Page 1

Instruction Manual

3390

POWER ANALYZER

December 2010 Revised edition 1 3390A981-01 10-12H

Page 2

Page 3

Contents

Introduction.................................................................................1

i

Contents

1

Confirming Packa g e Co n te n ts.............. .. ... .. ... ..................... ... .. ..1

Safety Notes... .. .. ...................... .. ... .. ...................... .. ... .. ..............3

Usage Notes................................................. ..............................5

Chapter 1

Overview___________________________________ 9

1.1 Product Overview ................................................................9

1.2 Features ........................................................ .................... 10

1.3 Operating Overview ..........................................................12

Chapter 2

Names and Functions of Parts,

Basic Operations & Screens__________________ 13

2.1 Names and Functions of Parts ..........................................13

2.2 Basic Operations ........................................... ............ ........16

2

3

4

5

6

7

2.3 Display Items and Screen Types ......................................17

2.3.1 Common Disp la y Ite m s ................... .......................................17

2.3.2 Measurement Scr een .............................................................18

2.3.3 Screen Types ............................ ................ .............................19

Chapter 3

Measurement Preparations___________________ 23

3.1 Operations in general ........................................................23

3.2 Initial Instrument Preparations ..........................................24

3.3 Pre-Operation Inspection ..................................................26

3.4 Connecting the Power Cord ..............................................27

3.5 Grounding the Instrument's Functional Earth

(when measuring in noisy environments) .........................27

3.6 Connecting the Voltage Measurement Cables .................28

3.7 Connecting the Current Sensors .......................................28

3.8 Turning the Power On and Off ..........................................29

8

9

10

11

12

付

3.9 Selecting the Wiring Mode ................................................30

3.10 Attaching to the Lines to be Measured and Zero Adjustment 34

3.11 Verifying Correct Wiring (Connection Check) ...................36

録

索

引

Page 4

ii

Contents

Chapter 4

Viewing Measurement Values_________________37

4.1 Measurement Value Display Procedure ...........................37

4.2 Viewing Power Measurements, and Changing the

Measurement Configuration .............................................41

4.2.1 Displaying Power Measurements .......................................... 41

4.2.2 Selecting Ranges ...................................................................43

4.2.3 Selecting the Sync Source ..................................................... 47

4.2.4 Frequency Measurement Settings .........................................49

4.2.5 Selecting the Rectification Method .........................................50

4.2.6 Setting Scaling (when using VT(PT) or CT) ...........................51

4.2.7 Setting the Low-Pass Filter .................................................... 52

4.3 Integration Value Observation ..........................................53

4.3.1 Displaying Integration Values ................................................53

4.3.2 Setti ng the Integration Mode ........................................ ..........56

4.3.3 Manual Int egration Method ................. ................ ...................57

4.3.4 Integration Combined with Timing Control .............................59

4.4 Viewing Harmonic Measurement Values ..........................62

4.4.1 Displayi ng the Harmonic Bar Graph ....................... .. .............62

4.4.2 Displaying the Harmonic List .................................................64

4.4.3 Displaying Harmonic Vectors ................................................. 65

4.4.4 Selecting the Harmonic Sync So ur c e .................................... 67

4.4.5 Selectin g the THD Calculation Method ............................ .. .... 68

4.5 Viewing Waveforms ..........................................................69

4.5.1 Displaying Waveforms ........................................................... 69

4.5.2 Resizing Waveforms .............................................................. 71

4.6 Viewing Noise Measurement Values (FFT Function) .......72

4.6.1 Displaying Noise Voltage and Current ...................................72

4.6.2 Setting the Sampling Frequency and Points ..........................73

4.6.3 Setting the Minimum Noise Frequency ..................................74

4.6.4 Measurement Channel and Window Function Settings ......... 76

4.7 Viewing Efficiency and Loss Measurement Values ..........77

4.7.1 Displaying E ffi c iency and Loss ... ...................................... .....77

4.7.2 Selecting the Calculation Formu la ......................................... 78

4.7.3 Measuremen t E x a m p le s ........... .. .................... ....................... 79

4.8 Viewing Motor Measurement Values

(With Hioki 9791 or 9793 installed) ...................................82

4.8.1 Motor Input Settings ...............................................................84

4.8.2 Measuring Mo to r Electrical Angle ............. ............................. 89

Page 5

Chapter 5

11

Operating Functions ________________________ 91

5.1 Timing Control Functions ..................................................91

iii

Contents

11

5.2 Averaging Function ...........................................................93

5.3 Data Hold and Peak Hold Functions .................................94

5.3.1 Data Hold Function .................................................................94

5.3.2 Peak Hold Function ..................................... .. .........................95

5.4 X-Y Plot Function ..............................................................97

5.5

Chapter 6

Changing System Settings ___________________99

6.1 Initializing the Instrument (System Reset) ......................101

6.2 Factory Default Settings ..................................................102

Chapter 7

Data Saving and File Operations _____________103

7.1 Inserting and Removing Storage Media ..........................104

7.2 The File Operation Screen ..............................................105

Δ-YConversion Function ...................................................98

12

12

13

3

4

4

5

5

6

6

7

7

7.3 CF Card Formatting ........................................................106

7.4 Saving Operations ..........................................................107

7.5 Measurement Data Saving .............................................108

7.5.1 Manually Saving Measurement Data ....................................108

7.5.2 Auto-Saving Measurement Data ..........................................110

7.5.3 Selecting Measurement Items to Save .................................112

7.6 Saving Waveform Data ...................................................114

7.7 Saving Screen Capture Images ......................................114

7.8 Saving Setting Configurations .........................................115

7.9 Reloading Setting Configurations ...................................116

7.10 File and Folder Operations .............................................117

7.10.1 Creating Folders ...................................................................117

7.10.2 Copying Files and Folders ................................. ...................118

7.10.3 Deleting Files and Folders ....................................................120

7.10.4 Renaming Files and Folders .................................................121

8

9

10

付

録

索

引

Page 6

iv

Contents

Chapter 8

Connecting External Devices ________________123

8.1 Connecting a Printer (to print captured screen images) .123

8.1.1 Printer Preparation and Connection .....................................124

8.1.2 Settings to Use Printer ......................................................... 125

8.1.3 Printing Screen Captures .....................................................126

8.2 Connecting a Thermometer (to acquire temperature data) 127

8.3 Connecting Multiple 3390 (Synchronized Measurements) 129

8.4 Using Analog and Waveform D/A Output Options

(must be factory installed before shipping) .....................132

8.4.1 Connecting Application-Specific Devic es to the Instrument .132

8.4.2 Output Item Selection ..........................................................134

8.4.3 Output Level ........................................................................ 136

8.4.4 D/A Output Exa m p le s ................................................... ....... 137

8.5 Using the Motor Testing Option (when specified before

factory shipping, for motor analysis) ...............................138

Chapter 9

Operation with a Computer __________________141

9.1 Control and Measurement via Ethernet ("LAN") Interface 142

9.1.1 LAN Settings and Network Environment Configuration ....... 142

9.1.2 Instrument Connection .........................................................144

9.2 Remote Control of the Instrument by Internet Browser ..146

9.2.1 Connecti ng to the Instrument ...............................................146

9.2.2 Operati ng Procedure ...........................................................147

9.3 Control and Measurement via USB Interface .................148

9.3.1 Connecti ng to the Instrument ...............................................148

9.3.2 After Connec ting .......... ..................................... ................... 14 8

Chapter 10

Specifications_____________________________149

10.1 General Specifications ....................................................149

10.2 Functions Specifications .................................................156

10.3 Setting Specifications .....................................................160

10.4 Measurement Item Details ..............................................162

10.5 Calculation Formula Specifications .................................166

Page 7

Chapter11

11

Maintenace and Service ____________________ 175

11.1 Cleaning ........................................................ .................. 175

v

Contents

11

11.2 Trouble Shooting .............................................................175

11.3 Error Indication ................................................................177

11.4 Disposing of the Instrument ............................................181

Appendix__________________________________A1

Appendix1Block Diagram............................................................. A1

Appendix2Measurement Data Saving Format.............................. A2

Appendix3Physical Illustration...................................................... A4

Appendix4Rack Mounting............................................................. A5

Index ______________________________________ i

12

12

13

3

4

4

5

5

6

6

7

7

8

9

10

Appendix

Index

Page 8

vi

Contents

Page 9

Introduction

3390 POWER ANALYZER ....................... 1

Confirm that these contents are provided.

Accessories

When you recei ve the instrument, in spect it careful ly to ensure that no damage occurred dur ing shipping. In particular, check the accesso ries, panel swit ches, and con nectors. If dam age is eviden t, or if it

fails to operate according to the specifications, contact your dealer or Hioki representative.

Instruction Manual......................................1

Measurement Guide...................................1

Grounded power cord................................ 1

USB Cable........... ...... ....... ......................... 1

D-Sub Connector....................................... 1

(for use only with Model 9792 or

9793 D/A output options)

Input Cable Labels....... ...... ....... ...... ....... .... 2

(to identify volta ge cab le lea ds and input ch ann els)

Please attach to the instrument before use.

(p. 24)

Introduction

Thank you for purcha si ng t he HI OKI " 339 0 P OW ER ANALYZER". To obtain maximum performance fr om

the product, please read this manual first, and keep it handy for future reference.

In this document, the "instrument" means the Model 3390 Power Analyzer.To measure current, the power

analyzer requires cla mp- o n c urr ent prob es o r AC /DC c urr en t p ro bes ( Opti ons , ( p. 2), a fter war ds re ferr ed

to generically as “current sensors”). See your current sensor’s instruction manual for details.

Registered trademarks

• CompactFlash is a regi ste red tr ade mar k of Sa ndi s k Corp or ation ( USA ) .Wind ows is a regis te re d trademark of Microsoft Corporation in the United States and/or other countries.

• Sun, Sun Micros ystems, Java, and any logos containing S un or Java are trademarks or register ed

trademarks of Sun Microsystems, Inc. in the United States and other countries.

• Adobe and Reader are either regist ered tradem arks or trademar ks of Ado be Systems In corporated in

the United States and/or other countries.

Confirming Package Contents

1

Page 10

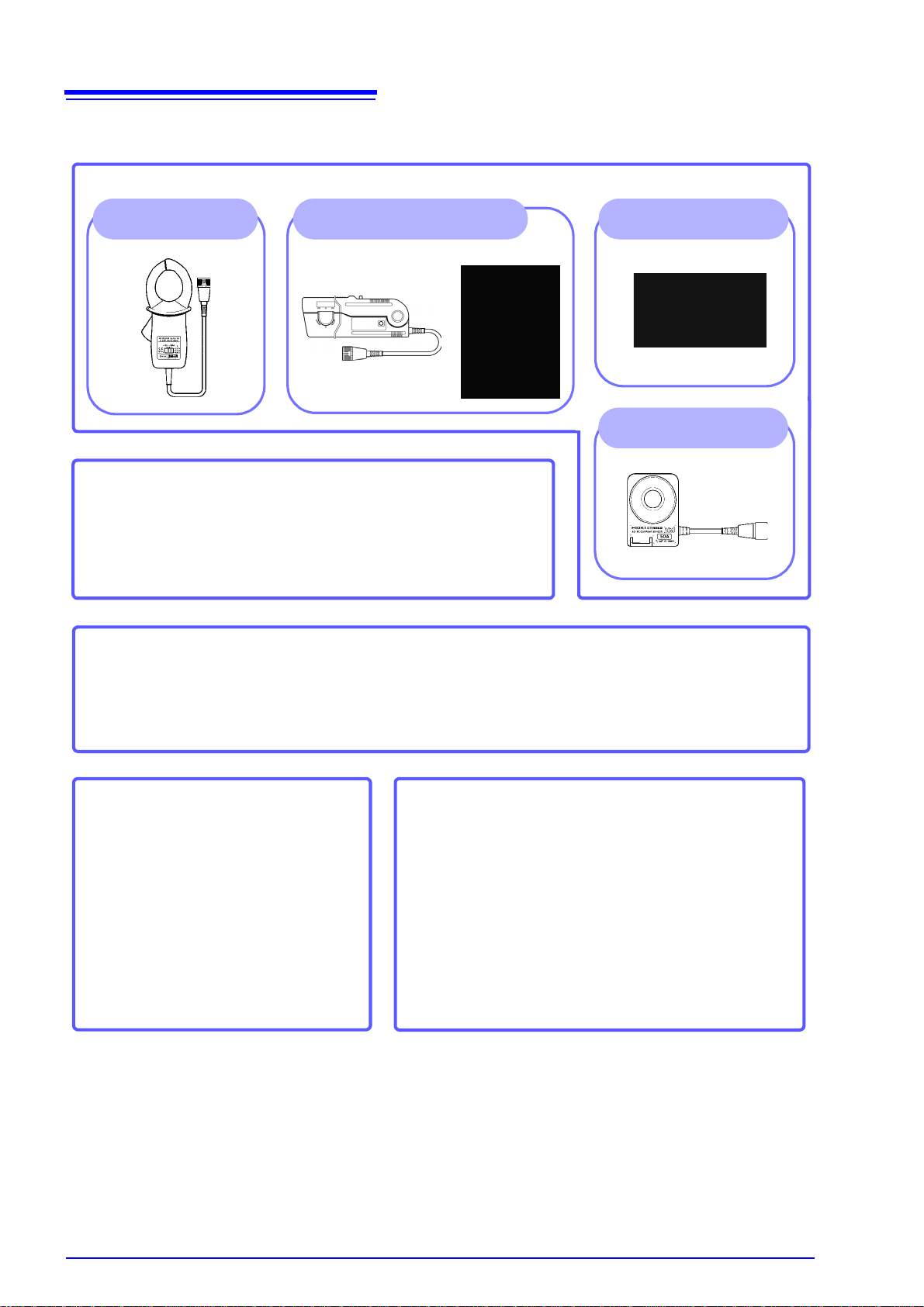

2

9272-10

Clamp On Sensor

Option

Others

• 9794 Carrying Case

• L9217 Connection Cord

(for Model 9791 and the 9793)

See "8.5 Using the Motor Testing Option (when specified

before factory shipping, for motor analysis)" (p. 138)

• 9683 Connection Cable (for synchronization)

See "Connecting Multiple 3390 (Synchronized Measure-

ments)" (p. 129)

Current Sensors

For Vol tage Measurement

• L9438-50 Voltage Cord (p. 24)

• 9243 Grabber Clip

• 9448 Concent Input Cord

For Computer Connection

• 9642 LAN Cable

• 9726 PC Card 128M

(128MB CFCard + Adapter)

• 9727 PC Card 256M

(256MB CFCard + Adapter)

• 9728 PC Card 512M

(512MB CFCard + Adapter)

• 9729 PC Card 1GB

(1GB CFCard + Adapter)

• 9830 PC Card 2GB

(2GB CFCard + Adapter)

9277, 9278, 9279

Universal Clamp On CT

For Printing

• 9670 Printer (includes one thermal paper roll, Sanei Electric Model BL-80RS II)

• 9671 AC Adapter (Sanei Electric Model BL-100W)

• 9237 RECORDING PAPER (thermal paper 80 mm × 25 m, 4 rolls)

• 9638 RS-232C Cable

CT6862, CT6863

AC/DC Current Sensor

9709

AC/DC Current Sensor

Confirming Package Contents

Page 11

Safety Notes

Safety Notes

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well a s damage t o the instrume nt. However, using the instrument in a way not described in this manual may negate the

provided safety features.

Be certain that you understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or injuries not resulting

directly from instrument defects.

This manual contains infor mation and warnings es sential for sa fe operati on of the produc t and for ma intaining it in safe operating condi tion. Before using the product, be sure to carefully read the following

safety notes.

Safety Symbols

3

In the manual, the symbol indicates particularly important information that the user should

read before using the product.

The symbol printed on the product indicates that the user should refer to a corresponding

topic in the manual (marked with the symbol) before using the relevant function.

Indicates a grounding terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the

product.

Advisory items related to performance or correct operation of the product.

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market after August

13, 2005, and producers of the Member States are required to display it on the appliance under Article

11.2 of Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to safety regulations set out by the EC Directive.

This symbol indicates applicability to the Electrical Appliance and Material Safety law (Japan on ly).

Page 12

4

Safety Notes

Other Symbols

Symbols in this manual

Indicates the prohibited action.

(p. )

*

[ ]

CURSOR

(Bold character)

Windows

Dialog

Indicates the location of reference information.

Indicates quick references for operation and remedies for troubleshooting.

Indicates that descriptive information is provided below.

Menus, commands, dialogs, buttons in a dialog, and other names on the screen and the keys

are indicated in brackets.

Bold characters within the text indicate operating key labels.

Unless otherwise specified, “Windows” represents Windows 95, 98, Me, Widows NT4.0, Windows 2000, Windows XP, or Windows Vista.

Dialog box represents a Windows dialog box.

Mouse action terminology

Click: Press and quickly release the left button of the mouse.

Right-click: Press and quickly release the right button of the mouse.

Double click: Quickly click the left button of the mouse twice.

Drag:

Activate: Click on a window on the screen to activate that window.

While holding down the left button of the mouse, move the mouse and then release the left

button to deposit the chosen item in the desired position.

Accuracy

We define measurement tol erances in terms of f.s. ( full sc ale), rdg. (readi ng) and dg t. (dig it) val ues, wi th

the following meanings:

f.s. (maximum display value or

scale length):

rdg. (reading or displayed value): The value currently being measured and indicated on the measuring instrument.

dgt. (resolution): The smallest disp layable unit o n a digital m easuring instru ment, i.e., the input

The maximum displ ay abl e v alu e o r scale length. This is u sua ll y th e name of

the currently selected range.

value that causes the d igital display to show a "1" as the l east-significa nt digit.

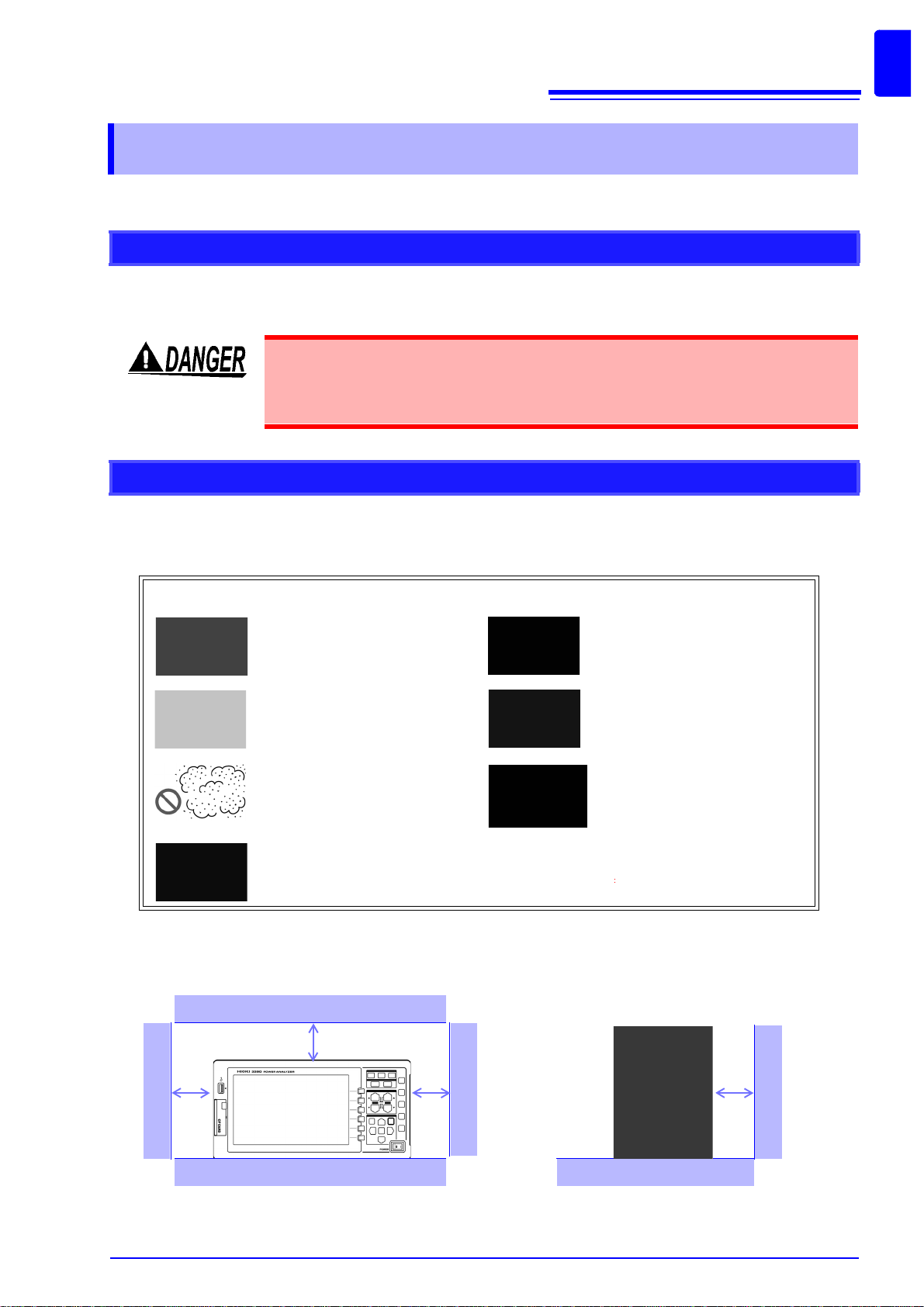

Measurement categories (Overvoltage categories)

This instrument complies with CAT II (1000 V)/ III (600 V) safety requirements.

To ensure saf e operation o f measur ement instr uments, IEC 61010 establishe s safety standards for v arious electrical envi r onm ents, c ateg oriz ed as C AT I to CAT IV, and called measurem ent categories. These

are defined as follows.

CAT Ⅰ :

CAT Ⅱ :

CAT Ⅲ :

CAT Ⅳ :

Higher-numbered categories correspond to electrical environments

with greater momentary energy. So a measurement device

designed for CAT III environments can endure greater momentary

energy than a device designed for CAT II.

Using a measurement instrument in an envi ronment designat ed with a

higher-numbered category than that for which the instrument is rated

could result in a seve re accid ent, an d m ust be car efu lly avoi ded.

Never use a CAT I measuring instrument in CAT II, III, or IV environments.

The measurement categories comply with the Overvoltage Categories of the IEC60664 Standards.

Secondary electrical circuits connected to an AC electrical outlet through a transformer or similar device.

Primary electrica l circuits i n equipmen t connected to an AC el ectrical outle t by a pow er cord (por table

tools, household appliances, etc.) CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heav y equipment (fixed installations) c onnected directly to the distribution

panel, and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance, and to the power meter and primary over-

current protection device (distribution panel).

Page 13

Usage Notes

50 mm or more

50 mm or more

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Before Use

Before using the ins trument the first ti me, verify that it operates normall y to ensure that t he no damage

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the instrumen t, make sure that t he insulation on the v oltage cords

is undamaged and that no bare conductors are improperly exposed. Using the

instrument in such conditions could cause an electric shock, so contact your

dealer or Hioki representative for replacements.

Instrument Installation

5

Operating temperature and humidity to RH or l ess, Indoors only (non-condensatingStoring tempe rature

and humidity to RH or l ess, In doors only (non-c ondens ating Temperature and humidity range for guar anteed accuracy, RH or less

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or

condensation

Exposed to high levels of particulate dust

Subject to vibration

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction

heating systems and IH cooking

utensils)

Installing

• The instrument should be operated only with the bottom or rear side downwards.

• Vents (on the right side of the instrument) must not be obstructed.

Page 14

6

Usage Notes

Shipping precautions

Hioki disclaims respo nsibili ty for any di rect or indi rect da mages that ma y occ ur when this instrume nt has

been combined with other devices by a systems integrator prior to sale, or when it is resold.

Handling the Instrument

To avoid electric shock, do not remo ve the ins trument's case. The interna l components of the instrument carry high voltages and may become very hot during

operation.

• If the instrument ex hib its ab nor ma l o per ation or dis pl ay du ri ng use , rev ie w the inf or mation in Trouble shooting section "11.2 Trouble Shooting" (p. 175) and E rror Indications section "11.3 Error Indication" (p. 177) before contacting your dealer or

Hioki representative.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

• To move the instrument, first d isconnect all cables, remo ve any CF card and USB

memory, and carry it by the handle.

• Do not apply hea vy downward pressure wit h the stand extended. The stand c ould

be damaged.

See "Using the Handle as a Stand" (p. 13)

Page 15

Handling the cords and current sensors

Connect the current sensors or voltage cords to the instrument first, and then to

the active lines to be measu red. Observe the following to avoid electric sho ck

and short circuits.

• Do not allow the voltage cord clips to touch two wires at t he same time. Never

touch the edge of the metal clips.

• When the current sensor is opened, do not allow the metal part of the clamp to

touch any exposed metal, or to short between two lines, and do not use over

bare conductors.

• T o avoid short ci rcuits and potentially life-threatening haz ards, never att ach the

current sensor to a circu it that operates at more than the ma ximum rated voltage to earth (See your current sensor's instruction manual for its maximum ratings.) Current sensor and voltage cables should only be connected to the

secondary side of a breaker, so the breaker can prevent an ac cident if a short

circuit occurs. Connections should never be made to the primary side of a

breaker, because unrestricted current flow could cause a serio us accident if a

short circuit occurs.

• Connect only those voltage cables necessary for measurement.

7

Usage Notes

In order to use the 9709 AC/DC Current Sens or, the line to be measured must be

temporarily disconnected.

To avoid shock and short circuits,turn off the power to lines to be measured

before making connections to terminals to be measured and turning on the

instrument.

• To avoid electric shock and short-circuit accidents, use only the specified voltage

cord to connect the instrument input terminals to the circuit to be tested.

• For safety reasons, when taking measurements, only use the optional voltage cord.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To prevent an electric shock accident, con firm that the white or red portion (insulation layer) inside the cab le is not exp osed. I f a colo r insid e the ca ble is expo sed, do

not use the cable.

• To avo id damaging the power cord, grasp the plug, not the cord, when unplugging it

from the power outlet.

• Keep the cables well away from heat sources, as bare conductors could be exposed

if the insulation melts.

• Be careful to avo id dropping the current sensors or otherwise subjecting them to

mechanical shock, which could damage the mating surfaces of the core and

adversely affect measurement.

• Be careful when handling the cords, since the conductor being measured may

become very hot.

• When disconnecting the con nec to r, be sure to release t he l oc k befo re pul li ng off the

connector. Forcibly pulling the connector without releasing the lock, or pulling on the

cable, can damage the connector.

• To prev ent dam age to th e in st ru men t and cu rre nt s ens ors , nev er c on nec t or di s co nnect a sensor while the power is on, or wh ile the sensor i s clamped aroun d a conductor.

Page 16

8

Usage Notes

Before Connecting Measurement Cables

• The maximum input voltage is 1500 VDC, 1500 Vrms. Attempting to measure

voltage in excess of the maximum input could destroy the instrument and

result in personal injury or death.

• Never exceed a current sensor’s input current rating. Doing so could destroy

the instrument and cause personal injury.

• The maximum rated voltage between input terminals and the ground is as follows;

(CAT II) 1000 VDC, 1000 Vrms

(CAT III) 600 VDC, 600 Vrms

Attempting to measure voltages exceeding this level with respect to ground

could damage the instrument and result in personal injury.

• Before turning the inst rument on, make sure the source voltage matches that

indicated on the instrument's power connector. Connection to an improper

supply voltage may damage the product and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety speci fications of this

instrument, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

The power supply voltage for this product is switchable. To avoid electrical accidents, check that the voltage selector is set correctly for the supply voltage you

are using.

Before Connecting to the Lines to be Measured

To avoid electrical hazards and damage to the instrument, do not apply voltage/

exceeding the rated maximum to the external input terminals.

• To avoid electrical accidents, confirm that all connections are secure. The

increased resistance of loose connections can lead to overheating and fire.

• Ensure that the input does not exceed the maximum input voltage or current to

avoid instrument damage, short-circuiting and electric shock resulting from

heat building.

• When the power is turned off, do not apply voltage or current to the voltage input terminals, current input termina ls, or curren t sensors. Do ing so may damag e the instru ment.

• Note that the instrument ma y be damaged if the ap plied voltage or curr ent exceeds

the measurement range.

While Measuring

If an abnormality such as smoke, strange sound or offensive smell occurs, stop

measuring immediately, disconnect from the measurement lines, turn off the

instrument, unplug the power cord from the outlet, and undo any changes to the

wiring. Contact your dealer or Hioki representative as soon as possible. Continuing to use the instrument may result in fire or electric shock.

Page 17

9

The HIOKI 3390 Power Analyzer is a high-precision, broad-range instrument for measuring electrical

power from DC to inverter freque ncies. Four input channels are provided to support single- and th reephase inverter motor system measurements.

For developing and evaluating high ef ficiency inverter motors

For developing and evaluating alternative energy sources such as solar,

wind power, and fuel cells

For inverter motor maintenance

1.1 Product Overview

1

Overview Chapter 1

1.1 Product Overview

• High precision and stability ensure highly reproducible power measurements

• Electrical phase angle measurements necessary for motor analysis

• Measure motor efficiency by connecting with a high precision torque meter or encoder.

Chapter 1 Overview

• Simu ltaneou sl y mea sure AC and DC power.

• Separate ly measure p ower inp ut, sold, co nsumed, a nd regener ated usin g the DC mo de and the current and integrated power (electrical energy) in RMS mode.

• Save long-term measurement data to high-capacity storage media.

• Easily measure inverter secondary power on site.

• Simultaneously measure primary and secondary inverter power.

• Measure inverter noise.

Page 18

10

Supports multiple power system configurations

High accuracy over a broad range

Provides both fast data processing and high accuracy

Extensive data analysis functions are included as st andard fe atures

Simultaneous analysis of all parameters

Supports measurements with both easy-to-use clamp probes and highprecision penetrating probes

Single-unit instrument ideal for portable as well as rack-mount

applications

1.2 Features

• Four isolated voltage and curren t input channels are pr ovided to support simultaneous multisystem measurements such as inverter primary and secondary power.

• Measure power system wiring configurations from single-phase to three-phase, four-wire.

• Broad frequency range (0.5 Hz to 5 kHz fundamental) supports DC to inverter frequencies.

• Basic accuracy is ±0.05% rdg. ±0.05% f.s. at DC and from 0.5 Hz to 150 kHz.

• Precise measurements over a broad range of inverter carrier frequencies: ±0.2% rdg. ±0.1% f.s.

at 10 kHz, and ±1.5% rdg. ±0.5% f.s. at 100 kHz.

• Whil e maintaining high accuracy, power measurements and harmonic analy sis updates every

50 ms.

• Durin g low-frequenc y measurem ents, data is automatica lly updated i n sync with frequen cy, so

no refresh (data update rate) switching is needed when changing from low to high rotation

rates.

• Simultaneously measure RMS, mean, AC and DC components, and fundamental waveforms.

th

• Perf orm harmonic analysis up to th e 100

kHz.

• Display high-speed waveforms sampled at up to 500 kS/s.

• Perform multifaceted analysis with X-Y graph functions.

• Simultaneously analyzes harmonics and noise while performing integration and displaying

waveforms.

order and inverter noise (FFT) analysis up to 100

• Select from various AC and AC/DC clamp-on current probes with ranges from 20 to 500 A.

• Measure high currents with high precision using clamp-on current sensor probes.

• Clamp-on current probes eliminate the need for problematic direct contact with wiring.

• In-phase effects on inverter measurements are greatly reduced by isolating current sensors

from the measurement objects.

• Small and light weight (4.8 kg), with a convenient carrying handle (p. 13).

• Rack mountable in 170 mm (EIA 4U) vertical space (p. 179).

Page 19

11

V ariety of interfaces are equipped in standard

PC application program provides remote control and data acquisition (p. 141)

Wiring confirmation function avoids wiring mistak es (p. 36 )

Multi-instrument synchronization capability supports additional

measuremnet channels (p. 129)

Prepared for motor evaluation options (p. 138)

D/A output option for waveform output (p. 132)

Easy-to-see color LCD (p. 13)

Radiation thermometer connection support (p. 127)

Printer connection support (p. 123)

1.2 Features

• Includes 100 Mbps Ethernet and USB 2.0 High Speed communications interfaces.

• Supp or ts high-spe ed data communication systems.

• Provides a dedicated front-panel USB port and CF card slot for removable storage devices.

• Supports high-capacity media for high-speed data storage.

• With the instrument connected to a computer by Ethernet or USB cable, use the PC application

program to acquire data on the computer and control the instrument remotely. Download the PC

application program from Hioki's website. (http://www.hioki.com)

• Even without the PC application program, the same operations can be performed using a

browser to access the HTTP server function.

1

Chapter 1 Overview

• The vector display avoids wiring mistakes by confirming even complicated three-phase wiring.

• Measure with up to four instruments simultaneously.

• Slave instruments measure and record data in synchronization with the master instrument.

• Usin g the PC a pplic ation p rogram, sync hronous ly acqui re an d recor d data on up to f our in struments.

• Motor power can be determined by measuring torque meter output and rotation rate.

• Supports both analog DC and frequency-output-type torque measurement inputs.

• Supports both analog DC and rotation pulse outputs for measurement inputs.

• Supports encoder Z-phase signals for phase measurements with standard encoder pulses.

• Outputs up to 16 analog measurement parameters on 16 D/A output channels.

• Voltage and current waveforms sampled at 500 kHz in the waveform output mode provide

safely isolated voltage and current waveforms for other waveform measuring instruments.

• Includes a 9-inch color TFT LCD.

• Easily view waveforms and graphs on the wide-screen 800 × 480 dot display.

• Connect to the RS-232C interface for simultaneous temperature recording.

• Connect an optional printer to print screen captures on site.

Page 20

12

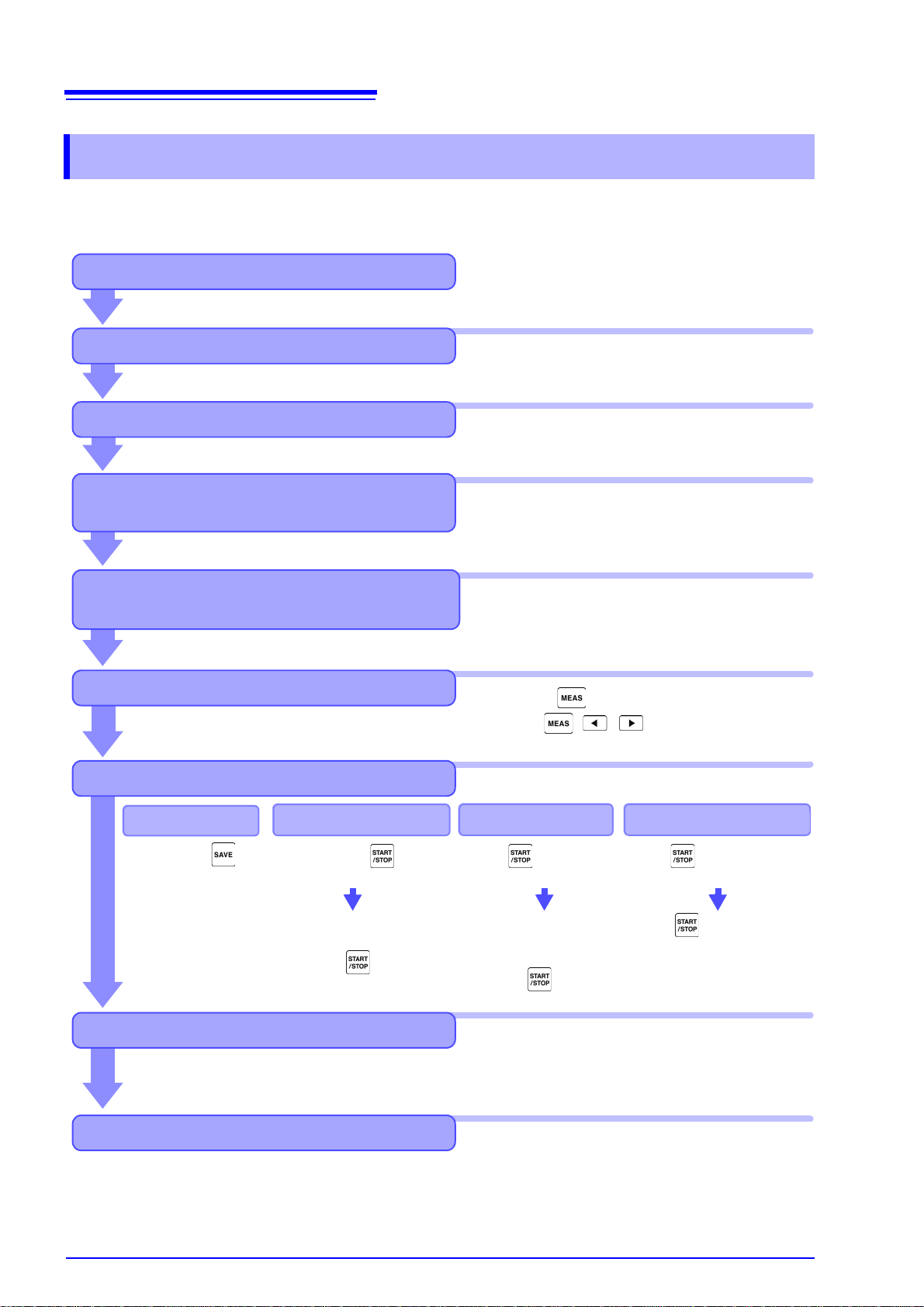

Saving

Turning Power Off

Analyzing Saved Data on a Computer

Installing the Instrument

Initial Instrument Preparations

Stops automatically at the

specified stop time.

Press the key to force

stop.

After pressing saving

starts at the specified start

time.

Connect the instrument to a computer with the supplied USB cable or an Ethernet cable and use the

dedicated PC applicati on program to transfer data to

the computer for analysis. This also enables remote

operation and control of the instrument.

See 3.2 ( p.24)

See 3.3 ( p.26)

See 3.4 ( p.27) to 3.8 ( p.29)

See 3.9 ( p.30) to 3.11 ( p.36)

See Chapter 7 ( p.103)

See "Instrument Installation" (p. 5)

See Chapter 9 ( p.141)

Press the key, and select display contents

with the , and F keys.

See "2.2 Basic Operations" (p. 16)

Viewing Measurement Values

Press the .

Manual saving

Pre-Operation Inspection

Connecting Cables and Probes, and

Turning Power On

Connecting and Checking Connections

to Measurement Objects

See 3.8 ( p.29)

Always perform these checks before connecting, and when turning the power on.

See Chapter 4 ( p.37)

For high-precision measurements, allow at least

30 minutes warm-up after power-on before executing zero adjustment.

Always execute zero adjustment before connecting to measurement objects.

Press to save for

a specified time span.

Save timer control

Press to start.

Save the specified time span.

Press to stop.

When the timer and real -time

control are set, stops at the

specified time.

Stops automatically

when the specified time

has elapsed.

Press the key to

force stop.

Save interval control

Save in realtimecontrol

1.3 Operating Overview

Be sure to read "Usage Notes" (p. 5) before measuring.

Follow the proced ures belo w to perform measurements. Da ta saving and an alysis on the computer can

be performed as necessary.

Page 21

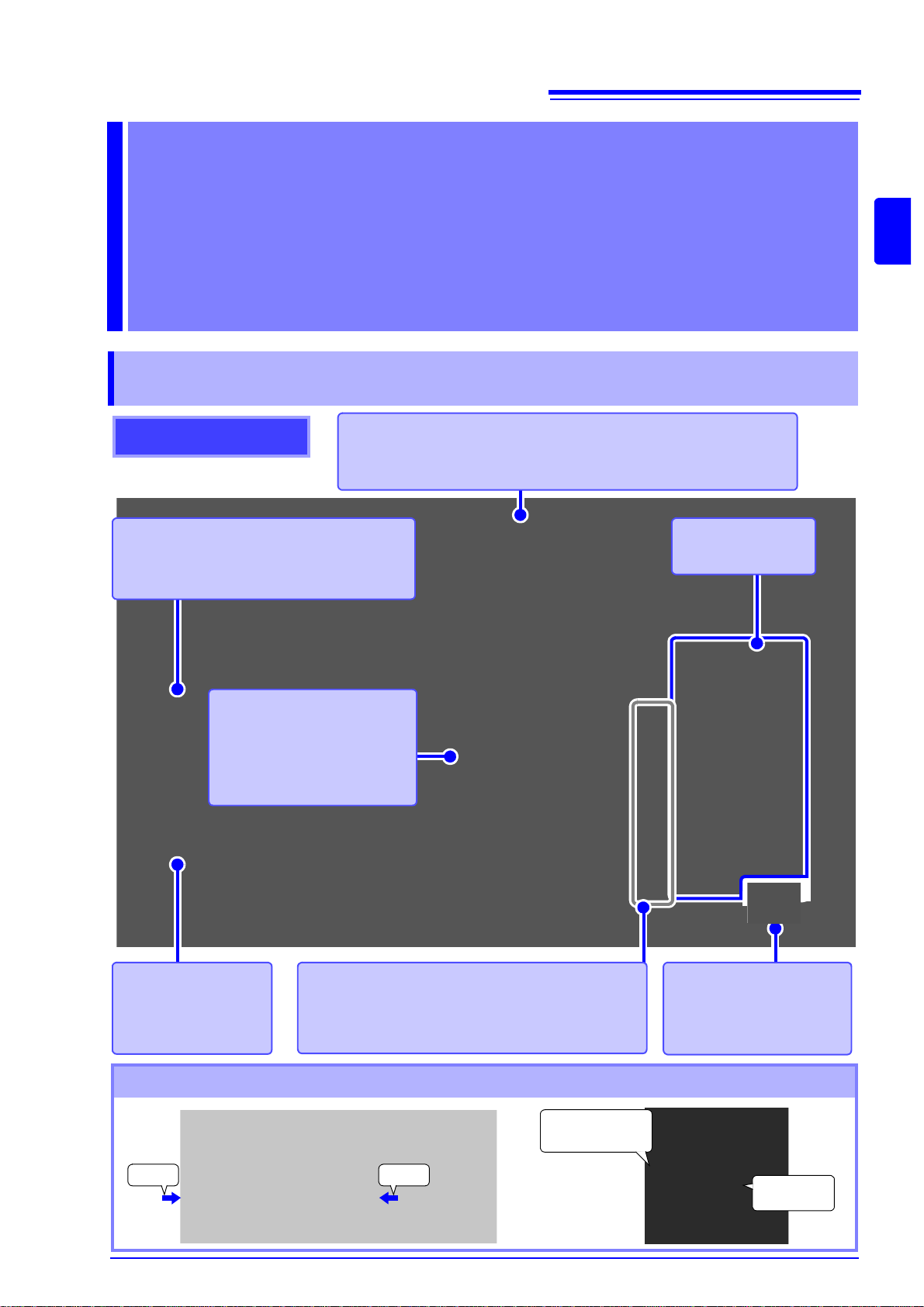

13

Display

Displays the Measurement,

Setting, or File Operation

screen.

See (p. 17)

CF card interface

Insert a CF card.

See (p. 104)

Front

F key (Function key)

Select and change display contents and settings.

See (p. 16)

Operation keys

See (p. 14)

Handle

Use to carry the instrument, and fold it down to serve as a stand.

See Latter of this chapter

Power switch

Turns the instrument on

and off.

See (p. 29)

USB memory interface

Connect a USB flash drive storage device.

See (p. 103)

Press Press

Keep on

pressing

Rotate the handle

to the click point.

12

2.1 Names and Functions of Parts

Names and Functions of Parts,

Basic Operations

& Screens Chapter 2

2.1 Names and Functions of Parts

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Using the Handle as a Stand

Page 22

14

SHIFT key

(Lit when running)

Activates alternate key functions.

START/STOP key

(Lit when running)

Starts and stops integration and saving operations.

To restart integrat ion and saving: Press the

DA TA RESET key to reset integration val-

ues, then press this key. (Press the START/

STOP key without resetting t he integrated

value if you wish to add the integration result to the previous one.)

SAVE key

Saves data to the storage media.

See 7.5.2 (p.110)

(Screen Capture)

Press SAVE while holding the

SHIFT key to capture a screen

image to the specified storage

media. (p. 114)

ESC key

Cancels the last

change to a setting,

and returns it to its o riginal state.

(Key-lock)

Hold for three seconds

to toggle the key lock.

The key lock st ate is indicated at the top of the

screen.(p. 17)

Operation keys

DATA RESET key

Resets the integratio n valu es .

See 4.3.1 (p.53)

0 ADJ key

Performs zero adjustment and

current sensor degaussin g.

See 3.10 (p.34)

HOLD key

(Lit when running)

Toggles the peak-hol d function.

See 5.3 (p.94)

RANGE keys

•The U + and – keys

change the voltage

measurement range,

and the I + and –

keys change the cur rent measurement

range.

• Pressing the + and –

keys at the same

time activates Auto

Ranging (p. 44).

• These keys also set

the low-pass filter (p.

52) and the lower

measurement limit

setting (p. 49).

PAGE key

Changes the screen

page.

MENU keys (Screen selection)

Press a key to select a screen (the lit key indicates the current selection).

Displays the Measurement screen for viewing measurement values. Voltage and current ranges can be selected, and low-pass filter settings can be changed.

(p. 19)

Displays the Setting screen for setting measurement criteria, wiring mode (phase systems), wiring check and system environment configuration.

(p. 20)

Displays the Fil e Operation sc reen for perf orming fil e operations on data saved to

storage media, and selecting data file formats.

(p. 21)

ENTER key

Accepts selections and

changes to settings.

CURSOR key

Move the cursors.

2.1 Names and Functions of Parts

• When the key lock function is enabled, all other key operations are disabled.

• The key lock state is retained even when power is off.

Page 23

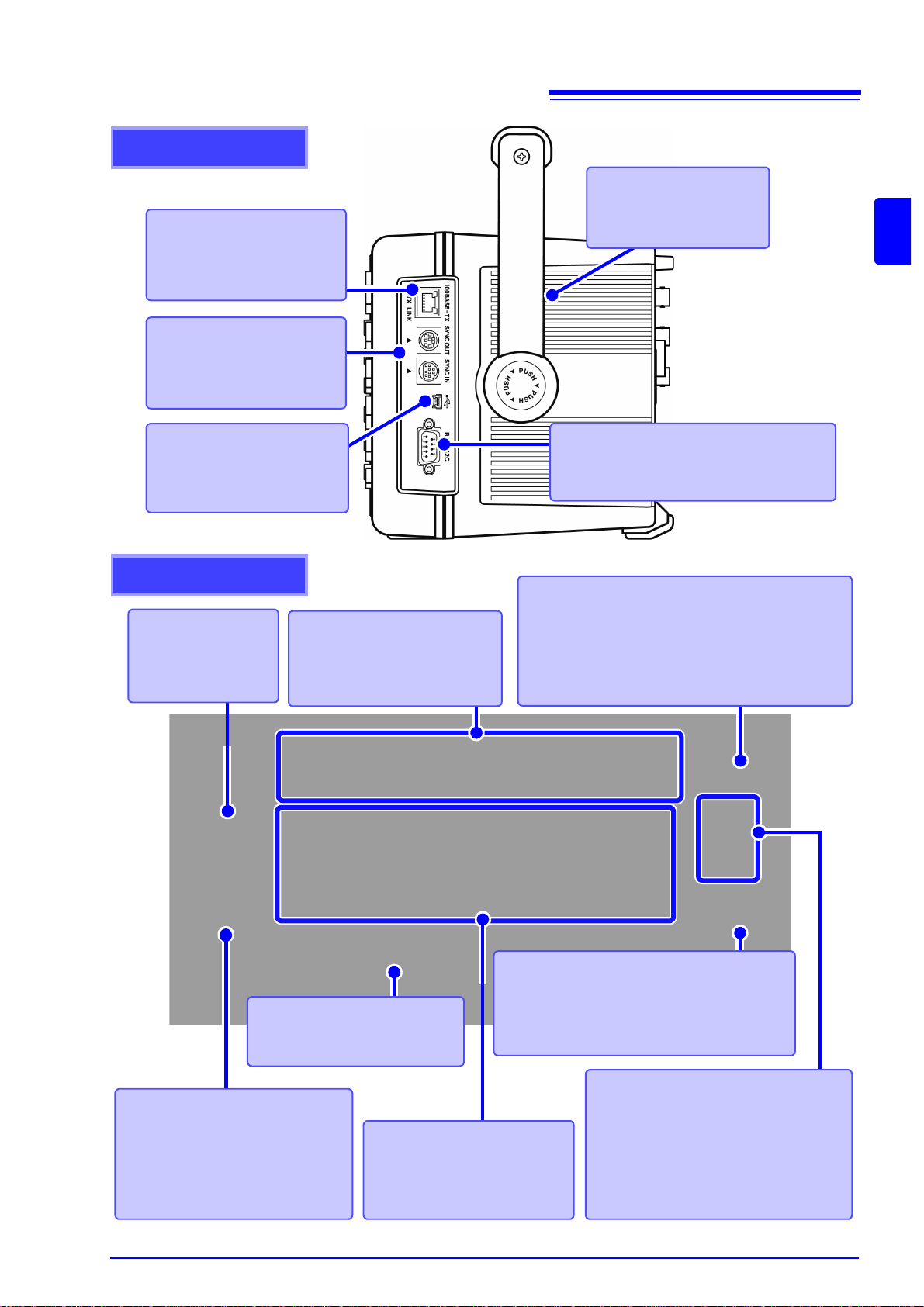

15

Right side

Ethernet interface jack

For LAN connection with an

Ethernet cable.

See (p. 144)

Sync interface

For synchronizing cables, as

needed.

See (p. 129)

Vent

Keep clear of obstructions.

See (p. 5)

RS-232C interface

For RS-232C cable connection, as needed.

See (p. 123), (p. 127)

USB port

For the supplied USB cable,

as needed.

See (p. 148)

Rear

Voltage input termi nals

Connect Hioki-specified voltage

measurement cables.

See (p. 28)

Current input terminals

Connect an Hioki-specified current sensor.

See (p. 28)

Power inlet

Connect the supplied

power cord.

See (p. 27)

Output terminal

Connect the supplied D-sub plug (only when

using the 9792 D/A Output option or the 9793

Motor Evaluation and D/A Output option).

See (p. 132)

CH A torque signal input BNC jack

Connect the Hioki L9217 BNC connection cable to

this terminal (only when using the 9791 Motor Evaluation option or the 9793 Mot or Evaluatio n and D/A

Output option).

See (p. 138)

CH B and CH Z rotation signal

input BNC jacks

Connect the Hioki L92 17 BNC connection

cable to these terminals (only when using

the 9791 Motor Evaluation option or the

9793 Motor Evaluation and D/A output option).

See (p. 138)

Serial No.

This is the in stru men t’ s s er ial

number.

Functional gr ou nd te r mi nal

Connect this terminal to a clean

common ground to suppress electrical nois e when measuring in an

electrically noisy envi ronm en t.

See (p. 27)

2.1 Names and Functions of Parts

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Page 24

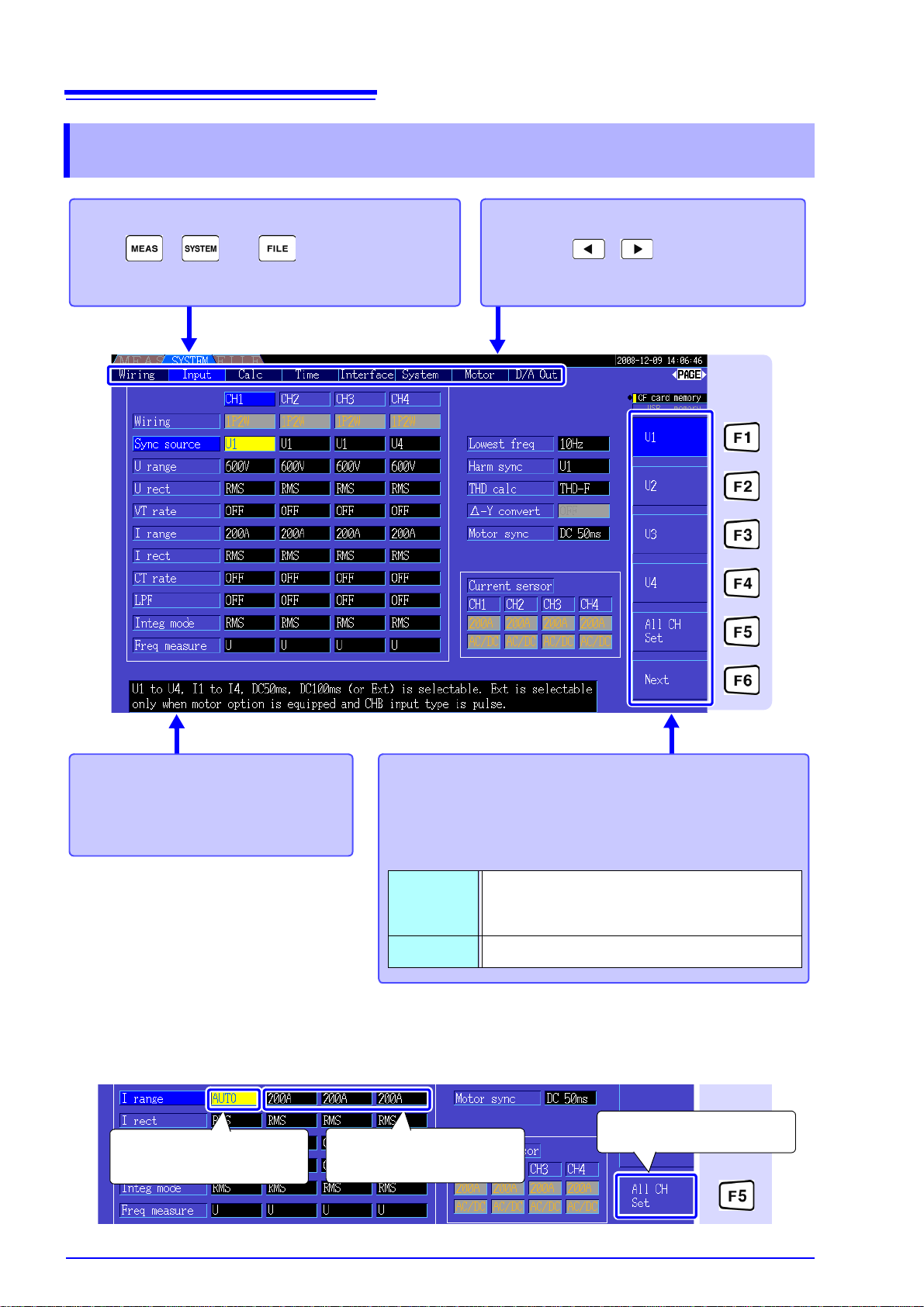

16

To select a display screen

Press , , or to display the corresponding screen.

See (p. 19) to (p. 21)

Help comment

Describes the object at the current

cursor position (only on Setting and

File Operations screens).

Set any channel to

[AUTO].

1

All channels are set to

[AUTO].

3

Select [All CH Set]

2

Using [All CH Set]

(For example, to enable auto-ranging on all channels.)

CH1 CH2 CH3 CH4

To select the displayed screen page

Press the keys to change.

See (p. 19), (p. 21)

T o select and c hange displ ay co ntents and settings

Press one of the F keys to select and change d isplay contents and settings. The displayed function labels depend on

the currently displayed screen.

Special Setting Items

Next

This appears when more than six setting

items are available. Press F6 to display the

function labels of the additional items.

All CH S et Select to apply th e same se tting t o a ll chan nel s.

2.2 Basic Operations

2.2 Basic Operations

Page 25

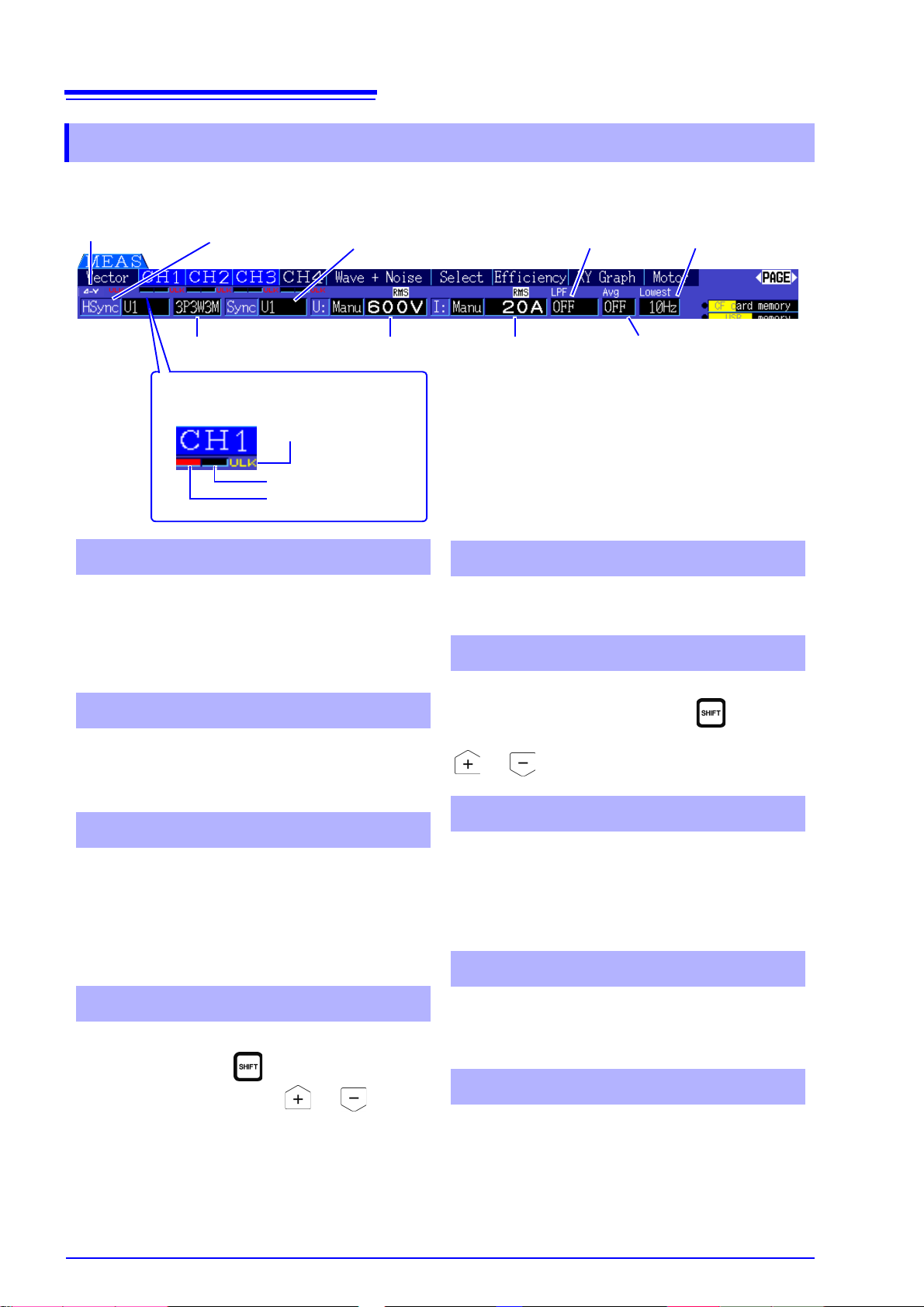

2.3 Display Items and Screen Types

Displayed Screen

Real-Time Clock

Operating State Indicators

Interface Indicators

Media-Busy Indicator

13

45

Key-Lock Indicator

2

Level indicators for the CF card and USB memory

stick. The used sto rage space is indicated in yellow, and it turns to red when the media is 95% full.

1 Storage Media Indicators

2 Key-Lock Indicator

Lights to indicate Key Lock is active

(keys are locked), after holding the

key for three seconds.

3 Interface Indicators

Lights when the instrument is connected to a computer by USB cable

(and the computer is on).

Lights when the instrument is connected to a LAN.

Indicates a pr inter is connected to the

RS-232 interface.

Indicates a the rmometer is connected

to the RS-232 interface.

Red: Temperature data has not been

acquired.

Blue: Temperature data has been

acquired.

Displays the current date and time.

To set the Clock: (p. 101)

4 Real-time clock

5 Operating State Indicators

Lights during integration and recording.

Indicates integration is in progress.

Indicates integration is stopped.

Indicates Data Hold is active.

Indicates Peak Hold is active.

Displayed Page

2.3 Display Items and Screen Types

17

2.3.1 Common Display Items

These items are displayed on every screen.

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Page 26

18

Current peak overrange

Voltage peakoverrange

Sync Unlocked

Peak Over display indicators

1

These indicators appear in red at the bottom of

each channel pag e tab (CH1 to CH4). These indicate (from the left) whe n voltage and curren t peaks

ranges are exce eded (p. 40), and when s ynchronization is unlocked (p. 48).

Indicates the selected wiring mo de (p. 30 ). The wi ring mode (phase system selection) must be set to

match actual measurement connections.

• Indicate the voltage and current range settings.

• The settings are made by the RANGE keys (p. 44).

• Wh en the range has been set manually, [MANU]

appears.

• When the auto-ranging is enabled, [AUTO]

appears (p. 43).

Indicates the low-pass filter setting (p. 52).

To change, hold the key while pressing an

LPF key (one of the left-most or RANGE

keys).

1 Peak Over display indicators

2 Wiring mode

3 Voltage range/Current range

4 Low-pass filter

Indicates the averaging setting state (p. 93).

The setting is made on the Setting screen.

Displays the lower measurement limit setting (p. 49).

To change the setting, hold the key while

pressing a LOW FREQ ke y (one of the right-most

or RANGE keys).

Indicates the synchronization source signal that

determines the period (between zero crossings)

used as the basis for all cal c ula tio ns .(p. 47) The setting is made on the Input Settin gs page of the Settings screen.

Indicates the synchronization signal source used for

harmonic measurem ents.(p. 67) The setting is made

on the Input Settings page of the Settings screen.

Indicates whether D-Y conversion is enabled or disabled (ON/OFF).(p. 98 ) The setting is mad e on the

Input Settings page of the Settings screen.

5 Average

6 Lower measurement limit

7 Sync source

8 Harmonic sync source

9 Δ-Y Conversion

Wiring mode

2

Voltage range

3

Current range

3

Average

5

low-pass filter

4

lower measurement limit

6

Sync source

7

Harmonic sync

source

8

Δ-Y Conversion

9

2.3 Display Items and Screen Types

2.3.2 Measurement Screen

These display items appear only on the Measurement screen.

Page 27

2.3.3 Screen Types

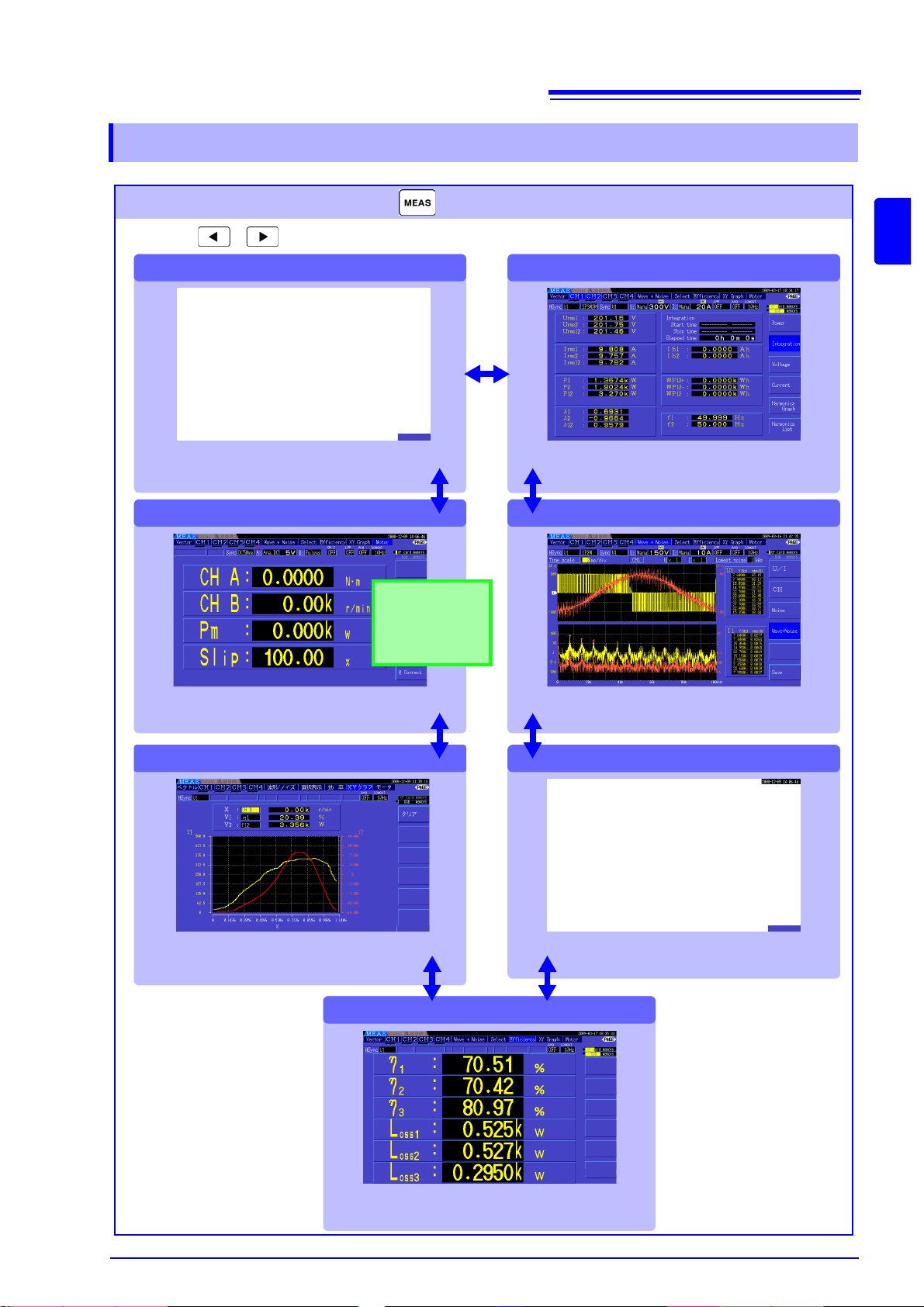

[CH1 to CH4]

[Efficiency]

[Motor]

[XY Graph]

[Wave + No is e]

[V ector]

[Select]

Measurement Screen (Press the key to display)

Press the keys to change the screen page as follows.

This screen displays measurement values.

This page displays measured voltage, current, and

power on channels 1 to 4 as numerical values

and as vectors.

This page display s measured values for the

motor analysis options.

This page displays an X-Y graph of measurement

parameters selected for horizontal and vertical

axes.

This page displays the numerical values of efficiency

and loss determined by calculation formulas.

This page displays measured power, voltage and current

values, integration values, and provides access to

harmonic graphs and lists for each channel.

This page displays vo ltage, current, an d noise

waveforms. The waveforms can be saved.

Select any parameter on this page for display.

Appears only when

the Model 9791 Motor Testing option or

the 9793 Motor Testing & D/A Output option is installed.

19

2.3 Display Items and Screen Types

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Page 28

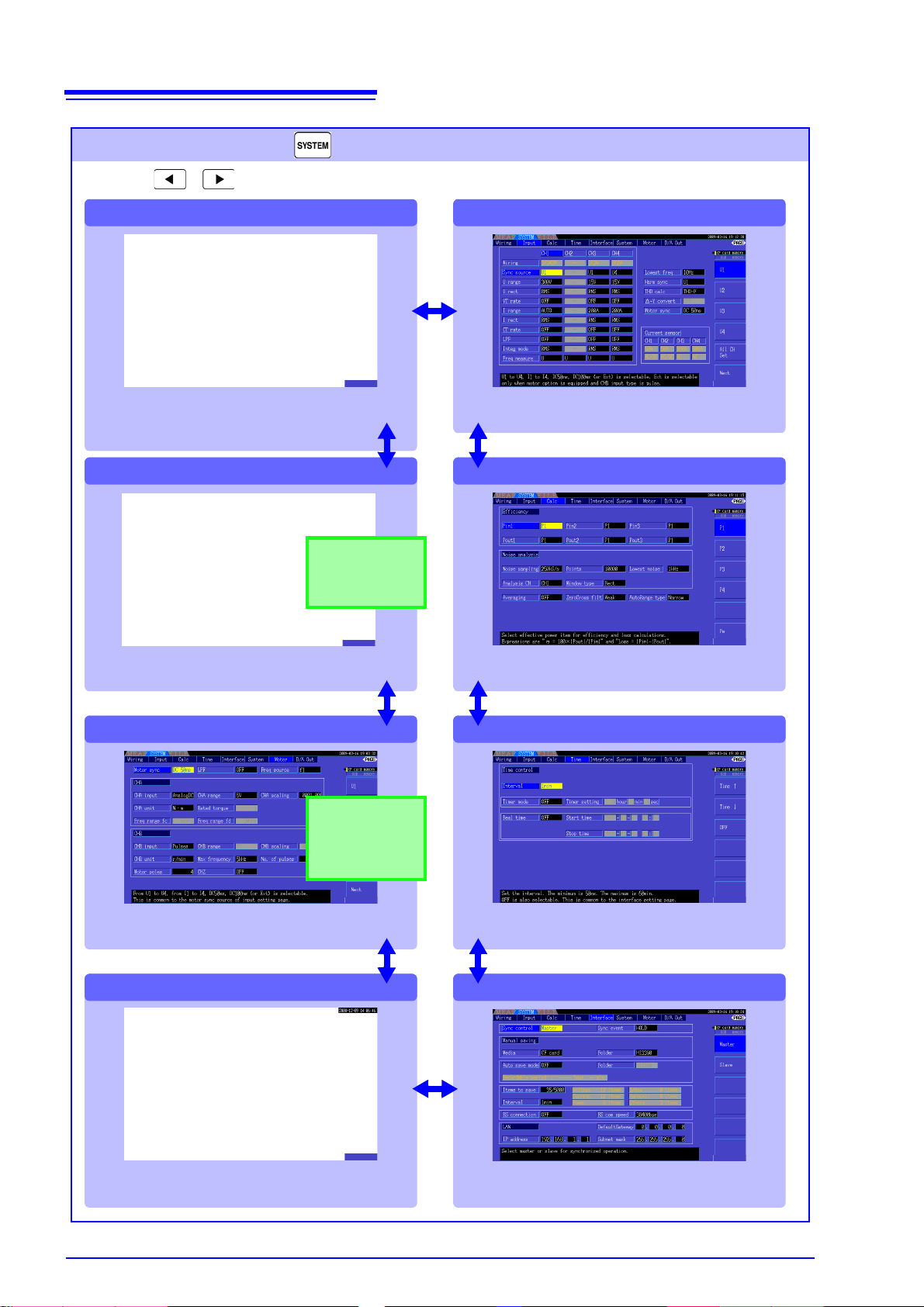

20

[Motor]

[Wiring]

[D/A Out]

[System]

Select the appropriate wiring mode (phase system configurations) and execute quick setup on this page. Wiring diagrams for each mode depict the appropriate

measurement cable connections.

Make D/A output-related settings on this page.

Make motor measureme nt-rela ted se ttings

on this page.

Configure system enviro nm ent settin gs and

perform system reset on this page.

[Input]

Make detailed measuremen t criteria settin gs on

this page.

[Calc]

Make calculation-related settings on this page.

[Time]

Set measurement timers and the number of parameters to save on this page.

[Interface]

Make settings related to synchronization, data

saving and interfaces on this page.

Setting Screen (Press the key to display)

Press the keys to change the screen page as follows.

Use this screen to view and change setti ngs for mea suremen t criteri a,

wiring mode, wiring check and system environment con figu ratio n.

Appears only when

the Model 9791 Motor Testing option or

the 9793 Motor Testing & D/A Output option is installed.

9792 D/A Output option or the 9793 Motor Testing & D/A

Output option is installed.

2.3 Display Items and Screen Types

Page 29

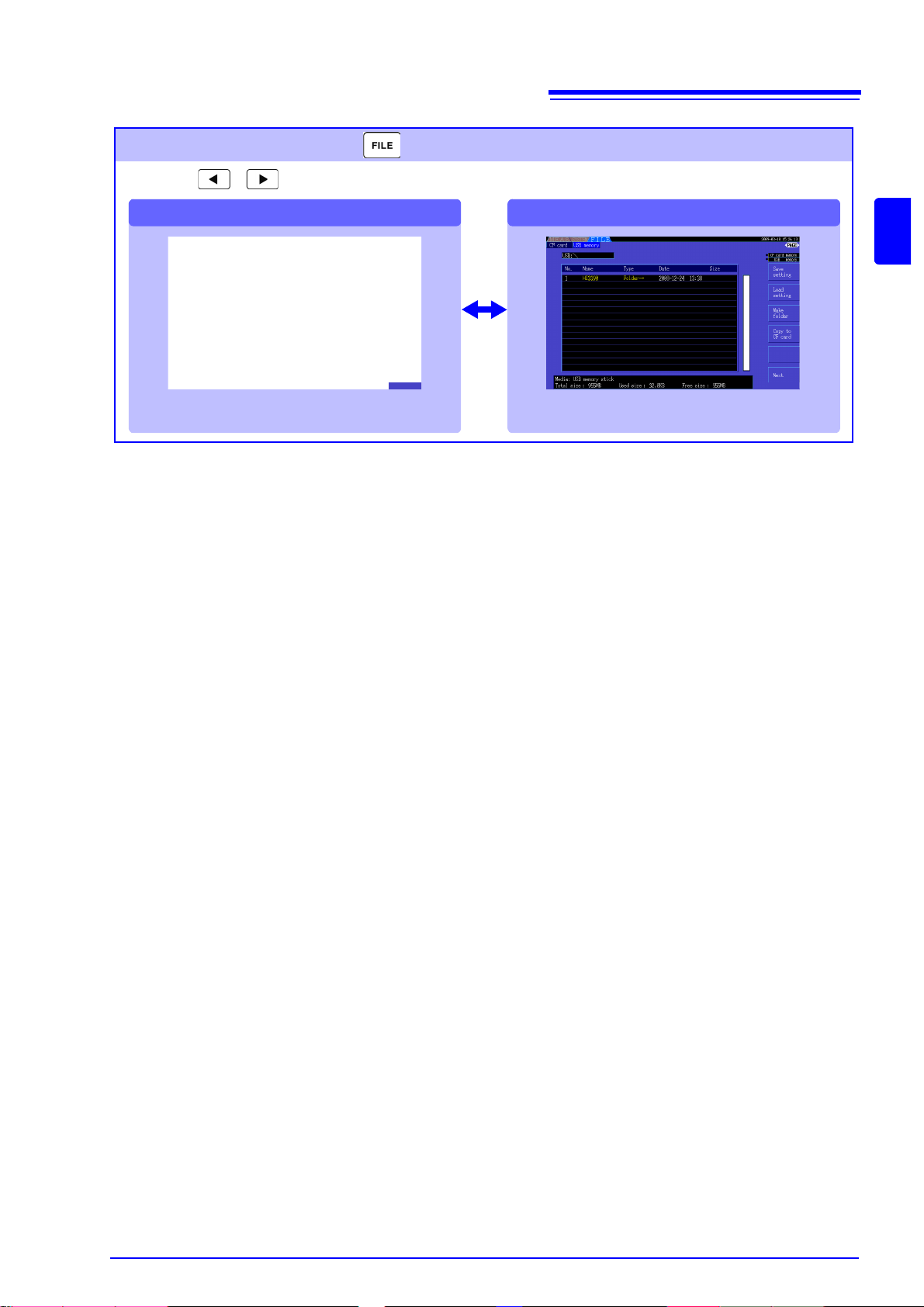

21

[USB drive][CF card]

File Operations Screen (Press the key to display)

Press the keys to change the screen page as follows.

Use this screen to configure savi ng of dat a fi les to removabl e

storage media, and to save and rel oad setti ngs fi les.

This page displays data files on a CF card. This page displays data files on a USB flash

drive.

2.3 Display Items and Screen Types

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Page 30

22

2.3 Display Items and Screen Types

Page 31

23

See 3.6 ( p.28)

Installing the Instrument

Initial Instru m e n t P r epar a ti o n s

See 3.2 ( p.24)

See 3.3 ( p.26)

See 3.7 ( p.28)

See 3.11 ( p.36)

See "Instrument Installation" (p. 5)

Pre-Operation Inspection

Verifying Correct Wiring

Always perform these checks before connecting, and when turning the power on.

Always execute zero adjustment before connecting to measurement objects.

See 3.10 ( p.34)

Connecting to the Lines to be Measured

See 3.9 ( p.30)

Setting the wiring mode

See 3.8 ( p.29)

Turning Power On

See 3.4 ( p.27)

Back side

Apply the approp riate adhesive lab els near the

input jacks and around the voltage and cu rrent

sensor measuremen t cables. Then bundle the

voltage cables together with the spiral tubes.

Connecting the V oltage Measurement

Cables

Connecting the Current Sensors

Connecting the Power Cord

For best precision, allow at least 30 minutes

warm-up before executing zero adjustm ent an d

measuring.

3.1 Operations in general

Measurement

Preparations Chapter 3

3.1 Operations in general

3

Chapter 3 Measurement Preparations

Page 32

24

Before applying the labels

Wipe any dust from the surface of the voltage measurement cables and current sensors,

and ensure that it is dry.

Measurement Cable Labels

For each input jack, apply labels

with the same color near the jack

and to its corresponding voltage

measurement cable lead or clamp

sensor cable.

Apply labels to both

ends of the volt age

measurement cables

Apply labels to both

ends of the current

sensor cables.

Red

Yellow

Blue

Gray

L9438-50 Voltage Cord

Alligator Clips (two, one each red and black)

Banana Plug Leads (two, one each red and black)

Spiral Tubes (five, for cable bundling)

3.2 Initial Instrument Preparations

3.2 Initial Instrument Preparations

Perform the following before starting measurement the first time.

Put the provided input cor d labels f or ea ch voltage cord and current sensor

The labels are provided to clearly indicate which cable connects to each input jack.

Bundle the voltage measurement cable leads with the spiral tubes

Five spiral tubes are supplied with the Model L9438-50 voltage measurement cables.

Use the spiral tubes as needed to wrap red and black leads together.

Preparation items

Page 33

Procedure

Red

Black

Spiral tube

3.2 Initial Instrument Preparations

Hold two cable leads (one each red and black) side-by-side.

1.

Start bundling from one end of the leads.

25

Wind the spiral tube around the leads.

2.

Wrap the two leads together with the spiral tube. The five supplied spiral

tubes should be applied with suitable spacing.

3

Chapter 3 Measurement Preparations

Page 34

26

Before using the instr ument the f irst ti me, v erify that i t operat es no rmally to e nsure that the n o dam age

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

An error is displayed

Do not use if damage is present, as

you could receive an electric shock.

Contact your dealer or H ioki repres entative if you find any damage.

Metal Exposed

Yes

No Metal Exposed

No

No

Yes

Contact your dealer or Hioki representative if you find any damage.

No

Yes

Initial Screen

HIOKI 3390 POWER ANALYZER 1.00

Pre-connection inspection

1

Power-on confirmation

2

Inspect the current sensors

Is a clamp cracked or damaged?

Inspect t he instrument

Is damage to the instrument evident?

Inspect the voltage measurement cables

Does any cable insul ati on app ear da mag ed,

or is bare metal exposed?

Does the self-test (model and version) display

appear?

(The version number may be changed t o the latest version number.)

The power cord may be damaged, or

the instrument may have internal

damage.

Please contact your dealer or Hioki

representative.

When the self-test finishes, does the [Wiring]

page of the Setting or Measurement screen

Yes

Inspection complete

The instrument may be

damaged internally.

Please contact yo ur dealer

or Hioki representative.

3.3 Pre-Operation Inspection

3.3 Pre-Operation Inspection

Page 35

3.4 Connecting the Power Cord

Plug the power cord into the mains outlet.

Back side of the instrument

1. Check that the instrument’s power switch is turned

off.

2. Confirm that the line voltage matches instrument

requirements, and plug the power cord into the

power inlet on the instrument.

3. Pl ug the other end of the power cord into an outlet.

Turn off the power before disconnecting

the power cord.

Power Inlet

Power cord

About the outlet with ground pin

Functional earth

3.4 Connecting the Power Cord

Be sure to read the "Usage Notes" (p. 5) before connecting power.

Connect the power cord to the power inlet on the instrument, and plug it into an outlet.

Connection Procedure

27

3

Chapter 3 Measurement Preparations

3.5 Grounding the Instrument's Functional

Earth (when measuring in noisy environments)

Ground the instrument's function al earth .

Connect the functional ground term inal to a c lean co mmon ground to s uppress noi se effects when m easuring in an electrically noisy environment. When measuring AC power lines using a VT (PT), connect the

PT ground to the same grounding point.

Page 36

28

Plug the voltage cables into the appropriate channels’ voltage

measurement jacks.

Insert the plugs into the terminals as far as they will go.

With the arrow on top of the plug, plug each current sensor cable

into the appropriate channel’s current measurement jack.

Insert each plug until you hear it lock.

To disconnect:

Holding the plug aro und its arrow, sl ide it forward to unlock, then pu ll out.

3.6 Connecting the Voltage Measurement Cables

3.6 Connecting the V oltage Measurement

Cables

Be sure to read the “Usage Notes” (p. 7) before connecting measurement cables.

Plug the voltage m easurement cable leads in to the voltage measurement jacks on the instrument (th e

number of connections depends on the lines to be measured and selected wiring mode).

Connection Procedure

3.7 Connecting the Current Sensors

Be sure to read the "Usage Notes" (p. 5) before connecting measurement cables.

Plug the current sensor cables into the current measurement jacks on the instrument (the number of connections depend s on the lines to be measure d and selected wiring mod e). See the instruction ma nual

supplied with the current sensor for specification details and usage procedures.

Connection Procedure

T o measure volt age and current beyond the range of the instrument or current sensor

Use an external VT (PT) or CT. By specifying the VT or CT winding ratio on the instrument, the input level

at the primary side can be read directly.

See"4.2.6 Setting Scaling (when using VT(PT) or CT)" (p. 51)

During wiring, avoid touc hing the VT(PT), CT or input termina ls. Exposed live contact s can cause electri c shock or other acc ident resultin g in personal inju ry or death.

• When using an external VT (PT), avoid short-circuiting the secondary winding.

If voltage is applied to the primary when the secondary is shorted, high current

flow in the secondary could burn it out and cause a fire.

• When using an external CT, avoid open-circuiting the secondary winding. If

current flows through the primary when the secondary is open, high voltage

across the secondary could present a dangerous hazard.

• Phase difference in an external VT (PT) or CT can cause power measurement

errors. For optimum power me as ur eme nt accu ra cy , use a VT (PT ) or CT that exh ib its minimal phase difference at the operating frequency.

• To ensure safe ty when u si ng a V T ( PT) or CT, one side of the secondar y shoul d be

grounded.

Page 37

3.8 Turning the Power On and Off

Turn the POWER switch on ().

The instrument performs a 10-second power-on self test.

See 3.3 ( p.26)

The instrument performs a 10-second power-on self test.

When the self test finishes, the [Wiring] page of the Se tting screen appear s (initial

screen). If [Start page] is set to [Last Screen] (p. 101), the last displayed Measure -

ment screen appears.

Turn the POWER switch off ( ).

3.8 Turning the Power On and Off

Be sure to read the “Usage Notes” (p. 7) before turning the instrument on.

Connect the power cord and voltage and current measurement cables before turning the instrument on.

Turni ng the power on

29

3

Chapter 3 Measurement Preparations

If the self-test fails, operation sto ps at the self-test scr een. If the fault recurs after turning the power off and on, the instrument m ay be damaged . Perform the fo llowing procedure:

1. Stop measuring, di sconnect the measurement cables from the o bject being measured, and turn the instrument off.

2. Disconnect the power cord and all cables from the instrument.

3. Contact your dealer or Hioki representative.

For best precision, allow at least 30 minutes warm-up before executing zero adjustment and measuring.

Turni ng the power off

Page 38

30

2

3

To accept the selection:

Press (or the key)

To cancel the selection:

Press (or the key)

1

Press the key to select

[Select] (or press the key)

to display the pull-down menu.

2

1

3

Select the wiring mo de

Accepting the selection displays the wiring

diagram of the selected wiring mode.(p. 31)

3.9 Selecting the Wiring Mode

3.9 Selecting the Wiring Mode

Select the wiring mode to match the phase system(s) to be measured. Eight wiring modes are available.

To open the [Wiring] page

Press the key and select the [Wiring] page with the .

To select the wiring mode

• To measure multiph ase powe r, use the sa me type of current sens or on ea ch phase

line. For example, to me asure 3-phase 4-wire power, us e the same model current

sensors on channels 1 to 3.

• When using a c urrent sensor with switchable sensor rating (such as Mode l 9272-

10), set the sensor rating to match the rating of the line.

• When the selected wiring m ode uses multiple channels, channel-specific settings

(such as voltage range) are linked to the first channel’s settings.

Page 39

Wiring configuration diagram

Wiring Mode 1. Single-phase, 2-wire (1P2W) × 4

Wiring configuration diagram

See

Pages 172 and 173 f or additional wiring diagrams.

Wiring Mode 2. Single-phase, 3-wire (1P3W) + single-phase, 2-wire (1P2W) × 2

Wiring Mode 3. 3-phase, 3-wire (3P3W2M) + single-phase, 2-wire (1P2W) × 2

31

3.9 Selecting the Wiring Mode

3

Chapter 3 Measurement Preparations

Page 40

32

Wiring Mode 4. Single-phase, 3-wire (1P3W) × 2

Wiring Mode 5. 3-phase, 3-wire (3P3W2M) + single-phase, 3-wire (1P3W)

Wiring Mode 6. 3-phase, 3-wire (3P3W2M) × 2

3.9 Selecting the Wiring Mode

Page 41

33

Wiring Mode 7. 3-phase, 3-wire (3P3W3M) + single-phase, 2-wire (1P2W)

Wiring Mode 8. 3-phase, 4-wire (3P4W3M) + single-phase, 2-wire (1P2W)

3.9 Selecting the Wiring Mode

3

Chapter 3 Measurement Preparations

Page 42

34

3. Press the key.( to cancel.)

[Executing zero adjustment] is displayed for 30

seconds, until finished.

2. Press the key.

[Execute Zero Adjust.] is displayed.

1. Press the key.

Securely clip the leads to metal parts such as load-side screw ter mi nal s or

bus bars.

Example:

Secondary side of breaker

L9438-50 Voltage Cord

3.10 Attaching to the Lines to be Measured and Zero Adjustment

3.10 Attaching to the Lines to be Measured and Zero Adjustment

Be sure to read the “"Usage Notes" (p. 5) before attaching to the lines.

Always perform zero adjustment before attaching to the lines.

Then attach the voltage meas urement clips and curr ent sensors to the meas urement lines acc ording to

the on-screen wiring diagrams. For proper accuracy, attach to the lines exactly as shown.*

* The diagram appears when the wiring mode is selected.(p. 30)

Although the instrument can measure multiple lines at the same time, to avoid

electric shock and short-circuit accidents, do not attach any unnecessary

cables.

The phases are named A, B, and C on the wiring diagram display. Substitute with

equivalent names such as R,S, and T or U,V, and W, as appropriate.

Zero Adjustment and Degaussing (DMAG)

To obtain the spe cified accuracy, after 30 minu tes warm-up, perform zero-adjustmen t on both voltage

and current measurement channels.

When using an AC/DC current sensor, perform degaussing (DMAG) along with zero adjustment.

• Perform zero adju st ment onl y after plu gging the curr ent se nsor into t he instr ument (proper adjustment requires that the current sensor be connected).

• Perform zero adjustm ent before attaching to the li nes to be me asured (prop er

adjustment requires the absence of any input voltage or current).

• For optimum measurement accuracy, zero adjustment should be performed

within the specified ambient temperature range.

• The operating keys are disabled during zero adjustment.

• When using a motor evalua tion option, zero adjustment is not applicable for

analog DC input on chann els A and B. Perform the special zero adj ustment

from the Motor screen.

See"4.8 Viewing M otor Meas urement Values (With Hioki 9791 or 9793 insta lled)" (p. 82)

Attach voltage measurement cables to measurement lines

Page 43

3.10 Attaching to the Lines to be Measured and Zero Adjustment

OK

Shield

(Example: 9272-10)

Source

side

Line

Load side

Current Flow

Direction Arrow

Be sure to attach each clamp around only one conductor.

Correct measurement cannot be obtained if a clamp is attached around more than one conductor.

Make certain that the current flow direction

arrow points toward the load.

If measurement line power is off, turn it on before performing quick setup.

Select [Easy Set] with the key.

A confirmation dialog box appears.

2

1

1

To execute: Press

To cancel: press .

What settings are affected by quick setup?

For accurate measurements, settings such as range and sync source must be properly configured. Executing qu ick setup automatic ally configures th e following settings to the Hioki-recommended values for the sel ected w iring mode (phase sy stem): voltage and c urrent ranges, s ync

source, lower measurement frequency limit, integration mode, harmonic sync source and rectification system.

Execute quick setup when using the instrument the first time, and when changing to a different

line configuration.

Attach current sensors to measurement lines

35

3

Chapter 3 Measurement Preparations

Easy set

Page 44

36

Voltage Current

For 1P2W systems For systems other than 1P2W

• Verify that an appropriate measurement

value is displayed.

• Verify that the vectors

are displayed with the

appropriate range.

Measured voltage value

Measured current value

Measured active power value

Verify that an appropriate

measurement value is displayed.

Vector line range

Colors match the corresponding lines in the wiring diagram.

If the measured voltage value is

too high or too low

If the measured current value is

not correct

If the measured active power

value is negative

If vectors are too short, or

unequal

If vector direction (phase) or

color is incorrect

• The display rang e of the vector diagrams assu mes inductive loads (su ch as with a motor).

The vectors may appear out of rang e when me asuring near- zero power fact or, or capacitive loads.

• When measuring multiple 1P3 W or 3-phase li nes at the same time, vectors are no t displayed correctly when the harmoni c sync source fr equency is dif feren t from that of the lines t o be measured .

• When measuring 3P3 W2M systems, the active p ower (P) measured on each c hannel may

be negative.

3.11 Verifying Correct Wiring (Connection Check)

3.11 Verifying Correct Wiring (Connection Check)

Correct attachment to the lines is necessary for accurate measurements.

Refer to the measured values and vector displays to verify that the measurement cables are corre ctly attached .

In this case Check

• Are the cables securely plugged into the voltage measurement jacks on

the instrument? (p. 28)

• Are the voltage measurement cables properly attached to the lines? (p. 34)

• Are the cables securely plugged into the current measurement jacks on

the instrument? (p. 28)

• Are the current sensors properly attached to the lines? (p. 35)

• Are the current sensors appropriate for the line current to be measured?

• If using the 9272-10 Clamp Sensor, is the sensor range set correctly?

• Are the voltage measurement cables properly attached to the lines? (p. 34)

• Is the arrow marker on the current sensors pointing toward the load? (p. 35)

Voltage vectors:

• Are the cables securely plugged into voltage measurement jacks on the

instrument? (p. 28)

• Are the voltage measurement cable clips pr operly attached to the l ines? (p. 34)

Current vectors:

• Are the cables securely plugged into the current measurement jacks on

the instrument? (p. 28)

• Are the current sensors properly attached to the lines? (p. 35)

• Are the current sensors appropriate for the line current to be measured?

• If using the 9272-10 Clamp Sensor, is the sensor range set correctly?

Voltage vectors:

• Check that the voltage measurement clips are attached to the lines

according to the wiring diagram.

Current vectors:

• Check that the current sensors are attached to the lines according to the

wiring diagram.

Page 45

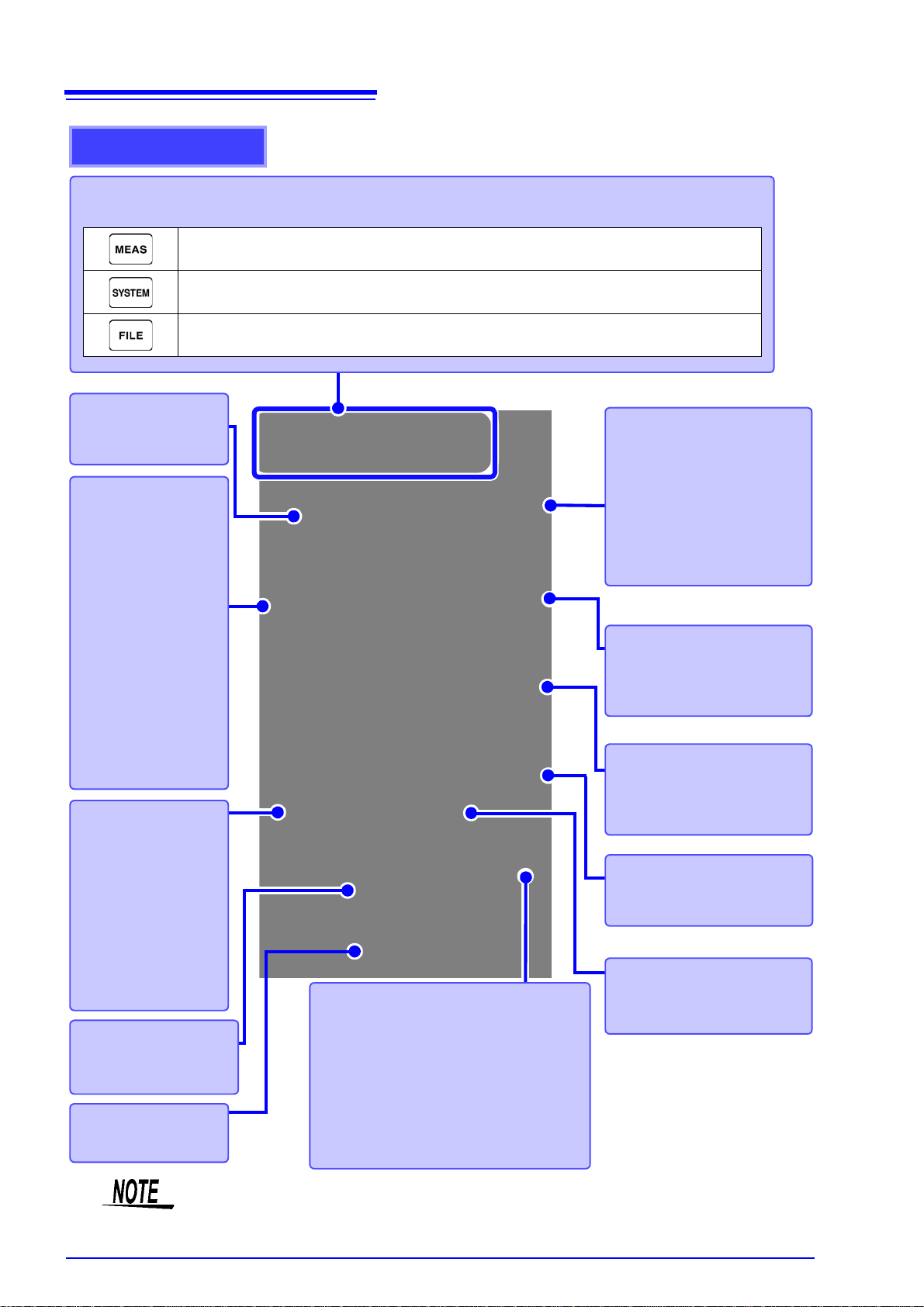

4.1 Measurement Value Display Procedure

Display the

[CH] page

See Displays the Harmonic Graph or Harmonic List.

"4.4 Viewing Harmonic Measurement Values" (p. 62)

The above screen is specific to the wiring mode (here showing four 1P2W systems)

he number of measurement items displayed depends on the selected wiring mode.

See Section "3.9 Selecting the Wiring Mode" (p. 30) to set the wiring mode.

Use the F keys to select

display contents

Viewing

Measurement

Values Chapter 4

4.1 Measurement Value Display Procedure

37

The following procedure display s mea sure men t valu es.

Display Procedure (the following shows 1P2W wiring mode)

4

Chapter 4 Viewing Measurement Values

Page 46

38

Four-Item Display Eight-Item Display

Sixteen-Item Display Thirtytwo-Item Display

4.1 Measurement Value Display Procedure

Selecting Measured Items for Display

From all measured items, select those you want to display on one screen.

Press to display the [Select] page.

First press an F key to select the number of items to be displayed.

Page 47

Display Item Selection Procedure

Display the

[Select] page

(a blinking cursor appears)

Enter

Select the item to

display

Cancel

Press when finished making changes.

Move the cursor

to the item to change

Accept

(the pull-down menu

appears)

39

4.1 Measurement Value Display Procedure

4

Chapter 4 Viewing Measurement Values

Page 48

40

Peak Over vol tage

Peak Over cur rent

(red indicators)

4.1 Measurement Value Display Procedure

About Valid and Displayable Ranges

The valid measur ement range (the ra nge of gua ranteed ac curacy) is 1% to 110% of the full-scale range

(except that valid voltage is limited to 1000 V in the 1500 V scale).

The display range of this unit is between the zero surpress level to 120% of the measurement range.

The following display indicates over-range measurement.

See Zero surpress level: OFF, 0.1%f.s., 0.5%f.s. (initial setting) (p. 101)

About Peak Over Indicators

Peak Over indicators light when an input voltage or current waveform peak value exceeds three times the

full-scale range (except the 1500 V range, when the voltage exceeds ±2000 V, see the figure below). The

indicators are shown on all screens, so that Peak Over can be seen even on channels not currently

selected.

Example. The following display indicates that the CH 1 voltage and CH 3 current are at Peak Over levels.

Page 49

41

RMS Voltage

RMS Current

Power Factor

Active Power

Apparent Power

Reactive Power

Power Phase Angle

Frequency

• Average rectified RMS c onver te d va lue is displayed for Urms or Irm s a ccor di ng to the r ecti fication setting.

See"4.2.5 Selecting th e Rectif ication Met hod" (p . 50)

• Polarity of power factor (λ), Reactive power (Q), and power phase angle (φ) shows the LEAD

or LAG. "No polarity sign" means "LAG" and "-" means "LEAD".

• The polarity of powe r factor, reactive power and pow er ph as e a ngle m ay n ot b e s table whe n

the voltage and current has big level difference or power phase angle is around zero.

• Each channel value of effective power (P), Reactive power (Q), Apparent power (S) and

power factor (

λ) is meaningless in the 3P 3W 2M wir ing. U se only the sum values (P12, P34,

etc.)

4.2 Viewing Power Measurements, and Changing the Measurement Configuration

4.2 Viewing Power Measurements, and

Changing the Measurement Configuration

4.2.1 Displaying Power Measurements

When viewing power measuremen ts, [P ow er], [Voltage], and [Current] are displayed so that measur ed

values can be confirmed . Press to display the Me asur ement s creen, and selec t the desire d [CH]

page with the keys. Power measurements can be displayed in a list, and detailed voltage

and current values can be displayed.

Displaying Power

Press . (The screen shows values for Wiring mode 1, four 1P2W systems.)

4

Chapter 4 Viewing Measurement Values

Page 50

42

RMS Voltage

Rectified Mean Valu e of

RMS Conversion

THD Voltage Percentage

Fundamental Voltage

Content

Voltage Waveform Peak+

AC Voltage Content

Frequency

Simple Averaged Voltage

Voltage Waveform Peak-

When the Wiring mode is 3P3W3M or 3P4W, voltage unbalance Uunb [%] is displayed.

RMS Current

Rectified Mean Value of

RMS Conversion

THD Current Percentage

Fundamental Current Cont ent

Current Waveform Peak+

AC Current Content

Simple Averaged Current

Current Waveform Peak-

When the Wiring mode is 3P3W3M or 3P4W, current unbalance Iunb [%] is displayed.

Frequency

4.2 Viewing Power Measurements, and Changing the Measurement Configuration

Displaying Voltage

Press . (The screen shows values for Wiring mode 1, four 1P2W systems.)

Displaying Current

Press . (The screen shows values for Wiring mode 1, four 1P2W systems.)

Page 51

43

Voltage Range Current Range

4.2 Viewing Power Measurements, and Changing the Measurement Configuration

4.2.2 Selecting Ranges

Measurement ranges are selected as described below.

• If the maximum voltage or current rating is exceeded , immediately stop measuring, shut off power to the measurement lines , and disconnec t from the measurement object.

• Continuing to measure when maximum ra tings are exceeded may d amage the

instrument and result in injury or death.