Page 1

QUICK START MANUAL

3169-20/21

CLAMP ON POWER

HiTESTER

Page 2

Page 3

Contents

i

Contents

Introduction .................................................................. 1

Safety Notes ................................................................ 1

1 Parts Names 3

1.1 Instrument Labels and Functions ....................... 4

1.2 Screen Names and Display Elements ................ 8

1.2.1 Screen Configuration ...........................................8

1.2.2 Common Display .................................................9

1.2.3 On-Screen Indicators .........................................10

2 Power Measurement 11

2.1 Outline .............................................................. 11

2.2 Measurement Procedure .................................. 13

2.3 Measurement Preparations .............................. 14

2.4 Connect to the Line to be Measured ................ 18

2.5 Perform Measurement ...................................... 26

1

2

3

4

5

6

7

8

9

10

11

APPX

IDX

Page 4

ii

Contents

Quick Start Manual

Page 5

Introduction

1

• The 3169-20/21 CLAMP ON POWER HiTESTER is supplied

with a instruction manual in addition to this manual. Please be

sure to read both manuals.

• This manual is a quick reference source with examples and information regarding the setting-up of and key operation for the

3169-20/21 CLAMP ON POWER HiTESTER for measurement

purposes.

• For current input with this device, a clamp-on sensor (optional) is

required. For details, refer to the instruction manual for the

clamp-on sensor you are using.

Safety Notes

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the product.

Advisory items related to performance or correct

operation of the product.

1

2

3

4

5

6

7

8

Other Symbols

❖

*

Indicates the prohibited action.

Indicates the reference.

Indicates quick references for operation and reme-

dies for troubleshooting.

Indicates terminology explained at the bottom of

the page.

9

10

11

Page 6

Quick Start Manual

2

Page 7

3

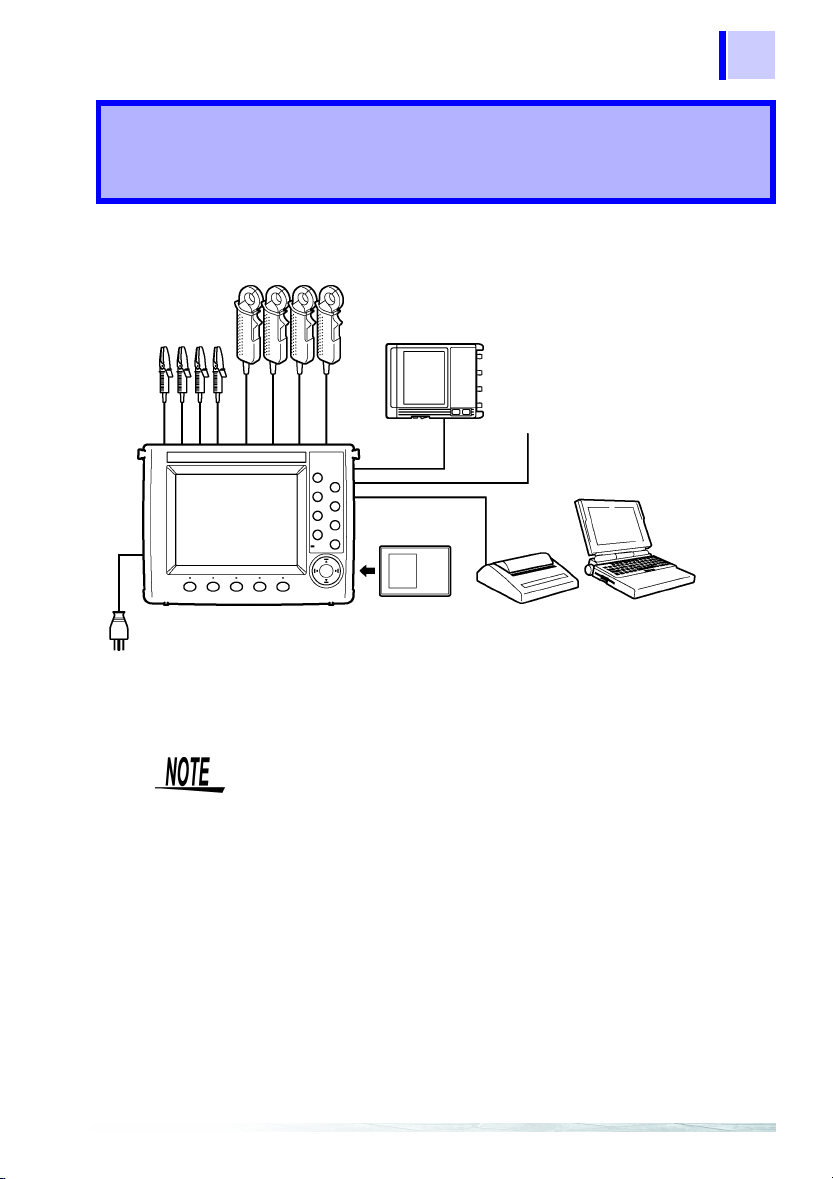

Parts Names

❖4 "Connecting to Lines to be Measured" (page 35)

❖11 "Using D/A Output (3169-21 only)"

(page 157)

Recorder, logger

D/A output

(3169-21)

PC card

❖7.2 "Using a PC Card"

(page 117)

❖3 "Measurement Preparations"

(page 25)

*: The RS-232C is connected to a printer or PC.

The reference pages referred to above are those in the instruction

manual.

EXT I/O

RS-232C

1

❖10 "Using the External Input/

Output Terminal" (page 151)

❖9 "Using the Instrument with

a Computer" (page 145)

PC

Printer

❖8 "Using a Printer"

(page 137)

1

2

3

4

5

6

7

8

9

10

11

Page 8

Quick Start Manual

4

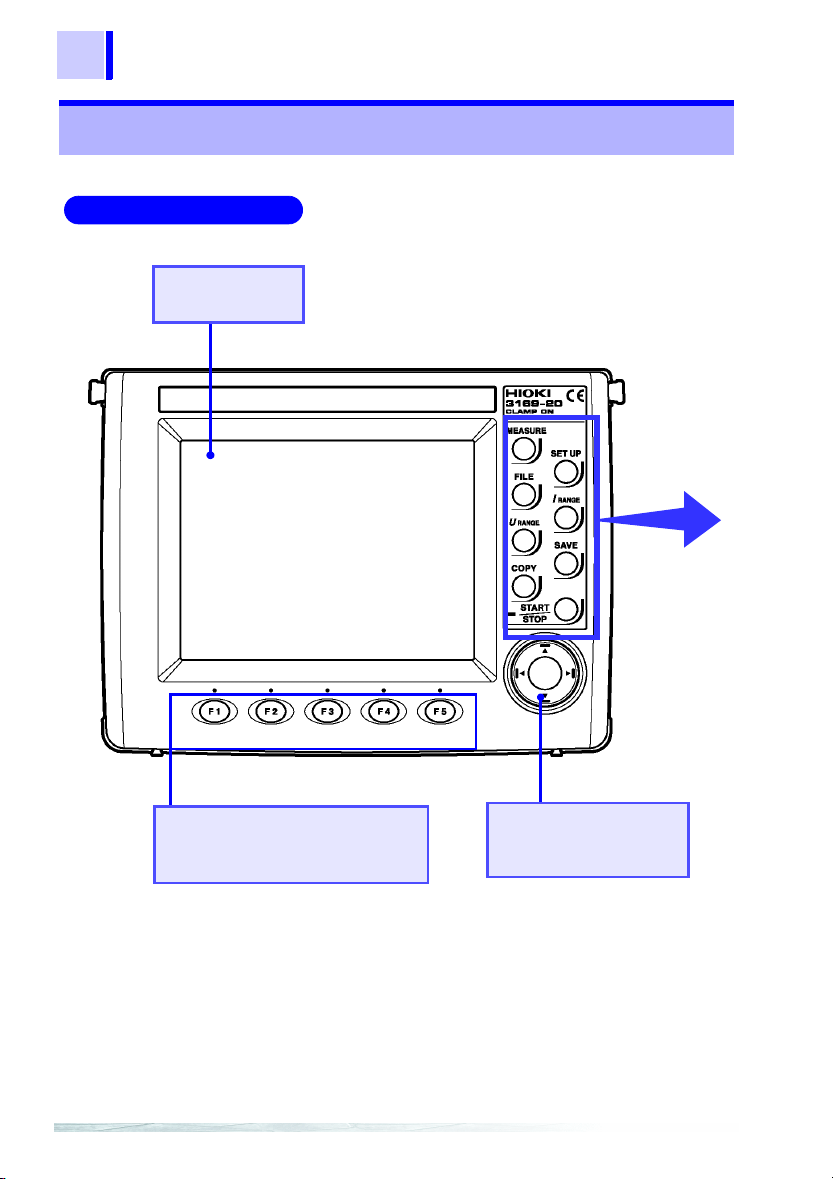

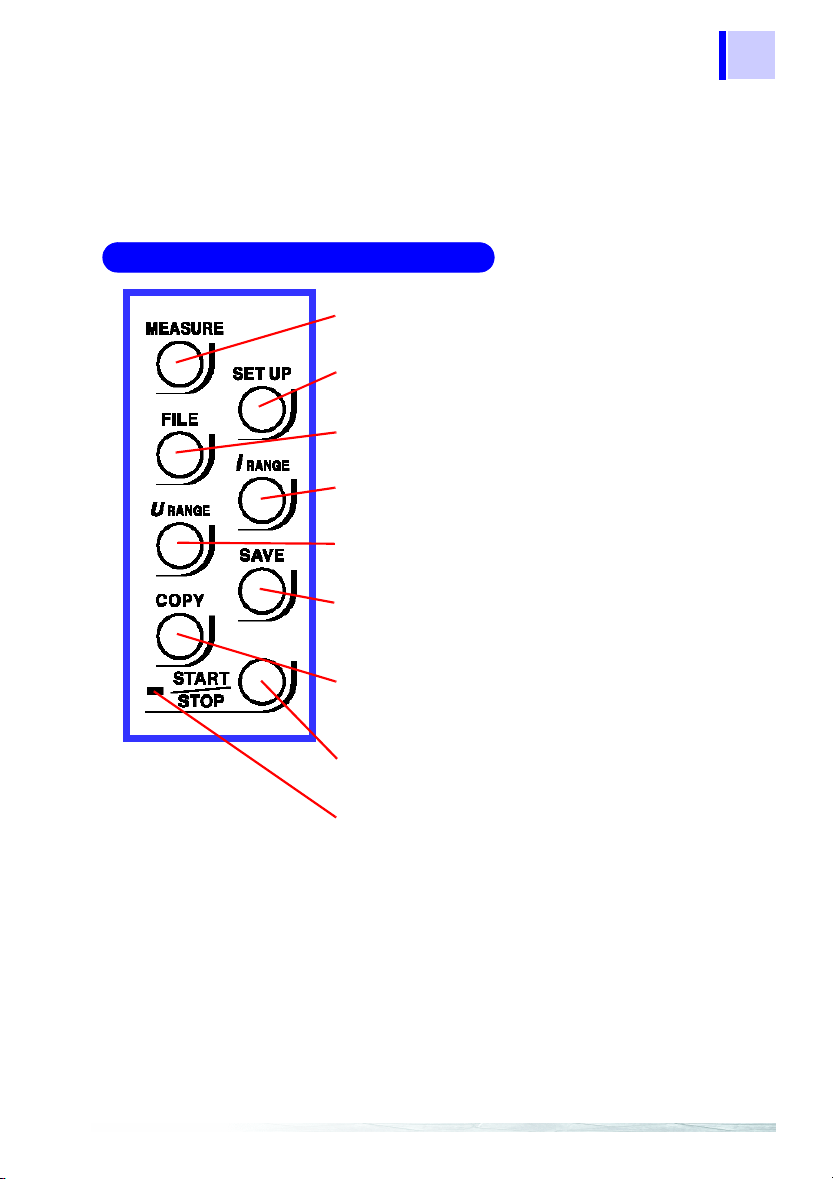

1.1 Instrument Labels and Functions

1.1 Instrument Labels and Functions

Front Panel

Display

5.7-inch STN LCD

Function (F1-F5) keys

Selects or switches the screens

and setting items.

Cursor key

These keys move the cursor on the screen.

Page 9

1.1 Instrument Labels and Functions

5

1

Front Panel Enhanced View

MEASURE key

Switches to a screen that displays measurements.

SET UP key

Switches to a screen that displays settings.

FILE key

Used to work on files.

I RANGE key

Sets the current measurement range for the circuit

to be measured on-screen.

U RANGE key

Sets the voltage measurement range.

SAVE key

Enables the manual saving of measurement data

on the PC card or in internal memory. Manual saving is not possible during time-series measurement.

COPY key

Outputs screen image data to the PC card, internal

memory, or a printer.

START/STOP key

Starts or stops time-series measurements including

integration measurement.

2

3

4

5

6

7

8

9

START/STOP LED

Flashes in green while the instrument is standing by

for time-series measurement, and lights in green

while the instrument is performing time-series measurement.

10

11

Page 10

Quick Start Manual

6

1.1 Instrument Labels and Functions

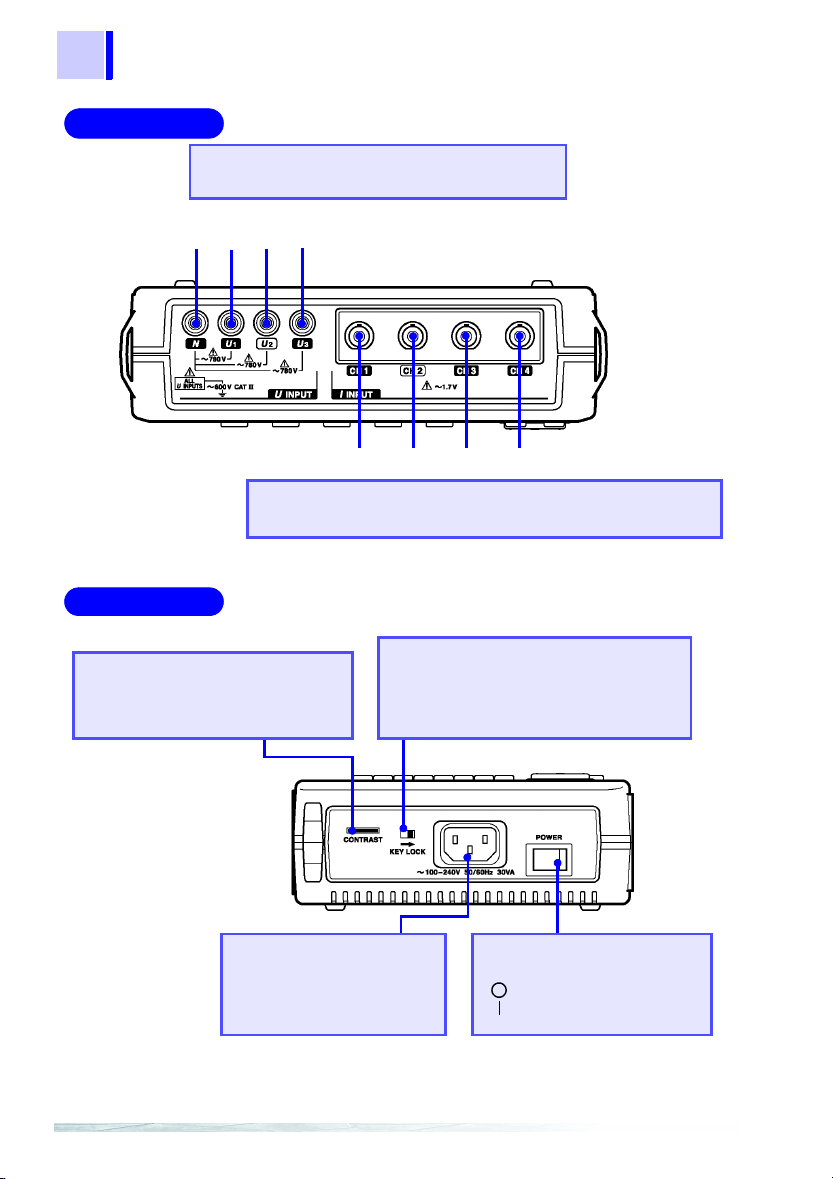

Top Panel

Left Panel

Voltage Input terminals

Connect the supplied 9438-03 VOLTAGE CORD.

Black Red Yellow Blue

NU1U2U

3

CH1 CH2 CH3 CH4

Current Input terminals

Connect an optional clamp-on sensor.

Contrast Control Knob

(CONTRAST)

Adjusts the contrast of the screen.

AC Power Inlet

Connects the power cord.

The supply voltage ranges

from 100 V to 240 V.

KEY LOCK switch

Sliding this switch in the direction of the

arrow disables all key operation except

the POWER switch.

POWER switch

Turns the instrument on and off.

: Power OFF

: Power ON

Page 11

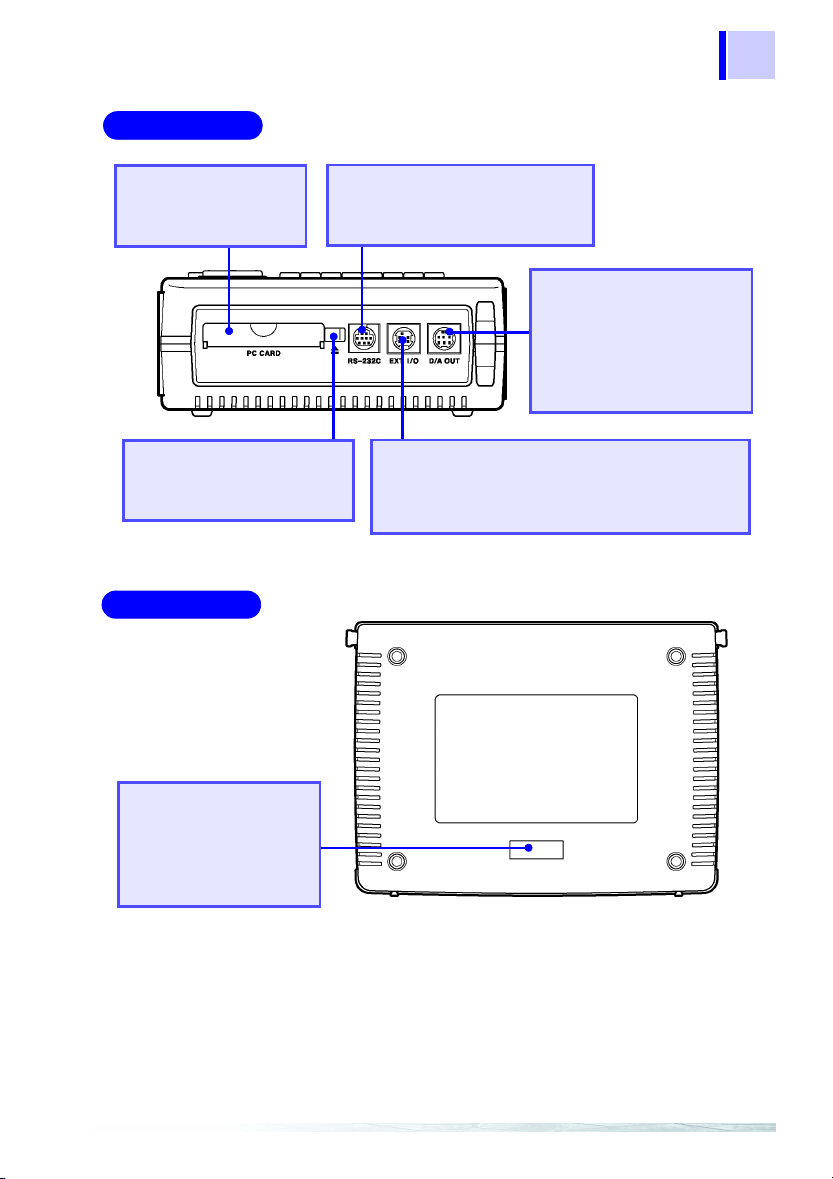

Right Panel

7

1.1 Instrument Labels and Functions

PC Card slot

A PC Card can be

inserted here.

Eject button

Press this button to eject a

PC Card from the slot.

Rear Panel

RS-232C Interface connector

Connects to a PC or printer using

an RS-232C cable.

D/A Output Terminal

(D/A OUT)

Installed in the 3169-21

only. Connects the supplied 9441 connection cable. Used for analog

output.

External Input/Output Terminal (EXT I/O)

Connects the optional 9440 connection cable.

Used to start and stop time-series measurement,

and control data storage on the PC card.

1

2

3

4

5

6

7

8

Number plate

Contains manufacturer’s ID

numbers. Please do not remove, as this information is

reguired for product management.

9

10

11

Page 12

Quick Start Manual

8

1.2 Screen Names and Display Elements

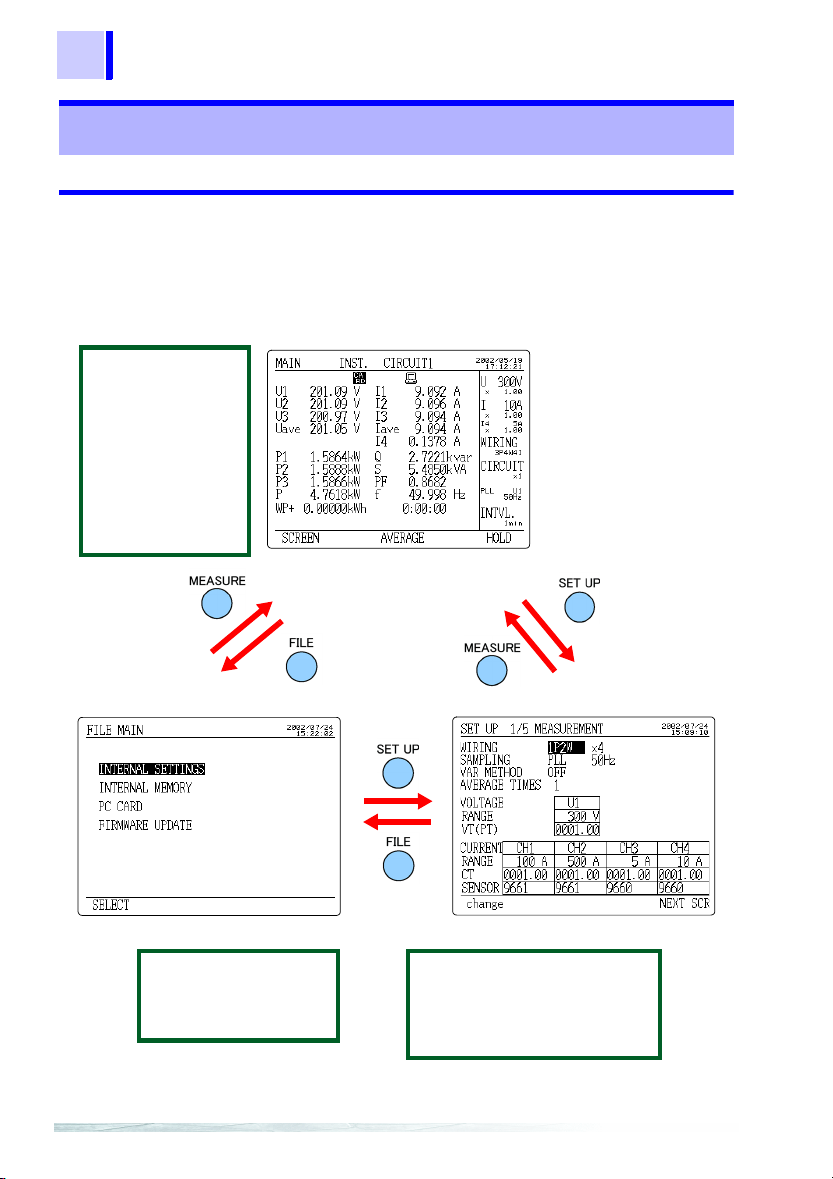

1.2 Screen Names and Display Elements

1.2.1 Screen Configuration

The screens are divided into three basic types: measurement

screens, setting screens, and file screens. Each screen is selected

using three panel keys:

Measurement screen

MAIN

POWER

INTEGRATE

DEMAND

ZOOM

HARMONIC LIST

HARMONIC GRAPH

WAVEFORM

WIRING CHECK

WIRING DIAGRAM

MEASURE, SET UP

, and

FILE

.

File screen

INTERNAL SETTINGS

INTERNAL MEMORY

PC CARD

FIRMWARE UPDATE

Setting screen

MEASUREMENT

DATA OUTPUT

SAVE, PRINT ITEMS

SYSTEM

D/A OUTPUT

(3169-21 only)

Page 13

1.2.2 Common Display

9

1.2 Screen Names and Display Elements

This section of the screen shows information common to all measurement screens (except the zoom screen and the wiring diagram

screen).

Common Display

Time

Range

Wiring

No. of circuits

Synchronization method

Interval

Time Displays the current time.

Range Displays the voltage range and current range of

Wiring Displays the wiring method set on the setting

No. of circuits Displays the number of circuits to be measured

Synchronization

method

Interval Displays the interval set on the setting screen.

the on-screen circuit. The VT(PT) ratio and CT

ratio are shown under these ranges. The current

range and CT ratio of I4 are shown only when

3P4W4I is set as the wiring method.

screen.

as set on the setting screen.

Displays the synchronization method and fre-

quency of the line to be measured as set on the

setting screen.

1

2

3

4

5

6

7

8

9

10

11

Page 14

Quick Start Manual

10

1.2 Screen Names and Display Elements

1.2.3 On-Screen Indicators

Goes on when the reactive-power-meter method is

ON.

Goes on when the displayed measurement is held.

Goes on when the medium for saving data is set to

PC card. Flashes when the PC card is accessed.

Goes on when the medium for saving data is set to

internal memory. Flashes when the internal memory

is accessed.

Goes on when the PC card or internal memory is full.

Goes on when the device to be connected to the RS232C is set to PC.

Goes on when the device to be connected to the RS232C is set to printer.

Goes on when the PLL is unlocked; the synchronization method is automatically switched over to the

fixed clock.

Goes on when the keys are locked.

Goes on when the voltage or current dynamic range

is exceeded.

Displayed when the range is exceeded.

U3* and I3* indicate that the data is obtained by calculating the 2-voltage, 2-current measurement results when 3P3W2M (three-phase, 3wire, 2-power-meter method) is selected.

❖

Instruction manual "Appendix" (page 195)

Page 15

2.1 Outline

11

Power Measurement

2.1 Outline

This chapter explains setting and measurement procedures using

the following conditions.

Measure the power of a Three-phase 3-wire line for 7 days.

Measurement location:

A Tree-phase 3-wire 200 V line of a switchboard (50 Hz, 50 A load)

Setting:

Time-series measurement start time: 2002/06/20 08:00

Time-series measurement stop time: 2002/06/27 08:00

Data is automatically output to the PC card at 5-minute intervals.

Average value (voltage, current, and power) and integrated power are

stored on the PC card. The reactive power-meter method is not used.

S

O

U

R

C

E

9438-03 VOLTAGE CORD

Upper side of the

3169-20/21

Red

A

Black

B

C

Yellow

2

L

O

A

D

9661 CLAMP ON SENSOR

1

2

3

4

5

6

7

8

3169-20/21

Face the arrow toward the Load

Instrument and Accessories Required for Measurement

Power cord

9438-03 VOLTAGE CORD

1 set (4 cords)(One each red, yellow,

blue, and black cords.)

9661 CLAMP ON SENSOR

x 2

PC card

9

10

11

Page 16

12

Quick Start Manual

2.1 Outline

Setting Screens under the Example Conditions

ÅîéûånóÒê›íËâÊñþÅî

<MEASUREMENT>

WIRING

2-power-meter method)

Number of circuits : X 1 (1 circuit)

SAMPLING : PLL

Measured frequency: 50 Hz

VAR METHOD : OFF

AVERAGE TIMES : 1

VOLTAGE RANGE : 300 V

VT (PT) : 0001.00

CURRENT RANGE : 50 A

CT : 0001.00

SENSOR : 9661

: 3P3W2M

(Three-phase 3-wire,

<DATA OUTPUT>

MEAS. START : TIME

MEAS. STOP : TIME

INTERVAL TIME : 5 min

SAVE IN... : PC CARD

DATA FILE NAME : INTEG

(2002/06/20 08:00)

(2002/06/27 08:00)

<SAVE, PRINT ITEMS>

NORM. MEAS.: ON

HARMONIC : OFF

INTEG. & DEM.: ON

INST. : OFF

AVE . : ON

MAX. : OFF

MIN. : OFF

Page 17

2.2 Measurement Procedure

2.2 Measurement Procedure

13

Measurement

Preparations

(page 14)

Connect to the

Line to be

Measured

(page 18)

Perform

Measurement

(page 26)

1. Connecting the Power Cord

2. Connecting the Voltage Cords

3. Connecting the Clamp-On Sensor

4. Inserting a PC Card

5. Turning the Power On

1. Setting the wiring details

2. Displaying the Wiring Diagram

3. Connectting the voltage cords and

clamp-on sensor to the line to be

measured

4. Checking the Wiring

1. Setting the measurement conditions

2. Confirm range

3. Start measurement

4. Stop measurement

1

2

3

4

5

6

7

8

9

Shutdown Procedure

1. Disconnect the voltage cords and

clamp-on sensor from the measured

line.

2. Turn off the power to the 3169-20/

21.

3. Disconnect the power cord from the

AC outlet.

4. Remove the PC card from the 3169-

20/21 and analyze the saved data

on PC.

10

11

Page 18

Quick Start Manual

14

2.3 Measurement Preparations

2.3 Measurement Preparations

1. Connecting the Power Cord

• Before turning the product on, make sure the source voltage matches that indicated on the product's power connector. Connection to an improper supply voltage may damage

the product and present an electrical hazard.

• To avoid electric shock and ensure safe operation, connect

the power cable to a grounded (3-contact) outlet.

Connect the power cord to

1.

the AC power inlet.

Plug the power cord into the

1

2.

AC mains outlet.

2

Page 19

2.3 Measurement Preparations

2. Connecting the Voltage Cords

15

Connect the voltage cords to the product first, and then to

the active lines to be measured. Observe the following to

avoid electric shock and short circuits.

• Voltage cord should only be connected to the secondary

side of a breaker, so the breaker can prevent an accident if

a short circuit occurs. Connections should never be made

to the primary side of a breaker, because unrestricted current flow could cause a serious accident if a short circuit

occurs.

• Do not allow Do not allow the voltage cable clips to touch

two wires at the same time. Never touch the edge of the

metal clips. Never touch the edge of the metal clips.

• Voltage input terminals U

terminal and are not insulated. To avoid the risk of electric

shock, do not touch the terminals.

• For safety reasons, when taking measurements, only use the

9438-03 VOLTAGE CORD provided with the product.

• The supplied voltage cords consist of one each red, yellow, blue

and black cords. Connect only the cords actually needed for

measurement. Cords not being used for measurement should

be disconnected.

Black

Red

Voltage input terminals

Yellow

, U2, and U3 are common to the N

1

Connect the 9438-03 VOLTAGE

CORD to the voltage input terminals of the 3169-20/21.

1

2

3

4

5

6

7

8

9

Insert plugs all the

way in.

10

11

Page 20

Quick Start Manual

16

2.3 Measurement Preparations

3. Connecting the Clamp-On Sensor

Connect the clamp-on sensors to the product first, and then

to the active lines to be measured. Observe the following to

avoid electric shock and short circuits.

• Clamp sensor should only be connected to the secondary

side of a breaker, so the breaker can prevent an accident if

a short circuit occurs. Connections should never be made

to the primary side of a breaker, because unrestricted current flow could cause a serious accident if a short circuit

occurs.

• When the clamp sensor is opened, do not allow the metal

part of the clamp to touch any exposed metal, or to short

between two lines, and do not use over bare conductors.

• To prevent damage to the product and sensor, never connect or disconnect a sensor while the power is on.

• The current input terminals of the 3169-20/21 are not insulated. To avoid the risk of electric shock, only use the specified optional clamp-on sensor.

Red

Yellow

3169-20/21 Current input

terminal

connector guide pins

When disconnecting the BNC connector, be sure to release the

lock before pulling the connectors apart. Forcibly pulling the connector without releasing the lock, or pulling on the cable, can

damage the connector.

Current input terminas

BNC plug slots

Lock

Connect the 9661 CLAMP ON

SENSOR to the current input terminals of the 3169-20/21.

Align the slots in the BNC plug

with the guide pins on the connector at the instrument side, then

push and turn the plug clockwise.

(to unplug the connector, push the

plug and turn it counterclockwise

before pulling it apart.)

Page 21

4. Inserting a PC Card

17

2.3 Measurement Preparations

Use only PC Cards sold by HIOKI. Compatibility and performance are not guaranteed for PC cards made by other manufacturers. You may be unable to read from or save data to

such cards.

• The PC card or the instrument can be damaged if the card is

inserted forcefully in the wrong direction.

• Never eject a PC card while it is being accessed by the instrument. Data on the PC card may be lost.

❖

Instruction manual 7.2 "Using a PC Card" (page 117)

5. Turning the Power On

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the

product and present an electrical hazard.

Open the cover and insert the

PC card with the arrow facing

up and in the direction of the PC

card slot, as far as it will go.

Turn the POWER switch ON ( | ).

1

2

3

4

5

6

7

8

Screen after the

power is turned on

(Self-test screen)

As soon as the power is turned on,

the self-test screen appears. Upon

completion of the self test, display

switches to the measurement screen.

Model No. of the

product

Version No.

Internal memory

test result

9

10

11

Page 22

Quick Start Manual

18

2.4 Connect to the Line to be Measured

2.4 Connect to the Line to be Measured

1. Setting the wiring details

Set the 3169-20/21 to measure a three-phase 3-wire 200 V line (50

Hz, 50 A load) using the 9661 CLAMP ON SENSOR (500 A rated).

(1) Set the

wiring

to "3P3W2M."

NEXT

SCR

change

Press the

Press the

screen.

Move the cursor to "

Press the

F5

key to display the setting screen.

SET UP

(NEXT SCR) key to display the measurement setting

(change) key to display the selection window.

F1

WIRING

."

select

Select "

using the cursor key.

Press the

3P3W2M

"(Three-phase 3-wire, 2-power-meter method) by

(select) key.

F1

Page 23

2.4 Connect to the Line to be Measured

(2) Make sure the number of circuits to be measured is set to

"X1 (1 circuit)."

When multiple circuits of the same voltage system (the same transformer) are to be measured, use a preset between X2 (2 circuits)

and X4 (4 circuits).

19

1

2

3

1P2W X1 (1 circuit), X2 (2 circuits),

1P3W X1 (1 circuit), X2 (2 circuits)

3P3W2M X1 (1 circuit), X2 (2 circuits)

3P3W3M,3P4W,

3P4W4I

(3) Make sure the synchronization method

(4) Make sure the frequency of the line to be measured is set to "50

Hz."

(5) Make sure the reactive power-meter method is "OFF."

X3 (3 circuits), X4 (4 circuits)

X1 (1 circuit) only

(sampling)

is set to "PLL."

4

5

6

7

8

9

10

11

Page 24

Quick Start Manual

20

2.4 Connect to the Line to be Measured

(5) Make sure the displayed data averaging times is set to "1."

(6) Set the voltage range to "300 V."

Move the cursor to "

Select "

-

300 V

VOLTAGE RANGE

" using the function keys.

+

(7) Make sure the VT (PT) ratio is set to "1."

Set the VT (PT) ratio, if necessary.

(Example)

When the primary voltage is 6.6 kV and the secondary voltage is

110 V, the VT ratio is 60 (6600 V/110 V). In this case, as the rated

measurement voltage is 110 V, set the voltage range to 150 V.

."

Page 25

2.4 Connect to the Line to be Measured

(8) Make sure "9661" is selected as the clamp-on sensor to be used.

21

1

(9) Set the current range to "50 A."

Move the cursor to "

Select "

-

+

Selectable current ranges vary according to the clamp-on sensor

used.

Clamp-On Sensor and Current Range:

9660, 9695-03 5 A, 10 A, 50 A, 100 A

9661 5 A, 10 A, 50 A, 100 A, 500 A

9667-5 kA (5000 A range) 5 kA

9667-500 A (500 A range) 500 A

9669 100 A, 200 A, 1 kA

9694 0.5 A, 1 A, 5 A

9695-02 0.5 A, 1 A, 5 A, 10 A, 50 A

" using the function keys.

50A

CURRENT RANGE

2

3

4

."

5

6

7

8

9

(10) Make sure the CT ratio is set to "1."

Set the CT ratio, if necessary.

(Example)

When the primary current is 100 A and the secondary current is 5

A, the CT ratio is 20 (100 A/5 A). In this case, as the rated measurement current is 5 A, set the current range to 5 A.

10

11

Page 26

Quick Start Manual

22

2.4 Connect to the Line to be Measured

2. Displaying the Wiring Diagram

SCREEN

select

Press the

Press the

Move the cursor to "

Press the F1 (select) key; the wiring diagram will appear.

MEASURE

(SCREEN) key to display the selection window.

F1

key to display the measurement screen.

WIRING DIAGRAM

."

Page 27

2.4 Connect to the Line to be Measured

3. Connectting the voltage cords and clamp-on

sensor to the line to be measured

23

(Example)

Connect the 9438-03 voltage cords and the 9661 clamp-on sensor

to the line to be measured, while referring to the wiring diagram.

We recommend that the color of a voltage cord be matched to that

of the attached input-cord label used for the same channel.

9438-03 VOLTAGE CORD

S

O

U

R

C

E

Red

A

Black

B

C

Yellow

O

S

Source

9661 CLAMP ON SENSOR

Input cord label (Red)

Input cord label (Yellow)

D

A

O

L

E

C

R

U

Conductor

Current flow

direction arrow

Face the arrow toward the Load

L

O

A

D

Load

The arrows on the

clamp indicating the

direction of current

flow should point toward the load side.

1

2

3

4

5

6

7

8

9

Clip securely to metal parts

such as connection screws

or bus bars at the power

side.

10

OK

11

Clamp around only one conductor. Measurement is not possible if the clamp is placed around two

lines in a single-phase circuit, or three lines in a

three-phase circuit.

Page 28

Quick Start Manual

24

2.4 Connect to the Line to be Measured

4. Checking the Wiring

SCREEN

select

Press the

Press the

Move the cursor to "

Press the

The connection status is shown by the voltage, current vectors,

and the connection check result.

If the wiring check result is not "

MEASURE

(SCREEN) key to display the selection window.

F1

(select) key.

F1

key to display the measurement screen.

WIRING CHECK

."

," check the wiring.

OK

The wiring check function may indicate improper connection

("NG") even when the actual wiring is correct, or vice versa.

Check the vectors and measurement data as well.

Page 29

2.4 Connect to the Line to be Measured

The wiring check result is NG.

25

The voltage input

is NG.

The current input

is NG.

The voltage phase

is NG.

The current phase

is NG.

The phase difference (I-U) is NG.

The voltage balance is NG.

• Do the voltage clips grip the wires properly?

• Is the voltage cord properly inserted into the

voltage input terminal of the 3169-20/21?

• Is the clamp-on sensor securely inserted

into the current input terminals?

• Is the set current range too large for the

input level?

• Are the voltage cords connected to the correct terminals?

• Does the arrow of the clamp-on sensor point

to the load side?

• Is the clamp-on sensor connected to the correct terminals?

• Are the voltage cords and clamp-on sensor

properly connected?

• Does the arrow of the clamp-on sensor point

to the load side?

• Is the power factor of the line to be measured too low, such as 0.5 or less?

• Does the connection method of the line to be

measured differ from that set?

• Do the voltage clips grip the wires properly?

• Is the voltage cord properly inserted into the

voltage input terminal?

1

2

3

4

5

6

7

8

9

10

11

Page 30

Quick Start Manual

26

2.5 Perform Measurement

2.5 Perform Measurement

1. Setting the measurement conditions

DATA OUTPUT

• Measurement start:

2002/06/20 08:00

• Measurement stop:

2002/06/27 08:00

• Data is automatically output to the

PC card at 5-minute

intervals.

• Data file name:

INTEG

SAVE, PRINT ITEMS

Saves the average

value (voltage, Current, and Power) and

integrated power on a

PC card

(1) Set the measurement start time to "2002/06/20 08:00."

Before setting the measurement start time, make sure the current

date and time displayed on the screen are correct.

❖

Instruction manual 5.5.7 "Setting the Clock" (page 92)

NEXT

SCR

Press the

Press the

screen.

SET UP

F5

key to display the setting screen.

(NEXT SCR) key to display the data-output setting

Page 31

2.5 Perform Measurement

27

Move the cursor to "

TIME

(2) Set the measurement stop time to "2002/06/27 08:00."

Press the F2 (TIME) key.

MANUAL Measurement starts when the START/STOP key is pressed

TIME Measurement starts at the time set by users.

JUST Measurement will begin as soon as the internal clock reaches

❖

Instruction manual 5.3.1 "Setting the Time-Series Measurement Start

Method" (page 69)

Move the cursor to the measurement start time.

Set the measurement start time to "

-

function keys. (Cursor : Moves left to next digit; Cursor :

Moves right to next digit)

+

If F3 (AUTO) key is pressed when the cursor is at the measurement start time, the start time will be set to a date and time close

to the current time.

(default setting).

a time that is evenly divisible by the set interval.

+

MEAS. START

Decrements the number.

Increments the number.

."

2002/06/20 08:00

1

2

3

4

" using the

5

6

7

Move the cursor to "

Press the

TIME

MANUAL Measurement stops when the START/STOP key is pressed

TIME Measurement stops at the time set by users.

TIMER Measurement stops when the duration set by the users has

-

Move the cursor to the measurement stop time and set it to "

06/27 08:00

+

(TIME) key.

F2

."

MEAS. STOP

(default setting).

elapsed. 1 second to 8784 hours

."

8

9

10

11

2002/

Page 32

Quick Start Manual

28

2.5 Perform Measurement

(3) Set the interval time to "5 minutes."

change

select

Move the cursor to "

Press the

Select "

Press the

Interval setting

1/2/5/10/15/30/60

minutes

1/2/5/10/15/30

seconds

All wave

(change) key to display the selection window.

F1

" using the cursor key.

5 min

(select) key.

F1

Storable Data According to Interval Setting

/100/200/

500 ms

INTERVAL TIME

Normal mea-

surement data

Yes Yes Yes

Yes Yes No

Yes

(Instantaneous

values only)

Binary data

."

integrated power/

demand measure-

ment data

No No

Harmonic mea-

surement data

(4) Make sure the medium for saving data to is set to "PC card."

Page 33

2.5 Perform Measurement

(5) Set the data output file name to "INTEG."

29

change

input

BS

enter

Move the cursor to "

Press the

Enter "

rection, press the

delete one letter.

Press the

• The file is saved as "INTEG.csv" on the PC card.

• If a filename is not specified or a file with the same name exists

on the PC card, the file will automatically be named

"69MEASXX" (XX: 00 to 99).

(change) key to display the selection window.

F1

INTEG

(enter) key.

F3

DATA FILE NAME

" using the cursor and F1 (input) key. To make a cor-

(BS) key. Pressing the F2 key once will

F2

."

1

2

3

4

5

6

7

8

9

10

11

Page 34

Quick Start Manual

30

2.5 Perform Measurement

(6) Set the data output items

NEXT

SCR

ON

Press the F5 (NEXT SCR) key to display the save/print items setting screen.

256 or less

7 days or more

Move the cursor to "

Press the

Turn ON "

(ON) key.

F1

" and "

AVE .

NORM. MEAS.

INTEG. & DEM.

."

" in a similar way.

All other items shall be turned OFF.

• Check the storable time. This indicates the length of time for

which the currently installed PC card stores data. If the storable time is shorter than the measurement time (7 days),

delete unnecessary files from the PC card or replace it with a

larger-capacity PC card.

• If the number of output is greater of equal to 256, all of the data

may not be read into common spreadsheet software.

• For details on settings for harmonics measurement-data output, see 5.4.4 "Setting Harmonic Measurement-data Output

Items" (page 82) of the instruction manual.

Page 35

2. Confirm range

31

2.5 Perform Measurement

Press the

Press the

range.

If you press the

sufficient margin, in consideration of fluctuations in the load current of the line to be measured.

MEASURE

U RANGE

I RANGE

3. Start measurement

Press the

Press the

mode (LED blinking).

The 3169-20/21 will automatically start measurement (LED

remaining ON) at the measurement start time.

Switch Over to Another Screen.

SCREEN

Press the F1 (SCREEN) key to display the selection window.

MEASURE

START/STOP

key to display the measurement screen.

key or

I RANGE

Key, it selects a current range with a

key to display the measurement screen.

key to place the 3169-20/21 in standby

key to select an appropriate

1

2

3

4

5

6

7

8

select

Select a screen to be viewed using the cursor key.

Press the

(select) key.

F1

9

10

11

Page 36

Quick Start Manual

32

2.5 Perform Measurement

4. Stop measurement

The 3169-20/21 will automatically stop measurement at the stop

time. The measurement data "INTEG.csv" has been saved on the

PC card.

Interrupt Measurement.

Press the

the time-series measurement?

yes

Press the F1 (yes) key.

All measurement data before the interruption is saved on the PC

card if the measurement is interrupted.

START/STOP

key. The message "

" is displayed for you to confirm.

Do you want to stop

Shutdown Procedure

1. Disconnect the voltage cords and clamp-on sensor from the

measured line.

2. Turn off the power to the 3169-20/21.

3. Disconnect the power cord from the AC outlet.

4. Remove the PC card from the 3169-20/21 and analyze the

saved data on PC.

Page 37

HIOKI 3169-20/21 CLAMP ON POWER HiTESTER

Quick Start Manual

Publication date: October 2003 Revised edition 2

Edited and published by HIOKI E.E. CORPORATION

Technical Support Section

All inquiries to International Sales and Marketing Department

81 Koizumi, Ueda, Nagano, 386-1192, Japan

TEL: +81-268-28-0562 / FAX: +81-268-28-0568

E-mail: os-com@hioki.co.jp

URL http://www.hioki.co.jp/

Printed in Japan 3169A983-02

• All reasonable care has been taken in the production of this

manual, but if you find any points which are unclear or in error,

please contact your supplier or the International Sales and

Marketing Department at HIOKI headquarters.

• In the interests of product development, the contents of this

manual are subject to revision without prior notice.

• Unauthorized reproduction or copying of this manual is prohibited.

Page 38

HEAD OFFICE

81 Koizumi, Ueda, Nagano 386-1192, Japan

TEL +81-268-28-0562 / FAX +81-268-28-0568

E-mail: os-com@hioki.co.jp / URL http://www.hioki.co.jp/

HIOKI USA CORPORATION

6 Corporate Drive, Cranbury, NJ 08512, USA

TEL +1-609-409-9109 / FAX +1-609-409-9108

3169A983-02 03-10H

Printed on recycled paper

Loading...

Loading...