Page 1

INSTRUCTION MANUAL

3255-50

DIGITAL HiTESTER

Page 2

Page 3

i

Contents

Contents

Introduction...............................................................1

Inspection..................................................................1

Safety Notes .............................................................2

Usage Notes.............................................................6

Chapter 1 Overview 13

1.1 Product Overview....................... ...... ..... ....13

1.2 Features....................................................13

1.3 Parts Names and Functions......................14

Chapter 2 Measurement Procedures 17

2.1 Connection................................................17

2.2 Voltage Measurement...............................19

2.3 Current Measurement ...............................21

2.4 Resistance Measurement..........................24

2.5 Continuity Check .......................................25

2.6 Diode Check..............................................26

Chapter 3 Additional Functions 27

3.1 Auto Range Function and Manual Range

Function.....................................................27

3.2 HOLD AUTO Function...............................29

3.3 Overflow Warning Function.......................30

3.4 Auto Power Save Function........................31

Page 4

Contents

ii

Chapter 4 Specifications 33

4.1 General Specifications..............................33

4.2 Accuracy ................................................... 37

Chapter 5 Maintenace and Service 39

5.1 Replacing the Batteries and Fuses........... 39

5.2 Cleaning and Storage............................... 42

5.3 Service......................................................43

Page 5

1

Introduction

Thank you for purchasing the HIOKI "3255-50

DIGITAL HiTESTER." To obtain maximum performance from the product, please read th is manual

first, and keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully

to ensure that no damage occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or

if it fails to operate according to the specifications,

contact your dealer or Hioki representative.

Introduction

Accessories

• 9207-10 TEST LEAD .....................................1

• Instruction Manual..........................................1

• R03 Manganese battery.................................2

(Supplied with this product, for monitor)

• 9371 CARRYING CASE ................................1

Options

• 9010 CLAMP ON PROBE

• 9018 CLAMP ON PROBE

Page 6

Safety Notes

2

Safety Notes

This manual contains information and warnings

essential for safe operation of the product and for

maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

This product is designed to conform to IEC

61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, mishandling during use could

result in injury or death, as well as damage to

the product. Be certain that you understand

the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not resulting

directly from product defects.

Page 7

3

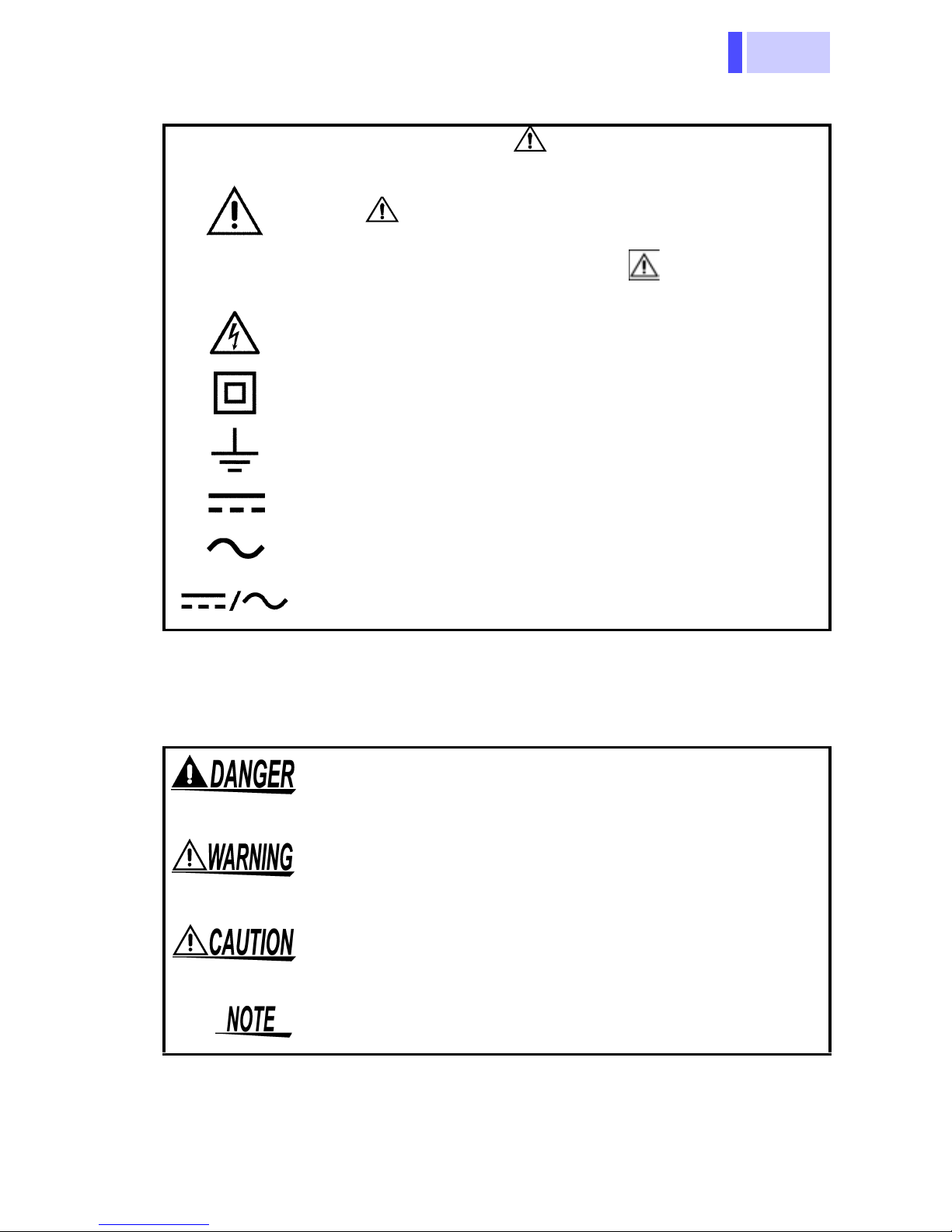

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should

read before using the product.

The symbol printed on the product indicates

that the user should refer to a corresponding topic

in the manual (marked with the symbol) before

using the relevant function.

Indicates that dangerous voltage may be present

at this terminal.

Indicates a double-insulated device.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Safety Notes

Symbols

Indicates AC (Alternating Current).

Indicates DC (Direct Current) or AC (Alternating

Current).

The following symbols in this manual indicate the

relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the product.

Advisory items related to performance or correct

operation of the product.

Page 8

Safety Notes

4

Other Symbols

Indicates the prohibited action

Accuracy

We define measurement tolerances in terms of f.s.

(full scale), rdg. (reading) and dgt. (digit) values,

with the following meanings:

f.s.

rdg.

dgt.

(maximum display value or scale length)

The maximum displayable value or the full length

of the scale. This is usually the maximum value of

the currently selected range.

(reading or displayed value)

The value currently being measured and indicated

on the measuring product.

(resolution)

The smallest displayable unit on a digital measuring product, i.e., the input value that causes the

digital display to show a "1".

Page 9

5

Safety Notes

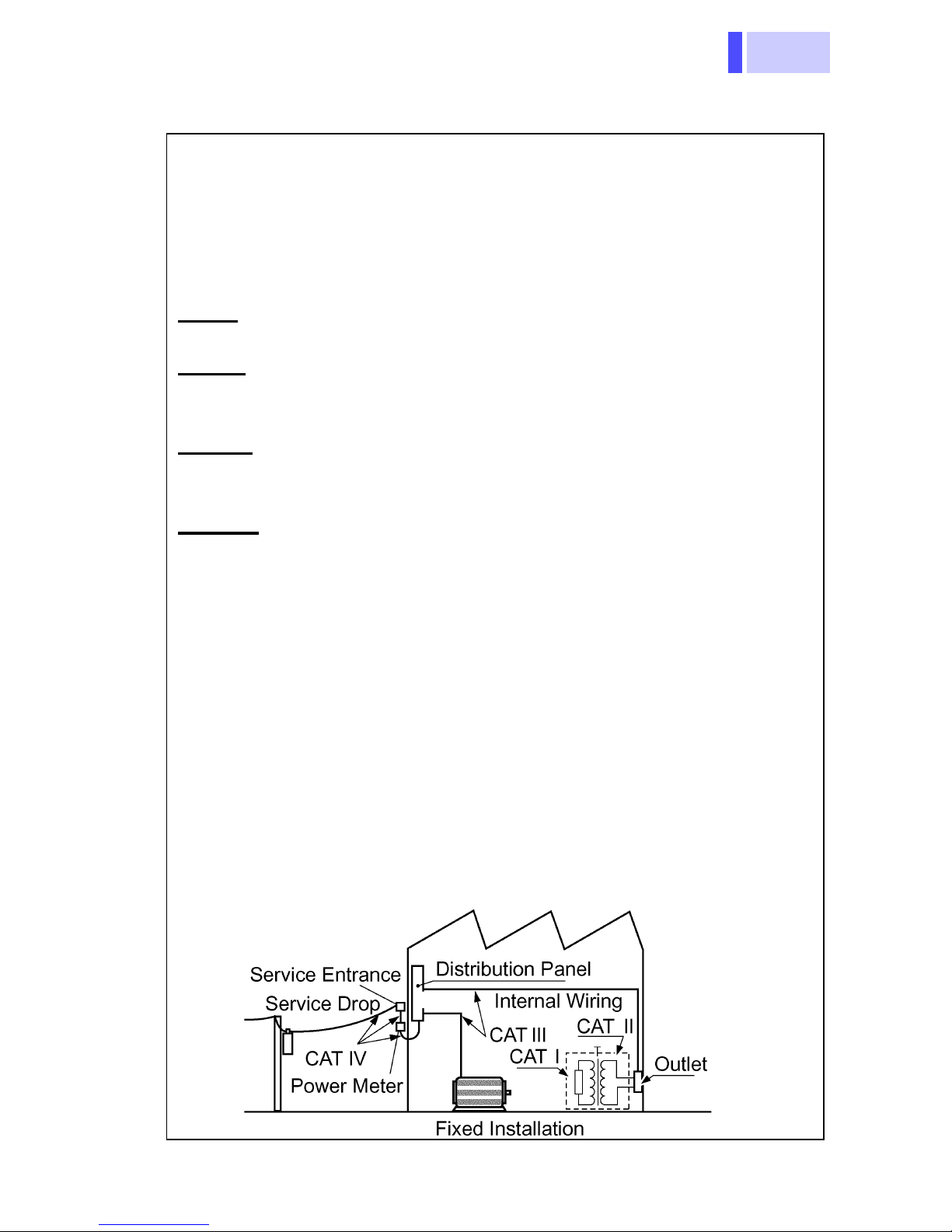

Measurement categories (Overvoltage categories)

This product conforms to the safety requirements for CAT III

600V, CAT II 1000V measurement products.

To ensure safe operation of measurement products, IEC

61010 establishes safety standards for various electrical environments, categorized as CAT I to CAT IV, and called measurement categories. These are defined as follows.

CAT I

trical outlet through a transformer or similar device.

CAT II

an AC electrical outlet by a power cord (portable tools, household appliances, etc.)

CAT III

installations) connected directly to the distribution panel, and

feeders from the distribution panel to outlets.

CAT IV

entrance, and to the power meter and primary overcurrent

protection device (distribution panel).

Higher-numbered categories correspond to electrical environments with greater momentary energy, so a measurement

: Secondary electrical circuits connect ed to an AC elec-

: Primary electrical circuits in equipment connected to

: Primary electrical circuits of heavy equipment (fixed

: The circuit from the service drop to the service

product designed for CAT III environments can endure

greater momentary energy than one designed for CAT II.

Using a measurement product in an environment designated

with a higher-numbered category than that for which the product is rated could result in a severe accident, and must be

carefully avoided.

Never use a CAT I measuring product in CAT II, III, or IV environments.

The measurement categories comply with the Overvoltage

Categories of the IEC60664 Standards.

Page 10

Usage Notes

6

Usage Notes

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various functions.

Inspection before Use

• Before using the product the first time, verify that it

operates normally to ensure that the no damage

occurred during storage or shipping. If you find any

damage, contact your dealer or Hioki representative.

• Before using the product, make sure that the insulation on the test leads is undamaged and that no

bare conductors are improperly exposed. Using

the product under such conditions could result in

electrocution. Replace the test leads with the

specified Hioki Model 9207-10.

Inst a llat ion, Ope ratin g Environm ent, and Handli ng

• To avoid electric shock, do not allow the

product to get wet, and do not use it when

your hands are wet.

• Do not use the product where it may be

exposed to corrosive or combustible

gases. The product may be damaged or

cause an explosion.

Page 11

7

Usage Notes

Observe the following to avoid damage to the

product.

• Installation and Operating Environment

Between 0°C and 40°C; 80% RH or less;

indoors only. Howev er, it can be safely operated

at as low as -10°C.

• Do not store or use the product where it could

be exposed to direct sunlight, high tem perature

or humidity, or condensation.

Under such conditions, the product may be

damaged and insulation may deteriorate so that

it no longer meets specifications.

• Although this product is designed to resist the

ingress of dust and water, it is not entirely wateror dust-proof, so to avoid shoc k or damage, do

not use it in a wet or dusty environment.

The protection rating for the enclosure of this

device (based on EN60529) is *IP54.

• Do not use the product near a device that generates a strong electromagnetic field or electrostatic charge, as these may cause erroneous

measurements.

• To avoid damage to the product , protect it from

vibration or shock during transport and handling,

and be especially careful to avoid dropping.

*IP54 This indicates the degree of protection provided by

the enclosure of the device against use in hazardous locations, entry of solid foreign objects, and

the ingress of water.

5: Protected against access to hazardous parts with

wire measuring 1.0 mm in diameter. Dust-proof

type (The penetration of dust cannot be prevented

completely, but quantities of dust that may hinder

the stated operation of equipment or safety cannot

penetrate the enclosure.)

4: The equipment inside the enclosure is protected

against the harmful effects of water splashed

against the enclosure from any direction.

Page 12

Usage Notes

8

• Adjustments and repairs should be made only

by technically qualified personnel.

• If the protective functions of the product are

damaged, either remove it from s ervice or mark

it clearly so that others do not use it inadvertently.

• To avoid corrosion from battery leakage, remove

the batteries from the product if it is to be stored

for a long time.

• Accurate measurement may be impossible in the

presence of strong magnetic fields, such as near

transformers and high-current conductors, or in

the presence of strong electromagnetic fields

such as near radio transmitters.

• To avoid battery depletion, turn the function

selector OFF after use (the Auto Power Save

feature consumes a small amount of current).

• The indicator appears when ba ttery voltage

becomes low. Replace the batteries as soon as

possible.

Handling the Cables

• The ends of the test leads are sharp. Be careful

to avoid injury.

• To avoid damaging the cables, do not bend or

pull the cables.

• Avoid stepping on or pinching the cable, which

could damage the cable insulation.

Page 13

9

Connection and Measurement

For other precautions and details, see explanations of the measurement procedures.

Use only the specified test lead or clamp-on probe.

Using a non-specified cable may result in incorrect

measurements due to poor connection or other

reasons.

When measuring a breaker

This product should only be connected to the

secondary side of a breaker, so the breaker

can prevent an accident if a short circuit

occurs. Connections should never be made

Usage Notes

to the primary side of a breaker, because

unrestricted current flow could cause a serious accident if a short circuit occurs.

Voltage Measurem ent

• The maximum input voltage is 1000

VDC,1000 Vrms(sin), or 10

ing to measure voltage in excess of the

maximum input could destroy the product

and result in personal injury or de ath.

• The maximum rated voltage between input

terminals and the ground is as follows;

(CAT II) DC 1000 V, AC1000 Vrms (sin) or

10

(CAT III) DC 600 V, AC600 Vrms (sin) or

10

7

V•Hz

7

V•Hz

7

V•Hz. Attempt-

Attempting to measure voltages exceeding

this level with respect to ground could

damage the product and result in personal

injury.

Page 14

Usage Notes

10

Resistance Measurement, Checking the

Continuity or Diode

Never apply voltage to test leads when the

Resistance, Continuity or Diode Check functions are selected. Doing so may damage

the product and result in personal injury.

To avoid electrical accidents, remove power

from the circuit before measuring.

Current Measurement

(When using the optional Clamp-on Probe)

Connect the Clamp-on probe to the product

first, and then to the active lines to be measured.

Observe the following to avoid electric shock

and short circui t s.

• Never attach the clamp-on probe to a circuit that operates at more than 600 V, or

over bare conductors.

• When the Clamp-on probe is opened, do

not allow the metal part of the clamp to

touch any exposed metal, or to short

between two lines.

To avoid electric shock when measuring live

lines, wear appropriate protective gear, such

as insulated rubber gloves, boots and a

safety helmet.

Page 15

11

Usage Notes

• To prevent damage to the product and Clampon probe, never connect or disconnect a sensor

while the power is on.

• Be careful to avoid dropping the Clamp-on

probe or otherwise subjecting them to mechani-

cal shock, which could damage the m ating surfaces of the core and adversely affect

measurement.

• Keep the clamp jaws and core slits free from foreign objects, which could interfere with clamping

action.

Page 16

Usage Notes

12

Page 17

13

1.1 Product Ov e r view

Overview Chapter 1

1.1 Product Overview

This measurement product is a multi-functional

digital multimeter capable of measuring DC and

AC voltages, AC currents, and the resistance, and

checking the diode and continuity.

1.2 Features

Compliance with CE marking requirements

The measurement product is designed to comply

with the international safety standard (IEC61010)

and EMC standards.

Handy and safe digital multimeter (DMM) with

protections against accidents

• No need to replace a test lead; two input termi-

nals are provided

• A fuse and protective resist or between input ter-

minals prevent an accident caused by a short circuit.

• The dustproof and waterproof structure pr events

dust and moisture from entering the product

(IP54).

Current measurement (AC) using a Clamp-on

probe

Displays the measured voltage output of an

optional Clamp-on probe as a current v alue using

a scaling function.

Page 18

1.3 Parts Names and Functions

14

t

t

1.3 Parts Names and Functions

LCD Display

SHIFT Button

RANGE Button

(page 15)

(page 15)

(page 15)

Selects functions

V, mV

CLAMPCurrent measuremen

+ Terminal

Tu rns the power on/off

Red

Connect the 9207-10 TEST LEAD

or optional Clamp-on probes.

Connection method: (page 17)

COM Terminal

Black

When the switch is rotated

clockwise from the OFF position, the power is turned on.

Function Selector

Voltage measuremen

Resistance measurement

Continuity checking

Diode checking

Page 19

15

1.3 Parts Names and Functions

k

-

it

s

-

-

it

I

f

B

f

I

D

f

I

A

c

f

P

i

t:

t

d

-

-

LCD Display

Indicates Auto Power Save is enable

Indicates Autoranging

function

ndicates

HOLD AUTO

unction is enable.

links when on standby

Indicates diode check function

Indicates continuity chec

function

Indicates current mea

surement function

or a trigger

ndicates

C voltage

unction

ndicates

C voltage/

urrent

unction

olarity

ndicator

Decimal point

Indicates low battery voltage

Current measurement un

Lights up when the voltage drops below t he battery accuracy guarantee voltage (2.3±0.15 V)

Clamp-on

probe range

(7-range)

Resistance

and continu

ity check

units

Voltage mea

surement un

Buttons

SHIFT button

• Selects DC/AC ( )

(Voltage measurement [V,mV])

• Selects function; Continuity

check [ ]/ Diode check [ ]/

Resistance measurement [ ]

• Turns the HOLD AUTO func-

*1

tion on/off

• Cancels the Auto Power Save

function

To reset from the Auto Power

Save state, turn off the power

and turn it on again.

(page 29)

*2

(page 31)

RANGE button

• Voltage measurement,

resistance measuremen

Changes the manual

range and auto range

Selects range (manual

range only).

*1

• Current measurement:

Selects the range of the

Clamp-on probe.

*1: Press the button for at leas

1 second.

*2:Turn on the power while

pressing the button, and hol

the button down until a beep

ing sound is generated (pow

er-on option).

.

Page 20

1.3 Parts Names and Functions

16

Page 21

17

Measurement

p

d

to

k

2.1 Connection

Procedures

Observe the following precautions to avoid

electric shock.

• Always verify the appropriate setting of the

function selector before connecting the

test leads.

• Disconnect the test leads from the measurement object before switching the function selector.

2.1 Connection

Chapter 2

Voltage measurement/ Resistance measurement/

Continuity check/ Diode check

Safety cap

9207-10

TEST LEAD

1. Remove the protective ca

from the test lead supplie

with the product.

2. Connec t the red test lead

terminal +, and the blac

test lead to terminal COM.

Connect the test lead to the

Red

9207-10 TEST LEAD

Black

terminals securely.

Page 22

2.1 Connection

18

e

,

al

Current measurement

To perform measurement, an optional Clamp-on probe is

required.

Connect the red plug of th

Clamp-on probe to terminal +

and the black plug to termin

COM.

Connect the plug to the terminals securely.

Red

Clamp-on probe

Black

Page 23

19

2.2 Voltage Measurement

2.2 Voltage Measurement

• The maximum input voltage is 1000

VDC,1000 Vrms(sin), or 10

ing to measure voltage in excess of the

maximum input could destroy the product

and result in personal injury or de ath.

• The maximum rated voltage between input

terminals and the ground is as follows;

(CAT II) DC 1000 V, AC1000 Vrms (sin) or

7

V•Hz

10

(CAT III) DC 600 V, AC600 Vrms (sin) or

7

V•Hz

10

7

V•Hz. Attempt-

Attempting to measure voltages exceeding

this level with respect to ground could

damage the product and result in personal

injury.

• To avoid electrical shock, be careful to

avoid shorting live lines with the test leads.

• For safety, test lead connections must

always be made at the secondary s ide of a

circuit breaker.

The indicated value may vary due to the existence

of induced voltage under no-power conditions.

However, this is not a problem.

Page 24

2.2 Voltage Measurement

20

n

r

r

f

t-

V

e

s

s

t

e

V measurement

AC Volt age

Measurement

Example

mV measurement

DC Volt age

Measurement

1. Move the functio

selector to the V o

mV position ("V" o

"mV" lights up,

lights up).

If you are not sure o

the approximate vol

age level, select

first.

2. When DC voltag

measurement, pres

the SHIFT button.

( lights up)

3. Connect the test lead

to the measuremen

object, and read th

indicated value.

Black

Red

Selecting the manual range ...

Reselecting the auto range

Holding the me asur ed

value

Appearance of O.F

(page 29).................

...............

....

Example

Black

Red

Press RANGE("AUTO" is turned off)

Press RANGE (for at least 1 second)

("AUTO" lights up)

Press SHIFT (for at least 1 second)→

Measurement

Move the test leads away from the measurement objec t.

The measured value exceeds maximum

display counts

420-V range: display up to 4199

1000-V range: display up to 1099

→Intermittent sound→

Page 25

21

2.3 Current Measurement

2.3 Current Measurement

To perform measurement, an optional Clamp-on

probe is required.

Connect the Clamp-on probes to the product

first, and then to the active lines to be measured. Obse rve the followin g to av oid elec tri c

shock and short circuits.

• To avoid short circuits and potentially lifethreatening hazards, never attach the

Clamp-on probe to a circuit that operates

at more than 600 V, or over bare conductors.

• Clamp-on probe should only be connected

to the secondary side of a breaker, so the

breaker can prevent an accident if a short

circuit occurs. Connections should never

be made to the primary side of a breaker,

because unrestricted current flow could

cause a serious accident if a short circuit

occurs.

• When the Clamp-on probe is opened, do

not allow the metal part of the clamp to

touch any exposed metal, or to short

between two lines, and do not use over

bare conductors.

• Never apply v olt age to the Clamp-on probe

when a current measurement function is

selected. Doing so may damage the product and result in personal injury.

Page 26

2.3 Current Measurement

22

• To prevent damage to the product and sensor,

never connect or disconnect a probe while the

power is on.

• Check the position of the range switch of the

Clamp-on probe before taking measurements.

• Make sure the range setting of the product is the

same as that of the Clamp-on probe before starting measurement. If the ranges differ, an accurate current measurement will not be displayed.

• Attach the clamp around only one conductor.

Single-phase (2-wire) or three-phase (3-wire)

cables clamped together will not produce any

reading.

OK

• For details on each Clamp-on probe, see the

respective Instruction Manual.

Page 27

23

1.

l

-

t

s

-

t

-

-

s

When the measurement

range is set to 100A

9010

3255-50

2.3 Current Measurement

Move the function selector to

the CLAMP position.

( lights up)

2. Set the measurement range

of the Clamp-on probe

(option).

If you are not sure of the leve

of the current to be mea

sured, select a large range.

3. Press the RANGE button and

select the same range as tha

of the Clamp-on probe.

LOAD

SOURCE

Conductor

Position the clamp with

the current direction indicator pointing toward

the load side.

The Auto Range function i

not available for current mea

surement.

Make sure the rang e setting of

the product is the same as that

of the Clamp-on probe before

starting measurement.

4. Clamp the measuremen

object, and read the indicated

value.

Change the range in accor

dance with the actual mea

surement. If the range of the

Clamp-on probe is changed

during measurement, change

the range of the product a

well.

Appearance of O.F...............

The measured value exceeds maximum

display counts

10, 100, 1000-A range: display up to 999

20, 200-A range: display up to 1999

50, 500-A range: display up to 499

Page 28

2.4 Resistance Measurement

24

o

e

d

2.4 Resistance Measurement

• Never apply voltage to the test leads

when the Resistance function is

selected. Doing so may damage the

product and result in personal injury.

• To avoid electrical accidents, remove

power from the circuit before measuring.

1. M ove the function selector t

the Ω position.

( lights up)

Black

Selecting the manual range...

Reselecting the auto range

Holding the measured

value

(page 29) ................

Red

....

2. Connec t the test leads to th

measurement object, an

read the indicated value.

Press RANGE("AUTO" is turned off)

Press RANGE (for at least 1 second)

("AUTO" lights up)

Press SHIFT(for at least 1 second)→

Measurement→Intermitt ent sound→

Move the test leads away from the measurement objec t.

Page 29

25

2.5 Continuity Check

o

-

T

e

-

2.5 Continuity Check

• Never apply voltage to the test leads

when the Continuity check function is

selected. Doing so may damage the

product and r esult in personal injury.

• To avoid electrical accidents, remove

power from the circuit before measuring.

1. Move the fu nction selector t

the Ω position.

2. Select Continuity check func

Black

Red

tion

button ( lights up).

()

using the SHIF

3. Connect t he test leads to th

measurement object.

When the continuity (threshold: 45±35 Ω or less) is estab

lished, the beeping sounds

and the resistance is displayed (fixed to the 420-Ω

range).

Page 30

2.6 Diode Check

26

o

n

t-

e

d

a

a

2.6 Diode Check

• Never apply voltage to the test leads

when the Diode Check function is

selected. Doing so may damage the

product and result in personal injury.

• To avoid electrical accidents, remove

power from the circuit before measuring.

1. Move the function selector t

the Ω position.

Cathode Anode

Forward

direction

Black

If displays for both directions

are the same, the following

may have occurred:

• The diode has malfunctioned.

Red

2. Select Diode check functio

()

ton twice ( lights up).

3. Connect the test leads to th

measurement object.

The display shows forwar

voltage (0.15 V to 2.0 V) for

normal diode.

When the diode is connected

in the forward direction (with

beeping sound):

When the diode is invertedly

connected or broken:

pressing the SHIFT

bu

• The forward voltage of the

diode is out of the measurement range.

Page 31

27

3.1 Auto Range Function and Manual Range

Additional

Functions

Chapter 3

3.1 Auto Range Function and Manual

Range Function

Functions

Auto range function_______________________

Auto range function: V/

Manual range function: V/ / CLAMP

The Autoranging function automatically selects the

optimum measurement range.

Turning on the power also switches Autoranging

(AUTO lights up).

on

The range automatically switches up when the dis-

play shows 4200 counts or more, and down when

the display shows less than 400 counts. (A beep

sound is generated when the 3255-50 is switched

to a different range, and decimal point is displayed.)

Page 32

3.1 Auto Range Function a nd Manual Range

28

Manual range function ____________________

Press the RANGE button to active the manual

range function (AUTO is turned off).

Only Manual Range is available for current measurement (CLAMP).

Range selection:

V/ Ω Each pressing of the RANGE button selects the

next larger range. After the largest range, pressing

the select button again returns you to the smallest

range.

CLAMP Each pressing of the RANGE button selects the

next smaller range. After the smallest range,

pressing the select button again returns you to the

largest range.

Switching from Manual Range to Auto

Range:

Press and hold down the RANGE button (for about

1 second). (AUTO lights up)

Page 33

29

3.2 HOLD AUTO Function

e

-

-

is

y

-

)

3.2 HOLD AUTO Function

Functions

Description

(example: )

HOLD

(blinks)

HOLD

(lights up)

Beeping

sound

V/ mV/

Simply moving the test leads away from the measurement object holds the measured value.

This function is useful when it is difficult to read

the displayed value in the current locat ion or both

hands are being used to conduct the measurement.

1. Move the function selector to th

desired position.

2. Pres s the SHIFT button.

(HOLD blinks)

In the measurement of resistance,

O.F is displayed.

3. Connect the test leads to the mea

surement object.

After the measured value is stabi-

lized, an intermittent sound is gener

ated.

(HOLD lights up)

4. When the intermittent sound

heard, move the test leads awa

from the measurement object.

HOLD

(blinks)

The measured value

is held.

The measured value immediately be

fore the test leads are removed is

held.

(HOLD blinks)

Blind zone V/ mV: less than 400 counts

Ω: 4200 counts or more

Canceling the HOLD AUTO mode:

Press SHIFT again. (HOLD is turned off

Page 34

3.3 Overflow Warning Function

30

3.3 Overflow Warning Function

Functions

Description

O.F is displayed and an intermittent sound is ge nerated also in

the cases described below.

Voltage

measurement

Current

measurement

V/ mV/ CLAMP

When the measured value exceeds the maximum indication (4199 counts), O.F is displayed

and an intermittent sound is generated.

Range

1000 V 1099 1100 or more

10/ 100/ 1000 A 999 1000 or more

20/ 200 A 1999 2000 or more

50/ 500 A 499 500 or more

Maximum

display value

O.F display

Example: When the measur ed value exceeds 1099 V in the

AC voltage measurement ( V)

The Overflow Warning function is disabled while

the HOLD AUTO function is on.

Page 35

31

3.4 Auto Power Save Function

3.4 Auto Power Save Function

Functions

Description

All functions

Approximately 10 minutes after completing final

operation, the measurement product automatically enters Power Sa ve mode. When the measurement product is turned on, it automatically

enters Auto Power Save mode (APS lights up).

• In Power Save mode, the LCD is blank but power

is supplied to the measurement product.

• To avoid battery depletion, turn the function

selector OFF after use (the Auto Power Save

feature consumes a small amount of current).

Recovery from Power Save mode:

Turn of f the function selector.

After the measurement product exits Power Save

mode, all conditions are reset . If the measurement

product is to be used for an extended period, Auto

Power Save mode should be canceled in advance.

Canceling the Auto Power Save function:

Turn on the measurement product while pressing

the SHIFT button. (Hold down the button until the

beeping sound is generated.)

The Auto Power Save function is disabled until the

measurement product is turned off (APS is turned

off).

Page 36

3.4 Auto Power Save Function

32

Page 37

33

4.1 General Specifications

Specifications Chapter 4

4.1 General Specifications

General

Measurement

method

AC measurement

system

Function DC voltage ( V), AC voltage( V),

Additional function Auto Range function (AUTO)

Circuit protection Circuit current-limiting resistor

Dual integration

Average rectifying measurement

AC current ( ) (using with the optional

clamp-on probe), Resistance (

Continuity check( ), Diode check( )

(judgment only)

Manual Range function

Hold Auto function (HOLD)

Auto Power Save function (APS)

Battery-Life Warning function

Overflow Warning function (OF)

Protective fuse [Model DMM-44/100, fastacting, Rating 0.44 A/1000 V (AC/DC),

breaking capacity 10 kA (made by Cooper

Bussmann*) *:

Bussmann Division, USA]

Cooper Industries Inc.,

Ω),

Display type TN type LCD, 1/4 duty, dynamic drive

Display elements 3(1/2) dgt. Max. 4199 counts

Units and symbols

1000V AC/DC range 1099 counts

Polarity indicator: "–" sign (automatic)

Overflow indicator: "OF" or "–OF"

Clamp range indicator (10 to 1000)

(AC), (DC), , AUTO, HOLD, ,

, APS, (CLAMP), M, k, m, V, Ω, A

Page 38

4.1 General Specifications

34

General

Range switching Auto/Manual Range

Sampling rate 2.5 S/s

Input terminals +(V, Ω, continuity, diode) terminal

COM terminal

Functions OFF/ V/ mV/ CLAMP/ Ω

Buttons SHIFT, RANGE

Power supply Two manganese (R03) batteries or

two alkaline (LR03) batteries

Battery-life

warning

Dimensions Approx.70W × 145H × 31D mm

Mass Approx. 210 g (7.4 oz) (including batteries)

Operating

environment

Operating temper-

ature and humidity

Storage tempera-

ture and humidity

Accessories Instruction Manual

indicates low battery

(2.3 V±0.15 V or less)

(2.76"W × 5.71"H × 1.22"D)

without protrusions

(

Indoors, altitude up to 2000 m (6562-ft.)

0 to 40°C (32 to 104°F), at 80%RH or less

(non-condensating)

-20 to 40°C (-4 to 104°F), at 80%RH or

less (non-condensating)

40 to 60°C (104 to 140°F), at 70%RH or

less (non-condensating)

T wo R03 manganese batteries

9207-10 TEST LEAD

)

(for monitor )

Options 9010 CLAMP ON PROBE

9371 CARRYING CASE

9018 CLAMP ON PROBE

Page 39

35

4.1 General Specifications

Applicable Standards

Safety EN61010-1:2001

EN61010-031:2002

Pollution Degree 2

Measurement Category CAT III 600 V,

CAT II 1000 V (Anticipated T ransient Overvoltage: 6000 V)

EMC EN61326:1997+A1:1998+A2:2001

+A3:2003

Dustproof and

EN60529:1991 IP54

waterproof

Electrical Chara ct eri st ics

Measurement

accuracy

Accuracy guarantee for temperature and humidity

Regulated power

supply range

Temperature

characteristic

Noise suppression

NMRR

Noise suppression

CMRR

See accuracy table (page 37)

23°C±5°C (73°F± 9°F), 80%RH or less

(non-condensating)

3.4 V or lower (until the mark lights up)

(Measurement accuracy) × 0.1/°C

(except 23°C±5°C)

DCV: 40dB or better (50/60 Hz)

ACV: 40dB or better (DC)

DCV:100dB or better (50/60 Hz)

ACV: 60dB or better (50/60 Hz)

(1 kΩ Unbalance)

Dielectric strength

Maximum input

voltage

Maximum rated

voltage between

input terminals and

ground

Input terminals to case: 5.55 kVrms sin

(50/60 Hz for one minute)

7

1000 VDC/ 1000 Vrms(sin) or 10

V•Hz

1000 VDC/ 1000 Vrms(sin) (CAT II) or

7

10

V•Hz

600 VDC/ 600 Vrms(sin) (CAT III) or

7

10

V•Hz

Page 40

4.1 General Specifications

36

Electrical Characteristics

Rated power

supply voltage

Maximum rated

power

Rated power 4 mVA (Typ) (supply voltage 3.0 VDC,

Power during auto

power saving

Continuous

operating time

3.0 VDC

12 mVA (Max) (supply voltage 3.0 VDC)

in DCV mode)

0.1 mVA (Max)

(supply voltage 3.0 VDC, during Auto

Power Saving)

Approx. 200 hours (in DCV mode, with

R03 manganese batteries)

Approx. 500 hours (in DCV mode, with

LR03 alkaline batteries)

Page 41

37

4.2 Accuracy

4.2 Accuracy

Accuracy Table

(Accuracy guaranteed for one year at 23°C±5°C (73°F±9°F),

80%RH or less.)

(rdg.: displayed value, dgt.: resolution)

Voltage Measurement

mV

V

Range

[V]

420.0 m

4.200

42.00

420.0

1000

Accuracy

±(rdg.)±(dgt.)

±1.0%±4

±1.0%±4

±0.5%±4

±0.7%±4

±0.7%±4

Approx.10 MΩ

Approx.11 MΩ

Approx.10 MΩ

Approx.10 MΩ

Approx.10 MΩ

(50

Approx.10 MΩ

Approx.11 MΩ

Approx.10 MΩ

Approx.10 MΩ

Approx.10 MΩ

mV

V

420.0 m

4.200

42.00

420.0

1000

±2.0%±4

±2.0%±4

±1.2%±4

±1.5%±4

±1.5%±4

Overload protection (for one minute):

7

1000 VDC,1000 Vrms(sin) or 10

V•Hz

Input Impedance

(Frequency range)

to 500 Hz)

Page 42

4.2 Accuracy

38

(rdg.: displayed value, dgt.: resolution)

Current Measurement

(3255-50 only. For accuracy of the combination of the Clamp-on

probe and the 3255-50, add the measurem ent accuracy of the

clamp-on probe)

CLAMP

(ACA)

Range

[A]

10.00

20.00

50.0

100.0

200.0

500

1000

Accuracy

±(rdg.)±(dgt.)

±2.0%±4

±2.0%±4

±2.0%±4

±2.0%±4

±2.0%±4

±2.0%±4

±2.0%±4

Input Impedance

(Frequency range)

Approx.10 MΩ

(50 to 500 Hz)

Overload protection (for one minute):

7

1000 VDC,1000 Vrms(sin) or 10

V•Hz

Resistance Measurement/ Continuity Check/

Diode Check

(Resistance)

Range

[Ω]

420.0

4.200 k

42.00 k

420.0 k

4.200 M

42.00 M

Accuracy

±(rdg.)±(dgt.)

±1.0%±8

±0.7%±4

±1.0%±4

±1.0%±4

±2.0%±4

±5.0%±4

Open terminal

voltage

3.4 V or less

Approx.0.7 V

Approx.0.5 V

Approx.0.5 V

Approx.0.5 V

Approx.0.5 V

Notes

Measurement

current: 850 μA

max.

Varies according to resistance

levels to be

measured.

(Continuity)

420.0 ±1.0%±8 3.4 V or less

Judgment only

(Diode)

(0.15V to 2.00V) 3.4 V or less

Overload protection (for one minute):

1000 VDC,1000 Vrms(sin) or 10

7

V•Hz

Threshold:

45 Ω±35 Ω

Measurement

current:

850 μA max.

Page 43

39

5.1 Replacing the Batteries and Fuses

Maintenace and

Service

Chapter 5

5.1 Replacing the Batteries and Fuses

• To avoid electric shock when replacing the

batteries and fuses, first disconnect the

test leads from the object to be measured.

• Before using the product after replacing

the batteries or fuses, replace the cover

and screw.

Replacing the Batteries

• Do not mix old and new batteries, or different types of batteries. Also, be careful to

observe battery polarity during installation.

Otherwise, poor performance or damage

from battery leakage could result.

• To avoid t he poss ibility of explo si on, do not

short circ ui t, d isas sem bl e or i ncine rate batteries.

• Handle and dispose of batteries in accordance with local regulations.

• The “ ” indicator appears when battery voltage

becomes low. Replace the batteries as soon as

possible.

• Use R03 manganese dry cells or LR03 alkaline

dry cells.

Page 44

5.1 Replacing the Batteries and Fuses

40

Replacing the Fuses

Replace the fuse only with one of the specified characteristics and voltage and current

ratings. Using a non-specified fuse or shorting the fuse holder may cause a life-threatening hazard .

Fuse type:

Model DMM-44/100, Fast-acting, Rating:

0.44 A/1000 V (AC/DC), Breaking capacity:

10 kA (made by Cooper Bussmann)

Be careful not to damage the circuit board or cas e

when changing fuses. If removing the fuse by

hand, be careful not to hurt your nails or fingers.

When measurement cannot be performed, the

fuse may have blown due to excess current. When

the fuse has blown, the beeping sound will not be

generated during a continuity check.

Fuse Protection Circuitry

A 5 Ω protective resistor and 0.44 A safety fuse

(1000 V AC/DC, 10 kA cut-off capacity) are

installed in series with the positive terminal of the

instrument to prevent short-circuit accidents during

voltage measurement of power line circuits. If a

short occurs in the instrument circuitry, current flow

is limited by the protective resistance until the

safety fuse opens. The protect ive resistance limits

the short-circuit current, minimizing arcing at the

tip of the test probe and providing safer operation.

Page 45

41

s

t

e

n

r

-

e

r

)

r

e

t

d

g

r

Front case

Front case

Fuse

5.1 Replacing the Batteries and Fuses

Necessary tool: Phillips screwdrive

1. Disconnect the test lead

from the measuremen

Rear case

circuit, and make sur

the function selector is i

the OFF position.

2. Turn the 3255-50 ove

Rear case

Batteries

and use a Phillips screw

driver to remove the on

retaining screw.

3. Lift and remove the rea

case.

4. Replace the two manga

nese batteries (R03

mounted to the rea

case, or the fus

mounted to the fron

case.

5. Mount the rear case an

tighten the retainin

screw.

Fuse type

Model:DMM-44/100, fast-acting

Rating:0.44 A/1000 V(AC/DC)

Breaking capacity:10 kA

(made by Cooper Bussmann*)

*Cooper Industries Inc., Bussmann Division, USA

Page 46

5.2 Cleaning and Storage

42

5.2 Cleaning and Storage

Cleaning________________________________

• To clean the product, wipe it gently with a soft

cloth moistened with water or mild detergent.

Never use solvents such as benzene, alcohol,

acetone, ether, ketones, thinners or gasoline, as

they can deform and discolor the case.

• Wipe the LCD gently with a soft, dry cloth.

Storage_________________________________

To avoid corrosion from battery leakage, remove

the batteries from the product if it is to be stored for

a long time.

Page 47

43

5.3 Service

• Adjustments and repairs should be made only by

technically qualified personnel.

• If the product seems to be malfunctioning, confirm that the batteries are not discharged, and

that the test leads, clamp-on probes, and fuse

are not open circuited before contacting your

dealer or Hioki representative.

• When sending the product for r epair, remove the

batteries and pack carefully to prevent damage

in transit. Include cushioning material so the

instrument cannot move w ithin the package. Be

sure to include details of the problem. Hioki cannot be responsible for damage that occurs during

shipment.

5.3 Service

Page 48

5.3 Service

44

Page 49

Page 50

Page 51

HIOKI 3255-50 DIGITAL HiTESTER

Instruction Manual

Publication date: September 2006 Revised edition 1

Edited and p ublished by HIOKI E .E. CORPO RATION

Technical Support Section

All inquiries to International Sales and Marketing De-

partment

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3255AD981-01

• All reasonable care has been taken in the production

of this manual, but if you find any points which are

unclear or in error, please contact your supplier or the

International Sales and Marketing Department at

HIOKI headqu arte rs.

• In the interests of product development, the contents

of this manual are subject to revision without prior

notice.

• Unauthorized reproduction or copying of this manual

is prohibited.

Page 52

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3255D981-01 06-09H

Printed on recycled paper

Loading...

Loading...