Page 1

Instruction Manual

3505

3506

C HiTESTER

February 2013 Revised edition 6 3505A981-06 13-02H

Page 2

Page 3

Contents

Introduction.................................................................................1

Verifying Package Contents.......................................................1

Safety Information......................................................................2

i

Contents

1

2

Operating Precautions................................................................4

Chapter 1

Overview___________________________________ 7

1.1 Product Overview .........................................................7

1.2 Features .......................................................................7

1.3 Entire Workflow ............................................................9

1.4 Names and Functions of Parts ...................................11

Chapter 2

Measurement Preparations___________________ 17

2.1 Preparation Flowchart ................................................17

2.2 Checking the Power Voltage...................................... 18

2.3 Connecting the Power Cord....................................... 19

2.4 Connecting the Probes and Fixtures.......................... 20

3

2.5 Turning the Power On and Off ...................................21

Chapter 3

Setting the Measurement Conditions __________ 23

3.1 Pre-Operation Inspection ...........................................23

3.2 Measurement Example ..............................................24

3.3 Setting the Measurement Conditions .........................26

3.3.1 Setting the Display Parameter .......................................26

3.3.2 Measurement Mode ......................................................27

3.3.3 Measurement Frequency ..............................................27

3.3.4 Measurement Signal Level ............................................28

3.3.5 Measurement Speed .....................................................28

3.3.6 Equivalent Circuit Mode ................................................29

3.3.7 Measurement Range .....................................................31

3.3.8 Trigger Signal ................................................................36

Page 4

ii

Contents

Chapter 4

Compensate for errors_______________________37

4.1 Open Circuit Compensation and Short Circuit

Compensation ........................................................... 37

4.2 Load Compensation .................................................. 45

4.3 Offset Compensation ................................................. 51

4.4 Self Calibration .......................................................... 55

4.5 Set the Cable Length ................................................. 58

Chapter 5

Judging measurement results ________________59

5.1 Comparator Function ................................................. 59

5.2 BIN Measurement Function ....................................... 74

Chapter 6

Application Functions _______________________91

6.1 Setting the Average Function .................................... 91

6.2 Trigger Delay Setting ................................................. 93

6.3 Using the Contact Check Function ............................ 95

6.3.1 Setting the Low C Reject Function ...............................96

6.3.2 Measurement Level Monitoring Function Settings ........98

6.4 Current Detection Circuit Monitoring Function ......... 100

6.5 Applied Voltage Value Monitoring Function ............. 100

6.6 Using the Frequency Shift Function ........................ 101

6.7 Setting the Display ON/ OFF ................................... 102

6.8 Trigger Synchronous Output Function ..................... 103

6.9 Disable Key Control (Keylock Function) .................. 104

6.10 Save the Measurement Conditions

(Panel Save Function) ............................................. 105

6.11 Load the Measurement Conditions

(Panel Load Function) ............................................. 106

6.12 Setting Beep Tones ................................................. 110

6.12.1 Setting the Beep Tone for Judgment Results of

Comparator and BIN ...................................................110

6.12.2 Setting the Beep Tone for Key Operations .................112

6.13 Switching the displayed item (SUB display) ............ 113

6.14 Performing a System Reset ..................................... 114

Page 5

6.15 Printing Function ......................................................115

6.15.1 Preparation Prior to Connecting the Printer ................115

6.15.2 Connection Procedure ................................................118

6.15.3 Printing ........................................................................119

Chapter 7

EXT I/O __________________________________ 121

7.1 About the EXT I/O Connector .................................. 121

7.2 Circuit Configuration and Connections of the EXT I/O

Connector .................................................................123

iii

Contents

7.3 About Input and Output Signals ...............................124

7.4 About Measurement Times ......................................127

Chapter 8

Controlling the Unit from a PC _______________ 129

8.1 Outline and Features ................................................129

8.2 Specifications ...........................................................130

8.2.1 RS-232C Specifications ..............................................130

8.2.2 GP-IB Specifications ...................................................131

8.3 Connection and Setting Procedures ........................132

8.3.1 Connecting the RS-232C Cable / GP-IB Cable ...........132

8.3.2 Setting the Interface Communication Conditions ........134

8.4 Remote Function ......................................................137

8.5 Communication Procedure .......................................137

8.6 Things to Know before Beginning Communication ..138

8.6.1 About Message Formats .............................................138

8.6.2 About the Output Queue and Input Buffer ...................143

8.6.3 About the Status Byte Register ...................................144

8.6.4 About Event Registers ................................................146

4

5

6

7

8

9

10

8.7 Message List ............................................................151

8.7.1 Common Commands ..................................................151

8.7.2 Unique Commands ......................................................152

8.8 Ability to Use Commands by State ...........................165

8.8.1 Common Commands ..................................................165

8.8.2 Unique Commands ......................................................165

8.9 Message Reference .................................................171

8.9.1 Common Commands ..................................................172

8.9.2 Unique Commands ......................................................177

8.9.3 Response Format of Queries for Returning Values ....244

8.10 Initialized Items ........................................................246

11

Appendix

Index

Page 6

iv

Contents

8.11 Creating Programs .................................................. 247

8.11.1 Creation Procedure .....................................................247

8.11.2 Sample Programs .......................................................249

8.12 Troubleshooting the Interface .................................. 251

8.13 Device Document Requirements ............................ 253

Chapter 9

Specifications_____________________________257

9.1 Basic Specifications ................................................. 257

9.2 Accuracy .................................................................. 261

9.3 Measurement Parameters and Arithmetic

Expressions ............................................................. 264

Chapter 10

Maintenance and Service ___________________267

10.1 Inspection, Repair, and Cleaning ............................ 267

10.2 Replacing the Power Fuse ...................................... 269

10.3 Discarding the Unit .................................................. 270

Appendix ______________________________ A1

Appendix 1 Countermeasures Against Incorporation of

External Noise.................................................A1

Appendix 1.1 Countermeasures Against Incorporation of Noise

from the Power Line .....................................................A1

Appendix 1.2 Countermeasures Against Incorporation of Noise

from the Input Line (Types of Probe) ...........................A2

Appendix 2 Measurement of High Impedance ComponentsA3

Appendix 3 Measurement of In-circuit Components...........A4

Appendix 3.1 Measurement Using Guarding Technique ...................A4

Appendix 3.2 Synchronous Measurement .........................................A5

Appendix 4 Mounting the Unit in a Rack ............................A6

Appendix 5 External View...................................................A8

Appendix 6 Options............................................................A9

Appendix 7 Initial Settings Table......................................A11

Index _________________________________Index 1

Page 7

Introduction

Thank you for purchasing the HIOKI “Model 3505/ 3506 C HiTester.” To obtain

maximum performance from the unit, please read this manual first, and keep it

handy for future reference.

Verifying Package Contents

When you receive the unit, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the acc essories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

1

Introduction

This unit 3505, 3506 C HiTester

Accessories • Instruction Manual. ................................................. ............................1

• Power cord......................................................................................... 1

• Spare fuse for power supply (according to voltage specification)......1

Shipping precautions

Use the original packing materials when transporting th e unit, if possible.

Options

See Appendix 6 "Options" (p. A9)

100 V, 120 V setting : 250 V F 1.0 AL 20 mm x 5 mm dia

220 V, 240 V setting : 250 V F 0.5 AL 20 mm x 5 mm dia

Probes, fixture are not supplied with the unit as standard equipment. You

should order them separately, according to requirements.

Page 8

2

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as da mage

to the instrument. Using the instrument in a way not described in this

manual may negate the provided safety features. Be certain that you

understand the instructions and precautions in the manual before use.

We disclaim any responsibility for accidents or injuries not resulting

directly from instrument defects.

This manual contains information and warnings essential for safe operation of

the unit and for maintaining it in safe operating condition. Before using it, be sure

to carefully read the following safety precautions.

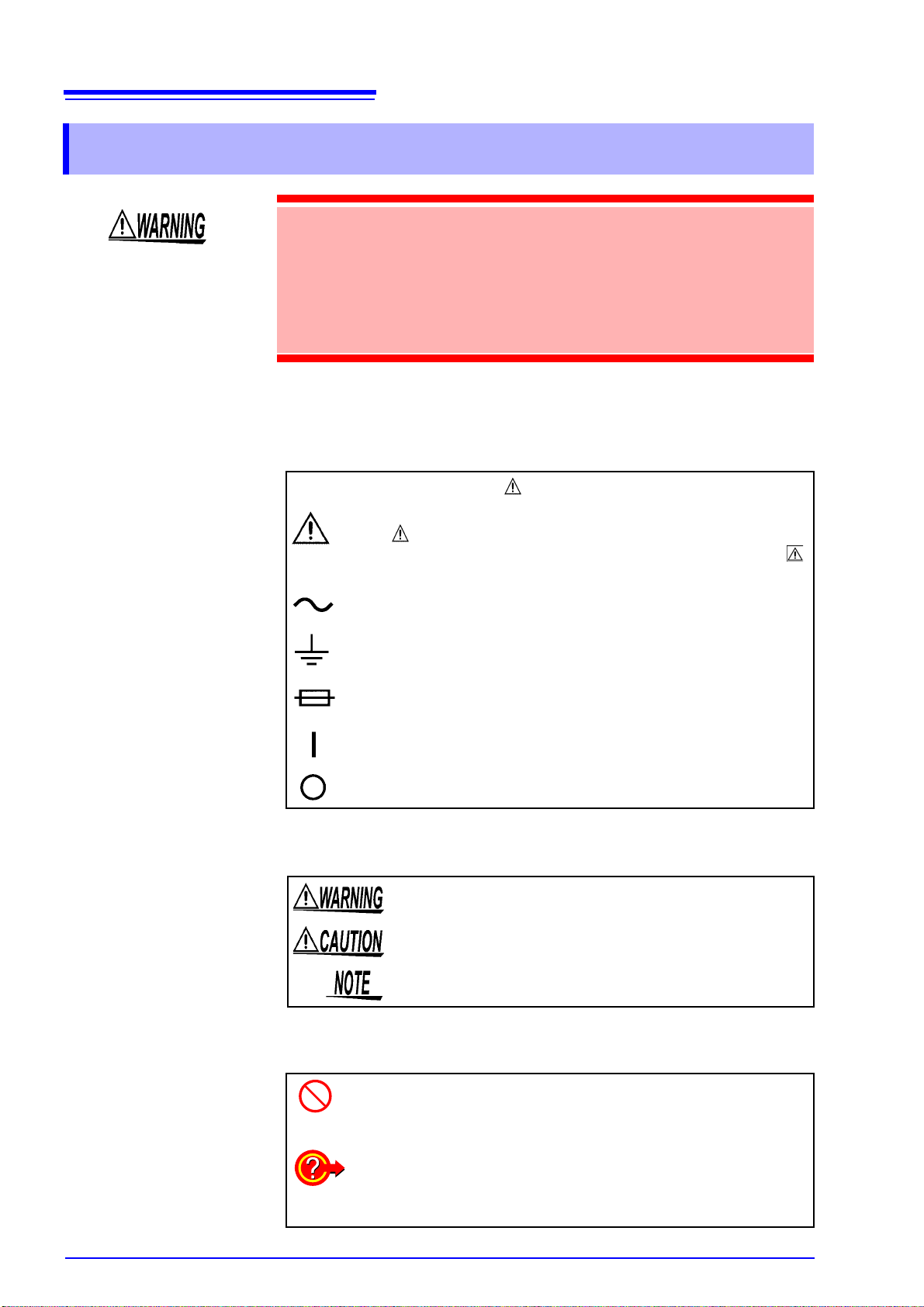

Safety Symbols

In the manual, the symbol indicates particularly important

information that the user should read before using the unit.

The symbol printed on the unit indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

Other Symbols

Indicates AC (Alternating Current).

Indicates a grounding terminal.

Indicates a fuse.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

injury to the user or damage to the unit.

Indicates advisory items related to performance or correct

operation of the unit.

Indicates a prohibited action.

See Indicates the location of reference information.

Indicates quick references for operation and remedies for

troubleshooting.

*

Indicates that descriptive information is provided below.

Page 9

Measurement Categories

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories. These are defined as follows.

CAT II: Primary electrical circuits in equipment connected to an AC

CAT III: Primary electrical circuits of heavy equipment (fixed installa-

CAT IV: The circuit from the service drop to the service entrance, and

Using a measurement product in an environment designated with a higher-numbered category than that for which the product is rated could result in a severe

accident, and must be carefully avoided.

Use of a measurement instrument that is not CA T-rated in CAT II to CAT IV measurement applications could result in a severe accident, and must be carefully

avoided.

3

Safety Information

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

tions) connected directly to the distribution panel, and feeders

from the distribution panel to outlets.

to the power meter and primary overcurrent protection device

(distribution panel).

Accuracy

We define measurement tolerances in terms of rdg. (reading) and dgt. (digit) values,

with the following meanings:

rdg.

(reading or displayed value)

dgt. (resolution) The smallest displayable unit on a digital

The value currently being measur ed and

indicated on the measuring instrument.

measuring instrument, i.e., the input

value that causes the digital display to

show a "1" as the least-significant digit.

Page 10

4

Unit Installation

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits

of the various functions.

Preliminary Checks

• Before using the unit the first time, verify that it operates normally to ensure

that the no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

• Before usin g the uni t, make sure that the insulation on the probes and cable s

is undamaged and that no bare conductors are improperly exposed. Using the

unit in such conditions could cause an electric shock, so contact your dealer

or Hioki representative for replacements.

Operating Temperature and Humidity: 0 to 40°C, 80%RH or less, no condensation

Storage Temperature and Humidity: -10 to 55°C, 80%RH or less, no condensation

Accuracy-guaranteed temperature and humidity ranges: 23

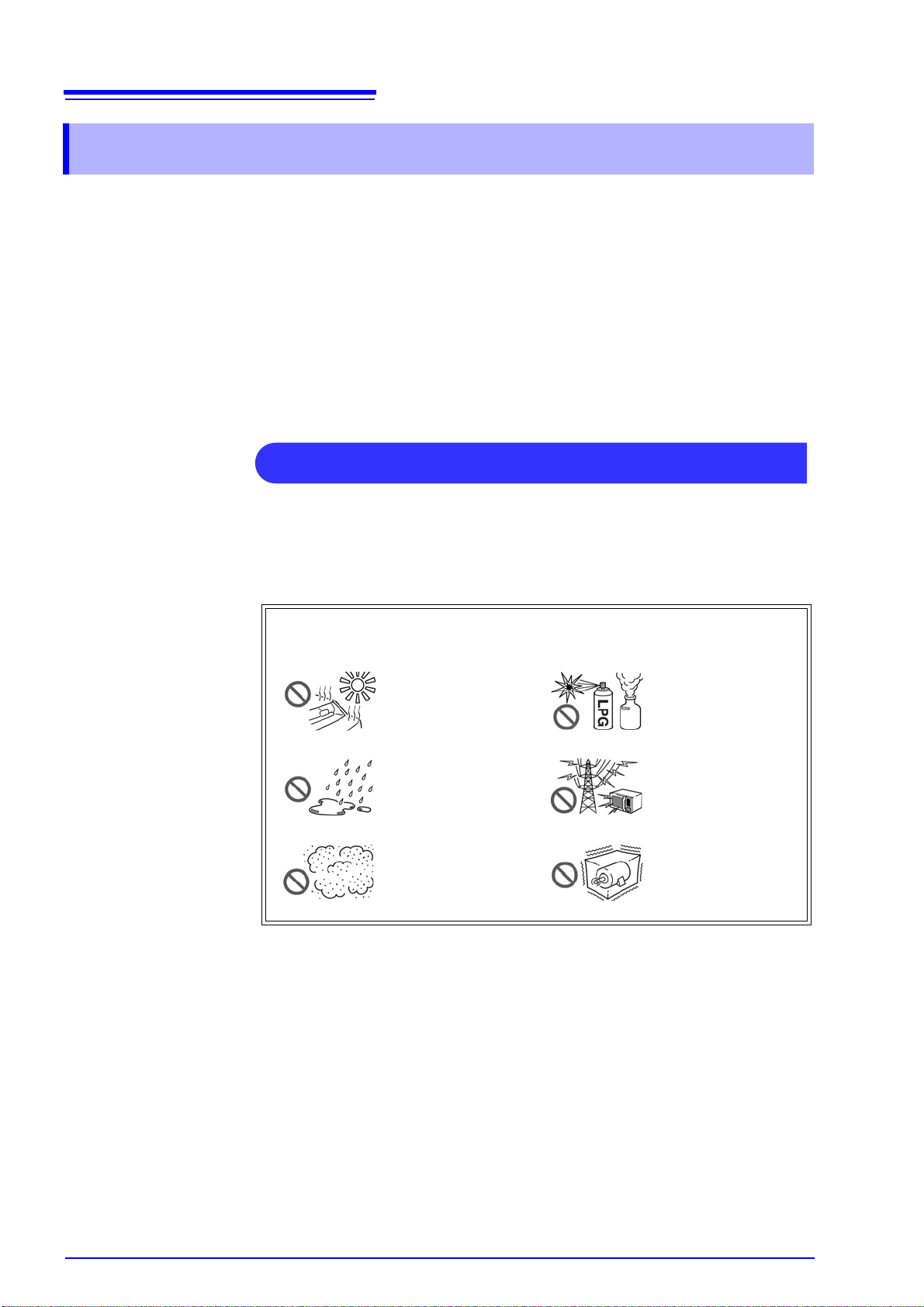

Avoid the following locations that could cause an accident or damage

to the unit.

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

±5°C, 80%RH

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

Page 11

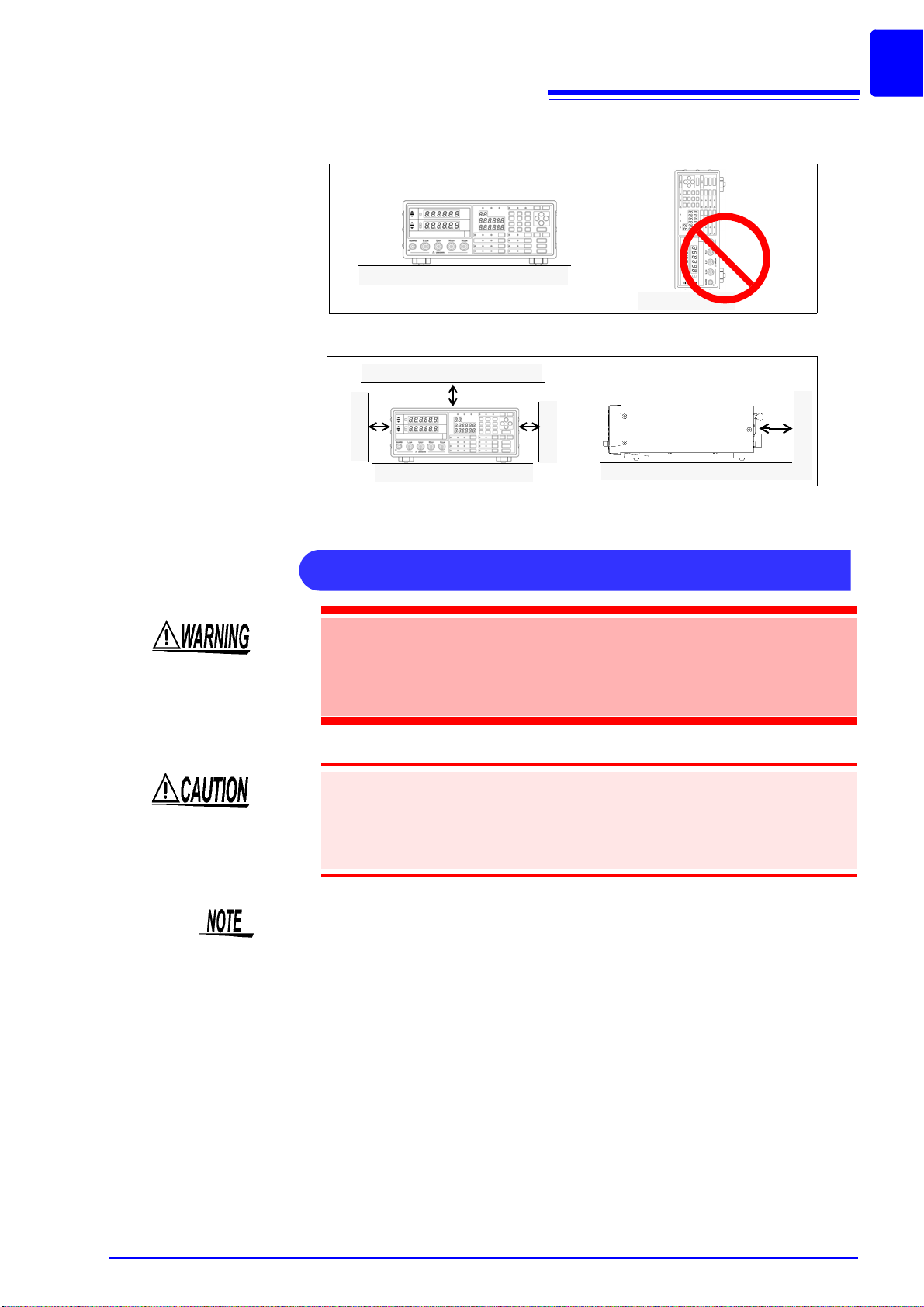

Installing

OK

10 cm or more

5 cm or more

Handling this device

5

Operating Precautions

• Do not install the unit with any side except th e bo tto m facin g down .

• Vents must not be obstructed.

• Do not allow the instrument to get wet, and do not take measurements

with wet hands. This may cause an electric shock.

• Never modify the unit. Only Hioki service engineers should disassemble or repair the unit. Failure to observe these precautions may result

in fire, electric shock, or injury.

• If anything unusual happens during operation of the unit, turn off the

power switch immediately and contact any HIOKI service facility for

help, advice and service.

• To avoid damage to the unit, protect it from physical shock when tran sporting

and handling. Be especially careful to avoid physical shock from dropping.

This instrument may cause interference if used in residential areas. Such use

must be avoided unless the user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of radio and television broadcasts.

Page 12

6

Before connection and powering on

Operating Precautions

• Before turning the unit on, make sure the supply voltage matches that

indicated on the its power connector. Connection to an improper supply voltage may damage the unit and pres ent an electrical hazard.

• The power supply voltage for this unit is switchable. To avoid electrical

accidents, check that the voltage selector is set correctly for the supply

voltage you are using.

Setting Procedure for the Power Voltage : 2.2 "Checking the Power Voltage" (p.

See

18)

• To avoid electrical accidents and to maintain the safety specifications

of this unit, connect the power cord provided only to a 3-contact (twoconductor + ground) outlet.

Connection Procedure : 2.3 "Connecting the Power Cord" (p. 19)

See

• To avoid shock and short circuits, turn off all power before connecting

probes.

About the guarantee

You should be aware that HIOKI cannot accept any responsibility directly or indirectly if the unit has been incorporated in some other system, or if it is resold to a

third party.

Check the connections carefully in order to avoid any chance of setting

up a short-circuit etc.

Page 13

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

The HIOKI Model 3505, 3506 C HiTesters are capacitance meters employing 1

kHz and 100 kHz (only for 3505) and 1 MHz frequencies to measure large-value

multilayer ceramic capacitors with consta nt volt age at hi gh speed and hig h accuracy. Primary applications include pass-fail judgment and ranking of capacitors

on tape machines and sorters.

1.2 Features

7

1

Capacitance-specific units

These capacitance meters use 1 kHz, 100 kHz (only for 3505) and 1 MHz measurement frequencies.

High-speed measurement

The 3505,3506 are capable of high-speed measurement: 2 ms at FAST.

Bin sorting function (p. 74)

1

Capacitors are easily ranked according to C (Capacitance*

ues into as many as 13 classifications.

) measurement val-

Comparator function (p. 59)

Makes pass-fail judgment of co mpone nts based on C measurement value and D

2

(dissipation factor*

), or on Q (quality factor*3) measurement value.

LED display

Provides superior visibility.

Equipped with standard data transfer interfaces (p. 129)

9

The 3505,3506 offers external I/O for sequencing, a standard RS-232C interface, and a standard GP-IB interface.

Measurement value memory (p. 232)

Up to 1000 measurement values can be stored in memory.

*1. Capability to store electric charge.

*2. An indicator of capacitor losses.

*3. An indicator of capacitor purity.

Page 14

8

1.2 Features

Trigger-synchronous measurement capability (p. 103)

The measurement signal can be input to the sample in sync with a trigger.

Frequency shift function (p. 101)

When using multiple devices, decreases measurement value fluctuation due to

interference by shifting the measuring frequency of each device.

Contact check function (p. 95)

Checks for bad contacts using the Low C r eject functio n and measurement level

monitoring function.

Page 15

9

1.3 Entire Workflow

1.3 Entire Workflow

Measurement

Preparations

Pre-Operation

Inspection

Basic Measurement See 3.2 "Measurement Example" (p. 24)

End of Measurement 6. Disconnect the sample and turn the power off.

See Chapter 2 "Measurement Prepar at i on s" (p. 17 )

1. Check the power voltage.

2. Connect the power cord.

3. Connect the probes or fixture (option) to the measurement terminals.

4. Turn the power on.

5. Connect the sample.

See 3.1 "Pre-Operation Inspection" (p. 23)

Be sure to perform pre-operation inspection prior to measurement.

1. Prepare the unit, fixture, and sample.

2. Connect the fixture to the measurement terminals.

3. Set the measurement conditions.

4. Connect the sample to the fixture.

5. Check the measurement results.

1

9

Page 16

10

1.3 Entire Workflow

Application Functions

Function Description

Open and Short circuit

compensation

Load compensation Allows interchangeability between measuring instruments

Offset compensation Allows interchangeability between measuring instruments

Cable length compensation

Self calibration Reduces measurement value drift.

Comparator measurement

function

BIN measurement function Set variations of the upper limit and lower limit values and

Average function Reduces fluctuation of the measurement value by perform-

Trigger delay Provides a reliable measurement value even when taking a

Eliminates measurement errors due to residual impedance.

by measuring a known sample.

by subtracting the set value from the measurement value.

Compensates for error caused by extending the measure-

ment cable.

Set the upper limit and lower limit values and judge wh ether

samples pass or fail.

rank samples accordingly.

ing an averaging process of the measurement values.

measurement immediately after connecting to a sample.

Reference

Section

(p. 37)

(p. 45)

(p. 51)

(p. 58)

(p. 55)

(p. 59)

(p. 74)

(p. 91)

(p. 93)

Contact check function Discerns whether or not the contact pin and sample are

connected.

Current detection circuit

monitoring function

Applied voltage monitoring

function

Frequency shift Reduce the differences in measurement values caused by

Display

Trigger synchronous output

function

Key lock function Disable key operations. (p. 104)

Communication function Control the unit from a PC. (p. 129)

Panel save function Save measurement conditions. (p. 105)

Panel load function Load saved measurement conditions (p. 106)

Beep tone

System reset

Monitors whether or not current outside the allowed range

is being produced.

Monitors whether or not voltage outside the allowed r ange

is being produced.

interference when using multiple 3505,3506 units for measurement.

Turns the LED display ON/ OFF.

Apply the measurement signal only during me asurement to

reduce the generation of heat in the sample and decrease

electrode wear.

Turns ON/ OFF the beep tone for judgm ent results and key

operations.

Resets device settings.

(p. 95)

(p. 100)

(p. 100)

(p. 101)

(p. 102)

(p. 103)

(p. 110)

(p. 114)

Printing function Print measurement values. (p. 115)

Application Measurement

• Countermeasures Against Incorporation of External Noise

• Measurement of high impedance components

• Measureme nt of comp on en ts in circuit ne tw or ks

Appendix 1 "Countermeasures Against Incorporation of External Noise" (p. A1)

See

Appendix 2 "Measurement of High Impedance Components" (p. A3)

See

Appendix 3 "Measurement of In-circuit Components" (p. A4)

See

Page 17

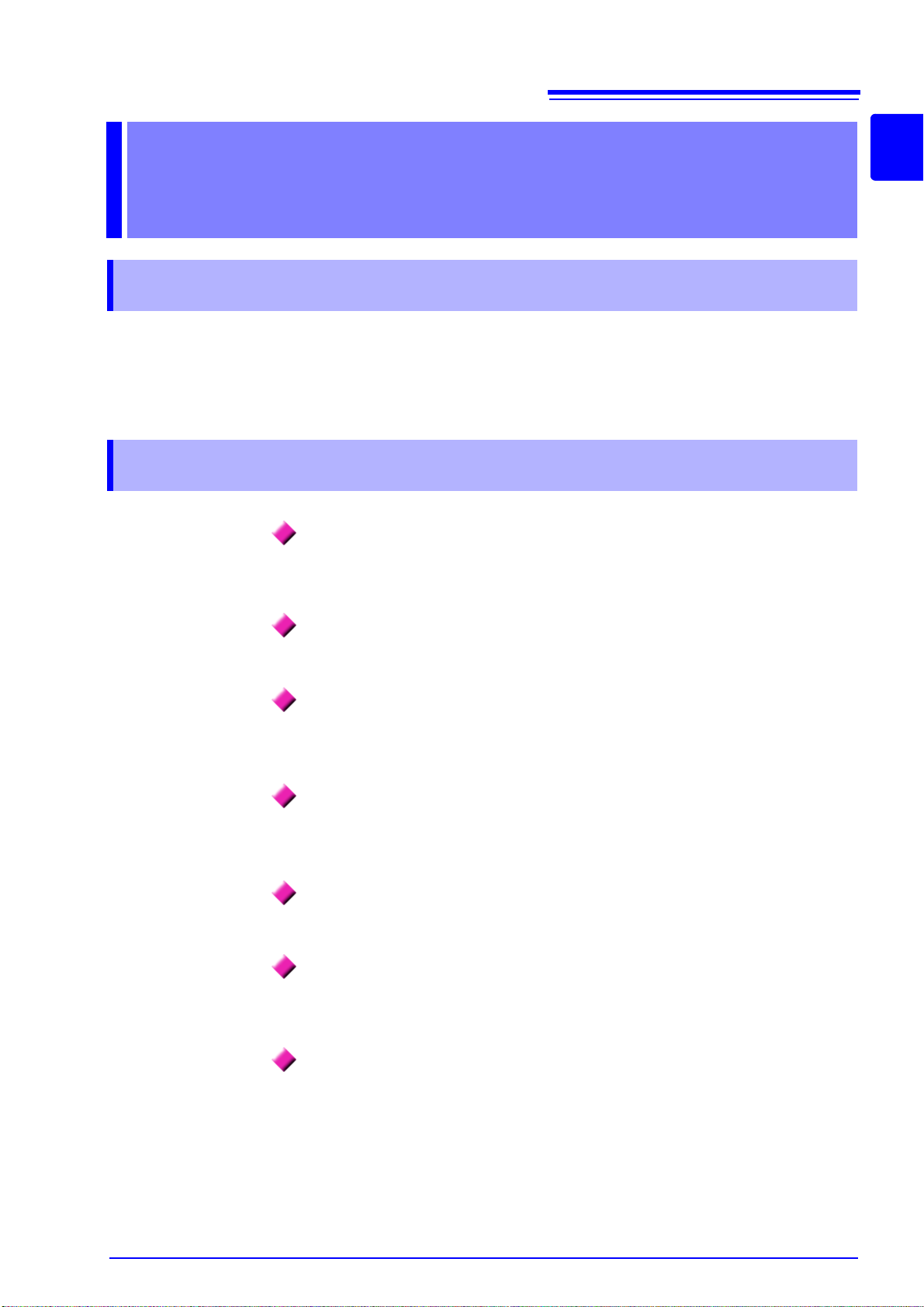

11

Front

MAIN Display

Displays the measurement

values of C and D ( or Q).

Displays the MENU items.

Comparator Evaluation

Result Display

Displays evaluation results in

Comparator Mode.

See

5.1 "Comparator Function"

(p. 59)

Setting Condition

Display

Displays current measurement conditions, presettings, and other information.

SUB Display

Displays the limit values of

BIN and comparator.

BIN Judgment Result

Display

Displays judgment results in

BIN mode.

See

5.2 "BIN Measurement

Function" (p. 74)

Error Display

Displays Low C reject and measured sine wave abnormality errors.

See

6.3.1 "Setting the Low C Reject

Function" (p. 96)

See 6.3.2 "Measurement Level Moni-

toring Function Settings" (p. 98)

Measurement Terminals

There are five measurement terminals:

H

CUR

The test signal is supplied to this terminal.

H

POT

Detected voltage high terminal

L

POT

Detected voltage low terminal

L

CUR

Measurement current detected terminal

GUARD Guard terminal

See

2.4 "Connecting the Probes and Fixtures" (p. 20)

Operating Panel

Use to set measurement

conditions and to make

other settings.

(p. 12)

1.4 Names and Functions of Parts

1.4 Names and Functions of Parts

1

9

Page 18

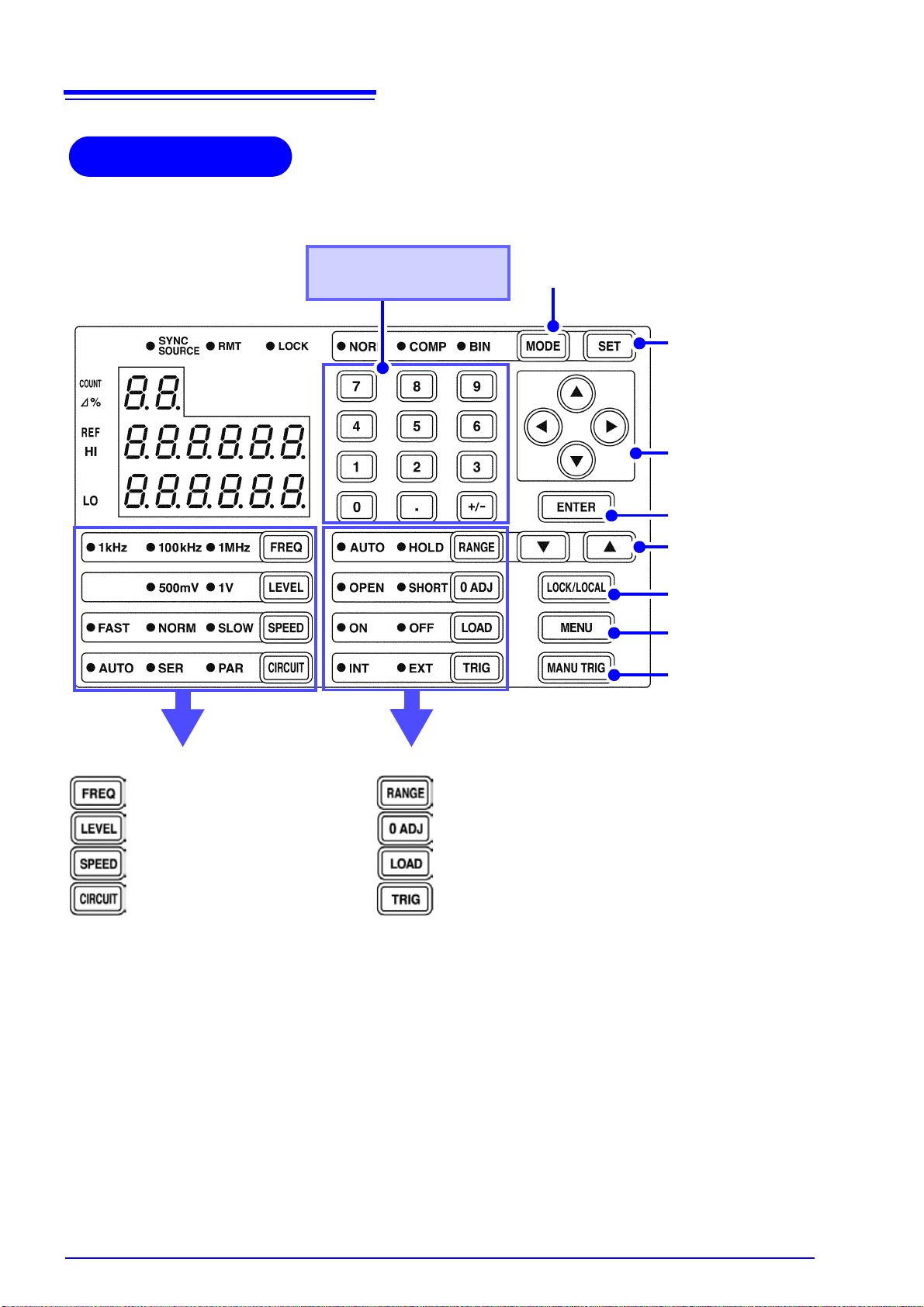

12

Operating Panel

Measurement frequency setting *2

(p. 27)

Measurement signal level setting

(p. 28)

Measurement speed setting

(p. 28)

Equivalent circuit mode

(p. 29)

Measurement range setting

(p. 31)

Open short circuit compensation

(p. 37)

Load compensation setting

(p. 45)

Trigger signal mode setting

(p. 36)

Keypad *1

Used to enter numeric values.

Measurement mode

setting (p. 26)

Comparator measurement function (p. 59)

BIN measurement

function (p. 74)

Manual trigger

(p. 36)

Menu

(p. 14)

Lock/ Local

(p. 104)

Measurement range

setting

(p. 31)

Enter

Arrow keys

Used to change settings

and move to menu items

or digits.

1.4 Names and Functions of Parts

*1 : A decimal point key is only effective when measuring the C offset compensation value.

*2 : 100 kHz measurement frequency display is only valid on the 3505.

Page 19

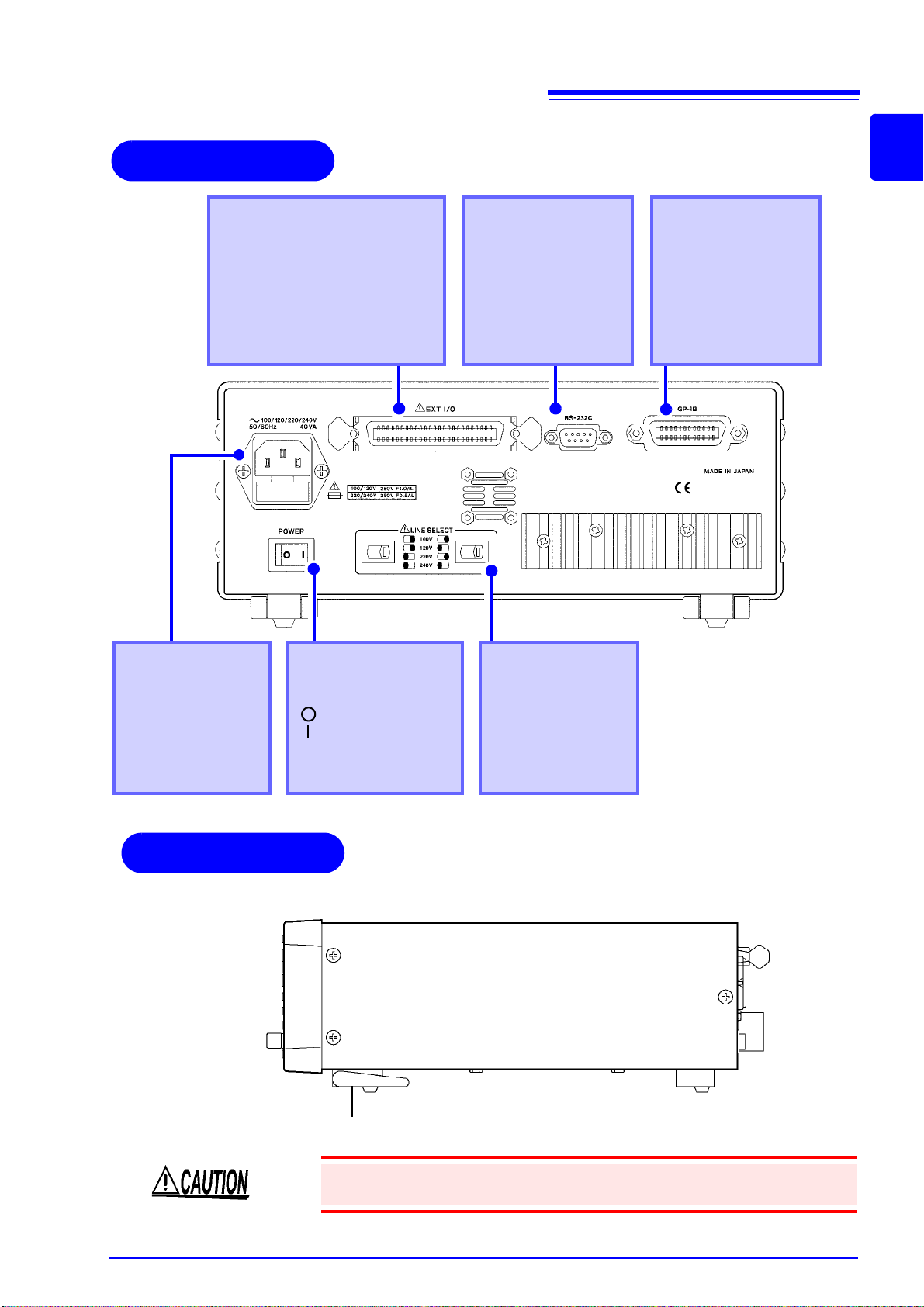

13

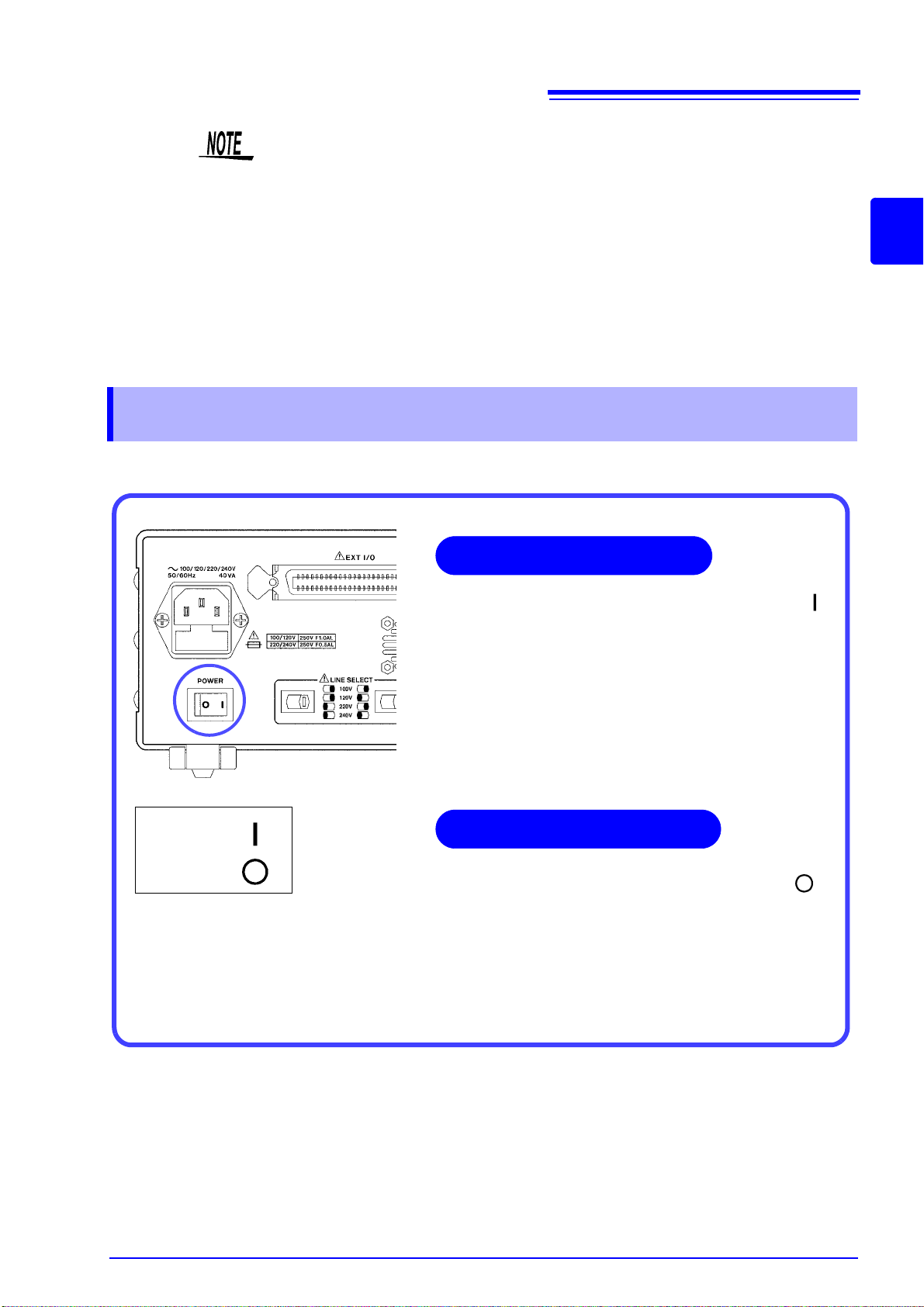

Back

Power Switch

Turns the power on and

off.

: Turns the power off.

: Turns the power on.

See 2.5 "Turning the

Power On and Off"

(p. 21)

Voltage

Selectors

Changes the

power voltage.

See 2.2 "Checking

the Power Voltage" (p. 18)

Power Inlet

Connect the supplied

power cord.

See 2.3 "Connecting

the Power Cord"

(p. 19)

RS-232C

Connector

Connect an RS-232C

cable.

See Chapter 8 "Control-

ling the Unit from a

PC" (p. 129)

EXT I/O Connector

Inputs external trigger signals and

outputs comparator result signals

and other signals. Supports connection to a PLC (Programmable

Logic Controller).

See 7.1 "About the EXT I/O Con-

nector" (p. 121)

GP-IB

Connector

Connect a GP-IB cable.

See Chapter 8 "Control-

ling the Unit from a

PC" (p. 129)

Stand

Side

Right side

1.4 Names and Functions of Parts

1

9

Do not apply heavy downward pressure with the stand extended. The stand

could be damaged.

Page 20

14

“LoAd_A(C/h)”

(p. 106)

“dELAY”

(p. 93)

“Lo C“

(p. 96)

“bEEP_K “

(p. 112)

“SAVE”

(p. 105)

“Frq.SFt”

(p. 101)

“LEV.ChK“

(p. 98)

“dISP”

(p. 102)

“Ld_tYP“

(p. 106)

“SYnC”

(p. 103)

“JudGE”

(p. 60)

“CAbLE”

(p. 58)

“AVErAG“

(p. 91)

“oFFSEt“

(p. 51)

“bEEP_J”

(p. 110)

Return to Panel Load Function.

(MAIN display area)

Panel Load

Function

Panel Save

Function

Load

Conditions

Average

Function

Trigger Delay

Frequency shift

Function

Trigger Synchro-

nous Function

Offset

Compensation

Low C Reject

Function

Level Check

Function

Judgment Mode

Beep Tone for

Judgment Results

Display

Cable length

Beep Tone for

Key Operations

“Sub.PAr“

(p. 26)

Second

Parameter

Returns to previous screen.

“IF”

(p. 134)

Communication

Conditions

“CALIb”

(p. 55)

Self Calibration

1.4 Names and Functions of Parts

Menu display organization

Displays menu screen

Page 21

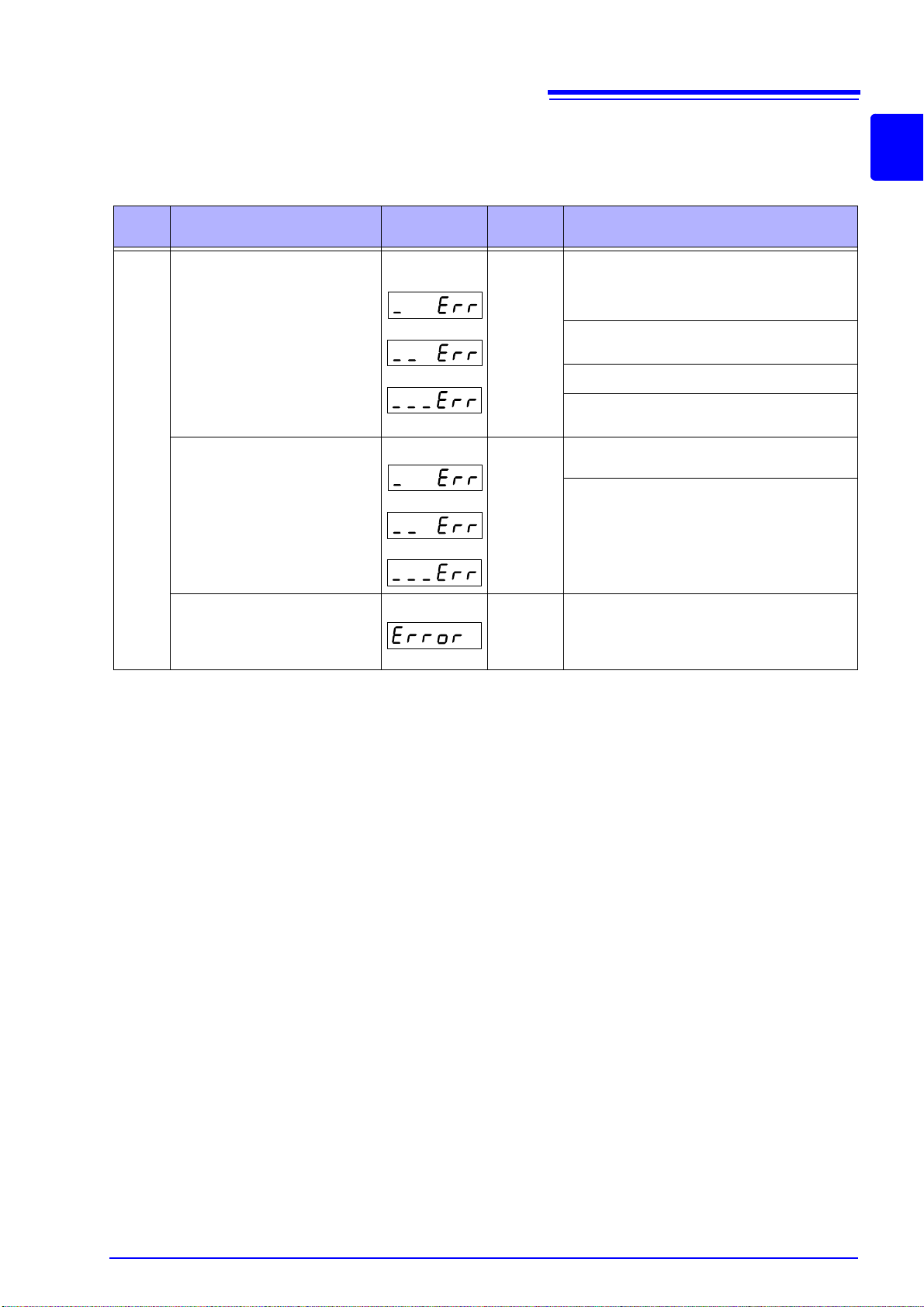

MAIN display area ERROR display

At 1 kHz

At 100 kHz

At 1 MHz

At 1 kHz

At 100 kHz

At 1 MHz

When the 3505/ 3506 detects a measurement abnormality, an error message is

displayed in the MAIN display area. When a measurement error occurs, the

device's condition is displayed in order of priority rank in the MAIN display area.

15

1.4 Names and Functions of Parts

1

Priority

rank

-

Error content

OPEN compensation error

Displayed when the OPEN

compensation value is less than

1 k.

SHORT compensation error

Displayed when the SHORT

compensation value is more

than 1 k

LOAD compensation error

Displayed when the LOAD compensation value is outside of

range.

MAIN display EXT.I/O Solution

Put the measurement terminals in an open

state. (Short circuit the H

H

terminal, and the L

POT

L

terminal.)

POT

-

-

-

Use the shielding process as a countermeasure against external noise.

Connect the 3505/ 3506 to ground.

Check to see if the measurement cable is bro-

ken.

Short the measurement terminals.

Check to see if the measurement cable is broken.

Perform compensation again after setting to

the appropriate range.

terminal to the

CUR

terminal to the

CUR

9

Page 22

16

Low

High

1.4 Names and Functions of Parts

Priority

rank

Error content

Sampling error

Displayed when the A/D conversion is not carried out normally.

Timeout

Displayed when measurement

does not commence following

trigger input.

Current detection

abnormality

Displayed when the measured

current is outside the present

range.

Applied voltage

abnormality

Displayed when the voltage between the measurement terminals is lower than the measured

voltage.

MAIN display EXT.I/O Solution

ERR

output,

HI

judgment,

OUT

judgment

ERR

output,

HI

judgment,

OUT

judgment

HI

judgment,

OUT

judgment

ERR

output,

HI

judgment,

OUT

judgment

It is possible that the device is being affected

by incoming noise.

The 3505/ 3506 is broken.

Submit it for repairs.

It is possible that the device is being affected

by incoming noise.

The 3505/ 3506 is broken.

Submit it for repairs.

The measurement range may be set too low.

Set the range to the appropriate setting and

measure again.

The object being measured may have a

SHORT circuit. Measure again to see if the

object being measured is normal.

The H

connected. Check the connection between

the measurement sample and the terminals.

There may be a high contact resistance between the H

object being measured.

POT

and H

CUR

terminals may be dis-

CUR

and L

CUR

terminals and the

Low C Connector error

Displayed when the measured

value is abnormally lower than

the measurement range.

Abnormal level detected

Displayed when the inspection

level abnormality monitor value

fluctuates.

When an error display occurs, the comparator and BIN measurement judgment

results will be HI and OUTOF-BINS.

Normal measurement value

ERR

output,

Standard

judgment

ERR

output,

HI

judgment,

OUT

judgment

The measurement terminals may not be connected to the object being measured.

Check the contact between the object being

measured and the measurement terminals.

Chattering may have occurred.

Check the connection between the measurement sample and the terminals.

It is possible that the device is being affected

by incoming noise.

Use the shielding process as a countermeasure against external noise.

Page 23

Measurement

1

Check the power voltage.

See 2.2 "Checking the Power Voltage" (p. 18)

2

Connect the power cord.

See 2.3 "Connecting the Power Cord" (p. 19)

3

Connect the probes or fixture

(option) to the measurement

terminals.

See 2.4 "Connecting the Probes and Fixtures" (p. 20)

4

Turn the power on.

See 2.5 "Turning the Power On and Off" (p. 21)

5

Connect the sample.

Unit Settings and Measurement

Chapter 3 "Setting the Measurement Conditions" (p. 23)

Chapter 6 "Application Functions" (p. 91)

Appendix 1 "Countermeasures Against Incorporation of

External Noise" (p. A1)

Appendix 2 "Measurement of High Impedance Component s"

(p. A3)

Appendix 3 "Measurement of In-circuit Components" (p. A4)

Back

Front

2

3

5

(Example)

Model 9677 (Option)

4

1

17

2.1 Preparation Flowchart

Preparations Chapter 2

Be sure to read "Follow these precautions to ensure safe operation and to

obtain the full benefits of the vario us functions." ( p. 4) pr ior to se tting u p the unit.

2.1 Preparation Flowchart

2

Page 24

18

Back

In the diagram, the voltage

value is 100 V because

both the left and right voltage selectors are set to the

right side.

Voltage selectors

2.2 Checking the Power Voltage

2.2 Checking the Power Voltage

• Before turning the unit on, make sure the supply voltage matches that

indicated on the its power connector. Connection to an improper supply voltage may damage the unit and pres ent an electrical hazard.

• The power of the unit can be changed with the voltage selectors. To

avoid an electric accident, use the unit with the voltage selectors set to

a voltage value that matches the voltage to be used.

• Make sure the power is off when you change the voltage with the voltage selectors. Changing the power voltage when the power is on may

result in damage to the unit or an electric accident.

• The maximum rated power is 40 VA.

• Replace the fuse only with one of the specified characteristics and voltage and current ratings. Using a non-specified fuse or shorting the

fuse holder may cause a life-threatening hazard.

Fuse type: 100 V 120 V setting: 250 V F1.0AL 20 mm x 5 mm dia

220 V 240 V setting: 250 V F0.5AL 20 mm x 5 mm dia

10.2 "Replacing the Power Fuse" (p. 269)

See

The power voltage specification of the unit is set as specified when the unit was

ordered.

You can select from 100 V, 120 V, 220 V, and 240 V .

You can determine which voltage is set by checking the positions of the voltage

selectors.

Refer to the diagram between the voltage selectors.

Voltage

100 V

120 V

220 V

240 V

Example:

Position of Left Voltage

Selector

(Right side) (Right side)

(Right side) (Left side)

(Left side) (Right side)

(Left side) (Left side)

Position of Right V olt age

Selector

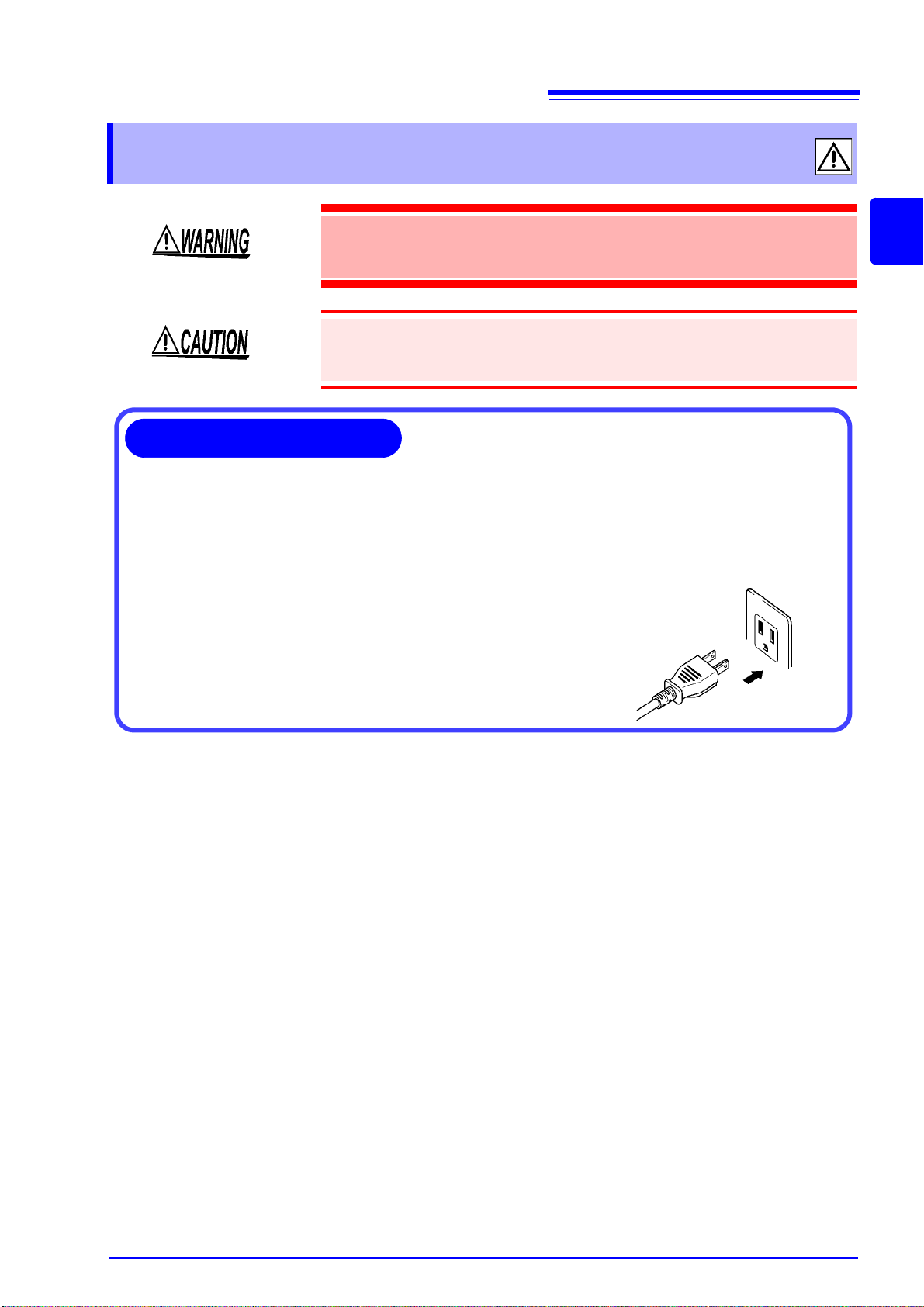

Page 25

2.3 Connecting the Power Cord

1. Make sure the power switch of the unit is off.

2. Make sure the power voltage matches and connect the power

cord to the power inlet with voltage selectors on the rear of the

unit.

3. Insert the plug into the power outlet.

Connection Procedure

2.3 Connecting the Power Cord

19

To avoid electrical accidents and to maintain the safety specifications of

this unit, connect the power cord provided only to a 3-contact (two-conductor + ground) outlet.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• Turn off the power before disconnecting the power cord.

2

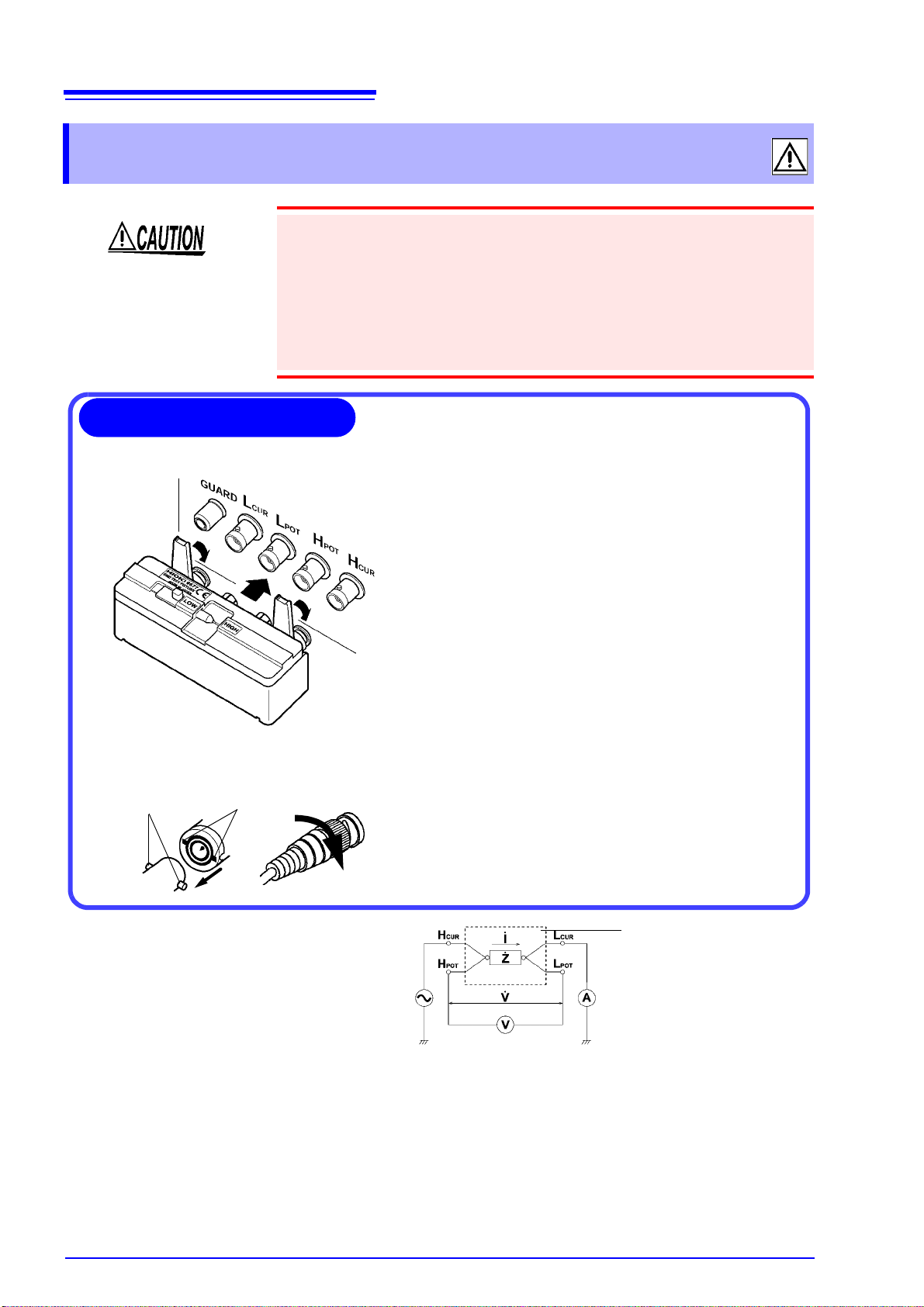

Page 26

20

Position upwards the side of the device with the

model number imprinted on it, plug directly into the

measurement terminals and use the right-left levers

to lock the connections.

The measurement terminal for this device is the following four terminal configuration.

H

CUR

terminal Terminal for applying measurement

signals

H

POT

terminal Voltage detection HIGH terminal

L

POT

terminal Voltage detection LOW terminal

L

CUR

terminal Measurement current detection ter-

minal

GUARD terminal Connect this terminal to the case

Example: Connecting a Model 9677 Test Fixture (Option)

Lock

Align the grooves of the BNC connector with the

connector guides of the connector of the unit and

then insert the connector and ro tate it clockwise

until it locks into position.

To disconnect the connector, rotate it counterclockwise until it unlocks and then remove it.

Connector guides of the

Model 3505/ 3506 measurement terminal

Measurement cables

BNC Connector Grooves

Example: Connecting the measurement cables

21

Measurement

Terminal

Connection Procedure

Fixture

Measurement Terminal

Configuration

2.4 Connecting the Probes and Fixtures

2.4 Connecting the Probes and Fixtures

• Do not apply a voltage to the measurement terminals. Doing so may damage

the unit.

• When disconnecting the BNC connector, be sure to release the lock before

pulling off the connector. Forcibly pulling the connector without releasing the

lock, or pulling on the cable, can damage the connector.

• To avoid breaking the probes, do not bend or pull them.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

For details such as the connection procedure for a fixture, refer to the corresponding instruction manual.

Page 27

2.5 Turning the Power On and Off

Set the power switch on the rear of the unit to ON ( ).

All LEDs on the front panel light up.

The measurement conditions at startup are the same as

the last time the power was turned off.

After turning the power on, wait 60 minutes for the unit to

warm up before beginning measurement.

Power ON

Power OFF

Turning the power On

Turning the power Off

Set the power switch on the rear of the unit to OFF ( ).

The measurement conditions are saved when the power is

turned off.

Even if there is a power failure or other problem with the

power, the unit will be in the measurement mode prior to

the power failure after it recovers.

• Use Hioki fixtures (option), etc.

Appendix 6 "Options" (p. A9)

See

• This device is adjusted for 1.5D-2V coaxial cable use. Using other cable

types may cause an increase in measurement errors.

• If all four terminals are disconnected, a meaningless number may be displayed on the unit.

• As this device has a four terminal configuration, always connect all 4 terminals’ shields in the vicinity of the sample. If you do not make a connection to

the 4 terminals’ shields in the vicinity of the sample, there is the possibility of

the measurement error becoming greater.

2.5 Turning the Power On and Off

21

2

Page 28

22

2.5 Turning the Power On and Off

Page 29

23

3.1 Pre-Operation Inspection

Setting the

Measurement

Conditions Chapter 3

3.1 Pre-Operation Inspection

To ensure safe use of the unit, be sure to check the following inspection

items prior to performing measurements.

3

Items Countermeasure Reference

Inspect the unit, probe,

and fixture.

(Are there any damaged

parts?)

Inspect the power cord

and connection cord.

(Is the covering cracked or is

any metal exposed?)

Check the power supply

voltage setting.

(Does the setting of the voltage selector on the rear of

the unit match the power

supply voltage to be used?)

When the power is turned

on, does the fan spin and do

the “3505/ 3506 ” and version number indications appear on the MAIN display

area?

If there is damage:

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

Do not use a damaged cord because doing so

may result in electric shock. (Replace the cord

with a new one.)

Use of the unit outside the specified power supply voltage range may result in the unit being

damaged or an electrical fault. Set the voltage

selector in accordance with the power supply

voltage to be used.

If the fan does not spin or the “3505/ 3506 ” and

version number indications are not displayed,

the unit may be malfunctioning. Submit it for repairs.

Setting the Voltage Selector:

2.2 "Checking the Power Voltage" (p. 18)

9

Are the measurement values

indicated on the unit normal

when measuring known

samples such as standard

capacitors?

If the measurement values are abnormal, check/

perform the following.

• Are the measurement conditions set appropriately?

• Perform open circuit and short circuit compensation again.

• Turn load compensation off.

If the measurement values are still abnormal after you have checked/performed the above, the

unit, probe, or fixture may be malfunctioning.

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

3.3 "Setting the Measurement Conditions"

(p. 26)

Chapter 4 "Compensate for errors" (p. 37)

Page 30

24

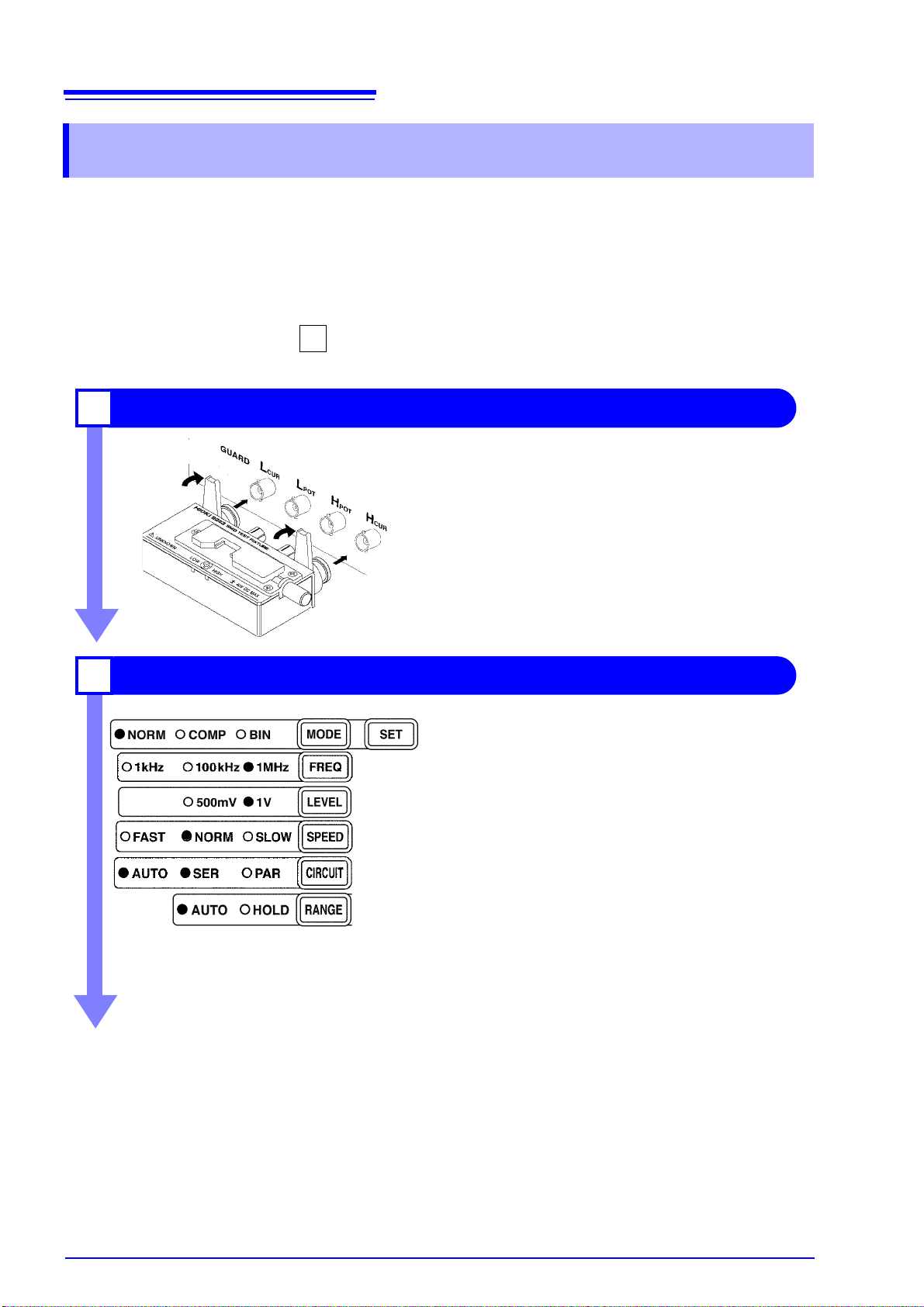

2

Connect the 9263 SMD Test Fixture (Option).

1

Connect the 9263 SMD Test Fixture to the

measurement terminal.

For the connection method, refer to the instruction manual supplied with the fixture.

Set the measurement conditions.

2

Using the keys on the operating panel, set the measurement conditions as shown at left.

Make other settings as necessary.

4.1 "Open Circuit Compensation and Short Circuit

Compensation" (p. 37)

4.2 "Load Compensation" (p. 45)

4.3 "Offset Compensation" (p. 51)

4.4 "Self Calibration" (p. 55)

4.5 "Set the Cable Length" (p. 58)

3.3.8 "Trigger Signal" (p. 36)

6.1 "Setting the Average Function" (p. 91)

6.2 "Trigger Delay Setting" (p. 93)

The open circuit compensation and short circuit compensation and self calibration settings improve measurement accuracy .

Display parameter .. ... ....... ... ... ... .... ... ... .. D (p. 26)

MODE

Measurement mode........ NORM (p. 27)

FREQ

Frequency...... .... ... ... ... .... .1 MHz (p. 27)

LEVEL

Measurement signal level.....1 V (p. 28)

SPEED

Measurement speed....... NORM (p. 28)

CIRCUIT

Equivalent-circuit mode .. AUTO (p. 29)

RANGE

Measurement range......... AUTO (p. 31)

3.2 Measurement Example

3.2 Measurement Example

Example The 9263 SMD Test F ixture is used for the measurement of multi-

layer ceramic capacitors.:

Necessary tools • Model 3505/ 3506

• Model 9263 SMD Test Fixture

• Sample to be me as ur ed : Mu ltila ye r cer ami c capacitor

Measurement

See .

Conditions

Page 31

25

Connect the sample to be measured to the 9263 SMD Test Fixture.

3

For the connection method, refer to the instruction

manual supplied with the fixture.

Check the measurement results.

4

Capacitance

Dissipation Factor

The voltage monitor and the current monitor can be

checked on the SUB display. (p. 113)

3.2 Measurement Example

3

9

Page 32

26

(MAIN display area)

S

e

c

o

n

d

P

a

r

a

me

t

e

r

(Display parameter settings screen)

3.3 Setting the Measurement Conditions

3.3 Setting the Measurement Conditions

3.3.1 Setting the Display Parameter

The lower parameter (second parameter) of the MAIN display can either be set

to D (dissipation factor) or Q (quality factor).

1. Press .

The upper part of the MAIN display area displays the menu contents and the

lower part displays the setting information.

(Refer to "Menu display organization" (p. 14) for menu order)

2. Use to select the “Sub.PAr” menu item.

The state becomes as follows.

3. Press to enable or disable the second parameter.

It toggles “d” and “q” each time is pressed.

4. Press to confirm the second parameter.

Once selected, "CALIb" (Self calibration settings screen) will be shown in the

upper part of the MAIN display area.

The second parameter will not be confirmed unless is pressed.

5. Press .

The unit returns to normal measurement mode.

Page 33

3.3.2 Measurement Mode

Select a measurement mode.

Press to change the mode.

27

3.3 Setting the Measurement Conditions

Mode:

The selected item is indicated by the lit LED lamp.

NORM, COMP, BIN

NORM

COMP

BIN

Select this when using normal measurement mode.

Select this when using comparator measurement mode.

5.1 "Comparator Function" (p. 59)

See

Select this when using BIN measurement mode.

5.2 "BIN Measurement Function" (p. 74)

See

3.3.3 Measurement Frequency

Set the measurement frequency.

Set a frequency appropriate for the sample to be measured.

Press to change the mode.

3

Measurement frequency:

The selected item is indicated by the lit LED lamp.

At 1 MHz the measured frequency can be shifted by ±1% or ±2% with th e use of

the frequency shift function.

6.6 "Using the Frequency Shift Function" (p. 101)

See

1 kHz, 100 kHz (only for 3505), 1 MHz

9

Page 34

28

3.3 Setting the Measurement Conditions

3.3.4 Measurement Signal Level

Set the measurement signal level.

Set a signal level appropriate for the sample to be measured.

Press to change the mode.

Measurement signal level:

The selected item is indicated by the lit LED lamp.

• In some samples, the value may vary depending on the measurement-signal level.

• Because this is an open terminal voltage mode device it cannot measure

constant voltage. When measuring large capacity condensers the voltage

between condenser terminals will be lower than the set voltage. This is due

to the voltage decrease caused by output resistance and measurement

cable resistance.

Output resistance: Approx. 1 (Above 2.2

range at 100 kHz)

Approx.20 (Ranges other than the above-mentioned)

3.3.5 Measurement Speed

Set the measurement speed.

Press to change the mode.

500 mV, 1 V

F range at 1 kHz ; above 22 nF

Measurement speed:

The selected item is indicated by the lit LED lamp.

FAST

NORM

SLOW

The lower the measurement speed, the higher the measurement

accuracy becomes.

Measurement speed

FAST NORM SLOW

2.0 ms 5.0 ms 14.0 ms

(Allowance: ±5%±0.5 ms)

The measurement time varies depending on such factors as the open and

short and load circuit compensation ON/ OFF and the comparator/ BIN measurement function ON/ OFF.

FAST, NORM, SLOW

Measures at high speed.

Measures at normal speed.

Measures at low speed, but provides improved measure-

ment accuracy.

Page 35

3.3.6 Equivalent Circuit Mode

Measurement

Frequency

Range

Automatically selected

mode

1 kHz 100 pF to 100 nF Parallel equivalent circuit

220 nF to 10 F Series equivalent circuit

100 kHz

(only for 3505)

1 pF to 1 nF Parallel equivalent circuit

2.2 nF to 100 nF Series equivalent circuit

1 MHz 220 fF to 100 pF Parallel equivalent circuit

220 pF to 1 nF Series equivalent circuit

You may set an equivalent circuit mode (SER/ PAR).

Automatic selection is also possible.

See "Equivalent Circuit Mode" (p. 30)

Press to change the mode.

29

3.3 Setting the Measurement Conditions

3

Equivalent circuit mode:

The selected item is indicated by the lit LED lamp.

AUTO

SER

PAR

The series equivalent circuit mode or parallel equivalent circuit

mode is automatically selected according to the measurement

range.

About the Range No.(p. 33)

See

Series equivalent circuit mode

Parallel equivalent circuit mode

AUTO, SER, PAR

9

Page 36

30

Series-equivalent circuit

Parallel-equivalent circuit

3.3 Setting the Measurement Conditions

Equivalent Circuit Mode

This unit measures a current that flows through the sample and a voltag e applied

between terminals of the measurement sample to calculate and obtain impedance Z and phase angle . Static capacitance can be obtained using Z and

values.

A series-equivalent circuit mode calculates as though a captive component C

and a resistive component were connected in series, or alternatively a parallelequivalent circuit mode calculates as though connected in parallel. Because the

operation is different between a series-equivalent circuit mode and a parallelequivalent circuit mode, the appropriate equivalent circuit mode need be

selected to reduce error margin.

Normally, the series-equivalent circuit mode is used for a large capacitance (lowimpedance components: approx. 100 or less). While the parallel-equivalent

circuit mode is used for a small capacitance (high-impedance components:

approx. 10 k or more). When you are not sure about selection of equivalentcircuit mode for the impedance such as between approx. 100 to 10 k),

please call the parts maker.

Page 37

3.3.7 Measurement Range

Reference Values

Current, Voltage Detection Waveform (A/D) Input Range

Guaranteed Accuracy Range

Auto Range (Recommended range)

Reference Values

Select a measurement range. Automatic selection is also possible.

Press to change the mode.

31

3.3 Setting the Measurement Conditions

Measurement range

Measurement Range:

The selected item is indicated by the lit LED lamp.

AUTO

(Auto range)

HOLD

(

Hold range

)

AUTO, HOLD

The optimal measurement range is selected automatically.

This is useful for the measurement of unknown samples.

However, measurement takes longer.

The measurement range is fixed, and may only be altered

manually.

Take measurements in the same range regardless of the

value of the sample. This is useful for high-speed measurement.

Changing the range:

When the range is changed, the decimal point and unit in

the measurement value display area change. The measurement range is displayed in the SUB display area.

3

9

Page 38

32

3.3 Setting the Measurement Conditions

Guaranteed Accuracy Range

1 kHz 100 kHz (only for 3505) 1 MHz

No. Range

1 220 fF 0.000 fF to 330.000 fF

2 470 fF 68.000 fF to 680.000 fF

3 1 pF 0.00000 pF to 1.50000 pF 1 pF 0.15000 pF to 1.50000 pF

4 2.2 pF 0.33000 pF to 3.30000 pF 2.2 pF 0.33000 pF to 3.30000 pF

5 4.7 pF 0.68000 pF to 6.80000 pF 4.7 pF 0.68000 pF to 6.80000 pF

6 10 pF 1.0000 pF to 15.0000 pF 10 pF 1.0000 pF to 15.0000 pF

7 22 pF 3.3000 pF to 33.0000 pF 22 pF 3.3000 pF to 33.0000 pF

8 47 pF 6.8000 pF to 68.0000 pF 47 pF 6.8000 pF to 68.0000 pF

9 100 pF 0.000 pF to 150.000 pF 100 pF 15.000 pF to 150.000 pF 100 pF 15.000 pF to 150.000 pF

10 220 pF 33.000 pF to 330.000 pF 220 pF 33.000 p F to 330.000 pF 220 pF 33.000 pF to 330.000 pF

11 470 pF 68.000 pF to 680.000 pF 470 pF 68.000 pF to 680.000 pF 470 pF 68.000 pF to 680.000 pF

12 1 nF 0.15000 nF to 1.50000 nF 1 nF 0.15000 nF to 1.50000 nF 1 nF 0.15000 nF to 1.50000 nF

13 2.2 nF 0.33000 nF to 3.30000 nF 2.2 nF 0.33000 nF to 3.30000 nF

14 4.7 nF 0.68000 nF to 6.80000 nF 4.7 nF 0.68000 nF to 6.80000 nF

15 10 nF 1.5000 n F to 15.0000 nF 10 nF 1.5000 nF to 15.0000 nF

16 22 nF 3.3000 n F to 33.0000 nF 22 nF 3.3000 nF to 33.0000 nF

17 47 nF 6.8000 n F to 68.0000 nF 47 nF 6.8000 nF to 68.0000 nF

18 100 nF 15.000 nF to 150.000 nF 100 nF 15.000 n F to 150.000 nF

19 220 nF 33.000 nF to 330.000 nF

20 470 nF 68.000 nF to 680.000 nF

21 1 F 0.15000 F to 1.50000 F

22 2.2 F 0.33000 F to 3.30000 F

23 4.7 F 0.68000 F to 6.80000 F

24 10 F 1.5000 F to 15.0000 F

Guaranteed accuracy

range

Range

Guaranteed accuracy

range

Range

Guaranteed accuracy

range

Page 39

3.3 Setting the Measurement Conditions

Auto Range

1 kHz 100 kHz (only for 3505) 1 MHz

No.

Range Auto range Range Auto range Range Auto range

1 220 fF 0.000 fF to 330.000 fF

2 470 fF 220.000 fF to 680.000 fF

3 1 pF 0.00000 pF to 1.50000 pF 1 pF 0.47000 pF to 1.50000 pF

4 2.2 pF 1.00000 pF to 3.30000 pF 2.2 pF 1.00000 pF to 3.30000pF

5 4.7 pF 2.20000 pF to 6.80000 pF 4.7 pF 2.20000 pF to 6.80000 pF

6 10 pF 4.7000 pF to 15.0000 pF 10 pF 4.7000 pF to 15.0000 pF

7 22 pF 10.0000 pF to 33.0000 pF 22 pF 10.0000 pF to 33.0000 pF

8 47 pF 22.0000 pF to 68.0000 pF 47 pF 22.0000 pF to 68.0000 pF

9 100 pF 0.000 pF to 150.000 pF 100 pF 47.000 pF to 150.000 pF 100 pF 47.000 pF to 150.000 pF

10 220 pF 100.000 pF to 330.000 pF 220 pF 100.000 pF to 330.000 pF 220 pF 100.000 pF to 330.000 pF

11 470 pF 220.000 pF to 68 0.000 pF 470 pF 220.000 pF to 680.000 pF 470 pF 220.000 pF to 680.000 pF

12 1 nF 0.47000 nF to 1.50000 nF 1 nF 0.47000 nF to 1.50000 nF 1 nF 0.47000 nF to 1.50000 nF

13 2.2 nF 1.00000 nF to 3.30000 nF 2.2 nF 1.00000 nF to 3.30000 nF

14 4.7 nF 2.20000 nF to 6.80000 nF 4.7 nF 2.20000 nF to 6.80000 nF

15 10 nF 4.7000 nF to 15.0000 nF 10 nF 4.7000 nF to 15.0000 nF

16 22 nF 10.0000 nF to 33.0000 nF 22 nF 10.0000 nF to 33.0000 nF

17 47 nF 22.0000 nF to 68.0000 nF 47 nF 22.0000 nF to 68.0000 nF

18 100 nF 47.000 nF to 150.000 nF 100 nF 47.000 nF to 150.000 nF

19 220 nF 100.000 nF to 330.000 nF

20 470 nF 220.000 nF to 680.000 nF

21 1 F 0.47000 F to 1.50000 F

22 2.2 F 1.00000 F to 3.30 000 F

23 4.7 F 2.20000 F to 6.80 000 F

24 10 F 4.7000 F to 15.0000 F

33

3

Display range

Normal measurement, comparator

and BIN measurement

(count setting)

comparator and BIN measurement

(setting)

comparator and BIN measurement

(setting)

C display range D(Q) display range Note

MAIN Display shows -199999

-199999 to

999999

-99999 to 99999

-199999 to 199999

when C measurement value

falls below -199999

9

Page 40

34

仮

Outside of C display range?

YES

YES

OF(uF) is displayed only

in the upper area of

the MAIN display area

No

No

OF(uF) is displayed in the

upper area of the MAIN

display area

YES

measurement value is

displayed in the upper area

of the MAIN display area

No

Outside of D(Q) display range?

d(q)-OF(d(q)-uF) is displayed

in the lower area of the SUB

display area

measurement value is displayed

in the lower area of the SUB

display area

Outside of Current, Voltage Detection

Waveform Input Range?

outside of range?

measurement range?

AUTO

HOLD

3.3 Setting the Measurement Conditions

• If the measurement values displayed on the unit are outside of the guaranteed accuracy range, the HOLD LED flashes.

• For errors other than measurement value outside of range errors, refer to

"MAIN display area ERROR display" (p. 15).

• When measuring 2 test items that fall within the range of Auto Range,

choosing the item with a capacity nearer the upper value will give a better

repeat accuracy.

• An error message may be displayed in the MAIN display area if the value

falls outside the measurement range and display range following the flow

chart below.

• A negative measurement value may be displayed.

Factors which may cause this include the following:

• Measuring inductance that is in the opposite phase.

• The OPEN compensation value is not accurately taken.

• LOAD compensation enabled.

• Offset compensation is enabled.

The lowest display value in both the MAIN and SUB displays is "-199999". If

the measurement value is lower than this, "-199999" will be shown in the

MAIN display and "d-UF" will be shown in the SUB display.

• The possible measurement range setting differs depending on the frequency being measured. When the measured frequency falls outside of

range, the lowest range will be used for extremely small values and the largest range for frequencies larger than the largest value.

OF, UF Judgement Flow Chart

Page 41

MAIN display Cause

or

or

or

HOLD Setting: When input for current detection waveAUTO Setting: current detection waveform is out of the

HOLD Setting: When input for voltage detection waveAUTO Setting: voltage detection waveform is out of the

35

3.3 Setting the Measurement Conditions

form is out of the range.

range.

+

When measurement value is higher than

upper value of Auto Range

form is out of the range.

range.

+

When measurement value is lower than

lower value of Auto Range.

3

When C display range is exceeded.

When D display range is exceeded.

9

When Q display range is exceeded.

Page 42

36

3.3 Setting the Measurement Conditions

3.3.8 Trigger Signal

The internal trigger or the external trigger can be set.

Press to change the mode.

When inputting the

trigger signal through

the interface

Trigger signal:

INT

(Internal trigger

mode)

EXT

(External trigger

mode)

Measurement starts when a "*TRG" command is received through the interface.

For details on inputting the trigger signal through the interface, refer to "Sam-

pling Request" (p. 176)

INT, EXT

Continuous measurement is performed while automatically generating an internal trigger signal.

The INT LED lights up.

A trigger signal is input from the outside either manua lly

or automatically.

The EXT LED lights up.

Press to perform measurement once.

Measurement is performed with a trigger from the EXT

I/O connector TRIG terminal.

of section 8.9, "Message Reference".

When inputting the

trigger signal through

the EXT I/O connector

When a negative-logic pulse signal is input to TRIG (pin 1) of the EXT I/O connector on the rear panel, one measurement operation is performed.

7.1 "About the EXT I/O Connector" (p. 121)

See

Page 43

4.1 Open Circuit Compensation and Short Circuit Compensation

Measurement

frequency

Measurement

level

Compensate

for errors Chapter 4

4.1 Open Circuit Compensation and Short Circuit

Compensation

37

Open circuit compensation and short circuit compensation enable you to reduce

the effect of impedance remaining in parts such as the probe or fixture and

improve measurement accuracy.

There are two ways of performing open circuit compensation and short circuit

compensation.

• All Compensation

Compensates at measurement conditions set at Command: CORRection

:OPEN(SHORt):POINt (Frequencies: 1 kHz, 100 kHz (3505 only), 1 MHz,

Signal levels: 500 mV, 1 V’s optional point).

However, and 1 MHz it ca n only perform compensation on frequencies set to

frequency compensation.

This can be performed from the front panel or via a PC.

"Setting and Query of Open Compensation Points" (p. 204) and

See

"Setting and Query of Short Compensation Points" (p. 208) of

“8.9, "Message Reference".

All Compensation Example

For example, when all compensation is performed at 1% frequency shift and

compensation point set to all frequencies and 1 V signal level (:CORRectio n

:OPEN:POINt 42, :CORRection:SHORt:POINt 42), compensation is performed at the measurement conditions marked “Yes” below.

1 MHz

1 kHz 100 kHz

-2% -1% 0% 1% 2%

4

5

9

500 mV No No No No No No No

1 V Yes

• Spot Compensation

This performs compensation at the frequency currently set. Perform this from

a PC through the interface.

"Setting and Query of Open Circuit Compensation Function" (p. 201) and

See

"Setting and Query of Short Circuit Compensation Function" (p. 205) of

“8.9, "Message Reference".

Yes

No No No Yes No

Page 44

38

4.1 Open Circuit Compensation and Short Circuit Compensation

• The measurement accuracy values defined in the specifications are for

when open circuit compensation and short circuit compensation are performed.

• Be sure to perform compensation again after replacing the probe or fixture.

You will be unable to obtain correct values if measurement is performed in

the compensation state prior to replacement.

• The open circuit compensation range of impedance is 1 k or more. However, if the values are not suf ficiently hig h comp ar ed to the imped ance o f the

sample, the measurement errors will be larger and measurement may

become no longer possible.

• The short circuit compensation range of impedance is less than 1 k. How -

ever, if the values are not sufficiently low compared to the impedance of the

sample, the measurement errors will be larger and measurement may

become no longer possible.

• The compensation value is saved at varying values depending on the measured frequency, signal level, and frequency shift settings.

If these settings are changed and a measurement value has not been taken

with the changed measurement conditions, open circuit compensation and

short circuit compensation will be turned OFF.

However, when the frequency shift or cable length setting is changed, open

circuit compensation and short circuit compensation are set to OFF for all

measurement conditions.

• If there is an abnormality in the compensation value, measurement value

error will increase. The measurement value may be displayed as a negative

number.

• When performing compensation, make sure that there is no noise source

nearby. Noise may cause an error when performing compensation.

ex. Servo Motor, switching power source, high-voltage cable and etc.

Page 45

39

(Flash)

(MAIN display area)

Flash

(Example)

“AdJuSt”

Takes the compensation values.

“on”

Enables the compensation values.

“oFF”

Disables the compensation values.

4.1 Open Circuit Compensation and Short Circuit Compensation

Ta ke the open circuit compensation and

short circuit compensation values ________________________________

1. In normal measurement mode, press .

If you do not want to perform open circuit compensation, press to proceed to configuring the short circuit compensation settings. (The SHORT LED

flashes and the “Short AdJuSt” indication is displayed and the “AdJuSt” indication flashes in the MAIN display area.) Proceed to Step 5

.

2. Open the space between the HIGH and LOW terminals of the probe or fix-

ture connected to the measurement terminals to match the width of the

object being measured.

3. Use or to select setting the open circuit menu item.

Pressing or causes the display to change in the following manner.

4

5

9

• When performing compensation, the placement of things like the probe and

the distances between terminals must be as similar as pos sible to the state

when performing measurement.

• If compensatio n is being affected by external noise, use the sh ielding process.

Appendix 2 "Measurement of High Impedance Components" (p. A3).

See

Page 46

40

(Flash)

(MAIN display area)

1 kHz and 500 mV

of compensation

1 kHz and 1 V of

compensation

100 kHz and 500 mV

of compensation

100 kHz and 1 V of

compensation

1 MHz and 500 mV

of compensation

1 second displayed

End of all

compensation

3505

(MAIN display area)

1 kHz and 500 mV

of compensation

1 kHz and 1 V of

compensation

1 MHz and 500 mV

of compensation

1 second displayed

End of all

compensation

3506

(Light up)

(Flash)

(MAIN display area)

F

l

a

s

h

4.1 Open Circuit Compensation and Short Circuit Compensation

4. Select "AdJuSt" and press .

Incorporate the open circuit compensation values. (ALL Compensation)

End of Compensation:

When compensation ends, the state becomes as follows.

Page 47

41

(MAIN display area)

Light up

Compensation stops.

Error display Measurement

Frequency

1 kHz

100 kHz

1 MHz

(Example)

4.1 Open Circuit Compensation and Short Circuit Compensation

Compensation Error:

If a compensation error occurs, a warning beep will sound and the state

becomes as follows.

The measurement frequency at which the error occurred can be ascertained

from the underbar display.

"MAIN display area ERROR display" (p. 15)

See

4

What if there is an error?

• Are the measurement terminals open? Open the measurement terminals and

then perform compensation again. (To set the measurement terminals open,

short the H

L

terminal.)

POT

• If there is a compensation error even when the measurement terminals are

open, external noise may be affecting compensation or the unit, probe, or fixture may be malfunctioning. Use the shielding process, submit the unit or fixture for repairs, or replace the probe with a new one. (The probe cannot be

repaired.)

Appendix 2 "Measurement of High Impedance Components" (p. A3)

See

If is pressed, th e unit enters short cir cuit compensation incorp orate mode.

(Proceed to Step5) ( The settings for open circuit compensation remain the same

as last time.)

terminal to the H

CUR

terminal, and the L

POT

terminal to the

CUR

5. Use a shorting bar to create a short circuit state between the HIGH

terminal and LOW terminal of the probe or fixture connected to the

measurement terminals.

Use a shorting bar with as low an impedance as possible.

5

9

• When performing compensation, the placement of things like the probe and

fixture and the distances between terminals must be as similar as possible

to the state when performing measurement.

• If you do not want to perform short circuit compensation, press to

return to normal measurement mode.

Page 48

42

(Light up)

(Flash)

(MAIN display area)

1 kHz end of

compensation

1 second displayed

100 kHz end of

compensation

(only for 3505)

End of all

compensation

(Light up)

(Light up)

(MAIN display area)

Compensation stops.

Error display Measurement

Frequency

1 kHz

100 kHz

1 MHz

Light up

4.1 Open Circuit Compensation and Short Circuit Compensation

6. Use or to select setting the short circuit menu item.

7. Select "AdJuSt" and press .

Incorporate the short circuit compensation values. (ALL Compensation)

End of Compensation:

When compensation ends, the state becomes as follows.

The unit returns to normal measurement mode.

Compensation Error:

If a compensation error occurs, a warning beep will sound and the state

becomes as follows.

The measurement frequency at which the error occurred can be ascertained

from the underbar display.

"MAIN display area ERROR display" (p. 15)

See

What if there is an error?

• If is pressed, the unit returns to norma l measur ement mod e. (The settings for short circuit compensation remain the same as last time.)

• Are the measurement terminals in a short circuit state? Short circuit the measurement terminals and then perform comp ensation again.

• If there is a compensation error even when the measurement terminals are

short circuited, the unit, probe, or fixture may be malfunctioning. Use the

shielding process, submit the unit or fixture for repairs, or replace the probe

with a new one. (The probe cannot be repaired.)

Page 49

43

(Flash)

(Light up)

(MAIN display area)

Flash

“AdJuSt”

Takes the compensation values.

“on”

Enables the compensation values.

“oFF”

Disables the compensation values.

(SUB display area)

Cp

G

4.1 Open Circuit Compensation and Short Circuit Compensation

Setting Open Circuit and Short Circuit Compensation ON/ OFF ________

1. In normal measurement mode, press .

The state becomes as follows.

Pressing or causes the display to change in the following manner.

4

5

2. Press to set the open circuit compensation ON or OFF.

When open circuit compensation is in the ON state the open circuit compensation value will be displayed (as "Cp, G") in the SUB display area.

Pressing and on the control panel and changing measurement

conditions while the open circuit compensation values are being displayed will

cause the compensation value relative to the set measurement conditions to be

displayed.

9

Page 50

44

(Off) (Flash)

(Light up) (Flash)

When select the “on”

(Off) (Flash)

When select the “oFF”

(MAIN display area)

F

l

a

s

h

(SUB display area)

Rs

X

(Light up) (Off)(Off)(Off)

When select the “on”

When select the “oFF”

4.1 Open Circuit Compensation and Short Circuit Compensation

3. Press to confirm the open circuit compensation ON or OFF.

Open circuit compensation is set to OFF and the state becomes as follows.

The state of the open circuit compensation LED becomes as follows and the

device enters the short circuit compensation setting mode.

Press if not setting the open circuit compensation ON or OFF. The

device enters short circuit compensation ON or OFF setting.

(Proceed to Step 4.)

4. Press to set the short circuit compensation ON or OFF.

When short circuit compensation is in the ON state the open circuit compensation value will be displayed (as "Rs, X") in the SUB display area.

Pressing and on the control panel and changing measurement

conditions while the open circuit compensation values are being displayed will

cause the compensation value relative to the set measurement conditions to be

displayed.

5. Press to confirm the short circuit compensation ON or OFF.

Short circuit compensation is set to OFF and the state becomes as follows.

Press if not setting the short circuit compensation ON or OFF.

The unit returns to normal measurement mode.

Page 51

4.2 Load Compensation

Measurement frequency 1 kHz 1 00 kHz 1 MHz (-2% to 2%)

Load compensation

Yes No Yes

Load compensation allows for the calculation of the load compensation rate by

measuring a standard sample with known measurement values and compensating the measurement values.

With this function, when using multiple

of individual

produced. Alternately, the measurement values of the

matched to those of a reference device.

The compensation rate is determined by first calculating the impedance Z and

phase angle from the reference values of the measurement conditions, C, and

D (Q) and the actual measurement values and then using the following formula

for the calculation.

Z compensation rate = (Z reference value)/ (Z actual value)

compensation rate = ( reference value) ( actual value)

3505/ 3506 units can be reduced and a single me asurement value

45

4.2 Load Compensation

3505/ 3506 units, the measurement errors

3505/ 3506 can be

4

For the actual values of Z and , compensation is performed using the above

load compensation rate and then C and D (Q) are calculated from Z and after

compensation.

• The conditions that are currently set (frequency shift, level, range, display

parameter and cable length) are used as the measurement conditions for

load compensation.

However, load compensation values are separated by measurement

frequencies into separate data.

Changing the measurement conditions while load compensation in enabled

results in load compensation being disabled. (When this happens, the OFF

LED of LOAD flashes.)

If, however , the me asureme nt cond itio ns are retur ne d to wh at they wer e dur ing load compensation, then load compensation is resumed.

(The ON LED of LOAD lights up.)

For example, in the measurement frequencies shown in “Yes” in the table

below, the load compensation function is still enabled even when the

measurement value is changed to 1 kHz

compensation value has been acquired. The load compensation function

becomes disabled when the measurement frequency i s chang ed to 10 0 kHz,

or when the frequency shift, level, range, displa y para meter, and cable length

are changed.

1 MHz after the load

5

9

• When open circuit compensation and short circuit compensation are

enabled, load compensation performs compensation for Z and after open

circuit compensation and short circuit compensation are finished.

During settings for open circuit compensation and short circuit compensation, setting, enabling compensation value and disabling compensation

value, all compensation acquisition point setting, when current

measurement conditions are similar to the measurement conditions during

load compensation (frequency shift, level, cable length), the load

compensation value will be compensated at the latest open compensation

value, short compensation value and the load compensation rate will be recalculated.

Page 52

46

(Flash)

(MAIN display area)

F

l

a

s

h

“AdJuSt”

Acquire load compensation rates at current measurement

frequencies.

“SEt”

Setting of reference value for current measurement

frequency.

“oFF”