Hioki 3504-50, 3504-60 Instruction Manual

3504-40

3504-50

3504-60

C HiTESTER

Instruction Manual

Sept. 2018 Revised edition 4

3504D981-04 18-09H

EN

Contents

Introduction.................................................................................1

Verifying Package Contents .......................................................1

Safety Information ......................................................................2

Operating Precautions................................................................4

i

Contents

1

2

Chapter 1

Overview ___________________________________ 7

1.1 Product Overview .........................................................7

1.2 Features .......................................................................7

1.3 Entire Workflow ............................................................8

1.4 Names and Functions of Parts ...................................10

Chapter 2

Measurement Preparations___________________ 17

2.1 Preparation Flowchart ................................................17

2.2 Checking the Power Voltage...................................... 18

2.3 Connecting the Power Cord ....................................... 19

2.4 Connecting the Probes and Fixtures.......................... 20

2.5 Turning the Power On and Off ...................................21

3

4

4

5

5

6

6

7

7

8

Chapter 3

Basic Measurement _________________________ 23

3.1 Pre-Operation Inspection ...........................................23

3.2 Measurement Example ..............................................24

3.3 Setting the Measurement Conditions .........................26

3.3.1 Measurement Mode ......................................................26

3.3.2 Measurement Frequency ..............................................26

3.3.3 Measurement Signal Level ............................................27

3.3.4 Measurement Speed .....................................................28

3.3.5 Equivalent Circuit Mode ................................................29

3.3.6 Measurement Range .....................................................31

3.3.7 Trigger Signal ................................................................36

3504D981-04

8

9

9

10

10

Appendix

App

Index

Index

ii

Contents

Chapter 4

Compensatefor errors _______________________ 37

4.1 Open Circuit Compensation and Short Circuit

Compensation ........................................................... 37

4.2 Load Compensation .................................................. 47

4.3 Offset Compensation ................................................. 54

4.4 Self Calibration .......................................................... 58

Chapter 5

Judging measurement results ________________61

5.1 Comparator Function ................................................. 61

5.2 BIN Measurement Function

(Model 3504-50, 3504-60 only) ................................. 75

Chapter 6

Application Functions _______________________ 91

6.1 Setting the Average Function .................................... 91

6.2 Trigger Delay Setting ................................................. 93

6.3 Evaluate Contact Check Function ............................. 95

6.3.1 Setting the Low C Reject Function ............................... 96

6.3.2 Measurement Level Monitoring Function Settings ........ 98

6.3.3 Contact Check Function Settings

(Model 3504-60 only) .................................................. 100

6.4 Setting the Display ON/ OFF ................................... 103

6.5 Trigger Synchronous Output Function ..................... 104

6.6 Disable Key Control (Keylock Function) .................. 106

6.7 Save the Measurement Conditions

(Panel Save Function) ............................................. 107

6.8 Load the Measurement Conditions

(Panel Load Function) ............................................. 108

6.9 Setting Beep Tones ................................................. 112

6.9.1 Setting the Beep Tone for Judgment Results of

Comparator and BIN ................................................... 112

6.9.2 Setting the Beep Tone for Key Operations ................. 114

6.10 Switching the displayed item (SUB display) ............ 115

6.11 Performing a System Reset ..................................... 117

6.12 Printing Function ...................................................... 118

6.12.1 Preparation Prior to Connecting the Printer ................ 118

6.12.2 Connection Procedure ................................................ 121

6.12.3 Printing ........................................................................122

iii

Contents

Chapter 7

EXT I/O __________________________________ 123

7.1 About the EXT I/O Connector .................................. 123

7.2 Circuit Configuration and Connections of the EXT I/O

Connector .................................................................125

7.3 About Input and Output Signals ...............................126

7.4 About Measurement Times ......................................128

Chapter 8

Controlling the Unit from a PC _______________ 131

8.1 Outline and Features ................................................131

8.2 Specifications ...........................................................132

8.2.1 RS-232C Specifications ..............................................132

8.2.2 GP-IB Specifications

(Only for Models 3504-50, 3504-60) 133

8.3 Connection and Setting Procedures ........................134

8.3.1 Connecting the RS-232C Cable / GP-IB Cable ...........134

8.3.2 Setting the Interface Communication Conditions ........136

8.4 Remote Function ......................................................139

1

2

3

4

5

6

7

8.5 Communication Procedure .......................................140

8.6 Things to Know before Beginning

Communication 141

8.6.1 About Message Formats .............................................141

8.6.2 About the Output Queue and Input Buffer ...................146

8.6.3 About the Status Byte Register ...................................147

8.6.4 About Event Registers ................................................149

8.7 Message List ............................................................154

8.8 Ability to Use Commands by State ...........................167

8.8.1 Common Commands ..................................................167

8.8.2 Unique Commands ......................................................167

8.9 Message Reference .................................................172

8.9.1 Common Commands ..................................................173

8.9.2 Unique Commands ......................................................178

8.9.3 Response Format of Queries for Returning Values ....243

8.10 Initialized Items ........................................................245

8.11 Creating Programs ...................................................246

8.11.1 Creation Procedure .....................................................246

8.11.2 Sample Programs ........................................................248

8

9

10

Appendix

Index

iv

Contents

8.12 Troubleshooting the Interface .................................. 250

8.13 Device Document Requirements

(Only for Models 3504-50, 3504-60)........................ 252

Chapter 9

Specifications _____________________________ 255

9.1 Basic Specifications ................................................. 255

9.2 Accuracy .................................................................. 259

9.3 Measurement Parameters and

Arithmetic Expressions 261

Chapter 10

Maintenance and Service ___________________263

10.1 Inspection, Repair, and Cleaning ............................ 263

10.2 Replacing the Power Fuse ...................................... 265

10.3 Discarding the Unit .................................................. 266

Appendix _________________________________ A1

Appendix 1 Countermeasures Against

Incorporation of External Noise........................ A1

Appendix 1.1Countermeasures Against Incorporation of

Noise from the Power Line .............................................1

Appendix 1.2Countermeasures Against Incorporation of

Noise from the Input Line (Types of Probe) .................... 2

Appendix 2 Measurement of High Impedance ComponentsA3

Appendix 3 Measurement of In-circuit Components ...........A4

Appendix 4 Mounting the Unit in a Rack ............................. A5

Appendix 5 External View ...................................................A7

Appendix 6 Options ............................................................. A8

Appendix 7 Initial Settings Table ....................................... A11

Index ______________________________________ i

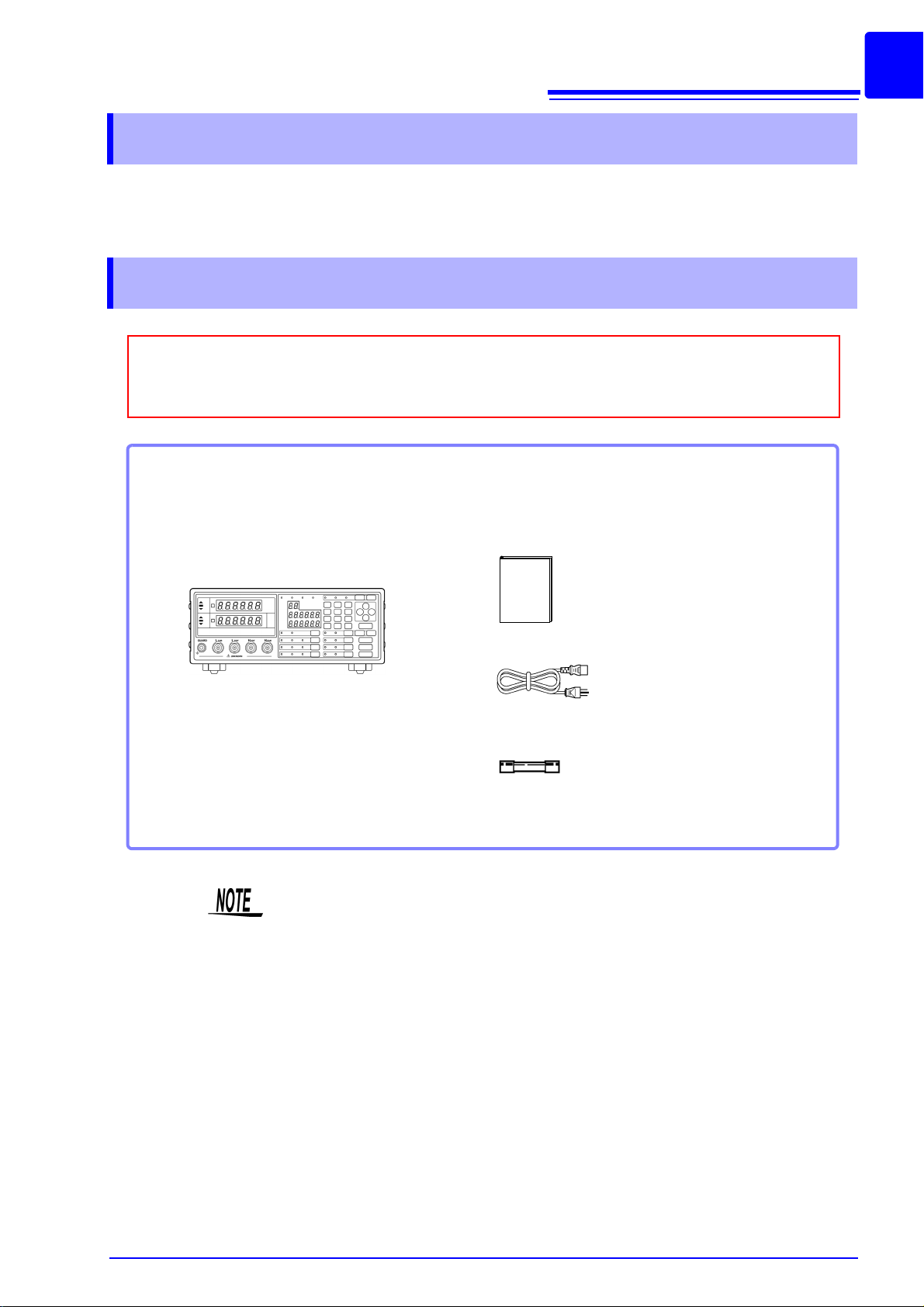

Introduction

3504-40 C HiTester

3504-50 C HiTester

3504-60 C HiTester

Confirm that these contents are provided.

Accessories

Instruction Manual................................... 1

Power cord.............................................. 1

Spare fuse for power supply

(according to voltage specification)........ 1

100 V, 120 V setting: 250 VF 1.0 AL5 x 20 mm dia

220 V, 240 V setting: 250 VF 0.5 AL5 x 20 mm dia

When you receive the unit, inspect it carefully to ensure that no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it

fails to operate according to the specifications, contact your dealer or Hioki representative.

This unit

Thank you for purchasing the HIOKI “Model 3504-40, 3504-50, 3504-60 C

HiTester.” To obtain maximum performance from the unit, please read this

manual first, and keep it handy for future reference.

Verifying Package Contents

1

Probes, fixture are not supplied with the unit as standard equipment. You

Options

should order them separately, according to requirements.

Appendix 6 "Options" (p. A8)

2

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has been thoroughly tested for afety prior to shipment.

However, mishandling during use could result in injury or death, as

well as damage to the instrument. Using the instrument in a way not

described in this manual may negate the provided safety features. Be

certain that you understand the instructions and precautions in the

manual before use. We disclaim a ny re sponsibility for a ccidents or

injuries not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of

the unit and for maintaining it in safe operating condition. Before using it, be

sure to carefully read the following safety precautions.

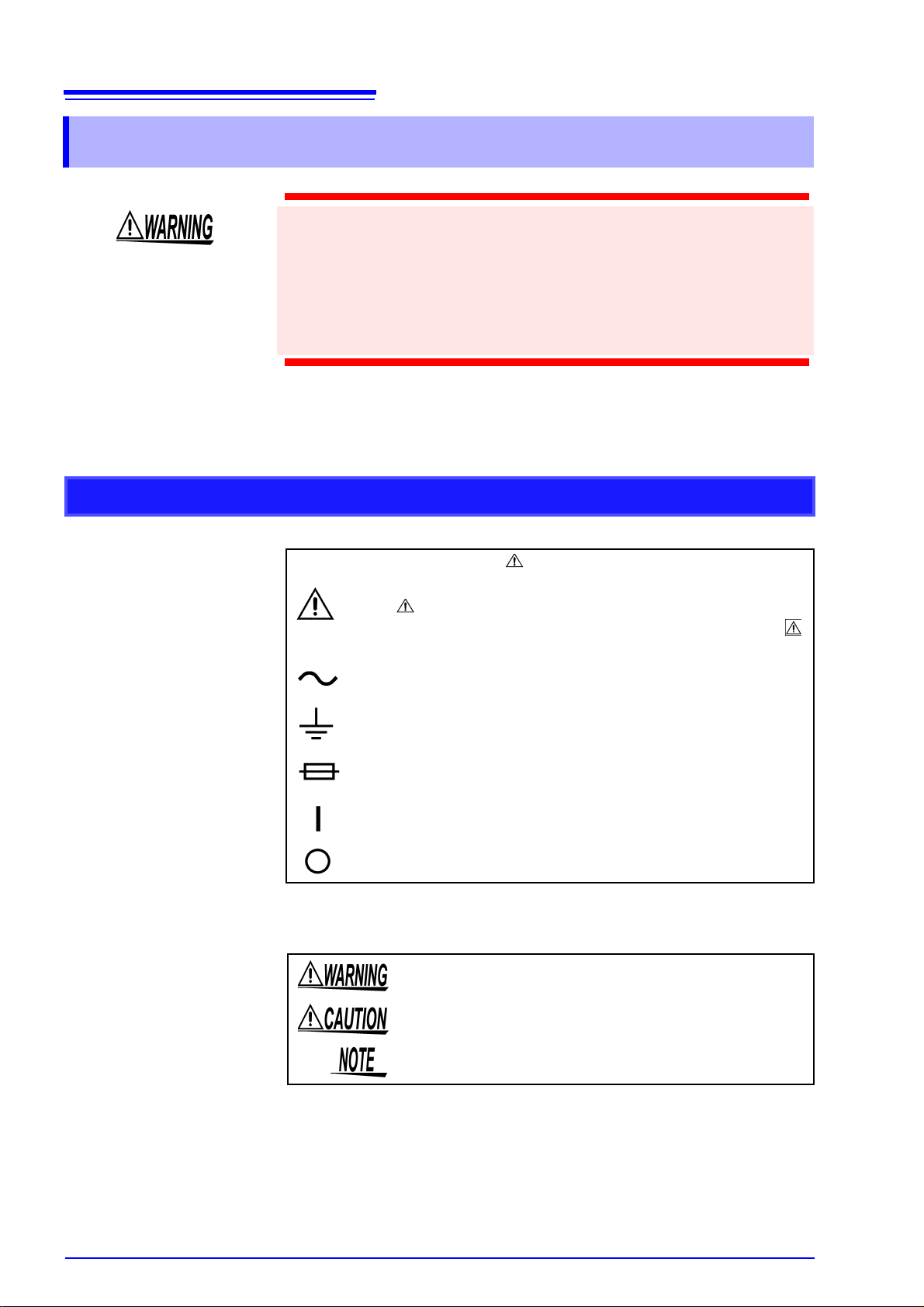

Safety Symbols

In the manual, the symbol indicates particularly important

information that the user should read before using the unit.

The symbol printed on the unit indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

Indicates AC (Alternating Current).

Indicates a grounding terminal.

Indicates a fuse.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

injury to the user or damage to the unit.

Indicates advisory items related to performance or correct

operation of the unit.

Other Symbols

3

Indicates a prohibited action.

See Indicates the location of reference information.

Indicates quick references for operation and remedies for

troubleshooting.

Accuracy

We define measurement tolerances in terms of rdg. (reading) and dgt. (digit) values, with the following meanings:

rdg.

(reading or displayed value)

dgt. (resolution) The smallest displayable unit on a digital

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as

CAT II to CAT IV, and called measurement categories.

CAT II: Primary electrical circuits in equipment connected to an AC electrical

CAT III: Primary electrical circuits of heavy equipment (fixed installations) con-

CAT IV:The circuit from the service drop to the service entrance, and to the

Using a measurement instrument in an environment designated with a

higher-numbered category than that for which the instrument is rated could

result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must be

carefully avoided.

*

outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

nected directly to the distribution panel, and feeders from the distribution panel to outlets.

power meter and primary overcurrent protection device (distribution

panel).

Indicates that descriptive information is provided below.

The value currently being measured and

indicated on the measuring unit.

measuring unit/ device/ product, i.e., the

input value that causes the digital display

to show a "1" as the least-significant digit.

4

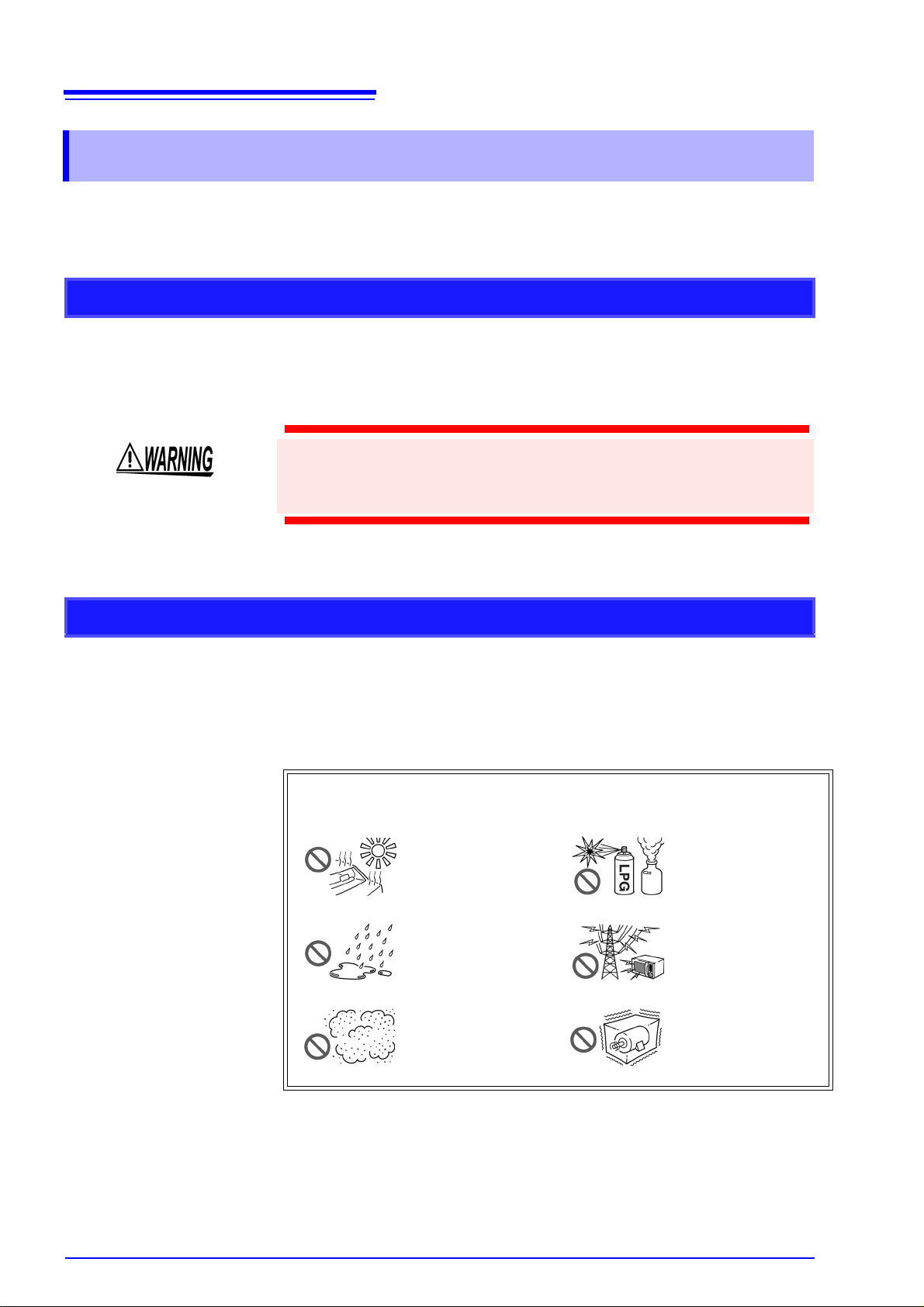

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary Checks

Before using the unit the first time, verify that it operates normally to ensure

that the no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the unit, make sure that the insulation on the probes and

cables is undamaged and that no bare conductors are improperly

exposed. Using the unit in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for replacements.

Unit Installation

Operating Temperature and Humidity: 0 to 40°C), 80%RH or less, no con-

densation

Storage Temperature and Humidity: -10 to 55

sation

Accuracy-guaranteed temperature and humidity ranges: 23

Avoid the following locations that could cause an accident or damage

to the unit.

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

°C, 80%RH or less, no undone-

±5°C, 80%RH

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

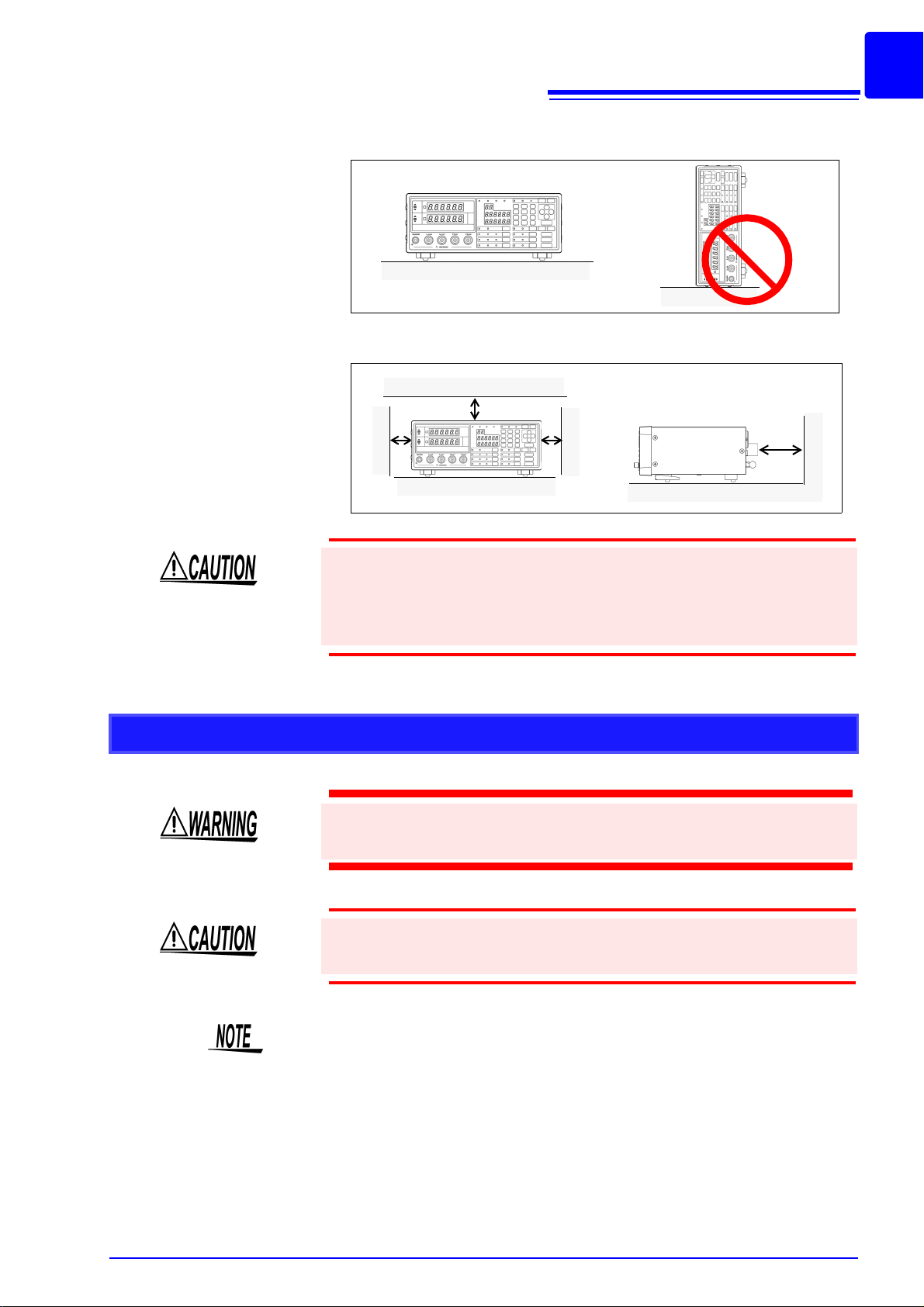

Installing

OK

10 cm or more

5 cm or more

5

• Do not install the unit with any side except the bottom facing down.

• Vents must not be obstructed.

Handling this device

• To avoid damage to the unit, protect it from physical shock when transporting and handling. Be especially careful to avoid physical shock from dropping.

• Do not apply heavy downward pressure with the stand extended. The stand

could be damaged.

Never modify the unit. Only Hioki service engineers should disassemble or repair the unit. Failure to observe these precautions may result in

fire, electric shock, or injury.

If anything unusual happens during operation of the unit, turn off the

power switch immediately and contact any HIOKI service facility for

help, advice and service.

This instrument may cause interference if used in residential areas. Such

use must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

6

Before connection and powering on

• Before turning the unit on, make sure the supply voltage matches

that indicated on the its power connector. Connection to an improper

supply voltage may damage the unit and present an electrical hazard.

• The power supply voltage for this unit is switchable. To avoid electrical accidents, check that the voltage selector is set correctly for the

supply voltage you are using.

See

Setting Procedure for the Power Voltage : 2.2 "Checking the Power Voltage"

(p. 18)

• To avoid electrical accidents and to maintain the safety specifications

of this unit, connect the power cord provided only to a 3-contact (twoconductor + ground) outlet.

See

Connection Procedure : 2.3 "Connecting the Power Cord" (p. 19)

• To avoid shock and short circuits, turn off all power before connecting probes.

About the guarantee

Shipping precautions

Check the connections carefully in order to avoid any chance of setting

up a short-circuit etc.

You should be aware that HIOKI cannot accept any responsibility directly or

indirectly if the unit has been incorporated in some other system, or if it is

resold to a third party.

Use the original packing materials when transporting the unit, if possible.

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

The HIOKI Model 3504-40, 3504-50 and 3504-60 C HiTesters are capacitance

meters employing 120 Hz and 1 kHz frequencies to measure large-value multilayer ceramic capacitors with constant voltage at high speed and high accuracy.

Primary applications include pass-fail judgment and ranking of capacitors on

tape machines and sorters.

1.2 Features

Capacitance-specific units

7

1

These capacitance meters use 120 Hz and 1 kHz measurement frequencies.

High-speed measurement

The Model 3504-40, 3504-50 and 3504-60 are capable of high-speed measurement: 2 ms at measurement frequency 1 kHz, and 10 ms at 120 Hz.

Constant-voltage measurements

Provides constant-voltage measurement capability.

With 1 kHz selected 1 V: to 70 F 500 mV, 100 mV (Model 3504-60 only): to 170 F

With 120 Hz selected1 V: to 0.7 mF 500 mV, 100 mV (Model 3504-60 only): to 1.45 mF

Bin sorting function (Model 3504-50, 3504-60 only) (p. 75)

Capacitors are easily ranked according to C (Capacitance*1) measurement values into as many as 14 classifications.

Comparator function (p. 61)

Easily perform pass-fail judgment of components according to measurements of

both C and D (Dissipation Factor*2).

LED display

Provides superior visibility.

Equipped with standard data transfer interfaces (p. 131)

The Model 3504-40, 3504-50 and 3504-60 offers external I/O for sequencing, a

standard RS-232C interface, and a standard GP-IB interface (

3504-60 only

).

Model 3504-50,

9

Measurement value memory (p. 232)

Up to 32,000 measurement values can be stored in memory.

Trigger-synchronous measurement capability (p. 104)

The measurement signal can be input to the sample in sync with a trigger.

Contact check function (p. 100)

You can check connection problems between the measurement terminal and the

object to be measured.

*1. Capability to store electric charge.*2. An indicator of capacitor losses.

8

See 3.1 "Pre-Operation Inspection" (p. 23)

Be sure to perform pre-operation inspection prior to measurement.

Check the power voltage.

Connect the power cord.

Connect the probes or fixture (option) to the measurement terminals.

Turn the power on.

Connect the sample.

Prepare the unit, fixture, and sample.

Connect the fixture to the measurement terminals.

Set the measurement conditions.

Connect the sample to the fixture.

Check the measurement results.

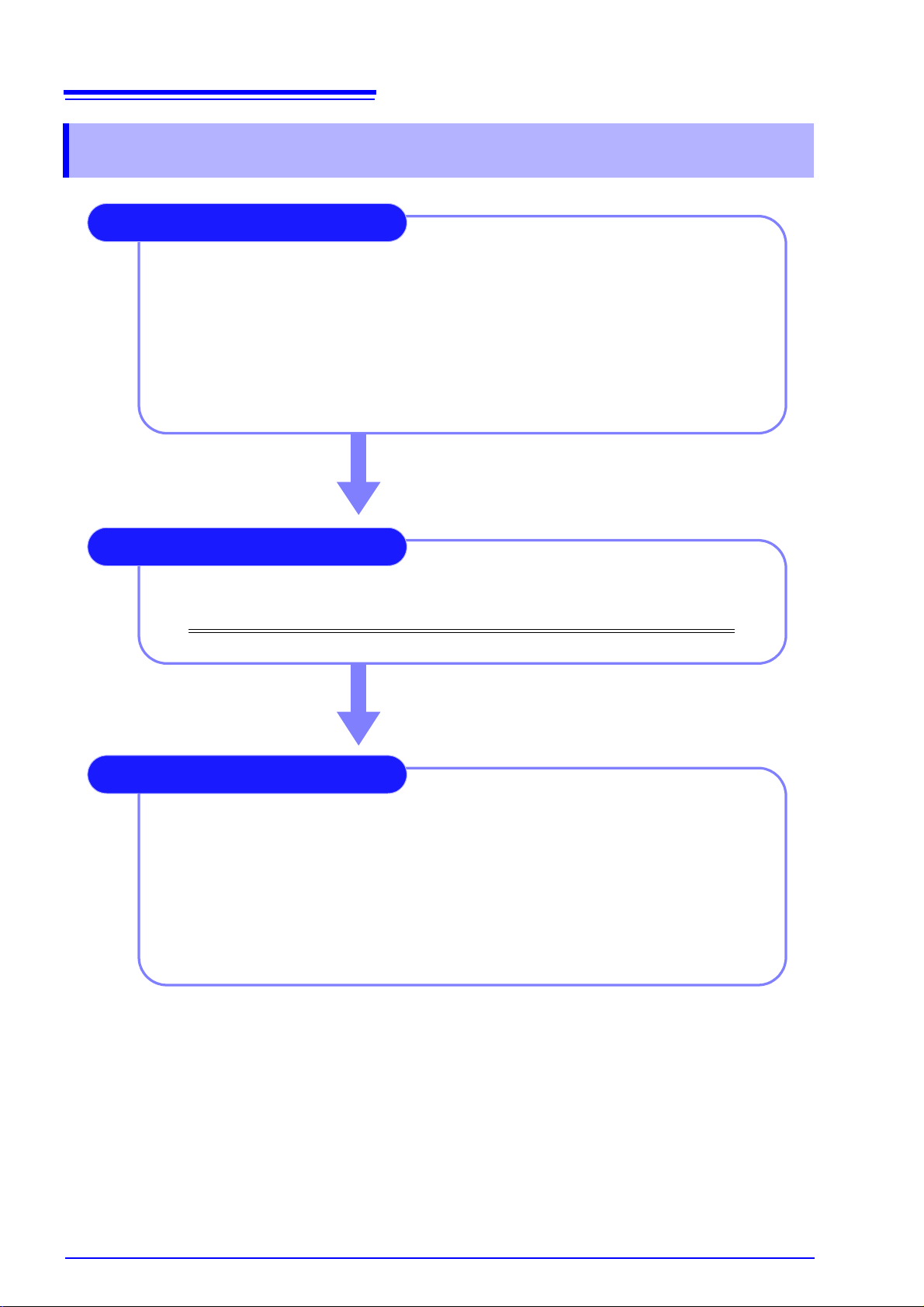

Measurement Preparations

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

See Chapter 2 "Measurement Preparations" (p. 17)

Basic Measurement

See 3.2 "Measurement Example" (p. 24)

Pre-Operation Inspection

1.3 Entire Workflow

1.3 Entire Workflow

Application Functions

9

1.3 Entire Workflow

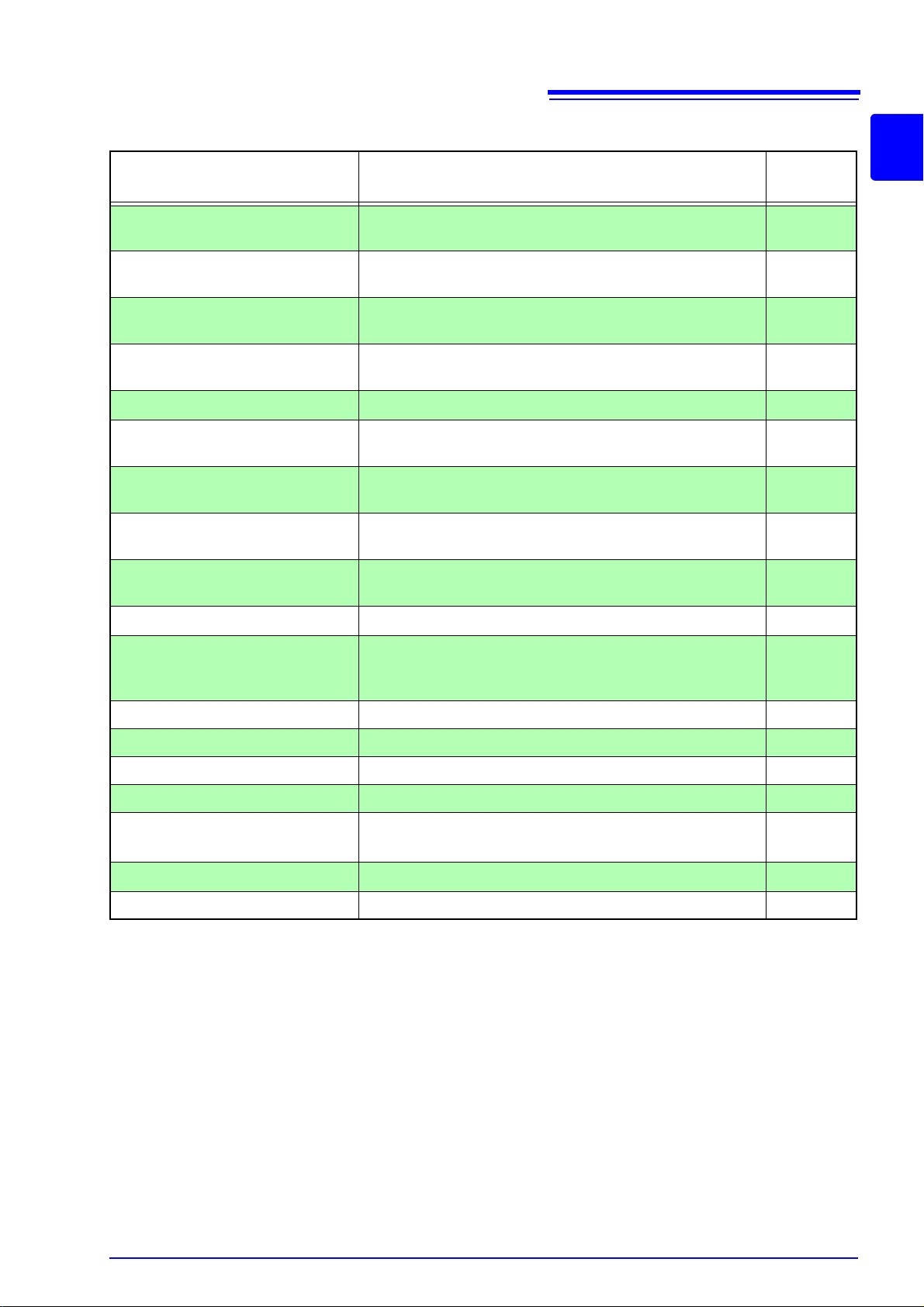

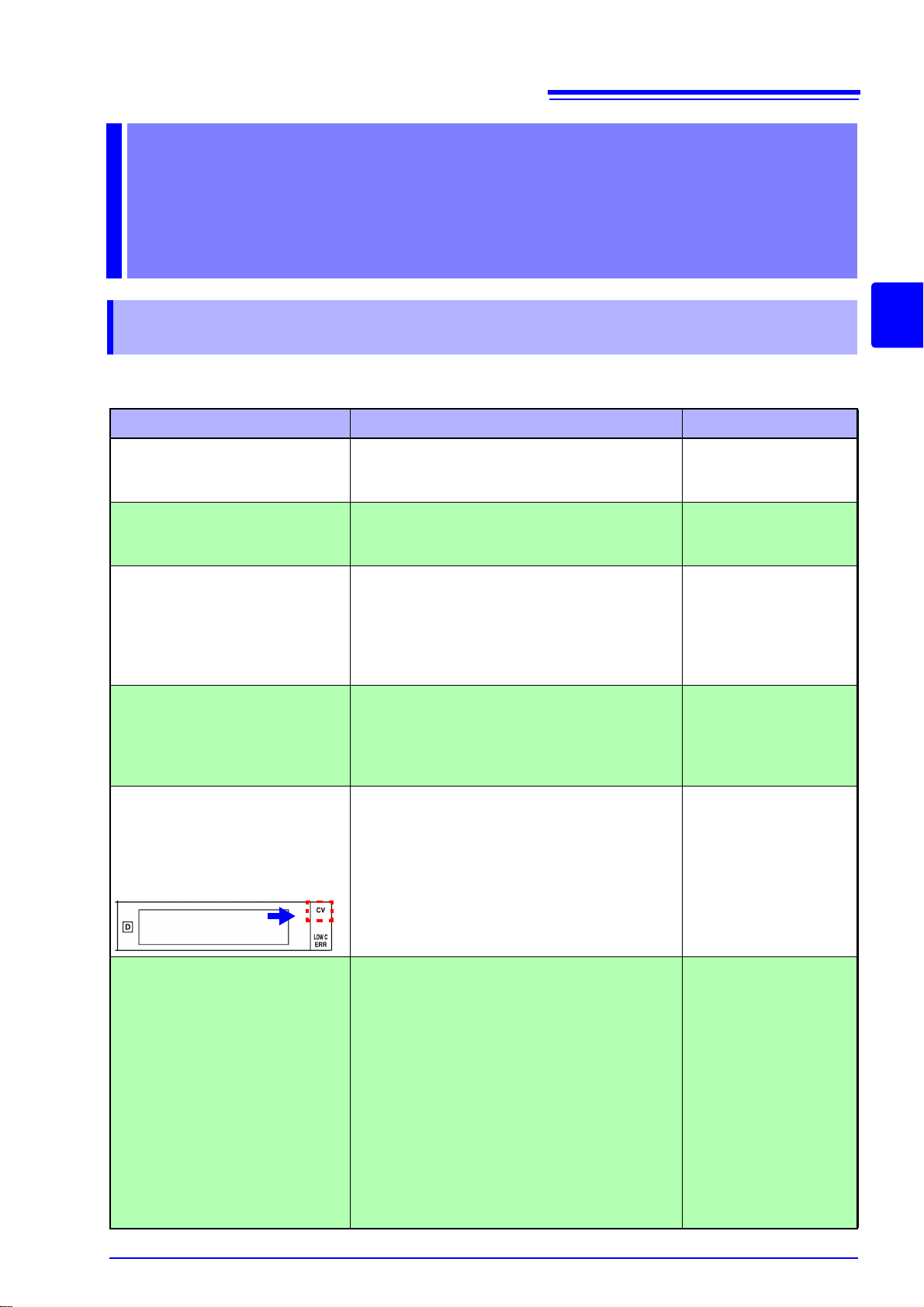

Function Description

Open and Short circuit

compensation

Load compensation Allows interchangeability between measuring instruments

Offset compensation Allows interchangeability between measuring instruments

Comparator measurement

function

Self calibration Reduces measurement value drift. (p. 58)

BIN measurement function Set variations of the upper limit and lower limit values and

Average function Reduces fluctuation of the measurement value by perform-

Trigger delay Provides a reliable measurement value even when taking

Contact check function Discerns whether or not the contact pin and sample are

Eliminates measurement errors due to residual impedance.

by measuring a known sample.

by subtracting the set value from the measurement value.

Set the upper limit and lower limit values and judge whether samples pass or fail.

rank samples accordingly.

ing an averaging process of the measurement values.

a measurement immediately after connecting to a sample.

connected.

Reference

Section

(p. 37)

(p. 47)

(p. 54)

(p. 61)

(p. 75)

(p. 91)

(p. 93)

(p. 95)

1

Display

Trigger synchronous output

function

Key lock function Disable key operations. (p. 106)

Communication function Control the unit from a PC. (p. 131)

Panel save function Save measurement conditions. (p. 107)

Panel load function Load saved measurement conditions (p. 108)

Beep tone

System reset

Printing function Print measurement values. (p. 118)

Turns the LED display ON/ OFF.

Apply the measurement signal only during measurement to

reduce the generation of heat in the sample and decrease

electrode wear.

Turns ON/ OFF the beep tone for judgment results and key

operations.

Resets device settings.

(p. 103)

(p. 104)

(p. 112)

(p. 117)

Application Measurement

• Measurement using EXT I/O

See

7.1 "About the EXT I/O Connector" (p. 123)

• Countermeasures Against Incorporation of External Noise

See

Appendix 1 "Countermeasures Against Incorporation of External Noise" (p. A1)

• Measurement of high impedance components

See

• Measurement of components in circuit networks

Appendix 2 "Measurement of High Impedance Components" (p. A3)

See

Appendix 3 "Measurement of In-circuit Components" (p. A4)

9

10

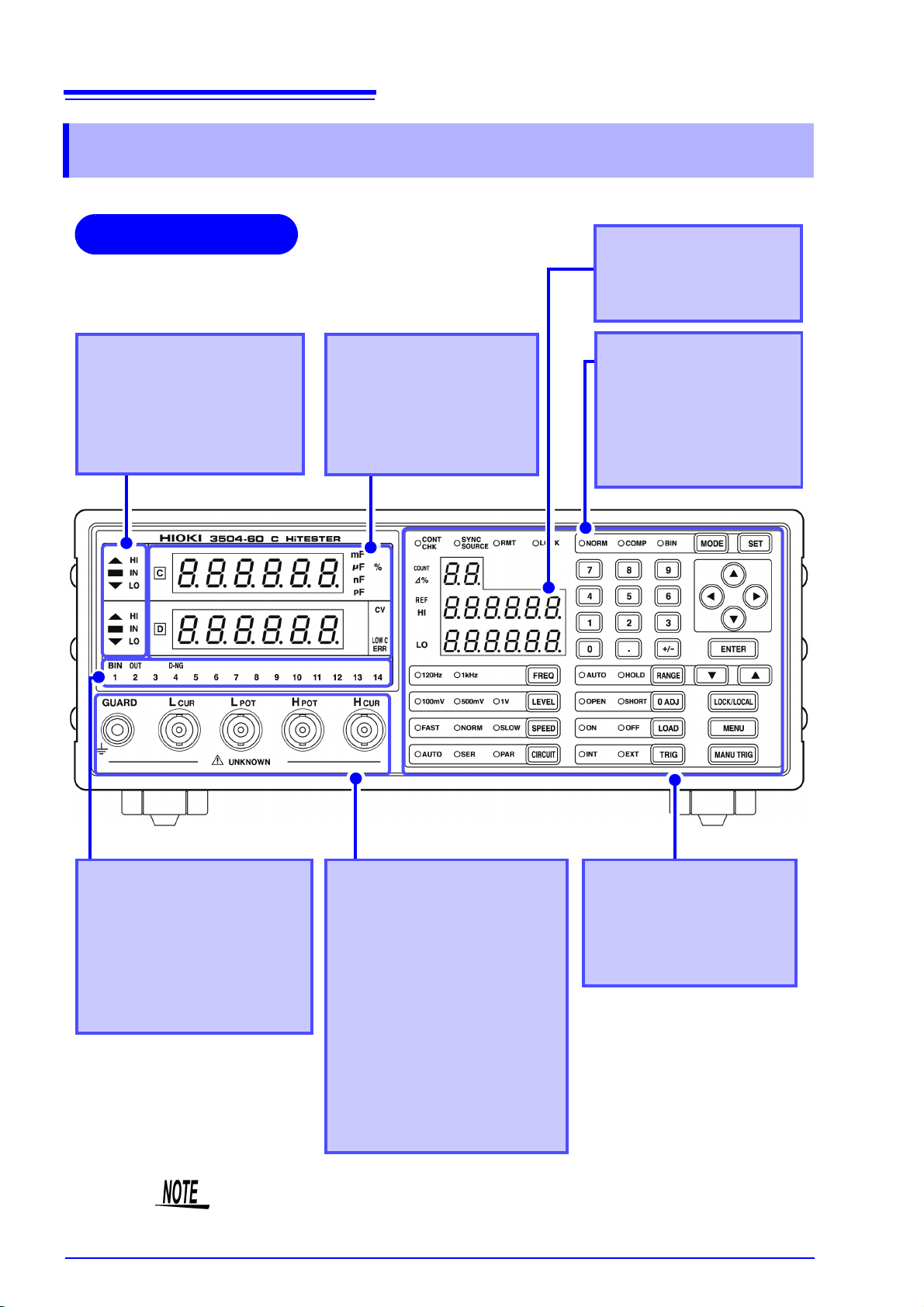

Front

MAIN Display

Displays the measurement

values of C and D.

Displays the MENU items.

Comparator Evaluation

Result Display

Displays evaluation results in

Comparator Mode.

See

5.1 "Comparator Function"

(p. 61)

Operating Panel

Use to set measurement

conditions and to make other

settings

See

(p. 11)

Measurement Terminals

There are five measurement terminals:

H

CUR

Measurement-signal

input terminal

H

POT

Detected voltage high

terminal

L

POT

Detected voltage low

terminal

L

CUR

Measurement current

detected terminal

GUARD Guard terminal

See

2.4 "Connecting the Probes

and Fixtures" (p. 20)

Setting Condition

Display

Displays current measurement conditions, presettings, and other information.

*BIN (Model 3504-50,

3504-60 only)

SUB Display

Displays the limit values of

BIN (Model 3504-50, 350460 only) and comparator.

BIN Judgment Result

Display (Model 3504-50,

3504-60 only)

Displays judgment results in

BIN mode.

See

5.2 "BIN Measurement

Function (Model 3504-50,

3504-60 only)" (p. 75)

1.4 Names and Functions of Parts

1.4 Names and Functions of Parts

The “CONT CHK” and the 100 mV of “LEVEL” in the SUB display portion will

only show 3504-60.

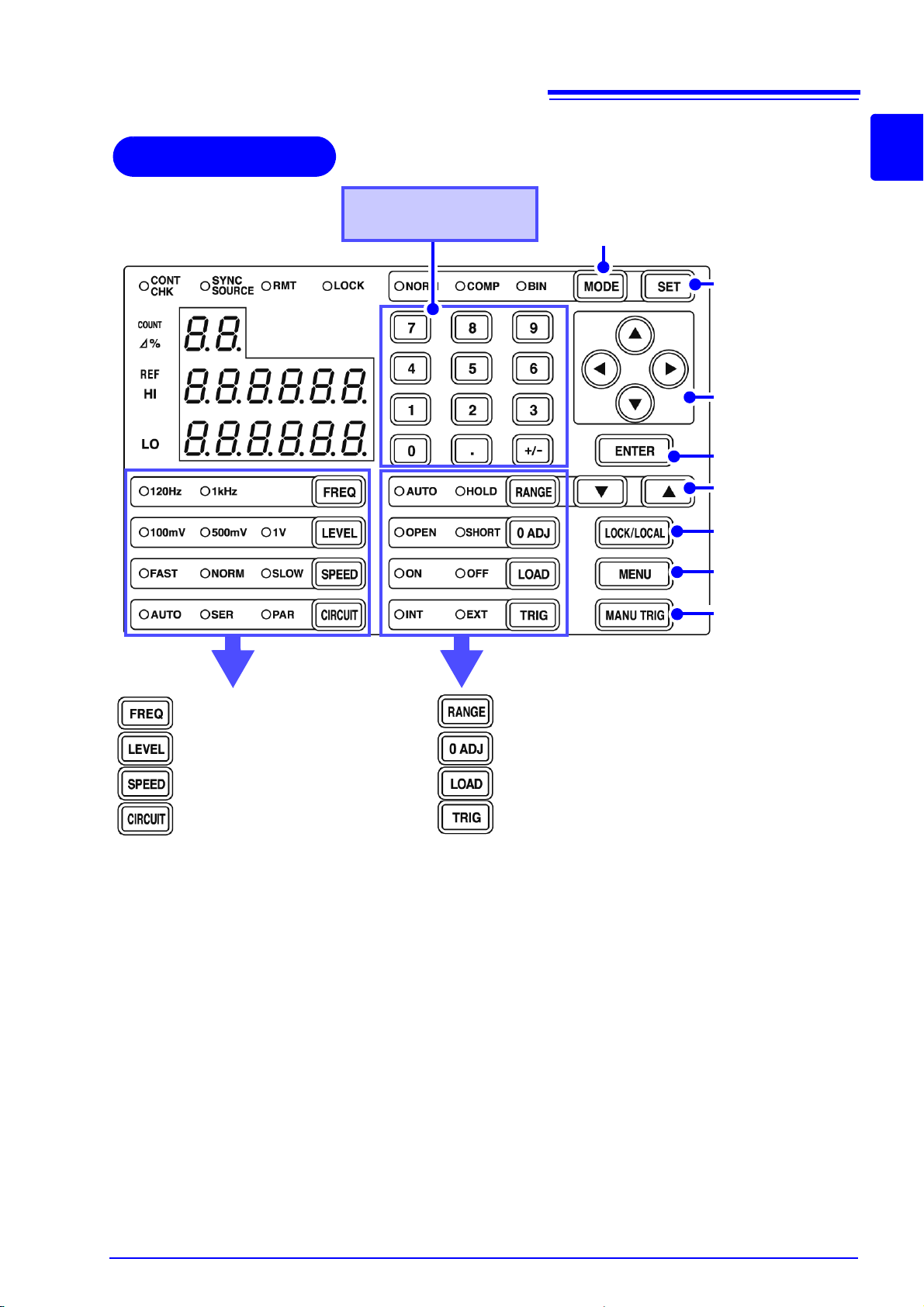

Operating Panel

Keypad

Used to enter numeric values.

Measurement mode

setting(p. 26)

Comparator measurement function

(p. 61)

BIN measurement

function (p. 75)

Arrow keys

Used to change settings and move to

menu items or digits.

Enter

Measurement range

setting

(p. 31)

Lock/ Local

(p. 106)

Menu

Manual trigger

(p. 36)

Measurement frequency setting

(p. 26)

Measurement signal level setting

(p. 27)

Measurement speed setting

(p. 28)

Equivalent circuit mode

(p. 29)

Equivalent circuit mode

(p. 29)

Measurement range setting

(p. 31)

Open (short) circuit compensation

(p. 37)

Load compensation setting

(p. 47)

Trigger mode setting

(p. 36)

11

1.4 Names and Functions of Parts

1

9

12

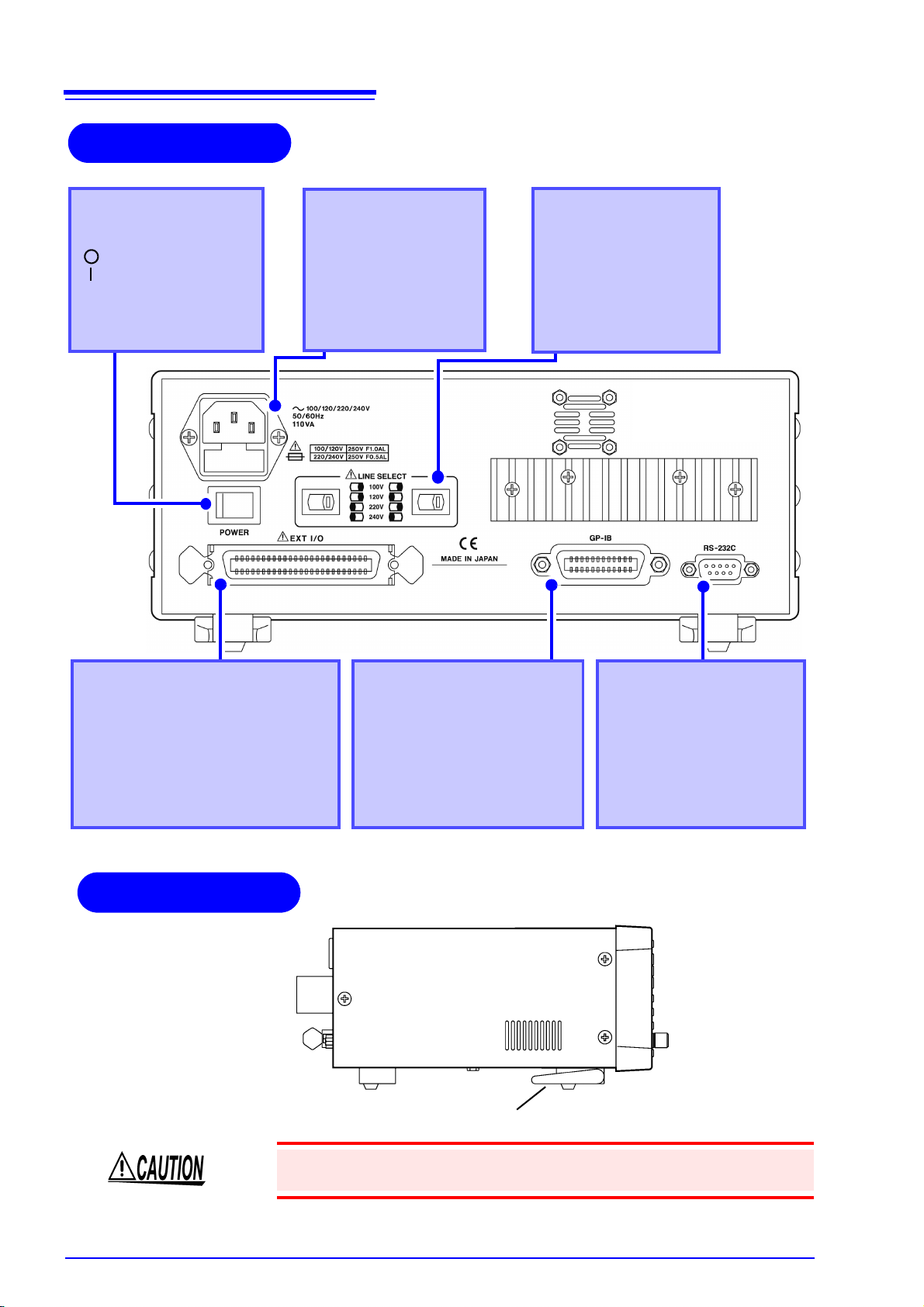

Back

GP-IB Connector

(Model 3504-50, 3504-60 only)

Connect a GP-IB cable.

See Chapter 8 "Controlling the

Unit from a PC" (p. 131)

EXT I/O Connector

Inputs external trigger signals and outputs comparator result signals and other

signals. Supports connection to a

sequencer.

See 7.1 "About the EXT I/O Connector"

(p. 123)

Power Switch

Turns the power on and off.

: Turns the power off.

: Turns the power on.

See 2.5 "Turning the Power

On and Off" (p. 21)

RS-232C Connector

Connect an RS-232C cable.

See Chapter 8 "Controlling the

Unit from a PC" (p. 131)

Voltage

Selectors

Changes the power voltage

Power Inlet

Connect the supplied

power cord

See 2.3 "Connecting the

Power Cord" (p. 19)

Stand

Side

Right side

1.4 Names and Functions of Parts

Do not apply heavy downward pressure with the stand extended. The stand

could be damaged.

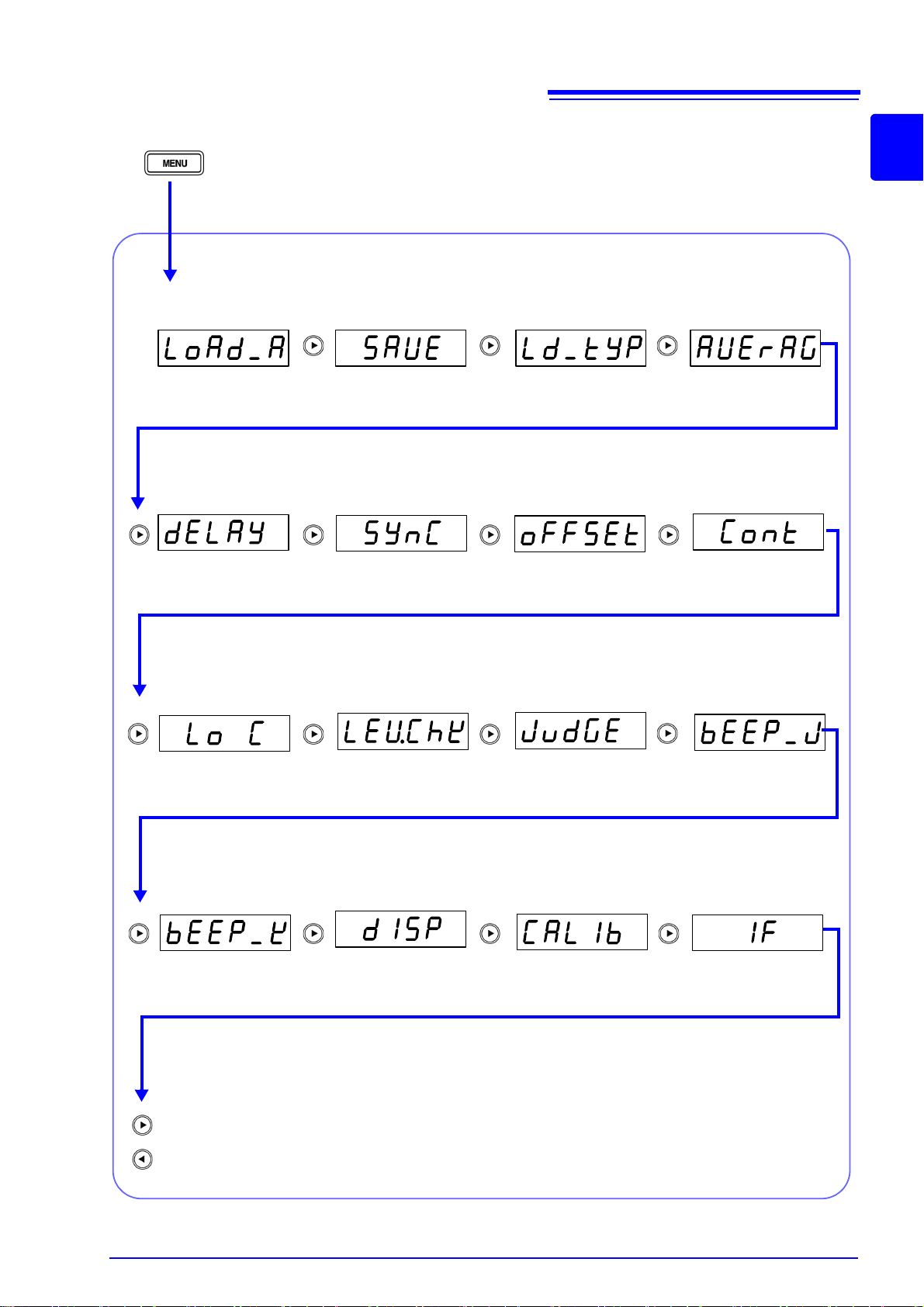

Menu display organization

“LoAd_A(C/h)”

(p. 108)

“dELAY”

(p. 93)

“bEEP_K “

(p. 114)

“SAVE”

(p. 107)

“LEV.ChK“

(p. 98)

“dISP”

(p. 103)

“Ld_tYP“

(p. 108)

“SYnC”

(p. 104)

“JudGE”

(p. 62)

“AVErAG“

(p. 91)

“oFFSEt“

(p. 54)

“bEEP_J”

(p. 112)

Return to Panel Load Function.

(MAIN display area)

Panel Load

Function

Panel Save

Function

Load

Conditions

Average

Function

Trigger Delay

Trigger Synchro-

nous Function

Offset

Compensation

Level Check

Function

Judgment Mode

Beep Tone for

Judgment Results

Display

Beep Tone for

Key Operations

Returns to previous screen.

“IF”

(p. 136)

Communication

Conditions

“Lo C“

(p. 96)

Low C Reject

Function

Contact Check

Function

(Model 3504-60 only)

“Cont”

(p. 100)

“CALIb”

(p. 58)

Self Calibration

13

1.4 Names and Functions of Parts

Displays menu screen

1

9

14

C

1.4 Names and Functions of Parts

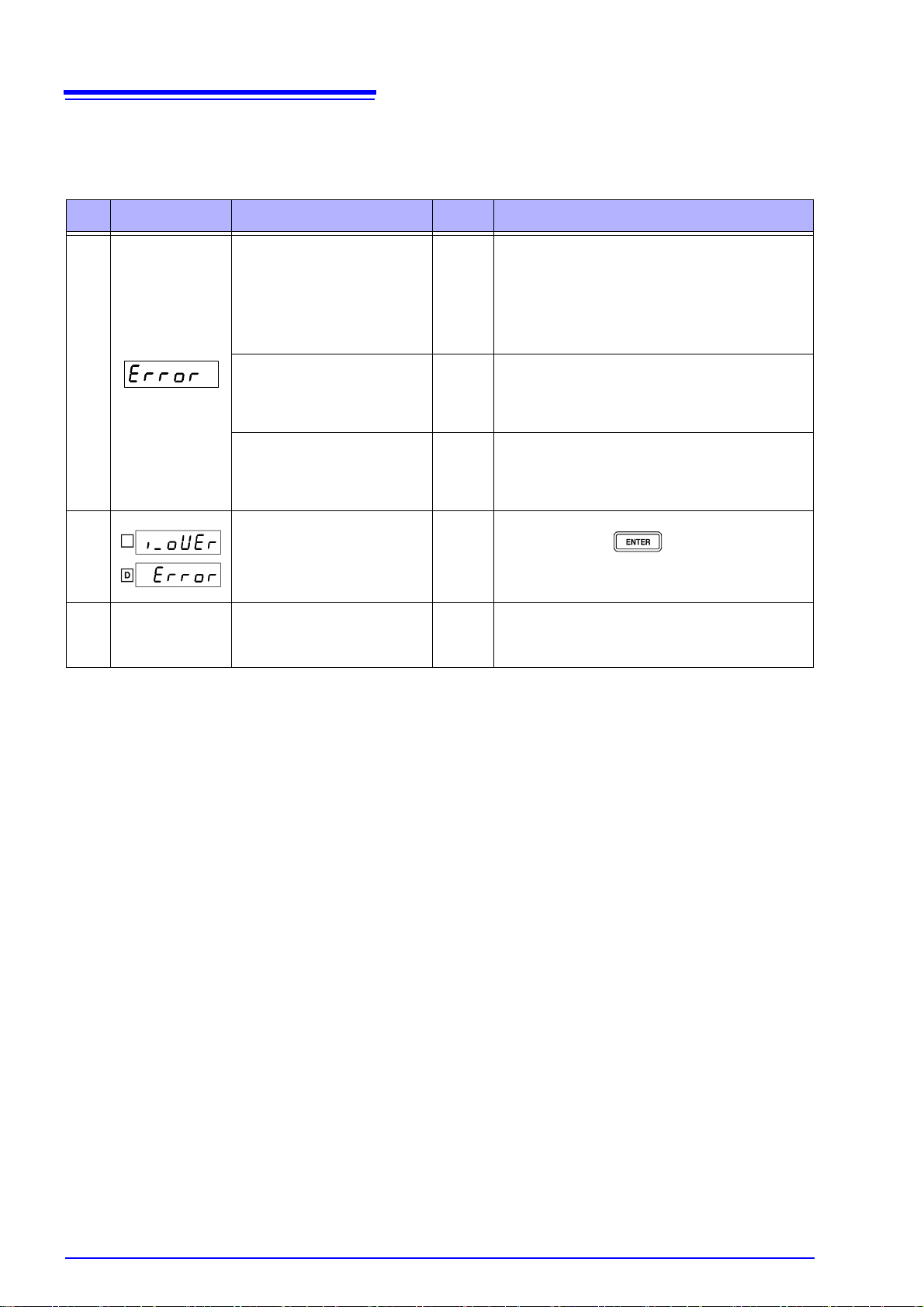

MAIN display area ERROR display

When the 3504-40, 3504-50 and 3504-60 C HiTesters detects a measurement abnormality, an error message is dis-

played in the MAIN display area.When a measurement error occurs, the device's condition is displayed in order of priority

rank in the MAIN display area.When an error display occurs, the comparator and BIN measurement judgment results will

be HI and OUTOF-B

Priority

rank

MAIN display Error content

-

-

-

measurement value

Normal

INS.

OPEN compensation error

Displayed when the OPEN

compensation value is less than

1 k.

See (p. 41)

SHORT compensation error

Displayed when the SHORT

compensation value is more

than 1 k

See (p. 43)

LOAD compensation error

Displayed when the LOAD compensation value is outside of

range.

See (p. 49)

Output current abnormality

Displayed when low impedance elements were connected for more than 10 min.

in range

7 or 8.

ERR LED light on

Acquiring self calibration

abnormal value

See (p. 58)

EXT I/O Solution

• Put the measurement terminals in an open

state. (Short circuit the H

terminal, and the L

H

POT

terminal.)

L

-

-

-

-

ERR

output

Normal

evalua-

tion

POT

• Use the shielding process as a countermeasure

against external noise.

• Earth the device.

• Check to see if the measurement cable is broken.

• Short the measurement terminals.

• Check to see if the measurement cable is broken.

• Perform compensation again after setting to the

appropriate range.

• Put the measurement terminals in an open state

and then press .

• In Range 7 and 8, do not leave low impedance

elements (1 or less) connected. It may result

in damage on the main unit.

• The device is acquiring an abnormal self calibration value. Reconnect the instrument to be

tested correctly and carry out self-calibration

again.

terminal to the

CUR

terminal to the

CUR

15

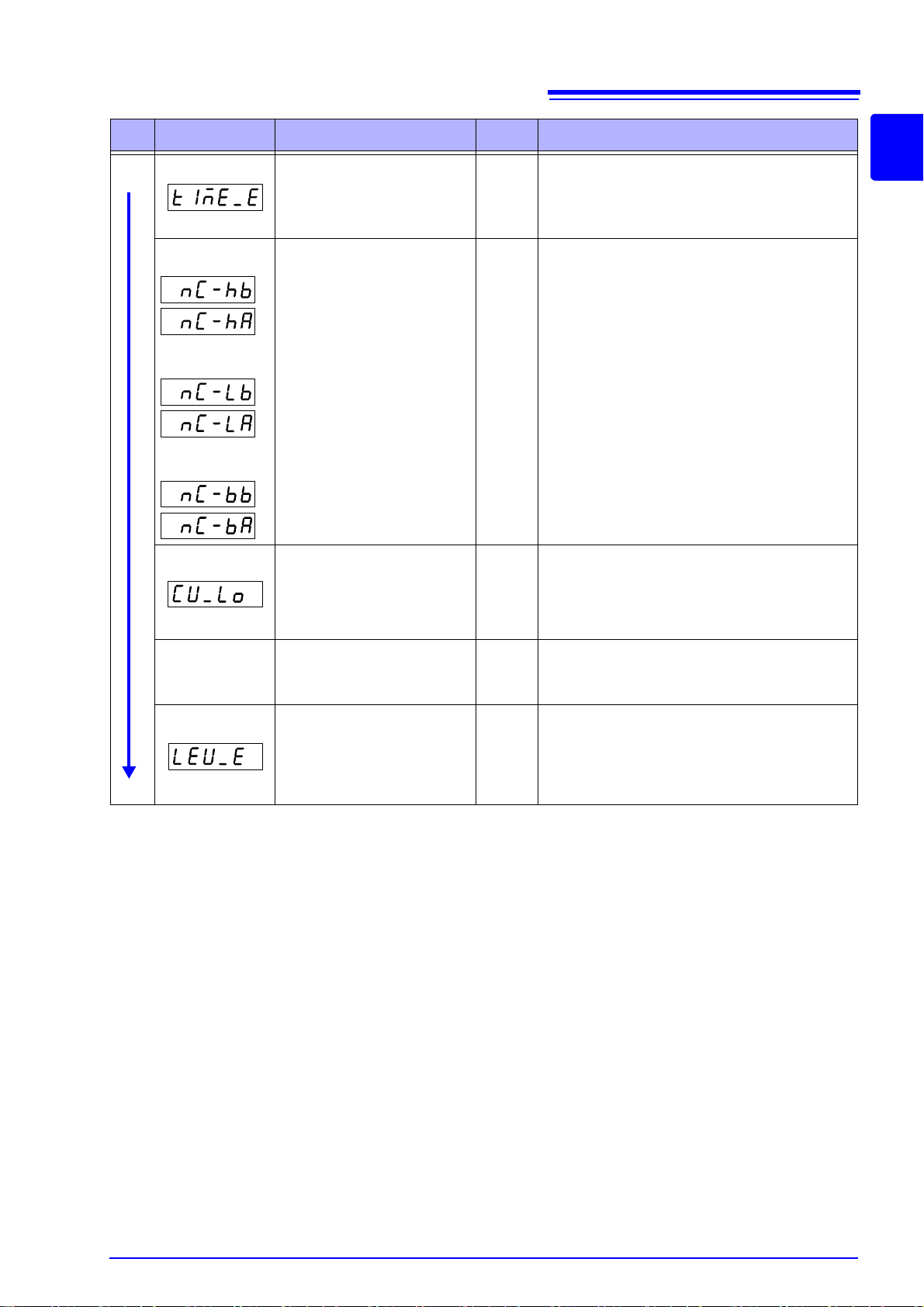

1.4 Names and Functions of Parts

Priority

rank

High

Low

MAIN display Error content

Sampling error

Displayed when the A/D

conversion is not carried out

normally.

Abnormal connection

on the H side

Contact Abnormality

Displayed when the connection

resistance between the measurement terminal and the object to be measured becomes

large.

See (p. 102)

Abnormal connection

on the L side

Abnormal connection

on the H, L side

Applied voltage

abnormality

Displayed when the voltage between the measurement terminals is lower than the measured

voltage.

Low C Connector error

Normal

measurement value

Displayed when the measured

value is abnormally lower than

the measurement range.

Abnormal level detected

Displayed when the inspection

level abnormality monitor value

fluctuates.

See (p. 99)

EXT I/O Solution

ERR

output,

judgment,

OUT

judgment

ERR

output,

judgment,

OUT

judgment

ERR

output,

judgment,

OUT

judgment

ERR

output

Normal

evalua-

ERR

output,

judgment,

OUT

judgment

• It is possible that the device is being affected by

HI

HI

HI

tion

HI

incoming noise.

• Problem with the device.

Submit it for repairs.

• The measurement terminals may not be connected to the object being measured.

Check the contact between the object being

measured and the measurement terminals.

•The H

nected. Check the connection between the

measurement sample and the terminals.

• There may be a high contact resistance

between the H

object being measured.

• The measurement terminals may not be connected to the object being measured.

Check the contact between the object being

measured and the measurement terminals.

• hattering may have occurred.

Check the connection between the measurement sample and the terminals.

It is possible that the device is being affected by

incoming noise.

• Use the shielding process as a countermeasure

agains

POT

and H

CUR

terminals may be discon-

CUR

and L

terminals and the

CUR

1

9

16

1.4 Names and Functions of Parts

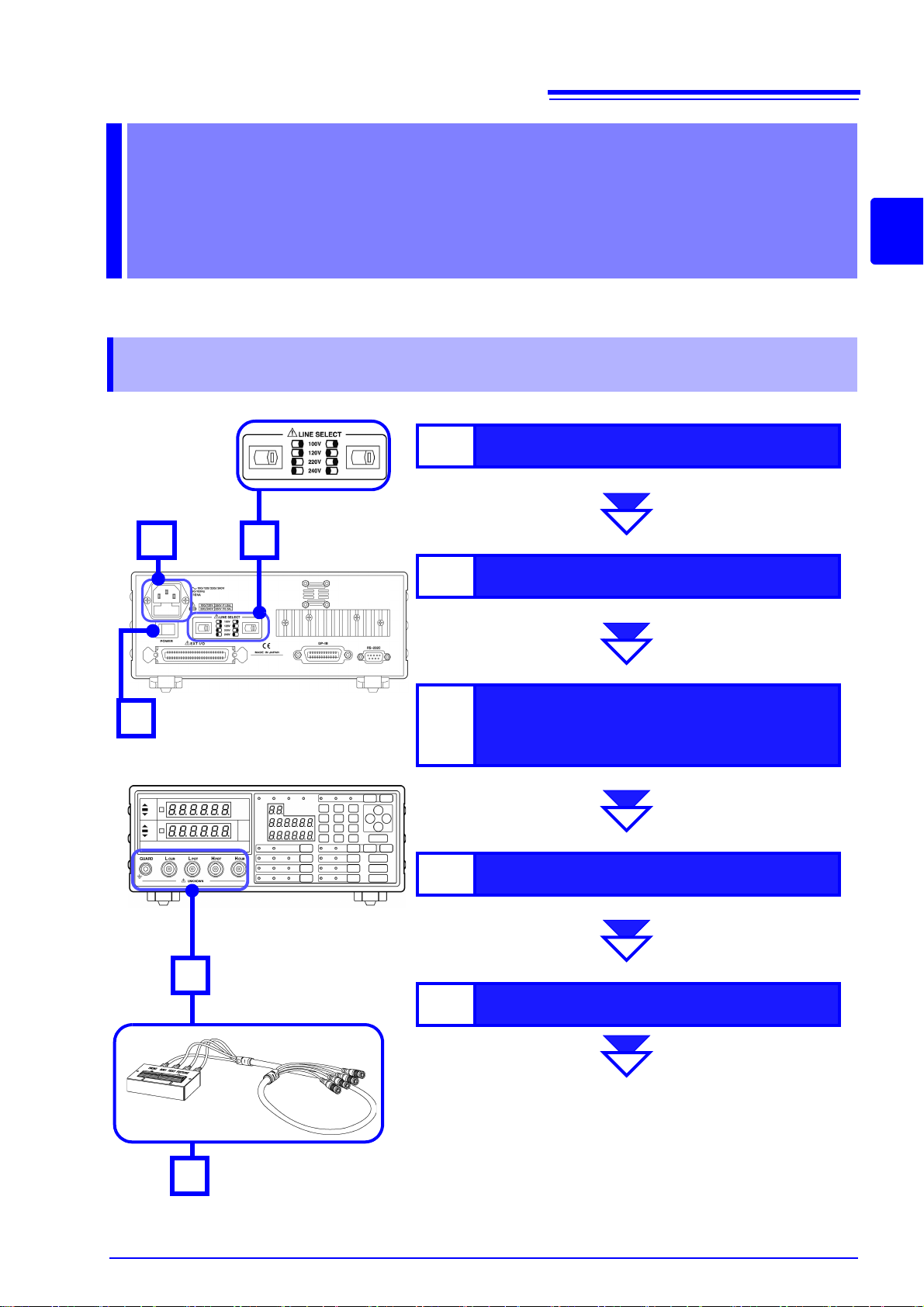

Measurement

1

Check the power voltage.

See 2.2 "Checking the Power Voltage" (p. 18)

2

Connect the power cord.

See 2.3 "Connecting the Power Cord" (p. 19)

3

Connect the probes or fixture

(option) to the measurement

terminals.

See 2.4 "Connecting the Probes and Fixtures" (p. 20)

4

Turn the power on.

See 2.5 "Turning the Power On and Off" (p. 21)

5

Connect the sample.

Unit Settings and Measurement

See Chapter 3 "Basic Measurement" (p. 23)

See Chapter 4 "Compensate for errors" (p. 37)

See Chapter 6 "Application Functions" (p. 91)

Back

Front

2

3

5

(Example)

Model 9261 Test Fixture

(Option)

4

1

17

2.1 Preparation Flowchart

Preparations Chapter 2

Be sure to read "Operating Precautions" (p. 4) prior to setting up the unit.

2.1 Preparation Flowchart

2

18

Back

In the diagram, the voltage

value is 100 V because

both the left and right voltage selectors are set to the

right side.

Voltage selectors

2.2 Checking the Power Voltage

2.2 Checking the Power Voltage

• Before turning the unit on, make sure the supply voltage matches that

indicated on the its power connector. Connection to an improper supply voltage may damage the unit and present an electrical hazard.

• The power of the unit can be changed with the voltage selectors. To

avoid an electric accident, use the unit with the voltage selectors set to

a voltage value that matches the voltage to be used.

• Make sure the power is off when you change the voltage with the voltage selectors. Changing the power voltage when the power is on may

result in damage to the unit or an electric accident.

• The maximum rated power is 110 VA.

• Replace the fuse only with one of the specified characteristics and voltage and current ratings. Using a non-specified fuse or shorting the

fuse holder may cause a life-threatening hazard.

Fuse type: 100 V 120 V setting: 250 V F1.0AL 20 mm x 5 mm dia

220 V 240 V setting: 250 V F0.5AL 20 mm x 5 mm dia

See

10.2 "Replacing the Power Fuse" (p. 265)

The power voltage specification of the unit is set as specified when the unit was

ordered.

You can select from 100 V, 120 V, 220 V, and 240 V.

You can determine which voltage is set by checking the positions of the voltage

selectors.

Refer to the diagram between the voltage selectors.

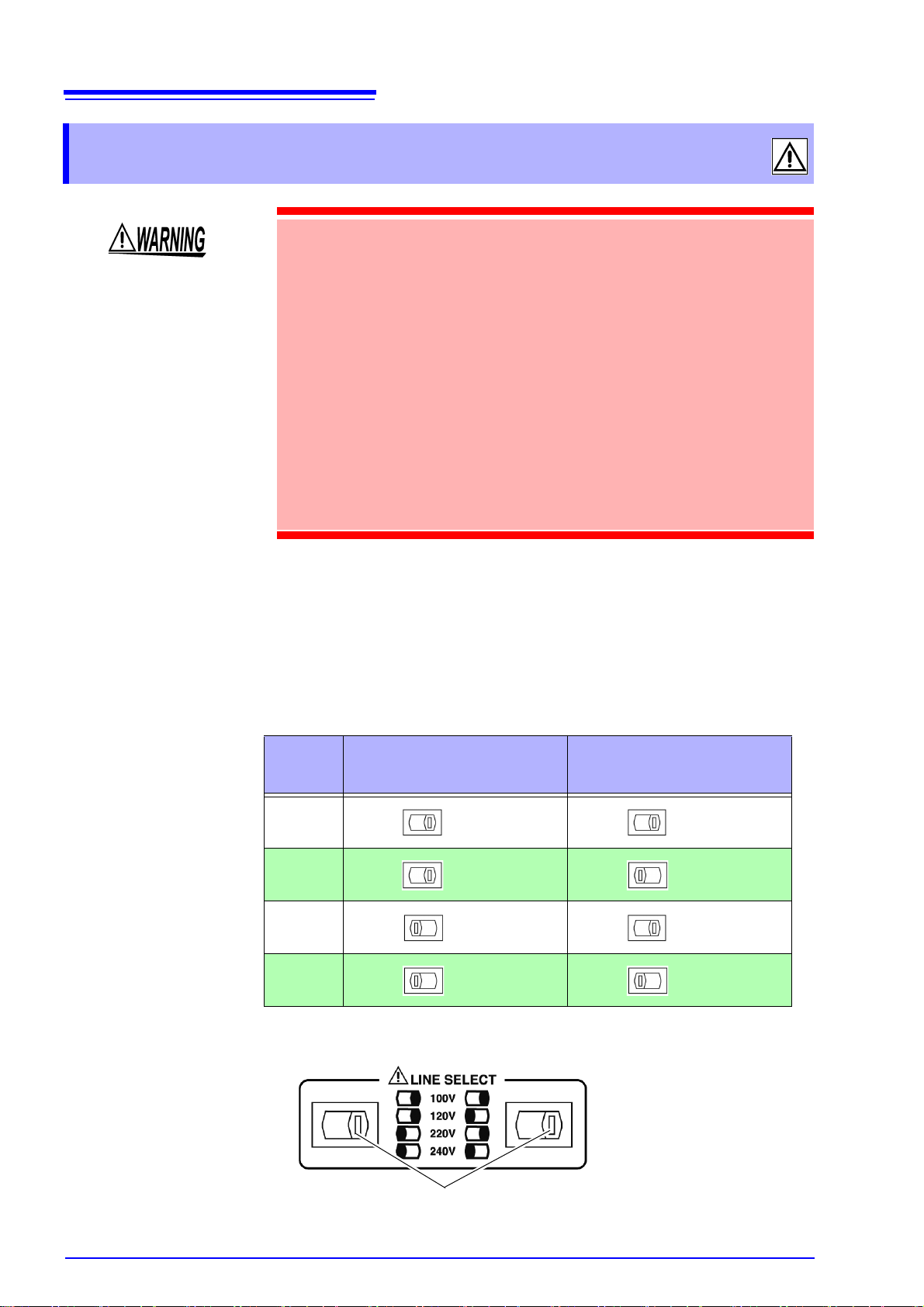

Voltage

100 V

120 V

220 V

240 V

Position of Left Voltage

Selector

(Right side) (Right side)

(Right side) (Left side)

(Left side) (Right side)

(Left side) (Left side)

Position of Right Voltage

Selector

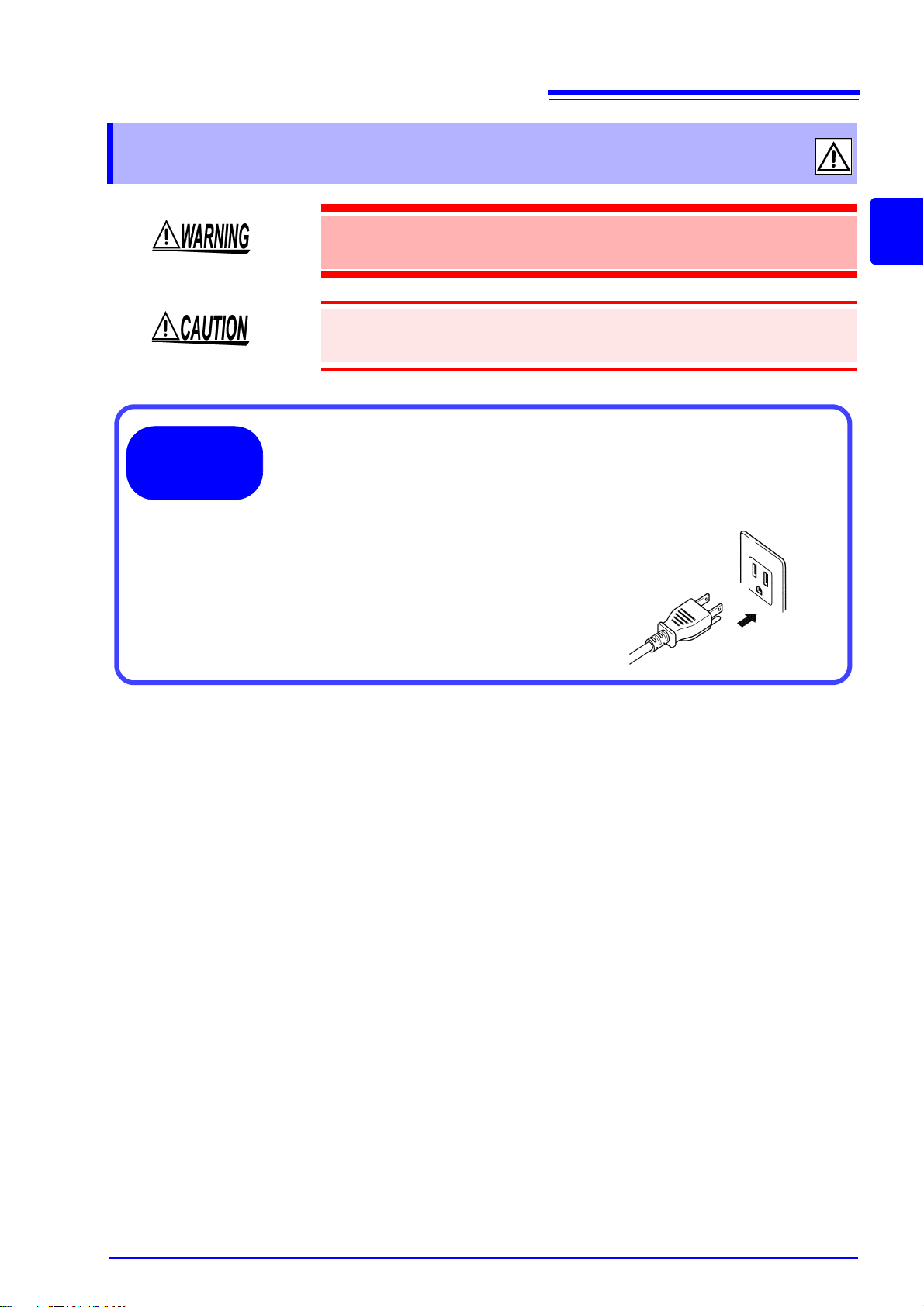

2.3 Connecting the Power Cord

1. Make sure the power switch of the unit is off.

2. Make sure the power voltage matches and connect the power

cord to the power inlet with voltage selectors on the rear of the

unit.

3. Insert the plug into the power outlet.

Connection

Procedure

2.3 Connecting the Power Cord

To avoid electrical accidents and to maintain the safety specifications of

this unit, connect the power cord provide only to a 3-contact (two-conductor + ground) outlet.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• Turn off the power before disconnecting the power cord.

19

2

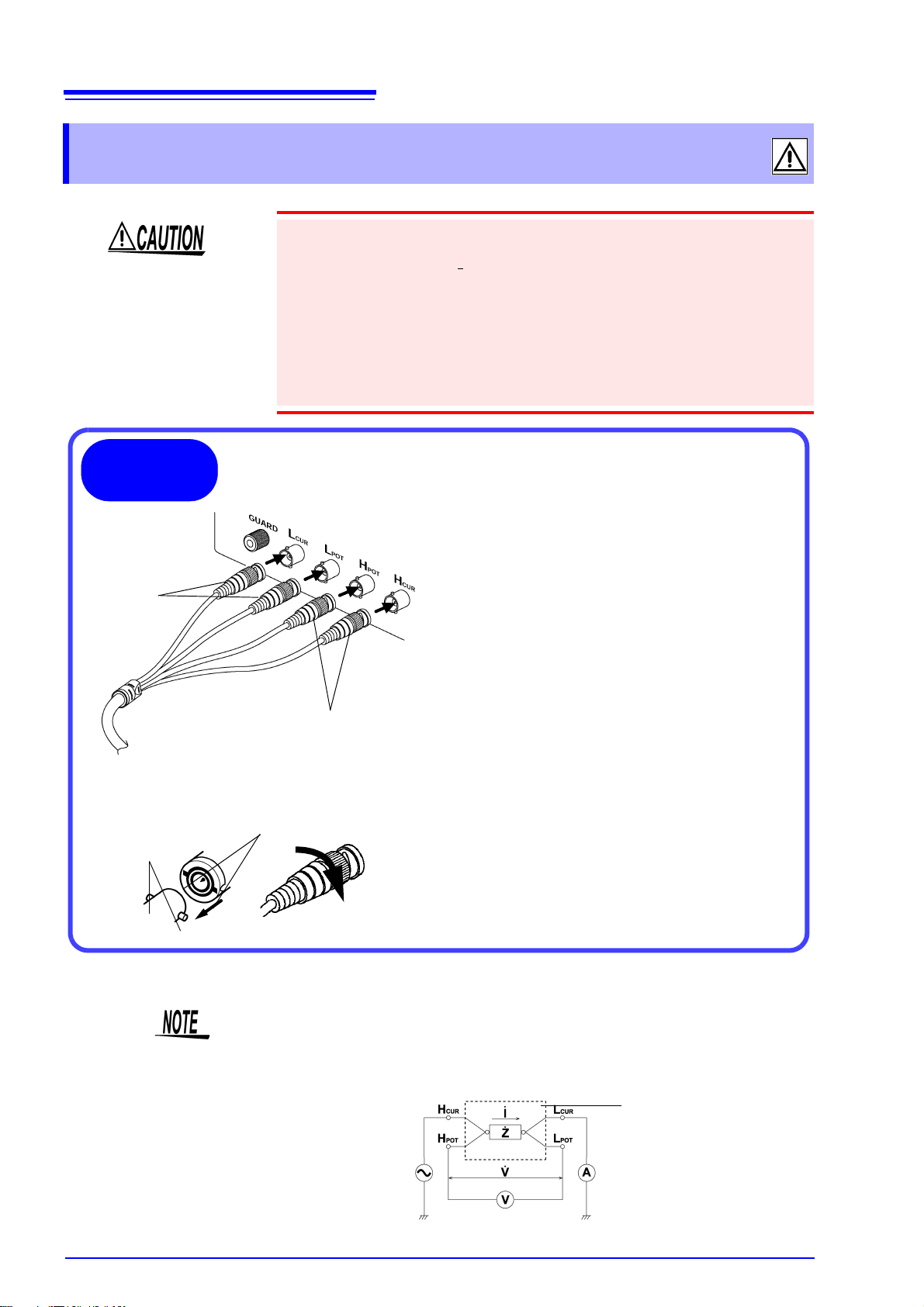

20

Red plugs

Black plugs

Measurement

Terminal

Connect the red plugs to the H

CUR

terminal and

H

POT

terminal and the black plugs to the L

CUR

terminal and L

POT

terminal.

The unit has the following five measurement terminals.

H

CUR

terminal Terminal for applying measurement

signals

H

POT

terminal Voltage detection HIGH terminal

L

POT

terminal Voltage detection LOW terminal

L

CUR

terminal Measurement current detection terminal

GUARD terminal Connect this terminal to the case

Connection

Procedure

Example: Connecting a Model 9261 Test Fixture (Option)

Lock

Align the grooves of the BNC connector with the

connector guides of the connector of the unit

and then insert the connector and rotate it clockwise until it locks into position.

To disconnect the connector, rotate it counterclockwise until it unlocks and then remove it.

3504-40, 3504-50, 3504-60

Measurement Terminal

Connector Guides

9261 Test Fixture

BNC Connector Grooves

Measurement Terminal Connections

21

Fixture

Measurement Terminal

Configuration

2.4 Connecting the Probes and Fixtures

2.4 Connecting the Probes and Fixtures

• Do not apply a voltage to the measurement terminals. Doing so may damage

the unit.

• When disconnecting the

pulling off the connector. Forcibly pulling the connector without releasing the

lock, or pulling on the cable, can damage the connector.

• To avoid breaking the probes, do not bend or pull them.

• The ends of the probes are sharp. Be careful to avoid injury.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• A voltage of ±12 V is generated at the L

minals are in an open state.

BNC connector, be sure to release the lock before

terminal when the L

CUR

POT

and L

CUR

ter-

For details such as the connection procedure for a fixture, refer to the corresponding instruction manual.

• Use Hioki probes, fixtures (option), etc.

See

• If all four terminals are disconnected, a meaningless number may be dis-

played on the unit.

Appendix 6 "Options" (p. A8)

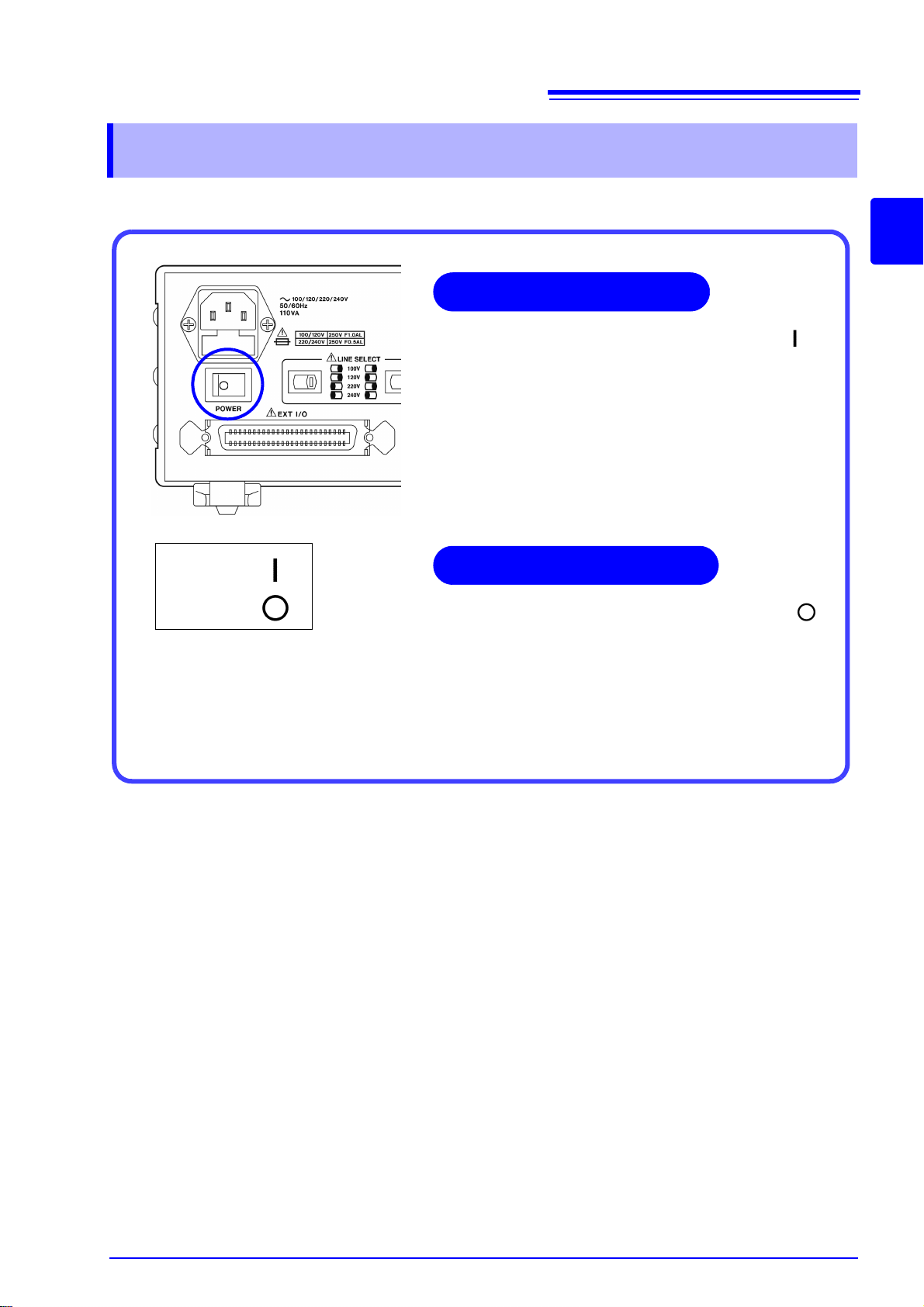

2.5 Turning the Power On and Off

Set the power switch on the rear of the unit to ON ( ).

All LEDs on the front panel light up.

The measurement conditions at startup are the same as

the last time the power was turned off.

After turning the power on, wait 60 minutes for the unit to

warm up before beginning measurement.

Power ON

Power OFF

Turning the power On

Turning the power Off

Set the power switch on the rear of the unit to OFF ( ).

The measurement conditions are saved when the power

is turned off.

Even if there is a power failure or other problem with the

power, the unit will be in the measurement mode prior to

the power failure after it recovers.

I

2.5 Turning the Power On and Off

21

2

22

2.5 Turning the Power On and Off

23

3.1 Pre-Operation Inspection

Basic

Measurement Chapter 3

3.1 Pre-Operation Inspection

To ensure safe use of the unit, be sure to check the following inspection

items prior to performing measurements.

Items Countermeasure See:

Inspect the unit, probe, and fixture

(Are there any damaged parts?)

Inspect the connection cord

(Is the covering cracked or is any

metal exposed?)

Check the power supply voltage

setting

(Does the setting of the voltage

selector on the rear of the unit

match the power supply voltage to

be used?)

When the power is turned on,

does the fan spin and do the

“3504-40, 3504-50, 3504-60” and

version number indications appear on the MAIN display area?

If there is damage:

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

Do not use a damaged cord because doing so

may result in electric shock. (Replace the cord

with a new one.)

Use of the unit outside the specified power supply voltage range may result in the unit being

damaged or an electrical fault. Set the voltage

selector in accordance with the power supply

voltage to be used.

If the fan does not spin or the “3504-40, 350450, 3504-60” and version number indications

are not displayed, the unit may be malfunctioning. Submit it for repairs.

Setting the Voltage

Selector:

2.2 "Checking the

Power Voltage" (p. 18)

3

Does the CV LED light up when

measurement is performed with

the measurement terminals

open while the probe and fixture

are connected to the unit?

(Range: AUTO)

Are the measurement values indicated on the unit normal when

measuring known samples such

as standard capacitors?

If the CV LED does not light up, the unit, probe,

or fixture may be malfunctioning.

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

If the measurement values are abnormal,

check/perform the following.

• Are the measurement conditions set appropriately?

• Perform open circuit and short circuit compensation again.

• Turn load compensation off.

• Set an appropriate trigger delay time or wait

time for trigger synchronous output function.

If the measurement values are still abnormal after you have checked/performed the above, the

unit, probe, or fixture may be malfunctioning.

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

Connecting the Probe

and Fixture:

2.4 "Connecting the

Probes and Fixtures" (p.

20)

3.3 "Setting the Measurement Conditions" (p. 26)

4.1 "Open Circuit Compensation and Short Circuit Compensation" (p. 37)

4.2 "Load Compensation"

(p. 47)

6.2 "Trigger Delay Setting"

(p. 93)

6.5 "Trigger Synchronous

Output Function" (p. 104)

"Setting and Query of

Wait Time for Trigger Synchronous Output Function"

(p. 239)

9

24

2

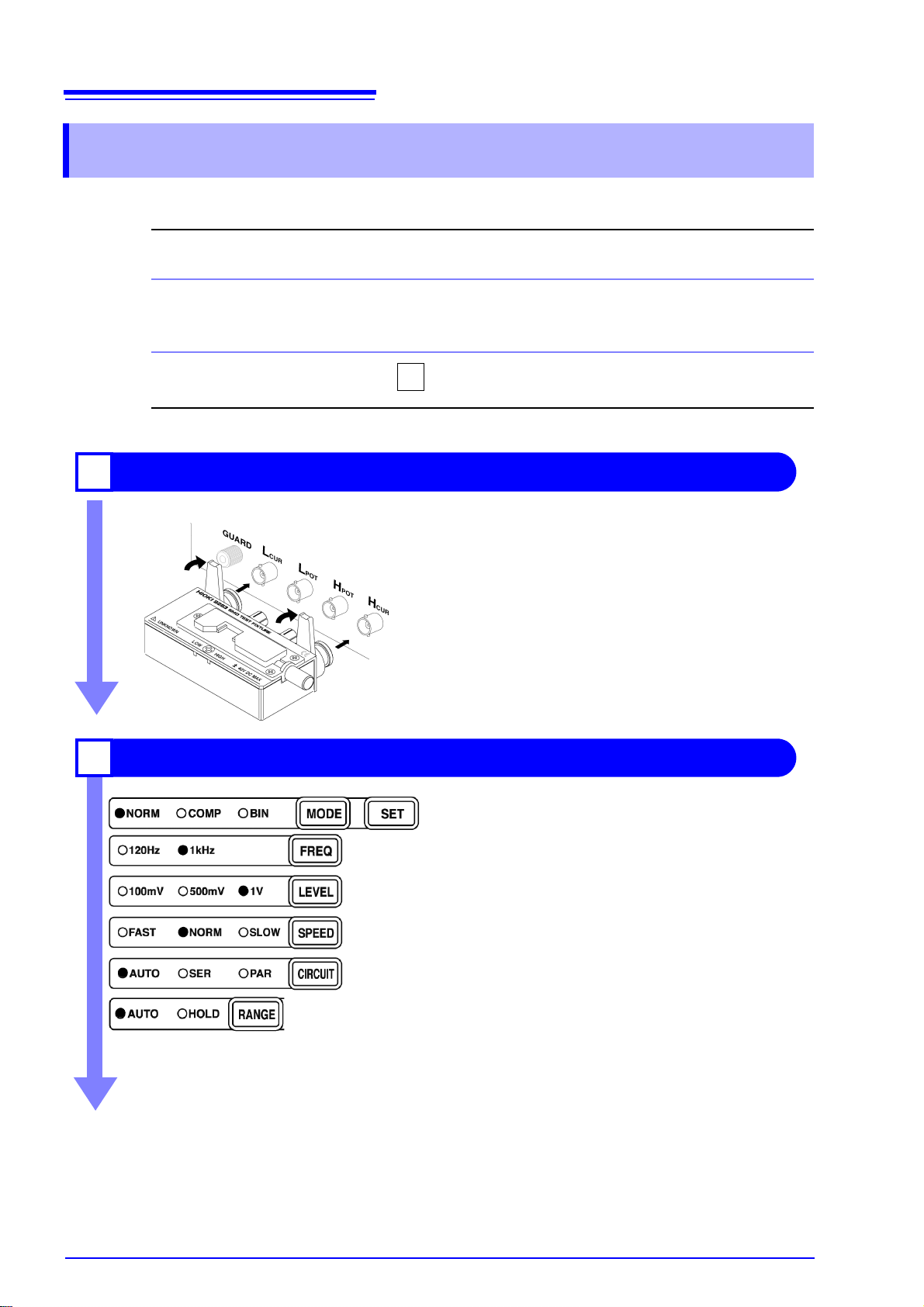

Connect the 9263 SMD Test Fixture (Option).

1

Connect the 9263 SMD Test Fixture to the measurement terminal.

For the connection method, refer to the instruction manual supplied with the fixture.

Set the measurement conditions.

2

Using the keys on the operating panel, set the measurement conditions as shown at left.

Make other settings as necessary.

See

4.1 "Open Circuit Compensation and Short Circuit

Compensation" (p. 37)

See 4.2 "Load Compensation" (p. 47)

See 4.3 "Offset Compensation" (p. 54)

See 4.4 "Self Calibration" (p. 58)

See 6.1 "Setting the Average Function" (p. 91)

See 6.2 "Trigger Delay Setting" (p. 93)

See 3.3.7 "Trigger Signal" (p. 36)

The open circuit compensation, short circuit compensation, load circuit compensation and self calibration

settings improve measurement accuracy.

MODE

Measurement mode........ NORM (p. 26)

FREQ

Frequency......................... 1 kHz (p. 26)

LEVEL

Measurement signal level..... 1 V (p. 27)

SPEED

Measurement speed ....... NORM (p. 28)

CIRCUIT

Equivalent-circuit mode .. AUTO (p. 29)

RANGE

Measurement range......... AUTO (p. 31)

3.2 Measurement Example

3.2 Measurement Example

The following example shows a measurement operation using the 3504-40, 3504-50, 3504-60.

Example

Necessary tools

Measurement

Conditions

The 9263 SMD Test Fixture is used for the measurement

of multilayer ceramic capacitors.

• 3504-40, 3504-50, 3504-60

• 9263 SMD Test Fixture

• Sample to be measured: Multilayer ceramic capacitor

See .

Loading...

Loading...