Page 1

HIGH VOLTAGE

INSTRUCTION MANUAL

3455

INSULATION HiTESTER

www. .com

information@itm.com1.800.561.8187

Page 2

1

2

3

4

5

6

7

8

9

10

11

付録

索引

i

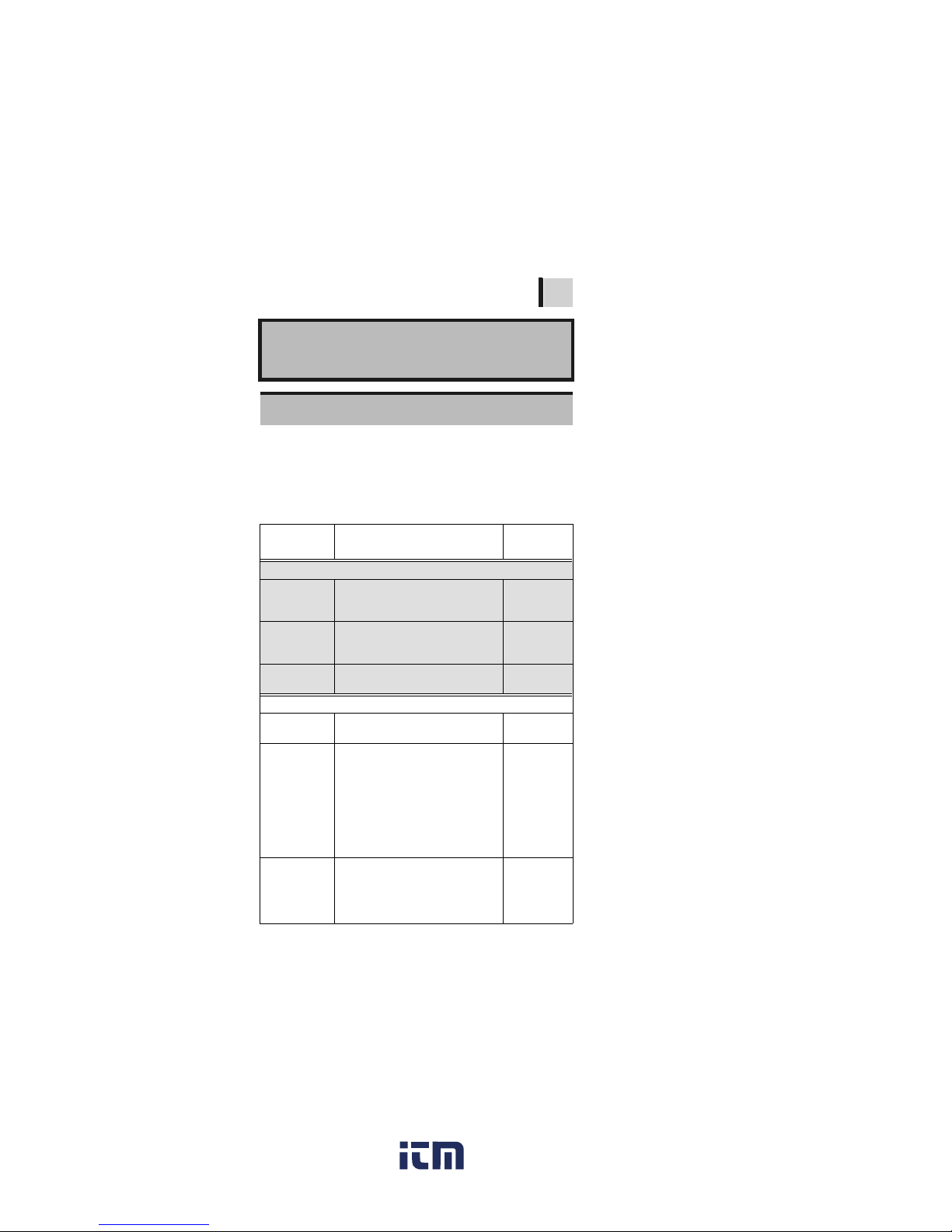

Contents

Introduction ...................................................... 1

Verifying Package Contents / Open the case ..1

Safety Infor ma tion ............ .. ........................... .. 5

Operating Precautions .....................................8

1 Overview 13

1.1 Product Overview .................................13

1.2 Features .............. ............. .............. ......15

1.3 Measure me nt Overview ......... .. ............17

1.4 Names and Functions of Parts .............24

1.5 Screen Setup .......................................28

2 Measurement Preparations 31

2.1 Supplying Power ..................................31

2.1.1 Installing or Replacing the Battery ......31

2.1.2 Installing the Battery Pack

(Rechargeable nickel-hydrogen battery) 34

2.1.3 Connecting the AC Adapter ................39

2.1.4 Charging the Battery Pack .................41

2.2 Turning Power On and Off ...................44

2.2.1 Auto Power Off ...................................45

2.3 Setting and Checking Date and Time ..46

2.3.1 Setting Date and Time ........................46

2.3.2 Checking Date and Time ....................49

2.4 Connecting Test Lead ..........................50

2.5 Connecting Temperature Sensor .........52

www. .com

information@itm.com1.800.561.8187

Page 3

ii

3 Measurement 53

3.1 Pre-Operation Inspection .....................53

3.2 Measuring Insulation Resistance .........56

3.2.1 Starting Measurement .........................58

3.2.2 Ending Measurement ..........................64

3.2.3 Checking and Deleting Held Data .......66

3.2.4 Automatic Discharge Function ............67

3.2.5 Switching to Leakage Current Indication 68

3.2.6 Insulation Resistance Measurement

Basis ...................................................69

3.2.7 Use of GUARD Terminal .....................71

3.3 Measuring Voltage ...............................73

3.4 Measuring Temperature .......................76

3.4.1 Measurement Procedure ....................76

4 Advanced Measurement 79

4.1 Using Time r .... .............. .............. ..........79

4.1.1 Setting Timer/Conducting Insulation

Resistance Measurement ...................79

4.2 Displaying PI and DAR .........................83

4.3 Temperature Correctio n ( T C ) ... ............87

4.3.1 Performing Temperature Correction ...88

4.3.2 Exiting Temperature Correction Mode 92

4.4 Step Voltage Test .................................93

4.4.1 Setting and Conducting a Step Voltage

Test .....................................................94

4.4.2 Viewing Detai led Da ta o f Each Ste p af ter

Step Voltage Test .......................... .....97

4.4.3 Exiting Step Voltage Test Mode ..........99

www. .com

information@itm.com1.800.561.8187

Page 4

1

2

3

4

5

6

7

8

9

10

11

付録

索引

iii

5 Recording Measurement Data

(Memory Function) 101

5.1 Recording Measurement Data ...........103

5.1.1 Manual Recording (Recording result

of one measurement session) ..........103

5.1.2 Logging Recording (Recording at

regular intervals) ...............................106

5.2 Checking Recorded Data ...................115

5.3 Deleting Recorded Data .....................120

5.3.1 Deleting Data of Chosen No. ............120

5.3.2 Deleting all Data ...............................121

6 Other Functions 123

6.1 Changing and Checking Interval Setting

for PI Calculation ................................123

6.1.1 Changing Interval Setting .................123

6.1.2 Checking Interval Setting .................125

6.2 Changing and Check i ng Vol tag e

Application Time for Step Voltage Test .126

6.2.1 Changing Time Setting ..................... 126

6.2.2 Checking Time Setting .....................128

6.3 Entering Temperature and Humidity

Measured with External Thermometer

and Hygrometer .................................129

6.3.1 Entering and Saving .........................130

6.3.2 Clearing Indications of Temperature

and Humidity Stored Data ................133

6.4 Communicating with PC ..................... 134

6.4.1 Installing Data Analysis Software for

3455 .................................................135

6.4.2 Installing Driver .................................136

6.4.3 Downloading Data to Save to PC/

Setting up Tester on PC ...................145

www. .com

information@itm.com1.800.561.8187

Page 5

iv

7 Specifications 147

7.1 General Specifications .......................147

7.2 Measurement Specifications .............. 152

7.2.1 Insulation Resistance Measurement .152

7.2.2 Leakage Current Measurement ........155

7.2.3 Voltage Measurement .......................156

7.2.4 Temperature Measurement ..............157

8 Maintenance and Service 159

8.1 Troubleshooting .................................160

8.2 Cleaning ............................................. 162

8.3 Error Display ......................................162

8.4 Performing System Reset ..................165

8.5 Discarding the Instrument ..................166

Appendix 169

Appendix 1 Test Voltage Characteristic

Graph ......................................169

Appendix 2 Example of Insulation Resistance

Criteria ..................................... 170

Appendix 3 Example of PI Criteria

(Polarization Index) ................. 170

Appendix 4 Temperature Correction Table 171

www. .com

information@itm.com1.800.561.8187

Page 6

Introduction

1

2

3

4

5

6

7

8

9

10

11

付録

索引

1

Introduction

Thank you for purchas i ng the HIOKI “Model

3455 HIGH VOLTAGE INSULATION HiTESTER” To obtain maximum performance

from the instrument, please read this manual first, and keep it handy for future reference.

• Windows and Internet Explorer are registered trademark of Microsoft Corp oration in

the United States and/or other countries.

• Adobe and Adobe Reader are registered

trademark of Adobe Systems Incorporated.

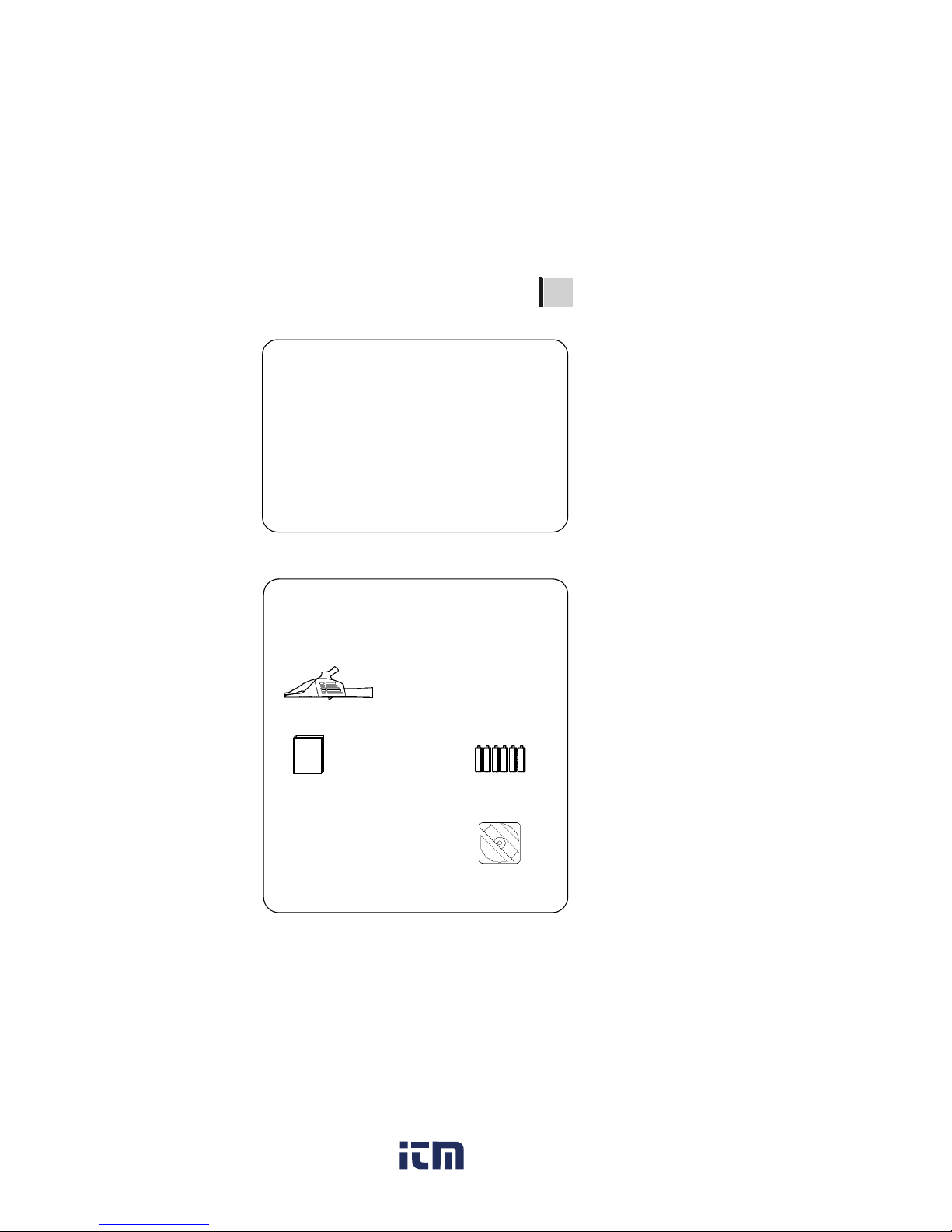

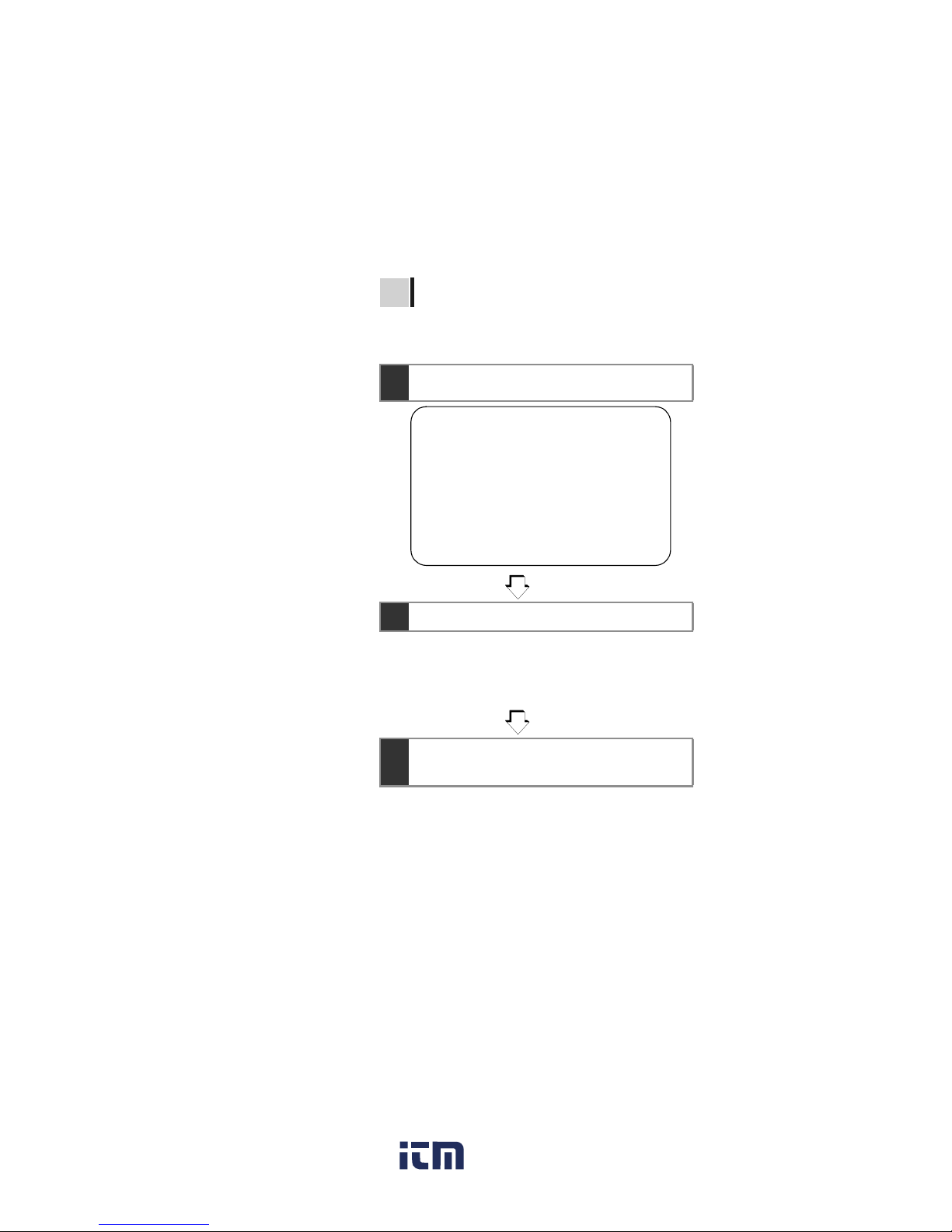

V erifying Package Contents / Open

the case

When you receive the instrument, inspect it

carefully to ensure that no damage

occurred during shipping. In particular,

check the accessories, panel switches, and

connectors. If da mage is evide nt, or if it f ails

to operate according to the specifications,

contact your dealer or Hioki representative.

Open the case by releasi ng the two latc hes.

(See next page.)

Registered trade mark

Open the case

Appearance of Case

Cover

Latches

Handle

www. .com

information@itm.com1.800.561.8187

Page 7

Verifying Package Contents / Open the case

2

Procedure

1. Draw the latch outwards with your fin-

ger.

2. While raising the entir e latch, place a

finger on the top of th e latch and pull

it out.

www. .com

information@itm.com1.800.561.8187

Page 8

Verifying Package Contents / Open the case

1

2

3

4

5

6

7

8

9

10

11

付録

索引

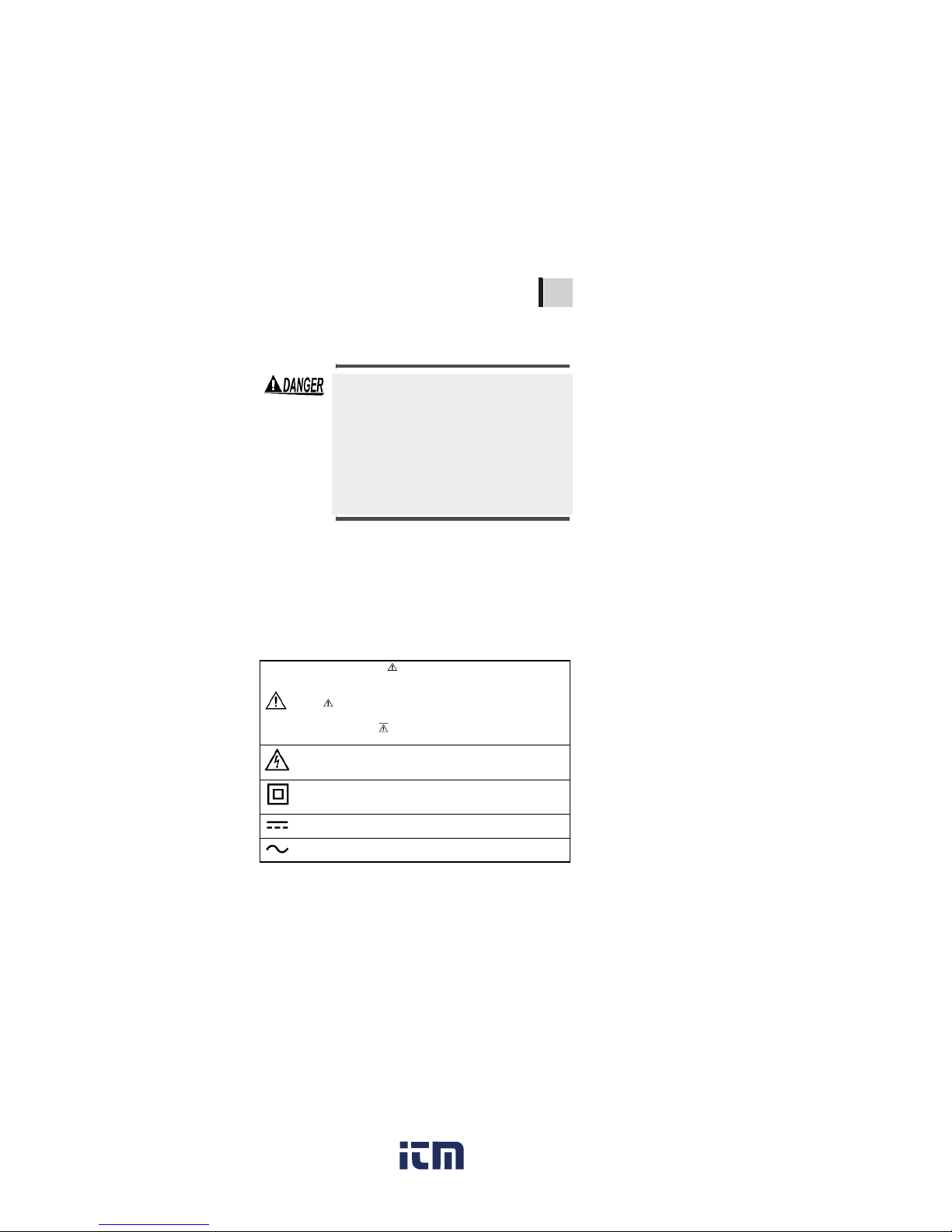

3

Main Unit

Accessories

3455 HIGH VOLTAGE INSULATION HiTESTER 1

9750-01,-02,-03 TEST LEAD (Red, Black, Blue)

Lead length Approx. 3 m 1 each

LR6 alkaline battery 6Instruction Manual

(This book) 1

USB Cable 1

9751-01,-02,-03 ALLIGATOR CLIP(Red, Black, Blue)

1 each

CD-R (Data Analysis

Software for 3455) 1

www. .com

information@itm.com1.800.561.8187

Page 9

Verifying Package Contents / Open the case

4

Options

9750-11,-12,-13 TEST LEAD

(Red, Black, Blue Lead length Approx. 10 m)

The specifications for the 9750-11 and

9750-12 models differ from the standard

specifications in regards to temperature

characteristics.

❖See 7.2"Measurement Specifications" (page

152).

9631-01,-05 TEMPERATURE SENSOR

Used for temperature measurement.

9631-01: Lead length Approx. 1 m

9631-05: Lead length Approx. 6 cm

9459 BATTERY PACK

(Rechargeable nickel-hydrogen battery)

The 9753 AC ADAPTER is required for

charging.

9753 AC ADAPTER

Input : 100 to 240 VAC

Output: 12 VDC 3.33 A

www. .com

information@itm.com1.800.561.8187

Page 10

Safety Information

1

2

3

4

5

6

7

8

9

10

11

付録

索引

5

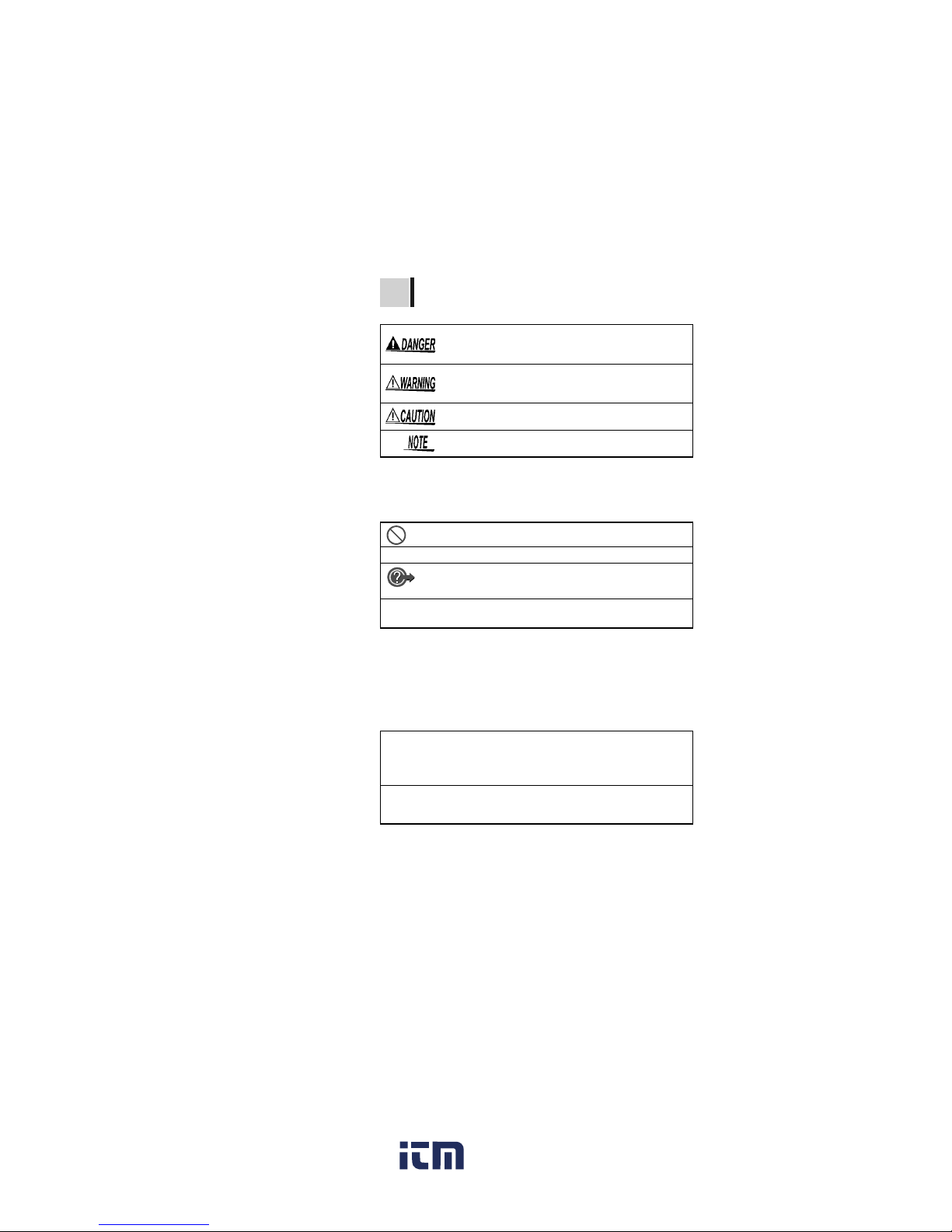

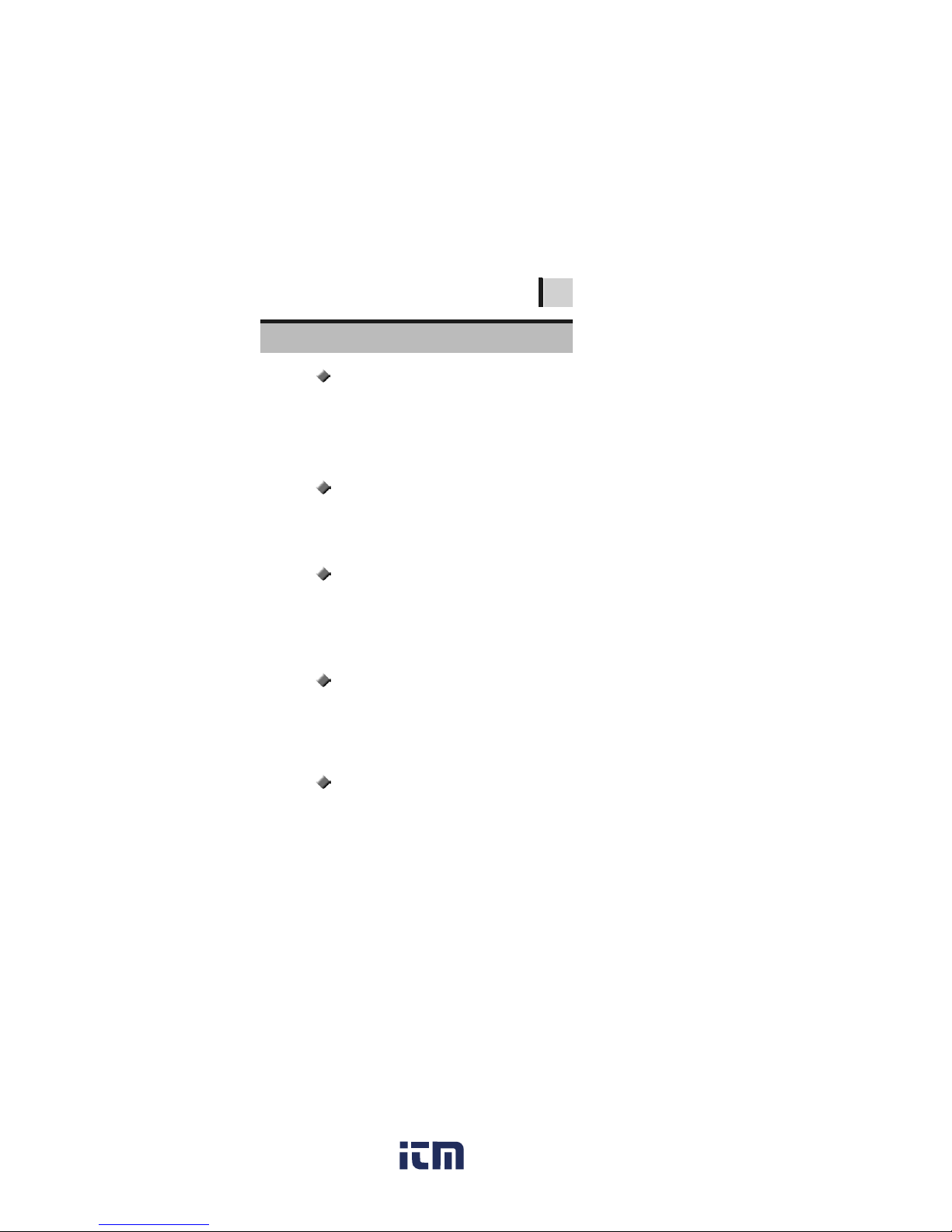

Safety Information

Safety Symbols

This manual contains information and warnings essential for safe operation of the

instrument and for maintaining it in safe

operating conditi on. Before using it, be su re

to carefully read the following safety precautions.

The following symbols in this manual indicate the relative i mp or tance of cautions and

warnings.

This instruments designed to comply

with IEC 61010 Saf ety Standard s, an d has

been thoroughly tested for safety prior to

shipment. However, mishandling during

use could result in injury or death, as well

as damage to the instrument. Be certain

that you understand the instructions and

precautions in the manual before use. We

disclaim any responsibility for accidents

or injuries not resulting directly from

instrument defects.

In the manual, the symbol indicates particularly important information that the user should read before using the

instrument.

The symbol printed on the instrument indicates that the

user should refer to a corresponding topic in the manual

(marked with the symbol) before using the relevant function.

Indicates that dangerous voltage may be present at this terminal.

Indicates a double-insulated device.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

www. .com

information@itm.com1.800.561.8187

Page 11

Safety Information

6

Other Symbols

Accuracy

We define measurement tolerances in

terms of rdg. (re ading) and dgt. (dig it) values, with the following meanings:

Indicates that incorrect operation presents an extreme

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a significant

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a possibility

of injury to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the

instrument.

Indicates a prohibited action.

❖

Indicates the location of reference information.

Indicates quick references for operation and

remedies for troublesh oo t i ng .

*

Indicates that descriptive information is provided

below.

dgt.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that causes

the digital display to show a "1" as the least-significant digit.

rdg. (reading

or displayed

value)

The value currently being measured and indicated on the measuring instrument.

www. .com

information@itm.com1.800.561.8187

Page 12

Safety Information

1

2

3

4

5

6

7

8

9

10

11

付録

索引

7

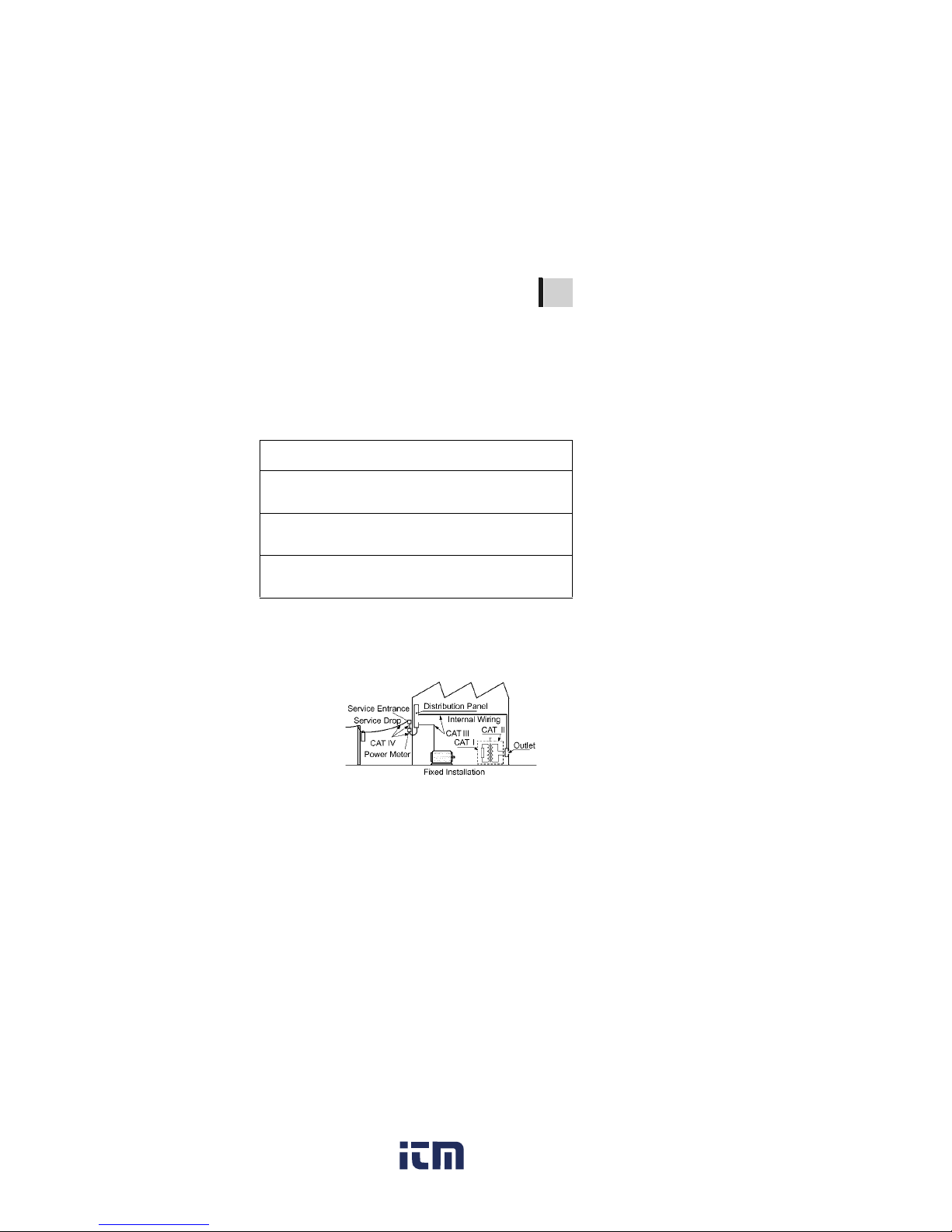

Measurement categories (Overvoltage categories)

This instrument complies with CAT IV (600

V), CAT III (1000 V) safety requirements.

To ensure safe operation of measurement

instruments, IEC 61010 establishes safety

standards for various electrical

environment s, categorized as CAT I t o CAT

IV, and called measurement categories.

These are defined as follows.

Higher-numbere d catego rie s cor res pond to

electrical envir onments with greater

momentary energy. So a measurement

device designed for CAT III environments

can endure greater momentary ene rgy than

a device desi gned for CAT II.

Using a measurement instrument in an

environment designated with a higher-numbered category than that for which the

instrument is rated could result in a severe

accident, and must be carefu l ly avoi de d.

Never use a CAT I measuri ng i nstrument in

CAT II, III, or IV environments.

The measurem ent categories comply with

the Overvoltage Categories of the

IEC60664 S tandards.

CAT I Secondary electrical circuits connected to an AC electri-

cal outlet through a transformer or similar device.

CAT II Primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT III Primary electrical circuits of heavy equipment (fixed in-

stallations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent protection device (distribution panel).

www. .com

information@itm.com1.800.561.8187

Page 13

Operating Precautions

8

Operating Precautions

Follow these precautions to ensure safe

operation and to obtain the full benefits of

the various functions.

Before using the instrument the first time,

verify that it operates normally to ensure

that the no damage occurred during storage or shipping. If you find any damage,

contact your dealer or Hioki representative.

Preliminary Checks

Before using the instrum ent, make sure

that the insulation on the test leads and

cables is undamaged and that no bare

conductors are improperly exposed.

Using the product in such conditions

could cause an electric shock, so contact

your dealer or Hioki representative for

replacements.

(Model 9750-01,-02,-03 TEST LEAD,

Model 9751-01,-02,-03 ALLIGATOR CLIP)

www. .com

information@itm.com1.800.561.8187

Page 14

Operating Precautions

1

2

3

4

5

6

7

8

9

10

11

付録

索引

9

• Operating t em pe rature and humidity:

0 to 40°C (32 to 104

°F

)

90%RH or less (no condensation)

• Temperature and humidity range for guaranteed accuracy:

Insulation resistance measurement / leakage current measurement

0 to 28°C (32 to 82

°F)

90%RH or less (no condensation)

Voltage measurement / temperature measurement

23±5°C (73± 9

°F)

90%RH or less (no condensation)

Placement

To avoid malfunctions and accidents, do not place the tester

where it will be exposed to any of the following:

•Direct

sunlight

•High

temperature

•Corrosive or

explosive gas

• Sprayed/

splashed

water

• High humidity

with

condensation

• Strong

electromagnetic fields

• Electrically

charged

objects

•Dust

• Mechanical

vibration

www. .com

information@itm.com1.800.561.8187

Page 15

Operating Precautions

10

Observe the following to avoid electric

shock and short circuits.

• Before connecting or disconn ecting the

test leads to/from the tester, be sure to

disconnect the test leads from the

object under test and turn off power.

• Do not perform measurement with the

battery cover r emoved

• Do not use the shutter if it is broken.

• Do not rem ove the

case from the main

unit.

(High-voltage/high-temperature parts

are present wi thin)

• Do not use the tester in environments

containing ignitable gases, explosiv e

powders, etc.

(Risk of explosion)

• Do not place the tester on an unstable

or uneven surfac e.

(If the tester falls, electric shock or

tester malfunction may result)

• This tester handles high voltages. To

avoid electric shock, always wear

appropriate insulated protection, such

as rubber gloves, rubber b oots, as well

as a safety helme t, as specified in the

Ordinance on Industrial Safety and

Health.

• Before using the tester, inform those

around you of your intention to do s o.

Shutter

www. .com

information@itm.com1.800.561.8187

Page 16

Operating Precautions

1

2

3

4

5

6

7

8

9

10

11

付録

索引

11

• This instrument is designed for use ind oor s.

It can be operated at temperatures

between 0 and 40° C (32 a nd 104

°F

) without

degrading sa fety.

• To avoid damage to the instrument, protect

it from physical shock when transporting

and handling. Be especially careful to avoid

physical shock from dropping.

• If the protective functions of the instrument

are damaged, either remove it from service

or mark it clearly so that others do not use it

inadvertently.

• Calibration and repair of this instrument

should be performed only under the supervision of qualified technicians knowledgeable about the dangers involved.

• Never modify the instrument. Only Hioki

service engineers should disassemble or

repair the instrument. Failure to observe

these precautions may result in fire, electric

shock, or injury.

• Place the cover on the tester when not in use.

• After use, always turn OFF the power.

• To avoid damage to the tester, do not connect

an external device to the USB terminal or the

temperature sensor terminal.

• Standby State

The use of "standby state" in this manual

means that measurement is not being

performed and that no parameters are

set. This includes the state in which

is on.

• If the tester is exposed to an abrupt large

variation in temperature, condensation

may occur, resulting in measurement

errors.

Leave the tester in a new environment for

a while before starting measurement.

www. .com

information@itm.com1.800.561.8187

Page 17

Operating Precautions

12

1 TΩ (Tera ohm) =1000 GΩ =1012 Ω

1 GΩ (Giga ohm) =1000 MΩ =10

9

Ω

1 MΩ(Mega ohm) = 1000 kΩ =10

6

Ω

1 mA (Milliampere) =0.001 A =10

-3

A

1 μA (Micro ampere) =0.001 mA =10

-6

A

1 nA (Nano ampere) =0.001 μA=10

-9

A

Electrical Units

Care and Handling of CD-R

• Alw ays hold the disc by the edges, s o as not

to make fingerprints on the disc or scratch the

printing.

• Never touch the recorded side of the disc. Do

not place the disc directly on anything hard.

• Do not wet the disc with volatile alcohol o r

water, as there is a possibility of the label

printing disappearing.

• To write on the disc label surface, use a spiritbased felt pen. Do not use a ball-point pen or

hard-tipped pen, because there is a danger of

scratching the surface and corrupting the

data. Do not use adhesive labels.

• Do n ot expose the disc directly to the sun's

rays, or keep it in condition s of high temperature or humidity, as there is a danger of warping, with consequent loss of data.

• To remove dirt, dust, or fingerprints from the

disc, wipe with a dry cloth, or use a CD

cleaner. Always wipe radially from the inside

to the outside, and do no wipe with circula r

movements. Never use abrasi ves or solvent

cleaners.

• Hioki shall not be held liable for any problems

with a computer sy stem that arises f rom the

use of this CD-R, or for any proble m related

to the purchase of a Hioki product.

www. .com

information@itm.com1.800.561.8187

Page 18

1.1 Product Overview

1

2

3

4

5

6

7

8

9

10

11

付録

索引

13

The 3455 is an insulation resistance tester

with a wide measurement range, for use in

such environments involving low to high

voltage.

The tester has the functions and purposes

given below.

Overview 1

1.1 Product Overview

Function Purpose

Reference

page

(Basic)

Insulation

resistance

measurement

To test the insulation resistance of

an electrical facility.

❖3.2 (P.56)

Voltage

measurement

To measure the voltage of an external circuit, e.g., commercial power

supply.

❖3.3 (P.73)

Temperature

measurement

To measure a temperature ❖3.4 (P.76)

(Applied)

Timer To automatically end measurement

after a predetermined time.

❖4.1 (P.79)

Display

PI and DAR

values

To check whether the insulation resistance increases with time after a

voltage is applied.

[When the PI (polarization index)

value or the DAR (dielectric absorption ratio) value is close to 1, the

tester determines that the insulation of the object to be measured

has deteriorated.]

❖4.2 (P.83)

Temperature

correction

(TC)

To obtain the insulation resistance

at various temperatures varied from

the actual environmental temperature at which measurement is performed.

❖4.3 (P.87)

www. .com

information@itm.com1.800.561.8187

Page 19

1.1 Product Overview

14

Step voltage

test

To determine whether the insulation resistance of an object changes according to test voltage

applied.

❖4.4 (P.93)

Memory

To save the measurement data.

❖5 (P.101)

PC

Communication

To create tables or graphs of the

data saved in the memory for reports, etc.

❖6.4 (P. 134)

Function Purpose

Reference

page

www. .com

information@itm.com1.800.561.8187

Page 20

1.2 Features

1

2

3

4

5

6

7

8

9

10

11

付録

索引

15

Generates a wide range of test voltages, from

250 V to 5 kV

The voltage may be chosen from the commonly used presets of 250 V, 500 V, 1 kV, 2.5

kV, and 5 kV; or set to a desired level by

increments or decrements of 25 V or 100 V.

❖3.2 "Measuring Insulation Resistance" (page 56)

For automatic ca lculation and indic ation of

PI (polarization index) and DAR (dielectric

absorption ratio), step voltage testing, and

temperature correction.

❖4 "Advanced Measurement" (page 79)

Stores up to 100 manual records and 10

logging records. The stored data may be

displayed on the LCD or downloaded to a

PC.

❖5 "Recording Measurement Data (Memory Func-

tion)" (page 101)

6.4 "Communicating with PC" (page 134)

The large display provides easy viewing.

Measurements may also be displayed

using a logari thmic bar graph, offeri ng the

feel of an analog meter.

The LCD is backlit, enabling measurement

in poor lighting condi t i on s .

The tester has a USB interface. Data stored

in the memory may be downloaded to PC

using the data download softwar e.

The same softw are also en ables re ports to

be created and printed with ease.

❖6.4 "Communicating with PC" (page 134)

1.2 Features

Wide test voltage range

Insulation diagnoses

Large memory

Large, clear display

PC software with report creation/

printing feature

www. .com

information@itm.com1.800.561.8187

Page 21

1.2 Features

16

The case is durable-designed to withstand

the toughest of working conditions, compact, and highly portable.

The tester may be powered by either alkaline or rechargeabl e ni ckel -hydro gen ba tter ies. (Selectable via switch)

❖2.1.1 "Installing or Replacing the Battery" (page

31)

2.1.2 "Installing the Battery Pack (Rechargeable

nickel-hydrogen battery)" (page 34)

Compact hard case

Dual battery power supply

www. .com

information@itm.com1.800.561.8187

Page 22

1.3 Measurement Overview

1

2

3

4

5

6

7

8

9

10

11

付録

索引

17

This tester is designed for measurement of

the following:

Measurement condition

When measuring insulation resistance,

ensure that power supply to the object

under test is turned off.

Performing Measurement

• 3455 HIGH VOLTAGE INSULATION HiTESTER

• LR6 alkaline battery, or

9459 BATTERY PACK

• 9750-01,-02,-03 TEST LEAD

• 9751-01,-02,-03 ALLIGATOR CLIP

• 9631-01,-05 TEMPERATURE SENSOR

(for temperature measurement)

1.3 Measurement Overview

Purpose : Inspection of high-voltage electrical

facilities

Location : High-voltage receiving station or trans-

forming station

Test object : Large motors, transformers, cables,

etc.

• Measures insulation resistance, voltage and temperature.

• Stores measurement data in the internal memory.

• Downloads data to a PC for table, graph, or report

creation.

www. .com

information@itm.com1.800.561.8187

Page 23

1.3 Measurement Overview

18

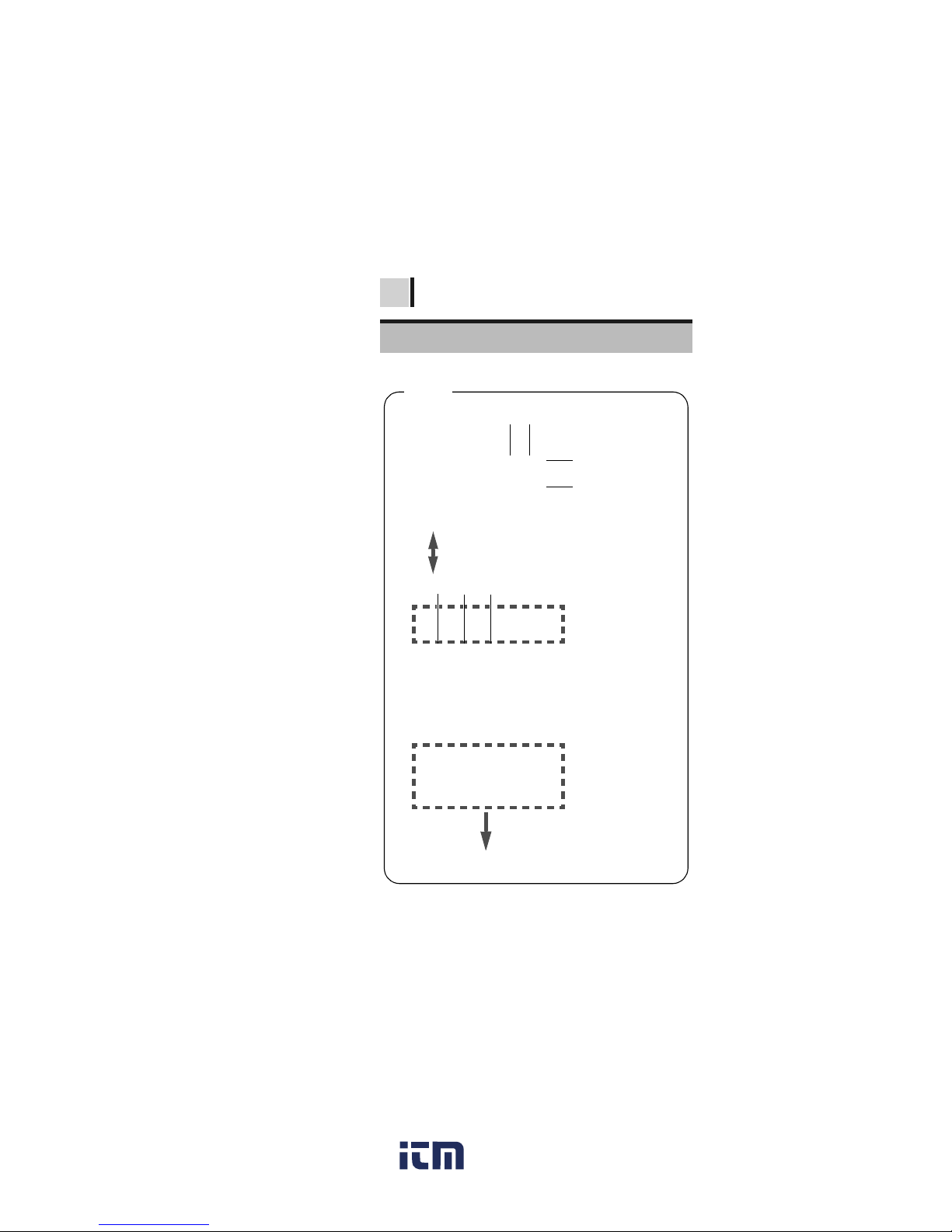

Flow of measurement

Before startin g mea surem ent, che ck th e f ollowing:

• The power supply method.

• The power ON/OFF method.

• That date and time are set.

• Connection of test leads, temperature

sensor, and USB cable .

Insulation Resistance Measurement

→3.2 "Measuring Insulation Resistance" (page 56)

1 Prepare for measurement

→2 "Measurement Preparations" (page 31)

2 Start measurement.

1.

Make sure that powe r supply to the object under

test is turned off.

2.

Press the key to turn on

the tester.

❖2.2 (page 44)

www. .com

information@itm.com1.800.561.8187

Page 24

1.3 Measurement Overview

1

2

3

4

5

6

7

8

9

10

11

付録

索引

19

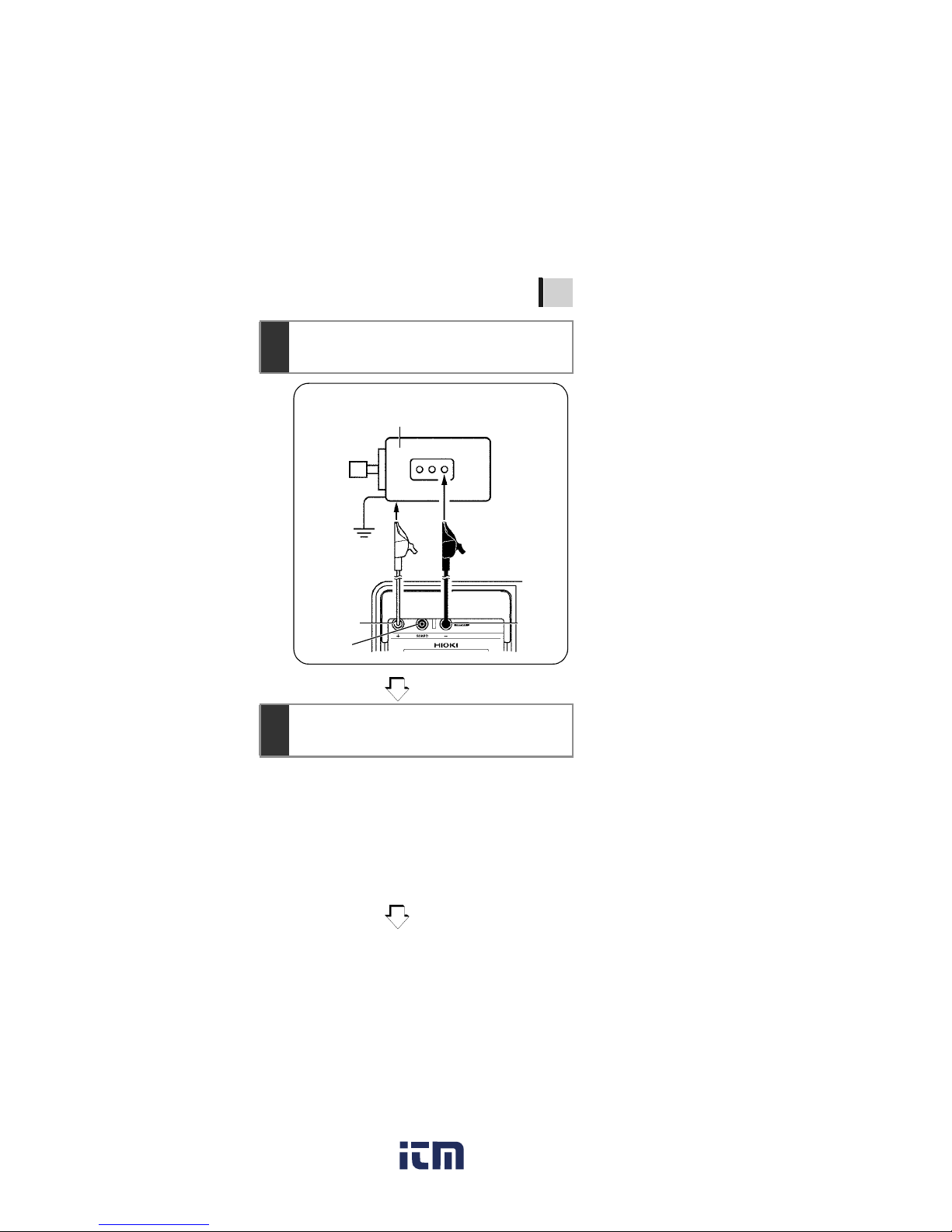

3.

Connect the test leads into the

"+" and "-" terminals of the tester

and to the object to be tested.

❖2.4 (page 50)

3.2.1 (page 58)

4.

Press the key and set

the test voltage.

❖3.2.1 (page 58)

GUARD

terminal

Warning: Confirm that the power supply to the

object under test has been turned off.

Object to be measured (Ex.: Motor)

+ terminal

- termina

l

Test lead (Red)

Attach to a metal

chassis or a ground

terminal.

Test lead (Black)

Attach to a metal part

of the power supply

terminal.

www. .com

information@itm.com1.800.561.8187

Page 25

1.3 Measurement Overview

20

5.

Press the key to generate a voltage and start measure-

ment.

❖3.2.1 (page 58)

6.

Read the indication.

❖3.2.1 (page 58)

7.

Press the key to stop

voltage generation and measure-

ment.

❖3.2.2 (page 64)

8.

The automatic discharge func tion

is activated.

❖3.2.4 (page 67)

9.

Measurement is terminated when

the voltage falls below 10 V.

www. .com

information@itm.com1.800.561.8187

Page 26

1.3 Measurement Overview

1

2

3

4

5

6

7

8

9

10

11

付録

索引

21

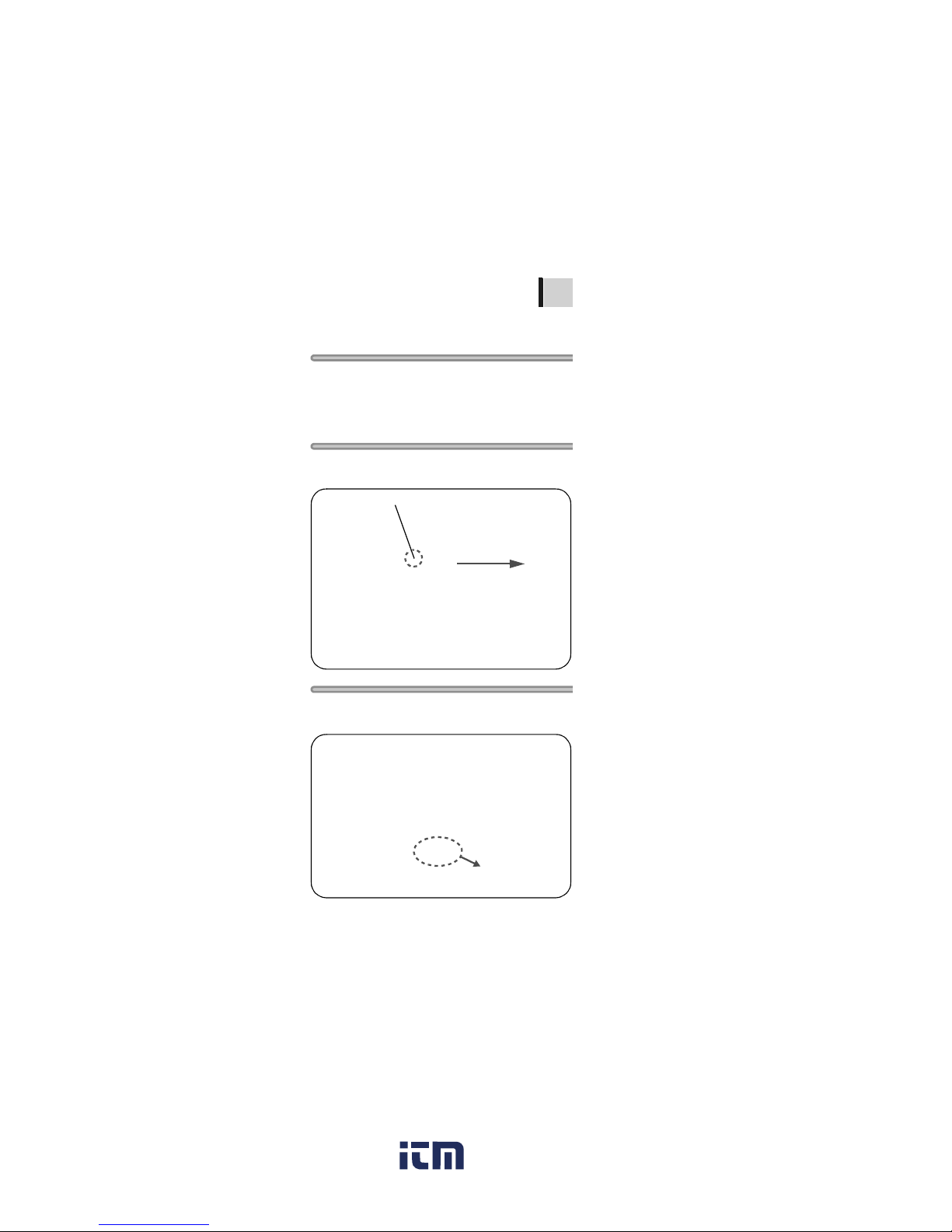

Voltage Measurement

→ 3.3 "Measuring Voltage" (page 73)

1.

Connect the test leads into the "+" and "-" terminals of the tester and to the object to be tested.

2.

Read the indication.

+ terminal

- terminal

GUARD

terminal

Test lead (Red) Test lead (Black)

www. .com

information@itm.com1.800.561.8187

Page 27

1.3 Measurement Overview

22

Temperature Measurement

→ 3.4 "Measuring Temperature" (page 76)

1.

Insert the temperature sensor into the temperature sensor terminal of the tester.

2.

Read the indication.

3.

Press the key to stop temperature measurement.

www. .com

information@itm.com1.800.561.8187

Page 28

1.3 Measurement Overview

1

2

3

4

5

6

7

8

9

10

11

付録

索引

23

Insulation resistance and temperat ure measurement data are held after measu rement

is completed.

This data will be cleared if power is turned

off. To store the data, use the memory function.

3 Record measurement data

→5 "Recording Measurement Data (Memory Function)

"

www. .com

information@itm.com1.800.561.8187

Page 29

1.4 Names and Functions of Parts

24

1.4 Names and Functions of Parts

Front

1. 2.

3.

LCD

Slide the shutter.

Operating panel

❖(page 26)

4.

567

www. .com

information@itm.com1.800.561.8187

Page 30

1.4 Names and Functions of Parts

1

2

3

4

5

6

7

8

9

10

11

付録

索引

25

Name Function

1

AC adapter

terminal

Connect the AC adapter to this terminal.

❖2.1.3 "Connecting the AC Adapter" (page

39)

2 USB terminal

Connect the USB Cable to this terminal.

❖6.4.3 "Downloading Data to Save to PC/

Setting up Tester on PC" (page 145)

3

Temperature

sensor

terminal

Connect the temperature sensor to this terminal.

❖2.5 "Connecting Temperature Sensor"

(page 52)

4 Shutter

Prevents connection to other terminals when

test leads are connected to the measurement

terminals-a safety feature.

5

+measurement

terminal

*

Connect the red test lead to this terminal.

❖2.4 "Connecting Test Lead" (page 50)

6

-measurement

terminal

*

Connect the black test lead to this terminal.

❖2.4 "Connecting Test Lead" (page 50)

7

GUARD

terminal

Connect the blue test lead to this terminal.

❖3.2.7 "Use of GUARD Terminal" (page 71)

*These are referred to simply as + and - terminals.

Back

Battery cover

Set screw

Battery pack compartment

(Under the battery cover)

Battery selector switch

(Under the battery cover)

Selects the type of battery.

LR6 alkaline battery

compartment

(Under the battery cover)

www. .com

information@itm.com1.800.561.8187

Page 31

1.4 Names and Functions of Parts

26

Key Function

1 Used to turn power on/off.

2

Used to set parameters.

Used to toggle between set voltage and monitor

voltage after resistance measurement.

3

Used to set parameters.

Used to set test voltage.

4

• Used to make fine adjustments to test voltage.

• Used to move the cursor to change units, values, etc.

• Used to display the date and time.

• Used to set the date and time.

5

• Used to make fine adjustments to test voltage.

• Used to move the cursor to change units, values, etc.

• Used to display the timer.

• Used to set the timer.

6

• Used to confirm entries.

• Used to stop temperature measurement.

Operating panel

6. 7.

2.

1.

8. 9. 10.

13.

14.

15.

11.12.

5.3.4.

www. .com

information@itm.com1.800.561.8187

Page 32

1.4 Names and Functions of Parts

1

2

3

4

5

6

7

8

9

10

11

付録

索引

27

7

(Warning lamp)

• Used to start and stop of resistance measurement.

• Blinks when a voltage is generated.

• Blinks when a voltage of 50 V or more is input

or when discharging is performed.

8

• Turns the LCD backlight on/off.

• LCD backlight automatically extinguishes after

30 seconds.

9

• Changes measurement units on the LCD.

•

When measuring resistance:

This key toggles between display of current

and resistance on the LCD

•

When the resistance value is held:

This key changes LCD display in the following

sequence: resistance→ current → DAR 1 min/

15s → DAR 1 min/30s → PI → resistance →

current → ...

10

• Used to view held temperature data.

• Used to enter the temperature of an external

thermometer.

11

Used to reduce drift of resistance or current

reading.

12 Used to enter the temperature correction mode.

13

• Used to store data in the memory.

• Used to display the date and time data was

stored in the memory.

14 Used to delete data in the memory.

15 Used to display data in the memory.

Key Function

www. .com

information@itm.com1.800.561.8187

Page 33

1.5 Screen Setup

28

❖3.3 "Measuring Voltage" (page 73)

❖3.4 "Measuring Temperature" (page 76)

1.5 Screen Setup

All On

Measuring Voltage

Measured

voltage

Blinking

Measuring Temperature

www. .com

information@itm.com1.800.561.8187

Page 34

1.5 Screen Setup

1

2

3

4

5

6

7

8

9

10

11

付録

索引

29

❖3.2 "Measuring Insulation Resistance" (page 56)

❖3.2.5 "Switching to Leakage Current Indication"

(page 68)

Measuring Insulation Resistance

Actual outp ut

voltage

Blinking

> blinks if the

input exceeds

the measurement range.

Elapsed time Insulation resistance

The screen is switched over with th

e

key.

Leakage Current Display

Blinking

Elapsed time

Actual ou tput

voltage

The bar graph

shows the

resistance

measurement.

< blinks at

below 1 nA.

Current measurement

www. .com

information@itm.com1.800.561.8187

Page 35

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

31

This tester may be powered by several

means.

• LR6 alkaline battery

❖See 2.1.1 "Installing or Replacing the Battery"

(page 31).

• 9459 BATTERY PACK (Option )

❖See 2.1.2 "Installing the Battery Pack

(Rechargeable nickel-hydrogen battery)" (page

34), and 2.1.4 "Charging the Battery Pack" (page

41)

• 9753 AC ADAPTER (Option)

❖See 2.1.3 "Connecting the AC Adapter" (page

39).

2.1.1 Installing or Replacing the Battery

Measurement

Preparations

2

2.1 S upplying Power

• To avoid electric shock, turn off the

power switch and disconnect the test

leads before repl ac i n g th e batteries.

• Do not mix old and new batteries, or dif ferent types of batteries. Also, be careful to observe battery polarity during

installation. Otherwise, poor performance or damage from ba ttery leakage

could result.

• After replacing the batteries, replace the

battery cover an d screws before using

the instrument.

• To avoid the possibility of explosion, do

not short circuit, disassemble or incinerate batteries .

• Handle and dispose of batteries in

accordance with local regulations.

www. .com

information@itm.com1.800.561.8187

Page 36

2.1 Supplying Power

32

Procedure

1. Turn off power and disconnect all the

test leads from the tester.

❖See 2.2 "Turning Power On and Off" (page 44).

2. Loosen the set screw on the re ar of the

tester and remove the battery cover.

• When the battery status indicator

is low, replace the batteries.

• Use the specified batteries on ly. Do not use

manganese batteries, for example, since

operating time will be greatly reduced.

• To avoid corrosion from battery leakage,

remove the batteries from the instrument

if it is to be stored for a long time.

Set screw

Remove

Battery cover

www. .com

information@itm.com1.800.561.8187

Page 37

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

33

3. Place six LR6 alkali ne batteries into the

battery compartment. (Replace a ll six at

the same time)

4. Turn the battery selector switch to LR6.

When the power i s t u rned on, “Lr6” appears

on the top left of the screen.

❖See 2.2 "Turning Power On and Off" (page 44).

5. Replace the battery cover and tighten

the set screw.

To LR6

www. .com

information@itm.com1.800.561.8187

Page 38

2.1 Supplying Power

34

2.1.2 Installing the Battery Pack

(Rechargeable nickel-hydrogen

battery)

• Use the optional 945 9 BATTERY PACK.

The operating t ime i s lon ger t han t hat with

alkaline batteries, and the pack is

rechargeable.

• Battery pack is dispatched in an uncharged

state. Charge before use.

❖Charging Procedure→

See 2.1.4 "Charging the Battery Pack" (page

41).

• For battery operation, use only the

HIOKI Model 9459 BATTERY PACK. We

cannot accept responsibility for accidents or damage related to the use of

any other batteries.

• To avoid heat buildup, rupture, or leakage of the battery, do not use if damaged, wires are expos ed, or the batter y/

tester connector is dam aged.

• To avoid electric shock, be sure to disconnect the test leads from the tester,

turn off power, and disconnect the AC

adapter from the tester, before installing

or removing the batter y pack.

• To avoid the possibility of explosion, do

not short circuit, disassemb le or incinerate battery pack. Hand le and dispose

of batteries in accordance with local

regulations.

Take care not to step on the battery pack

power cable, as this may dam age it.

www. .com

information@itm.com1.800.561.8187

Page 39

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

35

Installation

Procedure

Tools: Phillips screwdriver

1.

Turn off power and disconnect the test leads,

AC adapter and USB Cable from the tester.

❖See 2.2 "Turning Power On and Off" (page 44).

2. Loosen the set screw on the rea r of the

tester and remove the battery cover.

• If the battery pack is not used for an

extended period of time, remove it from the

tester and store at a temperature between

-20 to 30°C, to prevent deterioration.

• Charge the battery at least every 2

months. If the batte ry pack is lef t fo r a lo ng

period of time in a low state of charge, its

performance will be degraded.

• When the battery status indicator is low,

charge the battery pack.

• The charge stored in the battery pack

naturally dissipates over time, therefore be

sure to charge the battery pack before use.

If the operating time is extremely short

directly after the battery pack has been

charged, the battery needs to be replaced.

• The life of the battery pack is 500

charging cycles, i.e., about one year.

Set screw

Remove

Battery cover

www. .com

information@itm.com1.800.561.8187

Page 40

2.1 Supplying Power

36

3. Connect the battery pack to the tester.

(Align the protrusions.)

4. Place the battery pack in the battery

pack compartment.

5. Turn the battery selector switch to 9459.

When the power is turned on, “bP” appears

on the top left of the screen.

See 2.2 "Turning Power On and Off" (page 44).

6. Replace the battery cover and tighten the

set screw.

(Be careful not to catch the battery pack

cable in the battery cover, to prevent

damaged wiring.).

To 9459

www. .com

information@itm.com1.800.561.8187

Page 41

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

37

Replacement

Procedure

Tools: Phillips screwdriver

1. Turn off power and disconnect the test

leads, AC adapter, and USB cable from

the tester.

❖See 2.2 "Turning Power On and Off" (page 44).

2. Loosen the set screw on the rea r of the

tester and remove the battery cover.

3. Disconnect the plu g of the battery pack

from the connector of the tester.

Set screw

Remove

Battery cover

www. .com

information@itm.com1.800.561.8187

Page 42

2.1 Supplying Power

38

4.

Connect the new battery pack to the tester.

(Align the protrusions.)

5. Place the battery pack in the battery

pack compartment.

6. Turn the battery selector switch to 9459.

When the power is turned on, “bP” appears

on the top left of the screen.

See 2.2 "Turning Power On and Off" (page 44).

7. Place the battery c over and tighten the

screw.

To 9459

www. .com

information@itm.com1.800.561.8187

Page 43

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

39

2.1.3 Connecting the AC Adapter

• Optional 9753 AC ADAPTER can be used.

• When the AC adapter is connected to the

tester, you can ch arge the battery pack ,

communicate with a PC, perform temperature measurement, and edit the settings.

However, you cannot measure insulation

resistance, leakage current or voltage.

• Turn the instrument off before c onnecting the AC adapter to the instrument

and to AC power.

• Use only the specified Model 9753 AC

ADAPTER. AC adapter input voltage

range is 100 to 240 VAC (with ±10% stability) at 50/60 Hz. To avoid electrical

hazards and damage to the instrument,

do not apply voltage outside of this

range.

• To avoid electrical accidents and to

maintain the safety specifications of

this instrument, connect the power cord

only to a 3-contact (two-conductor +

ground) outlet.

The AC adapter cannot be used when

performing measurement using tester

leads.

www. .com

information@itm.com1.800.561.8187

Page 44

2.1 Supplying Power

40

Procedure

1. Insert the power cord into the AC

adapter.

2. Move the shutter of the tes ter to reveal

the AC adapter terminal.

3. Insert the output cable of the AC adapter

into the AC adapter terminal.

4. Make sure that the commercial power

source voltage matches the rated supply

voltage of the AC adapter. Insert the

plug into the AC outlet.

1

2 Move the shutter.

3

4

When the AC adapter is connected to the tester, power

is supplied from the AC adapter.

When both the battery and the AC adapter are connected to the tester, the battery is not used.

If the battery pack is installed, w hen the AC adapter is

connected to the tester, power of the tes ter is automatically turned on and charging of the battery pack begins.

www. .com

information@itm.com1.800.561.8187

Page 45

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

41

2.1.4

Charging the Battery Pack

The 9459 BATTERY PACK can be char ge d

while installed in the tester, using the

optional 9753 AC ADAPTER.

Short charge time: Approx. 3 hours (at

23°C room tem perature)

Procedure

1. Install the battery pack.

❖See 2.1.2 "Installing the Battery Pack

(Rechargeable nickel-hydrogen battery)" (page

34).

• Carry out battery charging at an ambient

temperature between 10°C and 40°C.

However, the ambient temperature may

influence the charging efficiency. Outside

this range, not onl y is the c harging c apacity

reduced, but also there is a possibility of

reduced performa nce o r electrolyte leak age.

• The battery pack cannot be charge d when

test leads are connected to the tester.

• The battery pack will be charged regard le ss

of the battery selector switch position.

• Communication with a PC and temp erature

measurement are available during charging.

But, insulation resistance measurement and

voltage measurement are not available.

• Only use the specified battery charger.

• Do not recharge a fully-charged battery

pack. If the ba ttery pack is o ver-charg ed,

a deterioratio n in performance or ba ttery

fluid leakage may result.

www. .com

information@itm.com1.800.561.8187

Page 46

2.1 Supplying Power

42

2. Move the shutter to reveal the AC

adapter terminal.

3. Connect the AC adapter to the AC

adapter terminal.

Rapid charging begins. During rapid charging, the battery status indicator blinks.

❖See 2.1.3 "Connecting the AC Adapter" (page

39).

Move the shutter.

1

2

3

Battery status indicator

Charging

If the AD adapter is connected to the tester when the

tester is off, the tester is automatically turned on and

rapid charging begins.

www. .com

information@itm.com1.800.561.8187

Page 47

2.1 Supplying Power

1

2

3

4

5

6

7

8

9

10

11

付録

索引

43

4. When rapid charging is completed, the

battery status indictor changes from

blinking to continuously lit. After rapid

charging finishes, the battery is tricklecharged (maintained in a fully-charged

state).

www. .com

information@itm.com1.800.561.8187

Page 48

2.2 Turning Power On and Off

44

Press and hold the key for

around one second.

After all the screen indications light, the

version and the position of the battery

selector switch appear and then the

tester enters the standby state.

The tester recalls the settings that were

present before power was last turned off.

Press the key.

The screen is switched off and power is

turned off.

2.2 Turning Power On and Off

T urning power On

Indicates the position of the battery selector switc

h.

bP: Using the Model 9459 BATTERY PACK

Lr6: Using the LR6 alkaline batteries

Version

When the battery status indicator

is low, replace the battery.

❖See 2.1.1 "Installing or Replacing the Battery"

(page 31).

If the batteries or the battery pac k i s ru nning

low, [

LObAt] is indicated. The tester turns

off if use is continued.

T uring power off

www. .com

information@itm.com1.800.561.8187

Page 49

2.2 Turning Power On and Off

1

2

3

4

5

6

7

8

9

10

11

付録

索引

45

2.2.1 Auto Power Off

• Power is automatically turned off around

10 minutes after the last operation. This

function, however, is not available during

insulation resistance measurement.

•[

APS] will start blinking around 30 sec-

onds before power is turned off .

• Auto power off is re-enabled upon turning

power on again . ([

APS] lights up.)

• When the AC adapter is connected to the

tester, auto power off is disabled.

• When the timer is set or when the tester is

in the step voltage test mode, auto power

off is disabled.

Turn on power while holding down the

key.

Canceling Auto Power Off

www. .com

information@itm.com1.800.561.8187

Page 50

2.3 Setting and Checking Date and Time

46

Set the time and date before use of the

tester. Use the Christian calendar.

2.3.1 Setting Date and Time

Procedure

1.

When the tester is in a standby state, press

the key. Year, month, and day appear .

2. Hold down key for more than one

second. The Year starts blinking.

2.3 Setting and Checking Date

and Time

www. .com

information@itm.com1.800.561.8187

Page 51

2.3 Setting and Checking Date and Time

1

2

3

4

5

6

7

8

9

10

11

付録

索引

47

3. Pressing moves the blinking

cursor. Place the cursor at the digit,

value, etc., you wish to change.

Year, month, day, hour, and minutes can

be changed.

The year-month-day screen and the hourminute-second screen are switched to and

from each other in the procedur e bel ow.

4. Press to change the number.

Hold down for fast increase/decrease.

5. The entry is confirmed by pressing the

key, after which the display returns

to the standby screen.

The clock starts to run from zero seconds

as soon as key is pressed.

Year-month-day

↓

Hour-minute-

second

• When year [

YEAR] is blink-

ing, press the key.

• When day [

DAY] is blinking,

press the key.

Hour-minute-

second

↓

Year-month-day

• When hour [

h] is blinking,

press the key.

• When minute [

min] is blink-

ing, press the key.

www. .com

information@itm.com1.800.561.8187

Page 52

2.3 Setting and Checking Date and Time

48

• The date and time can be set on a PC

using the data analysis software for

model 3455.

• The data analysis software for model

3455 must be installed on the PC.

❖Details → See 6.4 "Communicating with PC"

(page 134).

Date and time can be set on a PC.

www. .com

information@itm.com1.800.561.8187

Page 53

2.3 Setting and Checking Date and Time

1

2

3

4

5

6

7

8

9

10

11

付録

索引

49

2.3.2 Checking Date and Time

Procedure

1. When the tester is in the standby state,

press the key.

Year, mon th , an d da y app ea r.

2. Press the key.

Hours, minutes, and seconds appear.

3. Pressing key returns to the standby

screen.

www. .com

information@itm.com1.800.561.8187

Page 54

2.4 Connecting Test Lead

50

Procedure

1. Connect the alligat or clip to the end of

each test lead. Insert it fully.

2. Move the shutter to re veal the + and -

terminals.

2.4 Connecting Test Lead

• To avoid electric shock, be sure to disconnect the test leads from the object

under test and turn off power, before

connecting or disconnecting the test

leads to/from the tester.

• To avoid electric shock, never use the

tester if the shutter is broken.

Test leads cannot be connected to the

tester if the AC adapter, a temperature

sensor, or USB Cable i s connected.

www. .com

information@itm.com1.800.561.8187

Page 55

2.4 Connecting Test Lead

1

2

3

4

5

6

7

8

9

10

11

付録

索引

51

3. Connect the red test lead to the + terminal

and the black test lead t o the - t ermi nal.

For insulation resistance m easurement,

connect the blue test lead to the GUARD

terminal if necessary.

Check that the test leads are fully

inserted.

❖GUARD terminal → See 3.2.7 "Use of GUARD

Terminal" (page 71).

+ terminal

- termina

l

GUARD

terminal

Test lead (Red) Test lead (Black)

www. .com

information@itm.com1.800.561.8187

Page 56

2.5 Connecting Temperature Sensor

52

Procedure

1. Move the shutter to reveal th e temperat ure

sensor terminal.

2. Connect the tempe rature sensor to the

temperature sensor terminal.

Temperature measurement begins automatically.

2.5 Connecting Temperature

Sensor

Temperature sensors may be damaged by

high voltage or static electricity. Do not

expose the temperature sensor to excessive

impact, or allow the cable to be bent, since

malfunction or faulty connection may result.

Temperature sensors cannot be used

simultaneously with test leads.

Move the shutter.

Temperature

sensor terminal

www. .com

information@itm.com1.800.561.8187

Page 57

3.1 Pre-Operation Inspection

1

2

3

4

5

6

7

8

9

10

11

付録

索引

53

To ensure safe use of the tester, be

sure to check it before use.

Confirm that the tester chassis, shutter, test

leads, and clips are not damaged.

Do not used if damaged.

Equipment

•20 MΩ resistor that provides a voltage of

5 kV

• High-voltage meter with an input resistance of 1,000 MΩ or more, and capable

of measuring up to 5.5 kV DC

Measurement 3

3.1 Pre-Operation Inspection

Before using the inst rument, make sure

that the insulation on the test leads and

cables is undamaged and that no bare

conductors are improperly exposed.

Using the product in such conditions

could cause an electric shock, so contact

your dealer or Hioki representative for

replacements.

Make sure the terminals are clean and dry.

Wipe with a dry cloth to remove any

moisture, since measurement errors may

result if moisture is present.

❖See 8.2 "Cleaning" (page 162).

Checking for damage

Checking test voltage and resistance

reading

www. .com

information@itm.com1.800.561.8187

Page 58

3.1 Pre-Operation Inspection

54

Inspection

Procedure

1. Clip the resistor to the red and black test

leads connected to the tester.

2. Also, clip the resisto r to the test lead of

the high-voltage meter.

3. Set the test voltage of the tester to

[5.00 kV].

❖See 3.2Measuring Insulation Resistance, Proce-

dure 5. (page 60) to 8. (page 60).

4. Hold down key for more than

one second to start insulation re sistance

measurement.

5.

Check to see if the reading of the high-voltage meter is somewhere between 5 kV and

5.5 kV.

6. Check to see if the voltage reading of the

tester is somewhere betwee n 5 kV and

5.5 kV.

www. .com

information@itm.com1.800.561.8187

Page 59

3.1 Pre-Operation Inspection

1

2

3

4

5

6

7

8

9

10

11

付録

索引

55

7. Check to see if the insulation resistance

reading of the tester is 20 MΩ.

8. Stop insulation resistance measurement.

❖See 3.2.2 "Ending Measurement" (page 64).

9. Short-circuit the tips of the clips of the

red and black test leads of the tester.

10. Press the key to see if the test volt-

age setting is [5.00 kV].

11. Hold down the key for more than

one second to start insulation resistance

measurement.

12. Check to see if the insulation resistance

reading of the tester is 0.00 MΩ.

If a problem exists, discontinue use of

the tester.

Insulation resistance

Voltage

www. .com

information@itm.com1.800.561.8187

Page 60

3.2 Measuring Insulation Resistance

56

3.2 Measuring Insulation

Resistance

Observe the following to avoid electric

shock and short circuits.

A. Do not use the

tester if the shutter

is broken.

B. Check Table 1

before connecting test leads to the tester.

C. Ch eck to see if the o bject under test i s not

live or electrically charged using a high-voltage detector or other similar instrument,

before connecting test leads to it.

Table 1

Check item Result Action

Are the mark

and key lamp

off?

Off Connect test leads to the tester

and check C. above. If safe to

proceed, connect the test leads

to the object under test.

→ Go to Table 2.

Blinking Press the key to stop

voltage generation.

Table 2

Check item Result Action

Are the mark

and key lamp

blinking?

Not blinking Measurement may be com-

menced

Blinking Immediately disconnect the

test leads from the object under test and turn off power to

the object or discharge the

electric charge using a discharge rod.

Shutter

www. .com

information@itm.com1.800.561.8187

Page 61

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

57

• When measuring insulation resistance,

dangerous voltage is applied to the

measurement terminals. To avoid electric shock, do not touch the terminals

and test leads.

• Do not touch the object under test or

disconnect the test leads after measurement has been co mp l et ed u ntil the automatic discharge function is comple ted.

Electric shock may result due to high

voltage an d stored charge.

❖See 3.2.4 "Automatic Discharge Function" (page

67).

• Power of the tester may be turned off

during measure ment even if the

key is not pressed, for instance, due to

battery consumption. In such ca se, the

automatic discharge function may not

operate. Discharge the object under

test using a discharge rod for h igh volt age.

• To avoid damage to objects under test, be

sure to check the test voltage before

starting measurement.

• When repeating measurement, press the

key before next measurement to check

the test voltage.

• To avoid damage to the tester during

discharge, do not measure the insulation

resistance between the terminals of

capacitors (with a capacitance of over 4 μF).

• To avoid damage to the tester, do not

short-circuit the tips of the clips of the red

test lead (+ terminal) and the blue test lead

(GUARD terminal).

www. .com

information@itm.com1.800.561.8187

Page 62

3.2 Measuring Insulation Resistance

58

3.2.1 Starting Measurement

Procedure

1. Connect the alligat or clip to the end of

each test lead. Insert it fully.

2. Move the shutter to re veal the + and -

terminals.

www. .com

information@itm.com1.800.561.8187

Page 63

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

59

3. Connect the red test lead to the + terminal

and the black test lead t o the - t ermi nal.

Connect the blue test lead to the

GUARD terminal if necessary.

Fully insert the test leads.

❖See 3.2.7 "Use of GUARD Terminal" (page 71).

4. Clip the alligator clip at the end of each

test lead to the object under test.

GUARD

terminal

Warning: Confirm that the power supply to the

object under test has been turned off.

Object to be measured (Ex.: Motor)

+ terminal

- termina

l

Test lead (Red)

Attach to a metal

chassis or a ground

terminal.

Test lead (Black)

Attach to a metal part

of the power supply

terminal.

www. .com

information@itm.com1.800.561.8187

Page 64

3.2 Measuring Insulation Resistance

60

5. Press the key, after which the

voltage disp l ay starts blinki ng .

6. The test voltage is chosen from 250 V,

500 V, 1.00 kV, 2.50 kV, and 5.00 kV

using the keys.

7. Pressing keys, you can make

fine adjustment of the test voltage setting.

8.

Press the key to set the test voltage.

The voltage indication will change from

blinking to continuous.

This test voltage is now set.

For step voltage testing, h old down the key,

which will display [

STEP]. For non-stepped insula -

tion resistance measurement, pre ss the key

and choose a voltage.

www. .com

information@itm.com1.800.561.8187

Page 65

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

61

9. Hold down the key for more than

one second.

A voltage is generated and measurement

begins.

The mark and key lamp

starts blinkin g.

If > blinks, the input value is out of measurement range.

Example: > 5.00TΩ means "larger than 5.00 TΩ."

• During measureme nt, [

SET] is turned off in the voltage indica-

tion field and the indication ch anges from the test voltage to

the actual output voltage. A voltage approximatel y 5% higher

than the set level is output.

• To view the set voltage during measurement, press the

key. The set voltage is displayed for approximately 2 seconds.

• During measurement, i f the output voltage is lower than the

set level, the voltage indication blinks.

• Under the resistance indication appears time elapsed from the

start of measurement.

Actual outp ut

voltage

Blinking

>blinks if the

input exceeds the

measurement

range.

Elapsed time Insulation resistance

www. .com

information@itm.com1.800.561.8187

Page 66

3.2 Measuring Insulation Resistance

62

10. Read the indication.

• If the indication is unstable, press the key.

The average of the measurements is shown.

• Resistance indication is switched to leakage current

indication by pressing the key.

❖See 3.2.5 "Switching to Leakage Current Indication" (page

68).

• When the timer has been set, remaining time is displayed.

❖See 4.1 "Using Timer" (page 79).

Do not allow test leads to contact each other

or place objects on test leads, to avoid measurement errors and mal functions.

• Be sure to clean test leads after use. If test

leads are soiled, they may deteriorate.

• Insulation resistance is unstable. The

indication may not stabilize with some

objects.

• Due to factors such as capacitance of

objects under test, resistance values may

start low, then ri se gradually and set tle out.

• During measur ement, if the resis tance of

the object suddenly drops or if the test

lead tips are short-circuited, the tester

stops voltage generation as a safety

measure. (This applies to a test voltage of

1.1 kV or more.)

www. .com

information@itm.com1.800.561.8187

Page 67

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

63

When the display reflects the following

state, insulation resistance measurement

cannot be started.

• The setting value is blinking to indicate

that the instrument being set up

• The mark is blinking

• While [TC] is lit, the actual measurement

temperature is shown as [- - -]

• An error massage is displayed

If the indicat ion is unstable, the averag e of

the measurement is shown.

Pressing the average key togg l es [AVE] on/

off.

While [AVE] is on, display update interval is

four seconds, normally.

But in the following case, the interval is one

second even if [AVE] is on .

• During 15 seconds after the measurement started

• During 5 to 10 seconds after the measurement range changed

The state not to be started the meas urement

Average function

www. .com

information@itm.com1.800.561.8187

Page 68

3.2 Measuring Insulation Resistance

64

3.2.2 Ending Measurement

Procedure

1. Press the key with the test leads

connected to the object unde r te st.

The last measurement is held.

( lights up.)

2. Immediately after measurement has

been completed, the discharg e circuit in

the tester automatically discharges the

electric charge remaining in the object

under test.

❖See 3.2.4 "Automatic Discharge Function" (page

67).

3. During discharge, the mark and

key lamp blinks.

The voltage indication shows the progress

of discharge.

www. .com

information@itm.com1.800.561.8187

Page 69

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

65

4. When the voltage falls to about 1 0 V, the

tester stops discharging and the mark

and key lamp are turned off.

5. To restart measurement, press the

key to check the test voltage before

resuming measurement.

• If the key is press ed du ring mea surem ent,

automatic discharge is performed before power is

turned off.

• If the battery runs low during measurement, the

tester automatically stops measurement. Automatic

discharge is performed and then [LObAt] appears on

the screen.

LastElapsed time of the

Actual output

voltage

(last measurement)

end of measurement measurement value

Check

www. .com

information@itm.com1.800.561.8187

Page 70

3.2 Measuring Insulation Resistance

66

3.2.3 Checking and Deleting Held Data

The following data are held and displayed

after insulation resistance measurement

has been completed.

• Insulation resistance (digital value and

bar graph)

• Test voltage

• Actual output voltage

• Leakage current

• Elapsed time

Some data may not be di splayed. Press the

keys shown in the table below to switch the

indication.

To clear the data, press the key for more

than one second.

Temperature/humidity data will not be

cleared.

Checking Held Data

Data indications to be switched Keys used

key

key

Elapsed time ↔ Temperature/humidity

(When the data are held)

key

Insulation

resistance

Leakage

current

↓

← DAR 1 min/ 30 s

↑

PI (10/1 min.)

DAR 1 min/15 s

↓

→

Test voltage

(setting)

Actual outpu t

voltage

↔

The held data are cleared when power is

turned off. To save the data, use the

memory function.

❖See 5 "Recording Measurement Data (Memory

Function)" (page 101).

Deleting Held Data

www. .com

information@itm.com1.800.561.8187

Page 71

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

67

3.2.4 Automatic Discha rge Function

• When insulation resistance with a capacitance component is measured, this component remains charged with a highvoltage equivalent to the test voltage,

which is dangerous.

• This tester automatically discharges

remaining electric charge using the internal circuit after measuremen t.

• Make sure that the test leads are connected

to the measured object when pressing the

key to stop measurement.

• Discharging stops when the residual voltage falls below 10 V. The discharge time

varies depending on the capacitance.

After the voltage has been decreased by

the tester’s automatic discharge function,

the voltage in the measurement area may

rise again due to the remaining charge in

the capacitor C

A shown in the diagram in

section 3.2.6. Take great care when touching the object under test.

www. .com

information@itm.com1.800.561.8187

Page 72

3.2 Measuring Insulation Resistance

68

3.2.5 Switching to Leakage Current Indication

Insulation resistance indication may be

switched to leakage current indication.

Every time the key is pressed, the

indication changes in the order: resistance

→ current → PI → resistance → etc.

Every time key is pressed, the indication changes in the order: resistance

→

current → resistance → current → etc.

During measurement

Blinking

Elapsed time

Actual ou tput

voltage

The bar graph

shows the

resistance

measurement.

< blinks at

below 1 nA.

Current measurement

Before me asur ing in sul ati on r esi stance

and after se tting test v olt age

( indicator is off.)

Measuring insulation resistance

www. .com

information@itm.com1.800.561.8187

Page 73

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

69

Every time key is pressed, the indication changes in the order: resistance

→

current → DAR 1 m in/15s → DAR 1 min/30s

→ PI → resistance → current → etc.

❖PI/DAR → See 4.2 "Displaying PI and DAR"

(page 83).

3.2.6 Insulation Resist ance M easurement

Basis

When a high DC voltage is applied to an

object under test, a leakage current flows.

The insulation resistance tester measures

the applied voltage V and the combined

leakage current I and then calculates the

insulation resist ance R.

Calculation formula R = V/I

I

C and IA gradually decrease after the volt-

age is applied.

Holding data after measurement

If the indication is unstable, press the key. The

average of the measurements is shown.

[< 1.00 nA] means "below 1.00 nA."

Applied

voltage

V

Insulation

tester

Capacity

C

Insulation

resistance

R

Steady-state

leakage

current

I

R

Charge

current

I

C

Absorption

current

I

A

Insulating material

C

A

Combined leakage current I

A

Current

detector

R

A

www. .com

information@itm.com1.800.561.8187

Page 74

3.2 Measuring Insulation Resistance

70

When measuring the same object repeatedly, the insulation resistance and leakage

current indications may differ. This is caused

by polarization*, which occurs when a voltage is applied to an insulating material.

An insulating material is represented by an

equivalent circuit as shown by the diagram

on the previous page.

Absorption current due to relatively slow

polarization is represented by I

A, as shown

in the diagram above. It takes time for the

polarization caused by the previous measurement disappear. Until it does, electric

charge remains in C

A as shown in the dia-

gram. The electric charge level in C

A differs

at the start of previous measurement and at

the start of next measurement and thus

absorption current I

A differs, too. Further, the

combined leakage current and insulation

resistance vary from measurement to measurement. This will be become more apparent for higher insulation resistance values.

To ensure reproducibility of measurement,

leave a sufficient time interval between measurement sessions. Further, the ambient

temperature and humidity should not vary.

*Polarization: the phenomenon in which positive

negative charges on the atoms of a

material move in opposite directions

when an electric field is applied to the

material.

Reproducibility of insulation resistance

measurement

www. .com

information@itm.com1.800.561.8187

Page 75

3.2 Measuring Insulation Resistance

1

2

3

4

5

6

7

8

9

10

11

付録

索引

71

3.2.7 Use of GUARD T erminal

A GUARD terminal is used to prevent the

surface electrical resistance of an insulating

material affecting measurement, enabling

correct measurement of the entire volume of

the material.

When testing the insulation of a cable, as

shown in the diagram above, wind a bare

conductor around th e surface of the insulating material and connect the conduc tor to

the GUARD terminal. This prevents the

leakage current on the surface of the insulating material flowing into the current

detector, which enables the actual resistance of the entire vo lume of the insu lating

material to be measured.

Measurement unaffected by surface

electrical re sis t ance

Metallic shielding layer

Bare conductor

Insulating material

Cable

Core

Current

detector

Power supply

www. .com

information@itm.com1.800.561.8187

Page 76

3.2 Measuring Insulation Resistance

72

G terminal grounding is used for measuring

the insulation resistance between the core

and the metallic shielding layer of a highvoltage cable with the cable connected to

other high-voltage equipment. The diagram

below shows an example of measurement.

Rc: Insulation resistance of the insulating

material of the high-voltage cable

(Between core and metallic shielding

layer)

Rs: Insulation resistance of the sheath of

the high-voltage cable

(Between metallic shielding layer and

ground)

Rn: Insulation resistance between insulator

or high-voltage equipment and ground

Influence of Rs and Rn is removed and

solely Rc is measured.

Reference

→ High-voltage power receiving

facility code 2002

Measurement using G (GUARD)

terminal grounding

Meter transformer

Disconnecto

r

Load

Core

R

nRc

Rs

N

Remove

Grounding

P

Power supply

wire

Cable

Power

supply

side

side

wire

Metallic shielding layer

of the cable

Current

detector

www. .com

information@itm.com1.800.561.8187

Page 77

3.3 Measuring Voltage

1

2

3

4

5

6

7

8

9

10

11

付録

索引

73

The tester measures the voltage of an external circuit, e.g., commercial power supply.

AC and DC are d i stinguished automatically.

3.3 Measuring Voltage

To prevent damage to the tester and personal injury, observe the precautions

below.

• Maximum rated voltage to ground: 1,000

Vrms (CATIII), 600 Vrms (CATIV)

• Do not conduct m easurement exceeding

these voltages to ground.

• Maximum input voltage: 750 Vrms, 1,000

VDC

• Do not conduct m easurement exceeding

this maximum input voltage.

• Maximum input frequency: 70 Hz

• Do not conduct measurement exceeding this maximum input frequency.

• Do not short-circuit a line voltage

applied with the