Page 1

INSTRUCTION MANUAL

3460-50

2D THERMO HiTESTER

Page 2

Page 3

Contents

Introduction

Inspection

Safety Notes

Notes on Use

Chapter 1 Summary

1.1 Product Summary 1

1.2 Characteristic

1.3 Names of Parts

1.4 Switches and Controls

Chapter 2 Prior to Use 11

Chapter 3 Making Measurements

3.1 Measurement Screen 17

3.2 Measurement

3.3 Storage Image and Temperature Data

3.3.1 Measurement with Record Button 24

3.3.2 Logging Recording

3.3.3 Storage File

3.3.4 CSV File Data

3.4 View Saved Images 27

17

20

24

24

25

26

Chapter 4 Setting 29

4.1 Measurement Condition Setting

(PRESET)

4.2 Clock

4.2.1 Set DATE/TIME (clock date and time) 32

30

31

i

i

ii

v

1

2

3

8

Page 4

4.2.2 DISPLAY STYLE (display pattern) 32

4.2.3 Set AUTO POWER OFF

32

4.3 Automatic Data Recording (Logging)

Measurement (AUTO MODE)

4.4 Color Scale

33

35

Chapter 5Transfer Function 37

5.1 Interface Specifications 37

5.2 Connection

5.3 Transmission Data Format

5.3.1 Temperature Measurement Data 39

5.3.2 Data Timing

38

39

40

5.4 Temperature Measurement Result

Sequence and Measurement Location

41

Chapter 6 Specification 43

6.1 Product Specification 43

6.2 Measurement Range

46

Chapter 7 Maintenance and Service 49

7.1 Troubleshooting 49

7.2 Maintenance

7.3 Emissivity Table

7.4 Questions and Answers about

Measurement

51

52

53

Page 5

―――――――――――――――――――――――――――

Introduction

Thank you for purchasing the HIOKI "3460-50 2D

THERMO HiTESTER". To obtain maximum

performance from the product, please read this

manual first, and keep it handy for future reference.

Request

We have tried to bring this manual as close to

perfection as we could achieve. If perchance you

find any unclear portions, mistakes, omissions, or the

like, we would be most obliged if you could please

notify us of them via any Hioki agent, or directly.

Inspection

When you receive the product, inspect it carefully to

ensure that no damage occurred during shipping. If

damage is evident, or if it fails to operate according

to the specifications, contact your dealer or Hioki

representative.

Before using the product the first time, verify that it

operates normally to ensure that the no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

Accessories supplied

Check the Supplied Accessories

Strap 1

LR6 (AA) alkaline batteries 6

Compact Flash Card (16 MB) 1

Instruction Manual 1

――――――――――――――――――――――――

Introduction

i

Page 6

ii

―――――――――――――――――――――――――――

Safety Notes

CAUTION

Incorrect measurement procedures could result in

injury or death, as well as damage to the equipment.

Please read this manual carefully and be sure that

you understand its contents before using the

equipment. The manufacturer claims no liability for

any damage caused by this system except for

damage resulting from a defect in the system itself.

This manual contains information and warnings

essential for safe operation of the product and for

maintaining it in safe operating condition. Before

using the product, be sure to carefully read the

following safety notes.

Safety symbols

In the manual, the symbol indicates

particularly important information that the

user should read before using the

product.

Indicates DC (Direct Current).

――――――――――――――――――――――――

Safety Notes

Page 7

―――――――――――――――――――――――――――

iii

The following symbols in this manual indicate the

relative importance of cautions and warnings.

Indicates that incorrect operation

WARN ING

presents a significant hazard that could

result in serious injury or death to the

user.

Indicates that incorrect operation

CAUTION

presents a possibility of injury to the

user or damage to the product.

NOTE

Advisory items related to performance

or correct operation of the product.

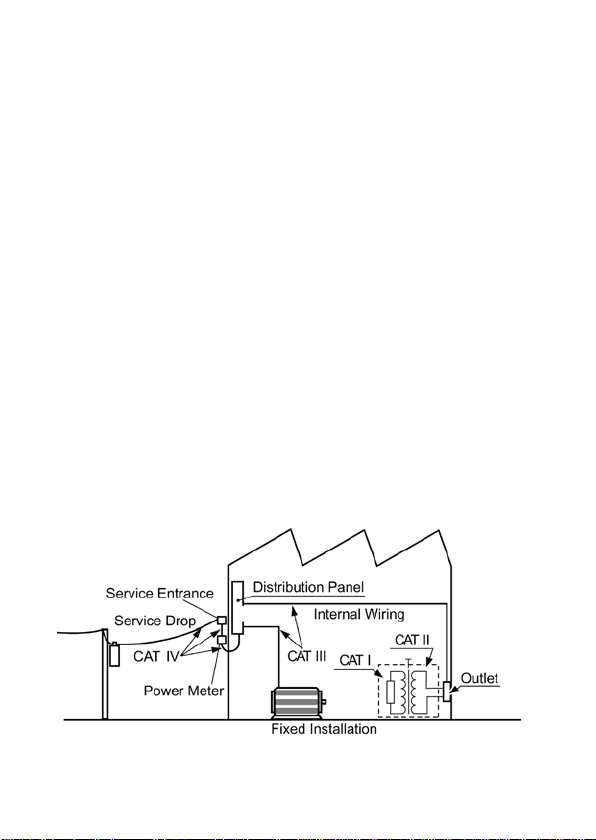

Measurement categories (Overvoltage

categories)

To ensure safe operation of measurementproducts,

IEC 61010 establishes safety standards for various

electrical environments, categorized as CAT I to

CAT IV, and called measurement categories. These

are defined as follows.

CAT I: Secondary electrical circuits connected to an

AC electrical outlet through a transformer or

similar device.

CAT II: Primary electrical circuits in equipment

connected to an AC electrical outlet by a

power cord (portable tools, household

appliances, etc.)

CAT III: Primary electrical circuits of heavy

――――――――――――――――――――――――

Safety Notes

Page 8

iv

―――――――――――――――――――――――――――

equipment (fixed installations) connected

directly to the distribution panel, and feeders

from the distribution panel to outlets.

CAT IV: The circuit from the service drop to the

service entrance, and to the power meter and

primary overcurrent protection device

(distribution panel).

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III

environments can endure greater momentary energy

than a device designed for CAT II.

Using a measurement product in an environment

designated with a higher-numbered category than

that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Never use a CAT I measuring product in CAT II,

III, or IV environments.

The measurement categories comply with the

Overvoltage Categories of the IEC60664 Standards.

――――――――――――――――――――――――

Safety Notes

Page 9

―――――――――――――――――――――――――――

Notes on Use

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various

functions.

WARNING

Do not use the product where it may be

exposed to corrosive or combustible gases.

The product may be damaged or cause an

explosion.

To avoid electric shock, do not allow the

product to get wet, and do not use it when your

hands are wet.

CAUTION

To avoid system damage and malfunction by

making sure that the object to be measured does

not touch the system.

Do not touch the lens with a hard object, apply

undue pressure to the lens, or insert a foreign

substance in the unit. These actions will cause

system damage or malfunction.

Do not point the lens at the sun or at any other

source of strong light. If you do, the sensor may

be damaged.

Do not touch the LCD screen surface, since doing

so may cause erroneous display or distortion.

v

――――――――――――――――――――――――

Notes on Use

Page 10

vi

―――――――――――――――――――――――――――

CAUTION

To avoid damage to the product, protect it from

vibration or shock during transport and handling,

and be especially careful to avoid dropping.

Do not store or use the product where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions,

the product may be damaged and insulation may

deteriorate so that it no longer meets

specifications.

This product is designed for indoor use, and

operates reliably from 0

to 40 .

This product is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a

wet or dusty environment.

Do not use the product near a device that

generates a strong electromagnetic field or

electrostatic charge, as these may cause

erroneous measurements.

If the protective functions of the product are

damaged, either remove it from service or mark it

clearly so that others do not use it inadvertently.

Do not disassemble or modify the system, since

doing so may prevent the system from satisfying

the specifications.

――――――――――――――――――――――――

Notes on Use

Page 11

―――――――――――――――――――――――――――

NOTE

Accurate measurement may be impossible in the

presence of strong magnetic fields, such as near

vii

transformers and high-current conductors, or in the

presence of strong electromagnetic fields such as

near radio transmitters.

If the set emissivity differs from the emissivity of

the object, a measurement error may result.

To avoid corrosion from battery leakage, remove

the batteries from the product if it is to be stored

for a long time.

To avoid problems with battery operation, remove

the batteries from the product if it is to be stored

for a long time.

――――――――――――――――――――――――

Notes on Use

Page 12

viii

―――――――――――――――――――――――――――

――――――――――――――――――――――――

Notes on Use

Page 13

―――――――――――――――――――――――――――

Chapter 1

Summary

1.1 Product Summary

1. Theory of Measurement

Every object emits infrared energy in accordance

with its temperature. By measuring the amount of

this radiant energy, it is possible to determine the

temperature of the emitting object.

2. About infrared

Infrared radiation is a form of light (electromagnetic

radiation), and has the property that it passes easily

through air, while it is easily absorbed by solid

matter.

With 3460-50 2D THERMO HiTESTER, accurate

measurement is possible, irrespective of the air

temperature or the measurement distance.

3. Emission Thermometer Structure

Infrared radiation which has been emitted from the

object is focused upon an infrared radiation sensor,

via an optical system which includes a lens which is

transparent to infrared radiation, an 8μm cuton

filter, etc..

1

The output signal from the infrared radiation sensor

is input to an electronic circuit along with the

output signal from a standard temperature sensor.

――――――――――――――――――――――――

Chapter 1 Summary

Page 14

2

―――――――――――――――――――――――――――

The electronic circuit calculates the object

temperature while applying standard temperature

compensation, thermal emissivity compensation,

etc., and displays the result.

1.2 Characteristic

Measures two-dimensional temperature using the

thermopile array (8 x 8 elements)

Equipped with a 3.8-inch color LCD

Built-in CMOS camera enables simultaneous display

of temperature image and optical image on a screen.

Compact and lightweight

Data stored on a compact flash card

The temperature alarm helps detect abnormal

temperatures.

Provided with an NTSC video terminal; images can

be recorded on a video recorder (video cable

available as an option).

Logging function and alarm function are available.

Temperatures can be recorded, monitored, and

alarms sent by connecting to a PC and creating a

program. (Interface cable is supplied separately.)

――――――――――――――――――――――――

Chapter 1 Summary

Page 15

―――――――――――――――――――――――――――

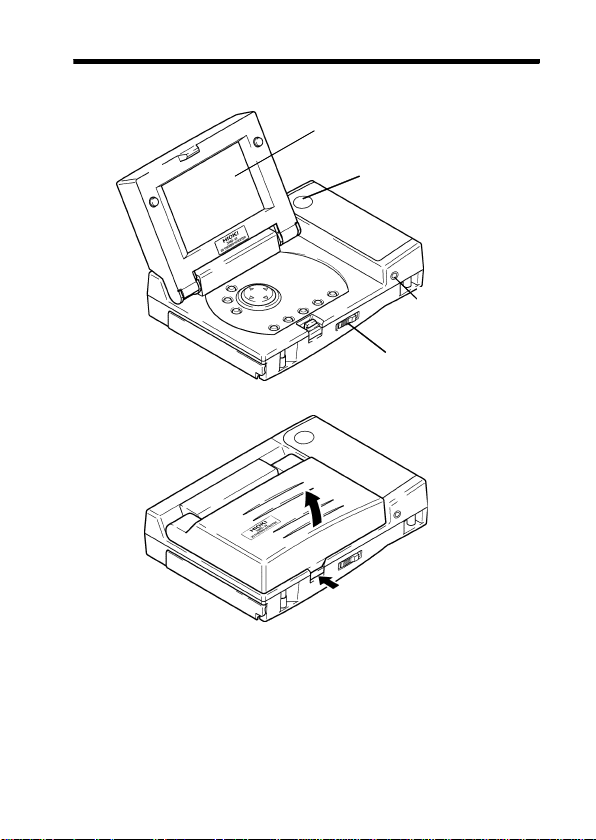

1.3 Names of Parts

Whole

LCD display

REC button

Power switch

Push and open

Interface

terminal

3

――――――――――――――――――――――――

Chapter 1 Summary

Page 16

4

―――――――――――――――――――――――――――

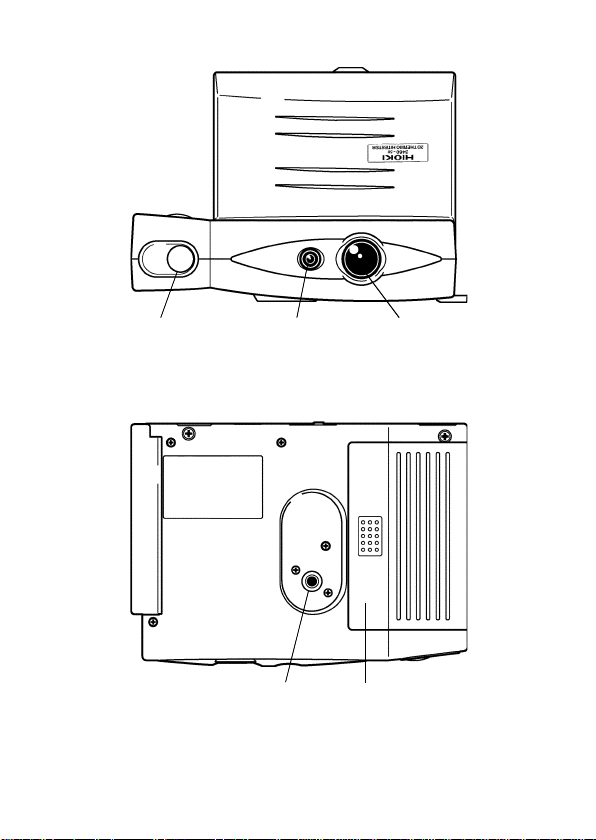

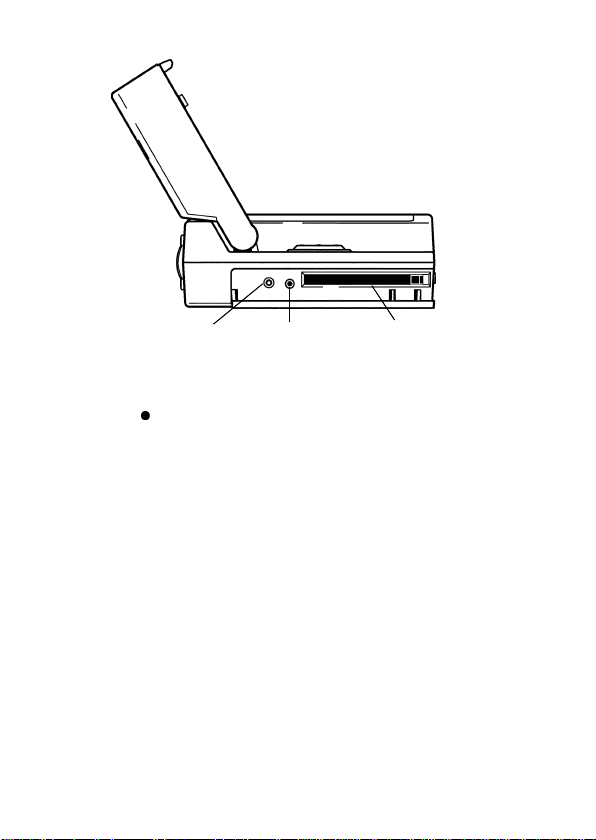

Front

Measurement/

hold button (HOLD)

Bottom

――――――――――――――――――――――――

Chapter 1 Summary

Visible camera lens Infrared lens

Screw hole for

camera tripod

Battery cover

Page 17

―――――――――――――――――――――――――――

Side

5

Exclusive use

AC adapter

input terminal

Video Output

Terminal

Compact flash card

slot

[Video Output Terminal]

The terminal outputs the same video signals as those

output to the LCD screen. To view the images on a

TV, use the optional cable to connect this terminal

to the TV monitor input terminal. The video image

size is 1/4 of a full screen.

The cable and AC adapter are included within the

3915 OPTION PACK.

Make sure the power is turned off before connecting

or disconnecting the AC adapter.

――――――――――――――――――――――――

Chapter 1 Summary

Page 18

6

―――――――――――――――――――――――――――

WARNING

To avoid damage, turn the product off before

connecting the AC adapter to the product and

to AC power.

Use only the AC adapter supplied with Model

3915 OPTION PACK. AC adapter input voltage

range is 100 to 240 VAC (with 10% stability) at

50/60 Hz. To avoid electrical hazards and

damage to the product, do not apply voltage

outside of this range.

Make sure the power is turned off before

connecting or disconnecting the AC adapter.

NOTE

To ensure proper system operation, do not use the

AC adapter with an unstable power supply. In

particular, be careful about the mixing-in of impulse

components.

――――――――――――――――――――――――

Chapter 1 Summary

Page 19

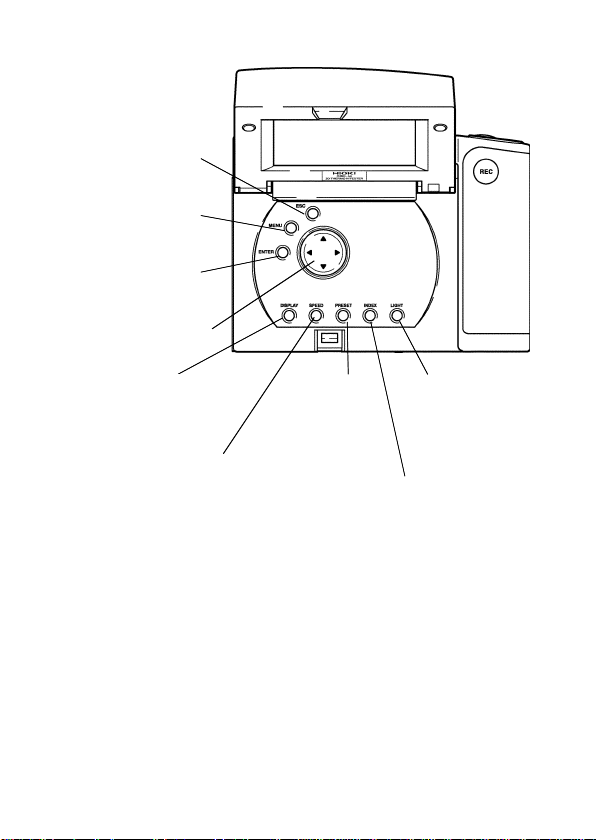

―――――――――――――――――――――――――――

LCD display,

operation panel

Cancel Button

(ESC)

Menu Button

(MENU)

Input Button

(ENTER)

Cursor Button

7

Display Selector

Button (DISPLAY)

Measurement Speed

Selector Button

(SPEED)

Measurement

Condition

Selector Button

(PRESET)

――――――――――――――――――――――――

Backlight

Brightness

Setting Button

(LIGHT)

Index Display Button

(INDEX)

Chapter 1 Summary

Page 20

8

―――――――――――――――――――――――――――

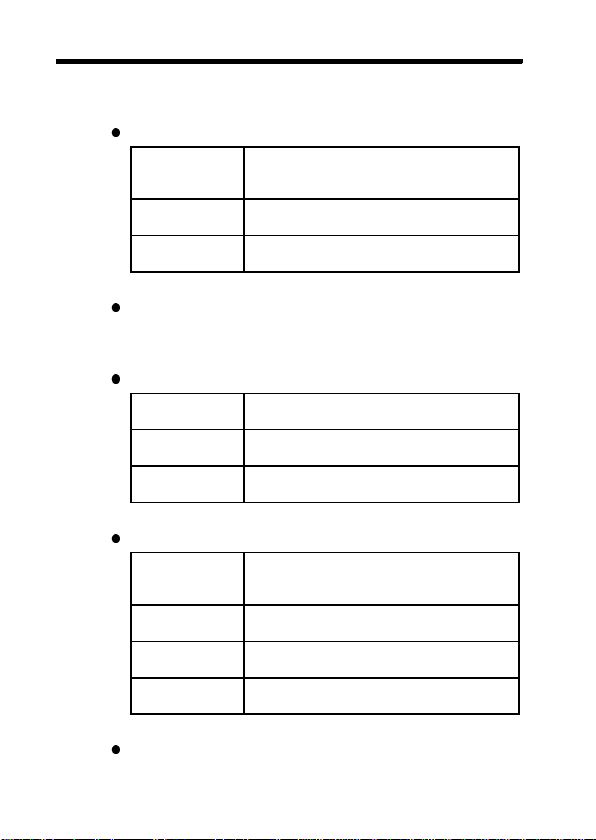

1.4 Switches and Controls

Input Button (ENTER)

During

Measurement/

Hold

During

Menu Screen

During

Index Screen

Menu Button (MENU)

Displays the menu for option settings.

Cancel Button (ESC)

During

Menu Screen

During

Setting Screen

During

Index Screen

Cursor Button

During

Measurement/

Hold

During

Menu Screen

During

Setting Screen

During

Index Screen

Set distance to object. (see page 22)

Use the cursor button to enter the

setting screen of the menu option.

Displays full-screen the image data

selected with the cursor button.

Returns to the measurement mode.

Returns to the menu screen with

confirming the setting.

Deletes the image data selected with

the cursor.

Use the cursor button to choose a

measurement point for which

numeric data must be displayed.

Use this screen to choose a setting

option.

Use this screen to choose an option

or edit the setting.

Selects image data.

Display Selector Button (DISPLAY)

Chooses a display mode (see page 21).

――――――――――――――――――――――――

Chapter 1 Summary

Page 21

―――――――――――――――――――――――――――

Measurement Speed Selector Button (SPEED)

Chooses a temperature measurement speed.

The resolution for high speed measurement is 1

NORMAL Display resolution is 0.1 . You can

FAST Display resolution is 1 .Moving

select a function that displays a

moving average for 10 data points,

or approx. 2 seconds of

measurements.

average is not available.

.

Measurement Condition Selector Button

(PRESET)

Selects a set of preset measurement conditions

including emissivity, scale, and alarm. The settings

for each preset are edited in the PRESET setting

screen. To go to the setting screen, enter the setting

mode (SETTING) and select the measurement

condition (PRESET) in the menu.

Index Display Button (INDEX)

Enters the index display mode and displays a list of

recorded image data.

Backlight Brightness Setting Button (LIGHT)

Adjusts the brightness of the LCD backlight (4

adjustable levels from no light to maximum

brightness).

When brightness is set to maximum, if no key

operation occurs for approximately 10 seconds,

brightness is automatically reduced to intermediate

or minimum settings (depending on the power

9

――――――――――――――――――――――――

Chapter 1 Summary

Page 22

10

―――――――――――――――――――――――――――

supply conditions).

Brightness cannot be set to the maximum setting

when the battery indicator indicates "Replace."

During automatic data recording, brightness is set to

the minimum setting.

Hold Button (HOLD)

The image is held on the LCD by pressing hold

button. (See page 4)

Record Button (REC)

Save the temperature data to the compact flash card.

(See page 3 and 24)

――――――――――――――――――――――――

Chapter 1 Summary

Page 23

―――――――――――――――――――――――――――

11

Chapter 2

Prior to Use

Prior to operating the thermometer, carry out the

following:

1. Attaching the strap

Attach the strap to the instrument to help prevent its

being dropped.

2. Loading the battery

Place the battery correctly in the battery box at the

back of main body.

For loading the battery, see page 14 "5. Battery

replacement".

3. Setting the date and time

When using the unit after replacement of the

battery, set the date and time. (See page 31)

――――――――――――――――――――――――

Chapter 2 Prior to Use

Page 24

12

―――――――――――――――――――――――――――

4. Installation of Compact Flash Card

CAUTION

Inserting a compact flash card upside down,

backwards or in the wrong direction may damage

the product.

Open the cover on the side of the system and insert the

compact flash card into the slot. Make sure that the

card faces in the correct direction and is fully inserted.

Compact Flash Card

The card stores image data and transfers data to a PC and

PDA (personal digital assistant) without special software.

Image: JPEG format

Measurement: CSV format

The system supports an 16-1 GB compact flash

cards ranging from 16 to 1 GB.

――――――――――――――――――――――――

Chapter 2 Prior to Use

Page 25

―――――――――――――――――――――――――――

WARNING

13

Use only PC Cards (Compact flash cards) sold by

HIOKI. Compatibility and performance are not

guaranteed for PC cards (Compact flash cards)

made by other manufacturers. You may be unable

to read from or save data to such cards.

Hioki options PC cards (includes adapter)

9726 PC CARD 128M, 9727 PC CARD 256M

9728 PC CARD 512M, 9729 PC CARD 1G

NOTE

An adapter is required to use a compact flash card

in the PC card slot of a PC.

To avoid data save or read errors, do not remove

the card when data is being saved or read. The

card can be inserted or removed at any time unless

data is being saved or read.

――――――――――――――――――――――――

Chapter 2 Prior to Use

Page 26

14

―――――――――――――――――――――――――――

5. Battery replacement

WARNING

To avoid electric shock, turn off the power

switch and disconnect the connection cables

before replacing the batteries.

Do not mix old and new batteries, or different

types of batteries. Also, be careful to observe

battery polarity during installation. Otherwise,

poor performance or damage from battery

leakage could result.

Attempting to charge alkaline batteries may

cause them to explode.

To avoid the possibility of explosion, do not

short circuit, disassemble or incinerate

batteries.

Handle and dispose of batteries in accordance

with local regulations.

NOTE

――――――――――――――――――――――――

Chapter 2 Prior to Use

The batteries are not pre-installed in the system.

Install the batteries as shown in the illustration.

Page 27

―――――――――――――――――――――――――――

NOTE

The supplied batteries are designed for a display

monitor. Thus, battery life may be short.

15

Do not use manganese batteries; use only alkaline

batteries.

Reset the system clock after replacing the batteries

(page 31).

To avoid corrosion from battery leakage, remove

the batteries from the product if it is to be stored

for a long time.

5. Battery Indicator

Remaining battery power is indicated in three levels

on the LCD.

When "Replace" is displayed, replace the batteries

immediately.

Normal Low Replace

NOTE

When "Replace" starts flashing, power will be shut

off within 5 minutes.

When "Replace" is displayed, the backlight

brightness cannot be set to maximum.

If you continue to use the tester after "Replace"

appears, either by switching to the AC adapter or

reducing backlight brightness, make sure that

temperature measurements are updated.

――――――――――――――――――――――――

Chapter 2 Prior to Use

Page 28

16

―――――――――――――――――――――――――――

――――――――――――――――――――――――

Chapter 2 Prior to Use

Page 29

―――――――――――――――――――――――――――

)

)

17

Chapter 3

Making

Measurements

3.1 Measurement Screen

tored

mage

esolution

Battery

indicator

No. of shots

taken/

No. of shots

remaining Date Time

Color scale

(upper limit

Alarm

setting

(upper limit

Alarm

setting

(lower limit)

Color scale

(lower limit)

Distance

Selected

frame

temperature

Example of a color frame display

――――――――――――――――――――――――

Measurement

speed

Measurement

condition

Chapter 3 Making Measurements

Status

Page 30

18

―――――――――――――――――――――――――――

Battery Indicator

Indicates the remaining battery power in three

levels.

When

is displayed, replace the batteries

immediately.

Number of Shots Taken/Number of Shots

Remaining

Indicates the number of shots remaining according

to the space remaining on the compact flash card.

The number of shots remaining is an estimate. The

actual number may be smaller or larger than the

number shown, as the size of data varies with

objects to measure. The maximum number of shots

remaining is 999.

Date/Time

Indicates date and time using the built-in clock.

Status

Indicates the operating status.

HOLD: Holding the image

MEAS: Performing measurement

REC: Performing the record

AUTO: Performing the record of data Automatically

WAIT: Waiting for start of automatic data recording

Color Scale Upper Limit Temperature

Indicates the upper limit temperature of the preset

selected with the PRESET button.

Color Scale Lower Limit Temperature

Indicates the lower limit temperature of the preset

selected with the PRESET button.

Alarm Upper Limit Temperature

Sets the upper limit on the measurement condition

setting screen (PRESET). The upper limit is

marked on the side of the scale.

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 31

―――――――――――――――――――――――――――

19

Alarm Lower Limit Temperature

Sets the lower limit on the measurement condition

setting screen (PRESET). This is marked on the

side of the scale.

Selected Frame Temperature

The selected frame is marked by a white cross

cursor. The cursor is moved up and down and right

and left with the cursor button.

Temperature Frame

Indicates the average temperature in the frame with

a color from the color scale.

Measurement Speed

Indicates the selected response speed. There are two

speed modes: high-speed mode (FAST) and

standard speed mode (NORMAL).

Measurement Condition

Indicates the measurement condition No. (1 to 3)

selected with the PRESET button.

Color Scale

This is a temperature color scale used for a frame or

mosaic display. There are three display patterns

available. Enter the setting mode (SETTING),

select COLOR SCALE in the menu, and choose a

display pattern from the COLOR SCALE setting

screen.

Stored Image Resolution

Sets the resolution of an image file. Select between

QVGA (320 x 240) and VGA (640 x 480). (page

24)

Distance

Sets the distance from the object to be measured.

Select between 0.5 m (0.5), 1.0 m (1.0), and 2.0 m

& over (

――――――――――――――――――――――――

). (page 22)

Chapter 3 Making Measurements

Page 32

20

―――――――――――――――――――――――――――

3.2 Measurement

(1) Turn on power

Open the LCD and slide the power switch to the

right. Following the opening screen, the visible

image, temperature data, and other information will

appear on the screen.

NOTE

After the power switch is moved to the ON

position, the LCD will first display a blue screen,

then the opening screen.

On any one occasion, slide the power switch to the

On position only once. Do not slide it back and

forth. If power does not turn on when you first slide

the switch to the On position, see Chapter 7 (P50).

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 33

―――――――――――――――――――――――――――

21

(2) Choose display mode

Choose a display mode using the Display Selector

button (DISPLAY).

Visible image only

Temperature

mosaic color display

Temperature frame

color display

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 34

22

―――――――――――――――――――――――――――

(3) Set distance to object

Press the input button (ENTER) and select a

distance to the object to be measured. Select from

0.5 m (0.5), 1.0 m (1.0), and 2.0 m & over ( ),

whichever most closely matches the actual distance.

(4) Measure temperature

(In the temperature frame color display mode or the

temperature mosaic color display mode)

Point the lens at the object. A visible image of the

object and the temperature measurement appear on

the screen. While the system is measuring, the

MEAS indicator is shown at the bottom right-hand

portion of the screen.

Press the measurement/hold button (HOLD)tohold

the image on the screen to the bottom right-hand

portion of the screen. Press the measurement/hold

button (HOLD) once again to release the image and

to display measurement results.

The temperature of the measuring point selected

with the cursor button is displayed at the bottom

left-hand portion of the screen.

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 35

―――――――――――――――――――――――――――

NOTE

If the emissivity is not set to the emissivity of the

object, the system will not display the correct

23

measurement results.

(See "Emissivity Table" on page 52 and

"Measurement Condition Setting" on page 30.)

When the emissivity of the object is low, the

thermal radiation from nearby heat sources may be

reflected on the measured surface, causing

measurement errors. Move the heat sources away

or shade the object from the heat sources.

When the distance to the object is set to 2.0 m &

over (

), the 3460-50's two optical axes are

parallel, parallax (the displacement between the

visual image optical axis and the optical axis of the

temperature sensor unit) is independent of the

distance from the measurement target, and is 26

mm in the horizontal direction and 0 mm in the

vertical direction.

(5) Turn off power

Slide the power switch to the right again.

When the Auto Power Off (page 32) is enabled

(ON), if the system has been idle for one minute,

power will be automatically turned off.

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 36

24

―――――――――――――――――――――――――――

3.3 Storage Image and Temperature

Data

Simultaneously press the cancel button (ESC) and

the input button (ENTER) to select between QVGA

(320 x 240) and VGA (640 x 480) for window size.

3.3.1 Measurement with Record Button

The image is held on the LCD by pressing the hold

button (HOLD). Press the record button (REC)for

saving the temperature data to the compact flash

card.

3.3.2 Logging Recording

You can set the system to perform automatic

logging. Set the recording start and end times.

(page 33)

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 37

―――――――――――――――――――――――――――

25

3.3.3 Storage File

ThefileextensionfortheimagedatafileisJPG.The

file extension for the temperature data file is CSV.

Image data is saved to the PICT folder, list of image

data is saved to the IPICT folder, while temperature

data is saved to the DATA folder.

Image : PICTxxxx.JPG

PICT0001.JPG

Each temperature data : DATAxxxx.CSV

DATA0001.CSV

Cumulative data : LOGDATA.CSV

LOGDATA.CSV

Image data files are paired with corresponding data files.

A new data file is named by incrementing the

number assigned for the previous data filename by

1. If no data file exists, the new data file is

assigned the name DATA0001.CSV.

If the last data file is DATA9999.CSV, the new data

file will be assigned the name DATA0001.CSV.

The images are recorded as shown on the screen.

The size of an image file is approximately 90 KB.

This may vary slightly from image to image and

from object to object. The supplied 16 MB card

will hold about 100 to 200 image and data files.

The data can be transferred to a PC using a

commercially-available compact flash card adapter.

The image data can be viewed in Internet

Explorer

(note1)

or other browser software.

(note1) Internet Explorer is a registered trademark of Microsoft

Corporation (USA).

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 38

26

―――――――――――――――――――――――――――

Temperature data can be read in EXCEL

(note2)

or

other software. You can copy or delete this data on

a PC.

3.3.4 CSV File Data

The CSV files store the following data:

Each image data: CSV file

Year/month/day, hour:minute:second, CH1

measurement --- CH64 measurement

2001/10/15, 11:55:36, 1000.0, 985.5, --- 123.4

Cumulative data: CSV file

No., year/month/day, hour:minute:second, CH1

measurement --- CH64 measurement

1, 2001/10/15, 11:55:36, 1000.0, 985.5, --- 123.4

2, 2001/10/15, 12:12:55, 856.3, 732.5, --- 55.8

Each channel corresponds to an individual

temperature display frame, as shown below.

(note2) Excel is a trademarks of Microsoft Corporation (USA).

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 39

―――――――――――――――――――――――――――

27

3.4 View Saved Images

Press the INDEX button to view a list of saved

images. Select an image in the list by using the

cursor button, then press the ENTER button. The

selected image will then be enlarged. Press the

ESC button to return to the list.

To delete an image, select an image, press the ESC

button, then press the ENTER button. Press the

DISPLAY button or INDEX button to return to

measurement mode.

NOTE

When many images are recorded (involving several

tens of files), it may take more time to read the

images.

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 40

28

―――――――――――――――――――――――――――

――――――――――――――――――――――――

Chapter 3 Making Measurements

Page 41

―――――――――――――――――――――――――――

29

Chapter 4

Setting

Press the MENU button to enter the setting mode

(SETTING). To return to measurement screen,

press the ESC button.

Choose a setting option using the up/down cursor

button.

The following setting options are available:

PRESET (measurement conditions)

You can register up to 3 combinations of color scale

temperature range, emissivity, and alarm

upper/lower limits.

CLOCK (time setting)

Set the time and choose the clock display pattern.

――――――――――――――――――――――――

Chapter 4 Setting

Page 42

30

―――――――――――――――――――――――――――

AUTO MODE (automatic data recording setting)

Enter the settings for the logging recording.

COLOR SCALE

Choose a color scale to display.

4.1 Measurement Condition Setting

(PRESET)

This is used to edit the settings of the measurement

condition presets 1 to 3. Select PRESET in the

menu and press ENTER to enter this screen.

Set SCALE (color scale temperature range), ε

(emissivity), and ALARM (alarm upper/lower

limits).

Move a cursor to the digit place you want to edit

using the right/left cursor button.

Increase or decrease the number using the up/down

cursor button.

――――――――――――――――――――――――

Chapter 4 Setting

Page 43

―――――――――――――――――――――――――――

The alarm upper/lower limits may be selected within

the measurement temperature range. The upper

limit must be greater than the lower limit.

The presets set on this screen are selected with the

measurement condition selector button (PRESET).

Press the ESC button to return to the Menu screen

(SETTING).

<Setting Range>

SCALE, ALARM : -50 to 1000

ε : 0.10 to 1.00 by every 0.01

by every 1

31

4.2 Clock

This sets date and time for the built-in clock and

auto power off function. Select CLOCK from the

menu and press ENTER to enter this screen.

Choose DATE/TIME (clock date and time),

DISPLAY STYLE (display pattern), or AUTO

POWER OFF.

――――――――――――――――――――――――

Chapter 4 Setting

Page 44

32

―――――――――――――――――――――――――――

The confirmed setting is shown in red.

Press the ESC button to return to the Menu screen

(SETTING).

4.2.1 Set DATE/TIME (clock date and time)

Move the cursor to DATE/TIME using the right/left

cursor button. Select the decimal place to be edited

using the right/left cursor button. Increase or

decrease the number by using the up/down cursor

button.

4.2.2 DISPLAY STYLE (display pattern)

Move the cursor to DISPLAY STYLE using the

right/left cursor button.

Choose 1 or 2 for the display pattern (DISPLAY

STYLE) using the up/down cursor button.

4.2.3 Set AUTO POWER OFF

Move the cursor to AUTO POWER OFF using the

right/left cursor button.

To set AUTO POWER OFF, choose between ON

and OFF using the up/down cursor button.

When the Auto Power Off is enabled (ON) and the

system has been idle for one minute, power will

automatically be turned off. To turn power on

again, slide the power switch to the right as in the

regular operation procedure.

――――――――――――――――――――――――

Chapter 4 Setting

Page 45

―――――――――――――――――――――――――――

33

4.3 Automatic Data Recording

(Logging) Measurement (AUTO

MODE)

This sets the time to start measurement (START),

the time to end measurement (END), and the

measurement interval (INTERVAL) for logging

measurements.

When INTERVAL is set to 00:00, the system does

not perform logging measurement.

Select AUTO MODE in the menu and press

ENTER to enter this screen.

Set the conditions for automatic data recording.

Chosen setting is shown in red.

START : Start time (year/month/day/hour/minute)

END : End time (year/month/day/hour/minute)

INTERVAL : Measurement interval (hour/minute)

Move the cursor to the field you want to edit using

the right/left cursor button.

Increase or decrease the number using the up/down

cursor button.

――――――――――――――――――――――――

Chapter 4 Setting

Page 46

34

―――――――――――――――――――――――――――

When INTERVAL is set to 00:00, the system does

not perform automatic data recording.

SAVE DATA : Sets whether or not to save the

image.

1:ALL PICTURE : Save the image at every

recording.

2:FIRST PICTURE: Save the image at the start of

recording only.

3:FIRST AND LAST PICTURE:

Save the image at the start and

end of recording.

Choose from 1 to 3 using the up/down cursor

button.

<Default Setting>

START : The start time entered in this screen.

END : The end time entered in this screen.

INTERVAL : 00:00

SAVE DATA : 1: ALL PICTURE

Press the ESC button to return to the Menu screen

(SETTING).

Press the ESC button during automatic data

recording to return to measurement screen.

Press the menu button (MENU) view the setting for

automatic data recording on the SETTING (AUTO

MODE) screen. When the setting is being displayed,

data recording is suspended. Press the menu button

(MENU) to return to the measurement screen and

resume data recording.

――――――――――――――――――――――――

Chapter 4 Setting

Page 47

―――――――――――――――――――――――――――

35

4.4 Color Scale

This selects among three display patterns of the

color scale used for temperature color frame or

mosaic display.

Select COLOR SCALE in the menu and press

ENTER to enter this screen.

Choose a pattern using the up/down cursor button.

On the scale, the top is high and the bottom is low.

Press the ESC button to return to the Menu screen

(SETTING).

――――――――――――――――――――――――

Chapter 4 Setting

Page 48

36

―――――――――――――――――――――――――――

――――――――――――――――――――――――

Chapter 4 Setting

Page 49

―――――――――――――――――――――――――――

37

Chapter 5

Transfer Function

Temperature measurement data is sent from the

interface terminal on the main unit. Temperatures

can be recorded, monitored, and alarms sent by

connecting to a PC and creating a program.

NOTE

The data transfer function on the main unit is only

able to transmit temperature measurement data

repeatedly. The unit cannot be controlled via a PC

(e.g. to change settings) and it is not possible to

acquire camera image data.

5.1 Interface Specifications

Item Specifications Remarks

Output data Temperature measurement

Transmission

interval

Interface RS-232C No flow control

Signal SD、GND Transmission only;

Transfer format Asynchronous : 38400 bps

――――――――――――――――――――――――

data (fixed-length binary data)

0.2 s

Data bit : 8

Startbit :1

Stop bit : 2

Parity bit : None

Chapter 5Transfer Function

no reception

Page 50

38

―――――――――――――――――――――――――――

5.2 Connection

WARNING

Always turn both devices OFF when connecting

and disconnecting an interface connector.

Otherwise, an electric shock accident may occur.

To avoid damage to the product, do not shortcircuit the terminal and do not input voltage or

current to the terminal.

1. Insert the interface cable plug into the interface

terminal on the main unit.

2. Connect the interface cable RS-232C connector to

the PC COM port.

Interface

Interface

terminal

terminal

――――――――――――――――――――――――

Chapter 5Transfer Function

Page 51

―――――――――――――――――――――――――――

39

5.3 Transmission Data Format

5.3.1 Temperature Measurement Data

Temperature measurement data is transmitted

repeatedly at intervals of approximately 200 ms

while measurement is in progress. Data is sent each

time as 133-byte fixed length binary data.

1st byte Header Measurement successfully

2nd byte Emissivity setting

3rd/4th bytes Sensor

5th-132nd bytes Temperature

133rd byte Check sum Last 8 bits of sum from 1st to

×

100

temperature

measurement results

completed

Invalid data

Not calibrated - Measurement

not possible

Data error - Calculation

not possible

64H for setting 1.00

2 bytes (first byte first)

2 bytes×64 points

132nd byte

Sensor temperatures and temperature measurements are

expressed as 2-byte data. Details are as shown below.

Sensor temperature,

temperature measurement

0000 Invalid temperature data (e.g. measurement

0001〜FFFEH Temperature (Celsius)×50+4096

FFFFH Data error (error occurred during

Status, conversion formula

results have not been saved)

measurement or calculation)

Example: 0℃→a Internal data 1000H

1000℃→ a Internal data D350H

:

20H

:

21H

:

22H

:

23H

――――――――――――――――――――――――

Chapter 5Transfer Function

Page 52

40

―――――――――――――――――――――――――――

5.3.2 Data Timing

200 msec

→

Power O N

Data

1st 2nd

n

n+1st

Temperature measurement data (133 bytes) is

transmitted automatically at 200 ms intervals.

Transmission of temperature measurement data takes

approximately 40 ms.

Measurement data is sent repeatedly, so the header

data must first be detected before receiving the

following 133 bytes to process the data. The header

data cannot be detected if it is not distinct from the

temperature measurement data. Processing is

therefore required to cope with this situation, such

as clearing the receipt buffer if no data is received

within a preset time interval.

――――――――――――――――――――――――

Chapter 5Transfer Function

Page 53

―――――――――――――――――――――――――――

41

5.4 Temperature Measurement Result

Sequence and Measurement Location

Each measurement data transmission contains 64

temperature measurement results. The sequence and

measurement locations are as shown below.

Measurement surface

upper

AB CD E F G H

8

57 49 41 33 25 17 9 1

7

58 50 42 34 26 18 10 2

6

59 51 43 35 27 19 11 3

5

left

60 52 44 36 28 20 12 4

4

61 53 45 37 29 21 13 5

62 54 46 38 30 22 14 6

3

63 55 47 39 31 23 15 7

2

1

64 56 48 40 32 24 16 8

lower

right

The figures in the table indicate the temperature

data transmission sequence.

――――――――――――――――――――――――

Chapter 5Transfer Function

Page 54

42

―――――――――――――――――――――――――――

――――――――――――――――――――――――

Chapter 5Transfer Function

Page 55

―――――――――――――――――――――――――――

43

Chapter 6

Specification

6.1 Product Specification

Temperature Measurement

Detection element Thermopile array

Measurement range -50 to 1000

Sampling rate Approx. 0.2 seconds

Number of elements 64 (Horizontal 8 x vertical 8)

Measurement view

angle for one element

Measurement view

angle

Infrared wavelength 8to16μm

Radiation ratio

correction

Resolution 0.1

Accuracy 10%rdg. 2 (-50.0 to -0.1 )

Relative accuracy 1.0 (P-P, 23 )

Note 1: At the standard measurement speed (

3.1square (55 mm square at 1 m)

24.8 square (440 mm square at 1 m)

0.1 to 1.00 (steps of 0.01)

(Note 1)

2.0 (0.0 to 200.0 )

1%rdg. (200.1 to 1000.0 )

(Note 1)

NORMAL

)

Visual Photography

Detection element Color CMOS

Frame Time Approx. 0.5 seconds

Number of pixels Approx. 300,000 pixels (640 x 480)

Image angle Horizontal 50.0 x vertical 37.5

Smallest distance 0.5 m

Display

――――――――――――――――――――――――

(Horizontal 930 mm x vertical 680 mm

when the object is 1 m away)

Chapter 6 Specification

Page 56

44

―――――――――――――――――――――――――――

Display element Transmission type color TFT liquid

Size 3.8 inch

Number of pixels Approx. 76800 pixels (320 x 240)

Display colors 65535 colors (16-bit)

Backlight Cold cathode tube

Backlight brightness 3 adjustable levels + no light

Temperature indication

(each element)

Temperature indication

(selected element)

Parallax error 26 mm constant (Correction possibility

Optical axis deviation 1.15 or less

Functions

Temperature units

Logging measurement Specified in units of minutes (hh:mm)

Interval 00:01 to 24: 00

Measurement data

memory

Storage format JPEG file (image data, Definition 320 x

Battery remaining

indicator

Other functions Image data deletion, audible click,

crystal

Frame color display (Display range

and display pattern are selectable.)

Indicated by numerals

with software)

(20 mm when the object is 1 m away,

excluding parallax error)

Compact flash card (16 to 1 GB)

240, 640 x 480: Selection possibility)

CSV file (temperature value data)

3-level display

alarm/buzzer, automatic power off, clock

Basic Specifications

Data output RS-232C (Temperature data only)

Image output NTSC video output

Power source LR6 (AA) alkaline batteries x 6,

Rated power source

voltage

――――――――――――――――――――――――

Chapter 6 Specification

AC adapter (S-8392, KAGA

COMPONENTS) (3915 OPTION

PACK)

1.5 V DC x 6 (LR6),

9 V DC (Exclusive use AC adapter )

Page 57

―――――――――――――――――――――――――――

Maximum rated power 13.5 VA

Continuous operating

time

Dimensions Approx. 165W x 55H x 123D mm

Mass Approx. 700 g,

Accessories supplied LR6 (AA) alkaline batteries x 6, Strap,

Options 3915 OPTION PACK (Portable case,

Environment condition

Operating temperature

and humidity range

Storage temperature

and humidity range

Temperature and

humidity for

guaranteed accuracy

Guaranteed accuracy

period

Location for use Indoor

Standards applying

Safety

EMC

Approx. 70 minutes (intermediate

level, about 23

Approx. 6.57" W x 2.17" H x 4.84" D

(The main unit only with the LCD closed)

Approx. 24.7 oz. (excluding battery)

Compact flash card (16 MByte),

Instruction manual

Video cable, AC adapter) Serial

communication cable, Black body spray,

Black body tape, PC cards (compact

flash and PC card adapter set) (9726

PC CARD 128M, 9727 PC CARD 256M,

9728 PC CARD 512M, 9729 PC CARD

1G) , PC card adapter (for compact

flash card)

0to40 , 32 to 104

35 to 75% RH; no condensation

-20 to 50 , -4 to 122

80% RH or less; no condensation

23 5 ,73 9

35 to 75%RH; no condensation

1 year

EN61010

Pollution Digree 2

EN61326

EN61000-3-2

EN61000-3-3

)

45

――――――――――――――――――――――――

Chapter 6 Specification

Page 58

46

―――――――――――――――――――――――――――

6.2 Measurement Range

Measurement range

The measurement range is proportional to the

distance between the 3460-50 and the object.

――――――――――――――――――――――――

Chapter 6 Specification

Page 59

―――――――――――――――――――――――――――

47

Parallax error

Temperat ure M easurement Ran ge

of Object 1 m Distant

Temperature frame

on the screen

Actual temperature

measurement frame

Temperat ure M easurement Ran ge

of Object 10 m Distant

Temperature frame

on the screen

Actual temperature

measurement frame

The axes of the camera and the thermopile array are

26 mm apart from each other in parallel.

Parallax error may be ignored if the distance to the

object is set properly.

――――――――――――――――――――――――

Chapter 6 Specification

Page 60

48

―――――――――――――――――――――――――――

Measurement Area of Each Temperature

Element (distance: 1.0 m)

Temperature frame on the screen

Actual temperature measurement

range (maximum)

The measurement result shows the average

temperature in the measurement area.

This range assumes that the optical efficiency is

90%.

――――――――――――――――――――――――

Chapter 6 Specification

Page 61

―――――――――――――――――――――――――――

49

Chapter 7

Maintenance and

Service

7.1 Troubleshooting

If damage is suspected, check the "Troubleshooting"

section before contacting your dealer or Hioki

representative.

When sending the product for repair, remove the

batteries and pack carefully to prevent damage in

transit. Include cushioning material so the

instrument cannot move within the package. Be sure

to include details of the problem. Hioki cannot be

responsible for damage that occurs during shipment.

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 62

50

―――――――――――――――――――――――――――

Problem Cause Solution

No display /

Power does

not come

on

Measured

temperature

value

peculiar

Batteries are dead. Replace the batteries.

Backlight is set to

no light.

The internal circuit

is in a reset state

due to a drop in

voltage (including

temporary drops).

Lens dirty and

Adhesion of the

drop of water

There is a high heat

source nearby.

The thermal

emissivity value is

not appropriate.

Remaining battery

power is low.

The temperature of

the 3460-50 is

unstable.

Press the LIGHT button.

Disconnect the AC adapter

and remove the batteries.

Wait at least one minute,

then reconnect the adapter

and reinstall the batteries.

Clean the lens.

Move the heat source

away or shade the object

from the thermal radiation

of the heat source.

Set the thermal emissivity

to an appropriate value.

Replace the batteries.

Wait until the temperature

stabilizes.

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 63

―――――――――――――――――――――――――――

51

7.2 Maintenance

Infrared lens

The infrared lens is the most critical component for the

temperature measurements. A dirty lens may cause

measurement errors or shorten the life of the lens.

If the lens is dirty

Ifthelensisdirty,cleandustetc.offitusinga

camera lens cleaning tissue, blower or similar means.

Wipe off moisture with gauze or cotton swab.

If the lens is very dirty, clean it using a cotton bud

containing a small quantity of alcohol.

Body

To clean the product, wipe it gently with a soft

cloth moistened with water or mild detergent. Never

use solvents such as benzene, alcohol, acetone,

ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

Wipe the LCD gently with a soft, dry cloth.

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 64

52

―――――――――――――――――――――――――――

7.3 Emissivity Table

When the emissivity of the object is low, the

readings may become unstable. In that case, use the

blackbody spray or blackbody tape available as

optional equipment.

Use the table below as a guide. Emissivity varies

depending on the smoothness of the surface and the

thickness of the material besides the material itself.

Substance

Thermal

emissivity

Asphalt 0.90 to 0.98 Charcoal

Concrete 0.94 Lacquer 0.80 to 0.95

Cement 0.96 Lacquer (matt) 0.97

Sand 0.90 Rubber (black) 0.94

Earth 0.92 to 0.96 Plastic 0.85

Water 0.92 to 0.96 Timber 0.90

Ice 0.96 to 0.98 Paper 0.70 to 0.94

Snow 0.83 Aluminium

Glass 0.90 to 0.95 Chromium

Ceramic 0.90 to 0.94 Copper oxides 0.78

Marble 0.94 Iron oxides 0.78 to 0.82

Fluorite 0.30 to 0.40 Nickel oxides 0.90

Plaster 0.80 to 0.90 Titanium

Mortar 0.89 to 0.91 Zinc oxides 0.11 to 0.28

Brick (red) 0.93 to 0.96 Brass oxides 0.56 to 0.64

Textiles 0.90 Uneven

Cloth (black) 0.98 Rolled

Human skin 0.98 Heavily rusted

Leather 0.75 to 0.80

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Substance

(powder)

oxides

oxides

oxides

bronze

surfaces

stainless steel

iron

Thermal

emissivity

0.96

0.76

0.81

0.40 to 0.60

0.55

0.45

0.69

Page 65

―――――――――――――――――――――――――――

53

7.4 Questions and Answers about

Measurement

Q: Why can't I measure the temperature on the other

side of a glass pane?

A: Normal glass absorbs infrared radiation of the

wavelength (8 to 16 μm) which this device uses for

temperature measurement. Therefore this device

cannot measure the temperature of an object on the

other side of a glass sheet, but instead measures the

temperature of the glass sheet itself.

Q: Light is shining on an object. Why can't I measure

its temperature accurately?

A: Since fluorescent light includes almost no infrared

radiation, it has almost no effect upon normal

temperature measurement. However sunlight and

incandescent lights emit radiation which includes

substantial amounts of the infrared radiation used by

this device for temperature measurement, and

accordingly may produce significant measurement

discrepancies.

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 66

54

―――――――――――――――――――――――――――

Q: Why can't I measure the temperature of a gas,

vapor, or flame?

A: Since gases, vapors, and flames are transparent to

infrared radiation, their temperatures cannot be

measured in this way.

Q: Why can't I measure temperature through rain or

fog?

A: Since rain and fog reflect and absorb infrared

radiation, accurate measurement through them is

impossible.

Q: Doesn't the measurement distance affect the

resulting measured value for temperature?

A: Air hardly absorbs at all infrared radiation of the

wavelengths (8 to 16 μm) used by this device for

temperature measurement. Therefore accurate

temperature measurement is possible, irrespective of

the measurement distance.

――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 67

Page 68

Page 69

HIOKI 3460-50 2D THERMO HiTESTER

Instruction Manual

Publication date: December 2007 Revised edition 2

Edited and published by HIOKI E .E. CORPO RATION

Technical Support Section

All inquiries to International Sales and Marketing De-

partment

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os- c om@hioki.co.jp

URL http://www.hioki.com/

Printed in Japan 3460C981-02

• All reasonable care has been taken in the production

of this manual, but if you find any points which are

unclear or in error, please contact your supplier or the

International Sales and Marketing Department at

HIOKI headquarters.

• In the interests of product development, the contents

of this manual are subject to revision without prior

notice.

• The content of this manual is protected by copyright.

No reproduction, duplication or modification of the

content is permitted without the authorization of Hioki

E.E. Corporation.

Page 70

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki .c om/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3460C981-02 07-12H

Printed on recycled paper

Loading...

Loading...