Page 1

3237,3237-01

3238,3238-01

3239,3239-01

DIGITAL HiTESTER

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Instruction Manual

Nov. 2016 Revised edition 14

3237A981-14 16-11H

EN

* 6 0 0 1 9 5 0 1 E *

Page 2

Page 3

Contents

Introduction i

Inspection

Safety Notes

Notes on Use

Chapter Summary

vi

Chapter 1 Overview 1

1.1 Product Overview 1

1.2 Major Features

1.3 Names and Functions of Parts

1.3.1 Front Panel 2

1.3.2 Rear Panel 6

Chapter 2 Installation and Preparation 7

2.1 Power Supply and Ground Connection 7

2.2 Test Lead/Clamp Sensor Connection

i

ii

v

1

2

8

2.3 Power On/Off

2.4 Selection of Power-supply Frequency

10

10

Chapter 3 Measurement Procedure 11

3.1 Voltage Measurement 12

3.1.1 DC Voltage Measurement 12

3.1.2 AC Voltage Measurement 12

3.2 2-Terminal Resistance Measurement 13

3.2.1 Resistance Measurement (2-Terminal) 13

3.2.2 Low-power Resistance Measurement (2-Terminal) 14

3.3 4-Terminal Resistance Measurement 15

3.3.1 Resistance Measurement (4-Terminal, on 3239 only) 15

3.3.2 Low-power Resistance Measurement

(4-Terminal, on 3239 only) 16

3.4 Continuity Test 16

3.5 Diode Test

17

3237A981-14

3.6 Frequency Measurement (3238/39)

18

Page 4

3.7 Current Measurement (3238/39) 19

3.7.1 DC Current Measurement 19

3.7.2 AC Current Measurement 19

3.8 Clamp Current Measurement 20

3.8.1 DC Clamp Current Measurement

(9277/9278/9279/3284/3285) 21

3.8.2 AC Clamp Current Measurement 22

Chapter 4 Basic Functions 23

4.1 Selection of Measurement Range 23

4.2 Switching of Sampling Period

4.3 Zero Adjust function

4.4 Average function

4.5 Trigger Function

4.5.1 Setup for Trigger mode 26

4.5.2 External Trigger 26

4.5.3 Trigger Delay 27

4.5.4 Trigger System 29

23

24

25

26

Chapter 5 Other Functions 31

5.1 Comparator Function 31

5.2 Comparator Buzzer Sound

5.3 Panel Save Function

5.4 Panel Load Function

5.5 Key Operation Sound

5.6 Key Lock Function

34

35

36

37

38

5.7 Remote Function

5.8 System Reset

5.9 Measurement States and Effective Keys

Chapter 6 External Control Terminal/

External output terminal 43

6.1 Explanation of Signal Wires 44

6.2 Timing Chart

6.3 Internal Circuit Configuration

39

40

42

46

48

Page 5

Chapter 7 RS-232C Interface 49

7.1 Preparing for Data Transfer 51

7.2 Communication

7.3 Command Code Table

7.3.1 Common Command 62

7.3.2 Specific Command 63

7.4 Command Reference 69

7.4.1 Explanation of Command Reference 69

7.4.2 Common Command Messages 70

7.4.3 Specific Command Messages 75

7.5 Initialized Item List 99

7.6 Notes on RS-232C Interface

7.7 Compatibility with the ADVANTEST Digital

Multimeter

7.8 Sample Program

53

62

99

100

102

Chapter 8 GP-IB Interface(3237-01/3238-01/3239-01) 103

8.1 Preparing for Data Transfer 105

8.2 Communication

8.3 GP-IB Command

8.4 Notes of the GP-IB

107

116

117

Chapter 9 Printer Interface 119

9.1 Setup for Interface 120

9.2 Setup for Printer

9.3 Printer Connection Method

9.4 Sample Prints

121

123

124

Chapter 10 Specifications 125

10.1 General Specifications 125

10.2 Accuracy

10.2.1 Accuracy of the 3237 127

10.2.2 Accuracy of the 3238 133

127

10.2.3 Accuracy of the 3239 140

Page 6

Chapter 11 Maintenance and Service 147

11.1 A-Terminal Fuse Replacement (3238/39) 147

11.2 Power Supply Fuse Replacement

11.3 Cleaning

11.4 Service

148

149

150

Appendix APPENDIX1

Page 7

_____________________________________________________________________________________________

p

i

Introduction

Thank you for purchasing the HIOKI "3237, 3238, 3239 DIGITAL

HiTESTER."

To obtain maximum performance from the product, please read this manual

first, and keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki representative.

Accessories

L9170-10 TEST LEAD 1

Instruction Manual 1

Power cord 1

Spare fuse 0.5 A (for 100 V, 120 V), 0.25 A (for 220 V, 240 V)

2 A (for the 3238/39) 1

Before using the product the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. If you find

any damage, contact your dealer or Hioki representative.

Inspection before use

When measuring a dangerous voltage or current, or when a measurement of

high reliability is required, always carry out the following confirmation

before using.

No damage to the power cord, test lead and the produt itself

No inaccurate measurement values are shown when connected to a

measurement target with clear values (non-defective sample, calibrator,

etc.) and under the setting for the test conditions used by the customer

NOTE

______________________________________________________________________________________________

Before using the product, make sure that the insulation on the probes is undamaged

and that no bare conductors are improperly exposed. Using the product in such

conditions could cause an electric shock, so contact your dealer or Hioki

resentative for repair.

re

Page 8

ii

_____________________________________________________________________________________________

Safety Notes

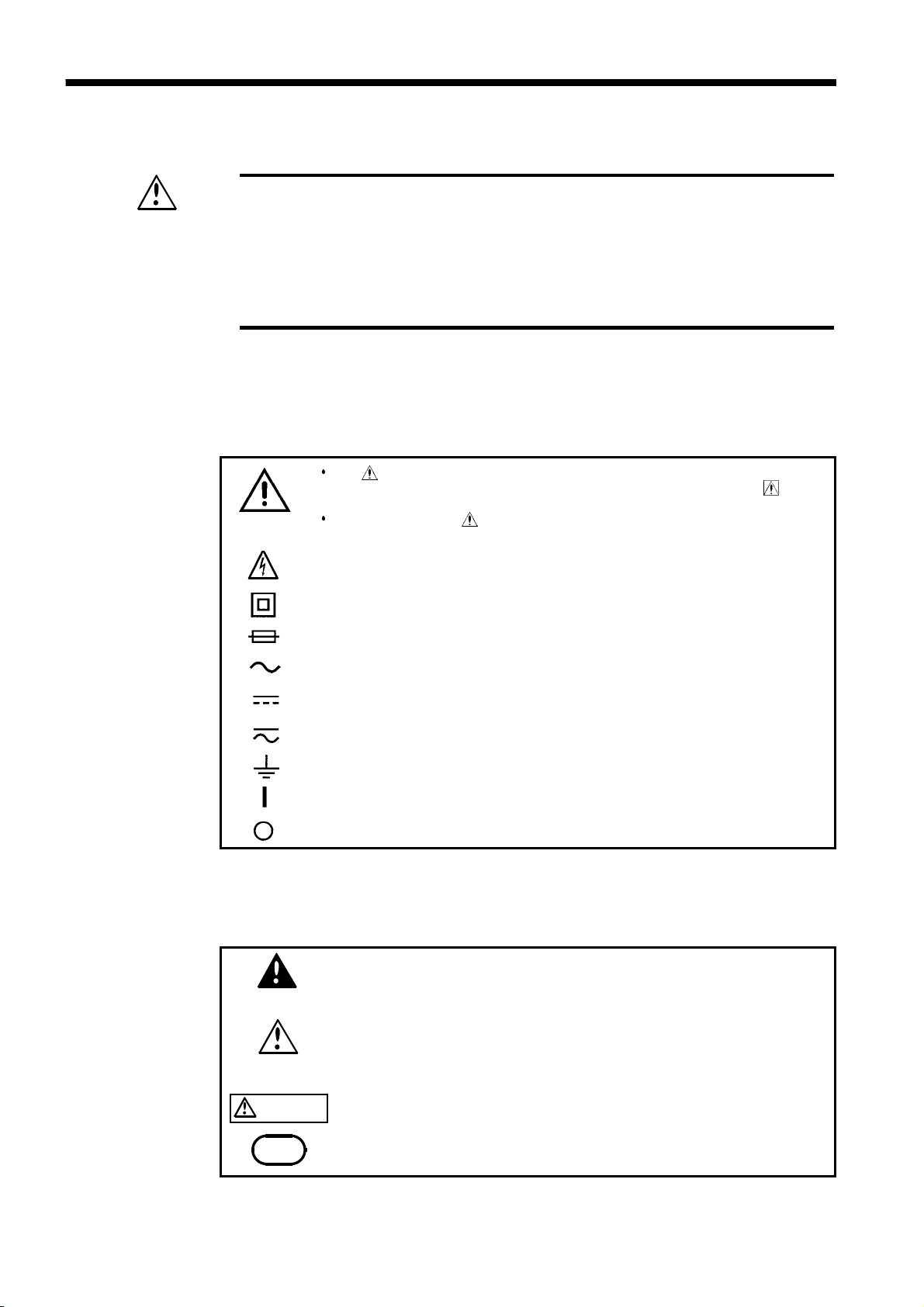

This instrument is designed to comply with IEC 61010 Safety Standards,

WARNING

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as

damage to the instrument. Be certain that you understand the

instructions and precautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting directly from

instrument defects.

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

The symbol printed on the product indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

Indicates that dangerous voltage may be present at this terminal.

Indicates a double-insulated device.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates a grounding terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of

cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that

DANGER

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

WARNING

CAUTION

NOTE

______________________________________________________________________________________________

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

Advisory items related to performance or correct operation of the

product.

Page 9

_____________________________________________________________________________________________

iii

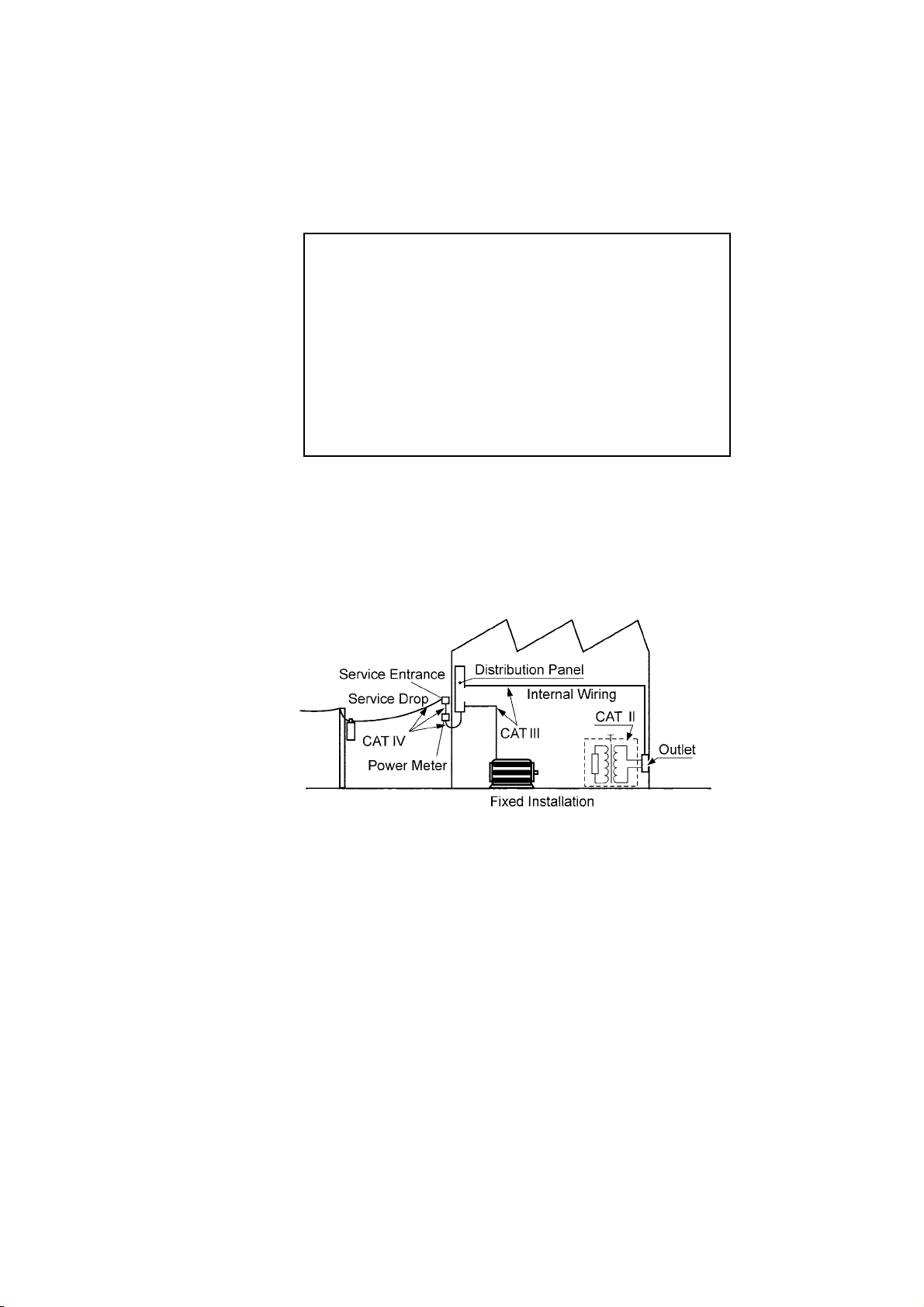

Measurement categories

This product complies with CAT II safety requirements.

To ensure safe operation of measurement product, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories.

CAT II

CAT III

CAT IV

Primary electrical circuits in equipment connected to

a wall outlet via a power cord (portable tools,

household appliances, etc.)

CAT II covers directly measuring electrical outlet

receptacles.

Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders between the distribution panel

and outlets.

The circuit from the service drop to the service

entrance, then to the power meter and to the primary

overcurrent protection device (distribution panel).

Using a measurement product in an environment designated with a highernumbered category than that for which the product is rated could result in

a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT

IV measurement applications could result in a severe accident, and must be

carefully avoided.

______________________________________________________________________________________________

Page 10

iv

_____________________________________________________________________________________________

Accuracy

The specifications in this manual include figures for "measurement accuracy"

when referring to digital measuring instruments, and for "measurement

tolerance" when referring to analog instruments.

f.s.

rdg.

dgt.

(maximum display or scale value, or length of scale)

Signifies the maximum display (scale) value or the length of the scale

(in cases where the scale consists of unequal increments or where the

maximum value cannot be defined).

In general, this is the range value (the value written on the range

selector or equivalent) currently in use.

(displayed or indicated value)

This signifies the value actually being measured, i.e., the value that is

currently indicated or displayed by the measuring instrument.

(resolution)

Signifies the smallest display unit on a digital measuring instrument,

i.e., the value displayed when the last digit on the digital display is

"1".

______________________________________________________________________________________________

Page 11

_____________________________________________________________________________________________

v

Notes on Use

In order to ensure safe operation and to obtain maximum performance from

the unit, observe the cautions listed below.

To avoid electric shock, do not allow the product to get wet, and do

WARNING

not use it when your hands are wet.

Do not use the product where it may be exposed to corrosive or

combustible gases. The product may be damaged or cause an

explosion.

To avoid electric shock, be sure to connect the protective ground

terminal to a grounded conductor.

CAUTION

Do not store or use the product where it could be exposed to direct

sunlight, high temperature or humidity, or condensation. Under such

conditions, the product may be damaged and insulation may deteriorate so

that it no longer meets specifications.

This product is not designed to be entirely water- or dust-proof. To avoid

damage, do not use it in a wet or dusty environment.

Do not use the product near a device that generates a strong

electromagnetic field or electrostatic charge, as these may cause

erroneous measurements.

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

______________________________________________________________________________________________

Page 12

vi

_____________________________________________________________________________________________

Chapter Summary

Chapter 1 Overviews

Provides a product overview and gives the names and describes the functions

of the component parts.

Chapter 2 Installation and Preparation

Describes ways to turn on power, connect test leads, and set up the powersupply frequency.

Chapter 3 Measurement Procedure

Describes basic measurements.

Chapter 4 Basic Functions

Describes basic functions such as range setup, sampling setup, and so on.

Chapter 5 Other Functions

Describes other functions, including comparator setup, Load Save function,

and so on.

Chapter 6 External Control Terminal/ External output terminal

Describes external control executed via the external control terminal and

external output terminal.

Chapter 7 RS-232C Interface

Describes external control executed via the RS-232C interface.

Chapter 8 GP-IB Interface

Describes external control executed via the GP-IB interface.

Chapter 9 Printer Interface

Describes output to the optional 9442 PRINTER.

Chapter 10 Specifications

Describes measurement methods designed to achieve maximum performance

from the unit.

Chapter 11 Maintenance and Service

Describes general specifications and measurement ranges.

Appendix

Describes services and options for this unit.

______________________________________________________________________________________________

Page 13

_____________________________________________________________________________________________

1

Chapter 1

1

2

1.1 Product Overview

In addition to measuring functions for DC voltages, AC voltages, resistances,

DC currents*, AC currents*, and frequencies*, the 3237/38/39 Digital High

Tester comes with a comparator function that is especially useful for line

use. The GP-IB interface (3237-01/3238-01/3239-01), RS-232C interface,

and the units comparator output permits use of the unit across a wide range

of applications, such as parts selection and data acquisition.

*: On the 3238/39.

1.2 Major Features

Overview

3

4

5

6

7

8

9

(1) High-speed measurement and fast OK/NG determination

Allows reduced tact time for the line in high-speed measurements and fast

OK/NG determinations. Thirty different setup conditions for the main unit

can be saved, including comparator conditions. This makes it possible to

determine OK or NG for many sample types being measured with a single

unit.

(2) Low-power resistance measurement

The unit enables low-power resistance measurement, with low measurement

current and open voltage, to minimize the potential for degraded sample

characteristics.

(3) A versatile array of interfaces

The unit comes equipped with a GP-IB interface (3237-01/3238-01/3239-01),

RS-232C interface, external output terminal, and external control terminal.

Through these interfaces, data can be exchanged with a computer or

sequencer.

10

11

12

13

14

A

______________________________________________________________________________________________

1.2 Major Features

Page 14

2

_____________________________________________________________________________________________

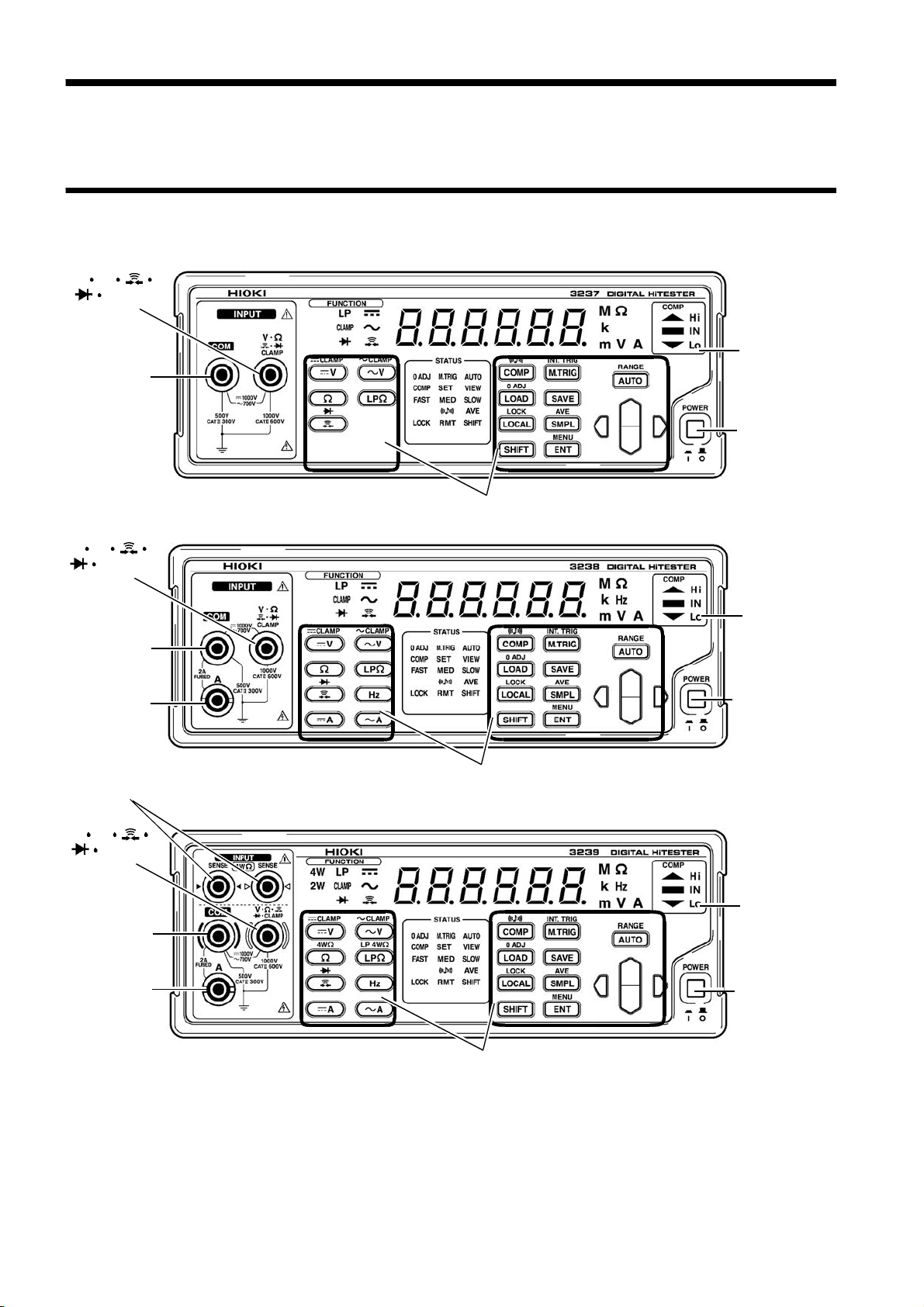

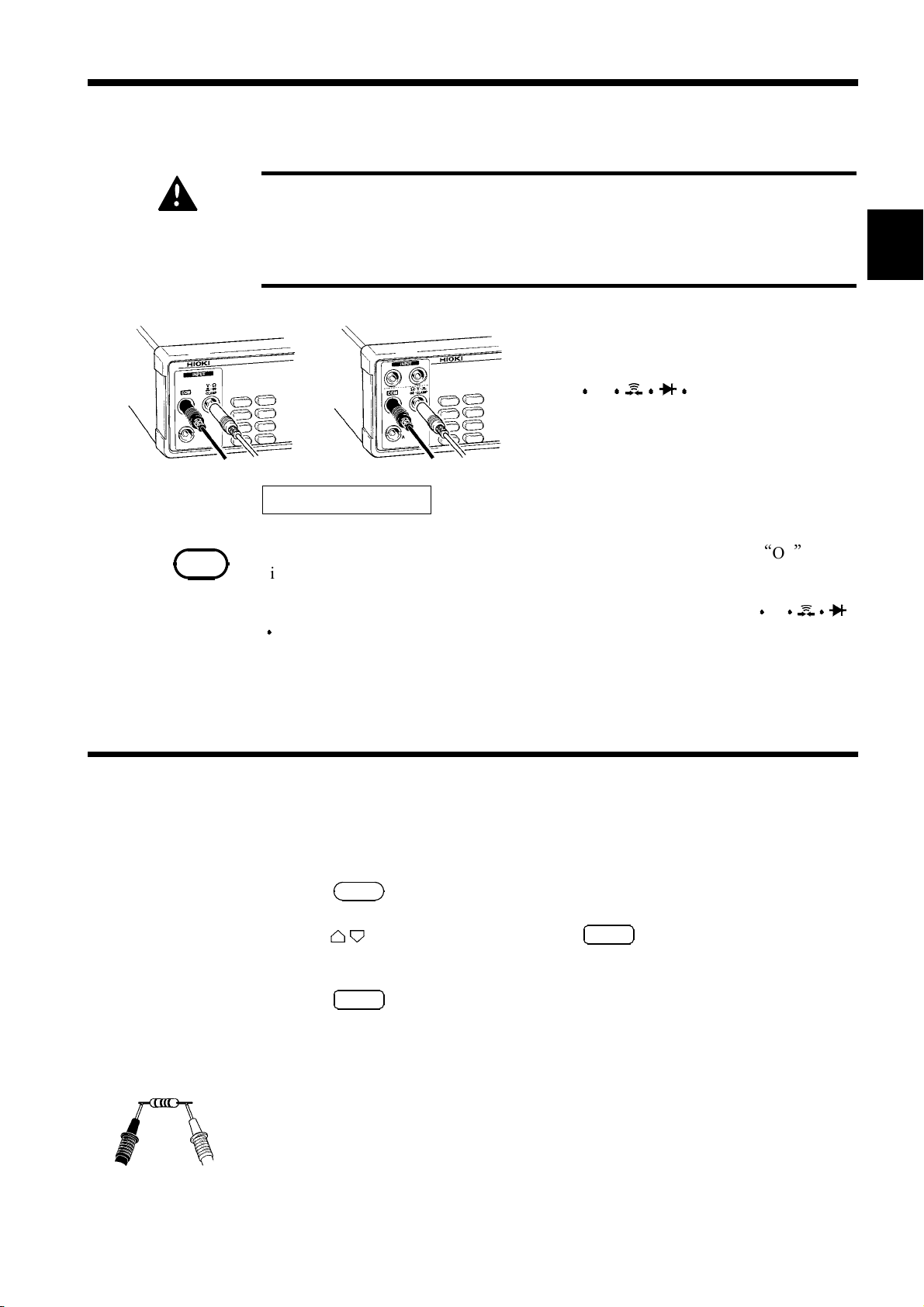

1.3 Names and Functions of Parts

1.3.1 Front Panel

Ω

V

CLAMP

terminal

COM

terminal

3237

LED

Display

Power switch

Ω

V

CLAMP

terminal

COM

terminal

A-terminal

SENSE terminal

Ω

V

CLAMP

terminal

COM

terminal

Operation keys

3238

LED

Display

Power swtich

Operation keys

3239

LED

Display

A-terminal

Operation keys

______________________________________________________________________________________________

1.3 Names and Functions of Parts

Power swtich

Page 15

_____________________________________________________________________________________________

3

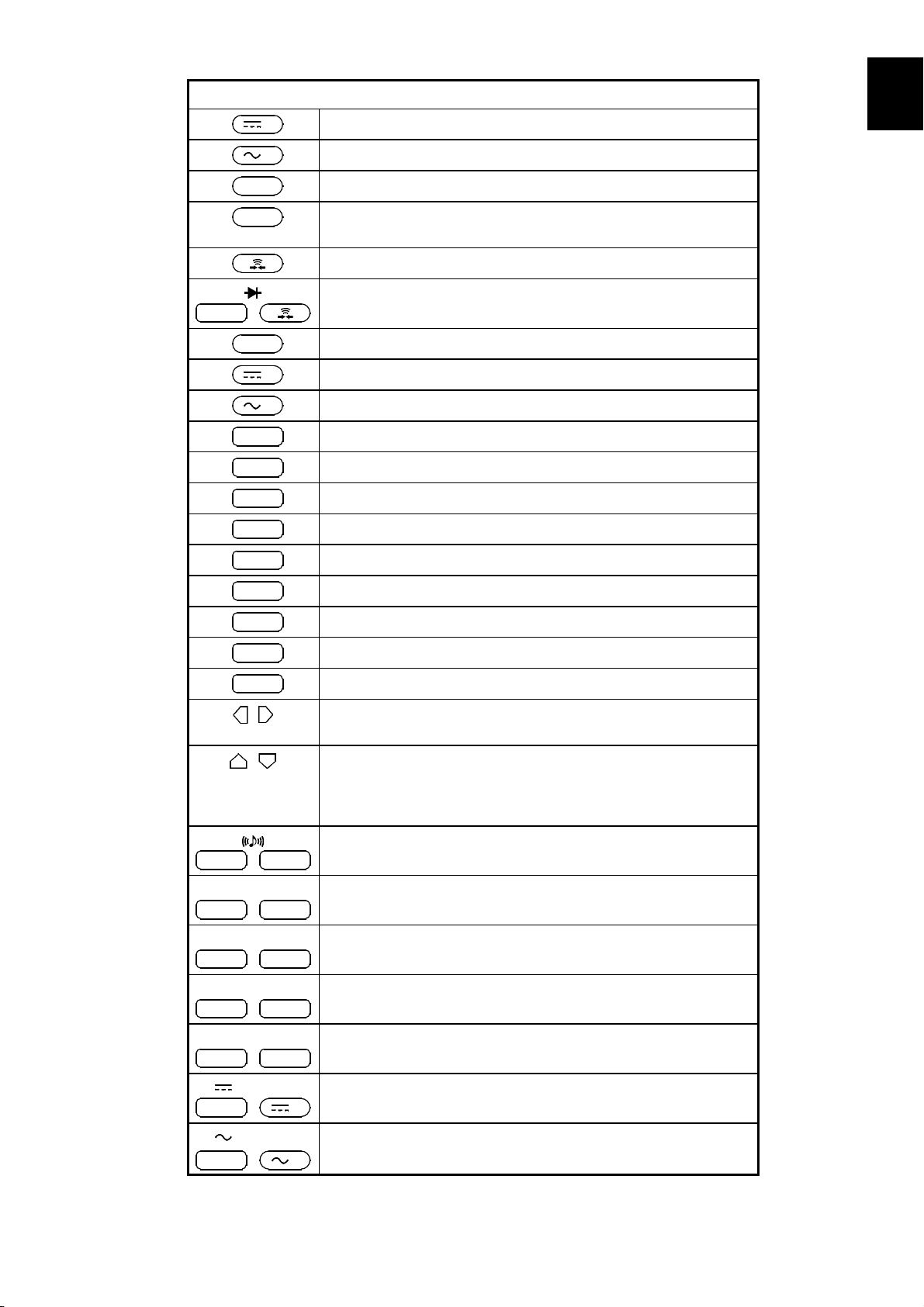

Operation keys

V

V

Ω

LPΩ

SHIFT

+

Hz

A

A

COMP

M.TRIG

LOAD

SAVE

LOCAL

Selects the DC voltage measurement function.

Selects the AC voltage measurement function.

Selects the 2-terminal resistance measurement function.

Selects the low-power 2-terminal resistance measurement

function.

Selects the continuity test function.

Selects the diode test function.

Selects the frequency measurement function. (3238/39)

Selects the DC current measurement function. (3238/39)

Selects the AC current measurement function. (3238/39)

Turns the comparator ON or OFF.

Applies a manual trigger.

Recalls saved information.

Saves the current status.

Clears the remote status.

1

2

3

4

5

6

7

SMPL

SHIFT

ENT

AUTO

SHIFT+COMP

INT.TRIG

SHIFT+M.TRIG

0ADJ

SHIFT+LOAD

LOCK

SHIFT+LOCAL

AVE

SHIFT+SMPL

CLAMP

SHIFT

V

+

Switches the sampling period.

Pressed before shift operation.

Confirms a setting.

Selects Auto Range.

Used to move the cursor indicated by flashing numbers or

characters on a setup screen.

Used to increment or decrement the currently flashing value.

These buttons are also used to edit character strings in

various setup screens, and to switch ranges when a

measurement is performed.

Turns the comparator buzzer ON or OFF.

Applies an internal trigger.

Subtracts the offset of a measurement value.

Locks the keys.

Sets the mean of the measurement values.

Selects the DC current measurement function that uses the

clamp sensor.

8

9

10

11

12

13

14

CLAMP

SHIFT

+

______________________________________________________________________________________________

Selects the AC current measurement function that uses the

clamp sensor.

V

1.3 Names and Functions of Parts

A

Page 16

4

_____________________________________________________________________________________________

Operation keys

4WΩ

SHIFT

+

4WΩ

SHIFT

+

MENU

SHIFT+ENT

Terminals

COM

Ω

V

CLAMP

A

SENSE

Switch

POWER

Ω

LPΩ

Selects the 4-terminal resistance measurement function.

(3239 only)

Selects the low-power 4-terminal resistance measurement

function. (3239 only)

Displays the menu screen for selection of the clamp sensor,

interfaces, power-supply frequency, etc.

The test lead (black) is connected here for various

measurements.

The test lead (red) is connected here to measure voltages,

resistances, frequencies, diodes, or clamp currents, or to

conduct a continuity test.

The test lead (red) is connected here to measure currents.

(3238/39)

The test lead (SENSE) is connected here to measure

resistance (4-terminal resistance measurement). (3239)

Turns the power ON ( )orOFF( ).

______________________________________________________________________________________________

1.3 Names and Functions of Parts

Page 17

_____________________________________________________________________________________________

5

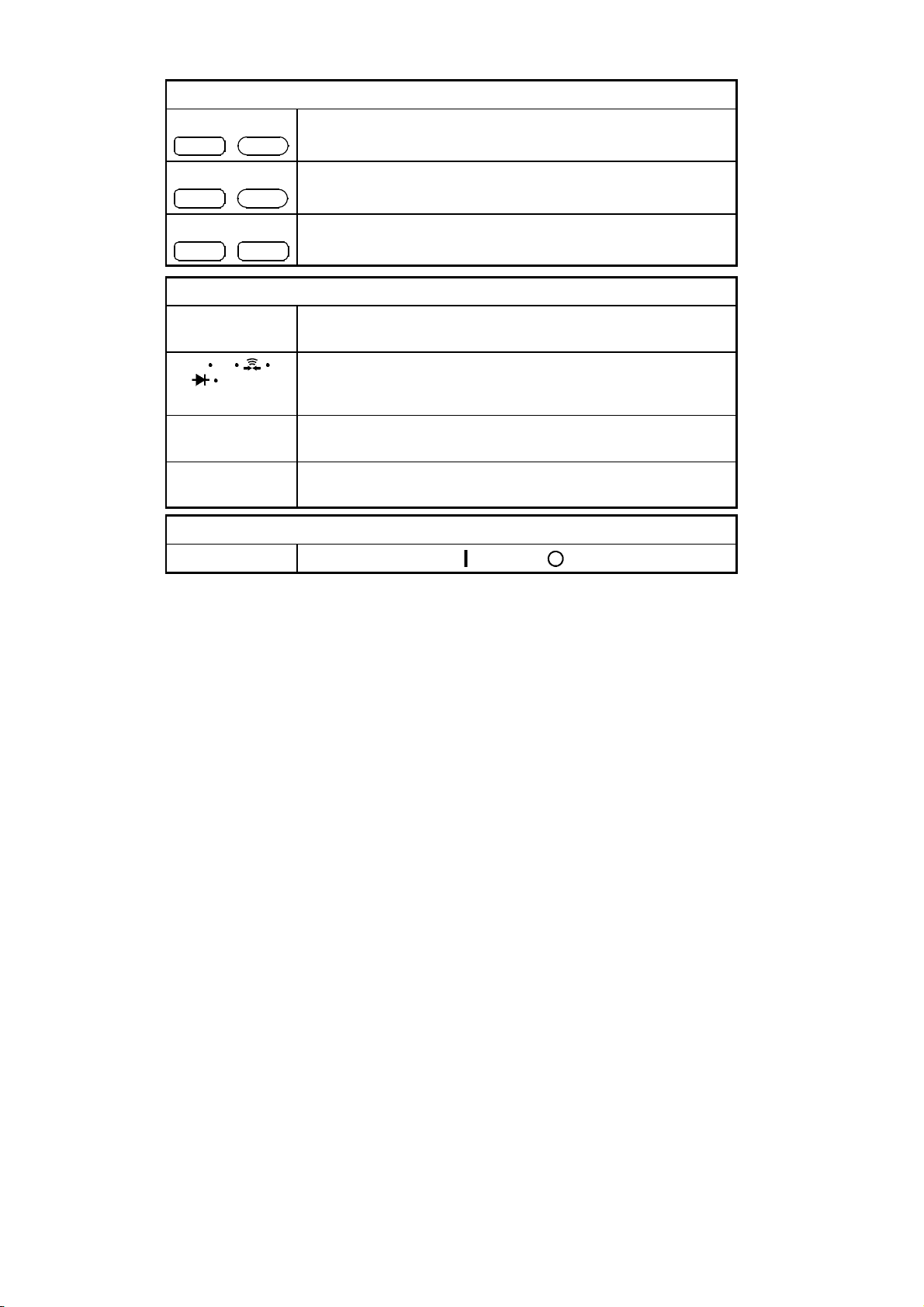

1

2

FUNCTION

LED display

LP

CLAMP

FUNCTION

4W

2W

0ADJ

M.TRIG

AUTO

COMP

SET

FAST

MED

STATUS

SLOW

AVE

LOCK

RMT

SHIFT

COMP

Hi

IN

Lo

COMP

STATUS

Lights up when a low-power resistance measurement is performed.

Lights up when a DC measurement is performed.

Lights up when a current measurement is performed using the clamp

sensor.

Lights up when a AC measurement is performed.

Lights up when a diode test is conducted.

Lights up when a continuity test is conducted.

Lights up when a 4-terminal resistance measurement is performed. (3239)

Lights up when a 2-terminal resistance measurement is performed. (3239)

Lights up when a measurement is in progress with the Zero Adjust

function activated.

Lights up when Manual Trigger is selected.

Lights up when Auto Range is selected.

Lights up when the comparator is in use.

Lights up together with COMP when a comparator threshold is set.

Lights up when FAST is selected for the sampling period.

Lights up when MEDIUM is selected for the sampling period.

Lights up when SLOW is selected for the sampling period.

Lights up when the comparator buzzer is turned ON.

Lights up when the Average function is in use.

Lights up when the Key Lock is active.

Lights up when remote control is underway through the RS-232C or GPIB interface.

Lights up when

Displays the comparator result.

: Lights up if the measurement value exceeds the upper-limit value.

Hi

: Lights up if the measurement value remains between the upper-

IN

limit and lower-limit values.

: Lights up if the measurement value is smaller than the lower-limit

Lo

value.

SHIFT

is pressed.

3

4

5

6

7

8

9

10

11

12

13

14

______________________________________________________________________________________________

1.3 Names and Functions of Parts

A

Page 18

6

_____________________________________________________________________________________________

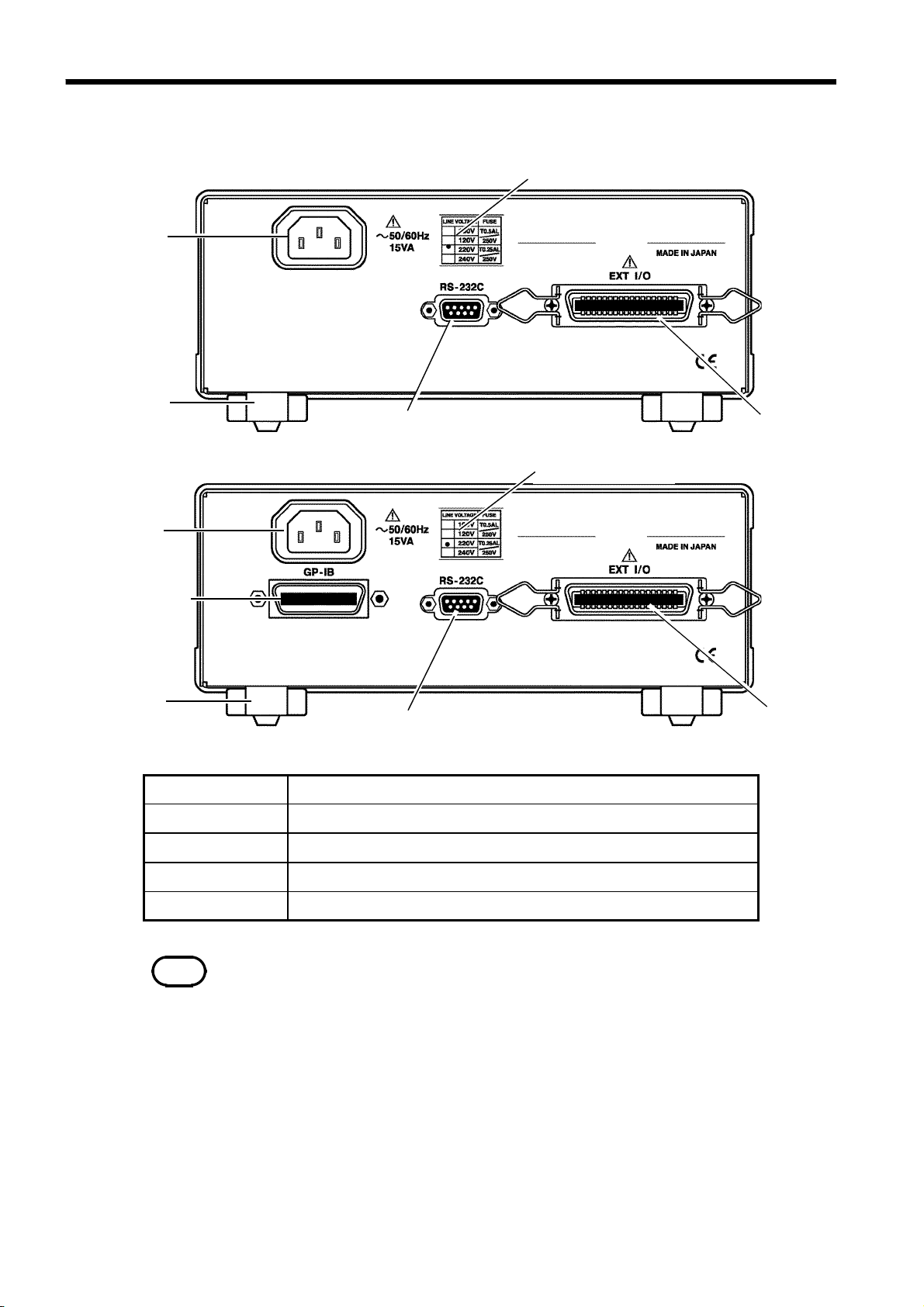

1.3.2 Rear Panel

Power/fuse ratings

3237

Inlet

Stand

RS-232C interface

Power/fuse ratings

3238

3239

External I/O

Inlet

GP-IB interface

Stande

GP-IB interface

RS-232C interface

Power/fuse ratings

NOTE

Inlet

ExternalI/O

Be sure not to bear down too hard on the top of the product when it is tilted

upwards. Doing so may damage the stand.

RS-232C interface

The power cord is connected here.

The GP-IB interface is connected here.

The RS-232C interface is connected here.

This is an external output terminal/external control terminal.

Indicates the power ratings and the fuse currently in use.

3237-01

3238-01

3239-01

External I/O

______________________________________________________________________________________________

1.3 Names and Functions of Parts

Page 19

_____________________________________________________________________________________________

7

Chapter 2

1

2

Installation and Preparation

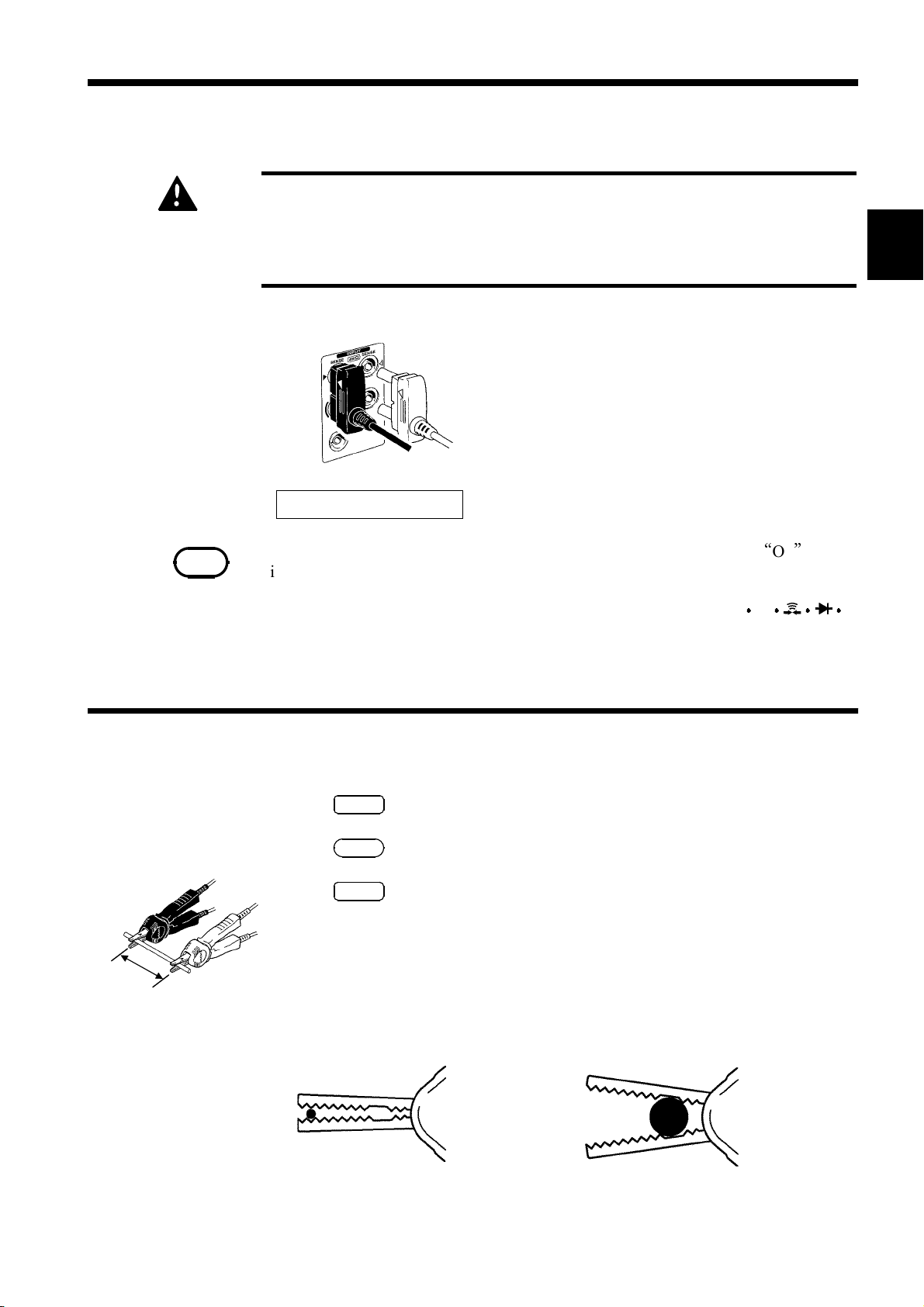

2.1 Power Supply and Ground Connection

Before turning the product on, make sure the source voltage matches

WARNING

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3contact (two-conductor + ground) outlet.

3

4

5

6

7

8

1

. Confirm the power switch is OFF.

2

. Make sure the source voltage matches that indicated on the product's

power connector and connect the power cord supplied to AC inlet on the

rear panel.

3

. Plug in the power cord. Insert the plug directly into the outlet.

9

10

11

12

13

14

______________________________________________________________________________________________

2.1 Power Supply and Ground Connection

A

Page 20

8

_____________________________________________________________________________________________

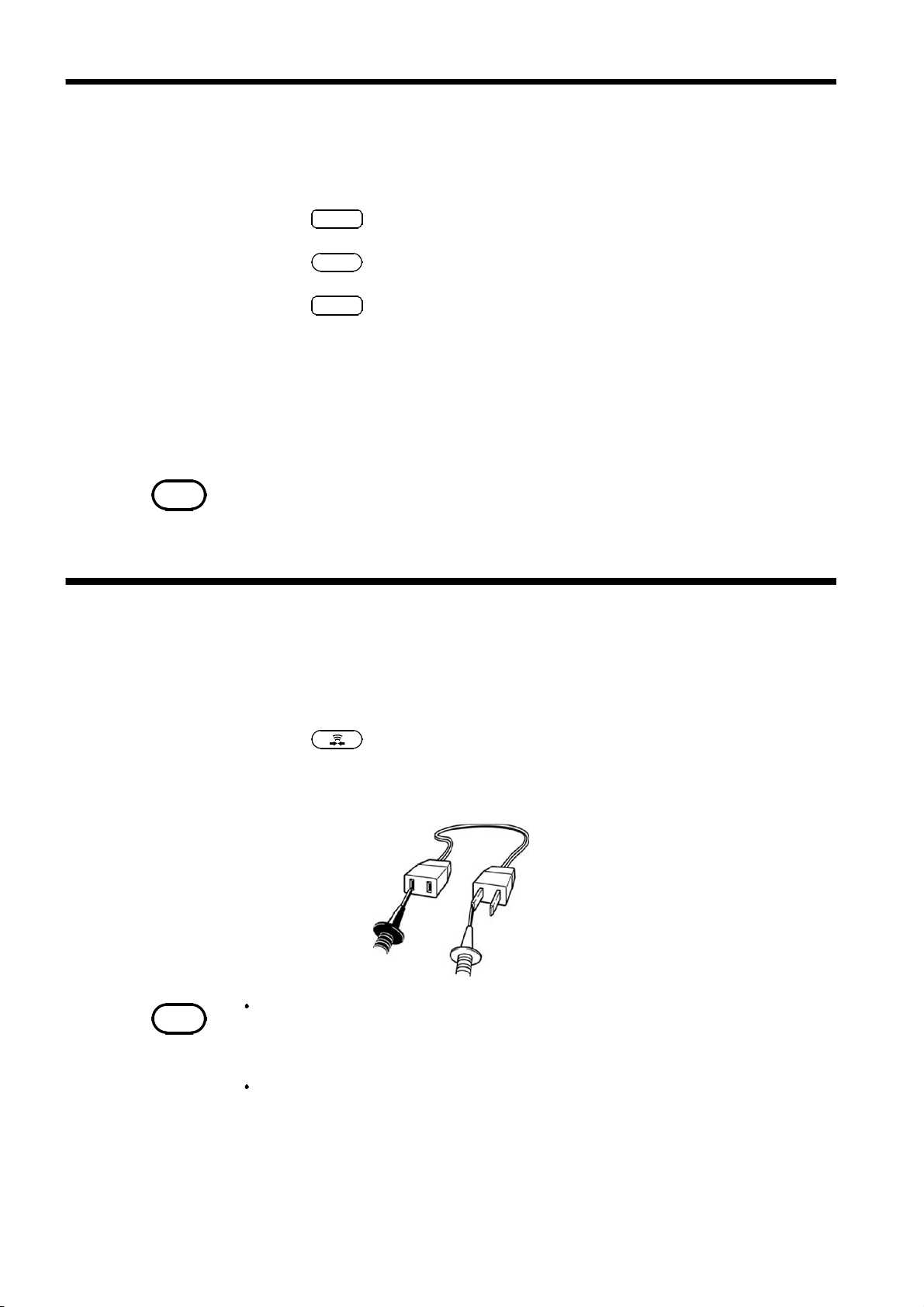

2.2 Test Lead/Clamp Sensor Connection

The terminals do not have sufficient spatial isolation. To avoid

WARNING

electrocution, observe the following precautions.

Connect test leads to the terminals only after shutting off the line

power.

Note that hazardous voltage may be present at the V

CLAMP terminal when using the A-terminal. Be careful to avoid

touching the V

Note that hazardous voltage may be present at the A-terminal when

using the V

careful to avoid touching the A-terminal.

When connecting the clamp-on sensor, should the metallic part of the

sensor, exposed while the clamp is open, touch the two wires of the

line, or if the sensor is used on a bare conductor, may result in a short

circuit or electrocution.

Ω

Ω

CLAMP terminal and SENSE terminal.

CLAMP terminal and SENSE terminal. Be

Ω

CAUTION

NOTE

CAUTION

Although CAT III, CAT IV are stated on the L9170-10 TEST LEAD, the

DIGITAL HiTESTER is only compatible with CAT I and CAT II.

To avoid electrocution, do not measure the lines of CAT III or CAT IV.

To prevent an electric shock accident, confirm that the white or red portion

(insulation layer) inside the cable is not exposed. If a color inside the cable is

exposed, do not use the cable.

Removable sleeves are attached to the metal pins at the ends of the test leads. The

test leads can also be used with the sleeves removed.

Removing and attaching the sleeves

The tips of the metal pins are sharp, so take care not to injure yourself.

Removing the sleeves

Gently hold the bottom of the sleeves and pull the sleeves off.

Safely store the removed sleeves so as not to lose them.

Attaching the sleeves

Insert the metal pins of the test leads into the holes of the sleeves, and firmly

push them all the way in.

______________________________________________________________________________________________

2.2 Test Lead/Clamp Sensor Connection

Page 21

_____________________________________________________________________________________________

9

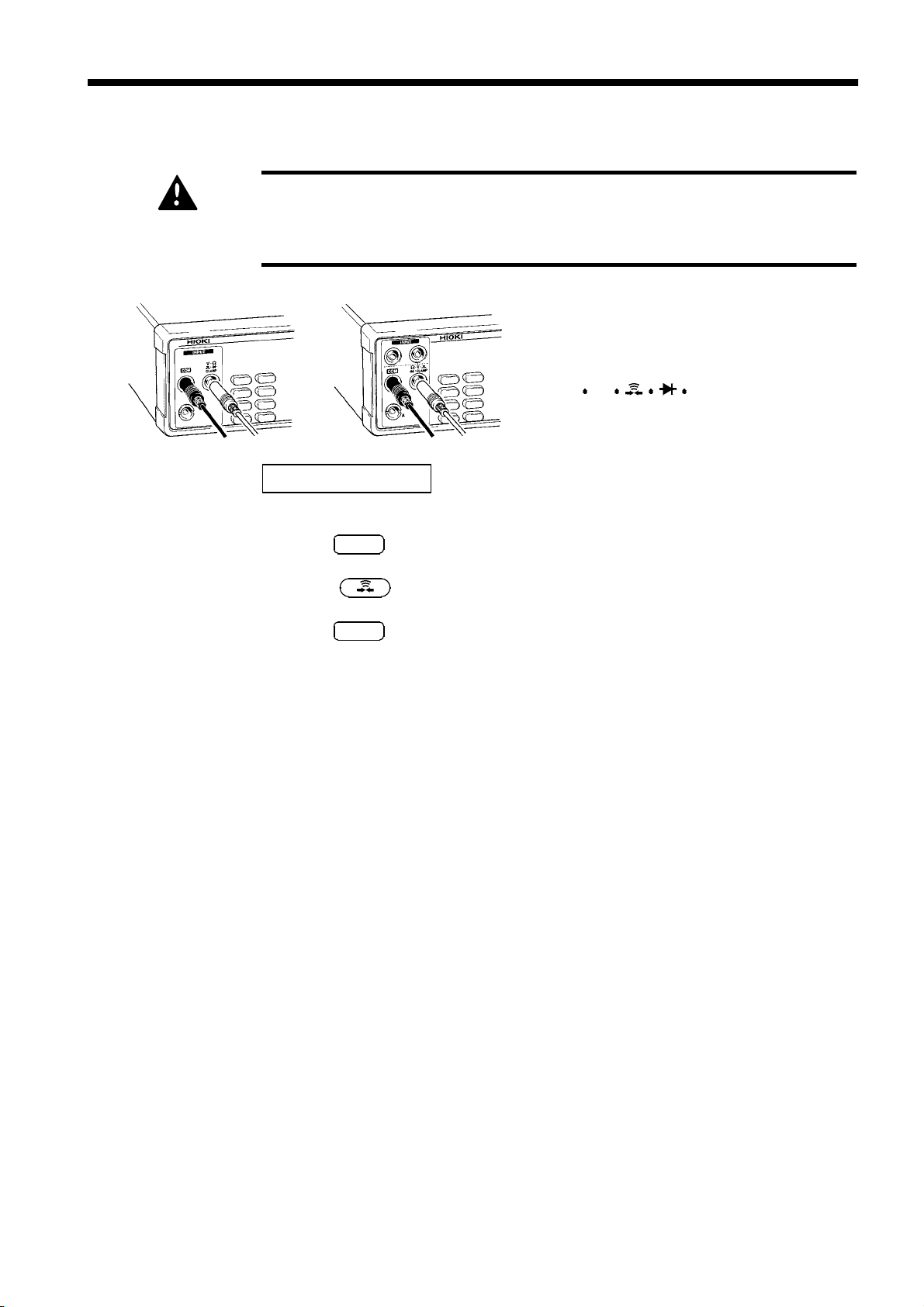

3238

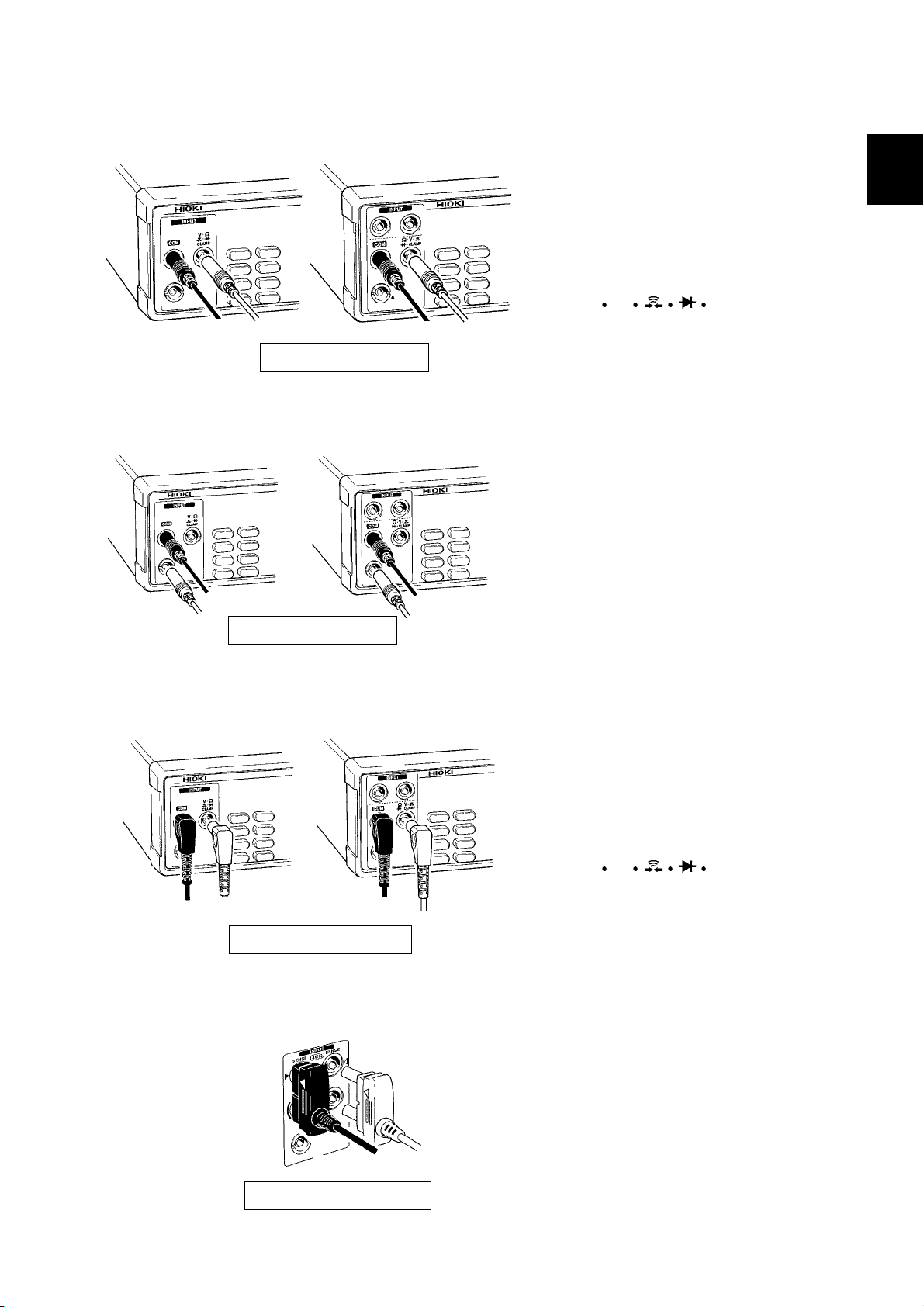

(1) Voltage measurement/ 2-terminal resistance measurement/

continuity test/ diode test/ frequency measurement

32393237/38

1

. Disconnect the L9170-10 TEST LEAD

from the sample being measured.

2

. Connect the black lead to the COM

terminal and the red lead to

the V Ω CLAMP terminal.

Black

Black

Red

Red

L9170-10 TEST LEAD

(2) Current measurement

L9170-10 TEST LEAD

Black

3239

Black

Red

Red

1

. Disconnect the L9170-10 TEST LEAD

from the sample being measured.

2

. Connect the black lead to the COM

terminal and the red lead to the Aterminal.

1

2

3

4

5

6

7

8

3237/38

Black

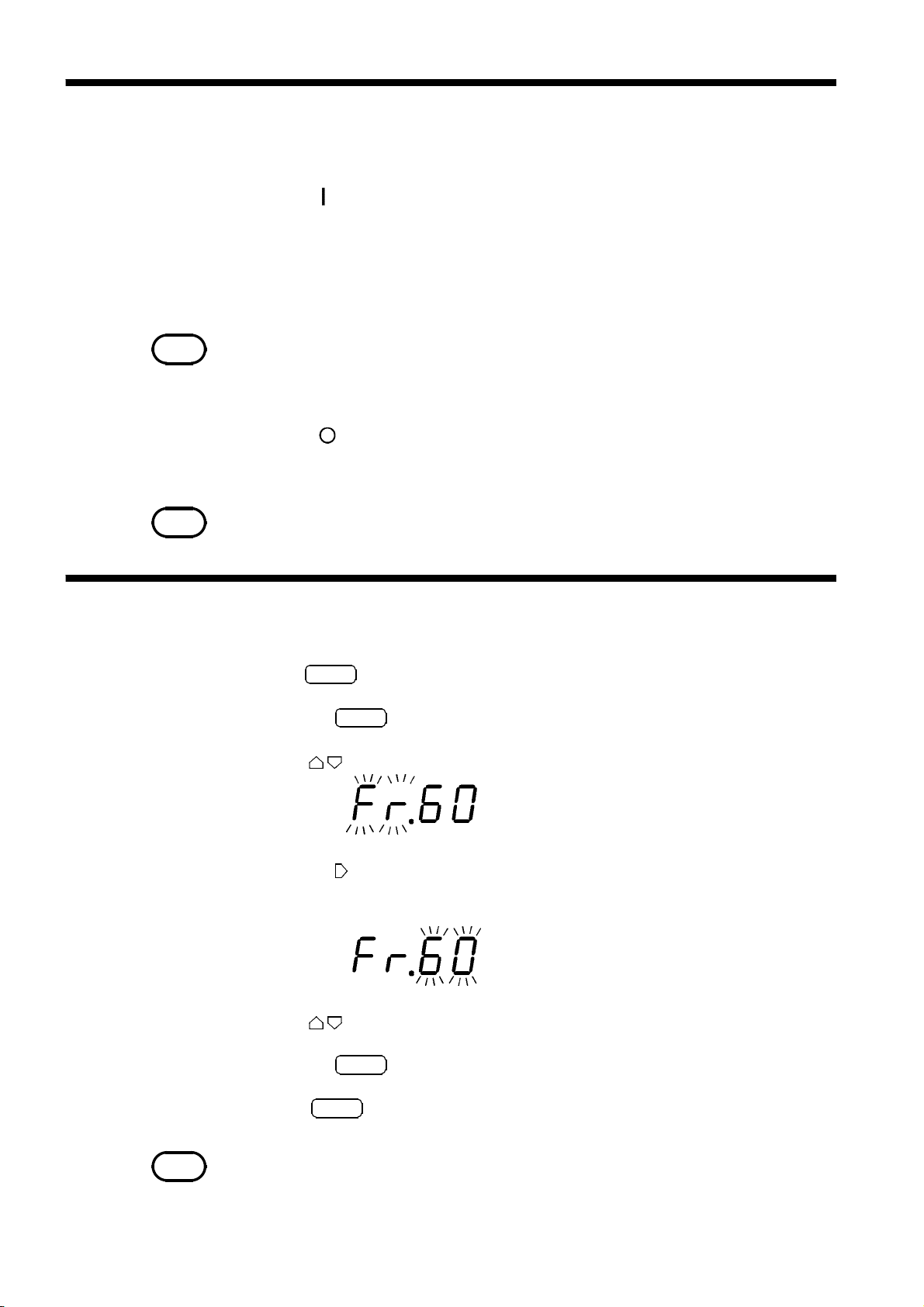

(3) Clamp current measurement

3239

Red

Clamp sensor connector

(4) 4-terminal resistance measurement

3239

Black

L2107 CLIP TYPE LEAD

Black

Red

Red

1

. Disconnect the clamp sensor from the

sample being measured.

2

. Connect the black lead to the COM

terminal and the red lead to

the V Ω CLAMP terminal.

1

. Disconnect the clamp sensor from the

sample being measured.

2

. Connect 4-terminal test leads like

those of the L2107 as shown in the

drawing. Align the triangular mark on

the red lead with the red triangular

mark on the chassis, and the triangular

mark on the black lead with the black

triangular mark on the chassis.

9

10

11

12

13

14

A

______________________________________________________________________________________________

2.2 Test Lead/Clamp Sensor Connection

Page 22

10

y

_____________________________________________________________________________________________

2.3 Power On/Off

(1) How to turn on power

Turn on ( ) the power switch on the front panel.

All the LEDs on the front panel will light to indicate the model, software

version and power-supply frequency of the unit. The unit readies itself for

measurement.

After power is turned on, the unit is set to the same measurement conditions

in effect when the unit was switched off.

NOTE

Allow the unit to warm up for 60 minutes before starting measurement.

(2) How to turn off power

Turn off ( ) the power switch on the front panel.

The measurement conditions will be saved.

NOTE

As long as the unit is in normal measurement or comparator execution modes, the

various conditions will be saved even in the event of a power blackout.

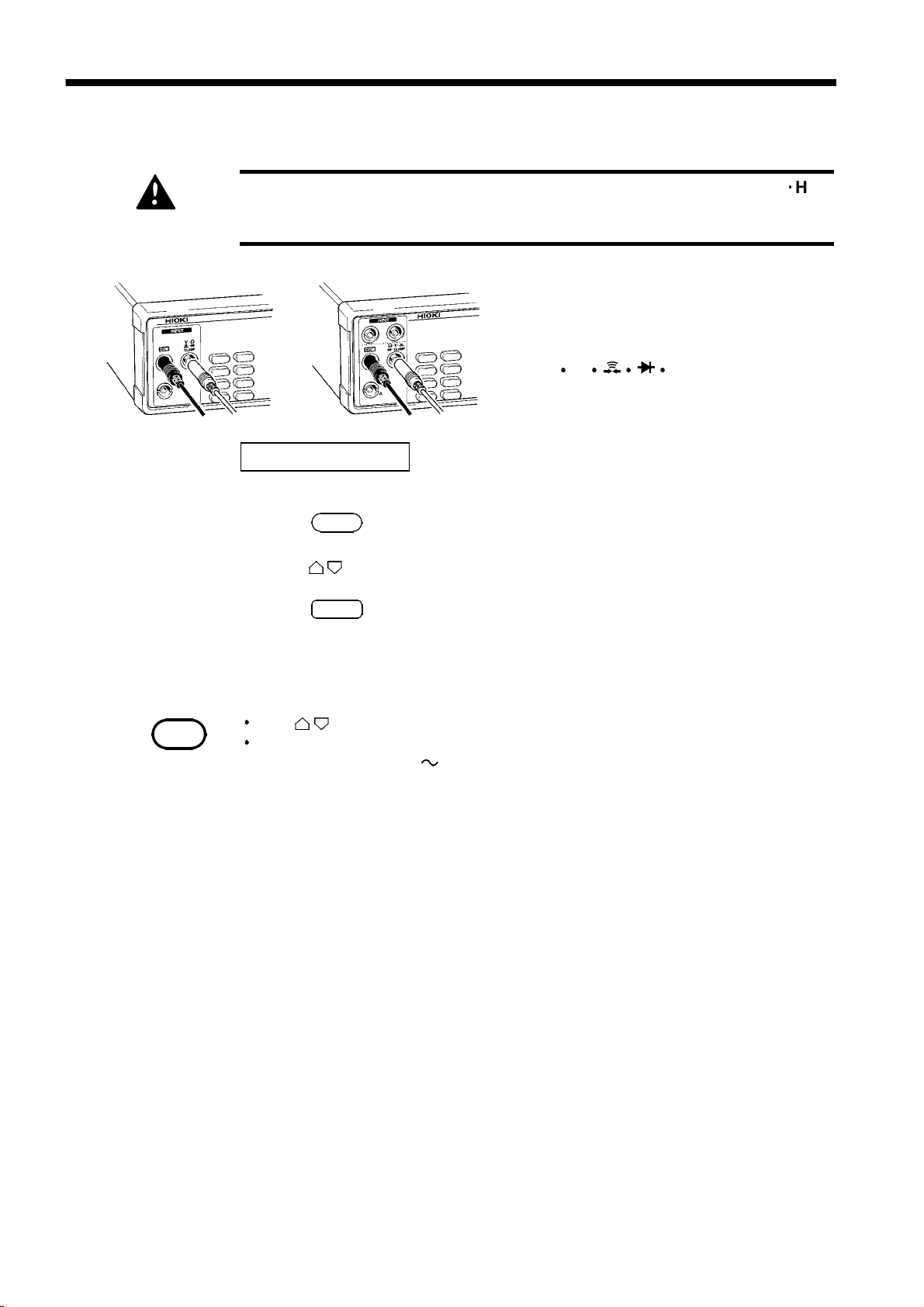

2.4 Selection of Power-supply Frequency

1

.Press

2

. Pressing

3

.Press to display the power-supply frequency setup screen.

SHIFT

."SHIFT" lights up on the display.

ENT

opens the menu screen for entering various settings.

4

. Pressing causes the frequency power-supply currently set to flash.

"50": 50 Hz

"60": 60 Hz

5

.Press to select a power-supply frequency.

6

. Pressing

7

.Press

NOTE

______________________________________________________________________________________________

2.4 Selection of Power-supply Frequency

To properly suppress noise, this product must be set to match the power supply

frequency. Before using the product, make sure the power supply frequency selector

is set correctl

ENT

causes "Fr" to flash.

ENT

again to define your selection.

, to avoid erroneous readings.

Page 23

_____________________________________________________________________________________________

11

Chapter 3

1

2

DANGER

Measurement Procedure

Observe the following precautions to avoid electric shock.

Always verify the appropriate setting of the measuring function before

connecting the test leads.

Disconnect the test leads from the measurement object before

changing the measuring function.

Clamp sensor/ Clamp-on probe/ Test leads should only be connected

to the secondary side of a breaker, so the breaker can prevent an

accident if a short circuit occurs. Connections should never be made

to the primary side of a breaker, because unrestricted current flow

could cause a serious accident if a short circuit occurs.

Do not measure an input in excess of the maximum rated working

voltage and current, as the resulting heat buildup may damage the

product or cause a short-circuit accident.

The maximum rated voltage to ground of the V

terminal is 600 VAC/DC (CAT II) or 1000 VAC/DC. (Cannot be used with

CAT II, CAT III and CAT IV. Can be used when not directly connected

to main power sources such as a battery or solar power, and transient

overvoltage is below 2.5 kV.) . Do not apply any voltage to this

terminal exceeding these ratings.

The maximum rated voltage to ground of the COM terminal is 300

VAC/DC (CAT II) or 500 VAC/DC (Cannot be used with CAT II, CAT III

and CAT IV. Can be used when not directly connected to main power

sources such as a battery or solar power, and transient overvoltage is

below 2.5 kV.). Do not apply any voltage to this terminal exceeding

these ratings.

The maximum rated voltage to ground of the A-terminal is 300 VAC/DC

(CAT II) or 500 VAC/DC (Cannot be used with CAT II, CAT III and CAT IV.

Can be used when not directly connected to main power sources such

as a battery or solar power, and transient overvoltage is below 2.5 kV.).

Do not apply any voltage to this terminal exceeding these ratings.

The maximum rated voltage to ground of the SENSE terminal is 300

VAC/DC (CAT II) or 500 VAC/DC (Cannot be used with CAT II, CAT III and

CAT IV. Can be used when not directly connected to main power sources

such as a battery or solar power, and transient overvoltage is below 2.5

kV.). Do not apply any voltage to this terminal exceeding these ratings.

To avoid electrical shock, be careful to avoid shorting live lines with

the test leads.

If the test leads are open-circuited, live high voltage lines cannot be

detected. After connecting the test leads, perform continuity tests to

confirm that the test leads are not open-circuited.

(See "3.4 Continuity Test".)

Ω

CLAMP

3

4

5

6

7

8

9

10

11

12

13

14

A

______________________________________________________________________________________________

Page 24

12

_____________________________________________________________________________________________

3.1 Voltage Measurement

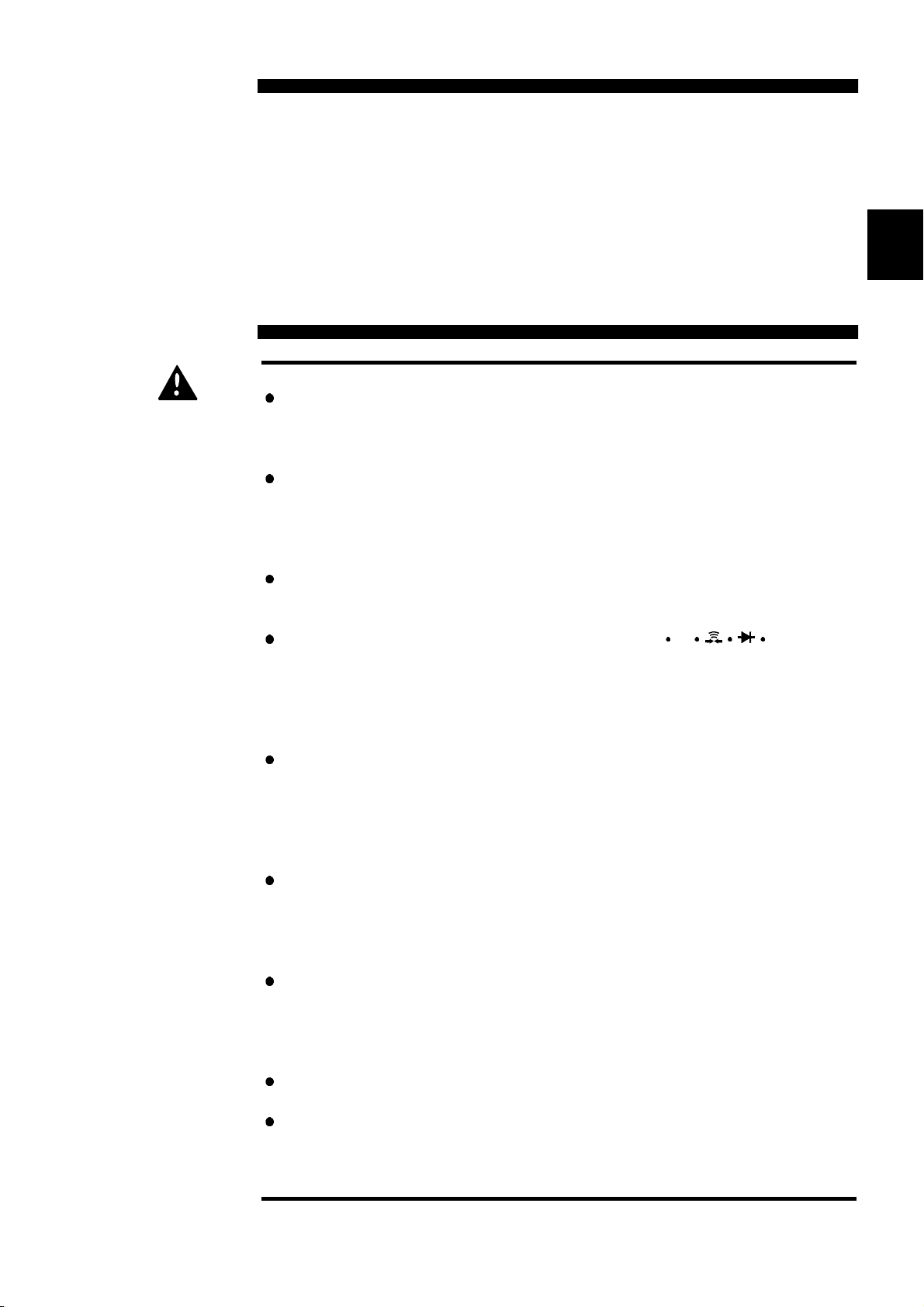

The maximum rated working voltage is 1000 VDC/700 VrmsAC (107V

DANGER

Black

Hz). Attempting to measure voltage in excess of the maximum rating

could destroy the product and result in personal injury or death.

32393237/38

Red

L9170-10 TEST LEAD

Black

3.1.1 DC Voltage Measurement

1

. Make sure that "SHIFT" does not light on the display.

2

.Press

V

.

・

Check to make sure that the black lead of

the L9170-10 TEST LEAD is connected

to the COM terminal and the red lead to

the V Ω CLAMP terminal.

Red

3

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

4

.Press

SMPL

to select a sampling period.

(See 4.2 Switching of Sampling Period.)

5

. Connect the test lead to the sample being measured and read the value.

3.1.2 AC Voltage Measurement

1

. Make sure that "SHIFT" does not light on the display.

2

.Press

3

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

N

L

4

.Press

(See 4.2 Switching of Sampling Period.)

V

SMPL

.

to select a sampling period.

AUTO

AUTO

to select Auto Range.

to select Auto Range.

5

. Connect the test lead to the sample being measured and read the value.

______________________________________________________________________________________________

3.1 Voltage Measurement

Page 25

_____________________________________________________________________________________________

13

3.2 2-Terminal Resistance Measurement

1

DANGER

Black

NOTE

Never apply voltage to test leads and SENSE terminal when the

Resistance, Low-power resistance or Continuity Check are selected.

Doing so may damage the product and result in personal injury.

To avoid electrical accidents, remove power from the circuit before

measuring.

32393237/38

Red

L9170-10 TEST LEAD

When measuring high resistance, there are cases in which an overload (“OF

displayed) occurs owing to external noise. Do not use the unit near fluorescent light

or power line.

When external noise is high, please shield the red lead (connected to the V

CLAMP terminal) and the sample to be measured. Connect the outer shield cover to the

COM terminal. (Or use a shielded line, such as the 9326 CONNECTION CORD.)

In case of using a dial resistor, connect the GUARD terminal to the COM terminal

of the unit.

Black

Red

Check to make sure that the black lead of

the L9170-10 TEST LEAD is connected

to the COM terminal and the red lead to

the V Ω CLAMP terminal.

”

Ω

2

3

4

5

6

7

8

9

3.2.1 Resistance Measurement (2-Terminal)

1

. Make sure that "SHIFT" does not light on the display.

2

.Press

3

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

4

.Press

(See 4.2 Switching of Sampling Period.)

5

. Performs zero-ajust for the 3237/38/39.

(See 4.3 Zero Ajust Function.)

6

. Connect the test lead to the sample being measured and read the value.

Ω

."2W" lights up on the display. (3239)

SMPL

to select a sampling period.

AUTO

to select Auto Range.

10

11

12

13

14

A

______________________________________________________________________________________________

3.2 2-Terminal Resistance Measurement

Page 26

14

_____________________________________________________________________________________________

3.2.2 Low-power Resistance Measurement (2-Terminal)

1

. Make sure that "SHIFT" does not light on the display.

2

.Press

3

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

4

.Press

(See 4.2 Switching of Sampling Period.)

5

. Performs zero-ajust for the 3237/38/39.

(See 4.3 Zero Ajust Function.)

6

. Connect the test lead to the sample being measured and read the value.

LPΩ

."2W"(3239) and "LP" lights up on the display.

SMPL

AUTO

to select a sampling period.

to select Auto Range.

______________________________________________________________________________________________

3.2 2-Terminal Resistance Measurement

Page 27

_____________________________________________________________________________________________

(

15

3.3 4-Terminal Resistance Measurement

1

DANGER

NOTE

Never apply voltage to test leads and SENSE terminal when the

Resistance, Low-power resistance or Continuity Check are selected.

Doing so may damage the product and result in personal injury.

To avoid electrical accidents, remove power from the circuit before

measuring.

3239

The four terminals of the L2107 CLIP TYPE

LEAD

Verify that all four terminals (SOURCE+,

SOURCE-, SENSE+, and SENSE-) are

connected. Also verify that the triangular mark

Black

L2107 CLIP TYPE LEAD

When measuring high resistance, there are cases in which an overload (“OF

displayed) occurs owing to external noise. Do not use the unit near fluorescent light

or power line.

When external noise is high, please shield the red lead (connected to the V

CLAMP terminal) and the sample to be measured. Connect the outer shield cover to the

COM terminal. (Or use a shielded line, such as the 9326 CONNECTION CORD.) In case

of using a dial resistor, connect the GUARD terminal to the COM terminal of the unit.

Red

on the red lead is aligned with the red

triangular mark on the chassis, and that the

triangular mark on the black lead is aligned

with the black triangular mark on the chassis.

”

Ω

2

3

4

5

6

7

8

3.3.1 Resistance Measurement (4-Terminal, on 3239 only)

SHIFT

."SHIFT" lights up on the display.

Ω

."4W" lights up on the display.

SMPL

to select a sampling period.

Rx

1

.Press

2

.Press

3

.Press

(See 4.2 Switching of Sampling Period.)

4

. Performs zero-ajust for the 3237/38/39.

(See 4.3 Zero Ajust Function.)

5

. Connect the test lead to the sample being measured and read the value.

9

10

11

12

13

14

A

When clipping a thin line

Clipthe line at the tip,

______________________________________________________________________________________________

When clipping a thick line

Clipthe line at the deep,non-

3.3 4-Terminal Resistance Measurement

Page 28

16

_____________________________________________________________________________________________

3.3.2 Low-power Resistance Measurement

(4-Terminal, on 3239 only)

1

.Press

2

.Press

3

.Press

(See 4.2 Switching of Sampling Period.)

4

. Performs zero-ajust for the 3237/38/39.

(See 4.3 Zero Ajust Function.)

5

. Connect the test lead to the sample being measured and read the value.

NOTE

When measurement is performed using the low-power resistance measurement

function or continuity test function, the measurement values may not be stable,

because the measurement current in this measurement mode is lower than for

normal resistance measurement.

3.4 Continuity Test

SHIFT

LPΩ

SMPL

SHIFT

."

" lights up on the display.

."4W"and"LP" lights up on the display.

to select a sampling period.

NOTE

1

. Make sure that "SHIFT" does not light on the display.

2

.Press .

3

. Connect the test lead to the sample being measured.

The buzzer will beep if the resistance value is below 50 ohms.

When measurement is performed using the low-power resistance measurement

function or continuity test function, the measurement values may not be stable,

because the measurement current in this measurement mode is lower than for

normal resistance measurement.

The resistance measurement and low-power resistance measurement will display

values that include the resistance value of the test lead. Use the Zero-Adjust

function to exclude this resistance value.

______________________________________________________________________________________________

3.4 Continuity Test

Page 29

_____________________________________________________________________________________________

17

3.5 Diode Test

Never apply voltage to test leads when the Diode test is selected. Doing

DANGER

so may damage the product and result in personal injury.

To avoid electrical accidents, remove power from the circuit before

measuring.

32393237/38

Check to make sure that the black lead of

the L9170-10 TEST LEAD is connected

to the COM terminal and the red lead to

the V Ω CLAMP terminal.

Black

Red

L9170-10 TEST LEAD

1

.Press

2

.Press .

3

.Press

SHIFT

."SHIFT" lights up on the display.

SMPL

to select a sampling period.

Black

Red

(See 4.2 Switching of Sampling Period.)

4

. Connect the test lead to the sample being measured and read the value.

A normal silicon diode indicates a forward voltage of 0.4 to 0.7 V. In the

reverse direction, "OF" will light.

______________________________________________________________________________________________

3.5 Diode Test

Page 30

18

_____________________________________________________________________________________________

3.6 Frequency Measurement (3238/39)

The maximum rated working voltage is 600 VDC/700 VrmsAC (107V・Hz).

DANGER

Attempting to measure voltage in excess of the maximum rating could

destroy the product and result in personal injury or death.

3238

Black

NOTE

3239

Check to make sure that the black lead of

the L9170-10 TEST LEAD is connected

to the COM terminal and the red lead to

the V Ω CLAMP terminal.

Red

L9170-10 TEST LEAD

1

.Press

2

.Press to select an attenuator range.

3

.Press

Hz

SMPL

Black

.

to select a sampling period.

Red

(See 4.2 Switching of Sampling Period.)

4

. Connect the test lead to the sample being measured and read the value.

Press to set a range for the attenuator circuit (voltage divider circuit).

Input sensitivity is approximately 10% of the selected attenuator range. Check

the signal level with the

Example: The frequency of a 10 V signal can be measured in the attenuator range

of 2 V or 20 V, but not in the attenuator range of 200 V or 700 V.

V function before measuring the frequency.

______________________________________________________________________________________________

3.6 Frequency Measurement (3238/39)

Page 31

_____________________________________________________________________________________________

19

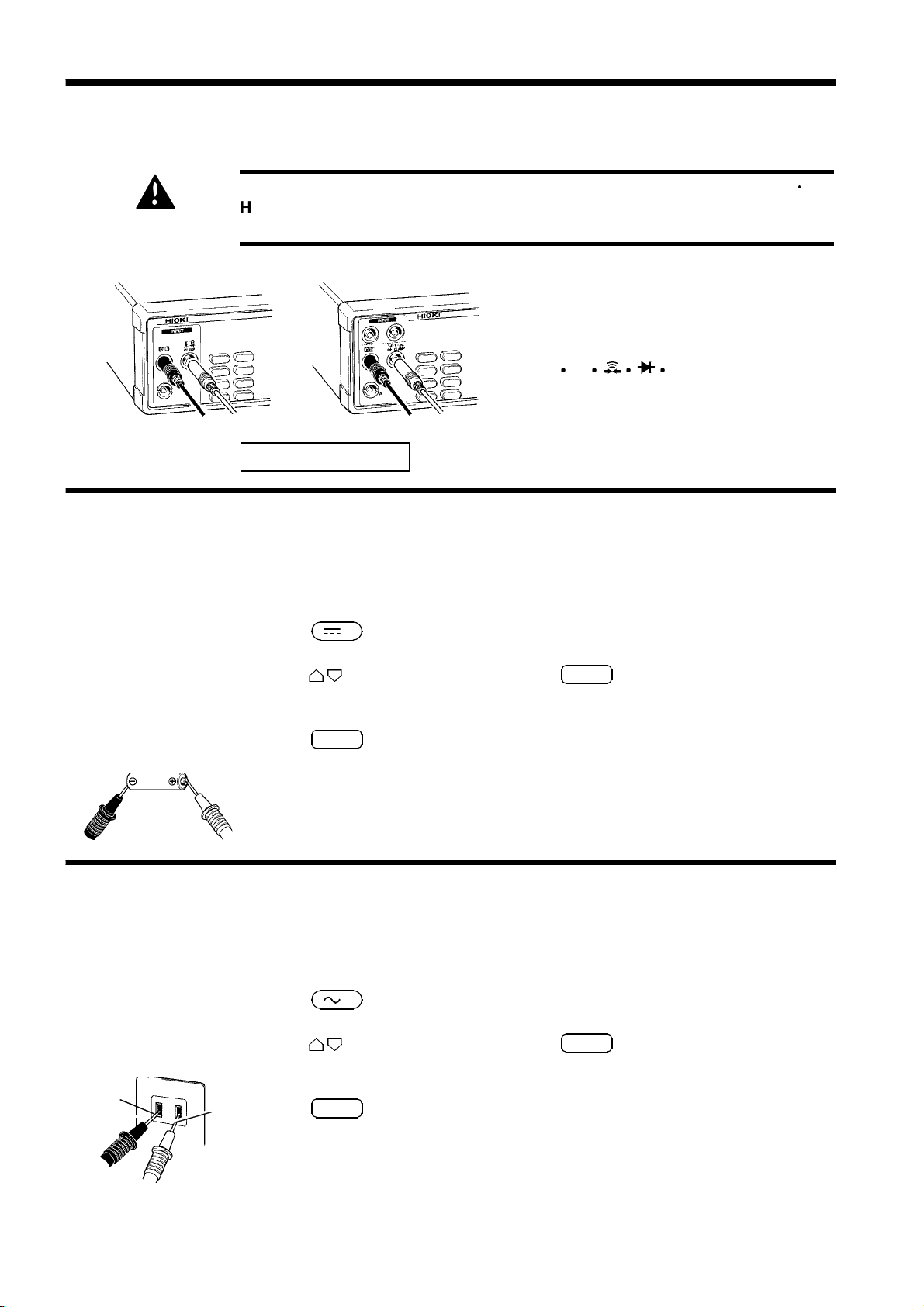

3.7 Current Measurement (3238/39)

The maximum rated working current is 2 ADC/AC. Attempting to input

DANGER

current in excess of the maximum rating could destroy the product

and result in personal injury or death.

Never apply voltage to A-terminal. Doing so may damage the product

and result in personal injury. To avoid electrical accidents, remove

power from the circuit before measuring.

3238

Red

Black

L9170-10 TEST LEAD

3239

Black

Red

3.7.1 DC Current Measurement

1

.Press

2

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

3

.Press

(See 4.2 Switching of Sampling Period.)

A

SMPL

.

to select a sampling period.

Check to make sure that the black lead of

the L9170-10 TEST LEAD is connected

to the COM terminal and the red lead to

the A-terminal.

AUTO

to select Auto Range.

4

. Connect the test lead to the sample being measured and read the value.

NOTE

After measuring large current, the terminal may become hot, producing

thermoelectric power that may cause incorrect measurement results.

Therefore, after measuring large current, wait a moment before measuring

again.

3.7.2 AC Current Measurement

1

.Press

2

.Press to select a range. Or press

(See 4.1 Selection of Measurement Range.)

3

.Press

(See 4.2 Switching of Sampling Period.)

4

. Connect the test lead to the sample being measured and read the value.

______________________________________________________________________________________________

A

SMPL

.

to select a sampling period.

AUTO

to select Auto Range.

3.7 Current Measurement (3238/39)

Page 32

20

_____________________________________________________________________________________________

3.8 Clamp Current Measurement

To avoid short circuits and potentially life-threatening hazards, never

DANGER

attach the clamp to a circuit that operates at more than the maximum

rated voltage, or over bare conductors.

Before using the clamp sensor, carefully read the supplied instruction

manual.

NOTE

3237, 3238

The Auto Range function cannot be used in clamp current measurement.

3239

Black

Red

Connect the Clamp sensor connector to

the 9704 CONVERSION ADAPTER.

9704

CONVERSION

ADAPTER

Connect the 9704 black COM terminal to

the COM terminal of the main unit and

the 9704 red terminal to the V Ω

CLAMP terminal of the main unit.

Clamp sensor connector

Selection of the clamp sensor

1

.Press

2

. Pressing

3

.Press to display the clamp sensor setup screen.

SHIFT

."SHIFT" lights up on the display.

ENT

displays the menu screen.

4

. Pressing causes the currently selected clamp sensor model to flash.

5

.Press to select a clamp sensor.

6

. Pressing

7

. Another press to

NOTE

______________________________________________________________________________________________

3.8 Clamp Current Measurement

If you plan to use the 9081 External Shunt Resistor, Class 1.0, specify 9278 on

the clamp sensor selection screen. The value can be read directly as a current

value.

The available clamp sensors as of Dec. 1, 2008, are 9010-50/9018-50/9132-50.

Accuracy cannot be guaranteed if you use clamp sensor unit models

9270/9271/9272/9277/9278/9279/3283/3284/3285.

ENT

causes "CL" to flash.

ENT

confirms your selection.

Page 33

_____________________________________________________________________________________________

21

3.8.1 DC Clamp Current Measurement

1

.Press

2

.Press

3

.Press to select a clamp sensor range.

4

.Press

(See 4.2 Switching of Sampling Period.)

5

. Clip the clamp around one of wires of the circuit to be measured and read

the value.

Source side

SHIFT

."SHIFT" lights up on the display.

V

.

SMPL

to select a sampling period.

Load side

(9277/9278/9279/3284/3285)

Corresponds the current

direction indication to

the direction of current

flow.

NOTE

The DC clamp current measurement function cannot be used if a clamp sensor

other than 9277/9278/9279/3284/3285 is selected.

Auto Range cannot be used.

______________________________________________________________________________________________

3.8 Clamp Current Measurement

Page 34

22

_____________________________________________________________________________________________

3.8.2 AC Clamp Current Measurement

1

.Press

2

.Press

3

.Press to select a clamp sensor range.

SHIFT

."SHIFT" lights up on the display.

V

.

(Clamp sensor: 9010-50/9018-50/9132-50/3283/3284/3285)

(See 4.1 Selection of Measurement Range.)

4

.Press

SMPL

to select a sampling period.

(See 4.2 Switching of Sampling Period.)

5

. Clip the clamp around one of wires of the circuit to be measured and read

the value.

Load side

Source side

Corresponds the current

direction indication to

the direction of current

flow.

NOTE

Auto Range cannot be used.

______________________________________________________________________________________________

3.8 Clamp Current Measurement

Page 35

_____________________________________________________________________________________________

23

Chapter 4

1

2

Basic Functions

4.1 Selection of Measurement Range

(1) Manual Range

Press to select a range.

(2) Auto Range

Press

automatically selects an optimum measurement range.

Press

range.

NOTE

AUTO

AUTO

If the Zero-Adjust function is in use, the unit will determine a suitable range

suited for the input signal level and indicate the value that results after

subtracting the Zero-Adjusted value from the measurement data.

Auto Range cannot be used with the clamp current measurement function or

frequency measurement function.

while Manual Range is selected. "AUTO" lights up and the unit

once again to restore Manual Range with the currently selected

3

4

5

6

7

8

9

10

4.2 Switching of Sampling Period

This unit allows you to change the sampling period in 3 steps: FAST,

MEDIUM, and SLOW. The longer the sampling period, the better the

measurement accuracy.

1

.Press

2

. Repeatedly press

settings in the order "FAST"→"MEDIUM"→"SLOW".

NOTE

______________________________________________________________________________________________

When FAST is chosen for the sampling period, the unit performs a self-

calibration

In a continuity test, only FAST can be selected for the sampling period.

*: Self-calibration: 3237/38/39 automatically self-correct offset and gain.

SMPL

.

SMPL

*

every 30 minutes. Each self-calibration takes approximately 55 ms.

to cycle through the available sampling period

4.2 Switching of Sampling Period

11

12

13

14

A

Page 36

24

_____________________________________________________________________________________________

4.3 Zero Adjust function

The Zero-Adjust function displays the computed result after subtracting the

Zero-Adjusted value (reference value) from the measurement data.

The function can be used to cancel an offset, such as the resistance of the

test lead, or to check the deviation from the reference value.

. Measure the sample that you want Zero-Adjusted.

1

.Press

2

.Press

3

SHIFT

LOAD

SHIFT

."

" lights up on the display.

."0ADJ" lights up on the display, and the unit loads the

current measurement value as the Zero-Adjusted value.

The display shows "Measurement value - Zero-Adjusted" value.

Zero-Adjust Procedure When Using the 4-terminal test leads (3239)

SENSE

SOURCE

SENSE

SOURCE

Correct connection

Bring the "v" marks together

at the same position.

SENSE

SOURCE

SOURCE

Wrong connection

Clearing the Zero-Adjust function

SENSE

SHIFT

."SHIFT" lights up on the display.

LOAD

clears the Zero-Adjust function.

NOTE

.Press

1

. Pressing

2

The Zero-Adjusted value is saved as an absolute value independent of a specific

range.

Example:

When 1.234 Ω is measured in the 200 Ω range and then Zero-Adjusted, 1.234 Ω

is also subtracted from the value measured in the 2000 Ω range before being

displayed.

In the case of an overload ("OF" displayed), the error message "

Err.002

"is

displayed. The Zero-Adjust function is unavailable under these conditions.

A Zero-Adjusted value can be set for each function.

If a value is not covered by the range of -199999 count≦(Measurement value -

" is displayed.

Zero-Adjusted value)≦+199999 count, "

OF

The Zero-Adjust function cannot be used with the continuity test function, diode

test function, or frequency measurement function.

______________________________________________________________________________________________

4.3 Zero Adjust function

Page 37

_____________________________________________________________________________________________

25

4.4 Average function

The Average function outputs a mean value after averaging measurement

values. This function allows you to minimize the deviation of measurement

values.

The averaging can be set to 2 to 100 measurements.

1

2

3

NOTE

.Press

1

.Press

2

screen.

.Press to select the number of averaged measurements.

3

Press the simultaneously to clear the set value (002 times).

.Press

4

measurement is enabled.

Clearing the Average function

.Press

1

. Pressing

2

The Average function cannot be used with the continuity test function.

SHIFT

."SHIFT" lights up on the display.

SMPL

SHIFT

to display the number of averaged measurements setup

ENT

."AVE" lights up on the display, and averaging

."SHIFT" lights up on the display.

SMPL

clears the Average function.

4

5

6

7

8

9

Eliminating power line noise

Measurements are more consistent when the sampling is synchronized to the

power line cycle. However, the measurement period of 3.33 ms of the FAST

sampling is not synchronized to the power line cycle (except for some

functions and ranges).

To ensure the most consistent measurement values with "

recommend the following settings:

Power-supply

frequency

Number of averaged

measurements

These settings synchronize the measurement time with the sampling period

FAST to the power line cycle to ensure consistent and reliable

measurements.

6 x n measurements 5 x n measurements n: 1,2,3,

50 Hz 60 Hz

FAST", we

10

11

12

13

14

A

______________________________________________________________________________________________

4.4 Average function

Page 38

26

_____________________________________________________________________________________________

4.5 Trigger Function

4.5.1 Setup for Trigger mode

The following two types of Trigger modes are available:

(1) Internal Trigger

Continuous measurement is performed with an automatically generated

internal trigger.

.Press

1

.Press

2

M.TRIG

Trigger mode is activated.

(2) External Trigger

Measurement is performed with a trigger applied externally or manually.

Press

M.TRIG

is activated.

NOTE

External Trigger mode is inactive when the continuity test function is used.

4.5.2 External Trigger

The following three types of External Trigger are available:

(1) Applied through the front panel

SHIFT

."

SHIFT

" lights up on the display.

."M.TRIG" is no longer lit on the display, and Internal

."M.TRIG" lights up on the display, and External Trigger mode

Pressing

M.TRIG

on the front panel causes the unit to perform a single

measurement.

(2) Applied through EXT I/O

When a pulse is applied to the TRIG terminal of the EXT I/O connector on

the rear panel, the unit performs a single measurement. (See 6.1 Explanation

of Signals.)

(3) Applied through the interface

When the ∗TRG command is issued through the interface, the unit performs

a single measurement.

NOTE

______________________________________________________________________________________________

4.5 Trigger Function

When Internal Trigger remains active, all inputs through the EXT I/O connector and

the ∗TRG command are ignored.

Page 39

_____________________________________________________________________________________________

27

4.5.3 Trigger Delay

1

The delay time from the application of a trigger signal until the start of

measurement is set. If this function is in use, measurement begins when the

measurement values have stabilized, even if a trigger is applied immediately

following the connection of the sample.

The following two types of trigger delay are available:

(1) Auto Delay

The unit automatically sets a delay time.

.Press

1

. Pressing

2

.Press to display the trigger delay setup screen.

3

. Pressing causes the currently set trigger delay to flash.

4

"AUt": Auto delay

"SEt": Manual delay

SHIFT

."SHIFT" lights up on the display.

ENT

displays the menu screen.

2

3

4

5

6

7

8

.Press to select auto delay ("AUt").

5

. Pressing

6

.Press

7

Wait Times of Auto Delay

DCV 3ms 3ms 3ms

ACV 500 ms 800 ms 1.5 s

DCA 3ms 3ms 3ms

ACA 500 ms 800 ms 1.5 s

Ω

LPΩ 2to20kΩ range 3ms 3ms 3ms

Hz 10 ms 10 ms 10 ms

200 Ω to 200 kΩ range 3ms 3ms 3ms

2MΩ range 20 ms 20 ms 20 ms

20 MΩ range 100 ms 100 ms 100 ms

100 MΩ range 500 ms 500 ms 500 ms

2MΩ, 200 kΩ range 20 ms 20 ms 20 ms

ENT

causes "dLy" to flash.

ENT

again to define your selection.

FAST MEDIUM SLOW

9

10

11

12

13

14

A

______________________________________________________________________________________________

4.5 Trigger Function

Page 40

28

_____________________________________________________________________________________________

(2) Manual Delay

Any desired delay time can be set.

The trigger delay time can be set from 0.000 to 9.999 s in increments of 1

ms.

.Press

1

. Pressing

2

.Press to display the trigger delay setup screen.

3

. Pressing causes the currently set trigger delay to flash.

4

AUt

"

SHIFT

": Auto delay

SHIFT

."

ENT

" lights up on the display.

displays the menu screen.

"SEt": Manual delay

.Press to select manual delay ("SEt").

5

. Pressing

6

ENT

causes the values indicating the trigger delay time to

flash.

. Set a trigger delay time by pressing .

7

. Pressing

8

.Press

9

ENT

causes "dLy" to flash.

ENT

again to define your selection.

______________________________________________________________________________________________

4.5 Trigger Function

Page 41

_____________________________________________________________________________________________

29

4.5.4 Trigger System

The trigger system functions as described further below, depending on the

setting for the Continuous trigger state (

Trigger Source (

:TRIGGER:SOURCE

). For trigger commands, refer to 7.4.3

"Specific Command Messages."

:INITIATE:CONTINUOUS

Continuous trigger state

:INITIATE:CONTINUOUS

ON OFF*

) or for the

NOTE

Trigger source

:TRIGGER:SOURCE

IMMEDIATE

Internal trigger state:

Pressing

M.TRIG

SHIFT

+

initiates this

Trigger is made on:

INITIATE (or :READ?)

state.

Free run.

EXTERNAL

External trigger state:

Pressing

M.TRIG

from

free run initiates this

state.

Trigger is made through

the TRIG terminal or

M.TRIG

with

.

The unit enters Wait

state for trigger on

:INITIATE (or

:READ?).

Trigger is made through

the TRIG terminal or

when

*: Can only be set by a remote command.

If the unit is switched off while it in

:INITIATE:CONTINUOUS ON/:TRIGGER:SOURCE EXTERNAL

switched on.

:INITIATE:CONTINUOUS OFF

M.TRIG

is pressed.

, it will be set to

when the unit is

______________________________________________________________________________________________

4.5 Trigger Function

Page 42

30

_____________________________________________________________________________________________

:INITIATE:CONTINUOUS ON

:TRIGGER:SOURCE IMMEDIATE

Measurement

Computed result

Measurement value

output

:INITIATE:CONTINUOUS ON

:TRIGGER:SOURCE EXTERNAL

Wait state for trigger

TRIG terminal

M.TRIG

Trigger delay

Measurement

computed result

Measurement value

output

:INITIATE:CONTINUOUS OFF

:TRIGGER:SOURCE IMMEDIATE

Idle state

:INITIATE:IMMEDIATE

Trigger delay

Measurement

computed result

Measurement value

output

:INITIATE:CONTINUOUS OFF

:TRIGGER:SOURCE EXTERNAL

Idle state

:INITIATE:IMMEDIATE

Wait state for trigger

TRIG terminal

M.TRIG

Trigger delay

Measurement

computed result

Measurement value

output

______________________________________________________________________________________________

4.5 Trigger Function

Page 43

_____________________________________________________________________________________________

q

31

Chapter 5

1

2

5.1 Comparator Function

The Comparator function compares the measurement value with the upperlimit and lower-limit values previously set, determines the appropriate range

for the measurement value, and displays the determination.

The flow of comparator setup is given below:

Setting of comparator

Measurement (comparator: OFF)

Other Functions

3

4

5

6

7

8

NOTE

ENT

The upper-limit value is set.

ENT

The lower-limit value is set.

ENT

Measurement (comparator: ON)

ENT

:

Confirms the current setting and proceeds to the next setup.

COMP

:

Proceeds to the next setup without confirming the current setting.

(Cancellation)

The Comparator function cannot be used in Auto Range.

The Comparator function cannot be used with the continuity test

function or fre

uencymeasurement function.

COMP

COMP

COMP

COMP

9

10

11

12

13

14

A

______________________________________________________________________________________________

5.1 Comparator Function

Page 44

32

_____________________________________________________________________________________________

Described below is the flow of operations from the measurement state with

comparator OFF to the start of the measurement state using the comparator.

In the following example, the upper-limit value will be set to 12 V and the

lower-limit value to 8 V.

(1) The upper-limit value is set.

1

.

Press

COMP

when the comparator is off.

"Hi" flashes, and the upper-limit value setup screen opens.

. Set the upper-limit value by pressing .

2

This is set to 12 V in the example.

(2) The lower-limit value is set.

1

.

Press

ENT

on the upper-limit value setup screen.

lower-limit value setup screen opens.

. Set the lower-limit value by pressing .

2

This is set to 8 V in the example.

(3) Turn the comparator ON.

Press

ENT

in the lower-limit value setup screen to initiate the

measurement state with the comparator ON.

"Lo"

flashes, and the

The comparator decides in which range the measurement value is covered

and displays the result. To enable the buzzer to beep depending on the

comparator determination, refer to 5.2 Setup for Comparator Buzzer Sound.

______________________________________________________________________________________________

5.1 Comparator Function

Page 45

_____________________________________________________________________________________________

33

NOTE

To turn the comparator OFF

If you press

unit shifts to measurement with the comparator OFF.

Pressing

screen opens the following screen without altering the current upper-limit or

lower-limit value.

When the comparator is ON, only the following keys are active:

COMP,LOAD,SAVE,LOCAL(M.TRIG

is set)

The conditions for measurment with the comparator ON are taken from

the conditions of the measurement conducted with the comparator

OFF.

The upper-limit and lower-limit values are saved as indication count

values that do not depend on the measurement functions or

measurement ranges. With a different measurement function or

different measurement range, the absolute values indicated by the

count values also change.

sFor example, specify 038000 to set the lower-limit value to 380 mV in

the 2 V range of the

If the unit is switched off while in the upper-limit value setup screen or

lower-limit value setup screen, the values entered during setup are

canceled and the previously set values retained.

If the comparator is turned on while Auto Range is active, Auto Range

will be cleared.

If the comparator is turned on while the upper-limit value of the

comparator is set to a value smaller than the lower-limit value, the

unit will indicate "

The relation between the threshold and indication values are as follows:

Indication value > Upper-limit value : Hi

Upper-limit value≧Indication value≧Lower-limit value: IN

Lower-limit value > Indication value: Lo

COMP

COMP

while the unit is measuring with the comparator ON, the

on the upper-limit value setup screen or lower-limit value setup

only when External Trigger

V function.

Err.004

", and the comparator will be turned off.

1

2

3

4

5

6

7

8

9

10

11

12

______________________________________________________________________________________________

5.1 Comparator Function

13

14

A

Page 46

34

_____________________________________________________________________________________________

5.2 Comparator Buzzer Sound

Set the buzzer to sound at comparator determination.

NOTE

1

2

.

Press

.

Press

SHIFT

COMP

"

.

SHIFT

"

lights up on the display.

. The comparator buzzer sound setup screen opens, and the

current setting for the comparator buzzer flashes.

.Press to select the comparator determination that should activate the

3

buzzer.

"HL" : The buzzer beeps when the determination is Hi or Lo.

"In" : The buzzer beeps when the determination is In.

"OF" : The buzzer is not activated to beep, regardless of the comparator

result.

.

Press

4

The unit is set to "HL" at the factory before shipment.

ENT

. You are returned to the measurement screen.

______________________________________________________________________________________________

5.2 Comparator Buzzer Sound

Page 47

_____________________________________________________________________________________________

35

5.3 Panel Save Function

The current measurement conditions are saved to the built-in nonvolatile

memory. A maximum of 30 different measurement conditions may be

saved. All the conditions in effect when Panel Save is executed are saved.

The saved measurement conditions can be loaded with the Panel Load

function described further below.

1

2

3

NOTE

.

Press

1

indicating the panel number flashes.

.Press to select the panel number you want to save.

2

.

Press

3

returned to the measurement screen.

When the Panel Save screen opens, it indicates panel numbers that

have not been saved previously.

If you select a panel number under which you previously saved data and press

ENT

Interruption of Panel Save function

If you inadvertently opened the Panel Save screen, press

without pressing

The measurement screen will be restored without executing a Panel Save.

The following items are saved:

SAVE

. The Panel Save setup screen opens, and a numerical value

ENT

. The measurement conditions are saved, and you are

, the previously saved data will be overwritten.

ENT

.

SAVE

again

4

5

6

7

8

9

10

Measurement speed

Function

Range

ON/OFF for the comparator function

Upper/lower limit value of comparator

function

Comparator buzzer sound

Internal trigger/ external trigger

Auto delay/ manual delay

Trigger delay time

ON/OFF for the zero ajust function

Zero adjust value

ON/OFF for the average function

Number of averaged measurements

Kind of the clamp sensor

______________________________________________________________________________________________

5.3 Panel Save Function

11

12

13

14

A

Page 48

36

_____________________________________________________________________________________________

5.4 Panel Load Function

This function loads the measurement conditions saved by Panel Save from

the built-in nonvolatile memory.

NOTE

1

.

Press

LOAD

. The Panel Load setup screen opens, and the numerical

value indicating the panel number flashes.

.Press to select the panel number from which you want to load data.

2

3

.

Press

ENT

. The measurement conditions are loaded, and you are

returned to the measurement screen.

For panel number selection, tables not saved are skipped.

When a System Reset is performed,

number has been saved.

LOAD

becomes inactive, since no panel

Interruption of Panel Load function

If you inadvertently opened the Panel Load screen, press

without pressing

ENT

.

LOAD

again

The measurement screen will be restored without executing a Panel Load.

______________________________________________________________________________________________

5.4 Panel Load Function

Page 49

_____________________________________________________________________________________________

37

5.5 Key Operation Sound

The setting made here determines whether or not the key operation sound

should be emitted when a key is pressed on the front panel of the main unit.

.

Press

1

.

Pressing

2

.Press to display the key operation sound setup screen.

3

. Pressing causes the current setting for the key operation sound to flash.

4

SHIFT

ENT

"

.

"

SHIFT

lights up on the display.

displays the menu screen.

"On": Key operation sound emitted

"OF": Key operation sound not emitted

.Press to select On or Off.

5

.

Pressing

6

.

Press

7

ENT

causes

ENT

again to define your selection.

"

bEEP

"

to flash.

______________________________________________________________________________________________

5.5 Key Operation Sound

Page 50

38

_____________________________________________________________________________________________

5.6 Key Lock Function

When Key Lock is executed, the key switches on the front panel are

disabled. The set data can be protected with the Key Lock function.

. Set measurement conditions.

1

NOTE

NOTE

2

3

.

Press

.

Press

SHIFT

LOCAL

"

.

SHIFT

"

lights up on the display.

to initiate the Key Lock state.

When the unit is in Key Lock status, the following keys remain active:

LOCAL,SHIFT,M.TRIG

Clearing the Key Lock function

.

Press

1

.

Pressing

2

The Key Lock function is not deactivated even if the unit is switched

off.

M.TRIG

active.

SHIFT

cannot be used when Key Lock is activated with the Internal Trigger

.

LOCAL

"

SHIFT

"

lights up on the display.

clears the Key Lock function.

______________________________________________________________________________________________

5.6 Key Lock Function

Page 51

_____________________________________________________________________________________________

39

5.7 Remote Function

This unit can be controlled externally through the RS-232C or GP-IB

interface. When the unit is placed in remote status (remote operation state),

"RMT" on the display lights up, and the keys on the front panel are disabled.

Clearing the Remote function

Pressing

LOCAL

clears the Remote function.

NOTE

Even after remote status has been cleared, the unit will reenter remote

status if externally controlled through the RS-232C or GP-IB interface.

When the trigger source is external (

can be used even while the unit is in remote status.

:TRIGGER:SOURCE_EXTERNAL

),

M.TRIG