Page 1

INSTRUCTION MANUAL

For...は専用機種。複数の場合は「/」で区切る。

不要の場合はとる。

形名を入力。 複数の場合は「/」で区切る。

3550

品名を入力。

BATTERY HiTESTER

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety ii

Precautions v

Organization of this Manual viii

Chapter 1 Overview 1

Chapter 2 Names and Functions of Parts 3

Chapter 3 Specifications 9

3.1 General Specification 9

3.2 Measurement Range

3.2.1 Maximum Input Voltage 14

3.2.2 Floating Voltage

3.2.3 Dielectric Strength

13

15

15

Chapter 4 Standard Measurement 17

4.1 Preparing for Measurement 17

4.2 Measurement

19

Chapter 5 Advanced Measurement Functions 23

5.1 Comparator Function 23

5.1.1 What is the Comparator Function? 23

5.1.2 Comparator Settings

5.1.3 Comparator Decision Result Table

5.1.4 Switching the Comparator On and Off

5.1.5 Changing the Comparator Number

24

29

30

31

Page 4

5.2 Measurement Value Memory Function 32

5.2.1 Memory 32

5.2.2 Clear

5.2.3 Readout

5.2.4 Printing

34

35

36

5.3 Beeper On/Off Function 38

5.4 Hold Function

5.5 Moving Average Function

5.6 Zero Adjust Function

5.7 Battery Low Warning

5.8 Auto Power Off

5.9 AC Four-Terminal Method

5.10 Internal Resistance of Lead-Acid Batteries

38

39

41

42

43

45

47

Chapter 6 Maintenance 49

6.1 Troubleshooting 49

6.2 Message Reference

6.3 Cleaning

51

51

Page 5

___________________________________________________________________

Introduction

Thank you for purchasing the HIOKI "3550 BATTERY

HiTESTER." To obtain maximum performance from the

product, please read this manual first, and keep it handy for

future reference.

Inspection

When you receive the product, inspect it carefully to ensure

that no damage occurred during shipping. In particular,

check the accessories, panel switches, and connectors. If

damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Accessories

9460 CLIP TYPE LEAD WITH TEMPERATURE SENSOR

9382 CARRYING CASE

Six LR6 alkaline batteries

Instruction Manual

Dust cover (for the printer interface)

i

Shipping

Use the original packing materials when reshipping the

product, if possible.

___________________________________________________________________

Inspection

Page 6

ii

y

___________________________________________________________________

Safet

DANGER

This product is designed to conform to IEC 61010

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling

during use could result in injury or death, as well as

damage to the product. Be certain that you

understand the instructions and precautions in the

manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from

product defects.

Safety symbols

This manual contains information and warnings essential for

safe operation of the product and for maintaining it in safe

operating condition. Before using the product, be sure to

carefully read the following safety notes.

The symbol printed on the product indicates

that the user should refer to a corresponding

topic in the manual (marked with the

before using the relevant function.

In the manual, the symbol indicates

particularly important information that the user

should read before using the product.

symbol)

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

___________________________________________________________________

Safety

Page 7

___________________________________________________________________

The following symbols in this manual indicate the relative

importance of cautions and warnings.

iii

DANGER

WARNING

CAUTION

NOTE

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

product.

Advisory items related to performance or correct

operation of the product.

___________________________________________________________________

Safety

Page 8

iv

___________________________________________________________________

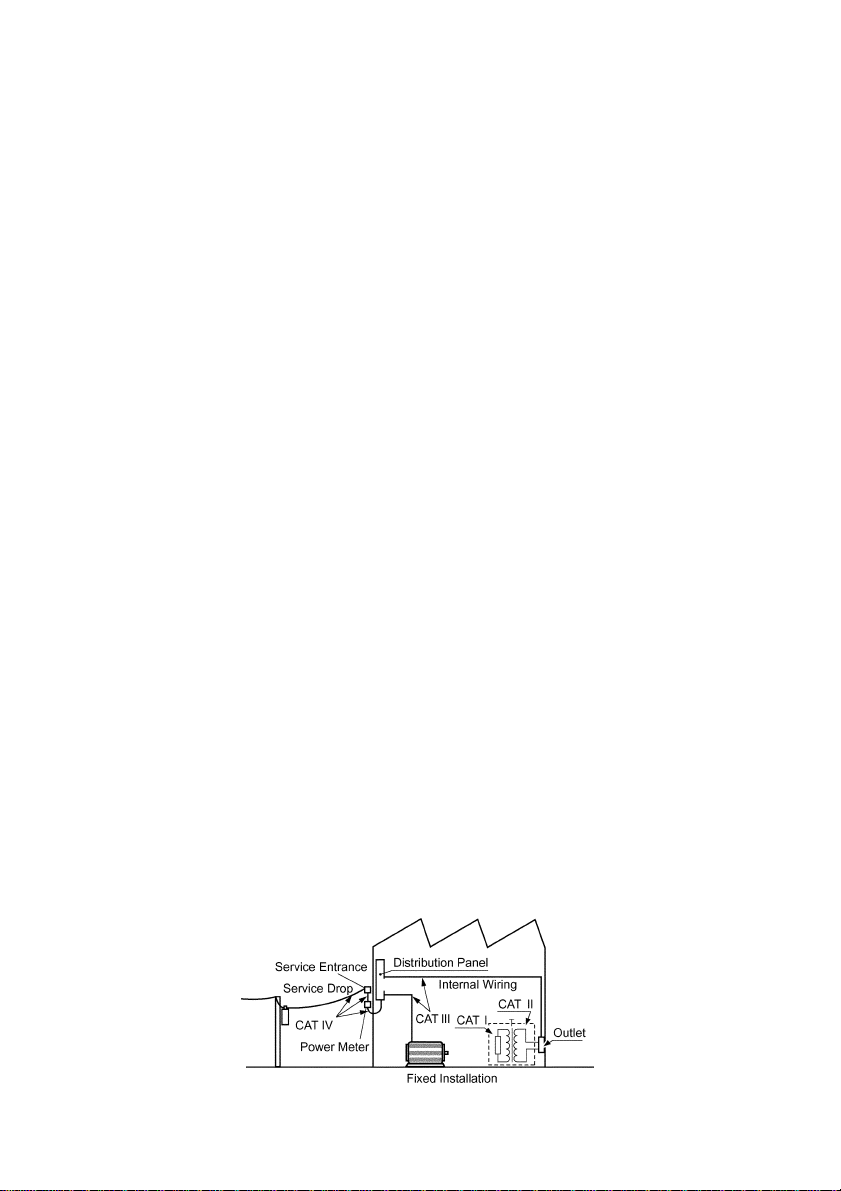

Measurement categories (Overvoltage categories)

This product conforms to the safety requirements for CAT I

measurement products.

To ensure safe operation of measurement products, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT I to CAT IV, and called measurement

categories. These are defined as follows.

CAT I : Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar device.

CAT II : Primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT III : Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets.

CAT IV : The circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent

protection device (distribution panel).

Higher-numbered categories correspond to electrical environments

with greater momentary energy, so a measurement product

designed for CAT III environments can endure greater momentary

energy than one designed for CAT II. Using a measurement

product in an environment designated with a higher-numbered

category than that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Never use a CAT I measuring product in CAT II, III, or IV

environments.

The measurement categories comply with the Overvoltage

Categories of the IEC60664 Standards.

___________________________________________________________________

Safety

Page 9

___________________________________________________________________

Precautions

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

v

DANGER

WARNING

The floating voltage between input terminals and

ground is 450V DC/AC. Attempting to measure

voltages exceeding 450V with respect to ground

could damage the product and result in personal

injury.

When voltages higher than 30 Vrms, 42.4 Vpeak or

battery circuits with more than 60 VDC are to be

measured, be sure to establish the floating state

first. Carrying out such measurements in the

grounded state involves the risk of electric shock.

When measuring batteries, always ensure sufficient

ventilation. Sometimes sparks may occur when the

test leads are connected to batteries, which can

ignite any accumulated inflammable gases such as

hydrogen.

To avoid electric shock accidents, when measuring

batteries being charged wear proper protective gear

such as rubber gloves.

Do not allow the product to get wet, and do not take

measurements with wet hands. This may cause an

electric shock.

Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged or cause an explosion.

___________________________________________________________________

Precautions

Page 10

vi

___________________________________________________________________

WARNING

Before using the product, make sure that the

insulation on the leads is undamaged and that no

bare conductors are improperly exposed. Using the

product in such conditions could cause an electric

shock, so contact your dealer or Hioki representative

for replacements. (Model 9460)

Be sure to connect the SOURCE and SENSE

terminals (banana plugs), and TEMP SENSOR

terminal (mini-plug) correctly. See Section 4.2,

"Measurement" for details of the connections.

To avoid injury or damage to the product, do not

attempt to measure AC voltage, or DC voltage

exceeding 50 V.

50 VDC max.

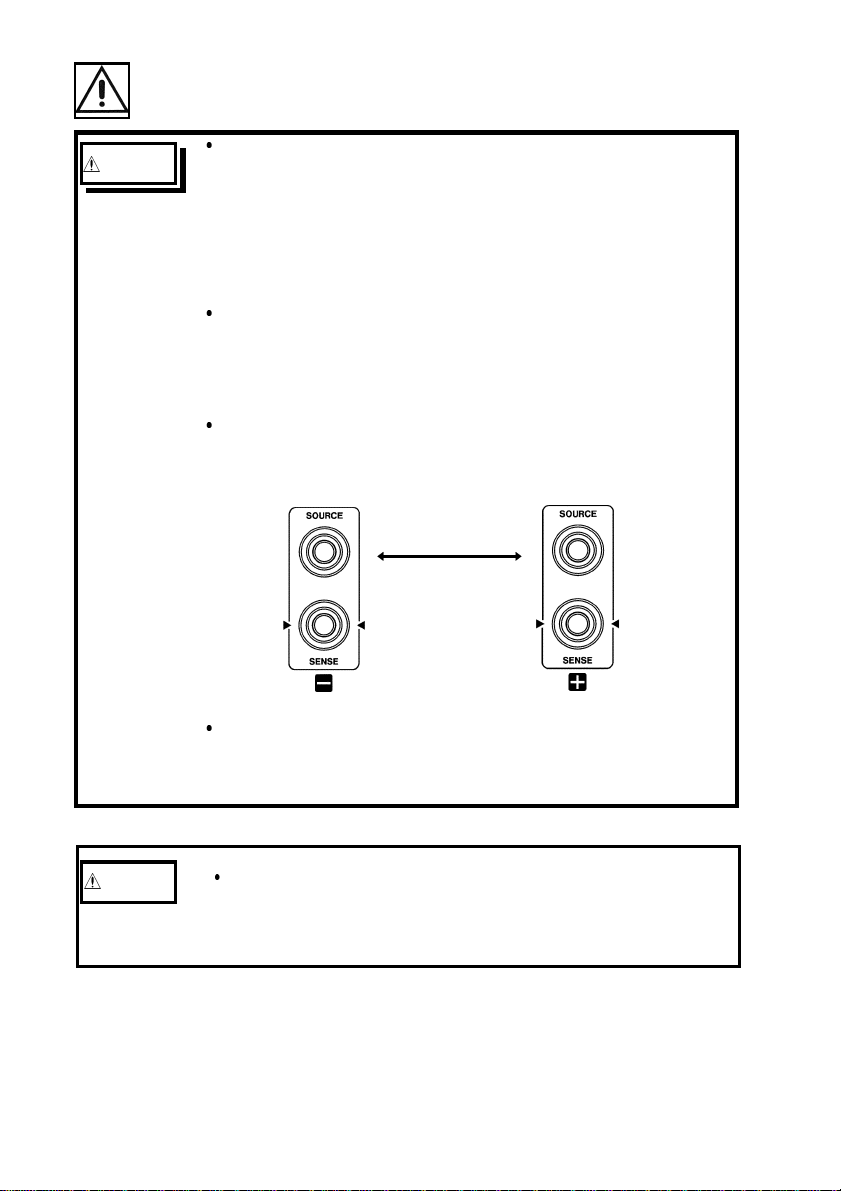

Do not apply a voltage between the SOURCE(+) and

SENSE(+) or SOURCE(-) and SENSE(-) terminals.

This could result in damage to the unit.

CAUTION

This product is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a wet or

dusty environment.

___________________________________________________________________

Precautions

Page 11

___________________________________________________________________

vii

CAUTION

NOTE

Do not store or use the product where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions, the

product may be damaged and insulation may

deteriorate so that it no longer meets specifications.

Do not use the product near a device that generates a

strong electromagnetic field or electrostatic charge, as

these may cause erroneous measurements.

Use the specified 9460 CLIP TYPE LEAD WITH

TEMPERATURESENSORwhenthistesterisused.

Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and highcurrent conductors, or in the presence of strong

electromagnetic fields such as near radio transmitters.

Service

Before using the product the first time, verify that it

operates normally to ensure that the no damage occurred

during storage or shipping. If you find any damage,

contact your dealer or Hioki representative.

When sending the product for repair, remove the batteries

and pack carefully to prevent damage in transit. Include

cushioning material so the product cannot move within the

package. Be sure to include details of the problem. Hioki

cannot be responsible for damage that occurs during

shipment.

___________________________________________________________________

Precautions

Page 12

viii

___________________________________________________________________

Organization of this Manual

This manual consists of the following chapters.

"Introduction", "Inspection", "Safety", "Precautions" include

some important notes which you should read before using

the unit.

Chapter 1 Overview

describes an outline of the unit, and lists its features.

Chapter 2 Names and Functions of Parts

lists the names of the parts of the unit, and the functions of

all of the indications, terminals, and switches.

Chapter 3 Specifications

lists the specifications of the unit.

Chapter 4 Standard Measurement

describes the basic operation of the unit.

Chapter 5 Advanced Measurement Functions

describes miscellaneous functions.

Chapter 6 Maintenance

gives troubleshooting information.

___________________________________________________________________

Organization of this Manual

Page 13

___________________________________________________________________

Chapter 1

Overview

The 3550 is designed for measuring the internal resistance,

open-circuit voltage, and terminal temperature of secondary

batteries, including lead-acid batteries, nickel-cadmium

batteries, nickel-metal hydride batteries, and lithium-ion

batteries.

Features

Since it uses the AC four-terminal method to measure the

internal resistance, it provides accurate results with the lead

resistances and contact resistances eliminated.

It is possible to display the readings for the battery internal

resistance, voltage, and terminal temperature, without

changing functions. Moreover, a composite comparator

function, which can be set on resistance and voltage values,

enables reliable detection of battery deterioration.

The unit's memory function also allows a number of sets of

readings to be stored at a touch, and later output to a

printer.

These functions make this an ideal tool for checking

batteries which are under constant trickle charging and

cannot be disconnected.

1

NOTE

___________________________________________________________________

Measurements are taken by using noise reduction technology to

attenuate noise at frequencies other than the measurement

frequency (1 kHz). Incorrect measurements may result if a large

1-kHz noise component from the charger is present at the battery

terminals.

Chapter 1 Overview

Page 14

2

___________________________________________________________________

___________________________________________________________________

Chapter 1 Overview

Page 15

___________________________________________________________________

Chapter 2

Names and Functions of

Parts

This chapter explains the keys, input and output terminals,

display, LED indicators, and leads.

3

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 16

4

___________________________________________________________________

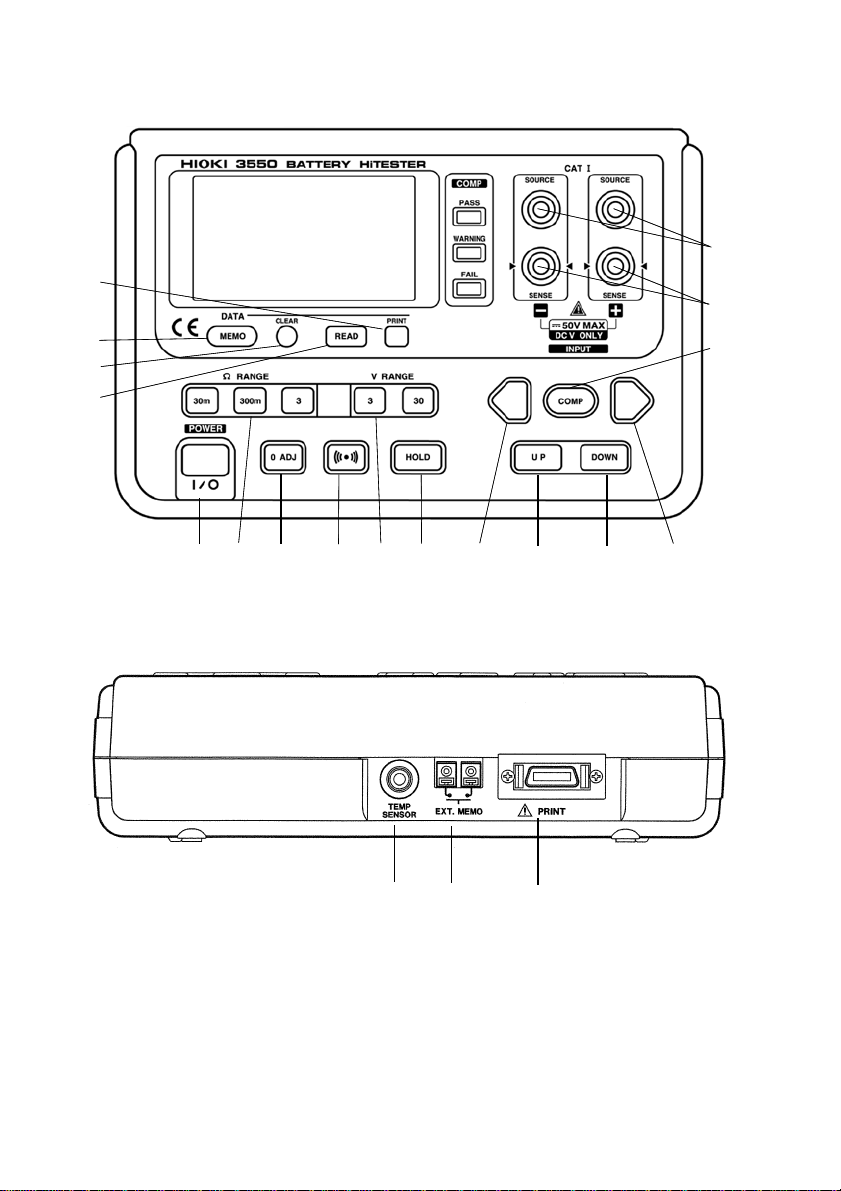

Front Panel

16

15

17

12

13

14

1 2 4 5 3 6 7 10 11 9

8

Side Panel

18 19 20

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 17

___________________________________________________________________

●

Keys and input/output terminals

POWER

1.

2.

300m

3.

0ADJ

4.

5.

HOLD

6.

7.

COMP

8.

30m

30

key Turns the power on or off.

Ω key

3

3

key

Ω key

Ω key

V key

V key

key

key

key

key

Selects the resistance range.

Selects the voltage range.

Zero adjustment key.

Turns the beeper on and off.

Locks out changes to the display.

Left cursor (flashing) key.

Switches the comparator on and off, and

changes display to the comparator setting

screen.

9.

10.

11.

12.

13.

14.

15.

16.

key

key

UP

DOWN

MEMO

CLEAR

READ

PRINT

SOURCE

key

key

key

key

key

Right cursor (flashing) key.

Increases the value of a numeric setting.

Decreases the value of a numeric setting.

Stores the display data in memory.

Clears data captured with the

Reads data captured with the

Prints data captured with the

MEMO

MEMO

MEMO

key.

key.

key.

Connects to the 9460 banana plug on the

SOURCE side.

17.

SENSE

Connects to the 9460 banana plug on the

SENSE side.

TEMP SENSOR

18.

EXT.MEMO

19.

Connects to the 9460 mini-plug.

Connects to an external foot switch or

similar, and stores the displayed data in

memory.

20.

PRINT

Connects to the printer.

5

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 18

6

___________________________________________________________________

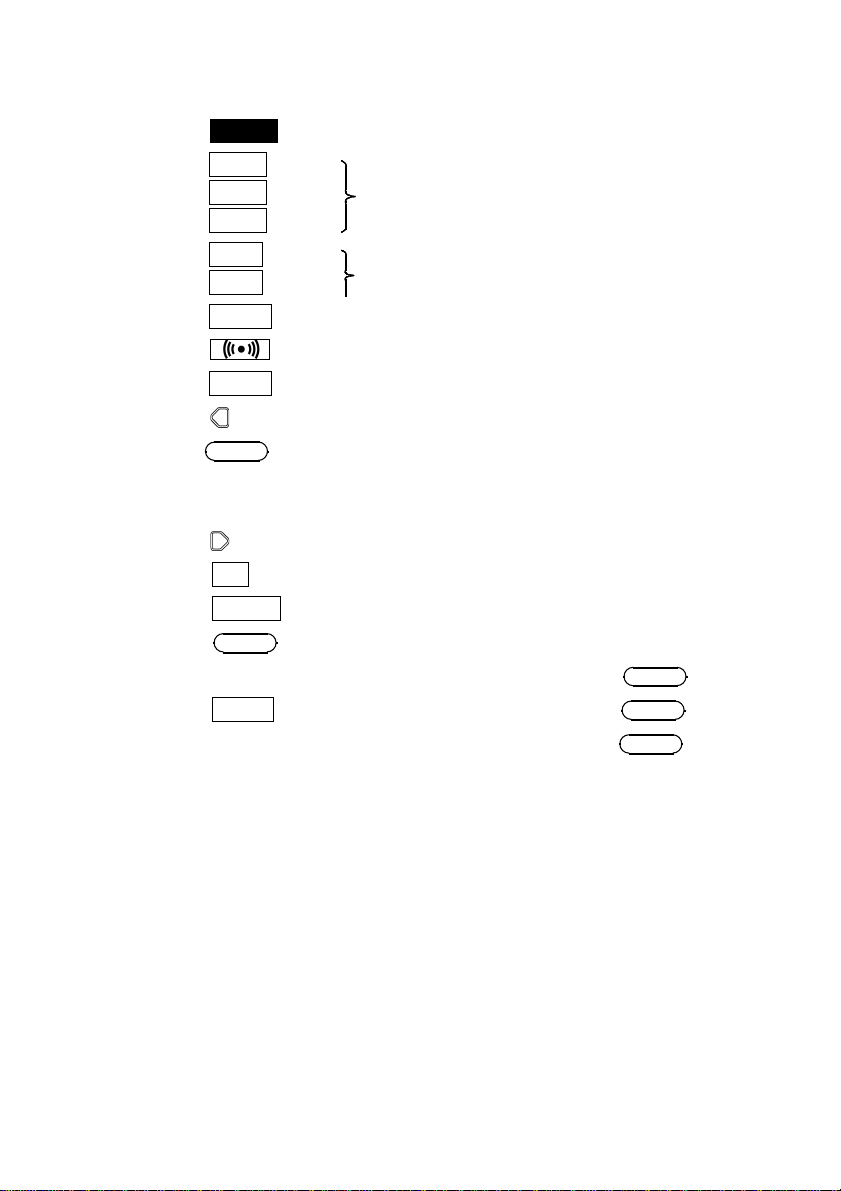

●

LCD (view with all elements displayed)

1

2 3

●

Display

1. Measured resistance

2. Temperature measurement value [comparator resistance

lower limit setting]

3. Temperature measurement value [comparator resistance

lower limit setting]

mΩ

V

HOLD

COMP

Indicates the unit of resistance.

Indicates the unit of voltage.

Indicates the unit of temperature.

Appears when the display is locked.

Appears when the comparator function is on.

Appears when the beeper is turned on.

DATA

No.

Indicates that data captured data with the

MEMO

key is present.

Indicates the number of data points captured

with the

MEMO

key.

Usually, this is the number of the last data

point captured.

[The comparator table number.]

[]: Appears in on the comparator setting screen.

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 19

___________________________________________________________________

7

MEMO

Flashes once when the

MEMO

pressed.

Appears when the battery voltage of the

tester is low, to prompt the user to replace

the battery.

COMP.SET

Appears during display of the comparator

setting screen.

OHM

Appears during display of the screen for

setting the comparator resistance upper and

lower limit values.

VOLT

Appears during display of the screen for

setting the comparator voltage threshold

value.

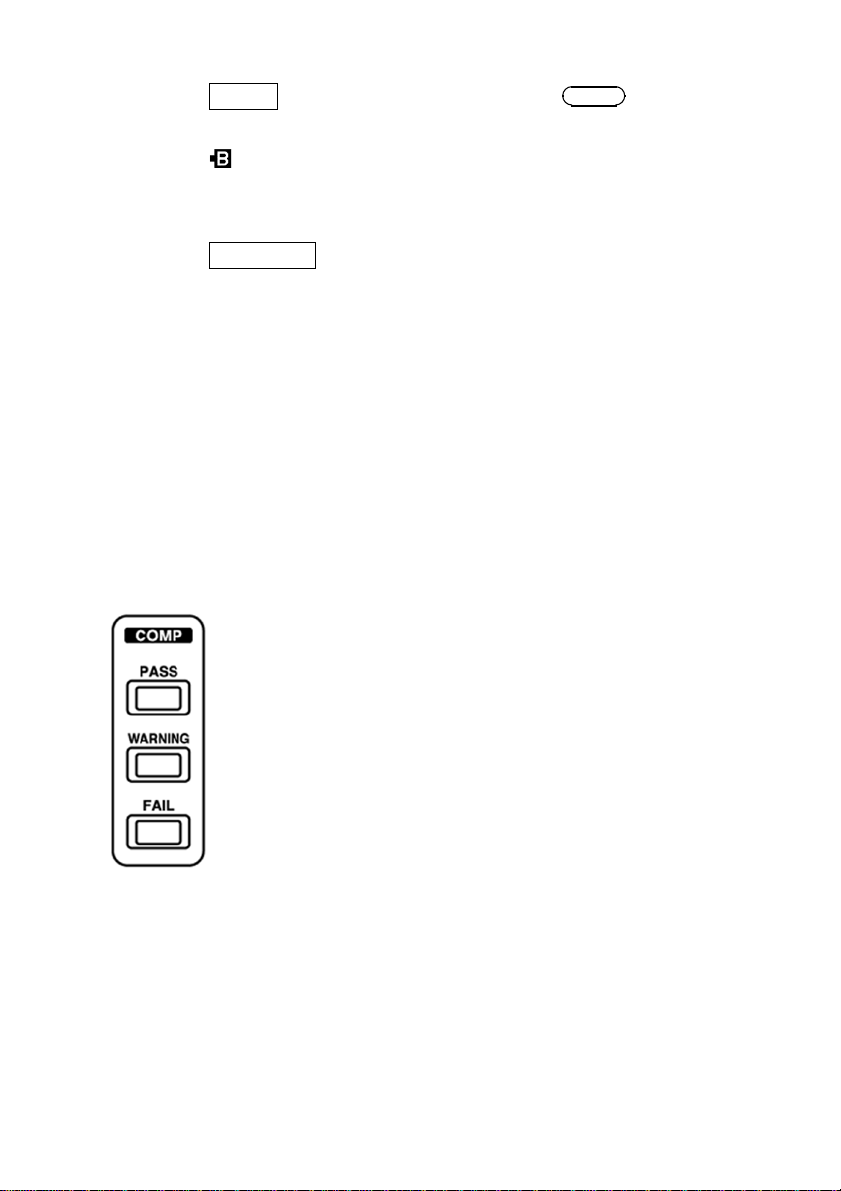

●

LEDs

PASS

Indicates that the tested battery is

satisfactory for operation.

key is

WARNING

Indicates that the tested battery is

beginning to deteriorate.

FAIL

Indicates that the tested battery has

deteriorated.

These indications appear when the upper and lower

comparator limits for internal resistance and the

comparator threshold value for voltage are all set.

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 20

8

___________________________________________________________________

●

9460 CLIP TYPE LEAD WITH TEMPERATURE SENSOR

Clip (red)

Temperature

sensor

Mini-plug

(TEMP.SENSOR)

Clip (black)

Banana plug (black)

Banana plug (red)

SOURCE SENSE

___________________________________________________________________

Chapter 2 Names and Functions of Parts

Page 21

___________________________________________________________________

Chapter 3

Specifications

3.1 General Specification

9

Measurement method

A/D conversion

Display

Panel abbreviations

and symbols

Sampling rate

Open-circuit terminal

voltage

Input overflow

Battery low detection

Constant current fault

detection

Moving average

function

Resistance: AC four-terminal method.

Temperature: platinum temperature

sensor.

Double inte

gration method.

LCD and LEDs (comparator output)

HOLD,COMP

MEMO

COMP.SET,OHM,VOLT,V

,

No.

, ,

,m,Ω, ,

DATA

,

o

C

,

0.83 sets (resistance, voltage, and

temperature measurements)/second.

5Vmax.

"OF" indication

" " indication (indicates at 6.4 V

with LR6 X 6)

"----" indication.

measurement (can be set to on or off)

Zero adjustment

function

Hold function

___________________________________________________________________

Circuit offset voltage is displayed as

0V.

Display is held.

Chapter 3 Specifications

Page 22

10

___________________________________________________________________

Beeper function

Auto power off

Comparator settings

Number of

comparator settings

Comparator output

Resistance

Voltage

LO

HI

Audible output for warning and fail

results.

Canbeturnedonandoff.

Power off automatically after about

30 minutes.

Resistance upper and lower limits

and voltage lower limit.

Ten sets.

LEDs for

(amber), and

Audible tone for

PASS

FAIL

(green),

(red) results.

WARNING

WARNING

results.

LO IN HI

WARNING

(Amber)*1

PASS

(Green)

WARNING

(Amber)

WARNING

(Amber)

and

FAIL

(Red)

FAIL

(Red)

FAIL

*1 Voltage low and internal resistance low: amber flashing

Data save

Save measurement value in memory

when

EXT.MEMO

MEMO

key pressed or

terminals shorted.

Memory holds 260 sets of resistance,

voltage, and temperature values, and

comparator result.

The LED for warning flashing is

stored in memory as a WARNING

result.

Data readout

Data in memory is read out to

display.

Data clear

___________________________________________________________________

Chapter 3 Specifications

Clear the data in memory.

Page 23

___________________________________________________________________

11

Printer interface

Operating

temperature and

humidity range

Storage temperature

and humidity range

Power source

Rated supply voltage

Location for use

Maximum power

consumption

Continuous operating

time

Dimensions

Centronics (can be connected to the

9203 DIGITAL PRINTER)

o

Cto40

0

o

C(32。F to 104。F)

80 %RH (no condensation)

-10

o

Cto50

o

C(14。F to 122。F)

80 %RH (no condensation)

Six LR6 alkaline batteries or six R6P

manganese batteries

1.5 VDC X 6 (Voltage fluctuations of

10% from the rated supply voltage

are taken into account.)

Altitude up to 2000 m (6562-ft.)

1.8 VA

Approx. 7 hours (at 30 mΩ range,

comparator ON, beeper ON, with

LR6 batteries)

Approx. 196W X 130H X 50D mm

(7.72"W X 5.12"H X 1.97"D)

Mass

Approx. 710 g (25.0 oz.)

(Including batteries)

Effect of radiated

radio-frequency

electromagnetic field

at 3V/m

Resistance measurement

3.0% f.s.

Voltage measurement

3.0%f.s.

___________________________________________________________________

Chapter 3 Specifications

Page 24

12

___________________________________________________________________

Standards applying

EMC

EN61326:1997+A1:1998+A2:2001

+A3:2003

Safety

EN61010-1:2001

Pollution Degree 1,

Measurement Category I

(anticipated transient overvoltage

2500 V)

Accessories

9460 CLIP TYPE LEAD WITH

TEMPERATURE SENSOR

9382 CARRYING CASE

Instruction Manual

Dust cover (for the printer interface)

Six LR6 alkaline batteries

Options

9203 DIGITAL PRINTER

9425 CONNECTION CABLE

(2-meter long for connecting to the

9203)

9233 RECORDING PAPER

(ten 10-meter rolls for the 9203)

Accuracy

We define measurement tolerances in terms of f.s. (full

scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or the full length of the

scale. This is usually the maximum value of the currently

selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the

measuring product.

dgt. (resolution)

The smallest displayable unit on a digital measuring product,

i.e., the input value that causes the digital display to show a

"1".

___________________________________________________________________

Chapter 3 Specifications

Page 25

___________________________________________________________________

13

3.2 Measurement Range

Conditions to guarantee accuracy:

o

Temperature :23

Humidity :80 %RH or less (no condensation)

Zero adjustment :After zero adjustment for each range

Warminguptime :Atleast10minutes

Period of guaranteed accuracy :1 year

(1) Resistance Measurement

Temperature coefficient: ( 0.01% rdg. 0.5 dgt.)/

Measurement current frequency: 1 kHz

Range

30 mΩ 30.00 mΩ 10 µΩ 50 mA

300 mΩ 300.0 mΩ 100 µΩ 5mA

3 Ω 3.000 Ω 1mΩ 500 µA

Maximum

indication

Resolution

Measurement

current

o

C 5

C

Six months

1 year

Six months

1 year

Six months

1 year

o

C

30 Hz

Accuracy

0.8% rdg. 6 dgt.

1.2% rdg. 6 dgt.

0.8% rdg. 6 dgt.

1.2% rdg. 6 dgt.

0.8% rdg. 6 dgt.

1.2% rdg. 6 dgt.

(2) Voltage Measurement

o

Temperature coefficient: ( 0.005% rdg. 0.5dgt.)/

Range

3V 3.000 V 1mV

30 V 30.00 V 10 mV

Maximum

indication

Resolution Accuracy

Six months

1 year

Six months

1 year

C

0.1% rdg. 6 dgt.

0.15% rdg. 6 dgt.

0.1% rdg. 6 dgt.

0.15% rdg. 6 dgt.

(3) Temperature Measurement

Measurement range Resolution Accuracy

-10oCto60oC 0.1oC

___________________________________________________________________

Six months

1 year

0.5% rdg. 10 dgt.

0.75% rdg. 15 dgt.

Chapter 3 Specifications

Page 26

14

___________________________________________________________________

3.2.1 Maximum Input Voltage

DANGER

The maximum input voltage is 50 VDC. Attempting

to measure voltage in excess of the maximum input

could destroy the product and result in personal

injury or death.

To avoid electrical hazards and damage to the

product, do not apply voltage exceeding the

maximum input to the measurement terminals.

50 VDC max.

50 VDC maximum

No AC voltage input

___________________________________________________________________

Chapter 3 Specifications

Page 27

___________________________________________________________________

15

3.2.2 FloatingVoltage

Between input terminals and ground, 450 VDC/AC

maximum.

DANGER

Do not input voltage in excess of this floating

voltage to the measurement terminal. This could

result in injury or damage to the unit.

When voltages higher than 30 Vrms, 42.4 Vpeak or

battery circuits with more than 60 VDC are to be

measured, be sure to establish the floating state

first. Carrying out such measurements in the

grounded state involves the risk of electric shock.

3.2.3 Dielectric Strength

Between input terminals and output terminals (including the

EXT.MEMO

DANGER

terminal): 1350 Vrms maximum for 1 minute.

1350 Vrms max.

for 1 minute

PRINT

___________________________________________________________________

Chapter 3 Specifications

Page 28

16

___________________________________________________________________

___________________________________________________________________

Chapter 3 Specifications

Page 29

___________________________________________________________________

17

Chapter 4

Standard Measurement

4.1 Preparingfor Measurement

To avoid electric shock when replacing the batteries,

WARNING

first disconnect the leads from the object to be

measured.

Do not mix old and new batteries, or different types

of batteries. Also, be careful to observe battery

polarity during installation. Otherwise, poor

performance or damage from battery leakage could

result.

After replacing the batteries, replace the cover

before using the product.

1. Remove the battery cover.

2. Insert the batteries into the battery compartment as shown in

the figure below.

___________________________________________________________________

Chapter 4 Standard Measurement

Page 30

18

___________________________________________________________________

To avoid the possibility of explosion, do not short

WARNING

circuit, disassemble or incinerate batteries.

Handle and dispose of batteries in accordance with

local regulations.

NOTE

The " " indicator appears when battery voltage becomes low.

Replace the batteries as soon as possible.

Removing the batteries clears all measurement data from

memory. (See Section 5.2, "Measurement Value Memory

Function.")

After replacing the batteries, the auto power off function is set

to 30 minutes, with the beeper on.

Be sure to press the

POWER

key to power the unit off before

removing the batteries. If the batteries are removed while the

unit is powered on, the previous comparator number may not be

recovered.

To avoid problems with battery operation, remove the batteries

from the product if it is to be stored for a week or more.

Even when the power to the main unit is switched off, a very

small current (approximately 0.7 mA) is drawn from the

batteries to back up internal data. Therefore if the unit is left

switched off with new batteries installed, they will become fully

drained within 2 to 2.5 months.

___________________________________________________________________

Chapter 4 Standard Measurement

Page 31

___________________________________________________________________

19

4.2 Measurement

WARNING

CAUTION

To prevent electric shock, before using this tester,

fit the supplied dust cover for the printer interface

over the PRINT terminal.

To avoid injury or damage to the product, do not

attempt to measure AC voltage, or DC voltage

exceeding 50 V.

Do not attempt to measure the voltage of a generator.

This would result in an AC voltage being applied to the

voltage-generating output terminals, which is

dangerous.

After measuring a high-voltage battery, before

continuing to measure a low-voltage battery first short

the measurement leads together. This will discharge

the DC-elimination capacitor which is connected across

the leads. Otherwise an excess voltage may be

applied to the low-voltage battery, which is dangerous.

___________________________________________________________________

Chapter 4 Standard Measurement

Page 32

20

___________________________________________________________________

1. Connect the 9460 leads as shown in the figure below.

Connect leads to all five terminals; SOURCE +/-, SENSE

+/-, and TEMP SENSOR.

Mini-plug

TEMP SENSOR

terminal

2. Press the

SOURCE and SENSE terminals

POWER

keytoturnonthepowerandstart

Banana plugs

Black Red

measurement.

After pressing the

POWER

key to power on, it is necessary to

wait for ten minutes of warming-up time, to allow the unit to

stabilize.

3. Connect the red clip to the positive (+) side of the battery to

be tested and connect the black clip to the negative (-) side.

Make the connections so that the temperature sensor is

firmly in contact with the battery terminal.

Battery

Black

Red

4. Using the range keys, select the voltage and resistance

___________________________________________________________________

Chapter 4 Standard Measurement

Page 33

___________________________________________________________________

21

measurement ranges.

5. When the measurement is completed, disconnect the leads

from the tested battery and press the

POWER

key to turn off

the power.

NOTE

When measuring the contact resistance of a relay or connector,

be careful of the open-circuit voltage across the test leads. It

may not always be possible to destroy an oxide layer on the

terminals of the object being measured in order to obtain an

accurate reading.

When the indication for a measurement value is "OF", this

indicates that the measured voltage, resistance, or temperature

value is outside the measurement range.

A resistance indication "----" means that the measurement could

not be made because there is a break in the test lead circuit.

The "----" indication may also appear if the leads are not

making good contact with the object to be measured, or if its

resistance is extremely large compared with the measurement

range.

The "----" indication may also appear immediately after

changing the resistance or voltage measurement range.

___________________________________________________________________

Chapter 4 Standard Measurement

Page 34

22

___________________________________________________________________

A temperature indication "---" means that the temperature sensor

is not connected. The "---" indication may also appear if there

is a break in the test lead circuit.

Except for setting the auto power off mode and the moving

average function, do not press the

POWER

key in combination

with other keys. (For details of the moving average settings, see

Section 5.5, "Moving Average Function", and for details of the

auto power off settings, see Section 5.8, "Auto Power Off".)

If you do press a combination of the

keys, and an "

press the

POWER

"or"

INSP

key to power off and on again. Otherwise,

" indication appears, immediately

Adju

POWER

key and other

continuing with key operations may destroy the calibration data

for the unit, and correct measurement will no longer be possible.

If the leads are open-circuit, a spurious voltage indication may

sometimes be given. This is not a malfunction.

___________________________________________________________________

Chapter 4 Standard Measurement

Page 35

___________________________________________________________________

23

Chapter 5

Advanced Measurement

Functions

5.1 Comparator Function

5.1.1 What is the Comparator Function?

The comparator function compares the measurement values

with preset lower and upper limit values for internal

resistance and voltage level, and determines which range the

measurement falls into, based on the preset conditions. It

then lights the corresponding LED, and sounds a beeper for

the WARNING and FAIL cases. (See Section 5.3 Beeper

On/Off Function)

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 36

24

___________________________________________________________________

5.1.2 Comparator Settings

(1) Before changing the settings

To set the comparator (upper and lower resistance limits and

voltage comparison value), do the following:

1. Press and hold the

upper and lower resistance limit settings appear.

COMP

key for at least 3 seconds. The

2. "

Resistance

range

COMP.SET

","

" appears at the lower left of the screen,

OHM

showing that you are ready to change the comparator

settings.

Comparator

number

Lower resistance limit Upper resistance limit

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 37

___________________________________________________________________

(2) Setting the comparator number

Change the comparator number with the

UP

and

DOWN

25

keys. You can select any comparator number up to 10.

(3) Setting the resistance range

Press the resistance range key (Ω

) corresponding to the resistance to be measured.

3

RANGE:30m,300m

,

The currently selected resistance range is displayed at the

center on the screen.

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 38

26

___________________________________________________________________

(4) Setting the resistance limits

1. Using the key, move the flashing number to the most

significant digit of the lower resistance limit setting at the

lower left of the screen.

Lower resistance limit Upper resistance limit

2. Set the lower and upper resistance limits with the

DOWN

keys.

UP

Both the upper and lower resistance limits can be set to any

value in the range 0 to 3000.

and

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 39

___________________________________________________________________

(5) Setting the voltage range

27

1. Using the key, move the flashing number to the least

significant digit of the upper resistance limit setting at the

lower right of the screen.

2. Press the

key again to display the voltage comparison

value setting screen will appear.

"

COMP.SET

"and"

" appear while setting the voltage

VOLT

comparison value.

Voltage range

3. Press the voltage range key (

VRANGE:3

corresponding to the voltage to be measured.

The position of the decimal point corresponds to the

currently selected voltage range.

,

30

)

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 40

28

___________________________________________________________________

(6) Setting the voltage comparison value

1. Using the key and the

UP

and

DOWN

keys, set the

voltage comparison value at the lower left of the screen.

The allowable range of settings for the voltage comparison

value is -3000 to 3000.

Voltage range

2. Move the flashing number to the least significant digit with

the

key.

3. Press the

key again to display the upper and lower

resistance limit settings.

4. Go on to set the next comparator number. You can make

voltage comparison values for up to 10 comparator numbers.

(7) Ending setup

When done with comparator selection, press the

COMP

key.

Display returns to the previous measurement screen.

NOTE

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

When the settings are made by setting a comparator number,

they are saved in memory at the point at which the comparator

setting screen is exited.

Comparator setting is not possible while the display is locked or

while reading out measurement values from memory.

Page 41

___________________________________________________________________

29

5.1.3 Comparator Decision Result Table

The decision result is indicated by the LEDs and by the

beeper, as shown in the following table.

Resistance

Voltage

Voltage

comparison

value

*1 Voltage low and resistance low: amber flashing

Beeper sounds when the comparator result is WARNING or FAIL. (Refer to

Section 5.3, "Beeper On/Off Function")

Lower resistance limit Upper resistance limit

LO IN HI

LO

HI

WARNING

Amber *1

PASS

Green

WARNING

Amber

WARNING

Amber

A"PASS" result is shown by the green LED, a

"WARNING" by the amber LED, and a "FAIL" by the red

LED.

The boundary conditions are as follows.

Resistance LO ≦ Lower resistance limit < Resistance IN

< Resistance HI

< Voltage HI

Example 1

Resistance IN ≦ Upper resistance limit

Voltage LO ≦ Voltage comparison value

Interpreting the comparator output table

●

When the measured resistance is at or below the lower

resistance limit, and the measured voltage is greater than the

voltage comparison value (that is, resistance: LO and

voltage: HI), the LED for

(green) lights. The beeper

PASS

does not sound.

Example 2

When the measured resistance is greater than the lower

resistance limit and lower than the upper resistance limit

value, and the measured voltage is greater than the voltage

comparison value (that is, resistance: IN, voltage: HI) the

LED for

WARNING

(amber) lights and the beeper sounds.

FAIL

Red

FAIL

Red

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 42

30

___________________________________________________________________

5.1.4 Switchingthe Comparator On and Off

Pressing the

and off. When the comparator is on, the "

COMP

key toggles the comparator function on

COMP

"

indication appears in the display, and the comparator

operates as measurements are taken. When the comparator

is off, the "

COMP

" indication disappears from the display,

and the comparator does not operate.

When one of the range keys (

Ω,

3

3

V,

30

V) is pressed and the range is

30m

Ω,

300m

Ω,

changed, comparator operation stops even if the comparator

function is being used. To use comparator function again,

press the

COMP

key. The range reverts to the setting extant

prior to the change.

When you turn on the power, the comparator is always set

to ON.

NOTE

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

If there is no measurement value, "----" is displayed and

comparator operation is not enabled.

Page 43

___________________________________________________________________

31

5.1.5 Changingthe Comparator Number

To change the comparator number, do the following

procedure.

1. Press and hold the

COMP

key for at least 3 seconds. The

resistance comparator setting screen appears.

"

COMP.SET

" appears at lower left of the screen.

2. Select the comparator number with the

You can select any number up to 10.

UP

and

DOWN

keys.

3. When the setting is completed, press the

NOTE

___________________________________________________________________

The selected comparator number remains in memory even when

the power is turned off.

Chapter 5 Advanced Measurement Functions

COMP

key.

Page 44

32

y

___________________________________________________________________

5.2 Measurement Value MemoryFunction

WARNING

To avoid damage to the product, do not apply voltage

to the EXT.MEMO terminals.

The currently measured values (resistance value, voltage

value, temperature, and comparator result), taken as a set can

be stored: up to 260 such sets of values can be held, and

later displayed and printed as required.

5.2.1 Memor

Store the current settings as follows.

Press the

"

MEMO

measurement value and comparator result are stored.

MEMO

key.

" appears at the upper right of the screen and the

MEMO Screen

"

" is displayed at the upper right of the screen and the

DATA

number of data points stored in memory is displayed.

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 45

___________________________________________________________________

33

Using the

MEMO

EXT. MEMO

key can be obtained.

terminals, the same effect as the

1. Using a blade screwdriver or a similar tool, insert the

individual leads into the terminal apertures. (Leads are not

supplied.)

When inserting or removing the leads, push in the terminal

button with a screwdriver as shown in the figure below.

Recommended wire

size

(AWG #18)

Usable limits

Single strand: 0.4 to 1.0 mm dia.

Single strand: 1.0 mm dia.

multi-strand: 0.75 mm

2

(AWG #26 to #18)

multi-strand: 0.3 to 0.75 mm

(AWG #22 to #20)

minimum strand diameter: 0.18 mm

Standard insulation

stripping length

Button pressing tool

10 mm

Blade screw driver

(tip width 2.6 mm)

2

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 46

34

___________________________________________________________________

2. Contact the leads together for at least 100 ms (use a switch)

to obtain the effect of pressing the

The "

MEMO

" indication appears in the display, and one set

MEMO

key.

of measurement values and comparator results are saved in

memory.

Contact for at least 100 ms

At least 2 s

Wait for at least 2 seconds until the next storing.

"

" is displayed at the upper right of the screen along

DATA

with the number of data points in memory.

NOTE

If while the

key is pressed, then the values may be saved twice.

Even when the unit is powered off the values are preserved in

memory.

If the batteries are removed, the values in memory are cleared.

5.2.2 Clear

Clear the latest value in memory as follows.

1. Press the

data point from memory.

2. To clear all data, press and hold the

seconds.

NOTE

Removing the batteries clears all data.

EXT.MEMO

CLEAR

terminals are shorted together another

key. This clears the most recently stored

CLEAR

key for five

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 47

___________________________________________________________________

35

5.2.3 Readout

Redisplay a measurement value from memory as follows.

1. Press the

READ

key.

NOTE

The "

MEMO

number of "

MEMO

" indication appears in the upper right and the

No.

" indication flashes.

means that the currently displayed readings are

values recalled from memory.

The flashing number is the number of the set of values

currently displayed.

2. Pressing the

UP

key or

DOWN

key increments or

decrements this number, to display whichever set of data

values is required.

The comparator result for previous data values read out from

memory is also shown, but a "WARNING" result does not flash.

In the case of a "WARNING" the display is permanently on.

Data cannot be redisplayed when "

upper right of the screen (when there is no data in memory).

" does not appear at the

DATA

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 48

36

g

___________________________________________________________________

5.2.4 Printin

WARNING

For safety, never connect the 3550 to the printer

during measurement.

To prevent electric shock, before using this tester,

fit the supplied dust cover for the printer interface

over the PRINT terminal.

To avoid damage to the product, do not apply

voltage to the PRINT terminal.

Print the measurement value stored in memory as follows.

1. Disconnect the lead from the tested battery.

2. Connect this tester to the 9203 DIGITAL PRINTER with the

9425 CONNECTION CABLE (2 m). (Refer to the printer

instruction manual for how to make printer settings.)

3. Press the

PRINT

key. "Prnt" appears on the screen and the

data is printed.

4. To stop the printing, press the

PRINT

key.

NOTE

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Use the HIOKI 9203 DIGITAL PRINTER.

It is also possible to connect a general-purpose printer with a

Centronics interface. The connector used for this unit is a 20-

pin half-pitch D-subminiature connector, DHA-RC20-R132N

(Daiichi Electronics) or equivalent.

It is not possible to print data while measurement is taking

place.

When printing comparator results, both a flashing "WARNING"

and a constant "WARNING"areprintedas"Warn."

When "

(there is no data in memory), printing is not possible.

" does not appear at the upper right of the screen

DATA

Page 49

___________________________________________________________________

37

Output Example of the 9203

Output Example of the General-purpose Printer

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 50

38

___________________________________________________________________

5.3 Beeper On/Off Function

Pressing the key toggles the beeper on and off.

When the beeper is on, the "

" indication appears in the

display, and the beeper sounds when there is a "Warning" or

"Fail" result. When the beeper is off, the

"

" indication disappears from the display, and the beeper

does not operate.

5.4 Hold Function

This suspends measurement, with the display values held the

same.

Press the

HOLD

and the display is locked to prevent it from changing.

key. "

" is displayed on the screen

HOLD

NOTE

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

While the display is locked, the resistance and voltage range keys

(

0ADJ

effective.

30m

Ω,

,

300m

COMP

Ω,

,

, ,

Ω,

3

UP

3

,and

V,

DOWN

30

V), and the

keys are not

Page 51

___________________________________________________________________

39

5.5 MovingAverage Function

If the resistance measurement value is unstable, this can be

corrected with the moving average function. This takes the

average of four samples of the resistance value and displays

the result.

The moving average takes the sum of the current value and

the previous three sampled values, and divides by four.

To take the moving average, use the following procedure.

1. Power the unit off.

2. Hold down the key while pressing the

3. Hold down the

key until a screen for setting the moving

average appears.

POWER

key.

4. Press the

___________________________________________________________________

key once more.

Chapter 5 Advanced Measurement Functions

Page 52

40

___________________________________________________________________

NOTE

5. When the above screen appears, press the

POWER

key to

power the unit off.

6. Press the

POWER

key again to power the unit on.

7. To cancel the moving average function, in the moving

average setting screen, press the

key to cancel the moving

average function.

If you hold down a key other than the key while powering

on, an "INSP"or"Adju" indication may appear. In this case,

press the

again. Continuing with other key operations will result in the

calibration data being lost, as a result of which correct

measurement will no longer be possible.

It is not possible to change the number of samples (i.e. four)

used for calculating the moving average.

When using the moving average function, the time taken for the

measurement value to stabilize is increased.

POWER

key once more, and to power on the unit

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 53

___________________________________________________________________

41

5.6 Zero Adjust Function

The zero adjustment function adjusts the zero position of the

resistance and voltage ranges of this unit.

The value read during zero adjustment is taken as zero, and

used to calibrate subsequent measurements.

1. Short the SOURCE and SENSE of the 9460 CLIP TYPE

LEAD WITH TEMPERATURE SENSOR together as shown in

the figure below.

2. Press the

0ADJ

key. During zero adjustment, "0Adj"is

displayed in the resistance measurement display position.

3. When "0Adj" disappears and measurement starts, connect the

leads to the battery to be tested.

NOTE

___________________________________________________________________

Keep the leads shorted together throughout the zero adjustment

process.

The zero adjustment is valid for the currently selected range

only, as long as the power remains on. Powering on the unit

resets all zero adjustment values.

When the resistance or voltage value is displayed as "----", or

whenthereadingismorethan"200", "FAIL" is displayed. The

zero adjustment is not carried out.

Chapter 5 Advanced Measurement Functions

Page 54

42

g

___________________________________________________________________

Shorting only the

Always make sure that both the

are shorted together.

If the leads are shorted but their ends are brought close to metal

parts, the measured value may fluctuate as a result of

electromagnetic induction. In this case, move the ends of the

leads away from the metal parts.

SENSE

terminals will not display 0 V.

5.7 BatteryLow Warnin

When the remaining battery capacity is low, the " "

indicator appears at the right of the display.

After printing out any held data values, replace the battery,

referring to Section 4.1, "Preparing for Measurement."

SENSE

and

SOURCE

terminals

NOTE

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

If the batteries are exhausted, you may be able to turn on the

power, but soon the "

off. (Momentary operation is possible because the battery partially

regains its former voltage after resting, but soon declines to the

exhausted state.) When the batteries wear out, replace them in

accordance with the specified procedure.

" mark will appear and the power will go

Page 55

___________________________________________________________________

43

5.8 Auto Power Off

In the following states, if there is no switch operation for 30

minutes the unit automatically powers off.

When the resistance value is "----" indication.

During hold

On the comparator setting screen

During the printing output

During reading the memory data

For continuous measurement, in some cases it may be

necessary to disable the auto power off function. Do this as

follows.

1. Turn the power off.

2. Press the

HOLD

POWER

key simultaneously. Press the

while. The auto-power off setting screen will appear.

key on the unit while holding down the

HOLD

key for a

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 56

44

___________________________________________________________________

NOTE

3. Press the

HOLD

4. When the above screen appears, press the

key again.

POWER

off the power.

5. Press the

POWER

6. To set to the auto-power off, press the

key again to turn the power on.

HOLD

key in the auto

power off setting screen and set the auto power off to 30

minutes.

If the

EXT.MEMO

the auto power off function does not operate.

If the

POWER

HOLD

key, is held down, and an "INSP"or"Adju"indication

appears, immediately press the

again. Otherwise, continuing with key operations may destroy

the calibration data for the unit, and correct measurement will

no longer be possible.

After the batteries are replaced, the auto power off is set to 30

minutes.

The set time of auto power off cannot be changed.

terminals are continuously shorted together,

key is pressed while another key, other than the

POWER

key to power off and on

key to turn

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 57

___________________________________________________________________

45

5.9 AC Four-Terminal Method

The 3550 uses the AC four-terminal method, so that

resistance measurement can be carried out with the resistance

of the leads, and the contact resistance between the object to

be measured and the leads canceled out. The following

figure shows the principle of the AC four-terminal

measurement method.

Constant current

source

Is

Voltmeter

DC-elimination

capacitor

R

1

R

2

Resistance R

Resistance measurement circuit

V

IS

R

3

Values R1 to R4 are the resistances of the test leads plus

contact resistances.

An AC current (Is) is supplied from the

SOURCE

terminals of

the 3550 across the tested battery.

The voltage drop across the internal impedance of the battery

) is measured by the

(V

IS

since the

SENSE

SENSE

terminals are connected to an internal

terminals. At this point,

voltmeter with a high impedance, almost no current flows

through the resistances R2 and R3 which represent the lead

resistances and contact resistances.

As a result, there is almost no voltage drop across the

resistances R2 and R3. Thus the voltage drop due to the

lead resistances and contact resistances is very small, and

these can be canceled out.

R

4

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 58

46

___________________________________________________________________

NOTE

In the 3550, a synchronized wave detection system is used,

whereby the internal impedance is separated into effective

resistance and reactance, and the resistive component only

displayed.

Reactance

Impedance

Effective resistance

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 59

___________________________________________________________________

)

47

5.10 Internal Resistance of Lead-Acid

Batteries

This shows the relationship between the capacity for leadacid batteries and the initial value for internal resistance.

(Quote: Text from battery fitters qualification lecture notes,

Battery Industry Association) The terms CS, HS, and MSE

appearing in the figure are battery types defined by JIS

(Japanese Industrial Standards).

Temperature of battery:25

)

Ω

m

(

e

c

n

a

t

s

i

s

e

r

l

a

n

r

e

t

n

I

CS

HS

MSE

Capacityof lead-acid battery(Ah

CS : Clad type stationary lead-acid battery

HS : High rate discharge paste type stationary lead-acid

battery

MSE : Seal type stationary lead-acid battery

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 60

48

___________________________________________________________________

From the figure, MSE internal resistance can be read as

approximately 1 mΩ (at 100Ah), or approximately 0.13 mΩ

(at 1000 Ah).

When the battery deteriorates, internal resistance rises to 1.5

to 2 times the initial value (reference value).

With an MSE (seal type stationary lead-acid battery), battery

condition is regarded as marginal when internal resistance

reaches 1.5 times the initial value, and complete

deterioration is assumed when internal resistance reaches 2

times the initial value.

NOTE

Even if different batteries have the same capacity, initial internal

resistance may vary according to battery type and maker. The

figure is only for reference.The internal resistance warning

(WARN) and fail (FAIL) values vary according to maker.

___________________________________________________________________

Chapter 5 Advanced Measurement Functions

Page 61

___________________________________________________________________

g

49

Chapter 6

Maintenance

If damage is suspected, check the "Troubleshooting" section

before contacting your dealer or Hioki representative.

6.1 Troubleshootin

Symptom Cause Follow-up

Nothing appears on

the screen when the

POWER

pressed.

Measurement values

are wrong.

"---" is displayed.

"OF" is displayed.

Comparator result is

not correct.

key is

Batteries are exhausted, or

not inserted.

Leads are not correctly

connected.

There is an electrical

discontinuity in the leads.

Zero adjustment is not

correct.

The measurement range is

not appropriate.

The comparator setting is

not correct.

Replace the batteries or reinsert

them correctly.

See Section 4.1, "Preparing for

Measurement."

Connect leads correctly.

See Section 4.1, "Preparing for

Measurement."

Replace with a new lead.

Perform correctly zero

adjustment.

See Section 5.6, "Zero Adjust

Function."

Select the appropriate range

with the range key.

See Section 4.2,

"Measurement."

Set the comparator correctly.

See Section 5.1, "Comparator

Function."

___________________________________________________________________

Chapter 6 Maintenance

Page 62

50

___________________________________________________________________

Symptom Cause Follow-up

Data in memory is not

displayed when the

READ

pressed.

Printing is not

possible.

key is

Thereisnodatain

memory.

Thereisnodatain

memory.

Storedatainmemory.

See Section 5.2, "Measurement

Value Memory Function."

Storedatainmemory.

See Section 5.2, "Measurement

Value Memory Function."

NOTE

The comparator setting

screen appears.

The connecting cable is

not correctly connected.

The printer is not ready. Turn the printer power on and

Exit the comparator setting

screen, to return to the

measurement screen.

See Section 5.1, "Comparator

Function."

Correctly connect the

connecting cable.

set correctly.

To avoid problems with battery operation, remove the

batteries from the product if it is to be stored for a week

or more.

When sending the product for repair, remove the batteries

and pack carefully to prevent damage in transit. Include

cushioning material so the instrument cannot move within

the package. Be sure to include details of the problem.

Hioki cannot be responsible for damage that occurs during

shipment.

Never modify the product. Only a Hioki service engineer

can disassemble or repair the product. Failure to observe

these precautions may result in fire, electric shock, or

injury.

___________________________________________________________________

Chapter 6 Maintenance

Page 63

___________________________________________________________________

g

51

6.2 Message Reference

Message Meaning Follow-up

FAIL

Prnt

0Adj

INI

INSP

Adju

Er10

Er11

Er12

Er20

Er21

Er22

Er23

Er24

Zero adjustment cannot be

carried out.

Data is being sent to the

printer.

Zero adjustment is being

carried out.

Initialization after battery

replacement.

Inspection and adjustment

modes for factory use.

Internal variable error. Servicing is required.

Connect correctly the lead and

execute the zero adjustment.

See Section 5.6, "Zero Adjust

Function."

Disappears when data output to the

printer is completed.

Disappears when zero adjustment is

completed.

This is not a malfunction.

Press the

power on.

POWER

key to turn the

6.3 Cleanin

To clean the product, wipe it gently with a soft cloth

moistened with water or mild detergent. Never use solvents

such as benzene, alcohol, acetone, ether, ketones, thinners or

gasoline, as they can deform and discolor the case.

When cleaning the LCD, gently wipe with a soft dry cloth.

___________________________________________________________________

Chapter 6 Maintenance

Page 64

52

___________________________________________________________________

___________________________________________________________________

Chapter 6 Maintenance

Page 65

Page 66

Page 67

HIOKI 3550 BATTERY HiTESTER

Instruction Manual

Publication date: September 2006 Revised edition 10

Edited and published by HIOKI E.E. CORPORATION

Technical Support Section

All inquiries to International Sales and Marketing Department

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3550A981-10

All reasonable care has been taken in the production of this manual,

but if you find any points which are unclear or in error, please

contact your supplier or the International Sales and Marketing

Department at HIOKI headquarters.

In the interests of product development, the contents of this manual

are subject to revision without prior notice.

Unauthorized reproduction or copying of this manual is prohibited.

Page 68

2003-01 改訂 枠消す

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp / URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3550A981-10 06 -09H

Printed on recycled paper

Loading...

Loading...