Page 1

3273-50

3276A981-05

3276

CLAMP ON PROBE

Instruction Manual

Mar. 2020 Revised edition 5

3276A981-05 20-03H

EN

Page 2

3276A981-05

Page 3

Contents

3276A981-05

Introduction i

Inspection

Notes on Safety

Notes on Use

Chapter 1 Overview

1.1 Product Overview 1

1.2 Features

1.3 Names of Parts

1.4 Parts of the Sensor

Chapter 2 Specifications 5

2.1 Product Specifications 5

2.2 Standards Applying

Chapter 3 Measurement Procedure 11

3.1 Notes on Use 11

3.2 Preparations for Measurement

3.3 Demagnetizing and Zero Adjustment

3.4 Measurement Procedure

11

12

16

i

i

iii

1

1

2

2

7

3276A981-05

Page 4

3276A981-05

Page 5

―――――――――――――――――――――――――――

3276A981-05

Introduction

Thank you for purchasing the HIOKI 3273-50,3276

CLAMP ON PROBE. To obtain maximum

performance from the device, please read this

manual first, and keep it handy for future reference.

Inspection

When you receive the device, inspect it carefully to

ensure that no damage occurred during shipping. If

damage is evident, or if it fails to operate according

to the specifications, contact your dealer or Hioki

representative.

Supplied accessories

Instruction manual 1

3273-50 Soft case 1

3276 Carrying case 1

Notes on Safety

WARNING

This deviceis designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested

for safety prior to shipment. However,

mishandling during use could result in injury or

death, as well as damage to the device. Be certain

that you understand the instructions and

precautions in the manual before use. W e

disclaim any responsibility for accidents or

injuries not resulting directly from device defects.

i

――――――――――――――――――――――――

Introduction

Page 6

ii

3276A981-05

―――――――――――――――――――――――――――

Safety Symbols

This manual contains information and warnings

essential for safe operation of the device and for

maintaining it in safe operating condition. Before

using the device, be sure to carefully read the

following safety notes.

The symbol printed on the device

indicates that the user should refer to a

corresponding topic in the manual (marked

with the

symbol) before using the

relevant function.

In the manual, the

symbol indicates

particularly important information that the

user should read before using the device.

Indicates that only insulated conductors

suited to the voltage of the circuit under

test can be measured.

――――――――――――――――――――――――

Notes on Safety

Page 7

―――――――――――――――――――――――――――

3276A981-05

iii

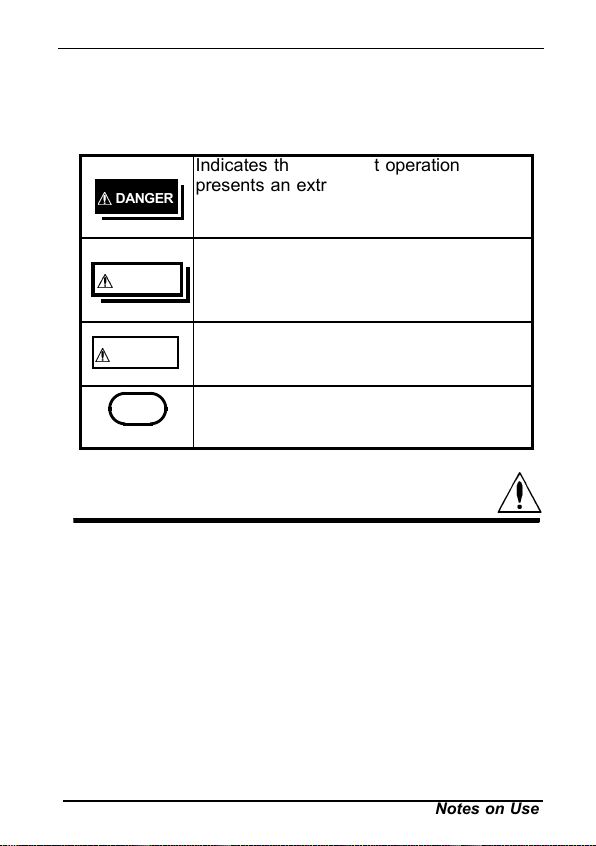

The following symbols in this manual indicate the

relative importance of cautions and warnings.

Indicates that incorrect operation

DANGER

presents an extreme hazard that could

result in serious injury or death to the

user.

Indicates that incorrect operation

WARN ING

presents a significant hazard that could

result in serious injury or death to the

user.

Indicates that incorrect operation

CAUTION

presents a possibility of injury to the user

or damage to the device.

NOTE

Indicates advisory items related to

performance or correct operation of the

device.

Notes on Use

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various

functions.

――――――――――――――――――――――――

Preliminary Check

Before using the device the first time, verify that it

operates normally to ensure that the no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

Notes on Use

Page 8

iv

3276A981-05

―――――――――――――――――――――――――――

DANGER

・

Do not measure around a bare conductor.

Doing so may result in short-circuit or electric

shock. Take measurements at a location on an

insulated wire where there is sufficient

insulation for the circuit voltage.

・

Refer to the derating characteristics when

measuring current that includes a

highfrequency component and never measure

any current that exceeds the rated current.

・

Use with high frequencies or strong magnetic

fields may cause the device to become

abnormally hot, resulting in fire, equipment

damage, or burns. (See“3 Specifications

”

(p5.))

・

Observe the following to avoid electric shock

and short circuits.

・

Connect the device to the 3269 or the 3272

Power Supply and waveform measurement

instrument (oscilloscope or recorder) first, and

then to the active lines to be measured

・

When the sensor is opened, do not shortcircuit

the conductor being measured or other two

wires with the metal part of the tip.

Be careful to avoid damaging the insulation

surface while taking measurements.

――――――――――――――――――――――――

Notes on Use

Page 9

―――――――――――――――――――――――――――

3276A981-05

DANGER

・

Before clamping the conductor being

measured,make sure that the insulation on the

conductor isundamaged. Also, take care not to

damage theinsulation when clamping the

conductor. Any damageto the insulation could

cause an electric shock.

This instrument is made for use with the 3269

or 3272 POWER SUPPLY.

To prevent fire or damage of the measurement

target and device as well as burns, exercise

caution concerning the following when

measuring high-frequency currents or currents

that contain high-frequency components:

Eddy current loss may cause heating of the

sensor head.

Dielectric heating may cause heating of cord

insulation and other materials.

This device should only be connected to the

secondary side of a breaker, so the breaker

can prevent an accident if a short circuit

occurs. Connections should never be made to

the primary side of a breaker, because

unrestricted current flow could cause a

serious accident if a short circuit occurs.

v

――――――――――――――――――――――――

Notes on Use

Page 10

vi

3276A981-05

―――――――――――――――――――――――――――

DANGER

Be sure to observe all operating precautions for

the waveform monitoring instrument

(oscilloscope or recorder) and other

measurement instruments to which this device

is connected.

When using a measurement instrument that

does not provide isolation between its input

terminals and chassis or other input terminals,

please pay attention to the following points.

If a signal is applied to an input terminal other

than that to which this device is connected, do

not connect the ground-side terminal to any

non-ground potential. Otherwise, short-circuit

current will flow through the 3269,3272 or this

device from the ground terminal, which could

cause an electrical accident or damage.

――――――――――――――――――――――――

Notes on Use

Page 11

―――――――――――――――――――――――――――

3276A981-05

vii

WARNING

Do not allow the device to get wet, and do not take

measurements with wet hands. This may cause an

electric shock.

・

Do not press the demagnetizing switch (DEMAG)

to perform demagnetization while the conductor

being measured is clamped. Doing so could

damage the circuitry or cause an accident that

might result in injury or death.

・

Ensure that the input does not exceed the

maximum rated current to avoid device damage,

shortcircuiting and electric shock resulting from

heat building.

――――――――――――――――――――――――

Notes on Use

Page 12

viii

3276A981-05

―――――――――――――――――――――――――――

CAUTION

To avoid damage to the device, protect it from

physical shock when transporting and handling. Be

especially careful to avoid physical shock from

dropping.

This device should be installed and operated

indoors only, between 0 and 40

(32 to 104 )

and 80% RH or less.

Do not store or use the device where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions,

the device may be damaged and insulation may

deteriorate so that it no longer meets

specifications.

This device is not designed to be entirely water- or

dust-proof. To avoid damage, do not use it in a wet

or dusty environment.

The sensor head is a precision assembly including

a molded component, a ferrite core, and a Hall

effect element. It may be damaged if subjected to

sudden changes in ambient temperature, or

mechanical strain or shock, and therefore great

care should be exercised in handling it.

The matching surfaces of the sensor head are

precisely ground, and should be treated with care.

If these surfaces are scratched, performance may

be impaired.

Measurements are degraded by dirt on the mating

surfaces of the sensor head, so keep the surfaces

clean by gently wiping with a soft cloth.

――――――――――――――――――――――――

Notes on Use

Page 13

―――――――――――――――――――――――――――

3276A981-05

ix

CAUTION

Foreign substances such as dust on the contact

surfaces of the sensor head can cause acoustic

resonance and degrade measurement, so it should

be cleaned by gently wiping with a soft cloth.

Refer to NOTE (p. 23) for resonance sound.

To avoid damaging the cables, do not bend or pull

the sensor cable and power supply cable.

Keep the clamp jaws and core slits free from

foreign objects, which could interfere with clamping

action.

・

Do not apply a static electricity or other source of

high voltage to the sensor. Doing so may damage

its internal Hall elements and circuitry

・

To clean the device, wipe it gently with a soft cloth

moistened with water or mild detergent. Never

use solvents such as benzene, alcohol, acetone,

ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

When the power is on, keep the core section of the

sensor closed, except when clamping them onto

the conductor to be measured. The facing surface

of the core section can be scratched while it is

open

.Do not short-circuit the output terminal and do not

input voltage to the output terminal. The device

may be damaged.

――――――――――――――――――――――――

Notes on Use

Page 14

x

3276A981-05

―――――――――――――――――――――――――――

CAUTION

Keep the cables well away from heat sources, as

bare conductors could be exposed if the insulation

melts.

Keep the sensor head closed when not in use, to

avoid accumulating dust or dirt on the mating core

surfaces, which could interfere with clamp

performance.

NOTE

Correct measurement may be impossible in the

presence of strong magnetic fields, such as

near transformers and high-current conductors,

or in the presence of strong electromagnetic

fields such as near radio transmitters.

Service

When sending the device for repair, carefully to

prevent damage in transit. Include cushioning

material so the instrument cannot move within

the package. Be sure to include details of the

problem. Hioki cannot be responsible for

damage that occurs during shipment.

IMPORTANT

Periodic calibration is necessary in order to

ensure that the device provides correct

measurement results of the specified accuracy.

――――――――――――――――――――――――

Notes on Use

Page 15

―――――――――――――――――――――――――――

3276A981-05

Chapter 1

Overview

1.1 Product Overview

This device can be directly connected to a BNC

input connector of a waveform measuring

instrument such as an oscilloscope or recorder, and

by clamping on a conductor to be measured, allows

the current waveform to be easily captured.

1.2 Features

Highly accurate current detection

Easy current measurement

Broadband frequency characteristics

3273-50: DC~50MHz

3276: DC~100MHz

Compact and permits measurement of low

current levels

Easy protect function at excessive input

Unique HIOKI development of thin film Hall

effect element

1

――――――――――――――――――――――――

Chapter 1 Overview

Page 16

2

3276A981-05

―――――――――――――――――――――――――――

1.3 Names of Parts

External view

Current direction

indication

Sensor Terminator

3

1

"UNLOCK" indication

2

Sensor cable

5

Power supply

cable

1.4 Parts of the Sensor

Opening lever

1

Operating lever for opening the sensor head. Always

use this lever to open the sensor head.

Sensor head

2

This clamps the conductor being measured, and

carries out the actual current measurement. It is a

precision assembly including a molded component, a

ferrite core, and a Hall effect element. It may be

damaged if subjected to sudden changes in ambient

temperature, or mechanical strain or shock, and

therefore great care should be exercised in handling

it.

――――――――――――――――――――――――

Chapter 1 Overview

6

7

4

Page 17

―――――――――――――――――――――――――――

3276A981-05

3

Demagnetizing switch (DEMAG)

This demagnetizes the core if it has been magnetized

by switching the power on and off, or by an

excessive input. Always carry out demagnetizing

before measurement.

The demagnetizing process takes about one second.

During demagnetizing, a demagnetizing waveform is

output.

4

Zero adjustment dial (ZERO ADJ)

Use the zero adjustment dial to correct for the effect

of a voltage offset or temperature drift on the device.

When beginning measurement, after demagnetizing

always carry out zero adjustment.

5

Coarse adjustment trimmer

Use this only when adjustment is not possible within

the range of the zero adjustment dial.Use a

nonconductive screwdriver (e.g. ceramic driver) for

adjustment.

6

Output connector

The current waveform of the measured conductor is

output at a constant rate (0.1 V/A).

Connect to the BNC input connector of the

waveform measuring instrument.

3

NOTE

――――――――――――――――――――――――

The output of this device is terminated internally.

Since the output resistance is 25Ω, the device

must be used with a waveform measurement

instrument (oscilloscope,recorder, etc.) that has an

input impedance of at least 1 MΩ. Accurate

measurement is not possible with waveform

measurement instruments that have an input

resistance of 50Ω.

Chapter 1 Overview

Page 18

4

3276A981-05

―――――――――――――――――――――――――――

NOTE

If using BNC-banana plug adapters or similar to

connect to input terminals other than BNC

connectors, make sure the polarity is correct.

Turn the collar until it clicks, and check that it is

locked securely.

Power plug

7

Connect this to the 3269 or 3272 POWER SUPPLY

receptacle to supply power to the sensor terminator.

――――――――――――――――――――――――

Chapter 1 Overview

Page 19

―――――――――――――――――――――――――――

3276A981-05

Chapter 2

Specifications

2.1 Product Specifications

Accuracy is guaranteed at 23 5 (73 9 )

after the power has been on for 30 minutes.

Frequency

range

Rise time

Maximum

continuous input

range

Maximum peak

current value

Output voltage

rate

Amplitude

accuracy

Noise

Input impedance

3273-50:DC to 50 MHz (-3 dB)

(Characteristics shown in Fig.1)

3276:DC to 100 MHz (-3 dB)

(Characteristics shown in Fig.2)

3273-50 :7 ns or less

3276 :3.5 ns or less

30 Arms

(Derating according to frequency shown

in Fig.3 Fig.4)

Non-continuous 50 A peak

0.1 V/A

1.0% rdg. 1mV;to30Arms

2.0% rdg. ; to 50 A peak

(DC, and 45 to 66 Hz, input within

continuous maximum input range)

Equivalent to 2.5 mArms or less (for 20

MHz band measuring instrument)

(Characteristics shown in Fig.5 Fig.6)

5

――――――――――――――――――――――――

Chapter 2 Specifications

Page 20

6

3276A981-05

―――――――――――――――――――――――――――

Temperature

coefficient for

sensitivity

Maximum rated

power

Rated supply

voltage

Operating

temperature and

humidity range

Storage

temperature and

humidity range

Location for use

Effect of

external

magnetic fields

Diameter of

measurable

conductors

Measurable

conductors

Guaranteed

accuracy period

Cable lengths

2% or less (During input of 50 Hz 30

Arms within range of 0 to 40 (32 to

))

104

3273-50:5.3 VA 3276:5.3VA

12 V 0.5 V

0to40 (32 to 104 ), 80 % RH or

less (no condensation)

-

10 to 50 (14 to 122 ), 80 % RH or

less (no condensation)

Indoor, altitude up to 2000 m (6562 feet)

Pollution Degree 2

3273-50:Equivalent to a maximum of

20 mA

3276:Equivalent to a maximum of 5 mA

(DC and 60 Hz, Magnetic field of 400

A/m)

5 mm dia.

0.2" dia.

Insulated conductor

1year

(Opening/closing up to 10,000 times)

Sensor cable Approx. 1.5 m (59.0")

Power supply cable Approx. 1 m (39.4")

――――――――――――――――――――――――

Chapter 2 Specifications

Page 21

―――――――――――――――――――――――――――

3276A981-05

External

dimensions

Mass

Accessories

Product

warranty period

Sensor

Approx. 175W×18H×40Dmm

Approx. 6.89"W×0.71"H×1.58"D

(excluding protrusions)

Terminator

Approx. 27H×55W×18D mm

Approx. 1.06"W×2.17"H×0.71"D

3273-50 Approx. 230g Approx. 8.1 oz.

3276 Approx. 240g Approx. 8.5 oz.

3273-50 Instruction manual, Soft case

3276 Instruction manual, Carrying case

1year

2.2 Standards Applying

Safety

EMC

EN61010

EN61326

7

――――――――――――――――――――――――

Chapter 2 Specifications

Page 22

8

3276A981-05

―――――――――――――――――――――――――――

Fig.1 Frequency characteristics

(Typical characteristics of 3273-50

)

Fig.2 Frequency characteristics

(Typical characteristics of 3276)

――――――――――――――――――――――――

Chapter 2 Specifications

Page 23

―――――――――――――――――――――――――――

3276A981-05

Fig.3Derating according to frequency(3273-50)

9

――――――――――――――――――――――――

Fig.4 Derating according to frequency(3276)

Chapter 2 Specifications

Page 24

10

3276A981-05

―――――――――――――――――――――――――――

Fig.5 Input impedance

(Typical characteristics of 3273-50

)

Fig.6 Input impedance

(Typical characteristics of 3276

――――――――――――――――――――――――

Chapter 2 Specifications

)

Page 25

―――――――――――――――――――――――――――

3276A981-05

11

Chapter 3

Measurement

Procedure

3.1 Notes on Use

Before using the instrument, make sure to refer to

Notes on Use" (p. iii to xi)

3.2 Preparations for Measurement

(1) Have the 3269,3272 POWER SUPPLY, and

oscilloscope or recorder for waveform measurement

ready.

CAUTION

Before turning on the power, make sure that the

voltage of the power supply being used matches the

supply voltage indicated on the rear panel of the

3269,3272.

――――――――――――――――――――――――

(2) Turn the power switch off and connect the power

cord.

Chapter 3 Measurement Procedure

Page 26

12

3276A981-05

―――――――――――――――――――――――――――

(3) Connect the power plug of the 3273-50,3276 to the

power receptacle of the 3269,3272.

(4) Turn the 3269,3272 power switch on, and check

that the front panel power indicator lights.

3.3 Demagnetizing and Zero Adjustment

(1) With the waveform measurement instrument input at

ground, adjust the trace to the zero position.

(2) Set the input coupling of the waveform measurement

instrument to DC.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 27

―――――――――――――――――――――――――――

3276A981-05

13

(3) Connect the output connector of the 3273-50,3276

to the input connector of the waveform measurement

instrument. Turn the collar until it clicks, and check

that it is locked securely.

CAUTION

When disconnecting the output connector, be sure

to release the lock before pulling off the connector.

Forcibly pulling the connector without releasing the

lock, or pulling on the cable, can damage the

terminator.

If using BNC-banana plug adapters or similar to

connect to input terminals other than BNC

connectors, make sure the polarity is correct.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 28

14

3276A981-05

―――――――――――――――――――――――――――

CAUTION

Do not demagnetize while the 3273-50,3276 is

clamping a conductor to be measured.

Demagnetizing causes current to flow into the

conductor, which may damage parts in the circuit

to be measured.

Demagnetizing

NG

Conductor

Check that the conductor being measured is not

clamped when supplying power to the 327350,3276 for the same reason. Demagnetized

waveforms are generated when supplying electric

power.

(4) Without clamping the conductor to be measured,

press the opening lever until the "UNLOCK"

indication disappears, and check that the sensor

head is properly closed.

(5) Press the demagnetizing switch (DEMAG) on the

terminator.

(6) Turn the zero adjustment dial on the terminator, to

adjust the trace to the zero position.

NOTE

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

If zero adjustment is not possible in step 6, turn the

coarse adjustment trimmer to bring the trace

within the range of adjustment by the zero adjustment

dial.

Page 29

―――――――――――――――――――――――――――

3276A981-05

NOTE

Turning the coarse adjustment trimmer, do not

subject it to a thrust. Doing so may cause the

15

trimmer to come off. To turn the trimmer, use

a screwdriver with the following flat blade made

of a non-conductive material including ceramic:

0.4 mm in thickness, 1.8 mm in width,and 10 mm

in length or longer.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 30

16

3276A981-05

―――――――――――――――――――――――――――

3.4 Measurement Procedure

(1) Check that the system is safe, and that the

preparations described in the preceding section have

been carried out.

(2) Pull the sensor opening lever, so that the sensor

head opens.

Opening lever

(3) Align the sensor so that the current direction

indication corresponds to the direction of current

flow through the conductor to be measured, and

clamp so that the conductor is in the center of the

sensor aperture.

(4) Press the opening lever on the sensor head until the

"UNLOCK" indication disappears, and check that

the opening lever is firmly locked and the sensor

head securely closed.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 31

―――――――――――――――――――――――――――

3276A981-05

17

(5) It is now possible to monitor the current waveform.

The output rate of the 3273-50,3276 is 0.1 V/A.

The current sensitivity can be derived from the

voltage sensitivity of the waveform measurement

instrument. For example, if the voltage sensitivity is

10 mV/division, the current sensitivity is 100

mA/division.

NOTE

――――――――――――――――――――――――

When using the 3273-50,3276, note that two clampon probes may not be used simultaneously with the

3269or3272 POWER SUPPLY, depending on the

current to be measured.

The current consumption of clamp-on probes

depends on the current to be measured. Confirm

that the total current consumption of the clamp-on

probes does not exceed the rated output current of

the 3269or3272. See Fig. 7,8.

Chapter 3 Measurement Procedure

Page 32

18

3276A981-05

―――――――――――――――――――――――――――

600

500

400

300

200

100

Current consumption (mA)

0

0 1020304050

AC(f=50Hz)

DC

Current(A

)

Fig.7 Current consumption* vs. current to be measured

*The sum total of a positive and negative current consumption

600

500

400

300

200

100

Current consumption (mA)

0

Fig.7 Current consumption* vs. current to be measured

*The sum total of a positive and negative current consumption

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

(typical of 3273-50)

AC(f=50Hz)

DC

0 1020304050

Current (A)

(typical of 3276)

Page 33

―――――――――――――――――――――――――――

3276A981-05

CAUTION

19

The maximum continuous input range is based

on heat that is internally generated during

measurement. Never input current in excess of

this level. Exceeding the rated level may result

in damage to the probe.

・

The device may sustain damage from self-

heating even at current levels that are lower

than the maximum current value defined by the

maximum rated current.The maximum rated

current is a recommended value that assumes

sine-wave input under standard conditions.

Self-heating may increase if the ambient

temperature increases or the measurement

current waveform contains other frequency

components. Refer to the derating

characteristics in the product specifications.

Current measurement exceeding approx. 1kHz

may result in temperature rise on the sensorhead. This is attributed to excitation loss that

cannot be prevented due to natural physical

principles. Be careful to avoid injury, electric

shock due to short-circuits, or damage to the

device that may be caused by the increased

temperature.

If excess current is input, generated heat

activates a built-in safety function that blocks

normal output. If this happens, remove the

input immediately (remove the sensor from the

conductor being measured, or reduce the input

current to zero). Wait until the sensor has had

sufficient time to cool before resuming

operation.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 34

20

3276A981-05

―――――――――――――――――――――――――――

CAUTION

Even if the input current does not exceed the

rated continuous maximum, continuous input

for an extended period of time may result in

activation of the safety circuit to prevent

damage resulting from heating of the sensor.

At high ambient temperatures, the built-in safety

circuit may activate at current input levels

below the rated continuous maximum.

Continuous input of current exceeding the rated

maximum or repeated safety circuit activation

will degrade performance of the safety circuit,

possibly resulting in damage to the device.

The maximum input range is indicated by the

continuous maximum input range. It is also

indicated by another product specification

Maximum peak current: Noncontinuous 50 A

peak. This means that the upper limit of the

waveform response is 50 A peak. Make sure

that the input does not exceed the continuous

maximum input range in rms.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 35

―――――――――――――――――――――――――――

3276A981-05

CAUTION

21

Do not place any unclamped conductor with an

electriccurrentofafrequencyof10kHzor

more near the sensor head. Current flo wing in

the conductor nearby may heat up the sensor

head and cause its temperature to rise, leading

to damage to the sensor. For example, when

one side of a go-and-return conductor is

clamped and the other side is also placed near

the sensor head as shown in the diagram, even

iftheelectriccurrentislowerthanthe

consecutive maximum current, electric currents

in both sides will heat up the wires and raise

the temperature, thereby causing damage to the

sensor.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 36

22

3276A981-05

―――――――――――――――――――――――――――

CAUTION

When opening the sensor head of the probe, be

sure to operate with the opening lever. If an

upper core is forced to open, when the sensor

head is locked, the open-close mechanism can

be damaged.

Do not press

NOTE

Upper core

Immediately after powering on, this device may be

subject to an appreciable offset drift due to the

Lock state

effect of self-heating. To counteract this, allow the

device to warm up for about 30 minutes before

carrying out measurement.

When performing continuous measurements, it is

necessary to be aware that the offset voltage drifts,

depending on factors such as the ambient

temperature.

Under certain circumstances, oscillation may occur

if the probe is connected to the 3269 or 3272

POWER SUPPLY while the power supply is on.

This does not indicate a malfunction. Oscillation

can be stopped and operation restored to normal by

opening and closing the sensor head.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 37

―――――――――――――――――――――――――――

3276A981-05

NOTE

A resonant sound may be emitted depending on the

amplitude and frequency of the current being

measured. Such a sound may also be emitted dur

demagnetization. Measurement is not affected

Depending on the amplitude and frequency of the

current being measured, the sensor head may emit a

resonant sound. This sound may also occur during

demagnetizing operation, but it does not represent a

malfunction (device failure).

If foreign matter becomes adhered to the facing

surfaces on the sensor head so that a slight gap

exists between the upper and lower sensors, the

sensor head may emit a resonant sound. Any foreign

matter should be removed using the cleaning method

described in this manual (see“4.3 Cleaning”(p.

63)).

An increase in the volume of the resonant sound

during use may indicate that the gap between the

upper and lower sensors has increased in size. Since

the sensor characteristics may change, it is

recommended to calibrate the device (see“4

Maintenance and Service”(p. 57)).

Pressing the demagnetizing switch (DEMAG) will

cause a demagnetized waveform to be output from

the instrument. Although it may be asymmetry with

respect to the zero-volt line, the instrument has no

malfunction.

The measurement may be affected by the position

within the clamp aperture of the conductor being

measured. The conductor should be in the center of

the clamp aperture.

When carrying out measurement, press the opening

lever until the "UNLOCK" indication disappears,

and check that the sensor head is properly closed. If

the sensor head is not properly closed, accurate

measurement will not be possible.

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

23

Page 38

24

3276A981-05

―――――――――――――――――――――――――――

At high frequencies, common mode noise may affect

measurements taken on the high voltage side of circuits. If

this occurs, reduce the frequency range of the waveform

measuring instrument, or clamp onto the low-voltage side

of the circuit, as appropriate.

H

Power

source

L

Accurate measurement may be impossible in locations

subject to strong external magnetic fields, such as

transformers and high-current conductors, or in locations

subject to strong external electric fields, such as radio

transmission equipment.

NG

Load

OK

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 39

3276A981-05

HIOKI E.E. CORPORATION

Page 40

3276A981-05

Page 41

3276A981-05

Page 42

3276A981-05

Loading...

Loading...