Page 1

INSTRUCTION MANUAL

For...は専用機種。複数の場合は「/」で区切る。不要の場合はとる。

形名を入力。 複数の場合は「/」で区切る。

3511-50

品名を入力。

LCR HiTESTER

Page 2

Page 3

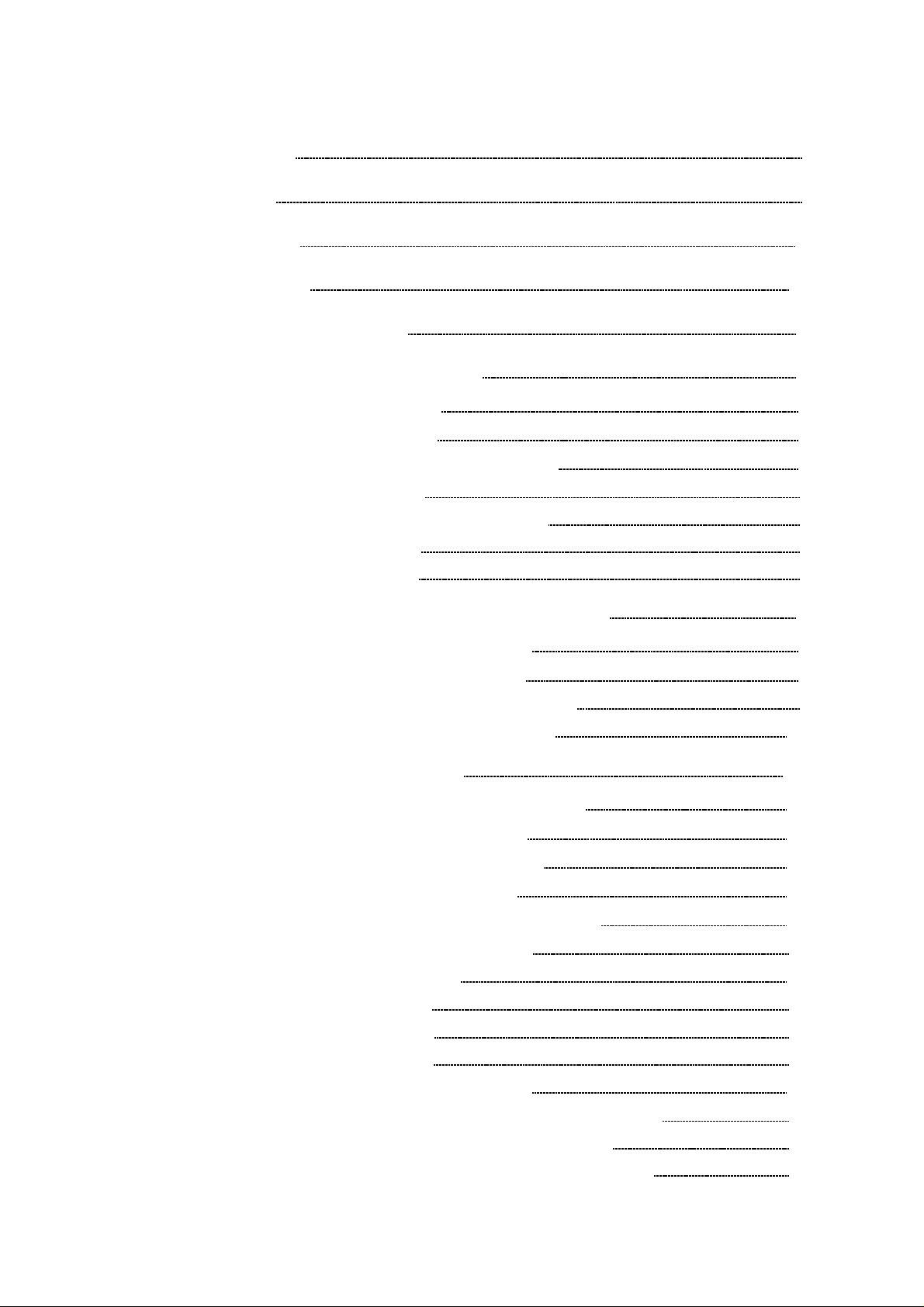

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use iv

Layout of This Manual v

Chapter 1 Product Overview 1

1.1 Product Overview 1

1.2 Product Features

1.3 Names and Functions of Parts

1.3.1 Front View 3

1.3.2 Operation Section Details 4

1.3.3 Rear View 5

1.3.4 Side View 6

Chapter 2 Before Starting Measurement 7

2.1 Connecting the Power Cord 7

2.2 Connecting the Test Leads

2.2.1 Establishing the Connections 9

2.3 Turning the Power On and Off 10

Chapter 3 Basic Functions 11

3.1 Choosing the Testing Parameters 11

3.2 Setting the Test Frequency

3.3 Setting the Test Signal Level

12

12

2

3

8

3.4 Setting the Testing Speed

3.5 Setting the Equivalent Circuit Mode

3.5.1 Equivalent Circuit Mode 14

3.6 Setting the Ranging 16

3.6.1 Test Range 16

3.6.2 Auto Range 20

3.6.3 Hold Range 20

3.7 Open Circuit Compensation 21

3.7.1 Performing Open Circuit Compensation 21

3.7.2 Open Circuit Compensation Error 22

3.7.3 Canceling Open Circuit Compensation 22

13

14

Page 4

3.8 Short Circuit Compensation 23

3.8.1 Performing Short Circuit Compensation 23

3.8.2 Short Circuit Compensation Error 25

3.8.3 Canceling Short Circuit Compensation 25

3.9 Setting the Trigger Signal 26

3.9.1 Setting the Trigger Mode 26

Chapter 4 Other Functions 27

4.1 Comparator Function 27

4.1.1 Operation Sequence 28

4.1.2 Setting the Upper and Lower Limits 28

4.1.3 Comparator Test Mode 30

4.2 Panel Save Function 31

4.2.1 Setting Panel Save 31

4.2.2 Aborting Panel Save 31

4.3 Panel Load Function 32

4.3.1 Setting Panel Load 32

4.3.2 Aborting Panel Load 32

4.4 Key Lock Function 33

4.4.1 Executing the Key Lock Function 33

4.4.2 Cancelling the Key Lock Function 33

4.5 Various Settings Made After Switching on Power 34

4.5.1 Setting Screen Flow After Power ON 34

4.5.2 Setting the Interface 35

4.5.3 Setting Beep 36

4.5.4 Executing System Reboot 37

4.6 Remote Function 38

4.6.1 Remote Mode 38

4.6.2 Cancelling the Remote Mode 38

4.7 The Residual Charge Protection Function 39

Chapter 5 Applications 41

5.1 Testing Using EXT I/O 41

5.1.1 The EXT I/O Connector 41

5.1.2 Pinouts for the EXT I/O Connector 42

5.1.3 Signal Lines for the EXT I/O Connector 43

5.1.4 Circuit Construction and Connections for the EXT I/O

Connector 45

5.1.5 Electrical Characteristics of the Output Signals 46

5.1.6 I/O Signal Timing 47

5.1.7 Time Taken for Testing 48

Page 5

5.2 Supplying DC Bias 50

5.2.1 How to Supply a DC Bias Voltage 51

5.2.2 How to Supply a DC Bias Current 52

5.3 9442 PRINTER (Option) 53

5.3.1 Preparation 53

5.3.2 Connection Method 55

5.3.3 Printing Results 56

5.4 Testing High Impedance Elements 57

5.5 Testing an Element in a Circuit

5.6 External Interference

5.6.1 Countermeasures Against Interference from

the Power Supply Line 59

5.6.2 Countermeasures Against Noise from

the Test Cables 60

58

59

Chapter6 RS-232C Interface 61

6.1 Overview 61

6.1.1 Introduction to the RS-232C Interface 61

6.1.2 Specifications 62

6.2 Connecting Method 63

6.2.1 Handshake 64

6.3 Operation 65

6.3.1 Communication Methods by the RS-232C 65

6.3.2 Message Format 66

6.3.3 Program Message 66

6.3.4 Response Messages 66

6.4 Headers 67

6.5 Data Formats

6.6 Delimiters

6.7 Separators

6.8 Abbreviation of Compound Commands

6.9 Output Queue

6.10 Input Buffer

6.11 Event Registers

6.12 Command Reference

6.12.1 Command Summary 74

68

69

69

70

71

71

72

74

6.13 Format of Command Explanations 76

6.14 Particular Commands

6.15 Commands Specific to the 3511-50

6.16 Initialization Items

6.17 Sample Programs

6.18 Troubleshooting

77

80

98

99

103

Page 6

Chapter 7 Maintenance, Adjustment, and Disposal 105

7.1 Maintenance and Servicing 105

7.2 How to Change the Power Supply Fuse and Change

the Power Supply Voltage

106

7.3 Shipping the Unit

7.4 Troubleshooting

7.5 Disposing of the Unit

109

109

110

Chapter 8 Specifications 113

8.1 General Specifications 113

8.2 Testing Parameters and Calculation Equations

8.3 Test Accuracy

116

118

Chapter 9 Options 121

Page 7

______________________________________________________________________________________________________________

Introduction

Thank you for purchasing the HIOKI "3511-50 LCR HiTESTER." To obtain

maximum performance from the product, please read this manual first, and

keep it handy for future reference.

i

A request

Inspection

Check the 3511-50 unit and the supplied accessories

We have tried to bring this manual as close to perfection as we could

achieve.

If perchance you find any unclear portions, mistakes, omissions, or the like,

we would be most obliged if you could please notify us of them via any

HIOKI agent, or directly.

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki representative.

Main unit

3511-50 LCR HiTESTER

Supplied accessories

(1) Instruction Manual

(2) Grounded three-core power cord (selected according to shipping destination)

(3) Spare fuse for power supply (according to voltage specification)

100 V, 120 V setting: 250 V F1.0AL 20 mm x 5mmdia.

220 V, 240 V setting: 250 V F0.5AL 20 mm x 5mmdia.

NOTE

No interface boards and no test cables are supplied with the unit as standard

equipment. You should order them separately, according to requirements.

__________________________________________________________________________________________________

Introduction

Page 8

ii

______________________________________________________________________________________________________________

Safety Notes

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

This product is designed to conform to IEC 61010 Safety Standards,

WARNING

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as

damage to the product. Be certain that you understand the

instructions and precautions in the manual before use. We disclaim

any responsibility for accidents or injuries not resulting directly from

product defects.

The following symbols in this manual indicate the relative importance of

cautions and warnings.

WARNING

CAUTION

Safety symbols

The symbol printed on the product indicates that the user

should refer to a corresponding topic in the manual (marked with

the

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates a fuse.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

symbol) before using the relevant function.

NOTE

__________________________________________________________________________________________________

Safety Notes

Advisory items related to performance or correct operation of the

product.

Page 9

iii

______________________________________________________________________________________________________________

Overvoltage Categories

This product conforms to the safety requirements for CAT II measurement

products.

To ensure safe operation of measurement products, IEC 60664 establishes

safety standards for various electrical environments, categorized as CAT I to

CAT IV, and called overvoltage categories. These are defined as follows.

CAT I Secondary electrical circuits connected to an AC electrical outlet

through a transformer or similar device.

CAT II Primary electrical circuits in equipment connected to an AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT III Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance, and to

the power meter and primary overcurrent protection device

(distribution panel).

Higher-numbered categories correspond to electrical environments with

greater momentary energy, so a measurement product designed for CAT III

environments can endure greater momentary energy than one designed for

CAT II. Using a measurement product in an environment designated with a

higher-numbered category than that for which the product is rated could

result in a severe accident, and must be carefully avoided.

__________________________________________________________________________________________________

Safety Notes

Page 10

iv

______________________________________________________________________________________________________________

Notes on Use

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

WARNING

CAUTION

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the product

and present an electrical hazard.

To avoid electric shock and ensure safe operation, connect the

power cable to a grounded (3-contact) outlet.

Use this unit near the power supply socket.

The interior of the unit contains some components which are

subject to high voltage, and therefore dangerous. Absolutely do

not remove the cover panel.

Various connectors are present on the outside of the 3511-50. Never

connect any cable to any of these connectors without first turning off the

power supply and removing the power cord. Moreover, check the

connections carefully in order to avoid any chance of setting up a short

circuit etc..

In the event that the equipment malfunctions in any manner during use,

turn off the power immediately, and contact your dealer or HIOKI

representative.

Do not store or use the unit where it will be exposed to direct sunlight,

high temperatures, high humidity, or condensation. If exposed to such

conditions, the unit may be damaged, the insulation may deteriorate, and

the unit may no longer satisfy its specifications.

This product should be installed and operated indoors only, between 0

and 40

-10

The unit should always be stored in a range from -10 to 55 , 80% RH

or less.

Do not store or use the product where it could be exposed to direct

sunlight, high temperature or humidity, or condensation. Under such

conditions, the product may be damaged and insulation may deteriorate

so that it no longer meets specifications.

Do not drop the unit or subject it to severe shock. Doing so can cause

serious damage.

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

and 35 to 80%RH. However, it can be safely operated down to

.

Warranty

HIOKI cannot be responsible for losses caused either directly or indirectly by

the use of the unit with other equipment, or if ownership is transferred to a

third party.

__________________________________________________________________________________________________

Notes on Use

Page 11

v

______________________________________________________________________________________________________________

Layout of This Manual

Chapter 1 Product Overview

Describes the product generally, and lists the parts and functions.

Chapter 2 Before Starting Measurement

How to connect the power cord etc., and important precautions before

operation.

Chapter 3 Basic Functions

Description of operating procedures and normal measurement functions

Chapter 4 Other Functions

Special functions.

Chapter 5 Detailed Description of Applications

Various testing applications.

Chapter 6 RS-232C Interface

General description of RS-232C and explanation of related commands.

Chapter 7 Maintenance, Adjustment, and Disposal

Chapter 8 Specifications

Chapter 9 Options

__________________________________________________________________________________________________

Layout of This Manual

Page 12

vi

______________________________________________________________________________________________________________

__________________________________________________________________________________________________

Layout of This Manual

Page 13

1

_____________________________________________________________________________________________________________

Chapter 1

1

2

1.1 Product Overview

The HIOKI 3511-50 LCR HiTESTER is capable of measuring the impedance

of various devices. With a wide range of test frequencies (from 120 Hz to 1

kHz), the 3511-50 offers high-speed, high-accuracy measurement

capabilities.

Product Overview

3

4

5

6

7

8

9

10

11

12

13

14

A

________________________________________________________________________________________________________________

1.1 Product Overview

Page 14

2

_____________________________________________________________________________________________________________

1.2 Product Features

(1) Compact, lightweight single-function model

Streamlined to provide a single function for test frequencies 120 Hz and

1 kHz, the 3511-50 is compact and lightweight.

(2) High-speed measurement

The 3511-50 is capable of high-speed measurement: 5 ms at test frequency

1 kHz, and 13 ms at 120 Hz.

(3) Comparator function

On the 3511-50, comparator functions are standard. Different comparators

may be executed for two separate displayed parameters.

(4) LED display

Provides superior visibility.

(5) Two interfaces

The 3511-50 offers external I/O for sequencing and a standard RS-232C

interface. An optional 9518-01 GP-IB INTERFACE is also available.

________________________________________________________________________________________________________________

1.2 Product Features

Page 15

_____________________________________________________________________________________________________________

1.3 Names and Functions of Parts

3

1

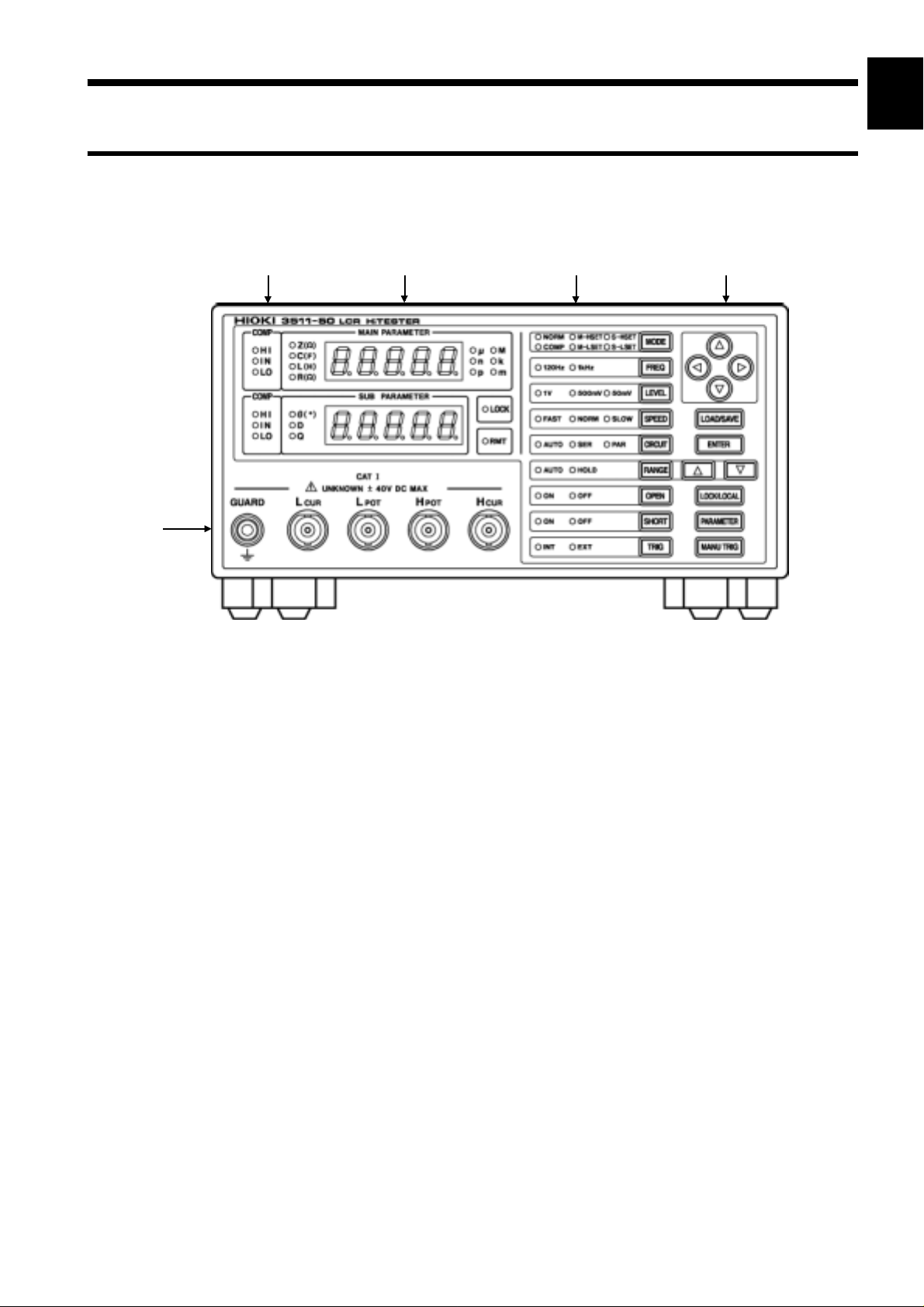

1.3.1 Front View

3 1 2 4

5

2

3

4

5

6

7

8

1. Measurement display

Displays a testing parameter and corresponding measurement.

2. Status display

Displays current test conditions, presettings, and other information.

3. Comparator judgment display

Displays judgment in comparator mode.

4. Operation section

Use to set test conditions and to make other settings (see next page for more

information).

5. Test terminals

There are five test terminals:

H

: The test signal is supplied to this terminal.

CUR

H

: Detected voltage high terminal

POT

L

: Detected voltage low terminal

POT

L

: Test current detected terminal

CUR

GUARD: Guard terminal

These test terminals are designed according to the safety standard;

Pollution Degree 2, Overvoltage Category I.

9

10

11

12

13

14

________________________________________________________________________________________________________________

1.3 Names and Functions of Parts

A

Page 16

4

_____________________________________________________________________________________________________________

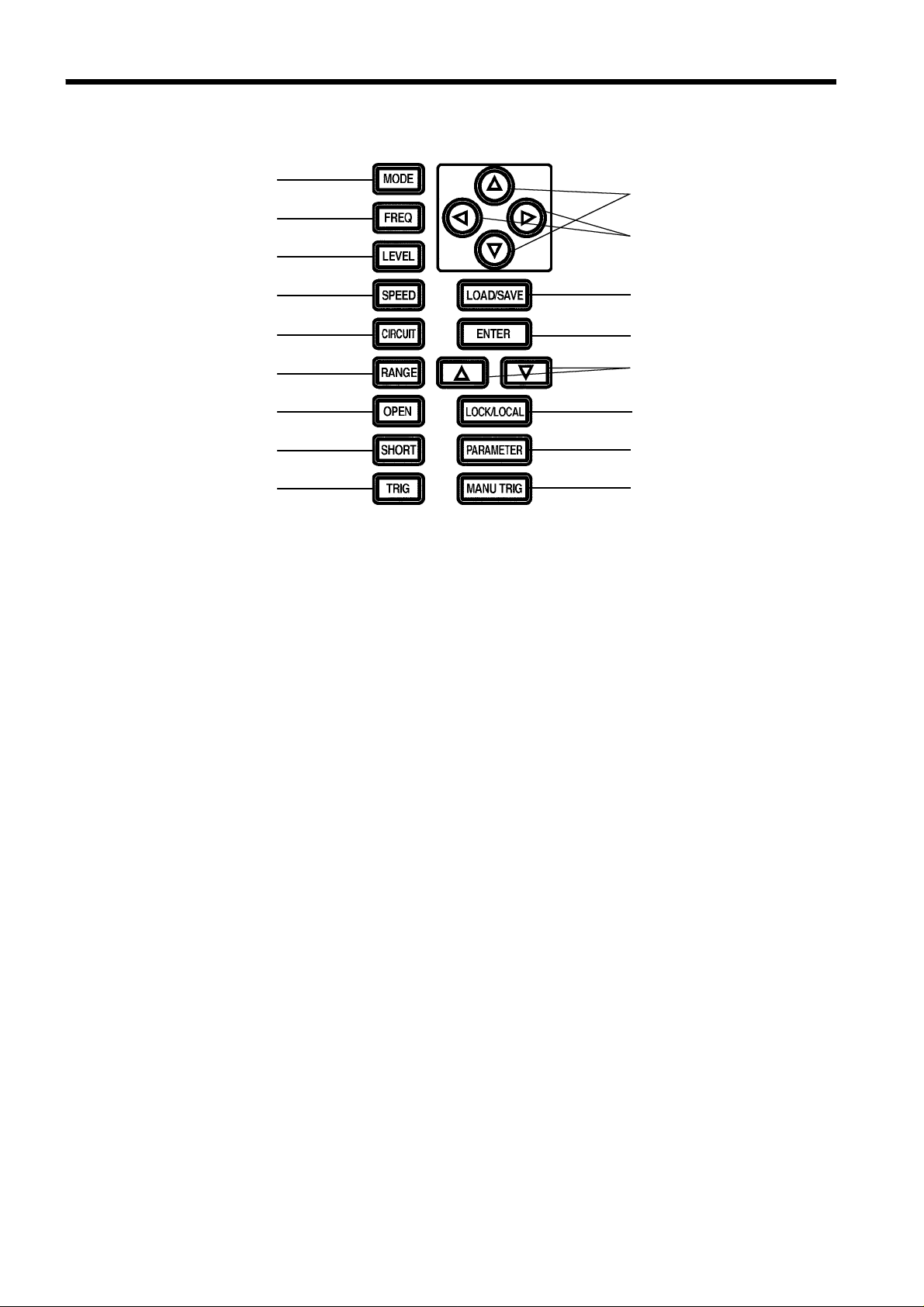

1.3.2 Operation Section Details

1

17

2

16

3

4

5

6

7

8

9

15

14

13

12

11

10

1. Test mode selector key 10. Manual trigger key

2. Test frequency selector key 11. Testing parameter selector key

3. Test signal level selector key 12. LOCK/LOCAL key

4. Testing speed selector key 13. Test range selector key (up/down)

5. Equivalent circuit mode selector key 14. ENTER key

6. Test range selector key 15. LOAD/SAVE key

7. Open circuit compensation key 16. Digit selector key (left/right)

8. Short circuit compensation key 17. Count-setting key (up/down)

9. Trigger mode selector key

________________________________________________________________________________________________________________

1.3 Names and Functions of Parts

Page 17

_____________________________________________________________________________________________________________

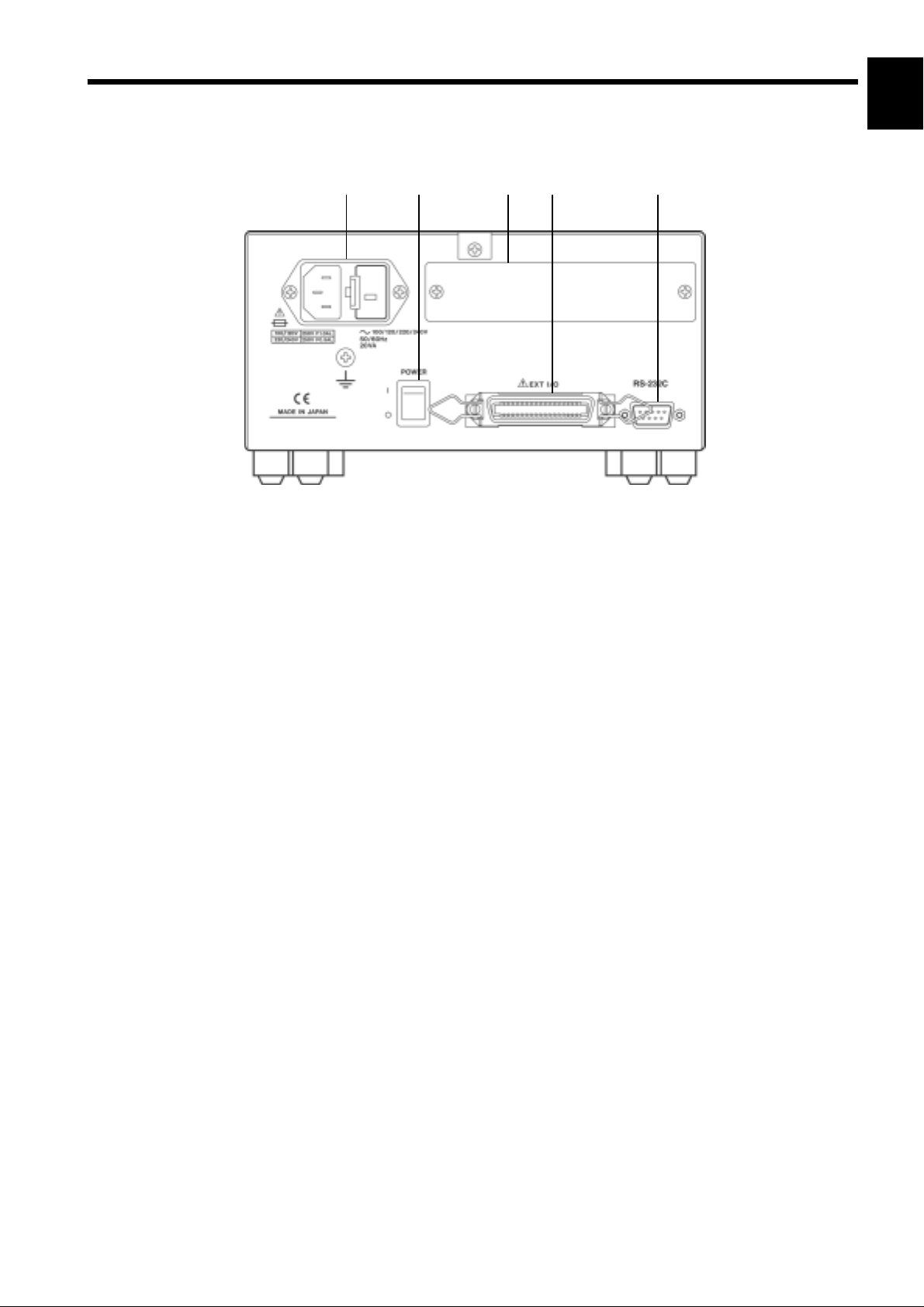

1.3.3 Rear View

5

1

12 34 5

1. Power input socket with voltage selector

Connect the supplied power cord here.

2. Power switch

Turns the power for the unit on and off.

2

3

4

5

6

7

8

3. Optional equipment interface

The optional 9518-01 GP-IB INTERFACE is connected here.

4. EXT I/O connector

For input of an external trigger signal and output of comparator results.

Compatible with sequencer connection.

5. RS-232C connector

Connect the RS-232C cable here.

9

10

11

12

13

14

________________________________________________________________________________________________________________

1.3 Names and Functions of Parts

A

Page 18

6

_____________________________________________________________________________________________________________

1.3.4 Side View

1

CAUTION

1. Stand

Do not apply strong downward pressure with the stand extended. Damage

to the stand will result.

________________________________________________________________________________________________________________

1.3 Names and Functions of Parts

Page 19

7

_____________________________________________________________________________________________________________

Chapter 2

1

2

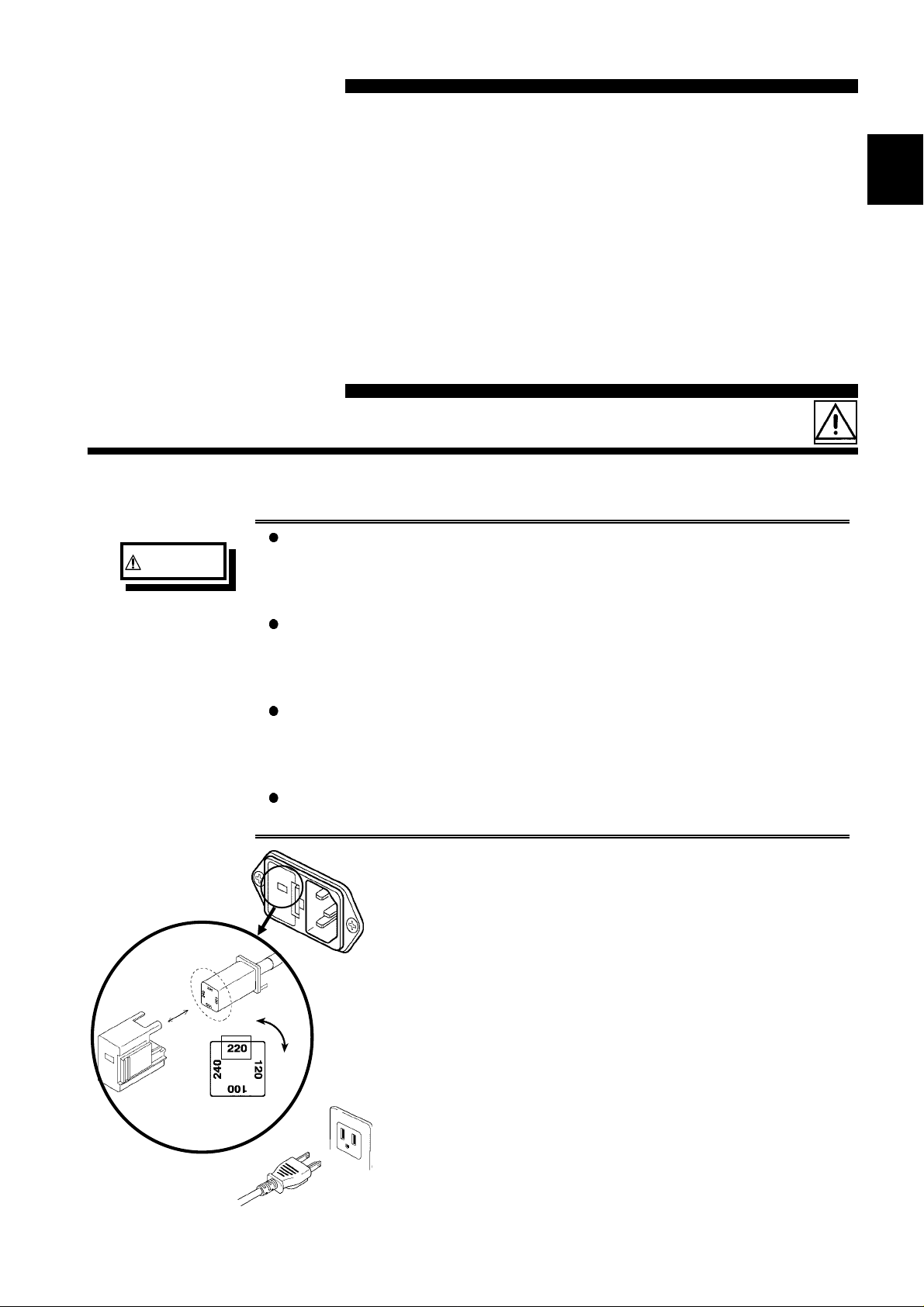

2.1 Connecting the Power Cord

When a 3511-50 unit is ordered, the supply voltage is set in

WARNING

the factory to the value specified, which can be 100 V, 120 V,

220 V, or 240 V.

The maximum rated power (with all options fitted) is 20 VA.

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the

product and present an electrical hazard.

The power supply voltage for this product is switchable. To

avoid electrical accidents, check that the voltage selector is

set correctly for the supply voltage you are using.

(For details, refer to Section 7.2)

To avoid electric shock and ensure safe operation, connect

the power cable to a grounded (3-contact) outlet.

Before Starting

Measurement

3

4

5

6

7

8

9

10

The power cord is connected according to the following

procedure.

1. Check that the main power switch of the unit is off.

2. Check that the power supply voltage is correct, and

connect the proper end of the power cord to the power

input socket (with voltage selector) at the rear of the unit.

3. Plug the other end of the power cord into the power

supply socket.

Grounding

Use the grounding type (three-wire) power cord supplied.

The unit will be grounded automatically.

________________________________________________________________________________________________________________

2.1 Connecting the Power Cord

11

12

13

14

A

Page 20

8

_____________________________________________________________________________________________________________

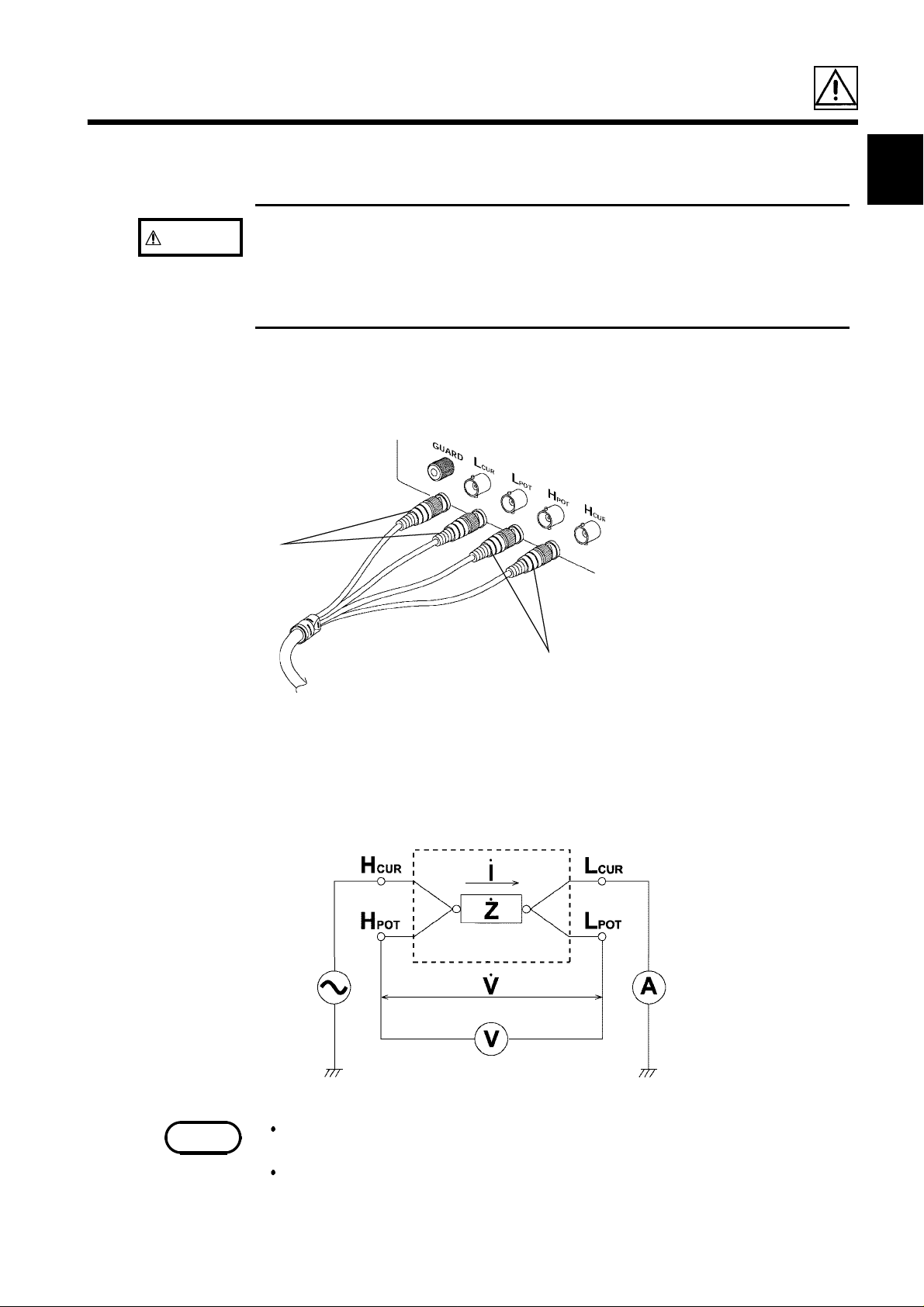

2.2 Connecting the Test Leads

The 3511-50 has five test terminals:

H

terminal (to which the test signal is supplied)

CUR

H

terminal (detected voltage high terminal)

POT

L

terminal (detected voltage low terminal)

POT

L

terminal (test current detected terminal)

CUR

GUARD terminal (connected to the chassis of the unit).

These test terminals are designed according to the safety standard;

Pollution Degree 2, Overvoltage Category I.

________________________________________________________________________________________________________________

2.2 Connecting the Test Leads

Page 21

_____________________________________________________________________________________________________________

2.2.1 Establishing the Connections

9

1

2

CAUTION

The maxim um voltage whic h can be applied to the test terminals of t he

3511-50 unit is 40 V DC. If a DC voltage greater than this is applied

continuously, t he unit m ay be damaged.

For how to apply a DC bias voltage, refer to Section 5.2, " Supplying DC

Bias."

If using a test lead set supplied by HIOKI, connect the red leads to the H

terminal and to the H

terminal and to the L

Black

terminal, and connect the black leads to the L

POT

terminal.

POT

Red

CUR

3

4

CUR

5

6

7

8

NOTE

The unit is designed and adjusted for 75 Ω coaxial cable test leads. It is

best to use HIOKI test leads.

The connections to the article to be tested are as shown in the

following figure.

Test fixture

No test cables are included with the 3511-50 unit. They must be

purchased separately. For details, refer to Chapter 9, "Options."

If all four terminals are left floating, the numbers which appear on the

display are completely meaningless.

9

10

11

12

13

14

A

________________________________________________________________________________________________________________

2.2 Connecting the Test Leads

Page 22

10

_____________________________________________________________________________________________________________

2.3 Turning the Power On and Off

How to turn the power on

Turn on the power switch on the rear panel. All LEDs on the front panel

light.

The test conditions will start off the same as they were when last the power

was turned off.

NOTE

NOTE

Wait for 60 minutes after turning on the power before starting testing, so as

to allow the unit to warm up fully.

How to turn the power off

Turn off the power switch on the rear panel. The test conditions will be

preserved.

Even if the power supply is interrupted because of a power failure or the

like, the test conditions (settings) will not be lost; when the power is turned

on again, the unit will return to its state just before the interruption.

This happens, however, in the normal test mode or comparator execution

mode only.

________________________________________________________________________________________________________________

2.3 Turning the Power On and Off

Page 23

11

________________________________________________________________________________________________________________

Chapter 3

1

2

Basic Functions

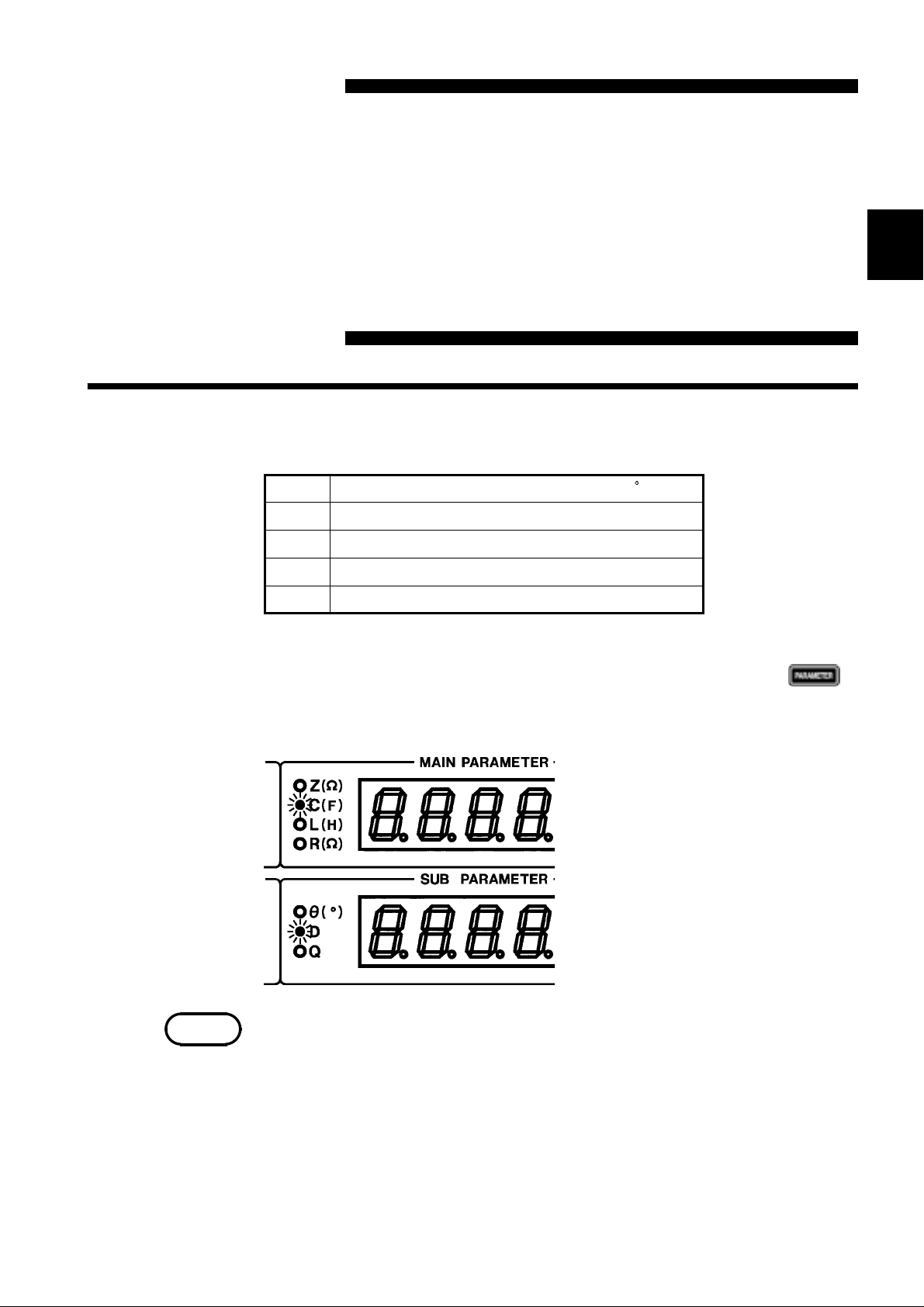

3.1 Choosing the Testing Parameters

Z-θ Impedance (Ω) - Impedance phase angle ( )

C-D Static capacitance (F) - Loss coefficient (=tan δ)

L-D Inductance (H) - Loss coefficient (=tan δ)

L-Q Inductance (H) - Q factor

R Effective resistance (Ω)

As shown above, the 3511-50 permits five possible combinations of testing

parameters. Cycle through the combinations by repeatedly pressing .

Use the LED lamps to the left of the measurement display to check on

selected testing parameters.

3

4

5

6

7

8

9

NOTE

Check polarity via the impedance phase angle. Except for impedance phase

angle, all values are displayed as absolute values.

For details, refer to Section 8.2, "Testing Parameters and Calculation

Equations."

10

11

12

13

14

A

________________________________________________________________________________________________________________

3.1 Choosing the Testing Parameters

Page 24

12

________________________________________________________________________________________________________________

3.2 Setting the Test Frequency

For the 3511-50's test frequency, you may specify either 120 Hz or 1 kHz.

Procedure

Press to toggle between 120 Hz and 1 kHz. Use the LED lamp to the

left of the key to check on a set test frequency.

3.3 Setting the Test Signal Level

For the 3511-50's test signal level, you may specify 1 V, 500 mV or 50 mV.

Procedure

Press repeatedly to cycle through available settings: 1 V, 500 mV, and

50 mV. Use the LED lamp to the left of the key to check on a set test

signal level.

Precautions for changing test signal levels

The value of the test signal level may change according to the sample which

is being tested. During measurement, keep in mind that inductance is often

current-dependent.

________________________________________________________________________________________________________________

3.2 Setting the Test Frequency

Page 25

13

________________________________________________________________________________________________________________

3.4 Setting the Testing Speed

1

NOTE

For testing speed, select from one of the following three levels, depending on

the specific purpose. The slower the testing speed is, the more accurate are

the results.

FAST : Low accuracy testing is performed at high speed.

NORM : The speed used for normal testing

SLOW : High accuracy testing is performed slowly.

Procedure

Press repeatedly to cycle through available settings: FAST, NORM, and

SLOW. Use the LED lamp to the left of the key to check on a set testing

speed.

Testing speed

Test frequency FAST NORM SLOW

120 Hz 13 ms 90 ms 400 ms

1kHz 5ms 60 ms 300 ms

The testing time values above are for reference only, valid when Z-θ is

displayed and varying according to testing parameter setting conditions,

range mode, OPEN/SHORT compensation, and other conditions.

2

3

4

5

6

7

8

9

10

11

12

13

14

A

________________________________________________________________________________________________________________

3.4 Setting the Testing Speed

Page 26

14

________________________________________________________________________________________________________________

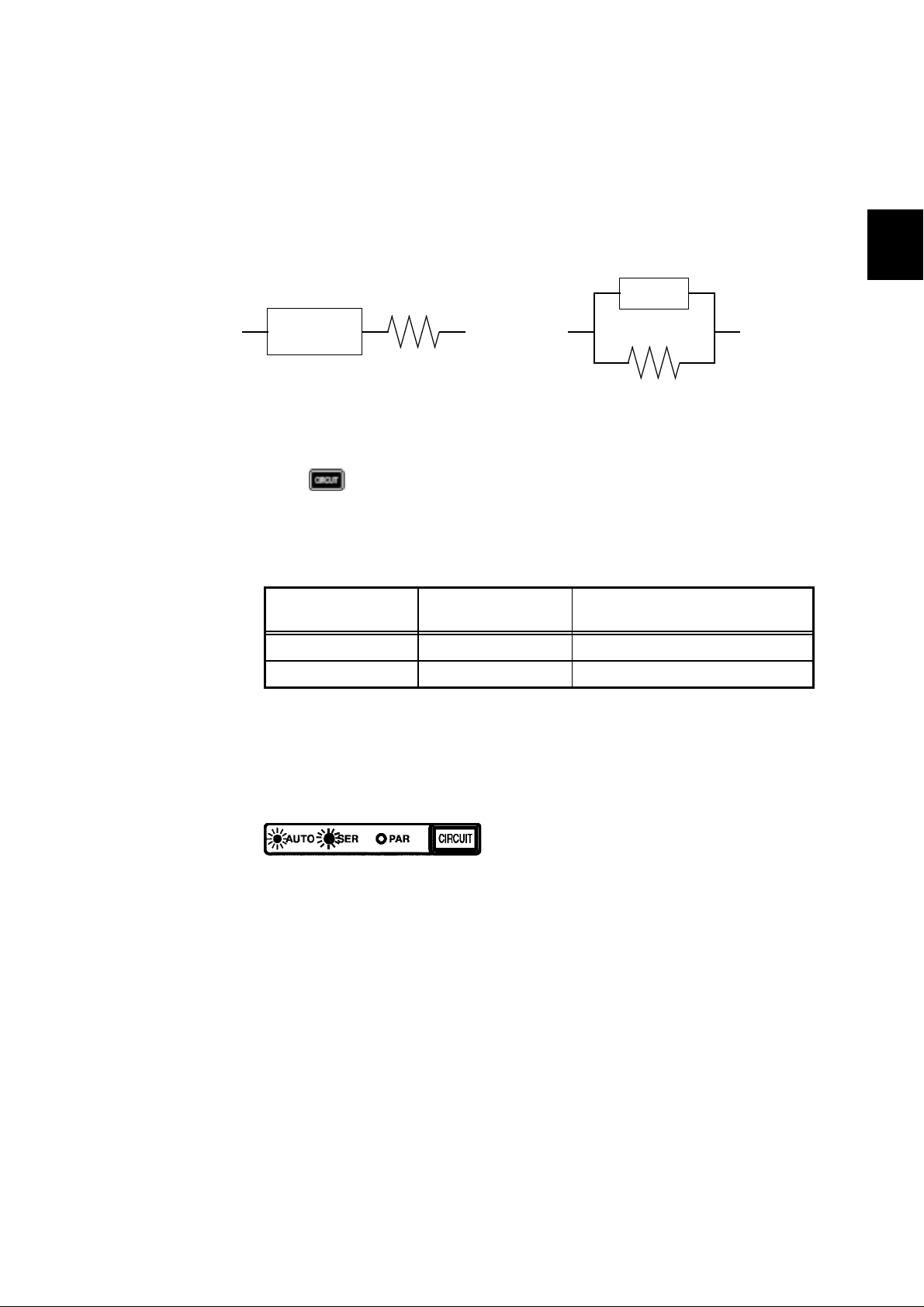

3.5 Setting the Equivalent Circuit Mode

You may set an equivalent circuit mode. Automatic selection is also

possible.

3.5.1 Equivalent Circuit Mode

The 3511-50 unit analyses the test sample in terms of a pure inductive

component (L), an equivalent circuit construction composed of a pure

capacitive component (C), and a pure resistive component (R), and

calculates as though these components were connected in series, or

alternatively connected in parallel. Therefore, it is possible for the user to

select either a series equivalent circuit mode or a parallel equivalent circuit

mode for this conceptual connection together of these L, C, and R

components.

When the impedance of the sample being tested is relatively high, the

parallel equivalent circuit mode should be selected manually, and when the

impedance of the sample being tested is relatively low, the series equivalent

circuit mode should be selected manually.

Generally, for a device such as an electrolytic capacitor or the like with a

high D value (i.e., a low Q value), the test values obtained when testing

using series equivalent circuit mode differ from those obtained when testing

using parallel equivalent circuit mode. The greater the resistance component

in the sample being tested, the more this difference in the test values

appears.

For example, the test values for capacitors of the same capacitance which

have different values of D in series equivalent circuit mode and in parallel

equivalent circuit mode may be as follows:

Series equivalent circuit mode

D=0 C C

D = 0.1 1.005C 0.995C

D = 0.5 1.118C 0.8944C

Parallel equivalent circuit mode

(Where C is the static capacitance)

________________________________________________________________________________________________________________

3.5 Setting the Equivalent Circuit Mode

Page 27

15

________________________________________________________________________________________________________________

Therefore it is necessary for the user clearly to understand the setting of this

test mode, in order properly to assess test samples.

In general, parallel equivalent circuit mode should be used for elements

which have relatively low capacitance and high impedance such as film

capacitors and ceramic capacitors, since parallel resistance can cause great

loss in this case; while series equivalent circuit mode should be used for

elements which have relatively high capacitance and low impedance such as

electrolytic capacitors, since series resistance can cause great loss in this

case.

Series equivalent circuit Parallel equivalent circuit

Procedure

Press repeatedly to cycle through available settings: AUTO, SER, and

PAR.

AUTO : The series equivalent circuit mode or the parallel equivalent circuit

mode is selected automatically according to the following table,

following the measurement range.

1

2

3

4

5

6

7

Z,L,R-range number C-range number

1to5 6to10 Series equivalent circuit

6to10 1to5 Parallel equivalent circuit

SER : Series equivalent circuit mode

PAR : Parallel equivalent circuit mode

Use the LED lamp to the left of the key to check on a set equivalent circuit

mode.

The equivalent circuit mode is

set automatically.

8

9

10

11

12

13

________________________________________________________________________________________________________________

3.5 Setting the Equivalent Circuit Mode

14

A

Page 28

16

________________________________________________________________________________________________________________

3.6 Setting the Ranging

You may set a test range. Automatic selection is also possible.

3.6.1 Test Range

A test range is set, with impedance as a reference. The range numbers,

corresponding impedance ranges, and first parameter display ranges are as

follows:

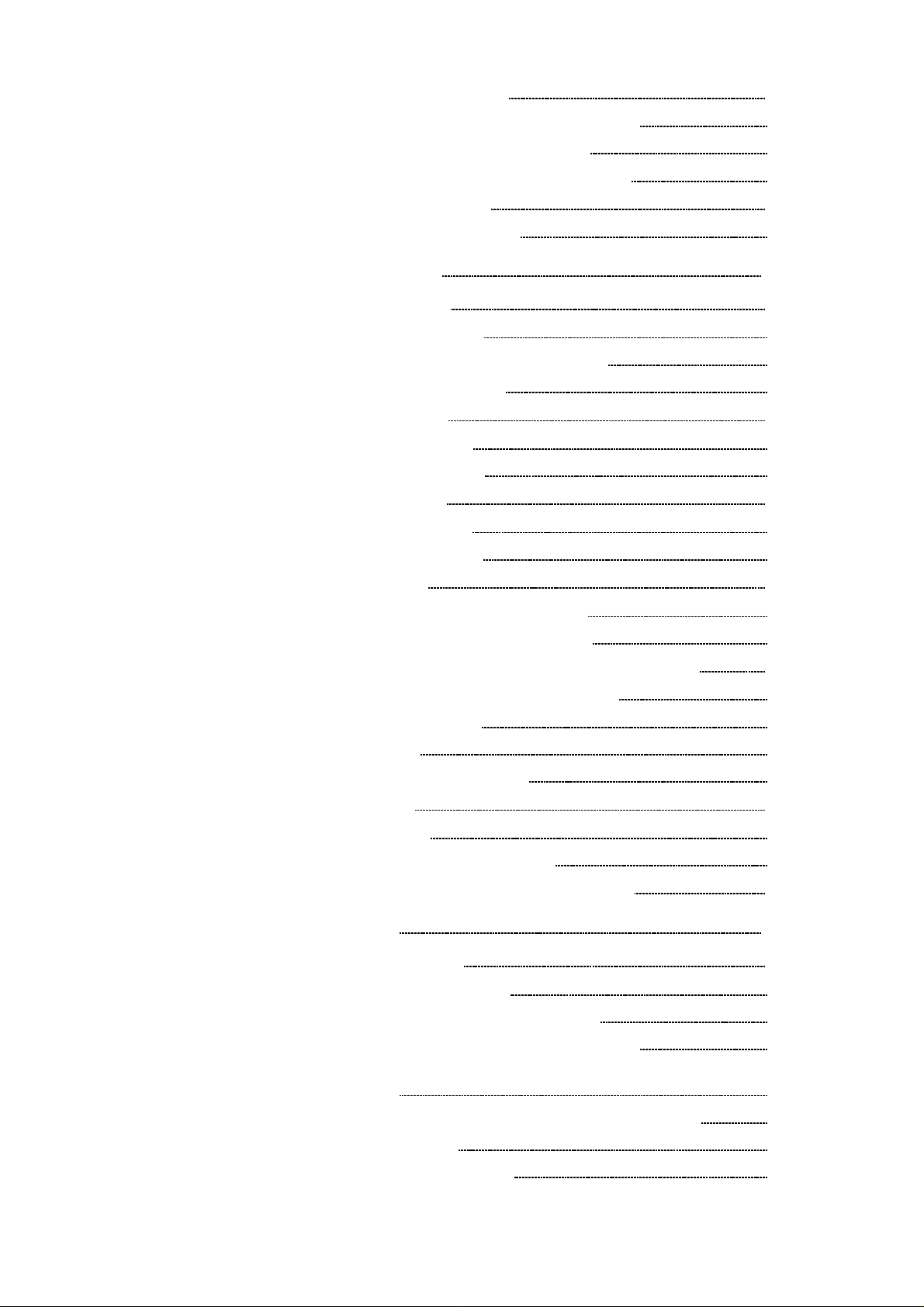

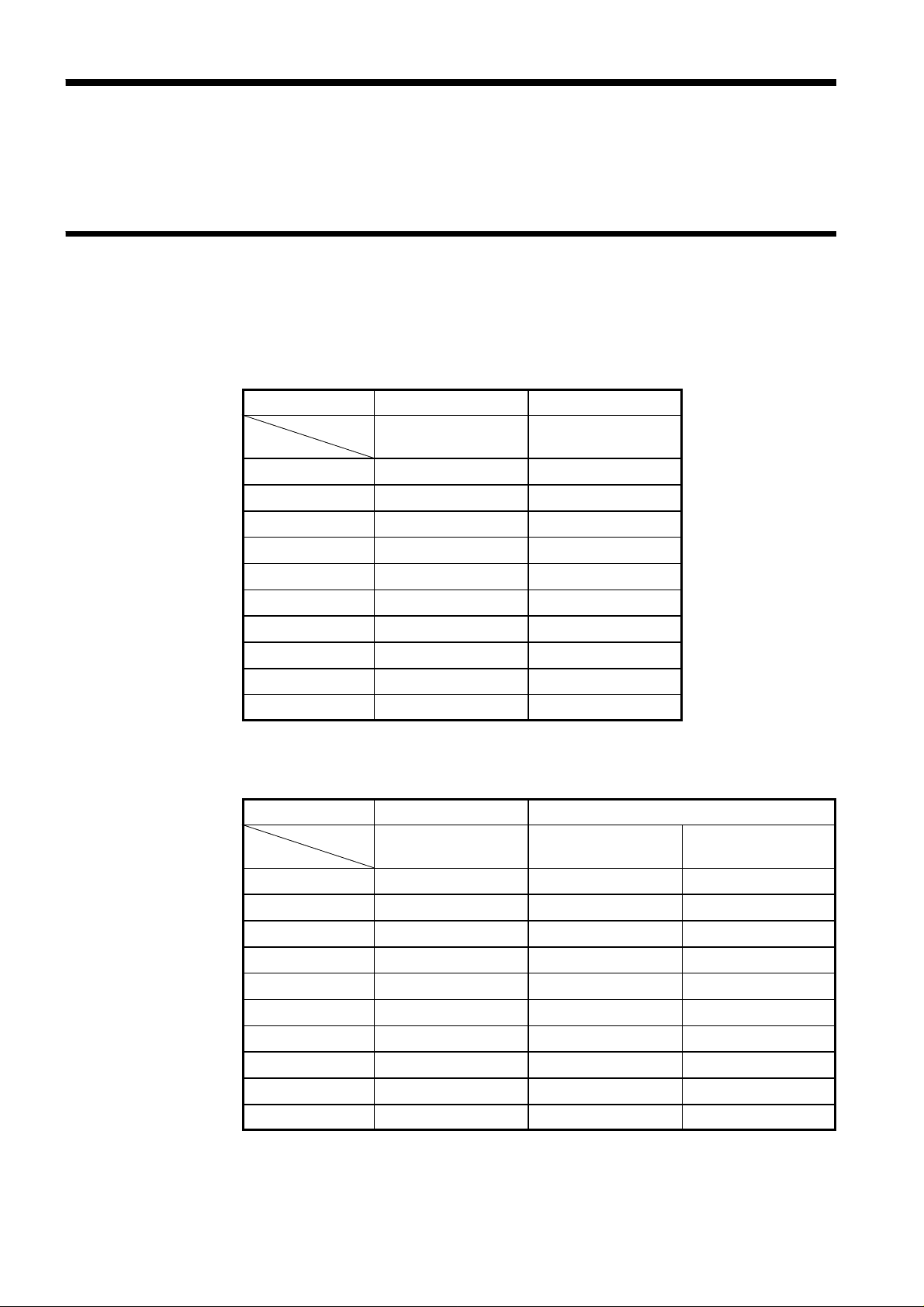

Z-display range * R-display range

Frequency

Range number

10 009.00 to 200.00 MΩ 000.00 to 999.99 MΩ

9 0.9000 to 9.9999 MΩ 0.0000 to 9.9999 MΩ

8 090.00 to 999.99 kΩ 000.00 to 999.99 kΩ

7 09.000 to 99.999 kΩ 00.000 to 99.999 kΩ

6 0.9000 to 9.9999 kΩ 0.0000 to 9.9999 kΩ

5 090.00 to 999.99 Ω 000.00 to 999.99 Ω

4 09.000 to 99.999 Ω 00.000 to 99.999 Ω

3 0.9000 to 9.9999 Ω 0.0000 to 9.9999 Ω

2 0.0900 to 0.9999 Ω 0.0000 to 9.9999 Ω

1 0.0100 to 0.0999 Ω 0.0000 to 9.9999 Ω

Common to

120 Hz and 1 kHz

Common to

120 Hz and 1 kHz

*: Range of impedance which can be measured within the accuracy

guaranteed

Z-display range * L-display range

Frequency

Range number

10 009.00 to 200.00 MΩ 000.00 to 999.99 kH 00.000 to 99.999 kH

9 0.9000 to 9.9999 MΩ 00.000 to 99.999 kH 0.0000 to 9.9999 kH

8 090.00 to 999.99 kΩ 0.0000 to 9.9999 kH 000.00 to 999.99 H

7 09.000 to 99.999 kΩ 000.00 to 999.99 H 00.000 to 99.999 H

6 0.9000 to 9.9999 kΩ 00.000 to 99.999 H 0.0000 to 9.9999 H

5 090.00 to 999.99 Ω 0.0000 to 9.9999 H 000.00 to 999.99 mH

4 09.000 to 99.999 Ω 000.00 to 999.99 mH 00.000 to 99.999 mH

3 0.9000 to 9.9999 Ω 00.000 to 99.999 mH 0.0000 to 9.9999 mH

2 0.0900 to 0.9999 Ω 0.0000 to 9.9999 mH 000.00 to 999.99 µH

1 0.0100 to 0.0999 Ω 000.00 to 999.99 µH 00.000 to 99.999 µH

*: Range of impedance which can be measured within the accuracy guaranteed

Common to

120 Hz and 1 kHz

120 Hz 1 kHz

________________________________________________________________________________________________________________

3.6 Setting the Ranging

Page 29

17

________________________________________________________________________________________________________________

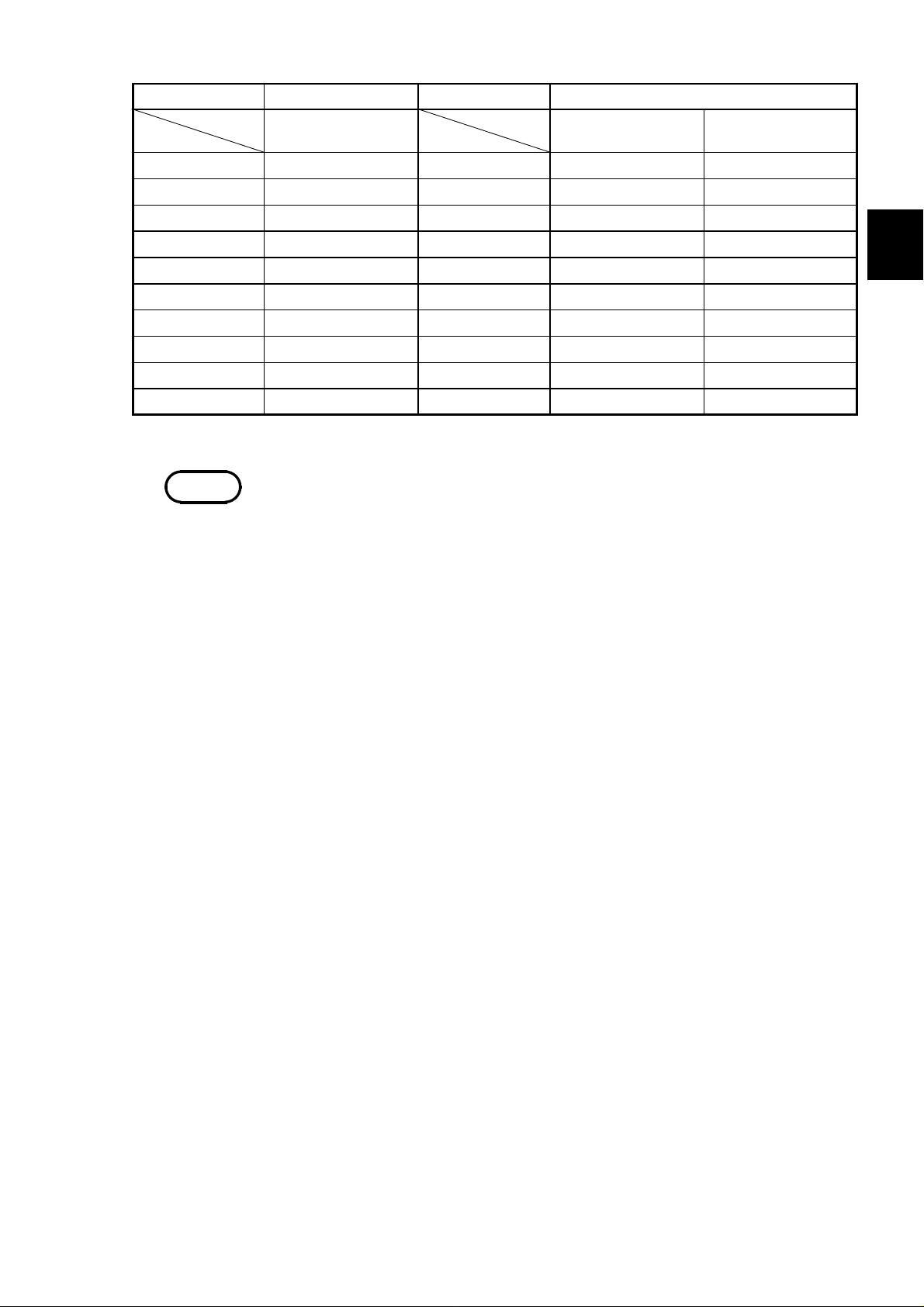

Z-display range * C-display range

Frequency

Range number

10 009.00 to 200.00 MΩ 1 000.00 to 999.99 pF 00.000 to 99.999 pF

9 0.9000 to 9.9999 MΩ 2 0.0000 to 9.9999 nF 000.00 to 999.99 pF

8 090.00 to 999.99 kΩ 3 00.000 to 99.999 nF 0.0000 to 9.9999 nF

7 09.000 to 99.999 kΩ 4 000.00 to 999.99 nF 00.000 to 99.999 nF

6 0.9000 to 9.9999 kΩ 5 0.0000 to 9.9999 µF 000.00 to 999.99 nF

5 090.00 to 999.99 Ω 6 00.000 to 99.999 µF 0.0000 to 9.9999 µF

4 09.000 to 99.999 Ω 7 000.00 to 999.99 µF 00.000 to 99.999 µF

3 0.9000 to 9.9999 Ω 8 0.0000 to 9.9999 mF 000.00 to 999.99 µF

2 0.0900 to 0.9999 Ω 9 00.000 to 99.999 mF 0.0000 to 9.9999 mF

1 0.0100 to 0.0999 Ω 10 000.00 to 999.99 mF 00.000 to 99.999 mF

*: Range of impedance which can be measured within the accuracy guaranteed

NOTE

Common to

120 Hz and 1 kHz

If the impedance exceeds the measurement range, the first parameter display

is "UF" (underflow, i.e., impedance below the measurement range) or "OF"

(overflow, i.e., impedance above the measurement range), and the second

parameter display disappears.

Range number

Frequency

120 Hz 1 kHz

1

2

3

4

5

6

7

8

9

10

11

12

13

14

________________________________________________________________________________________________________________

3.6 Setting the Ranging

A

Page 30

18

________________________________________________________________________________________________________________

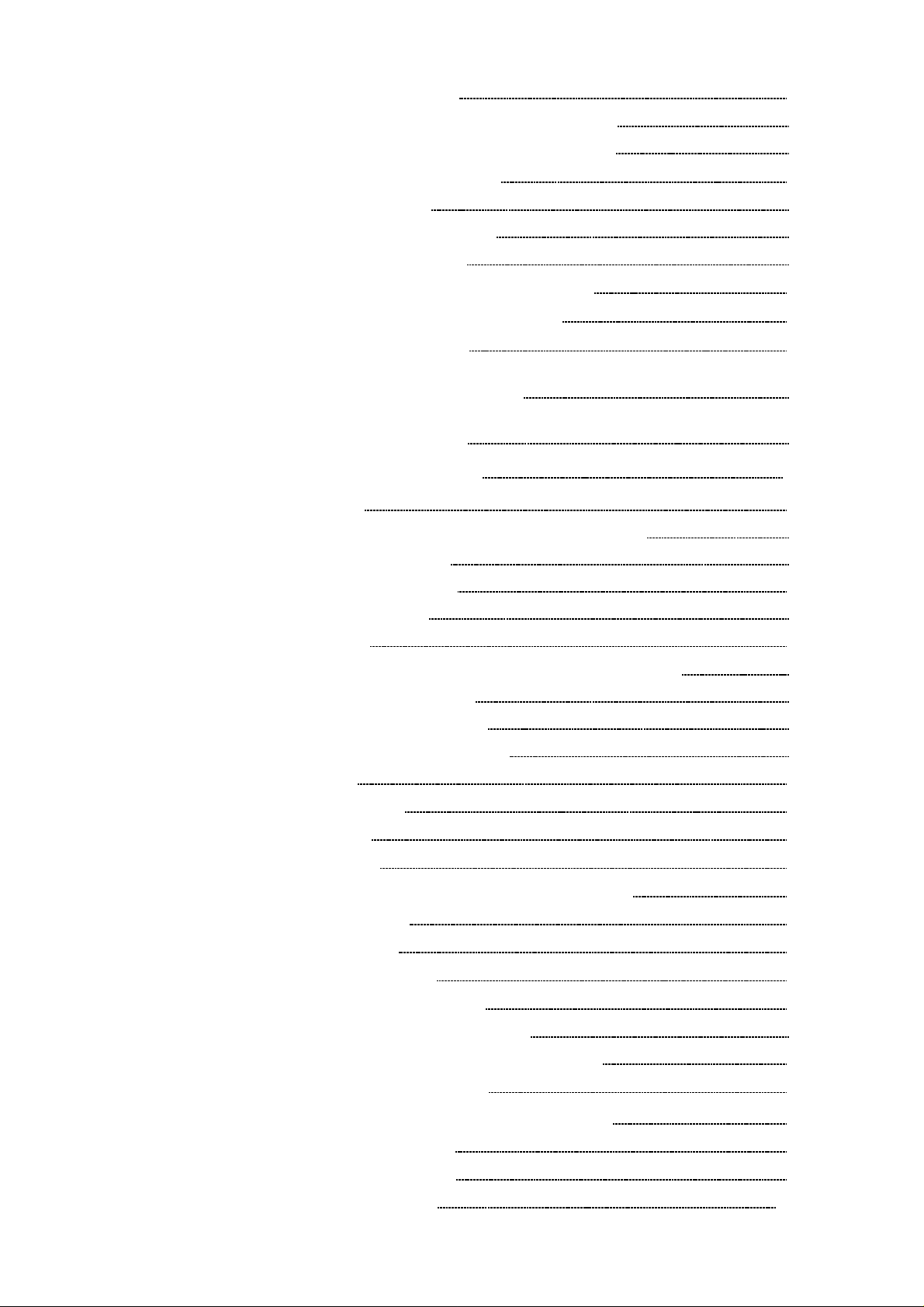

To measure a parameter other than Z - i.e., C, L, or R - determine an

appropriate range based on impedance. The following table presents

appropriate ranges for C and L when D is equal to or smaller than 0.1 and

those when θ is equal to or smaller than 6 .

Test range Z R

Frequency Common to

120Hzand1kHz

Range number Range Display range Range Display range

10 100 MΩ 200.00 MΩ 100 MΩ 200.00 MΩ

009.00 MΩ 009.10 MΩ

9 10 MΩ 9.9999 MΩ 10 MΩ 9.9000 MΩ

0.9000 MΩ 0.9100 MΩ

8 1MΩ 999.99 kΩ 1MΩ 990.00 kΩ

090.00 kΩ 091.00 kΩ

7 100 kΩ 99.999 kΩ 100 kΩ 99.000 kΩ

09.000 kΩ 09.100 kΩ

6 10 kΩ 9.9999 kΩ 10 kΩ 9.9000 kΩ

0.9000 kΩ 0.9100 kΩ

5 1kΩ 999.99 Ω 1kΩ 990.00 Ω

090.00 Ω 091.00 Ω

4 100 Ω 99.999 Ω 100 Ω 99.000 Ω

09.000 Ω 09.100 Ω

3 10 Ω 9.9999 Ω 10 Ω 9.9000 Ω

0.9000 Ω 0.9100 Ω

2 1 Ω 0.9999 Ω 1 Ω 0.9900 Ω

0.0900 Ω 0.0900 Ω

1 100 mΩ 0.0999 Ω 100 mΩ 0.0990 Ω

0.0100 Ω 0.0110 Ω

Common to

120Hzand1kHz

________________________________________________________________________________________________________________

3.6 Setting the Ranging

Page 31

19

________________________________________________________________________________________________________________

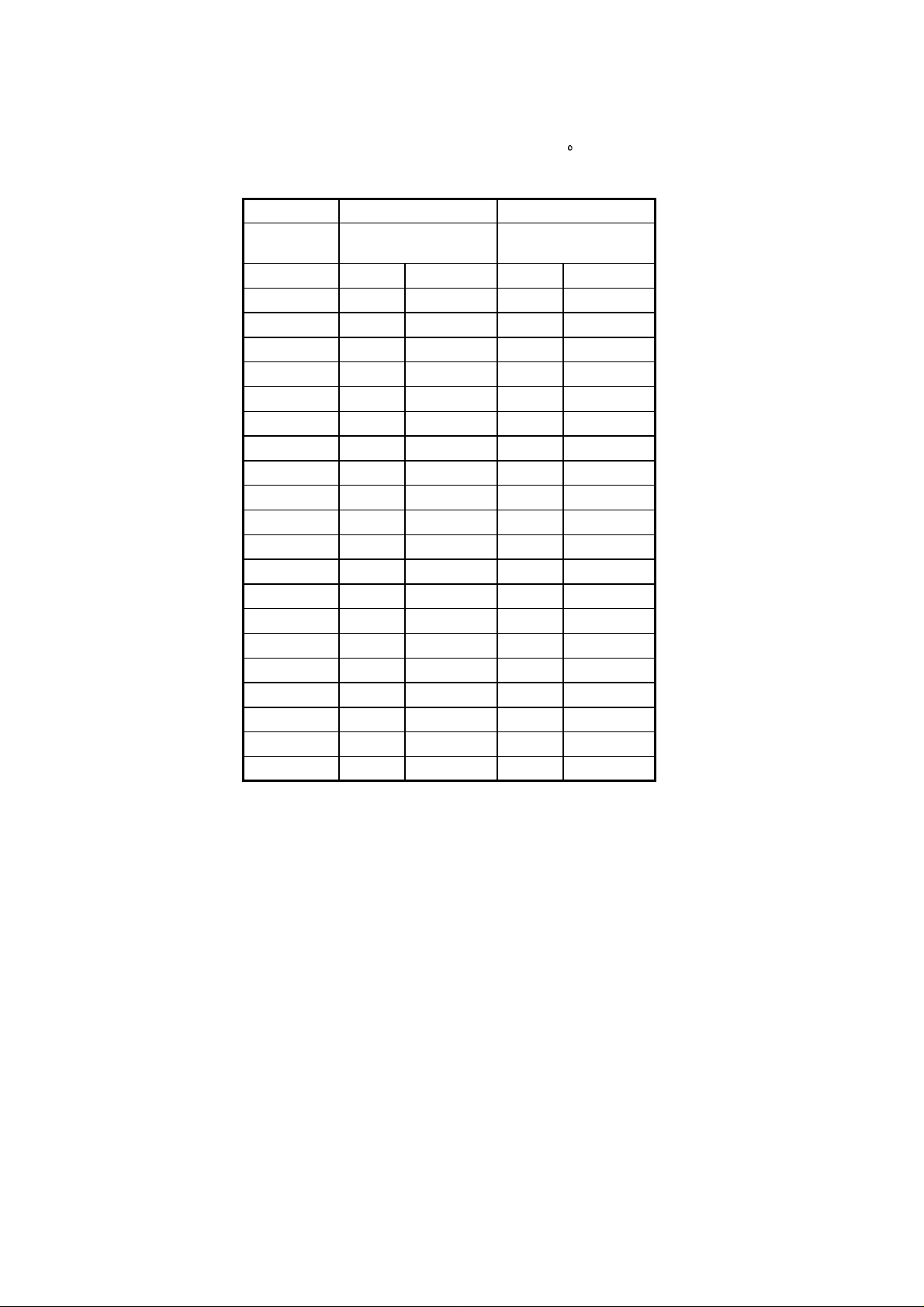

Test range C L

Frequency 120 Hz 1kHz 120 Hz 1kHz

Range number Range Display range Range Display range Range Display range Range Display range

10 1F 999.99 mF 100 mF 99.999 mF 200 kH 200.00 kH 20 kH 20.000 kH

013.50 mF 01.600 mF 012.00 kH 01.450 kH

9 14.5 mF 14.500 mF 1.7 mF 1.7000 mF 13 kH 13.000 kH 1.55 kH 1.5500 kH

01.350 mF 0.1600 mF 01.200 kH 0.1450 kH

8 1.45 mF 1.4500 mF 170 µF 170.00 µF 1.3 kH 1.3000 kH 155 H 155.00 H

0.1350 mF 016.00 µF 0.1200 kH 014.50 H

7 145 µF 145.00 µF 17 µF 17.000 µF 130 H 130.00 H 15.5 H 15.500 H

013.50 µF 01.600 µF 012.00 H 01.450 H

6 14.5 µF 14.500 µF 1.7 µF 1.7000 µF 13 H 13.000 H 1.55 H 1.5500 H

01.350 µF 0.1600 µF 01.200 H 0.1450 H

5 1.45 µF 1.4500 µF 170 nF 170.00 nF 1.3 H 1.3000 H 155 mH 155.00 mH

0.1350 µF 016.00 nF 0.1200 H 014.50 mH

4 145 nF 145.00 nF 17 nF 17.000 nF 130 mH 130.00 mH 15.5 mH 15.500 mH

013.50 nF 01.600 nF 012.00 mH 01.450 mH

3 14.5 nF 14.500 nF 1.7 nF 1.7000 nF 13 mH 13.000 mH 1.55 mH 1.5500 mH

01.350 nF 0.1600 nF 01.200 mH 0.1450 mH

2 1.45 nF 1.4500 nF 170 pF 170.00 pF 1.3 mH 1.3000 mH 155 µH 155.00 µH

0.1350 nF 016.00 pF 0.1200 mH 014.50 µH

1 145 pF 145.00 pF 17 pF 17.000 pF 130 µH 130.00 µH 15.5 µH 15.500 µH

009.40 pF 00.940 pF 014.00 µH 01.600 µH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

________________________________________________________________________________________________________________

3.6 Setting the Ranging

Page 32

20

________________________________________________________________________________________________________________

Procedure

Press to toggle between AUTO and HOLD.

AUTO

HOLD

Use the LED lamp to the left of the key to check on a set test range.

3.6.2 Auto Range

The most suitable test range is set automatically. Useful when measuring an

unknown sample.

NOTE

Measurement requires more time.

3.6.3 Hold Range

Take measurements in the same range regardless of the value of the sample.

This is useful for high-speed measurement.

: The most suitable test range is set automatically.

: The test range is fixed, and mayonlybealteredmanually.

Procedures

(ei th er 1 o r 2 w il l do)

1. Press to set HOLD mode.

2. Press or . The range select key moves up or down.

As the range changes with or , the range number appears on the

measurement display for about a half-second, then returns to measurement

mode.

________________________________________________________________________________________________________________

3.6 Setting the Ranging

Page 33

21

________________________________________________________________________________________________________________

3.7 Open Circuit Compensation

With open circuit compensation, it is possible to reduce the influence of the

floating impedance of the test cables and thereby to enhance the accuracy of

measurement. It is effective for test samples whose impedance is relatively

high.

NOTE

With open circuit compensation set, compensated values for 120 Hz and 1

kHz are input. These are unrelated to test frequency setting conditions.

The testing accuracy specified in the specification of the 3511-50 unit

assumes that open circuit compensation and short circuit compensation is

being performed, as appropriate.

When you have changed the test cables, be sure to perform compensation

again. Correct test values will not be obtained if you go on testing using

the same old compensation values which were obtained before the cable

change.

Compensation is possible for the impedance range of 1 kΩ or greater.

3.7.1 Performing Open Circuit Compensation

Procedures

(1) Make sure that the HIGH and LOW leads are not contacted together.

NOTE

As closely as possible, route the test cable and set the probe-terminal

distance duri ng this procedure as if performing actual measurement.

Execute the guarding process. For the guarding process, refer to Section 5.4,

"Testing High Impedance Elements."

(2) Press . Begin compensation upon confirmation that the first

parameter measurement display (MAIN PARAMETER) is as shown.

The LED lamp flashes during open circuit compensation.

(3) If compensation ends properly, the unit beeps once and returns to normal

test mode.

(4) Refer to the LED lamp to the left of the key to check for normal

completion of open circuit compensation.

NOTE

________________________________________________________________________________________________________________

Open circuit compensation takes about 30 s.

3.7 Open Circuit Compensation

Page 34

22

________________________________________________________________________________________________________________

If an error occurs during open circuit compensation, the unit beeps to notify

you of the error. An error message appears, as shown, and compensation is

aborted.

Press to return the unit to normal test mode.

NOTE

If an error occurs, when you return to normal test mode after aborting open

circuit compensation, the measurement value is not compensated for.

3.7.2 Open Circuit Compensation Error

The following are possible causes:

1. The circuit across HIGH and LOW terminals is not open.

2. The test cable is not connected correctly.

3. The impedance across the terminals does not reach 1 kΩ.

3.7.3 Canceling Open Circuit Compensation

Procedures

(1) Press with open circuit compensation ON. Open circuit

compensation is canceled. The value compensated for is not saved.

(2) The open circuit compensation will remain invalid until the

compensation data is deleted and another open circuit compensation is

performed.

________________________________________________________________________________________________________________

3.7 Open Circuit Compensation

Page 35

23

________________________________________________________________________________________________________________

3.8 Short Circuit Compensation

With short circuit compensation, i t is possible to reduce the influence of the

residual impedance of the test cables and thereby to enhance the accuracy of

measurement. It is effective for test samples whose impedance is relatively

low.

NOTE

With short circuit compensation set, compensated values for 120 Hz and 1

kHz are input. These are unrelated to test frequency setting conditions.

The testing accuracy specified in the specification of the 3511-50 unit

assumes that open circuit compensation and short circuit compensation is

being performed, as appropriate.

When you have changed the test cables, be sure to perform compensation

again. Correct test values will not be obtained if you go on testing using

the same old compensation values which were obtained before the cable

change.

Compensation is possible for the impedance range of 1 kΩ or less.

3.8.1 Performing Short Circuit Compensation

Procedures

(1) A shorting bar is used. This shorting bar is for short circuiting together

the ends of the test leads. Use an object whose impedance is as low as

possible.

Metallicplate

Possible

Metallic wire

Not possible

________________________________________________________________________________________________________________

3.8 Short Circuit Compensation

Page 36

24

________________________________________________________________________________________________________________

(2) Short circuit together the HIGH and LOW leads. In order to keep

external influences as low as possible, be sure to thrust the shorting bar

in all the way.

NOTE

NOTE

As closely as possible, route the test cable during this procedure as if

performing actual measurement.

(3) Press . Begin compensation upon confirmation that the first

parameter measurement display (MAIN PARAMETER) is as shown.

The LED lamp flashes during short circuit compensation.

(4) If compensation ends properly, the unit beeps once and returns to normal

test mode.

(5) Refer to the LED lamp to the left of the key to check for normal

completion of short circuit compensation.

Short circuit compensation takes about 30 s.

If an error occurs during short circuit compensation, the unit beeps to notify

you of the error. An error message appears, as shown, and compensation is

aborted.

Press to return the unit to normal test mode.

NOTE

If an error occurs, when you return to normal test mode after aborting short

circuit compensation, the measurement value is not compensated for.

________________________________________________________________________________________________________________

3.8 Short Circuit Compensation

Page 37

25

________________________________________________________________________________________________________________

3.8.2 Short Circuit Compensation Error

The following are possible causes:

1. The circuit across HIGH and LOW terminals is not short.

2. The test cable is not connected correctly.

3. The impedance across the terminals exceeds 1 kΩ.

3.8.3 Canceling Short Circuit Compensation

Procedures

(1) Press with short circuit compensation ON. Short circuit

compensation is canceled. The value compensated for is not saved.

(2) The short circuit compensation will remain invalid until the

compensation data is deleted an d another short circuit compensation is

performed.

________________________________________________________________________________________________________________

3.8 Short Circuit Compensation

Page 38

26

________________________________________________________________________________________________________________

3.9 Setting the Trigger Signal

The internal trigger or the external trigger can be set.

INT (Internal trigger mode):

Continuous testing is performed while automatically generating an internal

trigger signal.

EXT (External trigger mode):

A trigger signal is input from the outside either manually or automatically.

3.9.1 Setting the Trigger Mode

Press to toggle between INT and EXT. Use the LED lamp to the left

of the key to check on a set test frequency.

(1) Internal trigger mode

Testing is performed continuously.

(2) External trigger mode

Testing is performed with (manual trigger).

Press this key to perform testing once.

Testing is performed with a trigger from the EXT I/O connector TRIG

terminal.

When inputting the trigger signal through the interface:

Testing is performed once, when the "*TRG" command is transferred from

the interface. For details, see Chapter 6, "RS-232C Interface", or Chapter 6,

"Command Reference for 3511-50" of the Instruction Manual for the

optional 9518-01 GP-IB INTERFACE.

When inputting the trigger signal through the EXT I/O connector:

Testing is performed once, each time a negative sense pulse signal is

supplied to the EXT I/O connector on the rear panel of the 3511-50. For

details, refer to Section 5.1, "Testing Using EXT I/O."

________________________________________________________________________________________________________________

3.9 Setting the Trigger Signal

Page 39

27

________________________________________________________________________________________________________________

Chapter 4

1

2

4.1 Comparator Function

With the upper and lower limits of the first and second parameters set, the

3511-50 compares measurements with the upper and lower limits and

produces a judgment (HI, IN, or LO)*, which is then displayed on the

comparator judgment display. Moreover, a corresponding signal can be

output via the EXT I/O connector on the rear panel of the 3511-50 unit.

* HI: exceeds the upper limit; IN: within upper and lower limits; LO: below the lower limit

You can set comparator upper and lower limits in the first and second

parameters, respectively. The judgment and the output of EXT I/O are

displayed for each parameter. The AND result of judgment for both first

and second parameters is also output from EXT I/O.

Other Functions

3

4

5

6

7

8

9

NOTE

If power is switched off in comparator test mode, switching on the 3511-50

again will start it in comparator test mode.

Switching off power in the upper or lower limit setting mode invalidates

the set upper or lower limit. If this occurs, the unit defaults to the

previous settings.

For parameters for which comparator judgment is unnecessary, the upper

and lower limits can be set to OFF. In such cases, the parameters set to

OFF are not compared for judgment.

Test conditions during comparator execution are as for normal test, with

one exception: the AUTO range is automatically switched to the HOLD

range.

10

11

12

13

14

A

________________________________________________________________________________________________________________

4.1 Comparator Function

Page 40

28

________________________________________________________________________________________________________________

4.1.1 Operation Sequence

Normal test mode

First parameter upper

limit setting mode

First parameter lower

limit setting mode

Second parameter

upper limit setting mode

Second parameter lower

limit setting mode

Comparator test mode

Set this among test conditions for executing a comparator.

Press .

Automatically switches the range setting to HOLD.

Use the COUNT setting key to set the upper limit.

Press to acknowledge and save the set value; then set the

lower limit.

Use the COUNT setting key to set the lower limit.

Press to acknowledge and save the set value; then set the

second parameter upper limit.

Use the COUNT setting key to set the upper limit.

Press to acknowledge and save the set value; then set the

lower limit.

Use the COUNT setting key to set the upper limit.

Press to acknowledge and save the set value.

If all upper and lower limits are OFF at this point, the system

switches to normal test mode. If setting upper and lower limits is

valid, the system switches to comparator test mode.

Press , and the system switches to normal test mode.

4.1.2 Setting the Upper and Lower Limits

(1) Press to enter a desired setting mode, for either the upper or lower

limit.

The current upper and lower limit settings are displayed in the status display

next to , and in the comparator judgment display.

Status display Comparator judgment

Conditions being

set

First parameter

upper limit

First parameter

lower limit

Second parameter

upper limit

Second parameter

lower limit

Set values are displayed at the following locations.

First parameter upper and lower limits : First parameter measurement

Second parameter upper and lower limits : Second parameter measurement

If the upper or lower limit value is set to OFF, the displayed setting will be

"-----." Upper or lower limit values set to OFF are not used for comparison

with a measurement.

"M-HSET" lights.

"M-LSET" lights.

"S-HSET" lights.

"S-LSET" lights.

display

"HI" lights to indicate the judgment

result for the first parameter.

"LO" lights to indicate the judgment

result for the first parameter.

"HI" lights to indicate the judgment

result for the second parameter.

"LO" lights to indicate the judgment

result for the second parameter.

display

display

________________________________________________________________________________________________________________

4.1 Comparator Function

Page 41

29

________________________________________________________________________________________________________________

NOTE

(2) Use the COUNT setting key to change the value digit by digit.

The value in the blinking digit may be altered. Navigate through the digits

with the keys, and through values with the keys.

To set the upper or lower limit to OFF, move the cursor to the left or right

end with

right extremes for 2 s or longer. The display changes to "-----." At the next

step, press to store the OFF setting.

Press the COUNT setting key when "-----" is displayed to redisplay the

former value.

Upper and lower limits are stored as counts displayed, regardless of test

conditions. As test conditions change, the absolute values indicated by

the counts change accordingly.

Use normal test conditions for comparator test conditions. Set upper and

lower limits only after setting test conditions for the comparator to be used

in normal test mode.For example, to set the upper limit to 0.999 µFwhen

test frequency is 120 Hz and test range is 1.45 µF in C-D display, enter

"09990."

(3) Press to store the setting, then move to the setting mode for the next

upper and lower limits.

If you press instead of , the mode switches to the next upper

and lower limit setting mode without recording the setting.

. Continue pressing if the cursor is at the left or

1

2

3

4

5

6

7

NOTE

The following verifications are not performed when upper and lower limits

are saved. Note that incorrect upper and lower limit settings will produce

incorrect judgments.

1. Is the set value within the parameter display range?

2. Is the relation between upper and lower limits correct?

The comparator judgments are made in the following order:

1. If the measured value is "OVER FLOW", HI is displayed, and the value

is "UNDER FLOW", LO is displayed.

2. Is the measured value greater than the lower limit or not? If not (NG

judgment result), then LO is displayed.

3. Is the measured value lower than the upper limit or not? If not (NG

judgment result), then HI is displayed.

4. If both 2 and 3 give an affirmative result, then IN is displayed.

No judgment is made if both upper and lower limits for a parameter are set

to OFF.

8

9

10

11

12

13

14

________________________________________________________________________________________________________________

4.1 Comparator Function

A

Page 42

30

________________________________________________________________________________________________________________

4.1.3 Comparator Test Mode

Upon completion of all upper and lower limit setting, if upper and lower

limit setting is not OFF, the system enters comparator measurement mode

and outputs a judgment each time a measurement is made, as a result of

comparison between the measurement and the upper or lower limit.

(1) Displaying judgment

Judgment for the first and second parameters is displayed in the comparator

judgment display.

For parameters for which upper and lower limit setting is OFF, no judgment

is displayed.

(2) Outputting judgment

Judgment (LO, IN, or HI) for the first and second parameters and the

AND result (valid when both parameters are IN) for both judgments are

output from EXT I/O. For details, refer to Section 5.1, "Testing Using

EXT I/O."

Comparator judgments (IN or NG) are indicated by a beep.

For more information on setting beeps to indicate judgment, see Section

4.5.3, "Setting Beep."

(3) Valid keys

In comparator test mode, test conditions cannot be changed, except for the

trigger setting. To change test conditions, press to switch to normal

test mode.

The following are valid keys and key functions:

Key Function

Moves to normal test mode.

Toggles the trigger setting between INT and EXT

Valid only when trigger setting is EXT Press this once to

permit one measurement.

Moves to the panel LOAD/SAVE screen. You can save

current test conditions or load previously saved test

conditions.

Switches key lock functions. Cancels remote mode.

________________________________________________________________________________________________________________

4.1 Comparator Function

Page 43

31

________________________________________________________________________________________________________________

4.2 Panel Save Function

1

The current test conditions may be saved to internal memory, up to a

maximum of 99 panels (or combinations) of test conditions.

All the set conditions are saved when panel save is performed, including

comparator upper and lower limits and OPEN/SHORT compensation values.

You can read saved measurement conditions later with the panel load

function.

4.2.1 Setting Panel Save

(1) Press repeatedly to cycle through available settings: panel load, panel

save and normal test (or comparator test) modes. For more information on

panel load mode, see Section 4.3, "Panel Load Function."

(2) Enter panel save mode and specify the panel number to save. In panel save

mode, only unsaved panel numbers are displayed. (The panel number at

shipment is "01.")

If all panels are used for the saving, when the panel mode is entered, "01"

appears.

COUNT

To overwrite a panel already in use, choose the panel number and correct.

Use the COUNT setting key to specify a panel number.

keys increase/decrease the value.

move the cursor to a digit to be set (up to two digits).

The LED for the digit under setting flashes.

2

3

4

5

6

7

8

9

NOTE

The set values must fall between 01 and 99.

(3) After specifying a panel number, press . The 3511-50 saves the test

conditions and reverts to normal or comparator test mode.

4.2.2 Aborting Panel Save

After specifying a panel number in panel save mode, press instead of

. The 3511-50 reverts to normal or comparator test mode without

performing the panel save.

NOTE

Under normal conditions of use, the average life of the backup battery for

the internal memory is about 6 years.

If the internal battery becomes exhausted, it is no longer possible to save

the test conditions. You should have the battery changed by an approved

HIOKI service facility (which is chargeable).

10

11

12

13

14

A

________________________________________________________________________________________________________________

4.2 Panel Save Function

Page 44

32

________________________________________________________________________________________________________________

4.3 Panel Load Function

You can read or load saved test conditions from internal memory.

4.3.1 Setting Panel Load

(1) Press repeatedly to cycle through available settings: panel load, panel

save and normal test (or comparator test) modes. For more information on

panel save mode, see Section 4.2, "Panel Save Function."

(2) Enter panel load mode and specify the panel number to load. Use the

COUNT setting key to specify a panel number. If no test condition is set, as

on shipment or reboot, "--" is displayed as a panel number. In this state, no

panel number can be set.

COUNT

The LED for the digit under setting flashes.

Each time a panel number is specified, the test conditions for the

corresponding panel are indicated by the LED lamp. You cannot select

panel numbers that are not panel-saved.

keys increase/decrease the value.

move the cursor to a digit to be set (up to two digits).

permit automatic specification of a panel number if it is panel-saved.

NOTE

The set values must fall between 01 and 99.

(3) After specifying a panel number, press . The 3511-50 loads the test

conditions and reverts to normal or comparator test mode.

4.3.2 Aborting Panel Load

After specifying a panel number in panel load mode, press instead of

. The 3511-50 moves to panel save mode without performing the

panel load. Press again. The 3511-50 reverts to normal or

comparator test mode.

________________________________________________________________________________________________________________

4.3 Panel Load Function

Page 45

33

________________________________________________________________________________________________________________

4.4 Key Lock Function

1

When the key lock is turned on, all key switches on the front panel are

disabled to protect settings.

4.4.1 Executing the Key Lock Function

Press for 2 s or longer. Use the LED lamp to the right of the second

parameter measurement display (SUB PARAMETER) to check on the key

lock condition.

NOTE

In the external trigger mode, the key lock does not apply to .The

external trigger can be activated manually.

The key lock function can be set only in normal or comparator test mode.

Note that, as long as is kept pressed, the key lock function is

activated and inactivated alternately.

2

3

4

5

6

7

8

4.4.2 Cancelling the Key Lock Function

Press for 2 s or longer. The LED lamp goes out to indicate that key

lock is canceled.

NOTE

Even if the power supply is interrupted, the key lock function is not

canceled.

9

10

11

12

13

14

A

________________________________________________________________________________________________________________

4.4 Key Lock Function

Page 46

34

________________________________________________________________________________________________________________

4.5 Various Settings Made After Switching o n Power

Enter settings for conditions related to system reboot (initialization of all test

conditions), interfaces, and beep sounds at comparator judgment immediately

after switching on power.

4.5.1 Setting Screen Flow After Power ON

With power turned on, screens are displayed in succession in the following

order:

1. All displays light.

2. Version information displayed

3. Interface setting

4. Beep sound setting

5. Test mode (normal test or comparator test)

To change a setting, press the COUNT setting key while screens 3 and 4 are

displayed. Press after screen 1 is displayed and before screen 2 is

displayed. The system reboot setting screen appears before screen 3 is

displayed.

________________________________________________________________________________________________________________

4.5 Various Settings Made After Switching on Power

Page 47

35

________________________________________________________________________________________________________________

4.5.2 Setting the Interface

You can print measurements by connecting an optional 9442 PRINTER to

the RS-232C interface. This is possible only with the EXT trigger.

Described below are procedures for switching the RS-232C interface settings

to settings appropriate for the 9442 PRINTER and PC connection.

1

2

NOTE

To use the RS-232C interface, remove the 9518-01 GP-IB INTERFACE

before switching on power. If you power on with the board (optional)

inserted in the optional board slot, the RS-232C setting screen will not

appear. Instead, the system will display "GP-iB" in the first parameter

measurement display, and the 3511-50 GP-IB address in the second

parameter measurement display.

Procedures

Once power has been switched on, the 3511-50 displays version information,

"rS232" in the first parameter measurement display and settings for the

RS-232C interface in the second parameter measurement display for

approximately 3 s.

Press the COUNT setting key as this information is displayed to switch the

display in the second parameter measurement display between "PC" and

"Print."

When connecting a PC and when not using the RS-232C interface, make

sure "PC" is displayed. When using a 9442 PRINTER, make sure that

"Print" is displayed.

Display in the first parameter

measurement display

3

4

5

6

7

8

9

Display in the second

Setting

When connecting a PC

When not using the RS-232C

interface

When using a 9442

PRINTER

With a 9442 PRINTER, if no key input is made for approximately 3 s, the

current setting is acknowledged, and the screen switches to the next screen

(the "Beep sound setting" screen).

parameter measurement

display

10

11

12

13

14

A

________________________________________________________________________________________________________________

4.5 Various Settings Made After Switching on Power

Page 48

36

________________________________________________________________________________________________________________

4.5.3 Setting Beep

Set the beep to be sounded when a comparator judgment is made.

The following three modes are available:

1. No beep

2. Beeps when judgment of both first and second parameters is "IN."

3. Beeps when judgment of one of the first or second parameters is not "IN."

Procedures

After power is switched on, the system displays the "Interface setting." For

approximately 3 s, the system will display "bEEP" in the first parameter

measurement display and the desired beep sound setting in the second

parameter measurement display.

Press the COUNT setting key during this display. The indication in the

second parameter measurement display cycles through "oFF," "in" and

"Lo-Hi." If no key input occurs for 3 s, the current setting is acknowledged,

and the system enters measurement mode.

Display in the first parameter

measurement display

Setting

No beep

Beeps when judgment of both

first and second parameters

is "IN."

Beeps when judgment of one

of the first or second

parameters is not "IN."

Display in the second

parameter measurement

display

________________________________________________________________________________________________________________

4.5 Various Settings Made After Switching on Power

Page 49

37

________________________________________________________________________________________________________________

4.5.4 Executing System Reboot

All test conditi ons are initialized to the conditions i n force at shipment.

All measurement conditions include panel-saved conditions.

Procedures

Restart the 3511-50 while pressing . All displays will light, and in

approximately 1.5 s, the Section switches to the version information screen.

You can release the key when this occurs.

The 3511-50 displays version information, "rESEt" in the first parameter

measurement display and "no" in the second parameter measurement display.

Display in the first parameter

measurement display

Display in the second

Setting

parameter measurement

display

No system reboot

System reboot

Press the COUNT setting key to switch the display in the second parameter

measurement display between "no" and "YES." Press in either state.

Pressing in the "YES" state initializes all test conditions to the

conditions in force at shipment and switches the screen to "Interface setting."

The conditions in force at shipment are as follows:

Test mode Normal test mode

Test parameters |Z|-θ

Test frequency 1kHz

Test signal level 1V

Test speed NORM

Equivalent circuit mode AUTO

Test range AUTO

Open circuit

compensation

Short circuit

compensation

Trigger mode INT (Internal trigger)

Key lock function OFF

Beep sound setting OFF (when a comparator judgment is

Panel save All contents clear

Comparator Upper and lower limits for the first and

OFF

OFF

made)

second parameters both OFF

________________________________________________________________________________________________________________

4.5 Various Settings Made After Switching on Power

Page 50

38

________________________________________________________________________________________________________________

4.6 Remote Function

4.6.1 Remote Mode

External control via an interface will place the 3511-50 in remote mode

(remote control state), in which front panel key switch operations are

disabled.

Use the LED lamp to the right of the second parameter measurement display

(SUB PARAMETER) to check on the remote mode condition. This LED

lamp lights when the 3511-50 enters remote mode.

4.6.2 Cancelling the Remote Mode

Press to cancel the remote mode. The LED lamp goes out to

indicate that remote mode is canceled.

________________________________________________________________________________________________________________

4.6 Remote Function

Page 51

39

________________________________________________________________________________________________________________

4.7 The Residual Charge Protection Function

CAUTION

The quoted maximum voltage from which the unit c an be protected by

this f unct ion is f or reference purposes only, and is not a guaranteed

value. There may be danger of damage to the 3511-50 unit,

depending upon the operational circu m stances and upon how often

such charged capacitors are connected. In general, you should not

rely upon thi s protection function; be sure to discharge charged

capacitors properly before connecting them to the test terminals.

The residual charge protection function is for protection of the 351150 unit against the discharge of voltage present in c harged capacitors,

and is not capable of protecting the unit ag ai n s t DC vo l ta ge which is

constantly applied such as a superimposed DC voltage. (The

maximum volt age for supply to th e test termi n al s of the 35 11-50 unit

is 40 VDC.) If this is done, there is a danger of damage to the unit.

(For how to supply a DC bias voltage, refer to Secti on 5.2, " Supplying

DC Bi a s ".)

The 3511-50 has been enhanced by the incorporation of a residual charge

protection funct ion. If by mistake a charged capacitor is connected to the

test terminals, this function protects the internal circuitry of the unit from

discharge of such residual charge.

The maximum voltage from which the unit can be protected by this function

is determined from the capacitance value of the sample under test by the

following equation:

V: Voltage (volts) (maximum 400 VDC)

C: Capacitance (farads)

________________________________________________________________________________________________________________

4.7 The Residual Charge Protection Function

Page 52

40

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

4.7 The Residual Charge Protection Function

Page 53

41

________________________________________________________________________________________________________________

Chapter 5

1

2

5.1 Testing Using EXT I/O

5.1.1 The EXT I/O Connector

This is a connector for output of comparator result signals, of a measurement

finished signal (

_______

(

INDEX

performing selection of the number of the panel to be loaded.

Connector used :

57RE-40360-730B (D29) (made by DDK)

Compatible connector:

57-30360 (solder cup connector without rib, made by DDK)

57-30360R (solder cup connector with rib, made by DDK)

RC30-36P (made by HIROSE ELECTRIC CO.,LTD.)

), and for input of an external trigger signal, and a signal for

______

EOM

Applications

), and of an analog measurement finished signal

3

4

5

6

7

8

9

10

18 1

36 19

EXT I/O Connector pin numbering (seen from 3511-50)

________________________________________________________________________________________________________________

5.1 Testing Using EXT I/O

11

12

13

14

A

Page 54

42

________________________________________________________________________________________________________________

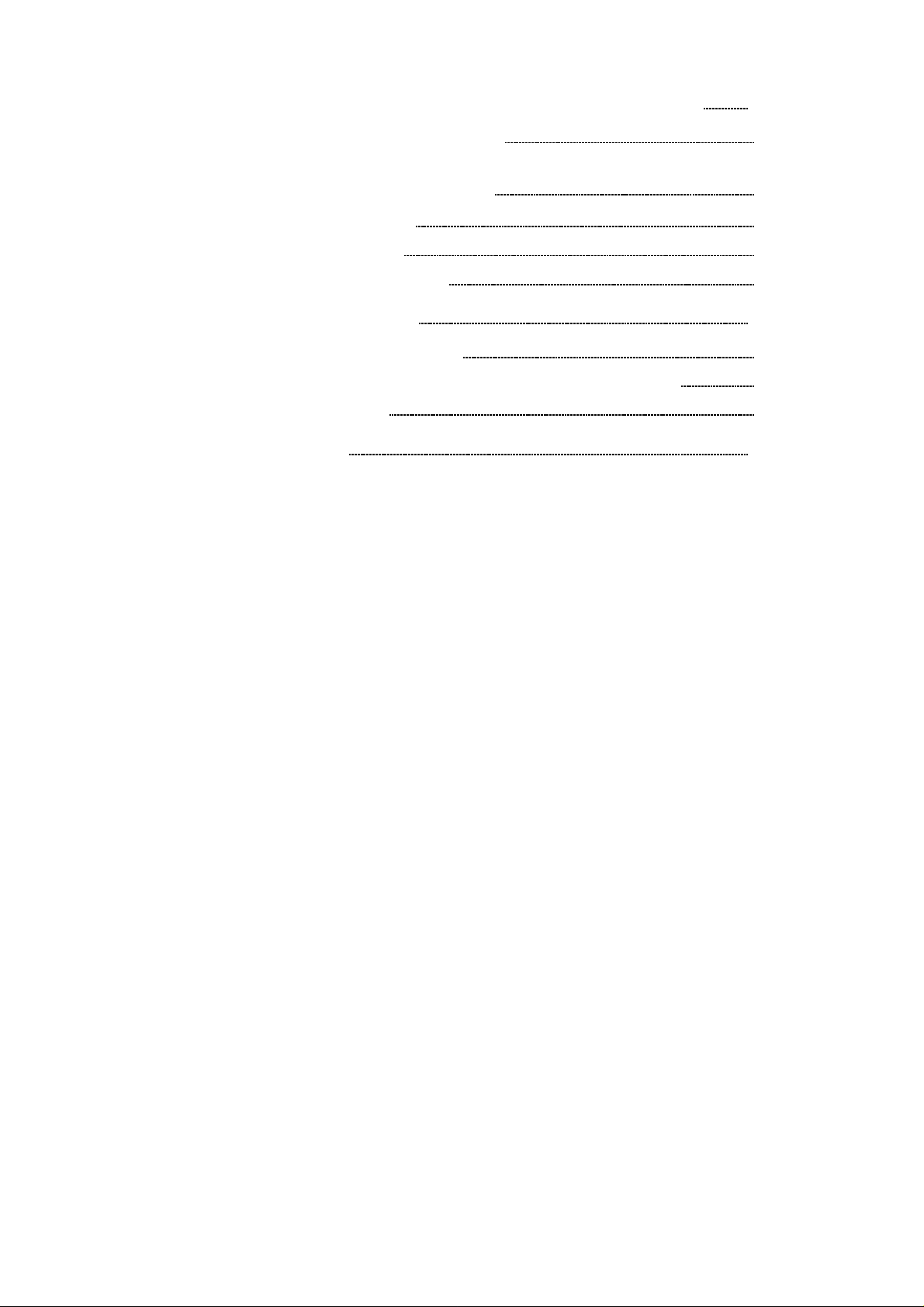

5.1.2 Pinouts for the EXT I/O Connector

Pin number I/O Signal line name Pin number I/O Signal line name

1 IN

2 IN

3 IN

4 IN

5 IN

6 OUT

7 OUT

8 OUT

9 OUT

10 - Unused 28 - Unused

11 to 14 IN EXT DCV 29 to 32 OUT INT DCV

15 to 18 IN EXT COM 33 to 36 OUT INT GND

_____

TRIG

BCD01

BCD03

BCD11

BCD13

_____

M-IN

____

S-HI

_____

S-LO

______

INDEX

19 IN

20 IN

21 IN

22 IN

23 OUT

24 OUT

25 OUT

26 OUT

27 OUT

BCD00

BCD02

BCD10

BCD12

_____

M-HI

_____

M-LO

____

S-IN

____

AND

_____

EOM

________________________________________________________________________________________________________________

5.1 Testing Using EXT I/O

Page 55

43

________________________________________________________________________________________________________________

5.1.3 Signal Lines for the EXT I/O Connector

1

NOTE

All input and output signals excluding BCD 00 to 03, BCD 10 to 13, and the

power supply are all negative logic.

______

(1)

TRIG

When the 3511-50 is set to external trigger mode, a negative logic signal is

input from outside via this line. Testing is initiated once when this signal

goes low level.

(2) BCD00, BCD01, BCD02, BCD03

For the panel number to load, choose the ones digit.

When a trigger signal is input in external trigger mode, the panel chosen is

read and measurement begins.

(3) BCD10, BCD11, BCD12, BCD13

Choose the tens digit for the panel number to be loaded.

When a trigger signal is input in external trigger mode, the panel chosen is

read and measurement begins.

BCD Digit of 10 Digit of 1

BCD13 BCD12 BCD11 BCD10 BCD03 BCD02 BCD01 BCD00

0 0 0 0 0 0 0 0 0

1 0 0 0 1 0 0 0 1