Page 1

INSTRUCTION MANUA

L

For...は専用機種。複数の場合は「/」で区切る。不要の場合はとる

。

形名を入力。 複数の場合は「/」で区切る

。

322

7

品名を入力

。

mΩ HiTESTE

R

Page 2

Page 3

Contents

Introduction i

Inspection

i

Safety Notes

ii

Notes on Use

iv

Organization of this Manual

vi

Chapter 1 Overview

1

1.1 Features 1

1.2 Specifications 2

1.2.1 General Specifications 2

1.2.2 Resistance Measurement

4

1.2.3 Temperature Measurements

5

1.2.4 Temperature Correction Function

5

1.3 Measurements and Working Systems 6

1.3.1 4-terminal Measurements 6

1.3.2 Temperature Probe

7

1.3.3 Measurement Value Display

10

1.3.4 Comparator Function

12

Chapter 2 Part Names 15

2.1 Front Panel 15

2.2 Rear Panel 16

2.3 Displays

17

2.4 Accessory and Options

18

Chapter 3 Unit Installation 19

3.1 Installing the Interfaces 19

3.2 Turning on the Power Supply 21

3.3 Selecting the Power Supply Frequency 23

3.4 Preparation for Measurements 24

3.4.1 Resistance Measurements 24

3.4.2 Temperature Correction and Temperature Measurements

25

3.5 Handle Operation 26

Page 4

Chapter 4 Basic Operations 27

4.1 Operating Procedure 27

4.1.1 Function Classes 27

4.1.2 Key Shift States

28

4.1.3 Key Lock State

28

4.1.4 Remote State

28

4.1.5 Valid Input Key Table

29

4.2 Selecting the Measurement Mode 30

4.3 Resistance Measurement Mode 31

4.3.1 Selecting the Sampling Rate 31

4.3.2 Selecting the Measuring Range

32

4.3.3 Zero Adjustment

34

4.4 Resistance Measurement 35

4.5 Temperature Measurement

36

4.6 Holding the Measurement Value

37

Chapter 5 Applied Operations 39

5.1 Setting the Comparator 39

5.1.1 Setting the Comparator 1 39

5.1.2 Setting the Comparator 2

41

5.1.3 Eliminating the Comparator Table

42

5.2 Executing the Comparator 43

5.3 Setting the Temperature Correction

44

5.4 Executing the Temperature Correction

45

5.5 Setting the Temperature Conversion 46

5.6 Executing the Temperature Conversion 47

Chapter 6 External Control Terminals 49

6.1 Connector 49

6.1.1 Terminal Block 49

6.1.2 Digital I/O

50

6.2 Connecting Method 51

6.2.1 Terminal Block 51

6.2.2 Digital I/O

51

6.3 Electrical Specifications 53

6.3.1 Power Supply Rating 53

6.3.2 Input and Output Rating

53

6.3.3 Input and Output States

54

Page 5

6.4 Using the Signals 58

6.4.1 Measurement Control 58

6.4.2 Outputting Measurement Results

61

Chapter 7 The Other Functions 63

7.1 System Resetting 63

7.2 Error Indications 64

Chapter 8 GP-IB Interface 67

8.1 Specifications 67

8.2 Setting the GP-IB Address 68

8.3 Introduction for the GP-IB 69

8.3.1 Messages 69

8.3.2 Command Syntax

70

8.3.3 Headers

70

8.3.4 Message Terminators

71

8.3.5 Separators

71

8.3.6 Data Formats

72

8.3.7 Abbreviation of Compound Command Type Header

73

8.3.8 Output Queue

73

8.3.9 Input Buffer

74

8.3.10 Status Model

74

8.3.11 Status Byte Register

75

8.3.12 Event Register

76

8.3.13 GP-IB Commands

78

8.4 Command Reference 79

8.5 Command Summary 109

8.5.1 Standard Command 109

8.5.2 Commands Specific to the 3227

110

8.6 Valid Command According to the Modes 113

8.7 Initialization 114

8.8 Notes on GP-IB Interface 115

8.9 Sample Programs 116

8.9.1 Hewlett Packard Series 300 Sample Programs 116

8.9.2 DOS/V Sample Program

124

Page 6

Chapter 9 Printer Interface 127

9.1 Printer Interface 127

9.1.1 Connecter 127

9.1.2 Connecting Method

128

9.2 Print Method 129

Chapter 10 Maintenance and Service 131

10.1 Changing the Fuse 131

10.1.1 Power Fuse 131

10.1.2 Circuit Protection Fuse

132

10.2 Disposing the Unit 134

10.3 Trouble Shooting 135

Page 7

i

────────────────────────────────────────────────────

Introduction

────────────────────────────────────────────────────

I

ntroduction

I

nspection

Thank you for purchasing this HIOKI "3227 mΩ HiTESTER." To get the

maximum performance from the unit, please read this manual first, and keep

this at hand.

When the unit is delivered, check and make sure that it has not been

damaged in transit. In particular, check the accessories, panel switches, and

connectors. If the unit is damaged, or fails to operate according to the

specifications, contact your dealer or HIOKI representative.

Accessories

9287 CLIP TYPE LEAD 1

9188 TEMPERATURE PROBE 1

Power code 1

Converter plug 1

Instruction Manual 1

Spare fuse for the circuit protection F1.0A/250V 1

Spare fuse for the power supply 1

T0.5A/250V (at 100/110/120V)

T0.25A/250V (at 200/220/240V)

(The spare fuse is stored inside the AC power supply inlet, and is of a rating

appropriate to the actual operational voltage of the unit.)

Shipment

If reshipping the unit, preferably use the original packing.

Page 8

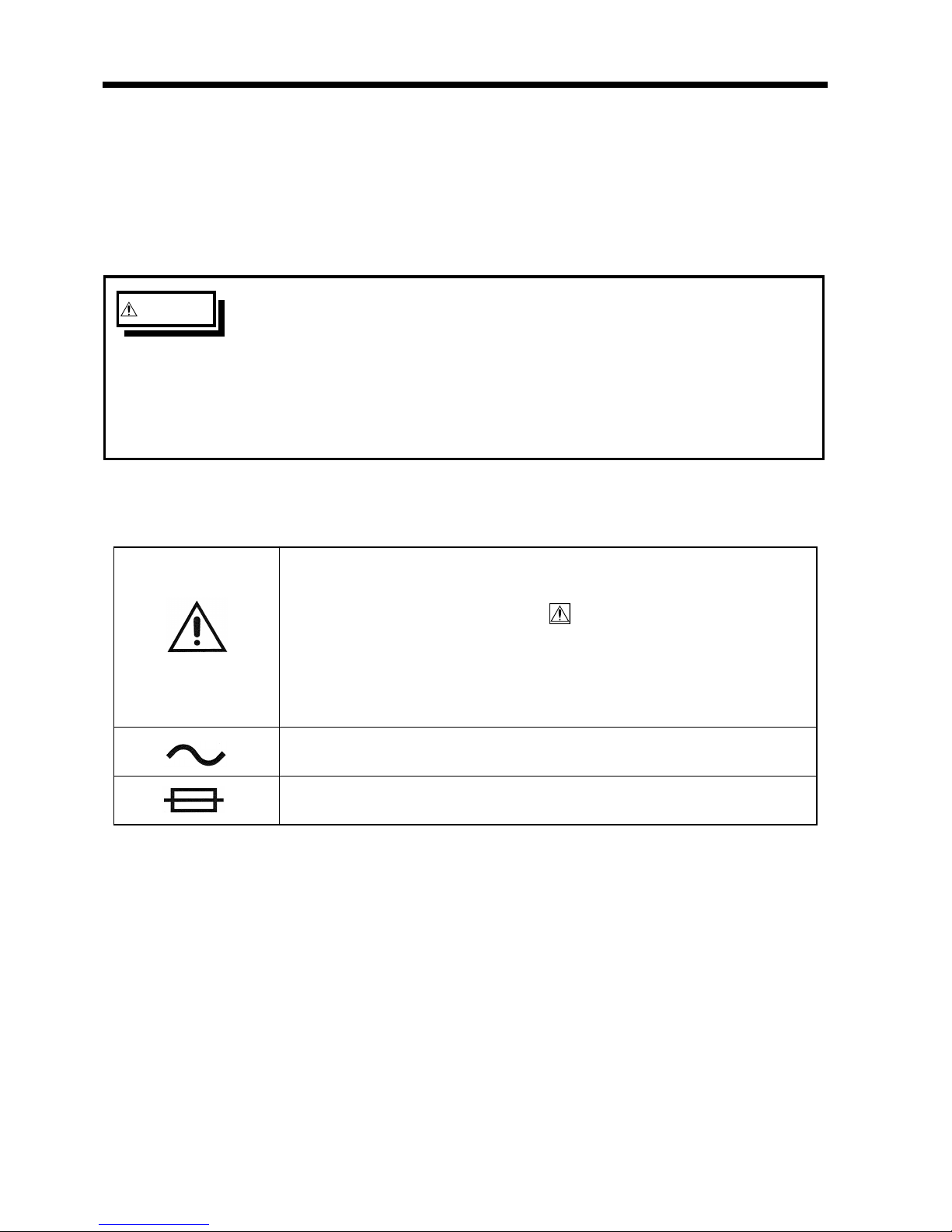

ii

────────────────────────────────────────────────────

Safety Notes

────────────────────────────────────────────────────

WARNIN

G

This equipment is designed to according to IEC 348 Safety Standards,

and has been tested for safety prior to shipment. Incorrect measurement

procedures could result in injury or death, as well as damage to the

equipment. Please read this manual carefully and be sure that you

understand its contents before using the equipment. The manufacturer

disclaims all responsibility for any accident or injury except that resulting

due to defect in its product.

・This symbol is affixed to locations on the equipment where the

operator should consult corresponding topics in this manual

(which are also marked with the

symbol) before using relevant

functions of the equipment.

・In the manual, this mark indicates explanations which it is

particularly important that the user read before using the

equipment.

Indicates AC (Alternating Current).

Indicates a fuse.

S

afety Notes

This Instruction Manual provides information and warnings essential for

operating this equipment in a safe manner and for maintaining it in safe

operating condition. Before using this equipment, be sure to carefully read the

following safety notes.

Safety symbols

Page 9

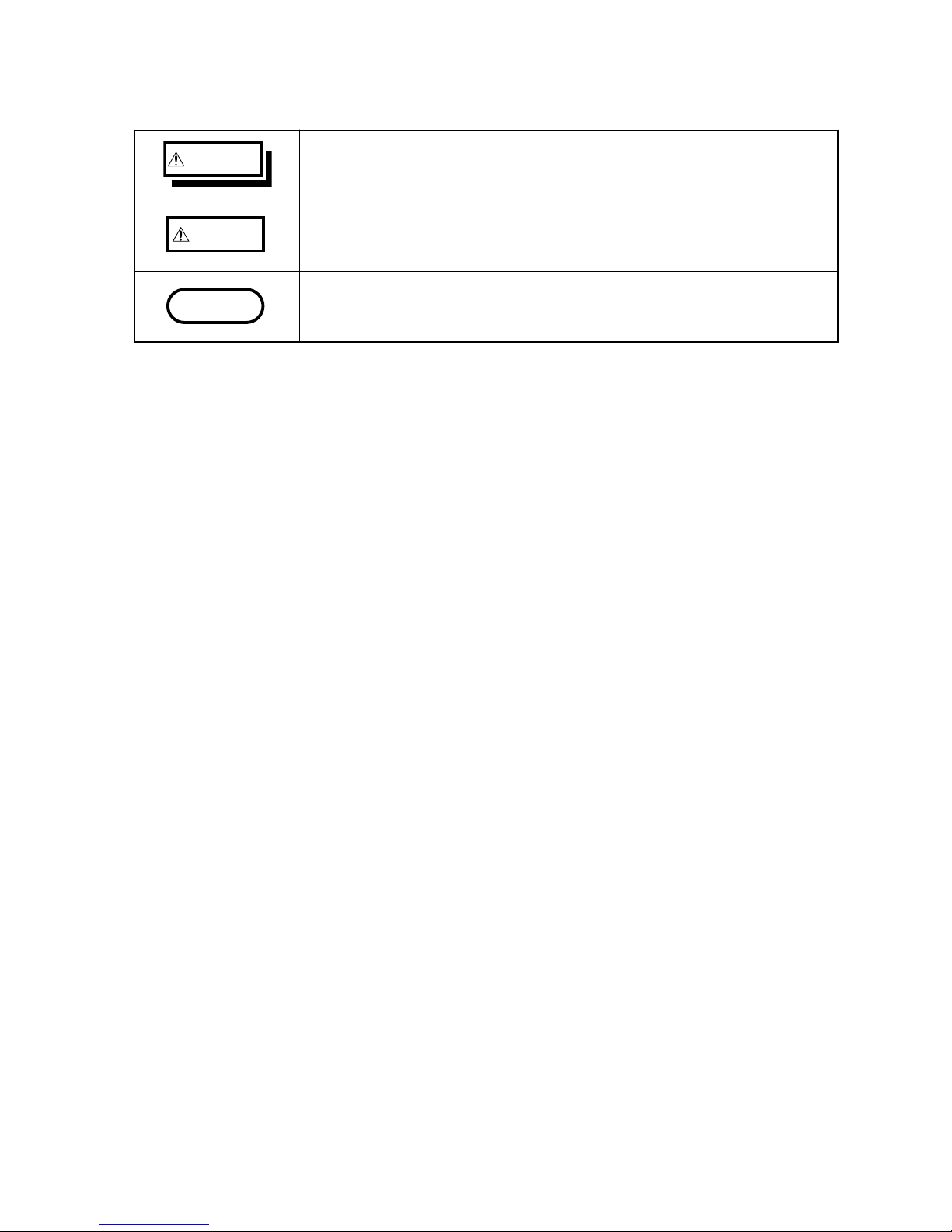

iii

────────────────────────────────────────────────────

Safety Notes

────────────────────────────────────────────────────

WARNIN

G

Indicates that incorrect operation presents significant danger of

accident resulting in death or serious injury to the user.

CAUTIO

N

Indicates that incorrect operation presents possibility of injury to the

user or damage to the equipment.

NOTE

Denotes items of advice related to performance of the equipment or

to its correct operation.

The following symbols are used in this Instruction Manual to indicate the

relative importance of cautions and warnings.

Page 10

iv

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

WARNIN

G

In order to prevent electric shock and short-circuit accidents, shut off

the power to the line to be measured before connecting the direct

connection voltage and current cables to the terminals.

Be sure to connect the input terminal, SENSE, or SOURCE terminals

correctly. Measurement which is attempted with the wiring connected

incorrectly may cause damage to the unit or a short-circuit.

Before turning on the power, make sure that the voltage of the power

supply being used matches the supply voltage indicated on the rear

panel of the unit.

The unit is constructed so as to be connected to a ground line via a

three-core power cord that is supplied with the unit.

In order to avoid electric shock, connect the unit to a properly grounded

(3-pin) outlet using the power cord provided. In addition, if using a

ground adapter, be absolutely sure to connect the green ground wire

which protrudes from the adapter to a ground line.

In order to avoid electric shock, if not connecting the unit to a properly

grounded (3-pin) outlet using the power cord provided, be sure to

connect the ground terminal to a proper ground.

The maximum permissible input is mentioned on specifictioins. Do not

measure voltage in excess of these limitations, as doing so may damage

the unit or cause an accident that might result in infuty or death.

CAUTIO

N

・To avoid damage to the unit, do not input a voltage or current exceeding the

rated maximum to the external input terminals.

・To avoid damage to the unit, do not input a voltge or current exceeding the

rated to the output terminal.

・To avoid damage to the unit, do not subject the equipment to vibrations or

shocks during transport or handling. Be especially careful to avoid dropping

the equipment.

・Before using the unit, make sure that the sheathing on the probes is not

damaged and that no bare wire is exposed. If there is damage, using the

unit could cause electric shock. Replace the probe with the specified 9287.

・The unit should always be operated indoors in a range from 0℃ to 40℃ and

80% RH or less. Do not use the unit in direct sunlight, dusty conditions, or in

the presence of corrosive gases.

・Do not measure the voltage applied point. Particularly, the 3227 would be

damaged by induced voltage when measuring soon after the temperature

rise test or the pressure test of the trans or the motor.

N

otes on Use

In order to ensure safe operation and to obtain maximum performance from

the unit, observe the cautions listed below.

Page 11

v

────────────────────────────────────────────────────

Notes on Use

────────────────────────────────────────────────────

NOTE

・ Always set the power supply frequency before measurement. When it has

been set incorrectly, inaccurate measurement would be performed. How to set

this, Section 3.3, "Selecting the Power Supply Frequency."

・ Accurate measurement may be impossible in locations subject to strong

external magnetic fields, such as transformers and high-current conductors, or

in locations subject to strong external electric fields, such as radio

transmission equipment.

・ For accurate measurement, allow the unit to warm up for 30 minutes before

starting the operation.

・ In the source of current (SOURCE), there is a fuse for the circuit protection.

When it is ruptured, the measurement should be impossible.

・ Do not use such relay as dealing with the small signals, for fear of breaking

the pellicle of the contact point.

・ When the one that includes the L component such as the transformer for the

power supply a lot is measured a measured value may not stabilize.

Page 12

vi

────────────────────────────────────────────────────

Organization of this Manual

────────────────────────────────────────────────────

O

rganization of this Manual

Chapter 1 Overview

Summary and features of the 3227

Chapter 2 Part Names

Description of part names

Chapter 3 Unit Installation

Preparation for measurements

Chapter 4 Basic Operations

Description of basic operations

Chapter 5 Applied Operations

Setting the comparator and the temperature correction

Chapter 6 External Control Terminals

Description of the external control terminals

Chapter 7 The Other Functions

System resetting and error indications

Chapter 8 GP-IB Interface

Specifications and commands of GP-IB

Chapter 9 Printer Interface

Use of the printer interface

Chapter 10 Maintenance and Service

Disposing and trouble shooting

Index

Page 13

1

────────────────────────────────────────────────────

1.1 Features

────────────────────────────────────────────────────

Chapter

1

Overvie

w

1

.1 Features

(1) 10μΩ minimum high accuracy and high resolution resistance measurement,

by 4-terminal measurement

(2) High speed resistance measurement of 90 times/second in its top

(3) Connecting the temperature probe makes 0℃ to 40℃ temperature

measurement possible

(4) Auto range function is contained

(5) Measurement ranges can be selected from external control terminal.

(6) The components can be selected by the comparator. When changing the

measurement subjects, the 15 comparator tables set in advance make it

possible. They can also be selected by external control terminal.

(7) When connecting the temperature probe, the resistance temperature is able to

be corrected by optional temperature and resistance temperature coefficient.

(8) The temperature of the measured object can be displayed, by conversion from

the measured resistance. Either the temperature (t) or the temperature rise

(Δt) of the measured object can be selected for display.

A comparator can also be used to provide a pass/fail decision from the

displayed value.

(9) The unit can hold up to 15 sets (tables) of temperature conversions in memory.

The setting table can also be selected using the external control terminals.

(10) Trigger input, BCD output and comparator output make the unit match for

the line use.

(11) The measurement results can be printed with the 9203 DIGITAL PRINTER.

The results also can be shown as statistics. (option)

(12) Full remote control by GP-IB is possible (option).

(13) The measurement results can be printed to the centronics printer (option).

Page 14

2

────────────────────────────────────────────────────

1.2 Specifications

────────────────────────────────────────────────────

1

.2.1 General Specifications

Measurement method and

operating method

4-terminal and dual integrator circuit

Maximum number of display digit

Resistance measurement "30000" 4 digit (3 digit when at FAST)

Temperature measurement "4000" 3 digit

Temperature conversion "±999.9" 4 digit

Sampling rate

Resistance measurement "SLOW" Approx. 4 times/second

"MEDIUM" Approx. 16 times/second

"FAST" Approx. 90 times/second

Temperature measurement Approx. 2 times/second

NOTE: When performing the comparator as reference value-per-range, in "FAST", the sampling rate

would be approximately 75 times/seconds

Response time

Resistance measurement "SLOW" Approx. 500 ms

"MEDIUM" Approx. 150 ms

"FAST" Approx. 50 ms

Auto range Contains (invalid when using the comparator)

Input over "OF" display

Comparator Set with each 15 table (selected by key operation and external

control)

Comparison method selection (HIGH/LOW, REF/%)

External control terminal mode selection (AUTO/EXT)

Buzzer mode selection (Hi/Lo, IN, OFF)

3-level (Hi, IN, Lo) fluorescent character display tube display,

external control output.

Temperature correction function Correctional temperature (0.00℃ to 40.00℃,32F to 104 F)

Standard temperature (-10.0℃ to 99.9℃,14F to 122 F)

Temperature coefficient (±9999ppm)

Optional settings are possible

Temperature conversion function Absolute temperature/temperature rise(Δt) selectable

initial resistance (0.00 mΩ to 300.00 kΩ)

initial temperature ( −10.0 ℃ to 99.9 ℃)

coefficient ( ±999.9)

Optional settings are possible

Maximum over load input 100 VDC or VAC rms (circuit protection by fuse)

1

.2 Specifications

Page 15

3

────────────────────────────────────────────────────

1.2 Specifications

────────────────────────────────────────────────────

Dielectric strength

Between the case and the input

terminal

1.5 kVAC

Between the case and the powe

r

supply line

1.5 kVAC (sensitivity current: 5 mA)

Insulation resistance Between the case and the input terminal (for a minute)

Between the case and the power supply line (for a minute)

100 MΩ or more

External control

Open corrector output BCD 5 digit, measurement end, NG, comparator result

TTL input measuring range, comparator table, measurement trigger, print

,

zero adjustment, comparator output, temperature conversion

table

External interface The 9588 GP-IB INTERFACE (IEEE 488.2) (option)

Printer interface 9589 CENTRONICS (option)

Operating temperature/humidity 0℃ to 40℃ (32 Fto104F), 80% RH or less (no condensation)

Storage temperature/humidity -10℃ to 50℃ (14 Fto122F), 80% RH or less (no condensation)

Power supply and power

consumption

100, 110, 120, 200, 220, 240 VAC (±10%, 250 V MAX), 50/60 Hz,

maximum 40 VA

Dimensions and mass 215W×80H×320D mm (8.46"W×3.15"H×12.6"D) (excluding

protrusions), approx. 3.0 kg (105.8 oz.)

NOTE

・ The temperature correction function or the temperature conversion function is

selected when the unit is powered on, and only one of these functions can be

used at a time.

・ When using the temperature conversion function, the comparator uses its own

table (High/Low only).

・ Selection of the comparator table with the external interface constitutes a

temperature conversion table selection.

・ Auto ranging is always used when the temperature conversion function is

used.

Page 16

4

────────────────────────────────────────────────────

1.2 Specifications

────────────────────────────────────────────────────

1

.2.2 Resistance Measurement

Condition 23℃±5℃ (73 F ±9 F), 80% RH or less (no condensation),

After zero adjustment

Pre-heating period 30 minutes

Accuracy assurance period 6 months

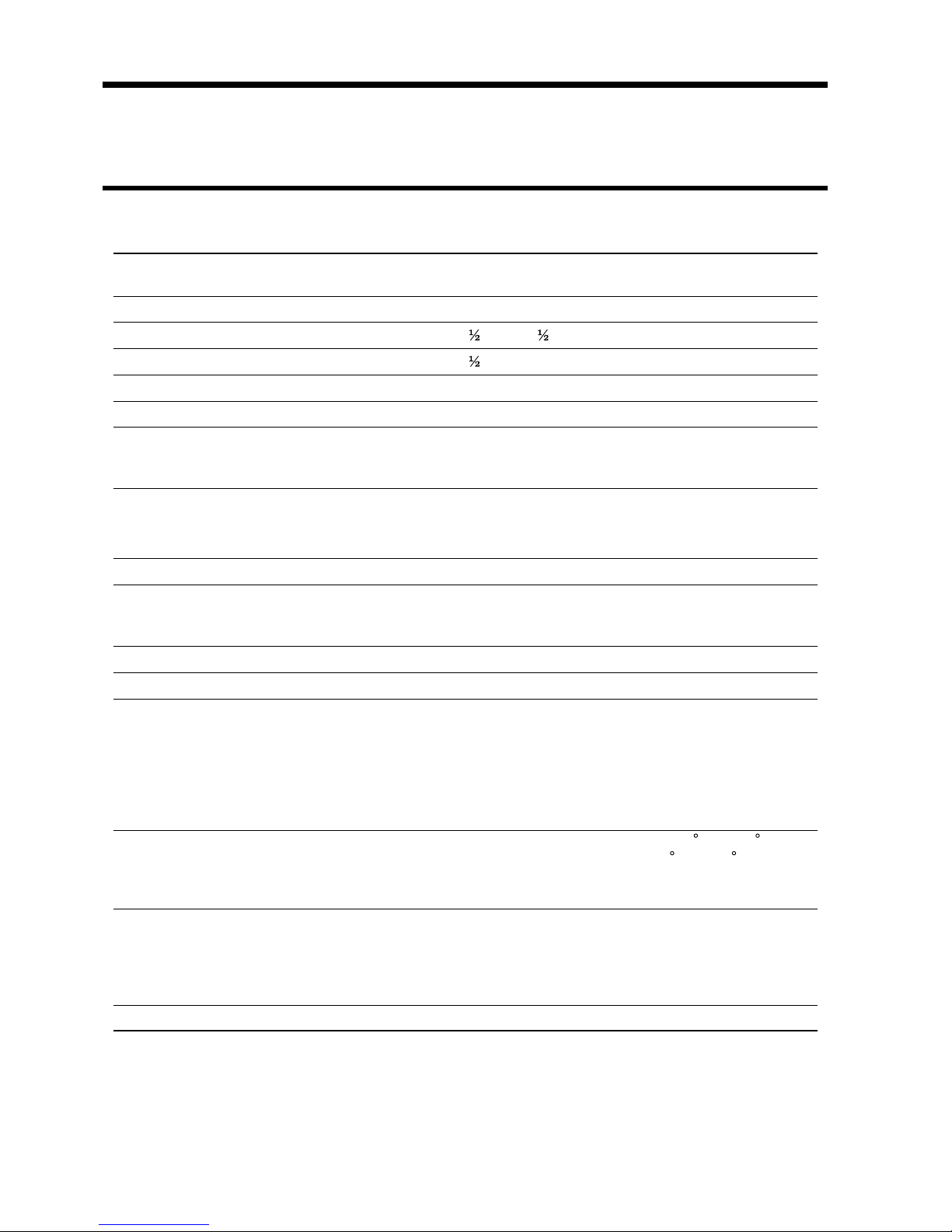

Table 1 4-1/2 digit (sampling rate:SLOW)

Range 300 mΩ 3 Ω 30 Ω 300 Ω 3kΩ 30 kΩ 300 kΩ

Resolution 10 μΩ 100 μΩ 1mΩ 10 mΩ 100 mΩ 1 Ω 10 Ω

Measurement

current

100 mA 10 mA 1mA 10 μA

Maximum

applied voltage

30 mV 300 mV 3V 300 mV 3V

Accuracy *

±0.1% rdg

.

±8 dgt.

0.08% rdg. ±3 dgt. ±0.1% rdg.±3dgt.

Temperature

coefficient

(±0.01% rdg.±0.5 dgt.)/℃

Open-terminal

voltage

7.0 Vmax

* If the sampling rate is set to MEDIUM, add 3 dgt to the digit accuracy error.

Table 2 3-1/2 digit (sampling rate:FAST)

Range 300 mΩ 3 Ω 30 Ω 300 Ω 3kΩ

Resolution 100 μΩ 1mΩ 10 mΩ 100 mΩ 1 Ω

Measurement

current

100 mA 10 mA 1mA

Maximum

applied voltage

30 mV 300 mV 3V

Accuracy ±0.2% rdg. ±5 dgt.

Temperature

coefficient

(±0.01% rdg.±0.1 dgt.)/℃

Open-terminal

voltage

7.0 Vmax

Page 17

5

────────────────────────────────────────────────────

1.2 Specifications

────────────────────────────────────────────────────

1

.2.3 Temperature Measurements

Temperature sensor Platinum resistance element

Dielectric strength 1000 VAC between the temperature sensor sheath and the

voltage terminal(-).

Accuracy assurance range 0.00℃ to 40.00℃

Resolution 0.01℃

Accuracy ±0.5℃

Temperature coefficient ±0.02×(t-23)℃

t : environment temperature where the 3227 is located (℃).

1

.2.4 Temperature Correction Function

Temperature correction range 0.00℃ to 40.00℃ (32 F to 104 F)

Standard temperature range -10.0℃ to 99.9℃ (14 F to 212 F)

Resistance temperature coefficient

range

-9999 ppm to 9999 ppm

Accuracy In the temperature correction, add the value obtained by the

expression below to the accuracy of the resistance measurement

.

±0.5α×100

(%)

1+α((t

0.5) - t

0

)

t: Environment temperature

t

0

: Standard temperature

α: Resistance temperature coefficient

0.5: Temperature measurement accuracy

Page 18

6

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

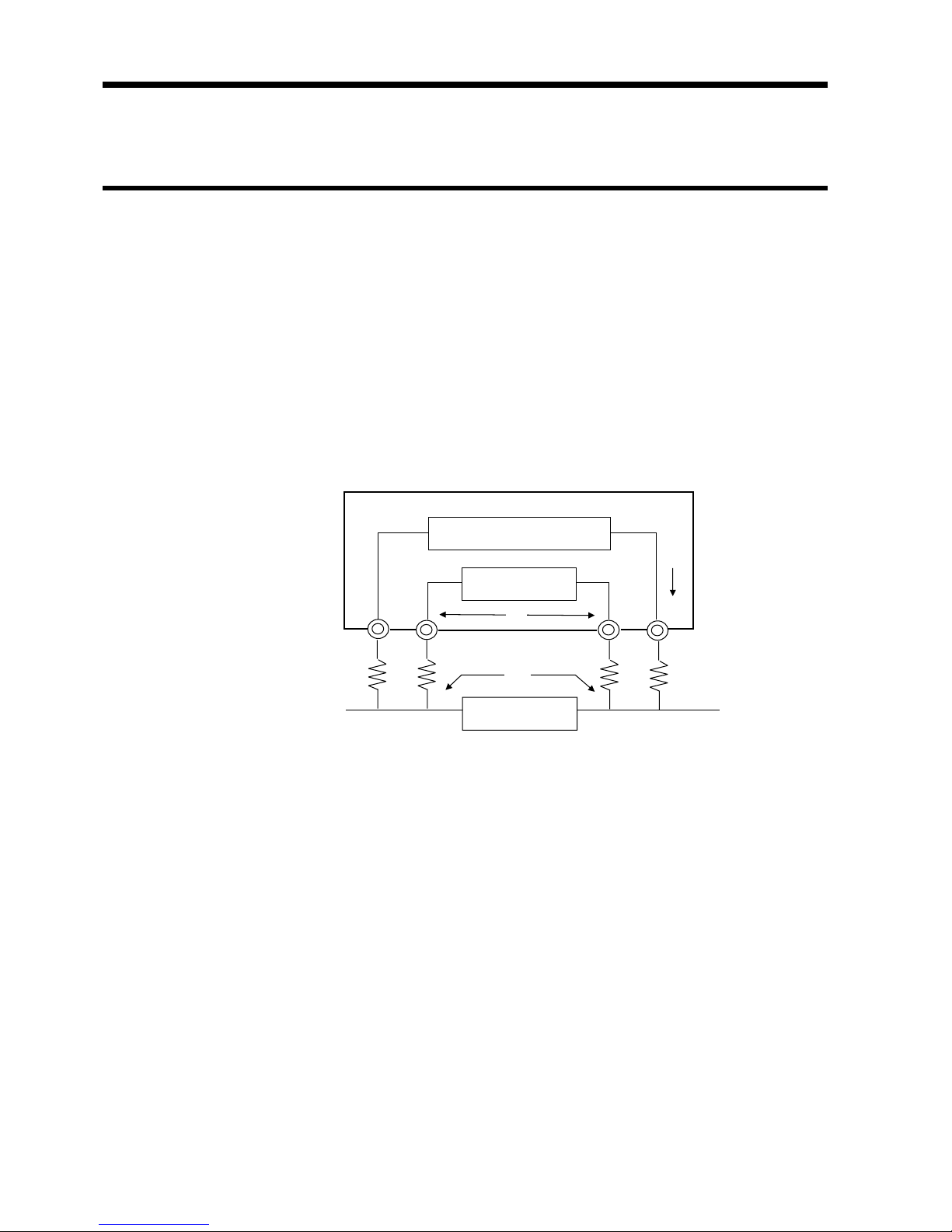

1

.3.1 4-terminal Measurements

r

2

r

4

r

3

r

1

I

Ohmmete

r

Resistance R

0

Voltmeter

Constant current sourc

e

E

0

E

Measurement Using the 4-terminal Method

1

.3 Measurements and Working Systems

Regular 2-terminal measurement measures even the value which includes the

resistance of the measurement leads or the terminal area. Particularly, when

measuring the low resistance, it is necessary to measure the value without

this resistance value. 4-terminal measurement is able to measure that value.

4-terminal measurement and 2-terminal measurement are explained as

follows. In the figure below, there is very big input impedance in the

voltmeter, and all of the current I flows to the measured resistance R

0

. The r

1

to r

4

means the resistance of the measurement leads or the contact resistance

of the terminal area.

All of the current I flows to the measured resistance R

0

. Therefore, the

voltage drop of r

3

and r

4

become 0, and voltage E and the voltage drop E

0

of

each end of the measured resistance R

0

become equal. Accordingly, the

resistance measurement without influence of r

1

to r

4

becomes possible.

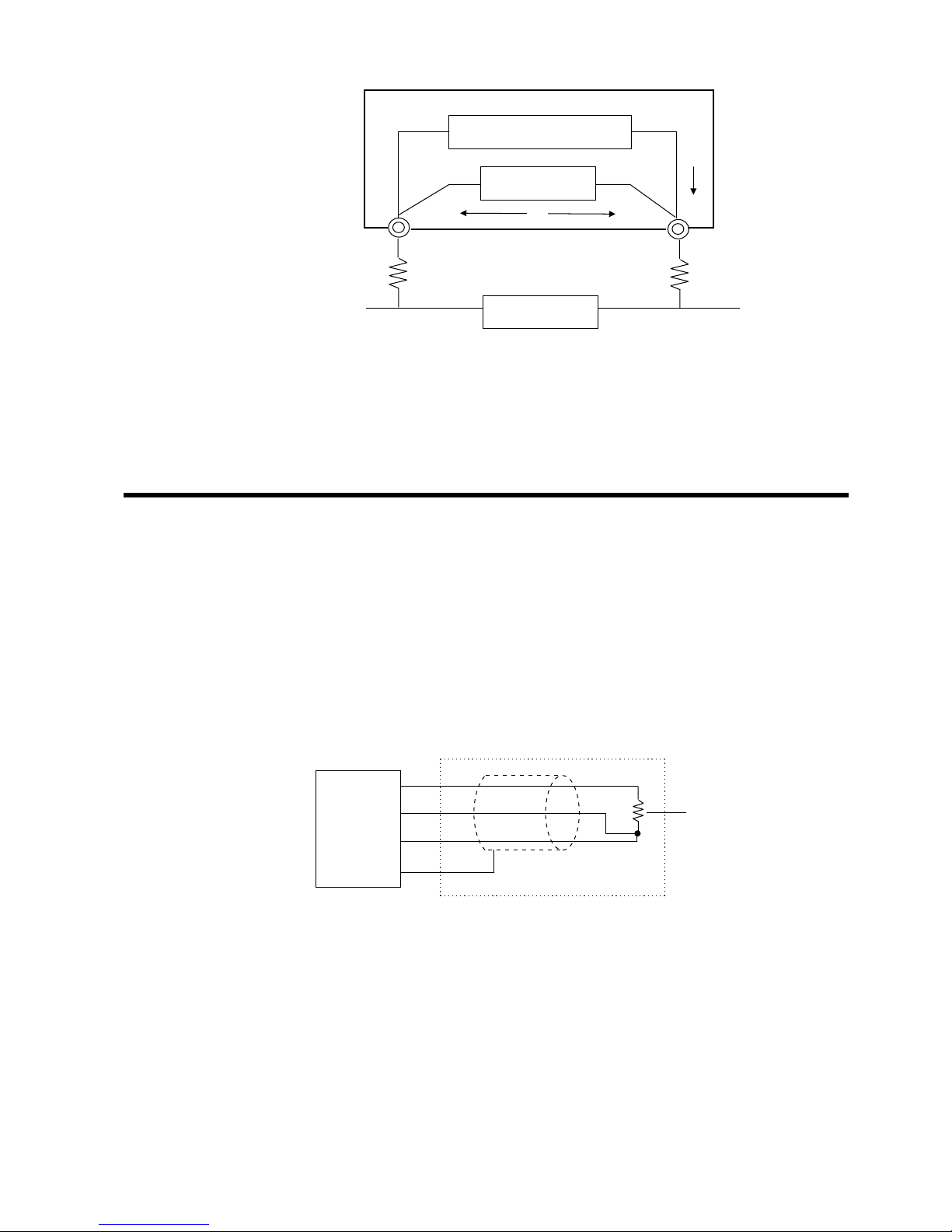

Page 19

7

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

r

2

r

1

I

Ohmmete

r

Resistance R

0

Constant current sourc

e

E

Voltmeter

Measurement Using the 2-terminal Method

1

.3.2 Temperature Probe

Shield cabl

e

Platinum film resisto

r

322

7

The Internal Circuit of the Temperature Probe

The current I flows to the measured resistance R

0

and the wiring resistance r

1

and r

2

. Therefore, the measuring voltage E can be obtained by E=I(r

1

+R

0

+r

2

),

and it would include the wiring resistance r

1

and r

2

.

The 9188 TEMPERATURE PROBE makes temperature measurement and the

temperature correction function easy. In this section, explain the principle of

them.

See Section 3.4.2, "Temperature Correction and Temperature Measurement",

for connecting the temperature probe.

(1) Temperature measurement

The internal circuit of the temperature probe is as follows.

The temperature probe uses the platinum film resistor which is changeable

according to the temperature, as the temperature sensor. This probe displays

the resistance value of that register, detected by the 3227, after converting it

to the temperature using the CPU.

Page 20

8

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

(2) Temperature Correction Function

The temperature correction function displays the optional temperature

coefficient resistance value after converting to the resistance value of the

optional temperature. The resistance depends on the ambient temperature,

and it is of little use to measure the resistance while ignoring this

temperature dependence.

In the following expression, the resistance value R

t

and R

t0

corresponds to the

resistance value of t ℃ and the measured subjects of t

0

℃ (resistance

temperature coefficient in t

0

℃ : αt

0

)

R

t

= R

t0

× {1+α

t0

× (t−t

0

)}

The 3227 obtains the correctional resistance value (R

t0

) from calculating the

temperature measured by the temperature probe (t), the resistance value of

the measured subjects (R

t

), the standard temperature (t

0

) and temperature

coefficient (α

t0

) by CPU.

For example, the resistance value of the copper wire that will be 100Ω under

30℃ would be followingly under 20℃.

R

t

R

t0

=

{1+α

t0

× (t−t

0

)}

100

=

{1+(3930×10

−6

)×(30−20)}

=96.22

See Section 5.3, "Setting the Temperature Correction" and Section 5.4,

"Executing the Temperature Correction", for how to set and execute the

temperature correction. Also see "Reference Material" at the end of this

chapter.

(3) Temperature conversion function

The temperature conversion function uses the temperature dependence of the

resistance to convert measured resistance values to temperature values and

display them.

According to JIS C4004, the temperature rise can be derived by the resistive

method as follows:

r

t

Δt=

r

0

(T + t

0

) − (T + t)

r

0

: coil resistance under cold conditions

r

t

: present coil resistance

t

0

: ambient temperature when measuring coil resistance under cold

conditions

t: present ambient temperature

T: constant (copper: 235, aluminum: 230)

Page 21

9

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

NOTE

For example, for a copper conductor, if when the initial temperature t

0

is 20℃

the resistance value r

0

is 200 mΩ, and the present ambient temperature is 25

℃ and the measured resistance value r

t

is 210 mΩ, then the temperature rise

is given as follows:

r

t

Δt=

r

0

(T + t

0

) − (T + t)

210×10

-3

=

(200×10

-3

)×(235 + 20) - (235 + 25)

= 7.75[℃]

As a result, the present temperature of the resistance, t

r

can be found as

follows:

t

r

=t

0

+ Δt = 20 + 7.75 = 27.75℃

When the measured object is not copper or aluminum, from the expression

shown for the temperature correction and the above expression, if the

temperature coefficient is α

t0

, the constant T can be found from the following

expression:

1

T=

-t

0

α

r0

For example, since the temperature coefficient of copper at 20℃ is 3930 ppm,

the constant T at this time is given by

1

T=

- 20 = 234.5,

3930×10

-6

and is substantially the same as the constant 235 laid down by the JIS

standard.

Note that the temperature probe is only designed to measure ambient air

temperature, and it is impossible to measure the surface temperature.

If the temperature probe is to be used in the measurement, make sure that

the 3227 and the temperature probe are thoroughly warmed up before the

measurement. The temperature probe and the device to be measured should

be placed close together during the warm-up, so that both will be as close to

the same temperature as possible during the measurement.

Page 22

10

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

1

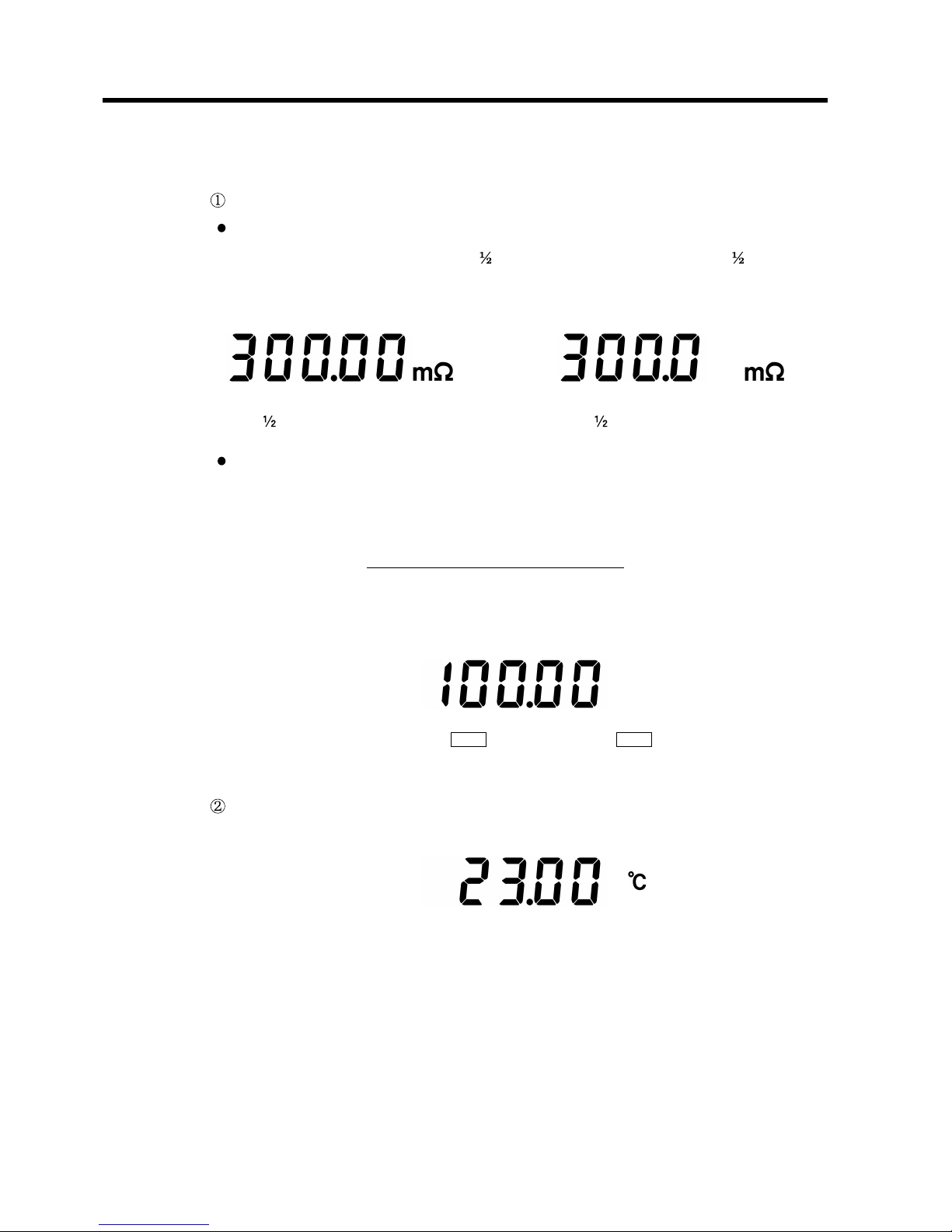

.3.3 Measurement Value Display

S

4 Digit Display

F

3 Digit Display

M

REF

%

(1) Measurement value display

Resistance measurement mode

Resistance value display

Display the resistance value of 4

digit (MEDIUM, SLOW) and 3 digit

(FAST) by the sampling rate.

Deviation display

Display the deviation (see the expression below), when comparing with

comparison of the standard value/range.

Resistance measurement value

Deviation =

Standard value

See Section 1.3.4, "Comparator Function", for the comparator.

Temperature measurement mode

Page 23

11

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

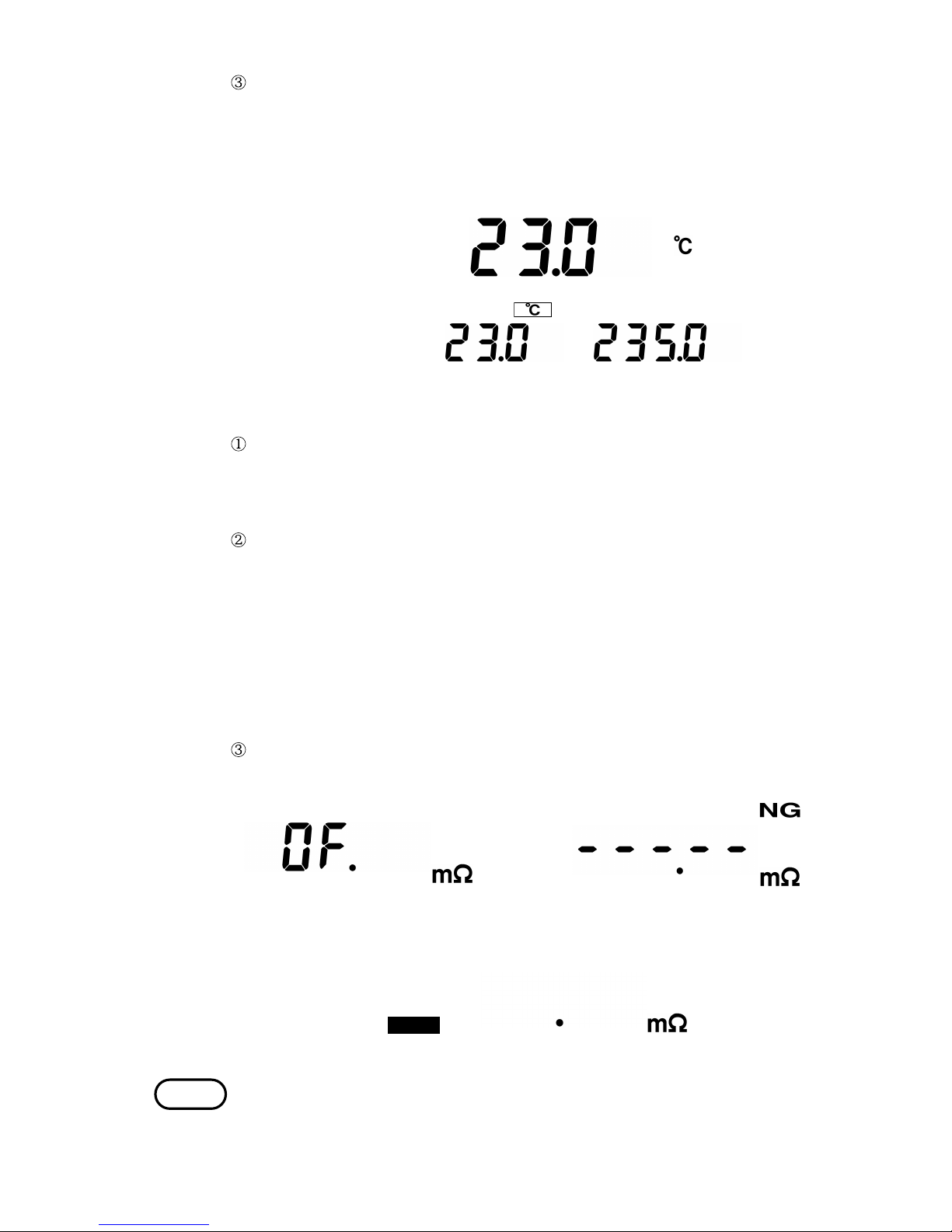

AUTO

TC

M

Over Flow Display

M

NG Display

S

HOLD

Invalid Data Display

NOTE

Temperature conversion mode

When the temperature conversion function is selected at power on, when the

TC indication on the display is on continuously the converted temperature

value is displayed. When it is blinking, the temperature difference (Δt) is

displayed.

(2) The other display

When the measurement value exceeds the measuring range (30000 count), the

over flow (OF) display is indicated. However, while using the temperature

correction function, this display is indicated when the measuring range

exceeds 99999 count.

When the constant current in the source of current (SOURCE) has any error,

NG display is indicated.

・When the measured resistance value is too big, compared with the measuring

range.

Example:

・When intended to measure 300Ω in the 300mΩ range.

・When the lead wire has been ruptured.

・When the different connection has done among 4-terminals.

・When the leads has opened.

When no measurement has done after turning on the power supply, the

invalid data display is indicated.

An "NG" result is always detected even when not carrying out measurement.

Thus even in the HOLD state, if there is a constant current fault, "NG" on the

display lights with displaying the measurement value being held.

Page 24

12

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

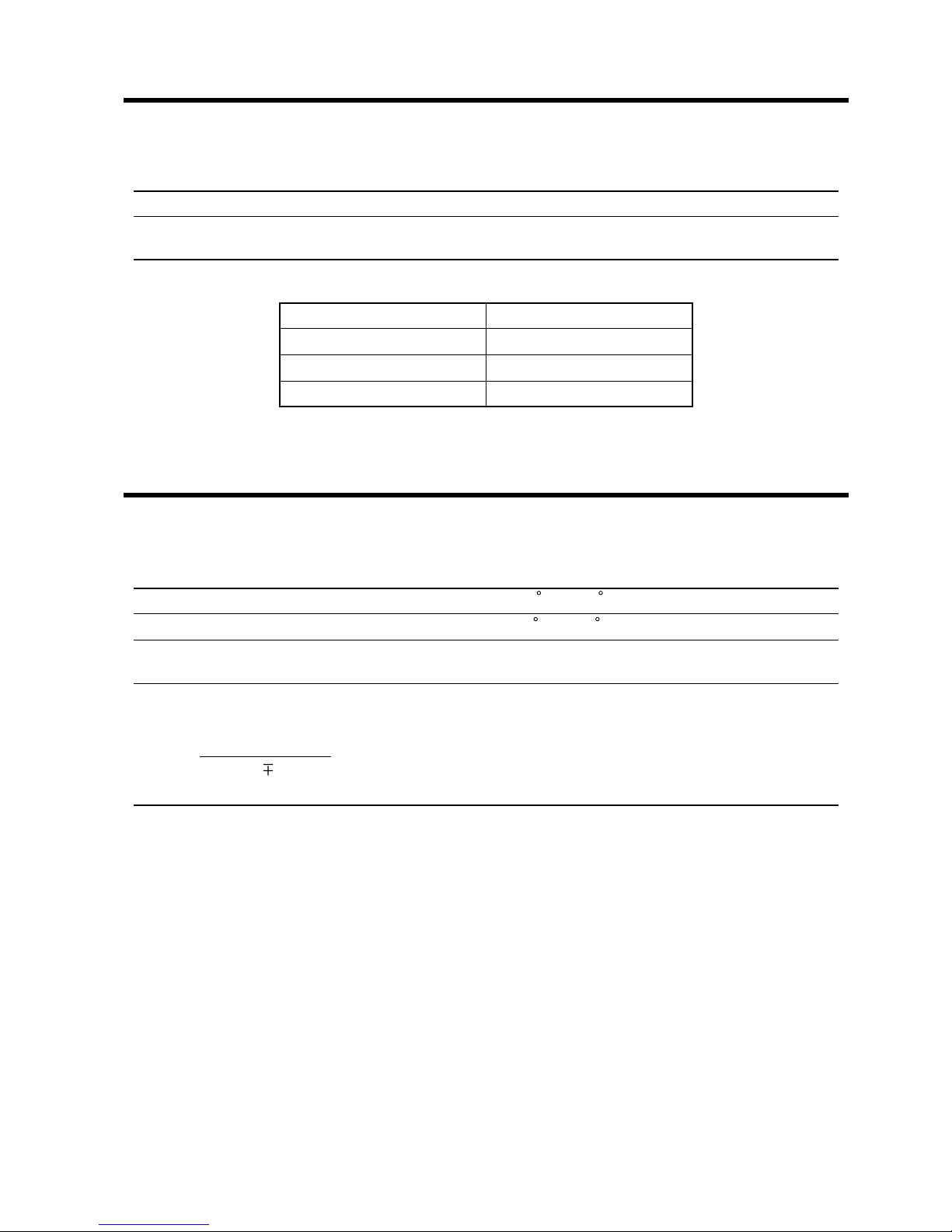

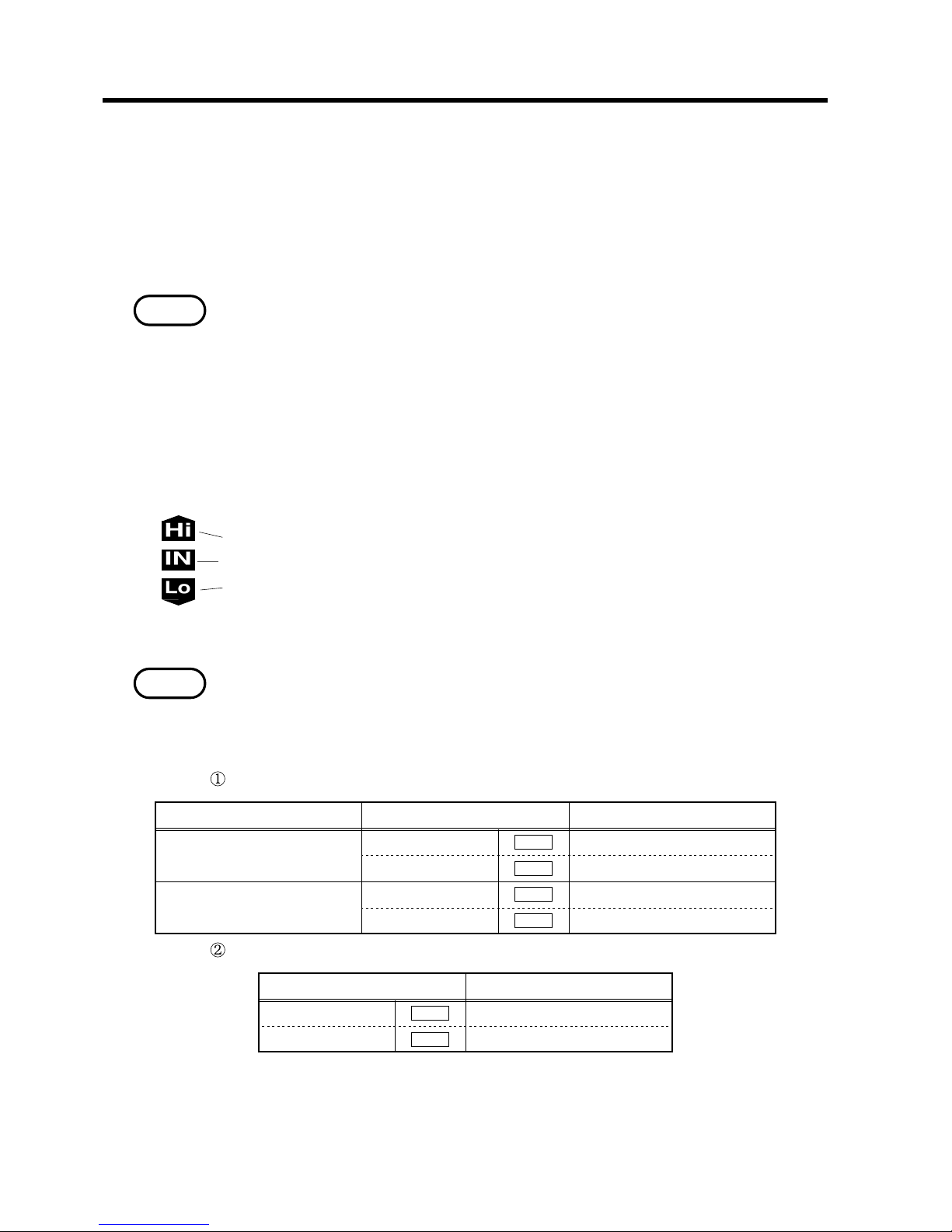

1

.3.4 Comparator Function

NOTE

NOTE

Setting limit Display

Resistace measurement

High limit value

HIGH

0 to 99999

Low limit value

LOW

0 to 99999

Temperature

High limit value

HIGH

-999.9 to 999.9℃

Low limit value

LOW

-999.9 to 999.9℃

Setting limit Display

Standard value

REF

0 to 99999

Range

%

0.00 to 99.99%

There are 15 comparator setting tables in the 3227, and the different contents

are able to set to each table.

See Section 5.1, "Setting the Comparator" and Section 5.2, "Executing the

Comparator", for how to set and execute the comparator. See Chapter 6,

"External Control Terminals", for the external control terminals.

The comparator is valid only in the resistance measurement mode, and unable

to use in the temperature measurement mode.

The comparator and the auto range should be used separately.

While displaying the converted temperature, the 3227 has only one

comparator setting table. The comparator tables for normal resistance

measurement cannot be used. In this case reference value/range comparisons

also cannot be executed.

(1) Executing the comparator

The result of the comparator is displayed as follows.

Displayed value > High limit value

High limit value ≧ Displayed value ≧ Low limit value

Low limit value > Displayed value

The result of the comparator is able to output to the external control terminal.

In the over range and the NG states, the comparator result is HIGH.

(2) Comparison method of the comparator

Comparison according to high limit value/low limit value

Comparison according to standard value/range

Comparison value

High limit value = standard value + (|standard value|×range ÷ 100)

Low limit value = standard value - (|standard value|×range ÷ 100)

Page 25

13

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

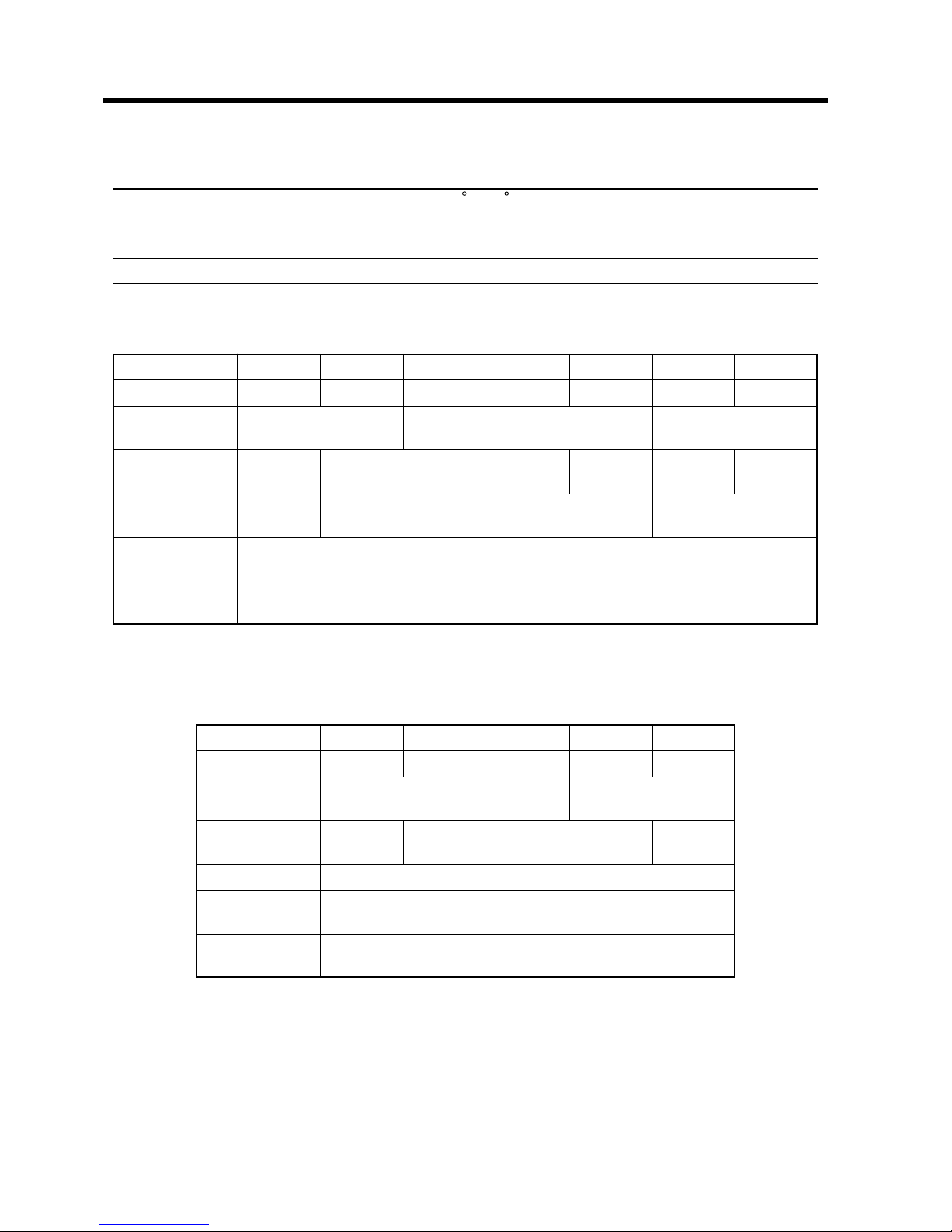

NOTE

Type Constituents [%]

Density (×10

3

)

[kg/m

3

]

Conductivity

Temperature

coefficient of

resistance (20℃

)

[ppm]

Annealed copper

wire

Cu > 99.9 8.89 1.00 to 1.02 3810 to 3970

Hard drawn coppe

r

wire

Cu > 99.9 8.89 0.96 to 0.98 3770 to 3850

Cadmium-copper

alloy wire

Cd 0.7 to 1.2 8.94 0.85 to 0.88 3340 to 3460

Silver-copper alloy

wire

Ag 0.03 to 0.1 8.89 0.96 to 0.98 3930

Chromium copper Cr 0.4 to 0.8 0.89

0.40 to 0.50

0.80 to 0.85

20

30

Corson alloy wire

Ni 2.5 to 4.0

Si 0.5 to 1.0

0.25 to 0.45 980 to 1770

Annealed aluminum

wire

AI > 99.5 2.7 0.63 to 0.64 42

Hard drawn

aluminum wire

AI > 99.5 2.7 0.60 to 0.62 40

Aldrey wire

Si 0.4 to 0.6

Mg 0.4 to 0.5

Parts containing A

l

0.50 to 0.55 36

・ When comparing by the standard value/range, the measurement value is

displayed as the deviation.

・ Always set the high limit value bigger than the low limit value.

・ Ignoring the measurement range, perform the comparison only by the

measurement count value.

・ The digit which is not indicated on the display is dealt as 0, when performing

the comparison.

(3) Buzzer mode

HL The buzzer would sound in case of HIGH or LOW.

IN The buzzer would sound in case of IN.

OFF No buzzer would sound.

(4) External control terminal mode

AUTO The comparator result is output with each samples.

EXT The comparator result is output by the MANU

―――――――

terminal state in the

external control terminal.

Reference Material

Page 26

14

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

Diameter [mm]

Annealed copper

wire

Tin-plated annealed

copper wire

Hard drawn coppe

r

wire

0.10 to 0.26

(excluding 0.26

)

0.98 0.93

0.26 to 0.50

(excluding 0.50

)

0.993 0.94 0.96

0.50 to 2.00

(excluding 2.00

)

1.00 0.96 0.96

2.00 to 8.00

(excluding 8.00

)

1.00 0.97 0.97

α

Ct

=

1

α

20

× C

+(t 20

)

1

α

20

=

1

0.00393 × 0.9

3

+ (20 20

)

1

≒ 3650 (ppm

)

(1) Properties of metal and alloy conductive materials

(2) Conductivity of copper wire

The temperature coefficient changes in relation to temperature and

conductivity. Assume the temperature coefficient is α

20

at 20℃ and that the

temperature coefficient is α

Ct

at t (℃) with a conductivity of C. Then Ct at

around room temperature is represented as follows:

The temperature coefficient of international standard annealed copper is 3930

ppm at 20℃. For tin-plated annealed copper wire (not less than 0.10 but

below 0.26 in diameter), the temperature coefficient α

20

at 20℃ can be

calculated using the following formula:

Page 27

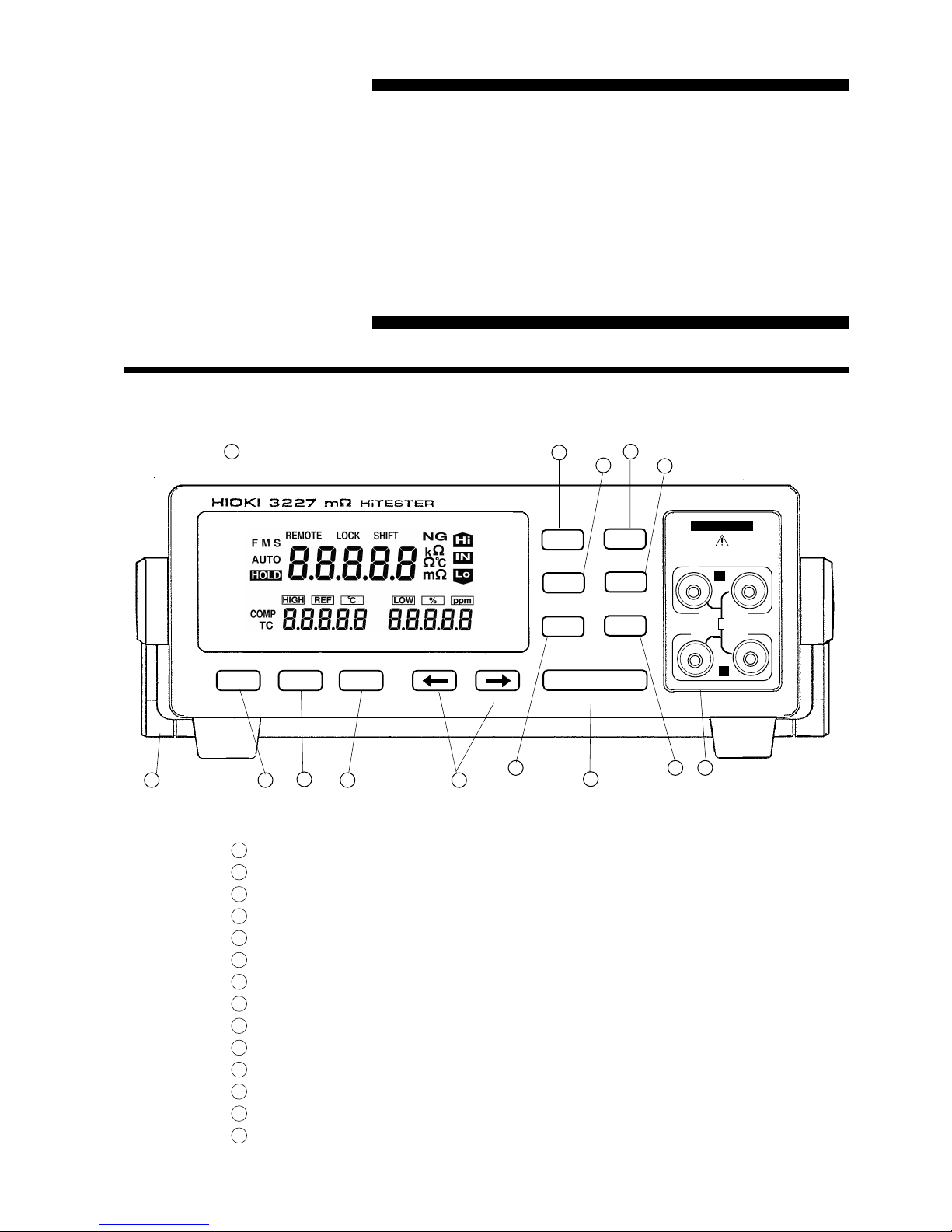

15

────────────────────────────────────────────────────

2.1 Front Panel

────────────────────────────────────────────────────

AUTO UP DOWN

GP-IB ADRS

ENTER

CLEAR

TC

SHIFT

COMP

LOCK

TEMP

HOLD

0 ADJ

SAMP

50/60Hz

SET

SET

INPUT

SENSE SOURCE

H

L

Rx

▼

▼

12345678910111213

14

1234567

8

91011121314

Chapter

2

Part Name

s

2

.1 Front Panel

Display

AUTO key

UP key

DOWN key

Cusor keys

ENTER key

TEMP key (Temperature measurement (zero adjustment) )

HOLD key (Sampling rate setting)

COMP key (Comparator setting)

LOCK key (Power supply frequency setting)

TC key (Temperature correction setting)

SHIFT key

Input terminals

Handle

Page 28

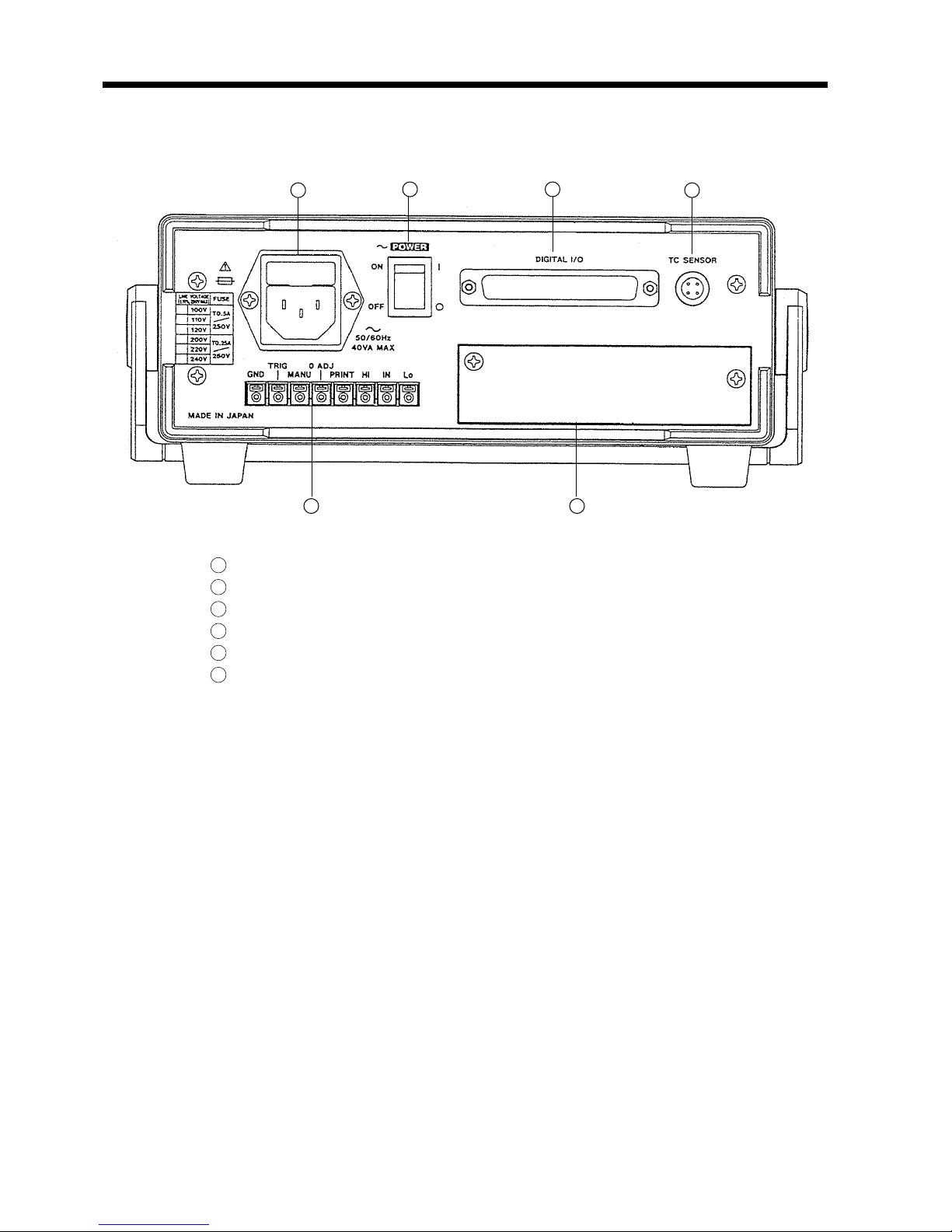

16

────────────────────────────────────────────────────

2.2 Rear Panel

────────────────────────────────────────────────────

1516171819

20

1

51617181920

2

.2 Rear Panel

Power supply inlet

POWER switch

Digital I/O connector

Temperature probe connector

External control terminal block

Option slot

Page 29

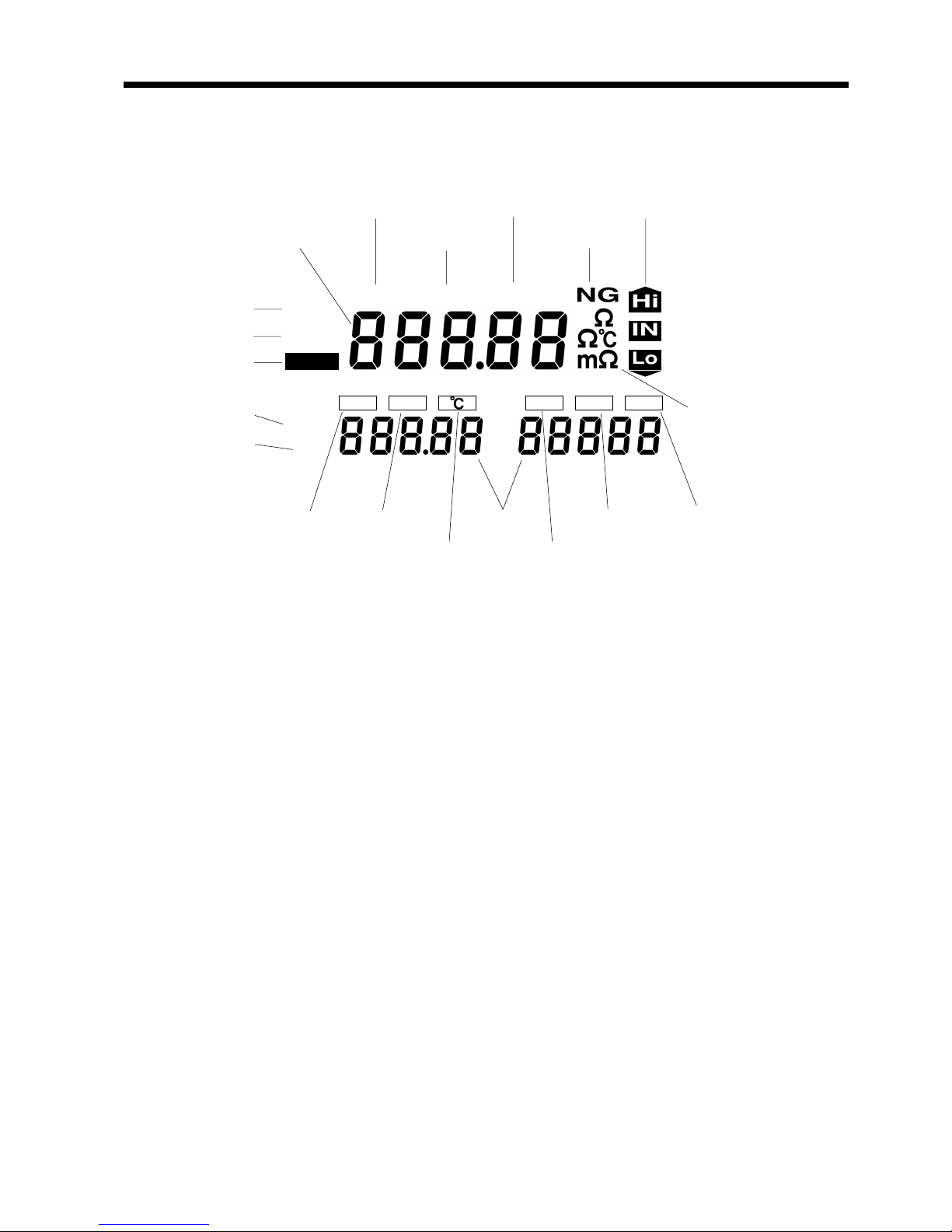

17

────────────────────────────────────────────────────

2.3 Displays

────────────────────────────────────────────────────

REMOTE LOCK SHIFT

FMS

AUTO

HOLD

k

HIGH

REF

LOW

%

ppm

COMP

TC

High limit value Standard value Setting value Range Resistance coefficien

t

Standard temperature Low limit value

Sampling rat

e

Auto rang

e

Hold stat

e

Comparato

r

Temperatur

e

correctio

n

Measurement unit

Remote state Key shift state Comparator resu

lt

Measurement value Key lock state NG

2

.3 Displays

Page 30

18

────────────────────────────────────────────────────

2.4 Accessory and Options

────────────────────────────────────────────────────

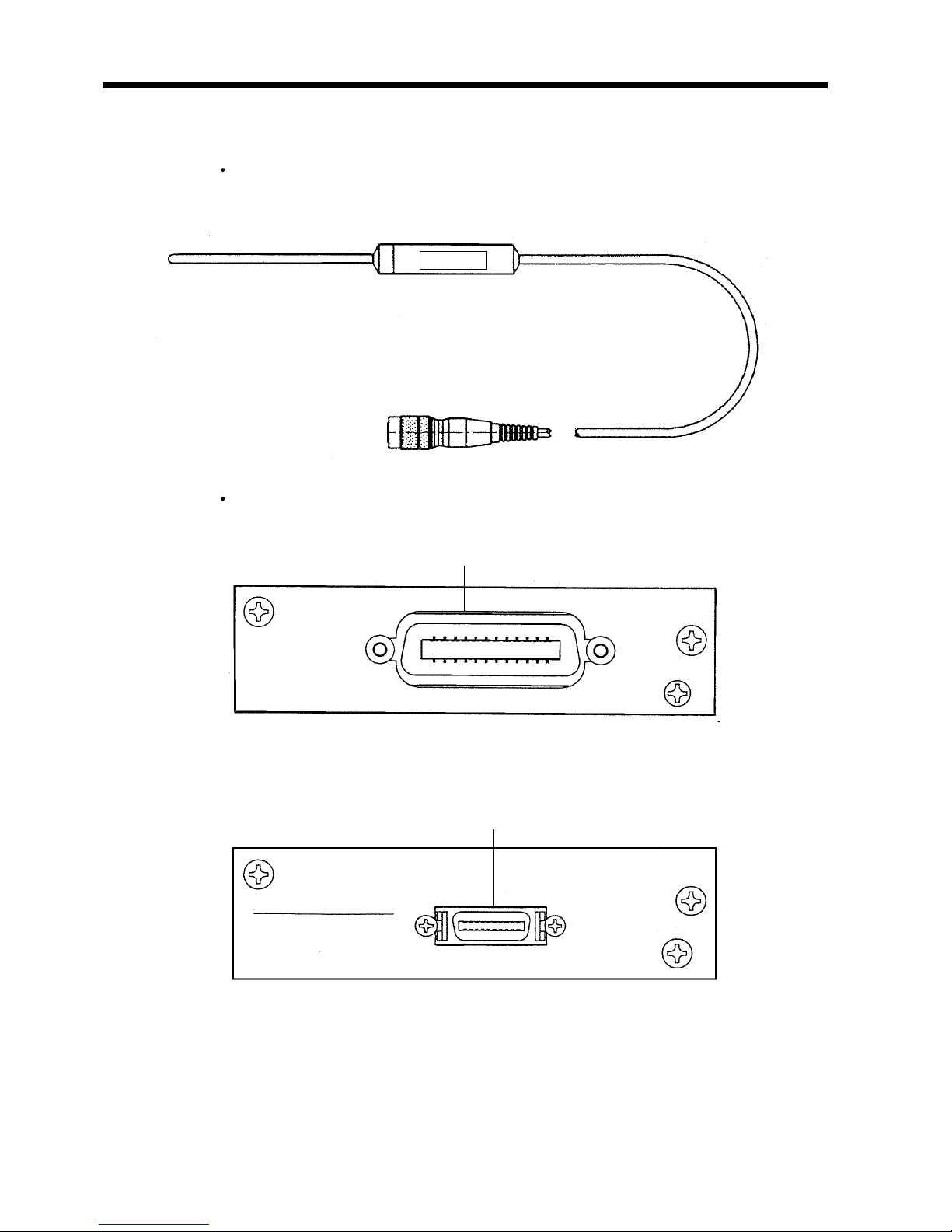

Sensor par

t

Cabl

e

Connecto

r

HIOKI 9188

MADE IN JAPAN

GP-IB connecto

r

9588 GP-IB INTERFACE

GP-IB

MADE IN JAPAN

9589 PRINTER INTERFACE

MADE IN JAPAN

Printer connecto

r

2

.4 Accessory and Options

Accessory

9188 TEMPERATURE PROBE

Options

9588 GP-IB INTERFACE

9589 PRINTER INTERFACE

Page 31

19

────────────────────────────────────────────────────

3.1 Installing the Interfaces

────────────────────────────────────────────────────

WARNIN

G

To prevent electric shock, before adding or replacing the interface,

check that the power for the unit is off and the power cord and

connectors are disconnected. The fixing screws must be firmly

tightened, or the input unit may not function up to specification, or may

even fail.

To avoid the danger of electric shock, never operate the unit with an

interface removed. If you should wish to use the unit after removing an

interface, fit a blank panel over the opening of the removed unit.

NOTE

Chapter

3

Unit Installatio

n

3

.1 Installing the Interfaces

The following is the explanation for the installing method of the 9588 GP-IB

INTERFACE and the 9589 PRINTER INTERFACE.

Do not install any interface unit except the 9588 and the 9589.

Page 32

20

────────────────────────────────────────────────────

3.1 Installing the Interfaces

────────────────────────────────────────────────────

On the rear panel of this unit, the option slot to install the interfaces is

covered with the blank plate. Please install the interfaces according to

following order.

1. Take off the blank plate. (Please keep the screws.)

2. Insert the interface with holding the guide rail between the rail of the 3227.

3. Insert the interface tightly, be sure to tighten the screws which have been

unscrewed in step 1.

Page 33

21

────────────────────────────────────────────────────

3.2 Turning on the Power Supply

────────────────────────────────────────────────────

3

.2 Turning on the Power Supply

(1) Confirm whether the power supply voltage shown on the rear panel and that

intended to use are same.

(2) Confirm whether the POWER switch is OFF.

(3) Connect the accessory power code to the power supply inlet.

(4) Connect the power code to the 3-pole power outlet which has the protective

grounding terminal. When using the 2-pole power outlet, use the accessory

converter plug. In this case, always ground the green grounding wire of that

plug.

(5) Turn on the

POWER switch.

Press the

TC key (temperature conversion key) until it beeps to select the

temperature correction function or the temperature conversion function.

If the last setting was the temperature correction function, this switches to the

temperature conversion function and vice versa.

(6) Start the self test (self testing of the unit).

Light all displays.

Check ROM, RAM, the back up and the proofreading data, and the error

indications are displayed for the items of which any errors have generated.

When no error has generated, these indications are not displayed.

See Section 7.2, "Error Indications", for the error indications.

Page 34

22

────────────────────────────────────────────────────

3.2 Turning on the Power Supply

────────────────────────────────────────────────────

When the temperature correction

function is selected

TC

When the temperature conversion

function is selected

NOTE

Display the name of this unit, the version number and the power supply

frequency settings.

TC on the display indicates the function to be used, the temperature correction

function or temperature conversion function. When TC on the display is

blinking, the temperature conversion function is used.

(7) Enter the normal measurement state.

・ Before measurement, perform the warm up at least for 30 minutes after

turning on the power supply.

・ This unit contains the back up function. The previous settings appear, when

turning on the power supply. The back up function works until the internal

lithium battery has consumed.

・ The battery would run down after four years. Please contact your nearest

service representative for the battery change.

・ It is not possible to use the temperature correction function and the

temperature conversion function at the same time.

・ In resistance measurement mode, if pressing the

TC key switches to the ℃

indication on the display, the temperature conversion function can be used.

Page 35

23

────────────────────────────────────────────────────

3.3 Selecting the Power Supply Frequency

────────────────────────────────────────────────────

SHIFT

LOCK

50/60Hz

DOWNUP

ENTER

CLEAR

NOTE

3

.3 Selecting the Power Supply Frequency

1. Press the SHIFT key and enter the shift states.

"SHIFT" on the display lights.

2. Press the LOCK key (power supply frequency setting

key) and enter the power supply frequency setting

mode.

The power supply frequency is displayed with flashing.

3. Press the

UP or DOWN key to change the power supply

frequency.

50 Hz: Set the power supply frequency to 50.

60 Hz: Set the power supply frequency to 60.

4. Press the

ENTER key and decides the power supply

frequency. Then, return to the measurement mode.

When the incorrect power supply frequency has set, it is impossible to

measure accurately. Always set the power supply frequency.

Page 36

24

────────────────────────────────────────────────────

3.4 Preparation for Measurements

────────────────────────────────────────────────────

3

.4.1 Resistance Measurements

Re

d

Blac

k

Re

d

Blac

k

SOURCE

SOURCE

SENSE

SENCE

SOURCE SENSE

SOURCE SENSE

Re

d

Blac

k

SOURCE

SENSE

SOURCE

SENSE

Red

Black

SOURCE

SENSE

SOURCE

SENSE

Shield

NOTE

3

.4 Preparation for Measurements

(1) When using the 9287 CLIP-TYPE LEAD (accessory)

Insert the lead to the input terminal of the front panel. Connect them with

putting the red ▼ mark of the 3227 upon the same mark of the red lead, and

the black ▼ mark upon the same mark of the black lead.

(2) When using the self-made leads

Connect them as follows.

When making the leads on your own work, be sure to shield to measure

accurately, and make the cable length within 5 m (the resistance of the wires

are 100 mΩ/m or less.)

Page 37

25

────────────────────────────────────────────────────

3.4 Preparation for Measurements

────────────────────────────────────────────────────

3

.4.2 Temperature Correction and Temperature Measurements

NOTE

Connect the 9188 to the temperature probe connector of the rear panel with

putting the grooves of the temperature probe and that connector together,

until it clicks.

Note that the temperature probe is only designed to measure ambient air

temperature, and it is impossible to measure the surface temperature.

If the temperature probe is to be used in the measurement, make sure that

the 3227 and the temperature probe are thoroughly warmed up before the

measurement. The temperature probe and the device to be measured should

be placed close together during the warm-up, so that both will be as close to

the same temperature as possible during the measurement.

Page 38

26

────────────────────────────────────────────────────

3.5 Handle Operation

────────────────────────────────────────────────────

3

.5 Handle Operation

The handle is able to use as the stand. Pull the each side of the handle and

turn it, then push it in.

The handle is able to fix every 22.5。. Use after fixing it to the proper direction.

Page 39

27

────────────────────────────────────────────────────

4.1 Operating Procedure

────────────────────────────────────────────────────

4

.1.1 Function Classes

Turning on the powe

r

Self test

Resistance measurement mode

Comparator setting mode

Temperature correction setting mode

Frequency setting mode

GP-IB address setting mode

Temperature measurement mode

Selecting the measurement range

Selecting the sampling rate

Selecting the comparator executing

Selecting the temperature correction

executing

Selecting the measurement holding

Executing the zero adjustment

Selecting the measurement holding

A

B

A: This shows every kind of mode. The key input are accepted in this mode. Otherwise, in the

resistance measurement mode and the temperature measurement mode, execute and display

the measurement.

B: Select and execute each settings. After selecting or executing, return to the primary mode.

Selecting the temperature correction/the temperature conversio

n

Temperature conversion setting mode

Selecting the temperature

conversion executing

Chapter

4

Basic Operation

s

4

.1 Operating Procedure

Page 40

28

────────────────────────────────────────────────────

4.1 Operating Procedure

────────────────────────────────────────────────────

NOTE

4

.1.2 Key Shift States

TEMP

0 ADJ

4

.1.3 Key Lock State

LOCK

50/60Hz

4

.1.4 Remote State

NOTE

・ It is impossible to move to the GP-IB address setting mode without installing

the GP-IB interface unit as an option.

・ It is not possible to use the temperature correction function and the

temperature conversion function at the same time.

Under the key shift states, "SHIFT" on the display lights. When pressing any

key under this state, execute the function shown in the blue words under the

keys.

When pressing any key out of this state, execute the function shown in the

white words on the keys.

TEMP Executable functions out of the key shift state (white words).

0 ADJ Executable functions under the key shift state (blue words).

For example, pressing

TEMP key executes zero adjustment under the key shift

state, and selects the measurement mode out of the key shift state.

Pressing the

SHIFT key is able to select either the key shift state or the normal

state.

Under the key lock states, "LOCK" on the display lights and all key except are

invalid. To enter or release the key lock state, press the

LOCK key.

Under the remote states, "REMOTE" on the display lights and all key except

LOCK are invalid. When receiving any commands from GP-IB, enter this state.

In the each kind of setting mode, such as the comparator setting mode, when

receiving any commands from GP-IB, the 3227 returns to the primary

measurement mode automatically and enters the remote state.

To release the remote state, press

LOCK key, except receiving LLO (Local Lock

Out) command from GP-IB. When receiving this command, to release the

remote state, send GTL (Go To Local) command from GP-IB.

Page 41

29

────────────────────────────────────────────────────

4.1 Operating Procedure

────────────────────────────────────────────────────

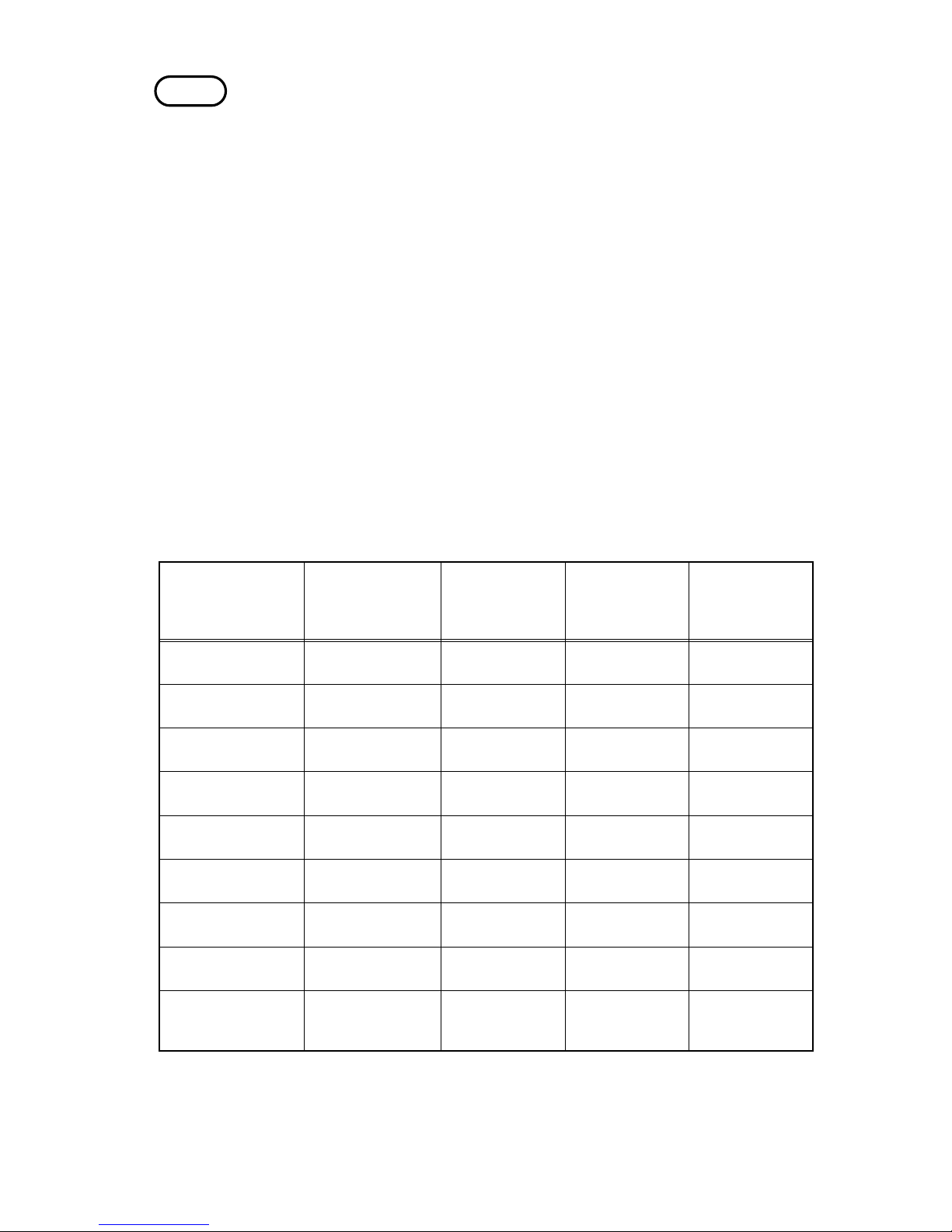

4

.1.5 Valid Input Key Table

● : Key input is valid.

−: Key input is invalid.

Keys

Out of the shift state In the shift state

Lock

state

Remote

state

Resistanc

e

Temper-

ature

Setting Res istanc

e

Temper-

ature

Setting

TEMP

0 ADJ

● ● − ● − − − −

COMP

SET

● − − ● *

4

● − − −

TC

SET

● − − ● *

4

● − − −

HOLD

SAMPL

● ● − ● − − − −

LOCK

50/60Hz

● ● ● ● ● − ● ●*3

SHIFT

● ● ● *

2

● ● ● *

2

− −

AUTO

● *

5

− ● *

6

− − − − −

UP

● − ● − − − − −

DOWN

● − ● − − − − −

● − ● *1 − − − − −

GP-IB ADRS

● − ● *1 ● ● − − −

ENTER

CLEAR

− − ● − − ● *

2

− −

*1: Invalid when setting the GP-IB address or the power supply frequency

*2: Valid only when setting the comparator tables or the temperature conversion tables

*3: Invalid under the LLO (Local Lock State) state

*4: Invalid under the holding state and when using the auto range (excluding when the temperature

conversion functino is selected)

*5: Invalid when using the comparator or displaying the temperature conversion

*6: Valid only when setting the temperature conversion tables

Page 42

30

────────────────────────────────────────────────────

4.2 Selecting the Measurement Mode

────────────────────────────────────────────────────

TEMP

0 ADJ

M

Resistance Measurement Mode

Temperature Measurement Mode

NOTE

4

.2 Selecting the Measurement Mode

Pressing the TEMP key (temperature measurement key) selects either the

resistance measurement mode or the temperature measurement mode.

When the 9188 is not connected, the temperature mode is unable to select. If

intend to select, error is generated.

Page 43

31

────────────────────────────────────────────────────

4.3 Resistance Measurement Mode

────────────────────────────────────────────────────

4

.3.1 Selecting the Sampling Rate

SHIFT

HOLD

SAMPL

S

SLOW

M

MEDIUM

F

FAST

S

N

G

k

REF

%

SLOW

REF

%

M

N

G

k

MEDIUM

F

N

G

k

REF

%

FAST

4

.3 Resistance Measurement Mode

1. Press the SHIFT key and enter the shift states. "SHIFT" on the display

lights.

2. Press the

SAMPL key (sampling rate setting key) and select the sampling

rate.

3. The sampling rate changes in order of SLOW, MEDIUM and FAST with

repeating the step 1. and 2., and the displays change as follows.

Resistance value display

Deviation display

Page 44

32

────────────────────────────────────────────────────

4.3 Resistance Measurement Mode

────────────────────────────────────────────────────

S

AUTO

TC

SLOW

M

AUTO

TC

MEDIUM

F

AUTO

TC

FAST

NOTE

4

.3.2 Selecting the Measuring Range

AUTO

UP

DOWN

Temperature conversion display

When the sampling rate is FAST, 30 k and 300 kΩ range are unable to select.

When set the sampling rate to FAST in 30 kΩ and 300 kΩ range, the

measurement range becomes 3 kΩ range automatically.

The measurement range can also be selected by the external control terminal.

See Chapter 6, "External Control Terminals", for the external control

terminals.

Auto range

Pressing the

AUTO key selects whether the auto range or the manual range.

In case of the auto range, on the display lights, the measuring range changes

to proper range according to the resistance value of the measured subjects.

Manual range

Select the measuring range by the

UP and DOWN key.

When pressing these keys under the auto range state, the range would be the

manual range, but not select any measuring range.

Page 45

33

────────────────────────────────────────────────────

4.3 Resistance Measurement Mode

────────────────────────────────────────────────────

M

M

300 mΩrange 3Ωrange

M

M

30Ωrange 300Ωrange

M

M

k

k

3kΩrange 30 kΩrange

M

k

300 kΩrange

NOTE

The displays change as follows, according to the measuring range (in case of

the resistance value display)

When intend to execute the comparator during using the auto range, the

range becomes the manual range automatically.

During executing the comparator, the auto range is unable to use.

When the sampling rate is FAST, 30k Ω and 300 kΩ range are unable to

select.

During displaying the deviation, the state of the measuring range are not

displayed on the display. To confirm it, turn off the comparator once.

When moving the measuring range under the measurement holding state, the

measuring range is able to change, but the measurement point value is unable

to change.

During temperature conversion display, auto ranging is used. It is not

possible to select the measurement range.

Page 46

34

────────────────────────────────────────────────────

4.3 Resistance Measurement Mode

────────────────────────────────────────────────────

4

.3.3 Zero Adjustment

Red Black

SENSE

Right method Wrong method

SOURCE

SENSE

SENSE

SOURSE

Red Black

SOURCE

SENSE

SOURCE

SENSE

Connect

SENSE SOURCE

HI LO HI LO

Connect

SHIFT

TEMP

0 ADJ

NOTE

The zero adjustment cancels the wiring resistance in case that the accurate 4terminal measurement is impossible. This is also able to execute from the

external control terminal.

See Chapter 6, "External Control Terminal", for details.

(1) Short the leads as follows.

When executing by the 9287

When executing by the self-made lead

(2) Press the

SHIFT key and enter the shift states. "SHIFT" on the display lights.

(3) Press the

0 ADJ key and execute the zero adjustment.

Display "O AdJ" during executing the zero adjustment.

After the zero adjustment, return to the resistance measurement mode.

To measure accurately, the leads should connect correctly.

The zero adjustment is valid only in the measuring range which execute it.

Always execute the zero adjustment in the measuring range which is intended

to use.

The zero adjustment is unable to execute while using the auto range.

However, during using the auto range, the wiring resistance is canceled

according to the result of the zero adjustment executed in the manual range.

The zero adjustment is unable to execute under the holding state.

The range able to execute the zero adjustment is within 100 count. When the

value over 100 count is input, an error is generated.

Page 47

35

────────────────────────────────────────────────────

4.4 Resistance Measurement

────────────────────────────────────────────────────

NOTE

R

x

4

.4 Resistance Measurement

(1) Insert the measurement lead into the input terminal.

See Section 3.4.1, "Resistance Measurement", for how to connect the

measurement leads.

To measure accurately, the leads should connect correctly.

(2) Set the measurement mode to the resistance measurement.

See Section 4.2, "Selecting the Measurement Mode", for how to select the

measurement mode.

(3) Select the sampling rate and the measurement range.

(4) Execute the zero adjustment.

See Section 4.3, "Resistance Measurement Mode", for the sampling rate,

selecting the measuring range, and the zero adjustment.

(5) Connect the lead to the measured subjects (Rx), and read the measurement

value.

See Section 1.3.3, "Measurement Value Display", for measurement value

display.

Page 48

36

────────────────────────────────────────────────────

4.5 Temperature Measurement

────────────────────────────────────────────────────

NOTE

4

.5 Temperature Measurement

(1) Connect the 9188 to the temperature probe connector.

See Section 3.4.2, "Temperature Correction and Temperature Measurements",

for connecting the temperature probe.

(2) Set the measurement mode to the temperature measurement.

See Section 4.2, "Selecting the Measurement Mode", for selecting the

measurement mode.

(3) Put the sensor part of the 9188 to the measuring place, and read the

measurement value.

See Section 1.3.3 "Measurement Value Display", for the display of the

measurement value.

・ The temperature measurement is unable to execute when the temperature

probe is unconnected or ruptured.

・ To prevent the inaccurate temperature measurement, do not take the

temperature probe with bare hands.

・ It is impossible to measure with the sensor part of the temperature probe on

the subjects. It should be used only for measuring the surrounding

temperature.

・ If the temperature probe is to be used in the measurement, make sure that

the 3227 and the temperature probe are thoroughly warmed up before the

measurement. If it is not used to the surrounding temperature, the serious

error is generated.

Page 49

37

────────────────────────────────────────────────────

4.6 Holding the Measurement Value

────────────────────────────────────────────────────

HOLD

SAMPL

NOTE

4

.6 Holding the Measurement Value

During holding the measurement, the value which is obtained on the HOLD

key is pressed is held. The measurement and its display are not renewed

except when the external control terminal requires the measurement.

During free-running, they are renewed according to the rate which is set as

the sampling rate. See Chapter 6, "External Control Terminal", for the

measurement requirement from the external control terminal.

Pressing the

HOLD key selects either the measurement holding or the free-

running.

During holding the measurement, "HOLD" on the display lights.

An "NG" result is always detected even when not carrying out measurements.

Thus even in the HOLD state, if there is a constant current fault, "NG" on the

display lights.

Page 50

38

────────────────────────────────────────────────────

4.6 Holding the Measurement Value

────────────────────────────────────────────────────

Page 51

39

────────────────────────────────────────────────────

5.1 Setting the Comparator

────────────────────────────────────────────────────

5

.1.1 Setting the Comparator 1

SHIFT

COMP

SET

N

G

k

HIGH

LOW

Comparator table number Buzzer mode External control terminal mod

e

Comparison method

High limit value or standard valu

e

Low limit value or rang

e

NOTE

HIGH

LOW

Chapter

5

Applied Operation

s

5

.1 Setting the Comparator

(1) Press the SHIFT key and enter the shift states. "SHIFT" on the display lights.

(2) Press the

COMP key and enter the comparator table setting mode.

The comparator table which never has been set or been invalidated in Section

5.1.3, "Eliminating the Comparator Table" is displayed as shown below.

Page 52

40

────────────────────────────────────────────────────

5.1 Setting the Comparator

────────────────────────────────────────────────────

HIGH

LOW

GP-IB ADRS

DOWN

UP

NOTE

ENTER

CLEAR

NOTE

While displaying the converted temperature, the 3227 has only one

comparator setting table. In this case reference value/range comparisons also

cannot be executed. The comparator setting in this case is displayed as shown

below.

(3)Move the flashing cursor to the setting items with the cursor keys.

(4) Set the items with the

UP or DOWN key.

See Section 1.3.4, "Comparator Function", for the details of the setting

contents.

Select the comparator table number ( "01"to "15").

During using the temperature conversion function, comparator table number

is unable to change.

Select the buzzer mode.

HL The buzzer sounds in case of HIGH or LOW.

IN The buzzer sounds in case of IN.

OF No buzzer sound.

Select the mode of the external control terminal

A The comparator result is output with each samples.

E The comparator result is output by the "MANU

―――――――

" state in the external

control terminal.

Select the comparison method of the comparator

HIGH , LOW The comparator is compared as high limit value/low limit value.

REF, % The comparator is compared as standard value/range.

Select either high limit value/low limit value or standard value/range.

To change the value, move the cursor to that digit ("0" to "9").

The comparison range of the comparator is decided by these selection and the

comparison method of the comparator.

(5) Pressing the

ENTER key decides the setting contents and return to the

resistance measurement mode. Start comparing of the comparator according to

the comparator table.

Always set the high limit value bigger than the low limit value. If the bigger

low limit value is set, the setting contents are not decided, and the mode does

not return to the resistance measurement mode.

Page 53

41

────────────────────────────────────────────────────

5.1 Setting the Comparator

────────────────────────────────────────────────────

5

.1.2 Setting the Comparator 2

GP-IB ADRS

N

G

k

HIGH

LOW

Comparison

method

High limit value or standard value Low limit value or rang

e

NOTE

GP-IB ADRS

DOWN

UP

ENTER

CLEAR

NOTE

(1)Pressing the cursor keys, enter the comparator setting mode.

In this mode, set the current comparator table to be used. When the

comparator is not used, set the comparator table 1.

(2) Move flashing cursor to the setting items with the cursor keys.

(3) Set the items with the

UP or DOWN key.

See Section 1.3.4, "Comparator Function", for the details of the setting

contents.

Select the comparison method of the comparator

HIGH , LOW The comparator is compared as high limit value/low limit value.

REF, % The comparator is compared as standard value/range.

Select either high limit value/low limit value or standard value/range.

To change the value, move the cursor to that digit ("0" to "9").

The comparison range of the comparator is decided by these selection and the

comparison method of the comparator.

(4) Pressing the

ENTER key decides the setting contents and return to the

resistance measurement mode. Start comparing of the comparator according to

the comparator table.

Always set the high limit value bigger than the low limit value. If the bigger

low limit value is set, the setting contents are not decided, and the mode does

not return to the resistance measurement mode.

Page 54

42

────────────────────────────────────────────────────

5.1 Setting the Comparator

────────────────────────────────────────────────────

5

.1.3 Eliminating the Comparator Table

SHIFT

DOWNUP

ENTER

CLEAR

COMP

SET

SHIFT

(1) Press the SHIFT key and enter the shift states.

"SHIFT" on the display lights.

(2) Press the

COMP key and enter the comparator table

setting mode.

(3) Select the comparator table intend to eliminate.

See Section 5.1.1, "Setting the Comparator Table", for

details.

(4) Press the

SHIFT key and enter the shift states.

"SHIFT" on the display lights.

(5) Pressing the

CLEAR (ENTER) key invalidates the

displaying comparator table and return to the

resistance measurement.

In this case, the comparator is not executed. (It would

be OFF.)

Page 55

43

────────────────────────────────────────────────────

5.2 Executing the Comparator

────────────────────────────────────────────────────

COMP

SET

NOTE

5

.2 Executing the Comparator

Pressing the COMP key displays the comparator table number in order ("01" to

"15", "OFF"). In this case, skip the comparator table which has not been set

or been invalidated in Section 5.1.3, "Eliminating the Comparator Table."

Return to the resistance measurement mode after displaying the comparator

table number about for a second, and execute the comparator.

When intend to execute the comparator during using the auto range, the

range becomes the manual range automatically. During executing the

comparator, the auto range is unable to use.

Page 56

44

────────────────────────────────────────────────────

5.3 Setting the Temperature Correction

────────────────────────────────────────────────────

SHIFT

TC

SET

GP-IB ADRS

DOWN

UP

ENTER

CLEAR

ppm

Standard temperature Temperature coefficient

NOTE

5

.3 Setting the Temperature Correction

(1) Press the SHIFT key and enter the shift states. "SHIFT" on the display

lights.

(2) Press the

TC key and enter the temperature correction setting mode.

(3) Move flashing display to the setting items with the cursor keys.

(4) Set the digits of the standard temperature or the temperature coefficient

with the UP or DOWN key ("0" to "9","-").

(5) Pressing the enter key decides the setting contents and return to the

resistance measurement mode. Start executing the temperature correction

according to the setting contents.

・ When intend to decide the setting contents with the

ENTER key in case that

standard temperature exceeds the range of -10.0℃ to 99.9℃,the error is

generated. In this case, the setting contents are not decided, and the mode

does not return to the resistance measurement mode.

・ When the temperature conversion function is selected at power on, the setting

screen for the temperature conversion function appears.

・ See Section 5.5, "Setting the Temperature Conversion", for details.

Page 57

45

────────────────────────────────────────────────────

5.4 Executing the Temperature Correction

────────────────────────────────────────────────────

TC

SET

NOTE

5

.4 Executing the Temperature Correction

Pressing the TC key selects whether executing the temperature correction or

not.

When executing the temperature correction, "TC" on the display lights.

When the 9188 is not connected, the temperature mode is unable to select. If

intend to select, an error is generated.

When the value after executing the temperature correction exceeds 99999

count, the over flow display is indicated. For example, in case that the

standard temperature is set to 90.0℃,the temperature coefficient is set to

8000 ppm, the measurement value is 30000 count, and the environment

temperature is 0 ℃,the corrected resistance value exceeds 99999 count (see

the expression below), and the over flow display is indicated.

30000

Rt =

= 107142 (count)

1 + 8000 × 10

-6

×(0-90.0)

When the temperature conversion function is selected at power on, the

temperature conversion function is executed.

For details, see Section 5.6, "Excecuting the Temperature Conversion

Function".

Page 58

46

────────────────────────────────────────────────────

5.5 Setting the Temperature Conversion

────────────────────────────────────────────────────

TC

SET

SHIFT

Table Number Display

Initial resistance value

Initial temperature Constant

Setting Screen

AUTO

NOTE

GP-IB ADRS

DOWN

UP

ENTER

CLEAR

NOTE

5

.5 Setting the Temperature Conversion

(1) Press the SHIFT key and enter the shift states. "SHIFT" on the display lights.

(2) Pressing the

TC key first displays the temperature conversion table number

for a while, then enters the temperature conversion setting mode. Pressing

the

TC key again makes it possible to select the table number.

(3) Pressing the

AUTO key sets the initial resistance and initial temperature

values to the measured values before entering the temperature conversion

mode. The constant value is also set to 235.0 (constant for copper).

When setting the current measurement value by pressing the

AUTO key, if a

valid resistance value or temperature is not measured, the initial resistance

value is set to a 99999 display value (current measurement range) and the

initial temperature is set to 99.9 ℃.

(4) Move flashing display to the setting items with the cursor keys.

(5) Set the digits of the initial resistance, the initial temperature, or the constant

with the

UP or DOWN key.

(6) Pressing the ENTER key decides the setting contents and return to the

temperature conversion mode. Start executing the temperature conversion

according to the setting contents.

・ The setting range for each item is as follows. An attempt to set a value out of

range generates an error. In this case, the setting contents are not decided,

and the mode does not return to the measurement mode.

Initial resistance: 0.00 mΩ to 999.99 kΩ

Initial temperature: -10.0℃ to 99.9℃

Constant: -999.9 to 999.9

・ When the temperature correction function is selected at power on, the setting

screen for the temperature correction function appears. See Section 5.3,

"Setting the Temperature Correction."

Page 59

47

────────────────────────────────────────────────────

5.6 Executing the Temperature Conversion

────────────────────────────────────────────────────

TC

SET

S

AUTO

Resistance Value Display

S

AUTO

TC

Temperature Conversion Display

S

AUTO

TC

Δt Display

DOWN

UP

NOTE

5

.6 Executing the Temperature Conversion

(1) Pressing the TC key changes the displays as shown below, cycling the

measurement mode through the resistance value display, the temperature

conversion display, and the Δt display.

(2) Pressing the

UP or DOWN key selects the temperature conversion table. After

displaying the temperature conversion table number for a while, start

executing the temperature conversion according to the selected table.

・ Connect the 9188 TEMPERATURE PROBE to execute the temperature

conversion. If it is not connected, an execution error is generated.

・ When temperature correction function is selected at power on, the function is

executed.

Page 60

48

────────────────────────────────────────────────────

5.6 Executing the Temperature Conversion

────────────────────────────────────────────────────

Page 61

49

────────────────────────────────────────────────────

6.1 Connector

────────────────────────────────────────────────────

6

.1.1 Terminal Block

TRIG 0 ADJ

GND MANU PRINT Hi IN Lo

Signals Input and output Signals Input and output

GND Ground

PRINT

――――――

Input

TRIG

―――――

Input Hi Output

MANU

―――――

Input IN Output

0 ADJ

―――――

Input Lo Output

Chapter

6

External Control Termina

ls

6

.1 Connector

Page 62

50

────────────────────────────────────────────────────

6.1 Connector

────────────────────────────────────────────────────

6

.1.2 Digital I/O

11920

37

Socket side

Pin

numbe

r

Input and

output

Signals

Pin

numbe

r

Input and

output

Signals

1 Power supply VCC 20 Power supply VCC

2 Power supply VCC 21 Power supply VCC

3 Output BCD (1 digit) bit 0 22 Output BCD (1 digit) bit 1

4 Output BCD (1 digit) bit 2 23 Output BCD (1 digit) bit 3

5 Output BCD (2 digit) bit 0 24 Output BCD (2 digit) bit 1

6 Output BCD (2 digit) bit 2 25 Output BCD (2 digit) bit 3

7 Output BCD (3 digit) bit 0 26 Output BCD (3 digit) bit 1

8 Output BCD (3 digit) bit 2 27 Output BCD (3 digit) bit 3

9 Output BCD (4 digit) bit 0 28 Output BCD (4 digit) bit 1

10 Output BCD (4 digit) bit 2 29 Output BCD (4 digit) bit 3

11 Output BCD (5 digit) bit 0 30 Output BCD (5 digit) bit 1

12 Output BCD (5 digit) bit 2 31 Output BCD (5 digit) bit 3

13 Output EOC 32 Output NG

14 Input

COMP 0

――――――――

33 Input

RANGE 0

―――――――――

15 Input

COMP1

――――――――

34 Input

RANGE 1

―――――――――

16 Input

COMP 2

――――――――

35 Input

RANGE 2

―――――――――

17 Input

COMP 3

――――――――

36 Ground GND

18 Ground GND 37 Ground GND

19 Ground GND

Using socket DCSP-JB37S (made by Japan aviation electron)

50 pins receptacle

Adaptive pin DCSP-JB37P (conform to made by Japan aviation electron)

50 pins plug

Page 63

51

────────────────────────────────────────────────────

6.2 Connecting Method

────────────────────────────────────────────────────

6

.2.1 Terminal Block

6

.2.2 Digital I/O

CAUTIO

N