Instruction Manual

For...は専用機種。複数の場合は「/」で区切る。不要の場合はとる。

形名を入力。 複数の場合は「/」で区切る。

3532-50

品名を入力。

LCR HiTESTER

February 2013 Revised edition 10 3532C981-10 13-02H

Contents

Introduction i

Shipping Check

Safety

Points for Attention During Use v

Layout of This Manual

Chapter 1 Product Overview 1

1.1 Product Overview 1

iii

vi

ii

1.2 Product Features

1.3 Names and Functions of Parts

Chapter 2 Before Starting Measurement 7

2.1 Connecting the Power Cord 7

2.2 Connecting the Test Leads 8

2.2.1 Establishing the Connections 8

2.3 Turning the Power On and Off 10

Chapter 3 Outline of Operation 11

3.1 About the Touch Panel 11

3.2 About the Screen

3.2.1 Control Screen Sequence 14

3.3 Basic Measurement 15

3.3.1 Basic Flow up to Testing of the Sample 15

3.3.2 Setting the Test Parameters to be Displayed

(Cs, D) 16

3.3.3 Setting the Test Frequency 18

12

2

3

3.3.4 Setting the Constant Voltage Level 21

3.3.5 Setting Open Circuit Compensation 23

3.3.6 Setting Short Circuit Compensation 26

3.3.7 Starting Testing 28

Chapter 4 Detailed Description of Functions 29

4.1 Description of the Screens 29

4.1.1 The Initial Screen 30

4.1.2 The Menu Screen and Application Menu Screen 31

4.2 Setting the Parameters to be Displayed 32

4.2.1 Control Screen Sequence 32

4.2.2 Details of the Setting Process 32

4.2.3 Series Equivalent Circuit Mode and Parallel

Equivalent Circuit Mode 34

4.3 Setting the Test Frequency 35

4.3.1 Control Screen Sequence 35

4.3.2 Selecting the Input Method 36

4.3.3 Input Using the Ten Key Screen 37

4.3.4 Input Using the Digit Screen 38

4.4 Setting the Test Signal Level 39

4.4.1 Control Screen Sequence 39

4.4.2 Selecting the Level Type 40

4.4.3 Setting the Open Circuit Voltage (V) Level 42

4.4.4 Setting the Constant Voltage (CV) Level 43

4.4.5 Setting the Constant Current (CC) Level 44

4.5 Setting the Voltage/Current Limit 45

4.5.1 Control Screen Sequence 45

4.5.2 Details of the Setting Process 46

4.6 Setting the Ranging 48

4.6.1 Control Screen Sequence 48

4.6.2 Setting the Ranging 49

4.6.3 Setting AUTO Ranging 49

4.6.4 Setting the Ranging to HOLD 50

4.7 Open Circuit Compensation 52

4.7.1 Control Screen Sequence 52

4.7.2 Setting the Compensation Method 53

4.7.3 ALL Compensation 54

4.7.4 Spot Compensation 56

4.7.5 When an Error Message Appears and

Compensation Has Stopped 59

4.7.6 Clearing Compensation Data 59

4.8 Short Circuit Compensation 60

4.8.1 Control Screen Sequence 60

4.8.2 Setting the Compensation Method 61

4.8.3 ALL Compensation 63

4.8.4 Spot Compensation 65

4.8.5 When an Error Message Appears and

Compensation Has Stopped 68

4.8.6 Clearing Compensation Data 68

4.9 Open Circuit Compensation and Short Circuit

Compensation 69

4.10 Setting the Trigger

4.10.1 Control Screen Sequence 71

4.10.2 Details of the Setting Process 72

71

4.11 Setting the Trigger Delay 74

4.11.1 Control Screen Sequence 74

4.11.2 Details of the Setting Process 75

4.12 Setting Averaging 77

4.12.1 Control Screen Sequence 77

4.12.2 Details of the Setting Process 78

4.13 Setting the Testing Speed 80

4.13.1 Control Screen Sequence 80

4.13.2 Details of the Setting Process 81

4.14 Setting the Measurement Cable Length 82

4.14.1 Control Screen Sequence 82

4.14.2 Details of the Setting Process 83

4.15 Setting and Activating the Comparator 84

4.15.1 Control Screen Sequence 85

4.15.2 Setting the Comparator 85

4.15.3 Returning from Comparator Operation to

Normal Testing 88

4.15.4 Choosing How to Set the Upper and Lower Limit

Values 88

4.15.5 Setting the Upper or Lower Limit Value as an

Absolute Value (ABS) 90

4.15.6 Setting the Upper or Lower Limit Value as a

Percentage (%) Relative to a Standard Value 92

4.15.7 Displaying Measurement Values as Deviations

from the Reference Value(Δ%) 95

4.16 Setting and Activating the Scaling 97

4.16.1 Control Screen Sequence 97

4.16.2 Setting Scaling 98

4.16.3 Canceling the Scaling Function 99

4.16.4 Setting the Compensation Coefficient (a, b) 100

4.17 Panel Save Function 102

4.17.1 Control Screen Sequence 102

4.17.2 Details of the Setting Process 103

4.18 Panel Load Function 106

4.18.1 Control Screen Sequence 106

4.18.2 Details of the Setting Process 107

4.19 Setting the Beep Sound 109

4.19.1 Control Screen Sequence 109

4.19.2 Details of the Setting Process 110

4.20 Enlarged Display of Measurement Values 111

4.20.1 Control Screen Sequence 111

4.20.2 Details of the Setting Process 112

4.21 System Reset 113

4.21.1 Control Screen Sequence 113

4.21.2 Details of the Setting Process 114

4.22 Continuous Test Function 116

4.22.1 Control Screen Sequence 116

4.22.2 Details of the Setting Process 117

4.23 Setting the Number of Displayed Digits 120

4.23.1 Control Screen Sequence 120

4.23.2 Details of the Setting Process 121

4.24 Setting for Display 122

4.24.1 Control Screen Sequence 122

4.24.2 Details of the Setting Process 123

4.25 Key Lock Function 124

4.25.1 Turning the Key Lock On and Off 124

Chapter 5 Applications 125

5.1 Example of Comparator Application 125

5.2 Testing High Impedance Elements

5.3 Testing an Element in a Circuit

5.4 External Interference

5.4.1 Countermeasures Against Interference from

the Power Supply Line 129

5.4.2 Countermeasures Against Noise from the Test

Cables 131

127

128

129

5.5 The EXT I/O Connector 132

5.5.1 Pinouts for the EXT I/O Connector 132

5.5.2 Signal Lines for the EXT I/O Connector 133

5.5.3 Circuit Construction and Connections for

the EXT I/O Connector 135

5.5.4 Electrical Characteristics of the Output Signals 136

5.6 Testing Using EXT I/O 137

5.6.1 Normal Testing 137

5.6.2 Test on the Continuous Test Screen 139

5.7 Supplying DC Bias 140

5.7.1 How to Supply a DC Bias Voltage 141

5.7.2 How to Supply a DC Bias Current 142

5.8 The Residual Charge Protection Function 143

5.9 9442 Printer (option) 144

5.9.1 Preparation 144

5.9.2 Connection Method 146

5.9.3 Control Screen Sequence 147

5.9.4 Returning from Comparator Operation to

Normal Testing 148

5.9.5 Screen Copy Mode 149

5.9.6 Auto Print Mode 150

5.9.7 Manual Print Mode 150

Chapter 6 Maintenance, Adjustment, and Disposal 151

6.1 Maintenance and Servicing 151

6.2 How to Change the Power Supply Fuse and

Change the Power Supply Voltage 153

6.3 Shipping the Unit

6.4 Troubleshooting

6.5 Disposing of the Unit

155

156

157

Chapter 7 Specification and Options 159

7.1 General Specification 159

7.2 Testing Parameters and Calculation Equations

7.3 Time Taken for Testing

7.4 Options

7.5 Test Accuracy

164

166

169

172

Index INDEX 1

_____________________________________________________________________________________________

i

Introduction

Thank you for purchasing the

HIOKI

"3532-50 LCR HiTESTER." To obtain

maximum performance from the product, please read this manual first, and

keep it handy for future reference.

This manual contains information and points for attention which are

necessary for safe operation of the unit and for storing it safely in proper

operational condition.

______________________________________________________________________________________________

ii

_____________________________________________________________________________________________

Shipping Check

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki representative.

Check the 3532-50 unit and the supplied accessories

Main unit

3532-50 LCR HiTESTER

Supplied accessories

(1) Instruction manual ... 1

(2) Grounded power cord ... 1

NOTE

(3) Spare fuse for power supply (according to voltage specification) ... 1

100 V, 120 V setting: 250 V T1.0AL 20 mm x 5mmdia.

220 V, 240 V setting: 250 V T0.5AL 20 mm x 5mmdia.

No interface boards and no test cables are supplied with the unit as standard

equipment. You should order them separately, according to requirements.

______________________________________________________________________________________________

_____________________________________________________________________________________________

iii

Safety

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

WARNING

Safety symbols

This product is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment.

However, mishandling during use could result in injury or death, as

well as damage to the product. Using the product in a way not

described in this manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in

the manual before use. We disclaim any responsibility for accidents

or injuries not resulting directly from product defects.

The following symbols in this manual indicate the relative importance of

cautions and warnings.

The symbol printed on the product indicates that the user

should refer to a corresponding topic in the manual (marked with

the

symbol) before using the relevant function.

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

Indicates a grounding terminal.

WARNING

CAUTION

NOTE

Indicates AC (Alternating Current).

Indicates a fuse.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

Advisory items related to performance or correct operation of the

product.

______________________________________________________________________________________________

iv

_____________________________________________________________________________________________

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories.

CAT II Primary electrical circuits in equipment connected to an AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

CAT III Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance, and to

the power meter and primary overcurrent protection device

(distribution panel).

Using a measurement instrument in an environment designated with a

higher-numbered category than that for which the instrument is rated could

result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT

IV measurement applications could result in a severe accident, and must be

carefully avoided.

______________________________________________________________________________________________

_____________________________________________________________________________________________

v

Points for Attention During Use

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

WARNING

CAUTION

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the product

and present an electrical hazard.

To avoid electrical accidents and to maintain the safety

specifications of this instrument, connect the power cord provided

only to a 3-contact (two-conductor + ground) outlet.

To avoid electric shock, do not remove the instrument's case. The

internal components of the instrument carry high voltages and may

become very hot during operation.

Various connectors are present on the outside of the 3532-50. Never

connect any cable to any of these connectors without first turning off the

power supply and removing the power cord. Moreover, check the

connections carefully in order to avoid any chance of setting up a short

circuit etc..

If anything unusual happens during operation of the unit, turn off the

power switch immediately and contact any HIOKI service facility for help,

advice and service.

This product should be installed and operated between 0 and 40 and

80% RH or less, and less than 2000 m height.

The unit should always be stored in a range of temperature and humidity

from -10

Do not store or use the product where it could be exposed to direct

to 55 , 80% RH or less.

sunlight, high temperature or humidity, or condensation. Under such

conditions, the product may be damaged and insulation may deteriorate

so that it no longer meets specifications.

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

Do not use excessive force on the touch panel, and do not use sharp

objects that could damage the touch screen.

Before using the instrument, make sure that the insulation on the probes

is undamaged and that no bare conductors are improperly exposed.

Using the instrument in such conditions could cause an electric shock, so

contact your dealer or Hioki representative for repair.

Ventilation holes for heat radiation are provided on the side panels of the

product. Leave sufficient space around the ventilation holes and install

the product with the holes unobstructed. Installation of the product with

the ventilation holes obstructed may cause a malfunction or fire.

About the guarantee

You should be aware that HIOKI cannot accept any respo nsibility directly or

indirectly if the unit has been incorporated in some other system, or if it is

resold to a third party.

______________________________________________________________________________________________

vi

_____________________________________________________________________________________________

Layout of This Manual

Chapter 1 Product Overview

Describes the product generally, and lists the parts and functions.

Chapter 2 Before Starting Measurement

How to connect the power cord etc., and important precautions before

operation.

Chapter 3 Outline of Operation

Explains the touch panel and basic testing.

Chapter 4 Detailed Description of Functions

Detailed explanation of the functions.

Chapter 5 Detailed Description of Applications

Various testing applications.

Chapter 6 Maintenance, Adjustment, and Disposal

Chapter 7 Specification and Options

Index

______________________________________________________________________________________________

_____________________________________________________________________________________________

1

Chapter 1

1

2

1.1 Product Overview

The HIOKI 3532-50 LCR HiTESTER is an impedance meter which uses a

touch panel as the user interface. This interactive touch panel enables

extremely easy operation. The test frequency can be set from 42 Hz to 5

MHz at high resolution.

The values of a maximum of any four of the fourteen test parameters,

including not only impedance |Z| and phase angle θ, but also L, C, and R

etc., can be simultaneously displayed upon the screen.

Moreover, this widely applicable impedance meter can be set, not only to a

floating voltage setting, but also to a constant voltage setting or a constant

current setting.

Product Overview

3

4

5

6

7

8

9

10

11

12

13

14

A

______________________________________________________________________________________________

1.1 Product Overview

2

_____________________________________________________________________________________________

1.2 Product Features

Wide range of test frequencies

The test frequency can be selected from a wide range - 42 Hz to 5 MHz - at

high resolution (Three-digit resolution for not more than 100 Hz, and fourdigit resolution for not more than 5 MHz). Frequency dependent assessment

of electronic components and materials, etc., is possible.

Constant voltage and constant current testing

Assessment of dependence upon voltage or current is possible.

Outstanding operability

All control operations are initiated via a touch panel on the display. All the

keys currently available for use are shown on the display, and can be

operated interactively.

Simultaneous display of four parameters

Up to four of the test parameters (such as L,C,R, etc.) can be displayed

simultaneously.

Interface

Using a computer, any required parameters can be captured

Changing settings without stopping measurement

Various background settings can be changed without stopping measurement

(when an internal trigger is set).

______________________________________________________________________________________________

1.2 Product Features

_____________________________________________________________________________________________

3

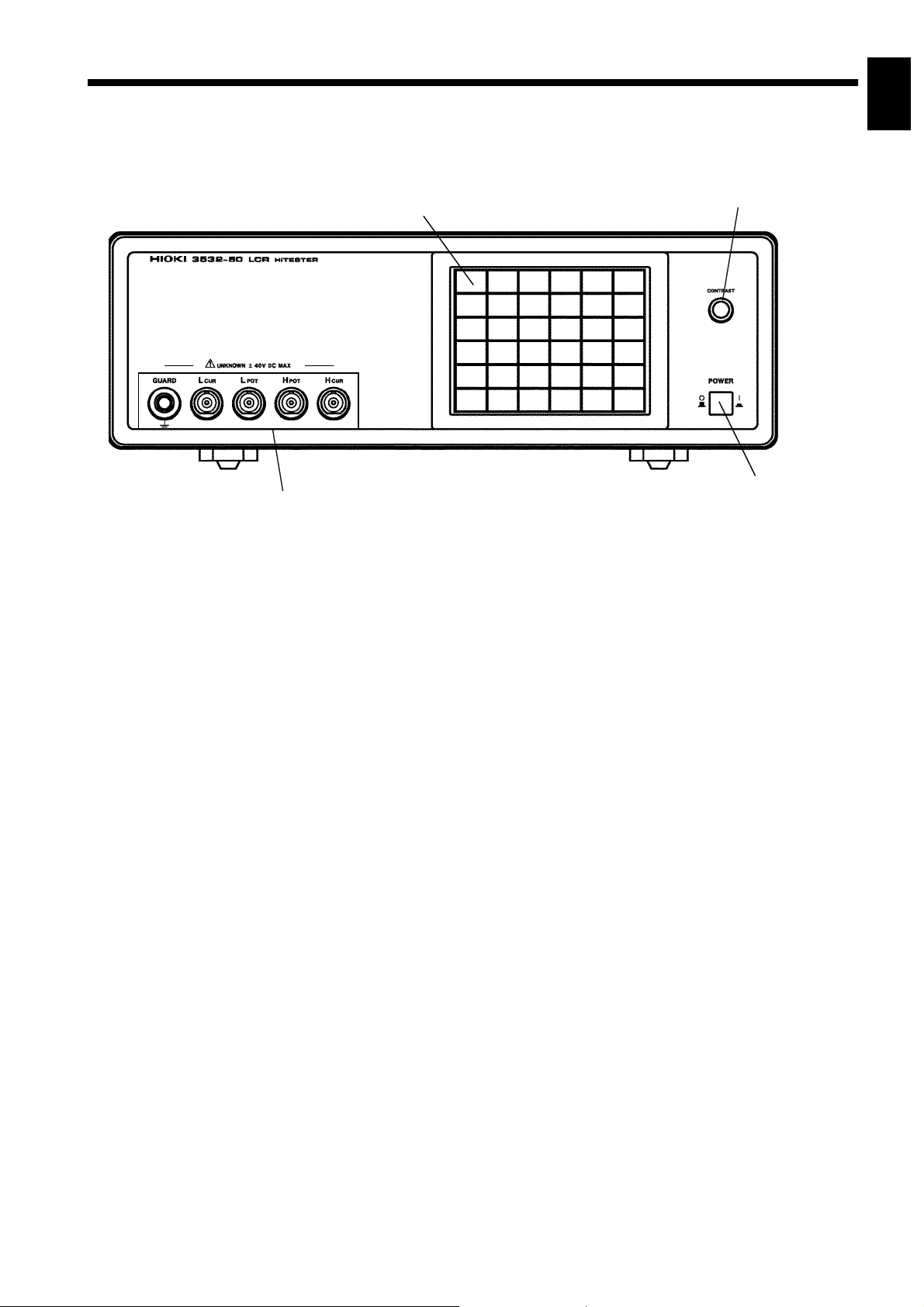

1.3 Names and Functions of Parts

Liquid crystal display

Test terminals

Contrast adjustment knob

Power switch

1

1

2

2

3

3

4

4

5

5

6

6

Front View

Liquid crystal display

This is a 5-inch liquid crystal display fitted with a touch panel. It also

serves to provide input keys.

Power switch

Turns the power for the unit on and off.

Contrast adjustment knob

This knob adjusts the screen contrast. Turning it clockwise decreases the

contrast, and vice versa.

Test terminals

There are five test terminals:

The test signal is supplied to this terminal.

H

CUR

H

POT

Detected voltage low terminal

L

POT

L

CUR

GUARD

These test terminals are designed according to the safety standard;

Pollution Degree 2, Measurement category I.

Detected voltage high terminal

Test current detected terminal

Guard terminal

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

______________________________________________________________________________________________

1.3 Names and Functions of Parts

A

A

4

_____________________________________________________________________________________________

Power input socket

with voltage selector

Optional equipment interface

Key lock switch

EXT I/O connector

Heat sink

Rear View

Power input socket (internally fused type) with voltage selector

Connect the supplied power cord here.

Optional equipment interface

Optional interface boards are connected here.

EXT I/O connector

For input of an external trigger signal and output of comparator results.

Compatible with sequencer connection.

Key lock switch

Puts the touch panel keys into the input-not-accepted state.

______________________________________________________________________________________________

1.3 Names and Functions of Parts

_____________________________________________________________________________________________

5

1

1

2

2

3

3

4

4

5

5

6

6

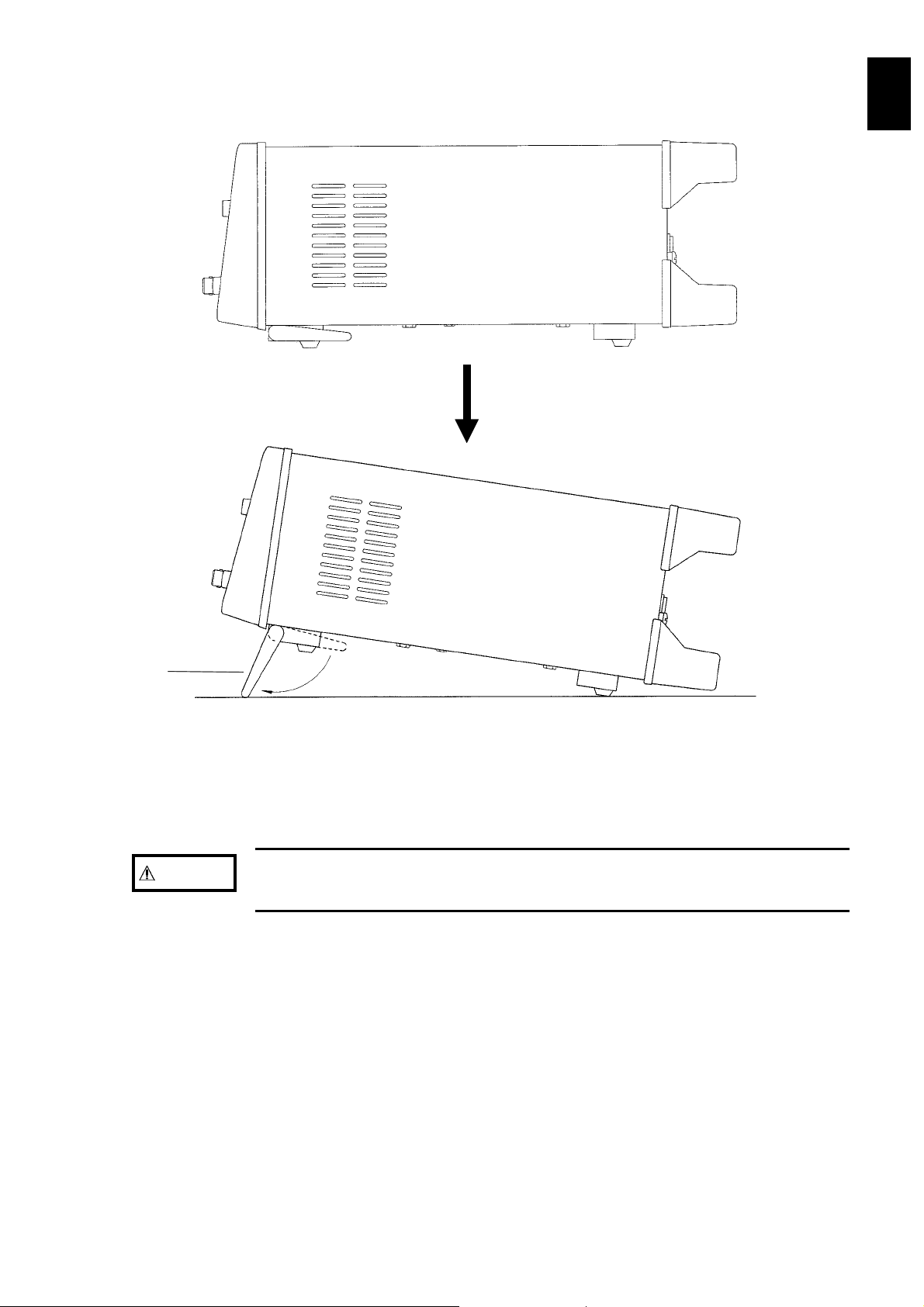

Stand

CAUTION

Right View

Stand

Can be opened to tilt the unit upwards.

Do not apply strong downward pressure with the stand extended.

Damage to the stand will result.

7

7

8

8

9

9

10

10

11

11

12

12

13

13

______________________________________________________________________________________________

1.3 Names and Functions of Parts

14

14

A

A

6

_____________________________________________________________________________________________

Handle

Left View

Handle

Used when carrying the unit.

______________________________________________________________________________________________

1.3 Names and Functions of Parts

_____________________________________________________________________________________________

7

Chapter 2

1

2

Before Starting Measurement

2.1 Connecting the Power Cord

WARNING

When a 3532-50 unit is ordered, the supply voltage is set in the

factory to the value specified, which can be 100 V, 120 V, 220 V, or

240 V.

The maximum rated power (with all options fitted) is 50 VA.

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the product

and present an electrical hazard.

The power supply voltage for this product is switchable. To avoid

electrical accidents, check that the voltage selector is set correctly for

the supply voltage you are using. (For details, refer to Section 6.2)

3

4

5

6

7

8

9

To avoid electrical accidents and to maintain the safety

specifications of this instrument, connect the power cord provided

only to a 3-contact (two-conductor + ground) outlet.

The power cord is connected according to the following

procedure.

1. Check that the main power switch of the unit is off.

2. Check that the power supply voltage is correct, and

connect the proper end of the power cord to the power

input socket (with voltage selector) at the rear of the unit.

3. Plug the other end of the power cord into the power

supply socket.

Grounding

Use the grounding type (three-wire) power cord supplied.

The unit will be grounded automatically.

10

11

12

13

14

A

______________________________________________________________________________________________

2.1 Connecting the Power Cord

8

_____________________________________________________________________________________________

2.2 Connecting the Test Leads

The 3532-50 has five test terminals: H

is supplied); H

terminal (detected voltage high terminal); L

POT

(detected voltage low terminal); L

terminal), and GUARD terminal (connected to the chassis of the unit).

2.2.1 Establishing the Connections

CAUTION

Using a low frequency to measure capacitors with a particular polarity (for

example, electrolytic capacitors) results in a reverse bias being applied.

In some cases this could damage or destroy the capacitor, and therefore

a DC bias should always be applied while making the measurements.

Also be sure that the positive terminal of the capacitor is connected to

the Hcur terminal on this unit.

When measuring capacitors with a particular polarity (for example,

electrolytic capacitors), always apply a DC bias.

If the DC bias is not applied, a reverse bias may be applied, damaging or

destroying the capacitor.

terminal (to which the test signal

CUR

terminal (test current detected

CUR

POT

terminal

If using a test lead set supplied by HIOKI, connect the red leads to the H

terminal and to the H

terminal and to the L

Black

terminal, and connect the black leads to the L

POT

terminal.

POT

Red

CUR

The unit is designed and adjusted for 75 Ω coaxial cable test leads. It is

best to use HIOKI test leads.

CUR

______________________________________________________________________________________________

2.2 Connecting the Test Leads

_____________________________________________________________________________________________

9

NOTE

The connections to the article to be tested are as shown in the following

figure.

Test fixture

No test cables are included with the 3532-50 unit. They must be

purchased separately. (For details, refer to Section 7.4, "Options")

If all four terminals are left floating, the numbers which appear on the

display are completely meaningless.

1

2

3

4

5

6

7

8

9

10

11

12

13

______________________________________________________________________________________________

2.2 Connecting the Test Leads

14

A

10

_____________________________________________________________________________________________

2.3 Turning the Power On and Off

How to turn the power on

1. Turn on the power switch on the front panel. The Initial screen will be

displayed on the liquid crystal display.

Off

On

The test conditions will start off the same as they were when last the power

was turned off.

2. Adjust the contrast knob so as to make the display as easy to see as possible.

Darker

Brighter

3. Wait for 60 minutes after turning on the power before starting testing, so as

to allow the unit to warm up fully.

How to turn the power off

Turn off the power switch on the front panel. The test conditions will be

preserved.

NOTE

Even if the power supply is interrupted because of a power failure or the

like, the test conditions (settings) will not be lost; when the power is turned

on again, the unit will return to its state just before the interruption.

______________________________________________________________________________________________

2.3 Turning the Power On and Off

_____________________________________________________________________________________________

11

Chapter 3

1

2

3.1 About the Touch Panel

CAUTION

Do not use excessive force on the touch panel, and do not use sharp

objects that could damage the touch screen.

The 3532-50 uses a touch panel for setting and changing all of the test

conditions. Simply by touching the LCD screen at certain areas - termed soft

keys - which appear in reverse video, the items associated with these soft

keys, and numerical values, can be selected.

In this manual, lightly touching a soft key area on the screen is termed

"pressing" a key.

Outline of Operation

3

4

5

6

7

8

9

Initial Screen

10

11

12

13

14

A

______________________________________________________________________________________________

3.1 About the Touch Panel

12

_____________________________________________________________________________________________

3.2 About the Screen

(1) The Initial screen

When the power is first turned on, the basic screen for controlling the 3532-

50 immediately appears, called the "Initial screen". A maximum of four of

the test parameters (L, C, R, etc.) can be set for display, and all of the test

conditions can be checked, on this Initial screen.

The Menu screen can be displayed by pressing the key.

The Parameter setting screen can be displayed by pressing a parameter key.

Parameter

keys

Monitor

display

For details, refer to Section 4.1.1, "The Initial Screen."

(2) The Menu screen

The Menu screen is used for selecting whichever of the test conditions you

want to change. Pressing one of the keys on this screen changes over the

display to the appropriate test condition setting screen.

To change any one of the test

conditions (frequency, controlled

level, etc.), press the corresponding

key on this menu.

Menu key

Initial Screen

Menu

Screen

For details, refer to Section 4.1.2, "The Menu Screen and Application Menu

Screen"

______________________________________________________________________________________________

3.2 About the Screen

_____________________________________________________________________________________________

13

(3) The Parameter setting screen

Pressing a parameter key on the Initial screen causes the Parameter setting

screen to be displayed, using which the test parameters to be displayed (up

to a maximum of four) are selected.

By pressing a key for any test parameter, that parameter is set to be

displayed, and the unit automatically returns to displaying the Initial screen

again.

1

2

3

4

Test

parameters

5

6

(4) The Test condition setting screen

This screen is for changing a test condition (for example, the test frequency).

When you have finished setting the test condition, press the key, and the

unit will return to displaying the Initial screen again.

The inactive keys

(which cannot currently

be operated) appear as white

rectangles with black character

legends, i.e. in non-reversed

video.

7

Parameter Setting Screen

8

9

10

11

12

13

14

Test Condition Setting Screen

(Test frequency setti ng screen)

A

______________________________________________________________________________________________

3.2 About the Screen

14

_____________________________________________________________________________________________

3.2.1 Control Screen Sequence

The basic flow for the change of screens as control operation is performed is

as follows.

The measurement values can be checked in real time on all of the screens.

The measured values of any of the test parameters

can be displayed for checking (up to a maximum

of four) and all of the test conditions can be

checked on the Initial screen.

To make a change to the test conditions:

Press the soft key, and the Menu screen will

be displayed.

Initial Screen

Select the test condition to alter on the Menu

screen (for example, when changing the test

frequency).

Menu Screen

Setting Screen

Press the soft key, and the Frequency setting

screen will be displayed.

Set or change that test condition on the appropriate

Test condition setting screen.

When the test condition setting is complete,

press the soft key, and the display will return

to displaying the Initial screen.

Initial Screen

______________________________________________________________________________________________

3.2 About the Screen

_____________________________________________________________________________________________

15

3.3 Basic Measurement

1

In order to explain the basic operation of the 3532-50 unit, as an example,

the procedure will be shown for establishing the following settings:

Example

NOTE

Sample to be tested

Capacitor 0.1 μF

Test conditions

Test frequency 100 kHz

Constant voltage level 0.4 V

Open circuit compensation setup ALL compensation

Short circuit compensation setup ALL compensation

Parameters to be displayed

Capacitance Cs, Loss coefficient D

The trigger is internal. The 3532-50 unit, when it is dispatched from the

factory, is in the internal trigger state.

3.3.1 Basic Flow up to Testing of the Sample

The basic flow up to starting testing of the sample is as shown in the

following chart in correspondence to the applicable reference sections:

2

3

4

5

6

7

8

Step Reference sections

Select the test parameters

to be displayed

Set the test frequency

Set the voltage level

Open circuit compensation

Short circuit compensation

Start testing

3.3.2, "Setting the Test Parameters to be Displayed

(Cs, D)"

3.3.3, "Setting the Test Frequency"

3.3.4, "Setting the Constant Voltage Level"

3.3.5, "Setting Open Circuit Compensation"

3.3.6, "Setting Short Circuit Compensation"

9

10

11

12

13

14

______________________________________________________________________________________________

3.3 Basic Measurement

A

16

_____________________________________________________________________________________________

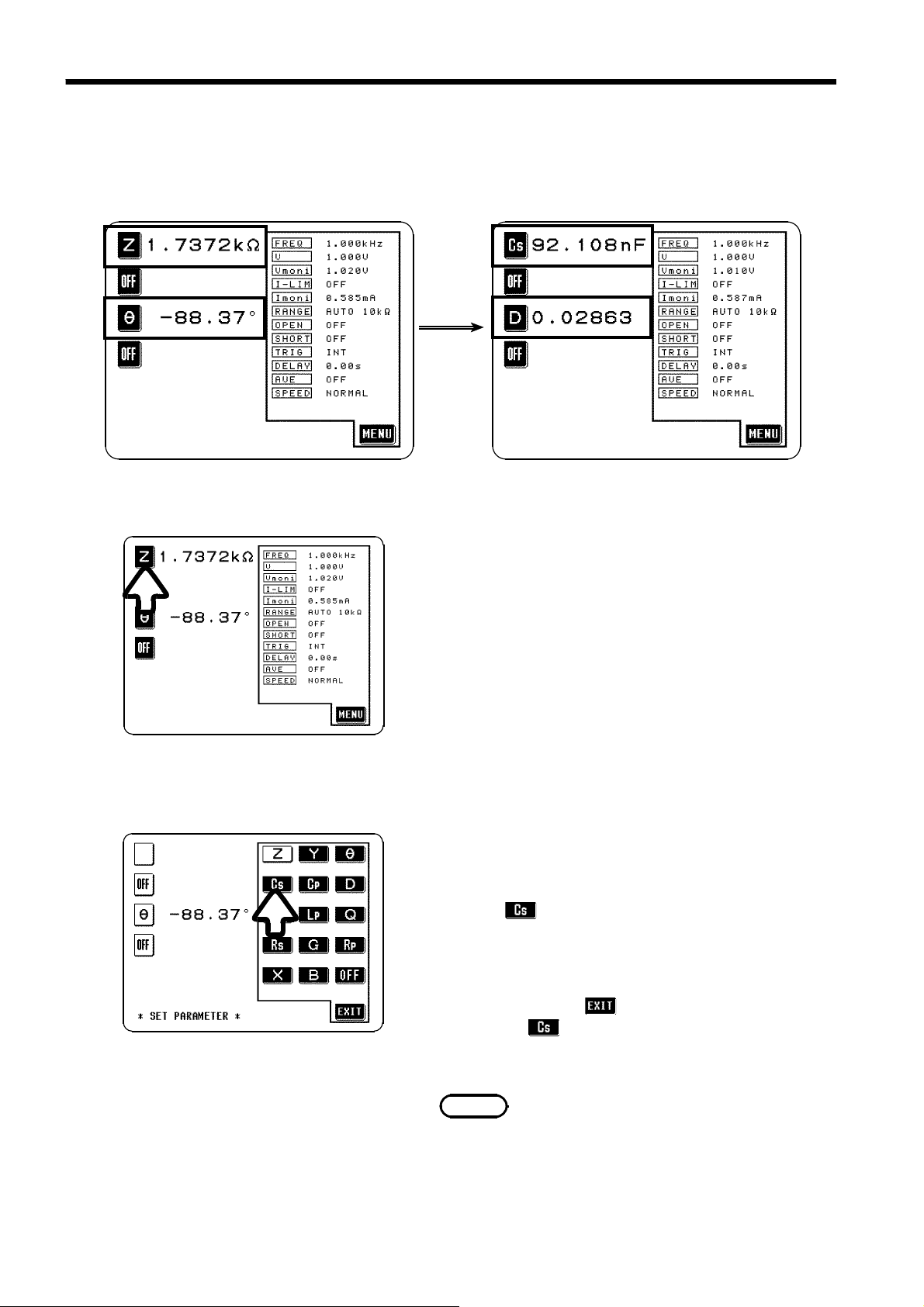

3.3.2 Setting the Test Parameters to be Displayed (Cs, D)

Here the first (i.e., the uppermost) parameter key will be set to capacitance

Cs, and the third parameter key will be set to loss

coefficient D.

Before Setting

Setting procedure

Initial Screen

After Setting

1. In order to change the first parameter displayed

on the Initial screen, press the first (uppermost)

parameter key.

2. The Parameter setting screen is displayed. (The

test parameter (currently Z) to which the pressed

parameter key currently corresponds is shown in

black characters on a white ground, i.e. in nonreversed video).

Press on this screen, and the display will

automatically return to displaying the Initial

screen, with capacitance Cs being displayed as

the first parameter.

If you press the key on this screen without

Parameter Setting Screen

pressing

the display just returns to displaying the Initial

no new setting is performed, and

,

screen.

NOTE

Any of the test parameters (Z,L,C,R, etc.) (up

to a maximum of four) can be set to correspond

to any of the four parameter keys.

______________________________________________________________________________________________

3.3 Basic Measurement

Loading...

Loading...