Page 1

3184

Instruction Manual

DIGITAL POWER HiTESTER

Oct. 1996 Revised edition 2

3184A981-02 96-10H

EN

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use iv

Chapter 1 Overview 1

1.1 Features 1

1.2 Names and Functions of Parts 2

Chapter 2 Specifications 7

2.1 General Specifications 7

Chapter 3 Basic Operating Principle 9

3.1 Active Power Measurements 9

3.2 Voltage and Current Measurements 10

3.3 Crest-Factor 11

Chapter 4 Operating Instructions 13

4.1 Operating Procedure 13

Chapter 5 3184-02 GP-IB Specifications 17

5.1 Outline 17

5.2 Interface Specifications 18

5.3 Panel Description 19

5.4 Talker Function 20

5.5 Listener Functions 21

5.6 Service Requests 23

5.7 Usage Precautions 24

5.8 Sample Programs 25

Chapter 6 Maintenance and Service 29

6.1 Fuse Replacement 29

6.2 Service 30

Page 4

Page 5

―――――――――――――――――――――――――――――――――――――――

I

I

ntroduction

Thank you for purchasing this HIOKI "3184 DIGITAL

POWER HiTESTER." To get the maximum performance

from the unit, please read this manual first, and keep

this at hand.

nspection

When the unit is delivered, check and make sure that it

has not been damaged in transit. In particular, check the

accessories, panel switches, and connectors.

If the unit is damaged, or fails to operate according to the

specifications, contact your dealer or HIOKI

representative.

Accessories

Fuse M0.5 A/250 V 1

(20×5.2 dia. mm arc-quencing midget)

Power cord 1

Instruction Manual 1

i

―――――――――――――――――――――――――――――――――――

Inspection

Page 6

ii

G

S

―――――――――――――――――――――――――――――――――――――――

afety Notes

WARNIN

Incorrect measurement procedures could result in

injury or death, as well as damage to the equipment.

Please read this manual carefully and be sure that

you understand its contents before using the

equipment. The manufacturer disclaims all

responsibility for any accident or injury except that

resulting due to defect in its product.

This Instruction Manual provides information and

warnings essential for operating this equipment in a safe

manner and for maintaining it in safe operating

condition. Before using this equipment, be sure to

carefully read the following safety notes.

Safety symbols

In the manual, this mark indicates explanations

which it is particularly important that the user read

before using the equipment.

―――――――――――――――――――――――――――――――――――

Safety Notes

Page 7

―――――――――――――――――――――――――――――――――――――――

R

G

N

The following symbols are used in this Instruction

Manual to indicate the relative importance of cautions

and warnings.

iii

DANGE

WARNIN

CAUTIO

NOTE

Indicates that incorrect operation presents extreme

danger of accident resulting in death or serious

injury to the user.

Indicates that incorrect operation presents

significant danger of accident resulting in death or

serious injury to the user.

Indicates that incorrect operation presents

possibility of injury to the user or damage to the

equipment.

Denotes items of advice related to performance of

the equipment or to its correct operation.

―――――――――――――――――――――――――――――――――――

Safety Notes

Page 8

iv

R

.

G

N

―――――――――――――――――――――――――――――――――――――――

otes on Use

In order to ensure safe operation and to obtain maximum

performance from the unit, observe the cautions listed

below.

DANGE

WARNIN

Always connect the voltage cable to the secondary

side of a breaker. On the secondary side of a

breaker, even if the lines are shorted the breaker

can trip and prevent an accident. On the primary

side, however, the current capacity may be large,

and in the event of a short-circuit there may be a

serious accident.

This unit cannot be used on voltage lines of 500

Vrms. If the voltage exceeds 500 VAC, there will be

a short-circuit accident or an electrocution accident

Be sure to connect the voltage input terminals and

current input terminals correctly. Measurement

which is attempted with the wiring connected

incorrectly may cause damage to the unit or a

short-circuit.

To prevent an electric shock and a short-circuit

accidents, shut off the power to the line to be

measured before connecting the load to the

terminals.

To avoid electric shock when replacing the fuse,

turn the power switch off, disconnect the power

code from the connector, and remove the input

cable from the object to be measured.

M0.5 A/250 V 20 mm×5.2 mm dia.

―――――――――――――――――――――――――――――――――――

Notes on Use

Page 9

―――――――――――――――――――――――――――――――――――――――

G

N

v

WARNIN

CAUTIO

Only use fuses of the specified type that is rated for

the specified current and voltage. Using a fuse that

does not meet the specifications or shorting the fuse

holder may cause an accident that might result in

injury or death.

・ Do not store or use the unit where it will be exposed to

direct sunlight, high temperatures, high humidity, or

condensation. If exposed to such conditions, the unit

may be damaged, the insulation may deteriorate, and

the unit may no longer satisfy its specifications.

・ To avoid electric shock, the wiring which is used for

making the connections to the current input terminals

should have sufficient current carrying capacity and

insulation.

・ To avoid damage to the unit, do not short the analog

output terminal and the GP-IB connector terminal and

do not input voltage to them.

・ To avoid damage to the unit, do not subject the

equipment to vibrations or shocks during transport or

handling. Be especially careful to avoid dropping the

equipment.

・ Before using the unit, make sure that the sheathing on

the leads is not damaged and that no bare wire is

exposed. If there is damage, using the unit could

cause electric shock.

―――――――――――――――――――――――――――――――――――

Notes on Use

Page 10

vi

―――――――――――――――――――――――――――――――――――――――

NOTE

・ Accurate measurement may be impossible in locations

subject to strong external magnetic fields, such as

transformers and high-current conductors, or in locations

subject to strong external electric fields, such as radio

transmission equipment.

・ When a measuring device such as a recorder or voltmeter

is connected to the analog output terminals, there is a

possibility of oscillatioin due to the input capacitance of

the measuring device.

If such oscillation occurs, insert a resistor (100 ohms or

thereabouts) in series between the analog output

terminals and the measuring device.

―――――――――――――――――――――――――――――――――――

Notes on Use

Page 11

1

1

w

1

―――――――――――――――――――――――――――――――――――――――

Chapter

Overvie

.1 Features

The 3184 is a 3-phase power meter designed to measure

voltage, current, and power in single-or-3-phase circuits.

The meter’s internal circuit converts voltage and current

measurements to true rms value, giving it the capability

to accurately measure the special waveforms produced by

thyristors and other semiconductor switching devices.

The basic instrument is provided with an analog output

terminal, and models are available equipped with and

GP-IB interface (3184-02).

(1) Voltage, current, single-and 3-phase power measurement

capability

(2) Voltage and current quantified as true rms values

(3) Good frequency response characteristics

(4) Minimum metering losses

(5) Overvoltage, overcurrent warning indicators provided

(6) Analog outputs provided for power and selected function

(7) Optional models with GP-IB interface capability available

(8) Lightweight, compact

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 12

2

1

―――――――――――――――――――――――――――――――――――――――

.2 Names and Functions of Parts

Front Panel

Rear Panel

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 13

3

e

―――――――――――――――――――――――――――――――――――――――

POWER switch

Always turn the power switch ON before a measurement.

Allow the instrument approximately 5 minutes of warm-

up.

Display panel

3-1/2 digits LED display with a maximum display

capability of 1999. Measurement unit annunciators are

coupled to function switch operation, with the

measurement value of V

to W, and the unit displayed.

12

At power ON, the display reading is 0000, and an

overrange input is indicated by "1" in the MSD column,

with all other digits blanked. OVER V and OVER A are

the overvoltage and overcurrent warning indicators.

These light when peak-value of the input exceeds the

crest-factor of the meter circuit. The REMOTE lamp is

functional only when the instrument is used in a optional

automatic measurement system, and lights to indicate

that function and range settings are under remote-control.

Function switches (V

12

,V

3

1

32

,W)

,A

,A

Used to select the display function. At power ON, the

non-select state is entered automatically. When selection

is made, the selected function switch LED lights.

Range switches (500V/200V, 20A/2A)

Selects the range for voltage and current measurements.

At power ON, both ranges are set to Lo (indicator OFF).

Range switch Hi Lo changes each time the button is

pressed. The range for power measurements is a

combination of voltage and current range settings,

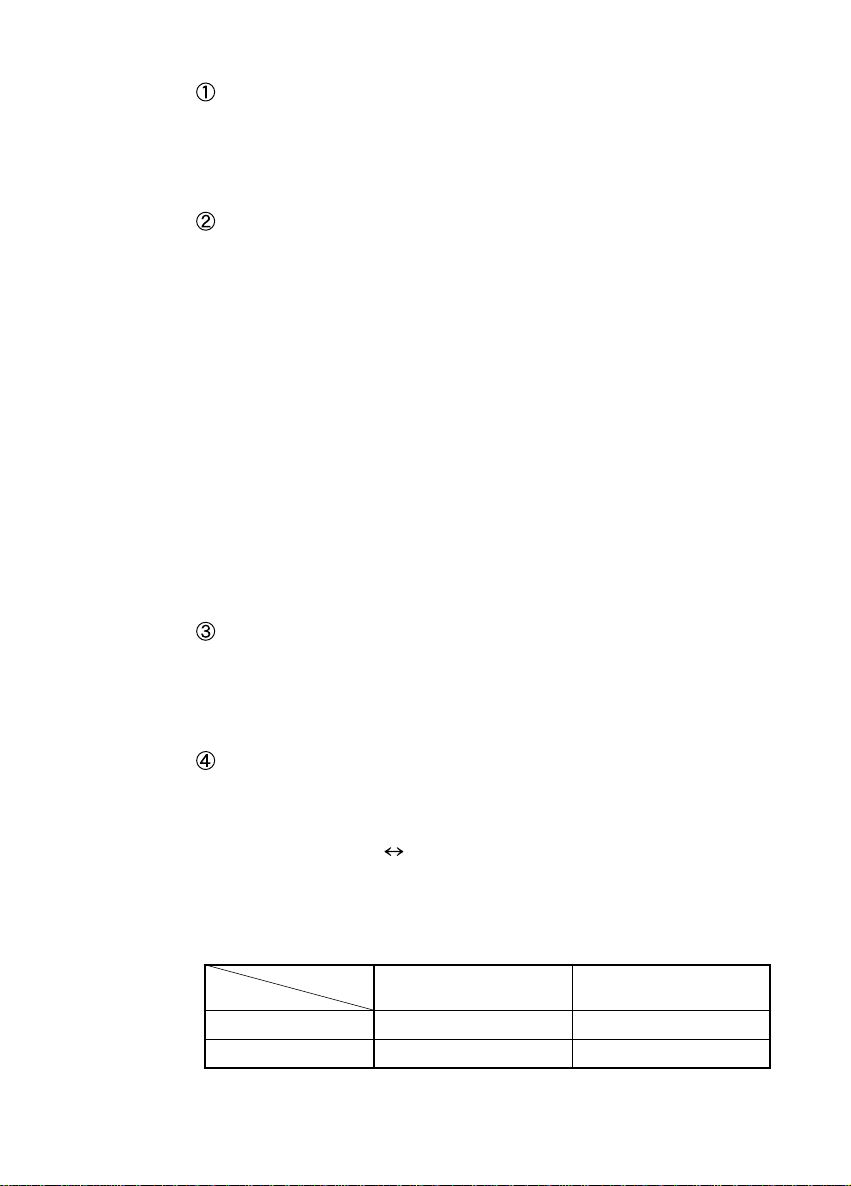

determined as follows.

V rang

A range

Lo (2 A) 0.2 kW 2kW

Hi (20 A) 2kW 20 kW

Lo (200 V) Hi (500 V)

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 14

4

N

y

e

d

―――――――――――――――――――――――――――――――――――――――

Output Terminals

Output is a DC voltage value equivalent to the

measurement value (2 VDC/f.s.).

CH1: Power only (continually outputs regardless of

selected function).

CH2: Outputs the value for the displayed function.

CAUTIO

To avoid damage to the unit, do not short the output

terminal and do not input voltage to the output terminal.

The response waveform for analog output appears as

follows.

Output

voltage

Output stabilit

Tim

Input applie

Voltage, current: T ≒ 1.2 s (when input is 95 % of fullscale)

Power: T ≒ 1.4 s (when input is 95 % of full-scale)

These figures are also applicable when function or range

changes are made.

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 15

5

N

―――――――――――――――――――――――――――――――――――――――

Measurement Terminal Board

The rear panel terminal board is used to connect the

device under test with the power source. Connection

cables should have sufficient capacity ratings, and be

connected securely (and neatly) to avoid accidental short-

circuits.

Fuse Holder

The instrument takes a 0.5 A/250 V arc-quencing, midget

type fuse. Unplug the power cord when changing the

fuse.

AC Inlet

This receptacle is used to connect the instrument to the

AC power supply (AC mains). Use the power cord

provided with the instrument. The power source rating

for your particular instrument is marked in the table

above the fuse holder. Make sure that this rating agrees

with the power source being used.

Handle

As shown in figure on the next page, the handle may be

rotate by sliding the grip at the sides of the handle in the

direction of the SLIDE TO ROTATE arrow. When the

proper position has been attained, push the slide in the

LOCK arrow direction. The handle may be set at 30

。

detents to fix it in position.

CAUTIO

The handle can be used as a stand to incline the

instrument. Force should not be applied to the

instrument from above when using it in this manner.

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 16

6

―――――――――――――――――――――――――――――――――――――――

E

T

A

T

O

R

O

T

E

D

I

S

L

Handle

―――――――――――――――――――――――――――――――――――

Chapter 1 Overview

Page 17

7

)

2

s

2

―――――――――――――――――――――――――――――――――――――――

Chapter

Specification

.1 General Specifications

Measurement

functions

Measurement range

Maximum display

value

Crest factor

Meter losses (typical

values, at 55 Hz)

Maximum allowable

input (continuous)

Display

Sampling rate

Accuracy

(23。±5。, 50/60 Hz)

AC voltage, AC current (true rms), single-and

3-phase active (real) power

V

A

12

,A

1

32

3

2 A/20 A

200 V/500 V

,V

W 0.2 kW/2 kW/20 kW

,V

V

12

,A

A

1

199.9 V/500 V

32

1.999 A/19.99 A

3

W .1999 kW/1.999 kW/19.99 kW

V

A

12

,A

1

32

2 or less at full-scale

3

2 or less at full-scale

,V

W Same as voltage and current

V

A

V

A

32

12

0.012 VA at 2 A, 1.3 VA at 20 A

,A

3

1

600V

,V

32

12

30 A

,A

3

1

0.017 VA at 200 V, 0.12 VA at 500 V

,V

3-1/2 digit LED display (1999 max)

Approximately 2.5 samples-per-second

,V

V

12

,A

A

1

±0.5% rdg. ±6 dgt.

32

±0.5% rdg. ±6 dgt.

3

W ±0.5% rdg. ±6 dgt. (power-factor=1.0

Frequency response

,V

V

12

,A

A

1

within ±0.5% rdg., 40 Hz to 1 kHz

32

within ±0.5% rdg., 40 Hz to 1 kHz

3

(≦18 A)

within ±0.5% rdg., 45 Hz to 1 kHz

(>18 A)

―――――――――――――――――――――――――――――――――――

Chapter 2 Specifications

Page 18

8

r

.

―――――――――――――――――――――――――――――――――――――――

Frequency response

Affect of power facto

on accuracy

(50/60 Hz)

Temperature

characteristics

Analog output

Dielectric strength

Rated supply voltage

Affect of power

source voltage

W within ±1.0% rdg., 40 Hz to 1 kHz

(When current input ≦ 18 A, and

power-factor = 1.0)

within ±1.0% rdg., 45 Hz to 1 kHz

(When current input > 18 A, and

power-factor = 1.0)

0.2 kW range within ±1.0% rdg.,

power factor=0.5

2 kW range within ±0.8% rdg.,

power factor=0.5

20 kW range within ±0.8% rdg.,

power factor=0.5

Within ±2.0% rdg. at 0 to 40°

CH1 power only (continual output), 2 VDC/f.s

CH2 selected function, 2 VDC/f.s.

2.2 kVAC/1 min (between input terminals and

case), 1.5 kVAC/1 min (between power

terminals and case)

100/120/220/240 VAC (specify one) 50/60 Hz

(voltage fluctuations of ±15% from the rated

supply voltage are taken into account)

Accuracy of above specifications assured within

specified power source range.

Rated power

Approximately 5.5 W at 100 V, 60 Hz (7 VA

approximately) (3184-02: approximately 9.5 W

(11 VA approx.))

Dimensions

Mass

Accessories

250 (W) × 85 (H) × 220 (D) mm

2.9 kg (3184-02: 3.0 kg)

Fuse (M0.5 A/250 V arc-quencing midget 20 mm

×5.2 mm dia.) ×1

Power cord ×1

Instruction manual ×1

Options

9084 CARRYING CASE

9149 CARRYING CASE

―――――――――――――――――――――――――――――――――――

Chapter 2 Specifications

Page 19

9

r

s

r

r

y

o

l

)

-

r

r

r

r

r

o

)

PT

P

C

CT

V

V

A

A

3

g

le

3

―――――――――――――――――――――――――――――――――――――――

Chapter

Basic Operatin

Princip

.1 Active Power Measurements

12

32

T

1

3

Amplifie

T

Amplifie

Multiplie

Multiplie

Selector

Auto-zer

Auto-zer

Panel switch contro

Analog output (CH1

Rms

converte

Analog output (CH2

Low

pass

filte

Control

A/D

converte

Amplifie

Displa

Figure 3.1-1 Circuit Block Diagram

A block diagram of the various circuits contained in the

3184 is shown in Figure 3.1-1. As shown in the figure,

supply voltage and current of the device under test is

sensed by the PT and CT respectively. These values are

converted to a 2 V/f.s. signal for application to the

multipliers where power is calculated.

―――――――――――――――――――――――――――――――――――

Chapter 3 Basic Operating Principle

Page 20

10

Voltage-Current Waveforms

Power Conversion Waveform

3

―――――――――――――――――――――――――――――――――――――――

The DC component of the calculated waveform is

proportional to active power. Output is obtained by

extracting this DC component and adjusting it to a 2

VDC/f.s. level.

Figure 3.1-2

Figure 3.1-3

.2 Voltage and Current Measurements

In conventional measuring instruments, the method of

measuring an AC signal is to sense its average value,

then make the necessary calculations to convert it to an

rms value. However, using this method does not account

for waveform distortion, or non-true sine waves, normally

resulting in an inaccurate measurement. These

instruments use special rms converters that work by

sampling the instantaneous value of the signal, and thus

produce a true rms reading of the signal.

―――――――――――――――――――――――――――――――――――

Chapter 3 Basic Operating Principle

Page 21

11

3

―――――――――――――――――――――――――――――――――――――――

.3 Crest-Factor

In measuring instruments, the dynamic range of the

meter circuit is expressed as a crest-factor. In

measurements where peak-values are high relative to rms

value, selecting a suitable range for the rms value will

likely result in the waveform peaks exceeding the

dynamic range of the signal. Crest-factor is the ratio of

peak-value to rms value, defined as follows.

Peak-value

Crest-factor =

Rms value

For these instruments, crest-factor is as follows.

): Two or less at full-scale

AC voltage (V

AC current (A

Single-and 3-phase active power (W): Same as voltage and

current.

,V

32

12

): Two or less at full-scale

,A

3

1

For example, when measuring AC current in the Lo range

with the 3184, maximum display value(full-scale) is 2 A,

so maximum allowable peak-value input (maintaining

accuracy) is as follows.

Peak-value = rms value × crest-factor

= 2 [A] × 2 = 4 [A]

When measuring AC voltage in the Hi range full-scale is

500 V, so 500 [V] × 2 = 1000 [V] (peak-value)

The overcurrent and overvoltage warning indicators will

light when input value exceeds the peak-value in the

table on the next page.

―――――――――――――――――――――――――――――――――――

Chapter 3 Basic Operating Principle

Page 22

12

―――――――――――――――――――――――――――――――――――――――

Function Range 3184

NOTE

Voltage

Current

Lo

1000 V peak

Hi

Lo 4 A peak

Hi 40 A peak

If the crest factor in the specification is exceeded, the

displayed data will not be accurate.

―――――――――――――――――――――――――――――――――――

Chapter 3 Basic Operating Principle

Page 23

13

G

N

4

s

4

―――――――――――――――――――――――――――――――――――――――

Chapter

Operating Instruction

.1 Operating Procedure

WARNIN

CAUTIO

In order to prevent electric shock and short-circuit

accidents, shut off the power to the line to be

measured before connecting the load or power

supply to the terminals.

In order to maintain safety and assure the stable

operating performance of this unit, be sure to

connect the ground terminal to a proper ground.

Before turning on the power, make sure that the

voltage of the power supply being used matches the

supply voltage indicated on the rear panel of the

unit.

If an attempt is made to use an improper supply

voltage, there is danger of damage to this unit and

of life-threatening risk to the operator.

・ To avoid damage to the unit, do not input a

voltage/current exceeding the rated maximum to the

terminals.

・ Before measurement, check the position of the range

switch. The unit may be damaged if current or voltage

exceeds the measurement limit is applied for a long

time.

―――――――――――――――――――――――――――――――――――

Chapter 4 Operating Instructions

Page 24

14

―――――――――――――――――――――――――――――――――――――――

NOTE

・ Approximately two seconds is required for display to

reach stability after applying input, or selecting function

or range.

・ Using the instrument in the presence of magnetic fields

(and sometimes meter noise itself) will produce a reading

of a few digits even though input is zero.

・ For an indication of 1999, the analog output is 1.999 VDC

(1 mV/dgt.). Therefore, when measuring 500 V the

indication is 500, and the output is 500 mV.

・ The 3184 uses a voltage transformer (PT) and current

transformer (CT), which do not transmit DC. It is

therefore not possible to measure a signal (for example

full-wave or half-wave rectified) which includes a DC

component.

・ Because of characteristics of the internal circuit design,

when measuring a load which includes a component of a

certain frequency, the power indication may be unstable,

with a periodic fluctuation.

(1) Turn the power switch ON, and allow the instrument

approximately 5 minutes of warm-up prior to starting the

measurement.

(2) Set the range switches according to the expected voltage

and current of the device under test. When this is

unknown, start with a Hi range setting.

(3) Connect the power source and device under test to the

measurement terminal board as illustrated in Figure 4.11 and 4.1-2. Install the protective cover, and turn power

ON to the power source and the device under test.

(4) Use the function switches to select the various functions

for measurement and display.

(5) If the OVER V or OVER A lamps should light while in

the Lo range, switch to the Hi range.

―――――――――――――――――――――――――――――――――――

Chapter 4 Operating Instructions

Page 25

15

―――――――――――――――――――――――――――――――――――――――

(6) When voltage or current in the device under test exceeds

the measurement range of the instrument that you are

using, reduce the level of the input signal using PTs and

CTs connected as illustrated in figure 4.1-3. Note

however, that PTs and CTs produce phase errors that

adversely affect the accuracy of power measurements, and

caution is advised when using this setup.

Power

source

Load

Figure 4.1-1 3-Phase, 3-Wire Connection Procedure

―――――――――――――――――――――――――――――――――――

Chapter 4 Operating Instructions

Page 26

16

―――――――――――――――――――――――――――――――――――――――

Power

source

Figure 4.1-2 Single-Phase Connection Procedure

Power

source

Load

Load

Figure 4.1-3 Connection Procedure Using PTs and CTs

―――――――――――――――――――――――――――――――――――

Chapter 4 Operating Instructions

Page 27

17

5

B

s

5

―――――――――――――――――――――――――――――――――――――――

Chapter

3184-02 GP-I

Specification

.1 Outline

The 3184-02 feature built-in GP-IB interfaces. This

allows the instruments to be connected to a GP-IB system

for automated measurement data reading, and for

program-control of function and range settings. Interface

functions also include the ability to transmit a service

request in the event of an overvoltage or overcurrent.

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 28

18

.

5

―――――――――――――――――――――――――――――――――――――――

.2 Interface Specifications

Applicable standard: IEEE 488-1978

Interface functions:

SH1

AH1

T6

L4

SR1

RL2

PP0

DC1

DT0

C0

(E1)

All SH functions.

All AH functions.

Basic talker function,

Serial poll function,

Unaddress if MLA function.

No talk-only mode function.

Basic listener function,

Unaddress if MTA function

No listen-only mode function.

All SR functions.

Remote/Local switching function

No PP function

All DC functions.

No DT function.

No controller function.

(Open-collector driver.)

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 29

19

5

―――――――――――――――――――――――――――――――――――――――

.3 Panel Description

GP-IB status lamps

When operated under GP-IB system control, these lamps

indicate present device status.

RMT Indicates that the device can be controlled

externally.

SRQ Indicates that the device is transmitting a service

request to the controller.

TLK Indicates that the device is transmitting data as

the talker.

LTN Indicates that the device is receiving data as the

listener.

GP-IB connector

24-pin connector conforming to the IEEE 488 bus

standard. Used with a standard bus cable.

Address switch

Used to set the device address for the GP-IB system.

(Left-hand switch not usable.)

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 30

20

5

―――――――――――――――――――――――――――――――――――――――

.4 Talker Function

Output data format

±DDDDDE±D CR LF

AAA

(1) (2) (3)

(1) Measurement Functions

Header

V

V

A

A

NO Indicates no setting has been made.

OVR Overrange

V12(Voltage measurement)

12

V32(Voltage measurement)

32

A1(Current measurement)

1

A3(Current measurement)

3

W W (Power measurement)

(2) Measurement Values

Measurement

function

V12,V

32

A1,A

3

W

Range Mantissa Exponent

200 V +ddd.d E+0

500 V +dddd. E+0

2A +d.ddd E+0

20 A +dd.dd E+0

0.2 kW ±ddd.d E+0 *

2kW ±d.ddd E+3

20 kW ±dd.dd E+3

Function

Note: Data marked by asterisk (*) is formatted different

than the examples shown on the instrument’s

instruction label.

Output data for an overrange is as follows.

OVR 19999. E + 9

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 31

21

5

―――――――――――――――――――――――――――――――――――――――

(3) Delimiter

"CR" and "LF" are sent as delimiters. An EOI is

transmitted simultaneous with "LF".

.5 Listener Functions

Programming code

(1) Function

F0

F1

F2

F3

F4

F5

(2) Range

Voltage range

Current range

(3) Service Request

S0

S1

No service request mode.

Service request mode set.

Function not set.

V

12

V

32

A

1

A

3

W

V0 Lo 200 V

V1 Hi 500 V

A0 Lo 2A

A1 Hi 20 A

(4) Header Output

H0

H1

No header output mode.

Header output mode set.

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 32

22

―――――――――――――――――――――――――――――――――――――――

Programming precautions

Delimiter Usage

When receiving data as the listener, the incoming

transmission will be interrupted for internal processing in

the following two cases.

・When an "EOI" is received.

・When an "LF" is received.

This is disregarded for a "CR". (An unaccompanied "CR"

is only effective in breaking the incoming transmission for

internal processing when the LACS (Listener Active

State) is terminated.)

Note also that when programmed backwards (i.e., "LF"

"CR"), the break in transmission when "LF" is received

leaves "CR" on the bus, and this is likely to lock the next

handshake routine.

Syntax Errors

When undefined codes, or strings of over 21 characters

are received, the syntax error bit in the status byte will

be set, and if the "S1" mode is programmed, a service

request will be sent.

Setting Time Requirements

When setting function and range externally, these

settings will be made after all codes have been received,

requiring a maximum of 2.5 ms. Operation commands

received during that interval will not be properly

executed.

Note also that approximately 2 seconds is required for the

display to stabilize after a voltage or current input, or

whenever a function or range change is made. That

amount of wait time must be allowed in the program.

(Response time for analog output is noted in Section 1.2,

"Names and Functions of Parts.")

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 33

23

S

X

R

O

A

O

V

l

5

―――――――――――――――――――――――――――――――――――――――

.6 Service Requests

When the "S1" mode is set, a service request will be sent

in the event of an overvoltage or overcurrent input, or for

programming errors such as undefined codes or format

errors.

Following transmission of the service request, the

controller sends a serial poll, and the device responds by

transmitting its status byte and resetting the SRQ bit (bit

6).

When "S0" is set, a service request is not sent, but the

status byte is transmitted.

The OVER V or OVER A bit (bit 0 and 1) will be reset

with the serial poll, but a SYNTAX ERROR bit (bit 2)

remains until the next time the device is designated as

the listener, at which time it is reset.

Status Byte

Bit 7 6 5 4 3 2 1 0

0 SRQ 0 0 0

Service request sent Undefined code, or code

containing over 21 characters

received

Overvoltage input 01000001 65

Overcurrent input 01000010 66

Undefined code received 01000100 68

, , and occurring together01000111 71

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

YNTA

ERRO

VER

Overcurrent input

Binary Decima

VER

Overvoltage input

Page 34

24

5

―――――――――――――――――――――――――――――――――――――――

.7 Usage Precautions

(1) Address setting

The GP-IB address for the device with this interface is set

using the rear panel DIP switch. Any address 0 thru 30

not used by another device in the system can be used.

The ON side of the switch represents "1", and the OFF

side "0". Addresses are set using the five right switches

as shown in the following table.

Address 54321 Address 54321 Address 54321

0 00000 11 01011 21 10101

1 00001 12 01100 22 10110

2 00010 13 01101 23 10111

3 00011 14 01110 24 11000

4 00100 15 01111 25 11001

5 00101 16 10000 26 11010

6 00110 17 10001 27 11011

7 00111 18 10010 28 11100

8 01000 19 10011 29 11101

9 01001 20 10100 30 11110

10 01010

NOTE

The device address is read into the system when the

power turned ON. Consequently, whenever address

changes are made, power must be turned OFF, then back

ON for the new address to be effective.

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 35

25

5

―――――――――――――――――――――――――――――――――――――――

(2) Items Regarding Local and Remote Control

a. When switching between local and remote control,

function and range settings remain the same.

b. In the remote status, all panel controls (except the power

switch) are ineffective.

c. Measurement data is output according to function and

range setting, and has no bearing on remote or local

status.

.8 Sample Programs

The program below is written for an HP-9816 computer.

It assumes that the address for the 3184 is "1".

(1) HP-9816 serves to read the value for power from the

power meter, and direct print-out.

Overvoltage and overcurrent is tested for each sample.

10 DIM A$[20], B$[4]

20 ON INTR 7 GOSUB 120

30 CLEAR 701

40 OUTPUT 701;"F5V1A0H1S1"

50 B$=""

60 ENABLE INTR 7:2

70 WAIT 2

80 ENTER 701;A$

90 PRINT A$.B$

100 GOTO 50

110 !

120 S=SPOLL (701)

130 IF S>64 THEN B$="OVER"

140 RETURN

150 END

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 36

26

―――――――――――――――――――――――――――――――――――――――

Program Explanation

10 Defines the data area.

20 Defines the subroutine used when an OVER V/A

interrupt occurs.

30 Initializes the power meter.

40 Sets W as function, range for voltage Hi, current

Lo, header output, and service request mode.

50 Resets memory used for detecting OVER V/A.

60 Enables interrupt.

70 Wait for two seconds.

80 Reads data.

90 Prints out data.

100 Returns to line 50.

110 REM statement.

120 Polls the power meter, reads the status byte.

130 If OVER V/A has occurred, sets "OVER" in B$.

140 Returns to main routine.

150 Ends program.

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 37

27

―――――――――――――――――――――――――――――――――――――――

(2) With this program, HP-9816 reads voltage, current, and

power(single-phase) from the power meter and uses this

data to calculate power-factor. Input is taken from V

and A

.

1

12

10 CLEAR 701

20 OUTPUT 701;"F1V0A0H0S0"

30 WAIT 2

40 ENTER 701;V

50 PRINT V;"V"

60 OUTPUT 701;"F3"

70 WAIT 2

80 ENTER 701;A

90 PRINT A;"A"

100 OUTPUT 701;"F5"

110 WAIT 2

120 ENTER 701;W

130 PRINT W;"W"

140 PRINT USING "14A,Z,2D"; "Power Factor", W/(V*A)

150 END

Program Explanation

10 Initializes the power meter.

20 Sets V

as function, Lo range for both voltage and

12

current. No header output, no service request.

30 Allows two seconds for display to stabilize.

40 Reads data.

50 Prints out data.

60 - 130 Data from A 1 and W processed like V

.

12

140 Calculates power-factor, and prints out according to

prescribed format.

150 Ends program.

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 38

28

―――――――――――――――――――――――――――――――――――――――

―――――――――――――――――――――――――――――――――――

Chapter 5 3184-02 GP-IB Specifications

Page 39

29

G

6

d

e

6

―――――――――――――――――――――――――――――――――――――――

Chapter

Maintenance an

Servic

.1 Fuse Replacement

WARNIN

To avoid electric shock, disconnect the power cord

and the input cord from the connectors before

replacing the fuse.

Only use fuses of the specified type that is rated for

the specified current and voltage. Using a fuse that

does not meet the specifications or shorting the

fuse holder may cause an accident that might result

in injury or death.

M0.5 A/250 V (arc-quencing midget) 20 mm × 5.2

mm dia.

―――――――――――――――――――――――――――――――――――

Chapter 6 Maintenance and Service

Page 40

30

N

6

―――――――――――――――――――――――――――――――――――――――

Replacing the Fuse

.2 Service

CAUTIO

―――――――――――――――――――――――――――――――――――

Chapter 6 Maintenance and Service

If the unit is not functioning properly, check the batteries

and fuse blowing. If a problem is found, contact your

dealer or HIOKI representative. Pack the unit carefully so

that it will not be damaged during transport, and write a

detailed description of the problem. HIOKI cannot bear

any responsibility for damage that occurs during

shipment.

Page 41

Page 42

Loading...

Loading...