Page 1

Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

3272

POWER SUPPLY

December 2014 Revised edition 12 3272A981-12 14-12H

Page 2

Contents

Introduction i

Inspection

Notes on Safety

Precautions

i

ii

vi

Chapter 1 Overview

1.1 Product Overview 1

1.2 Names of Parts

Chapter 2 Specifications 5

2.1 Product Specifications 5

2.2 Standards Applying

Chapter 3 Measurement Procedure 7

3.1 Preparations 8

3.2 Measurement Procedure

Chapter 4 Description of Parts 13

4.1 Power Supply Receptacle 13

4.2 How to Change the Power Supply Fuse

and Change the Power Supply Voltage

3272A981-12

1

2

6

9

13

Page 3

―――――――――――――――――――――――――――

Introduction

Thank you for purchasing the HIOKI "Model 3272

POWER SUPPLY."

To obtain maximum performance from the product,

please read this manual first, and keep it handy for

future reference.

Inspection

When you receive the product, inspect it carefully to

ensure that no da mage occurred during shipping. If

damage is evident, or if it fails to operate according

to the specifications, contact your dealer or Hioki

representative.

Supplied accessories

Power cord 1

Instruction manual 1

Spare fuse 1

100 V, 120 V: F1.0 AL/250 V, 20 mm x 5 mm dia.

220 V, 240 V: F0.5 AL/250 V, 20 mm x 5 mm dia.

i

――――――――――――――――――――――――

Introduction

Page 4

ii

―――――――――――――――――――――――――――

Notes on Safety

WARNING

This product is designed to comply with IEC

61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However,

mishandling during use could result in injury or

death, as well as damage to the product. Using

the product in a way not described in this manual

may negate the provided safety features.

Be certain that you understand the instructions

and precautions in the manual before use. W e

disclaim any responsibility for accidents or

injuries not resulting directly from product

defects.

――――――――――――――――――――――――

Notes on Safety

Page 5

―――――――――――――――――――――――――――

iii

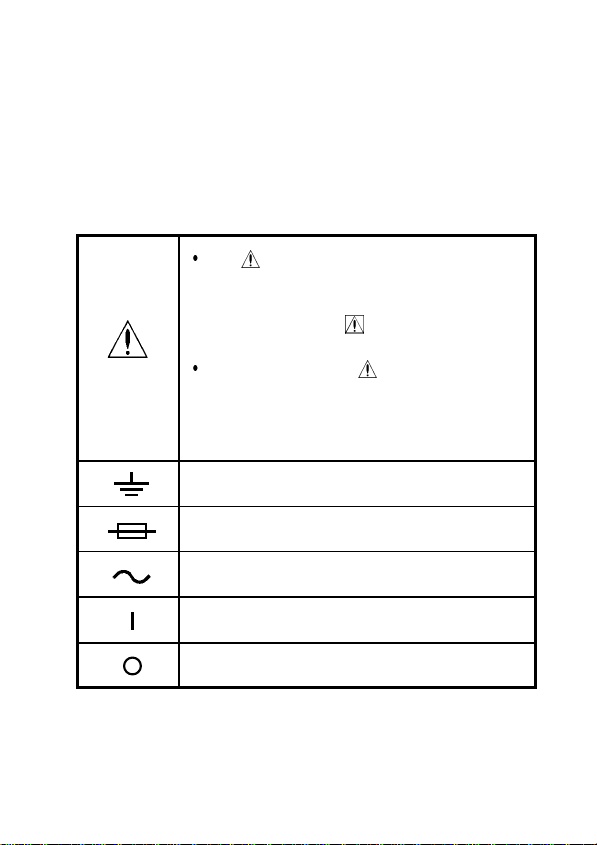

Safety Symbols

This manual contains information and warnings

essential for safe operation of the product and for

maintaining it in safe operating condition. Before

using it, be sure to carefully read the following

safety precautions.

The symbol printed on the product

indicates that the user should refer to a

corresponding topic in the manual

(marked with the

symbol) before

using the relevant function.

In the manual, the symbol indicates

particularly important information that

the user should read before using the

product.

Indicates a grounding terminal.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates the ON side of the power

switch.

Indicates the OFF side of the power

switch.

――――――――――――――――――――――――

Notes on Safety

Page 6

iv

―――――――――――――――――――――――――――

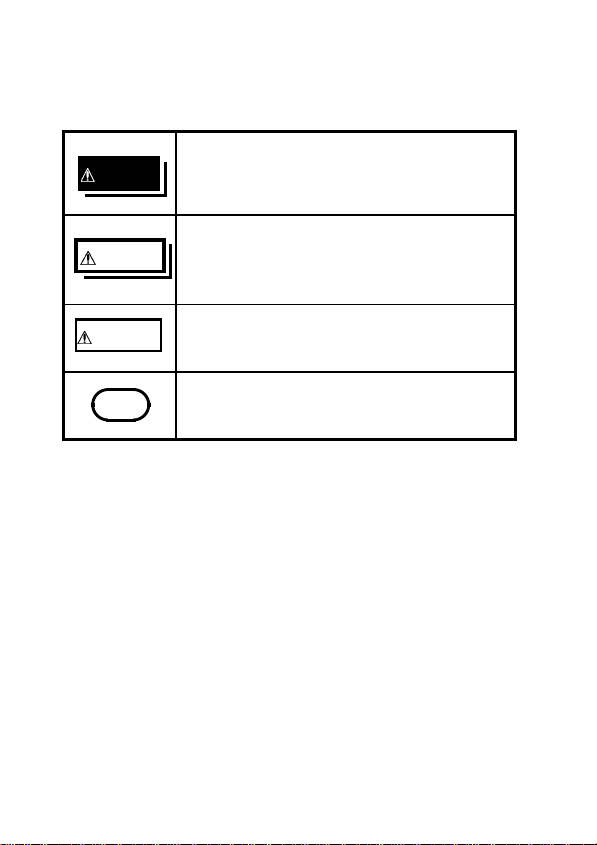

The following symbols are used in this Instruction

Manual to indicate the relative importance of

cautions and warnings.

Indicates that incorrect operation

DANGER

presents an extreme hazard that could

result in serious injury or death to the

user.

Indicates that incorrect operation

WARNING

presents a significant hazard that could

result in serious injury or death to the

user.

Indicates that incorrect operation

CAUTION

presents a possibility of injury to the

user or damage to the product.

Indicates advisory items related to

NOTE

performance or correct operation of the

product.

――――――――――――――――――――――――

Notes on Safety

Page 7

―――――――――――――――――――――――――――

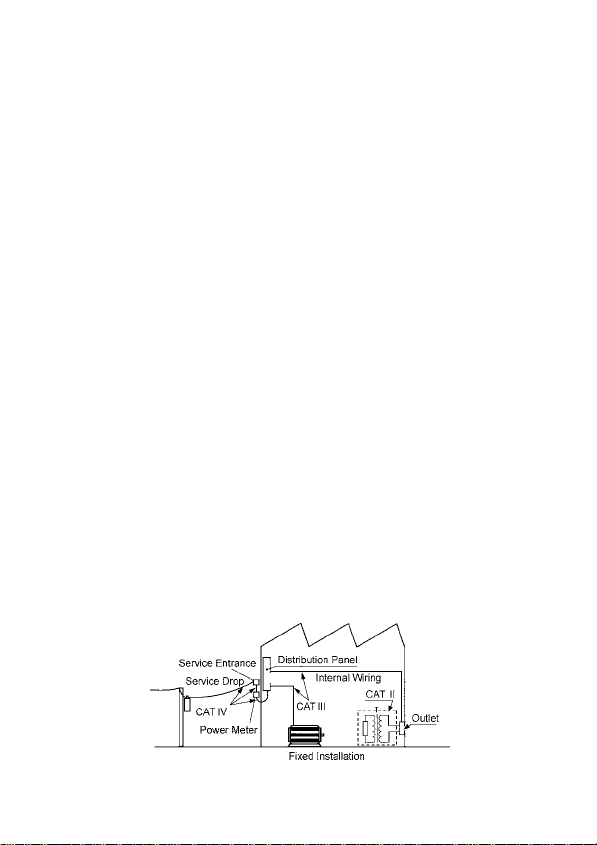

Measurement categories

To ensure safe operation of measurement products,

IEC 61010 establishes safety standards for various

electrical environments, categorized as CAT II to

CAT IV, and called measurement categories.

CAT II : Primary electrical circuits in equipment

connected to an AC electrical outlet by a

power cord (portable tools, household

appliances, etc.) CAT II covers directly

measuring electrical outlet receptacles.

CAT III : Primary electrical circuits of heavy

equipment (fixed installations) connected

directly to the distribution panel, and

feeders from the distribution panel to

outlets.

CAT IV : The circuit from the service drop to the

service entrance, and to the power meter

and primary overcurrent protection device

(distribution panel).

Using a measurement product in an environment

designated with a higher-numbered category than

that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CATrated in CAT II to CAT IV measurement

applications could result in a severe accident, and

must be carefully avoided.

v

――――――――――――――――――――――――

Notes on Safety

Page 8

vi

―――――――――――――――――――――――――――

Precautions

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various

functions.

Preliminary Check

Before using the product for the first time, verify

that it operates normally to ensure that no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

――――――――――――――――――――――――

Precautions

Page 9

―――――――――――――――――――――――――――

vii

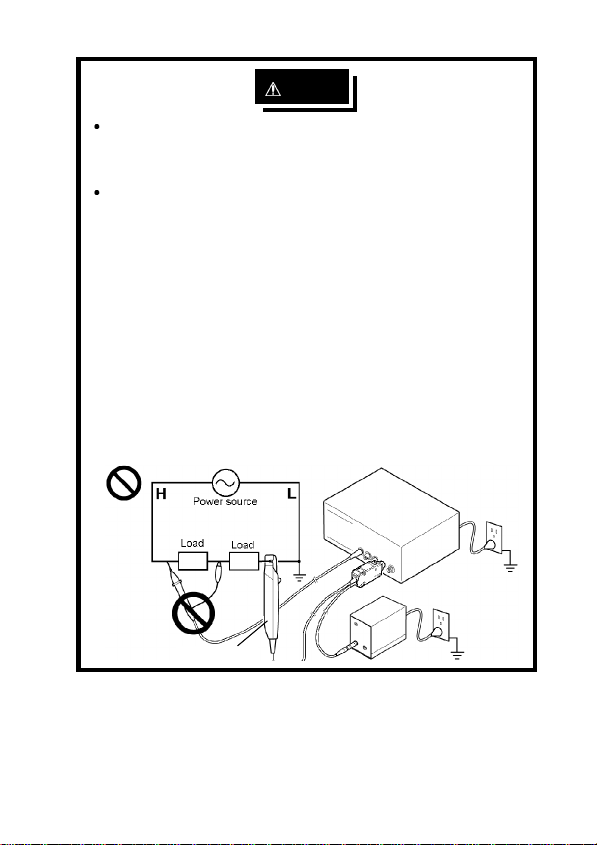

DANGER

To avoid accidents, when using other

measurementdevices with this one, observe the

usage precautions described for each device.

When using a measurement instrument that

does not provide isolation between its input

terminals and chassis or other input terminals,

please pay attention to the following points.

If a signal is applied to an input terminal other

than that to which the current probe is

connected, do not connect the ground-side

terminal to any non-ground potential.

Otherwise, short-circuit current will flow

through the current probe or this device from

the ground terminal, which could cause an

electrical accident or damage.

Current Probe

――――――――――――――――――――――――

Precautions

Page 10

viii

―――――――――――――――――――――――――――

WARNING

To avoid electrical accidents and to maintain the

safety specifications of this instrument, connect

the power cord only to a 3-contact (two-conductor

+ ground) outlet.

CAUTION

To avoid damage to the product, protect it from

physical shock when transporting and handling. Be

especially careful to avoid physical shock from

dropping.

Do not store or use the product where it could be

exposed to direct sunlight, high temperature or

humidity, or condensation. Under such conditions,

the product may be damaged and insulation may

deteriorate so that it no longer meets

specifications.

To avoid damaging the power cord, grasp the plug,

not the cord, when unplugging the cord from the

power outlet.

This product is not designed to be entirely water- or

dust-proof. Do not use it in an especially dusty

environment, nor where it might be splashed with

liquid. This may cause damage.

――――――――――――――――――――――――

Precautions

Page 11

―――――――――――――――――――――――――――

ix

Maintenance & Service

To clean the product, wipe it gently with a soft

cloth moistened with water or mild detergent.

Never use solvents such as benzene, alcohol,

acetone, ether, ketones, thinners or gasoline, as

they can deform and discolor the case.

If the product seems to be malfunctioning, contact

your dealer or Hioki representative.

When sending the product for repair, pack

carefully to prevent damage in transit. Include

cushioning material so the instrument cannot

move within the package. Be sure to include

details of the problem.

Hioki cannot be responsible for damage that

occurs during shipment.

――――――――――――――――――――――――

Precautions

Page 12

―――――――――――――――――――――――――――

Chapter 1

Overview

1.1 Product Overview

This unit is the power supply dedicated to Models

3273-50, 3273, 3274, 3275, and 3276 Clamp on

Probe (hereafter referred to as thecurrent probe),

as well as Models CT6700 and CT6701 Current

Probe.

1

――――――――――――――――――――――――

Chapter 1 Overview

Page 13

2

―――――――――――――――――――――――――――

1.2 Names of Parts

External view

Power

indicator

Power supply receptacles

Front view

――――――――――――――――――――――――

Chapter 1 Overview

Page 14

―――――――――――――――――――――――――――

Power supply

connector Fuse holder

Power

switch

Voltage

window

On

Off

Grounding terminal

Rear view

3

――――――――――――――――――――――――

Chapter 1 Overview

Page 15

―――――――――――――――――――――――――――

Chapter 2

Specifications

2.1 Product Specifications

Compatible

sensors

Number of

power supply

connectors

Output voltage

Rated output

current

Ripple voltage

Load influence

Temperature

influence

Power supply

voltage

influence

Operating

temperature and

humidity range

3273-50, 3273, 3274, 3275, 3276 Clamp

On Probe and CT6700, CT6701 Current

Probe

2

12 V 0.5 V

600 mA (sum total of all channels and

all output voltages)

3 mVp-p or less (at rated output current)

Within output voltage limits indicated

above for current output in the range 0

to 600 mA.

Within output voltage limits indicated

above for ambient temperature in the

range 0 to 40

Within output voltage limits indicated

above for the rated power supply

voltage,

0to40 (32 to 104 ), 80% RH or

less (no condensation)

(32 to 104 ).

10%.

5

――――――――――――――――――――――――

Chapter 2 Specifications

Page 16

6

―――――――――――――――――――――――――――

10 to 50 (14 to 122 ), 80% RH or

Storage

temperature and

humidity range

Location for use

Rated supply

voltage

Rated supply

frequency

Maximum rated

power

External

dimensions

Mass

Accessories

-

less (no condensation)

Indoor,altitude up to 2000 m (6562 feet)

100 V AC (120, 220, and 240 V require

specification) (Voltage fluctuation of

10% from the rated supply voltage are

taken into account.)

50/60 Hz

20 VA

Approx. 73W x 110H x 186D mm

Approx. 2.87"W x 4.33"H x 7.32"D

Approx. 1.1 kg

Approx. 38.8 oz.

Power cord, Instruction manual,

Spare fuse

F1.0 AL/250 V, 20 mm x 5 mm dia.

(for 100 V and 120 V models)

or

F0.5 AL/250 V, 20 mm x 5 mm dia.

(for 220 V and 240 V models)

2.2 Standards Applying

Safety

EMC

――――――――――――――――――――――――

Chapter 2 Specifications

EN61010, Pollution Degree 2

EN 61326

EN 61000-3-2

EN 61000-3-3

Page 17

―――――――――――――――――――――――――――

Chapter 3

Measurement

Procedure

7

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 18

8

―――――――――――――――――――――――――――

3.1 Preparations

DANGER

To avoid accidents, when using other

measurementdevices with this one, observe the

usage precautions described for each device.

When using a measurement instrument that

does not provide isolation between its input

terminals and chassis or other input terminals,

please pay attention to the following points.

If a signal is applied to an input terminal other

than that to which the current probe is

connected, do not connect the ground-side

terminal to any non-ground potential.

Otherwise, short-circuit current will flow

through the current probe or this device from

the ground terminal, which could cause an

electrical accident or damage.

Current Probe

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 19

―――――――――――――――――――――――――――

WARNING

Before turning the p roduct on, make sure the

supply voltage matches that indicated on its

power c onnector. Connection to an improper

supply voltage may damage the product and

present an electrical hazard.

(1) Turn the power switch off and connect the power

cord.

(2) Connect the power plug of the sensor to be used to

the power receptacle of the 3272.

(3)

Turn the 3272 power switch on, and check that the

front panel power indicator lights.

3.2 Measurement Procedure

See the 3273-50, 3273, 3274, 3275, 3276, CT6700

or CT6701 instruction manual.

NOTE

Make sure the sum of the current consumption of

the connected current probe does not exceed the

rated output current of the 3272 (See Fig.1).

When using the 3272 with Model 3273-50, 3273,

3274, 3275, 3276, CT6700 or CT6701 in general

only one current probe may be connected.

However, depending on the current level of the

object under test, two current probes may be

connected simultaneously.

The current consumption of a current probe is

dependent upon the current level of the object under

test.

9

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 20

10

―――――――――――――――――――――――――――

600

)

A

500

m

(

n

o

400

i

t

p

m

300

u

s

n

200

o

c

t

n

100

e

r

r

u

0

c

0 1020304050

AC(f=50Hz)

DC

(1) 3273-50 current (A)

600

)

A

500

m

(

n

o

400

i

t

p

m

300

u

s

n

o

200

c

t

n

100

e

r

r

u

c

0

0 100 200 300

AC(f=50Hz)

DC

(2) 3274 current (A)

600

)

A

500

m

(

n

400

o

i

t

p

300

m

u

s

n

200

o

c

t

100

n

e

r

r

u

0

c

0 100 200 300 400 500 600 700

AC(f=50Hz)

DC

(3) 3275 current (A)

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 21

―――――――――――――――――――――――――――

600

)

A

500

m

(

n

400

o

i

t

p

300

m

u

s

n

200

o

c

t

n

100

e

r

r

u

0

c

0 1020304050

AC(f=50Hz)

DC

11

(4) 3276 current (A)

600

)

A

500

m

(

n

400

o

i

t

p

300

m

u

s

200

n

o

c

100

t

n

e

0

r

r

u

0102030

c

AC(f=50Hz)

DC

(5) 3273 current (A)

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 22

12

―――――――――――――――――――――――――――

)

A

m

(

n

o

i

t

p

m

u

s

n

o

c

t

n

e

r

r

u

c

(6) CT6700, CT6701 current (A)

Fig.1

Current consumption* vs. current to be measured(typical)

*The sum total of a positive and negative current consumption

――――――――――――――――――――――――

Chapter 3 Measurement Procedure

Page 23

―――――――――――――――――――――――――――

13

Chapter 4

Description of Parts

4.1 Power Supply Receptacle

The pin assignment of the receptacle is shown in the

following.

1 Not used

12

43

4.2 How to Change the Power Supply

Fuse and Change the Power Supply

Voltage

2Ground

3-12V

4+12V

The power supply fuse for the 3272 unit, and the

power supply voltage selector, are housed in the

power input socket on the rear panel.

――――――――――――――――――――――――

Chapter 4 Description of Parts

Page 24

14

―――――――――――――――――――――――――――

WARNING

To avoid electric shock, turn off the power

switch and disconnect the current probe before

replacing the fuse.

Replace the fuse only with one of the specified

characteristics and voltage and current ratings.

Never use unspecified fuses and never use the

product after the fuse holder has shorted. This

will damage the product and cause injury.

Supply voltage

100 V, 120 V : F1.0 AL/250 V 20 mm x 5 mm

dia.

220 V, 240 V : F0.5 AL/250 V 20 mm x 5 mm

dia.

To change the fuse, or to alter the power supply

voltage setting, use the following procedure with

reference to the figures.

1. Turn the power switch off, and then remove the

power cord.

2. Using a slot head screwdriver or the like, bias

sideways the catch which holds the fuse holder into

the power input socket as shown in the figure, and

then remove the fuse holder.

3. When changing the power supply fuse:

Change the power supply fuse for a new one of the

same rating and specification.

When altering the power supply voltage setting:

(1) Remove the voltage selector from the fuse

holder, and reinsert it after having rotated it so

that the desired new power supply voltage

――――――――――――――――――――――――

Chapter 4 Description of Parts

Page 25

―――――――――――――――――――――――――――

15

setting appears in the voltage window as shown

in the figure.

Then recheck the setting value shown in the

voltage window. (The voltage display is upside

down and backwards.).

(2) Change the power supply fuse for a new one

whose rating and specification are appropriate

for the new power supply setting.

4. Replace the fuse holder by reinserting it into the

power input socket.

Power input socket

Screwdriver

Pry the catch with a

slot head screwdriver

or the like and remove

the fuse holder.

Fuse holder

――――――――――――――――――――――――

Chapter 4 Description of Parts

Page 26

16

―――――――――――――――――――――――――――

When altering the power

supply voltage setting:

Fuse holder

Voltage

selector

Remove the voltage

selector, rotate it so that

the figures which will

appear in the voltage

window represent the

voltage of the power

supply which will now be

used, and then replace

it.

When changing the power

supply fuse:

Fuse holder

Voltage window

――――――――――――――――――――――――

Chapter 4 Description of Parts

Page 27

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Loading...

Loading...