Page 1

INSTRUCTION MANUAL

3181-01

DIGITAL POWER HiTESTER

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use iii

Chapter 1 Introduction 1

1.1 Features 2

Chapter 2 Specifications 3

Chapter 3 Principle of Operation 5

3.1 Power Measurement 5

3.2 Current and Voltage Measurement 7

3.3 Integrated Watt Value 8

3.4 Crest Factor 10

Chapter 4 Names and Functions of Parts 11

Chapter 5 Operation 19

5.1 Preparing for Measurement 19

5.2 Power, Current and Voltage Measurement 22

5.3 Integrated Watt Value Measurement 23

Chapter 6 Applications 27

6.1 Determing the Power Factor 27

6.2 Connecting the Recorder 27

6.3 Printer Connection 28

6.4 External Control Terminal 30

6.5 Data Output Connector 31

6.6 Inputs Exceeding the Measurement Range 34

6.7 Three-Phase Three-Wire Connection 35

Page 4

Chapter 7 Maintenance and Service 37

7.1 Battery Replacement 37

7.2 Fuse Replacement 39

7.3 Cleaning 40

7.4 Service 40

Page 5

―――――――――――――――――――――――――――――――――――――――

I

I

ntroduction

Thank you for purchasing this HIOKI "3181-01 DIGITAL

POWER HiTESTER ." To get the maximum performance

from the unit, please read this manual first, and keep

this at hand.

nspection

When the unit is delivered, check and make sure that it

has not been damaged in transit. If the unit is damaged,

or fails to operate according to the specifications, contact

your dealer or HIOKI representative.

Accessory

Instruction Manual 1

Power cord 1

i

―――――――――――――――――――――――――――――――――――

Inspection

Page 6

ii

R

G

N

S

―――――――――――――――――――――――――――――――――――――――

afety Notes

This Instruction Manual provides information and

warnings essential for operating this equipment in a safe

manner and for maintaining it in safe operating

condition. Before using this equipment, be sure to

carefully read the following safety notes.

Safety symbols

In the manual, this mark indicates explanations

which it is particularly important that the user read

before using the equipment.

The following symbols are used in this Instruction

Manual to indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents extreme

DANGE

danger of accident resulting in death or serious

injury to the user.

Indicates that incorrect operation presents

WARNIN

significant danger of accident resulting in death or

serious injury to the user.

Indicates that incorrect operation presents

CAUTIO

possibility of injury to the user or damage to the

equipment.

NOTE

Denotes items of advice related to performance of

the equipment or to its correct operation.

―――――――――――――――――――――――――――――――――――

Safety Notes

Page 7

―――――――――――――――――――――――――――――――――――――――

R

G

.

N

iii

otes on Use

In order to ensure safe operation and to obtain maximum

performance from the unit, observe the cautions listed

below.

DANGE

WARNIN

Always connect the voltage cable to the secondary

side of a breaker. On the secondary side of a

breaker, even if the lines are shorted the breaker

can trip and prevent an accident. On the primary

side, however, the current capacity may be large,

and in the event of a short-circuit there may be a

serious accident.

This unit cannot be used on voltage lines of 250

Vrms. If the voltage exceeds 250 VAC, there will be

a short-circuit accident or electrocution accident

will result.

In order to prevent an electrical accident, do not

make any connections while the power supply or

the device to be measured is on. Turn off the

power for both devices before proceeding.

The power supply voltage for this unit is switchable

To avoid electrical accidents, check that the voltage

selector is set correctly for the supply voltage you

are using.

In order to maintain safety and assure the stable

operating performance of this unit, be sure to

connect the ground terminal to a proper ground.

―――――――――――――――――――――――――――――――――――

Notes on Use

Page 8

iv

N

―――――――――――――――――――――――――――――――――――――――

CAUTIO

NOTE

・ Before measurement, check the position of the range

switch. The unit may be damaged if current or voltage

exceeds the measurement limit is applied for a long

time.

・ Before using the unit, make sure that the sheathing on

the leads is not damaged and that no bare wire is

exposed. If there is damage, replace it with a new one.

・ Do not store or use the unit where it will be exposed to

direct sunlight, high temperatures, high humidity, or

condensation. If exposed to such conditions, the unit

may be damaged, the insulation may deteriorate, and

the unit may no longer satisfy its specifications.

・ To avoid damage to the unit, do not short the output

terminal and do not input voltage to the output terminal.

・ After initiating watthour measurement by pressing the

start button, do not alter the settings of the range switch,

the time setting dial or the time unit switch.

・ The 3181-01 is not certified for commercial metering.

・ The 3181-01 uses a voltage transformer (PT) and current

transformer (CT), which do not transmit DC. It is

therefore not possible to measure a signal (for example

full-wave or half-wave rectified) which includes a DC

component.

・ Do not use the 3181-01 to measure equipment with

ratings outside its ranges or whose current consumption

continuously exceeds 15A.

―――――――――――――――――――――――――――――――――――

Notes on Use

Page 9

1

1

n

―――――――――――――――――――――――――――――――――――――――

Chapter

Introductio

The 3181-01 is a compact, multifunction power meter

providing power, current, voltage and watthour

measurements on equipment such as consumer products.

Current and voltage are indicated as true rms values,

enabling accurate measurements even on distorted

waveforms.

The integrator contains a timer allowing integration time

to be set in ranges 1 to 99 minutes or 1 to 99 hours. With

several output terminals, the 3181-01 can be linked to a

data recorder or a printer, enabling easy recording of

measurement data.

―――――――――――――――――――――――――――――――――――

Chapter 1 Introduction

Page 10

2

1

―――――――――――――――――――――――――――――――――――――――

.1 Features

(1) Power, current, voltage and watthour measurements in a

single unit

(2) True rms reading of voltage and current values

unaffected by distorted waveforms

(3) Integrator timer can be set in ranges 1 to 99 minutes or 1

to 99 hours. (set timer at 00 for continuous integration)

(4) Auto-zero circuit ensures accurate power and watthour

measurements over long time spans.

(5) Three simultaneous outputs for power, current and

voltage

(6) Connecting the optional 3171 DIGITAL PRINTER to the

data output connector makes it possible to record power

consumption and average power values over time.

(7) Watthour data is protected against power failures by a

battery backup function.

(8) Compact, lightweight and highly portable

―――――――――――――――――――――――――――――――――――

Chapter 1 Introduction

Page 11

3

,

)

2

s

―――――――――――――――――――――――――――――――――――――――

Chapter

Specification

Display (Power meter) 1999 digit LCD

(Integrator) 999999 digit LCD

Sampling rate (Power meter) Approx. 3 samples/s

Measurement

functions

Timer setting ranges (Integrator) 1 to 99 min/1 to 99 h

Timer accuracy (Integrator) ±0.01 %±1 s (at 0℃ to 40℃)

Measurement range (Power meter) Power: 200/2000 W

Accuracy (Ambient

temperature: 23℃±5℃

line power: 50/60 Hz,

power factor: 1.0)

Frequency response

(40 to 500 Hz)

Influence of power

factor

Temperature

characteristics (in

range 0 to 40 ℃)

Maximum circuit

voltage

(Power meter) Single-phase active power

AC current and AC voltage (rms

reading)

(Integrator) Watthour value

Current: 2/20 A

Voltage: 0 to 250 V (resolution 1 V)

(Integrator) Lo: 200 W range 103/105Wh

Hi: 2000 W range 104/106Wh

(Power meter) Power: ±0.5% of rdg. ±0.3% of f.s.

Current: ±0.5% of rdg. ±0.3% of f.s.

Voltage: ±0.7% rdg. ±1 dgt.

(Integrator) ±1% rdg. ±1 dgt. (at input of 2.5% to

120% of f.s.)

(Power meter) Power: ±1% of max (power factor 1.0

Current, Voltage: ±0.5 % max

(Power meter) ±0.8% of rdg. max (power factor 0.5)

(Power meter) ±0.1% f.s./℃ max

(Integrator) ±0.05% f.s./ ℃ max

(Power meter) 250 Vrms

―――――――――――――――――――――――――――――――――――

Chapter 2 Specifications

Page 12

4

―――――――――――――――――――――――――――――――――――――――

Rated current (Power meter) 15 Arms (continuous rating)

Crest factor (Power meter) Power, current: 2 max at maximum

display or 30 A peak (lower value)

Voltage: 500 V peak value max

Output terminals (Power meter) 2 VDC/f.s. 2 VDC output for 200 V

input in voltage function only.

(Integrator) Hi: 5V, Lo: 0 V CMOS level

External control

terminal

Dielectric strength AC 2.4 kV/1 min (between input terminals and case)

Power supply 100, 120, 220, 240 VAC ±15%, 50/60 Hz

Rated power Approx. 3.5 W

Effect of power supply

voltage

Backup power R6P manganese batteries×3 (supplies more than 100

Dimensions Approx. 218 (W) × 85 (H) × 240 (D) mm

Mass 2.6 kg

Accessories Power cord 1

Options 3171 DIGITAL PRINTER

(Integrator) OFF: Open (or Hi: 5 V)

ON: Closed (or Lo: 0V)

Specified accuracy satisfied within above specified

line voltage ranges.

hours backup capability)

(excluding protrusions)

Instruction Manual 1

9084 CARRYING CASE

9149 CARRYING CASE

―――――――――――――――――――――――――――――――――――

Chapter 2 Specifications

Page 13

5

y

h

3

n

3

―――――――――――――――――――――――――――――――――――――――

Chapter

Principle of Operatio

.1 Power Measurement

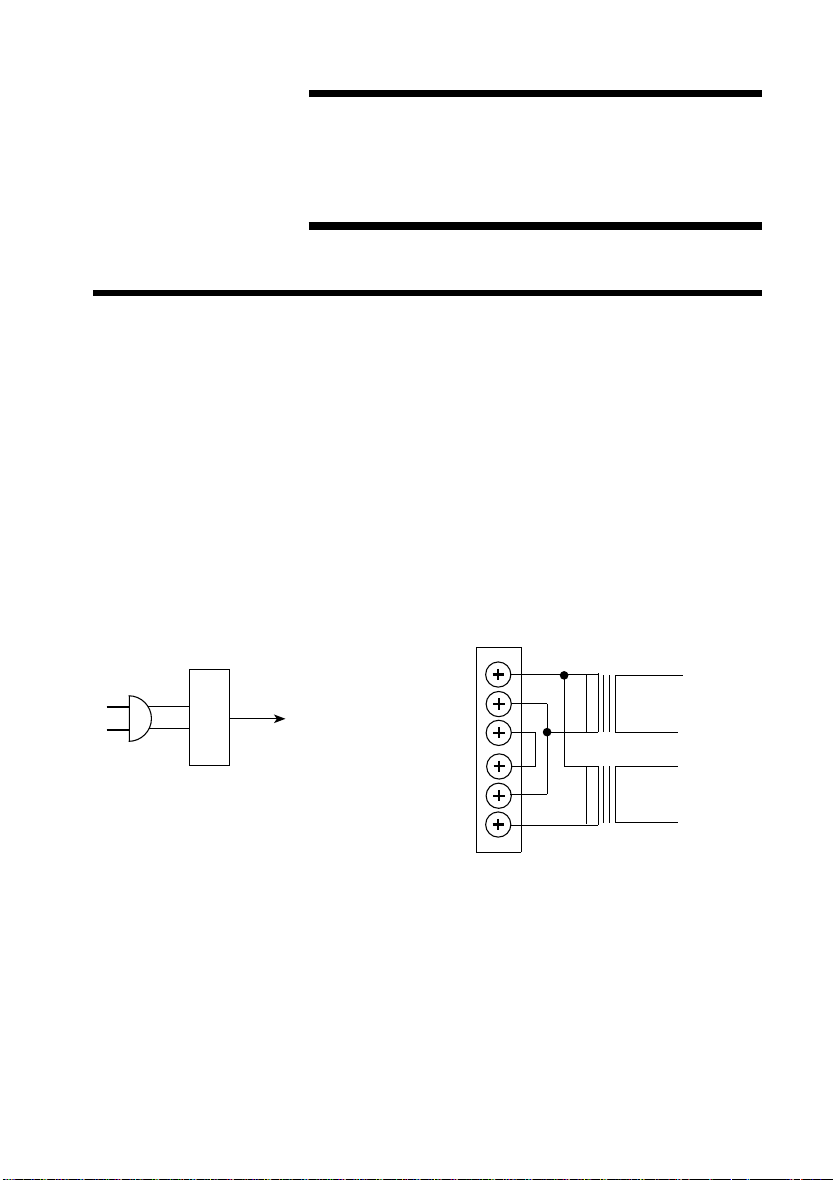

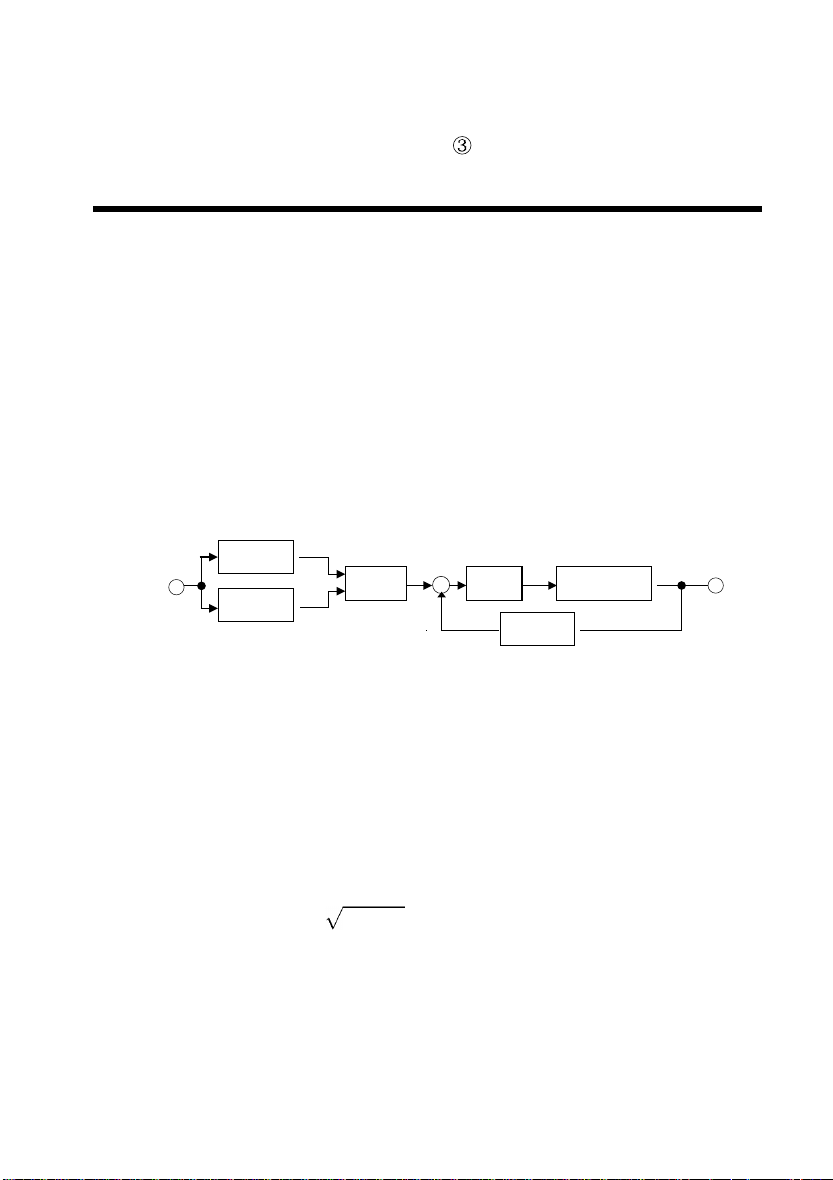

Figure 3.1-1 and 2 show the block diagram. The line

voltage and current of the device under measurement are

detected by a voltage transformer (PT) and current

transformer (CT), respectively. The resulting detected

signals are voltage-level converted and input to a

multiplier. Since the DC component of the output of this

multiplier is proportional to the active power, after the

level is adjusted, this is displayed and output as the

power value.

Power suppl

To eac

section

Figure 3.1-1 The Block Diagram 1

INPUT

OUTPUT

PT

To V IN

To A IN

CT

―――――――――――――――――――――――――――――――――――

Chapter 3 Principle of Operation

Page 14

6

e

n

o

s

r

e

n

3

it

3

it

r

r

Power output

Voltage output

Current output

To VF converter

V IN

A IN

r

z

e

Figure 3.1-2 The Block Diagram 2

)

)

θ

―――――――――――――――――――――――――――――――――――――――

Low-pas

filter

Rms

conversio

Rms

conversio

Division

(106)

1 s pulse 1 min pulse 1 h puls

6-digit

counter

Division

(60)

-1/2 dig

A-D

Decode

driver

Division

(60)

Multiplie

VF

converte

32.768 kH

Clock

oscillato

Auto-zer

Absolut

value

Absolut

value

Division

(215)

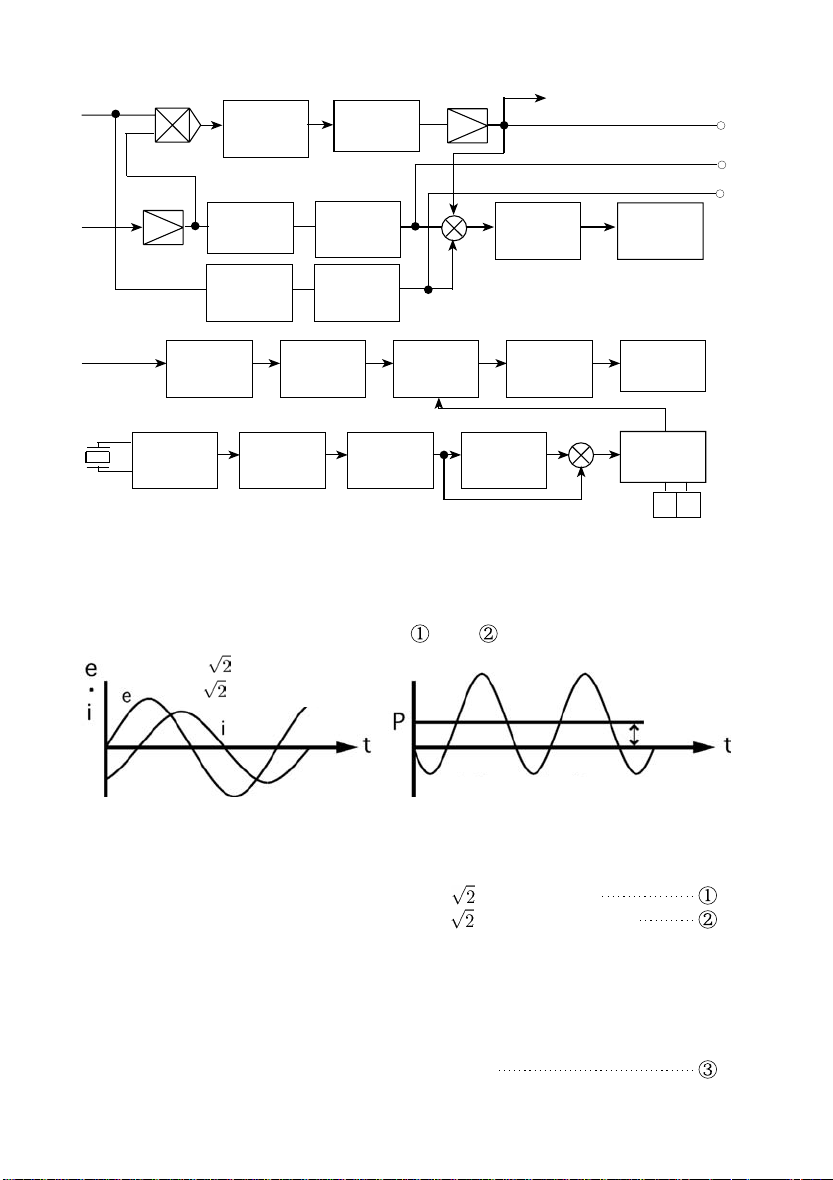

The voltage and current waveforms in Figure 3.1-3 are

described by equations and .

e = Ecosωt

i = lcos(ωt+θ

-1/2 dig

LCD

6-digit

LCD

Timer

9 9

P=Elcos

P=e・i=Elcosθ+ Elcos(2ωt+θ

Figure 3.1-3 Power Calculation Waveform

Sinewave AC voltage e = Ecosωt [V]

Sinewave AC current i = Icos(ωt+θ) [A]

The product of e and i representing the voltage-current

product is the instantaneous power.

Instantaneous power p = e・i = 2EIcosωt・cos(ωt+θ)

= EIcos(2ωt+θ) + EIcosθ

[W]

―――――――――――――――――――――――――――――――――――

Chapter 3 Principle of Operation

Page 15

7

r

o

a

E

)

─────

3

―――――――――――――――――――――――――――――――――――――――

Thus, the active power P = EIcosθ [W] is the DC

component of the product of the voltage and current (the

second term in equation ( )).

.2 Current and Voltage Measurement

When measuring AC signals using a general-purpose

measuring instrument, an average-value detection is

performed, after which conversion to the rms value is

made. Therefore, measurements on distorted or otherwise non-sinusoidal waveforms will result in errors. In

the 3181-01, the true rms value is read by an absolute

value detection circuit and a true rms value conversion

circuit.

lnx

Ei(t)

lnx

+

x

e

ー

L. P. Fadde

lnx

True Rms Conversion Circuit

In the true rms conversion circuit shown in the figure

above, if we observe point a, we find the following

relationship.

─────

ln Ei(t)

──────

ln Ei2(t)

∴ Eo =

────

+ln E(t)

=lnEo

2

i2(t

- ln Eo = ln Eo

Now let Ei(t) be the result of performing absolute-value

detection on the voltage and current signals from the

voltage transformer and current transformer, then the

output voltage Eo is proportional to the voltage-current

rms value.

―――――――――――――――――――――――――――――――――――

Chapter 3 Principle of Operation

E

Page 16

8

3

―――――――――――――――――――――――――――――――――――――――

.3 Integrated Watt Value

The DC voltage Ei(2 V f.s.) is proportional to the power

measured by the power meter. The V-F converter

converts Ei into a pulse train, the pulses are counted by

the counter and the result is displayed as the watthour

value. (V-F conversion rate α = 27.7....(Hz/V))

For example, if 100 [W] is the power measured in the low

range (200 [W] f.s.), the voltage Ei input to the V-F

converter is given by the following formula.

Ei = 2 [V](f.s.)×100 [W] /200 [W]= 1 [V]

The time-unit switch on the 3181-01 front panel is also

the integrator RANGE switch. If integration is

performed at Wh:Lo (TIME:MIN) for one hour, the

resulting integration value N is calculated thus:

N=α [Hz/V]×Ei [V]×T [s]

= 27.7.... [Hz/V]× 1 [V]× 3600 [s]

= 100000

By interlocking ranges and setting the decimal point at

the fourth digit from the right, it is possible to directly

display watthour values of up to 100.000 Wh. If

integration is performed for one hour with Wh:Hi

(TIME:HOUR) set, after the divide-into-100 circuit, the

following value is obtained:

N = 27.7.... [Hz/V]× 1 [V]× 3600 [s]× 1/100

= 1000

If the decimal point is set at the second digit from the

right in this case, the value 100.0 Wh is displayed. As

the above discussion shows, the maximum display value

of the integrator can be changed by different

combinations of time units and ranges (table on the next

page).

―――――――――――――――――――――――――――――――――――

Chapter 3 Principle of Operation

Page 17

9

e

―――――――――――――――――――――――――――――――――――――――

The Wh/TIME and the time setting dial on the 3181-01

front panel are used to set the integration time in the

range 1 to 99 minutes or 1 to 99 h. Once the desired time

is set, pressing the START switch resets the internal

circuits and integration begins. When the set time is

reached, the counter output is put on hold. If the

integrator is started with the timer set to "00", it

performs continuous integration. The HOLD/RUN switch

on the front panel is used to stop the counter and start

again. Below the V-F converter there is a backup battery

which maintains continuous operation in the event of a

power failure, so there is no danger of loosing watthour

values measured up to the power failure.

Integrator Maximum Display Values

Rang

Time unit

TIME: MIN

Wh: Lo

TIME: HOUR

Wh: Hi

―――――――――――――――――――――――――――――――――――

Lo(200W) Hi(2000W)

999.999 Wh 9999.99 Wh

99999.9 Wh 999999 Wh

Chapter 3 Principle of Operation

Page 18

10

3

―――――――――――――――――――――――――――――――――――――――

.4 Crest Factor

Crest factor is a measure of the dynamic range of a

measurement. In measurements in which the peak value

is high but the rms value is low, if the measuring

instrument range is selected based on the rms value,

waveform peaks will exceed the dynamic range of the

circuit, causing errors since the circuit is not operating

linearly in this region.

The relation between the crest factor, peak value and rms

value is defined as follows.

Crest factor = Peak value/rms value

The 3181-01 has the following specifications.

AC voltage

AC current

Single-phase

active power

For example, using the 3181-01 to measure AC current in

the Lo range, since the maximum display value is 2 A,

the largest allowable peak value on the input being

measured can be calculated as follows.

From the definition,

Peak value = rms value × crest factor

500 V peak value max

2 max at maximum display value or 30 A

peak (lower value)

same as for voltage and current

=2× 2

= 4 [A]

―――――――――――――――――――――――――――――――――――

Chapter 3 Principle of Operation

Page 19

11

Rear Panel

910111213

1415161718

Front Panel

123

45678

4

of

ts

―――――――――――――――――――――――――――――――――――――――

Chapter

Names and Functions

Par

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 20

12

123

4

e

―――――――――――――――――――――――――――――――――――――――

POWER switch

Allow approximately five minutes of warm-up before

performing measurements.

POWER METER display

This 3 1/2 digit LCD display has a maximum display

value of 1999. The function switches are selected to

enable it to indicate measured voltage, current and power

values.

If the input exceeds the maximum display value, the

uppermost digit will appear as 1 and the decimal point

will be displayed, while the lower three digits will be

blanked.

If the voltage of the backup battery falls below 4 V, BATT

will appear in the lower left corner.

INTEGRATOR display

This 6-digit LCD display has a maximum display value of

999999. If the integration value exceeds this, the decimal

point will occupy the uppermost digit. It will blink at

approximately one-second intervals, and integration will

start again from 000000. The colon (:) after the second

digit from the left blinks when the display is running at

approximately one-second intervals, and is blanked when

the display is on hold.

RANGE and functions (WATT, ACA, ACV) switches

These switches are used to switch the display between

power, current and voltage.

Range

switch

Hi

Lo

Function

switch

WATT 1999 W

AC A 19.99 A (Rating is 15 A)

WATT 199.9 W

AC A 1.999 A

Maximum display valu

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 21

13

567

―――――――――――――――――――――――――――――――――――――――

The maximum display values for voltage measurements

are independent of RANGE switch settings and are ACV:

"1999" V (0 to 250 V)

START switch

Immediately the START switch is pressed the watthour

value accumulated up to that time is cleared and

integration begins anew from 000000.

Start has priority over hold, so if the INTEGRATOR display

is on hold when the START switch is pressed, integration

begins immediately from zero.

HOLD/RUN switch

This button stops the INTEGRATOR display and clears the

hold condition. When the HOLD/RUN switch is pressed,

the INTEGRATOR display value is held. If the button is

pressed a second time, the display returns to the

watthour value accumulated from the time integration

began and display is continued.

If the INTEGRATOR display is held because the preset time

period has elapsed, this button cannot be used to release

the hold condition.

This is an important point, because if a mistake is made

pressing the start and HOLD/RUN switches, the watthour

value is invalidated.

Wh/TIME switch (time unit switch)

This switch is used to change the time unit for the time

setting dial described in the next section and the

integrator range simultaneously.

Switch setting TIME Wh

HOUR Hi

MIN Lo

Refer to Sections 3.3, "Integrated Watt Value" and 5.3,

"Integrated Watt Value Measurement."

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 22

14

8

910

―――――――――――――――――――――――――――――――――――――――

TIME SET dial

This dial is used with the Wh/TIME to set the integration

time interval.

For example, if the

Wh/TIME is set at HOUR and the time

setting dial is set to 24, integration is performed

continuously for 24 hours after the integrator

START

switch is pressed and then automatically stops.

If the dial is set to "00", the timer does not operate and

continuous integration is performed.

Data output connector[DATA OUTPUT]

(Integrated watt value measurements only)

This connector is used to connect the 3171. Do not

connect any other equipment to this connector, as

applying voltage to or shorting the terminals of this

connector can cause damage.

Battery compartment[BATTERY BOX]

This holds the three R6P manganese batteries used for

power backup. The batteries have a life of more than 100

hours when run continuously. BATT shown in the lower

left corner of the power display indicates that the backup

batteries have run down. When this happens, the

batteries must be replaced immediately. (Refer to Section

7.1, "Battery Replacement.")

If the power switch is turned on while the AC plug is

disconnected, only the INTEGRATOR display will operate.

This indicates that the backup power batteries are

functioning normally, it is not a fault. However,

operation without the AC plug inserted should not be

continued for any length of time, as it will run down the

backup batteries.

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 23

15

1

N

Output voltage

Input

applied

Time

Output ≒ stabilized

Response Time

2

G

―――――――――――――――――――――――――――――――――――――――

1

Output terminals [OUTPUT]

CAUTIO

To avoid damage to the unit, do not short the output

terminal and do not input voltage to the output terminal.

These output terminals output DC voltages proportional

to the measured values of current and power (2 VDC/f.s.).

The voltage output (Ch1) is 2 VDC for 200 VAC.

The three channels are output simultaneously, regardless

of the setting of the function switches. These channels

are assigned as follows.

CH1: AC voltage

CH2: AC current

CH3: Active power

The output response time is as follows.

WARNIN

―――――――――――――――――――――――――――――――――――

T ≒ 2.3 s for voltage and current

T ≒ 3.3 s for power

1

Ground terminals [

]

In order to maintain safety and assure the stable

operating performance of this unit, be sure to

connect the ground terminal to a proper ground.

Chapter 4 Names and Functions of Parts

Page 24

16

314151617

―――――――――――――――――――――――――――――――――――――――

1

Fuse holder

The 3181-01 requires a fuse with ratings of 250 V and 3 A.

The 3181-01 power cord must be removed from the socket

before replacing the fuse. (Refer to Section 7.2, "Fuse

Replacement.")

Voltage selector

This is used to select the line voltage for the 3181-01.

Ensure that the number indicating the line voltage

selection is aligned with the arrow (↑) below the selector

switch.

AC inlet

This inlet is used to apply line power to the instrument

using the accessory power cord. A line filter and a fuse

are built in.

Measuring terminal

These terminals are used to make connection between the

power line and the equipment being measured. When

making connections, always use conductors which have

sufficient current carrying capacity, tighten them securely

and be careful to avoid looseness and shorts.

External control terminal[EXT.CONTROL]

Leave this terminal open (or at Hi level: 5 V) during

normal operation. It is closed (or at Lo level: 0 V) during

integration to obtain the watthour value for the specified

time period. As soon as this terminal is closed, the

instrument goes directly into operation as if the START

switch had been pressed. That is, the integration value

accumulated up to that moment is cleared and integration

is begun anew. If the external control terminal is opened

during integration, the instrument behaves just as if the

HOLD/RUN switch had been pressed and the accumulated

integration value is displayed. (Refer to Section 6.4,

"External Control Terminal.")

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 25

17

8

N

―――――――――――――――――――――――――――――――――――――――

1

Handle

CAUTIO

The handle can be used as a stand to incline the

instrument. Force should not be applied to the

instrument from above when using it in this manner.

As shown in the figure below, the handle may be rotated

by sliding the grip at the sides of the handle in the

direction of the SLIDE TO ROTATE arrow. When the

proper position has been attained, push the slide in the

LOCK arrow direction. The handle may be set at 30 °

detents to fix it in position.

E

T

A

T

O

R

O

T

E

D

S

I

L

Handle

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 26

18

―――――――――――――――――――――――――――――――――――――――

―――――――――――――――――――――――――――――――――――

Chapter 4 Names and Functions of Parts

Page 27

19

G

.

5

n

5

―――――――――――――――――――――――――――――――――――――――

Chapter

Operatio

.1 Preparing for Measurement

WARNIN

NOTE

The power supply voltage for this unit is switchable

To avoid electrical accidents, check that the voltage

selector is set correctly for the supply voltage you

are using.

In order to prevent an electrical accident, do not

make any connections while the power supply or

the device to be measured is on. Turn off the

power for both devices before proceeding.

In order to maintain safety and assure the stable

operating performance of this unit, be sure to

connect the ground terminal to a proper ground.

To avoid damage to the unit, do not input a

voltage/current exceeding the specified maximum to

the input terminals.

Because of the internal circuit design, measurement of

load with a certain frequency component will cause cyclic

fluctuation (instability) in the power reading.

This has been observed especially for distorted waveforms

with large harmonic components in multiples of 512 Hz.

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 28

20

―――――――――――――――――――――――――――――――――――――――

(1) First make sure that the voltage selector switch agrees

with the line voltage before measuring.

(2) Connect the power lines and the equipment to be

measured to the measurement terminal strip as shown in

Figure 5.1-1 or 5.1-2 (either way).

When measuring only voltage or current, refer to Figure

5.1-3 or 5.1-4.

(3) Turn the power on.

(4) Leave the instrument powered ON for approximately five

minutes of warm-up.

(5) Set the RANGE switches appropriate to the current level of

the equipment to be measured.

(Lo range: 2 A max; Hi range: 15 A max). If these are not

known, select the Hi range.

SOURCE

LOAD

(Equipment to

be measured)

Figure 5.1-1 Power, Current and Voltage Measurement

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 29

21

―――――――――――――――――――――――――――――――――――――――

SOURCE

LOAD

Figure 5.1-2 Power, Current and Voltage Measurement

SOURCE

LOAD

Figure 5.1-3 Voltage Measurement Only

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 30

22

5

―――――――――――――――――――――――――――――――――――――――

SOURCE

Figure 5.1-4 Current Measurement Only

.2 Power, Current and Voltage

Measurement

Once all preliminaries have been completed, power,

current, and voltage are measured simply by setting the

function switches.

If the display scale exceeds in the Lo range when power

and current are being measured, switch the range to Hi.

Measurement accuracy goes down in the Hi range when

the display count falls below 200. When this happens,

switch the range to Lo.

LOAD

(Equipment to

be measured)

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 31

23

e

5

―――――――――――――――――――――――――――――――――――――――

.3 Integrated Watt Value Measurement

(1) Set the function switch to power measurement and check

that the power consumption of the equipment to be

measured does not exceed the power display scaly. Then

the integrated watt value measurement can be measured

with the function switch set to WATT, ACA, or ACV.

(2) Set the

power to be measured and the measurement time period.

Set the TIME SET dials and the timer to the desired

integration time period. If integration is to extend over a

long time beyond the timer setting range, if integration

time is controlled via the external control terminal, or if

the 3171 is connected, this dial should be set to "00" for

continuous integration which will avoid all problems.

A table below gives the relation between the integrator

maximum display value and the timer setting ranges.

Integrator Maximum Display Value and Timer Setting

Ranges

Wh/TIME switch to a value appropriate to the

Rang

Time unit

TIME: MIN

Wh: Lo

TIME: HOUR

Wh: Hi

Lo(200 W) Hi(2000 W)

999.999 Wh 9999.99 Wh

Timer:1 to 99 min, continuous(00)

99999.9 Wh 999999 Wh

Timer:1 to 99 h, continuous(00)

(3) Integration begins at the moment the START switch is

pressed (Figure 5.3-1)

(4) The settings of the RANGE switches, Wh/TIME and TIME

SET

dials should not be altered during measurement. If

they are, the measurement value displayed will be

invalid.

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 32

24

3

―――――――――――――――――――――――――――――――――――――――

(5) To check the integration value, press the HOLD/RUN

switch. This stops the INTEGRATOR display and displays

the integrated watt value accumulated up to that point.

(Refer to Figure 5.3-2.)

(6) To continue integration press the HOLD/RUN switch again.

Integration continues under the conditions established

when the START switch was pressed once the hold

condition is cleared. (Refer to Figure 5.3-3.)

(7) The display value can be put on hold as often as desired.

The value from the time integration was initiated by

pressing the START switch can be read at any time simply

by pressing the HOLD/RUN switch.

(8) If the integration time is set, once that time is reached

the INTEGRATOR display automatically stops and goes into

the hold condition.

In this situation, the hold condition can only be cleared by

pressing START switch and restarting integration.

(9) If the integration value exceeds the maximum integrator

display value, the uppermost digit appears as a blinking

decimal point. The display starts from zero again. Thus,

the integration value after this point can be obtained by

simply adding 1,000,000 to the display value.

The time elapsed before an overflow occurs is obtained

from the equations and the graph in Figure 5.3-4.

The count starts from

0 with the colon

blinking.

The colon erased and

the count is on hold.

Count returns to

integration conditions

initially set up with the

colon blinking.

Figure 5.3-1 Figure 5.3-2 Figure 5.3-

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 33

25

y

(count)

―――――――――――――――――――――――――――――――――――――――

Power displa

Time T to overflow time

Figure 5.3-4 Time Elapsed to Scale Overflow

For MIN/Lo: T = 10,000/power display

For HOUR/Hi: T = 1,000,000/power display

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 34

26

―――――――――――――――――――――――――――――――――――――――

―――――――――――――――――――――――――――――――――――

Chapter 5 Operation

Page 35

27

=

=

]

N

6

s

6

6

―――――――――――――――――――――――――――――――――――――――

Chapter

Application

.1 Determing the Power Factor

The 3181-01 measures active power, current and voltage.

The power factor of the equipment under measurement is

calculated from these measured values.

Power factor cosθ

Thus to get the power factor, divide the measured power

by the product of voltage and current.

Effective power [W]

Reactive power [VA

(WATT) W

(ACV)V × (ACA)A

.2 Connecting the Recorder

CAUTIO

―――――――――――――――――――――――――――――――――――

To avoid damage to the unit, do not short the output

terminal and do not input voltage to the output terminal.

The 3181-01 has three analog output terminals on the

rear panel. They are for voltage, current, and power

which are always active simultaneously. These can be

connected to the input terminals of a recorder. It enables

to observe and record the measured values.

Note that although the analog outputs of current and

power are 2 VDC/f.s., 2 VDC is output for 200 VAC input

in the voltage function only.

Chapter 6 Applications

Page 36

28

6

―――――――――――――――――――――――――――――――――――――――

.3 Printer Connection

The 3181-01 has a data output connector on the rear

panel. The integrated watt and average power values

can be printed out by connecting the 3171 at this

connector.

NOTE

・ Do not put the

the 3171 to print out integration values. Increases in the

integration value will be ignored and the value when the

display is put on hold will be printed out continuously.

The same situation will arise if the display is

automatically held by the timer. Thus, the timer setting

also must be taken into account when using the printer.

・ If the 3181-01 is connected to an old version of the 3171

(i.e., one produced before June, 1982), the units that can

be printed are those on the 3171 function switches: kWh,

kVar or kVarh.

・ The old model printers must be modified to print units W

and Wh. HIOKI will perform the necessary modifications

on request.

INTEGRATOR display on hold when using

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 37

29

s

h

e

..

t

d

.

tt

l

s

.

e

―――――――――――――――――――――――――――――――――――――――

The 3171 Print Exampl

Printed on the 3171 over a time interval of 10 minute

0:00 to 00:30 total integrated watt value W

00:20 to 00:30 average power W

00:20 to 00:30 10 minutes integrated watt valu

Wh (demand value)

The 3181-01 START switch on.

prints START and Wh

The 3171 Manual print and external prin

The 3171 external print terminal closed...

prints EXT.PRINT, the integrated watt value, an

the time elapsed in seconds.

The 3171 manual print ON...

prints MANUAL, the integrated watt value, and

the time elapsed in seconds.

Prints in normal time intervals

The 3181-01 START switch ON

Under external contro

The 3181-01 external control terminal is

opened ... prints EXT.STOP, the integrated wa

value and the time elapsed in seconds.

The 3181-01 external control terminal i

closed ... prints START and Wh.

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 38

30

N

I

e

(

)

T

e

S

h

R

y

E

C

L

E

C

L

E

C

L

6

―――――――――――――――――――――――――――――――――――――――

.4 External Control Terminal

CAUTIO

NOTE

・ To avoid damage to the unit, do not short the output

terminal and do not input voltage to the output terminal.

・ To avoid electric shock, the wiring which is used for

making the connections to the current input terminals

should have sufficient current carrying capacity and

insulation.

To avoid malfunction, use a shielded wire or a twisted

pair, which should be as short as possible, to the external

control terminal.

The 3181-01 has an external control terminal for external

control of the integrated watt value measurement time.

XT.

ONTRO

witc

XT.

Drive voltage

ela

ime bas

ntegration tim

ONTRO

XT.

ONTRO

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 39

31

6

―――――――――――――――――――――――――――――――――――――――

.5 Data Output Connector

(Integrated watt value only)

The signal levels and timing of the outputs from the data

output connector are as follows.

Pin No. Name

Function

1 1MP 1 Minute pulse

2 RST Reset

Output when the START switch is pressed or when

the external control terminal is closed.

3

4

5

6

7

8

T1

―――

T2

―――

T3

―――

T4

―――

T5

―――

T6

Digit signal

―――

T1

corresponds to the most significant digit.

9

10 H/R Hold/Run

Output Lo level (0 V) when the power display is put

on hold, and Hi level (5 V) in all other cases.

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 40

32

5

―――――――――――――――――――――――――――――――――――――――

Pin No. Name

11 E.S

――――

External Stop

Function

Output when power measurement is stopped by

external control.

12 CK81 Check the 3181-01.

The 3171 identification signal, directly coupled to the

3181-01 CMOS logic power line ( + 5 V).

13

14

15

16

DP3

DP4

DP5

Decimal Point 3 to 5

Indicate the INTEGRATOR display decimal point

position, outputs Hi level (5 V) signal when display is

turned on.

DP3 DP4 DP

17

18

19

20

D

BCD data

C

Synchronously output with the digit signals. (D is the

B

most significant digit.)

A

21 1SP 1 Second Pulse

22

23 VFC VF converter output

Output the signal to convert the DC voltage

proportional to the measured power value to a pulse.

24 GND Connected to the circuit common.

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 41

33

Hold

H

d

O

H

C

D

al

t

E

l

s

:

s

s

s

s20s

0.5 s

s

40 s

s

―――――――――――――――――――――――――――――――――――――――

xternal contro

old

60 μ

60 μ

0.5

5V

0V

old cleare

pen(5 V)

losed(0 V)

70 μ

5V

0V

2.8 m

T=36/V (ms), V

90 μs

80 μ

720 μ

―――――――――――――――――――――――――――――――――――

C voltage (2 V/f.s.) proportion

o the measured power value.

5V

0V

Chapter 6 Applications

Page 42

34

6

―――――――――――――――――――――――――――――――――――――――

.6 Inputs Exceeding the Measurement

Range

If the voltage or current level of the equipment under

measurement exceeds the measurement range of the

3181-01, measurement should be performed after stepping

these down using a voltage transformer (PT) and/or

current transformer (CT). Refer to figure below for the

proper method of connection. Note, however, that such

transformers have a phase error which can greatly affect

the power measured value. An important consideration

has to be taken into if accurate power measurement is

required.

PT

SOURCE

Voltage/Current Transformer Measurement Method

Power = (Watt display value) × (PT ratio) × (CT ratio)

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

CT

LOAD

LOAD

Page 43

35

E

E

g

6

―――――――――――――――――――――――――――――――――――――――

.7 Three-Phase Three-Wire Connection

Two 3181-01 units may be used to calculate the algebraic

sum of measured values, enabling the determination of

three-phase power. A voltage or current transformer can

be used if measurement ranges are exceeded (Refer to

figures below).

SOURC

SOURC

Three-Phase Power Measurement

PT

PT CT

CT

Three-Phase Power Measurement usin

Voltage/Current Transformers

CT

PT

LOAD

CT

LOAD

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 44

36

―――――――――――――――――――――――――――――――――――――――

―――――――――――――――――――――――――――――――――――

Chapter 6 Applications

Page 45

37

G

7

d

e

7

―――――――――――――――――――――――――――――――――――――――

Chapter

Maintenance an

Servic

.1 Battery Replacement

WARNIN

To avoid electric shock when replacing the

batteries, first disconnect leads from the object to

be measured. Also, after replacing the batteries

always replace the cover before using the unit.

When replacing the batteries, do not install old

batteries with new ones, and do not mix different

types of batteries. Check the battery polarity

carefully when inserting the batteries.

Do not short-circuit used batteries, disassemble

them, or throw them in a fire. Doing so may cause

the batteries to explode.

Be sure to dispose of used batteries according to

their type in the prescribed manner and in the

proper location.

―――――――――――――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 46

38

―――――――――――――――――――――――――――――――――――――――

(1) Remove the battery box cover.

(2) Remove the battery snap.

(3) Slide out the battery box and replace the batteries.

(4) Slide the battery box back in and replace the battery snap

and battery box cover.

―――――――――――――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 47

39

G

7

―――――――――――――――――――――――――――――――――――――――

.2 Fuse Replacement

WARNIN

To avoid electric shock when replacing the fuse,

turn the power switch off and disconnect the power

code from the connector and remove the object to

be measured.

Only use fuses of the specified type that is rated for

the specified current and voltage. Using a fuse that

does not meet the specifications or shorting the

fuse holder may cause an accident that might result

in injury or death.

3 A/250 V 20 mm × 5 mm dia.

(1) Make sure that the power switch is OFF.

(2) Remove the power cord from the AC inlet.

(3) Take off the AC inlet holder using a coin or a screwdriver.

(4) After correctly disconnecting the fuse, insert the new one.

Use only midget fuses with ratings of 250 V and 3 A.

(5) Return the fuse holder to its original position and attach

it to the AC inlet.

―――――――――――――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 48

40

N

N

7

7

―――――――――――――――――――――――――――――――――――――――

.3 Cleaning

CAUTIO

・ Gently wipe dirt from the surface of the unit with a soft

cloth moistened with a small amount of water or mild

detergent.

・ Do not try to clean the unit using cleaners containing

organic solvents such as benzine, alcohol, acetone,

ether, ketones, thinners, or gasoline. They may cause

discoloration or damage.

.4 Service

CAUTIO

If the unit is not functioning properly, check the batteries

and fuse blowing. If a problem is found, contact your

dealer or HIOKI representative. Pack the unit carefully so

that it will not be damaged during transport, and write a

detailed description of the problem. HIOKI cannot bear

any responsibility for damage that occurs during

shipment.

―――――――――――――――――――――――――――――――――――

Chapter 7 Maintenance and Service

Page 49

Page 50

Page 51

Loading...

Loading...