Page 1

Warranty

3280-10

CLAMP ON HiTESTER

Instruction Manual

September 2013 Revised edition 7

Printed in Japan

3280C981-07 13-09H

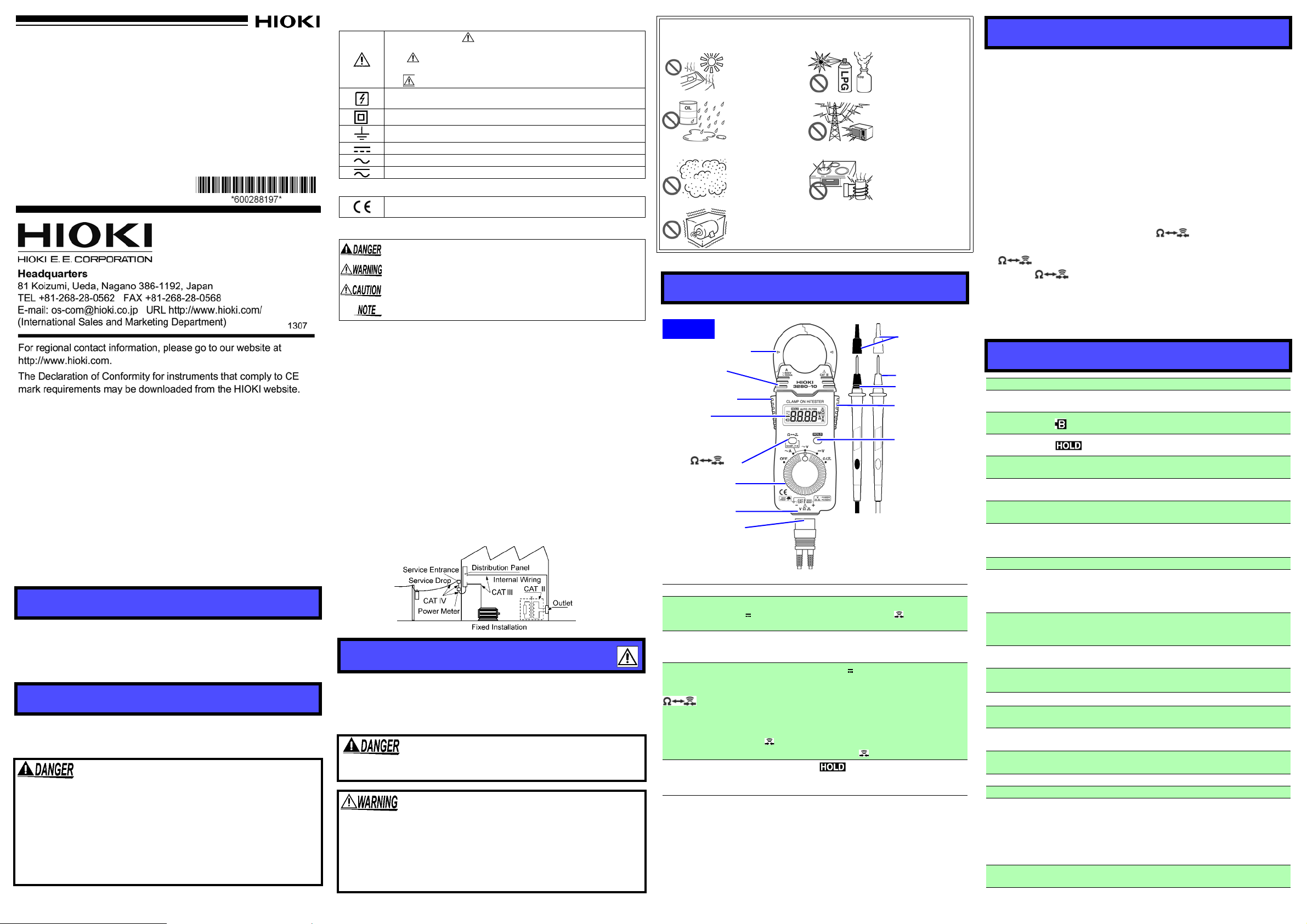

Clamp sensor

Operation grip

LCD panel

(Display: Measurement value,

Units, Symbols, Decimal

point)

,

SAMP. F/S

key

Measurement

terminal

Test lead plug

*Battery cover (rear side)

Function switch

Front

Sleeves

Black test lead (-)

Red test lead (+)

HOLD key

Operation grip

Barrier

Warranty malfunctions occurring under conditions of normal use in conformity

with the Instruction Manual and Product Precautionary Markings will be

repaired free of charge. This warranty is valid for a period of three (3) years

from the date of purchase. Please contact the distributor from which you purchased the product for further information on warranty provisions.

Introduction

Thank you for purchasing the HIOKI Model 3280-10 CLAMP ON HiTESTER.

To obtain maximum performance from the instrument, please read this manual

first, and keep it handy for future reference.

Initial Inspection

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. If damage is evident, or if it fails to operate according

to the specifications, contact your dealer or Hioki representative.

Overview

The 3280-10 is a clamp-on AC meter using an average value type measurement formula. (It also contains multi-meter functions for AC voltage,

DC voltage, resistance and continuity checking.) The 3280-10 handles

measurements of low-distortion load current of commercial line, up to maxi-

mum 1000 A.

Safety

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using it,

be sure to carefully read the following safety precautions.

This instrument is designed to comply with IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, mishandling during use could result in

injury or death, as well as damage to the instrument. However,

using the instrument in a way not describe d in this manual may

negate the provided safety features.

Be certain that you understand the instructions and precautions

in the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from instrument defects.

1234

Safety Symbols

In the manual, the symbol indicates particularly important

information that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual (marked with

the symbol) before using the relevant function.

Indicates that the instrument may be connected to or disconnected

from a live circuit.

Indicates a double-insulated device.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Symbols for Various Standards

This symbol indicates that the product conforms to safety regulations set out by the EC Directive.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Measurement categories

The current input section conforms to CAT III (600 V) safety requirements, and

the voltage input section confirms to CAT III (300 V), CAT II (600 V) safety

requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories.

CAT II Primary electrical circuits in equipment connected to an AC electrical

CAT III Primary electrical circuits of heavy equipment (fixed installations)

CAT IV The circuit from the service drop to the service entrance, and to the

Using a measurement instrument in an environment designated with a highernumbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must be carefully avoided.

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Before using the instrument the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

To avoid electric shock, do not touch the portion beyond the

protective barrier during use.

• During current measurement, to avoid an electric shock accident, do not

• To avoid electric shock when measuring live lines, wear appropriate protec-

• Check that there is no damage to the clamp sensor, instrument case, and

outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

power meter and primary overcurrent protection device (distribution

panel).

Usage Notes

connect the test leads to the instrument.

tive gear, such as insulated rubber gloves, boots and a safety helmet.

test leads before using. Do not use if there is any damage as it could lead to

electric shock.

Avoid the following locations that could cause an accident or damage

to the instrument.

Exposed to

direct sunlight

Exposed to high

temperature

Exposed to water,

oil, other chemicals, or solvents

Exposed to high

humidity or condensation

Exposed to high

levels of

particulate dust

Subject to vibration

In the presence of

corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic

radiators

Near induction heating

systems (e.g., highfrequency induction

heating systems and

IH cooking utensils)

Names and Functions of Parts

Operation grip The clamp sensor at the same side as the pushed grip opens.

Function

switch

Test lead plug

SAMP. F/S

key

HOLD key

Switching for OFF/AC current [~A] /AC voltage [~V]/DC voltage [ V]/Resistance, Continuity check [

(Power is turned on in any position other than OFF.)

Connect the test lead plug to the measurement terminal of the

instrument for voltage measurement, resistance measurement

or continuity testing.

/]

n For any function of [~A],[~V],[ V]:

Display update rate (FAST or SLOW) is switchable

If an indicated value fluctuates rapidly and is difficult to read,

a slower display update rate is available to make it easier to

read the indicated value.

(SLOW: about once every three seconds, unit on the LCD

panel flashes at the same time.)

n For [/] function:

Resistance [

When press HOLD key, appears in the display and the

digital display value is maintained. Press HOLD key again to

cancel the data HOLD function.

] or Continuity test [] is switchable

Functions and Display

The display is blanked automatically.

(Auto Power Save Function)

• The auto power save function is activated automatically when the power is

turned on. (Not possible to cancel)

• If no key is pressed for about 30 minutes, the display is blanked automatically. (Power save state)

• To restore from the power save state, turn the function switch to the OFF

position once.

The measurement range is automatically set to the most

appropriate range.(Auto-range Function)

• Except for continuity test, the measurement range is automatically set to the

most appropriate range.

• The "AUTO" indication appears in the display.

A manual range setting becomes available.

(Manual Range Function)

• Power on the tester while holding down ,SAMP. F/S key or HOLD

key, then a manual range setting becomes available except when testing

continuity. Either display update rate is selectable by the keys.

( ,SAMP. F/S key: SLOW, HOLD keys: FAST)

• Press the , SAMP. F/S key to switch the range.

• The "AUTO" indication disappears.

Indication when the input is out of range.

(Overflow indication)

• When the input exceeds the measurement range, "OF" or "-OF" is displayed.

Specifications

LCD panel 4199 maximum display value

Out of range

indication

Battery low

warning

Data hold

indication

Zero

suppression

Display update

interval

Range

switching

Withstand

voltage

Location of use Altitude up to 2000 m (6562 feet), indoors, Pollution Degree 2

Maximum

conductor

diameter for

measurement

Operating

temperature

and humidity

Storage

temperature

Temperature

characteristics

Power supply

Maximum rated

power

Continuous

operating time

Dimensions and

mass

Drop proof One meter to concrete

Accessories Instruction manual, 9398 Carrying Case, L9208 Test Leads

Maximum rated

voltage to earth

Applicable

standards

OF or -OF

(during which time accuracy cannot be guaranteed).

5 count or less (current measurement only)

FAST: 400 ms ±25 ms, SLOW: 3.2 s

Auto range / Manual range

Between case and circuit: AC4290 Vrms for 1 min.

Between clamp sensor and case: AC7060 Vrms for 1 min.

Between clamp sensor and circuit: AC5400 Vrms for 1 min.

33 mm (1.30") or less

0 to 40C (32 to 104F), 80%RH max (no condensation)

-10 to 50C (14 to 122F) (no condensation)

In 0 to 40C (32 to 104F) range: 0.1 x Measurement

accuracy / (C)

Lithium battery: CR2032 x 1 (Rated supply voltage 3 V DC)

15 mVA

Approx. 150 hours (standard), Approx. 80 hours min. (in AC

current measurement mode, continuous, no load)

Approx. 57W x 175H x 16D mm, approx. 100 g

(Approx. 2.24"W x 6.89"H x 0.63"D, approx. 3.5 oz.)

Current measurement section:

Measurement category CAT III 600 V

(anticipated transient overvoltage 6000 V)

Voltage measurement section:

Measurement Category CAT III 300 V, CAT II 600 V

(anticipated transient overvoltage 4000 V)

Safety :EN61010

EMC :EN61326

±0.2 s

Page 2

Measurement Procedures

1. Set the function switch to ~A.

2. Clamp the tester on the conductor, so that the conductor passes through

the center of the clamp core. Clamp the tester on one lead only.

1

2

2

3

4

Outlet

Test leads

1. Plug the test leads into the

measurement terminal.

2. Set the function switch to ~V.

3. Connect the test leads to

the object to be measured.

When measuring AC voltage,

the polarity of the leads can

be ignored.

4. Read the display.

2

3

4

Red (+)

test lead

Black (-)

test lead

Battery

1. Plug the test leads into

measurement terminal.

2. Set the function switch

to V.

3. Connect the test leads to

the object to be measured.

4. Read the display.

2

3

4

Resistor

Test leads

1. Plug the test leads into

the measurement terminal.

2. Set the function switch

to

/ .

3. Connect the test leads

to the object to be

measured.

4. Read the display.

2

3

4

Test leads

Cord

1. Plug the test leads into

the measurement

terminal.

2. Set the function switch

to

/ .

3. Press key to

display " " indication.

4. Connect the test leads

to the object to be measured.

Conductivity is

good when the buzzer

sounds.

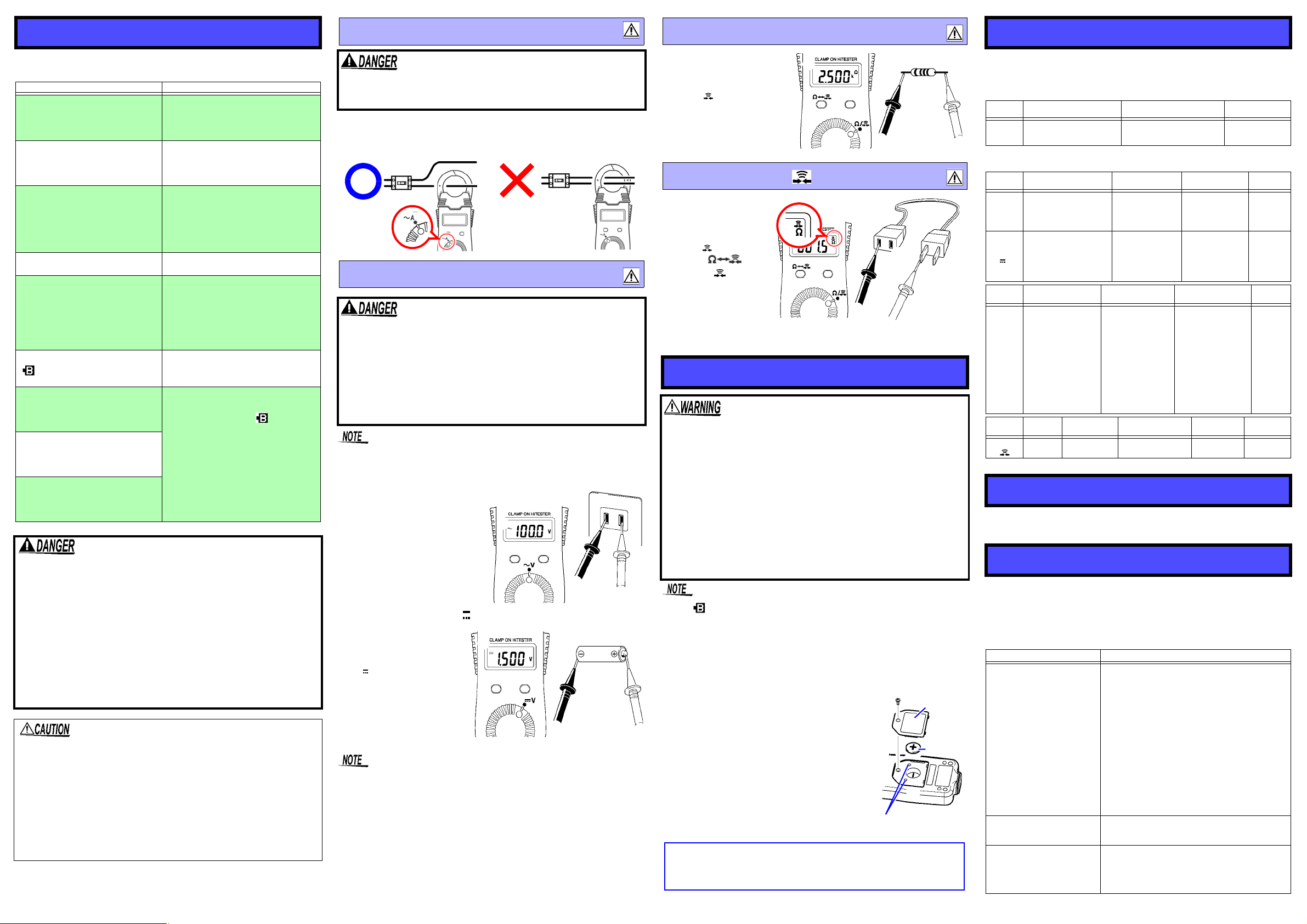

Battery

cover

Battery

1. Disconnect the test leads from the object to be mea-

sured and then switch the function selector to

[OFF].

2. Remove the instrument from the case, and remove

the screws on the battery cover.

3. Remove the used battery.

4. Being careful about the polarity, insert the new bat-

tery of the specified type.

(CR2032 lithium battery: Panasonic or MAXELL)

5. Replace the battery cover and fasten the screws.

Adjustment screws

CALIFORNIA, USA ONLY

This product contains a CR Coin Lithium Battery which contains Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

AC Current Measurement [

A]

Resistance Measurement [

]

Accuracy

Pre-Operation Inspection

Check the following before using the instrument.

Checkpoints In case of failures

Check whether the cladding of the

test lead is not torn and the white or

red portion (insulation layer) inside

the cable is not exposed.

Check whether the clamp sensor or

the case is free of damage.

Make sure that the mating portion of

the clamp sensor tip is mate properly.

Make sure there are no missing display of the LCD panel.

Make sure that the display of the

LCD panel is not dim or faint.

Make sure that the battery indicator

" " does not light up when power

is turned on.

Check whether the reading is

around 0 A when no measurements

are being made in current measurement mode.

Check whether the reading is

around 0 V while the test leads are

short-circuited in voltage measurement mode.

Check whether the reading is

around 0 while the test leads are

short-circuited in resistance measurement mode.

• Observe the following precautions to avoid electric shock.

• Always verify the appropriate setting of the function selector before connecting the test leads.Disconnect the test leads from the measurement object

before switching the function selector.

• Never apply voltage to the test leads when the Resistance, or Continuity

functions are selected. Doing so may damage the instrument and result in

personal injury.To avoid electrical accidents, remove power from the circuit

before measuring.

• Test leads and this product should only be connected to th e second ary side

of a breaker, so the breaker can prevent an accident if a short circuit occurs.

Connections should never be made to the primary side of a breaker,

because unrestricted current flow could cause a serious accident if a short

circuit occurs.

• Removable sleeves are attached to the metal pins at the ends of the test

leads.

To prevent a short circuit accident, be sure to use the test leads with the

sleeves attached when performing measurements in the CAT III measurement category. Remove the sleeves from the test leads when performing

measurements in the CAT II measurement categories. For details on measurement categories, see "Measurement categories" in the instruction

manual.

• When performing measurements with the sleeves attached, be careful to

avoid damaging the sleeves. If the sleeves are inadvertently removed during measurement, be especially careful in handling the test leads to avoid

electric shock.

• The tips of the metal pins are sharp, so take care not to injure yourself.

When damage is found, replace with

the specified new test leads Model

L9208. Failure to do so may result in

electric shock.

If damage has occurred,

avoid using the instrument. Use of the

instrument under these conditions may

result in electric shock.

If the mating portions do not mate properly, accurate measurements cannot

guaranteed. Gently wipe off any dirt

with a soft cloth found on the surface of

the mating portions. If the sensors do

not mate properly, repair is necessary.

If missing, repair is necessary.

If the display is dim or faint, the envi-

ronmental condition may be low temperature (lower than 0°C) or battery

may be exhausted. In case of battery

exhaustion, replace battery.

If the display remains dim even after

the battery is replaced, repair is necessary.

If the indicator is on, the measurement

accuracy cannot be guaranteed.

Replace battery immediately.

If not, confirm that the " " indication

does not appear in the display or confirm that the test leads are not disconnected.

If no problems for the above, the instrument is possibly being damaged.(SeeTroubleshooting)

5678

To avoid short circuits and potentially life-threatening hazards, never attach the

instrument in current measurement mode to a circuit that operates at more

than the maximum rated voltage to earth CAT III 600 V.

Voltage Measurement

• The maximum input voltage is 600 VDC/AC

Attempting to measure voltage in excess of the maximum input could

destroy the instrument and result in personal injury or death.

• To avoid electrical shock, be careful to avoid shorting live lines with the test

leads.

• In voltage measurement mode, the maximum rated voltage between input

terminals and ground is CATIII 300 V or CATII 600 V. Do not measure voltages exceeding these CATIII 300 V or CATII 600 V with respect to ground.

The attempt may damage the instrument and result in personal injury.

Make sure that the test lead plug is inserted into the measurement terminal of

the instrument correctly.

Measuring AC Voltage [~V]

Measuring DC Voltage [ V]

Reversing the polarity of the test leads displays a negative value.

Continuity Test [ ]

Replacing Battery

• If the instrument is connected to a line that is to be measured, dangerous

voltage levels may be applied to the terminals, and removing the case may

expose live components.

To avoid electric shock when replacing the battery, first disconnect the test

leads from the object being measured. Also, after replacing the battery,

always replace the cover and tighten the screw before using the instrument.

• Use only CR2032 (Panasonic or MAXELL) lithium battery. Use of any other

battery may result in explosion.

• Be careful to observe battery polarity during installation.

Otherwise, poor performance or damage from battery leakage could result.

• Battery may explode if mistreated.

Do not short-circuit, recharge, disassemble or dispose of in fire.

• Handle and dispose of batteries in accordance with local regulations.

• Keep batteries away from children to prevent accidental swallowing.

• The " " indicator lights up when the remaining battery capacity is low. In

this case, the instrument's reliability is not guaranteed. Replace the battery

immediately.

• The test battery is built in this instrument. The usable time depends on the

battery.When the test battery is exhausted, replace a new battery.

• CR2032 lithium batteries (Panasonic or MAXELL) can be purchased at electronics and appliance stores where specialized batteries are sold.

• Do not turn the adjustment screws as this may disrupt the m easurement

values.

• Guaranteed accuracy period is 1 year

sor 10,000 times, whichever comes first).

• Accuracy guarantee for temperature and humidity: 23±5°C (73°F±9°F) and 80%

RH or less (no condensation, battery warning indicator is not lighting)

• AC measurement: mean value measurement.

Func-

tion

ACA

[~A]

• Effect of conductor position: within±5.0%(in any direction from sensor center)

• Zero suppress: 5-count

Function Range (A ccur acy ra nge ) Accuracy* Input impedance

ACV

[~V]

DCV

[ V]

Function

Resistance

[]

Function

Continuity

[]

* rdg.: reading or displayed value, dgt.: resolution

Range (Accuracy range) Accuracy*

42.00 A

(4.00 to 41.99 A)

420.0 A (40.0 to 419.9 A)

1000 A (100 to 1000 A)

4.200 V (0.400 to 4.199 V)

42.00 V (4.00 to 41.99 V)

420.0 V (40.0 to 419.9 V)

600 V (400 to 600 V)

420.0 mV (40.0 to 419.9 mV)

4.200 V (0.400 to 4.199 V)

42.00 V (4.00 to 41.99 V)

420.0 V (40.0 to 419.9 V)

600 V (400 to 600 V)

Range

(Accuracy range)

420.0

(40.0 to 419.9 )

4.200 k

(0.400 to 4.199 k)

42.00 k

(4.00 to 41.99 k)

(40.0 to 419.9 k)

(0.400 to 4.199 M)

(4.00 to 41.99 M)

Range

420.0

k

420.0

4.200 M

42.00 M

Accuracy*

±2.0%rdg.±6dgt Less than 50 ±40 3.4 V or less

±10.0%rdg.±4dgt.

(Opening and closing of the Clamp sen-

±1.5%rdg. ±5dgt.

(Frequency range 50 -60 Hz)

±2.3%rdg. ±8dgt.

(Frequency range

50 -500 Hz)

±1.3%rdg. ±4dgt.

Accuracy*

±2.0%rdg. ±4dgt.

±2.0%rdg. ±4dgt.

±2.0%rdg. ±4dgt.

±2.0%rdg. ±4dgt.

±5.0%rdg. ±4dgt.

Threshold level

(beep sound)

11 M ±5%

10 M ±5%

10 M ±5%

10 M ±5%

100 M and over

11 M ±5%

10 M ±5%

10 M ±5%

10 M ±5%

Open terminal

voltage

3. 4 V or less

0.7 Vtyp. 3.4 V or less

0.47 Vtyp. 3.4 V or less

0.47 Vtyp. 3.4 V or less

0.47 Vtyp. 3.4 V or less

0.47 Vtyp. 3.4 V or less

Open terminal

voltage

Max. input

current

AC 2000 Arms

continuous

Max. input

voltage

AC

600 Vrms

DC

600 V

Overload

protection

250 V

AC/DC

Overload

protection

250 V

AC/DC

Maintenance and Service

To clean the instrument wipe it gently with a soft cloth moistened with water or

mild detergent. Never use solvents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and discolor the case.

Troubleshooting

When the instrument is not functioning properly and if you have not performed

the pre-operation inspection, please do so now. If you cannot find a problem in

the pre-operation inspection, please refer to the following symptoms before contacting your dealer or the nearest Hioki representative. When you send the unit

for repair, please pack the unit carefully so that it will not be damaged during

transport, and write a detailed description of the problem. Hioki cannot bear any

responsibility for damage that occurs during shipment.

Symptom Description

• Waveform containing components out of the

frequency property range cannot be measured accurately.

• In the case that the sample to be measured is a

distorted waveform, the measured value with

The measured value of

current or voltage is different

from the measured value

with other clamp-on tester.

The measured current value

is smaller than expected.

The measured current value

is larger than expected.

(current value is displayed

even with no input.)

the 3280-10 (Average value rectified, effective

value display) and that with another clamp-on

tester using the True RMS method are different.

For measuring a distorted waveform, we recommend using a true RMS clamp-on tester.

• In the case that the sample to be measured is

the waveform with both AC and DC components, half or full-wave rectified waveform,

accurate measurement is not be possible due

to the large margin of error. We recommend

using another instrument with AC+DC mode.

The measurement value is not correct, if the

measurement is performed leaving the clamp

jaws open.

Accurate measurement is not possible in the

presence of strong magnetic fields, such as

transformers and high-current conductors, or in

the presence of strong electromagnetic fields

such as radio transmitters.

Loading...

Loading...