________________

DANGE

R

This equipment is designed according to IEC 61010

Safety Standards, and has been tested for safety prior

to shipment. Incorrect measurement procedures

could result in injury or death, as well as damage to

the equipment. Please read this manual carefully and

be sure that you understand its contents before using

the equipment. The manufacturer disclaims all

responsibility for any accident or injury except that

resulting due to defect in its product.

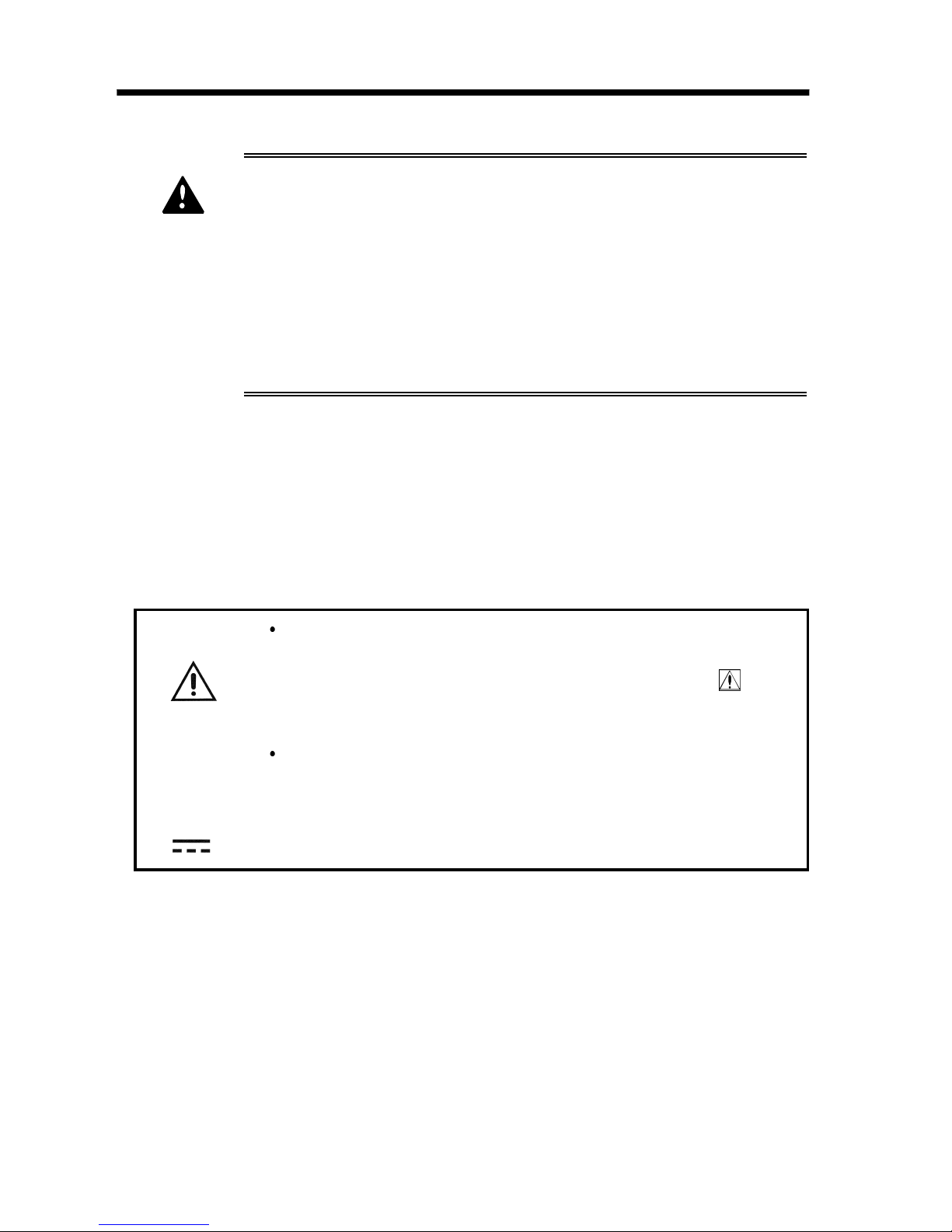

Safety Symbols

This symbol is affixed to locations on the equipment

where the operator should consult corresponding topics

in this manual (which are also marked with the

symbol) before using relevant functions of the

equipment.

In the manual, this mark indicates explanations which it

is particularly important that the user read before using

the equipment.

Indicates DC (Direct Current).

SafetyNotes

This Instruction Manual provides information and warnings

essential for operating this equipment in a safe manner and

for maintaining it in safe operating condition. Before using

this equipment, be sure to carefully read the following

safety notes.

Page 7

iii

_____________________________________________________________________

Safety Notes

______________________________________________________________

DANGE

R

Indicates that incorrect operation presents extreme

danger of accident resulting in death or serious injury

to the user.

WARNING

Indicates that incorrect operation presents significant

danger of accident resulting in death or serious injury

to the user.

CAUTION

Indicates that incorrect operation presents possibility

of injury to the user or damage to the equipment.

f.s.

(maximum display or scale value, or length of scale)

Signifies the maximum display (scale) value or the length

of the scale (in cases where the scale consists of unequal

increments or where the maximum value cannot be

defined).

In general, this is the range value (the value written on

the range selector or equivalent) currently in use.

rdg.

(displayed or indicated value)

This signifies the value actually being measured, i.e., the

value that is currently indicated or displayed by the

measuring instrument.

dgt.

(resolution)

Signifies the smallest display unit on a digital measuring

instrument, i.e., the value displayed when the last digit on

the digital display is "1".

The following symbols are used in this Instruction Manual

to indicate the relative importance of cautions and

warnings.

Accuracy

The specifications in this manual include figures for

"measurement accuracy" when referring to digital

measuring instruments, and for "measurement tolerance"

when referring to analog instruments.

Page 8

iv

_____________________________________________________________________

Safety Notes

______________________________________________________________

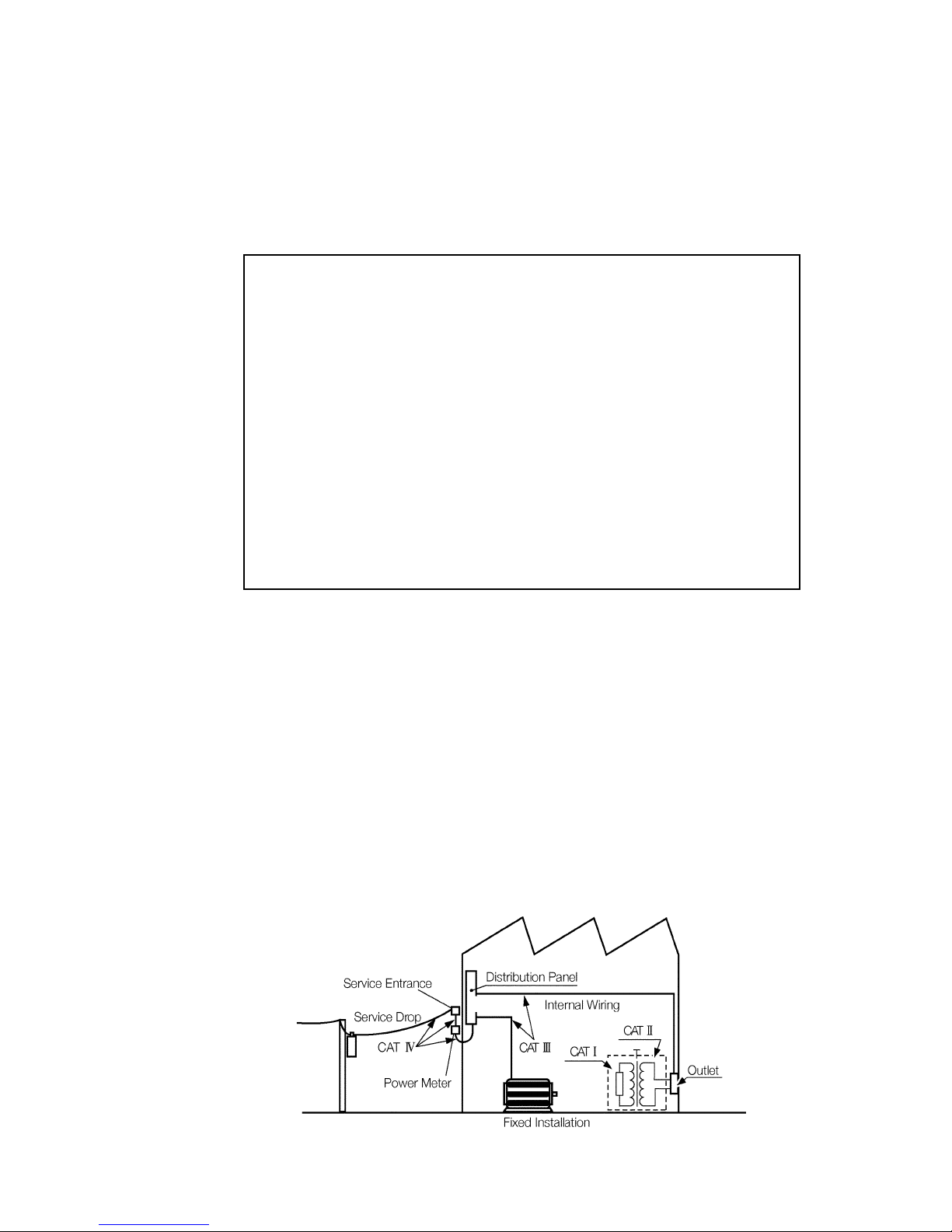

CAT I

Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar

device.

CAT II

Primary electrical circuits in equipment connected

to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT III

Primary electrical circuits of heavy equipment

(fixed installations) connected directly to the

distribution panel, and feeders from the distribution

panel to outlets.

CAT IV

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Measurement categories (Overvoltage categories)

To ensure safe operation of measurement product, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT I to CAT IV, and called

measurement categories. These are defined as follows.

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III environments can

endure greater momentary energy than a device designed for

CAT II. Using a measurement product in an environment

designated with a higher-numbered category than that for

which the product is rated could result in a severe accident,

and must be carefully avoided.

Never use a CAT I measuring product in CAT II, III, or IV

environments. The measurement categories comply with the

Overvoltage Categories of the IEC60664 Standards.

Page 9

v

_____________________________________________________________________

Notes on Use

______________________________________________________________

DANGE

R

To avoid short circuit and the risk of accidental injury

or death, working voltage must be under AC300 Vrms

(CAT III) for 9650 and under AC600 Vrms (CAT III) for

9651.

The maximum rated voltage to earth of clamp sensor

must be under AC300 Vrms for 9650 and under AC600

Vrms for 9651.

Do not measure voltage in excess of these limitations,

as doing so may damage the unit or cause an accident

that might result in injury or death.

Clamp sensor should only be connected to the

secondary side of a breaker, so the breaker can prevent

an accident if a short circuit occurs. Connections

should never be made to the primary side of a breaker,

because unrestricted current flow could cause a

serious accident if a short circuit occurs.

WARNING

To avoid electric shock, do not allow the product to get

wet, and do not use it when your hands are wet.

CAUTION

To avoid electric shock when measuring live lines, wear

appropriate protective gear, such as insulated rubber

gloves, boots and a safety helmet.

This product is designed for indoor use, and operates reliably from

0to50

.

Do not store or use the product where it could be exposed to

direct sunlight, high temperature or humidity, or condensation.

Under such conditions, the product may be damaged and

insulation may deteriorate so that it no longer meets

specifications.

Notes on Use

In order to ensure safe operation and to obtain maximum

performance from the unit, observe the cautions listed

below.

Page 10

vi

_____________________________________________________________________

Measurement Flow Chart and Reference Guide

______________________________________________________________

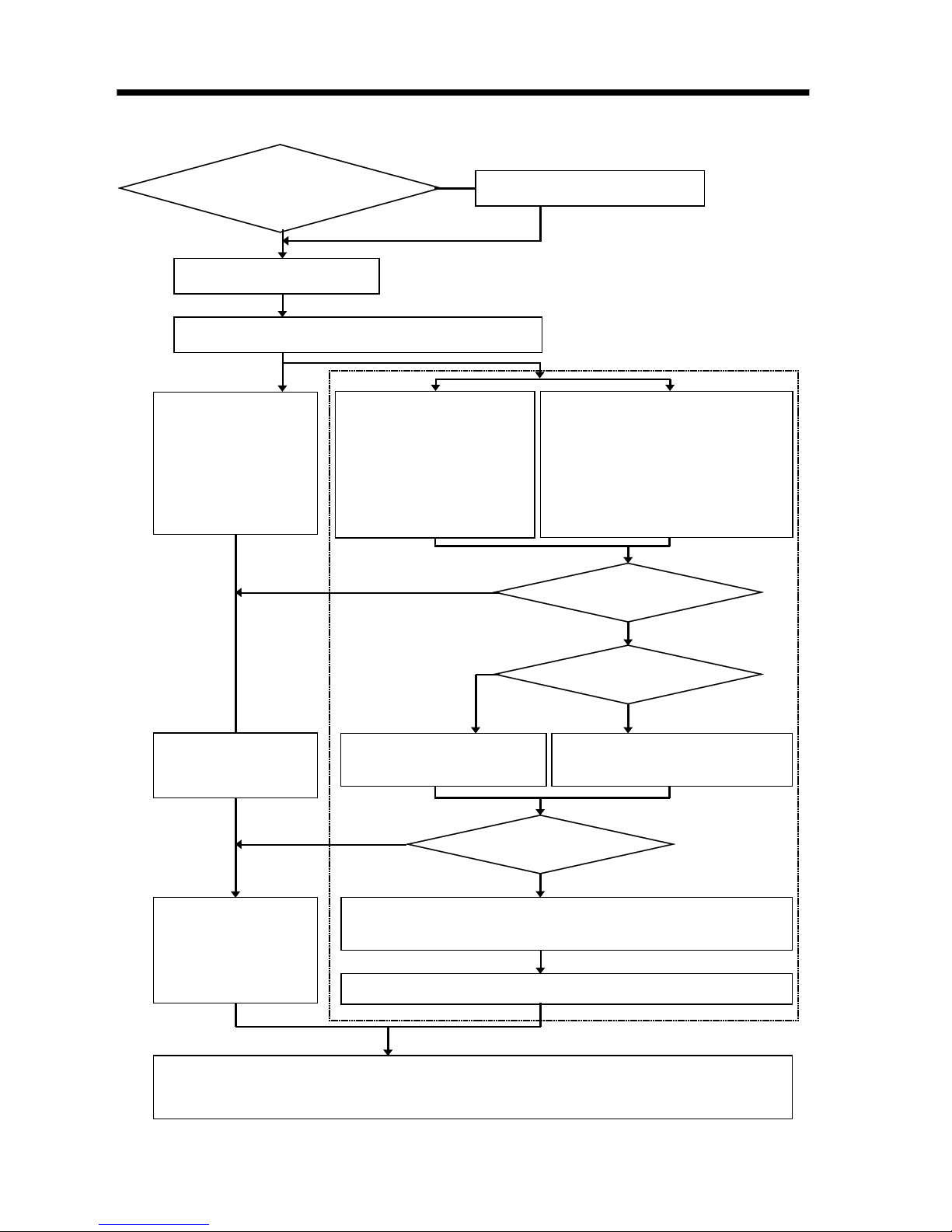

Is there sufficient

battery charge remaining

to operate 3

636-20?

Replace batteries

Setting current time

Setting 3636-20

stand-alone

・Interval

・Number of

channels

・Recording mode

・Range

Setting 3636-20 with

COMMUNICATION

BASE

・Interval

・Current time

・Start control

・Recording method

Setting 3636-20 with

COMMUNICATION BASE and PC

・Interval ・Current time

・Start control ・Range

・Recording method

・Number of channels

・Recording mode

・Alarm ・Comment

See 2.1.

See 3.2.

Connecting clamp on sensor/connection cables

See 2.4.

Press REC/STOP

button to start

measurement.

Settingstart control

Start control options

No

Yes

Quick start

Prescheduled start

Starts measurement

immediately.

Starts measurement at

prescheduled time.

Setting

recordingmethod

Endless

One time

When recording data

reaches 32000

(

16000 in 2 channels

),

measurement stops.

When recording data exceeds 32000(

16000 in 2 channels

), it

overwrites previously recorded data.

Press REC/STOP button to stop measurement.

After measurement is complete, disconnect sensor cables.

Use COMMUNICATION BASE to send measurement data to personal computer.

(See COMMUNICATION BASE instruction manual.)

See 3.2.

Set current time when using 3636-20 for the

first time or replacingbatteries. See 2.3.

Measurement Flow Chart and Reference Guide

Page 11

1

_____________________________________________________________________

Product Outline

______________________________________________________________

3636-20 CLAMP LOGGER cannot be set with

3910-20 COMMUNICATION BASE.

Chapter 1

Product Outline

3636-20 CLAMP LOGGER with clamp on sensor records 1

or 2 channels of data at current value.

9650 CLAMP ON SENSOR enables effective value

measurement with intervals and recording up to 100 Arms

AC current and when using 9651 CLAMP ON SENSOR,

up to 500 Arms.

With two optional recording modes; recording instantaneous

value and recording average value, extended duration of

current recording is possible with battery operation.

Data is saved in nonvolatile memory when batteries are

weak or removed for replacement.

Page 12

2

_____________________________________________________________________

Product Outline

______________________________________________________________

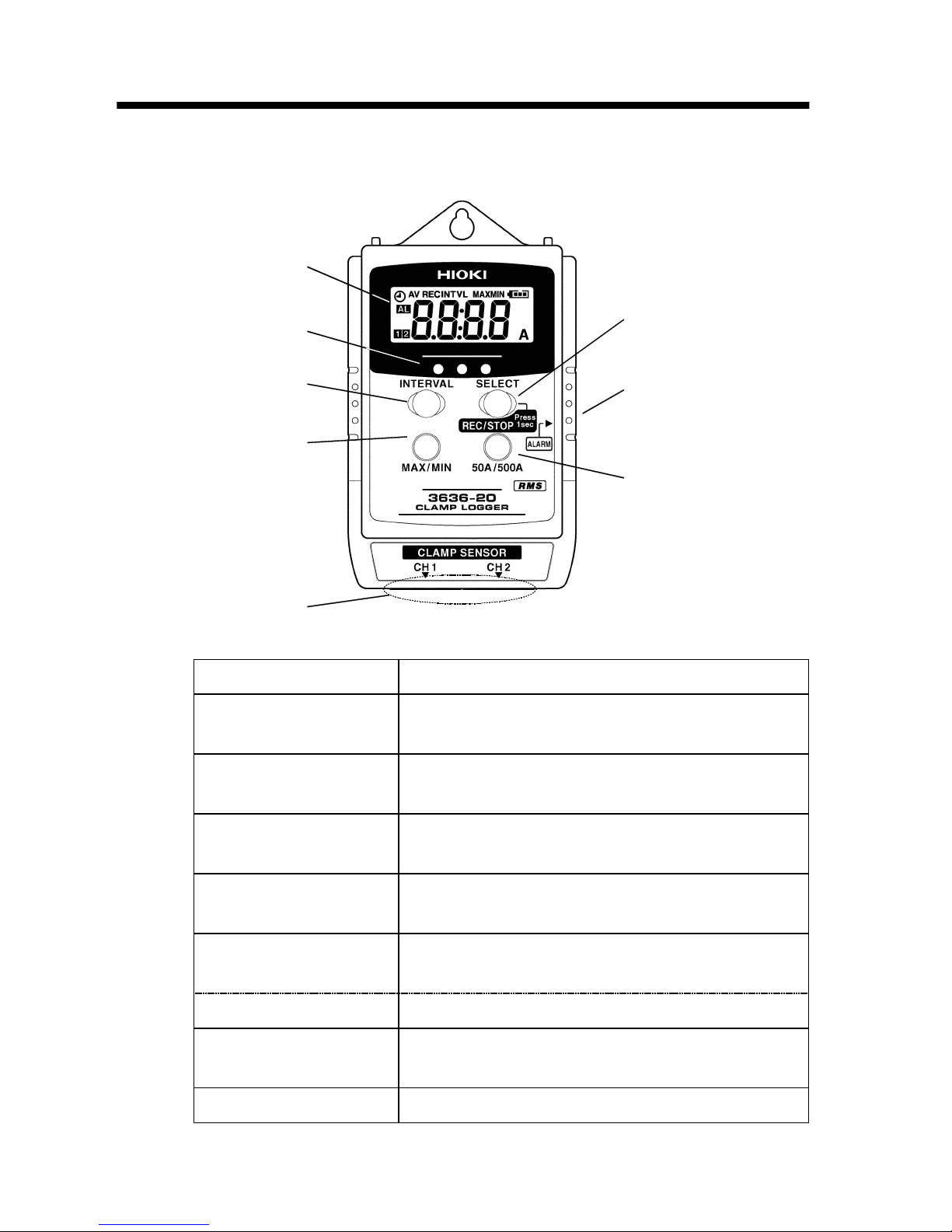

1

2

3

4

6

7

5

8

1. LCD Displays measurement value and settings.

2. Optical data transfer

ports

Enables optical data transfer to

COMMUNICATION BASE.

3. INTERVAL button Calls up interval setting display to set interval,

recording mode and measurement channels.

4. MAX./MIN. button Displays maximum value or minimum value of

recorded data.

5. Clamp connection

terminal

Connects 9650 or 9651 CLAMP ON SENSOR.

6. REC/STOP button Pressing more than 1 second initiates or stops

recording.

(SELECT) button Interval is selected in interval setting display.

7. Alarm output

terminal

Connects 9632 CONNECTION CABLE and

outputs alarm signal (open drain output).

8. 50A/500A button Changes measurement range from 50A/500A.

1.1 Name and Functions of Parts

Page 13

3

_____________________________________________________________________

Product Outline

______________________________________________________________

INTVL Maximum Recording Time

1s 4h26min40s

2s 8h53min20s

5s 22 h 13 min 20 s

10 s 1 day 20 h 26 min 40 s

15 s 2 day 18 h 40 min

20 s 3 day 16 h 53 min 20 s

30 s 5 day 13 h 20 min

1min 11 day 2 h 40 min

2min 22 day 5 h 20 min

5min 55 day 13 h 20 min

10 min 111 day 2 h 40 min

15 min 166 day 16 h

20 min 222 day 5 h 20 min

30 min 333 day 8 h

60 min 666 day 6 h

1.2 Interval and Maximum Recording Time

The table below shows the record interval and the

maximum recording time (when instantaneous values are

recorded with the power save function enabled).

The maximum recording time varies depending on the

remaining power level of the battery.

When average values are recorded with the power save

function enabled, the recording time will be approximately

one month.

When 3636-20 CLAMP LOGGER is used in 2 channels,

maximum recordable data is 16000 per unit.

Page 14

4

_____________________________________________________________________

Product Outline

______________________________________________________________

INTVL Maximum Recording Time

1s 8h53min20s

2s 17 h 46 min 40 s

5s 1 day 20 h 26 min 40 s

10 s 3 day 16 h 26 min 40 s

15 s 5 day 13 h 20 min

20 s 7day9h46min40s

30 s 11 day 2 h 40 min

1min 22 day 5 h 20 min

2min 44 day 10 h 40 min

5min 111 day 2 h 20 min

10 min 222 day 5 h 20 min

15 min 333 day 8 h

20 min 444 day 10 h 40 min

30 min 666 day 6 h

60 min 1333 day 8 h

When 3636-20 CLAMP LOGGER is used in 1 channel,

maximum recordable data is 32000 per unit.

Page 15

5

_____________________________________________________________________

Product Outline

______________________________________________________________

Maximum 400 points partitioned

at complete cycle

250µs

Interval

Records instantaneous value

Interval

One second interval

Recordingstarts Records averagevalue

1.3 Measurement Value Recording Modes

Effective value calculation

To calculate effective value, measurement signal is sampled

every 250 µs and operation is carried out from data with

maximum 400 points to seek effective value.

Recording instantaneous value

To record instantaneous value, calculate effective value only

oncepersetintervalandrecordinmemory.

Recording average value

To record average value, calculate effective value only once

per second and record average value of all data within

interval in memory.

After recording starts, average value within interval is

recorded, so the initial data is not recorded immediately

after recording starts but is recorded from the following

interval.

Page 16

6

_____________________________________________________________________

Product Outline

______________________________________________________________

Page 17

7

_____________________________________________________________________

Set Up

______________________________________________________________

WARNING

To avoid electric shoc

k when replacing the batteries,

first disconnect the connection cables from the object

to be measured.

During battery replacement, use caution not to put any

foreign materials such as a metal object into the unit to

avoid damage to the unit.

After replacing the batteries, replace the cover and

screws before using the product.

Do not mix old and new batteries, or different types of

batteries. Also, be careful to observe battery polarity

during installation. Otherwise, poor performance or

damage from battery leakage could result.

Handle and dispose of batteries in accordance with

local regulations.

Chapter 2

Set Up

2.1 Installing or Replacing the Batteries

Page 18

8

_____________________________________________________________________

Set Up

______________________________________________________________

Installing new batteries ensures about 1 year of

instantaneous value recording (when interval is set at more

than 1 minute) and about 1 month of average value

recording. (reference value with power save setting set to

valid and at 20

)

Remaining battery power indicator (

)indicates

remaining battery life reducing incrementally from right.

Empty battery power indicator (

) indicates time to

replace batteries.

(1) Remove back cover screw to remove cover. Verify

polarity and install four new LR03 alkaline batteries.

(2) Fit cover properly and tighten screw.

Page 19

9

_____________________________________________________________________

Set Up

______________________________________________________________

Sleeping......

See COMMUNICATION BASE instruction

manual to connect logger and to install

application software. To use application

software, see operation guide.

2.2 Power Save Function

Display window is automatically turned off in

approximately 15 seconds after last key entry. (Sleep)

However, while recording, REC/AV/ / / AL mark

shows each conditions.

Press any button to turn display on to display measurement

value or to set settings.

Note when interval setting display is on, sleep does not

engage with no button press.

Initially, power save function is on. To turn off power save

function, follow the instructions below.

When power save function is off, maximum continuous

duration is approximately 15 days.

(1) Connect logger, COMMUNICATION BASE and

personal computer.

(2) Start up application software packaged with

COMMUNICATION BASE.

(3) Go to Communications on the menu bar and select

Power Save Options. Choose Off to turn off power save

function.

Page 20

10

_____________________________________________________________________

Set Up

______________________________________________________________

2.3 Setting Current Time

When replacing 3636-20 CLAMP LOGGER batteries or

using 3636-20 stand-alone (with manual operation) for the

first time, connect with COMMUNICATION BASE and set

current time.

See how to set current time in COMMUNICATION BASE

instruction manual.

Page 21

11

_____________________________________________________________________

Set Up

______________________________________________________________

WARNING

Maximum input current for 9650 is 100 Arms, 9651 is

500 Arms. Do not exceed the continuous maximum

input current.

To avoid short circuit and the risk of accidental injury or

death, working voltage must be under AC300 Vrms (CAT

III) for 9650 and under AC600 Vrms (CAT III) for 9651.

When the clamp sensor is opened, do not allow the

metal part of the clamp to touch any exposed metal, or

to short between two lines, and do not use over bare

conductors.

When connecting with 9650 CLAMP ON SENSOR and

3636-20 measurement range is set at 50 A, do not

exceed 50 Arms.

To avoid damaging the unit, do not use any other

sensors except 9650 or 9651 CLAMP ON SENSOR as

sensor connector.

9650 or 9651

CLAMP ON SENSOR

9650 9651

Carefully read 9650 and 9651 CLAMP ON

SENSOR instruction manuals before use.

Improper measurement method may result in

accidental injury, death or damage in the unit.

2.4 Connecting Sensor/Cable

Connecting clamp on sensor

3636-20 CLAMP LOGGER enables 2 channels of data

measurement when connected with 9650 or 9651 CLAMP

ON SENSOR.

When measuring, affix clamp to one conductor only.

Page 22

12

_____________________________________________________________________

Set Up

______________________________________________________________

9632 CONNECTION CABLE

GND

non connection

White: Signal

Black: GND

Signal

Cord length: 1000 mm

Connecting 9632 CONNECTION CABLE

Connecting 9632 CONNECTION CABLE to alarm output

terminal.When connecting connection cable, securely insert

connection cable to unit as designated by triangle mark ▲

on connection terminal.

Improper connection results in failure to output accurate

signal.

9632 CONNECTION CABLE

Page 23

13

_____________________________________________________________________

Settings

______________________________________________________________

3636-20

3636-20+

COMMUNICATION

BASE

3636-20+

COMMUNICATION

BASE+PC

1. Start recording Vaild Vaild Vaild

2. Stop recording Vaild --- ---

3. Interval setting Vaild Vaild Vaild

4. Current time setting --- Vaild Vaild

5. Start control --- Vaild Vaild

6. Recording method setting --- Vaild Vaild

7. Range setting Vaild --- Vaild

8. Setting number of channels Vaild --- Vaild

9. Recording mode setting Vaild --- Vaild

10. Alarm setting --- --- Vaild

11. Comments --- --- Vaild

12. Minimum/

Maximum value display

Vaild --- ---

・

When PC, COMMUNICATION BASE and

3636-20 are connected, separate range can

be set in each channel. Once settings are set,

range setting with manual operation sets

common range.

・

Alarm and comment setting are available

when personal computer is connected to both

logger and COMMUNICATION BASE.

Chapter 3

Settings

3.1 Setting Items

Logger stand-alone manual settings and settings in

combination with COMMUNICATION BASE with

measurement conditions stored in memory loaded from

personal computer.

Page 24

14

_____________________________________________________________________

Settings

______________________________________________________________

1. Start recording

Start manual recording by pressing logger REC/STOP

button for 1 second or initiate by prescheduled start set

using COMMUNICATION BASE.

When time scheduled start is engaged, clock icon appears

in display. When batteries are weak, recording does not

start. During recording, weak battery interrupts recording.

2. Stop recording

Stop recording by pressing logger REC/STOP button for 1

second. Or recording stops automatically when data is full

when set to recording method: one time.

3. Interval setting

Set interval with logger alone or using COMMUNICATION

BASE. (1/2/5/10/15/20/30 s, 1/2/5/10/15/20/30/60 min)

4. Current time setting

To set current time, see COMMUNICATION BASE

instruction manual.

5. Start control

Set specific recording date and time using

COMMUNICATION BASE to engage time scheduled start.

When time scheduled start is engaged, clock icon appears

in display.

6. Recording method setting

Set recording method using COMMUNICATION BASE.

Choose either one time or endless recording method.

Default setting is one time.

One time: Ends recording when data reaches 32000

(2 ch: 16000).

Endless : Overwrites previously recorded data when data

exceeds 32000 (2 ch: 16000).

Page 25

15

_____________________________________________________________________

Settings

______________________________________________________________

When using 9650, set at 50 A or 500 A.

When 3636-20 measurement range is set at 50

A, do not exceed 50 Arms.

When using 9651, set at 500 A.

When PC, COMMUNICATION BASE and 363620 are connected, separate range can be set in

each channel. Once settings are set, range

setting with manual operation sets common

range.

7. Range setting

With 3636-20 stand-alone, or connected with

COMMUNICATION BASE and PC, range setting is

available.

Two measurement range options are 50.00 A range and

500.0 A.

Select and set in accordance with clamp on sensor. When

manually operated, common settings apply to channel 1 and

channel 2.

8. Setting number of channels

With 3636-20 stand-alone, or connected with

COMMUNICATION BASE and PC, setting is available.

Select input for channel 1 or channel 2.

At factory shipment settings, both channel 1 and channel 2

are valid.

Page 26

16

_____________________________________________________________________

Settings

______________________________________________________________

Average value recording mode records average

value within interval, so the initial data is not

recorded immediately after recording starts but

is recorded from the following interval.

For example, when measurement started at

12:00 at 1 minute intervals, the first data is data

recorded when 1 minute has passed at 12:01.

Alarm signal output terminal is an open drain

output. During signal output, signal side and

GND side are internally grounded and any other

time, it remains open. When external power

supply is supplied, alarm signal can control

relay or sequencer. Maximum rate: 30 V, 200

mA (allowable loss 200 mW)

9. Recording mode setting

With 3636-20 stand-alone, or connected together with

COMMUNICATION BASE and PC, setting is available.

Two recording mode options are instantaneous value

recording and average value recording (AV displayed).

At factory shipment setting, average value recording is

selected.

10. Alarm setting

Alarm setting is available when 3636-20,

COMMUNICATION BASE and personal computer are

connected.

Designate upper limit and lower limit value of measurement

value with personal computer to output alarm signal when

measurement value goes outside of set range. Two channels

pass individual judgment.

During signal output, AL appears on the display.

Page 27

17

_____________________________________________________________________

Settings

______________________________________________________________

・

Maximum value and minimum value are from

data recorded in memory and may vary from

each displayed value per second.

・

When recording method is set as endless,

maximum value and minimum value from the

beginning of recording are displayed. When

old data is overwritten after extended

recording, data currently recorded may differ

from displayed maximum value and minimum

value.

11. Comments

Set comments entered by personal computer to logger using

COMMUNICATION BASE. When sorting collected

recording data, comments are helpful.

Comment setting is available when personal computer is

connected to both logger and COMMUNICATION BASE.

12. Maximum/Minimum value display

3636-20 stand-alone enables maximum/minimum value

display settings. Maximum value or minimum value of

recorded data is alternately displayed.

Page 28

18

_____________________________________________________________________

Settings

______________________________________________________________

3.2 Manual Setting

3636-20 CLAMP LOGGER stand-alone manual operation

settings are shown below.

(1) Interval setting

Press INTERVAL button to switch measurement value

display to interval setting display. (INTVL appears.)

Press SELECT button to designate interval.

Press INTERVAL button to complete setting.

(2) Setting number of channels

Press INTERVAL button to display interval setting

display.

Each 50A/500A button press selects channel to be used.

When channel 1 is selected, only display "

"isturned

on and when channel 2 is selected, display "

"is

turned on. When both channel 1 and channel 2 are

selected, display "

" is turned on.

(3) Setting recording mode

Press INTERVAL button to display interval setting

display.

Each MAX/MIN button press alternates and selects

instantaneous value recording and average recording

(AV displayed).

To set instantaneous value recording and average

recording, see 1.3 Measurement Value Recording

Modes.

Page 29

19

_____________________________________________________________________

Settings

______________________________________________________________

50 A range 500 A range

(4) Setting range

Press 50A/500A button on monitor screen to select 50A

or 500A.

When measurement range is reselected, decimal point

moves its position.

To set 3636-20 measurement range, select 50 A or

500A with 9650 and 500A with 9651.

When manual operation is conducted, common range

settings apply to both channel 1 and channel 2.

(5) Starting and ending recording

Press REC/STOP button for 1 second to clear last

recorded data and start recording. (REC appears.)

Press REC/STOP button for 1 second to stop recording.

When memory is full, recording automatically stops

when recording method: one time is selected.

When batteries are weak, recording does not start.

During recording, weak batteries interrupt recording.

(6) Maximum/Minimum value display

Press [MAX/MIN] button to display maximum or

minimum value from recorded data.

Each button press alternates display.

Page 30

20

_____________________________________________________________________

Settings

______________________________________________________________

・

Previously recorded logger data is erased

when recording is resumed. Be sure to load

data to be saved to COMMUNICATION BASE

or to personal computer before recording.

・

At any other time even when interval setting

display is not shown, except during recording

and waiting for recording, communication with

COMMUNICATION BASE is available.

However communication is disabled when

logger is set to sleep.

3.3 Setting by COMMUNICATION BASE

(1) Press logger INTERVAL button lightly to display LCD.

(2) When logger LCD shows REC mark or clock icon,

press REC/STOP button for more than 1 second to stop

recording.

During recording or waiting time before recording start

time, data transfer cannot be established with

COMMUNICATION BASE.

(3) Press logger INTERVAL button to display interval

setting display. (INTVL appears.)

(4) Connect COMMUNICATION BASE with logger.

(5) Press COMMUNICATION BASE SEND button for

more than 1 second to send data settings to logger.

Page 31

21

_____________________________________________________________________

Settings

______________________________________________________________

・

Comment, recording mode, measurement channel,

range and alarm setting are only available in 3636

setting items. Personal computer,

COMMUNICATION BASE and 3636-20 must be

connected during setting.

・

Common settings are available to be set in '3911,

3912' settings.

3636-20 settings in application software

COMMUNICATION UTILITY packaged with

COMMUNICATION BASE are as follows.

Go to 'Communication' on the menu bar in

COMMUNICATION UTILITY and select 'Set measurement

condition'. When measurement condition setting window is

open, select '3636' setting items to set settings.

Page 32

22

_____________________________________________________________________

Settings

______________________________________________________________

Page 33

23

_____________________________________________________________________

Specifications

______________________________________________________________

Sensor types

9650, 9651 CLAMP ON SENSOR

Input AC current

Maximum input

current

AC0.6 Arms, 1 A peak value

Number of input 2 channels

(1 or 2 channels settable from personal computer)

Measurement

range

0to500A

Range structure 50.00 A, 500.0 A

Measurement

method

True effective value calculation

Measurement

accuracy

Unit : 1% rdg. 5 dgt. (50/60 Hz)

Unit + Sensor :

2.5% rdg. 8 dgt. (50/60 Hz)

When 9650 is in use, range at 50 A, 500 A.

When 9651 is in use, range at 500 A.

Operating temperature and

humidity for guaranteed

accuracy

Guaranteed

accuracy period

23 5 (73 9 ), 80%RH or less

1 year

Interval for

effective value

calculation

1 time per second

LCD display Measurement value, Interval, Battery status

(remaining battery power indicator: 4 phases)

Unit (A), recording (REC), prescheduled(

),

average value recording (AV), maximum value

(MAX), minimum value (MIN), alarm (AL)

Recording mode Recording instantaneous value

Recording average value (records average value

within interval)

Interval 1/2/5/10/15/20/30 s, 1/2/5/10/15/20/30/60 min

Recording

capacity

32,000 data X 1 channel

16,000 data X 2 channels

Recording start Manual start, Prescheduled start

Recording stop Manual stop, Memory full

Recording

method

One time, Endless

Chapter 4

Specifications

Page 34

24

_____________________________________________________________________

Specifications

______________________________________________________________

Displaying

Max/Min value

Displays maximum value and minimum value.

Alarm output Turns ON (open drain output) when value goes

outside previously set upper limit or lower limit.

Data backup Available

(Data not erased by weak batteries or battery

replacement)

Interface Infrared optical data transfer

Power supply LR03 alkaline battery X 4 (1.5 VDC X 4)

Maximum rated

power

0.1 VA

Battery life About one year

(temperature at 20

, power save function: valid,

when instantaneous value recording at 1 minute

intervals is selected)

About one month

(temperature at 20

, power save function: valid,

when average value recording is selected)

Dimensions Approx. 57W X 86H X 30D mm

(2.24"W X 3.39"H X 1.18"D) (excluding projections)

Mass Approx. 130 g (4.6 oz) (including batteries)

Location for use Indoors, altitude up to 2000 m (6562 feet)

Operate

temperature and

humidity range

0to50 (32 to 122 ), 80% RH or less

(no condensation)

Storage

temperature and

humidity range

-10 to 60 (14 to 140 ), 80% RH or less

(no condensation)

Accessories LR03 alkaline battery X 4

9632 CONNECTION CABLE

Instruction Manual

Options 3911-20 COMMUNICATION BASE

3912-20 COMMUNICATION BASE

9650 CLAMP ON SENSOR

9651 CLAMP ON SENSOR

Standards

Applying

EMC

EN61326:1997+A1:1998+A2:2001+A3:2003

Safety

EN 61010-1:2001 Pollution Degree 2

Page 35

25

_____________________________________________________________________

Maintenance and Service

______________________________________________________________

Chapter 5

Maintenance and Service

Cleaning

To clean the product, wipe it gently with a soft cloth

moistened with water or mild detergent. Never use solvents

such as benzene, alcohol, acetone, ether, ketones, thinners

or gasoline, as they can deform and discolor the case.

Wipe the LCD gently with a soft, dry cloth.

Service

If the product seems to be malfunctioning, confirm that the

batteries are not discharged, and that the probes are not

open circuited before contacting your dealer or Hioki

representative.

Page 36

26

_____________________________________________________________________

Maintenance and Service

______________________________________________________________

--MEMO--

Page 37

Page 38

Page 39

HIOKI 3636-20 CLAMP LOGGER

Instruction Manual

Publication date: September 2006 Revised edition 4

Edited and published by HIOKI E.E. CORPORATION

Technical Support Section

All inquiries to International Sales and Marketing Department

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3636A981-04

All reasonable care has been taken in the production of this manual,

but if you find any points which are unclear or in error, please

contact your supplier or the International Sales and Marketing

Department at HIOKI headquarters.

In the interests of product development, the contents of this manual

are subject to revision without prior notice.

Unauthorized reproduction or copying of this manual is prohibited.

Page 40

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp / URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3636A981-04 06-09H

Printed on recycled paper

Loading...

Loading...