Page 1

INSTRUCTION MANUAL

3174

3174-01

AC AUTOMATIC

INSULATION

/

WITHSTANDING HiTESTER

Page 2

Page 3

Contents

i

Contens

Introduction.................................................................................1

Confirming Packa g e Co n te n ts.............. .. ... ..................... ... ......... 1

Safety Informa tio n ............. .. ...................... .. ...................... .........2

Operating Precautions................................................................4

Chapter 1

Overview ___________________________________ 7

1.1 Product Overview .................................. .......................7

1.2 Features .......................................................................7

1.3 Names and Fu nctions of Parts . ... .. ... ..................... .......9

1.3.1 3174 (3174-01) ................................................................9

1.3.2 Display ..........................................................................12

1.3.3 Model 9615 H.V.Test Lead ...........................................13

1

2

3

1.4 External Dimensions ..................................................14

1.5 Testing Pro c e s s .............. .. ...................... ...................15

Chapter 2

Testing Arrangements ________________________ 17

2.1 Arrangements Work Flow ...........................................17

2.2 Connecting the Protective Conductor Terminal .........18

2.3 Connecting the Power Cord ............................ ...........19

2.4 Connecting the Test Lead ..........................................20

2.4.1 When using the Contact Check Function ......................21

2.4.2 When not using the Contact Check Function ................23

2.5 Turning the Power On and Off ...................................24

2.6 Pre-test Check ............................ ..................... ..........26

Chapter 3

Withstand-Voltage Test _______________________ 29

3.1 Setting the Test-Conditions ........................................31

Appendix

3.1.1 Setting the Test-Voltage Value .....................................32

3.1.2 Setting the Upper (Lower) Limit Value ..........................33

3.1.3 Setting the Test Time Timer ..........................................34

Index

Page 4

ii

Contents

3.1.4 Setting the Ramp-up (Ramp-down) Time Timer ...........35

3.1.5 Setting the Test-Frequency ......................... ..... .... ..... ...36

3.1.6 Setting the Initial voltage for ramp-up ...........................37

3.1.7 Setting the Confirm a tion Vol ta ge

used for upper and lower-limits for Contact Check .......38

3.2 Starting a Tes t ..... .. .. ...................... .. ...................... .... 4 0

3.3 Terminate the Test .................................................... 42

3.4 Displaying th e T es t Re su lt . .. ... .. ...................... .. ... .. .... 44

3.4.1 "PASS" Determination ..................................................45

3.4.2 "FAIL" Determination ....................................................46

Chapter 4

Insulation-Resistance Test_____________________47

4.1 Setting the Te st Co n dit io ns ......................... ... .. ... ...... 49

4.1.1 Setting the Test-Voltage Value ............................. ..... ...50

4.1.2 Setting the Upper (Lower) Limit Value ..........................51

4.1.3 Setting the Test Time Timer .........................................53

4.1.4 Setting the Delay Time .................................................54

4.1.5 Setting the Confirm a tion Vol ta ge

used for upper and lower-limits for Contact Check .......55

4.2 Starting a Tes t ..... .. .. ...................... .. ...................... .... 5 7

4.3 Terminate the Test .................................................... 59

4.4 Displaying th e T es t Re su lt . .. ... .. ...................... .. ... .. .... 61

4.4.1 "PASS" Determination ..................................................62

4.4.2 "FAIL" Determination ....................................................63

4.4.3 Influence of capacity on the test result (reference data) 65

Chapter 5

Automatic Test ______________________________69

5.1 Setting the Te st Co n dit io ns ......................... ... .. ... ...... 70

5.2 Starting a Tes t ..... .. .. ...................... .. ...................... .... 7 1

5.3 Terminate the Test .................................................... 73

5.4 Displaying th e T es t Re su lt . .. ... .. ...................... .. ... .. .... 75

5.4.1 "PASS" Determination ..................................................76

5.4.2 "FAIL" Determination ....................................................78

Chapter 6

Useful Functions_____________________________79

6.1 Functions for carrying out the tests safely ................. 79

6.1.1 Key-lock Function .........................................................79

Page 5

6.1.2 Momentary Out .............................................................80

6.1.3 Double Action ................................................................81

6.1.4 START Protection .........................................................82

6.1.5 Output-Voltage Restricting ............................................83

6.2 Display Hold ( H old Fu n ctio n ) ........... .. .. ... ...................84

6.2.1 PASS Hold ....................................................................85

6.2.2 FAIL Hold ......................... ............................ ..... ..... .......86

6.2.3 STOP Hold ....................................................................87

6.3 Evaluate even for forced termination of test ...............88

6.4 Continue testing even after FAIL result is shown

iii

Contents

3

(Continuous Test Mode, Only Withstanding-Test) .....89

6.5 Limiting the FAIL Hold Cancellation (FAIL mode) ......90

6.6 Changing the Output Voltage

during the withstanding test .......................................91

6.7 Insulation-Resistance Test Termination Mode ...........92

6.8 Auto-range for insulation-resistance test ....................95

6.9 Status Out .............................. ...................... .. ............96

Chapter 7

Saving / Loading test conditions ________________ 99

7.1 Saving the Test Conditions ........................................99

7.2 Loading the Test Conditions ....................................102

Chapter 8

External Interface_____________ __________ ____ 103

8.1 Outline of Ex t e r nal I/O .......... .. .. ...................... ..........103

4

5

6

7

8

9

8.1.1 Explanations of signal line ...........................................104

8.1.2 Connecting the External I/O connector .......................106

8.2 Example of Signal Connection .................................107

8.3 Inter-lo ck Fu n ctio n ........ ... ..................... ....................111

8.4 TEST-Signal Output ................ ............... ..................113

8.5 Selecting test mode and

saved test condition 114

8.6 Timing Chart .............................................................115

8.7 Adjusting the Buzzer sound .....................................119

Chapter 9

RS-232C/GP-IB Interface ____________________121

10

11

Appendix

Index

Page 6

iv

Contents

9.1 Specifications .......................................................... 122

9.2 Connect i o n an d S et tin g Pro c e d ure s ... .. ................... 1 2 3

9.2.1 Connecting the Connector ..........................................123

9.2.2 Setting the Communication Conditions .......................125

9.3 Communication Methods .............................. ...........127

9.3.1 Message Format .........................................................128

9.3.2 Output Queue and Input Buffer ...................................131

9.3.3 Status Byte Register ...................................................132

9.3.4 Event Registers ..........................................................134

9.3.5 Initialization Items ................................... ..... ..... .... ......137

9.3.6 Local Function ............................................................137

9.3.7 Command Reference List ...........................................138

9.4 Message Reference ........................................ .. ...... 142

9.4.1 Common Command ....................................................143

9.4.2 Device-Specific Commands ........................................148

9.4.3 Transmission and response formats ...........................181

9.4.4 Sample program Flowchart .........................................182

9.5 Interface Command "START" ..................................186

Chapter 10

Specifications______________________________187

10.1 Basic Specifications ................................................. 187

10.2 General Specifications .............................................193

10.3 H.V.Test Lead (Accessory) Specifications .............. 194

Chapter 11

Maintenance and Service_____________________195

11.1 Troubleshooting .......................................................195

11.2 Cleaning .................................................................. 196

11.3 Error Indication ........................................................ 197

11.4 System Reset ...... ..................... ...................... ......... 198

Appendix _________________________________ A 1

Appendix1 Remote Control Box..........................................A 1

Appendix2 List of Optional Functions .................................A 5

Index__________________________________ Index i

Page 7

Introduction

Thank you for purchasing the HIOKI “Model 3174, 3174-01 AC Automatic Insulation/Withstanding H iTester.” To obtain maximum performance from the instrument, please read this manual first, and keep it handy for future reference.

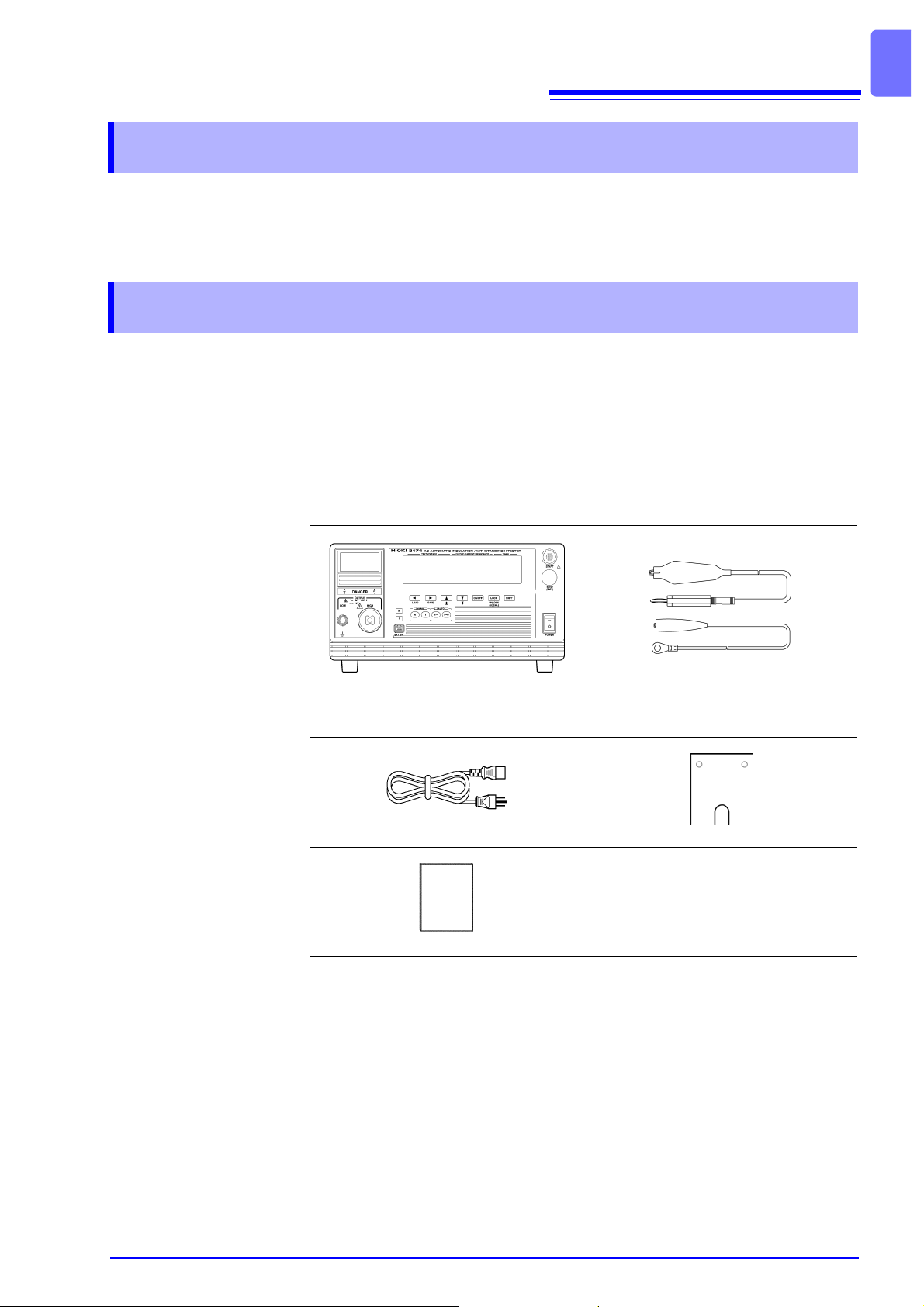

Confirming Package Contents

• When you receive the in strument, inspect it c arefully to ensu re that no damage occurred during shipping. In particular, check the accessories, panel

switches, and connec tor s. If d amage is evident, or if it fails to op er ate acc ording to the specifications, contact your dealer or Hioki representative.

• When transporting the in stru ment, u se the orig inal packing ma terials in wh ich

it was shipped, and pack in a double carto n. Damage oc curring during tr ansportation is not covered by warranty.

1

Introduction

Model 3174 (-01) AC Automatic Insulation/Withstanding HiTester

..........................................................1

Power Cord.......................................1 Slip Prevention Plate.........................1

Instructi on Manual.......................... 1

* The 3174-01 AC A utomatic Insul ation/ Withstan ding H iTester can be used with

GP-IB.

Options 9613 Remote Control Box (Single)

9614 Remote Control Box (Dual)

9615 H.V.Test Lead

9616 Warning Lamp

9267 Safety Test Data Management Software

9637 RS-232C Cable (1.8 m, 9-pin to 9-pin)

9638 RS-232C Cable (1.8 m, 9-pin to 25-pin)

9151-02 GP-IB Connector Cable (2 m)

9151-04 GP-IB Connector Cable (4 m)

Model 9615 H.V.Test Lead

.......................... (HIGH/ LOW, 1 each)

Page 8

2

Safety Information

Safety Information

This instrument is desi gned to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safe ty prior t o shipment. How ever, mishandling during use could result in injury or death, as well as damage to

the instrument. Using this instrument in ways other than those specified in

this manual may damage functions which guarantees the safety of this

instrument. Be certain that you understand the instructions and precautions in the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from instrument defects.

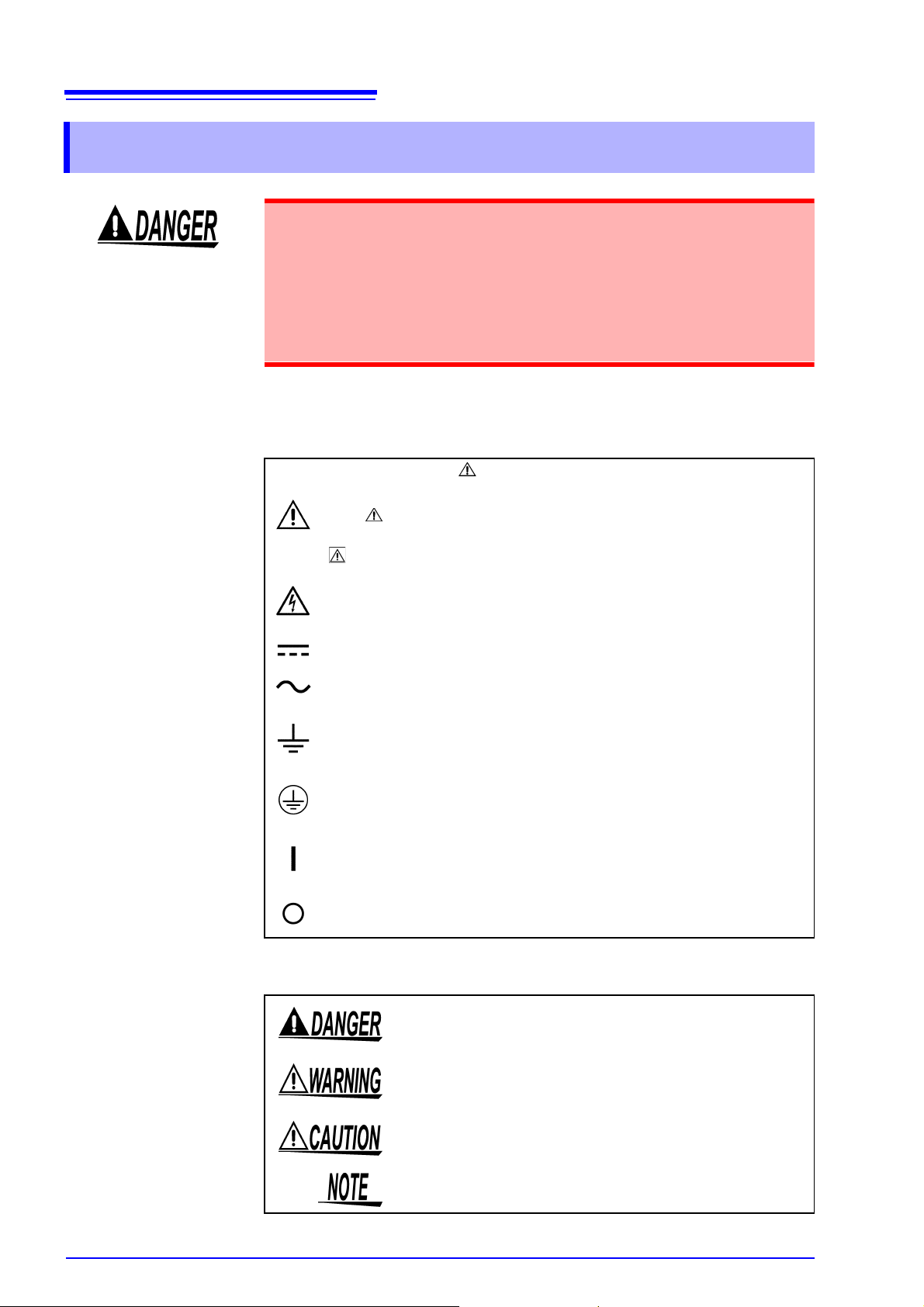

Safety Symbols

This manual contain s information and warnings essential for safe operation of

the instrument and for ma intainin g it in safe ope rating condi tion. Befo re using it,

be sure to carefully read the following safety precautions.

In the manual, the symbol indicates particularly important information that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user

should refer to a cor responding topic in the manual (marked with the

symbol) before using the relevant function.

Indicates that dangerous voltage may be present at this terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Curre nt).

Indicates a grounding terminal.

Indicates a protective conductor terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operati on pres en ts an extreme haz ard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant

hazard that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a possibility of

injury to the user or damage to the instrument.

Indicates advisory ite ms related to performance or corre ct

operation of the instrument.

Page 9

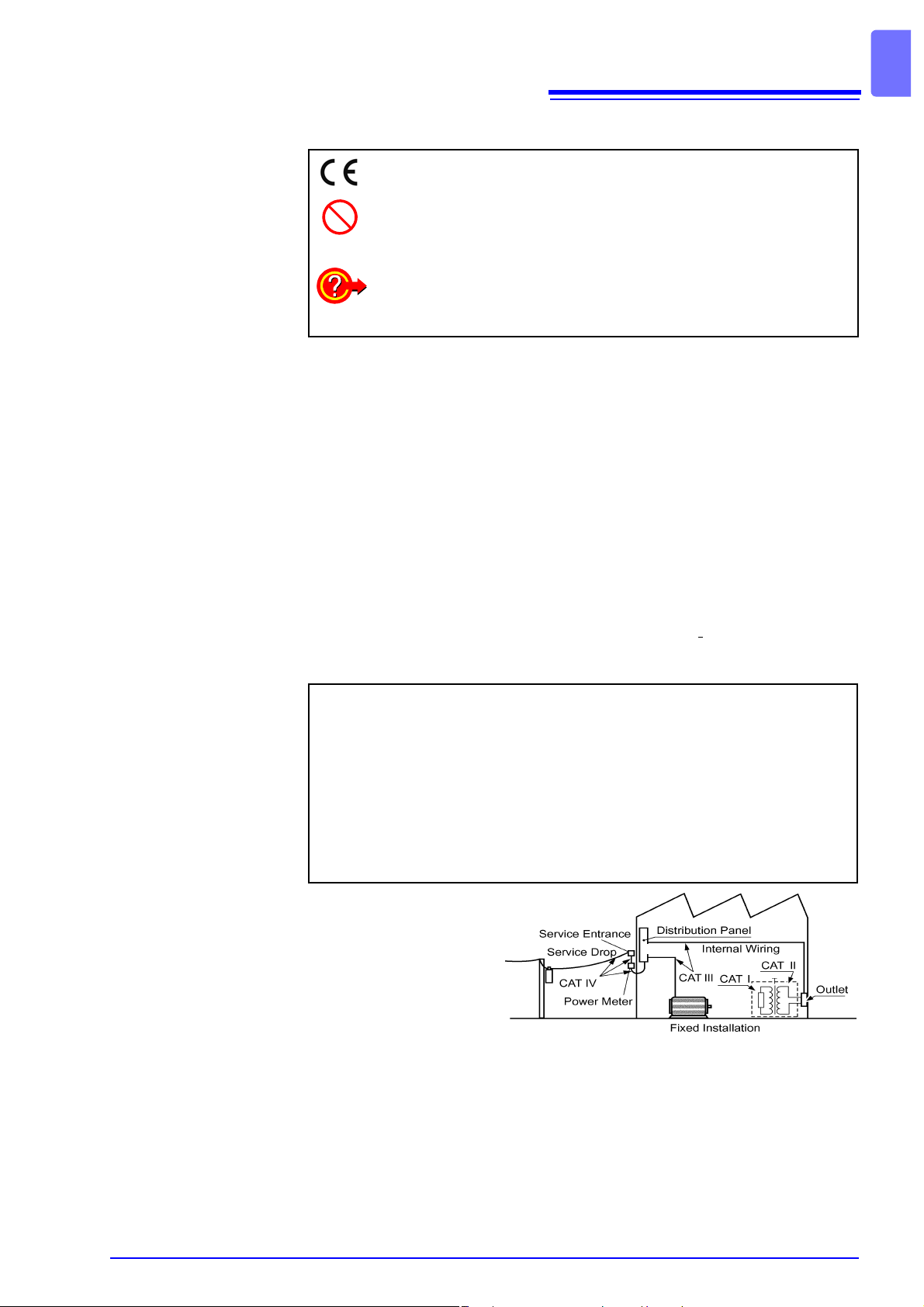

Other symbols

3

Safety Information

This symbol indicates that the product conforms to safety regulations

set out by the EC Directive.

Indicates a prohibited action.

( p. )

Indicates the location of reference information.

Indicates quick references for operation and remedies for trouble-

shooting.

*

Indicates that descriptive information is provided below.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and

dgt. (digit) values, with the following meanings:

f.s. (maximum display value or scale length)

The maximum d isplaya ble v alue o r scal e len gth. This is usually the na me of t he

currently selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

dgt. (resolution)

The smallest dis playable unit on a digital measurin g instrument, i.e., the input

value that causes the digital display to show a "1" as the least-significant digit.

Measurement categories (Overvoltage categories)

This instrument complies with CAT I, CAT II safety requirements.

To ensure safe operation of measurement instrument, I

safety standards for various electrical environments, categorized as CAT I to

CAT IV, and called measurement categories. These are defined as follows.

CAT I:

CAT II:

CAT III:

CAT IV:

Secondary electrical circuits connected to an AC electrical outlet

through a transformer or similar instrument.

Primary electrica l circui ts in equip men t connec ted to an AC ele ctr ica l

outlet by a power cord (portable tools, household appliances, etc.)

Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the distribution panel to outlets.

The circuit from the se rvice drop to the servi ce entrance, and to the

power meter and primar y overcu rrent pr otection in strum ent (di stribution panel).

EC 61010 establishes

Higher-numbered categories correspond to electrical environments with

greater momentary

energy. So a measurement

instrument designed for

CAT III environments can

endure greater momentary energy than a instrument designed for CAT II.

Using a measurement instrume nt in an environment designated with a hi ghernumbered category than that for which the instrument is rated c ould result in a

severe accident, and must be carefully avoided.

Never use a CAT I measuring instrument in CAT II, III, or IV environments.

The measurement categories comply with the Overvoltage Categories of the

IEC60664 Standards.

Page 10

4

Operating Precautions

Operating Precautions

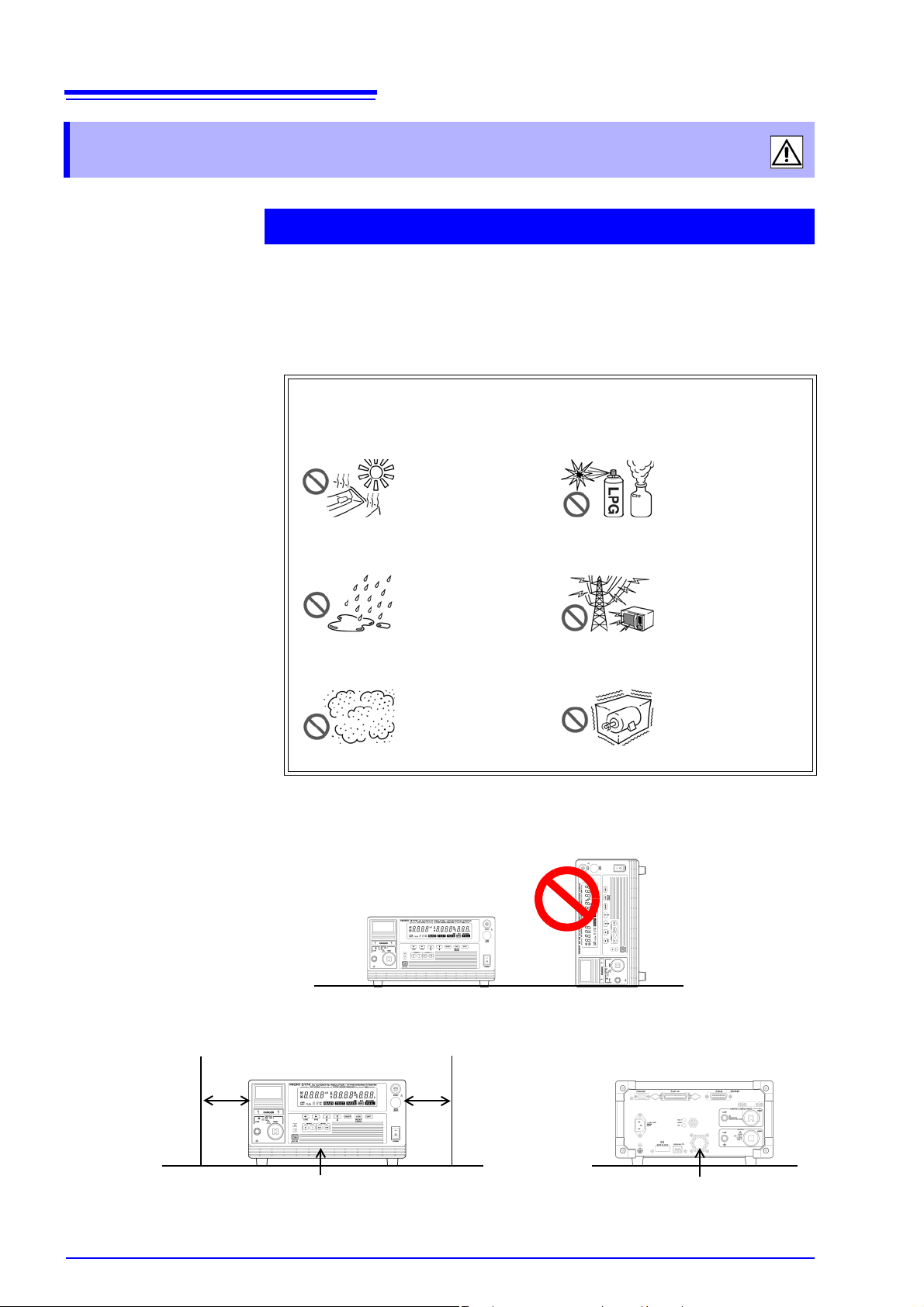

Instrument Installation

Operating temperature and humidity:

Temperature and humidity range for guaranteed accuracy:

Avoid the following locations that could cause an accident or damage

to the instrument.

0 to 40°C at 80% RH or less (no condensation)

23±5°C, 80%RH or less (no condensation)

after 10 minutes minimum warm-up

Installation

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

• The instrument should be operated only with the bottom side downwards.

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Subject to vibration

Spacing of more

than 10 cm

• Vents must not be obstructed.

Spacing of more

than 10 cm

Ventilation holes

Ventilation holes

Page 11

5

Operating Precautions

Before Use

Before using the instrument the first time, verify that it operates normally to

ensure that the no damage oc curred during sto rage or shipping. If y ou find any

damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the test

leads is undamaged and that no bare conductors are improperly exposed.

Using the instrument in su ch c o ndi tions co uld cause an elec tric sh ock, so

contact your dealer or Hioki representative for repl acements. (Model 9615

H.V.Test Lead)

Handling the Instrument

• To avoid electric shock, do not remove the instrument's case. The inter-

nal components of the instrument carry high voltages and may become

very hot during operation.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

Handling the test leads

• For safety reasons, when taking mea surements, only use the 9615 H.V. Test

Lead provided with the instrument.

• To avoid breaking the test leads, do not bend or pull them.

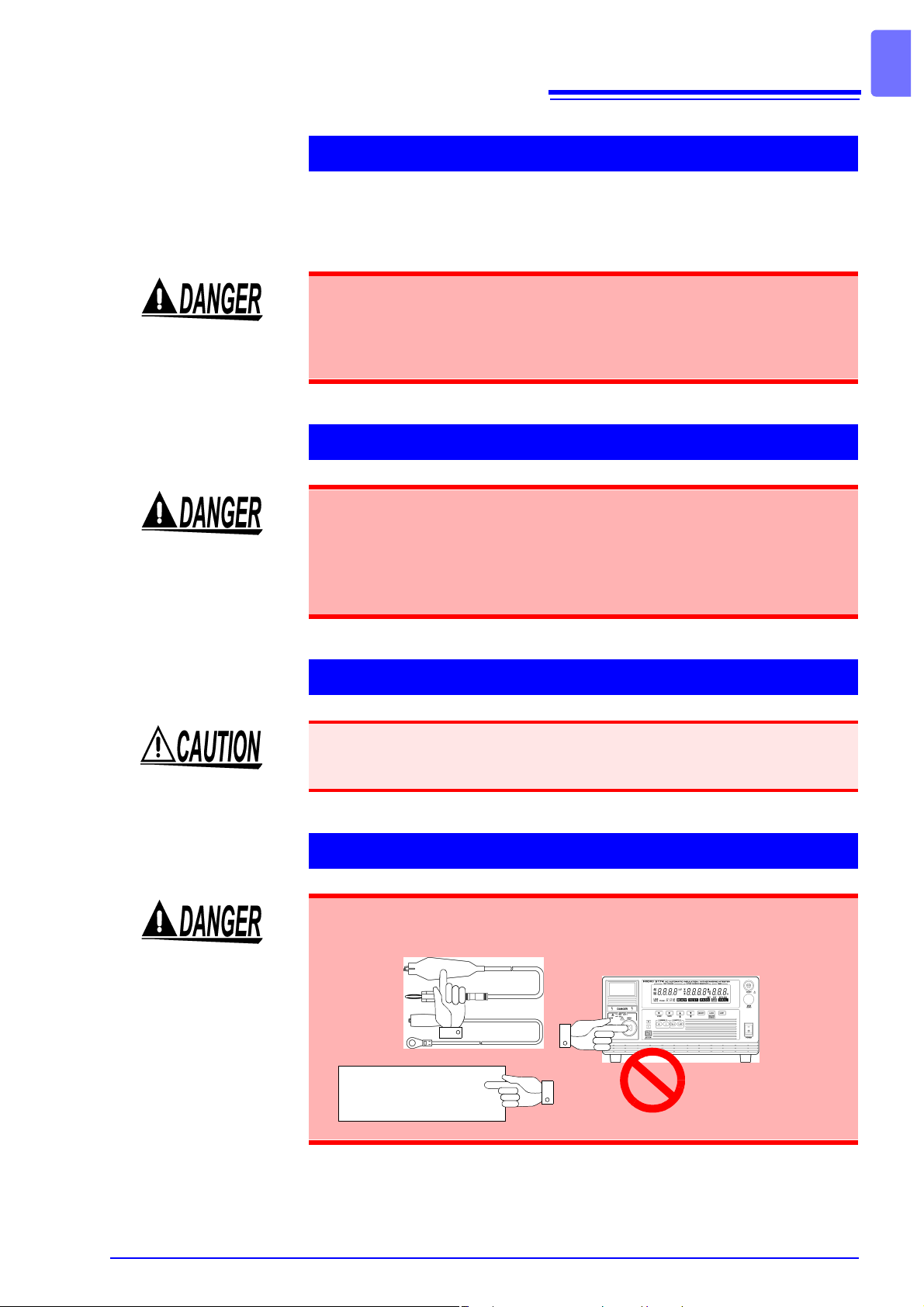

Safety Precautions during Testing

To prevent electric sho ck, whe n the DANGER lamp is lit or during the test,

never touch the voltage output terminals, test lead, or the tested object.

Tested object

Page 12

6

Operating Precautions

Page 13

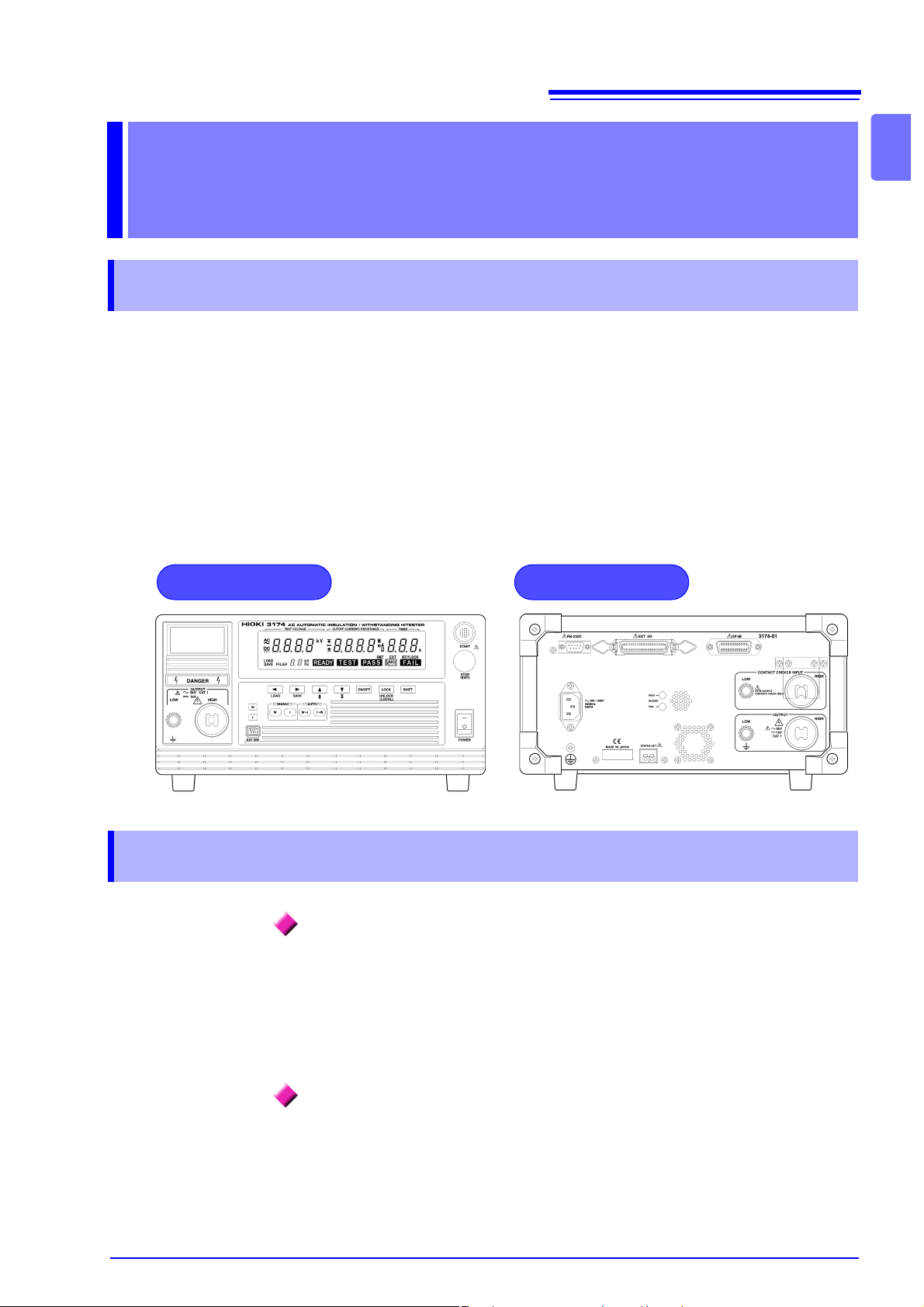

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

Inaccuracies i n measurements ha ve been noted to occur during th e withstandvoltage and insulatio n-resistance tests bec ause of variations in the tes t voltage

caused by fluctuations in the voltage supply, breaking of the test leads and

improper connection.

Model 3174, 3174-01 AC Automatic Insulation/Withstanding HiTester is an

affordable insu lation/withstanding testing instrument equipped with stab le voltage supply and c ontact check fu nction s t o preven t a decr ease in te stin g reliab ility caused by these factors.

In addition, to improve the efficiency of the testing process on the production

line, it allows testing setti ngs to be retrieve d from b oth RS-232 C (GP-IB) as well

as EXT I/O.

7

1

Front Panel Rear Panel

1.2 Features

Carry out standards-based tests with simple operations

Once test conditions have been pre-set beforehand, withstanding and insulationresistance tests w hich meet indu strial st andards ca n be carried out with just the

simple push of a button. Functions such as PASS-FAIL evaluation based on

upper-limit and lower-limit test values, testing time timer, ramp-up/ramp-down

time timer to control voltage fluctuations ensure accurate test results are

obtained.

Saving and loa ding test conditions

Once test conditi ons required for th e various ind ustrial standards and device to

be tested have been saved, tests can be carried out smoothly by just switching

to the required te st conditions. Up to 8 conditions can be saved for the withstanding and insu lation-re sistance te sts respec tively. In a ddition, tes t conditi ons

for the last test are automatically retrieved when the power is switched on.

Page 14

8

1.2 Features

Automatically carry out consecutive withstanding and insulationresistance tests

Withstanding and insulation-resistance tests can be carried out consecutively

when the respective test conditions have been pre-set. Pressing the W→I key

will automaticall y run th e withstand ing test f ollowed by the insu lation-resi stance

test, pressing the I→W key will automatically run the insulation-resistance test

followed by the withstanding test.

Contact check function to increase testing reliability

With the contact chec k functi on, the re lia bility o f tests carried o ut impr oves wi thout the need to incr ease t esting ti me (Ano ther s et of t he 9615 H.V. Tes t Lead is

necessary)

Real execution value shown

By showing t h e r e al ex ec u ti o n v al u e, te st s f a ith f ul t o in dustrial s t an d ar ds ar e carried out.

Cutting out influence from supply voltage fluctuations

By using PWM switching power supply, the desired voltage supply can be set so

even if the supply voltage flu ctuates within ±10% of the preset value, the test

voltage will not be affected. This improves the reliability of the test results.

Continuation of testing even after test failure makes analysis of

sample possible (Test Continuation status)

Under normal conditions, testing immediately stops when the test fails, making it

impossible to determine whether the cause is because of a short circuit or a

value exceeding the thresho ld value. The Test Continuation Status allows the

test to continue even after a FAIL r esult is obtained, thus making it possi ble to

analyze the problem.

EXT I/O in standard package

This instrument is equipped with EX T I/O as a standa rd package. This enab les

signal transmissions fro m E XT I/O, start and stop controls of tes ts an d retr i evals

of saved test conditions.

RS-232C (Standard Package)/GP -IB Interface (Standard Package

for 3174-01 only)

This instrument is equipped with RS-232C as a standard package and the 317401 is also equipped with GP -IB as a sta ndard package. By connecting to a computer, they allow for auto testing to be carried out and test results to be read.

Easy-to-see big screen

Big-sized fluo rescent dis play tubes are use d for the disp lay, allow ing te st c onditions and test results to be confirmed easily.

Remote Control Box for safer test administrations (optional)

When the optional Rem ote Co ntrol Box is conne cted to the instrument, test start

or test stop functions ca n be performed without touching the instrument, thus

making test adm inistr ations s afer. The 961 3 R emote C ontrol B ox ( Single) , 961 4

Remote Control Box (Dual) are available.

Page 15

9

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

1.3.1 3174 (3174-01)

Explanations on names and parts of instrument.

Front Panel

DANGER lamp

Light blinks to warn of voltage supply.

To prevent electric shock, when the

DANGER lamp is lit, never touch

the voltage output terminals, test

lead, or the tested object.

Display

(p. 12)

Please carry out the test regularly on th e instrument

by following the test procedures in "2.6 Pre-test

Check" (p. 26).

See "6.1.3 Double Action" (p. 81)

START Key

Start a test.

(Functions only when the lamp is lit.)

STOP Key

Terminate a test.

Operation Keys

(p. 10)

1

Connection terminal for

remote control

Connect the remote control box (optional)

HIGH Voltage output terminal

The HIGH terminal is a high-voltage terminal for voltage outputs.

LOW Voltage output terminal

The LOW terminal is a low-voltage terminal for voltage outputs.

It has the same electric potential

as the unit body.

POWER Switch

Turns the instrument on and off.

: Power on

: Power off

(The diagram shows a 3174 AC Automatic Insulation/Withstanding

HiTester.)

Page 16

10

1.3 Names and Functions of Parts

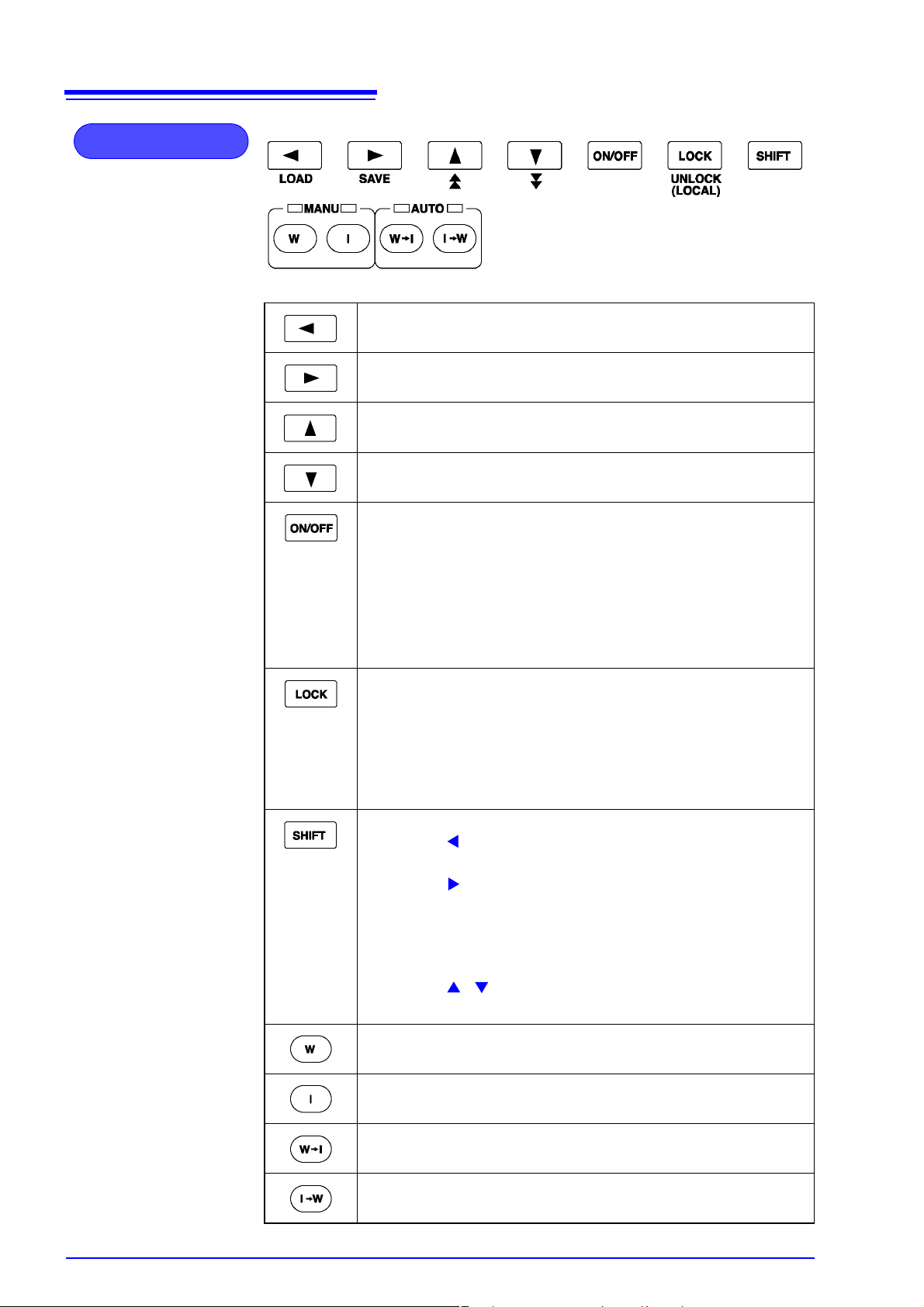

Operation Keys

Moves the flashing cursor to the left.

Moves the flashing cursor to the right.

Raise the selected value with the flashing cursor.

Lower the selected value with the flashing cursor.

UNLOCK

(LOCAL)

Change the ON/OFF for the selected setting with the flashin g

cursor. If turned off, the set value is not used in testing.

• The following item can't perform the switching on/off:

Withstand-voltage test:

Test-voltage value, Test-voltage frequency, Upper-limit test

value

Insulation-resistance test:

Test-voltage value, Lower-limit test value

Used to lock the keys.

Only the following keys are available during Key Lock. (p. 79)

UNLOCK key (LOCK + SHIFT key)

START key

STOP key

• In the remote state, this key functions as a LOCAL key.

It cancels the remote state.

Used in combination with other keys.

• SHIFT + key

Displaying the loading screen.(p. 102)

• SHIFT + key

Displaying the saving screen.(p. 99)

• SHIFT + LOCK key

Cancels the key lock.

When GP-IB is used for communication, go to LOCAL state.

• SHIFT + / key

Changing the increment size of setting values.

Performs withstand-voltage tests and settings.

"Chapter 3 Withstand- Voltage Test" (p. 29)

Performs insulation-resistance tests and settings.

"Chapter 4 Insulation- Resistance Test" (p. 47)

Tests for withstand-voltage, then insulation-resistance.

"Chapter 5 Automatic Test" (p. 69)

Tests for insulation-resistance, then withstand-voltage.

"Chapter 5 Automatic Test" (p. 69)

Page 17

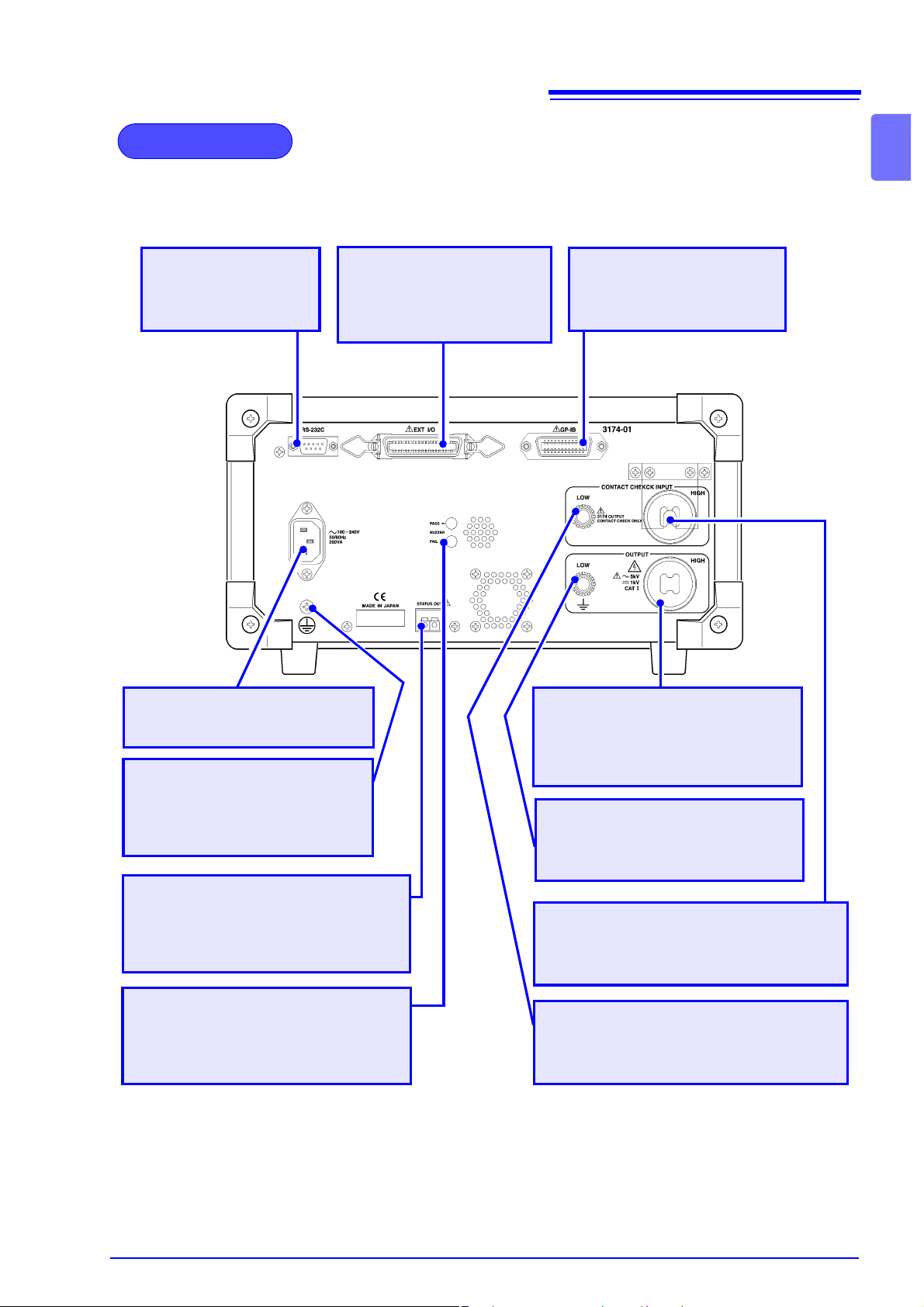

Rear Panel

11

1.3 Names and Functions of Parts

1

RS-232C connector

Used for remote control with RS-232C.

Power Inlet

Connect the supplied power cord

here

Protective conductor terminal

Used to earth a protective

ground wire. Be sure to make

grounding connections before

starting a test.

Status Out Relay Terminal

When conditions pre-set in the Status

Out setting are met, the relay connection gets switched ON.

EXT I/O connector

For output of 3174 state

and input of start and stop

signals.

GP-IB connector (3174-01)

Used for remote con trol with

GP-IB.

HIGH voltage output terminal

A high-voltage terminal for voltage output. Connected to the

HIGH terminal on the front panel.

LOW voltage output terminal

A low-voltage terminal for voltage

output. Contains the sa me electrical

potential as this units casing.

HIGH contact check terminal

A high-voltage terminal for c ontact check.

Use the Slip Prevention Plate.

Buzzer adjustment knob

Used for buzzer sound adjustment.

Two knobs are prov ided: one for PASS

screening and one for FAIL screening.

The diagram shows a 3174- 01 (wi th GP- IB) AC A utomati c Ins ulatio n/With standing HiTester.

LOW contact check terminal

A low-voltage terminal for contact check.

Page 18

12

.

1.3 Names and Functions of Parts

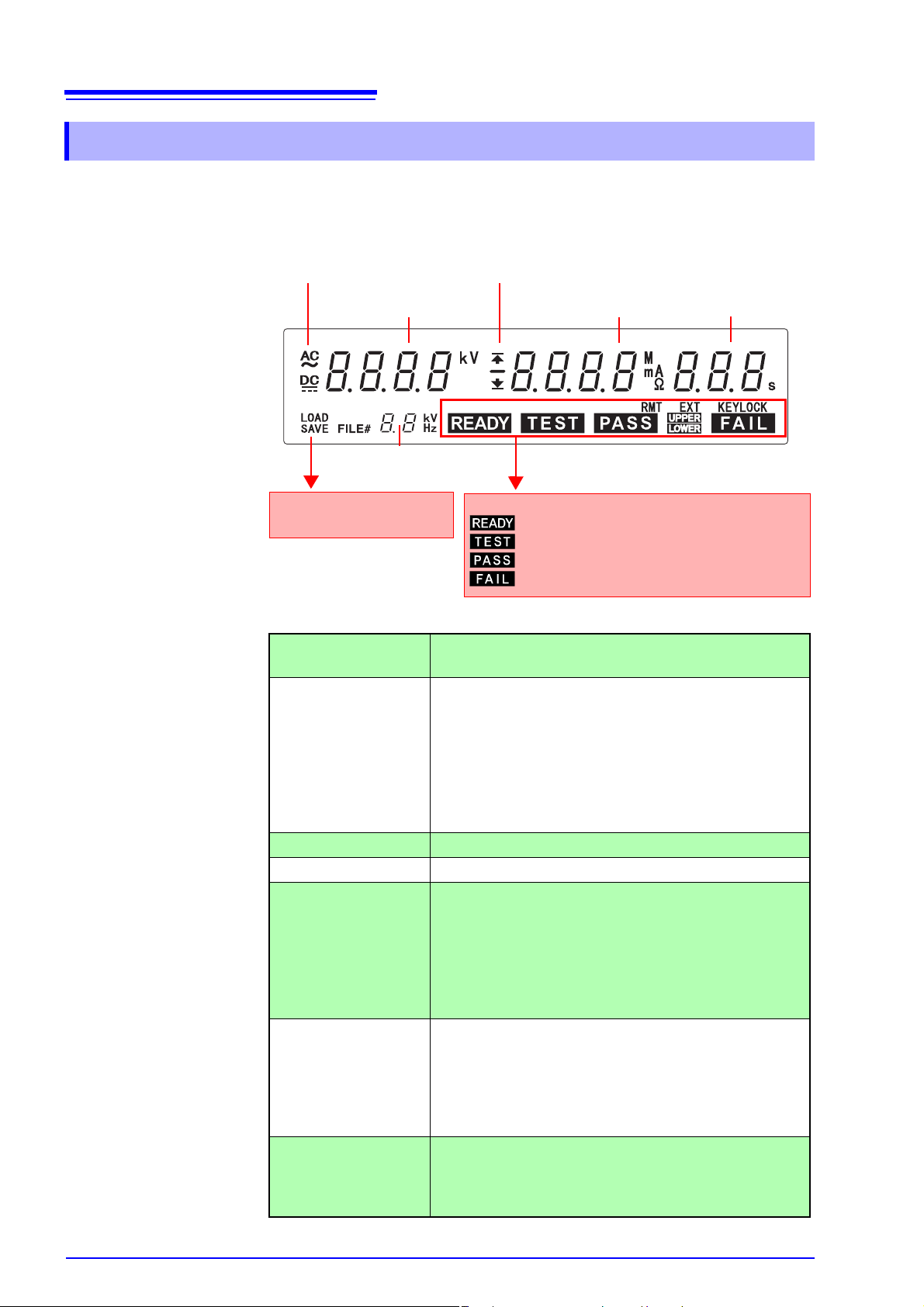

1.3.2 Display

Test setting conditions and current status of the instrument are shown in the

panel on front of the instrument.

Test type

Test-voltage value

Test-frequency

Initial voltage for ramp-up

SAVE: Saving screen

LOAD: Loading screen

Test type

Test-voltage value

Upper-limit value icon Lights up when indicating the upper-limit test value.

Lower-limit value icon Lights up when indicating the lower-limit test value.

Upper-limit test value

Lower-limit test value

Test time

Ramp-up time

Ramp-down time

Delay time

Test-frequency

Initial voltage for

ramp-up

Upper-limit value icon

Lower-limit value icon

Upper-limit test value

Lower-limit test value

Indicates the current condition of the instrument

: The instrument is ready for starting a test

: The instrument is in the TEST state.

: The tested object passed the test.

: The tested object failed to pass the test.

“AC” lights up during withstanding testing.

“DC” lights up during insulation-resistance testing.

During testing and READY:

Monitors and indicates the voltage of the output terminal.

During voltage setting:

Indicates the ea ch item set. (output voltage, Con -

tact Check upper (lower)-limit voltage)

Reverse current cannot b e detected bec ause monitor

shows voltage and residual voltage.

Indicates the upper-limit test value when the upperlimit value icon lights up and indicate s the lower-limit

test value when the lower-limit value icon lights up.

Also indicates the Contact Che ck upper-limit voltage

when [Hi] is shown in Test Frequency and Initial

Ramp-up Voltage, and indicates the Contact Check

lower-limit voltage with [Lo].

Indicates testing time.

Indicates the ramp-up time when [UP] is shown in T est

Frequency and Initi al Ramp -up Voltage, and indicates

the ramp-down time together with [dn].

Indicates the delay time together with [dL] during insulation-resistance testing.

Indicates Test Frequency (50 Hz/60 H z) when [Hz] is

shown. Indicates the Initial Voltage (proportion to Testing Voltage) when Ramp-up Timer is being used

within the range of 0 to 1.0.

Test time

Ramp-up time

Ramp-down time

Delay time

Page 19

13

1.3 Names and Functions of Parts

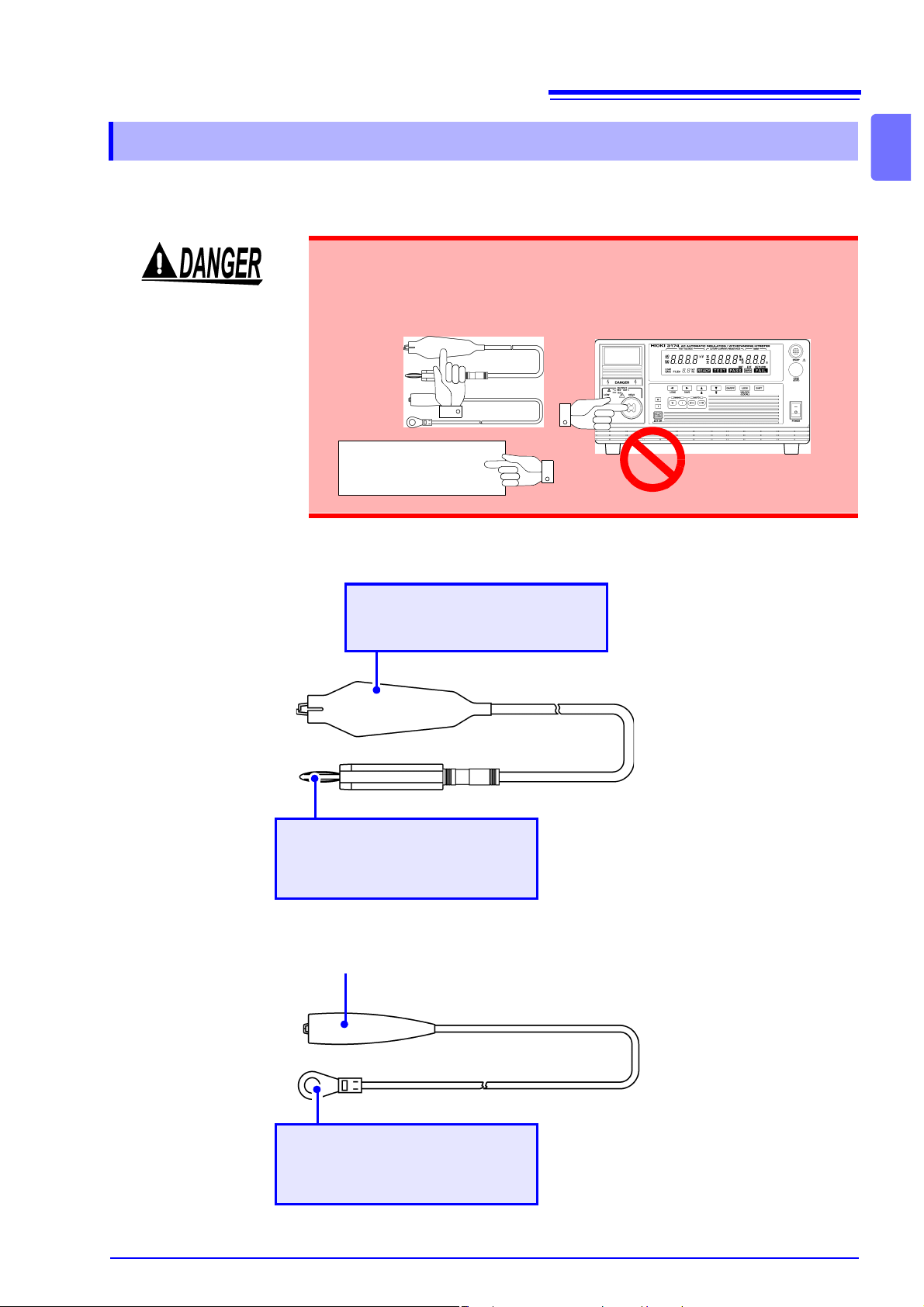

1.3.3 Model 96 15 H.V.Te st Lead

Explanations on names and parts of Test Lead.

To prevent electric sho ck, whe n the DANGER lamp is lit or during the test,

never touch the voltage output terminals, test lead, or the tested object.

There is no insulation/withstand-voltage on the Alligator clip vinyl covering.

Tested object

9615 H.V.Test Lead

1

Alligator Clip

Connect to a test point on the tested object.

High-voltage output plug

Connect to the HIGH voltage output

terminal on the instrument.

Alligator Clip

Low-voltage output plug

Connect to the LOW voltage output

terminal on the instrument.

Page 20

14

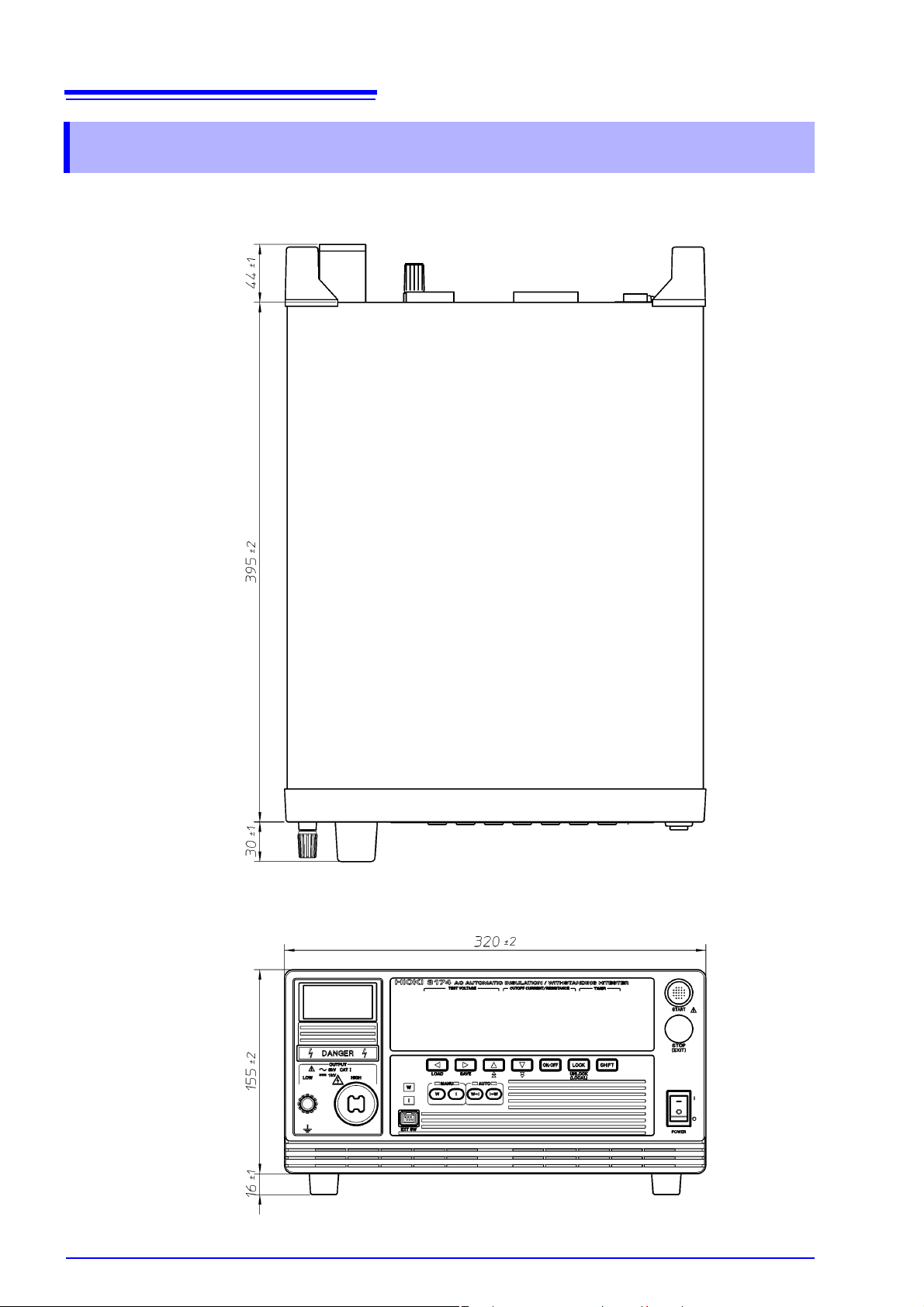

1.4 External Dimensions

1.4 External Dimensions

Model 3174, 3174-01 AC Automatic Insulation/Withstanding HiTester

Page 21

15

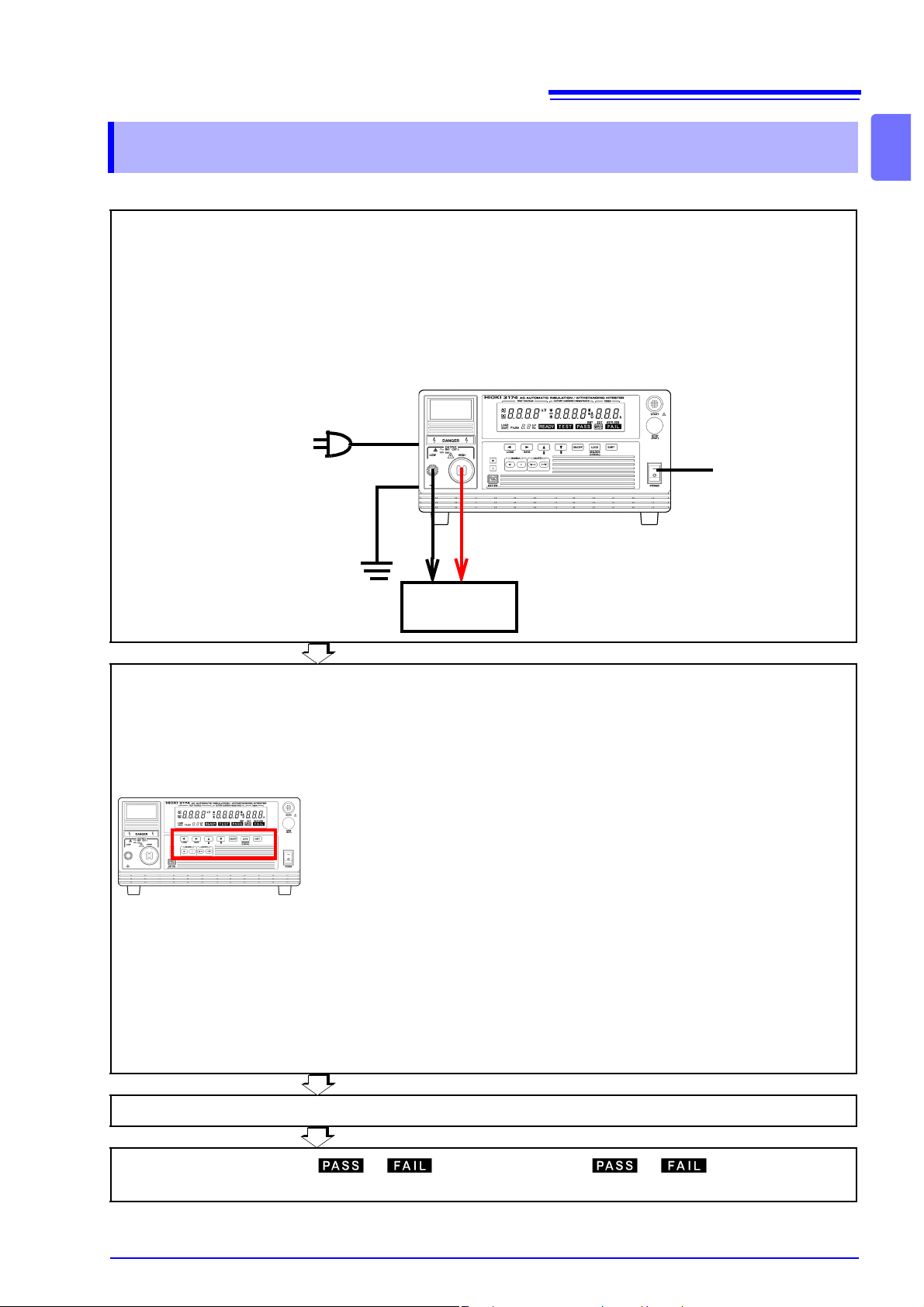

1.5 Testing Process

1.5 Testin g Proc e ss

Explanation of the basic flow of withstanding and insulation-resistance tests.

Testing Arrangements

(p. 17)

1. Connect the protective conductor terminal.

2. Connect the power cord.

3. Connect the test lead. (Voltage output terminal, Contact check terminal)

4. T u rn on the power.

5. Carry out pre-test check.

2

1

1

4

ON

3

Tested object

Withstand-voltage test (p. 29) Insulation-resistance test (p. 47)

Select the test type Press the W key. Press the I key.

Set test conditions 1. Set the test voltage value.

(p. 32)

2. Set the upper (lower) limit value.

(p. 33)

3. S et the tes t time timer .

(p. 34)

4. Set the ramp-up (ramp-down)

timer. (p. 35)

5. S et the tes t- freque nc y. (p. 36)

6. Set the Initial voltage for ramp-up.

(p. 37)

Set the upper-limit voltage and lower-limit voltage for Contact Check, if necessary.

(p. 38) (p. 55)

1. Set the test voltage value.

(p. 50)

2. Set the upper (lower) limit value.

(p. 51)

3. Set the test time timer.

(p. 53)

4. Set the delay time. (p. 54)

Executing a test Press the START key. (p. 40 ) Press th e START key. (p. 57)

Displaying the test result

or is displayed.

(p. 44)

or is displayed.

(p. 61)

Page 22

16

1.5 Testing Process

Page 23

Testing

17

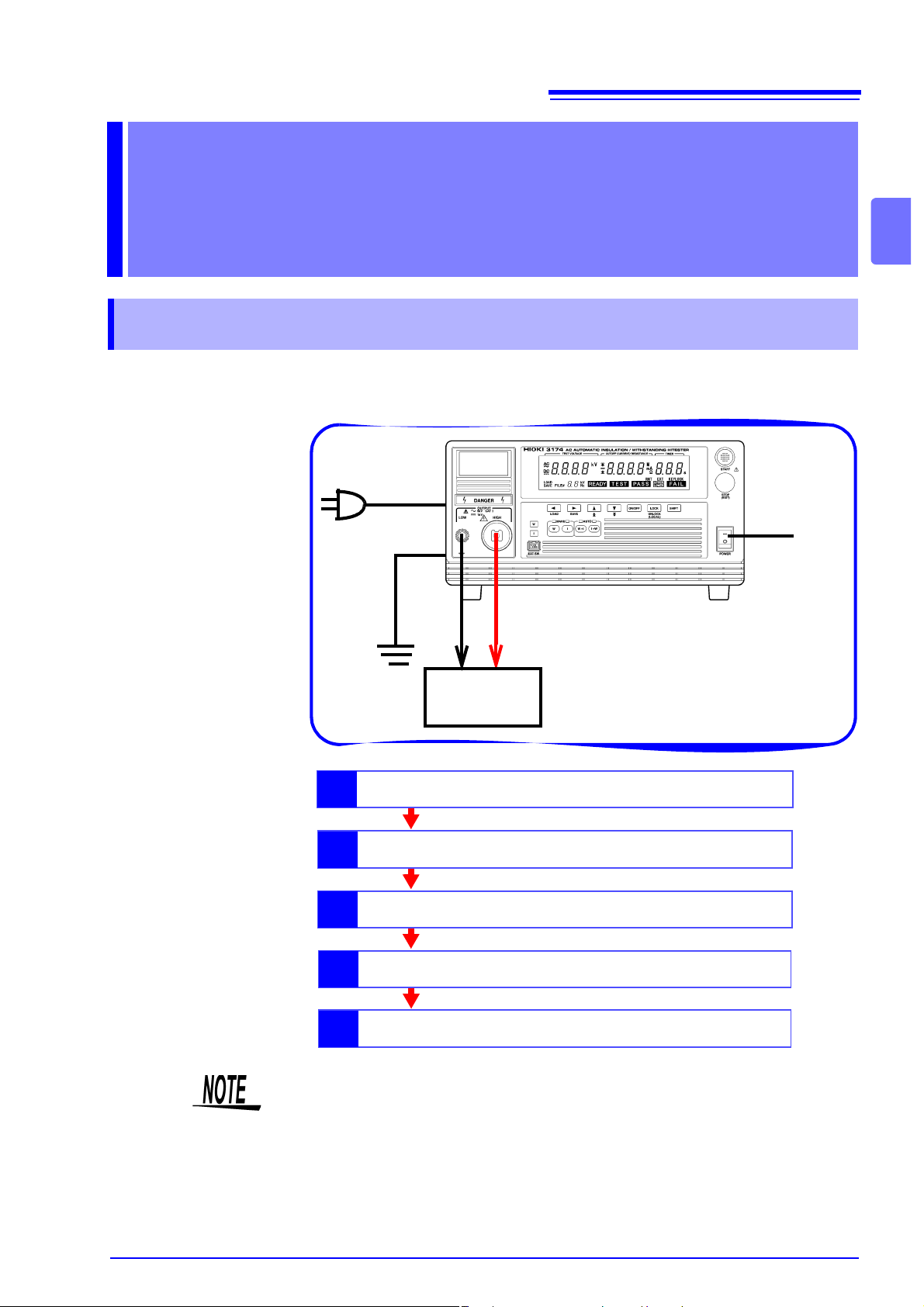

2.1 Arrangements Work Flow

Arrangements Chapter 2

2.1 Arrangements Work Flow

Getting ready to start the test.

2

1

3

2

4

ON

Tested object

1

2

3

4

5

To carry out a safer test

• The Remote Control Box to start or stop the test can be used.

"Appendix1 Remote Control Box" (p. A1)

•

The instrument can be controlled with EXT I/O, RS-232C or GP-IB (only

for 3174-01).

"Chapter 8 External Interface" (p. 103)

"Chapter 9 RS-232C/GP-IB Interface" (p. 121)

"Connecting the Protective Conductor Terminal" (p. 18)

"Connecting the Power Cord" (p. 19)

"Connecting the Test Lead" (p. 20)

"Turning the Power On and Off" (p. 24)

"Pre-test Check" (p. 26)

<Ex.>

Without Contact Check

Page 24

18

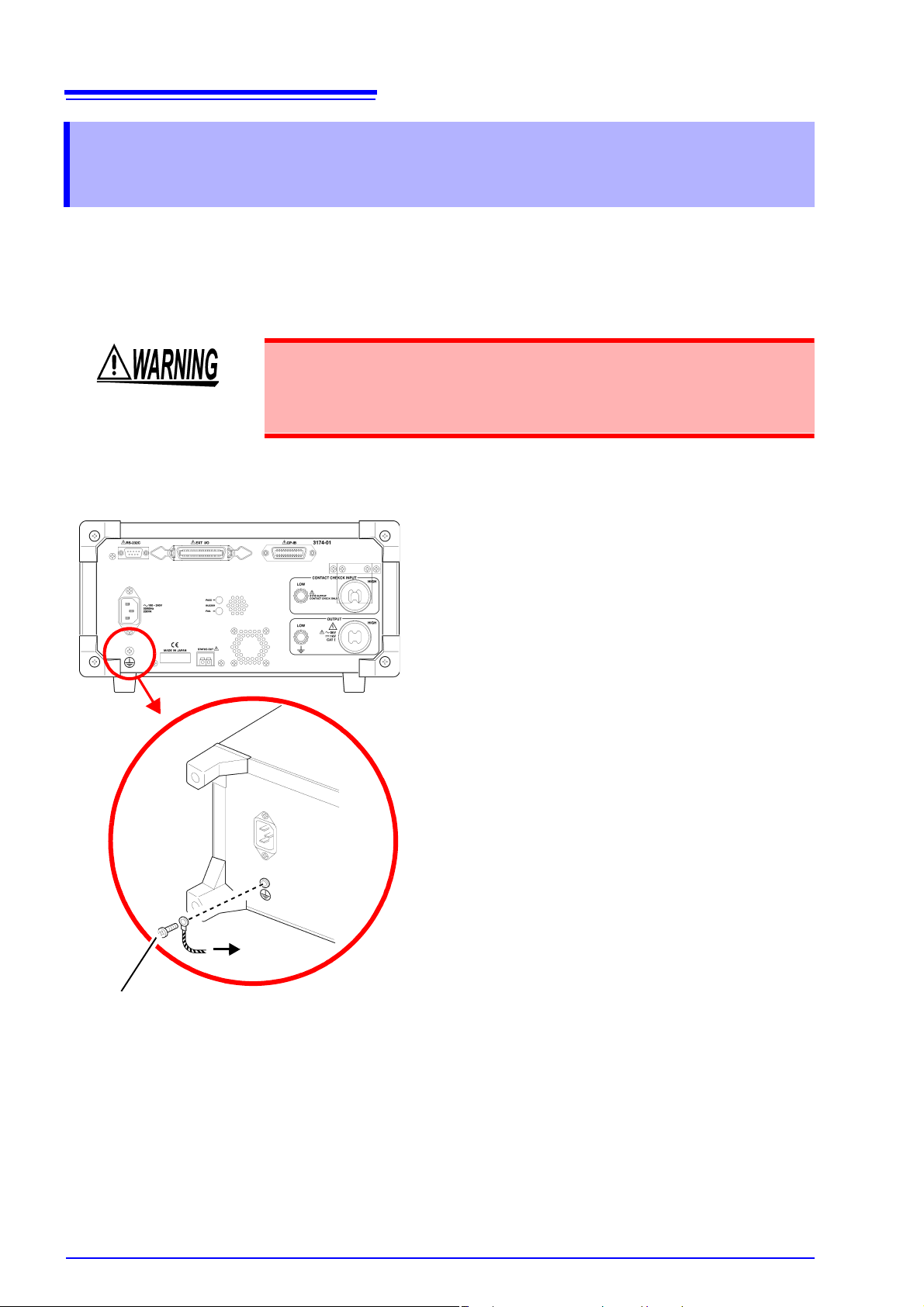

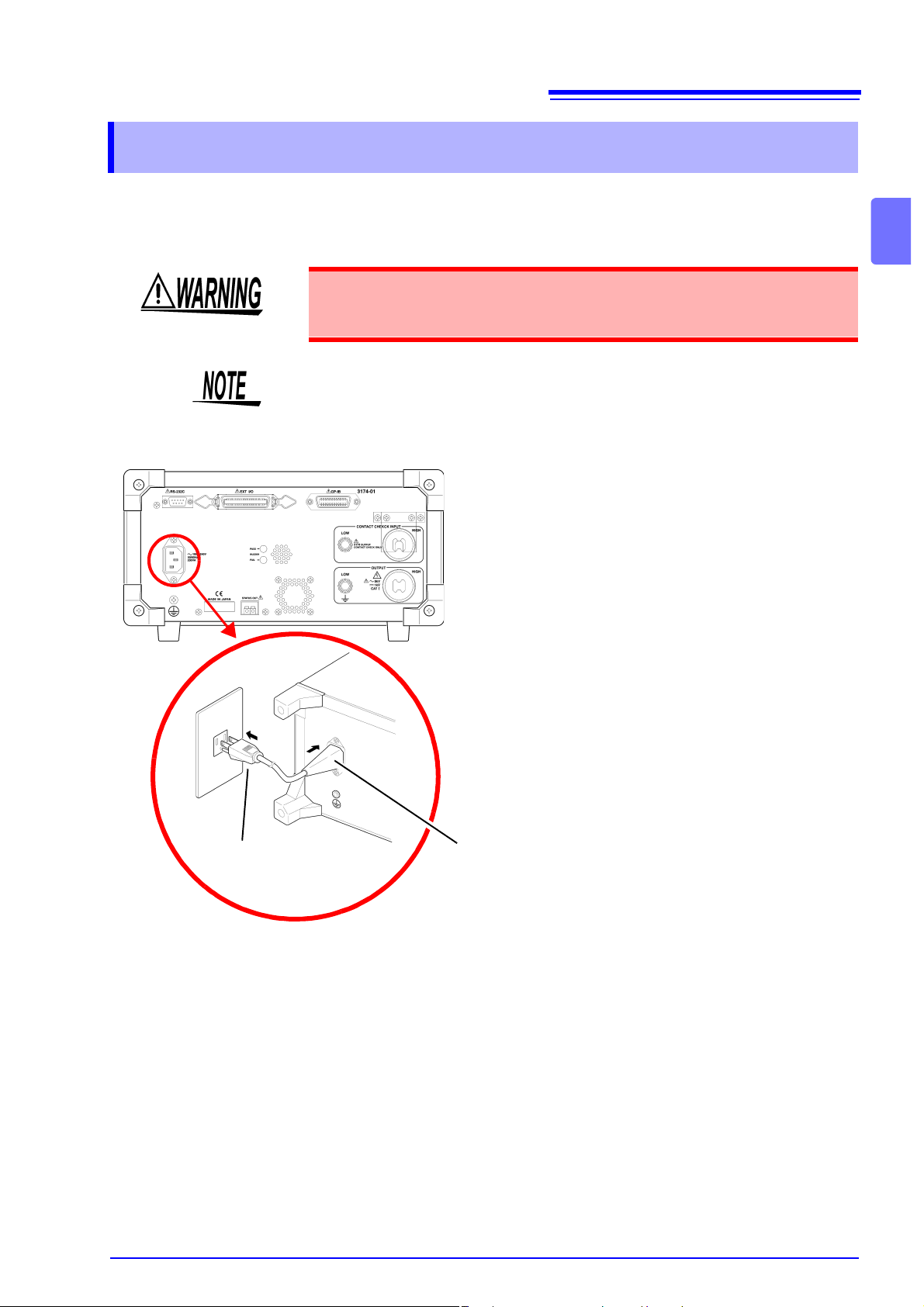

Rear panel

2.2 Connecting the Protective Conductor Terminal

2.2 Connecting the Protective Conductor Terminal

To carry out the test safel y, connect the protectiv e conductor termin al found on

the back of the instrument to earth.

If the ground-type dou ble- pole po wer cord that is suppl ied with th e inst rumen t is

used, the instrument is automatically grounded.

T o avoid electric shock, observe the following.

• Connect the protective conductor terminal to earth (earth ground) before

making any other connections.

• Be sure to connect the protective conductor to earth (earth ground).

Connect to

earth

Prepare:

Phillips-head screwdriver,

Earth wire or cable

1. Make sure that the power switch is turned

off.

2. Using a Phillips-head screwdriver, remove

the protective conductor terminal from the

rear of the instrument.

3. Connect an electric wire with a sufficient

current capacity to the protective conductor terminal.

(

A wire with a diameter of more than

2

1.25mm

is recommended.)

4. Secure the wire using a Phillips-head

screwdriver.

5. Ground the other end of the wire or cable.

Protective conductor terminal

Page 25

2.3 Connecting the Power Cord

Connect the power cor d to the p owe r inl et on the b ack o f the ins trument and the

plug to the wall socket to provide power to the instrument.

To avoid electrical accid ents and to maintain the safety specificati ons of

this instrument, connect the power cord only to a 3-conta ct (two-conduc tor

+ ground) outlet.

Make sure the po wer i s turned off befo re c onn ectin g or disconnecting the power

cord.

Rear panel

1. Make sure that the power switch is turned

off.

19

2.3 Connecting the Power Cord

2

Plug

2. Connect the power cord provided to the

power inlet on the back of the instrument.

3. Insert the plug into the grounded outlet.

Power inlet

Page 26

20

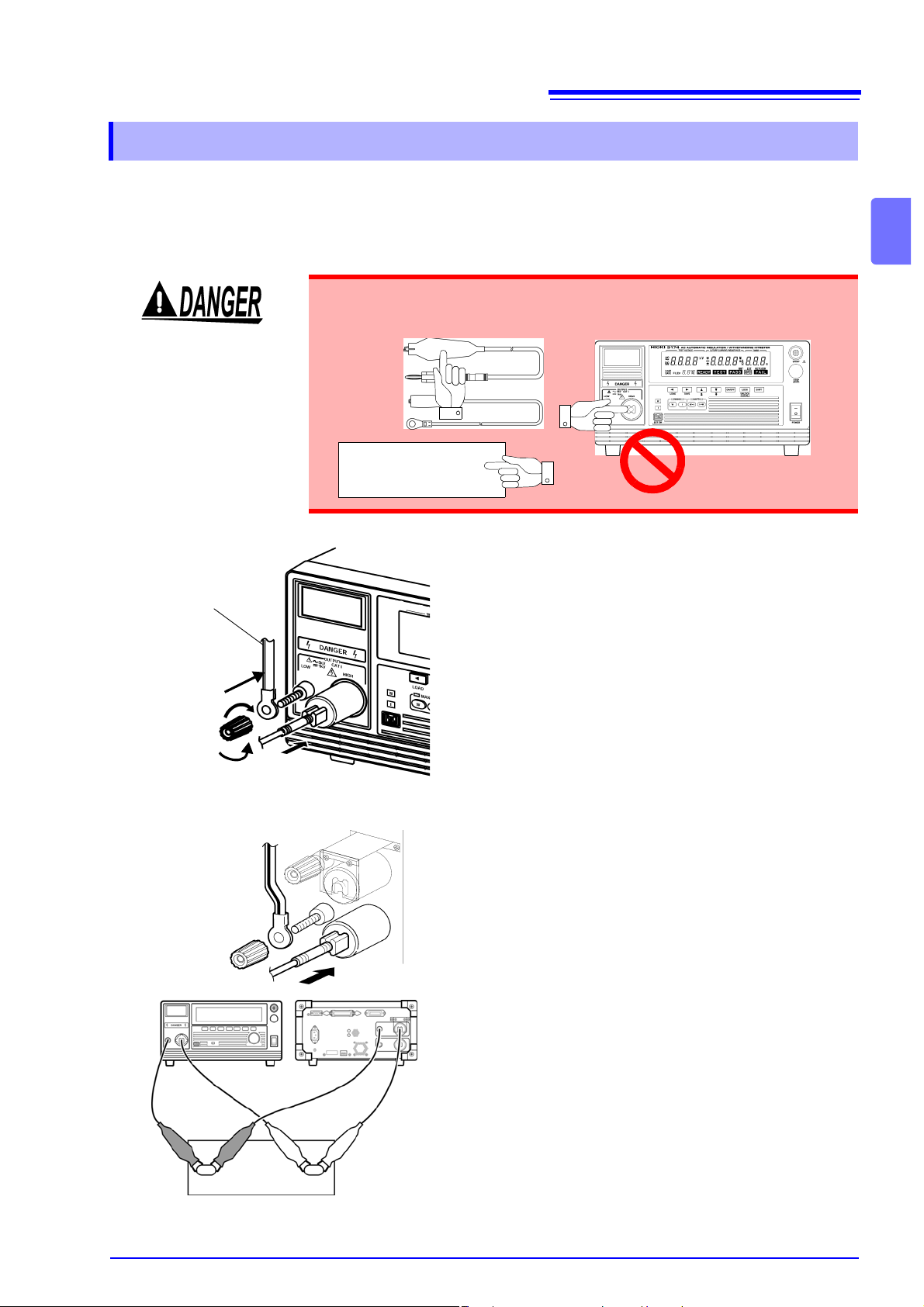

2.4 Connecting the Test Lead

2.4 Connecting the Test Lead

Connect the 9615 H.V. Test Le ad to the Vo ltage O utput T erminal on the fron t of

the instrument. When using Contact Ch eck, connect to th e Contact Check Te rminal on the back as well.

• Before using the instrument, make sure that the insulation on the test

leads is undamaged and that no bare conductors are improperly

exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or Hioki representative for replacements. (Model 9615 H.V.TEST LEAD)

• To avoid shock and short circuits, turn off power before connecting test

leads.

• To avoid electric shock, make sure the test lead is secur ely connected

before starting a test, as a loose test lead can cause a hazard when a

voltage is output.

• Never touch the voltage output term inals, test lead, or th e tested object

during a test (when is light up).

• Voltage may still remain on the voltage output terminal even after the test

has completed. Confirm that no more voltage is left on the voltage output

terminal when touching the voltage output terminals, test lead, or the

tested object.

• To av oid ele ctric sho ck, mak e su re t he power is switched off befor e co nnecting a ferrite or resistor to remove noise.

• Inaccuracy in meas urement m ay occu r during insulati on-resistance test if the

instrument is put in a humi d plac e so try t o avoid d oin g so. If th ere i s a poss ibility of the test lead becoming too humid, protecting the test lead with desiccant is recommended. If the test lead touches other metals, leakages in

electric current may i ncreas e so be ca reful when coi ling the test lea d to avoid

touching other parts.

• Do not allow the test l ead used for Contact Check (HIGH, LOW terminal s) to

directly touch the test lead for the voltage output terminals (HIGH, LOW terminals) as this may make detecting loose conn ection difficult.

• If the HIGH and LOW voltage output terminals short-circuit or a dielectric

breakdown occurs in the tested object during the test, noise will be generated

and such noise m ay lead to a malfunction of this instrument or o f a nearby

electronic device . If t his p robl em oc cu rs , connect a ferrite core or a r es istor to

the H. V. Test Lead (high voltage side). When using a r esistor, choose one

appropriate for the power rating and withstand voltage. Also, b e alert to any

drop in test voltage.

Page 27

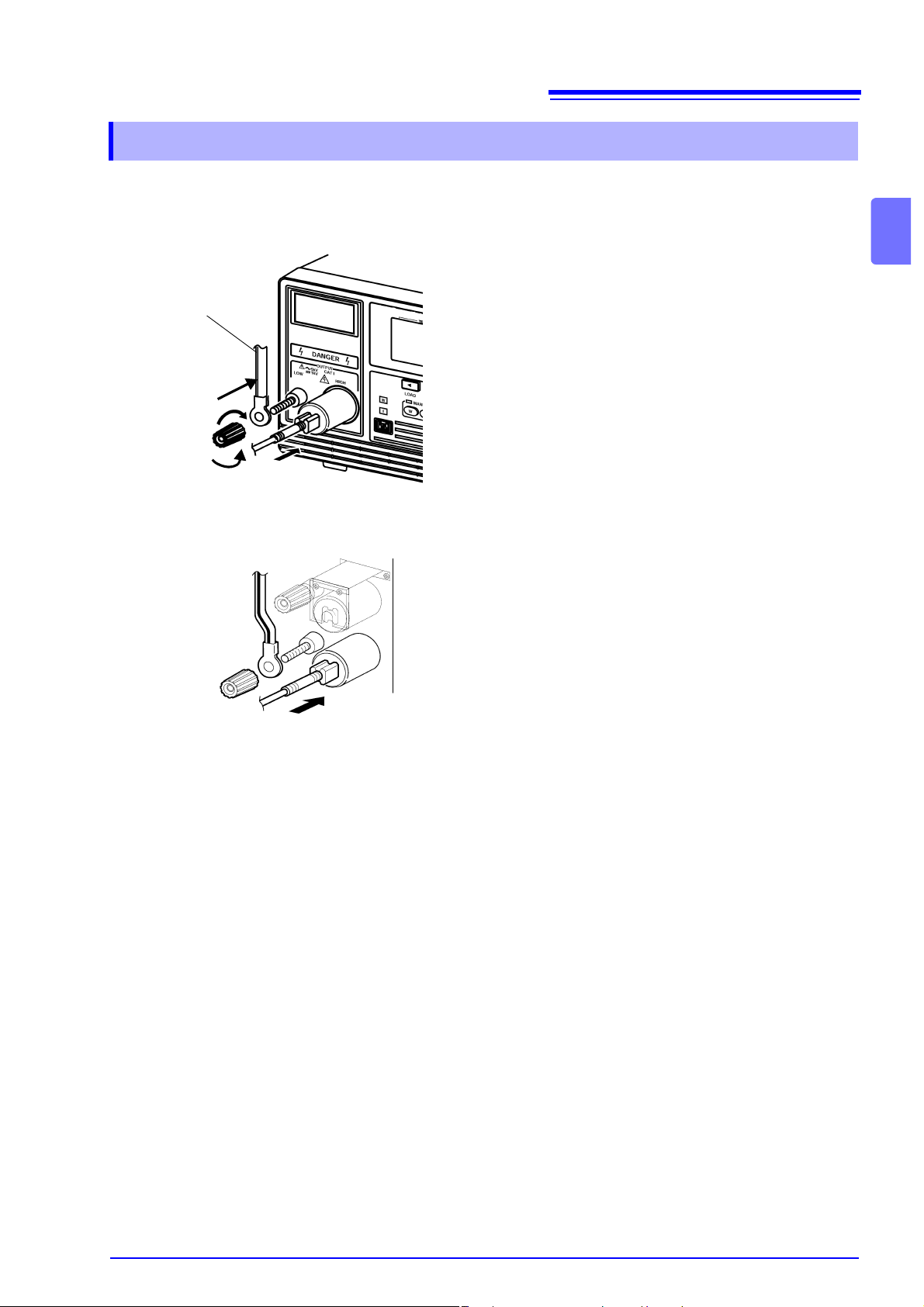

2.4 Connecting the Test Lead

1.

y

n

y

h

r-

e

e

e

ill

e

2.4.1 When using the Contact Check Function

When using the Contact Check Function, connect the test lead as follows.

On the usage of Contact Check,

ting the Confirmation Voltage used for upper and lower-limits for Contact Check".

To prevent electric sho ck, whe n the DANGER lamp is lit or during the test,

never touch the voltage output terminals, test lead, or the tested object.

Tested object

see "2.6 Pre-test Check" "3 .1.7" "4.1.5 S et-

21

2

When the front terminal is used

The H.V. Test Lead

(low voltage side)

2

3

4

1

When the back terminal is used

5

Remove the LOW voltage output terminal b

turning it counterclockwise.

2. As shown in the left figure, insert the plug o

the H.V. Test Lead (low voltage side).

3. Secure the LOW voltage output terminal b

turning it clockwise.

4. Connect the plug on the H.V. Test Lead (hig

voltage side) to the HIGH voltage output te

minal.

5. Connect in the same way when using th

voltage output terminals on the back of th

instrument as well.

6

7

Tested object

6. Connect the test lead of the LOW voltag

output terminal to the tested object.

Ensure the connection is secure so that it w

not come off during the test.

7. Connect the test lead of the HIGH voltag

output terminal to the tested object as well.

Page 28

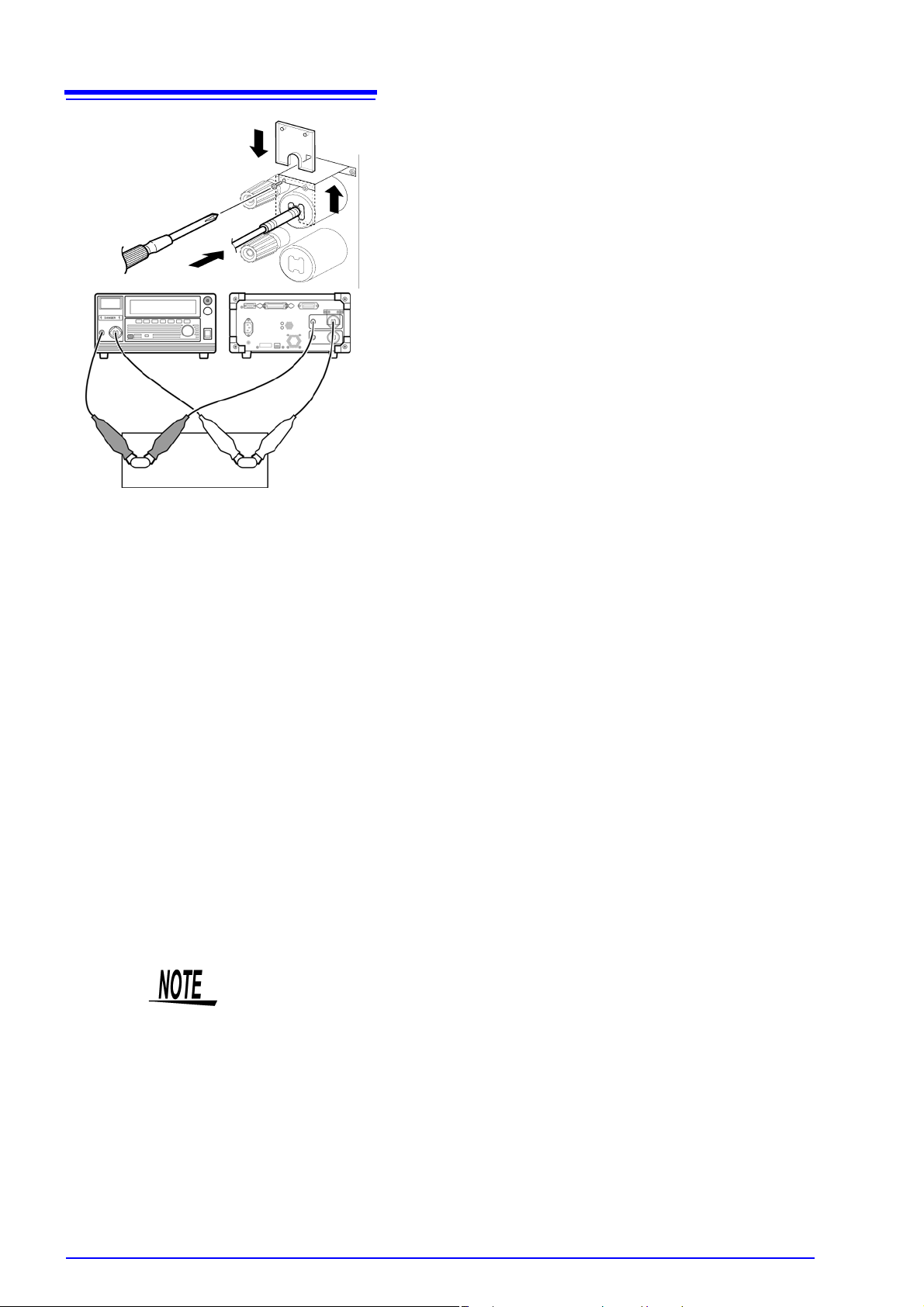

22

8.

i-

st

ct

ct

h

i-

ill

ct

s

-

2.4 Connecting the Test Lead

11

Tested object

Contact check function

By measuring the t erminal voltage of th e tested object, it i s possible to confir m

whether a test voltage is supplied to the tested object or not (Contact check function).

To use the Contact check function, besides the test output terminal, a set of

9615 H.V. Test Lead for test is necessary. (optional)

For this instrument, th e voltage detected by the Contact ch eck terminal will be

differentiated from the test voltage and referred to as the contact voltage.

When the Contact voltage is smaller than the pre- set lowe r-lim it voltage fo r contact check, broken wire or poor connection is suspe cted and a contact error wil l

be displayed (Refer to "3.1 .7", "4.1.5 Setting the Confirmation Volta ge used for

upper and lower-limits for Con tac t Che ck", "11 .3 Err or Indi c ati on" for erro rs) . By

setting an upper-lim it voltage for Contact check, d etection for any abnormality

(supply of voltage higher than the pre-set value) in the output voltage is possible.

When the Contact check terminal is conn ected to the test ed object, ens ure that

the test lead for the Contact check do es not directly touch the test lea d for the

test as shown in the di agram (ensure that the test lead for the C ontact check

touches the test lead for the test through the terminal for the tested object).

If the test lead for the Cont act ch eck d irectl y touches the tes t lead for the te st, a

broken wire will be detected but a supply of test voltage to the tested object cannot be confirmed.

• When the contact chec k terminal on the LOW side is connected not to the

• A voltage of approximately DC15 V runs thr ough the contact chec k term inals.

Remove the slip protection plate of the term

nals for Contact Check and connect the te

leads in the same way as steps 2 to 4.

9

8

10

9. Connect the test lead of the LOW Conta

Check terminal to the tested object.

Make sure the probe on the LOW Conta

Check terminal side does not directly touc

the probe on the LOW Voltage Output Term

nal side during this process.

Ensure the connection is secure so that it w

not come off during the test.

10. Connect the probe on the HIGH Conta

Check terminal side to the tested object a

well.

11. Put back the slip protection plate after con

nection.

tested object but to GND , an accurate contact check cannot be carried out.

Ensure that the contact c heck terminal on the LOW side does not touch th e

GND even when it is removed.

During insulation-resistance measurements, when the LOW Contact Check

terminal is connected to the HIGH measurement terminal, a voltage of approximately 15 V will be indicated however this is not a malfunction.

Page 29

2.4 Connecting the Test Lead

When the front terminal is used

2.4.2 When not using the Contact Check Function

When not using the Contact Check Function, connect the test lead as follows.

23

2

The H.V. Test Lead

(low voltage side)

2

3

1

When the back terminal is used

5

4

1. Remove the LOW voltage output terminal

by turning it counterclockwise.

2. As shown in the left figure, insert the plug

on the H.V. Test Lead (low voltage side).

3. Secure the LOW voltage output terminal

by turning it clockwise.

4. Connect the plug on the H.V. Test Lead

(high voltage side) to the HIGH voltage

output terminal.

5. Connect in the same way when using the

voltage output terminal s on the back of the

instrument as well.

6. Connect the test lead of the LOW voltage

output terminal to the tested object.

Ensure the connection is secure so that it

will not come off during the test.

7. Connect the test lead of the HIGH voltage

output terminal to the tested object as

well.

Page 30

24

2.5 Turning the Power On and Off

2.5 Turning the Power On and Off

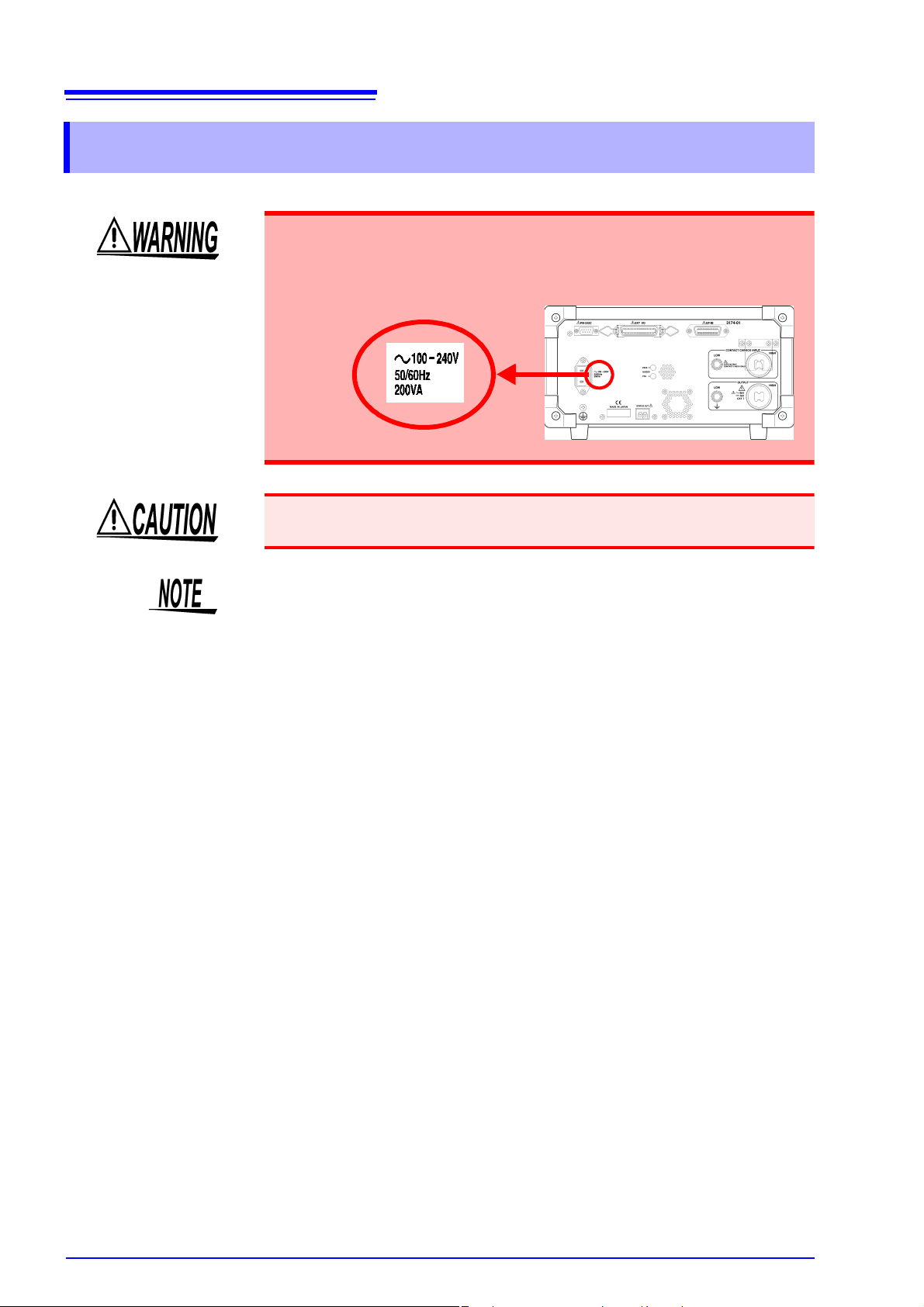

Before turning the instrument on, make sure the supply voltage matches

that indicated on the its power connector. Connection to an improper supply voltage may damage the instrument and present an electrical hazard.

To avoid dam aging the power cord, grasp the plug, not the cord, when unpl ugging it from the power outlet.

• Allow 10 minutes warming up after powering on.

The Remote Control Box, extern al I/O device, RS- 232C interface, and GP-IB

interface are active only when they are connected prior to startup. If these

devices are connected after the power is turne d on, thus causing a malfunction.

• After the power has been switched off, wait for about 5 minutes before turning

on the power again.

Page 31

Turning Power On

Front panel

25

2.5 Turning the Power On and Off

1. Turn the power switch to on ( ).

2. The “3174” (model name) and software

version are displayed on the screen.

Model name

Software version

(This diagram shows version 1.00.)

State of interface

"rS.0": RS-232C 9600 bps

"rS.1": RS-232C 19200 bps

"G.XX": GP-IB address XX

3. When the lamp is lit (it does not

light up in the Double Action mode), the

keys are ready for operation.

Action" (p. 81)

"6.1.3 Double

2

Turning Power Off

Front panel

1. For safety reasons, check the following.

• Test has completed

•The DANGER lamp is off.

• The lamp is lit.

2. Turn the power switch to off ( ).

Page 32

26

2.6 Pre-test Check

2.6 Pre-test Check

For safety reasons, check the following before starting test.

START key, STOP key

For safety reasons, switch off the power and pull the electric plug from the

socket before carrying out the check.

1. Press the center of the START key and STOP key in the front panel slowly with

your finger to confirm the feel of the key clicking. Pressing the side of the key will

make it difficult to feel the click.

(The feel of the c lick will be easier to unders tand when y ou press the key a f ew

times or compare it with the STOP key.)

* Feel of the click

When you press the key slowly, you will feel an initial resistance which seems to

be preventing the key from going down further. Press the key harder and you will

feel the clicking of the key.

Breaking current

2. The key is working properly if you feel the click.

3. The key may be damaged if you do not feel the click.

Contact your dealer or Hioki representative.

Before starting the withstanding test, check whether electric current has been

shut out when the pre-set voltage is outputted.

Recommended Insulation: High voltage-high insulat ion flat chip resist ors

GS series (from KOA Corporation) or similar

products

Note the usage voltage and power.

1. Prepare a resistor with a resistance smaller than that of the calculation result

from the test-voltage value and tes t upper- limit tes t value (breaki ng curr ent) that

are preset in the withstand -voltage test. When selecting the resistance, ensure

that the maximum volta ge usage is higher than the test voltage and the rate d

power is higher than the value which is calculated from the test voltage and

resistance values.

(Test-voltage)

(Test-voltage) < Maximum usage voltage of pre-set resistance

Square of test-voltage

÷ (Breaking current) > Resistance

÷ Resistance < Rated power of pre-set resistance

2. Set an upper-limit test value.

3. Connect the resistor that you prepared to the test lead.

4. Start the test. Confirm that the current is cut off whe n the preset voltage is out-

put. (i.e., make sure the instrument is in the FAIL state).

Page 33

Measured resistance

1. Prepare a resista nce with a val ue which is hig her than t he lo wer-limit te st val ue

2. Set a test voltage.

3. Connect the resistor that you prepared to the test lead.

27

2.6 Pre-test Check

Before starting the in sulat ion-res ista nce test , chec k th at the resi stance va lue for

measurement is the same as the pre-set value.

Recommended Insula tion: High voltage-high insulation flat chip resistors

GS series (from KOA Corporation) or similar

products

Note the usage voltage and power.

but close to it. W hen selec ting the re sist ance, ens ure that th e max imum volta ge

usage is higher than the test voltage and the rated power is higher than the value

which is calculated from the test voltage and resistance values.

(Test-voltage) < Maximum usage voltage of pre-set resistance

Square of test-voltage

÷ Resistance < Rated power of pre-set resistance

2

4. Make sure that the resistance measured matches the resistor that you prepared.

Inter-lock

If the Inter-lock fun ction is set, m ake sure the Inter-lock functi on works proper ly

before starting test.

See "8.3 Inter-lock Function" (p. 111)

Confirming the Contact Check Function

Check whether the Contact Check Function is functioning properly.

For safety reasons, carry out the check only after removing the high voltage

probe on the voltage output terminal side from the instrument.

1. Set the upper-limit and lower-limit voltages of the Contact Check Function.

Withstand-voltage test : "3.1.7 Setting the Confirmation Voltage used for

Insulation-resistance test : "4.1.5 Setting the Confirmation Voltage used for

2. Connect the low voltag e side for probe for Contact Check and lo w voltage side

for probe for voltage ou tput termin al side afte r removing the high v oltage pro be

on the voltage output terminal side.

upper and lower-limits for Contact Check" (p. 38)

upper and lower-limits for Contact Check" (p. 55)

3. Start testing and confirm “ ” appears immediately. Then,

the test is stopped wit h an error number display. T his is the correct functio n of

the contact check.

If the test is comp let ed and either " ", " " , " " or

" " appears, the Contact Check Function is not ON or the instrument is

defective.

4. Start the test after separatin g the low v oltage si de pr o be for Con tac t Che ck from

the low voltage side of the voltage output terminal side probe.

Confirm that there i s a beeping sou nd from the inst rument and /

(Err4) appears. If the test starts, this coul d mean that the Contact Check

Function is OFF or there is a malfunction.

Page 34

28

2.6 Pre-test Check

Self-testing of the Contact Check Function

After finishing laying ou t the wires for the test, hold down the SHIFT key and

press the START key to start the Contact Check self-testing (The wire layout for

the test is the actual test wire layout or the wire layout used d uring the pre-test

check).

1. Connect the instrument to the tested object following the instructions in "Chapter

2 Testing Arrangements " ( p. 17) in this manual. Connection used in the pr e- test

checks will work as well.

2. Set the test conditions (test voltage, upper and lower e lectric current li mits or

insulation-resis tance upper and l ower limits) fol lowing the ins tructions in "Chapter 3 Withstand- Voltage Test" (p. 29), "Chapter 4 Insulation- Resistance Test"

(p. 47) in this manual.

3. Check that the surrounding is clear the n in the READY status, hold down the

SHIFT key and press the START key. Contact Check self-testing will start. The

test-frequency and initial voltage for r amp-up parts will display “CC”. Pressing

the SHIFT and START keys in status other than READY will be ignored.

4. During the self-testing, the following will be checked and if no abnormality is

detected, “ ” wi ll be indicated and the inst ru men t wi ll r etu rn to RE ADY s tatus.

If an abnormality is detected, an error n umber (see "11.3 Error I ndication" (p.

197)) will be indicated followed by “ ”.

1. Test voltage check

Check if the output voltage is similar to the pre-set test voltage

Judgement includes error margin of the instrument’s voltmeter

2. Check for volta ge in excess of upper- limit Contact Check voltage for H side

terminal

The instrument will intentionally output a voltage higher than the pre-set Contact Check upper-limit voltage to check for excess upper-limit voltage.

This test will not be carr ied out if the Contact Check upper-limit value is n ot

set (during OFF)

3. Check for voltage below lower-limit Contact Check voltage for H side terminal

The instrument will intentiona lly outpu t a voltage l ower than the pre-set Contact Check lower-lim it voltage to check for volta ge below the lower-limit vo ltage.

This test will not be carr ied out if the Contact Check low er-limit value is not

set (during OFF)

• Take note that checks for the L side Contact Check will not be carried out. Be

sure to carry out the check for the L side using the procedures used for pretest check for the Contact Check Function.

• As the upper-limit vo ltage for Contact Chec k is 5. 00 kV, the judgment may be

inaccurate if the test voltage is set at 5.00 kV.

• As the lower-limit voltage for Contact Chec k is 0.2 0 kV, the judgment may be

inaccurate if the test voltage is set at 0.20 kV.

Page 35

29

Withstand-

Voltage Test Chapter 3

This chapter describes how to set withstand-voltage test conditions

and the proper testing procedure. Read "Chapter 2 Testing

Arrangements" (p. 17), and make the necessary preparations for

testing.

Refer to "Chapter 5 Automa tic Test" (p. 69) for carrying out withstanding and

insulation-resistance tests consecutively.

To prevent electric sho ck, whe n the DANGER lamp is lit or during the test,

never touch the voltage output terminals, test lead, or the tested object.

3

Tested object

• To prevent electric shocks, do not connect to or remove the test lead

from the tested object when there is a voltage supply during the test.

There is a danger of a voltage higher than the pre-set voltage being supplied due to the stabilization function of the voltage output. When this

happens, the instrument may malfunction due to the noise produced.

• The instrument and peripheral electrical devices may not function properly when the tested object’s insulation is broken or when the test lead s

are not connected properly. When this happens, connect a ferrite core or

a resistor to the test lead on the hi gh voltage side. Be careful of a dip in

the test voltage caused by the rated power, withstanding voltage and

resistor when choosing a resistor.

• Wear insulated gloves and confirm that automatic control is off before

changing the tested object or touching the test lead and tested object

directly.

• To in crease test efficienc y, this instrument can be controlled by EXT I/O

or RS-232C and GP-IB and can start tests automatically. As a result, there

is a danger of electric shock accidents. Measures to prevent people from

coming near the instrument or the tested object unintentionally must be

taken when starting the instrument automatically.

• When the tested objec t in use shows dependen cy on voltage (impedance of

ceramic condenser, etc.), the wavefo rms of the output v oltage may become

distorted. The tested object may malfunction depending on the distortion of the

waveforms.

• When the tested object in use possesses an induc tivity like a coil, a voltage

higher than the pre-se t voltage may appear transitionally, causing damage in

the tested object.

Page 36

30

Select the Withstand-voltage test mode

W

Set test conditions

"3.1.1 Setting the Test-Voltage Value" (p. 32)

"3.1.2 Setting the Upper (Lower) Limit Value" (p. 33)

"3.1.3 Setting the Test Time Timer" (p. 34)

"3.1.4 Setting the Ramp-up (Ramp-down) Time Timer" (p. 35)

"3.1.5 Setting the Test-Frequency" (p. 36)

"3.1.6 Setting the Initial voltage for ramp-up" (p. 37)

Starting a test

Press the START key to start a test. (p. 40)

START

Displaying the test result

PASS

Test result (p. 42)

Page 37

31

3.1 Setting the Test-Conditions

3.1 Setting the Test-Conditions

For safety reasons, be sure to carry out pre-test check (p. 26) before setting the test conditions.

Setting the test conditions.

Pre-set test conditions can be retrieved to carry out the test.

See "7.2 Loading the Test Conditions" (p. 102)

3

Test setting

state

When lights up on the screen, pressi ng the / key will change the

status to the test conditions status. The test voltage will flash ( will go off).

Set the test conditions in this status.

When Double Action is set, / key is enabled even when is not lit.

test-voltage

value

upper-limit for Contact Check voltage

lower-limit for Contact Check voltage

upper-limit

test value

(Initial voltage for ramp-up)

lower-limit

test value

test-time

ramp-up time

ramp-down time

test-frequency

If the item is not nee ded in the test, se t it to OFF using the ON/OFF key. However, the test-voltage value, the upper-limit test value, and the test-frequency

cannot be set to OFF.

Pre-set test conditions can be saved. (p. 99)

The initial voltage for ramp-up is displayed only when ramp-up time is set.

• In the test setting state, the test cannot start . Test will only start when

lights up.

• Indicates the voltage for the output te rminal in Test-voltage v alue in READY

and test status.

When lights up, READY for EXT I/O turns Lo at the same time.

•

Page 38

32

3.1 Setting the Test-Conditions

3.1.1 Setting the Test-Voltage Value

Set a test-voltage value. When the test is started, the pre-set voltage will be supplied to the tested object from the voltage output terminal via the test lead.

The test will not start if th e load is large and the out put voltage does not re ach

±30 V of the set test-voltage. ( flashes.)

If the output voltage fai ls to rea ch ±30 V of the test -vol tage wit hin app roxi mately

5 seconds after completion of the ramp-up time, the instrument will change to the

FAIL state and the test will be terminated.Also, if the output voltage deviates

from test-voltage and does not re turn to ±30 V of the set value with in 5 se co nds ,

the test is terminated.

1.

2.

When is lit on the screen, press the key to get to the test conditions mode.

* When Double Action is set, / key is enabled even when is not lit.

Press the / keys to set the test-voltage value.

or

<Ex.> Set to 0.3 kV.

Setting range: 0.20 to 5.00 kV (The value changes by 0.01 kV.)

To change the value by 0.1 kV, while holding down the SHIFT key, press /

keys.

3.

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

STOP

To continue to the setting for the next item, press the key.

• The output voltage can be re st rict ed to prevent accidents caused by imp roper

settings. (When the default is set to 5.00 kV.)

See"6.1.5 Output-Voltage Restricting" (p. 83)

• Note that the instrument do es not start test if the test-voltage valu e is greater

than the output-voltage restricting value.

See"6.1.5 Output-Voltage Restricting" (p. 83)

• The tested object may damage if a v ol tage high er than necessary is supplied.

Be careful when setting the output voltage to ensure that the teste d object

does not receive a voltage higher than necessary.

• The tested object m ay dam age if a voltage is supplie d l ong er than necessary.

Be careful when setting the test time.

• Refer to relevant safety regulations and laws when setting the test voltage

value.

Page 39

3.1 Setting the Test-Conditions

3.1.2 Setting the Upper (Lower) Limit Va lue

Set a upper-limit test v alue and a lower -limit te st value. For example, when the

upper-limit (lower-limit) test value is set at 10 mA, a “

when

a current less than (more than) 10 mA is supplied to the tested object. If no

lower-limit test value is required, set it to “OFF” using the ON/OFF key. However,

the upper-limit test value cannot be set to OFF.

33

PASS” will be shown

1.

2.

3.

4.

or

or

Press the key t o move t he flas hin g cursor to t he uppe r-li mit test value.

is lit.

Press the / keys to set the upper-limit test value.

<Ex.> Set to 0.2 mA.

Setting range: 0.1 to 20.0 mA (The value changes by 0.1 mA.)

To change the val ue by 1 mA , wh il e h old ing do wn the SHIFT key, press /

keys.

Press the key to move the flashing cursor to the lower-limit test value.

is lit.

Press the / keys to set the lower-limit test value.

3

5.

STOP

Setting range: 0.1 to 19.9 mA (The value changes by 0.1 mA.)

<Ex.> Set to 0.1 mA.

If no lower-limit test value is required, set it to “OFF” using the ON/OFF key.

<Ex.> Set to OFF.

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

To continue to the setting for the next item, press the key.

• The electric current range will be decided by the lower-limit test value (10 mA-

range for “lower-li mit test value ≤ 10.0 mA”, and 20 mA-range for “lower-lim it

test value > 10.0 mA”)

• The setting resolution of the upper (lower)-limit test value is 0.1 mA.

• The current measurement res olution during a tes t depends on the se t upper-

limit test value: 0.01 mA at 0.10 mA to 10.00 mA and 0.1 mA at 10.1 mA to

20.0 mA.

• If the set lower-limit test value is greater than the upper-limit test value,

unable to get out of setting screen. In such a case, correct the upper- or

lower-limit test value.

• A lower-limit test value is not necessary in the withstanding test but pre-setting

it will allow the instrument to be used for simple Contact Checks.

Page 40

34

3.1 Setting the Test-Conditions

3.1.3 Setting the Test Time Timer

When the test tim e t ime r is s et, the te st wil l auto mat ic al ly run and s top whe n the

time is up. If no test-time timer is required, set it to “OFF” using the ON/OFF key.

1.

2.

or

Press the key to move the flashing curs or to the test-time timer.

Press the / keys to set the test-time timer.

<Ex.> Set to 0.3 s.

Setting range: 0.3 to 999 s

• When the set time scale is 0.3 s to 99.9 s

The value changes by 0.1 s. To change the value by 1 s, while holding down

the SHIFT key, press /

• When the set time scale is 100 s to 999 s

The value changes by 1 s. To ch ange the v alue b y 10 s, while holdin g down

the SHIFT key, press /

If no test-time timer is required, set it to “OFF” using the ON/OFF key.

keys.

keys.

3.

Set to OFF .

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

STOP

To continue to the setting for the next item, press the key.

• The setting resolution of the t est-time timer is 0.1 s between 0.3 and 99.9 s,

and becomes 1 s between 100 and 999 s.

• If a test-time timer has been set, the reduction tim er will operate during the

test.

• If the test-time timer is set to OFF, the time elapsed during the test is displayed. When this time exce eds 999 s, "- - -" will appea r, but the test will continue.

Page 41

3.1 Setting the Test-Conditions

3.1.4 Setting the Ramp-up (Ramp-d own) Time Timer

Ramp-up time means the time to increase the voltage until it reaches the set

test-voltage value set in the "Setting the Test-Voltage Value" (p.32). Ramp-down

time means the time to dec rease the voltage upon comp letion of the test time.

When the ramp-u p t ime a nd ra mp-do w n tim e are set, the test voltage durin g t he

test can be controlled.

flashes during th e ramp-up time an d the ramp-down time.If no ramp-up

(ramp-down) time timer is required, set it to “OFF” using the ON/OFF key.

1.

Press the key to move the flashing cursor to the ramp-up time timer.

35

3

2.

3.

4.

Press the / keys to set the ramp-up time timer.

or

<Ex.> Set to 0.1 s.

Setting range: 0.1 to 99.9 s (The value changes by 0.1 s.

If no ramp-up time timer is required, set it to “OFF” using the ON/OFF key.

Press the key to move the flashing cursor to the ramp-down time

timer.

Press the / keys to set the ramp-down time timer.

or

<Ex.> Set to 0.1 s.

Setting range: 0.1 to 99.9 s (The value changes by 0.1 s.)

5.

STOP

If no ramp-down time timer is required, set it to “OFF” using the ON/OFF key.

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

To continue to the setting for the next item, press the key.

• During the ramp-down time, screening using the upper- or lower-limit test

value is invali d.

• A ramp-up time of 0.1 seconds is always inserted even when the ramp-up

time timer is set to OFF.

• Ramp-down time will not be inserted during a forced termination.

• Due to the response time of the ci rcui t, sometimes immediately after the w ithstand voltage test has started, both the time taken for the output voltage to

reach initial voltage of r amp-up and the time taken for the outp ut voltage to

reach the accurate tes t voltage after the ramp-up time ha s ended, may take

longer, depending on the loads. As a result, the actual test t ime will be; time

taken for the output voltage to reach the ini tial vo ltage level + setting ramp-up

time + time taken for the output voltage to reach the accurate test voltage level

+ test time + ramp-down time.

Page 42

36

3.1 Setting the Test-Conditions

3.1.5 Setting the Test-Frequency

In the withstand-voltage test, the test-frequency (50 Hz/ 60 Hz AC) can be

selected.

1.

2.

3.

Press the key to move the flashing curs or to the test-frequency.

Press the / keys to set the test-frequency.

or

<Ex.> Set to 50 Hz AC.

Setting range: 50 Hz/ 60 Hz AC

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

STOP

To continue to the setting for the next item, press the key.

Page 43

3.1 Setting the Test-Conditions

3.1.6 Setting the Initial voltage for ramp-up

When setting the vo lta ge-r ai sing ti me (ramp-up time), the initial value can be s et

by setting it as a p roportion of the test voltag e. The default v alue is 0.0 a nd the

initial voltage for ramp-up is 0 V.

37

1.

2.

Press the key to move the flashing cursor to the Initial voltage for

ramp-up.

3

In the frequency di sp la y, a d oub le- di gi t v ol tage rati o ( p ro porti on of t est voltage)

will be shown to indicate the ramp-up initial voltage setting.

Press the / keys to set the Initial voltage for ramp-up.

or

<Ex.> Set the initial voltage as 0.1 times the test voltage

3.

Setting range: 0.0 to 1.0 (The value changes by 0.1.)

• Setting is not possible when the ramp-up time is OFF.

• When the test is started, a voltage indi cated by the test voltage mu ltipl ied by

the voltage ratio will be outpu tted. After that, it wi ll use the pre-s et “ramp-up

time” to rise almost linearly until the test voltage is achieved.

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

STOP

To continue to the setting for the next item, press the key.

• Setting is not possible if the ramp-up time timer is not set.

• If the voltage calculated from a pro por ti on of th e in iti al voltage and t he pre- se t

voltage is less than 100 V, the initial voltage will be 100 V.

• Due to the response time of the ci rcui t, sometimes immediately after the w ithstand voltage test has started, both the time taken for the output voltage to

reach initial voltage of r amp-up and the time taken for the outp ut voltage to

reach the accurate tes t voltage after the ramp-up time ha s ended, may take

longer, depending on the loads. As a result, the actual test t ime will be; time

taken for the output voltage to reach the ini tial vo ltage level + setting ramp-up

time + time taken for the output voltage to reach the accurate test voltage level

+ test time + ramp-down time.

Page 44

38

.

3.1 Setting the Test-Conditions

3.1.7 Setting the Confirmation Voltage used for upper and lower-limits for Contact Check

Confirmation Voltage used for upper and lower-limits for Contact Check.

Contact Check can be carried out by measuring the terminal voltage of the

tested object. W hen this functio n is pre-set, test ab normalities ca n be detected

whenever the output vo ltage deviates from the pre-set ranges. The setting for

the upper or lower limit v oltage confirmati on is the same as that us ed for the H

side terminal Contact Chec k, but setting either the upper li mit or the lower limit

will also automatically allow for Contact Checks on the L side terminals.

By measuring the voltage on the H side terminals of the tested object, checks on

whether an accur ate voltage is supplied to t he tes t t er mi nals or n ot (w heth er th e

test lead is properl y connected or not: Contact Check ) can be ca rri ed o ut. W he n

a value outside the range of the pre-set terminal voltage is achieved, an error

number will show and the test will terminate.

When Contact Check Function is not in use, press the ON/OFF key to set to

"OFF".

1.

2.

Press the key to move the flashing cursor to the upper-limit confirmation voltage for Conta ct Check.

Press the / keys to set the upper-limit confirmation voltage for Contact Check.

or

<Ex.> Set to 0.4 kV

Setting range: 0.20 to 5.00 kV (The value changes by 0.01 kV.)

To change the value by 0.1 kV, while holding down the SHIFT key, press /

keys.

If no upper-limit confirmation voltage for Contact Check is required, set it to

“OFF” using the ON/OFF key.

3.

Press the key to move the flashing cursor to the lower-limit confirmation voltage for Contact Check.

Page 45

39

.

3.1 Setting the Test-Conditions

4.

5.

or

STOP

Press the / keys to set the lower-limit confirmation voltage for Contact Check.

<Ex.> Set to 0.2 kV

Setting range: 0.20 to 5.00 kV (The value changes by 0.01 kV.)

To change the value by 0.1 kV, while holding down the SHIFT key, press /

keys.

If no lower-limit confirmation voltage for Contact Check is required, set it to

“OFF” using the ON/OFF key.

Press the STOP key to complete the setting value.

The instrument reverts to the READY state.

To continue to the setting for the next item, press the key.

• A value for the Contact Check up per-limit co nfirmation voltage whic h is lower

than the test voltage o r a l owe r-l im it vo ltage which is higher than the test voltage can be set but during this time, pressing the START key will not start the

test.

• When contact error is detected, the following errors will be displayed and the

test will terminate.

Contact error at the L side terminal

Err4

Err5 Test voltage setting lower than the lower-limit confirmation voltage

(wrong setting)

Err6 Output measurement voltage lower than the lower-limit confirmation

voltage (output abnormality)

Err7 Contact voltage(p. 22) lower than the lower-limit confirmation voltage

(measurement-type malfunction, contact error)

Err8 Pre-set voltage higher than the upper-limit confirmation voltage

(wrong setting)

Err9 Output voltage higher than the upper-limit confirmation voltage

(output-type or measurement-type malfunction)

* Test for Err6 and Err7 will not be carri ed out during ramp-up and ramp-

down.

* When FAIL hol d is no t set, an err or mes sage will appe ar fo r abo ut 0.3 sec-

onds before returning to READY mode.

3

• To prevent ramp-up function and fluctuations in output voltage loads, carry out

the HIGH side terminal Contact Check only after the output voltage has

reached the test voltage value.

• As the upper-limit voltage for Contact Che ck is 5 .00 kV, the judgment may be

inaccurate if the test voltage is set at 5.00 kV.

• As the lower-limit voltage for Co ntact Check is 0.20 kV, the judgment may be

inaccurate if the test voltage is set at 0.20 kV.

• Setting the voltages for the upper-limit and lower-limit Contact Check after taking into account the error margin of this instrument is recommended.

• The detected voltage for the C ontact Check is the average d etected value.

Therefore, if the waveform dis tortions are large, the margins of error from the

test voltage display will also be large.

Page 46

40

3.2 Starting a Test

3.2 Starting a Test

Carry out the test after finishing setting the test conditions (p. 31).

For safety reasons, key lock is recommended. All keys except the START key

and STOP key are disabled while the key-lock function is active. (p. 79)

T o prevent electric shock, check the following before starting test.

Front panel

• When the tested objec t in use shows depend ency on voltage (impedance of

ceramic condens er, etc.), the waveforms of the output voltage may become

distorted. The tested object may malfunction depending on the distortion of the

waveforms.

• Continuous output of a high v oltage ma y h eat th e bottom of the instrument.

prevent from getting scalded, do not touch the bottom.

•The DANGER lamp is

OFF.

• The lamp is lit

(it is off in the Double

Action mode).

To

• There is a priority hierarchy for the START keys.

Priority hierarchy: Remote Control Box > E XT I/O > Front panel of the 3174

(3174-01)

Note that when a START key with a higher priority is in use, lower-priority

keys are disabled.

• When the tested obje ct in use possess es an inductivity l ike a coil, a voltage

higher than the pre- set voltage may appear tra nsitionally, causing damage i n

the tested object.

• The tested object may damage if a v ol tage high er than necessary is supplied.

Be careful when setting the output voltage to ensure that the teste d object

does not receive a voltage higher than necessary.

• The tested object m ay dam age if a voltage is supplie d l ong er than necessary.

Be careful when setting the test time.

Page 47

41

3.2 Starting a Test

Double action state

1.

2.

3.

( is lit)

STOP

START

will not be displayed because the default factory setting for this

instrument is Double Action.

is not lit.

Press the STOP key once in the beginning.

When the STOP key is pressed, will be shown for 0.5 seconds.

To start the test, press the START key when is shown.

The DANGER lamp on the front panel of instrument is lit.

3

• flashing on screen : Output voltage rising (within time shown on

ramp-up timer). (FAIL will display if the current

measurement value is higher than the upper-limit

test value.)

• lit up on screen : Output voltage has reached the test voltage. Test

starts.

•“UP”

•“dn”

• To forcibly terminate the test, press the STOP key.

If the DANGER lamp does not go off even after the test has finished, this

could mean that some voltage stronger than the safe voltage (about AC 30

V or DC 60 V) still remains in the voltage output terminal . To prevent electric shock, never touch the voltage output terminals.

Double Action can be released with the Option Setting.

In this case, will be displayed, and the test can be started by just pressing

the START key.

See "6.1.3 Double Action" (p. 81)

display : ramping up

display : ramping down