Page 1

INSTRUCTION MANUAL

3290-10

CLAMP ON AC/DC HiTESTER

Page 2

Page 3

10

APPX

Contents

i

Contents

Introduction .................................................................. 1

Checking the Contents of the Package ........................1

Safety Notes ................................................................2

Usage Notes ................................................................5

1Overview 9

1.1 Product Overview ...............................................9

1.2 Features ........................................................... 10

1.3 Identification of Controls and Indicators ...........12

1.3.1 Model 3290-10 CLAMP ON AC/DC Hi T ESTER 12

1.3.2 Model 9691, 9692, 9693 CLAMP ON AC/DC

SENSOR (Optional)............................................18

1.4 Buttons Operations ...........................................19

1.5 Measurement Modes ........................................ 20

1.6 Quick References .............................................21

2 Measurement Preparations 27

2.1 Attaching the Strap ...........................................28

2.2 Connecting Power ............................................29

2.2.1 Installing/ Changing the Batteries ......................29

2.2.2 Connecting the AC Adapter (Optional) ..............30

2.2.3 Using External Power ........................................31

2.3 Connecting the CLAMP ON AC/DC SENSOR .33

2.4 Connecting the Output Cords (Optional) .......... 34

2.5 Turning Power On and Off ...............................35

1

2

3

4

5

6

7

8

9

11

IDX

Page 4

ii

Contents

3 Basic Measurement Procedure 37

3.1 Measuring DC Current .....................................39

3.2 Measuring AC Current ...................................... 40

3.3 DC Integration ..................................................41

3.4 AC Integration by Timer ...................................42

3.5 Outputting Integral Values ................................44

3.6 Measuring Duty by Timer .................................46

4 Measurement Procedure 49

4.1 Verifications Before Measuring ........................ 49

4.2 Selecting the Measurement Parameter ............ 50

4.3 Measuring Current ............................................51

4.4 Measuring Peak Current ..................................62

4.5 Current Integration ...........................................66

4.6 Measuring Duty ................................................79

5 Applicable Measurement Modes 89

5.1 Auto Zero Adjustment Function ........................89

5.2 Display Update Rate ........................................90

5.3 Measurement Response Time ......................... 92

5.4 Filter Function ................................................... 95

5.5 Data Hold .........................................................96

5.6 Viewing Historical Data ....................................97

5.7 Saving Data ....................................................100

5.8 Saving Settings ..............................................101

5.9 Recalling Stored Data ....................................102

5.10 Button Lock .................................................... 102

5.11 Auto Power-off Enabled ................................. 103

5.12 Battery Checking ............................................104

5.13 Battery-Low Warning .....................................105

5.14 Beeper ............................................................106

Page 5

10

APPX

6 Specifications 107

6.1 Measurement Specifications .......................... 107

6.1.1 Current Measurement ......................................108

6.1.2 Frequency Measurement .................................110

6.1.3 Current Integral Measurement .........................111

6.1.4 Duty Measurement ..........................................112

6.2 General Specifications ................................... 113

6.3 CLAMP ON AC/DC SENSOR Specifications . 116

6.3.1 Model 9691 CLAMP ON AC/DC SENSOR ......116

6.3.2 Model 9692 CLAMP ON AC/DC SENSOR ......118

6.3.3 Model 9693 CLAMP ON AC/DC SENSOR ......120

6.4 Combined Accuracy .......................................122

6.4.1 Models 9691 + 3290-10 C om bined Accuracy .1 22

6.4.2 Model 9692 + 3290-10 Combined Accuracy ...124

6.4.3 Model 9693 + 3290-10 Combined Accuracy ...125

6.4.4 Method of Calculation .................. ....................126

7 Maintenance and Service 127

iii

Contents

1

2

3

4

5

6

7.1 Cleaning ......................................................... 127

7.2 Repair and Servicing ......................................128

Appendix 135

Extension Cables .....................................................135

Carrying Case ..........................................................137

Differences between Models 3290 and 3290-10 ..... 139

7

8

9

11

IDX

Page 6

iv

Contents

Page 7

10

Introduction

1

Introduction

Thank you for purchasing the HIOKI “Model 3290-10 CLAMP ON

AC/DC HiTESTER.” To obtain maximum performance from the

meter, please read this manual first, and keep it handy for future

reference.

This manual describes the operation of the 3290-10 when used

with the 9691, 9692, or 9693 CLAMP ON AC/DC SENSOR.

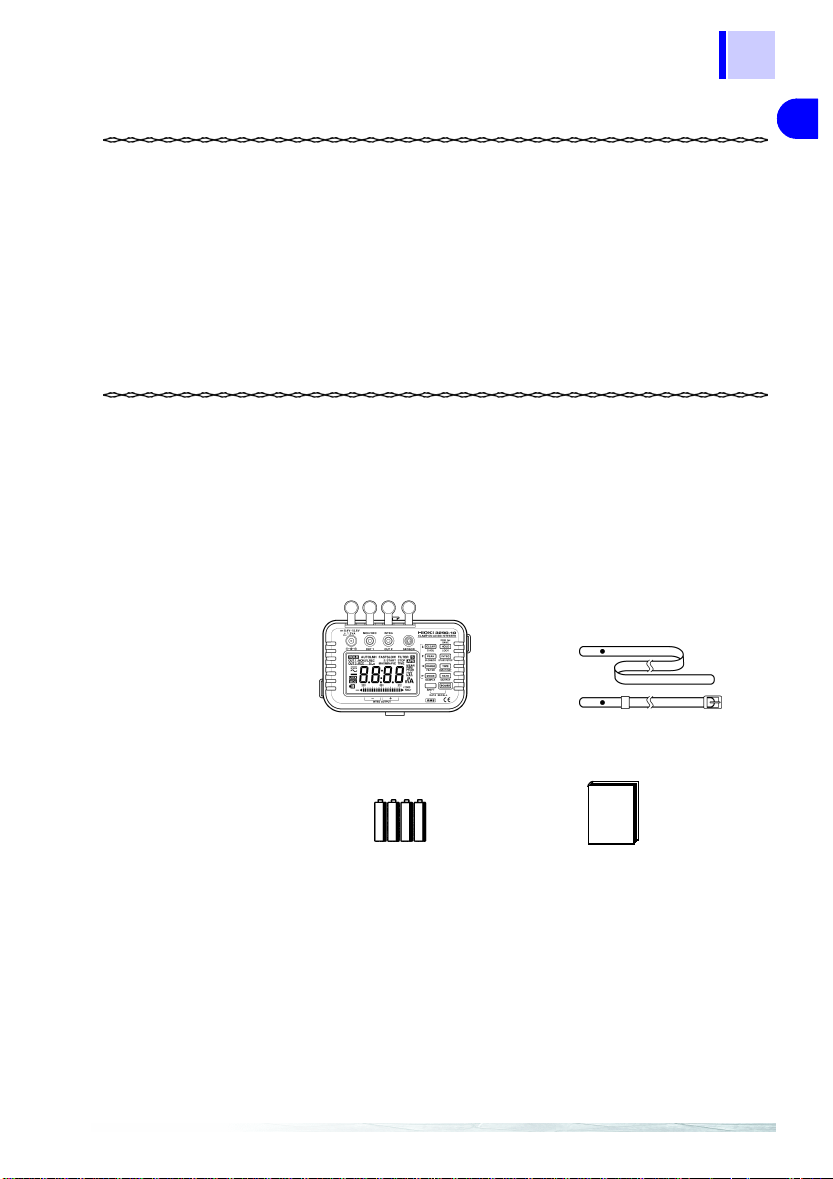

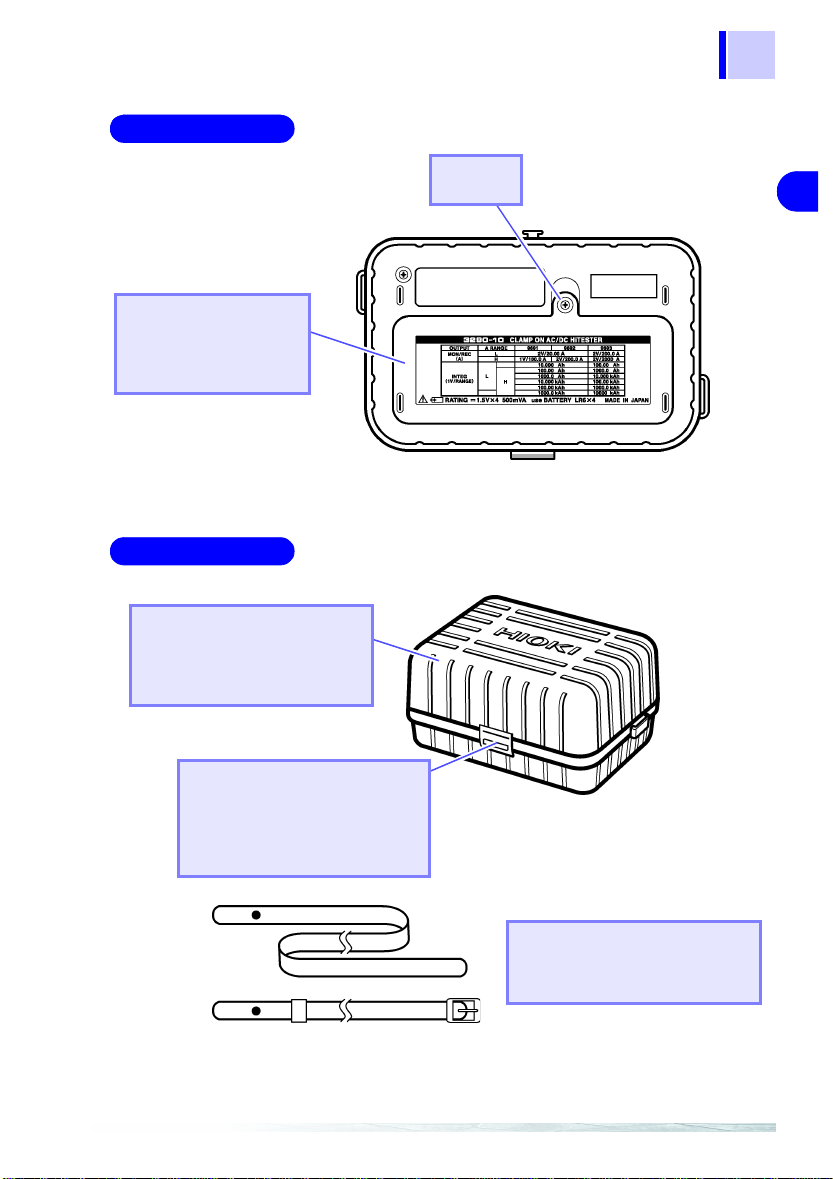

Checking the Contents of the Package

When you receive the meter, inspect it carefully to ensure that no

damage occurred during shipping. In particular, check the accessories, panel buttons, and jacks. If damage is evident, or if it fails to

operate according to the specifications, contact your dealer or

Hioki representative.

Use the original packing materials when transporting the meter, if

possible.

Model 3290-10 CLAMP ON AC/DC HiTESTER

X 1

Strap X 1

1

2

3

4

5

6

7

8

Options

Batteries (LR6) X 4

• Model 9445-02 AC ADAPTER ( SA10-0910N, SINO-AMERICAN)

• Model 9445-03 AC ADAPTER

(SA10-0910G, SINO-AMERICAN, for Europe)

• Model 9094 OUTPUT CORD

• Model 9400 CARRYING CASE

• Model 9691 CLAMP ON AC/DC SENSOR

• Model 9692 CLAMP ON AC/DC SENSOR

• Model 9693 CLAMP ON AC/DC SENSOR

Instruction Manual X 1

9

11

Page 8

2

Safety Note s

Safety Notes

This meter is designed to comply with IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to

shipment. However, mishandling during use could result in

injury or death, as well as damage to th e meter. Be certain

that you understand the instructions and precautions in the

manual before use. We disclaim any respon sibility for acci

dents or injuries not resulting directly from meter defects.

Safety Symbols

This manual contains information and warnings essential for safe

operation of the meter and for maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety

precautions.

-

In the manual, the symbol indicates particularly

important information that the user should read before

using the meter.

The symbol printed on the meter indicates that the

user should refer to a corresponding topic in the manual

(marked with the symbol) before using the relevant

function.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates a double-insulated device.

Indicates that the instrument may be connected to or disconnected from a live circuit.

Page 9

Safety No tes

10

The following symbols in this manual indicate the relative importance of cautions and warnings.

3

Other Symbols

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg.

(reading) and dgt. (digit) values, with the following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or scale length. This is usually the

name of the currently selected range.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the meter.

Indicates advisory items related to performance or

correct operation of the meter.

Indicates the prohibited action.

❖

Indicates the reference.

1

2

3

4

5

6

7

8

9

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring meter.

dgt. (resolution)

The smallest displayable unit on a digital measuring meter, i.e., the

input value that causes the digital display to show a "1" as the

least-significant digit.

11

Page 10

4

Safety Note s

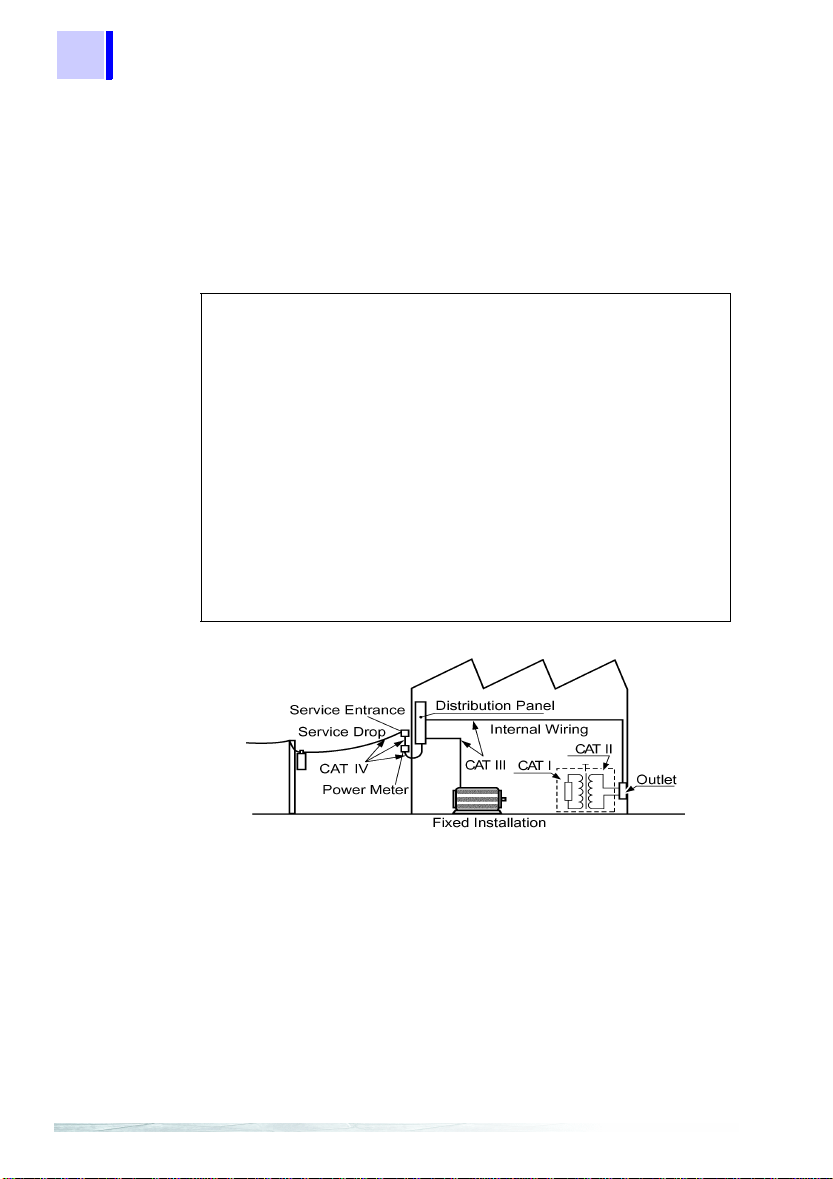

Measurement categories (Overvoltage categories)

This device complies with CATIII (600 V), CATII (1000 V) safety

requirements.

To ensure safe operation of measurement devices, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT I to CAT IV, and called measurement catego

ries. These are defined as follows.

-

CAT I Secondary electrical circuits connected to an AC

CAT II Primary electrical circuits in equipment connected to

CAT III Primary electrical circuits of heavy equipment (fixed

CAT IV The circuit from the service drop to the service

Higher-numbered categories correspond to electrical environments

with greater momentary energy. So a measurement device

designed for CAT III environments can endure greater momentary

energy than a device designed for CAT II.

Using a measurement device in an environment designated with a

higher-numbered category than that for w hich the device is rated

could result in a severe accident, and must be carefully avoided.

Never use a CAT I measuring device in CAT II, III, or IV environments.

The measurement categories comply with the Overvoltage Categories of the IEC60664 Standards.

electrical outlet through a transformer or similar

device.

an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

installations) connected directly to the distribution

panel, and feeders from the distribution panel to out

lets.

entrance, and to the power meter and primary over

current protection device (distribution panel).

-

-

Page 11

10

Usage Notes

5

Usage Notes

Avoid the following:

Corrosive or

explosive gases

High temperature

High humidity

Direct

sunlight

Electomagnetic

radiation

Dust

Impact, dropping

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Setting Up the 3290-10

• This meter should be installed and operated indoors only,

between 0 and 40°C and 80% RH or less.

• Do not use the meter where it may b e exposed to corrosive or

combustible gases. The meter may be damaged.

• Do not store or use the meter where it could be exposed to

direct sunlight, high temperature or humidity, or condensation.

Under such conditions, the meter may be damaged and insula

tion may deteriorate so that it no longer meets specifications.

• This meter is not designed to be entirely water- or dust-proof. Do

not use it in an especially dusty environment, nor where it might

be splashed with liquid. This may cause damage.

• Do not use the meter near a source of strong electromagnetic

radiation, or near a highly electrically charged object. These may

cause a malfunction.

• To avoid damage to the meter, protect it from physical shock

when transporting and handling. Be especially careful to avoid

physical shock from dropping.

1

2

3

4

5

-

6

7

8

9

Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and high-cur

rent conductors, or in the presence of strong electromagnetic

fields such as near radio transmitters.

-

11

Page 12

6

.

Usage Notes

Preliminary Checks

Before using the meter the first time, verify that it operates normally

to ensure that the no damage occurred during storage or shipping.

If you find any damage, contact your dealer or Hioki representative.

Before using the meter, make sure that the insulation on the

probes is undamaged and that no bare conductors are

improperly exposed. Using the meter in such conditions

could cause an electric shock, so contact your dealer or

Hioki representative for repair.

Measurement

• To avoid short circuits and potentially life-t hreatening hazards, never attach the clamp to a circuit that operates at

more than 600V, or over bare conductors.

• Clamp sensor should o nly be connected to the secondary

side of a breaker, so the breaker can preven t an a ccident if

a short circuit occurs. Connections should nev er be made

to the primary side of a breaker, because unrestricted cur

rent flow could cause a serious accide nt if a short circuit

occurs.

• To avoid electric shock, do not touch the portion be yond

the protective barrier during use.

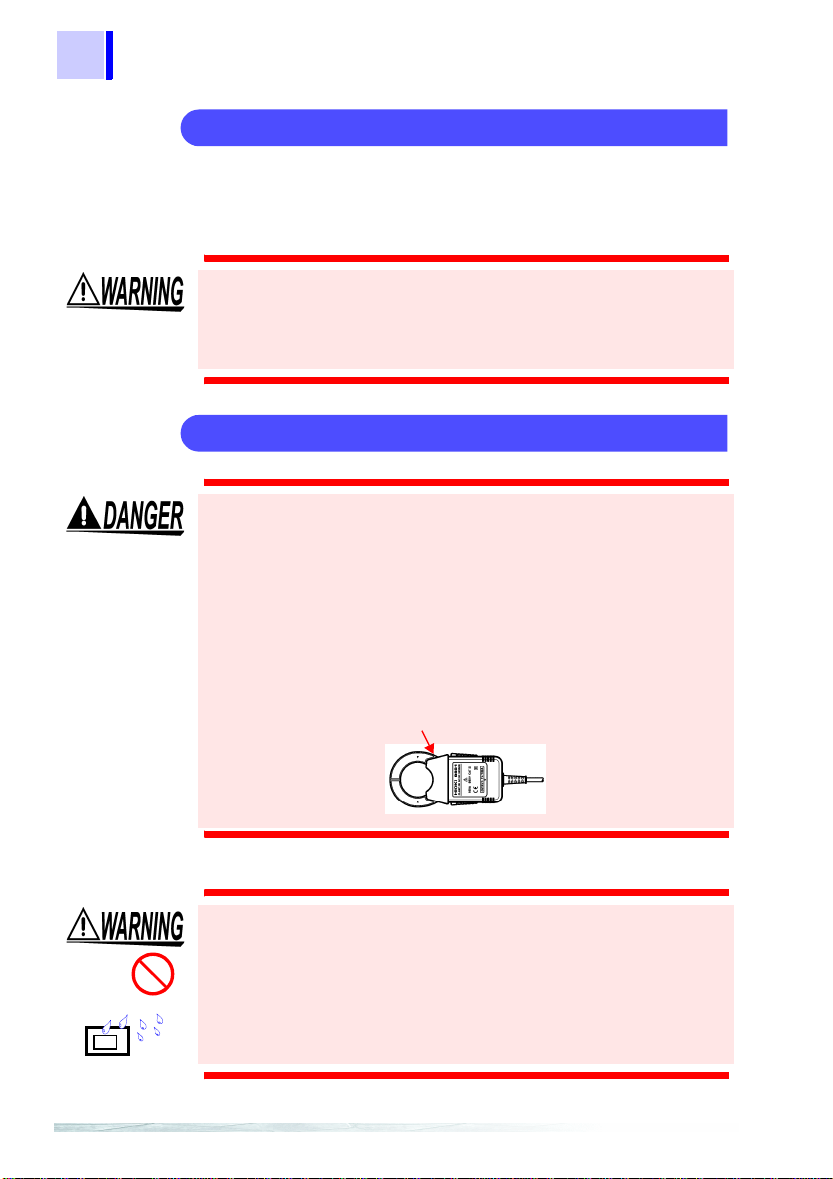

Barrier

-

Do not get wet.

This model is the 9661

• Do not allow the meter to get wet, and do not take measurements with wet hands. This may cause an electric shock.

• To avoid electric shock when measuring live lines, wear

appropriate protective gear, such as insulated rubber

gloves, boots and a safety helmet.

Page 13

7

10

Usage Notes

• The maximum continuous-input limit is obtained from the temperature increase due to self-heating during measurement. To

prevent damage to the clamp-on sensor, do not input a current

exceeding this limit.

• The maximum continuous-input limit varies depending on the

clamp-on sensor and the frequency of the current to be mea

sured.

❖ Maximum continuous-input limit varies:

See Section 6.3 "CLAMP ON AC/DC SENSOR Specifications" (page 116)

Each sensor’s derating acording to frequency

•The indicator appears when battery voltage becomes low.

Replace the batteries as soon as possible.

• After use, always turn OFF the power.

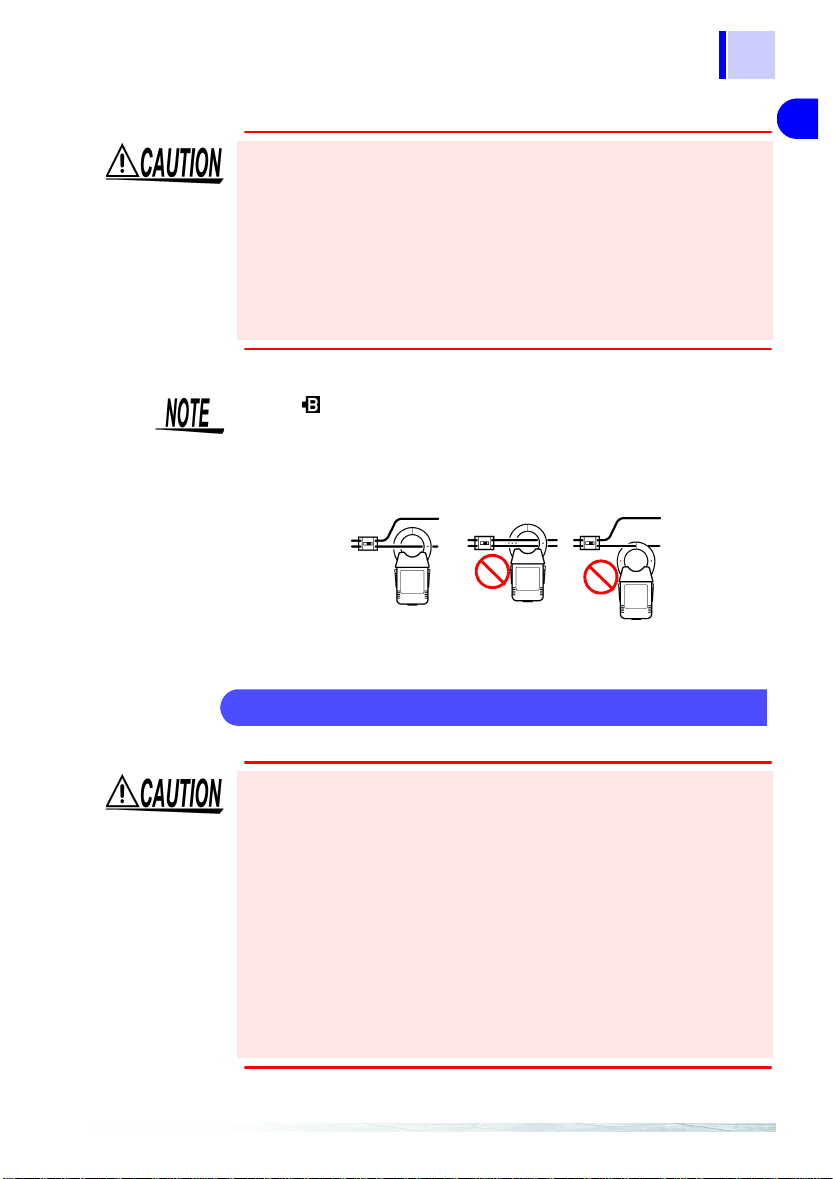

• Attach the clamp around only one conductor. Single-phase (2wire) or three-phase (3-wire) cables clamped to gether will not

produce any reading.

1

-

2

3

4

5

OK

Handling the Clamp Sensors

• The ends of the clamp sensor are very delicate. Be careful not to

drop the sensor or subject it to impact. If the sensor is deformed

or the contact surfaces of the clamps are damaged, the mea

surement may not be accurate.

• Be careful to avoid dropping the clamps or otherwise subjecting

them to mechanical shock, which could damage th e mating surfaces of the core and adversely affect measurement.

• The top part of the clamp sensor above the barrier (including the

clamps, but not the lever) is provided with double insulation to

ensure safety. Be careful not to drop the sensor or otherwise

subject it to impact. A damaged sensor may result in electric

shock during measurement. In case of sensor damage, contact

us immediately for repair or discard the damaged sensor to

avoid subsequent use.

-

6

7

8

9

11

Page 14

8

Usage Notes

Page 15

1.1 Product Overview

10

Overview 1

1.1 Product Overview

The 3290-10 CLAMP ON AC/DC HiTESTER is used with the 9691,

9692, or 9693 CLAMP ON AC/DC SE NSOR. These sensors are

interchangeable and any model can be used with the 3290-10.

The 3290-10 automatically detects the sensor connected and sets

up the appropriate range. When combined with the 9 691, 9692, or

9693 Sensor, the 3290-10 HiTESTER can perform DC, AC, and

AC+DC measurement of a live pow er line. In addition, current inte

gral and duty measurement functions are provided.

As well as operating from batteries or AC adapte r, operation from

an external DC power source is supported for long-term measure

ments.

See page 139 for details of the differences with the Model 3290

CLAMP ON AC/D C HiTESTER.

9

1

Overview

2

3

4

-

-

5

6

7

8

9

11

Page 16

10

1.2 Features

1.2 Features

Current integration functions

(total, positive and negative integrals)

Polarity-specific positive and negative current integrals can be

measured (at ten samples/second)

D/A output (selectable total, positive or negative integral).

Measures the mean current value within a specified interval (total

integral / integration interval).

Operating time and duty measurement

Any value can be set as the operating state threshold.

Duty (%) = operating time / measurement time X 100

Timer measurements available

(integral and duty measurements)

Measurement times can be set from one minute to 99 hours, 59

minutes.

Repeating measurements

Any timer can be set to perform up to 20 repeated measu rements.

Historical measurement data confirmation

Data from repeating measurements can be stored (integrals, interval mean, peak, maximum, minimum, duty and operating time).

Data storage

Measurement data and settings can be stored by pressing the

button for two seconds, and upon auto power-off or forced

power off due to low battery voltage.

Data recall

Holding the SHIFT button while pressing the button to turn the

meter on recalls stored data.

Peak measurement

Positive and negative current waveform peak values can be displayed in DC mode.

Page 17

11

10

1.2 Features

Low-frequency current measurement

AC current as low as 1 Hz can be measured in the SLOW AC+DC

mode.

1

Overview

Filter function

Switchable 500-Hz low-pass filter (in AC and AC+DC modes)

Switchable 1-Hz low-pass filter (in DC mode, for MON output)

AC+DC measurement

Measures superimposed AC and DC components and full- and

half-wave rectified waveforms.

Selectable measurement response time

Measurement response time can be set to FAST, NORMAL or

SLOW (in AC and AC+DC modes).

Multiple power source support

Accepts power from batteries, optional AC adapter or external DC

source.

Extension cable options

An extension cable can be connected between the meter and the 9691,

9692 or 9693 CLAMP ON AC/DC SENSOR. Optional extension cables

are available with lengths of 5, 10, 20, 30, 50 or 100 m.

2

3

4

5

6

7

8

9

11

Page 18

12

s

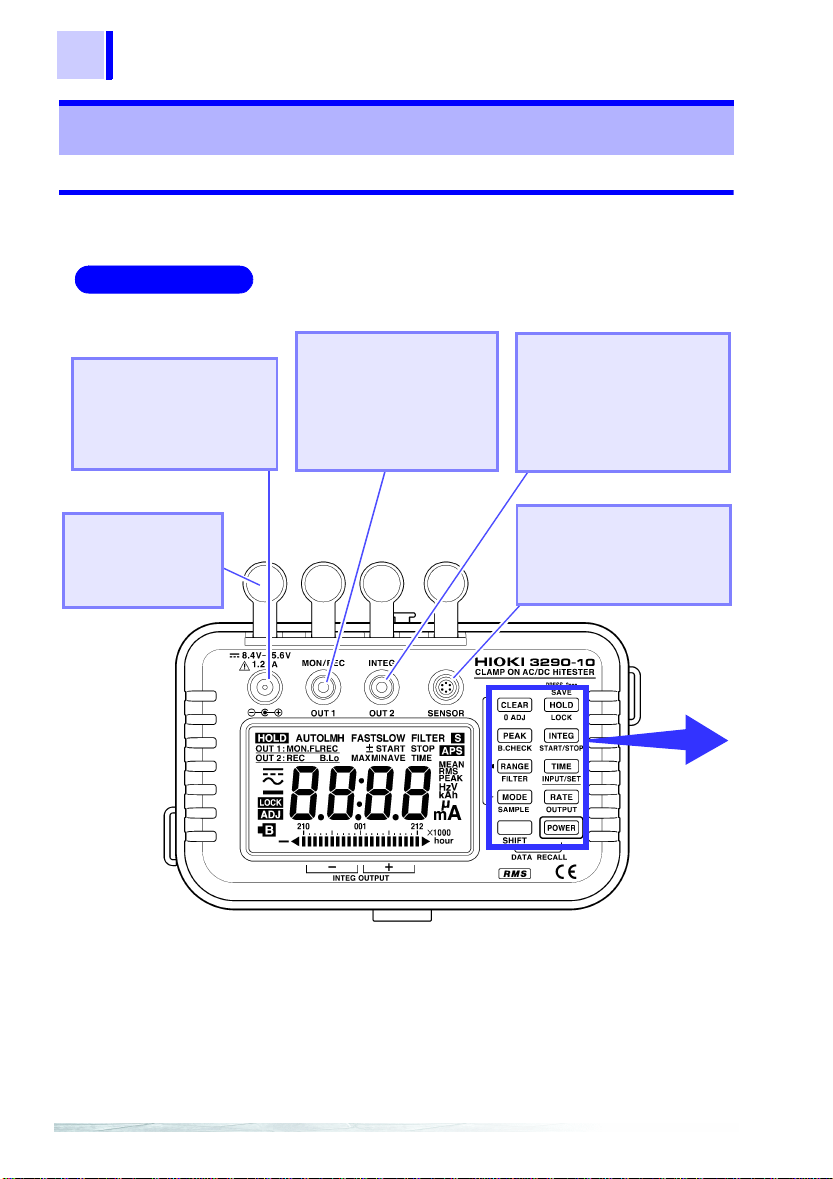

1.3 Identification of Controls and Indicators

1.3 Identification of Controls and Indicators

1.3.1 Model 3290-10 CLAMP ON AC/DC HiTESTER

Front Panel

AC Adapter

Connection Jack

The optional AC adapter

can be connected here to

power the meter.

Dust Caps

Used to protect the

jacks in a dusty environment.

Output Jack 1 (OUT1)

Connect the optional

9094 OUTPUT CORD to

this jack to obtain output

during current measurement.

Output Jack 2 (OUT2)

Connect the optional 9094

OUTPUT CORD to this

jack to obtain output during

integral measurement.

Sensor Jack (SENSOR)

Connect the 9691, 9692, or

9693 CLAMP ON AC/DC

SENSOR to this jack.

Buttons

Operation

Page 19

1.3 Identification of Controls and Indicat or s

10

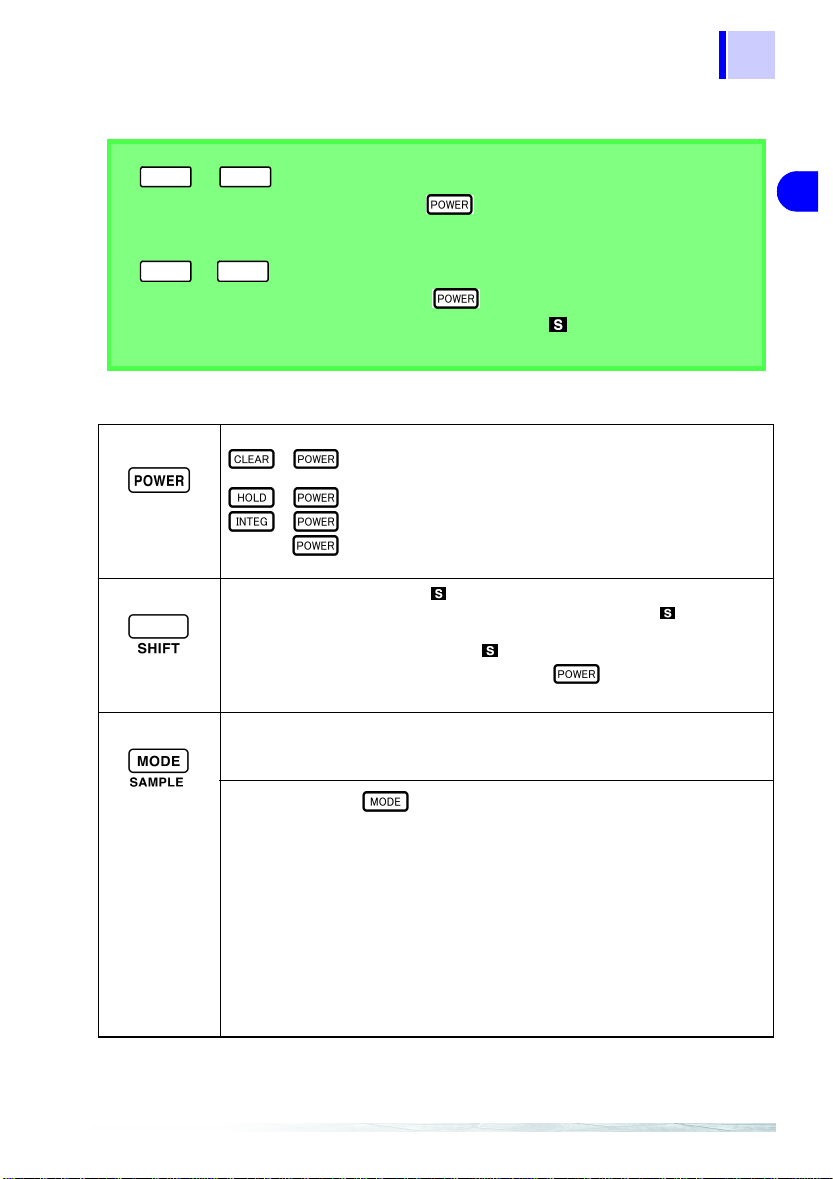

Notation for multi-button operations

A B

+ : Press Button A and button B at the same time.

Example: SHIFT +

Press the

A B

→ : Press Button A and then press Button B.

Example: SHIFT →

After pressing the

play), press the

SHIFT and POWER buttons at the same time.

SHIFT button ( appears on the dis-

POWER button.

13

1

Overview

2

3

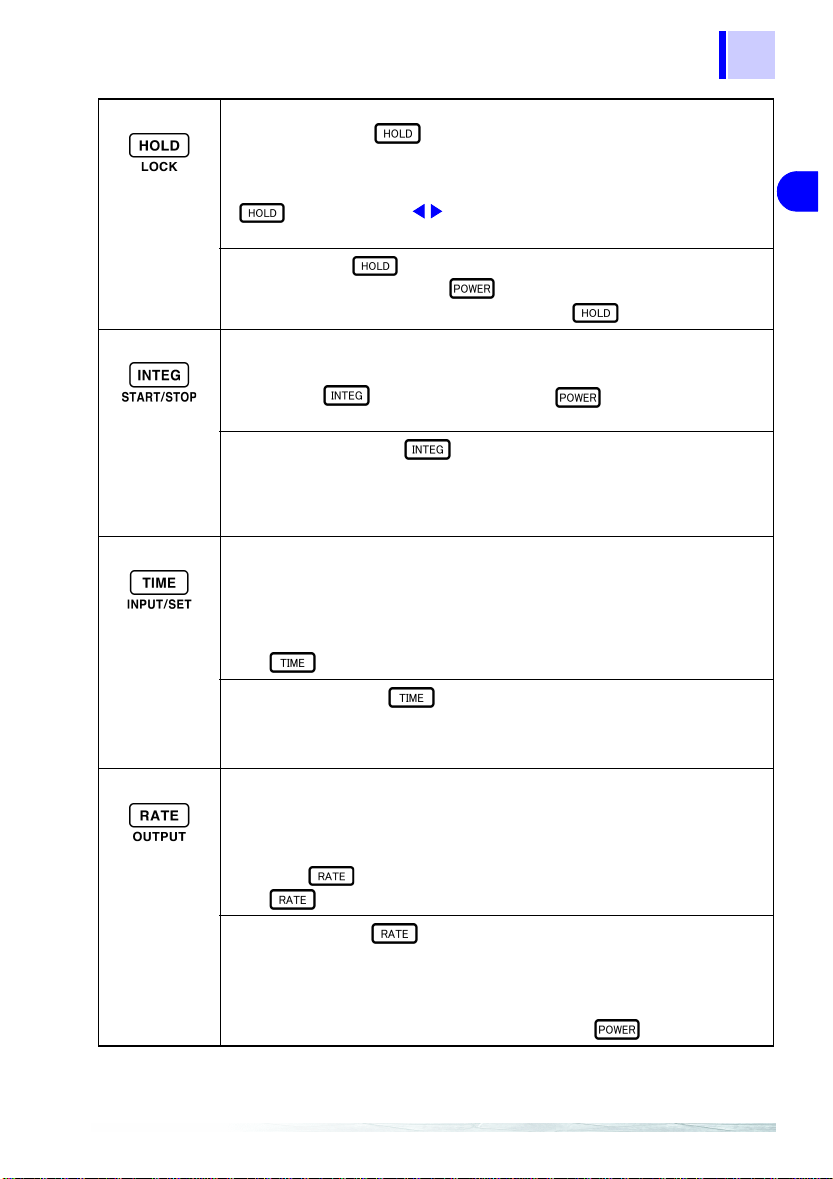

Buttons Operations

Turns power ON/OFF.

SHIFT + : Stored data such as integral values can be reviewed.

• Pressing this button causes to display, indicatin g tha t the a ddi ti on al function

(in blue letters) allocated to each button is available. To turn off, press the

SHIFT button again.

• Some buttons may be locked when is on.

• Holding the SHIFT button while pressing the button to turn the meter

on enables review of stored data such as integral values.

• Selects the current and frequency measurement mode.

DC → AC → AC+DC → Hz

• Button presses are ignored while TIME is displayed.

SAMPL (SHIFT → ):

• Switches display of refresh rate and measurement response time.

(AC and AC+DC modes) (see pages 90 and 92)

NORMAL (twice/ sec) → SLOW (once/ 3 sec) → FAST (10 times/ sec)

DC mode is fixed at once per second.

• The display update rate is usually set to NORMAL.

(Note that there is no indication for

• SLOW decelerates the speed of updating on-display measurement.

(with SLOW on)

Measurement response time also becomes SLOW.

• FAST accelerates the speed of updating on-display measurement.

(with

Measurement response time also becomes FAST.

+ : Cancels saved se tting s (retur ned t o fact ory defau lts) and erase s

stored measurement data. (see pages 100 and 101)

+ : Disables the auto power-off function. (see page 104)

+ : Turns off the beeper. (see page 107)

(see page 103)

(see page 103)

(see page 52)

NORMAL.)

FAST on)

4

5

6

7

8

9

11

Page 20

14

1.3 Identification of Controls and Indicators

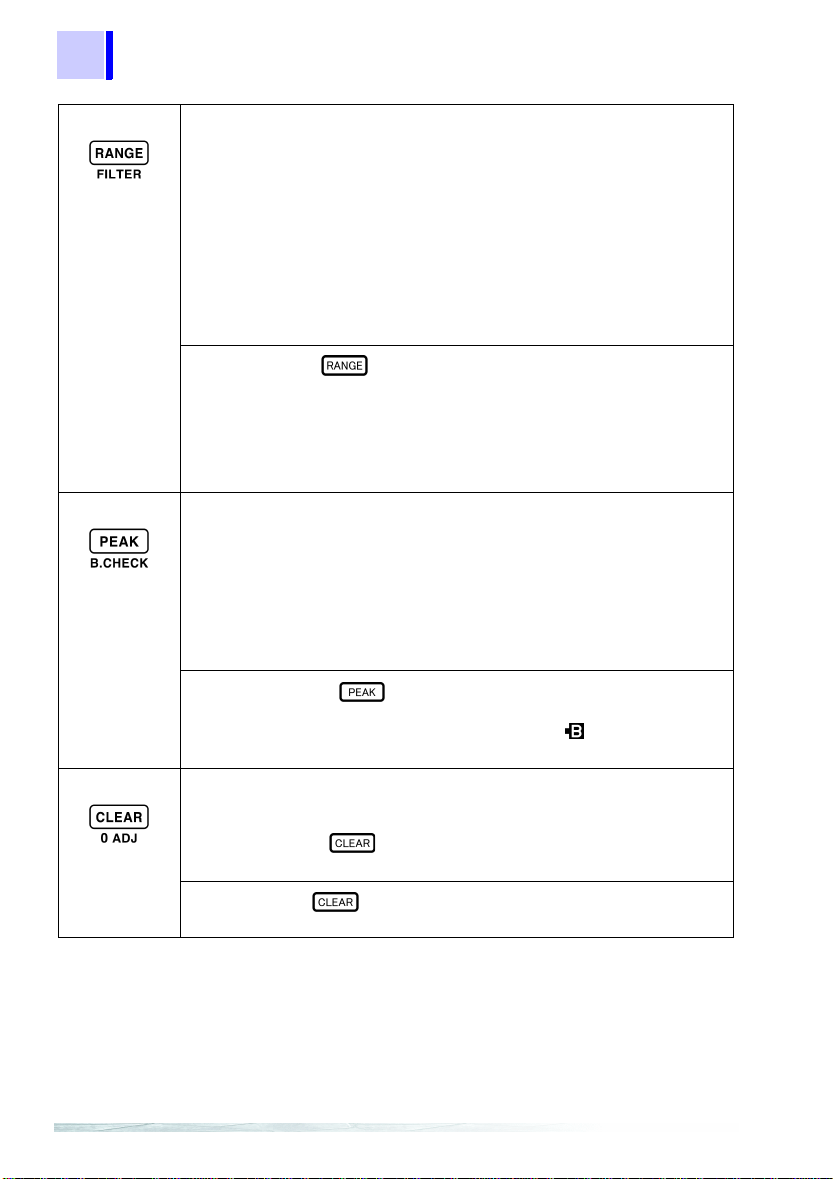

Current Measurement (see page 53)

• Selects auto range or manual range.

(Hz mode uses auto-ranging only) AUTO → L → H

• The current ranges for the 9691 and 9692 are 20 A and 200 A; the ranges for

the 9693 are 200 A and 2000 A.

• Button presses are ignored while TIME is displayed.

Integral Measurement (see page 70)

• Selects auto range or manual range.

• Available ranges depend on the connected clamp-on sensor.

• Five ranges can be manually selected for each integral range (four ranges are

shared in common as H and L ranges).

(SHIFT → ): (see page 95)

FILTER

•DC Mode

Applies low-pass filtering at about one Hz to the output when output jack 1

(OUT1) is set to MON output (low-pass filtering at about 0.5 Hz is always

applied to the display).

• AC and AC+DC Modes

Applies low-pass filtering at about 550 Hz to the display and output.

•DC Mode (see page 63)

Displays positive and negative peak values.

Peak measurement dete rmines the pe ak (cr est va lue) of th e curre nt wavef orm.

(Peak Hold)

+ PEAK → - PEAK

• AC and AC+DC Modes

Displays peak (absolute), maximum and minimum values (current measurement).

PEAK → MAX → MIN

(see page 63)

B.CHECK

• Displays remaining battery charge.

• When TIME and STOP are displayed, clears INTEG (integrals), RATE (duty)

• Clears data to “0” during peak measurement.

• Holding down the button and turning power on initializes the setting

0 ADJ (SHIFT → ): (See page 89)

• Performs auto zero adjustment in DC and AC+DC modes.

(SHIFT → ): (See page 105)

When the remainin g ba tte ry charge indicates 0%, the indicator (low-battery

warning) appears.

and PEAK data values on the corresponding displays (see pages 69 and 80).

(see page 65)

save function and restores the default settings. (See page 101)

Page 21

15

10

1.3 Identification of Controls and Indicat or s

• Suspends or deactivates the display-updatin g functi on .

• Holding down the button and turning power on disables the auto

power-off fu nction.

• Press and hold for two seconds to store settings and data. (See page 101)

• When TIME is displayed (other than when current is displayed), after pressing

button, press the buttons to review INTEG, RATE or PEAK mea-

surement history.

LOCK (SHIFT → ): (see page 103)

• Locks all buttons including the button.

• To cancel, press SHIFT button again, then press button.

• Displays the integral and interval mean current values (see page 74)

DC Mode: total integral → positive integral → negative interval → interval mean va lue

AC and AC+DC Modes: integral → interval mean value

• Holding the button while pressing the button to turn the meter

on disables the beeper.

START/STOP (SHIFT → ): (see pages 74 and 85)

• Starts and stops current integral and duty measurement.

When STOP is displa yed, measurement starts (and START appears)

When START is displayed, measurement stops (and STOP appears)

• TIME is displayed.

• Displays elapsed time from when measurement was started by the START/STOP

button, the timer setting and repetition number (alternating once per second).

Elapsed tim e → timer setting and repetition number

Elapsed time is displayed normally up to 99 hours and 59 minutes.

If the total time of repeating timer measurements exceeds 100 hours, the time

unit indicator (h) is di splayed.

• The button has to be pressed in order to set the timer.

(see page 104)

(see page 97)

(see page 107)

1

Overview

2

3

4

5

6

7

INPUT/SET

• Enables the setting display for the timer and current threshold (only for duty

measurement).

• Accepts displayed settings.

• Displays the duty, operating time and current threshold (see page 81)

Duty → operating time → current threshold

• Although no "%" unit indicator appears for duty measurements, the displayed

value is percentage.

• When the duty value exceeds 100 hours , "h" is d ispla yed to indicate hour u nit s.

Press the button to display.

• The button has to be pressed in order to set the current threshold.

OUTPUT

• Makes output settings (for current and integral measurements).

• Settings for the two output jacks are limited according to measurement mode.

• The auto power-off function i s di sab le d. Ho wev er, when the timer is set, data i s

stored and power turns off about 10.5 minutes after the timed measurement

ends (stored data can be read by pressing SHIFT + buttons).

(SHIFT → ): (see pages 67 and 82)

(SHIFT → ): (see pages 54 and 71)

8

9

11

Page 22

16

1.3 Identification of Controls and Indicators

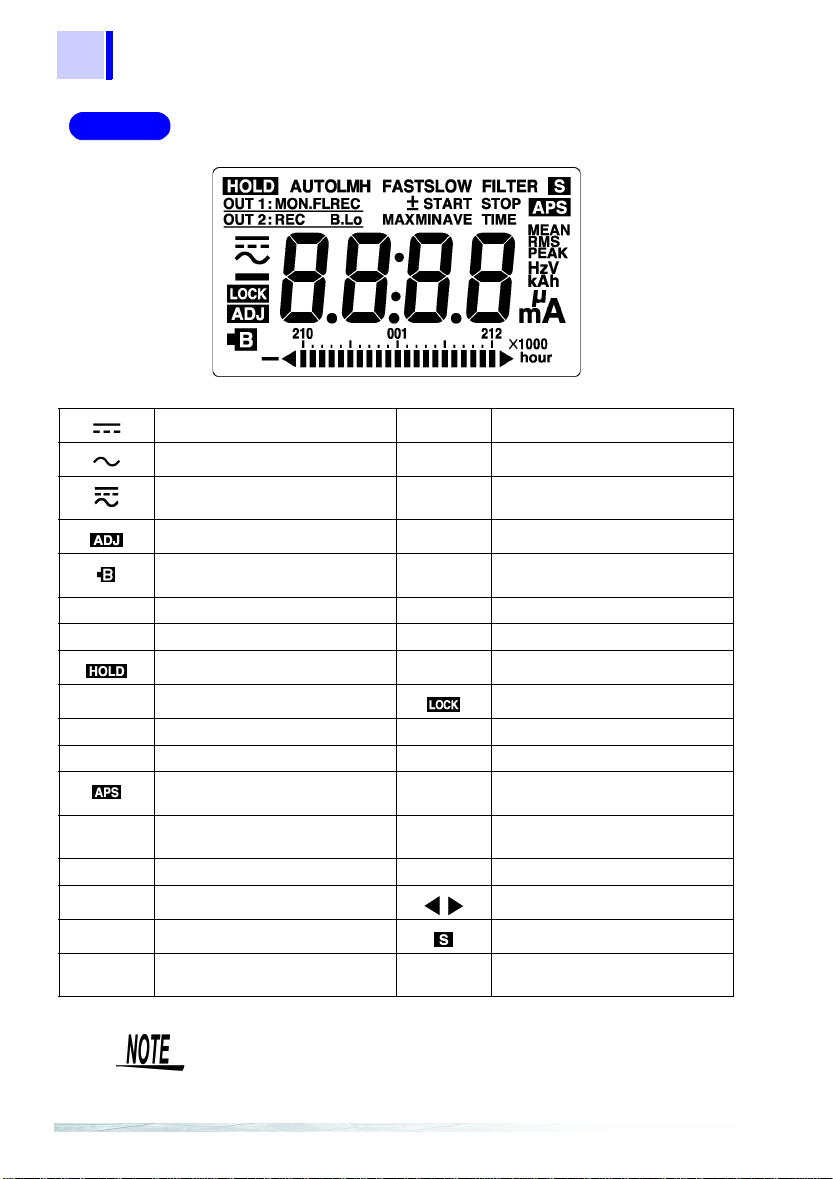

LCD

OUT1

OUT2

MON

MON.FL

REC

AUTO

L

H

FAST

SLOW

Direct Curren t (DC)

Alternating Current (AC)

Alternating Current and Direct

Current (AC+DC )

Auto zero adjustment is active.

Low battery warning

FILTER

MAX

MIN

AVE

TIME

500 Hz filter is active.

Maximum value

Minimum value

Interval mean current value

Stores integral and

duty measurement data

Setting of OUT1 RMS True root mean square value

Setting of OUT2

Data hold function

PEAK

Hz

Wave peak value

Frequency

Monitor is active. Button lock is active.

1 Hz filter for monitor is active.

Record is active.

Auto power-off is active.

Auto-range

Current L (low) range

A

Ah

START

STOP

hour

Current

Integral value

Starts integral or duty measure-

ment

Stops integral or duty measure-

ment

100 hours/segment (bar graph)

Current H (high) range Input over (bar graph)

Display-updating 10 times/sec. SHIFT

Display updating approx.

once/3 sec.

The letter of LCD is clearest, when it sees from the front side.

Page 23

10

Bottom Panel

17

1.3 Identification of Controls and Indicat or s

Battery Cover

Unfasten the screw,

then remove the case

to replace the battery.

Others

Top Case

Cover the 3290-10 with this

case when not in use to protect

the LCD, buttons and jacks.

Screw

1

Overview

2

3

4

5

6

7

8

Top Case Clasp

Insert the clasp into the top

case to attach the case. Move

the top case to the rear during

measurement.

Strap

Used to hang the 3290-10

around neck so as not to drop it.

9

11

Page 24

18

1.3 Identification of Controls and Indicators

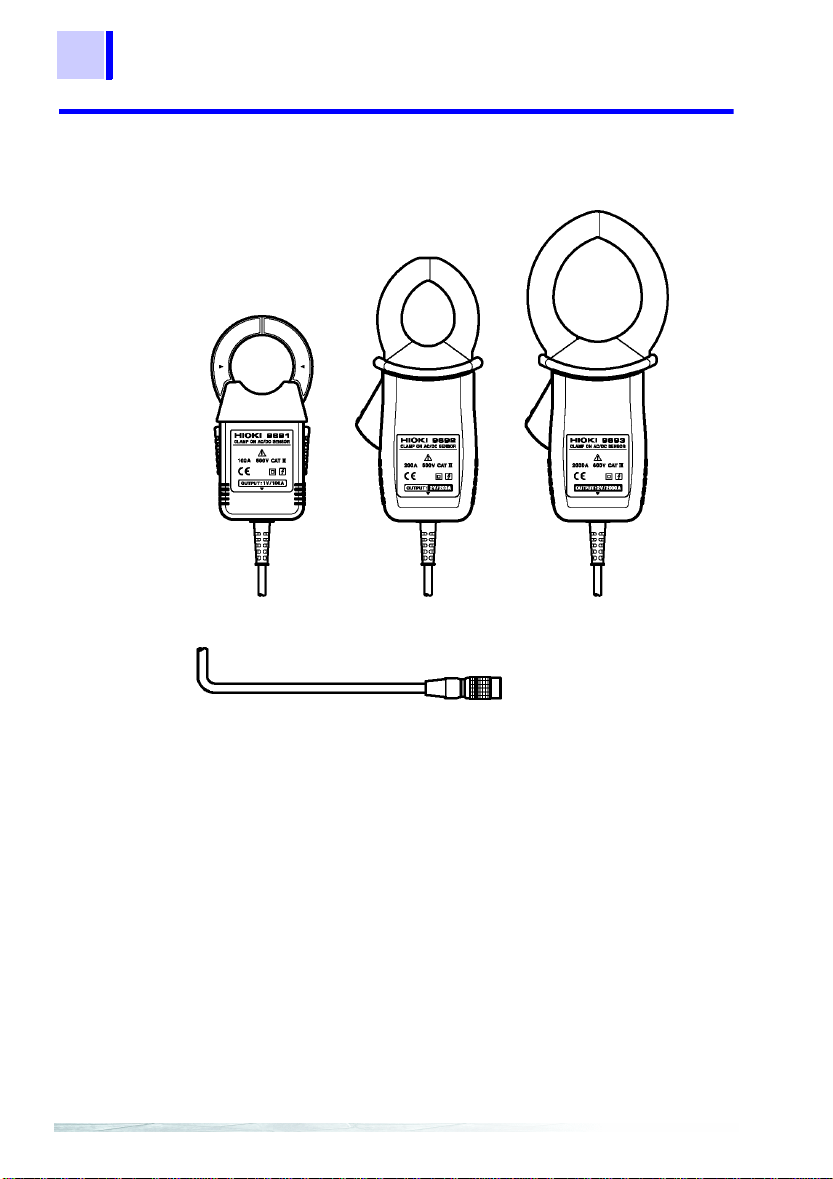

1.3.2 Model 9691, 9692, 9693 CLAMP ON AC/DC SENSOR (Optional)

Model 9691

Model 9692

Output Connector

Model 9693

Page 25

10

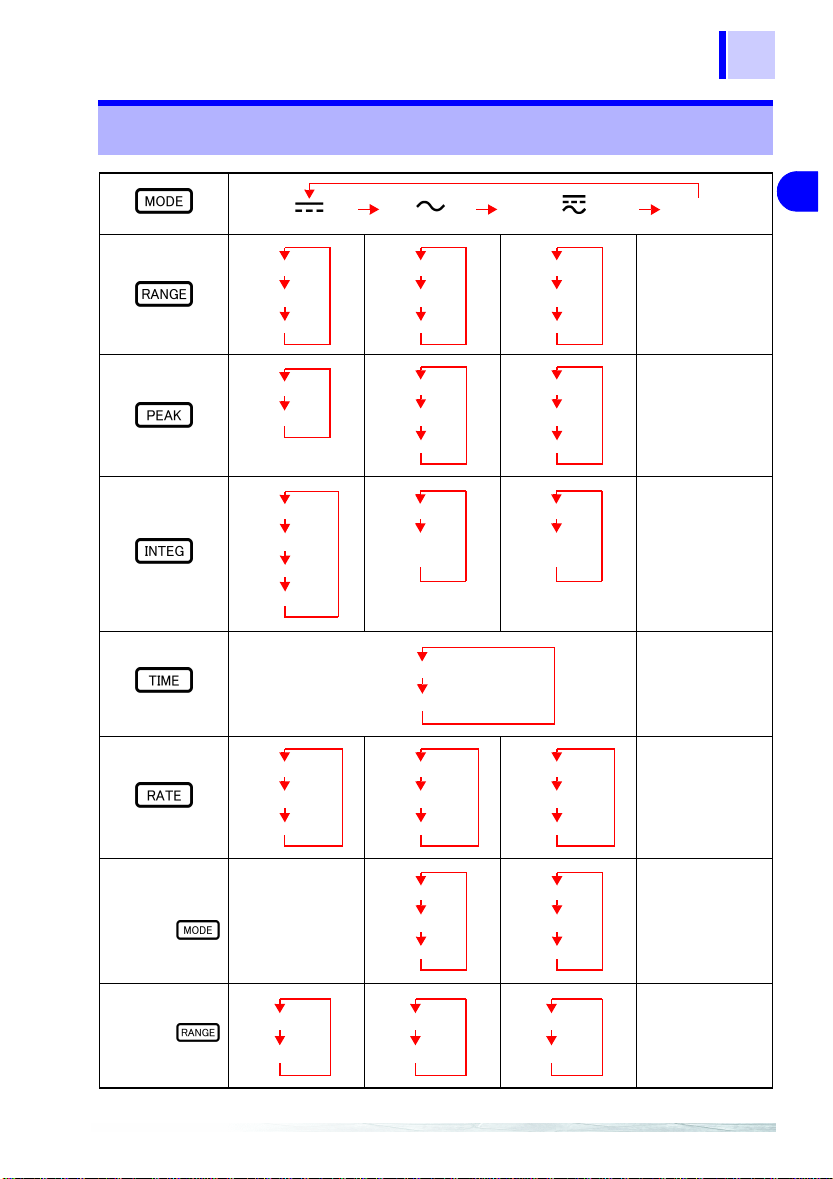

1.4 Buttons Operations

19

1.4 Buttons Operations

DC

AUTO range

L range

H range

+ PEAK

- PEAK

T otal integral

Positive integral

Negative integral

Elapsed time

Timer setting time (repetition number)

Duty

Operating time

Current threshold

AC AC+DC

AUTO range

L range

H range

PEAK

MAX

MIN

Integral value

Interval mean

current value

Elapsed time

Duty

Operating time

Current threshold

AUTO range

L range

H range

PEAK

MAX

MIN

Integral value

Interval mean

current value

Duty

Operating time

Current threshold

Hz

AUTO range

--

--

--

--

1

Overview

2

3

4

5

6

7

8

9

SAMPLE

SHIFT →

FILTER

SHIFT →

NORMAL

-- --

MON

MON.FL

SLOW

FAST

OFF

ON

NORMAL

SLOW

FAST

OFF

ON

11

--

Page 26

20

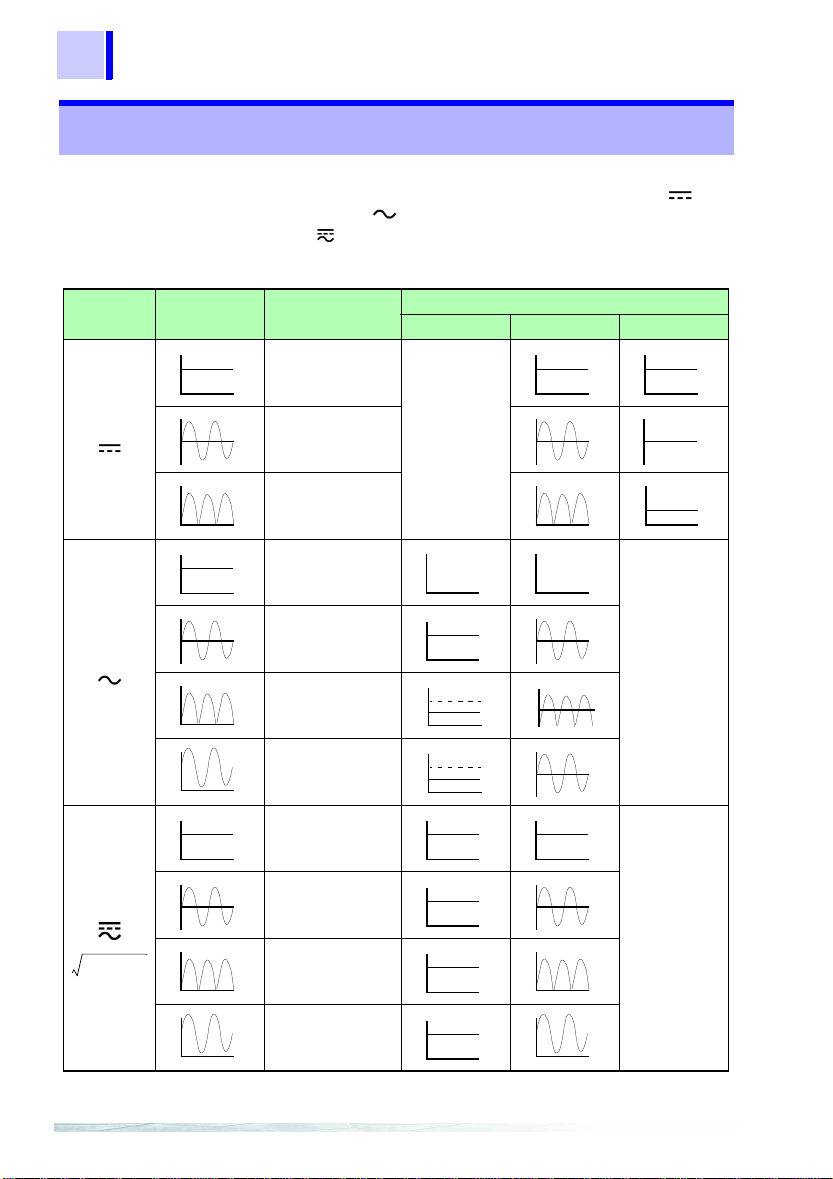

1.5 Measurement Modes

1.5 Measurement Modes

For current, three modes are provided: DC (direct current, ), AC

(alternating current, ), and AC+DC (alternating current and

direct current, ) modes. Select a proper mode according to the

waveform shown below:

Mode

DC

()

AC

()

Input

waveform

Display

OUTPUT (only for current mode)

REC MON MON.FL

Yes

0 0 0

0 0 0

No

Not measurable

Setting impos-

sible

Average

0 0 0

measurement

No

Not measurable

0

0

(zero displayed)

Yes

0 V

0

0

No

0

Not measurable

0

No

0

Not measurable

0

0 V

0

0

0

0

Yes

0 0 0

(without polarity)

--

AC+DC

()

AC2DC2+

0

Yes

0

0

--

Yes

0

0

0

Yes

0

0

0

Page 27

10

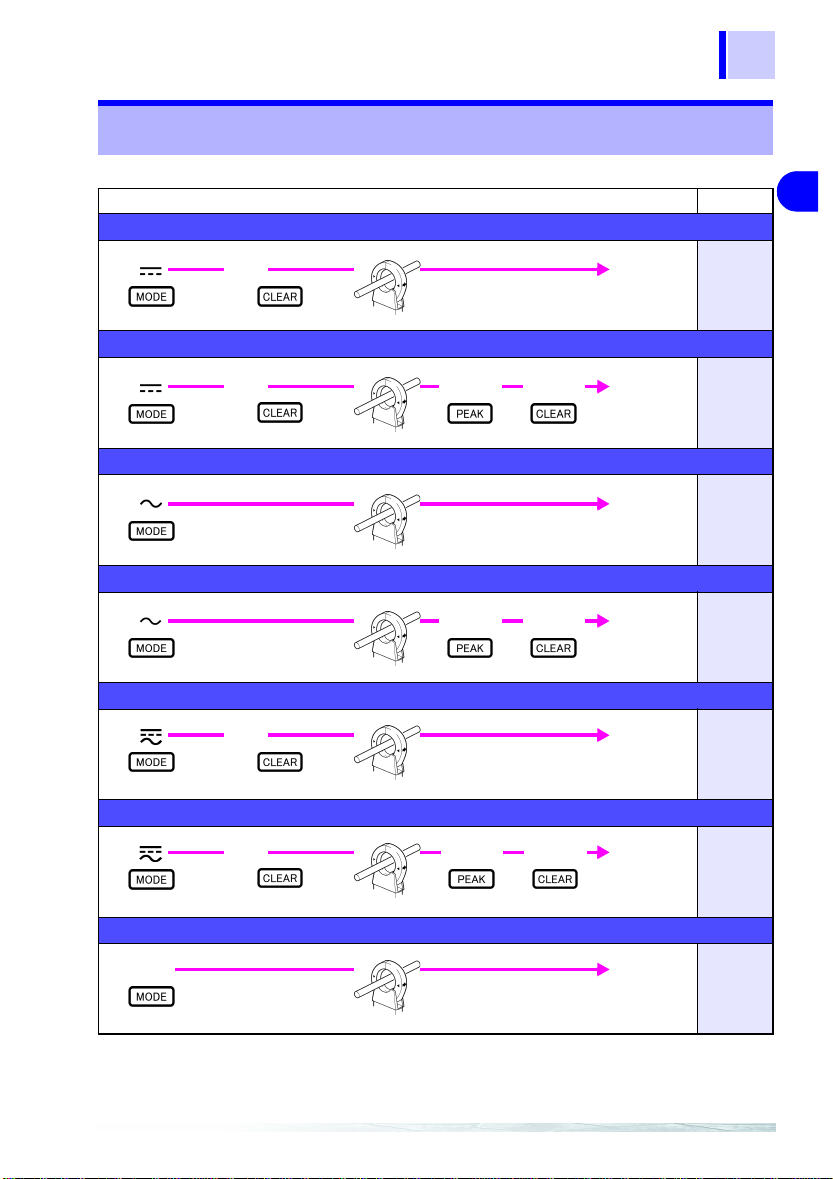

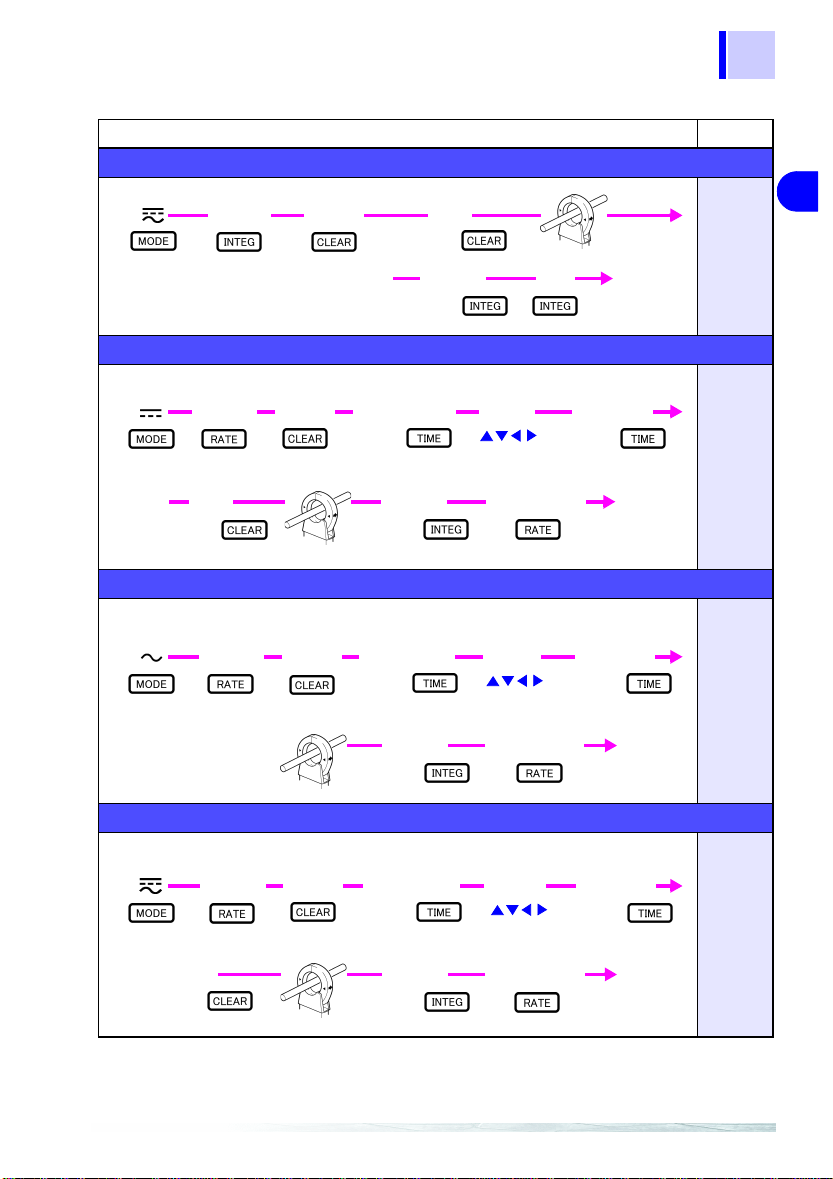

1.6 Quick References

21

1.6 Quick References

DC measure ment

ADJ

→

SHIFT

DC peak measurement

ADJ

→

SHIFT

AC measure ment

AC peak measurement

AC+DC measurement

ADJ

→

SHIFT

Press twice

AC+DC peak measurement

Operations Page

Measure-

PEAK

PEAK

CLEAR

CLEAR

ment

Measurement

Measurement

Measurement

Measurement

51

62

51

62

51

1

Overview

2

3

4

5

6

7

8

9

SHIFT

Hz measurement

Hz

Press three times

ADJ

→

PEAK

CLEAR

Measurement

Measurement

62

11

51

Page 28

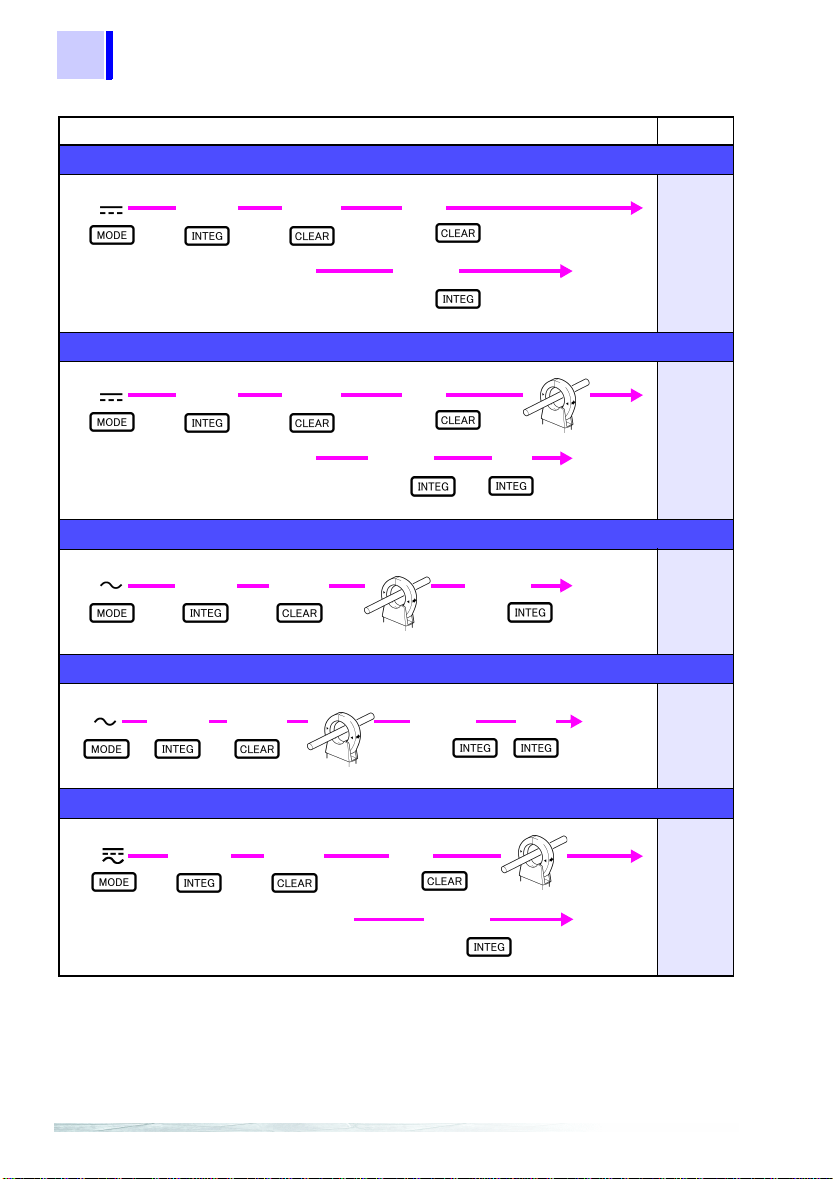

22

-

1.6 Quick References

DC integral measurement

Operations Page

INTEG CLEAR

DC interval mean current measurement

INTEG CLEAR

AC integral measurement

INTEG START

CLEAR

AC interval mean current measurement

INTEG

CLEAR

SHIFT

SHIFT

SHIFT

SHIFT

START

→

SHIFT

ADJ

→

START

→

ADJ

→

START

Press three times

SHIFT

→

Measure-

66

ment

AVE

Measurement

66

Measure-

AVE

ment

Measure

→

ment

66

66

AC+DC inte gral measurement

INTEG

Press twice

CLEAR ADJ

→

SHIFT

SHIFT

START

→

66

Measurement

Page 29

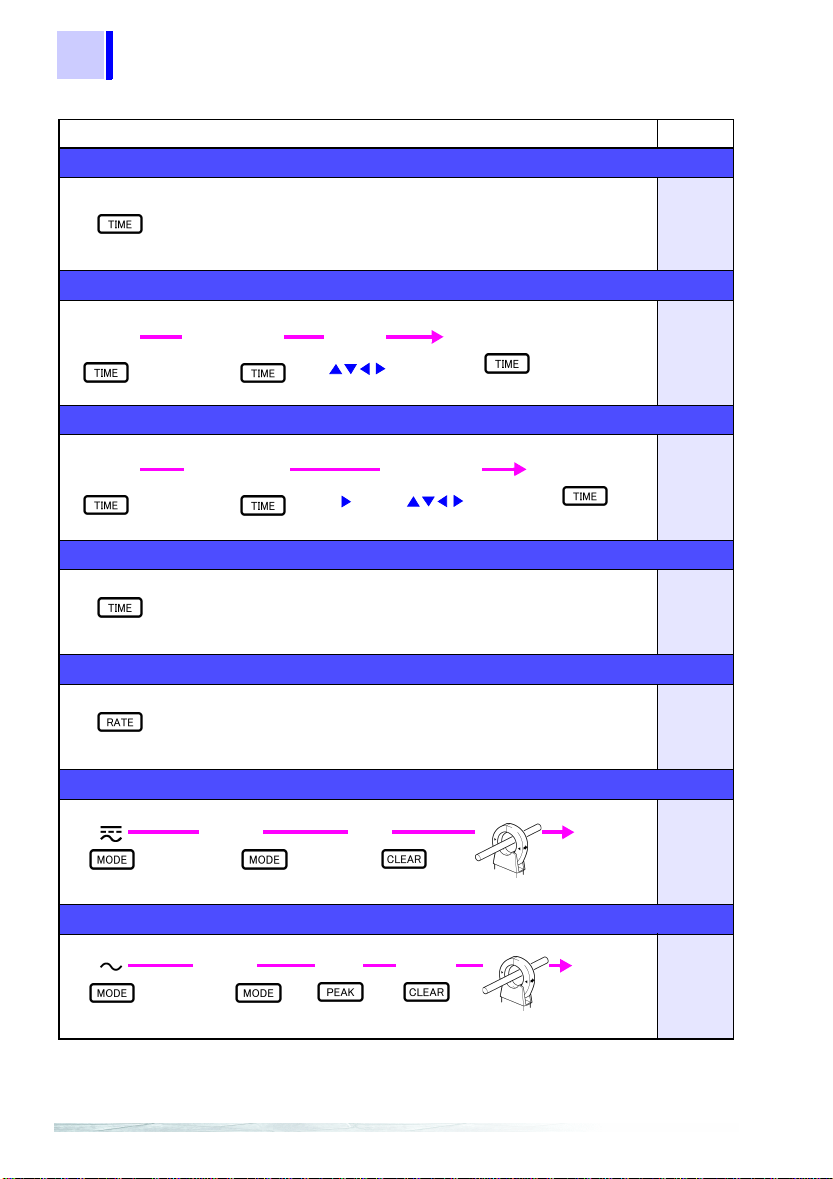

10

Operations Page

AC+DC interval mean current measurement

23

1.6 Quick References

INTEG

Press twice

DC duty and operating time measurements

Duty

Display

ADJ

→

SHIFT

AC duty and operating time measurements

Duty

Display

CLEAR ADJ

Numerical

CLEAR

CLEAR

Entry Display

→

SHIFT

Display the duty

SHIFT

Numerical

Entry Display

SHIFT

Display the duty

SHIFT

START

→

START

SHIFT

SHIFT

→

→

→

START

→

AVE

Setting

Display the

operating time

Setting

Display the

operating time

SHIFT

SHIFT

Measurement

Accept the

Setting

→

Measurement

Accept the

Setting

→

Measurement

1

Overview

66

2

3

4

79

5

6

7

79

8

AC+DC duty and operating time measurements

Press twice

SHIFT

ADJ

→

Duty

Display

CLEAR

Numerical

Entry Display

→

SHIFT

Display the duty

START

→

SHIFT

Setting

Display t he

operating time

Accept the

Setting

SHIFT

→

Measurement

9

79

11

Page 30

24

1.6 Quick References

View elapsed measurement time

Set the timer

Operations Page

66, 79

Timer

Display

Numerical

Entry Display

→

SHIFT

Setting

Set the number of repetitions

Timer

Display

Numerical

Entry Display

SHIFT

→

Press four times

Number of Times

Display

View timer and repetition settings

Press twice

View current threshold setting

Press three times

Low-frequency (below 10 Hz) current measurement

Press twice

SHIFT

SLOW

→

SHIFT

ADJ

→

Accept the

SHIFT

Setting

→

SHIFT

Accept the

Setting

→

Measurement

66, 79

66, 79

66, 79

79

51, 92

Measure starting current

FAST

→

SHIFT

Press twice

MAX CLEAR

Press twice

Measurement

51, 90

Page 31

10

Make output settings

25

1.6 Quick References

Operations Page

Output

→

SHIFT

Change the display update rate (AC and AC+DC modes)

→

SHIFT

Obtained through a low-pass filter (LPF) set to 1 Hz (MON Output Filter Function) (DC mode)

→

SHIFT

Obtained through a low-pass filter (LPF) to measurement value and output. (Filter Function)

(AC and AC+DC modes)

→

SHIFT

Store data (while TIME is displayed)

Hold down 2 seconds

OUT1: MON

OUT2: REC

Bar graph

SLOW → FAST → NORMAL

OUT1: MON

OUT2: REC

FILTER is displayed.

DC

→

±)

(

→

Disable:

MON

REC

(+)

MON.FL

REC

MON

→

REC

(-)

Disable:

Disable:

Power ON

+

OUT1: REC

OUT2: REC

SHIFT

SHIFT

AC, AC+DC

MON

→

REC

→

→

51, 62

90, 92

95

95

100

1

Overview

2

3

4

5

6

7

8

Store settings (while TIME is not displayed)

Hold down 2 seconds

Recall stored data (data recall)

Power ON

+

SHIFT

Disable:

Power ON

+

9

101

11

103

Page 32

26

1.6 Quick References

Operations Page

View repetition data (TIME is displayed)

→

→

Verify remaining battery charge

→

SHIFT

Suspend display updating (TIME is not displayed)

HOLD is displayed.

Button lock

SHIFT

→

LOCK is displayed.

Disabling the auto power off function

Power ON

+

APS is not displayed.

Disabling the beep tone

Disable:

Disable:

SHIFT

97

105

96

→

103

104

Power ON

+

107

Page 33

10

Measurement Preparations 2

e

"

27

1

Attaching the Strap

Connecting Power

Connecting the Clamp-on Sensor

Connecting the Output Cords

Turning Power On

❖See Section 2.1 "Attaching the

Strap" (page 28)

❖See Section 2.2 "Connecting

Power" (page 29)

❖See Section 2.3 "Connecting th

CLAMP ON AC/DC SENSOR

(page 33)

❖

See Secti on 2.4 "Conne cting

the Output Cords (Optional) "

(page 34)

❖See Section 2.5 "Turning Power

On and Off" (page 35)

2

Measurement Preparations

3

4

5

6

7

8

9

Page 34

28

2.1 Attaching the Strap

2.1 Attaching the Strap

Using the 3290-10 with the strap attached improves operability.

1. Fasten the two straps together into

one.

2. Attach each e nd to the 3290-10 as

shown in the figure above.

Page 35

2.2 Connecting Power

10

2.2 Connecting Power

2.2.1 Installing/ Changing the Batteries

29

1

• To avoid electric shock when r eplacing the batteries, first

disconnect the clamp from the object to be measured.

• After replacing the batteries, replace the cover and screws

before using the meter.

• Do not mix old and new batteries, or different typ es of batteries. Also, be careful to observe battery polarity during

installation. Otherwise, poor p erformance or damage from

battery leakage could result.

• To avoid the possibility of explosion, do not short circuit,

disassemble or incinerate batteries.

• Handle and dispose of batteries in accordance with local

regulations.

Remove the ba tteries when ope rating from exte rnal power. When

the batteries are installed, the 3290-10 will turn on even if the polar

ity of the external power is reversed, damaging the meter.

•The indicator appears when battery voltage becomes low.

Replace the batteries as soon as possible.

• If AC power is lost due to a power outage, measurement can

continue if the batteries have been installed (available backup

time depends on battery condition).

• While operating from the AC adapter, the remaining battery

charge indicator (bar graph) indicates the loaded output volt

age (about 6V) of the AC adapter. Although this may not display as 100%, measurements are unaffected.

-

2

Measurement Preparations

3

4

5

-

6

7

8

9

1. Confirm that the 3290-10 is turned off.

2. Use a Phillips screwdriver to unfasten the

setscrew on the battery cover.

3. Remove the battery cover.

4. Insert (Change) four new batteries while

confirming the correct polarity.

5. First fit the tab of the cover, then fit the

cover. Secure the cover in place by tighten

ing the setscrew.

-

Page 36

30

2.2 Connecting Power

2.2.2 Connecting the AC Adapter (Optional)

• Turn the meter off before connectin g the AC adapter t o the

meter and to AC power.

• Use only the specified Model 9445-02 AC ADAPTER (SA100910N, SINO-AMERICAN). AC adapter input voltage range

is 100 to 240 VAC (with ±10% stability) at 50/60 Hz. To avoid

electrical hazards and damag e to the meter, do not apply

voltage outside of this range.

• Make sure the power is turned off before connecting or discon-

necting the AC adapter.

• When using the AC adapter, note that current of approximately

3 mA is consumed regardless of whether th e power switch of

the meter is on or off. (Battery power is not consumed, how

ever, when power is turned off.)

• When the power supply is switched over from the battery to the

AC adapter or vice versa during peak measurement, an inac

curate measurement result (i.e., value larger than the actual

value) may be displayed.

• While operating from the AC adapter, the remaining battery

charge indicator (bar graph) indicates the loaded output volt

age (about 6V) of the AC adapter. Although this may not display as 100%, measurements are unaffected.

• The AC adapter may be used either with or without the batteries.

• If the AC adapter is connected but not providing power, mea-

surement is still possible if the batteries have been installed

(available backup time depends on battery condition).

When operating from the AC adapter, voltage is internally regulated to about 6 V. When battery voltage is higher than this

(such as with new batteries), the batteries power the meter

until battery voltage decreases, at which point operation

switches to the AC adapter.

-

-

-

Connecting the AC Adapter

1. Confirm that the 3290-10 is

turned off.

2. Remove the d ust cap over the

AC adapter jack, and plug in

the AC adapter securely.

3. Plug the AC adapter into a

wall outlet.

Page 37

10

2.2.3 Using External Power

• To avoid electric shock and short-circuit accidents when

connecting the optional 2m external po wer cable, first be

sure the meter is turned off.

• The external voltage requirements are 8.4 to 15.6 V DC at

1.2 VA. To avoid malfunctions or damage to the meter and

electric accidents, use only a power source that meets

these requirements.

• To avoid electric shock, connect the negative side to an

earth or chassis ground.

31

2.2 Connecting Power

1

2

Measurement Preparations

3

4

Connecting the External Power Cable

1. Confirm that the meter is t urned

off.

2. Remove the dust cap over the

AC adapter jack, and plug in the

external power cable securely.

3. Connect the external power

cable to the external power

source.

5

6

7

8

9

Page 38

32

2.2 Connecting Power

Observe the following to avoid damaging the meter:

• When using an external power source such as a battery, connect the positive (center) conductor of the external power cable

to the "+" battery terminal.

• Remove the batteries when operating from external power.

When the batteries are installed, the meter will turn on even if

the polarity of the external power is reversed, damaging the

meter.

• If the device under test is earth grounded, connect the negative

conductor to earth.

(Example: Indoor and outdoor line measurements R connect the

negative conductor to earth)

• If the device under test uses a ground level that is isolated from

earth, connect the negative conductor to the ground level used.

(Example: In a mobile installation, if the device under test is

grounded to the vehicle chassis R connect the negative conduc

tor to the chassis)

Plug

Battery

-

• Make sure the power is turned off before connecting or discon-

necting the external power cable.

• When using the external power, note that current of approxi-

mately 3 mA is consumed regardless of whether the power

switch of the 3290-10 is on or off.

• While operating from the external power, the remaining battery

charge indicator (bar graph) indicates the loaded output volt

age (about 6V) of the external power. Although this may not

display as 100%, measurements are unaffected. However,

proper operation cannot be guaranteed if external power drops

below 8.4 V.

• Please observe the following if providing your own external

power cable.

φ

12 or less

9.5

φ

1.7

φ

4.75

• An external powe r cable longer than about 3m may introduce

undesirable environmental EMC effects such as noise emission.

-

Page 39

2.3 Connecting the CLAMP ON AC/DC SENSOR

10

2.3 Connecting the CLAMP ON AC/DC SENSOR

• To prevent damage to the meter, never connect or disconnect a

sensor while the power is on, or while the sensor is clamped

around a conductor.

• When disconnecting the output connector of the clamp- on sensor from the 3290-10 sensor jack, be sure to hold it by the metal

part and pull it upward. Because the connectors lock, pulling or

twisting the cable can damage the cable.

Connecting the Clamp Sensor

1. Confirm that the 329 0-10 is

turned off.

2. Remove the dust cap from

the sensor jack and insert

the plug from the clamp-on

sensor.

The clamp-on sensor model

is recognized automatically.

33

1

2

Measurement Preparations

3

4

5

6

7

Connecting Disconnecting

Grasp the upper part of the

metal portion

The wide part is toward

the top of the meter

Hold the metal part

Output Connector

❖The sensor’s specifications :

See Section 6.1.1 "Current Meas urement" (page 108)

8

9

Page 40

34

2.4 Connecting the Output Cords (Optional)

2.4 Connecting the Output Cords (Optional)

To use current measurement output (OUT1) or integral output

(OUT2), connect the optional Model 9094 OUTPUT C ORD to the

output jack.

Connecting the Output Cord

OUT 1:

Current measurement

output

If the output cord plug is not inserted securely, poor connection

may prevent proper output.

OUT 2:

Integral output

1. Confirm that the 3290-10 is

turned off.

2. Remove the dust cap from the

output jack and insert the out

put cord plug securely.

Current measurement output:

OUT 1 (Output jack 1)

Integral output:

OUT 2 (Output jack 2)

-

Page 41

2.5 Turning Power On and Off

10

2.5 Turning P ower On and Off

35

Power On

Power Off

Remaining Battery Charge

1. Press the button to

turn the meter on.

2. All display segments should

appear.

3. After displaying the model

name (3290), the bar graph

shows the remaining battery

charge.

4. The DC measure ment mode

is enabled.

Press the button again to turn the

meter off.

100% remaining battery charge, new batteries

50% remaining battery charge

1

2

Measurement Preparations

3

4

5

6

7

8

0% remaining battery charge

The indicator appears and three beeps sound.

Low-Battery Detection Function

If battery voltage continues to drop after appears, the meter is

forced to turn itself off. At this time, is displayed.

If the save-setting function has been used, the pre-specified initial mode is enabled (the save-setting function is executed by

holding down the

To cancel the setting , first turn t he mete r off, then h old the

button while pressing button to turn the meter back on.

The default initial mode (DC) setting is restored.

❖See Section 5.8 "Saving Settings" (page 101)

button for two seconds).

9

Page 42

36

2.5 Turning Power On and Off

Page 43

10

Basic Measurement

37

Procedure 3

• To avoid short circuits and potentially life -threatening hazards, never attach the clamp to a circuit that operates at

more than 600V, or over bare conductors.

• Clamp sensor should only be connected to the secondar y

side of a breaker, so the breaker can prevent an accident if

a short circuit occurs. C onnections should never be made

to the primary side of a breaker, because unrestricted cur

rent flow could cause a serious accident if a short circuit

occurs.

• To avoid damage to the meter, do not short-circuit the output

jacks and do not input voltage to the output jacks.

• The maximum continuous-input limit is obtained from the temperature increase due to self-heating during measurement. To

prevent damage to the clamp-on sensor, do not input a current

exceeding this limit.

• The maximum continuous-input limit varies depending on the

clamp-on sensor and the frequency of the current to be mea

sured.

❖ Maximum continuous-input limit varies:

See Section 6.3 "CLAMP ON AC/DC SENSOR Specifications" (page 116)

Each sensor’s derating acording to frequency

1

2

3

Basic Measurement Procedure

-

4

5

6

7

-

8

9

Page 44

38

• Be sure to read the instruction manual for the clamp sensor to

be used before starting measurement.

• The hall element is used for the detector of the clamp-on sen sor. The hall element tends to drift with age or due to the ambient temperature. Keep this fact in mind when performing

measurement continuously.

❖See "Sensor Temperature Characteristics" (page 58)

• Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and highcurrent conductors, or in the presence of strong electromag

netic fields such as near radio transmitters.

• The reading may show a measurement greater than the actual

value due to magnetic-field interference. The amount of interference varies depending on the sensor.

❖See Section 6.3 "CLAMP ON AC/DC SENSOR Specifications" (page 116)

• The 9691 has a lock mechanism for the clamps so that the

clamps will not open due to vibration or other similar causes

during measurement. Lock the clamps as necessary. (If the

clamps should open even slightly during measurement, the

accuracy cannot be guaranteed.)

• Attach the clamp around only one conductor. Single-phase (2wire) or three-phase (3-wire) cables clamped togeth er will not

produce any reading.

-

OK

Page 45

10

3.1 Measuring DC Current

e

-

e

39

3.1 Measuring DC Current

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Range : AUTO

1. Press the button to select DC

( ).

Button presses are ignored if TIME is displayed: press → to clear it.

The 9691 CLAMP ON AC/DC SENSOR

LOAD

Electric

conductor

Position the clamp

with the cu rrent di-

SOURCE

rection indicator

pointing toward the

load side.

2. Press

3. Clamp around a conduc tor to be mea

SHIFT

automatic zero adjustment.

is displayed.

sured so that it is centered in th

clamp.

The figure shows the 9691 CLAMP ON AC/

DC SENSOR.

The current direction mark on Models 9692

and 9693 CLAMP ON AC/DC SENSORs is in

a different location.

→ (

0 ADJ

) to execut

1

2

3

Basic Measurement Procedure

4

5

6

7

8

9

4. Read the displayed value.

Since the range is AUTO, you do not need to

set it.

Page 46

40

C

-

-

"

-

e

3.2 Measuring AC Current

3.2 Measuring AC Current

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Range : AUTO

1. Press the button to select A

( ).

Button presses are ignored if TIME is displayed: press → to clear it.

When measuring current below 10 Hz, use the

AC+DC mode and press

PLE

) to set the display update rate (measure

ment response time) to SLOW.

❖See Section 5.3 "Meas urem ent Respo nse Time

(page 92)

The 9691 CLAMP ON AC/DC SENSOR

2. Clamp around a conductor t o be mea

Electric

conductor

Clamp direction is

irrelevant

sured so that it is centered in th

clamp.

SHIFT

→ (

SAM

3. Read the displayed value.

Since the range is AUTO, you do not need to

set it.

Page 47

10

3.3 DC Integration

e

-

e

-

e

o

o

41

3.3 DC Integration

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Measured current : 20 A or less

Manually stop measuring (no timer)

2

1

1. Press the button to select DC

( ).

Button presses are ignored if TIME is displayed: press → to clear it .

2. Press button once to select th

L range (20 A).

3. Press button to displa y the inte

gral.

Unless output is required, the integrating

range can be left as AUTO.

4. Press

SHIFT

automatic zero adjustment.

is displayed.

5. Clamp around a conduc tor to be mea

The 9691 CLAMP ON AC/DC SENSOR

LOAD

Electric

conductor

Position the clamp

with the current di-

SOURCE

rection indicator

pointing toward the

load side.

sured so that it is centered in th

clamp.

The figure shows the 9691 CLAMP ON AC/

DC SENSOR.

The current direction mark on Models 9692

and 9693 CLAMP ON AC/DC SENSORs is in

a different location.

6. Press

start integral measuremen t.

START and TIME are displayed.

7. Press

stop integral measurement.

STOP is displayed.

SHIFT

SHIFT

→ (

→ (

→ (

0 ADJ

) to execut

START/STOP

START/STOP

1

2

3

Basic Measurement Procedure

4

5

6

7

8

9

) t

) t

Page 48

42

C

e

r.

s-

0

3.4 AC Integration by Timer

3.4 AC Integration by Timer

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Measured current : at least 20 A

Timer : 30 minutes

Number of repetitions : 10 times

1. Press the button to select A

( ).

Button presses are ignored if TIME is displayed: press → to clear it.

2. Press button tw ice to select th

H range (200 A).

Blinking

Blinking

3. Press button to display the time

4. Press

SHIFT

→ (

play the numerical entry dis play.

INPUT/SET

) to di

5. Press the buttons to enter 3

minutes.

Page 49

43

10

y

.

-

e

-

e

s

t

3.4 AC Integration by Timer

6. Press to display the rep etition entr

display.

Blinking

Blinking

The 9691 CLAMP ON AC/DC SENSOR

Electric

conductor

Clamp direction is

irrelevant

7. Press the to set 10 repetitions

8. Press

SHIFT

→ (

accept the entered value s .

INPUT/SET

) to

9. Press button to display the inte

gral.

Unless output is required, the integrating rang

can be left as AUTO.

10. Clam p around a conductor to be mea

sured so that it is centered in th

clamp.

11. Press

SHIFT

→ (

start integral measuremen t.

START and TIME are displayed.

START/ST OP

) to

1

2

3

Basic Measurement Procedure

4

5

6

7

8

9

12. After ten 30-minute measurement

have occurred, integral measuremen

stops automatically.

STOP is displayed.

Page 50

44

C

e

-

t

.

3.5 Outputting Integral Values

3.5 Outputting Integral Values

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Measured current : 100 A or less

After two hours or less, stop measurement manually (no timer)

→ Maximum integral value derived from measured current and measurement

time is 200 Ah (100 A X 2 h) or less

OUT1 : MON output

OUT2 : Positive integral output

1. Press the button to select D

( ).

Button presses are ignored if TIME is displayed: press → to clear it.

2. Press button twice to select th

H range (200 A).

3. Press button to display the inte

gral.

4. Press the button tw ice to selec

the 1000.0 Ah range (999.9 Ah max

display).

Page 51

3.5 Outputting Integra l Values

10

-

d

t

"

e

-

e

o

o

45

The 9691 CLAMP ON AC/DC SENSOR

LOAD

Electric

conductor

Position the clamp

with the current di-

SOURCE

rection indicator

pointing toward the

load side.

5. Press

6. Press

7. Press

SHIFT

→ (

play the output settings.

The bar graph appears in both "+" an

"-" regions.

SHIFT

→ (

the bar graph appears only in the "+

region.

SHIFT

→ (

automatic zero adjustment.

is displayed.

OUTPUT

OUTPUT

0 ADJ

) to dis

) so tha

) to execut

8. Clamp around a conduc tor to be mea

sured so that it is centered in th

clamp.

The figure shows the 9691 CLAMP ON AC/

DC SENSOR.

The current direction mark on Models 9692

and 9693 CLAMP ON AC/DC SENSORs is in

a different location.

9. Press

start integral measuremen t.

START and TIME are displayed.

SHIFT

→ (

START/STOP

) t

1

2

3

Basic Measurement Procedure

4

5

6

7

8

9

10. Press

stop integral measurement.

STOP is displayed.

SHIFT

→ (

START/STOP

) t

Page 52

46

C

L

e

-

0

o

3.6 Measuring Duty by Timer

3.6 Measuring Duty by Timer

Sensor used : Model 9691 CLAMP ON AC/DC SENSOR

Measured current : 20 A or less

Current threshold :2 A AC (defines the operating state as 2 A or higher current)

Timer : 24 hours

Repetitions : none (one time only)

1

2

Blinking

1. Press the button to select A

( ).

Button presses are ignored if TIME is displayed: press → to clear it.

2. Press button to select the

range (20 A) .

3. Press the button to display th

duty.

4. Press

SHIFT

→ (

play the numerical entry display.

INPUT/SET

) to dis

Blinking

5. Press the but tons to enter 2.0

A.

6. Press

accept the entered value s .

SHIFT

→ (

INPUT/SET

) t

Page 53

3.6 Measuring Duty by Timer

10

-

-

4

o

e

-

e

o

)

47

Blinking

Blinking

7. Press

8. Press

SHIFT

→ (

play the tim er display.

SHIFT

→ (

play the numerical entry display.

INPUT/SET

INPUT/SET

) to dis

) to dis

9. Press the buttons to enter 2

hours.

10. Press

accept the entered value s .

SHIFT

→ (

11. Press the button to display th

duty.

Although no "%" unit indicator appears, the

displayed value is percentage.

INPUT/SET

) t

1

2

3

Basic Measurement Procedure

4

5

6

7

The 9691 CLAMP ON AC/DC SENSOR

Electric

conductor

Clamp direction is

irrelevant

12. Clam p around a conductor to be mea

sured so that it is centered in th

clamp.

13. Press

start duty measurement.

START and TIME are displayed.

14. Press

again to stop duty measu rem ent.

STOP is displayed.

SHIFT

→ (

SHIFT

→ (

STAR T/STO P

STAR T/STOP

) t

8

9

Page 54

48

3.6 Measuring Duty by Timer

Page 55

4.1 Verifications Before Measuring

10

Measurement Procedure 4

4.1 Verifications Before Measuring

Before using the meter the first time, verify that it operates normally

to ensure that the no damage occurred during storage or shipping.

If you find any damage, contact your dealer or Hioki representative.

Verification Location Verification Content Corrective Procedure

Clamp-on

sensor

Cables Is the insulation dam-

Model

3290-10

Jaw

teeth

Sensor

element

Battery

Range Is the range supported

Zero confirmation

Are they been deformed? If the teeth are deformed, current

Is it cracked or damaged

or bare metal exposed?

aged or bare metal

exposed?

Is the indicator displayed?

by the clamp-on sensor?

In AC mode, is the displayed value near 0 A?

In DC mode, is the displayed value near 0 A?

In DC or AC mode, with

output enabled and an

output cord connected to

OUT1 or OUT2, is the

value read by a DMM

near 0 V DC?

measurement cannot be performed.

Contact your dealer or Hioki representative.

If damaged, an electric shock accident could occur, so contact your

dealer or Hioki representative.

If damaged, contact your dealer or

Hioki representative.

indicates low battery voltage. In

this state, proper measurement

may not be possible, so the batteries should be replaced.

Verify the selected range with the

button (range are described

on the battery cover). If the current

being measured exceeds the

selected range, current consump

tion is high and the batteries are

discharged quickly.

If the displayed value is not near 0

A, contact your dealer or Hioki rep

resentative.

Press SHIFT → (0ADJ) to

execute automatic zero adjustment.

Verify that the displayed value is

now near 0 A.

If the output is not near 0 V, contact

your dealer or Hioki representative.

49

1

2

3

4

Measurement Procedure

5

6

7

8

-

9

-

Page 56

50

4.2 Selecting the Measurement Parameter

4.2 Selecting the Measurement Parameter

Select the parameter to measure from the following.

• Current (see page 51)

• Frequency (see page 51)

• Peak Current (see page 62)

• Integral (see page 66)

•Duty (see page 79)

Current is measured during both integral and duty measurements.

Also, when duty is measured, integral measurement occurs at the

same time.

A current threshold must be set in order to perform duty measurement.

Duty & Integral

Current

Frequency

Peak current

Duty Measurement

RATE data

Integral Measurement

INTEG data

PEAK data

Current Measurement

Frequency Measur ement

Peak Measurement

RATE data : duty and operating time

INTEG data : integral and interval mean

PEAK data : Peak, maximum and minimum

Measurement

Contents

Select Measurement

Parameter

values (current)

values

Duty Measurement

Integral Measurement

Page 57

10

4.3 Measuring Current

t

51

4.3 Measuring Current

DC Measurement

DC

Range Selection

❖See page 53 ❖ See page 53

Is Output Required?

Yes

SHIFT→

Output Settings

❖See page 54 ❖See page 54

Range Selection

No

Output Settings Output Settings

Not including DC

AC Measurement

AC

Yes

SHIFT→

Current

Measurement

Mode Selection

❖See page 52

No

AC+DC

Range Selection

❖See page 53

Is Output Required?Is Output Required?

Yes

SHIFT→

❖See page 54

1

2

3

Frequency

Measuremen

4

Hz

Measurement Procedure

5

6

No

7

8

At 0 A input

SHIFT→

Auto Zero

Adjustment

❖See page 57

Auto Zero

Adjustment

Clamp conductor and start measuring

At 0 A input

SHIFT→

❖See page 57

❖See page 60

9

Page 58

52

4.3 Measuring Current

Mode Selection

1. Press the button to select the mode.

Button presses are igno red if TIME is display ed: press → to clear it.

For Current Measurement

For Frequency Measurement

DC Mode

Select this to measure DC current.

AC Mode

Select this to measure AC current.

AC+DC Mode

Select this to measure current other than the above. Examples

are shown below: waveforms with both AC and DC components,

and half- and full-wave rectified waveforms.

Waveforms with both

AC and DC components

Half-wave rectified

waveform

Full-wave rectified

waveform

Hz Mode

Hz

Select this to measure frequency (in AC Mode)

• In the DC mode, a low-pass filter* of about 0.5 Hz is applied to

suppress 50/60 Hz AC mains current ripple. This filter sup

presses AC components leaving only the DC component for

display. However, this filter also slows measurement response,

so rapid current variations are not detected.

* Low-pass filter (LPF): a filter that passes only low frequencies

❖See Section 5.4 "F i lter Function" (page 95)

• In the AC mode, any DC component is removed. However,

when AC and DC components are both present and waveform

peaks exceed 2.5 times the range (crest factor), the waveform

is clipped by internal circuitry, and correct measurements are

not possible unless a higher range is selected.

❖See "Range Selection" (page 53)

• To measure both AC and DC together, we recommend rms

measurement with the AC+DC Mode. However, to measure

only the DC component, use the DC Mode.

• When measuring current at 10 Hz or less, select AC+DC mode

and set the display update rate ( measurement response time)

to SLOW. The SLOW display update rate is slower with the AC

mode selected than it is with the AC+DC mode selected.

• Frequency measurement uses AUTO ranging, so no current

range setting is needed.

-

Page 59

10

Range Selection

e

2. Press the button to select the range.

53

4.3 Measuring Current

For Current Measurement

AUTO Ranging

AUTO

• When measuring only current (so that no output settings are

needed), AUTO ranging can be used, but if the range is

exceeded during current integral or duty measurement, correct

measurements cannot be obtained.

• If you press the or button after AUTO ranging is

selected, the range that is active at setting time becomes the

fixed range (the L range if nothing is being measured).

• When selecting a range, both rms and peak values need to be

considered. For example, if the rms current is low but the peak

value is high, the waveform may be clipped (depending on the

range). The figure below left shows a waveform that can be

measured in the H range (200 A range). The waveform is not

clipped, so the measured value is 20 A. On the other hand, the

figure below right shows clipping at 50 A because of the 2.5

crest factor limitation (50 A in the case of the 20 A range). The

(incorrectly) measured value in this case is 10 A, and correct

measurement is not performed (crest factor is the peak value /

range rating).

When using the 9691 or 9692 : 20.00 A/ 200.0 A

When using the 9693 : 200.0 A/ 2000 A

L (Low) Range

L

When using the 9691 or 9692 : 20.00 A

When using the 9693 : 200.0 A

H (High) Range

H

When using the 9691 or 9692 : 200.0 A

When using the 9693 : 2000 A

1

2

3

4

Measurement Procedure

5

6

7

8

100 A

20 A

0 A

Peak value

50 A

Measured

value

For Frequency Measurement

AUTO Ranging

AUTO

The range switches upward at 1250 counts, and downward at

100 counts.

Example: 12.50 Hz → 12.6 Hz, 10.0 Hz → 9.99 Hz

Internal ranges 10.00, 100.0 and 1000 Hz

The current range does not need to be set.

10 A

0 A

L rangeH range

Peak valu

Measured

value

9

Page 60

54

4.3 Measuring Current

Output Settings

If you don’t need to make any output settings, proceed to "Auto

Zero Adjustment (for DC and AC+DC modes)" (page 57).

3. Confirm that the optional 9094 OUTPUT CORD is inserted

securely into output jac k 1 (O UT1) ( OUT2 is for integral value out-

put).

4. Press SHIFT → (OUTPUT) to display the output se ttings.

5. Set OUT1 to REC or MON.

MON

REC

Only REC output is available at OUT2.

MON (Monitor) Output

Outputs the measured waveform (settable for all mea-

surement modes).

REC (Record) Output

The measured waveform is converted from rms (RMS/

DC conversion) for output (settable for AC and AC+DC

modes).

The response speed can be changed by pressing

SHIFT → (SAMPLE).

• Be sure to select the measurement range before making output settings. If you make output settings with AU TO ranging

selected, the range that is active at setting time becomes the

fixed range (the L range if nothing is being measured).

• In the DC mode, INTEG OUTPUT (bar graph display) switches

between ±, + and -. Integral output can be set with current

measurement output settings.

For AC and AC+DC modes there is no ±, + or - selection.

• Auto power-off is disabled ( not displayed) when making

output settings. Output settings do not affect battery consumption.

Page 61

4.3 Measuring Current

10

Current measurement output levels are shown on the meter’s

battery cover. Determine the appropriate output range from the

range of the meter and that of the connected instrument (e.g.,

data recorder). Conversion tables are shown here.

Connected Instrument

Measuring Range

/DIV

20 A range 0.1 A 0.2 A 0.5 A 1 A 2 A 5 A 10 A 20 A

200 A range 1 A 2 A 5 A 10 A 20 A 50 A 100 A 200 A

* Numerical values are current per division on the connected instrument (e.g., data recorder).

Connected Instrument

Measuring Range

/DIV

200 A range 1 A 2 A 5 A 10 A 20 A 50 A 100 A 200 A

2000 A range 10 A 20 A 50 A 100 A 200 A 500 A 1000 A 2000 A

* Numerical values are current per division on the connected instrument (e.g., data recorder).

Frequency Characteristics of clamp-on sensor + Model 3290-10 MON Output

5

0

-5

-10

-15

GAIN (dB)

GAIN (dB)

-20

10 mV 20 mV 50 mV 0.1 V 0.2 V 0.5 V 1 V 2 V

10 mV 20 mV 50 mV 0.1 V 0.2 V 0.5 V 1 V 2 V

55

9

9

9

1

2

3

4

Measurement Procedure

5

6

7

8

-25

-30

1 10 100 1000 10000 100000

入力周波数(Hz)

Frequency (Hz)

Models 9691+3290-10

Models 9692+3290-10

Models 9693+3290-10

9

Page 62

56

4.3 Measuring Current

• The input impedance of the connected instrument should be at

least 1 M

affected.

• To use the out put function, be sure that OUT1 is displayed by

pressing

when it is not displayed, but because the auto power-off function is enabled, power will turn off after about 10 minutes.

• When measuring current of 10 Hz or less, select the AC+DC

mode and set the display update rate (measurement response

time) to SLOW. The SLOW display update rate is slower with

the AC mode selected than it is with the AC+DC mode

selected.

• Guaranteed output accuracy is applicable to current display

values that do not cause O.L. to be displayed in the L range

(MON output can be saturated when output exceeds 3.5 V in

the L range). Also, in the H range, output is limited by the max

imum peak current capability of the clamp-on sensor.

• Maximum MON output is 3.5 V just before the indicator

appears. When using the AC adapter or when remaining battery charge is 50% or more, maximum output is 4 V.

• Pressing the button during output does not affect output

values.

• Use the optional 9445-02 AC ADAPTER for long-term recording. If using the AC adapter with very noisy mains power, displayed measurements may be unstable, or noise may appear

in the output. Connect the grounding or L terminal of the connected instrument (data recorder) to earth ground.

Ω. If the impedance is lower, displayed values may be

SHIFT → (OUTPUT). Output is still available

-

Page 63

4.3 Measuring Current

10

Auto Zero Adjustment (for DC and AC+DC modes)

❖See Section 5.1 "Auto Zero Adjustment Function" (page 89)

57

6. Verify that the measurement current is zero, or that the clamp-

on sensor is not clamped around a conductor.

7. Press SHIFT → (0ADJ) to execute auto zero adj ustment.

• If Auto zero adjustment is not performed, the displayed (and

output) current value is always added to measurements.

• Auto zero adjustment is unnecessary in AC mode.

• Auto zero adjustment should be performed in DC and AC +DC

modes. In the L range, auto zero adjustmen t is possible when

the displayed value is up to ± 450 counts, and in the H range,

up to ± 45 counts.

• To cancel auto zero adjustment, tur n the power off and back

on.

• Auto zero adjustment cannot be performed during integral or

duty measurement (while

START is displayed).

1

2

3

4

Measurement Procedure

5

6

7

8

9

Page 64

58

4.3 Measuring Current

Sensor Temperature Characteristics

The 9691, 9692 and 9693 CLAMP ON AC/DC SENSORs employ a

Hall-effect element for current detection. The zero point and sensi

tivity are therefore temperature dependent according to the characteristics of the individual Hall-effect element.

Zero-Point Temperature Characteristics

Because of the individual differences between Hall-effect elements, the actual offset and rate of change cannot be specified. In

an operating environment with wide temperature variations, we

suggest being aware beforehand of changes to the zero point with

no input. However, while zero point variations affect DC values,

they have no effect in the AC mode. The examples show zero point

variations (normalized to 23°C) with temperature change for differ

ent sensors (characteristics vary widely from one element to

another).

Specified operating temperature range is 0 to 40°C.

2.0

-

-

Model 9691 Zero Point vs. Temperature

1.0

Deviation (A)

0.0

偏差(A)

-1.0

-2.0