Page 1

3283-20

Instruction Manual

CLAMP ON LEAK HiTESTER

June 2015 Edition 1

3283C981-00 15-06H

EN

Page 2

Page 3

Contents

Introduction .........................................................................1

Checking Package Contents .............................................1

Safety Information ..............................................................2

Operating Precautions .......................................................7

1 Overview 11

1.1 Overview and Features .................................11

1.2 Parts and Functions ......................................13

1.3 Liquid Crystal Display ..................................15

2 Pre-measurement Preparation 19

2.1 Flow of Measurement ...................................19

2.2 Installing/Replacing the Battery ..................20

2.3 Inspection Prior to Use .................................23

2.4 Attaching the Hand Strap .............................24

3 Performing Measurements 25

3.1 Measuring Leakage Current .........................25

Locating an insulation failure ....................................28

Selecting the measurement range ............................29

Setting a slower display update rate (SLOW) ...........30

Setting a faster display update rate (FAST) ..............30

Measuring an intensely uctuating load current .......31

Obtaining bar graph displays (BAR GRAPH) ...........32

Displaying the frequency (Hz) ...................................33

Measuring load current .............................................34

3.2 Reducing Noise

(Filter Function – FILTER) .............................35

3.3 Hold Data (Data Hold Function – HOLD) .....36

3283C981-00

i

Page 4

Contents

3.4 Checking Maximum, Minimum and

Average Values

REC) ...................................................................37

Bar graph displays (BAR GRAPH) ...........................39

3.5 Limiting Battery's Power Consumption

(Auto power-off function – APS) ..................41

3.6 Disabling the Buzzer .....................................42

(Recording Function –

4 Specications 43

4.1 MeasurementSpecications ........................43

AC current: Amperes rms (display of true rms) .........44

Frequency Hz ..........................................................45

4.2 GeneralSpecications .................................45

5 Maintenance and Servicing 49

5.1 Repair, Inspection and Cleaning ..................49

5.2 Troubleshooting ............................................51

5.3 Error Displays ................................................52

5.4 Message Displays .........................................52

ii

Page 5

Introduction

Introduction

Thank you for choosing the Hioki 3283-20 Clamp On Leak HiTester.

To ensure that your instrument performs as designed over the long

term, please handle this instruction manual carefully and keep it

handy for future reference.

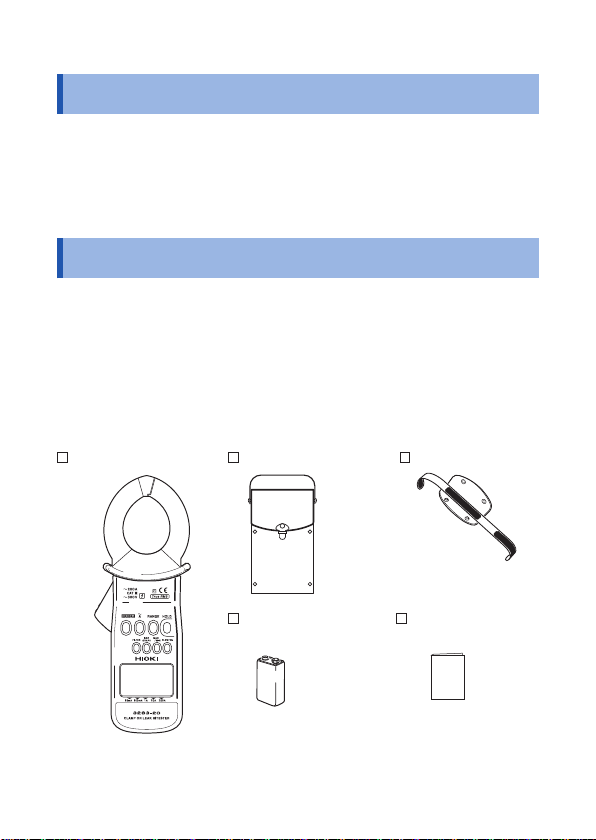

Checking Package Contents

Once you have received the instrument, verify that it has not suffered

any damage during shipment before using it. If you discover any

damage or nd that the instrument does not operate as stipulated in

its specications, please contact your authorized Hioki distributor or

reseller.

Verify that the packaging includes all contents.

3283-20 9399 Carrying Case Hand Strap

6LR61 Alkaline Battery

× 1

Instruction Manual

1

Page 6

Safety Information

Safety Information

The 3283-20 has been designed and tested in accordance with the

IEC 61010 safety standard and shipped in a safe state. However,

failure to adhere to the precautionary information and follow the

instructions provided in this manual may render safety-related

functionality provided by the instrument inoperable.

Before using the instrument, be sure to carefully read the following

safety information.

DANGER

Improper use of the instrument may result in bodily

injury or equipment damage. Read this instruction

manual carefully and ensure that you understand its

contents before operating the instrument.

WARNING

Electricity poses a number of hazards, including electric

shock, overheating, fire, and arc discharge (caused

by a short). Individuals using an electrical measuring

instrument for the first time should be supervised

by a technician who has experience in electrical

measurement.

Protective gear

WARNING

To avoid electric shock when measuring live lines,

wear appropriate protective insulation gear and

adhere to applicable laws and regulations.

2

Page 7

Safety Information

Safety-related notations

This manual classifies safety information on the basis of the

severity of the associated risk and hazard level using the following

categories.

DANGER

Indicates an imminent hazard that could lead to serious

injury or death.

WARNING

CAUTION

IMPORTANT

*

Indicates a hazard that could lead to serious injury or

death.

Indicates a hazard that could lead to minor injury or

that could be expected to result in equipment or other

damage.

Indicates information or content that is especially

important to keep in mind when operating the instrument

or performing maintenance work.

Indicates a high-voltage hazard.

Warns that failure to verify safety or improper use of the

instrument could lead to electric shock, burns, or death.

Indicates an action that you must refrain from performing.

Indicates an action that you must perform.

Indicates that there is additional information below.

3

Page 8

Safety Information

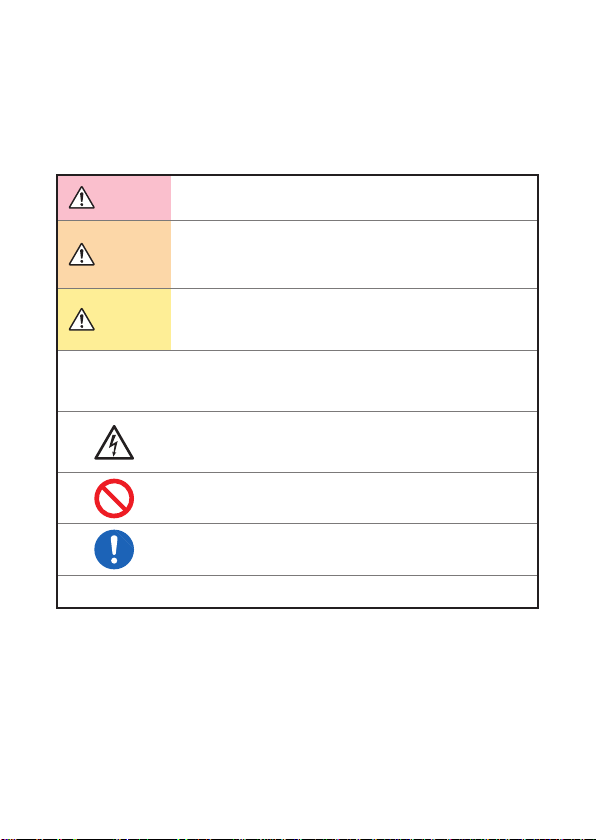

Symbols displayed on the instrument

Indicates the need for caution or a hazard.

When this symbol is displayed on the instrument, refer to the

corresponding section of the instruction manual.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates that the instrument may be connected to or

from a live circuit.

Indicates a double/reinforced-insulated device.

Symbols related to standards

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Indicates that the product conforms to regulations set out by the

EC Directive.

disconnected

Screen display

This instrument uses the following screen displays.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

1 2 3 4 5 6 7 8 9 0

4

Page 9

A different display is used in the case below.

Over-range indication (p. 17).

Other notations

Safety Information

HOLD

(

Bold text is used to indicate language used on keys and other

Bold

)

controls.

[ ] Language from the screen is enclosed in brackets ([ ]).

Accuracy

We dene measurement tolerances in terms of rdg. (reading) and

dgt. (digit) values, with the following meanings:

(Reading or displayed value)

The value currently being measured and indicated on the

rdg.

measuring instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument,

dgt.

i.e., the input value that causes the digital display to show a “1”

as the least-signicant digit.

5

Page 10

Safety Information

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Never use a measuring instrument whose measurement

category is lower than the location in which it will be

used. Doing so may result in a serious accident.

• Never use a measuring instrument with no category

labeling in a CAT II to CAT IV measurement category.

Doing so may result in a serious accident.

The 3283-20 conforms to the safety requirements for CAT III (300 V)

measuring instruments.

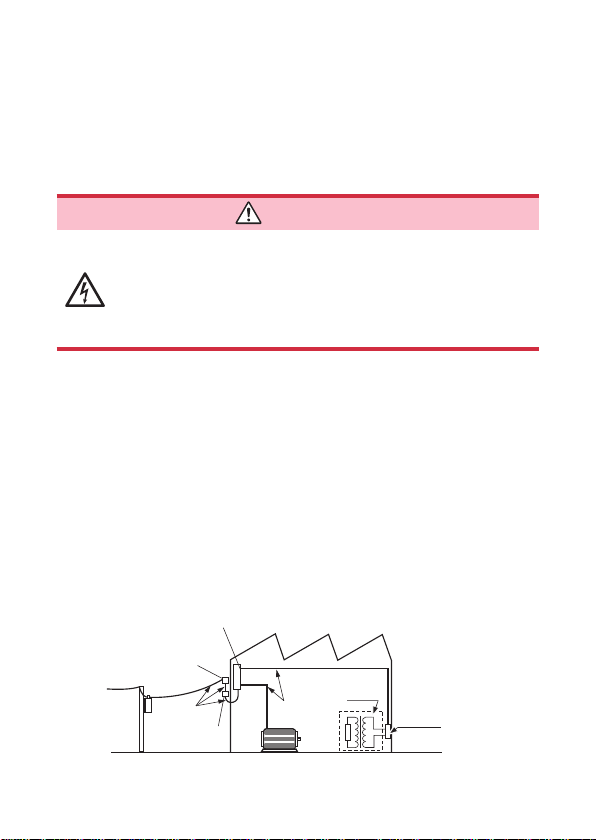

CATⅡ: When directly measuring the electrical outlet receptacles

of the primary electrical circuits in equipment connected

to an AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT Ⅲ: When measuirng the primary electrical circuits of heavy

eqiupment (fixed installations) connected directly to the

distribution panel, and feeders from the distribution panel

to outlets

CAT Ⅳ: When measuring the circuit from the service drop to the

service entrance, and to the power meter and primary

overcurrent protection device (distributi o n pa n e l )

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Internal wiring

CAT III

Fixed installation

CAT II

T

Outlet

6

Page 11

Operating Precautions

Operating Precautions

Please read the following precautions to ensure that you can use

the instrument safely and fully utilize its functionality.

Checking the instrument before use

Verify that the instrument operates normally to ensure that no

damage occurred during storage or shipping. If you find any

damage, contact your authorized Hioki distributor or reseller.

Installation

WARNING

Installing the instrument in inappropriate locations may

cause a malfunction of instrument or may give rise to an

accident. Avoid the following locations.

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or

charge

• Near induction heating systems (such as high-frequency

induction heating systems and IH cooking equipment)

• Susceptible to mechanical vibrations

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

electrostatic

7

Page 12

Operating Precautions

Handling of the instrument

DANGER

• Do not input a voltage or current in excess of the

ratings indicated on instrument labeling or the

measurement range listed in the specifications.

Doing so may cause damage to, or heating of, the

instrument, leading to bodily injury.

• The maximum measurement current varies with the

frequency, and the current that can be measured

continuously is limited. Operating the instrument at

less than this limitation is referred to as derating.

Do not measure currents in excess of the derating

curve. Doing so may result in instrument damage or

malfunction, re, or burns due to sensor heating.

• To avoid short circuits and potentially life-

threatening hazards, never attach the clamp to a

circuit that operates at more than 300 V AC rms.

• Be sure to connect the instrument to the secondary

side of circuit breakers. In the event of a short, this

side of the circuit breaker will be protected from any

short-circuit current by the breaker. The primary

side of circuit breakers is characterized by high

current capacity, and any short-circuit could result

in damage to the instrument or other equipment.

WARNING

To avoid electric shock, do not approach high-voltage

equipment or wiring when taking measurements

using a transformer's ground wire. If measurement

is difficult because the ground wire is located close

to an exposed high-voltage conductor, reroute the

ground wire before measurement.

8

Page 13

Operating Precautions

CAUTION

• Be careful to avoid dropping the instrument or otherwise

subjecting them to mechanical shock, which could

damage the mating surfaces of the jaw and adversely

affect measurement.

• Do not place foreign objects between the mating faces of

the jaw or insert foreign objects into the gaps of the jaw.

Doing so may worsen the performances of the sensor or

interfere with clamping action.

• It may not be possible to accurately measure electrical circuits

that have a superposed DC component.

• The

indicator lights up when the remaining battery capacity

is low. In this case, the instrument's accuracy is not guaranteed.

Replace the battery immediately.

Precautions when transporting the instrument

When shipping the instrument, handle it with care so as to avoid

damage due to vibration or mechanical shock.

9

Page 14

Operating Precautions

10

Page 15

Overview

1

1.1 Overview and Features

The 3283-20 is designed for wide-range measurement of current

in live circuits, from very small leak currents up to load currents of

200 amperes. The jaws are made of material with high magnetic

permeability to minimize adverse effects from external magnetic

elds and error due to the position of the conductor measured,

thus raising accuracy.

High-sensitivity ranges with 10 mA full scale

Accurate measurement even of minute leak currents (resolution

10 μA).

Extensive measurement range

Five ranges in a 10 mA to 200 A full scale, for measurement over

an extensive range.

Built-in microcomputers give multifunctionality

SLOW, MAX and MIN are just some of the functions offered by

this compact, multifunctional instrument.

Displays true RMS values

Packs true-rms conversion circuits for accurate measurements

unaffected by leak current distortion.

Filter functions

The widespread use of switching power supplies and equipment

incorporating inverter technology can cause high-frequency

11

Page 16

Overview and Features

components to be superimposed on leak current waveforms.

The lter functions allow measurement of two kinds of leak

current: the kind caused by insulation faults and the kind that

contains high-frequency components.

Minimized effects from external magnetic elds and

conductor position

The jaws are made of material with high magnetic

permeability, allowing precise measurement near to

transfo r me r s, e l ec t r i c m oto r s a nd ot h er s o urces of magnet i c

elds. And error due to conductor cable position is extremely

low, so that even if the i ns trument is use d as a r e si du al

current transformer, the residual current characteristics are

low and measu re m ent a c c ur ac y is g o o d.

Low power consumption

Rated power: 100 mVA

Approximately 40 hours of continuous operation on single

layered-type manganese dry cell batter y (6F22)

12

Page 17

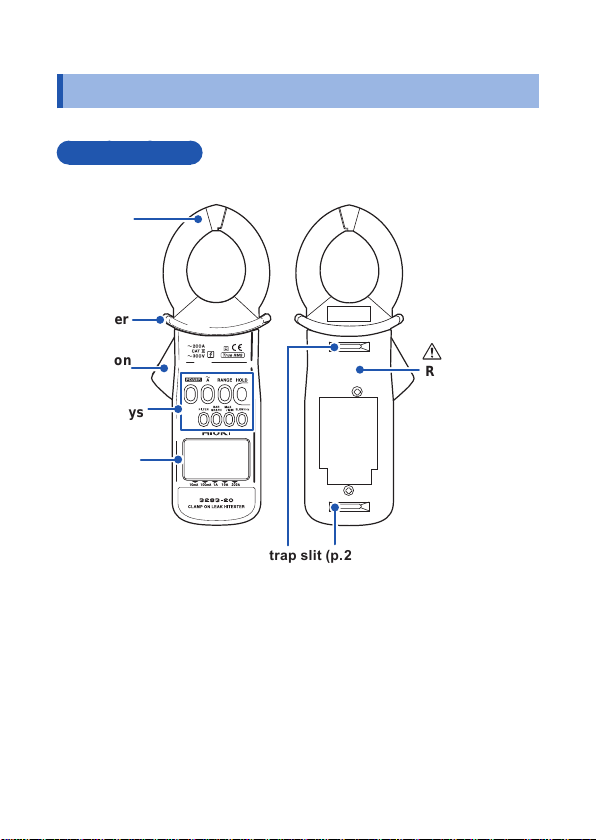

1.2 Parts and Functions

Front and rear

Jaw

Barrier

Parts and Functions

Operation

lever

Control keys

(p. 14)

LCD

display

(p. 15)

Rear cover

(p. 20)

Strap slit (p. 24)

13

Page 18

Parts and Functions

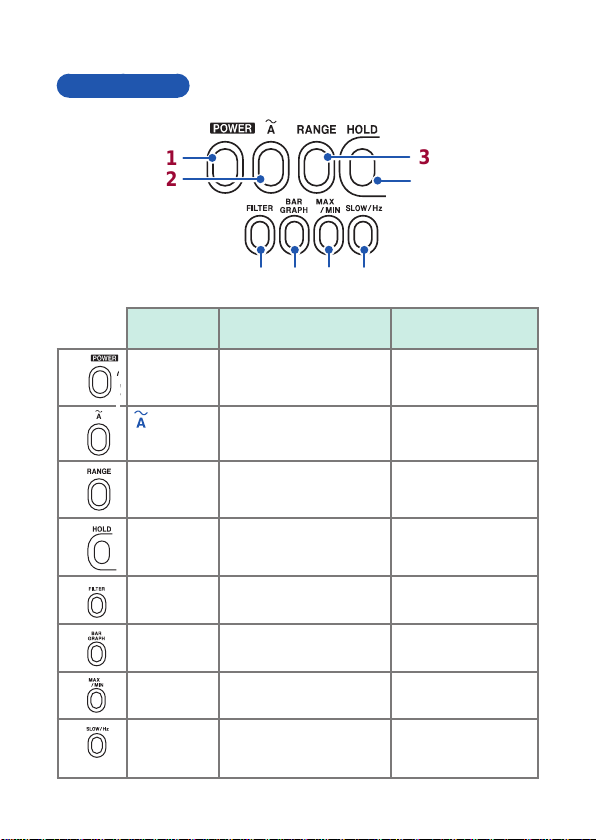

Control keys

1

2

5 6

Key Normally

1

2

3

4

5

6

7

8

POWER key Turns the power on/off –

key

RANGE key Switches the range

HOLD key

FILTER key Turns the lter function

BAR

GRAPH key

MAX/MIN

key

SLOW/Hz

key

Turns the recording

function off (p. 38)

(p. 29)

Turns the data hold

function on/off (p. 36)

on/off (p. 35)

Switches the bar graph

display (p. 32)

Turns the recording

function on (p. 37)

• Setting a sl owe r d is pl ay

update rate (p. 30)

• Freq. measurement (p. 33)

7

8

3

4

Power turned on while

holding key down

–

Disables the buzzer

(p. 42)

Cancels the auto

power-of f (APS)

function (p. 41)

–

–

–

–

14

Page 19

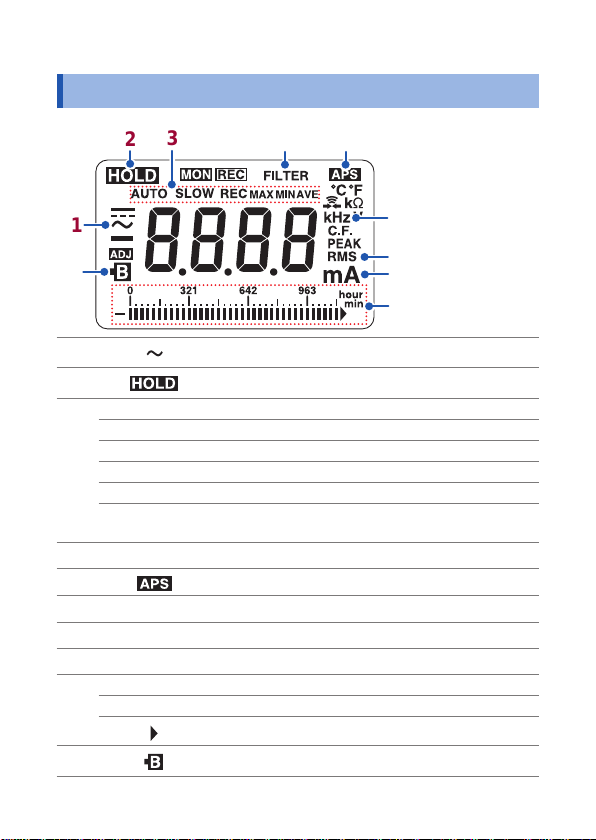

1.3 Liquid Crystal Display

3

2

4

5

Liquid Crystal Display

10

1

1

2

3

4

5

6

7

8

9

10

6

7

8

9

AC measurement (p. 25)

Hold data (p. 36)

AUTO

SLOW Update display approx. 1 time/3 seconds (p. 30)

REC Recording function is on (p. 37)

MAX Maximum value (p. 37)

MIN Minimum value (p. 37)

AVE

FILTER Filter function is enabled (p. 35)

Hz Frequency (p. 33)

RMS Tr ue root- mean- square value (p. 26)

mA Current (A, mA)

hour 1 hour/segment (bar graph)

min 1 minute/segment (bar graph)

Auto ranging is enabled (p. 29)

Average value

(p. 37)

Auto power-off function is enabled (p. 41)

Over-range indication (bar graph)

Batter y depleted (p. 16)

= (maximum value + minimum value)/2

15

Page 20

Liquid Crystal Display

Battery remaining power display

When the power is turned on, all the LCD's segments light up.

Then the model name is displayed, and the bar graph shows the

battery power for 1 second.

Bar graph display with fresh

battery

Power shut-off

16

If the battery

is zero,

the buzzer will sound three

beeps.

When

instrument's accuracy cannot

be assured.

When the battery voltage drops below a

certain level after

will be shut off automatically to protect the

internal memory. [bAtt] and [Lo] will be

displayed to indicate this.

When these are displayed and the power

has been shut off, replace the exhausted

battery with a new one.

remaining power

will light up and

is lighted, the

lights, the power

Page 21

Over-range indication

Liquid Crystal Display

[O.L.] will be displayed if the measured

current or frequency is beyond the

measurement limit.

When this display occurs, select an

appropriate range.

17

Page 22

Liquid Crystal Display

18

Page 23

Pre-measurement Preparation

2

2.1 Flow of Measurement

Before using the instrument, be sure to read

Preparing and connecting-up

Install the battery (p. 20).

Do pre-use checks (p. 23).

(As necessary)

Attach the hand strap (p. 24).

Measuring

Turn the power on.

Clamp the conductor to be measured.

(As necessary)

Select the measurement range (p. 29).

Reduce noise (p. 35).

Ending

Turn the power off.

“Operating Prec autions” (p. 7)

19

Page 24

Installing/Replacing the Battery

2.2 Installing/Replacing the Battery

Before using the instrument for the rst time, install a layered-type

alkaline battery (6LR61) or a layered-type manganese dry cell

battery (6F22). Also, before doing measurement, check that there

is adequate remaining power in the battery. If there is not, replace

the battery.

WARNING

• Battery may explode if mistreated. Do not short

circuit, recharge, disassemble or dispose of in re.

• To avoid electric shock, remove the jaws from the

object to be measured, and remove the rear cover,

before replacing the battery.

• Also, before using the instrument after replacing

the battery, fasten the rear cover with its screws.

• To avoid damage to the instrument or electric

shock accidents, use only the screws that came

with the instrument to fasten the rear cover in

place. If you lose or damage the screws, contact

your authorized Hioki distributor or reseller.

• Handle and dispose of batteries in accordance

with local regulations.

20

Page 25

Installing/Replacing the Battery

CAUTION

Heed the following instructions to avoid battery

performance drop or leakage.

• Pay attention to the polarity markings "+" and "–", so

that you do not insert the battery the wrong way around.

• Do not use a battery beyond its recommended use period.

• Do not leave a depleted battery

• Be sure to replace it with a battery of the specied type.

• Remove the battery and store it if the instrument will

not be in use for a long time.

To avoid damage to the instrument, do not screw the rear

cover screws in too tightly. Torque of about 0.5 N•m is

recommended.

• When appears, the battery is exhausted and accuracy is

not assured. Replace the battery as early as possible.

• Turn the power off before replacing the battery.

• When inst al li ng t he n ew b at t ery, make sure that the ba t te ry

snaps are se c ur el y c o nn ec t ed to i t . If a s na p is l o o se,

adjust it so th at i t is s ec u re ly connect ed. I f t he b attery i sn't

securel y c o nn ec te d, t h e po wer m ay not come on or may

turn of f du r i ng u se.

inside the instrument.

21

Page 26

Installing/Replacing the Battery

Rear

3, 8

4, 7

−

+

5, 6

Prepare the following:

1

• A layered-type alkaline battery

(6LR61) or a layered-type

manganese dry cell battery

(6F22)

• Phillips screwdriver

Turn the instrument's power

2

off.

Loosen the rear cover's two

3

fastening screws, using the

Phillips screwdriver.

Remove the rear cover.

4

Remove the old battery,

5

taking care not to pull on

the battery snap cords.

Firmly install the new

6

battery to the battery

snaps. Be sure to orient the

polarity correctly.

Fasten the rear cover.

7

Screw in the fastening

8

screws to fasten the rear

cover.

22

Page 27

Inspection Prior to Use

2.3 Inspection Prior to Use

Before using the instrument for the rst time, inspect it carefully

to ensure that no damage occurred during shipping. If damage

is evident, or if it fails to operate according to the specications,

contact your dealer or Hioki representative.

Exterior appearance check

Check item Action

• Any breakage or cracks in

the instrument's exterior?

• Any internal circuits

exposed?

Checks when turning on the power

Check item Action

Sufcient bat tery power

remaining?

All LCD segments are

displayed?

Check visually.

If there is any of this damage, the

instrument will not measure correctly. Do

not use the instrument in this condition.

Have it repaired rst.

If the in the left side of the LCD

display lights or if the power is shut off

soon after being turned on, measurement

accuracy cannot be assured and you must

immediately replace the battery with a new

one (p. 20).

Check that all of the LCD's segments light

up (p. 15).

If any of the segments does not light, you

must have the instrument repaired.

23

Page 28

Attaching the Hand Strap

2.4 Attaching the Hand Strap

Strap slits on the back of the instrument can be used for attaching

the included hand strap. Use the hand strap to help prevent

accidental dropping of the instrument.

CAUTION

Attach the strap securely, by inserting it through the

strap slits on the instrument. If the strap is not securely

attached, the instrument may fall and be damaged.

24

Page 29

Performing Measurements

3

3.1 Measuring Leakage Current

DANGER

To prevent electric shock, do not touch any part

beyond the barrier during use (p. 13).

1

Clamp the conductor at the center of the jaw.

2

To measure the ground wire of a circuit, clamp the ground wire only.

(See 1 in the gure)

To measure all the wires of a circuit, clamp them all together in a

bundle. (See 2 in the gure)

Clamp all three of the circuit's

wires in a bundle

Single-phase 3-wire circuit

2

Ig: Leak current

lg

Ground wire

1

2

equipment

Load

25

Page 30

Measuring Leakage Current

3-phase 3-wire circuit

Clamp all three of the circuit's wires in a bundle

2

lg

Load

equipment

1

2

Ground wire

1

Ground wire

• To measure a single-phase 2-wire circuit, clamp both of the

circuit's wires together.

• To measure a 3-phase 3-wire circuit, clamp all 3 of the

circuit's wires bundled together.

• To measure a 3-phase 4-wire circuit, clamp all 4 of the circuit's

wires bundled together. If that is not possible, carry out the

measurement on the equipment's ground wire.

The effective value (RMS) of the leak current

will be shown on the digital display .

26

Page 31

Measuring Leakage Current

• Do not input current that exceeds the current range's

maximum continuous input.

• Measurement may not be accurate in the cases below.

(1) If there is large current (of about 100 A) owing through a

nearby electric line.

(2) If you use the instrument to measure the waveforms on the

secondary side of an inverter, or other special waveforms.

(3) If the jaws are not fully closed.

In cases where the wires are thick, such as with clamping of a

3-phase cable, always make sure that the jaws are fully closed.

When the jaws are not fully closed, error occurs in the measured

values and accuracy cannot be assured.

• Note that a value of several tens of amperes may be displayed

when the jaws are opened or closed or when the current

range is changed, but this is not an error. Simply wait a little

while for the display to return to zero. Or start measurement

before it returns to zero – there will not be any adverse

effects.

• In cold areas, the display may not go to zero when the jaws are

taken off the conductor. This will not affect accuracy, provided that

you are measuring current of or above the 1 mA that is the bottom

limit of the guaranteed accuracy range.

• This instrument is designed for measuring electricity lines

up to CAT III 300 V (voltage to ground). However, in the

exceptional case of a 3-phase 3- or 4-wire line, or similar

line, whose neutral point is grounded ("Y" connection or star

connection), the instrument can be used on lines of up to 500

V line voltage (approx. 289 V voltage to ground) – but only in

such a case.

27

Page 32

Measuring Leakage Current

Locating an insulation failure

For a transformer, rst measure the ground wire to determine

the overall circuit leak current (see 1 in the gure), then use the

variation in the leak current to diagnose the presence or absence

of leakage.

If you diagnose leakage to be present, use bundled measurement

of all the wires to locate it. Start from the power source and work

toward the load.

• Suppose an insulation fault in the wiring has occurred at (1)

in the gure. It will be possible to detect the leak current with

bundled measurement at position 2, but not at 2'.

• Suppose an insulation fault in the load equipment has occurred at

(2) in the gure. It will be possible to detect the leak current with

bundled measurement at position 3, but not at 3'.

• To detect intermittent leak current (occurring only when a certain

piece of equipment is operating), the use of a memory recorder

will be helpful.

Single-phase

3-wire circuit

2

2'

3 3'

Ground wire

28

1

lg

(1)

Load

equipment

Load

equipment

(2)

Page 33

Measuring Leakage Current

Selecting the measurement range

You can set auto or manual ranging.

• Auto ranging The optimal range for the measured values

is set automatically.

• Manual ranging Setting is xed to a particular range.

With the frequency display, only auto ranging is available.

Auto ranging

Measurement will begin with auto ranging

when the power is turned on.

[AUTO] lights up (initial setting)

Manual ranging

10 mA ([AUTO] goes out)

100 mA

1 A

Bars will appear above the

currently selected range.

The gure above shows the

100 mA range selected.

10 A

200 A

Auto ranging ([AUTO] lights up)

29

Page 34

Measuring Leakage Current

Setting a slower display update rate (SLOW)

If the displayed current value uctuates rapidly and is hard to read, you

can set a slower update rate (approx. 1 time/3 seconds) by pressing the

SLOW/Hz key, to make the value easier to read.

[SLOW]

[Hz]

[RMS]

• Setting [Hz] or [RMS] will return the display to the normal update

rate.

• With the frequency display, the update rate cannot be changed.

Setting a faster display update rate (FAST)

A faster rate of approximately 4 times per second can be set for

the display update. This is useful for example to measure load

currents with intense uctuations and in similar applications.

FAST

NORMAL

(Split-second display each

time key is pressed)

Press twice in

succession

If you switch to [SLOW] display while the instrument is in the fast

mode, the display update rate will be the same as [NORMAL]

(approx. 2 times/second).

30

Page 35

Measuring Leakage Current

Measuring an intensely uctuating load current

First set the FAST display update rate and set the appropriate

range using the RANGE key. Then do the measurement.

FAST

NORMAL

1

Press twice in

succession

(Split-second display each

time key is pressed)

2

Set to a xed current range.

• If you don't know the magnitude of the current to be

measured, select the 200 A range.

• Using the recording function to retain the maximum value will

make it easier to take readings (p. 37).

31

Page 36

Measuring Leakage Current

Obtaining bar graph displays (BAR GRAPH)

You can have the current range displayed as a bar graph.

The bar graph will show the rms value of the measured current.

The bar graph display update rate will be FAST (approx. 4

times/second).

Current range display

The flas hing s egm ent in t he bar g rap h indi cat es th e full - sc ale

position.

Bar-graph display

32

Page 37

Measuring Leakage Current

Displaying the frequency (Hz)

When [SLOW] is displayed:

[SLOW]

[Hz]

[RMS]

The frequency of the current being measured

will be displayed.

If there is no input, or input is lower than 30 Hz,

"----" will be displayed.

• Enable the lter function when conducting measurement in

the cases below (p. 35).

(1) If meaningless data is displayed due to noise.

(2)

If you use the instrument to measure the waveforms on the

secondary side of an inverter, or other special waveforms.

• The instrument may not be able to perform measurement in

the cases below.

(1)

If the input current is 1/10 or less of the current range (fullsc ale).

(2)

If you measure high frequencies with the lter function

enabled.

• The frequency range is set automatically. If you press the

RANGE key, only the current range will be changed.

33

Page 38

Measuring Leakage Current

Measuring load current

To measure load current, clamp just one wire of the conductor.

The measurement will not be possible if you clamp both wires of a

single-phase cable or all 3 wires of a 3-phase cable.

OK

• The instrument may not be able to measure certain special

waveforms, for example on the secondary side of an inverter.

• Depending on the magnitude and frequency of the input

current, resonance may cause the jaws to emit noises, but

this will not affect the measurement.

• If you don't know the magnitude of input current, disable the

lter function and begin measurement with auto ranging or

with the 200 A range set.

NO

NO

34

Page 39

Reduci ng Noise ( Filter Func tion – FILTER)

20

1 10 100 1000 10000 100000

3.2 Reducing Noise

(Filter Function – FILTER)

The widespread use of switching power supplies and equipment

incorporating inverter technology can cause high-frequency

components to be superimposed on leak current waveforms. Use the

lter function to eliminate unwanted high-frequency components.

FILTER OFF FILTER ON

The frequency bandwidth with the lter function enabled is limited to

approximately 180 Hz (-3 dB), comparable to the frequency bandwidth

for an ordinary leakage breaker. It is recommended that the lter

function be used when analyzing leakage breaker operation.

10

FILTER: OFF

0

-10

-20

Amplitude [dB, 0 dB = 1 V ]

-30

Frequency bandwidths (with 10 mA current range used)

FILTER: ON

Frequency [Hz]

35

Page 40

Hold Dat a (Data H old Funct ion – HOL D)

3.3 Hold Data (Data Hold Function –

HOLD)

Use this to freeze the displayed data (put it on hold) for easy

reading.

OFF ON

36

Page 41

Check ing Max imum, Min imum and Average Values (Recor ding Funct ion – REC)

Checking Maximum, Minimum and

3.4

Average Values

Use the recording function to display the maximum/minimum measurement

value, the average of the maximum and minimum, or the instantaneous value .

(Recording Function – REC)

1

Select the current range.

2

The maximum, minimum, average or

instantaneous value for the period

from when the MAX/MIN key was last

pressed up to the present moment will

be displayed. The other data will be

retained in the internal memory. ([REC]

will ash)

[MAX], [MIN] and [AVE] displays Measurement value displayed

[MAX] Maximum value

[MIN] Minimum value

[AVE]

None Instantaneous value

Average value = (maximum value +

minimum value)/2

Press the MAX/MIN key

while current is being

measured

.

• Pressing the MAX/MIN key during auto ranging ([AUTO])

xes the range at the current setting.

• When you use the recording function, auto power-off will be

turned off automatically.

37

Page 42

Check ing Max imum, Min imum and Average Values (Recor ding Funct ion – REC)

3

Halt the recording

function.

(

4

lights, [REC] lights up)

Maximum value [MAX]

Minimum value [MIN]

Average va lue [AVE]

Instantaneous value

5

Turn the recording

function back on.

(

Turning the recording function off

The maximum, minimum or average value

will be cleared. ([REC] will go out)

goes out, [REC] a sh es)

38

Page 43

Check ing Max imum, Min imum and Average Values (Recor ding Funct ion – REC)

• The elapsed time count will stops for as long as lights

steady.

• Momentary power loss and power surges cannot be detected in

this mode.

• The maximum, minimum or average value will be cleared when

the power is turned off.

• The duration that the recording function can be used for depends

on the remaining battery capacity. Use a new lay ered-type alkaline

battery (6LR61) when using it for a long duration.

• The lowest frequency that can be displayed is 30.0 Hz.

• If you clamp the conductor after enabling the recording function,

there will be no input and so the minimum value will be zero. To

prevent this, clamp the conductor before pressing the MAX/MIN

key to enable the recording function.

• If you take the jaws off the conductor with the recording

function still enabled, the input will stop and so the minimum

value will be zero. To prevent this, press the HOLD key to halt

the recording function before taking the jaws off the object.

Bar graph displays (BAR GRAPH)

You can switch the bar graph between different displays.

RMS value display

(instantaneous value)

Elapsed time (hou rs) [hour]

Elapsed time (minut es) [min]

Current range display

When you set one of the elapsed time displays, a segment in the

bar graph will ash to indicate the time that has elapsed since the

MAX/MIN key was last pressed.

39

Page 44

Check ing Max imum, Min imum and Average Values (Recor ding Funct ion – REC)

When [min] is displayed at the right end of the bar graph:

1 segment in the bar graph represents 1 minute. The segment

for the currently elapsing minute ashes, and when the minute

has elapsed, that segment stops ashing and lights steady. The

segments do this one after the other, starting from the left end of

the graph and going rightward. When all the bar graph's segments

are lighted steady, 30 minutes have elapsed. From then on, the

segments will once more ash one by one from left to right, to

indicate the elapsing minute, but this time the ashing segment will

go out with each minute that elapses.

When the segments to the left of the ashing segment

are lighted steady:

The number of steady-lighted segments

represents the elapsed time in minutes

(0 to 29).

The example shows the display for

elapsed time = 20 minutes.

When the segments to the right of the ashing segment

are lighted steady:

The number of segments that have

gone out represents the elapsed

time (+ 30) in minutes (30 to 59).

The example shows the display for

elapsed time = 50 minutes.

When [hour] is displayed at the right end of the bar graph:

1 segment in the bar graph represents

1 hour. Up to 59 hours of elapsed time

can be displayed.

The example shows the display for

elapsed time = 1 hour 40 minutes

.

40

Page 45

Limiti ng Batte ry's Po wer Cons umption (Auto power-off f unctio n – APS)

Limiting Battery's Power Consumption

3.5

(Auto power-off function

Use this to limit the battery's power consumption. It turns the power

off automatically if the instrument is not operated for 10 minutes.

The APS function is congured at the factory to enabled (this is the

initial setting). ( lights up)

When APS is enabled, on the LCD display will ash, and a

beep will sound to warn you that the instrument will automatically

turn off in 30 seconds. To continue using the instrument, press any

key other than the POWER key. But note that even so, the power

will be shut of f automatically after another 10 minutes if you leave

the instrument unoperated for that period once more.

• When operating the instrument continuously for a long

duration, disable the auto power-off function in advance.

• Using the recording function disables the APS function.

Disabling the auto power-off function

If the power is on, turn it off.

– APS)

+

When you power up again, the buzzer will beep

twice and the APS function will be disabled.

( goes out)

Auto power-off will be disabled up until the power is turned off.

Be aware of this if the battery is low.

Press these

simultaneously

41

Page 46

Disabling the Buzzer

3.6

Disabling the Buzzer

The buzzer is congured at the factory to enabled (this is the initial

setting). To change this setting, rst turn the power off.

+

When you power up again, the buzzer will beep twice. Then it will be

disabled.

The buzzer will be disabled up until the power is turned off.

Press these simultaneously

42

Page 47

Specications

4

• rdg. (Reading or displayed value)

The value currently being measured and indicated on the measuring

instrument.

• dgt. (Resolution)

The smallest displayable unit on a digital measuring instrument, i.e.,

the input value that causes the digital display to show a “1” as the least-

signicant digit.

4.1 Measurement Specications

Conditions of

guaranteed

accuracy

Diameter of

measurable

conductors

Guaranteed accuracy period:

Guaranteed accuracy period

from adjustment made by

Hioki:

Number of jaw openingclosings:

Temperature and humidity for

guaranteed accuracy:

Battery low indicator

φ40 mm max.

must not be on.

1 year

1 year

Up to 10,000

23°C±5°C (73°F±9°F),

80% RH or less

43

Page 48

Measurement Specications

AC current: A rms (display of true rms)

Range

(accuracy range)

10.00 mA

(1.00 mA to 10.00 mA)

100.0 mA

(10.0 mA to 100.0 mA)

1.000 A

(0.100 A to 1.000 A)

10.00 A

(1.00 A to 10.00 A)

200.0 A

(10.0 A to 200.0 A)

Effect of

conductor position

Effects of ex ternal

magnetic elds

Maximum rated

voltage to ear th

Resolution Accuracy

0.01 mA

0.1 mA

0.001 A

0.01 A

0.1 A

Within ±0.1% rdg. (with any position relative to the

center of the jaw and current under 100 A)

Within ±0.5% rdg. (with current 100 A or higher)

Equivalent of 5 mA, max. 7.5 mA, with external

magnetic eld of 40 0 A/m AC

300 V AC (Measurement Category III)

Anticipated transient overvoltage: 4000 V

FILTER OFF:

45 Hz to 66 Hz:

±1.0% rdg. ±5 dgt.

40 Hz to 45 Hz,

66 Hz to 2 kHz:

±2.0% rdg. ±5 dgt.

FILTER ON:

50 Hz to 60 Hz:

±1.5% rdg. ±5 dgt.

FILTER OFF:

45 Hz to 66 Hz:

±1.5% rdg. ±5 dgt.

40 Hz to 45 Hz,

66 Hz to 2 kHz:

±2.0% rdg. ±5 dgt.

FILTER ON:

50 Hz to 60 Hz:

±2.0% rdg. ±5 dgt.

Maximum

allowable

current

20 A

AC rms,

continuous

(p. 47)

200 A

AC rms,

continuous

(p. 47)

44

Page 49

General Specications

Frequency Hz

Range (accuracy range) Resolution Accuracy

100.0 Hz (30.0 Hz to 99.9 Hz) 0.1 Hz ±0.3% rdg. ±1 dgt.

1000 Hz (95 Hz to 1000 Hz) 1 Hz ±1.0% rdg. ±1 dgt.

The frequency range is set automatically. If you press the RANGE

key in the frequency display mode, only the current range will be

changed.

4.2 General Specications

Auxiliary functions

Recording Maximum ([MAX]), minimum ([MIN]), and

Data hold Puts display on hold

Auto power-off Sounds intermittent beep alert and shuts off

Battery low voltage

power-off

Beep tone ON/OFF

LCD display

Digital indication 2000 counts, displaying values less than or

Bar-graph indication 35 segments

Over-range indication [O.L.] display (using 7 segments); bar-graph

average ([AVE]) value displayable for AC

current and frequency measurement

power automatically approximately 10 minutes

after last key operation (Shut-off can be

delayed or canceled)

When the battery voltage falls below a certain level,

this shuts the power off to prevent malfunctions

equal to 5 counts with a zero

Range display or rms display can be selected

display

45

Page 50

General Specications

Battery low warning

Battery low power- off [bAtt] → [Lo]

Data holding indication

Auto power- off indication

(This indicator lights to indicate the battery

is low. When this is lighted, accuracy is not

guaranteed.)

is displayed (using 7 segments),

then power is shut off

Other functions

Filter functions ON: 180 Hz ±30 Hz (-3 dB) / OFF

Display update rate • Digital indication

Display response time With AC current and frequency: 2.2 seconds

Ranging • For AC current: auto ranging or manual

Circuit dynamic

characteristic

(crest factor)

Dielectric withstand

voltage

Insulation resistance Between jaws and circuitry: 630 k

Operating environment Indoors, Pollution Degree 2, altitude up to

NORMAL 500 ms ±25 ms

(approx. 2 times/second)

SLOW 3 s ± 0.15 s

(approx. 1 time/3 seconds)

FAST 250 ms ±12.5 ms

(approx. 4 times/second)

• Bar-graph indication

250 ms ±12.5 ms (approx. 4 times/second)

or less

(xed) ranging can be selected

• Frequency:

Auto ranging

2.5 max. (max. 1.5 with 200 A range)

Between jaws and hand-held portion:

4.29 kV AC/minute

Ω

or higher

2000 m (6562 ft.)

46

Page 51

General Specications

10 100 1000 10000 100000

Standards Safety: EN61010

EMC: EN61326

Dust-proof, water-proof IP40 (EN60529)

Operating temperature

and humidity

Temperature

characteristics

0°C to 40°C (32°F to 104°F), 80% RH or less

(non-condensing)

In 0°C to 40°C (32°F to 104°F) range: 0.05 ×

accuracy specications/°C

Storage temperature -10°C to 50°C (14°F to 122°F) (non-

condensing)

Power supply Layered-type alkaline battery (6LR61) × 1, or

layered-type manganese dry cell battery

(6F22) × 1

Rated supply voltage: 9 V

Maximum rated power 100 mVA

Continuous operating

time

Approx. 40 hours (when unloaded and using a

layered-type manganese battery (6F22))

Dimensions Approx. 62 mm (2.44″) W × 225 mm (8.86″) H

× 39 mm (1.54″) D

Mass Approx. 400 g (14.1 oz.) (excluding battery)

Produc t warranty period 1 year

Accessories See “Checking Package Contents” (p. 1).

Frequency-dependent derating characteristics

250

200

150

100

Current [A rms]

50

0

Frequency [Hz]

47

Page 52

General Specications

48

Page 53

Maintenance and Servicing

5

WARNING

Touching any of the high-voltage points inside the

instrument is very dangerous.

Customers are not allowed to modify, disassemble,

or repair the instrument. Doing so may cause re,

electric shock, or injury.

5.1 Repair, Inspection and Cleaning

Calibration of the instrument

How often you should calibrate the instrument will depend on the

usage conditions and the environment. Determine a calibration

interval that is suited to your usage conditions and environment,

and request to have calibration done by Hioki.

49

Page 54

Repair, Inspection and Cleaning

Cleaning

CAUTION

If foreign matter gets jammed in the jaw tips, do not

attempt to remove it by forcibly opening/closing the

jaws. Remove it gently with a soft brush or similar.

Foreign matter must be removed, or measurement will

not be accurate. It will also not be accurate if the jaws

are deformed, by foreign matter or other cause. If the

jaws become deformed, contact your authorized Hioki

distributor or reseller.

• To clean the instrument, wipe it gently with a soft cloth

moistened with water or neutral detergent.

• Clean the display area by wiping it gently with a soft dry cloth.

IMPORTANT

Never use solvents containing benzene, alcohol, acetone, ether,

ketone, thinner, gasoline, or similar to clean the instrument. Deformation

or discoloration may result.

Disposal of the instrument

Dispose of the instrument in accordance with local regulations.

50

Page 55

Troubleshooting

5.2 Troubleshooting

If a problem occurs with the instrument, rst carry out the checks

in "Troubleshooting checklist" below. If the problem persists,

contact your authorized Hioki distributor or reseller.

Troubleshooting checklist

Problem Cause Solution

Power will not turn on

Power shuts off

during operation

lights up

lights, followed

by immediate power

shutdown

Power turns off

immediately after it

is turned on

The battery may be low

or depleted.

The battery snap

terminals may be

stretched causing contact

failure.

With the auto poweroff function enabled,

the power is shut off

automatically if the

instrument is not opera ted

for 10 minutes.

The battery may be low

or depleted.

Replace it with a new

batter y (p. 20)

Remove the battery, then

use radio pliers or similar

to readjust the battery

snap terminals.

Check the settings

for the APS function

(p. 41).

Replace it with a new

batter y (p. 20).

Range cannot be

changed

Recording function

([MAX]/[MIN]/[AVE]

display) is operating

– this renders range

change impossible.

Press the

turn off the recording

function. Then change

the range (p. 38).

key to

51

Page 56

Error Displays

Problem Cause Solution

Any of [E.001] to

[E.004] is displayed

The jaws generate

a sound during

measurement

Internal memory may

be damaged.

When large current or

high-frequency current

is measured, resonance

may occur, generating

a sound.

5.3 Error Displays

Have the instrument

repaired (p. 52)

The loudness will depend

on the individual case,

but the sounds will not

affect the measurement.

Error

display

[E. 001]

[E. 002]

[E. 003]

[E. 004]

Checksum error in single-chip

microcomputer's internal ROM.

R/W error in single-chip

microcomputer's internal RAM.

EEPROM checksum error.

Denition Solution

If any of these errors

is displayed in the LCD

display area, repair

is required. Contact

your authorized Hioki

distributor or reseller for

repair.

5.4 Message Displays

Display Denition See page

Battery depleted.

Replace it with a new battery.

52

p.20

Page 57

Message Displays

Display Denition See page

There is abnormality in the internal ROM

or EEPROM data. Have the instrument

repaired.

This is displayed if the measured current

or frequency is beyond the measurement

limit. Select an appropriate range.

When frequency display is set, this

message indicates that there is no input or

that the frequency is under 30 Hz.

p.52

–

p.33

53

Page 58

Error Displays

54

Page 59

13-09

Page 60

Page 61

Page 62

Loading...

Loading...