Page 1

3158

Instruction Manual

AC WITHSTANDING

VOLTAGE HiTESTER

Mar. 2019 Revised edition 12

3158A981-12 19-03H

EN

Page 2

Page 3

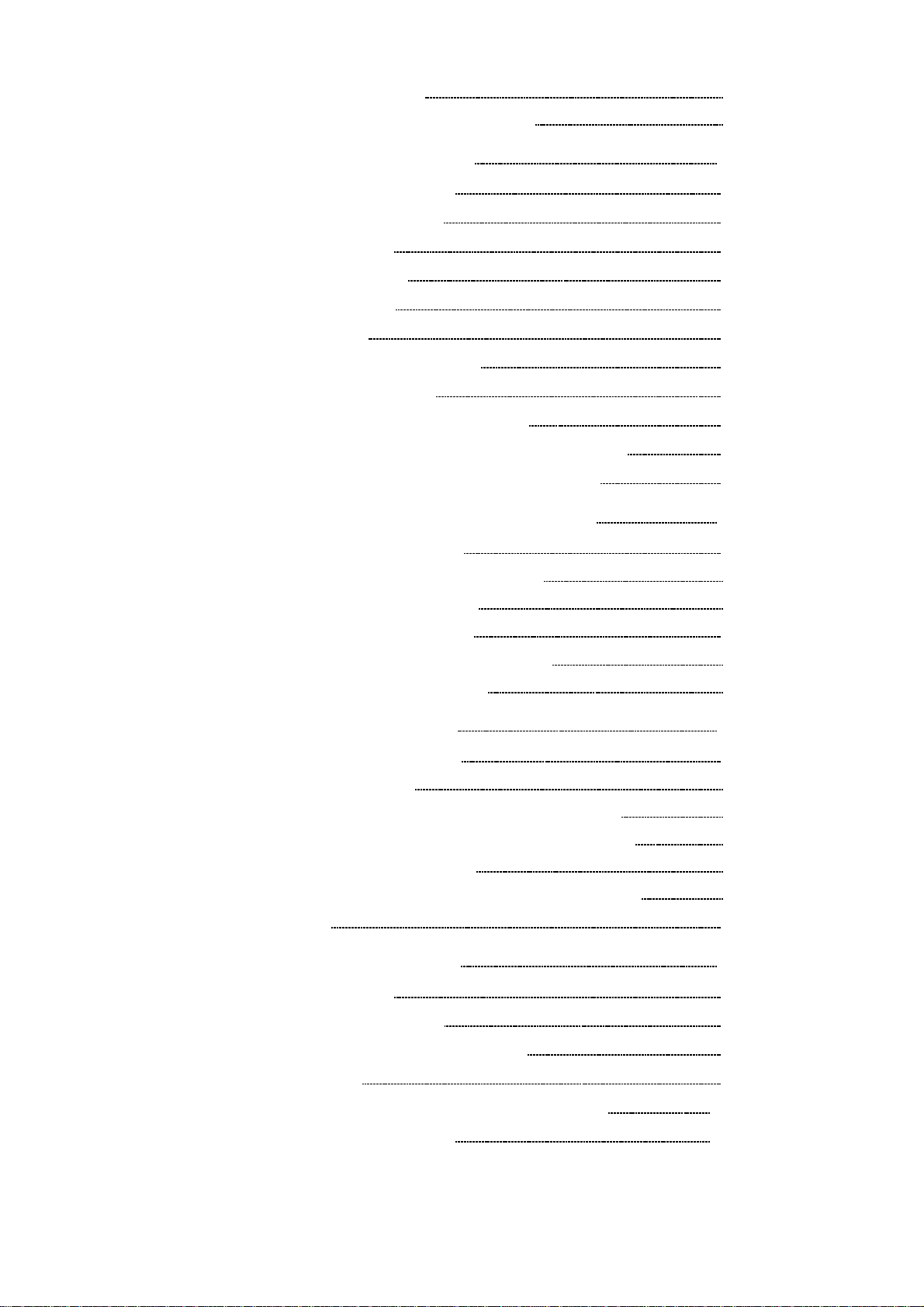

Contents

Inspection i

Safety Notes

Notes on Use

Contents and Indications of This Manual

iv

vi

Chapter 1 Overview 1

1.1 Product Introduction 2

1.2 Names and Functions of Parts

Chapter 2 Testing Arrangements 7

2.1 Connecting the Protective Ground Terminal 7

2.2 Wearing rubber gloves

2.3 Connecting the External I/O Connector

2.4 Power Cord Connection

2.5 Powering On and Off the Unit

2.6 Connecting the 9615 H.V. TEST LEAD

2.7 Connecting the REMOTE CONTROL BOX

2.8 Installation of the Unit

10

11

12

14

15

ii

3

8

9

2.9 Connection to the Measured Equipment

2.10 Startup Inspection

16

17

Chapter 3 Testing Method 19

3.1 State of the 3158 and Preset Parameters 20

3.2 Making Testing Arrangements (in READY State)

3.2.1 Selecting an Output-Voltage Range 23

3.2.2 Key-lock Function 23

3.2.3 Initial Settings for Optional Functions 24

3.3 Setting the "SETTING" State 25

3.3.1 Setting the Comparative Voltage Value 26

3.3.2 Setting the Upper (Lower) Level Value 27

3.3.3 Setting the Test Time 28

3.3.4 Examples of Settings 29

3.4 Starting a Test 32

3.4.1 Setting the Output Voltage 33

3.4.2 Executing a Test 35

22

3158A981-12

3.4.3 Screening in "TEST State" 37

3.5 PASS or FAIL Determination 38

3.5.1 "PASS" State 38

3.5.2 Screening in "PASS" State 39

Page 4

3.5.3 "FAIL" State 40

3.5.4 Screening in "FAIL" State 43

Chapter 4 Optional Functions 45

4.1 PASS Hold Function 48

4.2 FAIL Hold Function

4.3 Hold Function

4.4 Momentary Out

4.5 Double Action

4.6 FAIL Mode

4.7 RS Command [START]

4.8 Inter-lock Function

4.9 Voltage Comparator Position

4.10 Example of Optional Function Settings

4.11 Example of Optional Functions Use

49

50

52

53

54

55

56

57

58

59

Chapter 5 Saving/Loading Preset Values 61

5.1 Saving Preset Values 62

5.1.1 Procedure for Saving Data 63

5.1.2 Example of Saving 64

5.2 Loading Preset Values 66

5.2.1 Procedure for Loading Data 67

5.2.2 Example of Loading 68

Chapter 6 External Interface 71

6.1 External I/O Terminal 71

6.1.1 Signal Line 72

6.1.2 Example of Input Signal Connection 74

6.1.3 Example of Output Signal Connection 76

6.1.4 Inter-lock Function 78

6.1.5 Timing Chart of External I/O Terminal 80

6.2 Buzzer 83

Chapter 7 RS-232C Interface 85

7.1 Specifications 85

7.2 Connection Method

7.3 Command Transfer Methods

7.4 Command

7.5 Transmission and Response Formats

86

87

89

100

7.6 Command Summary

101

Page 5

Chapter 8 Maintenance and Inspection 103

8.1 Maintenance 104

8.2 Fuse Replacement

8.3 Troubleshooting

8.4 Displaying Errors

8.5 Resetting the System

8.6 External Dimensions

105

106

107

107

108

Chapter 9 Specifications 109

9.1 Basic Specifications 109

9.2 General Specifications

113

Appendix APPENDIX1

9613 REMOTE CONTROL BOX (SINGLE) APPENDIX1

9614 REMOTE CONTROL BOX (DUAL) APPENDIX2

9615 H.V. TEST LEAD (Standard Accessory) APPENDIX3

Table of Optional Functions APPENDIX4

Page 6

Page 7

────────────────────────────────────────────────────

Introduction

Thank you for purchasing the HIOKI "3158 AC WITHSTANDING VOLTAGE

HiTESTER". To obtain maximum performance from the product, please read this

manual first, and keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

i

NOTE

Checking the main unit and accessories

Main unit

"3158 AC WITHSTANDING VOLTAGE HiTESTER."

Accessories

Verify that the following standard accessories are complete.

(1) Instruction Manual

(2) Spare fuse (built into the power inlet)

(3) Grounded three-core power cord

(4) 9615 H.V. TEST LEAD

(High voltage and return side )

Shipment of the unit

If reshipping the unit, preferably use the original packing.

Warranty

HIOKI cannot be responsible for losses caused either directly or indirectly by the

use of the 3158 with other equipment, or if ownership is transferred to a third party.

1

1

1

1

Before using the product, make sure that the insulation on the test leads is

undamaged and that no bare conductors are improperly exposed. Using the

product in such conditions could cause an electric shock, so contact your

dealer or Hioki representative for repair.

────────────────────────────────────────────────────

Introduction

Page 8

ii

────────────────────────────────────────────────────

Safety Notes

DANGER

Thisproduct is designed to comply with IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as damage

to the product. However, using the product in a way not described in this

manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or

injuries not resulting directly from product defects.

This manual contains information and warnings essential for safe operation of the

product and for maintaining it in safe operating condition. Before using the

product, be sure to carefully read the following safety notes.

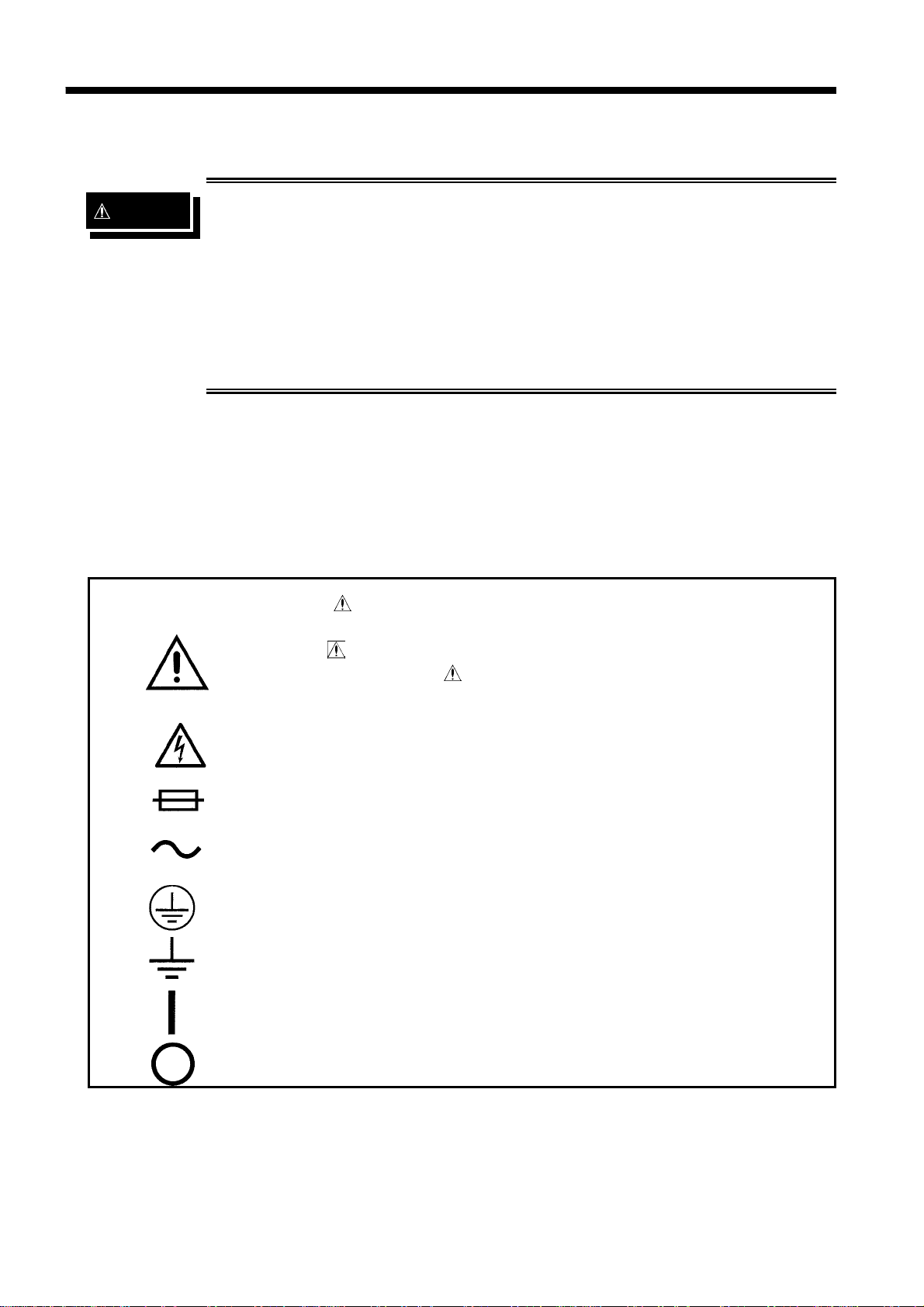

Safety symbols

・

The

should refer to a corresponding topic in the manual (marked with

the

・

In the manual, the

information that the user should read before using the product.

symbol printed on the product indicates that the user

symbol) before using the relevant function.

symbol indicates particularly important

Indicates that dangerous voltage may be present at this terminal.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates a protective conductor terminal.

Indicates a functional earth terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

────────────────────────────────────────────────────

Introduction

Page 9

iii

────────────────────────────────────────────────────

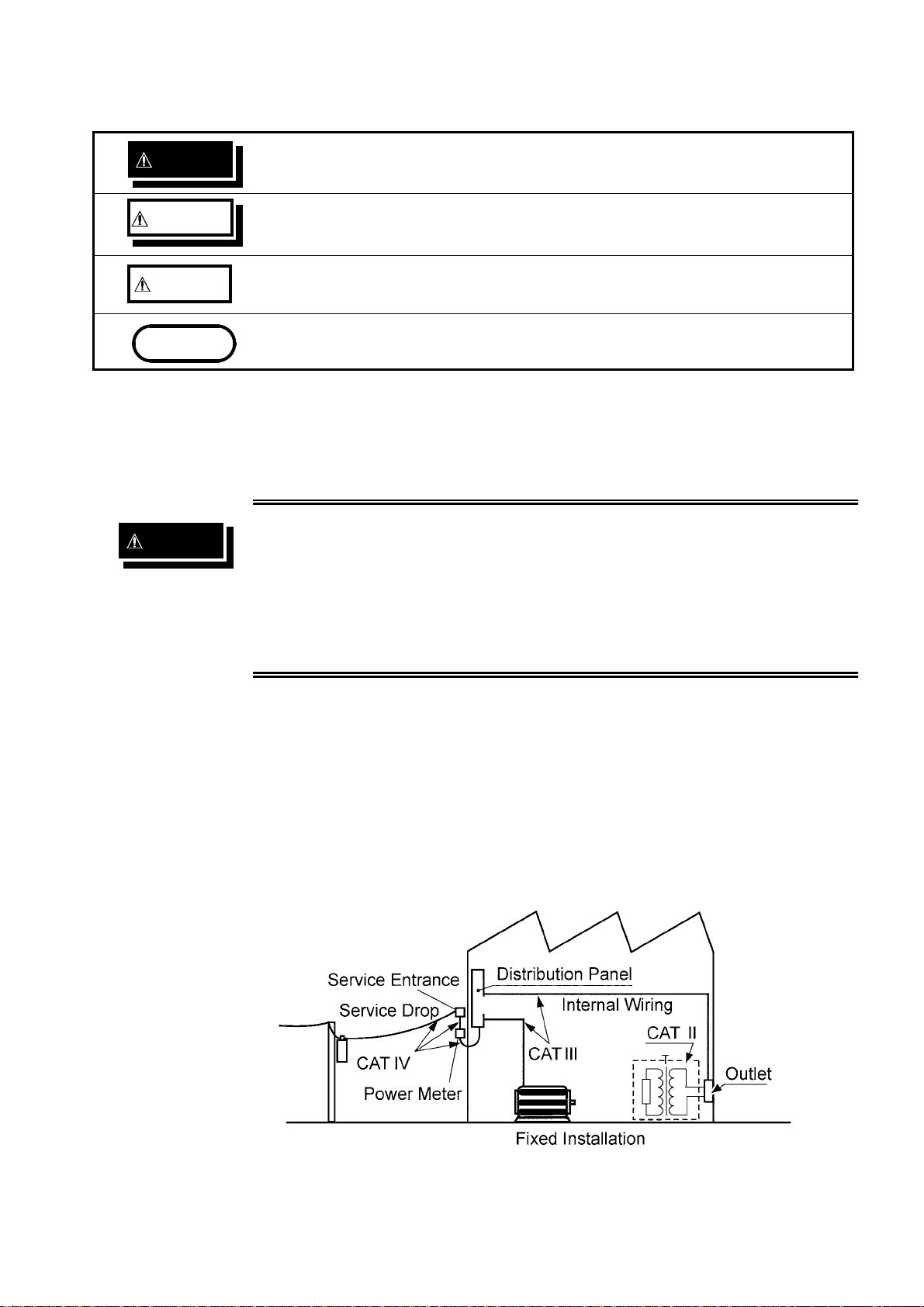

The following symbols in this manual indicate the relative importance of cautions

and warnings.

DANGER

WARNING

CAUTION

NOTE

DANGER

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard

that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the

user or damage to the product.

Advisory items related to performance or correct operation of the product.

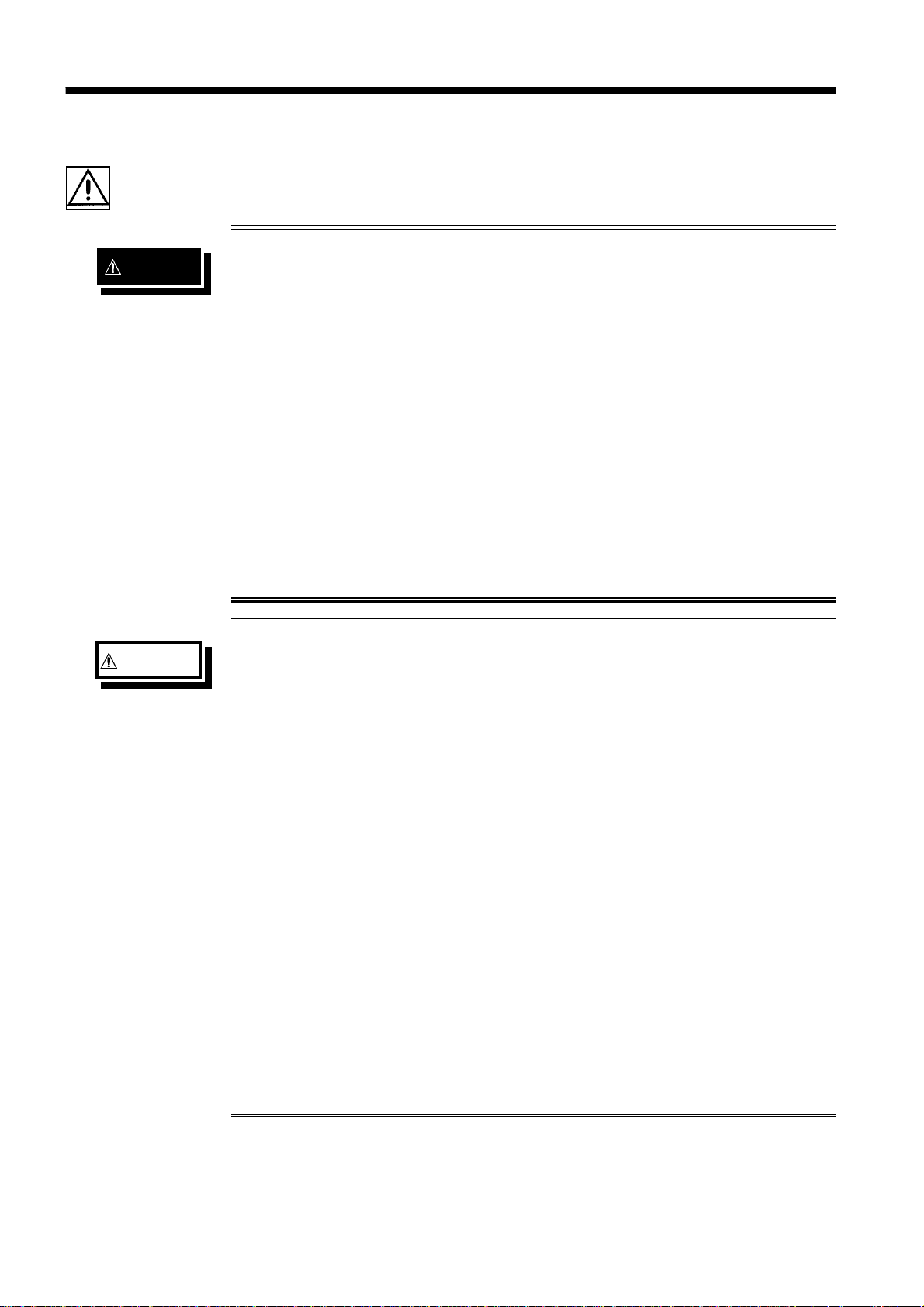

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety

standards for various electrical environments, categorized as CAT II to CAT IV, and

called measurement categories.

・

Using a measuring instrument in an environment designated with a

higher-numbered category than that for which the instrument is rated

could result in a severe accident, and must be carefully avoided.

・

Never use a measuring instrument that lacks category labeling in a

CAT II to CAT IV measurement environment. Doing so could result in

a serious accident.

CAT II: Whe n directly me as ur ing t he electrical outlet receptacles of t he p ri mar y

electrical circuits in e qui pme nt connected to a n AC electrical outlet by a power

cord (portable tools, household appliances, etc.)

CAT II I : When measuring the pr imary electrical circuits of heavy equipment (fixed

installati ons) connected directly to the distr ibuti on panel, and feeders from the

distribution panel to outlets

CAT IV: Wh en mea sur ing t he circuit from t he service drop to t he service entranc e, an d to

the power met er and prim ary o verc urrent protection device (di stribution panel)

────────────────────────────────────────────────────

Introduction

Page 10

iv

────────────────────────────────────────────────────

Notes on Use

Follow these precautions to ensure safe operation and to obtain the full benefits of

the various functions.

DANGER

WARNING

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding Voltage Hitester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. TEST

LEAD, etc.

・

To avoid electric shock, do not remove the cover panel. The internal

components of the product carry high voltages and may become very

hot during operation.

・

Vinyl shield on 9615 H.V. TEST LEAD alligator clip is not high voltage

insulated. DO NOT touch when high voltage is applied.

・

To avoid electric shock, be sure to connect the protective ground

terminal to a grounded conductor.

・

The unit is constructed so as to be connected to a ground line via a

three-core power cord that is supplied with the unit. To avoid

electric shock and ensure safe operation, connect the power cable to

a grounded (3-contact) outlet.

・

Before turning the product on, make sure the source voltage matches

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

・

To avoid electric shock, do not allow the product to get wet, and do

not use it when your hands are wet.

・

This product should be installed and operated indoors only, between

0℃and 40℃and 80%RH max. Do not use the unit in direct sunlight,

dusty conditions, or in the presence of corrosive gases.

・

Replace the fuse only with one of the specified characteristics and

voltage and current ratings. Using a non-specified fuse or shorting

the fuse holder may cause a life-threatening hazard.

Fuse type: 250VT8AL(3158-01

250VT4AL(3158-03 to 3158-05

)

)

────────────────────────────────────────────────────

Introduction

Page 11

v

────────────────────────────────────────────────────

・

CAUTION

Do not insert a board other than optional interface boards into the Interface

slot. The unit software or calibration data may be lost.

・

To avoid electrocution, turn off the power to all devices before pluggingor

unplugging any of the interface connectors.

・

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging the cord from the power outlet.

・

To avoid damaging test leads, do not kink or pull on the leads.

・

Keep in mind that, in some cases, conductors to be measured may be hot.

・

Take care not to block the ventilation openings on the sides of the unit.

・

For safety reasons, only use the 9615 H.V. TEST LEAD for measurement.

・

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

・

In the event that the equipment malfunctions in any manner during use,

turn off the power immediately, and contact your dealer or HIOKI

representative.

・

To avoid electric shock, do not exceed the lower of the ratings shown on

the instrument and test leads.

NOTE

・

Do not use the unit near any device which generates strong electromagnetic

radiation or near a static electrical charge, as these may cause errors.

・

This instrument may cause interference if used in residential areas. Such use

must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio and

television broadcasts.

────────────────────────────────────────────────────

Introduction

Page 12

vi

────────────────────────────────────────────────────

Contents and Indications of This Manual

Chapter 1: Overview

Describes an overview, features, and the names and functions of the parts of the

unit.

Chapter 2: Testing Arrangements

Describes particulars of testing arrangements.

Chapter 3: Testing Method

Describes procedures for setting, testing, and test results judgment.

Chapter 4: Optional Functions

Describes procedures for setting optional functions.

Chapter 5: Saving/Loading Preset Values

Describes procedure for saving and loading test values.

Chapter 6: External Interface

Describes use of the external I/O and REMOTE CONTROL BOX.

Chapter 7: RS-232C Interface

This chapter explains the testing procedure using RS-232C.

Chapter 8: Maintenance and Inspection

Covers the maintenance and inspection, fuse replacement, and ultimate disposal.

Chapter 9: Specifications

Contains the unit specifications such as the general specifications, measurement

accuracy, etc. of the unit.

Appendix:

Covers the options of the unit.

────────────────────────────────────────────────────

Introduction

Page 13

1

────────────────────────────────────────────────────

Chapter 1

1

Overview

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

Page 14

2

────────────────────────────────────────────────────

1.1 Product Introduction

(1) Easy testing conforming to standards

The unit allows pressure tests based on a wide variety of standards to be conducted.

The timer function and the comparative screening function using upper- and lowerlevel values provide accurate test results. The unit does not operate until the output

voltage preset using the voltage adjustment knob is within±5% (output voltage

1kV:±50 V) of the comparative voltage value, thus further ensuring accurate

readings.

(2) Fluorescent indicator

The large, easy-to-read fluorescent display permits q uick checking of the testing

state and result.

(3) Analog Voltage Measurement

The voltage is digitally displayed on the fluorescent indicator. This value can also

be checked on the analog voltmeter.

(4) Zero-Toggle Switch

This function ensure that test voltage can be toggled on and off only at a sine wave

zero crossings, to prevent damage to the device under test if it happens to be faulty.

(5) Saving testing set values

This unit is provided with a function for saving the set values used in a test,

allowing quick switching between different testing set values to meet a variety of

standards and regulations. Up to 20 values may be saved.

The values i mmediately prior to a power shutdown are saved in the unit. These

values are valid at the next startup.

(6) REMOTE CONTROL BOX

The 9613 REMOTE CONTROL BOX (SINGLE) or the 9614 REMOTE CONTROL

BOX (DUAL) can be connected to the external switch terminal to perform 3158

start/stop control.

(7) External I/O

The external I/O terminal generates signals according to the state of the 3158. It

can be used to feed signals for the start and stop key.

(8) RS-232C interface as a standard feature

Automatic testing and saving of the test results are possible with the use of a

computer.

≦

────────────────────────────────────────────────────

1.1 Product Introduction

Page 15

3

────────────────────────────────────────────────────

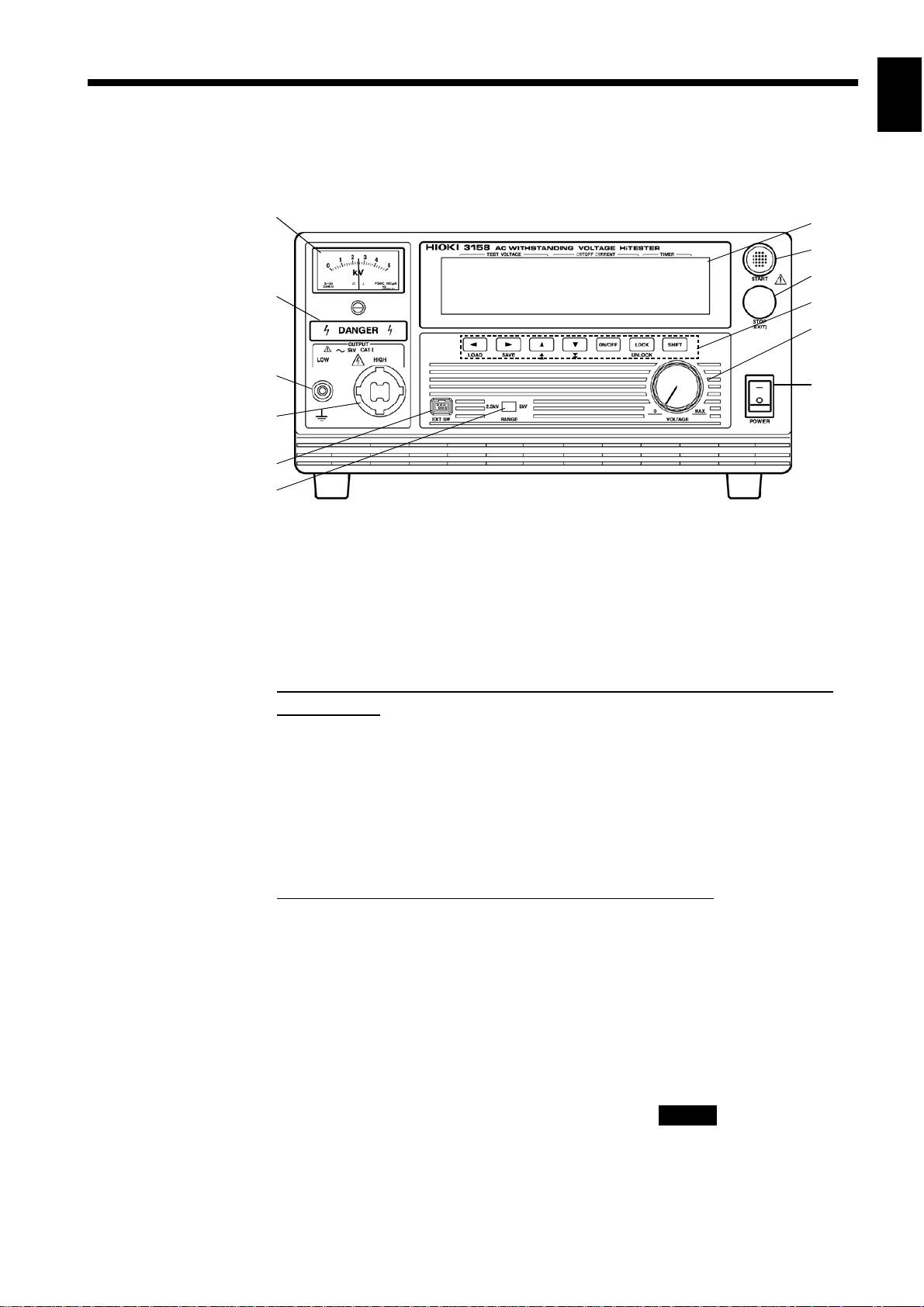

1.2 Names and Functions of Parts

Front panel

1

7

8

9

2

10

11

1

3

4

3

4

5

6

1 Analog voltmeter

Indicates output voltage.

2 Danger Lamp

This lamp lights to warn that voltage is present between the terminals during

testing.

When the DANGER lamp is lit, never touch the HIGH terminal, probe, or

tested object.

3LOWTerminal

The LOW terminal is a low-voltage terminal for voltage outputs. It has the same

electric potential as the unit body.

4 HIGH Terminal

The HIGH terminal is a high-voltage terminal for voltage outputs. A high voltage

is generated between this terminal and the LOW terminal.

When the DANGER lamp is lit, never touch this terminal.

12

5

6

7

8

9

10

11

5 External Switch Terminal

Used for the signal line for the remote-control box.

6 Range Selection switch

Used to switch among output-voltage ranges.

7 VFD ( Vacuum Fluorescent Display )

Displays various kinds of information, such as test state and results.

8 START key

Used to start a test. This key functions only when the READY lamp is lit.

9 STOP key

Normally used to terminate a test.

────────────────────────────────────────────────────

1.2 Names and Functions of Parts

12

13

14

A

Page 16

4

────────────────────────────────────────────────────

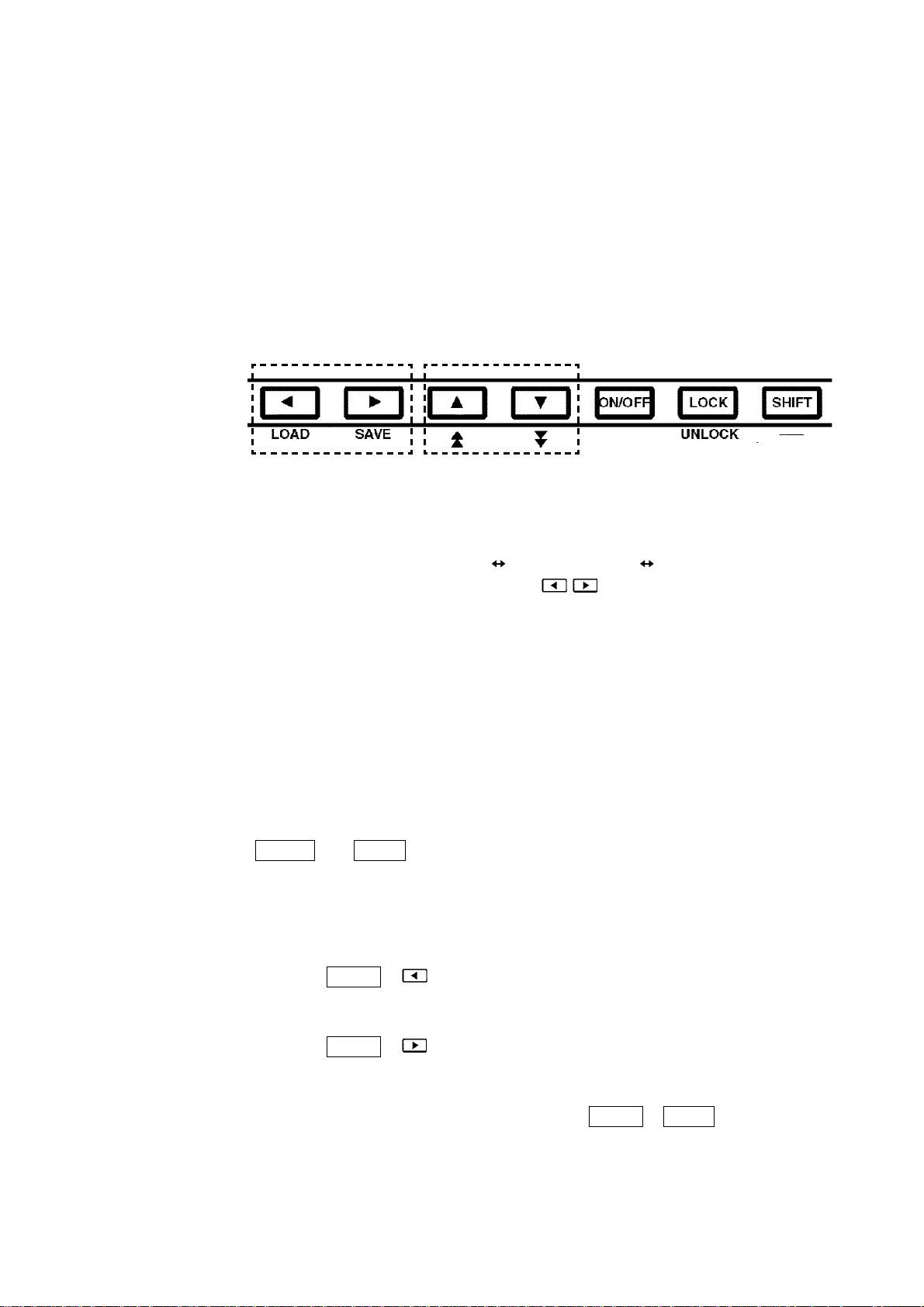

10 Rubber keys

The seven rubber keys include six function keys and a SHIFT key.

The six function keys offer a variety of settings, used in combination with the

SHIF T key.

11 Output Voltage Knob

Sets the output voltage.

12 Main power switch

Powers the 3158 on or off.

Rubber keys

1 2 3 4 5

1 Left/Right cursor key

Moves the flashing cursor. The switching range is preset before shipment:

Preset Comparative voltage value

To display the flashing cursor, press the

Upper limit Value Test time.

/ keys. The cursor appears,

displaying the preset comparative voltage value.

2 Up/Down cursor key

Changes the position at which the flashing cursor appears.

3 ON/OFF key

Switches on/off the set value for the position of the flashing cursor.

However, this key can't perform the switching on/off of the preset Upper level

Value. If turned off, the set value is not used in testing.

4 LOCK key

Used to lock the keys. When pressed, the LOCK key disables all keys except the

START

key,

STOP

key, and Key Lock Cancel key. See 3.2.2, "Key-lock

Function."

5 SHIFT key

Used in combination with other keys.

(1)

Displaying the Preset-data loading screen

Press

SHIFT

information, see Chapter 5, "Saving/loading the Parameters Set."

(2)

Displaying the Preset-data saving screen

Press

SHIFT

information, see Chapter 5, "Saving/Loading Preset Values."

(3)

Disabling the key lock function

To disable the key lock function, press the

+ keys to display the Preset-data loading screen. For more

+ keys to display the Preset-data saving screen. For more

SHIFT+LOCK

keys.

────────────────────────────────────────────────────

1.2 Names and Functions of Parts

Page 17

5

────────────────────────────────────────────────────

Rear panel

1

2

3

4

1 Fuse Holder

Contains a power fuse.

1

5

3

6

4

5

6

2 Power inlet

Connect the grounded three-core power cord supplied here. Integrated with a fuse

holder.

3 RS-232C terminal

Used for remote control with RS-232C.

4 Protective ground terminal

Used to earth a protective ground wire. Be sure to make grounding connections

before starting a test.

5 Buzzer adjustment knob

Used for buzzer sound adjustment. Two knobs are provided: one for PASS

screening and one for FA IL screening.

6 External I/O terminal

For output of 3158 state and input of start and stop signals.

7

8

9

10

11

12

13

────────────────────────────────────────────────────

1.2 Names and Functions of Parts

14

A

Page 18

6

)

)

────────────────────────────────────────────────────

9615 H.V. TEST LEAD

1

High-voltage side(red

2

1

Low-voltage side(black

3

1 Alligator clip

Connect to a test point on the tested object.

Vinyl shield on 9615 H.V. TEST LEAD alligator clip is not high voltage

insulated. DO NOT touch when high voltage is applied.

2 High-voltage output plug

Connect to the HIGH terminal on the unit.

3 Low-voltage output plug

Connect to the LOW terminal on the unit.

REMOTE CONTROL BOX

9613 REMOTE CONTROL BOX (SINGLE)

1

4

3

2

9614 REMOTE CONTROL BOX (DUAL)

1

2

1OPERATEswitch

Used to enable remote-control operation. When this switch is ON, the START and

STOP keys for remote control are active. Changing this switch during testing will

forcibly terminate the test.

2 START key

Works in the same manner as the

REMOTE CONTROL BOX (DUAL), the two START switches must be pressed.

START

key on the unit. With the 9614

4

3

2

3 STOP key

Works in the same manner as the

during a test or when a voltage is being output.

STOP

key on the unit. The STOP key is ON

4 Switch signal-line plug

Connect to the external switch terminal on the unit.

────────────────────────────────────────────────────

1.2 Names and Functions of Parts

Page 19

7

────────────────────────────────────────────────────

Chapter 2

1

2

Testing Arrangements

2.1 Connecting the Protective Ground Terminal

・

WARNING

To avoid electric shock, be sure to connect the protective ground

terminal to a grounded conductor.

・

To avoid electric shock, connect the protective ground terminal to a

grounded conductor before making any other connections.

(1) Using a Phillips-head screwdriver, remove the protective ground terminal from

the rear of the unit.

(2) Connect an electric wire with a sufficient current capacity to the protective

ground terminal, and secure the wire using a Phillips-head screwdriver.

(3) Ground the other end of the wire.

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

2.1 Connecting the Protective Ground Terminal

Page 20

8

────────────────────────────────────────────────────

2.2 Wearing rubber gloves

DANGER

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. Test

Lead, etc.

1. To avoid electrocution, always wear high-voltage protective rubber gloves when using

this product.

2. Contact your dealer or Hioki representative to help you look for high-voltage protective

rubber gloves.

────────────────────────────────────────────────────

2.2 Wearing rubber gloves

Page 21

9

────────────────────────────────────────────────────

2.3 Connecting the External I/O Connector

・

Always turn both devices OFF when connecting and disconnecting an

WARNING

interface connector. Otherwise, an electric shock accident may

occur.

・

To avoid electric shock or damage to the equipment, always observe

the following precautions when connecting to external I/O.

(1) Always turn off the power to the instrument and to any devices to

be connected before making connections.

(2) Be careful to avoid exceeding the ratings of external I/O signal.

2

4

5

Connect the external I/O connector before turning on the power. If the external I/O

connector is installed or removed following startup, malfunction may result.

(1) Make sure that the power switch is turned off.

(2) Insert the external I/O connector into the external I/O terminal.

(3) Secure the external I/O connector using the hooks of the external I/O terminal.

Hook of the external I/O terminal

6

7

8

9

10

11

NOTE

────────────────────────────────────────────────────

・

For the specifications of the external I/O connector, see 6.1, "External I/O

Terminal."

・

If the optional "Inter-lock" function is set to "1: Set," set Pin 10 of the external

I/O terminal to "Lo" before starting a test. "Err. 0" will be indicated until "Lo" is

set. For details, see 6.1.4, "Inter-lock Function."

2.3 Connecting the External I/O Connector

12

13

14

A

Page 22

10

────────────────────────────────────────────────────

2.4 Power Cord Connection

・

The rated power voltage for the 3158 varies depending on the

WARNING

Supply voltage indicated on the rear panel

settings of the unit. Before turning on the power, make sure that the

voltage of the power supply being used matches the supply voltage

indicated on the rear panel of the unit.

・

The unit has no protective ground terminal other than the power

inlet, and is connected to a ground line via a three-core power cord

that is supplied with the unit. In order to preent electric shock,

always connect the unit to a properly grounded power outlet using

the power cord provided.

(1) Be sure that the main power switch is turned to OFF.

(2) Connect the grounded three-core power cord provided to the power inlet on the

back of the unit.

(3) Insert the plug into the grounded outlet.

────────────────────────────────────────────────────

2.4 Power Cord Connection

Page 23

11

────────────────────────────────────────────────────

2.5 Powering On and Off the Unit

WARNING

NOTE

Before turning the product on, make sure the source voltage matches

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

・

The settings immediately prior to power shutdown are saved. The unit restarts

with these settings, even following a power interruption. When settings are

modified, however they are only saved after running a test.

・

Allow 5 minutes warming up after powering on.

・

The remote-control box, external I/O device, and RS-232C interface are active only

when they are connected prior to startup. If these devices are connected after the power

is turned on, the protective function may be activated, thus causing a malfunction.

Powering on the unit

(1) Turn the main power switch to ON(l).

Main power switch

2

3

4

5

6

7

8

(2) The model name and version number are displayed as below:

(3) When the READ Y lamp is lit (it does not light up in the Double Action mode),

the keys are ready for operation.

The model name is displayed. The version number is displayed.

"Version 1.00" is displayed.

Powering off the unit

(1) Following a test, make sure the analog voltmeter is at 0 kV, the DANGER lamp

is OFF, and the READY lamp is lit.

(2) Turn the voltage adjustment knob counterclockwise until the output reaches

0 kV. Do not turn OFF the Main Power switch when a voltage is being

output, as the unit may be damaged as a result.

)

(3) Turn OFF

(

the Main Power switch.

Output voltage knob

9

10

11

12

13

14

Main power switch

────────────────────────────────────────────────────

2.5 Powering On and Off the Unit

A

Page 24

12

────────────────────────────────────────────────────

2.6 Connecting the 9615 H.V. TEST LEAD

DANGER

WARNING

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding Voltage HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. TEST

LEAD, etc.

To prevent electrical shock, turn off the power unit and tested object,

make sure that there is no high voltage being applied to the output,

confirm the following 3 items, and connect the 9615 H.V. TEST LEAD.

(1) The analog voltmeter reads 0 kV.

(2) The DANGER lamp is OFF.

(3) The TEST lamp is OFF.

・

Before connecting the 9615 H.V. TEST LEAD, be sure to check its

insulation for tearing and metal exposure.Using the product in such

conditions could cause an electric shock, so contact your dealer or

Hioki representative for repair.

・

To avoid electric shock, make sure the 9615 H.V. TEST LEAD is

securely connected before starting a test, as a loose test lead can

cause a hazard when a voltage is output.

────────────────────────────────────────────────────

2.6 Connecting the 9615 H. V. TEST LEAD

Page 25

13

────────────────────────────────────────────────────

(1) Remove the LOW terminal by turning it counterclockwise.

Low terminal

(2) As shown in the figure, insert the plug on the low-voltage test lead.

(3) Secure the LOW terminal by turning it clockwise.

(4) Connect the plug on the high-voltage test lead to the HIGH terminal.

Plug on the low-voltage test lead

2

4

5

6

7

Plug on the high-voltage test lead

8

9

10

11

12

13

14

────────────────────────────────────────────────────

2.6 Connecting the 9615 H. V. TEST LEAD

A

Page 26

14

────────────────────────────────────────────────────

2.7 Connecting the REMOTE CONTROL BOX

・

To prevent electrical shock, turn off the power unit and tested object,

WARNING

make sure that there is no high voltage being applied to the output,

confirm the following 3 items, and connect the remote-control box.

(1) The analog voltmeter reads 0 kV.

(2) The DANGER lamp is OFF.

(3) The TEST lamp is OFF.

・

To prevent malfunctions, do not remove the REMOTE CONTROL BOX

following startup. Before removing it, be sure to turn OFF the power.

・

To avoid electric shock, when using the REMOTE CONTROL BOX,

provide safety measures to keep the output-voltage terminal, tested

object, and H.V. TEST LEAD out of contact with one another when

they are in the TEST state.

Connection of the remote-control box (9613/9614) enables start/stop operations to

be performed easily.

(1) Make sure the Main Power switch and OPERATE switch on the remote-control

box are OFF.

Main power switch OPERATE switch on the remote-control box

(2) Insert the switch signal-line plug into the external switch terminal.

Check the direction of the switch signal line.

(3) Turn ON the OPERATE switch of the remote-control box. The OPERATE

switch can be turned ON/OFF even following startup.

External switch terminal

Switch signal-line plug

────────────────────────────────────────────────────

2.7 Connecting the REMOTE CONTROL BOX

Page 27

15

────────────────────────────────────────────────────

2.8 Installation of the Unit

Install the unit on a stable surface using the four rubber feet on the bottom of the

unit.

Install on a stable surface using the four stands on the bottom of the unit.

(1) Temperature 0to40℃,23±5℃recommended for high-precision

measurements.

(2) Humidity 80 %RH max. (no condensation)

(3) Avoid the following locations:

・

Subject to direct sunlight.

・

Subject to high levels of dust, steam, or corrosive gases (Avoid using the

equipment in an environment containing corrosive gases (e.g., H

and CI

cyanides, and formalins)).

・

Subject to vibrations.

・

In the vicinity of equipment generating strong electromagnetic fields.

) or substances that generate harmful gasses (e.g., organic silicones,

2

S, SO2,NI

2

2

4

,

2

5

6

7

8

NOTE

9

Noise from the unit may affect peripheral equipment.

10

11

12

13

14

A

────────────────────────────────────────────────────

2.8 Installation of the Unit

Page 28

16

────────────────────────────────────────────────────

2.9 Connection to the Measured Equipment

DANGER

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding Voltage HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. TEST

LEAD, etc.

・

Make sure that no high voltage is being applied to the output,

confirm the following items, and connect the H.V. TEST LEAD.

(1) The analog voltmeter reads 0 kV.

(2) The DANGER lamp is OFF.

(3) The TEST lamp is OFF.

・

In the TEST state, never touch the output-voltage terminal, H.V. TEST

LEAD, or tested object.

・

Even following a test, there may be a residual voltage at the output

terminal. Therefore, before touching the output-voltage terminal, H.V.

TEST LEAD, or tested object, make sure that no high voltage is being

applied between the output terminals.

NOTE

・

If the HIGH and LOW voltage output terminals short-circuit or a dielectric

breakdown occurs in the tested object during the test, noise will be generated and

such noise may lead to a malfunction of this unit or of a nearby electronic device.

If this problem occurs, connect a ferrite core or a resistor to the H. V. TEST

LEAD (high voltage side).

When using a resistor, choose one appropriate for the power rating and withstand

voltage. Also, be alert to any drop in test voltage.

Beware of electric shock when connecting the resistor.

・

Do not the test lead and the EXT/IO cable arranged closely to each other.

Doing so may lead to a ma l functio n of the external control due to a noise.

Additionally, if the test lead touches to other metallic parts, it may cause an

increase in leakage current.

Prevent the test lead from coming into contact with other parts as much as possible .

(1) Make sure the analog voltmeter is at 0 kV and the DANGER lamp is OFF, and

the TEST lamp is OFF.

(2) Connect the LOW terminal probe to the tested object. Fasten the probe securely

to prevent it from loosening during a t est.

(3) Following the procedure described above, connect the HIGH terminal probe to

the tested object.

────────────────────────────────────────────────────

2.9 Connection to the Measured Equipment

Page 29

17

────────────────────────────────────────────────────

2.10 Startup Inspection

To ensure safe testing, check the following before starting operation:

Breaking current

(1) Calculate the resistance based on the output voltage to be set and the upper level

value, and then provide a resistor suitable for the resistance.

(Output voltage÷Upper-level value (Breaking current) = Resistance)

A high-voltage resistor with a power rating larger than the power calculated

from the output voltage and resistance is recommended.

2

÷

((Output voltage)

Ex.)

For the case that the output voltage is 2 kV and the upper level value is 4 mA,

Resistance value=2 kV/4mA=0.5 M

Rated power=(2 kV)

the 16 W resistor ((Rated power) x 2)) is recommendable to leave a margin.

Resistance<Power rating)

Ω

2

/

0.5 M

Ω=

8W

Example high-voltage resistor:

KOA Corp.'s GS Series High Voltage High Resistance Thick Film Resistor

(2) Set an upper-level value.

(3) Connect the resistor to the test lead.

(4) Increase the output voltage beyond the set value, and make sure the current is

cut off (i.e., make sure the unit is in the FAIL state).

Analog voltmeter

(1) Before turning on the power, make sure the analog voltmeter is at 0 kV.

(2) If the voltage reading is not at zero, adjust the value to zero using a slotted

screwdriver.

Inter-lock

If the Inter-lock function is set, make sure the Inter-lock function works properly

before starting operation.

Key inspection

(1) Turn off the power, and unplug the power cord from the power outlet.

(2) For both the START and STOP keys on the front panel of the unit, press the

center of the key, and make sure you feel it click. The click is less noticeable

when the edges of the keys are pressed.

* Clicking

When a key is pressed slowly, there is a moment of slight resistance and a

feeling that the key cannot be pressed any further. When the key is pressed

further after this point, a clicking sensation can be felt.

(3) If you do not feel a click, the key may be broken.

────────────────────────────────────────────────────

2.10 Startup Inspection

Page 30

18

────────────────────────────────────────────────────

────────────────────────────────────────────────────

2.10 Startup Inspection

Page 31

19

────────────────────────────────────────────────────

Chapter 3

1

DANGER

Testing Method

This chapter describes the procedural flow for testing, making settings, and proper

testing procedure.

Read Chapter 2, "Testing Arrangements" and make the necessary arrangements for

testing.

SHIFT+STOP

Press

Setting the optional functions allows testing under various conditions.

For more information, see Chapter 4, "Optional Functions."

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. Test

Lead, etc.

keys to display the Optional function setting screen.

3

5

6

7

8

9

10

11

NOTE

────────────────────────────────────────────────────

Note that the output waveform may be distorted when con ducting an AC

withstand voltage test for a voltage-dependent device or object (e.g., ceramic

capacitor). Excessively large distortion may damage the device or tested object.

When the device or tested object is a capacitive load, resonance may occur (when

conducting an AC withstand voltage test) with the coil inductance of the output

high-voltage transformer, depending on the capacitance value. This condition may

generate several tens of volts at the voltage output terminal before the test is

started. If the

set it bac k to the desired voltage after starting the test.

START

key is disabled, reset the output voltage knob to zero, then

12

13

14

A

Page 32

20

(1) (2) (3) (4) (5) (6) (7) (8) (9)

────────────────────────────────────────────────────

3.1 State of the 3158 and Preset Parameters

The 3158 is in one of the following five states:

READY state

「READY 状態」

Output voltage range

The unit is ready for starting a test. The READY lamp is turned on.

To enter TEST state, press the

START

Key-lock Function

key while in READY state.

Setting items

Output voltage range

Key-lock Function

Refer to 3.2.1

Refer to 3.2.2

Setting the optional functions allows testing under various conditions.

SHIFT+STOP

Press

Setting optional functions

Refer to Chapter 4

keys to display the Optional Function Setting screen.

(1) PASS Hold Function

(2) FAIL Hold Function

(3) Hold Function

(4) Momentary Out

(5) Double Action

(6) FAIL Mode

(7) RS Command

(8) Inter-lock Function

(9) Voltage Comparator

Position

SETTING state

「READY 状態」

To switch to the SETTING state, press the / keys. In this state, test

parameters can be set.

To terminate the test settings and return to the READY state, press the

STOP

Comparative voltage value

Setting items

────────────────────────────────────────────────────

3.1 State of the 3158 and Preset Parameters

key, which will finalize the settings.

Upper (Lower) level value Test time

Comparative voltage value

Upper (Lower) level value

Test time

Refer to 3.3.1

Refer to 3.3.2

Refer to 3.3.3

Page 33

21

────────────────────────────────────────────────────

"TEST" state

「READY 状態」

When the unit is in the TEST state, the TEST lamp is lit. This indicates that a test is in

progress. The measured-voltage value is compared with the comparative-voltage value set in the

SETTING state. If the measured-voltage value deviates from the comparative-voltage range, the

unit shifts to the FAIL state. The measured-current value is compared with the upper- and

lower-level values. If the measured-current value deviates from these values, the unit shifts to

the FAIL state and the test is terminated. When the preset test time has elapsed, if there have

been no deviations, the unit shifts to the PASS state.

Refer to 3.4.3

1

3

5

Key operation in the TEST status

"PASS" state

「READY 状態」

PASS indicates that the measured object passed the test set in READY state. The PASS

lamp is turned on. The PASS state screen is displayed for about 0.5 second before

switching to READY state.

The PASS state can be maintained if the PASS Hold function is disabled in the optional

settings. To return to the READY state, press the

Hold function.

"FAIL" state

「READY 状態」

READY indicates that the tested object failed to pass the test set in the READY state. The

FAIL lamp will light up, accompanied by UPPER if the measured value exceeds the upper-

level value, or by LOWER if the measured value is below the lower-level value. If the

measured value deviates from the comparative-voltage range, the FAIL lamp will light up,

accompanied by both UPPER and LOWER. The FAIL-state screen is displayed for 0.5

seconds, and the unit then switches to the READY state. The FAIL state can be maintained

if the FAIL Hold function is disabled in the optional settings. To return to the READY

state, press the

Refer to 3.5.1

Refer to 3.5.3

STOP

key, which will cancel the FAIL Hold function.

Forced ending

STOP

Press the

key, which will cancel the PASS

STOP

key.

6

7

8

9

10

11

12

13

14

────────────────────────────────────────────────────

3.1 State of the 3158 and Preset Parameters

A

Page 34

22

(1)

(2) (3)

(4)

(5)

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

In the READY state, the unit is always ready to start a test. The unit can be shifted

to the SETTING state only when it is in the READY state.

The

READY

setting data and the setting of optional functions are made following the READY

state.

lamp remains lit to indicate READY state. Saving and loading for

(1) Measured voltage value

Indicates the voltage value being output. In the READY state, the value

indicates at 0 kV.

(2) Upper level value icon and Lower level value icon

The symbol

appears when the upper level value is set, and the symbol

appears when the lower level value is set.

(3) Upper (Lower) level value

Indicates Upper (Lower) level value.

(4) Test time

Indicates the preset test time. "OFF" is indicated when no test-time setting has

been made.

(5) Output voltage range

Indicates the output-voltage range selected using the Range Selection switch

Analog voltmeter

Indicates the voltage value being output. In the READY state, the value remains at

0 kV.

Danger lamp

Indicates that a voltage is being output. This lamp remains lit as long as a voltage

of at least 0.0 3 kV is being applied to the output terminal. It does not light up in

the READY state.

External I/O

_________

The READY

_________

The READY

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

signal is ON when READY is lit on the fluorescent indicator.

signal is turned OFF when READY is not lit.

Page 35

23

────────────────────────────────────────────────────

3.2.1 Selecting an Output-Voltage Range

1

WARNING

The output voltage set using the output-voltage knob nearly doubles

when the output-voltage range is changed from 2.5 kV to 5.0 kV.

Conversely, if the range is changed from 5.0 kV to 2.5 kV, the output

voltage is reduced by approximately half. After changing the outputvoltage range, be sure to reset the output voltage using the outputvoltage knob.

In the READY state, change the output-voltage range (2.5 kV/5.0 kV) using the

Range Selection switch. When the output-voltage range is shifted, RANGE flickers.

This change is effective for the next test.

Flashing

3

5

6

7

8

Range Selection switch Output voltage knob

NOTE

If you turn the output-voltage knob fully clockwise, the voltage may exceed the set

output-voltage range.

3.2.2 Key-lock Function

It inactivates all keys except the

The KEYLOCK lamp is lit while the key-lock function is active.

To switch to the KEYLOCK state, press the

function, press the

SHIFT

The output-voltage set using the output-voltage knob will not become invalid.

key.

LOCK

START

key in the Key-lock state while holding down the

key,

STOP

LOCK

key, and the range switch.

key. To cancel the key-lock

9

10

11

12

13

14

NOTE

────────────────────────────────────────────────────

Even when the key-lock function is activated, the

remote control box and the signals on the external I/O terminal remain active.

3.2 Making Testing Arrangements (in READY State)

START

and

STOP

keys on the

A

Page 36

24

(1) (2) (3) (4) (5) (6) (7) (8) (9)

────────────────────────────────────────────────────

3.2.3 Initial Settings for Optional Functions

SHIFT+STOP

Press

function setting screen.

Setting the optional functions allows testing under various conditions.

Settings can be made for the following eight optional functions. One number is

assigned to each function. Settings are made by changing the number by using the

/ keys.

For more information on the settings, see Chapter 4, "Optional Functions."

keys while in READY state to display the Optional

The optional functions of the 3158 are factory-preset to the following settings:

Setting item Initial setting

(1) PASS Hold Function

(2) FAIL Hold Function

(3) Hold Function

(4) Momentary Out

(5) Double Action

(6) FAIL mode

(7) RS Command [Start]

(8) Inter-lock Function

(9) Voltage Comparator Position

0: PASS not held

1: FAIL held

0: Not held

0: Not set

0: Not set

0: Not set

0: Not set

0: Not set

0: Start test

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

Page 37

25

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

To change settings, switch to the SETTING state. In the READY state, press the

/ keys. The flashing cursor will then appear at the position where the

comparative voltage is indicated to show that the unit is in the SETTING state. The

READY light will go out. In the SETTING state, a test will not start even if the

START

the READY state.

key is pressed. To start a test, complete the test settings and then return to

1

3

Voltage measurement value

READY state

READY

SETTING state

試験設定状態

■

Setting procedure

In the SETTING state, set test values while moving the flashing cursor using the

The flashing cursor will move between the comparative-voltage value, the upperlevel value, the lower-level value, and the test time, in that order. If the value

indicated by the flashing cursor is not needed in the test, turn it OFF using the

ON/OFF

状態

Comparative voltage value

/ keys.

key. The upper-level value, however, cannot be turned OFF.

5

6

7

8

9

10

In the SETTING state, a test will not start even if the

finalize the test settings, press the

READY state. Note that the unit will not return to the READY state if the set

lower-level value is greater than the upper-level value. In such a case, correct the

settings and then press the

NOTE

────────────────────────────────────────────────────

A voltage being measured is displayed in the READY sate. In the SETTING state,

the comparative voltage value is displayed. Note that the display of the comparative

voltage value does not mean that the voltage is being output.

STOP

STOP

keytoreturntotheREADYstate.

key, which will return the unit to the

START

3.3 Setting the "SETTING" State

keyispressed.To

11

12

13

14

A

Page 38

26

────────────────────────────────────────────────────

3.3.1 Setting the Comparative Voltage Value

If a comparative-voltage value is to be set, value settings must be made. Once a

comparative-voltage value is set, a test will not start until the output voltage reaches

the comparative-voltage r ange, which is±5% of the comparative-voltage value

(output voltage:≦1kV:±50 V). TEST will flicker until the value reaches the

value range. If the value fails to reach the value range within approximately five

seconds, FAIL will light along with UPPER and LOWER and the test will quit

with the FAIL judgment. Also, in the same way the test will quit with the FAIL

judgment if it is outside of the standard voltage range during the test. If a

comparative-voltage value is not to be used, press the

ON/OFF

setting for that value OFF. Any voltage value can then be output in the TEST state.

key to turn the

Comparative voltage value: 3.50 kV

Comparative voltage value: OFF

(1) If no flashing cursor is displayed in the READY state, press either the

/

key to display the cursor while the comparative voltage value is l it.

(2) Change the comparative voltage value using the

changes in 0.01 kV increments. To change the value by 0.10 kV, press

/ keys. The value

SHIFT

+ / keys.

The comparative voltage value can be set from 0.00 kV to 5.00 kV.

If a comparative voltage value is not to be used, press the

ON/OFF

key to turn

the setting for that value OFF.

(3) When settings are complete, press the

(4) In the READY state, press the

START

STOP

key.

key to output the measured voltage. If

the value fails to reach the value range within approximately five seconds, the

unit returns to the READY state. During those five seconds, use the outputvoltage knob to set the output voltage to the comparative-voltage value.

(5) When the output voltage is equal to the comparative-voltage value, terminate the

settings for the comparative-voltage value.

NOTE

If the test time is set to OFF, the settings for the comparative-voltage value will

become invalid. Therefore, when the output-voltage settings are made, it is advisable

to set the test time to OFF.

You can select whether you want to check the output-voltage when the test starts or ends.

・

(Starting a test with default settings:) (See Section 4.9)

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 39

27

────────────────────────────────────────────────────

3.3.2 Setting the Upper (Lower) Level Value

Upper (Lower) level value: 20 mA

(1) If the flashing cursor does not appear in the READY state, display the cursor at

the position where the Upper-Level Value (Lower-Level Value) is indicated by

pressing the

(2) Set the upper (lower) level value using the

The upper (lower)-level value will change by 0.1 mA (by 1 mA at 10 mA to 120

mA). While holding down the

(lower)-level value will change by 1.0 mA (by 10 mA at 10 mA to 120 mA).

If no lower level value is required, turn off the

can not be turn off.

(3) When settings are complete, press the

/ keys.

SHIFT

/ keys.

key, press the / keys. The upper

STOP

ON/OFF

key.

key. Upper level value

1

3

5

6

7

NOTE

Lower level value: 1.0 mA

Lower level value: OFF

・

The setting resolution of the upper (lower)-level value is 0.1 mA at 0.1 mA to 9.9

mA, and 1 mA at 10 mA to 120 mA.

・

The current measurement resolution during a test depends on the set upper-level

value: 0.01 mA at 0.1 mA to 8.0 mA, 0.1 mA at 8.1 mA to 32 mA, and 1 mA at

33 mA to 120 mA.

・

If the set lower-level value is greater than the upper-level value, the unit will not

return to the READY state even when the

correct the upper- or lower-level value.

・

The electric current range will be decided by the upper-limit test value (2 mArange for "upper-limit test value≦2.0 mA", 8 mA-range for "2.0 mA<upperlimit test value≦8.0 mA", 32 mA-range for "8.0mA<upper-limit test value≦32

mA", 120 mA-range for "32 mA<upper-limit test value")

STOP

key is pressed. In such a case,

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 40

28

────────────────────────────────────────────────────

3.3.3 Setting the Test Time

Test Time: 60.0s

Test Time: OFF

NOTE

(1) If the flashing cursor does not appear in the READY state, display the cursor at

the position where the Test Time is indicated by pressing the

(2) Set the test time using the

/ keys.

/ keys.

With time set the time changes in 0.1 s increments (1 s increments when the set

time scale is 100 s to 999 s).

With time set at 0.5 s to 9 9.9 s, press

SHIFT

+ / keys. The time

changes in 1.0 s increments (10 s increments when the set time scale is 100 s to

999 s).

Settings may be made along a scale ranging from 0.5 s to 999 s (in gradations of

0.1 s for the range 0.5 s to 99.9 s and 1 s for the range 100 s to 999 s).

If no testing time is required, turn off the

(3) When settings are complete, press the

・

If a test time has been set, the reduction timer will operate during the test.

・

If the test time is set to OFF, the time elapsed during the test is displayed. When

ON/OFF

STOP

key.

key.

this time exceeds 999 s, "_" will appear, but the test will continue.

・

If the test time is set to OFF, the comparative-voltage value becomes ineffective.

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 41

29

────────────────────────────────────────────────────

3.3.4 Examples of Settings

NOTE

The settings immediately prior to power shutdown are saved. The unit restarts with

these settings, even following a power interruption. When settings are modified,

however they are only saved after running a test.

The following shows an example of a test at a comparative-voltage value of 2.00 kV

and an upper-level value of 20 mA, with the lower-level value set to OFF, at a test

time of 60.0 s. The 3158 is in the READY state.

Values currently set

Comparative voltage

value

Upper level value 120 mA Upper level value 20 mA

Lower level value 40 mA Lower level value OFF

Test time 120 s Test time 60.0 s

OFF Comparative voltage

Values to be set

2.00 kV

value

(1) Changing to the SETTING state

Press the / keys to switch to the SETTING state. The READY light will

go out, and the flashing cursor will be displayed at the position where the

comparative-voltage value is indicated.

In the READY state, a measured-voltage value is displayed. In the SETTING

state, the display changes to the comparative-voltage value (in this example,

OFF).

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 42

30

────────────────────────────────────────────────────

(2) Setting the comparative-voltage value

The comparative-voltage value is initially set to OFF. It must be changed to ON

before the value is changed. To do so, press the

ON/OFF

key.

The comparative-voltage value in the OFF state is displayed. In this example,

the value is 1.50 kV.

Using the

To change the value by 0.01 kV, press

To change the value by 0.10 kV, press

/ keys, set the comparative voltage value to 2.0 0 kV.

/ keys.

SHIFT

+ / keys.

(3) Setting an upper-level value

Press the

key to move the flashing cursor to the upper-level value.

In this example, switch from 120 mA to 20 mA using the

To change the upper level value by 1 mA, press

To change the upper level value by 10 mA, press

(4) Setting a lower-level value

Using the

key, move the flashing cursor to the lower level value.

/ keys.

SHIFT

/ keys.

+ / keys.

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 43

31

────────────────────────────────────────────────────

The lower-level value is set at 40 mA. Turn it OFF, as it is not needed. To

change to OFF, press the

ON/OFF

key.

(5) Setting the test time

Using the

key, move the flashing cursor to the test time.

In this example, change the test time from 120 s to 60.0 s.

(6) Changing to the READY state

To conduct a test using these settings, switch to the READY state. To return to

the READY state, press the

STOP

key, which will finalize the test settings. In

the READY state, the displayed comparative-voltage value is replaced with a

measured-voltage value, and READY lights up.

The new parameters following setting are shown below:

Comparative voltage value 2.00 kV

Upper level value 20 mA

Lower level value OFF

Test time 60.0 s

Press the

START

key while in this state. The unit enters TEST state to begin

testing.

────────────────────────────────────────────────────

3.3 Setting the "SETTING" State

Page 44

32

────────────────────────────────────────────────────

3.4 Starting a Test

The flowchart below explains how a test is carried out.

Setting the "READY"state

READY

「

状態」での設定

Output Voltage Range

Refer to 3.2.1

Key-lock Function

Optional Function

Setting the "SETTING"state

Comparative Voltage Value

Upper (Lower) level value

Test Time

Setting the "Output voltage"

READY

「

Before starting a test, make output voltage settings using the output-voltage knob.

A voltage is output during output-voltage setting using the output-voltage knob. Never touch the HIGH

terminal, test lead, or tested object.

Starting a Test

READY

「

Press the

TEST and the DANGER lamp are lit in the TEST state.

If a comparative-voltage value has been set, the test will not start until the output voltage is within±5%

of the comparative-voltage value (output voltage:≦1 kV:±50 V).

状態」での設定

状態」での設定

START

key when READY is lit. The unit will change to the TEST status and a test will start.

Refer to 3.4.1

Refer to 3.4.2

Refer to 3.2.2

Refer to Chapter 4

Refer to 3.3.1

Refer to 3.3.2

Refer to 3.3.3

Determination

READY

「

状態」での設定

Refer to 3.5

PASS/FAIL screening is conducted based on whether a measured-current value exceeds the

upper- or lower-level value. The test is failed (FAIL) if, with a comparative-voltage value set, the

output-voltage value fails to reach the comparative-voltage range within 5 seconds after the

START

key is pressed, or if the output-voltage value deviates from the comparative-voltage

range.

────────────────────────────────────────────────────

3.4 Starting a Test

Page 45

33

────────────────────────────────────────────────────

3.4.1 Setting the Output Voltage

DANGER

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not touch

this product, any tested object that is connected or any H.V. Test

Lead, etc.

・

Make sure that no high voltage is being applied to the output,

confirm the following items, and output voltage.

(1) The analog voltmeter reads 0 kV.

(2) The DANGER lamp is OFF.

(3) The READY lamp is lit (it is off in the Double Action mode).

・

A voltage is output during output-voltage setting using the

outputvoltage adjustment knob. Never touch the HIGH terminal, H.V.

TEST LEAD, or tested object.

Before starting a test, make output voltage settings using the output-voltage knob . If

a comparative-voltage value has already been set, press the

output voltage within 5 seconds after pressing the

successful, the test switches to the FAIL state.

START

START

key. If the setting is not

key and set an

(1) In accordance with the instructions given in 2.9, "Connection to the Measured

Equipment," connect the probe to the tested object.

(2) Make sure the analog voltmeter is at 0 kV, the DANGER lamp is OFF, and the

unit is in the READY state.

(3) Set the output-voltage range using the Range Selection switch.

(4) Press the

(5) Set an output voltage using the output-voltage knob. The output-voltage knob

increases the output voltage when turned clockwise, and decreases the voltage

when turned counterclockwise. The maximum value is 2.5 kV or 5.0 kV,

depending on the output-voltage range set in Step (3). The output voltage is

displayed on the analog voltmeter and the fluorescent indicator.

(6) Upon completion of the output-voltage settings, press the

output.

START

key. TEST will light up and a voltage will be output.

STOP

key to stop the

────────────────────────────────────────────────────

3.4 Starting a Test

Page 46

34

────────────────────────────────────────────────────

Set an output voltage using

the output-voltage knob.

Range Selection Switch Output voltage knob

NOTE

If you turn the output-voltage knob fully clockwise, the voltage may exceed the set

output-voltage range.

■

Rated time for output voltages (at an ambient temperature of 40℃)

The transformer capacity of the unit is approximately half the rated output. Use the

unit within the rated time. If the rated time is exceeded, the un it may overheat and

thereby cause the thermal fuse for the internal circuit to blow out.

Current measurement range Maximum test time Pause

I ≦60 mA Continuous None

60 mA < I ≦100 mA 30 minutes 30 minutes

100 mA < I ≦ 120 mA 10 minutes 30 minutes

・

NOTE

If the test time is set to OFF, the comparative-voltage value becomes ineffective,

thereby facilitating output-voltage adjustments.

・

The output-voltage range can only be changed in the READY state. The range

cannot be changed in other states, even using the Range Selection switch.

The Double Action increases the safety of testing by preventing operational errors.

Refer to Section 4.5 Double Action

────────────────────────────────────────────────────

3.4 Starting a Test

Page 47

35

────────────────────────────────────────────────────

3.4.2 Executing a Test

DANGER

To avoid any life-threatening electric shock accidents, ensure that the

following rules are observed.

・

The AC Withstanding HiTester is a dangerous product which

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

・

Be careful when using the product and ensure that you do not

touch this product, any tested object that is connected or any H.V.

Test Lead, etc.

・

Make sure that no high voltage is being applied to the output,

confirm the following items, and output voltage.

(1) The analog voltmeter reads 0 kV.

(2) The DANGER lamp is OFF.

(3) The READY lamp is lit (it is off in the Double Action mode).

・

A voltage is output during output-voltage setting using the

outputvoltage adjustment knob. Never touch the HIGH terminal,

H.V. TEST LEAD, or tested object.

・

When the

on the analog voltmeter and the fluorescent indicator is being

output. Never touch the HIGH terminal, test lead, or tested object.

and DANGER lamps are lit, the voltage displayed

TEST

CAUTION

NOTE

・

For output, the unit uses a high-voltage transformer that boosts the

power voltage. If an unstable power voltage is used to operate the unit,

the tested object may be damaged by the distortion of the output-voltage

waveform and by the output of a voltage higher than the preset voltage.

・

If a capacity load is applied to the tested object, the output voltage may

exceed the preset voltage, thereby damaging the equipment.

・

Continuous output of a high voltage may heat the bottom of the unit.

Take special care when handling the unit (e.g. transporting the unit).

Priority for control of the

the START switch on the REMOTE CONTROL BOX, the external I/O, and the

front panel of the unit. Connecting the switch signal line plug on the REMOTE

CONTROL BOX disables the

start signal for the external I/O.

(1) Press the

status and a test will start. TEST and the DANGER lamp are lit in the TEST

state.

(2) If a comparative-voltage value has been set, the test will not start until the

output voltage is within±5% of the comparative-voltage value (output voltage:

≦

1kV:±50 V).

START

START

key when READY is lit. The unit will change to the TEST

key is in the following order:

START

key on the front panel of the unit and the

────────────────────────────────────────────────────

3.4 Starting a Test

Page 48

36

────────────────────────────────────────────────────

(3) In a test with a comparative-voltage value set, the test is forcibly terminated

when the output voltage deviates by±5% from the comparative-voltage value

(output voltage:≦1kV:±50 V). In such a case, UPPER, LOWER,and

FAIL will light up. Reset the output voltage and restart the test.

To terminate the test, press the

STOP

key. The unit will immediately stop

outputting a voltage and switch to the READY state. In such a case, no screening is

conducted.

The Hold function can be used to hold the value that was effective at the time of forced

・

termination of the test. Refer to Section 4.3 Hold Function.

When a comparative-voltage value is set, the FAIL Hold function enables the unit to forcibly

・

terminate the test when the output voltage deviates from the comparative-voltage range. The

most recently set value is held. Refer to Section 4.2 FAIL Hold Function.

You can select whether you want to check the output-voltage when the test starts or ends.

・

(Starting a test with default settings:) Refer to Section 4.9 Voltage Comparator Position

The Double Action increases the safety of testing by preventing operational errors.

・

Refer to Section 4.5 Double Action

────────────────────────────────────────────────────

3.4 Starting a Test

Page 49

37

(1)

(2) (3)

(4)

(5)

────────────────────────────────────────────────────

3.4.3 Screening in "TEST State"

(1) Measured voltage value

Indicates the voltage value being output.

(2) Upper level value icon and Lower level value icon

The symbol

appears when the upper level value is set, and the symbol

appears when the lower level value is set.

(3) Measured current value

Represent the value of a current flowing between the HIGH a nd LOW terminals.

(4) Test time elapsed

When the testing time is set, countdown starts from the time set, and is

displayed. When the testing time is set to OFF, the time elapsed after the start

of the test is displayed.

If the elapsed test time exceeds 999 s, "_" is displayed, but the voltage

continues to be output.

(5) Output voltage range

Indicates the output-voltage range selected using the Range Selection switch

(6) TEST

Remains lit during the test. TEST flickers for up to five seconds at the start of a

test and when the output voltage exceeds the comparative-voltage range.

Analog voltmeter

Indicates the voltage value being output.

Danger lamp

Indicates that a voltage is being output. This lamp remains lit as long as a voltage

of at least 0.0 3 kV is being applied to the output terminal. It does not light up in

the READY state.

External I/O

_______

The TEST

_________

The H.V.ON

signal is turned ON when TEST on the fluorescent indicator lights up.

signal is turned on when the DANGER lamp lights up. The two

signals are turned OFF at the same time. At the start of a test, the unit waits for up

to five seconds for the output voltage to switch to the comparative-voltage range.

During this period, TEST flickers but the TEST

________

L-FAI L

signals are turned ON when the output-voltage value deviates from the

_______

_________

signal is ON. The U-FAIL

and

comparative-voltage value range when UPPER, LOWER,andFAIL are lit.

────────────────────────────────────────────────────

3.4 Starting a Test

Page 50

38

g

p

g

────────────────────────────────────────────────────

3.5 PASS or FAIL Determination

3.5.1 "PASS" State

WARNING

Even when a test has been terminated, there may still be voltage in

the output-voltage terminal when the DANGER lamp is lit. Before

touching the output-voltage terminal, test lead, or tested object, make

sure the analog voltmeter is at 0 kV, the DANGER lamp is OFF, and

the TEST lamp is OFF.

When the preset test time has elapsed, the unit switches to the PASS state and

immediately stops outputting a voltage. If the test time has not been set, PASS

screening is not performed. To the test, press the

STOP

key, which will forcibly

terminate the test.

The PASS state is held using the PASS Hold function.

・

Refer to Section "4.1 PASS Hold Function".

■

Flow of PASS determination

Output voltage

Comparative

volta

evalue

Testingtime when it set u

Time

Flashin

(1) Press the

START

key to start a test.

(2) If a comparative-voltage value has been set, TEST flickers until the output

voltage switches to the comparative-voltage range. When the output voltage

switches to that range, TEST remains lit and the reduction timer begins

counting down the test time.

(3) A voltage is output until the test time elapses. (If the measured-current value deviates

from the upper- and lower -le vel values , the unit switches to the FAIL state.

(4) When the preset test time has elapsed, the unit stops outputting a voltage and

switches to the PASS state. PASS lights up in the PASS state.

NOTE

If a comparative-voltage has not been set, TEST does not flicker.

If the optional "Voltage Comparator Position" function is set to "1: End of test

time", TEST does not flicker.

────────────────────────────────────────────────────

3.5 PASS or FAIL Determination

Page 51

39

(1)

(2) (3)

(4)

(5)

(6)

────────────────────────────────────────────────────

3.5.2 Screening in "PASS" State

(1) Measured voltage value

Indicates the voltage in the PASS state.

(2) Upper level value icon and Lower level value icon

The symbol

appears when the upper level value is set, and the symbol

appears when the lower level value is set.

(3) Measured current value

Indicates the value of the current flowing between the HIGH a nd LOW terminals

in the PASS state.

(4) Test completion time

Displays the time in which the test has been completed. In PASS state, 0.0s is

displayed.

(5) Output voltage range

Indicates the output-voltage range selected using the Range Selection switch.

(6) PASS

Indicates that the unit is in the PASS state.

Analog voltmeter