Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Measurement Guide

3159

INSULATION/

WITHSTANDING

HiTESTER

August 2014 Revised edition 1 3159A985-01 14-08H

Page 2

The Model 3159 Insulation/Withstanding HiTester is a hazardous instrument that generates high voltage.

For safe use, please read the “Introduction,” “Inspection,” “Safety Notes,” and “Notes on Use” in the 3159

Instruction Manual.

This document provides, as an example, a simple method for testing withstanding voltage of electrical

appliances by using the Model 3159 Insulation/Withstanding HiTester. For details on how to use the 3159,

refer to the 3159 Instruction Manual. (Insulation resistance tests can also be performed with the 3159.)

Symbols and Notations Used in this Manual

···· Indicates that incorrect operation presents an extreme hazard that could result in serious

injury or death of the user.

···· Indicates that incorrect operation presents a possibility of injury to the user or damage to the

instrument.

1

The Model 3159 Insulation/Withstanding HiTester is a hazardous instrument that

generates high voltage. Please use due caution when handing the 3159. To prevent

electric shock, wear high-voltage rubber gloves and electric-proof rubber boots, and

put an electric-proof rubber sheet on the work surface.

Pleas

e read this manual thoroughly to ensure safe testing.

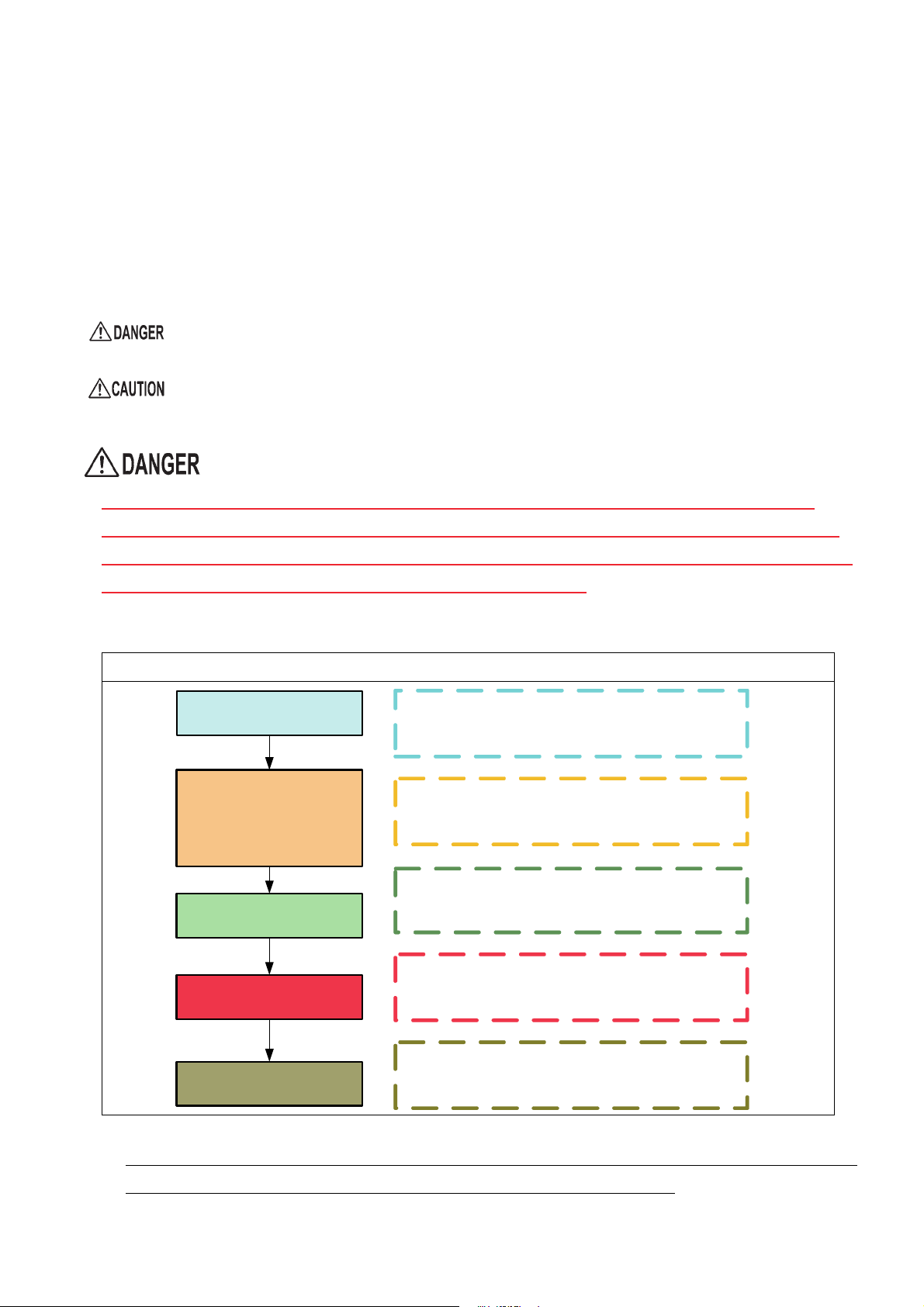

Measurement procedure with the 3159 (This flowchart shows the procedure for using the 3159.)

1. Preparation

Check that you have the necessary tools for

the test.

2. Simple Startup

Inspection

(From connection

Perform a simple startup inspection for safe

testing.

to check)

Prepare for withstanding voltage test.

3. Preparation

Before the Test

(Connect the electrical appliance and set the

test conditions)

Start the test, taking measures to prevent

4. Start the Test

5. Finish the Test

If you accidentally set the wrong settings while checking the operations, turn on the main power switch

while holding down the SHIFT key to reset the system (return to initial state).

electric shock.

Set the test voltage.

Check and record the test results.

Clean up after turning off the power.

Page 3

2

A

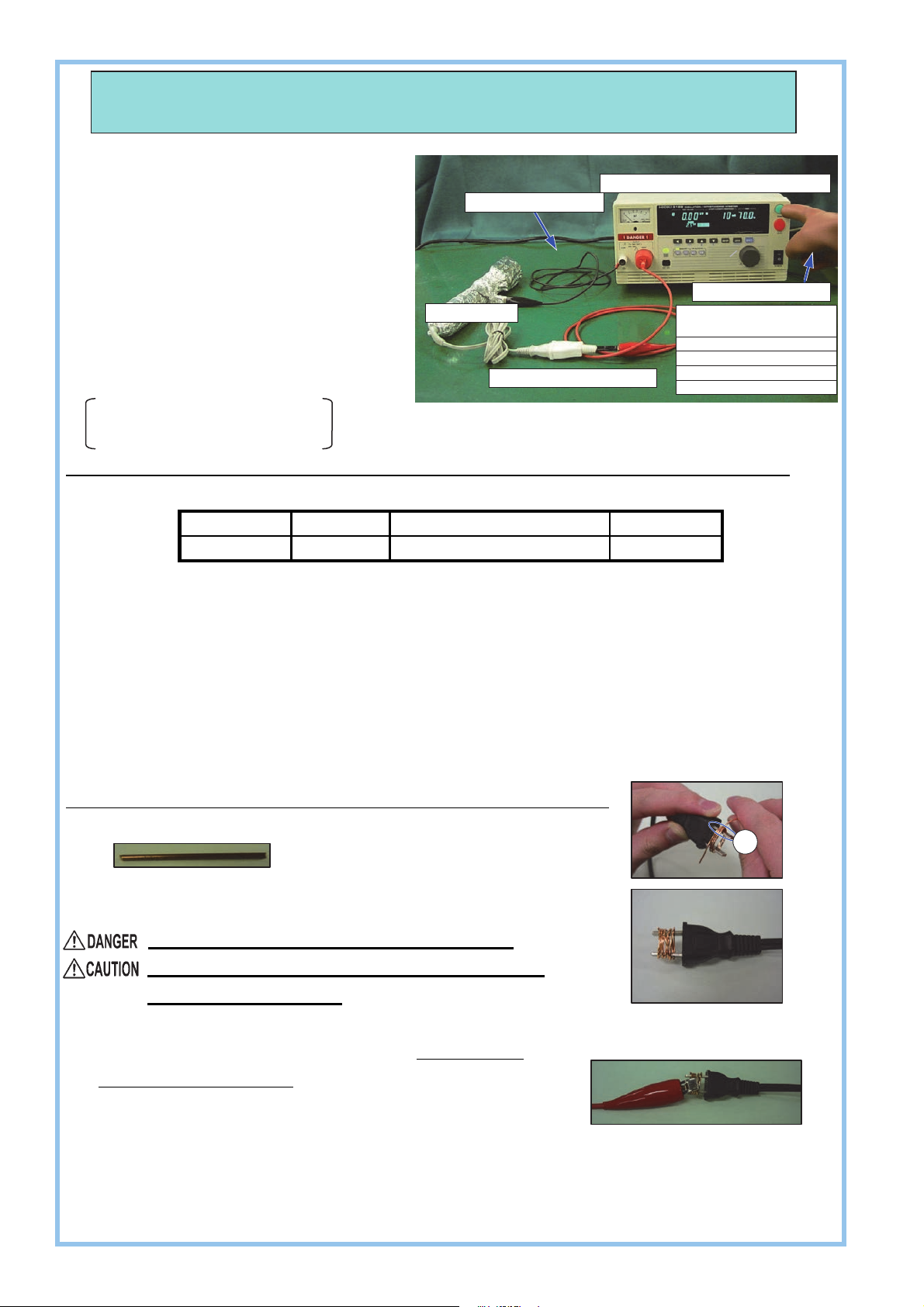

1. Preparation

(1) Before starting a test using the 3159,

check the following information regarding

Electric-proof rubber sheet

Model 3159 Insulation/W ithstanding HiTester

the electrical appliance to be tested.

1. Test voltage

2. Reference leakage current value

(upper limit for the test)

3. Test time

4. Test points

Points to connect with test leads

Electric appliance

Short-circuited receptacle

(Example test setup)

High-voltage rubber gloves

Do not perform tests in

locations that are:

• exposed to direct sunlight

• poorly ventilated

• subject to frequent mechanical vibrations

• near flammable objects

(red, black) of the 3159

* This measurement guide explains the procedure based on an example using the following settings.

(Sample settings: Parameters and Values)

Parameter Test voltage Reference leakage current value Test time

Value 1000 V 10 mA 60 seconds

(2) Things to prepare:

1. Model 3159 Insulation/Withstanding HiTester

2. Electrical appliance to be tested

3. Rubber gloves for protection from high voltages (for safe testing)

4. Forms or a computer to record test results

5. Conductive wire (tinned wire or other non-insulated wire)

This wire is used to short-circuit the plug pins.

See figure below for details.

Short-circuit the plug pins with the conductive wire by following these steps.

1. Prepare a conductive wire.

2. Wind the wire tightly around the plug pins as shown

in the figure. Wind the wire around the pins 5 or 6 times.

Wind the wire tightly to ensure short-circuiting.

Wind the wire being careful not to bend the part of

the plug indicated by (A).

3. Check:

Conduct a final check to make sure that the wire is wound

<Example>

(Short-circuited plug)

tightly around the plug pins.

* Alternatively, use a receptacle, which is custom-made for the test, with the two leads short-circuited as

shown in the “Example test setup” above.

Page 4

2. Simple Startup Inspection (Connection)

During startup inspection, the operator intentionally applies electric current to check

whether the 3159 and the test leads are functioning properly.

Wear high-voltage rubber gloves when connecting the lead wires.

Connect the test leads securely so that they do not disconnect during the test,

Do not place the test leads directly on the ground or floor during the test. Do not

bring them into contact with any metal products in the vicinity.

3

(1)

(2)

(3)

Check that the power switch of the 3159 is

turned off and the output voltage knob is in the

zero position.

Connect the power cord (supplied with the

3159) to the inlet of the main unit and a

grounded outlet.

Always properly ground the 3159 in order

to prevent electric shocks.

Tightly attach the supplied low-voltage test

lead (black) to the LOW terminal (black).

Insert the supplied high-voltage test lead (red)

to the HIGH terminal (red) all the way so that it

is firmly seated.

(4)

Short-circuit the high-voltage test lead

(red) and low-voltage test lead (black) as

shown in the picture.

Place the connected test leads on a board

made of refractory insulated material, such as

an electric-proof rubber sheet.

Page 5

4

A

(1)

(2)

3. Simple Startup Inspection (Settings)

Check that no one is near the testing area,

and turn on the main power switch of the 3159.

Press the

lights up.

Check that the analog voltmeter indicates

that the lamp does

.

up

key and check that the lamp

0 kV

not light

and

(3)

Check that

is displayed on the screen.

Take due care when the 3159 enters the READY state in which testing can start.

(4) Set the parameters as follows:

Parameter Comparative-voltage Upper limit for test Lower limit for test Test time Range

Value OFF

10 mA

OFF

70.0 seconds 2.5 kV

(5)

Before setting

fter setting

Range

Range

Comparative-voltage

Comparative-voltage

Test upper limit Test time

Test upper limit

Test time

Use the and keys to select range.

The selected

be edited.

Use the

(Only the test upper limit and the test time are set here. Leave

the comparative-voltage and lower limit set to OFF.)

item blinks

and

, which indicates that it can

keys to edit

each

(6)

Press the STOP (EXIT) key to confirm the test

conditions. The 3159 enters the READY state.

(The figure on the left shows the 3159 when the test

conditions have been confirmed.)

Set the test voltage using the output voltage knob after starting the test.

Page 6

4. Simple Startup Inspection (Check)

Wear high-voltage rubber gloves when connecting the lead wires.

5

(1)

(2)

(3) Inspection Result

Press the START key to start the test.

When a test is started, high voltage is generated by

the 3159 when it enters the state.

Do not touch the output voltage HIGH terminal (red)

or the test lead while the lamp is

illuminated.

Turn the output voltage knob clockwise during

the (70 second) test.

During the inspection, you do not need to adjust

the voltage accurately. As a general guide, turn

the knob about a quarter turn.

Normal:

Abnormal: will be displayed on the screen. (Perform steps (4) and (5), then follow the instruction

* Check the test lead connections (insertion/tightening) and test again. If the result is still “PASS,” a test lead may be

(4)

The 3159 will beep and will be displayed on the screen.

below.)

damaged or the 3159 may be malfunctioning. Please contact your authorized Hioki distributor or reseller.

Press the STOP (EXIT) key to cancel the hold state.

(5)

Turn the output voltage knob all the way

counter-clockwise, returning it to zero. Turn the

main power switch of the 3159 off.

(6)

Disconnect the test leads (short-circuited part).

The startup inspection is now complete.

Page 7

6

5. Preparation Before the Test

(1)

(2)

Enlarged

Wear high-voltage rubber gloves when connecting the lead wires.

Connect the test leads securely so that they do not disconnect

during the test.

Turn on the power switch of the electrical

appliance while power is not supplied to

Switch ON

the electrical appliance.

You cannot take accurate measurements if the

power switch of the electrical appliance is turned off.

Connect the low-voltage test lead (black) to the

test point on the electrical appliance (surface of

the body of the appliance, ground terminal, or

other test point).

(3)

Check that no one is near the testing area and turn on the main power to the 3159.

(4)

(5)

Connect the high-voltage test lead (red) to the test

point on the electrical appliance (the short-circuited

part of the plug or the short-circuited leads of the

receptacle that is connected to the plug).

Check that the analog voltmeter is indicating

and that the

illuminated

.

(6)

Measured voltage value Test timeLeakage current value

lamp is

0 kV

not

Set the three parameters mentioned in “1. Preparation”: Test voltage, Reference leakage current

value (upper limit for the test), and Test time. Refer to “3. Simple Startup Inspection (Settings).”

Set the test voltage after starting the test (while checking the measured voltage value).

Page 8

p

6. Start the Test

Set the test voltage after pressing the START key to start the test.

7

Check the values to be used before

When a test is started, high voltage is generated by the 3159 when it enters the state.

Do not touch the output voltage HIGH terminal (red), test leads, electrical appliance (device to

be tested), or short-circuited receptacle while the lamp is illuminated.

ressing the START key.

(1)

Press the START key to start the test.

To forcibly terminate the test process,

press the STOP (EXIT) key.

(2)

Measured voltage value Leakage current value Remaining time

The test requires the voltage to be applied for 60 seconds.

After pressing the START key, turn the output voltage knob to set the voltage

to the test voltage before the remaining time reaches 60 seconds.

Turning the output voltage knob excessively can raise the

voltage over the test voltage, resulting in damage to the

electrical appliance.

To Set the Test Voltage

To set the test voltage, turn the output voltage knob while checking the

measured voltage value.

It may take time to get used to setting the test voltage.

Page 9

8

pp

)

7. Finish the Test

(1) When the result is “PASS”

A "PASS" judgment will be given if the electric appliance withstands the test voltage for the set

test time. (“PASS” will be displayed for approximately 0.5 seconds by default; however the

“PASS” indication can be retained. See “4.1 PASS Hold Function” in the 3159 instruction

manual.)

Record the result as PAS S in the record form or other documents.

(2) When the result is “FAIL”

An "UPPER FAIL" judgment will be given and the 3159 will beep if the electric

Measured voltage value

Measured voltage value Remaining timeLeakage current value

Leakage current value

Remaining time

a

liance fails to withstand the test voltage for the set test time.

Record the result as FAI L in the record form or other documents.

(If the measured voltage value, leakage current value, and remaining time are also

necessary, record them as well.)

(3) If the FAIL Hold function is enabled, press the STOP (EXIT) key to cancel the hold state.

<After the test>

(1)

Return the output voltage knob to zero. (Turn the knob

all the way counter-clockwise

(2)

Check that the analog voltmeter indicates

the

lamp is

not illuminated

0 kV

and that

.

(3) Turn the main power switch of the 3159 off.

To conduct further tests, start from “5. Preparation Before the Test” of this measurement guide.

(4) Disconnect the electrical appliance, test leads, and power cord in the reverse order of

connection.

Page 10

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

TestEquipmentDepot.com

Loading...

Loading...