Page 1

Instruction Manual

3504

3504-10

C HiTESTER

December 2008 Revised edition 2 3504A981-02 08-12H

Page 2

Page 3

Contents

Contents

Introduction.................................................................................1

Verifying Package Contents.......................................... .. ...........1

Safety Informa tio n ............. .. ................. .. ................. ... ................2

Operating Precautions................................................................4

Chapter 1

Overview ___________________________________ 7

1.1 Product Overview ........................................ .. ...............7

1.2 Features .......................................................................7

1.3 Entire Wo r kflow ... .. ... ................ ... .. ................. .. ... .........9

i

1.4 Names and Fu nctions of Parts ....................... .. ... .......11

Chapter 2

Measurement Preparations ____________________ 15

2.1 Preparation Flowchart ................................................15

2.2 Checking th e P ower Voltage.................... .. ................ 16

2.3 Connecting the Power Cord................... .................... 17

2.4 Connecting the Probes and Fixtures............ .............. 18

2.5 Turning the Power On and Off ...................................19

Chapter 3

Basic Measurement__________________________ 21

3.1 Pre-Op e ra t ion In sp e ction .................................... .......21

3.2 Measurement Example ..............................................23

3.3 Setting the Measurement Conditions

(Required Settings) ....................................................25

3.3.1 Measurement Mode ......................................................2 5

3.3.2 Measurement Frequency ......................... .... ..... ............25

3.3.3 Measurement Signal Level ............................................2 6

3.3.4 Measurement Speed .................................... ..... ..... .... ...2 7

3.3.5 Equivalent Circuit Mode ................................................27

3.3.6 Measurement Range ......................................... ..... .......29

3.4 Measurement Conditions (Optional Settings) ............31

3.4.1 Open Circuit Compensation • Short Circuit

Compensation ...............................................................31

3.4.2 Load Compensation ......................................................36

3.4.3 Trigger Signal ................................................................39

Page 4

ii

Contents

Chapter 4

Application Functions_________________________41

4.1 Compara t or Fu n ctio n .............. .. ... ................ ... ........... 41

4.2 BIN Measurement Function (Only for 3504) .............. 50

4.3 Synchronous Measurement Function

(3504 special specification) ....................................... 60

4.4 Trigger Synchronous Output Function ............. .......... 62

4.5 Keylock Function ....................................................... 64

4.6 Panel Save Function ......................... ................... ..... 65

4.7 Panel Load Function ..................... ...................... .. ..... 66

4.8 Printing Function ........................................................ 69

4.8.1 Preparation Prior to Connecting the Printer ..................69

4.8.2 Connection Procedure ..................................................71

4.8.3 Printing ..........................................................................72

Chapter 5

Other Settings ______________________________73

5.1 Setting Beep Tones ............... ....................................73

5.1.1 Setti ng the Beep Tone for Judgment Results of

Comparator and BIN .....................................................73

5.1.2 Setting the Beep Tone for Key Operations ...................74

5.2 Performi n g a Sy ste m Re se t . ................. ... .. ................ 76

5.3 Countermeasures Against Inco rporation of External

Noise ......................................................................... 78

5.3.1 Countermeasures Against Incorporation of Noise from

the Power Line ..............................................................78

5.3.2 Countermeasures Against Incorporation of Noise from

the Input Line (Types of Probe) ....................................79

Chapter 6

Application Measurement______________________81

6.1 Measure m e n t Usin g EX T I/O........................... .. ........ 81

6.1.1 About the EXT I/O Connector .......................................81

6.1.2 Circuit Configuration and Connections of the EXT I/O

Connector..................................................................... 83

6.1.3 About Input and Output Signals ....................................84

6.1.4 About Measurement Times ...........................................86

6.2 Measurement of High Impedance Components ........ 87

6.3 Measurement of In-circuit Components ..................... 88

6.3.1 Measurement Using Guarding Technique ....................88

6.3.2 Synchronous Measurement ..........................................89

Page 5

Contents

Chapter 7

Controlling the Unit from a PC __________________ 91

7.1 Outline and Fe a tu r es .... ... ................. ................ ... .......91

7.2 Specifications .............................................................92

7.2.1 RS-232C Specifications ............................... ..... ..... .... ...92

7.2.2 GP-IB Specifications (Only for 3504) ............................93

7.3 Connection and Setting Procedures ........... ...............94

7.3.1 Connecting the RS-232C Cable / GP-IB Cable .............94

7.3.2 Setting the Interface Communication Conditions ..........96

7.4 Remote Fu nction ............. ................. .. ................. .. ..... 9 8

7.5 Communication Procedure .........................................98

7.6 Things to Know before Beginning Communication ....99

7.6.1 About Message Formats ...............................................99

7.6.2 About the Output Queue and Input Buffer ...................104

7.6.3 About the Status Byte Register ...................................105

7.6.4 About Event Registers ................................................107

iii

7.7 Message List .................... .. ......................................112

7.8 Ability to Use Commands by State ...........................121

7.9 Message Reference ............................... ..................124

7.9.1 Common Commands ..................................................125

7.9.2 Unique Commands ......................................................131

7.9.3 Response Format of Queries for Returning Values ....172

7.10 Initialized Items ........................................................174

7.11 Creating Programs ...................................................175

7.11.1 Creation Procedure .....................................................175

7.11.2 Sample Programs ........................................................178

7.12 Troubleshooting the Interface ......................... .........181

7.13 Device Document Requirements

(Only for the 3504 ) ............ ................. ................. .. ...183

Chapter 8

Specifications______________________________ 187

8.1 Basic Specifications .................................................187

8.2 Accuracy ..................................................................190

8.3 Measurement Parameters and Arithmetic

Expressions .. ......... ............ ............ ............ .......... ..... 19 2

Page 6

iv

Contents

Chapter 9

Maintenance and Service_____________________195

9.1 Inspection, Repair, and Cleaning ............................195

9.2 Replac in g th e Powe r Fu se ............. ................. .. ...... 197

9.3 Discarding the Unit ...................... .. ................. .. ... .. .. 198

Chapter 10

Options___________________________________199

Appendix _________________________________ A1

Appendix 1 Mounting the Unit in a Rack..............................A1

Appendix 2 External View..................... ................... ............A3

Index__________________________________ Index i

Page 7

Introduction

Thank you for purchas ing the HIOKI “Model 3504, 3504-10 C HiTester.” To

obtain maximum performance from the unit, please read this manual first, and

keep it handy for future reference.

Verifying Package Content s

When you receive the unit, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or if it fails to operate according to the specifications, contact your dealer or Hioki representative.

This unit 3504 C HiTester

3504-10 C HiTester

1

Introduction

Accessories • Instruction Manual.............................................................................. 1

• Power cord......................................................................................... 1

• Spare fuse for power supply (according to voltage specification) ......1

100 V, 120 V setting : 250 V F 1.0 AL 5 x 20 mm dia

220 V, 240 V setting : 250 V F 0.5 AL 5 x 20 mm dia

Probes, fixture are not supp lied with the unit as standard equipment. You

should order them separately, according to requirements.

Shipping precautions

Use the original packing materials when transporting the unit, if possible.

Options

Chapter 10 "Options" (p. 199)

About Special Specifications

These specifications are not included in standard products.

Page 8

2

Safety Information

Safety Information

This unit is designed to comply with IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage

to the unit. Be certain that you understand the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from unit defects.

This manual contains information and warnings essential for safe operation of

the unit and for m aintaining it in s afe operating condition. B efore using i t, be

sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important

information that the user should read before using the unit.

The symbol printed on the unit indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

Other Symbols

Indicates AC (Alternating Current).

Indicates a grounding terminal.

Indicates a fuse.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbol s in this manu al indicat e the rela tive importance of c autions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious inju ry or death to the user.

Indicates that inc orrect operation presents a possi bility of

injury to the user or damage to the unit.

Indicates advisory items related to performance or corr ec t

operation of the unit.

Indicates a prohibited action.

Indicates the location of reference information.

Indicates quick references fo r operati on and remed ies for

troubleshooting.

*

Indicates that descriptive information is provided below.

Page 9

Measurement Categories (Overvoltage categories)

To ensure safe operation of measurement units, IEC 60664 establishes

safety standards fo r various electrical environ ments, catego rized as CAT I to

CAT IV, and called overvoltage categories. These are defined as follows.

CAT I: Secondary electrical circuits connected to an AC elec-

trical outlet through a transformer or similar device.

CAT II: Primary electrical cir cuits in equipment connected to

an AC electrical outlet by a power cord (portable tools,

household appliances , etc.)

CAT III: Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distributi on panel to outlets.

CAT IV: The circuit from the service drop to the service

entrance, and to t he power meter and primary overcurrent protection device (distribution panel).

3

Safety Information

Accuracy

Higher-numbered categories correspond to electrical environments with

greater momentary ener gy. So a meas urement device designed for CAT III

environments can endur e greater mo mentary en ergy than a de vice design ed

for CAT II.

Using a measurement uni t in an environment desig nated with a high er-numbered category than that for which the unit is rated could result in a severe

accident, and must be carefully avoided.

We define measuremen t t olera nces in ter m s of rdg . (r eadin g) and dgt . ( di git) va lues, with the following meanings:

rdg.

(reading or displayed value)

The value currently bei ng measured and

indicated on the measuring unit.

dgt. (resolution) The smallest dis playable unit o n a digital

measuring unit/ device/ product, i.e., the

input value that cau ses the digi tal display

to show a "1" as the least-significant digit.

Page 10

4

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Unit Installat ion

Operating Temperature and Humidity: 0 to 40°C), 80%RH or less, no con-

densation

Storage Temperature and Humidity: -10 to 55

sation

Accuracy-guaranteed temperature and humidity ranges: 23

Avoid the following locations that could cause an accident or damage

to the unit.

°C, 80%RH or less, no conden-

±5°C, 80%RH

Installing

Exposed to direct s unlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

• Do not install the unit with any side except the bottom facing down.

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

OK

• Vents must not be obstructed.

5 cm or more

10 cm or more

Page 11

Operating Precautions

• To avoid dam age to the unit, protec t i t from physical shock whe n t ra nspor ting and handling. Be especially c areful to avoid physical shock fr om dropping.

• Do not apply heavy downward pressure with the stand extended. The stand

could be damaged.

Handling this device

Never modify the unit. Only Hioki service engineers should disassemble or repair the unit. Failure to observe these precautions may result in

fire, electric shock, or injury.

5

If anything unusual happens during operation of the unit, turn off the

power switch immediately and contact any HIOKI service facility for

help, advice and service.

Before connection and powering on

• Before turning the unit on, make sure the supply voltage matches

that indicated on the its power connector. Connection to an impr oper

supply voltage may damage the unit and present an electrical hazard.

• The power supply voltage for this unit is switchable. To avoid electrical accidents, check that t he voltage selector is set correctly for the

supply voltage you are using.

Setting Procedure for the Power V olt age : 2.2 "Che ckin g the Power Voltage" (p.

16)

• T o avoid electrical accidents and to maintain the safety specifications

of this unit, connect the power cord only to a 3-contact (two-conductor + ground) outlet.

Connection Procedure : 2.3 "Connecting the Power Cord" (p. 17)

• To avoid shock and short circuits, turn off all power before connecting probes.

Check the connections carefully in order to avoid any chance of setting

up a short-circuit etc.

Page 12

6

Operating Precautions

About the guarantee

Preliminary Checks

You sho uld be aware that HIOKI cannot ac cept any responsibil ity directly or

indirectly if the unit has been incorporated in some other s ystem, or if it is

resold to a third party.

Before using the u nit the first time , verify that it o perates normally to ensure

that the no damage occurre d durin g storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the unit, make sure that the insulation on the probes and

cables is undamaged and that no bare conductors are improperly

exposed. Using the unit in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for replacements.

Page 13

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

The HIOKI Model 3504 and 3504-10 C HiTesters are capacitance meters

employing 120 Hz an d 1 kHz frequencies to measure capacitors other th an

electrolysis capacitor s (Capacitor s other t han the n on-electr olytic capaci tors)

at high speed and hi gh accur acy. Primary application s inclu de pass- fail judgment and ranking of capacitors on tape machines and sorters.

1.2 Features

7

1

Capacitance-specific units

These capacitance meters use 120 Hz and 1 kHz measurement frequencies.

High-speed measurement

The 3504 and 3504-10 are capable of high-speed measurement: 2 ms at

measurement frequency 1 kHz, and 10 ms at 120 Hz.

Constant-voltage measurements

Provides constant-volta ge mea sure men t capabil ity.

(With 1 kHz selected) 1V: to 70 μF 500 mV: to 170 μF

(With 120 Hz selected) 1V: to 700 μF 500 mV: to 1.45 mF

Bin sorting function (Model 3504 only)

Capacitors are easil y ranked according to C (Capacitance *1) measurement

values into as many as 14 classifications.

Comparator function

Easily perform pass-fail judgment of components according to measurements

of both C and D (Dissipation Factor*2).

LED display

Provides superior visibility.

Equipped with standard data transfer interfaces

The 3504 offers external I/O for sequencing, a s tandard RS-232C interface,

and a standard GP-IB interface (Model 3504 only).

Page 14

8

1.2 Features

Measurement value memory

Up to 200 measurement values can be stored in memory.

Trigger-synchronous measurement capability

The measurement signal can be input to the sample in sync with a trigger.

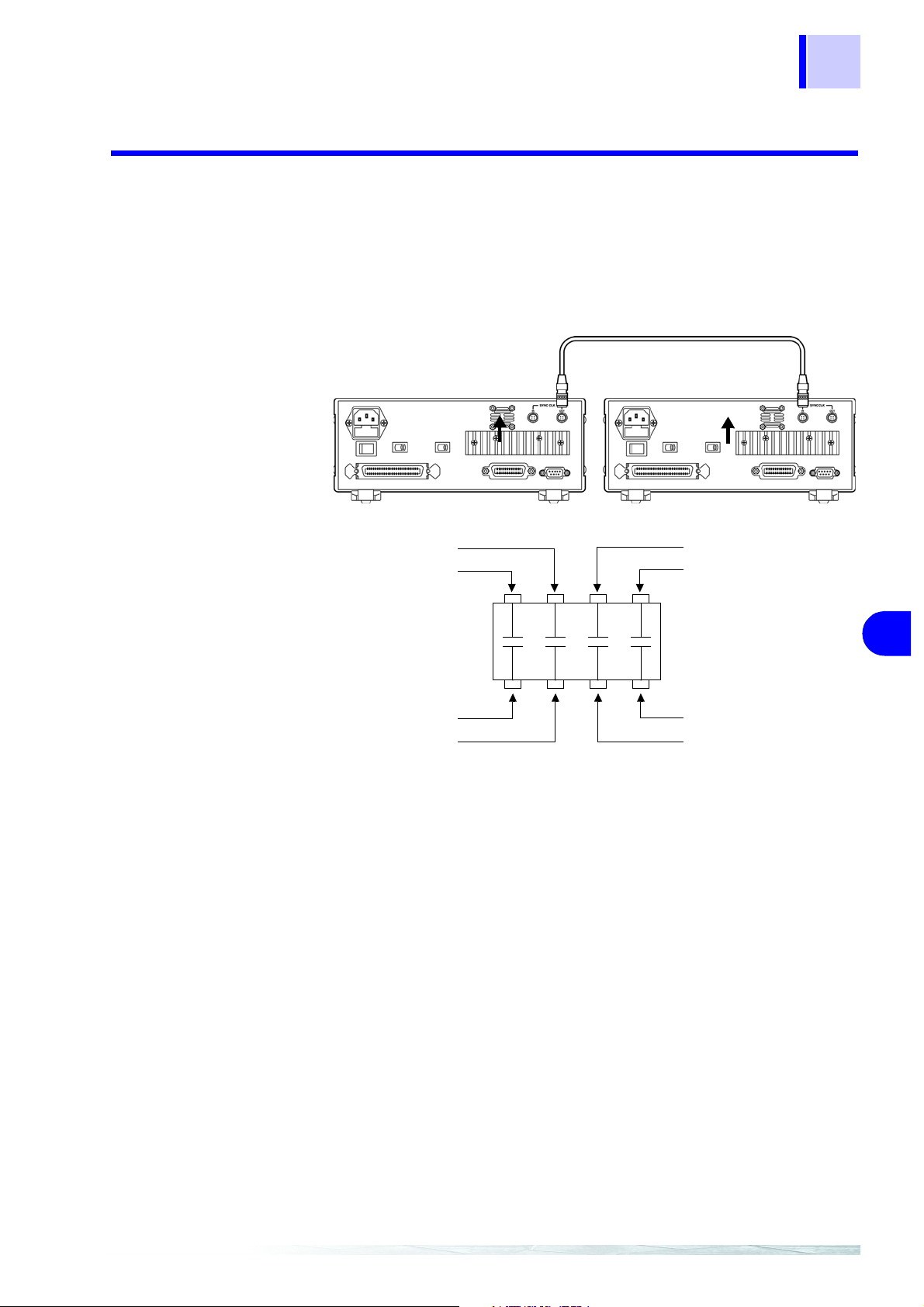

Synchronous measurement (Special feature of Model

3504)

Synchronize multiple meters to reduce interference-induced measurement

instability.

*1. Capability to store electric charge.*2. An indicator of capacitor losses.

Page 15

1.3 Entire Workflow

9

1.3 Entire Workflow

Measurement

Chapter 2 "Measurement Preparations" (p. 15)

Preparations

1.Check the power voltage.

2.Connect the power cord.

3.Connect the probes or fixture (option) to the measurement terminals.

4.Turn the power on.

5.Connect the sample.

Pre-Operation

3.1 "Pre-Operation Inspection" (p. 21)

Inspection

Be sure to perform pre-operation inspection prior to measurement.

Basic Measurement 3.2 "Measurement Example" (p. 23)

1.Prepare the unit, fixture, and sampl e.

2.Connect the fixture to the measurement term inals.

3.Set the measurement conditions.

4.Connect the sample to the fixture.

5.Check the measurement results.

Application Functions Chapter 4 "Application Functions" (p. 41), Chapter 7 "Controlling the Unit from a

PC" (p. 91)

Function Description

Comparator measurement function

BIN measurement

function

(only for 3504)

Synchronous measurement function

(special specification

for 3504)

Trigger synchronous output function

Key lock function Disable key operations.

Communication

function

Panel save function Save measurement conditions.

Panel load function Load saved measurement condi-

Printing function Print measurement values.

Set the upper limit and lower limit

values and judge whether samples

pass or fail.

Set variations of the upper limit

and lower limit values and rank

samples accordingly.

Reduce the differences in measurement values caused by interference when using multiple 3504

units for measurement.

Apply the measurement signal

only during measurement to reduce the generation of heat in the

sample and decrease electrode

wear.

Control the unit from a PC.

tions

Reference

Section

4.1 (p. 41)

4.2 (p. 50)

4.3 (p. 60)

4.4 (p. 62)

4.5 (p. 64)

Chapter 7 (p. 91)

4.6 (p. 65)

4.7 (p. 66)

4.8 (p. 69)

1

Page 16

10

1.3 Entire Workflow

Application

Measurement

Chapter 6 "Application Measurement" (p. 81)

Measurement using EXT I/O

Measurement of high impedance components

Measurement of components in circuit networks

Other Settings Chapter 5 "Other Settings" (p. 73)

Beep tone setting

Reset of system

Countermeasures against incorporation of external noise

Page 17

1.4 Names and Functions of Parts

1.4 Names and Functions of Parts

Front

SUB Display

Displays the limit values of

BIN (only for 3504) and

comparator.

11

1

Comparator Evaluation

Result Display

Displays evaluation results in

Comparator Mode.

4.1 "Comparator Function" (p.

41)

MAIN Display

Displays the measurement

values of C and D.

Displays the MENU items.

Setting Condition

Display

Displays current measurement conditions, presettings, and other information.

*BIN (3504 only)

BIN Judgment Result

Display (only for 3504)

Displays judgment results in

BIN mode.

4.2 "BIN Measurement Func-

tion (Only for 3504)" (p. 50)

Measurement Terminals

There ar e five measurement terminals:

H

CUR

H

POT

L

POT

L

CUR

GUARD Guard terminal

2.4 "Connecting the Probes and

Fixtures" (p. 18)

Measurement-signal

input terminal

Detected voltage high

terminal

Detected voltage low

terminal

Measurement current

detected terminal

Operating Panel

Use to set measurement

conditions and to make other

settings

(⇒ p. 12)

Page 18

12

1.4 Names and Functions of Parts

Operating Panel

Keypad

Used to enter numeric values.

Measurement mode

setting

(⇒ p. 25)

Comparator and BIN

measurement function settings

4.1 "Comparator

Function" (p. 41),

4.2 "BIN Measurement Function

(Only for 3504)" (p.

50)

Arrow keys

Used to change settings and move to

menu items or digits.

Enter

Measurement range

setting

(⇒ p. 29)

Lock/ Local

(⇒ p. 64)

Menu

Manual trigger

(⇒ p. 39)

Measurement frequency setting

(⇒ p. 25)

Measurement signal level setting

(⇒ p. 26)

Measurement speed setting

(⇒ p. 27)

Equivalent circuit mode

(⇒ p. 27)

Measurement range setting

(⇒ p. 29)

Open short circuit compensation

(⇒ p. 31)

Load compensation setting

(⇒ p. 36)

Trigger mode setting

(⇒ p. 39)

Page 19

Back

Power Inlet

Connect the supplied

power cord

2.3 "Connecting the

Power Cord" (p. 17)

Voltage

Selectors

Changes the power

voltage

I

1.4 Names and Functions of Parts

Phase Synchronization Connector

(Special Spec ification)

Connect this to another 3504 (3504-10) unit when performing synchronous measurement.

4.3 "Synchronous Measurement Function (3504 special

specification )" (p. 60)

13

1

Power Switch

Turns the power on and

off.

: Turns the power off.

: Turns the power on.

2.5 "Turning the Power

On and Off" (p. 19)

Side

Left side

EXT I/O Connector

Inputs external trigger signals and outputs comparator

result signals and other signals. Supports connection to

a sequencer.

6.1 "Measurement Using

EXT I/O" (p. 81)

GP-IB

Connector

(only for 3504)

Connect a GP-IB

cable.

Chapter 7 "Control-

ling the Unit from a

PC" (p. 91)

Right side

RS-232C

Connector

Connect an RS-232C

cable.

Chapter 7 "Controlling

the Unit from a PC" (p.

91)

Stand

Do not apply heavy downwar d pressure with the stand e xtended. The stand

could be damaged.

Page 20

14

1.4 Names and Functions of Parts

Page 21

2.1 Preparation Flo wchart

Measurement

Preparations Chapter 2

15

Be sure to read "Operating Precautions" (p. 4) prior to setting up the unit.

2.1 Preparation Flowchart

Check the power voltage.

Connect the power cord.

Connect the probes or fixture

(option) to the measurement

4

2

1

2.2 "Checking the Power Voltage" (p. 16)

1

Back

2

2.3 "Connecting the Power Cord" (p. 17)

3

Front

2.4 "Connecting the Probes and Fixtures" (p. 18)

2

terminals.

(Example)

3

Model 9261 Test Fixture

(Option)

5

4

2.5 "Turning the Power On and Off" (p. 19)

5

Unit Settings and Measurement

Chapter 3 "Basic Measurement" (p. 21)

Chapter 4 "Application Func tions" (p. 41)

Chapter 6 "Application Measurement" (p. 81)

Turn the power on.

Connect the sample.

Page 22

16

2.2 Checking the Power Voltage

2.2 Checking the Power Voltage

• Before turning the unit on, make sure the supply voltage matches

that indicated on the its power connector. Connection to an improper

supply voltage may damage the unit and present an electrical hazard.

• The power of the unit can be changed with the voltage selectors. To

avoid an electric accid ent, use t he unit wit h the voltage sele ctors set

to a voltage value that matches the voltage to be used.

• Make sure the power is off when you change the voltage with the voltage selectors. Changing the power voltage when the power is on may

result in damage to the unit or an electric accident.

• The maximum rated power is 110 VA.

The power voltage spec ification of the un it is set as spec ified when the uni t

was ordered.

You can select from 100 V, 120 V, 220 V, and 240 V.

You can determine which voltage is set by checki ng the positi ons of the vo ltage selectors.

Refer to the diagram between the voltage select or s.

Voltage

100 V Right side Right side

120 V Right side Left side

220 V Left side Right side

240 V Left side Left side

Back

Position of Left Voltage

Selector

Voltage selectors

Position of Right Voltage

Selector

In the diagram, the voltage

value is 100 V because

both the left and right voltage selectors are set to the

right side.

Page 23

2.3 Connecting the Power Cord

2.3 Connecting the Power Cord

To avoid electrical acc idents and to maintain the safety specifications

of this unit, connect the power cord only to a 3-contact (two-conductor

+ ground) outlet.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• Turn off the power before disconnecting the power cord.

17

2

Connection

Procedure

1. Make sure the power switch of the unit is off.

2. Make sure the power voltage matches and connect the power

cord to the power inlet with voltage selectors on the rear of the

unit.

3. Insert the plug into the power outlet.

Page 24

18

Measurement Terminal

2.4 Connecting the Probes and Fixtures

2.4 Connecting the Probes and Fixtures

• Do not apply a voltage to the measur ement ter minals. Doing so may damage the unit.

• When disconnectin g the

pulling off the connector. Forcibly pulling the connector without releasing

the lock, or pulling on the cable, can damage the connector.

• To avoid breaking the probes, do not bend or pull them.

• The ends of the probes are sharp. Be careful to avoid injury.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• A voltage of ±12 V is generated at the L

terminals are in an open state.

BNC connector, be sure to release the lock before

terminal when the L

CUR

POT

and L

CUR

Connection

Example: Connecting a Model 9261 Test Fixture (Option)

Procedure

Black plugs

Red plugs

Measurement Terminal Connections

3504 (3504-10) Measurement Terminal Connector Guides

9261 Test Fixture

BNC Connector Grooves

Measurement

Terminal

Lock

21

Connect the red plugs to the H

and H

the L

The unit has the following five measurement

terminals.

H

CUR

H

POT

L

POT

L

CUR

GUARD terminal Connect this terminal to the

Align the grooves of the BNC connector with the

connector guides of the connector of the unit

and then insert the connector and rotate it clockwise until it locks into position.

To disconnect the connector, rotate it counterclockwise until it unlocks and then remove it.

terminal and the black plugs to

POT

terminal and L

CUR

terminal Terminal for applying measure-

ment signals

terminal Voltage detection HIGH termi-

nal

terminal Voltage detection LOW termi-

nal

terminal Measurement current detection

terminal

case

terminal.

POT

CUR

terminal

Configuration

For details such as the connectio n procedure for a fixtu re, refer to the corr esponding instruction manual.

• Use Hioki probes, fixtures (option), etc.

Chapter 10 "Options" (p. 199)

• If all fou r te rmina ls ar e disc on nec ted , a mea ni ngl es s nu mbe r m ay be di splayed on t he unit.

Fixture

Page 25

2.5 Turning the Power On and Off

2.5 Turning the Power On and Off

Turning the power On

Set the power switch on the rear of the unit to ON

().

19

2

Power ON

Power OFF

I

All LEDs on the front panel light up.

The measurement condi tions at startup are the same

as the last time the power was turned off.

After turning the power on, wait 60 minutes for the un it

to warm up before beginning measurement.

Turning the powe r Off

Set the power switch on the rear of the unit to OFF

().

The measurement conditions are saved when the

power is turned off.

Even if there is a power fail ure or other problem with

the power, the unit will be in the measurement mode

prior to the power failure after it recovers.

Page 26

20

2.5 Turning the Power On and Off

Page 27

21

3.1 Pre-Operation Inspection

Basic

Measurement Chapter 3

3.1 Pre-Operation Inspection

To ensure safe use of the unit, be sure to check the following inspection

items prior to performing measurements.

Items Countermeasure See:

3

Inspect the unit, probe, and

fixture

(Are there any damaged

parts?)

Inspect the connection cord

(Is the covering c racked or is

any metal exposed?)

Check the power supply voltage setting

(Does the setting of the voltage selector on the rear of

the unit match the power

supply voltage to be used?)

When the power is turned

on, does the fan spin and do

the “3504 (3504-10)” and

version number indications

appear on the MAIN display

area?

Does the CV LED light up

when measurement is performed with the measurement terminals open while

the probe and fixture are

connected to th e un it ?

(Range: AUTO)

If there is damage:

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

Do not use a damaged cord because doing so

may result in electric shock. (Replace the cord

with a new one.)

Use of the unit outside the specified power supply voltage range may result in the unit being

damaged or an electrical fault. Set the voltage

selector in accordance with the power supply

voltage to be used.

If the fan does not spin or the “3504 (3504-10)”

and version number indications are not displayed, the unit may be malfunctioning. Submit

it for repairs.

If the CV LED does not light up, the unit, probe,

or fixture may be malfunctioning.

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

_______________

_______________

Setting the Voltage Selector:

2.2 (page 16)

_______________

Connecting the Probe

and Fixture:

2.4 (page 18)

Page 28

22

3.1 Pre-Operation Inspection

Items Countermeasure See:

Are the measur ement values

indicated on the unit normal

when measuring known

samples such as standard

capacitors?

If the measurement values are abnormal, check/

perform the following.

• Are the me asurement conditions set appropriately?

• Perform open circuit and short circuit compensation again.

• Turn load compensation off.

If the measurement values are still abnormal after you have checked/performed the above, the

unit, probe, or fixture may be malfunctioning.

Unit and fixture: Submit them for repairs.

Probe: Replace it with a new one.

• Measurement Conditions:

3.3.2 (page 25)

3.3.3 (page 26)

3.3.4 (page 27)

3.3.5 (page 27)

3.3.6 (page 29)

•

Open Circuit Compensation and Short

Circuit Compensation

:

3.4.1 (page 31)

Load Compensation:

•

3.4.2 (page 36)

Page 29

3.2 Measurement Example

e

-

-

The following example shows a measurement operation using the 3504

(3504-10)

Example The 926 3 SMD Te st Fi xture i s used for the measurement of mul-

tilayer ceramic capacitors.:

Necessary tools • 3504 (3504-10)

• 9263 SMD Test Fixture

• Sample to be measured: Multilayer ceramic capacitor

.

23

3.2 Measurement Example

Measurement

See .

2

Conditions

Connect the 9263 SMD Test Fixture (Option).

1

Connect the 9263 SMD Test Fixture to the

measurement terminal.

For the connection method, refer to the instruction manual supplied with the fixture.

Set the measurement conditions.

2

Using the keys on the oper ating p an el, set th

measurement conditions as shown at left.

3

MODE

FREQ

LEVEL

SPEED

CIRCUIT

RANGE

Make other settings as necessary.

3.4.1 "Open Circuit C omp ensati on • Short Circ uit Com pen

sation" (p. 31)

3.4.2 "Load Compensation" (p. 36)

3.4.3 "Trigger Signal" (p. 39)

The open circuit compensation and short circuit co m

pensation settings improve measurement accuracy.

Measurement mode........ NORM

Frequency......................... 1 kHz

Measurement signal level.....1 V

Measurement speed....... NORM

Equivalent-circuit mode .. AUTO

Measurement range......... AUTO

(⇒ p. 25)

(⇒ p. 25)

(⇒ p. 26)

(⇒ p. 27)

(⇒ p. 27)

(⇒ p. 29)

Page 30

24

3.2 Measurement Example

Connect the sample to be measured to the 9263 SMD Test Fixture.

3

For the connection method, refer to the instruction manual supplied with the fixture.

Check the measurement results.

4

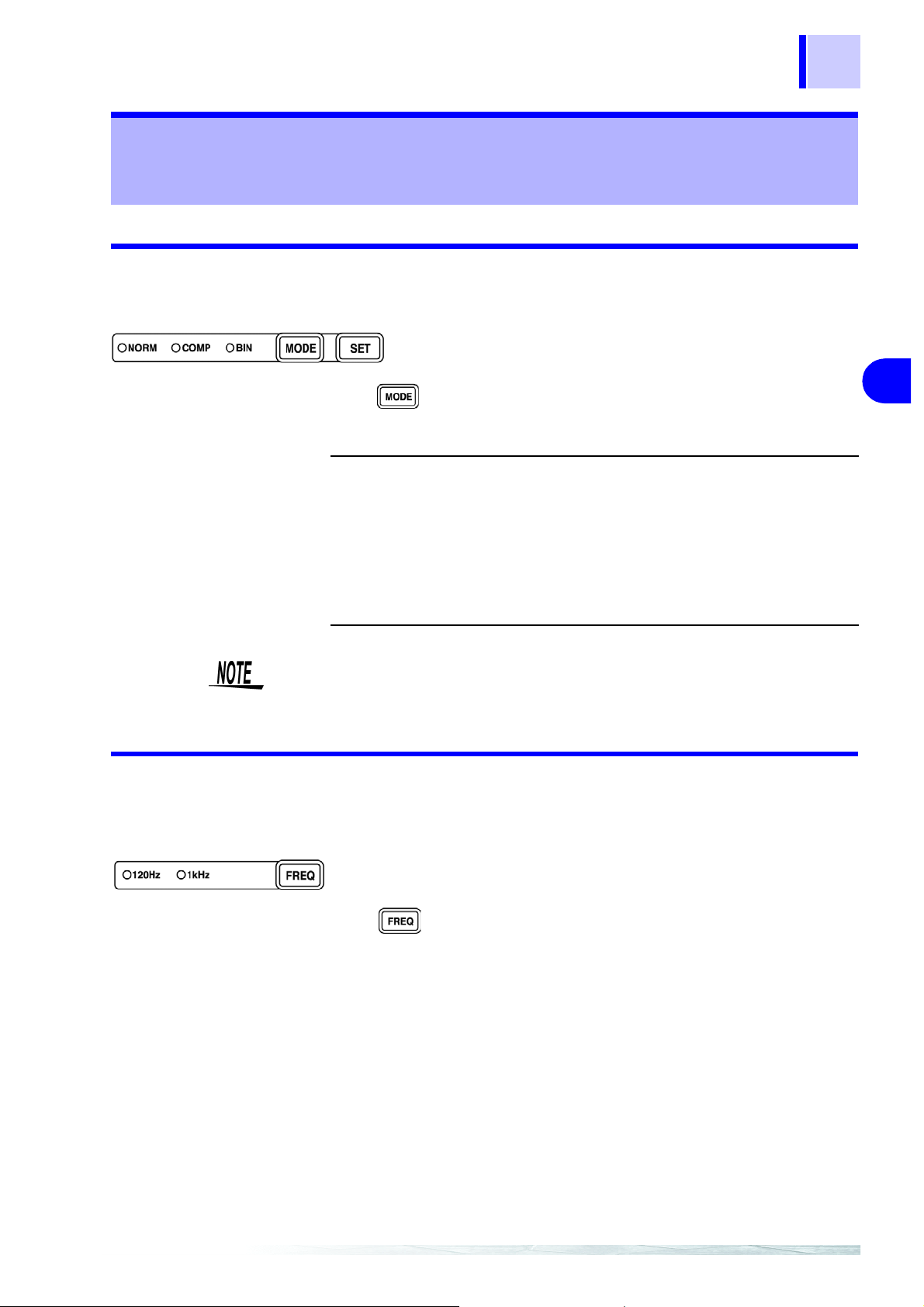

C

D

Page 31

3.3 Setting the Measurement Conditions (Required Settings)

3.3 Setting the Measurement Conditions

(Required Settings)

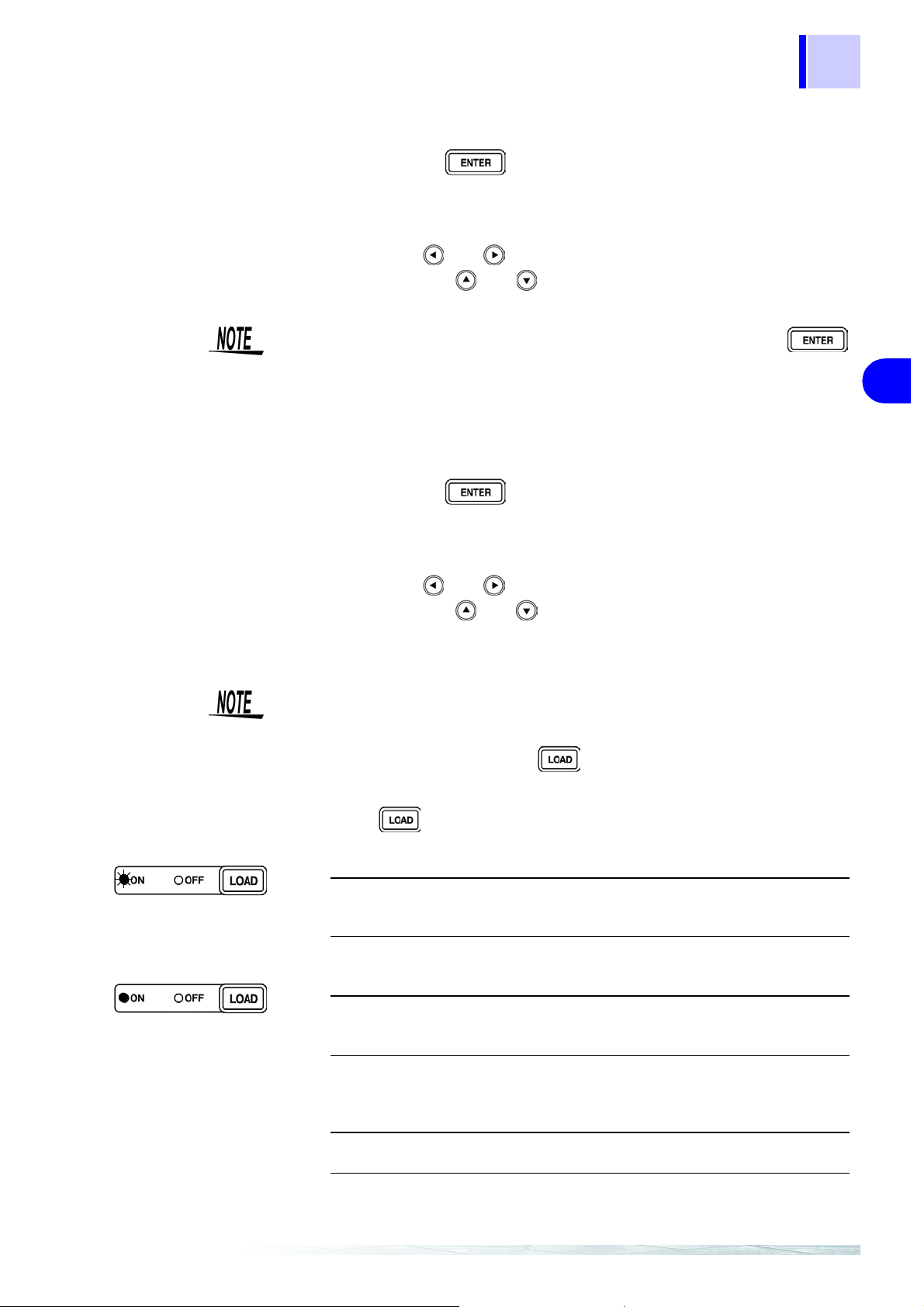

3.3.1 Measurement Mode

Select a measurement mode.

25

Mode:

Press to change the mode.

The selected item is indicated by the lit LED lamp.

NORM

COMP

BIN

(Model 3504

only)

The measurement conditions cannot be changed in comparator mode

and BIN mode. Set them in normal measurement mode.

NORM, COMP, BIN

Select this when using normal measurement mode.

Select this when using comparator measurement mode.

Select this when using BIN measurement

mode.

3.3.2 Measurement Frequency

Set the measurement frequency.

Set a frequency appropriate for the sample to be measured.

3

_________

4.1 (page 41)

4.2 (page 50)

Measurement frequency: 120 Hz, 1 kHz

Press to change the mode.

The selected item is indicated by the lit LED lamp.

Page 32

26

3.3 Setting the Measurement Conditions (Required Settings)

3.3.3 Measurement Signal Level

A voltage of ±12 V is generated at the L

L

terminals are in an open state.

CUR

Set the measurement signal level.

terminal when the L

CUR

POT

and

Set a signal level appropriate for the sample to be measured.

Measurement signal lev el : 500 mV, 1 V

Press to change the mode.

The selected item is indicated by the lit LED lamp.

500mV

1V

When the set voltage is appl ied to bot h sides of the sample , the CV indicator

lights up. The CV indicator does not light up when the applied voltage is lower

than the set voltage. In such a case, the EXT.I/O outputs a CV-ERR signal.

Constant-voltage measurement can be performed within the

range of 0.94 pF up to 170 μF (1 kHz) or 9.4 pF up to 1.45

mF (120 Hz).

Constant-voltage measurement can be performed within the

range of 0.94 pF up to 70 μF (1 kHz) or 9.4 pF up to 700 μF

(120 Hz).

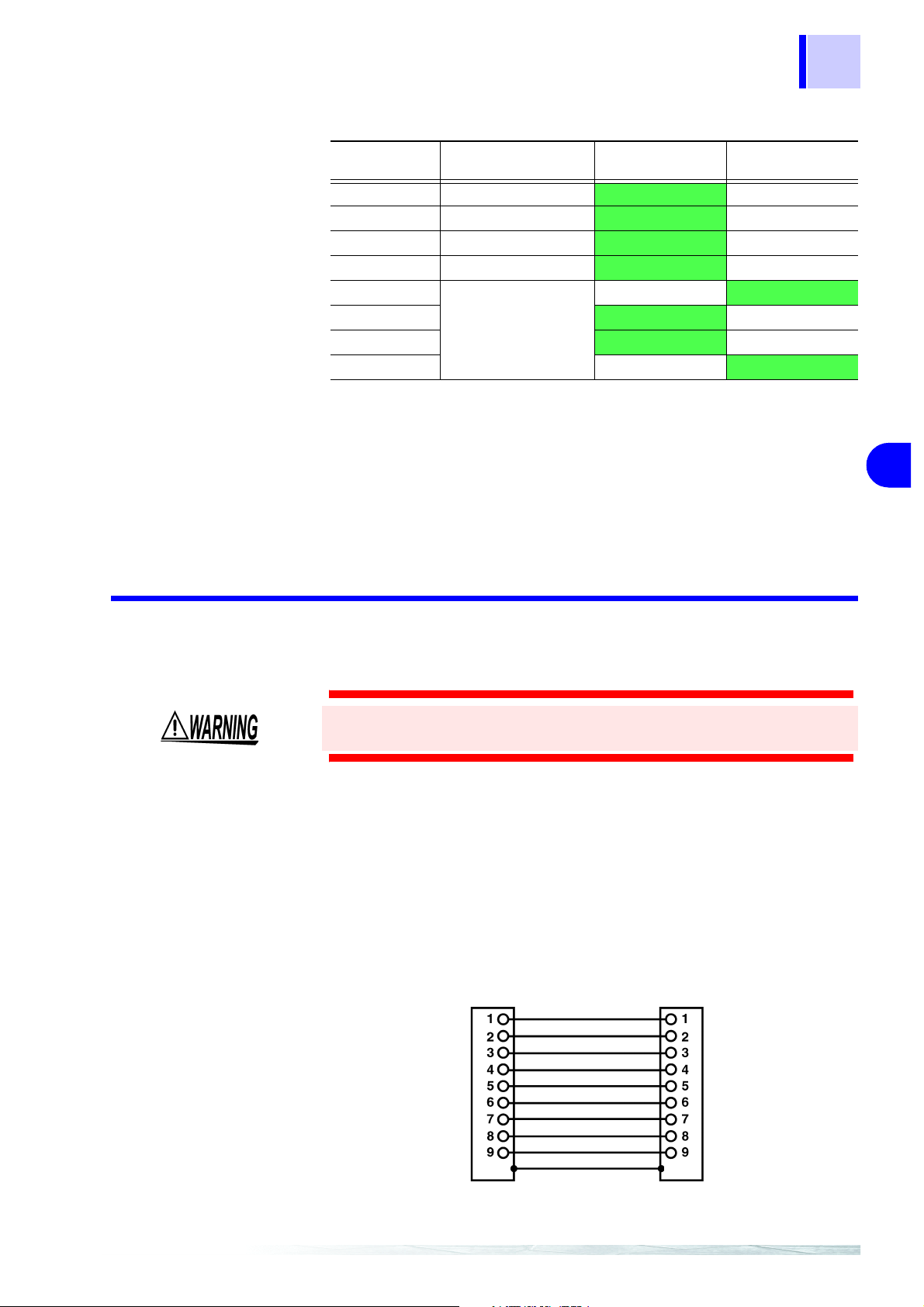

Range

No.

1 200 pF 20 pF

2 2 nF 200 pF

3 20 nF 2 nF

4 200 nF 20 nF

52 μF 200 nF

6 20 μF 2 μF

7200 μF20 μF

8

1.45 mF (

9 2 mF 200 μF Open terminal

10 20 mF 2 mF

• In some s amples, the value may vary dependi ng on the measurementsignal level.

• Constant v oltage measurement may not be possibl e if the value of the

contact resistance between t he measurement terminals and the sample

is high. When thi s is t he ca se , “ – – – – – – ” app ears on the MAIN display

area, CV LED goes out, and a CV-ERR

120 Hz 1 kHz

700 μF (when 1 V)

when 500mV)

170 μF (

70 μF (when 1 V)

when 500mV)

signal is output from EXT.I/O.

Measurement

Voltage Mode

Constant voltage

mode

voltage mode

Output resistance

of 5 Ω

Page 33

3.3 Setting the Measurement Conditions (Required Settings)

3.3.4 Measurement Speed

Set the measurement speed.

27

Measurement speed:

Press to change the mode.

The selected item is indicated by the lit LED lamp.

FAST

NORM

SLOW

The lower the measurement speed, the higher the measurement

accuracy becomes.

Measurement speed

Measurement frequency FAST NORM SLOW

120 Hz 10 ms 37.5 ms 146 ms

1 kHz 2.0 ms 5.5 ms 29.5 ms

(Allowance: ±5%±0.5 ms)

The measurement ti me va ries d epe ndi ng on s uch factors as the ope n/s hor t

circuit compensation ON/OFF and the comparator ON/ OFF.

FAST, NORM, SLOW

Measures at high speed.

Measures at normal speed.

Measures at low speed, but provides improved measure-

ment accuracy.

3

3.3.5 Equivalent Circuit Mode

You may set an equivalent circuit mode (SER/ PAR).

Automatic selection is also possible.

"Equivalent Circuit Mode" (page 28)

Equivalent circuit mode: AUTO, SER, PAR

Press to change the mode.

The selected item is indicated by the lit LED lamp.

AUTO

SER

PAR

The series equivalent circuit mode or parallel equivalent circuit

mode is automatically selected according to the measurement

range.

Range No. Automatically selected mode

6 to 10 Series equivalent circuit

1 to 5 Parallel equivalent circuit

Series equivalent circuit mode

Parallel equivalent circuit mode

Page 34

28

3.3 Setting the Measurement Conditions (Required Settings)

Equivalent Circuit

Mode

The 3504 (3504-10) u nit analyses the measurement s ample in terms of an

equivalent circu it constru ction c omposed of a p ure capaci tive com pon ent (C)

and a pure resistive compone nt (R), and calcul ates as though these components were connected in ser ies, or alterna tivel y conn ect ed in parallel. Therefore, it is poss ib le f or the us er t o se lect ei t h er a ser i es -e qu iv al e nt ci rc ui t mo de

or a parallel-equiv alent circuit mode f or this conceptual connection together

of these C and R components.

Normally, the parallel-equivalent circuit mode is used for a small capacitance

(high-impedance components) because a small capacitance is a major cause

of parallel resistance loss. While the series-equivalent circuit mode is used for

a large capacitance (low-impedance components) because a large capacitance is a major cause of ser ies resistance loss from the resistive parts of

lead wires, etc.

Series-equivalent circuit

Parallel-equivalent circuit

The measuremen t errors are likely to be larg e if the equi valent c ircuit se tting

is configured inco rrectly. If the parallel-equivalent circuit is use d to measure,

for example, an electrolytic capacitor with a large D (low Q [quality factor]

the measurement valu es will differ from those when a series-equ ivalent circuit is used for measurement. The table below shows an example of the measurement values obtained using a parallel-equivalent circuit and a seriesequivalent circuit when D is altered for a capacitor for which the capacitance

is the same.

3504 (3504-10) displayed value

D Cs Cp

0C’ C’

0.1 1.005C’ 0.995C’

0.5 1.118C’ 0.8944C’

C' : Static capacitance (nominal value)

Cs: Static capacitance in series-equivalent circuit mode

Cp: Static capacitance in parallel-equivalent circuit mode

D : Dissipation factor

Therefore it is neces sar y for t he us er cle arly to u nderstand th e se ttin g of t his

measurement mode, in order properly to assess measurement samples.

*1

),

*1:

Measure of reactance purity.

Page 35

3.3 Setting the Measurement Conditions (Required Settings)

3.3.6 Measurement Range

Select a measurement range. Automatic selection is also possible.

29

Measurement Range:

Press to change the mode.

The selected item is indicated by the lit LED lamp.

AUTO

(Auto range)

HOLD

(

Hold range

)

AUTO, HOLD

The optimal measurement range is selected automatically.

This is useful for the measurement of unknown samples.

However, measurement takes longer.

The measurement range is fixed, and may only be altered

manually.

Take measurements in the same range regardless of the

value of the sample. This is useful for high-speed measurement.

Changing the range:

When the range is changed, the decimal point and unit in

the measurement value display area change. The range

number is displayed in the SUB display area.

Measurement ranges and display ranges

3

Range

No.

1 009.400 pF to 200.000pF 00.9400 pF to 20.0000 pF

2 0.09400 nF to 2.00000nF 009.400 pF to 200.000 pF

3 00.9400 nF to 20.0000nF 0.09400 nF to 2.00000 nF

4 009.400 nF to 200.000nF 00.9400 nF to 20.0000 nF

5 0.09400 μF to 2.00000 μF 009.400 nF to 200.000 nF

6 00.9400 μF to 20.0000 μF 0.09400 μF to 2.00000 μF

7 009.400 μF to 200.000 μF 00.9400 μF to 20.0000 μF

8 0.09400 mF to 0.70000 mF (when 1 V)

9 0.13500 mF to 2.00000 mF 016.000 μF to 200.000 μF

10 01.3500 mF to 20.0000 mF 0.16000 mF to 2.00000 mF

Guaranteed Accuracy Range of C (when D ≤ 0.1)

120 Hz 1 kHz

009.400 μF to 070.000 μF (when 1 V)

1.45000 mF (when 500 mV)

170.000 μF (when 500 mV)

Page 36

30

e

e

e

Over flow:

3.3 Setting the Measurement Conditions (Required Settings)

• If the me asurement v alues disp laye d on the unit ar e outside of the guaranteed accuracy range, the HOLD LED flashes.

• If the values are outside of the measurement va lue range, the following

may be displayed.

MAIN Display Area

Under flow:

C is smaller than th

measurement rang

Over flow:

C is larger than the

measurement rang

SUB Display Area

D is larger than the

measurement

range

• Do not co nnect a low-impedance compon ent with, for example, a static

capacitance larger than the Range 8 guaranteed accuracy range for a

prolonged period of time while the unit is in a Range 8 HOLD state.

If a low-impeda nce compone nt is c onnected for at leas t ten minu tes, the

“i-ovEr Error” i ndication flashes in the MAIN di splay area and measurement stops. To clear the error, open the measurement terminals and then

press .

Page 37

3.4 Measurement Conditions (Optional Settings)

3.4 Measurement Conditions (Optional Settings)

3.4.1 Open Circuit Compensation • Short Circuit Compensation

Open circuit compensation and short circuit compensation enable you to

reduce the effect of impedance remaining in parts such as the probe or fixture

and improv e measurement accuracy.

There are two ways of performing open circuit compensation and short circuit

compensation.

• All Compensation

This performs compens ation at all frequencies (120 Hz and 1 kHz). Thi s

can be performed from the front panel or via a PC.

• Spot Compensation

This performs compe nsation at the frequency currently set. Perform this

from a PC through the interface.

"Setting and Query of Open Circuit Compensation Function" (page 145) and "Set-

ting and Query of Short Circuit Compensation Function" (page 148) of “7.9, "Message Reference".

31

3

• The measurem ent accuracy values defin ed in the specifications are for

when open circuit compensati on and short cir cuit com pensation are performed.

• Be sure to perform compensat ion again after r eplacing the probe or fixture. Yo u will be unable to obtain correc t values if measurement is pe rformed in the compensation state prior to replacement.

• The open circuit compensation range of impedance is 1 kΩ or more.

However, if the values are not sufficiently hi gh compared to the impedance of the sample, t he measur ement errors wi ll be large r and meas urement may become no longer possible.

• The short circuit compensation range of impedance is less than 1 kΩ.

However, if the values are not sufficiently low compared to the impedance

of the sample, the measur ement errors will be larger and me asurement

may become no longer possible.

Page 38

32

3.4 Measurement Conditions (Optional Settings)

Performing Open Circuit Compensation, Short Circuit Compensation

1. In normal measurement mode, press .

The state becomes as follows.

• The OPEN LED flashes.

• The “oPEn SEt” indication is displayed and the “SEt” indication flashes in

the MAIN display area.

If you do not want to perform open circuit compensation, press to

proceed to configuring the short circuit compensation settings. (The

SHORT LED flashes and the “Short SEt” indication is displayed and the

“SEt” indication flashes in the MAIN display area.) Proceed to Step

(page 33)

.

2. Set an open state between the HIGH and LOW terminals of the probe or

fixture connected to the measurement terminals.

4.

• When perfo rming compensation, the placement of th ings like the probe

and the distances b etween terminals must be as s imilar as possible to

the state when performing measurement.

• If compensation is being affected by external noise, use the shielding process.

For details on the shielding process, refer to 6.2 "Measurement of High Imped-

ance Components" (p. 87).

3. Press .

Incorporate the open circuit compensation values. (AL L Compensation)

• The OPEN LED flashes.

• The “o PEn AdJuSt” indication is displayed and the “AdJuSt” indication

flashes in the MAIN display area.

End of Compensati on:

When compensation ends, the state becomes as follows.

• A beep tone sou nds onc e and the “oPEn End” indi cation i s disp layed i n

the MAIN display area for one second.

• The OPEN LED flashes.

• The SHORT LED flashes.

• The “Short SEt” indication is displayed and the “SEt” indication flashes in

the MAIN display area.

Compensation Error:

If there was a compensation error, the state becomes as follows.

• A warning beep tone sounds

• The “oPEn Error” indication is displayed in the MAIN display area.

Compensation stops.

Page 39

3.4 Measurement Conditions (Optional Settings)

33

What if there is an

error?

4. Use a shorting bar to create a short circuit state between the HIGH ter-

• If is pressed, the unit enters sh ort circu it comp ensat ion inc orpora te

mode. (Proceed to Step 4. (page 33).) (T he settings for op en circuit compensation remain the same as last time.)

• Are the measu rement terminals open? O pen the measurement termin als

and then perform compensation again.

• If there is a compensation error even when the measurement terminals are

open, external noise may be affecting com pensation or the unit, probe, or

fixture may be ma lfunctioning. Use the s hielding process, su bmit the unit

or fixture for repairs, or replac e the probe w ith a new o ne. ( The p ro be c annot be repaired.)

6.2 "Measurement of High Impedance Components" (p. 87)

3

minal and LOW terminal of the probe or fixture connected to the measurement terminals.

Use a shorting bar with as low an impedance as possible.

• When performing compensation, the placement of things like the probe

and fixture and the dis tances between terminals must be as similar as

possible to the state when performing measurement.

• If you do not want to perform short circuit compensation, press to

return to normal measurement mode.

5. Press .

Incorporate the short circuit compensation values. (ALL Compensation)

• The SHORT LED flashes.

• The “Short A dJuSt” indic ation is displayed and the “AdJuSt” indication

flashes in the MAIN display area.

End of Compensation:

When compensation ends, the state becomes as follows.

• A beep tone sounds once

• The “Short En d” ind ication i s displ ayed i n the MAI N display area fo r one

second.

• The SHORT LED flashes.

The unit returns to normal measurement mode.

Compensation Error:

If there was a compensat ion error, the state becomes as follows.

• A warning beep tone sounds

• The “Short Error” indication is displayed in the MAIN display area.

Compensation stops.

Page 40

34

3.4 Measurement Conditions (Optional Settings)

What if there is an

error?

• If is pressed, the unit returns to normal measurem ent mode. (The

settings for short circuit compensation remain the same as last time.)

• Are the measur ement terminals in a short circuit state? S hort circuit the

measurement terminals and then perform compensation again.

• If there is a compensation error even when the measurement terminals are

short circuited, the unit, pr obe, or fixture may be malfunctioni ng. Use the

shielding process, submit the unit or fixture for repairs, or replace the probe

with a new one. (The probe cannot be repaired.)

Canceling Open Circuit Compensation and Closed Circuit Compensation

1. In normal mode, press for at least two seconds while op en circ uit

compensation and closed circuit compensation are in an ON state.

The state becomes as follows.

• The OPEN LED flashes.

• The “oP En oFF” indic ation is display ed and the “o FF” indication fl ashes

in the MAIN display area.

* State when the OPEN or SHORT LED is flashing.

• While open circuit compensation and closed c ircuit compens ation are i n

an OFF state, the unit w ill not enter cancel m ode even if you press and

hold for at least two seconds.

• If only short circuit compensation is in an ON state, the unit enters short

circuit compensation cancel mode. (Proceed to Step 3. (page 34)).

2. Press .

Open circuit compensation is set to OFF and the state becomes as follows.

• The OPEN LED goes out.

• The “oPEn CAnSEL” indication lights up in the MAIN display area for

one second.

• The SHORT LED flashes.

• The “S hort oFF” i ndication is displayed and the “o FF” indicat ion flashes

in the MAIN display area.

• If you do not want to cancel open circuit compensation, press to

enter short circuit compen satio n canc el mode . (Proceed to Step 3. (page

34).)

• If sho rt compensat ion mode i s OFF, the unit retu rns to no rmal measurement mode.

3. Press .

Page 41

35

3.4 Measurement Conditions (Optional Settings)

Short circuit compensation is set to OFF and the state becomes as follows.

• The SHORT LED goes out.

• The “Short CAnSEL” indication lights up in the MAIN display area for one

second.

The unit returns to normal measurement mode.

If you do not want to cancel short circuit co mpensatio n, press to return

to normal measurement mode

3

Page 42

36

3.4 Measurement Conditions (Optional Settings)

3.4.2 Load Compensation

Load compensation allows for the calculation of the compensation rate by

measuring a standard sample with known measurement values and compensating the measurement values .

This function c an be used for the following.

• When using multiple 3504 (3504-10) units, reduce the measurement errors

of individual 3504 (3504-10) units and match the measurement values.

• Match the meas urement values of the 3504 (3504- 10) unit to thos e of the

reference measure device.

The conditions tha t are currently set (frequency, level, range, equivalent circuit mode, open circuit compensation, and short circuit compensation) are

used as the measur ement conditions for load compensation. Changing the

measurement conditi ons while load compensation i n enabled results in load

compensation being disabled. (When this happens , the OFF LED of LOAD

flashes.)

If, however, the measurement cond iti on s ar e retur ne d t o w hat the y wer e du ring load compensation, then load compensation is resumed. (The ON LED of

LOAD lights up.)

The compensation rate is determined by first calculating the impedance Z

and phase angle θ from the reference values of the measurement conditions,

C, and D and the actua l measurement values and then using the following

formula for the calculation.

Z compensation rate = (Z reference value)/(Z actual value)

θ compensation rate = (θ reference value) − (θ actual value)

For the actual values of Z and θ, compe ns ation is per formed u sing the abov e

compensation rate and then C a nd D are cal culated fr om Z and θ after compensation.

When open circuit compensation and short circuit compensation are

enabled, load compe nsation pe rforms com pensatio n for Z and θ after open

circuit compensation and short circuit compensation are finished.

Perform open circuit co mpensation and short circuit compensati on before

you incorporate load compensation data.

Performing Load Compensation

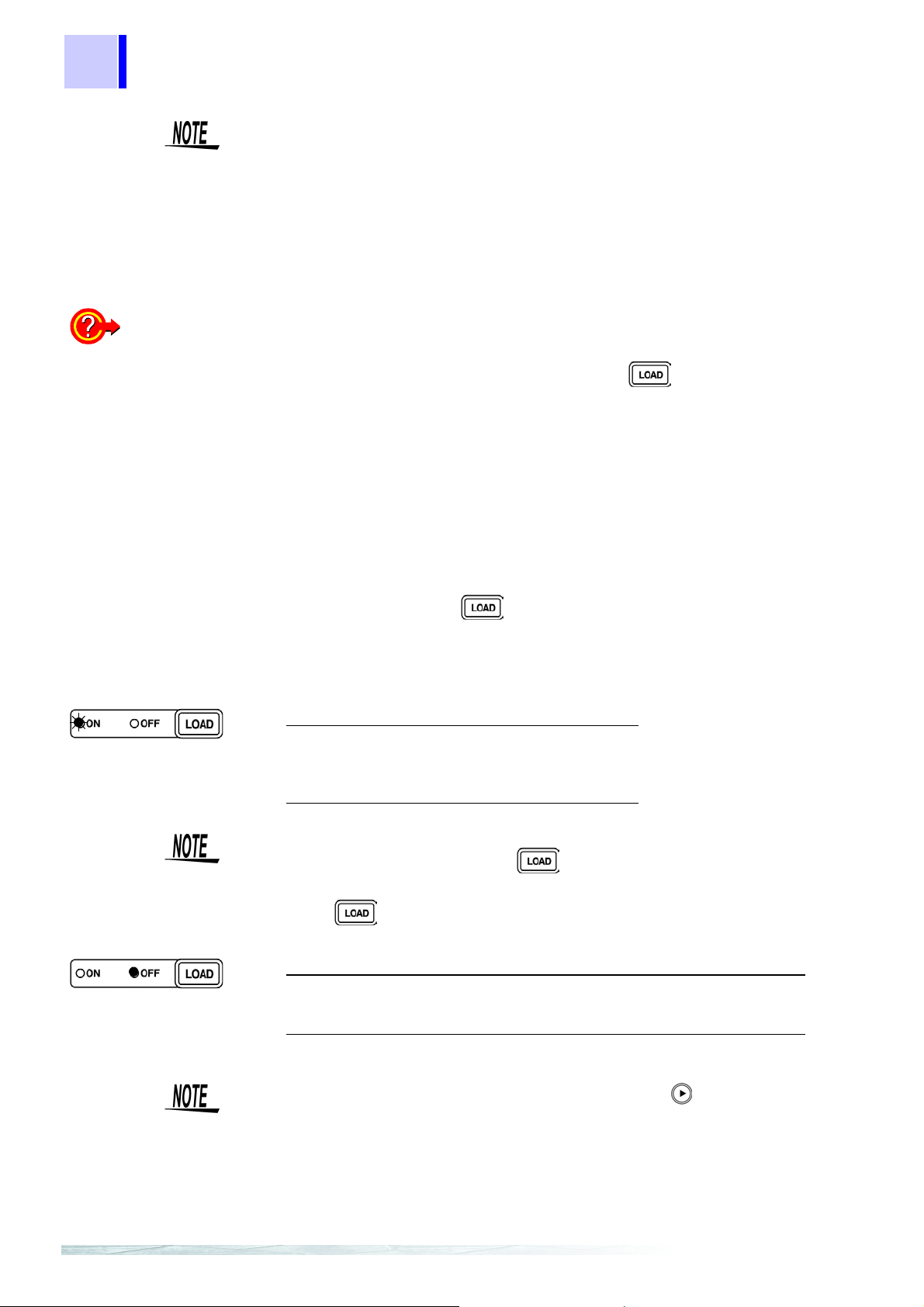

1. In normal measurement mode, press .

The state becomes as follows.

• The ON LED flashes.

Light up

• The “LoAd SEt” indication is displayed and the “SEt” indication flashes in

the MAIN display area.

• The COUNT and REF LEDs light up in the SUB display area.

• The reference values for C and D are displayed in the SUB display area.

• The LED on the far left of the C reference value flashes.

If you want to ex it the reference value input s creen and return to normal

measurement mode, press for at least two seconds.

Page 43

37

3.4 Measurement Conditions (Optional Settings)

2. Use the numeric keypad or arr ow keys to enter a reference valu e for C

and then press .

Use the numeric keypad to enter a number. (If you enter a number, each digit

moves one place to the right.) Settable Range: 1 to 999999

You can use and to move to the digit you want to change.

You can also use and to change the number set for a digit.

• If you do not want to ch ange the reference value of C, press

without changing the number. The reference va lue input screen for D is

displayed.

• Set count val ues for the reference values. The reference values at the

time of shipment are 100000 for C and 0 for D.

3. Use the numeric keypad or arr ow keys to enter a reference valu e for D

and then press .

3

Use the numeric keypad to enter a number. (If you enter a number, each digit

moves one place to the right.) Settable Range: 0 to 199000

You can use and to move to the digit you want to change.

You can also use and to change the number set for a digit.

The unit returns to the state of Step 1. (page 36).

• If there is no need to change the reference value of D, proceed to Step 4.

(page 37) without changing the number.

• If you want to exit the refer ence value input screen and return to normal

measurement mode, press for at least two seconds.

4. Press .

Incorporate the load compensation values.

• The ON LED flas hes.

• The “LoAd AdJuSt” indication is displayed and the “AdJuSt” indication flashes in the MAIN display area.

End of Compensation:

When compensation ends normally, the state becomes as follows.

• A beep tone sounds once.

• The “LoAd End” indication lights up in the MAIN display for one second.

• The ON LED lights up.

The unit returns to normal measurement mode.

Compensation Error:

If there was a compensat ion error, the state becomes as follows.

• A warning beep tone sounds

• The “LoAd Error” indication lights up in the MAIN display area.

Compensation stops.

Page 44

38

3.4 Measurement Conditions (Optional Settings)

The conditions that ar e cu rre n tly s et (f re que nc y, level, range, equivalent ci rcuit mode, open circu it compensation, and short circ uit compensation) are

used as the measur ement condit ions for load compensati on. Changing th e

measurement conditions while load compensation in enabled results in load

compensation being di sabled. (When th is happens, th e OFF LED of LOAD

flashes.)

If, however, the measurement conditions are returned to what they were

during load compe nsation, then load compensation is resumed. (The ON

LED of LOAD lights up.)

What if there is an

error?

• To return to normal measurement mode, press .

• If the value is o utside the mea surement r ange (under flow or over flow) or

the constant voltage is not output (C V erro r), a com pensa tion erro r is generated. Set an appropriate range and then perform compensation again.

Canceling Load Compensation

1. In normal mode, press for at least two seconds while load com-

pensation is in an ON state.

* State when the ON LED of LOAD is lit.

The state becomes as follows.

• The ON LED flashes.

• The “LoA d oFF” indication is dis played and the

“oFF” indication flashes in the MAIN display

area.

While load compensati on is in an OFF state, the unit will not enter cance l

mode even if you press and hold for at least two seconds.

2. Press .

Load compensation is set to OFF and the state becomes as follows.

• The “LoAd CAnSEL” indication lights up in the MAIN display area for one

second.

• The OFF LED lights up.

The unit returns to normal measurement mode.

If you do not want to cancel lo ad compensation , press to enter normal

measurement mode.

Page 45

3.4.3 Trigger Signal

The internal trigger or the external trigger can be set.

39

3.4 Measurement Conditions (Optional Settings)

When inputting the

trigger signal through the

interface

Trigger signal:

Press to change the mode.

INT

(Internal trigger

mode)

EXT

(External trigger mode)

Measurement starts when a "*TRG" comman d is received through the interface.

INT, EXT

• Continuous measurement is performed while automatically generating an internal trigger signal.

The INT LED flashes.

•

• A trigger signal is input from the outside either manually or automatically.

• The EXT LED lights up.

• Manual setting:

Press to perform measurement once.

• Measurement is performed with a trigger from the

EXT I/O connector TRIG terminal.

For details on i nputting the trigger signal through the interface, refer to

"Sampling Request" (page 130) of 7.9, "Message Reference".

3

When inputting the

trigger signal through the

EXT I/O connector

When a negative-log ic pulse signal is input to TRIG (pin 1) of the EXT I/O

connector on the rear panel, one measurement operation is performed.

6.1 "Measurement Using EXT I/O" (p. 81)

Page 46

40

3.4 Measurement Conditions (Optional Settings)

Page 47

4.1 Comparator Function

Application

Functions Chapter 4

4.1 Comparator Function

This function enables you to set the upper limit and lower limit values for each

of C and D, and then ind icates the judgment re sult with HI, IN, or LO in t he

comparator judgment result display area.

The judgment result enables you to determine whether the sample has

passed or failed.

41

4

The corresponding si gnal is also output from the EXT.I/O conn ector on the

rear of the unit.

There are two judgment modes for comparator measurement: the count

value setting and deviation percent (

• Count Value Setting

Set count values for the uppe r limit and lowe r limit value s of the measurement parameters. The values of measurement parameters are display ed

unchanged as the measurement values.

• Deviation Percent (Δ%) Setting

•Enter reference values and then set percentages corresponding to the

reference values as the upper limit and lower limit values. The differences from referenc e values (C:

surement values.

•When

If the power is turned off while the unit is in comparator me asurement mod e,

the unit will be in comparator measurement mode when the unit is turned

back on again.

Δ% is set, the displayed results are calculated with C as Δ

%=(measurement v alue – referen ce v alue)/| referenc e va lue| × 100 a nd

D as

Δ=(measurement value – reference value).

Δ%) setting.

Δ%, D: Δ) are displayed as th e mea-

• Set the upper limit and lower limi t values o f any param eter that does not

require a comparator judg ment to be made to OFF s o that judgm ent will

not be performed.

• The measurem ent conditions for normal meas urement mode are inherited as is for the measu rement conditions when the comparator is e xecuted. However, the AUTO range is automatically set to the HOLD range.

Page 48

42

4.1 Comparator Function

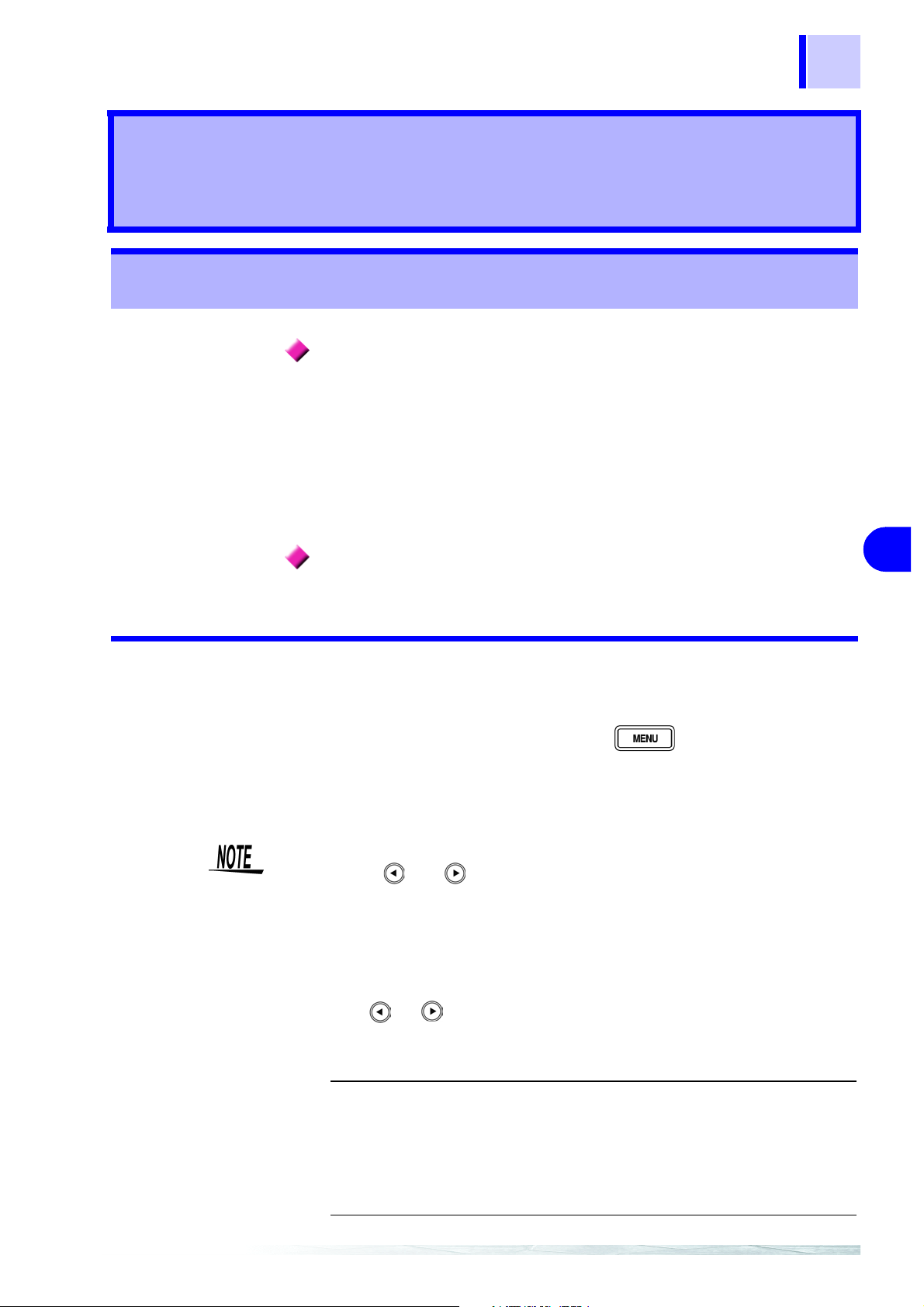

Setting Judgment Mode

First, set the judgment mode. (Sele ct the count value setting or the deviatio n

percent [

The judgment modes are the same for both the comparator and BIN.

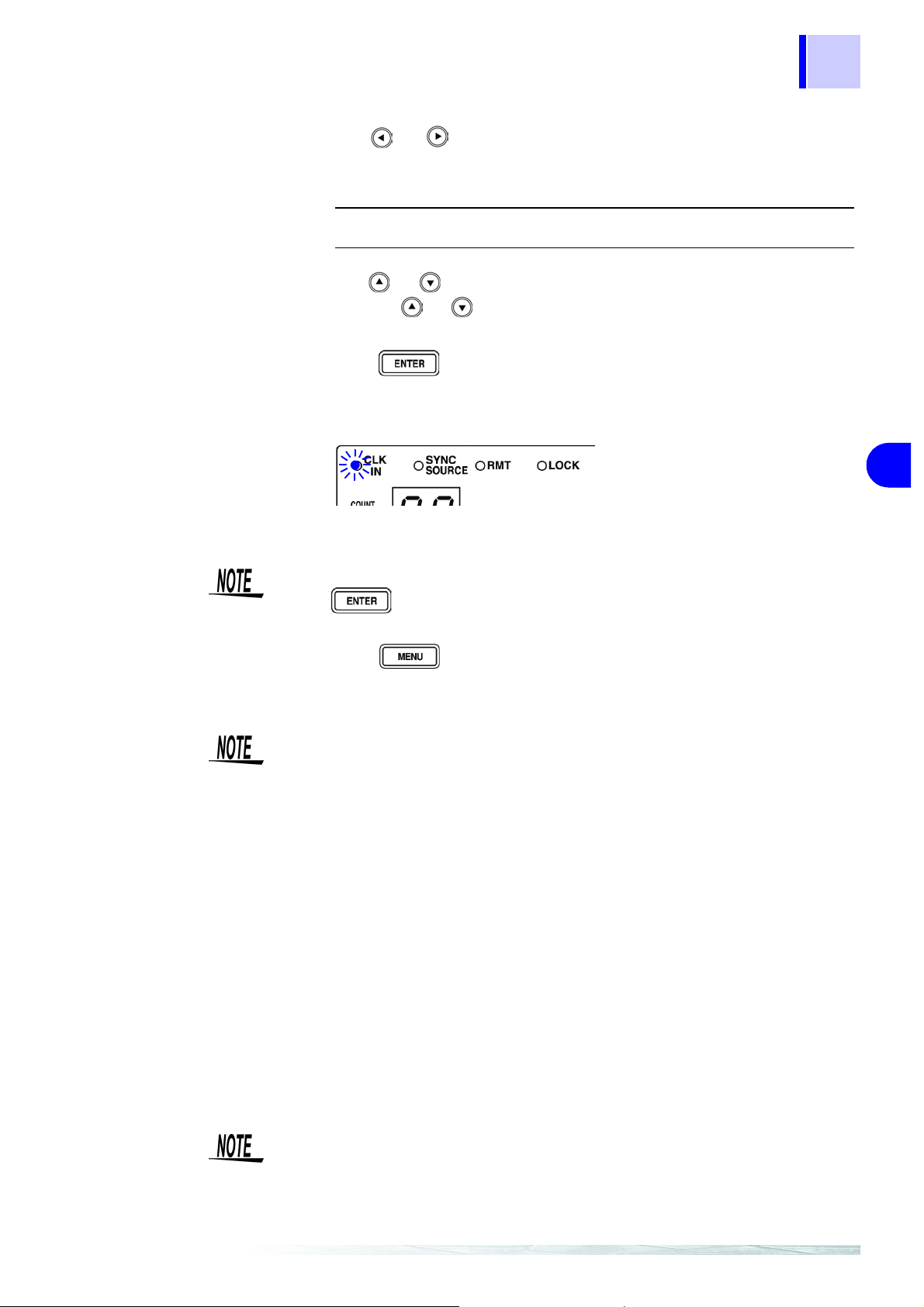

1. In normal measurement mode, press .

The menu items are displ ayed at the to p of the MAIN displ ay area and th e

setting items are displayed at the bottom of the MAIN display ar ea.

• This setting cannot be changed in comparator mode and BIN mode.

• Use and to move through the menu items as follows.

Δ%] setting.)

“LoAd_A(C/h)” ÅÆ “SAVE” ÅÆ “Ld_tYP” ÅÆ “JudGE ” ÅÆ “bEEP_ J”

ÅÆ “bEEP_K” ÅÆ “CLK” (only for special specifica tions) ÅÆ “SYnC”

ÅÆ “IF.GPib(rS/Prnt)” ÅÆ “LoAd_A(C/h)” ÅÆ …

2. Use or to select the “JudGE” menu item. ( Judgment mode set-

ting screen)

The setting items are as follows.

“Count”: Count setting

“d-PAr”: Deviation percent (

Δ%) setting

3. Use or to select a setting item.

Pressing or switches between “Count” ÅÆ “d-PAr.”

4. Press .

The judgment mode is confirmed

After confirmation, “bEEP_J” is displayed at the top of the MAIN display area.

(Beep setting screen for judgment result)

The judgment mode is not confirmed unless is pressed.

5. Press .

The unit returns to normal measurement mode.

Page 49

4.1 Comparator Function

• Num eric

s

• Num eric

s

• Num eric

s

• Num eric

s

• Num eric

s

• Num eric

s

Setting the Upper Limit and Lower Limit Values for the Comparator

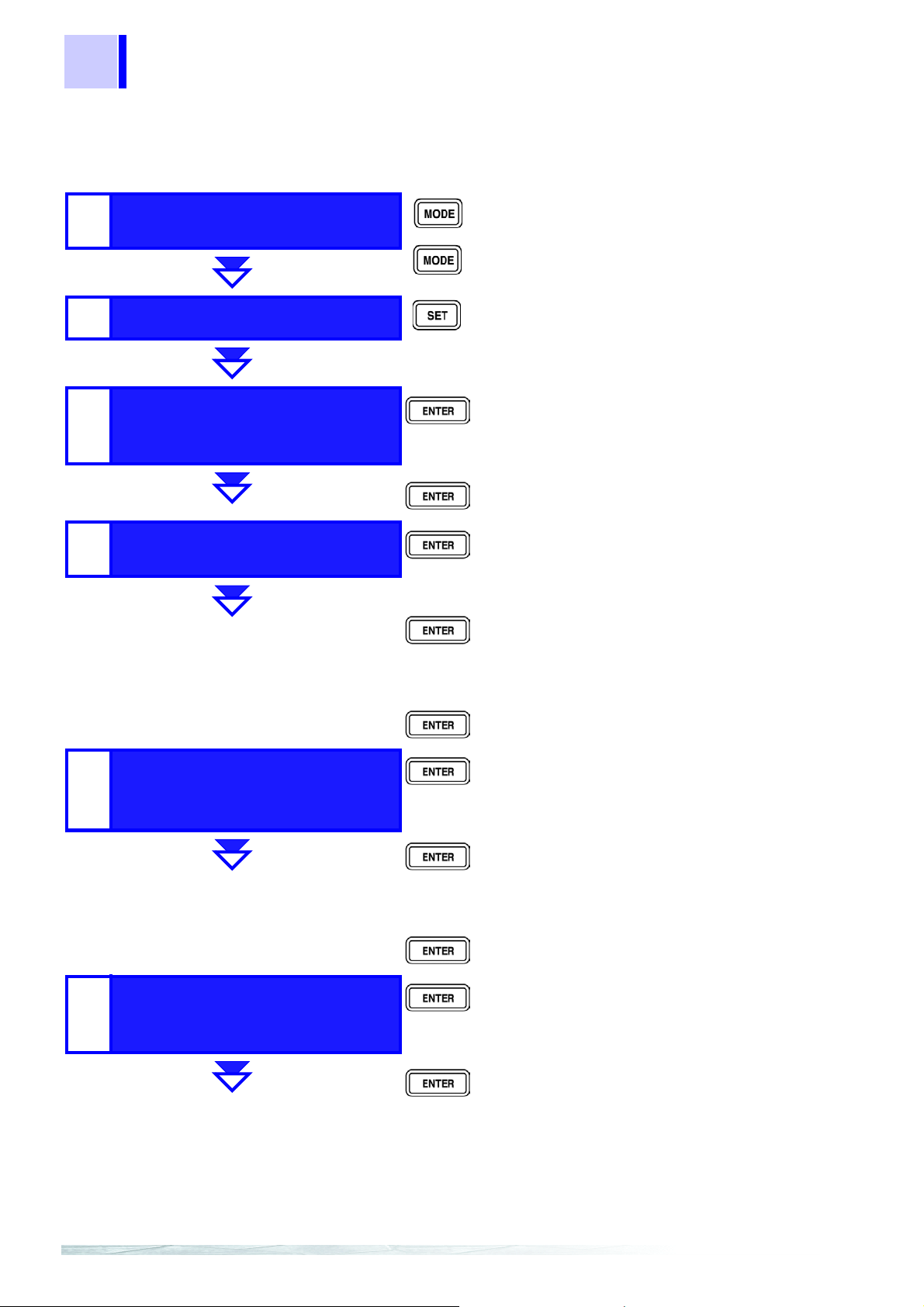

Setting Workflow

43

Normal measurement

1

mode

Comparator measurem ent

2

3

mode

C setting

Reference value setting for

4

(Only for the Δ% setting)

C

Upper limit and lower limit

5

value settings for C

keypad

• Arrow key

keypad

• Arrow key

Switch to comparator measurement mode.

The range is automatically set to HOLD.

Switch to the setting mode for the upper limit

and lower limit values.

Confirm C.

Move to the next setting.

Set the reference value for C.

Move to the next setting.

Set the upper limit value for C.

Confirm the upper limit value.

4

6

D setting

Reference value setting for

7

(Only for the Δ% setting)

D

Upper limit and lower limit

8

value settings for D

keypad

• Arrow key

keypad

• Arrow key

keypad

• Arrow key

keypad

• Arrow key

Set the lower limit value for C.

Confirm the lower limit valu e.

Move to the next setting.

Select D.

Confirm D.

Move to the next setting.

Set the reference value for D.

Move to the next setting.

Set the upper limit value for D.

Confirm the upper limit value.

Set the lower limit value for D.

Confirm the lower limit valu e.

Page 50

44

4.1 Comparator Function

Setting Procedure

1. Use to switch to the comparator measurement mode and press

.

The state becomes as follows.

• The COMP LED flashes.

• The “C” indication at the top of the SUB display area flashes.

• For the

• For the count setting: The COUNT, HI, and LO LEDs light up.

• When the “C” or “D” indication is flashing at the top of the SUB display

area, you can configur e the setti ngs in any order if yo u us e or to

Δ% setting: The Δ% and REF LEDs light up.

(Only for the

(Only for the

2.

Δ% setting)

3. Use the numeric keypad or arrow keys to enter a reference value for

Δ% setting)

change the setting mode as follows and then press .

C Reference Value (only for the

Lower Lim it Values ÅÆ D Reference Value (only for the

D Upper Limit and Lower Limit Values ÅÆ C Reference Value …

• For the count setting, proceed to Step 5. (page 45).

Press to confirm C.

The unit switches to th e s ett ing mo de for th e C refer en ce va lu e a nd t he state

becomes as follows.

• The “C” indication at the top of the SUB display area flashes.

• The LED on the far left of the C reference value flashes.

• The C reference val ue index number at the bottom of the SUB dis play

area lights up.

C.

Use the numeric keypad to enter a number. (If you enter a number, each digit

moves one place to the right.) Settable Range: 1 to 999999

You can use and to move to the digit you want to change.

You can also use and to change the number set for a digit.

Set a count value for the reference value. At the time of shipment, the

reference value for C is 100000.

Δ% setting) ÅÆ C Upper Limit and

Δ% setting) ÅÆ

(Only for the

4.

Δ% setting)

Press to confirm the C reference value.

The state becomes as follows.

• The “C” indication at the top of the SUB display area flashes.

• The HI and LO LEDs light up.

The reference value entered this time is not confirmed unless

is pressed. The re ference value used last time becomes valid.

Page 51

Light up

45

4.1 Comparator Function

5. Press to confirm C.

The unit switches to the setting mode for the C upper limi t value and the

state becomes as follows.

• The HI and LO LEDs light up.

• The “C” indication at the top of the SUB display area lights up.

• The LED on the far left of the C upper limit value of the SUB display area

flashes.

6. Use the numeric keypad or arrow keys to enter an upper limit val ue for

C and then press .

Lights up

The C upper limit value is confirmed and the unit switches to the setting

mode for the C lower limit value.The state becomes as follows.

The LED on the far left of the C lower limit value of the SUB display area

flashes.

The settable ranges for the C upper limit and lower limit values are as follows.

• For the

• For the count setting: OFF/0 to 999999

Δ% setting: OFF/−999.99 to 999.99

7. Use the numeric keypad or arrow keys to enter a lower limit value for

C and then press .

(Only for the Δ% setting)

The C lower limit value is confirmed and the state becomes as follows.

• The “d” indication at the top of the SUB display area flashes.

• The REF LED lights up.

4

For the count sett ing, proceed to Step 10. (page 46).

Page 52

46

4.1 Comparator Function

8. Press to confirm “d”.

(Only for the

(Only for the

Δ% setting)

The unit switches to the setting mode for the D reference value and the

state becomes as follows.

• The “d” indication at the top of the SUB display area lights up.

• The LED on the far left of the D reference value flashes.

9. Use the numeric keyp ad or arrow keys to ent er a ref eren ce value f or D

and then press .

Δ% setting)

The D reference value is confirmed and the state becomes as follows.

• The “d” indication at the top of the SUB display area flashes.

• The HI and LO LEDs light up.

Settable range: 0 to 199000

Set a count value for the reference value. At the time of shipment, the

reference value for D is 0.

Light up

10. Press to confirm “d”.

The unit switches to the setting mode for the D upper limit value and the

state becomes as follows.

• The HI and LO LEDs light up.

• The “d” indication at the top of the SUB display area lights up.

• The LED on the far left of the D upper limit value of the SUB display area

flashes.

11. Use the numeric keypad or arrow keys to enter an upper limit value for

D and then press .

The D upper limit value is confirmed and the unit switches to the setting mode

for the D lower limit value.

The state becomes as follows.

The LED on the far left of the D lower limit value of the SUB display area

flashes.

The settable ranges for the D upper limit and lower limit values are as follows.

• For the Δ% setting: OFF/−199000 to 199000

• For the count setting: OFF/0 to 199000

Page 53

47

4.1 Comparator Function

12. Use the numeric keypad or arrow keys to enter a lower limit value for

D and then press .

The D lower limit value is confirmed and the state becomes as follows.

• The COMP LED flashes.

• The “C” indication at the top of the SUB display area flashes.

• For the

• For the count setting: The COUNT, HI, and LO LEDs light up.

Δ% setting: The Δ% and REF LEDs light up.

13. Press .

4

The unit switches to the comparator measurement mode. (The COMP

LED lights up.)

• The upper li mit and lo wer limit v alues for the count setting an d the refe rence value for the

pendent of the measureme nt conditions. If the measurement c onditions

differ, the absolute values that signify the count values change.

• The measurement conditions for normal measurement mode are used for

the comparator measurem ent mode. Set the measurement conditions to

use for comparator measu rement mode whil e the unit is in normal measurement mode.

• The comparator judgment is performed in the following order.

1.When the measurement value is “– – – – – –”: HI is displayed

When the measurement value is “OF”: HI is displayed

When the measurement value is “UF”: LO is displayed

2.The unit judges whether or not the measurement value is large r than

the lower limit value a nd then displays LO if it is not.

3.The unit judges whether or not the meas ureme nt valu e is smalle r than

the upper limit value and then displays HI if it is not.

4.IN is displayed if the conditions of 2 and 3 are satisfied.

• The large/small judgment for th e upper limit and l ower limit valu es is not

performed. An error i s no t g ener at ed if the upper limit and l ower li mit v alues are set in reverse, but the judgment cannot be performed properly.

Δ% setting become display count values that are inde-

Page 54

48

4.1 Comparator Function

Setting the Upper Limit and Lower Limit Values to OFF

1. When entering the upper limit and lower limit values, use to move

left until the far left digit flashes and then press and hold for at

least two seconds or use to move right until the far right digit

flashes and then press and hold for at least two seconds.

The display changes t o “– – – – – –” and OFF is set.

2. Press to confirm the OFF setting.

3. Press .

The unit switches to comparator measurement mode. (The COMP LED lights

up)

Canceling Comparator Measurement Mode

In comparator measurement mode, press twice.

The measurement mode LEDs light in the order of COMP Æ BIN (only for

3504) Æ NORM, and then the unit switches to normal measurement mode.

Performing Comparator Measurement

Follow the procedure below to perform comparator measurement.

In normal measurement mode, press

The state becomes as follows (comparator measurement mode).

• The COMP LED lights up.

• For the deviation percent setting:

The

Δ% and REF or HI and LO LEDs light up.

The comparator setting state is displayed in the SUB display area.

• For the count setting:

COUNT, HI, and LO LEDs light up.

The comparator setting state is displayed in the SUB display area.

• You can use and to change the indications in the SUB display

area.

• C Reference Value (only for the

Lower Lim it Values ÅÆ D Reference Value (only for the

D Upper Limit and Lower Limit Values ÅÆ C Reference Value …

• The measurement range is automatically set to HOLD.

Δ% setting) ÅÆ C Upper Limit and

Δ% setting) ÅÆ

Page 55