Page 1

3283

CLAMP ON

LEAK HiTESTER

INSTRUCTION MANUAL

Page 2

Page 3

i

Contents

Introduction 1

Inspection

1

Safety Notes

2

Notes on Use

5

Chapter Summary

11

Chapter 1 Product Outline

13

1.1 Product Outline

13

1.2 Features

13

1.3 Parts and Functions

16

Chapter 2 Measurement Procedure

19

2.1 Preparations

19

2.2 Leak Current Measurement

A

20

2.3 Filter Function FILTER

27

2.4 Data Hold Function

HOLD

28

2.5 Recording Function REC

28

2.6 Auto Power-Off Function

APS

33

2.7 Battery Low Warning

33

2.8 Beep Tone

33

2.9 Fast Mode

34

2.10 Output Function OUTPUT

35

Chapter 3 Battery Replacement

39

Chapter 4 Attaching the Hand Strap

41

Chapter 5 Specifications

43

5.1 Measurement Specifications

43

5.1.1 AC current Arms(true rms indication)

44

5.1.2 Frequency Hz

45

5.2 General Specifications

46

Chapter 6 Troubleshooting

51

Chapter 7 Service

55

Page 4

ii

Page 5

1

__________________________________________________

_____________________________________________

Introduction

Inspection

Thank you for purchasing the HIOKI "3283

CLAMP ON LEAK HiTESTER." To obtain

maximum performance from the product,

please read this manual first, and keep it

handy for future reference.

We have tried to bring this manual as close

to perfection as we could achieve. If

perchance you find any unclear portions,

mistakes, omissions, or the like, we would be

most obliged if you could please notify us of

them via any HIOKI agent, or directly.

When you receive the product, inspect it

carefully to ensure that no damage occurred

during shipping. In particular, check the

accessories, panel switches, keys, and

terminals. If damage is evident, or if it fails to

operate according to the specifications, contact

your dealer or HIOKI representative.

Accessories

9399 Carrying Case 1

Hand Strap 1

Battery: 6F22(006P) 1

Instruction manual 1

Options

9094 OUTPUT CORD

9445-02 AC ADAPTER

(SA10-0910N, SINO-AMERICAN)

9445-03 AC ADAPTER (EU)

(SA10-0910G, SINO-AMERICAN)

Page 6

2

__________________________________________________

_____________________________________________

DANGER

This product is designed to conform to IEC

61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment.

However, mishandling during use could result

in injury or death, as well as damage to the

product. Be certain that you understand the

instructions and precautions in the manual

before use. We disclaim any responsibility for

accidents or injuries not resulting directly from

product defects.

Safety Notes

This manual contains information and warnings

essential for safe operation of the product and

for maintaining it in safe operating condition.

Before using the product, be sure to carefully

read the following safety notes.

Page 7

3

__________________________________________________

_____________________________________________

The symbol printed on the product

indicates that the user should refer to a

corresponding topic in the manual (marked

with the symbol) before using the

relevant function.

In the manual, the symbol indicates

particularly important information that the

user should read before using the product.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates a double-insulated device.

Wear appropriate protective insulation

(insulating rubber gloves and boots, helmet

and etc.) when connecting and disconnecting

from live electric circuits.

DANGER

Indicates that incorrect operation presents an

extreme hazard that could result in serious

injury or death to the user.

WARNING

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

CAUTION

Indicates that incorrect operation presents a

possibility of injury to the user or damage to

the product.

NOTE

Advisory items related to performance or

correct operation of the product.

Safety symbols

The following symbols in this manual indicate

the relative importance of cautions and

warnings.

Page 8

4

__________________________________________________

_____________________________________________

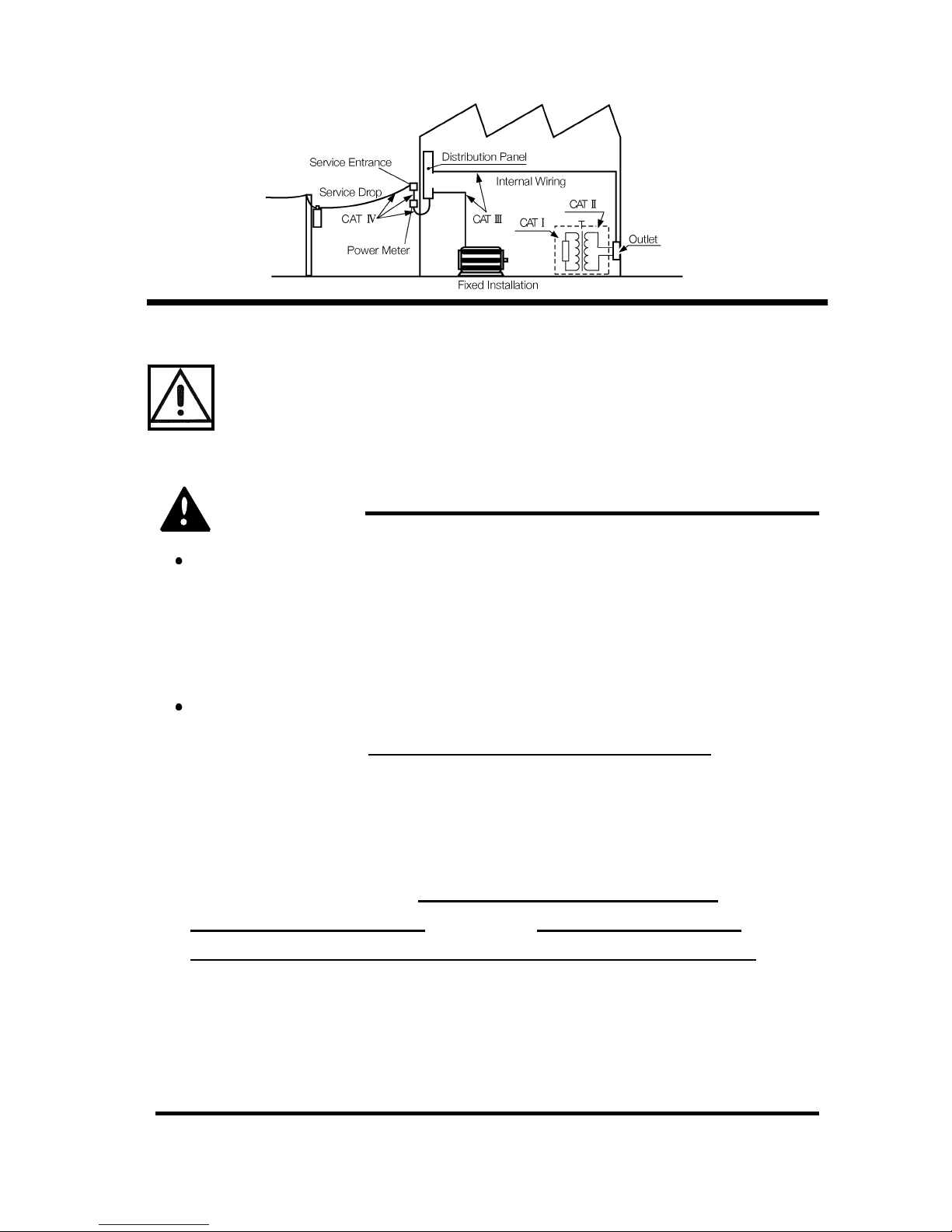

CAT I Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar

device.

CAT II Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT III Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distribution panel to

outlets.

CAT IV The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Measurement categories

(Overvoltage categories)

This product complies with CAT III safety

requirements.

To ensure safe operation of measurement

product, IEC 61010 establishes safety

standards for various electrical environments,

categorized as CAT I to CAT IV, and called

measurement categories. These are defined as

follows.

Higher-numbered categories correspond to

electrical environments with greater momentary

energy. So a measurement device designed for

CAT III environments can endure greater

momentary energy than a device designed for

CAT II.

Using a measurement product in an

environment designated with a higher-numbered

category than that for which the product is rated

could result in a severe accident, and must be

carefully avoided.

Never use a CAT I measuring product in CAT

II, III, or IV environments.

The measurement categories comply with the

Overvoltage Categories of the IEC60664

Standards.

Page 9

5

__________________________________________________

_____________________________________________

DANGER

Before using the product the first time, verify

that it operates normally to ensure that the no

damage occurred during storage or shipping. If

you find any damage, contact your dealer or

Hioki representative.

When conductors being measured carry in

excess of the safe voltage level (SELV-E)

and

not more than 300 V, to prevent short circuits

and electric shock while the clamp sensor jaw

is open, make sure that conductors to be

measured are insulated with material

conforming to (1) Overvoltage Category

Ⅲ

,(2)

Pollution Degree 2

, and (3) Basic Insulation

Requirements for Working Voltages of 300 V.

Refer to the following standards regarding the

meanings of underlined terms.

IEC61010-1

IEC61010-2-031

IEC61010-2-032

Notes on Use

Follow these precautions to ensure safe

operation and to obtain the full benefits of the

various functions.

Page 10

6

__________________________________________________

_____________________________________________

DANGER

Do not use clamp testers on bare conductors.

When the clamp sensor jaw is open, there is a

risk of short-circuits and accidents that could

result in injury or death.

Use clamp testers only on power lines up to AC

300 V rms, to avoid short-circuits and accidents

that could result in injury or death.

This product should only be connected to the

secondary side of a breaker, so the breaker can

prevent an accident if a short circuit occurs.

Connections should never be made to the

primary side of a breaker, because unrestricted

current flow could cause a serious accident if a

short circuit occurs.

Use only the specified Model 9445-02 (SA100910N, SINO-AMERICAN) or 9445-03 (for EU)

(SA10-0910G, SINO-AMERICAN). AC adapter

input voltage range is 100 to 240 V AC (with

10% stability) at 50/60 Hz. To avoid electrical

hazards and damage to the product, do not

apply voltage outside of this range.

Page 11

7

__________________________________________________

_____________________________________________

WARNING

To avoid electric shock, do not allow the

product to get wet, and do not use it when your

hands are wet.

To avoid electric shock when measuring live

lines, wear appropriate protective gear, such as

insulated rubber gloves, boots and a safety

helmet.

To avoid electric shock when measuring the

ground conductor on a transformer Class 2

connection site, be careful not to approach high

voltage devices or conductors. Also, if close to

high voltage charging devices or if

measurement is otherwise difficult, first change

the route of the grounding wire.

To avoid electric shock when replacing the

batteries, first disconnect the clamp portion

from the object to be measured. Also, before

using the product after replacing the batteries,

replace the cover and screw.

When replacing the batteries, be sure to insert

them with the correct polarity. Otherwise, poor

performance or damage from battery leakage

could result.

To avoid the possibility of explosion, do not

short circuit, disassemble or incinerate

batteries.

Handle and dispose of batteries in accordance

with local regulations.

Page 12

8

__________________________________________________

_____________________________________________

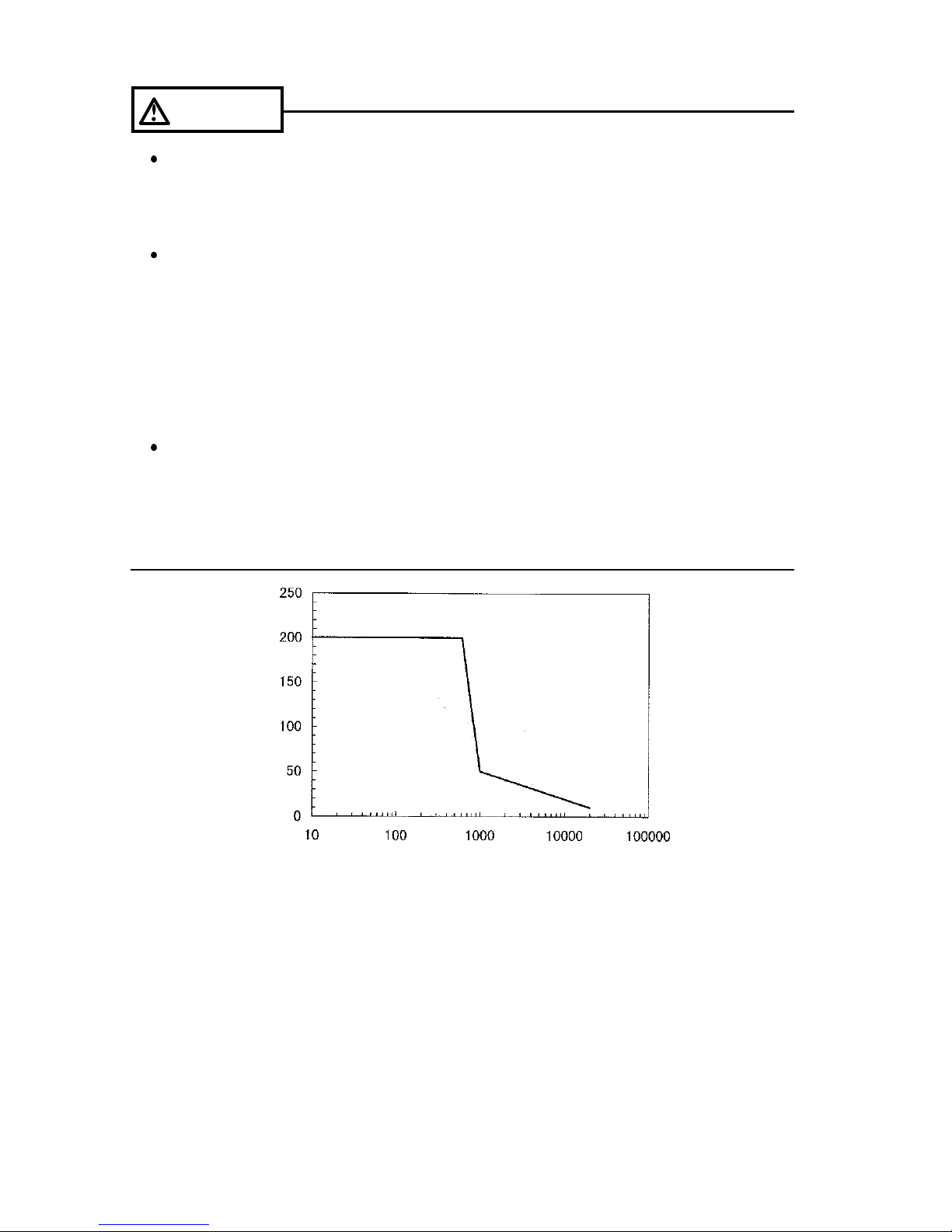

CAUTION

This is a precision instrument: do not clamp any

foreign objects in the end of the clamp sensor, or

insert anything in the clamp sensor gap.

To avoid damage to the product, protect it from

vibration or shock during transport and handling,

and be especially careful to avoid dropping. Do not

exert excessive pressure on the clamp sensor or

attempt to wedge the sensor into a tight spot for

measurement.

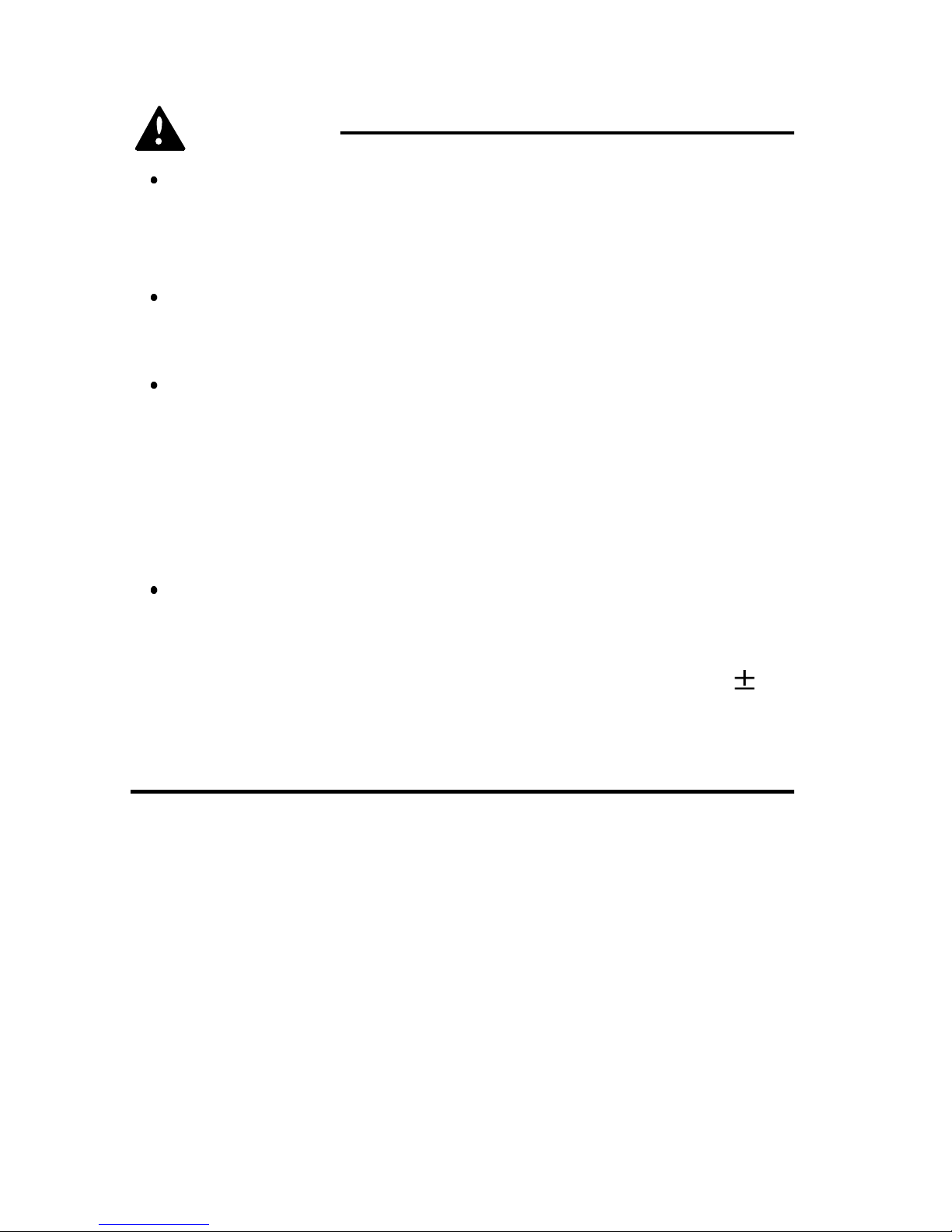

To avoid damage to the product, do not exceed the

maximum input current rating, which depends on

the frequency of the current being measured (see

following Figure).

Frequency [Hz]

Fre

q

uency-dependent deletion characteristics

C

u

r

r

e

n

t

[

A

]

Page 13

9

__________________________________________________

_____________________________________________

CAUTION

Do not use the unit if the battery is exhausted

(when the mark lights in the display area). Be

sure to replace the exhausted battery with a new

one.

When replacing the battery, make sure that the

metal battery snap fitting is firmly connected. If the

metal fitting is loose, adjust it and recheck the

connection. If it isn't connected securely, the power

may not be turned on, and a power may be turned

off during the use.

Adjustments and repairs should be made only by

technically qualified personnel.

For the inside memory protection, make sure the

power is turned off before connecting or

disconnecting the AC adapter.

This product is designed for indoor use, and

operates reliably from 0 to 40 .

Do not store or use the product where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions,

the product may be damaged and insulation may

deteriorate so that it no longer meets specifications.

Page 14

10

__________________________________________________

_____________________________________________

NOTE

For circuits which carry several superimposed

currents, correct measurements may not be

obtained.

Accurate measurement may be impossible in

the presence of strong magnetic fields, such

as near transformers and high-current

conductors, or in the presence of strong

electromagnetic fields such as near radio

transmitters.

Page 15

11

__________________________________________________

_____________________________________________

Chapter Summary

This manual consists of the following chapters.

"Introduction", "Safety Notes", "Notes on Use"

describe precautions on use, overview, and

features of this unit.

Be sure to read them all. Next, check Chapter

1 to 3 and the unit to confirm your

understanding of the function.

Chapter 1 Product Outline

Explains the parts and functions of the unit.

Chapter 2 Measurement Procedure

Explains how to use the 3283 for measurement.

Chapter 3 Battery Replacement

Explains how to replace the battery used to

power the 3283.

Chapter 4 Attaching the Hand Strap

Explains how to attach the hand strap, for easy

handling of the unit in the field.

Chapter 5 Specifications

Lists the specifications of the 3283 CLAMP ON

LEAK HiTESTER.

Chapter 6 Troubleshooting

Describes points to check before requesting

service.

Chapter 7 Service

Explains how to get the unit serviced.

Page 16

12

__________________________________________________

_____________________________________________

Page 17

13

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

Chapter 1

Product Outline

1.1 Product Outline

1.2 Features

The 3283 CLAMP ON LEAK HiTESTER is

designed for wide-range measurement on live

circuits, from very small leak currents up to load

currents of 200 amperes. The clamp part is

made of material with high magnetic

permeability, to minimize adverse effects

caused by external magnetic fields, and to

reduce tolerances due to the position of the

measured conductor.

High-sensitivity range with 10 mA full-scale point

Allows accurate measurement even of minute

leak currents (resolution 10μA).

Wide measurement range

Five range settings from 10 mA to 200 A make

the 3283 suitable for many applications.

Microprocessor-controlled functions

In spite of the compact dimensions of the unit,

versatile functions such as SLOW and MAX/MIN

are made possible by the built-in

microprocessor.

Page 18

14

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

True rms indication

The true rms conversion circuit delivers accurate

results not affected by leak current distortion.

Filtering

The widespread use of switching power supplies

and equipment incorporating inverter technology

frequently causes harmonics to be

superimposed in the leak current waveform. The

filter in the 3283 allows two kinds of

measurement, for leak current caused by

insulation faults and for leak currents including

harmonics.

Output jack

The output jack allows easy connection to a

level recorder or other equipment (level

recorder output: DC, waveform output: AC).

Unaffected by external magnetic fields and

conductor position

The clamp sensor and magnetic shield are

made of material with high magnetic

permeability, allowing precise measurement also

in the vicinity of transformers, electric motors

and other sources of magnetic fields. Since the

influence of the conductor position on the

measurement result is negligible, residual

current characteristics are not a problem even

when using the unit as a zero-phase

transformer.

Low power consumption

Power consumption is less than 100 mV A,

allowing the unit to operate continuously for up

to 40 hours on a single 6F22 (006P) battery.

Page 19

15

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

Dual power supply design

The unit can be powered using the optional

9445-02 AC adapter (SA10-0910N, SINOAMERICAN), 9445-03 AC adapter (for EU)

(SA10-0910G, SINO-AMERICAN), or from a

battery.

Page 20

16

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

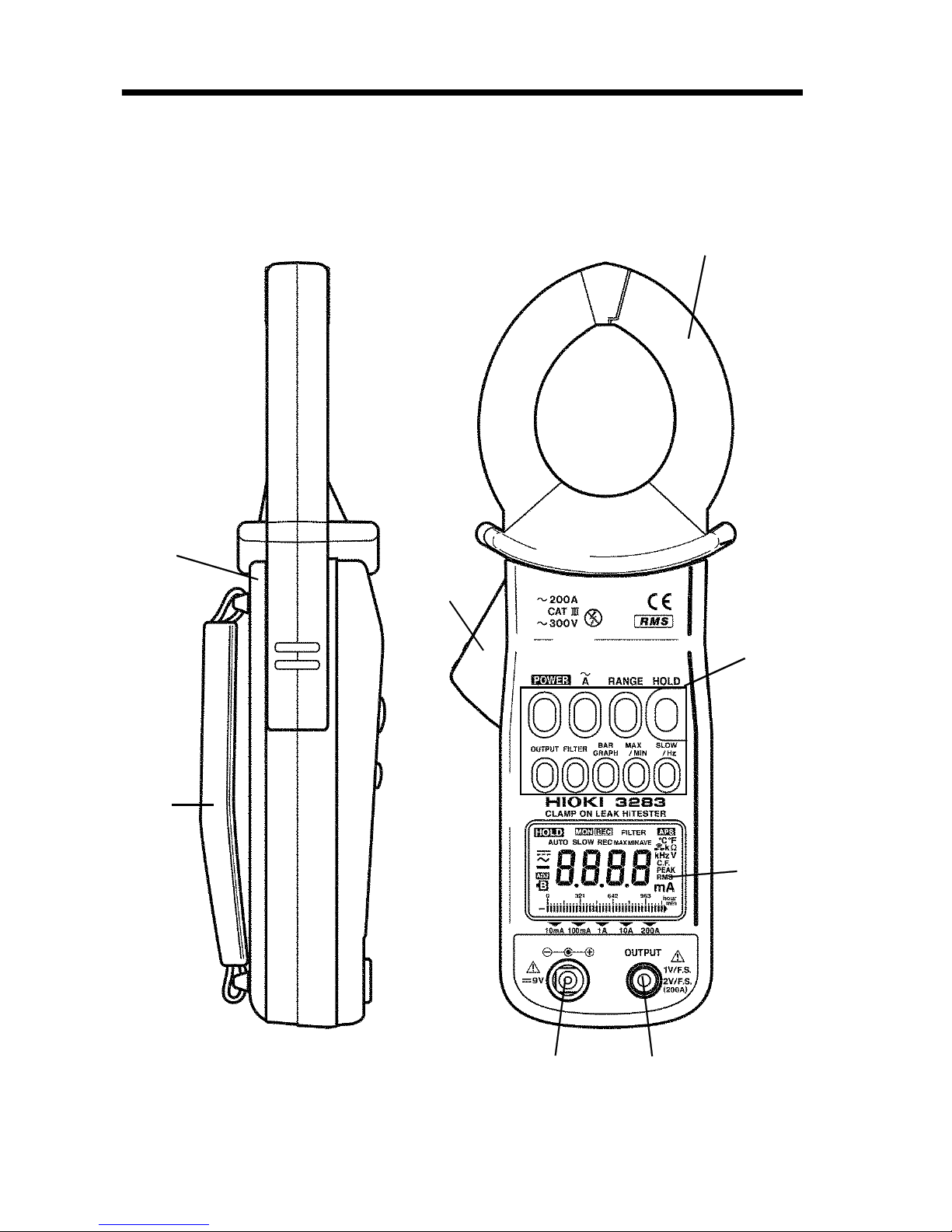

Top and Side View

1

2

3

4

5

6

7

8

1.3 Parts and Functions

Page 21

17

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

1. Clamp sensor

2. Operation lever

3. Key switches

4. Display (LCD)

5. Output jack

6. AC adapter jack

7. Rear cover

8. Hand Strap

Page 22

18

__________________________________________________

Chapter 1 Product Outline

_____________________________________________

AC

AUTO

Auto-range

SLOW

Update display once every 3 seconds

REC

Record function

MAX

Maximum value

MIN

Minimum value

AVE

Average value = (maximum value +

minimum value/2)

min

1 minute/segment (bar graph)

hour

1 hour/segment (bar graph)

HOLD

Data hold function

APS

Auto power off function

MON

Waveform output (AC) is active

REC

Recording output (DC) is active

FILTER

Filter function is active

Hz

Frequency

A, mA

current

RMS

True root mean square value

Input over (bar graph)

Battery low warning

Page 23

19

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

Fresh battery

Battery capacity 50%

Battery capacity 0

Beep tone sounds 3 times

Chapter 2

Measurement Procedure

2.1 Preparations

1. Remove the rear cover and insert the battery.

(Refer to "Chapter 3 Battery Replacement".)

2. Press the

POWER

key to turn the unit on.

Verify that all segments of the display light up

briefly. Then the model name is shown, and the

bar graph indicates the battery condition for a

second.

3. The AC current measurement mode is activated

【 Battery low voltage power-off】

After the mark lights and battery voltage

drops below a certain level, for the inside

memory protection, the power goes off

automatically. When this occurs,

bAtt

and

Lo

are displayed.

When power goes off after display of these

marks, replace the exhausted battery with a

new one.

Page 24

20

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

single-phase 3-lead circuits

Transformer

b

clamp all three leads

of the circuit

b

a

Ig: leak Current

E (PE)

Load

device

Ig

2.2 Leak Current Measurement

A

1. Press the

A

key.

2. Clamp the tester on the conductor, so that the

conductor passes through the center of the

clamp sensor. For measurement of grounded

leads, clamp the tester on one lead only (see

a). For overall measurements, clamp the tester

on the entire circuit path (see B).

Page 25

21

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

three-phase 3-lead

circuits

b

clamp all three leads of the circuit

b

E (PE)

a

Ig

a

PE

Load

device

NOTE

For measurement of single-phase 2-lead

circuits, clamp both leads of the circuit.

For measurement of three-phase 4-lead

circuits, clamp all four leads of the circuit. If

this is not possible, the measurement can also

be carried out on the ground lead of the

equipment.

Page 26

22

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

Do not input current that exceeds the

maximum continuous input of the electric

current range.

Measurement may not be accurate in the

cases below.

(1) When there is large current (of about 100

A) flowing through a nearby electric line

(2) When using the 3283 to measure special

waveforms, such as those on the secondary

side of an inverter

Note that a value of several tens of amperes

may be displayed when opening or closing the

clamp sensor, or when changing the electric

current range. This is not an error. It may take

some time for the display to return to zero.

However, starting measurement before the

display returns to zero will not affect

measurement.

3. The effective value (

RMS

) of the leak current is

shown on the digital display. The selected

current range is shown at the bottom of the

display.

Page 27

23

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

b

b′

a

Ig

c

c′

A

B

single-phase 3-lead

circuits

Load

device

Load

device

E (PE)

【Checking for insulation faults】

Normally, for a E (PE) grounding installation of

a transformer, the measurement will first be

made to check for overall circuit leak current in

the ground lead (a). Current changes can be

used to diagnose the leak current condition.

When leak current has been detected, the

measurement should proceed from the power

source towards the load, using overall

measurement.

1. If an insulation fault in the wiring has occurred

at position A in the illustration, leak current will

be detected at position b using overall

measurement, but not at position b'.

2. If an insulation fault in the load equipment has

occurred at position B in the illustration, leak

current will be detected at position c using

overall measurement, but not at position c'.

3. For detection of intermittent leak current

conditions (such as only when a certain piece of

equipment is operating), the use of a level

recorder will be helpful.

Page 28

24

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

SLOW→Hz→RMS

NOTE

The update speed cannot be changed for

frequency display.

RMS value display→Current range display

NOTE

The flashing segment indicates the full-scale

position.

【Range switching】

Each push of the

RANGE

key switches the

range in the order 10 mA → 100 mA → 1A→

10 A → 200 A →

AUTO

.

【Changing the display characteristics SLOW】

If the indicated current value fluctuates rapidly

and is hard to read, you can select a slower

update rate (once every 3 seconds) by pressing

the

SLOW/Hz

key.

The key cycles through the following modes:

【Bar graph display BAR GRAPH】

The current range display can be switched to

bar graph operation. The bar graph shows the

rms value of the measured current.

The bar graph display refresh rate is "FAST" (4

times per second).

1. Press the

BAR GRAPH

key.

2. The current range display is switched to bar

graph operation.

Each push of the

BAR GRAPH

key toggles

between the following modes:

Page 29

25

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

There is no frequency output function.

Enable the filter function (see 2.3) when

conducting measurement in the cases below.

(1) When meaningless data is displayed due to

noise

(2) When using the 3283 to measure special

waveforms, such as those on the

secondary side of an inverter

The 3283 may not be able to perform

measurement in the cases below.

(1) When using input current that is 1/10 or

less of the full electric current range

(2) When measuring high frequencies with the

filter function enabled

The range display (

AUTO

and Bar graph)

indicates the electric current range.

SLOW→Hz→RMS

【Frequency (Hz) display】

1. While the display is switched to

SLOW

mode,

press the

SLOW/Hz

key.

2. The frequency of the measured current is

displayed.

If there is no input, and input is lower than

30Hz, "----" is shown.

Each push of the

SLOW/Hz

key cycles

through the following modes:

Page 30

26

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

X

NOTE

The frequency of special waveforms such as

at the secondary side of an inverter may not

be indicated correctly.

Depending on the magnitude and frequency of

the input current, resonances may be heard

from the clamp jaw. This does not affect the

measurement.

When the size of input current is unknown,

begin measurement with the 200 A range (filter

function is invalid) selected .

Do not input a current which exceeds the

maximum continuous input rating of the current

range.

【Load current measurement】

Be sure to clamp only one lead of the

conductor.

Page 31

27

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

output rate:1 V/10 mA

A

m

p

l

i

t

u

d

e

[

d

B

,

0

d

B

=

1

V

]

Frequency [Hz]

MON output frequency bandwidth (example: 10 mA range)

NOTE

The effect of the filter function is reflected in

numeric data output and waveform output.

2.3 Filter Function FILTER

The widespread use of switching power supplies

and equipment incorporating inverter technology

can cause harmonics to be superimposed on

the leak current waveform.

1. Press the

FILTER

key. The

FILTER

indication

appears. The integrated low-pass filter is now

active, cutting off unwanted higher-frequency

components.

2. Pressing the

FILTER

key once more turns the

low- pass filter off, allowing measurement of

leak current including any high-frequency

components. The

FILTER

indication disappears.

Page 32

28

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

Pressing the

MAX/MIN

key during auto-

ranging (

AUTO

) fixes the range at the current

setting.

2.4 Data Hold Function HOLD

2.5 Recording Function REC

This function allows freezing the display at any

desired point for easy reading.

1. Press the

HOLD

key. The

HOLD

indication

appears on the display and the digital display

value is maintained.

To cancel the data hold function, press the

HOLD

key again.

The recording function can be used to display

the maximum display value, minimum display

value, maximum/minimum average, and the

instantaneous value.

1. Press the

RANGE

key to select the current

measurement range.

2. Press the

MAX/MIN

key while measuring

current with the conductor clamped. The

REC

indication flashes and the maximum, minimum,

or average value for the period starting when

the key was pressed to the present point can be

displayed. The instantaneous value can also be

displayed. Only one of these values can be

shown at any one time, but the other values are

kept in memory.

Page 33

29

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

MAX→MIN→AVE→instantaneous value

(no indication)

3. During measurement, the MAX/MIN key can

be used to select the value that should be

shown.

MAX: Maximum value is shown.

MIN: Minimum value is shown.

AVE: Average value is shown = (maximum

value + minimum value)/2

If none of the MAX, MIN,orAVE indicators is

shown, the display shows the instantaneous

value.

4. Pressing the HOLD

key will stop the recording

function. The HOLD indication appears and the

REC indication stops flashing.

By pressing the MAX/MIN

key in this

condition, the MAX, MIN, and AVE values

stored in the internal memory can be called up

on the display, as follows.

While HOLD is shown, the elapsed time is not

incremented. Also if the clamp sensor is

removed from the conductor for easier reading,

the minimum value will not return to zero.

Pressing the HOLD

key once more causes the

HOLD indication to go out. The recording

function resumes, and REC flashes again.

Page 34

30

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

Momentary power loss and power surges

cannot be detected.

When the unit is turned off, accumulated data

are lost.

The maximum recording duration depends on

the remaining battery capacity.

The lowest possible frequency that can be

displayed is 30.0 Hz.

If the measurement object was clamped after

activating the recording function, the minimum

value is always zero. To prevent this, clamp

the conductor first and the press the

MAX/MIN

key to activate the recording

function.

If the clamp sensor is removed from the

measurement object while the recording

function is active, the minimum value will

become zero. To prevent this, press the

HOLD

key before removing the clamp

sensor.

To turn off the recording function, press

A

key. The maximum value, minimum value,

and average value are cleared.

Page 35

31

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

rms value → elapsed time → elapsed time → current range

(instantaneous value) (hours) (minutes)

【

Bar graph indication BAR GRAPH

】

The bar graph display can be changed. It is

also possible to display the current range,

effective (rms) value of the measured current,

and the elapsed time (hours and minutes).

1. Press the BAR GRAPH

key.

2. The current range display switches to bar graph

indication.

Each push of the BAR GRAPH

key cycles

through the following modes:

When the elapsed time display is activated, the

bar graph segments flash and the elapsed time

from the point when the MAX/MIN

key was

pressed is displayed.

When "min" is shown in the right-hand corner

of the bar graph, each segment of the bar graph

corresponds to one minute. Every time one

minute elapses, one segment of the flashing

bar graph goes on. When all segments on the

bar graph go on, the elapsed time is 30

minutes.

When the elapsed time exceeds 30 minutes,

one segment of the flashing bar graph goes off

every time one minute elapses.

Page 36

32

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

When the segments left of a flashing segment

remain on: the number of "on" segments

represents the elapsed time (0 to 29).

The illustration below shows when 20 minutes

have elapsed:

When the segments right of a flashing segment

remain on: the number of "off" segments (+30)

represents the elapsed time (30 to 59).

The illustration below shows when 50 minutes

have elapsed:

When "hour" is selected, one segment

corresponds to one hour, and the maximum

length of time that can be displayed is 59 hours.

The illustration below shows indication when 1

hour 40 minutes have elapsed.

Page 37

33

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

2.6 Auto Power-Off Function

APS

2.7 Battery Low Warning

2.8 Beep Tone

When APS is displayed, the auto power-off

function is active.

If no key is pressed for about 10 minutes, the

unit turns itself off automatically.

Immediately before turning off, the APS

indication flashes and a beep tone is heard for

about 30 seconds.

Pressing any key except the POWER key will

extend the powered state for another 10

minutes.

To disable the auto power-off function, hold

down the HOLD

key while turning the unit on

by pressing the POWER key. The APS

indication then is not shown.

While using the recording function or the output

function of the unit, auto power-off is disabled.

When this indication appears, the battery is

exhausted and correct measurement is not

assured. Replace the battery as early as

possible.

Refer to "Chapter 2【Battery low voltage poweroff】".

To disable the beep tone, hold down the

RANGE

key while turning the unit on by

pressing the POWER key.

Page 38

34

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

If SLOW is selected while the unit is in fast

mode, the display update rate will be normal (2

times per second).

NOTE

Circuit time constant 200 ms MAX.

2.9 Fast Mode

The display update rate can be set to 4 times

per second. This is useful for example to

measure load currents with frequent variations

and similar applications.

1. Press the

A

key twice in succession.

The indication "F" is briefly shown, and the unit

switches to fast mode. From now on, the

indication "F" will appear every time the

A

key

is pressed.To cancel the fast mode, press

the

A

key twice in succession.

【

Example to measure load currents with

frequent variations

】

1. Press the

A

key twice in succession to

activate fast mode.

2. Press the RANGE key to set the current range

to a fixed setting.

When the drive current is unknown, begin

measurement with the 200 A range selected

3. Use the recording function to record the

maximum value, for easier reading.

Page 39

35

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

REC

(recording output) → MON(waveform output) → out

(auto power-off disabled) (auto power-off disabled) (auto power-off enabled)

2.10 Output Function OUTPUT

The output type is indicated by the

REC

(recording output, DC) or

MON

(waveform

output, AC) indication.

An output signal corresponding to the measured

value can be obtained from the unit. The output

voltage (AC/DC) normally is 1 V for the fullscale count (1000). In the 200 A range, the

output voltage (AC/DC) is 2 V for the full-scale

count (2000).

1. Press the

RANGE

key to set the current range

to a fixed setting.

2. Press the

OUTPUT

key so that the

REC

indication appears. The output function is now

active.

Auto power-off is disabled. (The

APS

indication

goes out.)

Each push of the

OUTPUT

key cycles through

the following modes:

Page 40

36

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

【Output rate】

MON

(waveform output : AC)

REC

(recording output : DC)

Current

Range

Output rate Accuracy

Crest

Factor

10 mA AC/DC 1 V/10 mA

AC/DC:

3.0% rdg. 10 mV

(40Hz to 2 kHz)

2.5 or less

100 mA AC/DC 1 V/100 mA

1 A AC/DC 1 V/1 A

10 A AC/DC 1 V/10 A

200 A AC/DC 2 V/200 A 1.5or less

【Output response】

REC MON

(Circuit time constant)

200 ms or less

frequency bandwidth

(-3 dB) 5 Hz to 15 kHz

Page 41

37

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

NOTE

To use the output function, be sure to push the

OUTPUT

key so that either

REC

or

MON

is

shown.

There is no frequency output function.

The filter function can be used to cut unwanted

high- frequency components.

If the

OUTPUT

key is pressed while auto-

range (

AUTO

) is enabled, the range is fixed at

the current setting (

AUTO

indication goes out).

For connection to a level recorder, use the

separately available 9094 OUTPUT CORD.

Use a high-impedance input device (e.g.,

recorder) for receiving output. (We recommend

a device with input impedance of at least 100

kΩ.)

NOTE

Even if the AC adapter is connected, if the

battery is exhausted (the mark lights), the

power may turn off in order to preserve the

data in the internal memory. To continue using

the instrument, replace the depleted battery

with a new battery, or remove the battery

completely.

When the AC adapter is used and there is a

high amount of noise in the power line, the

display may show several counts or noise may

be present in the output. In such a case,

connect the ground terminal of the level

recorder or the L side of the input to ground.

Pressing the

HOLD

key does not hold the

output signal.

Please note that the output signal is available

also when

REC

and

MON

indications are out,

but the auto power-off function is enabled.

【Using AC Adapter】

For long-term recordings, use the AC adapter (option).

Page 42

38

__________________________________________________

Chapter 2 Measurement Procedure

_____________________________________________

Page 43

39

__________________________________________________

Chapter 3 Battery Replacement

_____________________________________________

CAUTION

Do not fix the back casing screws too tightly.

The torque about 0.5N・m is recommended.

NOTE

Fix the terminals of battery snap and battery

exactly.

Chapter 3

Battery Replacement

1. Remove the two fastening screws of the rear

cover, using a Phillips screwdriver.

2. Remove the rear cover.

3. Remove the old battery without pulling the

codes of the snap.

4. Securely connect the battery to the battery

snap.

5. Replace the rear cover and tighten the fastening

screws.

Page 44

40

__________________________________________________

Chapter 3 Battery Replacement

_____________________________________________

Page 45

41

__________________________________________________

Chapter 4 Attaching the Hand Strap

_____________________________________________

Chapter 4

Attaching

the Hand Strap

Explains how to attach the hand strap, for easy

handling of the unit in the field.

Page 46

42

__________________________________________________

Chapter 4 Attaching the Hand Strap

_____________________________________________

Page 47

43

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Chapter 5

Specifications

5.1 Measurement Specifications

Temperature and humidity for guaranteed

accuracy:

23 5 (73 9), 80% RH or

less

Guaranteed accuracy period:

1 year, or

opening and closing of the Clamp Sensor

10,000 times, whichever comes first

Page 48

44

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Current Range

(Accuracy

Range)

Resolution

Accuracy

(NOTE)

(%rdg.+dgt.)

Maximum

permitted

current

10 mA

(1.00 to 10.00 mA)

0.01 mA

45 to 66 Hz:

(1.0%+5)

40 to 45

66 to 2 kHz:

(2.0%+5)

20 Arms

AC,

continuous

(see fig. A)

100 mA

(10.0 to 100.0 mA)

0.1 mA

1A

(0.100 to 1.000 A)

0.001 A

10 A

(1.00 to 10.00 A)

0.01 A

200 A

(10.0 to 200.0 A)

0.1 A

45 to 66 Hz:

(1.5%+5)

40 to 45

66 to 2 kHz:

(2.0%+5)

200 Arms

AC,

continuous

(see fig. A)

NOTE

Accuracy with filter function disabled.

When the filter function is enabled.

10 mA Range to 10 A Range:

50 Hz to 60 Hz (1.5%+5)

200 A Range: 50 Hz to 60 Hz (2.0%+5)

5.1.1 AC current Arms(true rms indication)

Page 49

45

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Effect of conductor

position

within 0.1%

(in any direction from clamp sensor

center)

100 A MAX: within 0.5%

Effect of external

magnetic fields

AC 400 A/m corresponds to 5 mA,

max. 7.5 mA

Maximum rated

voltage to earth

max. 300 V rms AC (insulated

conductor)

Frequency [Hz]

C

u

r

r

e

n

t

[

A

]

Fig.A Frequency-dependent deletion characteristics

Frequency Range

(Accuracy Range)

Resolution

Accuracy

(%rdg.+dgt.)

100 Hz

(30.0 to 99.9 Hz)

0.1 Hz (0.3%+1)

1000 Hz

(95 to 1000 Hz)

1Hz (1.0%+1)

NOTE

The frequency range is automatically specified.

5.1.2 Frequency Hz

Page 50

46

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Functions

Recording

Maximum (MAX), minimum (MIN),

average (AVE) value display

selectable for AC current and

frequency measurement

Data hold

Data hold function

Auto power-off

Automatic shutdown after 10.5 1

minutes. Beep tone warning.

Extension and disabling possible.

Battery low voltage

power-off

When the battery voltage falls below

a certain level, the function shuts

down the unit to prevent

malfunctions.

Beep tone

ON/OFF

Display

LCD panel

Digital indication

2000 counts

Bar graph indication

35 segments

Current range display or rms display

selectable

Over-range

indication

"

O.L.

" (bar graph)

Over range warning sound (buzzer)

Battery low warning

Battery low voltage

power-off

"

bAtt Lo

"

(7 segments used)Power turned off

after display

5.2 General Specifications

Page 51

47

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Data hold indication

HOLD

Auto power-off

indication

APS

Filter function

Cutoff frequency 180 Hz 30 Hz

(-3 dB)

Display update rate

Digital indication

NORMAL: 500 ms 25 ms

(approx. 2 times/second)

SLOW : 3 s 0.15 s

(approx. 1 time/3seconds)

FAST : 250 ms 12.5 ms

(approx. 4 times/second)

Bar graph indication

FAST only

Display response

time

2.2 s max.

Range switching

Auto range, manual (fixed) range

(selectable). Frequency

measurement with auto-range only.

Output function

REC (recording output),

MON (waveform output) (selectable)

Output rate

REC : 1 V DC at full-scale point

(In the 200 A range only, 2

VDC/f.s.)

MON : 1 V AC at full-scale point

(In the 200 A range only, 2

VAC/f.s.)

Output Accuracy

3.0%rdg. 10 mV (40 to 2 kHz)

Output response

REC (DC) : circuit time constant 200

ms max.

MON (AC) : frequency bandwidth

(-3 dB) 5 Hz to 15 kHz

Output impedance

200Ω max.

Page 52

48

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Circuit dynamic

characteristics

(crest factor)

2.5 max. (1.5 for 200 A range)

Withstand voltage

Chassis - clamp core: 3536 Vrms AC

for 15 seconds

Insulation

resistance

Clamp core - circuitry: 630 kilohms

min.

Location for use

Indoor, altitude up to 2000 m

Applicable

standards

Safety:

EN 61010-1:2001

Voltage input: Pollution level

2, Measurement categories

Ⅲ

(expected transient

overvoltage: 4000 V)

EN 61010-2-032:2002

Type B current sensor

EN 60529:1991 IP40

(protected against access to

hazardous parts with a wire)

EMC:

EN 61326:1997+A1:1998+

A2:2001+A3:2003

EN 61000-3-2:2000

EN 61000-3-3:1995+A1:2001

Maximum

conductor diameter

for measurement

φ40 mm max.

Operating

temperature and

humidity range

0to40 , 80%RH or less

(no condensation)

Temperature

characteristics

In 0 to 40 range: 0.05 x accuracy

specifications/

Storage

temperature

range

-10 to 50 (no condensation)

Page 53

49

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Power source

One 6F22 (006P) 9 V battery or

9445-02 AC ADAPTER

(SA10-0910N, SINO-AMERICAN) or

9445-03 AC ADAPTER (EU) (SA100910G, SINO-AMERICAN) (option)

Maximum power

consumption

100 mVA

Battery life

approx. 40 hours

(continuous, no load)

External

dimensions

approx. 62W x 225H x 39D mm

Mass

approx. 400 g

Accessories

9399 CARRYING CASE 1

Hand Strap 1

Battery: 6F22(006P) 1

Instruction manual 1

Options

9445-02 AC ADAPTER

(SA10-0910N, SINO-AMERICAN)

9445-03 AC ADAPTER (EU)

(SA10-0910G, SINO-AMERICAN)

9094 OUTPUT CORD

Page 54

50

__________________________________________________

Chapter 5 Specifications

_____________________________________________

Page 55

51

__________________________________________________

Chapter 6 Troubleshooting

_____________________________________________

Problem Cause Action

Problems related to the power supply

Power will not

turn on

Power shuts

off during

operation

The battery may

be low or

depleted

Replace it with a

new battery

The battery snap

terminal may be

deformed,

causing contact

failure

Remove the

battery, then use

radio pliers to

straighten the

battery snap

terminal

When the AC

adapter is used,

power is only

supplied through

the AC adapter

When using the

battery,

disconnect the

AC adapter.

Insert the AC

adapter into the

AC outlet

lights

lights,

followed by

immediate

power

shutdown

The battery may

be low or

depleted

Replace it with a

new battery

Chapter 6

Troubleshooting

If the unit seems not to be working normally,

check the following points first before requesting

service.

Page 56

52

__________________________________________________

Chapter 6 Troubleshooting

_____________________________________________

Problem Cause Action

Problems related to display

An error

between E.001

and E.005 or

E.100 is

displayed.

Internal memory

may be

damaged

Request repair

Problems related to the clamp sensor

The clamp

sensor

generates a

sound during

measurement

When large

current or highfrequency

current is

measured,

resonance may

occur,

generating a

sound

Reclamp the

conductor.

Measure microcurrent or lowfrequency

current to

determine

whether a sound

is generated

Page 57

53

__________________________________________________

Chapter 6 Troubleshooting

_____________________________________________

Problem Cause Action

Problems related to output function

The output

rate differs

from the

specification

The output is

too low

The 200 A range

is used

Check the

electric current

range. Unlike

other ranges, the

full scale of the

200 A range is 2

V/fs

The input

impedance of

the device used

to receive output

is too low

Check the input

impedance of

the device used

to receive

output. We

recommend

input impedance

of at least 100

kΩ

MON output is

used for

measurement at

high frequency

The guaranteed

range of

accuracy is 40

Hz to 2 kHz. The

specified

frequency band

of 5 Hz to 15 Hz

is a -3 dB band.

At 15 kHz, the

amplitude is

reduced to

approximately

70%

Page 58

54

__________________________________________________

Chapter 6 Troubleshooting

_____________________________________________

Page 59

55

__________________________________________________

Chapter 7 Service

_____________________________________________

Chapter 7

Service

To clean the product, wipe it gently with a soft

cloth moistened with water or mild detergent.

Never use solvents such as benzene, alcohol,

acetone, ether, ketones, thinners or gasoline,

as they can deform and discolor the case.

The minimum stocking period for replacement

parts is five years after end of production.

For information regarding service, please

contact your dealer or the nearest HIOKI

representative.

If the unit is not functioning properly, check

the battery. If a problem is found, contact

your dealer or HIOKI representative. Pack

the unit carefully so that it will not be

damaged during transport, and write a

detailed description of the problem. HIOKI

cannot bear any responsibility for damage

that occurs during shipment.

Page 60

56

__________________________________________________

Chapter 7 Service

_____________________________________________

Page 61

Page 62

Page 63

HIOKI 3283 CLAMP ON LEAK HiTESTER

Instruction Manual

Publication date: September 2006 Revised edition 13

Edited and published by HIOKI E.E. CORPORATION

Technical Sales Support Section

All inquiries to International Sales and Marketing

Department

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3283A981-08

・

All reasonable care has been taken in the production of

this manual, but if you find any points which are

unclear or in error, please contact your supplier or the

International Sales and Marketing Department at HIOKI

headquarters.

・

In the interests of product development, the contents of

this manual are subject to revision without prior notice.

・

Unauthorized reproduction or copying of this manual is

prohibited.

Page 64

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp/

URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3283A980-13 06-09H

Printed on recycled paper

Loading...

Loading...