Page 1

INSTRUCTION MANUAL

3290

CLAMP ON

AC/DC HiTESTER

Page 2

Page 3

i

Contents

Introduction .............................................................1

Inspection ............................................................... 2

Safety Notes ...........................................................3

Usage Notes........................................................... 6

Organization of This Manual .................................10

Chapter 1 Overview 13

1.1 Product Overv iew ........................... ......13

1.2 Features ................................................13

1.3 Parts Names and Functions .................16

1.3.1 3290

CLAMP ON AC/DC HiTESTER ........ 16

1.3.2 9691, 9692, 9693

1.4 Flowchart Of Key Operations ................25

1.4.1 Current Measurements Mode .......... 25

1.4.2 Frequency Mode ..............................28

1.5 Modes ...................................................29

Chapter 2

Basic Measure ment Procedures 35

2.1 DC Measurement (DC A) ......................36

2.2 AC Measurement (AC A) ......................38

2.3 Peak Measurement In AC+DC A Mode 39

CLAMP ON AC/DC SENSOR .......... 24

Page 4

ii

Chapter 3 Measurem en t Proc edu re s 43

3.1 Preparations ..........................................43

3.2 Current Measurement ........................... 45

3.2.1 Measuring DC Current (DC A) ..........46

3.2.2 Measuring AC Current (AC A) ..........47

3.2.3 Measuring AC + DC Current (AC+DC A)

...........................................................49

3.2.4 Bar Graph .........................................50

3.2.5 Peak Measur ement ...........................51

3.2.6 Output Function

(Current Measu rem en t) ............... ..... .53

3.3 Frequency Measurement ......................57

3.3.1 Frequency Measurement ..................57

3.3.2 Output Function

(Frequency Measurement) ................58

3.4 Auto-Zero Adjustment Function .............60

3.5 Data Hold Function ................................61

3.6 Changing the Screen Update Rate .......61

3.6.1 SLOW Mode ......................... ...... ..... .61

3.6.2 FAST Mode .......................................62

3.7 Recording Function ...............................63

3.7.1 Measurement Reading ......................63

3.7.2 Display of Elapsed Time ...................64

3.7.3 Interrupting the Recording Function ..64

3.7.4 Clearing Recorded Data ...................64

3.7.5 Disabling the Recording Function .....65

3.8 Measurement Method

Switching Function ................................66

3.8.1 RMS Measurement ........................... 66

3.8.2 MEAN Measurement .........................66

3.9 Measurement Response Speed

Switching Function ................................67

Page 5

iii

3.9.1 NORMAL Mode ................................67

3.9.2 SLOW Mode ............................... ......67

3.9.3 FAST Mode ...................................... 67

3.10 Filter Function ....................................... 70

3.11 Ke y Loc k Fun cti on ................................71

3.12 Bar Graph Enlargement Function .........71

3.13 Battery Check Function ........................72

3.14 MON Output Filter Function ..................73

3.15 Auto Power Off Function .......................74

3.16 Setting the Save Function .....................75

3.17 Battery-Low Warning ............................76

3.18 Beep Tone ............................................77

Chapter 4 Batteries Replacement 79

Chapter 5 AC Adapter 81

Chapter 6 Attaching the Strap 83

Chapter 7 Specifications 85

7.1 Measurement Specifications .................85

7.2 General Specifications ..........................88

Chapter 8 Clamp Sensor Specifications 93

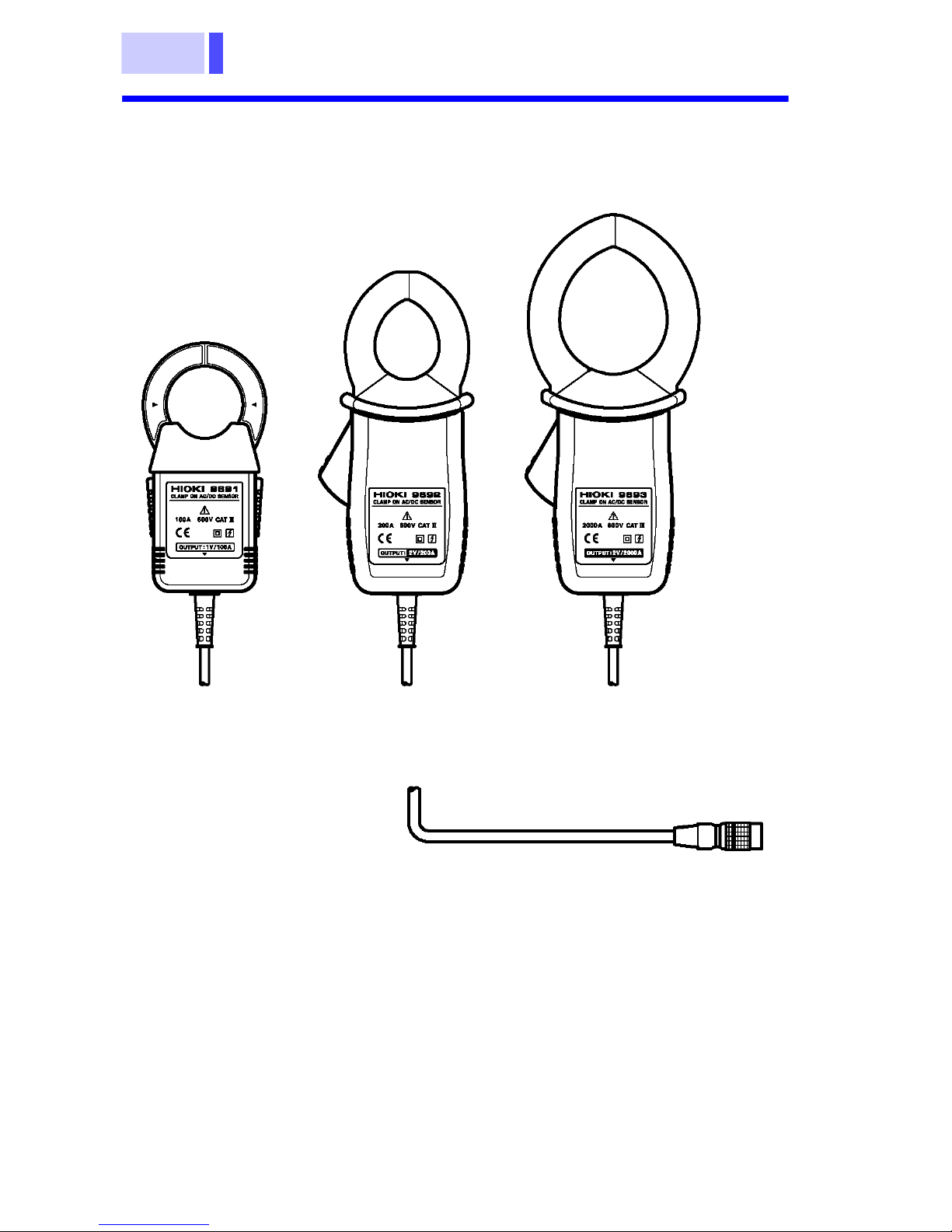

8.1 9691 CLAMP ON AC/DC SENSOR ......93

8.2 9692 CLAMP ON AC/DC SENSOR ......96

8.3 9693 CLAMP ON AC/DC SENSOR ......99

Page 6

iv

Chapter 9 Carrying Case 103

Chapter 10 Troubleshooting 105

Chapter 11 After - sale Servi ce 111

11.1 Cleaning ..............................................111

11.2 Service ................................................111

Chapter 12 Appe ndix 113

12.1 Combined Accuracy ............................113

12.1.1 Accuracy Tables .............................113

12.1.2 Method of Calculation .....................118

12.2 Use of Intermediate Cable ...................119

Page 7

1

Introduction

Thank you for purchasing the HIOKI "3290 CLAMP ON

AC/DC HiTESTER". To obtain maximum performance

from the product, please read this manual first, and keep it

handy for future refer ence.

This manual describes the operation of the 3290 when

used with the 9691, 9692, or 9693 CLAMP ON AC/DC

SENSOR.

Request

We have tried to bring this manual as close to perfection

as we could achieve. If perchance you find any unclear

portions, mistakes, omissions, or the like, we would be

most obliged if you could please notify us of them via any

HIOKI agent, or directly.

Page 8

2

Inspection

• When you receive the product, inspect it carefully

to ensure that no damage occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or

if it fails to operate according to the specifications,

contact your dealer or Hioki representative.

• Before using the product the first time, verify that it

operates normally to ensure that the no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

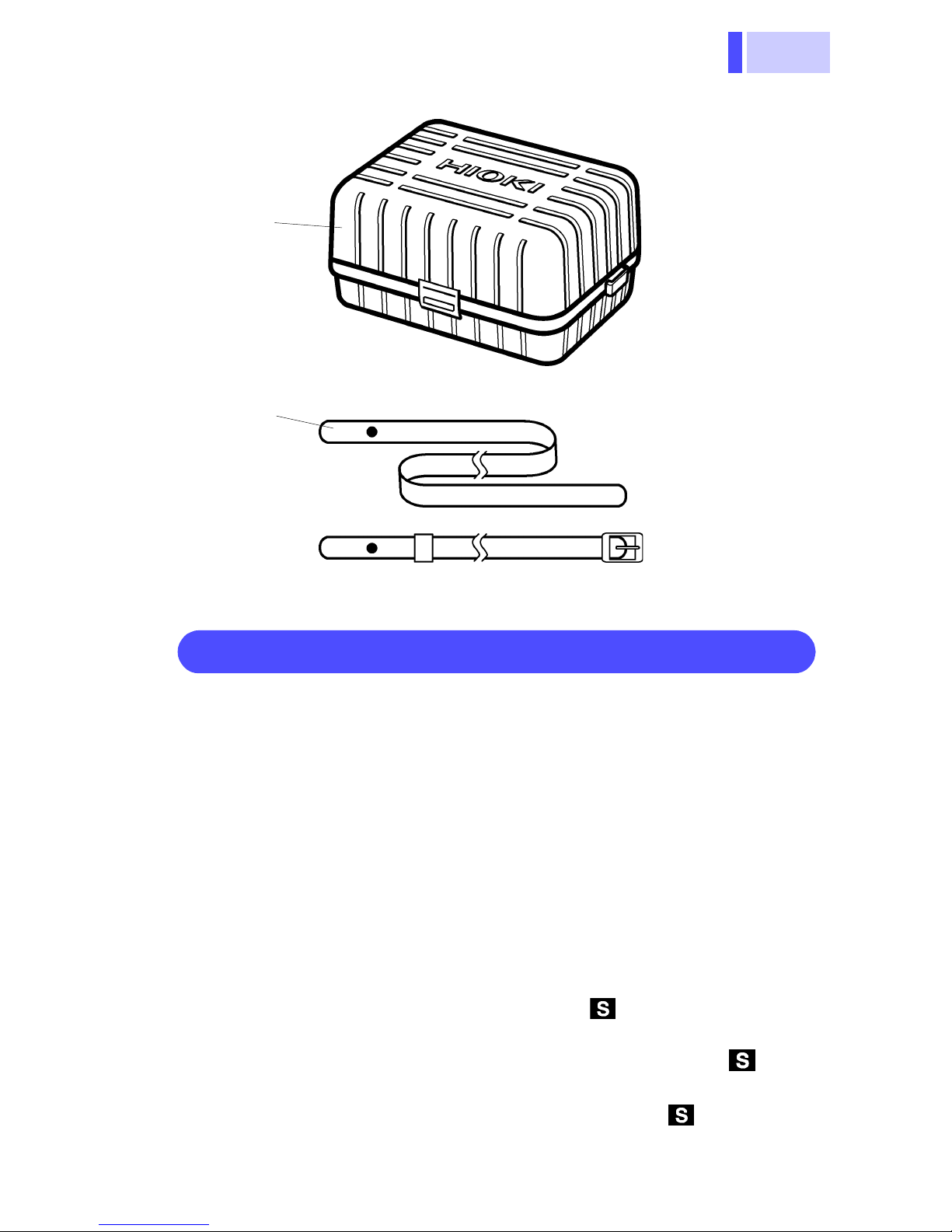

Accessories

Strap .........................................................................................................1

LR6 Manganese battery............................................................................4

Instruction Manual.....................................................................................1

Options

9400 CARRYING CASE

9094 OUTPUT CORD

9445-02 AC ADAPTER (SA10-0910N, SINO-AMERICAN)

9445-03 AC ADAPTER (EU) (SA10-0910G, SINO-AMERICAN)

9691 CLAMP ON AC/DC SENSOR

9692 CLAMP ON AC/DC SENSOR

9693 CLAMP ON AC/DC SENSOR

Page 9

3

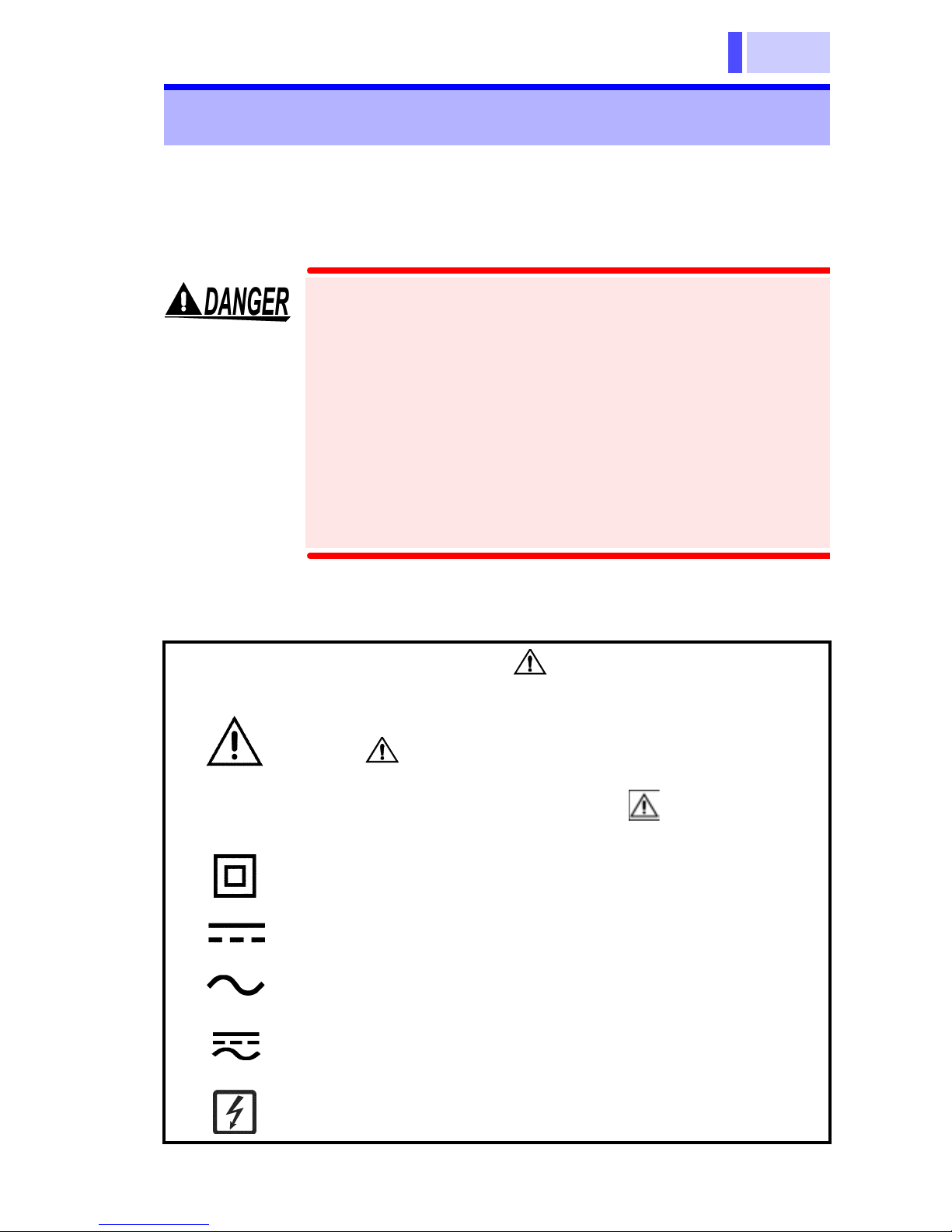

Safety Notes

This manual contains information and warnings essential

for safe operation of the product and for maintaining it in

safe operating condition. Before using the product, be

sure to carefully read the following safety notes.

This product is designed to conform to IEC

61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, mishandling during use could

result in injury or death, as well as damage to

the product. Be certain that you understand

the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not resulting

directly from product defects.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should

read before using the product.

The symbol printed on the product indicates

that the user should refer to a corresponding topic

in the manual (marked with the symbol) before

using the relevant function.

Indicates a double-insulated device.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates that the instrument may be connected to

or disconnected from a live circuit.

Page 10

4

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to t he user or damage to the product.

Advisory items related to performance or correct

operation of the product.

Other Symbols

Indicates the prohibited action

Accuracy

We define measurement tolerances in terms of f.s. (full

scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

(maximum display value or scale length)

f.s.

rdg.

The maximum displayable value or the full length

of the scale. This is usually the maximum value of

the currently selected range.

(reading or displayed value)

The value currently being measured and indicated

on the measuring product.

(resolution)

dgt.

The smallest displayable unit on a digital measuring product, i.e., the input value that causes the

digital display to show a "1".

Page 11

5

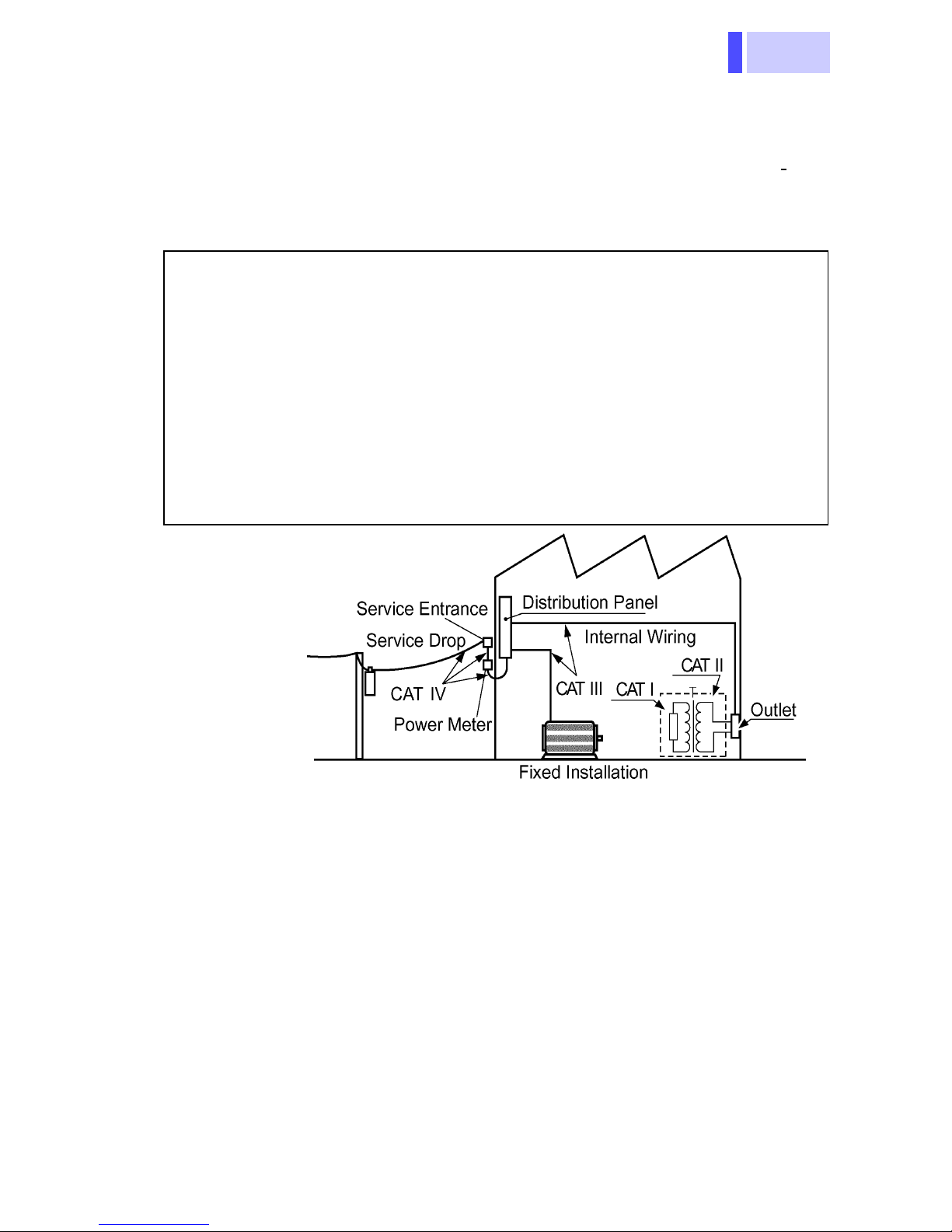

Measurement categories (Overvoltage categories)

This product complies with CATIII (600 V), CATII (1000 V)

safety requirements.

To ensure safe operation of measurement products, I

61010 establishes safety standards for various electrical

environments, categorized as CAT I to CAT IV, and called

measurement categories. These are defined as follows.

EC

CAT I

CAT II

CAT III

CAT IV

Secondary electrical circuits connected to an AC electrical outlet through a transformer or similar device.

Primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent

protection device (distribution panel).

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III environments

can endure greater momentary energy than a device

designed for CAT II.

Using a measurement product in an environment

designated with a higher-numbered category than that for

which the product is rated could result in a severe

accident, and must be careful ly avo ided .

Never use a CAT I measuring iproduct in CAT II, III, or IV

environments.

The measurement categories comply with the

Overvoltage Categories of the IEC60664 Standards

Page 12

6

Usage Notes

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

• To avoid short circuits and potentially life-

threatening hazards, never attach the

product to a circuit that operates at more

than the 600V, or over bare conductors.

• Clamp sensor should only be connected to

the secondary side of a breaker, so the

breaker can prevent an accident if a short

circuit occurs. Connections should never

be made to the primary side of a breaker,

because unrestricted curr ent flo w could

cause a serious accident if a short circuit

occurs.

• Use only the specified Model 9445-02 AC

ADAPTER (SA10-0910N, SINO-AMERICAN) or 9445-03 (for EU) AC ADAPTER

(SA10-0910G, SINO-AMERICAN).

AC adapter input voltage range is 100 to

240 VAC (with ±10% stability ) at 50/60 Hz.

To avoid electr ica l h az ards an d da ma ge to

the product, do not apply voltage outside of

this range.

• To avoid electric shock, do not allow the

product to get wet, and do not use it when

your hands are wet.

• Do not use the product where it may be

exposed to corrosive or combustible

gases. The product may be damaged or

cause an explosion.

Page 13

7

• The top part of the clamp sensor above the

barrier (including the clamps, but not the

lever) is provided with double insulation to

ensure safety. Be careful not to drop the

sensor or othe rwis e s ub jec t i t to im p act. A

damag ed sens or may result in el ectric

shock during measurement. In case of

sensor damage, contact us immediately for

repa ir or disc ard the dam ag ed se nso r to

avoid su bse qu ent use .

• To avoid damage to the product, do not

exceed the maximum input current rating,

which depends on the frequency of the

current being measured (see Chapter 8

Clamp Sensor Specifications - Frequencydependent del eti on cha r ac teri sti cs) Be

careful about the evolution of heat, when

the input frequ enc y is high.

• To avoid electri c s ho ck when rep lac in g th e

batteries, first disconnect the clamp from

the object to be measu red.

• After replacing the batteries, replace the

cover and screws before usi ng the

product.

• Do not mix old and new batteries, or

different types of batteries. Also, be careful

to observe battery polarity during

installation. Otherwise, poor performance

or damage from battery leakage could

result.

• To avoid the possibility of explosion, do not

short circuit, disassemble or incinerate

batteries.

• Handle and dispose of batteries in

accordance with local regulations.

Page 14

8

• Do not use the product when the battery is

depleted ( lights on the LCD). When

is on, accuracy and other specifications cannot

be guaranteed.

• For the inside memory prot ection, make sure

the power is turned off before plugging in or

unplugging the AC adapter.

• Adjust ments and repairs should be made only

by technically qualified personnel.

• If the protective functions of the product are

damaged, either remove it from service or mark

it clearly so that others do not use it inadvertently.

• To avoid corrosion from batter y leakage, remo ve

the batteries from the product if it is to be stored

for a long time.

Page 15

9

Observe the following to avoid damage to the

-

st

-

n

n

product.

• Installation and Operating Environment

Between 0°C and 40°C; 80% RH or less;

indoors only.

Direct

sunlight

High temper

ature, high

humidity, du

Electromag

etic radiatio

• Do not store or use the product where it could

be exposed to direct sunlight, high temperature

or humidity, or condensation. Under such conditions, the product may be damaged and insulation may deteriorate so that it no longer meets

specifications.

• This product is not designed to be entirely

water- or dust-proof. To avoid damage, do not

use it in a wet or dusty environment.

• Do not use the product near a device that generates a strong electromagnetic field or electrostatic charge, as these may cause erroneous

measurements.

• To avoid damage to the product, protect it from

vibration or shock during transport and handling,

and be especially careful to avoid dropping.

Impact,

dropping

• Accurate measurement may be impossible in the

• To clean the product, wipe it gently with a soft

presence of strong magnetic fields, such as near

transformers and high-current conductors, or in

the presence of strong electromagnetic fields

such as near radio transmitters.

cloth moistened with water or mild detergent.

Never use solvents such as benzene, alcohol,

acetone, ether , ketones, thinners or gasoline, as

they can deform and discolor the case.

Page 16

10

Organization of This Manual

Chapter 1 Product Ov erview

Provides an overview of the product and describes the

parts and functions.

Chapter 2 Basic Measurement Procedure

Describes the basic measurement procedure for quick

reference and the peak measurement procedure in DC

current (DC A) mode, AC current (AC A) mode, and

AC+DC A mode.

Chapter 3 Measurement Procedure

Describes the measurement procedure for the 3290

CLAMP ON AC/DC HiTESTER when combined with the

9691, 9692, or 9693 CLAMP ON AC/DC SENSOR.

Chapter 4 Battery Replacement

Explains how to replace the battery used for the 3290

Clamp On AC/DC HiTESTER.

Chapter 5 AC Adapter

Explains how to use the 9445-02 AC Adapter (optional).

Chapter 6 Attaching the Strap

Explains how to attach the strap.

Chapter 7 Specifications

Lists the specifications of the 3290 CLAMP ON AC/DC

HiTESTER.

Chapter 8 Clamp Sensor Specifications

Lists the specifications of the 9691, 9692, and 9693

CLAMP ON AC/DC SENSORs.

Chapter 9 Carrying Case

Explains how to use the 9400 CARRYING CASE

(optional).

Page 17

11

Chapter 10 Troubleshooting

Lists common symptoms that may indicate a malfunction.

If you encounter a problem, be sure to read this chapter

before requesting repair.

Chapter 11 Service

Describes our customer support service.

Chapter 12 Appendix

• Provides the accuracy table and explains how to

calculate accuracy for the 3290 CLAMP ON AC/

DC HiTESTER when combined with the 9691,

9692, or 9693 CLAMP ON AC/DC SENSOR.

• Describes how to use the intermediate cable.

Page 18

12

Page 19

13

Chapter 1 Overview

Overview Chapter 1

1.1 Product Overview

The 3290 CLAMP ON AC/DC HiTESTER is used with the

9691, 9692, or 9693 CLAMP ON AC/DC SENSOR.

These sensors are interchangeable and any model can

be used with the 3290. The 3290 automatically detects

the sensor connected and sets up the appropriate range.

When combined with the 9691, 9692, or 9693 Sensor, the

3290 HiTESTER can perform DC, AC, and AC+DC

measurement of a live power line. Various functions are

available (using the SHIFT key) to make the 3290 suitable

for various current measurement applications. The 3290

is also equipped with two output terminals to enable a

variety of advanced measurements, such as simultaneous

output of both monitor and rms record. Moreover, the

3290 can operate using battery power or the AC adapter

(for long-term measurement use).

1.2 Features

The 3290 has the following features:

Multif unc tion Microcom puter

The 3290 both compact and multifunctional thanks to the

built-in microcomputer and use of the SHIFT key.

Large-Screen LCD

The large-screen LCD employed is easy to read.

Clamp Sensor

The 3290 is compatible with three clamp-on AC/DC

sensors (9691, 9692, and 9693) having different ratings.

Because the 3290 automatically detects the sensor

connected, you need not edit the setting each time you

change the sensor.

Page 20

Chapter 1 Overview

14

Multif unc tion Microcom puter

The 3290 both compact and multifunctional thanks to the

built-in microcomputer and use of the SHIFT key.

Large-Screen LCD

The large-screen LCD employed is easy to read.

Clamp Sensor

The 3290 is compatible with three clamp-on AC/DC

sensors (9691, 9692, and 9693) having different ratings.

Because the 3290 automatically detects the sensor

connected, you need not edit the setting each time you

change the sensor.

Two Output Terminals

Two signals are output simultaneously from among the

four following: current (REC = record and MON =

monitor), current frequency (REC = record), and low

battery warning signal.

• Current monitor & low battery warning signal

• Current monitor & current record

• Current record & low battery warning signal

• DC component & AC component (AC/DC separate output)

• Frequency record & current record

Method of measurement

In AC A mode, you can select either the true rms (RMS)

or average rectified rms indication (MEAN).

Measurement Response Speed

For RMS measurement, you can select a response speed

from FAST, NORMAL, or SLOW.

Low-frequency Current Measurement

In AC+DC A mode, you can measu re curr en t from 1 Hz

when the measurement response speed is set to SLOW.

Filter Function

This function turns on and off a low-pass filter (LPF) of

approximately 500 Hz.

Setting Save Function

This function saves the current measurement conditions

so that settings are retained even after power is turned

OFF.

Key Lock Function

This locks all keys including the POWER key (except the

keys used to unlock).

Page 21

15

Chapter 1 Overview

AC+DC Measurement

The 3290 measures AC superimposed on DC, half-wave

rectified, and full-wave rectified.

Peak Measurement

The peak hold current can also be measured.

REC Function

You can select whether the maximum or minimum

measurement value is displayed.

Dual-power supply

The 3290 run s on either battery power or an AC power

source.

Dustproof Cap

The dustproof cap is provided for use in a dusty

environment.

Intermediate Cable

In case the 9691, 9692, or 9693 sensor cable (about 2 m

long) is too short, an interme diate cable can be used to

extend connection length. Insert the intermediate cable

between the 3290 and the sensor cable.

Page 22

Chapter 1 Overview

16

5,

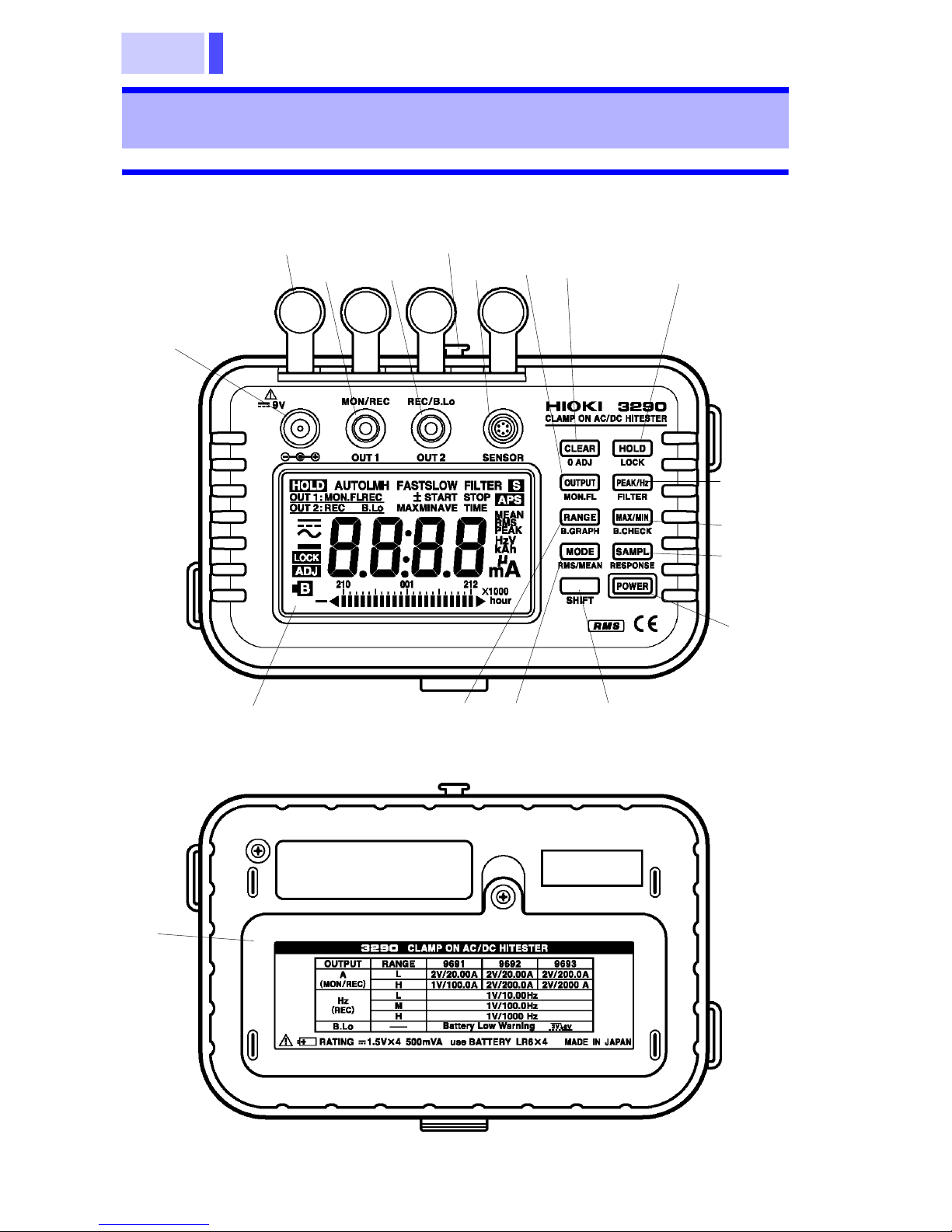

1.3 Parts Names and Functions

1.3.1 3290 CLAMP ON AC/DC HiTESTER

21

24

22

23

27

20

14

6,

11

7,15

8,16

9,17

10,18

1

28

19

4,

13

3,

12

2

Page 23

17

26

25

Chapter 1 Overview

Keys for Basic Measurement

1. POWER Key

• Turns power ON/OFF.

• Holding down the CLEAR key and turning power

on initializes the setting save function and

restores the default settings.

• Holding down the HOLD key and turning power

on disables the auto power-off function.

• Holding down the PEAK/Hz key and turning

power on turns off the buzzer.

2. SHIFT Key

• Pressing this key causes to light, indicating

that the additional function (in blue letters) allo-

cated to each key is available. To turn off,

press the SHIFT key again.

• Some keys may be locked when is on.

Page 24

Chapter 1 Overview

18

3. MODE Key

• Selects the current measurement mode.

4. RANGE Key

• Selects auto range or manual range.

• Selects a measurement range when manual

range is selected.

• The current ranges for the 9691 and 9692 are 20

A and 200 A; the ranges for the 9693 are 200 A

and 2000 A. The frequency ranges are 10 Hz,

100 Hz, and 1000 Hz.

5. OUTPUT Key

• Sets the output (for current and frequency measurement).

Two outputs are available. The settings available for each current measurement mode are

fixed.

AUTO

AC ADC A

L

M

(Hz only)

AC+DC A

H

• Disables the auto power-off function.

6. CLEAR Key

• Clears data to “0” during peak measurement.

• Clears data to “0” during activation of the recording function.

• Holding down the CLEAR key and turning power

on initializes the setting save function and

restores the default settings.

7. HOLD Key

• Suspends or deactivates the screen-updating

function. (See 15 under “Keys for Advanced

Measurement” for details of the key lock function.)

• Holding down the HOLD key and turning power

on disables the auto power-off function.

Page 25

19

8. PEAK/Hz Key

• PEAK performs peak measurement of waveforms (peak hold).

• Hz performs frequency measurement (in AC A

mode).

• Holding down the PEAK/Hz key and turning

power on turns off the buzzer.

9. MAX/MIN Key

• Activates the recording function and displays the

maximum value (MAX), minimum value (MIN),

mean value of both maximum & minimum values

(AVE), and elapsed time (TIME).

• Pressing this key immediately activates the

recording function.

• MAX displays the maximum value of measurements taken after the recording function is activated.

Chapter 1 Overview

• MIN displays the minimum value of measurements taken after the recording function is activated.

• AVE displays the mean value of the maximum

and minimum values measured after the recording function is activated.

• TIME displays the time elapsed after the recording function is activated.

• The auto power-off function is deactivated.

10. SAMPL Key

• Selects a screen-updating rate from NORMAL

(twice/sec.), SLOW (once/3 sec. ), or FAST (4

times/sec.). Each time this key is pressed, the

rate changes in the order above.

MINMAX

TIMEAVE

Measurement

value

• The rate is usually set to NORMAL. (Note that

• SLOW decelerates the speed of updating on-

• FAST accelerates the speed of updating on-

there is no indication for NORMAL.)

screen measurement (with SLOW on).

screen measurement (with FAST on).

Page 26

Chapter 1 Overview

20

• During RMS measurement in AC mode or when

in AC+DC mode (with RMS on), the measurement response speed changes according to the

screen-updating rate (SLOW, FAST, or NORMAL).

• Y ou can only change the measurement response

speed. For details, see 18 under “Keys for

Advanced Measurement.”

NORMAL

SLOW

FAST

11. 0 ADJ Key (SHIFT CLEAR Keys)

• Performs auto zero adjustment in DC A or

AC+DC A mode.

Keys for Advanced Measurement

12. RMS/MEAN Key (SHIFT MODE Keys)

• Selects the true rms measurement (RMS) or

average rectified rms indication (MEAN) in AC A

mode. RMS provides accurate measurement of

distorted waveforms. MEAN only provides accurate measurement of undistorted sine waves.

13. B.GRAPH Key (SHIFT RANGE Keys)

• Enlarges the range of a bar graph.

14. MON.FL Key (SHIFT OUTPUT Keys)

• Turns on a low-pass filter of approx. 1 Hz when

MON is selected for OUT1 in DC A mode.

• Turns on a low-pass filter of approx. 1 Hz when

MON is selected for OUT1 (REC for OUT2) in

AC+DC A mode. This enables separate output

of the DC component (OUT1) and AC component (OUT2). (The value of the AC component is

indicated on the LCD.)

Page 27

21

Chapter 1 Overview

15. LOCK Key (SHIFT HOLD Keys)

• Locks all keys including the POWER key.

• To unlock, press the same keys again (SHIFT

HOLD keys).

16. FILTER Key (SHIFT PEAK/Hz Keys)

• Turns on a low-pass filter of approx. 500 Hz in

AC A or AC+DC A mode .

• To turn the filter off, press the same keys again

(SHIFT PEAK/H z key s).

17. B.CHECK Key (SHIFT MAX/MIN Keys)

• Indicates remaining battery power. When power

is depleted to 0%, the low battery warning ( )

goes on.

18. RESPONSE Key (SHIFT SAMPL Keys)

Display

19. LCD

• Selects a measurement response speed independently from the screen-updating rate when

RMS is selected in AC A mode or when AC+DC

mode is selected.

• Press the SAMPL key to return to the measurement response speed that matches the selected

screen-updating rate.

The letter of LCD is clearest, when it sees from the front

side.

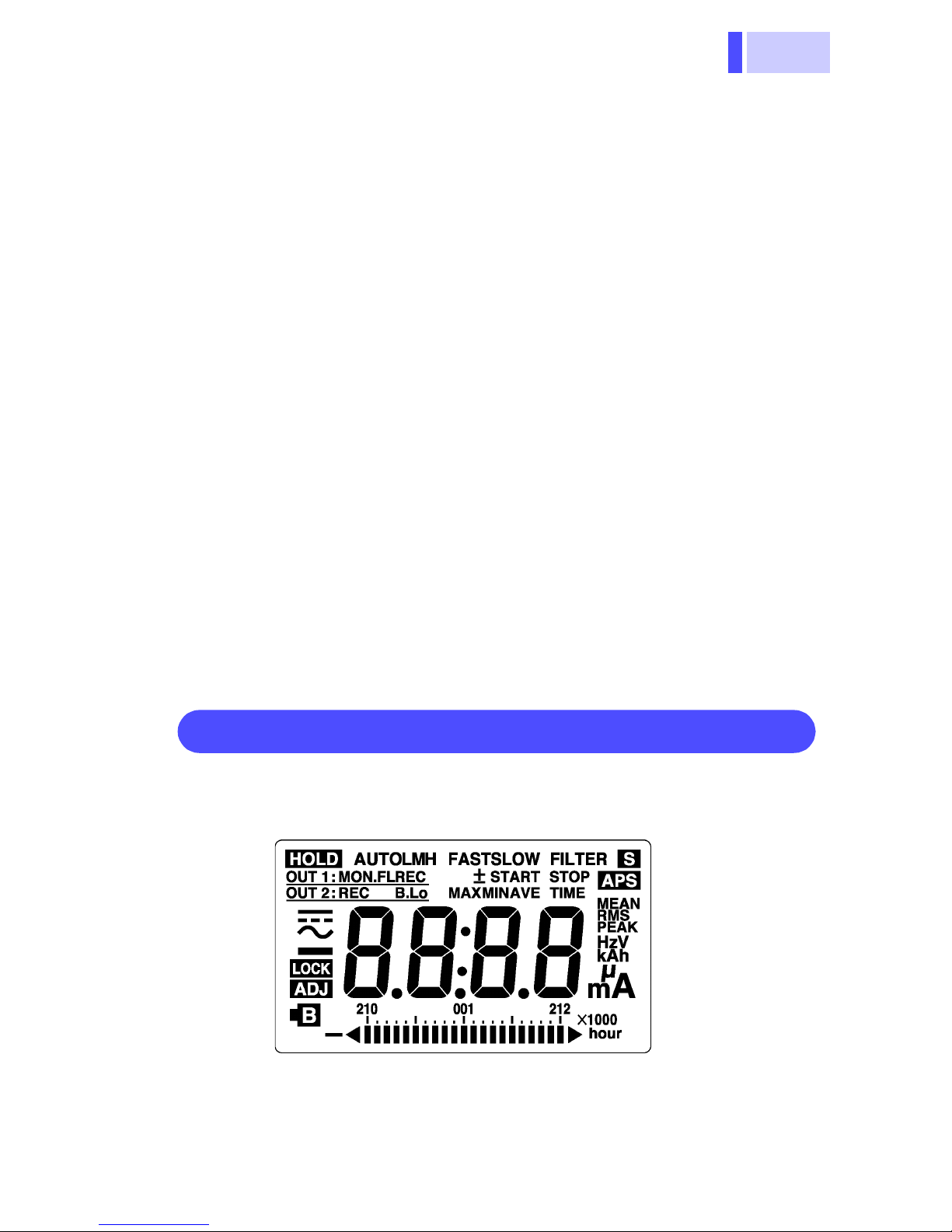

Page 28

Chapter 1 Overview

22

Direct Current (DC)

Alternating Current (AC)

Alternating Current and Direct Current (AC+DC)

Auto zero adjustment is active.

Low battery war ning

OUT1 Setting of OUT1

OUT2 Setting of OUT2

Data hold function

MON

MON.FL

Monitor is active.

1 Hz filter for monitor is active.

REC Record is active.

Auto power-off is active.

AUTO Auto-range

L Current/frequency low range

M Frequency mid range

H Current/frequency high range

FAST Screen-updating 4 times/sec.

SLOW Screen updating approx. once/3 sec.

FILTER 500 Hz filter is active.

MAX Maximum value

MIN Mini mum value

AVE Average value

TIME Elapsed time

MEAN Average rectified rms indication

RMS True root mean squar e value

PEAK Wave peak value

Hz Frequency

Key lock is active.P

A Current

hour 100 hours/segment (bar graph)

Input over (bar graph)

SHIFT

Page 29

23

Chapter 1 Overview

Parts

20. Sensor Connector (SENSOR)

Connect the 9691, 9692, or 9693 CLAMP ON AC/DC

SENSOR to this connector.

21. AC Adapter Connection Terminal

Connect the 9445-02 AC ADAPTER (optional) to this

terminal when not using the battery or for long-term

measurement.

22. Output Terminal 1 (OUT1)

Connect the 9094 OUTPUT CORD (optional) to this

terminal to obtain output during current or frequency

measurement.

23. Output Terminal 2 (OUT2)

Connect the 9094 OUTPUT CORD (optional) to obtain

output during current measurement or at detection of the

low battery warning signal.

24. Dustproof Caps (4 pcs.)

Used to protect the terminals in a dusty environment.

25. Strap

Used to hang the 3290 around neck so as not to drop it.

26. Top Case

Cover the 3290 with this case when not in use to protect

the LCD, keys and terminals.

27. Top Case Clasp

Insert the clasp into the top case to attach the case. Move

the top case to the rear during measurement.

28. Battery Cover

Unfasten the screw, then remove the case to replace the

battery.

Page 30

Chapter 1 Overview

24

1.3.2 9691, 9692, 9693

CLAMP ON AC/DC SENSOR

9691

9692

9693

Output connector

Page 31

25

Chapter 1 Overview

R

M

1.4 Flowchart Of Key Operations

1.4.1 Current Measurements Mode

MODE key

AC ADC A

ANGE key

AC+DC A

PEAK/Hz key

AX/MIN key

AUTO range

L range

H range

DC A

PEAK

MAX

AUTO range

L range

H range

AC A

PEAK

Hz

MAX

AUTO range

L range

H range

AC+DC A

PEAK

MAX

MIN

AVE

TIME

Measured

value

MIN

AVE

TIME

Measured

value

MIN

AV E

TIME

Measured

value

Page 32

26

S

R

MODE key

Chapter 1 Overview

DC A

AC A

AC+DC A

OUTPUT key

AMPL key

MS/MEAN key

OUT1 OUT2

OFF OFF

MON B.Lo

NORMAL

SLOW

FAST

Disabled

OUT1 OUT2

OFF OFF

REC B.Lo

MON REC

NORMAL

SLOW

FAST

OUT1 OUT2

OFF OFF

REC B.Lo

MON REC

NORMAL

SLOW

FAST

Disabled

RMS

MEAN

Page 33

27

Chapter 1 Overview

MODE key

MON.FL key

FILTER key

RESPONSE キー

MON

MON.FL

Disabled

Disabled

AC ADC A

Disabled

OFF

ON

NORMAL

(No displayed)

AC+DC A

MON

MON.FL

OFF

ON

NORMAL

(No displayed)

SLOW ( )

FAST ( )

Effective on RMS

SLOW ( )

FAST ( )

Page 34

Chapter 1 Overview

28

1.4.2 Frequency Mode

PEAK/Hz key

RANGE key

MAX/MIN key

PEAK

AUTO range

L range

H range

MAX

MIN

Hz

(AC A only)

AUTO range

10.00 Hz(L) range

100.0 Hz(M) range

1000 Hz(H) range

MAX

MIN

Current

Measured

value

OUTPUT key

AV E

TIME

Measured

value

OUT1 OUT2

OFF OFF

MON B.Lo

AVE

TIME

Measured

value

OUT1 OUT2

OFF OFF

REC (Hz) REC(A)

Page 35

29

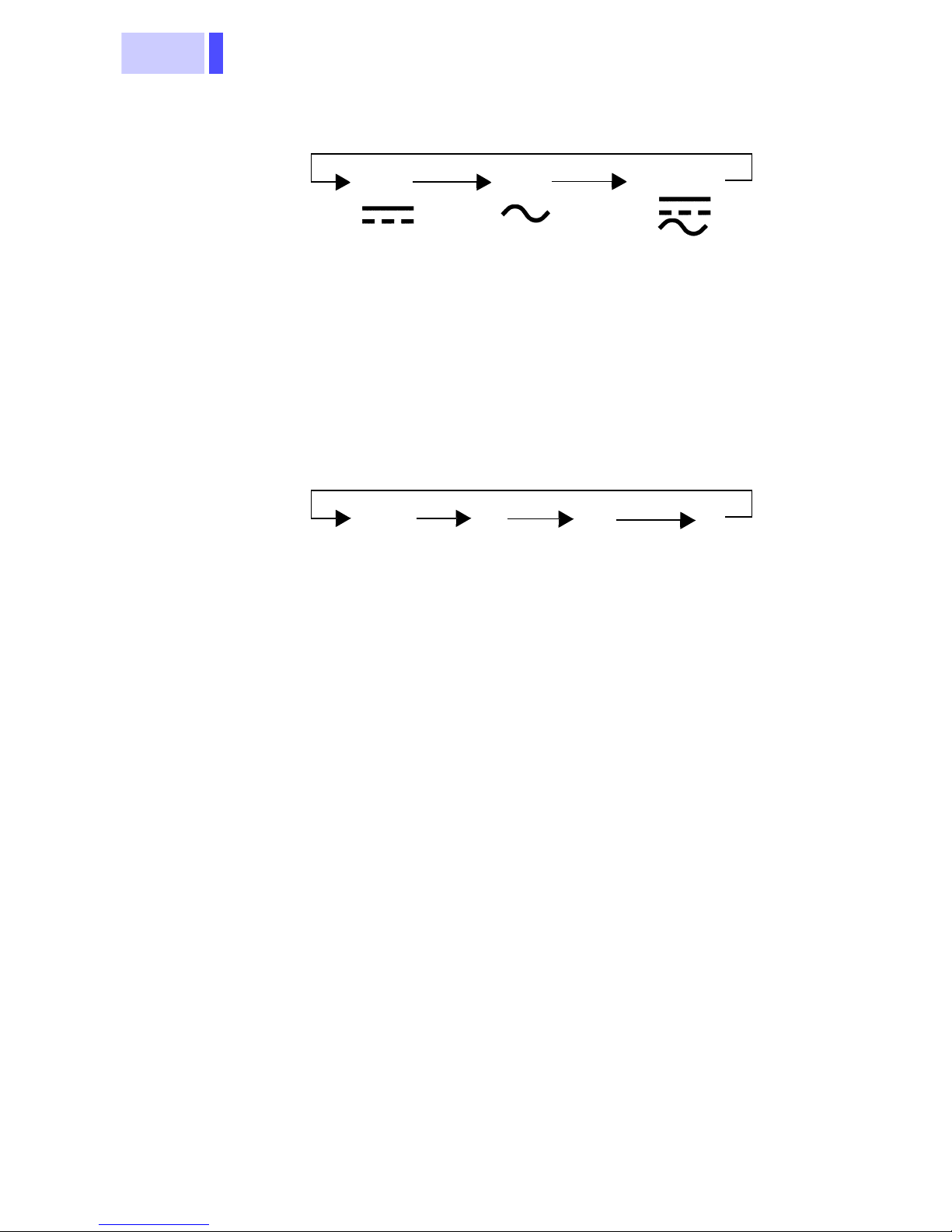

1.5 Modes

For current, three modes are provided: DC (direct current,

), AC (alternating current, ), and AC+DC (alternating

current and direct current, ) modes. Select a proper

mode according to the waveform shown below:

Chapter 1 Overview

0

0

0

0 V

0

0

0

0

0

0

0

0

0

0 V

0

0

0

0

0

0

0

0

0

0

0

0

Page 36

30

Mode

Chapter 1 Overview

Input

Display

waveform

OK

(with polarity)

OUTPUT

(only for current mode)

REC MON

DC

()

AC

()

No

Not meas urab le

No

Not measurable

No

Not meas urab le

(zero displayed)

OK

No

Not measurable

OK

(without

polarity)

Setting

impossible

AC+DC

()

OK

OK

Page 37

31

Chapter 1 Overview

-

-

-

-

-

-

-

-

-

-

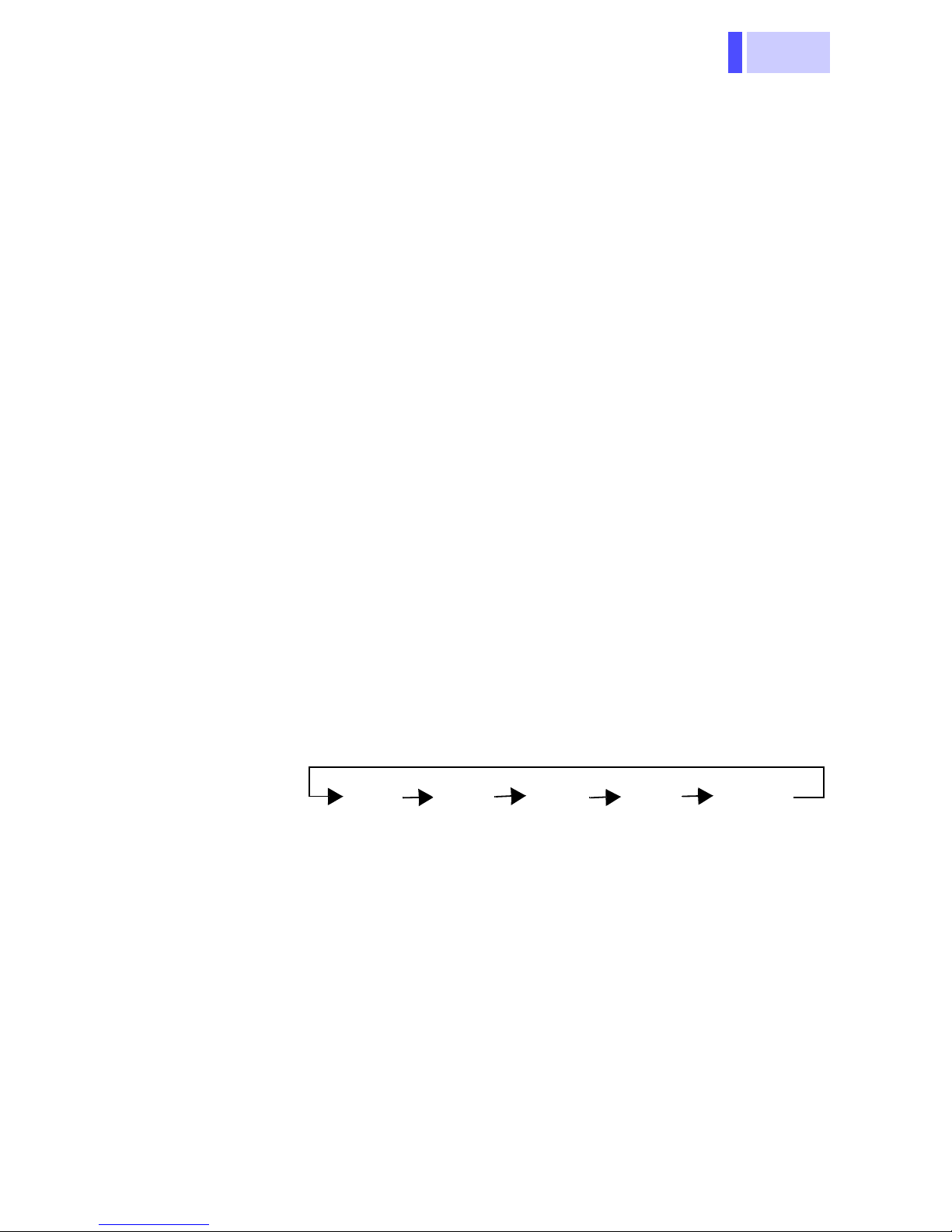

Quick Reference

Measurements Operations

DC A

AC A RMS

AC A MEAN

AC+DC A

DC A peak

PEAK

ADJ

→

RMS

→

MEAN

→

ADJ

→

ADJ

→

Measure

ment

Measure

ment

Measure

ment

Measure

ment

Measure

ment

(pa g e)

44

45

46

47

49

AC A RMS

peak

AC A MEAN

peak

AC+DC A

peak

AC A RMS

Hz

AC A MEAN

Hz

RMS

MEAN

PEAK

RMS

MEAN

→

→

→

→

PEAK

PEAK

ADJ

→

Hz

Hz

Measure

49

ment

49

Measure

ment

49

Measure

ment

55

Measure

ment

55

Measure

ment

Page 38

Chapter 1 Overview

32

/peak/

H

/peak/

H

W

i

/peak/

H

/peak/Hz

/peak/

H

Quick Reference (application)

Operations

(page)

Hold the measured value (Data Hold Function)

//

z/record

Measurement

HOLD

59

"O.L." is displayed (Overflow Warning Function)

//

z/record

hen the measured value exceeds the max-

mum value, "O.L." is displayed.

−

Change the screen update rate

(Changing the Screen Update Rate)

//

(NORMAL/SLOW/FAST) switch

59

z

Measurement speed can be changed

(Measurement Response Speed Switching Function)

/

Outputs (Output Function)

//

z

(NORMAL/SLOW/FAST) switch

→

AC A mode: RMS

AC+DC A mode only

OUT1: OUT2: on

65

51

56

Page 39

33

Chapter 1 Overview

O

O

D

/peak

/

/peak/

H

/peak/

H

/peak/

H

Operations

(page)

Obtained through a low-pass filter (LPF) set to approximately 1

Hz (MON Output Filter Function)

/

UT1:

MON

UT2:

REC

isable:

→

→

OUT1:

MON.FL

OUT2:

REC

Press the key

again.

71

Obtained through a low-pass filter (LPF) to measurement

value and output. (Filter Function)

/

→

FILTER : on

68

500 Hz の Hz

Disable:

→

Press the key

again.

Disabling the auto power off function (Auto Power Off Function)

//

z

+

Power ON

APS : O FF

72

Disabling the beep tone (Beep Tone)

//

z

+

Power ON

75

Hold the maximum measurement, minimum measurement, and

mean value. (Recording Function)

//

z/record

Bar graph

The elapsed

time is

displayed.

MAX: maximum value /MIN: minimum value

/AVE: average value /TIME: elapsed time

(MAX/MIN/AVE/

TIME/

Instantaneous

value switch

61

Disable:

Press the key.

Page 40

Chapter 1 Overview

34

/peak/

H

D

" " display

/Hz

/peak/

H

/peak/

H

on

Operations

(page)

Saved the settings (Setting the Save Function)

//

73

z

(Hold down 2 seconds. )

isable:

+

Power ON

"" ""

display

Enlarged to the Bar graph. (Bar Graph Enlargement Function)

//

→

Disable:

Bar Graph Enlargement

→

Press the key

again.

69

Battery check

//

z/record

Key lock

//

z

→

→

Disable:

→

70

69

Press the key

again.

Page 41

35

Chapter 2 Basic Measurement Procedures

Basic

Measurement

Procedures

• To avoid short circuits and potentially lifethreatening hazards, never attach the

product to a circuit that operates at more

than the 600V, or over bare conductors.

• Clamp sensor should only be connected to

the secondary side of a breaker, so the

breaker can prevent an accident if a short

circuit occurs. Connections should never

be made to the primar y side of a breaker,

because unre stri ct ed current flow cou ld

cause a serious accident if a short circuit

occurs.

• Use only the specified Model 9445-02 AC

Chapter 2

ADAPTER (SA10-0910N, SINO-AMERICAN) or 9445-03 (for EU) AC ADAPTER

(SA10-0910G, SINO-AMERICAN).

AC adapter input voltage range is 100 to

240 VAC (with ±10% stability ) at 50/6 0 H z.

To avoid electri ca l ha za rds and damage t o

the product, do not apply voltage outside of

this range.

This chapter describes t he basic meas urement

procedure. For details of the measurement procedure, see Chapter 3, “Measurement Procedure.”

Page 42

Chapter 2 Basic Measurement Procedures

36

2.1 DC Measurement (DC A)

1. Press the MODE key to

display DC A ( ).

2. Press the SHIFT key to

display .

Page 43

37

Chapter 2 Basic Measurement Procedures

.

3. Press the 0 ADJ key

(CLEAR key) to perform

zero adjustment.

4. will appear on the

LCD.

9691 CLAMP ON AC/DC SENSOR

Load

Measured

conductor

Power

source

5. Align the current direction

indicator on the clamp

with the current directio n

of the conductor to be

measured, then clamp

the conduct or so that it

passes through the

center of the clamp core.

The figure shows the

9691 CLAMP ON AC/DC

SENSOR. When using

the 9692 or 9693 CLAMP

ON AC/DC SENSOR,

note that the current

direction indicator is

located in a different

position.

6. Read the displayed value

Since the measurem en t

range is set to AUTO, you

need not set the range.

Page 44

Chapter 2 Basic Measurement Procedures

38

.

2.2 AC Measurement (AC A)

1. Press the MODE key to

display AC A (

* When measuring

current up to 10 Hz, use

AC+DC A mode and

select SLOW.

).

9691 CLAMP ON AC/DC SENSOR

Measured

conductor

2. Clamp the conductor to

be measured so that it

passes through the

center of the clamp core.

You need not align the

direction of the clamp.

3. Read the displayed value

Since measurem ent

range is set to AUTO, you

need not set the range.

Page 45

39

Chapter 2 Basic Measurement Procedures

2.3 Peak Measurement

In AC+DC A Mode

1. Press the MODE key to

display AC+DC A ( ).

2. Press the PEAK/Hz to

display PEAK.

Page 46

Chapter 2 Basic Measurement Procedures

40

3. Press the SHIFT key to

display .

9691 CLAMP ON AC/DC SENSOR

Measured

conductor

4. Press the 0 ADJ key

(CLEAR key) to perform

zero adjustment.

5. will appear on the

LCD.

6. Clamp the conductor to

be measured so that it

passes through the

center of the clamp core.

You need not align the

direction of the clamp.

Page 47

41

Chapter 2 Basic Measurement Procedures

.

7. Press the CLEAR key (0

ADJ key) to clear the

data.

8. Read the displayed value

Since the measurem en t

range is set to AUTO, you

need not set the range.

Page 48

Chapter 2 Basic Measurement Procedures

42

Page 49

43

Chapter 3 Measurement Procedures

Measurement

Procedures

• Do not connect or disconnect the output connector of the clamp-on sensor while power is

supplied to the 3290 or the sensor is clamping a

conductor to be measured.

• When disconnecting the output connector of the

clamp-on sensor from the 3290 sensor connector , be sure to hold it by the metal part and pull it

upward. If it is pulled by the cable, the lock will

not be released and a broken wire in the cable

may result.

• The maximum continuous-input limit is obtained

from the temperature increase due to self-heating during measurement. To prevent damage to

Chapter 3

the clamp-on sensor, do not input a current

exceeding this limit.

• The max imum continuous-input limit varies

depending on the clamp-on sensor and the frequency of the current to be measured. Please

see the dilating-characteristics graph by frequency in "Chapter 8 Clamp Sensor Specifications".

3.1 Preparations

1. Remove the battery cover and insert the bat-

tery (see Chapter 4 Battery Replacement).

2. Connect the output connector of the clamp-on

sensor to the sensor connector. The type of

clamp-on sensor will be detected automatically.

Page 50

Chapter 3 Measurement Procedures

44

3. Press the POWER key to turn on the power.

Make sure all segments of the LCD light up.

Then, the model No. (3290) is displayed and

the charge remaining in the battery is shown

by a bar graph.

New battery

50% battery charge

The battery charge is 0.

lights up.

The beep tone sounds three

times.

remaining

4. The 3290 is ready for operation in DC-current

measurement mode.

• If the setting save function has been used (if the

HOLD key is held down for approximately 2 seconds, the current setting is saved), the 3290 will

be in the saved measurement mode.

• To cancel the saved setting, turn off the power

and then turn it on again while holding down the

CLEAR key. The 3290 will return to the default

setting (DC current).

Low-Battery-Voltage Detection Function

If the battery voltage falls when is on, the power will be

turned off. On the LCD, “ ” and “ ” will appear.

Connecting/Disconnecting the Clamp On Sensor

When connecting the clamp-on sensor to the 3290, hold it

by the area above the metal part of the output connector

when inserting it. If it is held by the metal part, it won’t be

possible to insert the output connector into the sensor

connector. Make sure the wide terminal of the connec tor

is at the top when the connector is inserted.

When disconnecting the clamp-on sensor from the 3290,

hold the metal part of the connector when pulling it out. If i t

is held by the area above the metal part, it won’t be

possible to disconnect the connector.

Page 51

45

Chapter 3 Measurement Procedures

Wide termina l

Connecting

Disconnecting

3.2 Current Measurement

• The ends of the clamp sensor are very delicate.

Be careful not to drop the sensor or subject it to

impact. If the sensor is deformed or the contact

surfaces of the clamps are damaged, the measurement may not be accurate.

• Be sure to read the instruction manual for the

clamp sensor to be used before starting measurement.

Output connector

• The hall element is used for the detector of the

• Accurate measurement may be impossible in the

clamp-on sensor. The hall element tends to drift

with age or due to the ambient temperature.

Keep this fact in mind when performing measurement continuously.

presence of strong magnetic fields, such as near

transformers and high-current conductors, or in

the presence of strong electromagnetic fields

such as near radio transmitters.

Page 52

Chapter 3 Measurement Procedures

46

• The reading may show a measurement greater

than the actual value due to magnetic-field interference. The amount of interference varies

depending on the sensor. For detail s, see “External magnetic-field interference” in Chapter 8

Clamp Sensor Specifications.

• The 9691 has a lock mechanism for the clamps

so that the clamps will not open due to vibration

or other similar causes during measurement.

Lock the clamps as necessary. (If the clamps

should open even slightly during measurement,

the accuracy cannot be guaranteed.)

• Attach the clamp around only one conductor.

Single-phase (2-wire) or three-phase (3-wire)

cables clamped together will not produce any

reading.

OK

3.2.1 Measuring DC Current (DC A)

1. Press the MODE key to display “ .”

2. Select a measurement range suitable for the

current to be measured.

3. Before clamping the conductor to be measured, press the 0ADJ key (SHIFT CLEAR

key) with the clamp sensor fully closed to perform the auto zero adjustment (see 3.4 AutoZero-Adjustment Function). Upon completion

of the auto zero adjustment, “ ” will light

up. (When auto range is selected, the auto

zero adjustment is made for the two ranges.)

Page 53

47

Chapter 3 Measurement Procedures

The auto zero adjustment range is ± 450 dgt.

for the L range and ± 45 dgt. for the H range. If

the sensor’s offset exceeds these ranges, the

auto zero adjustment cannot be performed.

4. Open the clamps of the sensor. Orient the cur-

rent direction indicator on the clamps in the

current direction of the conductor to be measured, place the conductor in the center of the

clamp core, and clamp it.

Load

Power

source

Current direction

indicator

• In DC A mode, only a DC current that does not

contain an AC component can be measured correctly (see 1.5 Modes).

• When a conductor to be measured is placed in

the center of the clamp core, measurement is

performed the most accurately, with no effect of

the conductor position.

• The measurement may change if the direction of

the clamp sensor is changed. However, the measurements are within the guaranteed accuracy

range.

• If the reading fluctuates rapidly and is difficult to

read, press the SAMPL key to select SLOW.

• The L range displays up to 2500 dgt.

3.2.2 Measuring AC Current (AC A)

1. Press the MODE key to display “ .”

2. Select a measurement range suitable for the

current to be measured.

Page 54

Chapter 3 Measurement Procedures

48

3. Open the clamps of the sensor, place the conductor to be measured in the center of the

clamp core, and clamp it. In addition, make

sure the clamp sensor is perpendicular to the

conductor.

• When measuring a current of 10 Hz or less, use

AC+DC A mode. Press the SAMPL key to set

the screen-updating rate to SLOW (the measurement response speed must be SLOW; the

unit symbol “A” will blink slowly). If SLOW is

selected in AC A mode, the measurements may

become smaller than those in AC+DC A mode.

• DC, full-wave rectified waveforms, half-wave

rectified waveforms, and DC+AC waveforms

cannot be measured in AC A mode (see 1.5

Modes).

• When a conductor to be measured is placed in

the center of the clamp core, measurement is

performed the most accurately without effect of

the conductor position. If the clamp sensor is not

perpendicular to the conductor, there may be a

slight effect on the measurement when the measured current frequency is high.

• We recommend that RMS measurement be per-

formed. By switching over to MEAN (SHIFT

MODE key), the MEAN value can be compared

with the RMS value and a check can be conducted for distortion in the measured current. If

the values are nearly the same, the current is

close to a sine wave with little distortion (the ratio

of the peak to rms is close to 1.4:1).

• When the MEAN and RMS measurements differ ,

the measured current may be distorted.

• During MEAN measurement, the measurement

response speed cannot be changed.

• Select RMS measurement and the FAST

screen-updating rate if the rise in the current

waveform is sharp (the measurement response

speed must be FA ST; the unit symbol “A” will

blink quickly).

• The L range displays up to 2500 dgt.

Page 55

49

Chapter 3 Measurement Procedures

3.2.3 Measuring AC + DC Current (AC+DC A)

1. 1. Press the MODE key to display “ .”

2. 2. Select a measurement range suitable for

the current to be measured.

3. 3. Before clamping the conductor to be mea-

sured, press the 0ADJ key (SHIFT CLEA R

key) with the clamp sensor fully closed to perform the auto zero adjustment. Upon comple-

tion of the auto zero adjustment, “ ” will

light up (see 3.4 Auto-Zero-Adjustment Function).

4. 4. Open the clamps of the sensor, place the

conductor to be measured in the center of the

clamp core, and clamp it. In addition, make

sure the clamp sensor is perpendicular to the

conductor.

• When measuring a current of 10 Hz or less,

press the SAMPL key to set the screen updating

rate to SLOW (the measurement response

speed must be SLOW; the unit symbol “A” will

blink slowly).

• When a conductor to be measured is placed in

the center of the clamp core, measurement is

performed the most accurately with no effect of

the conductor position. If the clamp sensor is not

perpendicular to the conductor, there may be a

slight effect on the measurement when the measured current frequency is high.

• RMS measurement is performed.

• When DC measurement is performed, the polar-

ity will not be displayed. The measurement may

change if the direction of the clamp sensor is

changed. However, the measurements are

within the guaranteed accuracy range.

• Set the screen-updating rate to FAST if the

increase in the current waveform is sharp (the

measurement response speed must be FAST;

the unit symbol “A” will blink quickly).

• The L range displays up to 2500 dgt.

Page 56

Chapter 3 Measurement Procedures

50

3.2.4 Bar Graph

The bar graph shows the current measurement range and

the measurement.

The blinking segment represents the current

measurement range. When AUTO range is selected, it

represents the range for internal operation. For example,

if the segment at “2” is blinking and the number to the right

is “x10,” the range is 20 A.

In DC A mode, the negative polarity is shown to the left of

“0” and the positive polarity is shown to the right.

Therefore, two segments will blink.

The measurement is represented by the segments that

light up. For instance, when the 20-A range is selected in

AC A mode, if the segments up to 1 (11 segments) are on,

the measurement is 10 A or more but below 11 A.

• Because the segment at the number that repre-

sents the range blinks, if a measurement is 1900

dgt. or more but below 2100 dgt. (1800 dgt. or

more but below 2200 dgt. in DC A mode), the

bar graph will not show any change.

• If a measurement is 2100 dgt. or more (2200 dgt.

or more in DC A mode), “ ” will appear.

• The numerical reading may differ from the mea-

surement on the bar graph (e.g., “ ” appears

even if the numerical reading is 2099 dgt.).

• If the reading shows O.L., “ ” will appear.

• When a measurement is unstable, the segments

that represent the measurement may blink.

Page 57

51

Chapter 3 Measurement Procedures

When the 9691 clamp on the AC/DC sensor is connected

and the H range is selected, the indication will differ from

that when ot her sensors are used as below.

• Because the sensor rating is 100 A, the segment

at “1” blinks and the number to the right of the

bar graph shows “x100,” indicating the 100-A

range.

• If a measurement is between 900 dgt. and 1050

dgt., the bar graph will not show any change.

(Normally, one segment lights up for every 100

dgt..)

• If a measurement exceeds 1050 dgt., the seg-

ment 12th onward will light up and “ ” will

appear (“ ” will appear in DC A mode).

3.2.5 Peak Measurement

1. Press the MODE key and select a measure-

ment mode for the circuit to be measured.

2. The measurement mode is changed as shown

below each time the PEAK/Hz key is pressed.

Sele ct PEAK.

PEAK

3. In DC A or AC+DC A mode, perform the auto

zero adjustment by pressing the 0ADJ key

(SHIFT CLEAR key). (See 3.4 Auto-ZeroAdjustment Function.)

4. 4. Select a measurement range. (When AUTO

range is selected, some time may be required

for the 3290 to detect an appropriate range

and switch over to the range. This may delay

the peak measurement. If it is not possible to

estimate the peak current value, use the H

range.)

Hz

(AC only)

Measurement

Page 58

Chapter 3 Measurement Procedures

52

5. Before conducting the measurement, press

the CLEAR key to clear (reset) the previous

data. In DC A or AC+DC A mode, when there

is no input, pressing the 0ADJ key (SHIFT

CLEAR key) performs the auto zero adjustment and clears the data at the same time.

6. Open the clamps of the sensor, place the conductor to be measured in the center of the

clamp core, and clamp it.

• When measuring a current of 10 Hz or less, use

AC+DC A mode (it is not necessary to select

SLOW when only peak measurement is performed).

• Be careful to prevent the power from being

turned off by the auto-power-off function (see

3.15 Auto-Power-Off Function). If the measurement exceeds the auto-power-off time, disable

the auto power off.

• When peak measurement is performed, the

polarity will not be displayed. When the direction

of the clamp sensor is changed, the measurement may change within the guaranteed accuracy range.

• Clear the data using the CLEAR key, if neces-

sary, after clamping the conductor.

• There is no difference in peak measurement

between RMS and MEAN in AC A mode.

• The output function is not available for peak

measurements. If the OUTPUT key is pressed in

peak measurement mode, the current measurement will be output.

• To check the transitional peak values, press the

MAX/MIN key to display a measurement (no

indicator). (The largest value will be displayed

each time the screen is updated.)

• The bar graph is not displayed in peak measure-

ment mode.

• During peak measurement, the peak detection

circuit performs analog processing (no digital

sampling is performed).

MAX

MIN

AVE TIME

Measure

ment

(No indicator)

Page 59

53

Chapter 3 Measurement Procedures

3.2.6 Output Function (Current Measurement)

Fully insert the 9094 output cord (optional) into the output

terminal.

To prevent malfunction, be careful not to

short-circuit the output terminal or apply a

voltage to it.

There are two output terminals, and different signals may

be output from these terminals. The current measurement

is output at the rate printed on the battery cover of the

3290.

The battery-low warning signal is output at approximately

DC 3 V until the warning indicator ( ) appears. After

has appeared, it will be reduced to approx. 0 V (see 3.17

Battery-Low Warning) .

• Output 1 (OUT1) is selectable between REC

(numerical record output) and MON (waveform

output) during current measurement (MON only in

DC A mode, see 1.5 Modes). During frequency

measurement, REC (numerical record output) can

be selected.

• Output 2 (OUT2) is selectable between REC

(numerical record output) and B.Lo (battery-low

warning signal) during current measurement (B.Lo

only in DC A mode). During frequency measurement, REC (numerical record output) can be

selected.

1. Press the MODE key to select a measurement

mode suitable for the circuit to be measured.

2. Press the RANGE key to fix the measurement

range.

3. Press OUTPUT key , and OUT1 and OUT2 will

light up, indicating that the output function is

enabled. This automatically disables the auto

power off (“ ” goes out ).

Page 60

Chapter 3 Measurement Procedures

54

4. 4. Press the OUTPUT key to edit the output

setting.

DC A Mode

OUT1

OUT2

OUT1

OUT2

MON

B.Lo

( OFF)

OFF

OFF

( OFF)

AC A Mode and AC+DC A Mode

REC

B.Lo

( OFF)

MON

REC

( OFF)

OFF

OFF

( OFF)

5. Determine the range setting from both the

measurement range of the 3290 and that of

the instrument used, such as a recorder. See

the conversion tables below.

Instrument

range /DIV

200 A range 1 A 2 A 5 A 10 A 20 A 50 A 100 A 200 A

20 A range 0.1 A 0.2 A 0.5 A 1 A 2 A 5 A 10 A 20 A

10 mV 20 mV 50 mV 0.1 V 0.2 V 0.5 V 1 V 2V

*The figures above represent the currents per DIV of the

measuring instr um ent.

Instrument

range /DIV

2000 A range 10 A 20 A 50 A 100 A 200 A 500 A 1000 A 2000 A

200 A range 1 A 2 A 5 A 10 A 20 A 50 A 100 A 200 A

10 mV 20 mV 50 mV 0.1 V 0.2 V 0.5 V 1 V 2V

*The figures above represent the currents per DIV of the

measuring instr um ent.

Page 61

55

Chapter 3 Measurement Procedures

Clamp-On Sensor + 3290 MON Output

Frequency Characteristics

5

0

-5

-10

-15

GAIN (dB)

-20

-25

-30

1

10010

1k

10k

Input frequency (Hz)

100k

• Make sure measuring instruments connected to

the 3290 have input impedance over 1 M. If the

impedance is low, the readings will be affected.

• When using the output function, be sure to press

the OUTPUT key, and make sure OUT1 is on.

Data is output even if OUT1 is not shown on the

LCD. However, the auto power off is valid, and

the power will be turned off approximately 10

minutes later.

• If the auto zero adjustment is not performed in

DC A or AC+DC A mode, errors may occur in the

reading and output.

• When measuring a current of 10 Hz or less, use

AC+DC A mode. Press the SAMPL key to set

the screen updating rate to SLOW (the measurement response speed must be SLOW; the unit

symbol “A” will blink slowly). If SLOW is selected

in AC A mode, the measurements may become

smaller than those in AC+DC A mode.

Page 62

Chapter 3 Measurement Procedures

56

• The guaranteed output accuracy range is that in

which the current measurements are not O.L. in

the L range (MON output may saturate if it

exceeds 4 V in the L range). In the H range, the

accuracy range is determined by the maximum

peak current of the clamp-on sensor.

• There is no difference in MON output between

RMS and MEAN in AC A mode.

• If the OUTPUT key is pressed in AUTO range,

the measurement range is set to the range in

effect when the key is pressed (AUTO goes out).

• The REC output is analog. During RMS measurement, the measurement response speed

changes in accordance with the screen updating

rate. The measurement response speed may be

changed separately by pressing the RESPONSE

key (SHIFT SAMPL key ). (See 3.9 Measurement-Response-Speed Switching Function.)

• During MEAN measurement, the measurement

response speed will not change when the screen

updating rate is changed.

• While current measurements are being output,

peak measurement or frequency measurement

can be performed, and the recording function or

data hold function can be used (if the screen

updating rate, measurement mode, or measurement range is changed, or auto zero adjustment

is performed, the output will fluctuate).

• If the HOLD key is pressed during output, the

output value will not be held.

• If the MODE key is pressed to switch over to the

current measurement mode while frequency

measurement records are being output, the

3290 continues to output the frequency records.

To output current measurements, press the

OUTPUT key to cancel the frequency output and

edit the output setting.

• Use the 9445-02 or 9445-03 (EU) AC adapter

(optional) for long-term recording.

• When the AC adapter is used, if the commercial

power line contains a large amount of noise, the

display may show several counts or noise may

be present in the output. In such a case, connect

the ground terminal or the L terminal of the

recorder to the ground.

Page 63

57

Chapter 3 Measurement Procedures

3.3 Frequency Measurement

3.3.1 Frequency Measurement

1. Press the MODE key to display “ .”

2. When the current range of the circuit to be

measured is known, set the current range to

the manual range (if the current range is

unknown, perform current measurement and

then set the range).

3. Each time the PEAK/Hz key is pressed, the

indication will change as shown below.

PEAK

Hz

(AC only)

Measurement

4. Select a frequency range suitable for the frequency to be measured.

5. Open the clamps of the sensor , and clamp the

conductor to be measured.

• When the 3290 is running on the battery, if fre-

quency measurement is performed with the current showing O.L., the current consumption will

be increased and the battery life will be shortened.

• If the input is too smal l for the range (5% or less),

the measurement may not be accurate. The

reading may show “----“ or O.L., or it may fluctuate.

• The reading will show “----“ if the input is below

10 Hz in the 100-Hz or 1000-Hz range, and

below 1 Hz in the 10-Hz range.

• If the input exceeds 1 kHz, the reading shows

• Some time may be required for the reading to

O.L..

stabilize, depending on the frequency range and

input frequency.

Page 64

Chapter 3 Measurement Procedures

58

• The 10-Hz range or 100-Hz range will display up

to 125% of each range.

• Pressing the MAX/MIN key will not affect the output.

• The bar graph shows the current measurement.

• Zero cross detection of waveforms is used for

frequency measurement. In the case of special

waveforms, such as those of inverters, the frequencies may not be measured despite the fact

that a low-pass filter is used (when the carrier

frequencies are as low as several kHz, the carrier component cannot be removed and zero

cross detection therefore cannot be performed

correctly, thereby increasing the reading).

• If there is a DC waveform including 0 V, zero

cross detection cannot be performed correctly

and the reading may be increased or become

unstable.

3.3.2 Output Function

(Frequency Measurement)

Fully insert the 9094 output cord (optional) into the output

terminal.

To prevent malfunction, be careful not to

short-circuit the output terminal or apply a

voltage to it.

An output of DC 1 V is produced for 1000 counts on the

full scale of the frequency range. The output is

synchronized with the screen updating rate. (The output

waveform will be in a stepped shape due to D/A outputs.)

1. Edit the settings while referring to 3.3.1 Frequency Measurement.

2. Press the OUTPUT key; OUT1 and OUT2 will

light up, indicating that the output function is

enabled. OUT1 outputs the frequency numerical record, and OUT2 outputs the current

numerical record.

Page 65

59

Chapter 3 Measurement Procedures

3. The auto-power-off function will be automati-

cally disabled ( goes out).

OUT1

OUT2

REC (Hz)

REC (A)

( OFF)

OFF

OFF

( ON)

4. Determine the range setting from both the

measurement range of the 3290 and that of

the instrument used, such as a recorder.

Instrument

range /DIV

1000 Hz range 10 Hz 20 Hz 50 Hz 100 Hz 200 Hz 500 Hz 1000 Hz

100 Hz range 1 Hz 2 Hz 5 Hz 10 Hz 20 Hz 50 Hz 100 Hz

10 Hz range 0.1 Hz 0.2 Hz 0.5 Hz 1 Hz 2 Hz 5 Hz 10 Hz

*The figures above represent the frequencies per DIV of

the measuri ng ins trument.

10 mV 20 mV 50 mV 0.1 V 0.2 V 0.5 V 1 V

• Make sure measuring instruments connected to

the 3290 have input impedance over 1 M.

• When using the output function, be sure to press

the OUTPUT key and confirm that OUT1 is on.

When OUT1 is off, the output will not reflect the

value for frequency measurement.

• When the 3290 is running off battery power, per-

forming frequency measurements with the current showing O.L. will increase current

consumption and reduce battery life.

• If the OUTPUT key is pressed in the AUTO

range, the frequency range is set to the range in

effect at the time the key is pressed (AUT O goes

out).

• If the HOLD key is pressed, the output value will

also be held.

• If the measurement mode is changed to fre-

quency measurement mode while current measurement records are being output, the 3290 will

continue to output current records. To output frequency measurements, press the OUTPUT key

to cancel current output and edit the output setting.

Page 66

Chapter 3 Measurement Procedures

60

• When “----“ is displayed, the output is 0 V. When

O.L. is displayed, the output is approx. 1.4 V.

• Use the 9445-02 or 9445-03 (EU) AC adapter

(optional) for long-term recording.

• When the AC adapter is used, if the commercial

power line contains a large amount of noise, the

display may show several counts or noise may

be present in the output. In such a case, connect

the ground terminal or the L terminal of the

recorder to the ground.

3.4 Auto-Zero Adjustment Function

The auto-zero adjustment function automatically adjusts

the offset in the internal circuit that results from

temperature characteristics or clamp-sensor

magnetization. This function is used for measurement in

DC A mode and AC+DC A mode. The clamp core is

magnetized when a large DC current is measured or a

powerful magnet is placed close to the clamp core.

1. Fully close the clamps of the sensor and confirm that the reading has stabilized with no

input. Press the 0ADJ key (SHIFT CLEAR

key). “ ” blinks during auto-zero adjustment and stops blinking and remains on upon

completion.

• Perform auto-zero adjustment even if the read-

ing is zero.

• The adjustable range in current measurement

mode is ±450 dgt in the L range and ±45 dgt. in

the H range. If the sensor’s offset exceeds these

ranges, auto-zero adjustment cannot be performed.

• If auto-zero adjustment is performed during cur-

rent measurement or while the reading fluctuates, zero adjustment may not be performed

correctly.

• If the 0ADJ key (SHIFT CLEAR key) is pressed

again during auto-zero adjustment ( is

blinking), zero adjustment will be canceled.

Page 67

61

Chapter 3 Measurement Procedures

3.5 Data Hold Function

Use this function to hold the current reading. “ ” will

light up, and the numerical reading and bar graph will be

held. The data hold function is available in any

measurement mode.

1. Press the HOLD key; the reading and bar

graph will be held.

2. To cancel, press the HOLD key again.

• If the HOLD key is pressed while current mea-

surements are being output, the output will not

be held. While frequency measurements are

being output, the output reflects the reading.

3.6 Changing the Screen Update Rate

The screen update rate is set to twice per second when

power is turned on. This rate may be changed according

to measurement conditions. Every time the SAMPL key is

pressed, the indication changes as shown below.

SLOW

3.6.1 SLOW Mode

If the reading fluctuates rapidly, making it hard to read

during current or frequency measurement, select a slower

screen update rate (approximately once every 3

seconds).

• To meas ure currents of 10 Hz or less, measure-

ment accuracy is guaranteed only when AC+DC

A mode is selected and the measurement

response speed is set to SLOW.

FAST

NORMAL

• During RMS measurement in AC A mode or in

AC+DC A mode, the measurement response

speed (RMS measurement conversion speed)

changes according to the screen update rate

(“ ” lights up for approximately 1 second). In

SLOW mode, the unit symbol “A” blinks slowly.

Page 68

Chapter 3 Measurement Procedures

62

• During RMS measurement in AC A mode or in

AC+DC A mode, measurement response time is

approximately 8 seconds. If there is a transient

change in measurement, some time will be

required for the reading to stabilize.

3.6.2 FAST Mode

This mo de sets the scree n up da t e ra t e t o ap pro x i mat el y 4

times/second during current or frequency measurement. It

is suitable for measurement of abrupt changes such as

starting currents.

When measuring a starting current, press the MAX/MIN

key to use the recording function in order to hold the

maximum value (MAX). This will make measurements

easier to read.

• When the measurement response speed is set

to FAST during measurement of currents below

45 Hz, measurement accuracy cannot be guaranteed.

• During RMS measurement in AC A mode or in

AC+DC A mode, the measurement response

speed (RMS measurement conversion speed)

changes according to the screen update rate

(“ ” lights up for approximately 1 second). In

FAST mode, the unit symbol “A” blinks quickly.

• During RMS measurement in AC A mode or in

AC+DC A mode, a continuous waveform of more

than 200 ms is required to start current measurement. With a shorter waveform, the reading will

indicate a value smaller than the actual value.

Page 69

63

Chapter 3 Measurement Procedures

3.7 Recording Function

Use the recording function to hold the maxi mu m

measurement, minimum measurement, and mean value

of the maximum & minimum.

3.7.1 Measurement Reading

Pressing the MAX/MIN key during current or frequency

measurements activates the recording function. The 3290

saves the maximum measurement (MAX), minimum

measurement (MIN), and mean value (AVE) in internal

memory when the MAX/MIN key is pressed. If the MAX/

MIN key is pressed while the recording function is

activated, the indication changes as shown below. When

MAX, MIN, AVE, or TIME is not displayed, the reading

represents an i nstantaneous value.

The unit for the bar graph is hours.

MAX

Data (MAX, MIN, AVE) will be held while the display is

being switched over. However, if the maximum or

minimum data is updated in the meantime, the data

values will be updated.

When the recording function is activated, the auto power

off function is disabled ( off).

The mean value (AVE) is calculated by the following

equation:

Mean Value = [(Maxim um + Mini mu m)/ 2]

If, after PEAK mode is selected using the PEAK/Hz key,

the recording function is activated and an instantaneous

value (no indicator) is selected, the transitional peak

values can be viewed.

MIN

AVE TIME

Instantan

eous

value

(No indicator)

Page 70

Chapter 3 Measurement Procedures

64

3.7.2 Display of Elapsed Time

When the MAX/MIN key is pressed to activate the

recording function, measurement of elapsed time will

begin. The elapsed time is displayed when “TIME” is on.

The digital readout can display a maximum of 99 hours 59

minutes. Each block of 100 hours is indicated by the

illumination of successive bar graph segments. An

elapsed time of up to 2099 hours 59 minutes can be so

indicated.

When the second segment lights up, 100 hours have

elapsed. When the 21st segment lights up, 2000 hours

have elapsed.

3.7.3 Interrupting the Recording Function

Press the HOLD key to interrupt the recording function.

“ ” will light up, and the elapsed time will stop

incrementing. While the recording function is interrupted,

data is not updated even if the clamp sensor is

disconnected from the conductor. While the recording

function is interrupted, the readings can be changed using

the MAX/MIN key. When the HOLD key is pressed again,

“ ” will disappear and recording will resume.

3.7.4 Clearing Recor ded Data

To clear data while the recording function is activated,

press the CLEAR key.

Page 71

65

Chapter 3 Measurement Procedures

3.7.5 Disabling the Recording Function

To disable the recording function, press the MODE key

during current or frequency measurement. If the recording

function is disabled, the auto power off function will be

enabled ( lights up). However, if the output function

is on, the auto power off function will not be enabled.

• When minimum and average data is required,

start the recording function during measurement.

If the recording function is started when there is

no input, the minimum measurements always

show zero. To end the recording, press the

HOLD key, then end measurement. If the clampon sensor is disconnected from the circuit to be

measured before the recording function is

ended, the minimum measurement will become

zero.

• The data will be lost when power is turned off.

• If the recording function is started in the AUTO

range, the measurement range will be set to the

range in effect at the time the MAX/MIN key is

pressed.

• Use the 9445-02 or 9445-03 (EU) AC adapter

(optional) for long-term recording. If the 3290 is

powered by batteries, press the B.CHECK key

(SHIFT MAX/MIN key and check the remaining battery power before starting measurement.

Page 72

Chapter 3 Measurement Procedures

66

3.8 Measurement Method Switching

Function

In AC A mode, the measurement method is selectable

between true rms measurement (RMS) and average

rectified rms indication (MEAN). RMS provides accurate

measurement of distorted waveforms. MEAN provides

accurate measurement of sine waves that are not

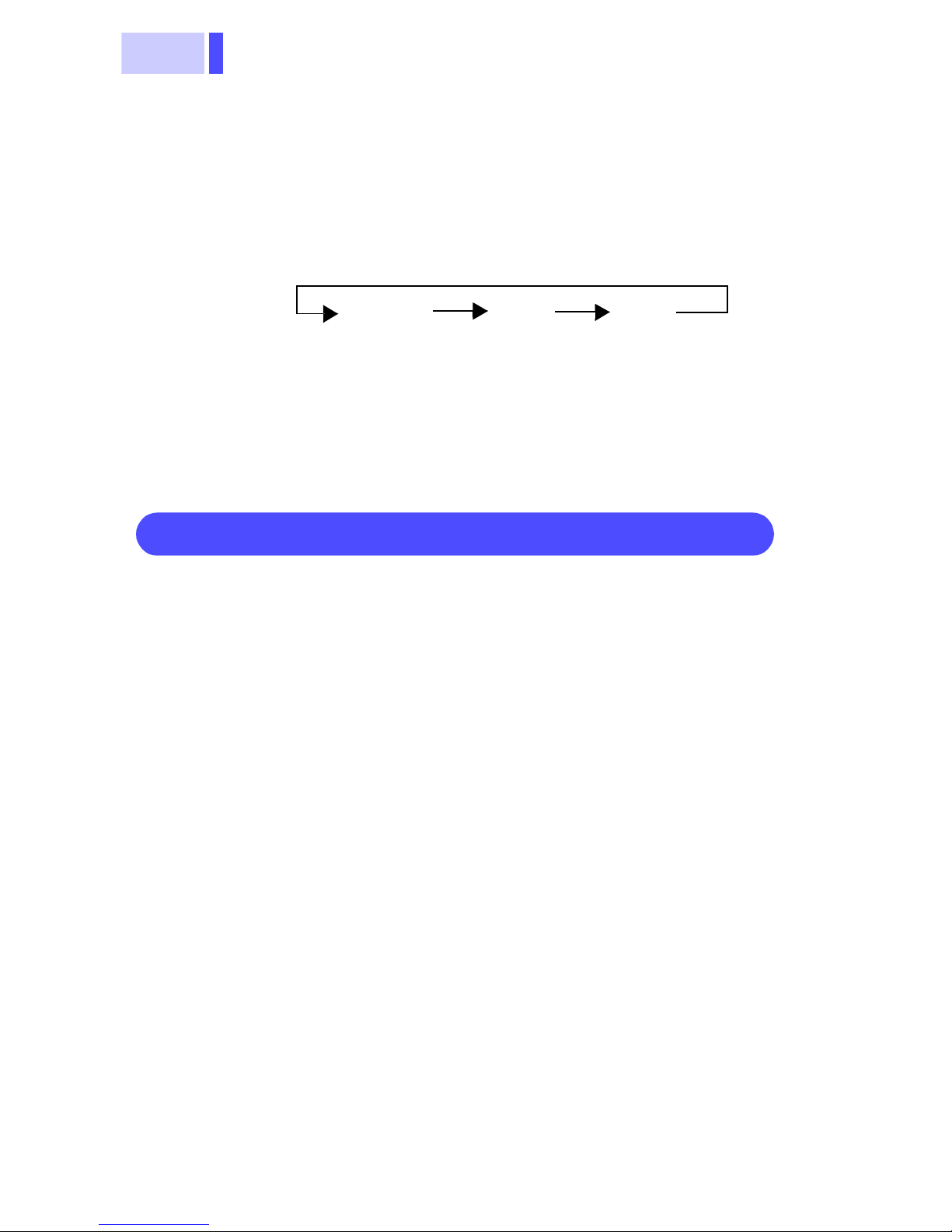

distorted. Press the RMS/MEAN key (SHIFT