Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

INSTRUCTION MANUAL

For...は専用機種。複数の場合は「/」で区切る。不要の場合はとる。

形名を入力。 複数の場合は「/」で区切る。

3157

3157-01

品名を入力。

AC GROUNDING

HiTESTER

August 2012 Revised edition 16 3157A981-16 12-08H

Page 2

Contents

Introduction i

Inspection

Safety Notes

Notes on Use

Contents and Indications of this Manual

Chapter 1 Overview

1.1 Product Introduction 1

1.2 Features of the 3157

1.3 Names and Functions of Parts

ii

iv

vi

1

Chapter 2 Testing Arrangements 9

2.1 Power Cord Connection 9

2.2 Powering on and off the Unit

2.3 Probe Connection

2.4 Short Bar Connection

2.5 Connecting the REMOTE CONTROL BOX

2.6 Installation Site and Position

2.7 Connection to the Measured Object

2.8 Connection to the 3155 LEAK CURRENT HiTESTER

2.9 Pre-operation Inspection

10

11

12

13

14

15

16

17

i

2

3

Chapter 3 Testing Method 19

3.1 Procedural Flow for Testing and Setting Parameters 20

3.2 Making Testing Arrangements (in READY State)

3.2.1 Setting Output Current Values 23

3.2.2 Setting the Maximum (Minimum) Test Value

3.2.3 Setting the Testing Time

3.2.4 Setting the Output Current Frequency

(in READY State)

3.2.5 Setting the Test Data Count (in READY State)

3.3 Initial Settings for Optional Functions 26

3.4 Zero Adjustment Function

3.5 Key-lock Function

3.6 Examples of Settings

3.7 Starting a Test

3.8 Testing (in TEST State)

3.9 Screening (in PASS State)

3.10 Screening (in FAIL State)

22

23

24

25

25

27

28

29

31

34

35

36

Chapter 4 Optional Functions 37

4.1 Switching the Output Current Frequency 40

4.2 PASS/FAIL Hold Function

4.3 HOLD Function

4.4 Setting the Minimum Test Value

41

42

44

Page 3

4.5 Endless Timer Function 45

4.6 Test Data Count Function

4.7 Buzzer Setting

4.8 Changing the Current Value in TEST State

4.9 Momentary OUT

4.9.1 Trigger Operation with Switching Probe 50

4.9.2 Momentary OUT Operation with Switching Probe

46

47

48

49

52

4.10 Setting the Test Mode 55

4.10.1 Soft Start Mode 55

4.10.2 Normal Mode

4.10.3 Continuous Test Mode

57

58

4.11 Printer Output 60

4.12 Example of Optional Function Settings

4.13 Example of Optional Functions Use

62

64

Chapter 5 Saving/loading Preset Values 67

5.1 Saving Preset Values 67

5.1.1 Procedure for Saving Data 68

5.1.2 Example of Saving

5.2 Loading Preset Values 71

5.2.1 Procedure for Loading Data 72

5.2.2 Example of Loading

69

73

Chapter 6 External I/O 75

6.1 Signal Line 76

6.2 Timing Chart of External I/O Terminal

80

Chapter 7 Maintenance, Inspection and Ultimate Disposal 83

7.1 Maintenance and Inspection 83

7.2 Fuse Replacement

7.3 Troubleshooting

7.4 Displaying Errors

7.5 Resetting the System

7.6 Ultimate Disposal (Removal of the Lithium Battery)

7.7 External Dimensions

84

85

85

86

87

88

Chapter 8 Specifications 89

8.1 Basic Specifications 89

8.2 General Specifications

91

Appendix APPENDIX1

Appendix 1 Options APPENDIX1

Appendix 1.1 9442 PRINTER APPENDIX1

Appendix 1.2 Probe

Appendix 1.3 9613 REMOTE CONTROL BOX (SINGLE)

Appendix 1.4 9614 REMOTE CONTROL BOX (DUAL)

Appendix 1.5 Interface Board

Appendix 2 Table of Optional Functions APPENDIX4

Appendix 3 Standards

APPENDIX2

APPENDIX2

APPENDIX3

APPENDIX3

APPENDIX5

Index INDEX 1

Page 4

────────────────────────────────────────────────────

Introduction

Thank you for purchasing the HIOKI "3157 AC GROUNDING HiTESTER". To

obtain maximum performance from the product, please read this manual first, and

keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories,and connectors. If

damage is evident, or if it fails to operate according to the specifications, contact

your dealer or Hioki representative.

i

NOTE

Checking the main unit and accessories

Main unit

"3157 AC GROUNDING HiTESTER"

Accessories

Verify that the following standard accessories are complete.

(1) Instruction Manual

(2) Spare fuse (built into the power inlet)

(3) Grounded three-core power cord

(4) Short bar (installed between the SOURCE and SENSE terminals)×2

The 9296 CURRENT PROBE and 9297 CURRENT APPLY PROBE are not

included. Please purchase separately according to your needs.

Shipment of the unit

Use the original packing materials when reshipping the product, if possible.

Warranty

HIOKI cannot be responsible for losses caused either directly or indirectly by the

use of the 3157 with other equipment, or if ownership is transferred to a third party.

────────────────────────────────────────────────────

Introduction

Page 5

ii

────────────────────────────────────────────────────

Safety Notes

DANGER

This product is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as

damage to the product. Using the product in a way not described in

this manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or

injuries not resulting directly from product defects.

This manual contains information and warnings essential for safe operation of the

product and for maintaining it in safe operating condition. Before using the product,

be sure to carefully read the following safety notes.

Safety symbols

・

The

should refer to a corresponding topic in the manual (marked with

the

・

In the manual, the

information that the user should read before using the product.

symbol printed on the product indicates that the user

symbol) before using the relevant function.

symbol indicates particularly important

DANGER

WARNING

CAUTION

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

NOTE

────────────────────────────────────────────────────

Safety Notes

product.

Advisory items related to performance or correct operation of the

Page 6

iii

────────────────────────────────────────────────────

We define measurement tolerances in terms of rdg. (reading) and dgt. (digit) values,

with the following meanings:

rdg. (displayed or indicated value)

The value currently being measured and indicated on the measuring product.

dgt. (resolution)

The smallest displayable unit on a digital measuring product, i.e., the input value

that causes the digital display to show a "1".

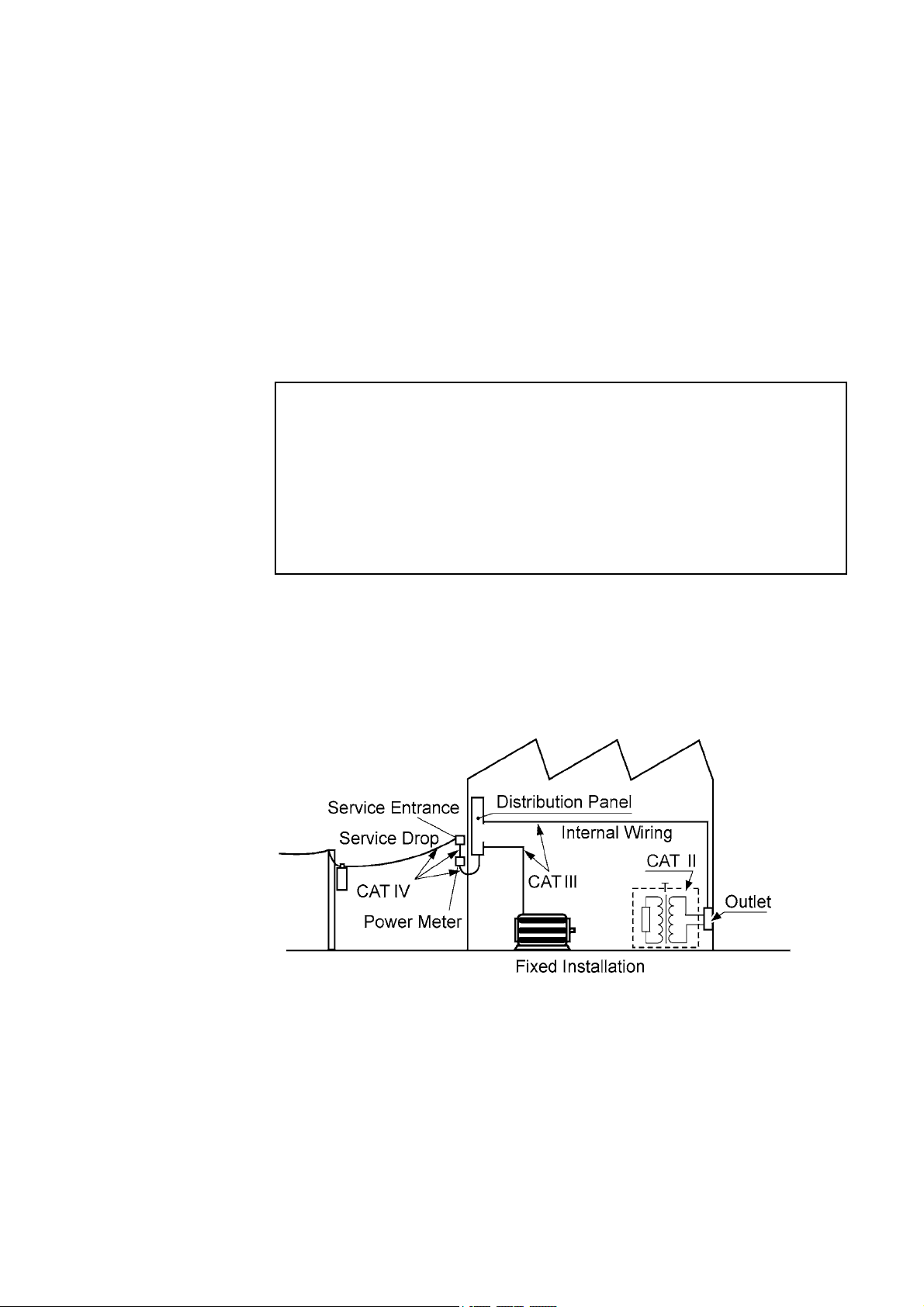

Measurement categories

To ensure safe operation of measurement product, IEC 61010 establishes safety

standards for various electrical environments, categorized as CAT II to CAT IV, and

called measurement categories.

CAT II Primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

CAT III Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance, and to the power

meter and primary overcurrent protection device (distribution panel).

Using a measurement product in an environment designated with a higher-numbered

category than that for which the product is rated could result in a severe accident,

and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV

measurement applications could result in a severe accident, and must be carefully

avoided.

────────────────────────────────────────────────────

Safety Notes

Page 7

iv

────────────────────────────────────────────────────

Notes on Use

Follow these precautions to ensure safe operation and to obtain the full benefits of

the various functions.

WARNING

Before turning the product on, make sure the source voltage

matches that indicated on the product's power connector.

Connection to an improper supply voltage may damage the product

and present an electrical hazard.

To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3contact (two-conductor + ground) outlet.

To avoid electric shock, do not remove the cover panel. The internal

components of the product carry high voltages and may become very

hot during operation.

To avoid electric shock, do not allow the product to get wet, and do

not use it when your hands are wet.

Replace the fuse only with one of the specified characteristics and

voltage and current ratings. Using a non-specified fuse or shorting

the fuse holder may cause a life-threatening hazard.

(Fuse type: 250 V T3.15 AL)

To avoid electric shock when measuring live lines, wear appropriate

protective gear, such as insulated rubber gloves, boots and a safety

helmet.

────────────────────────────────────────────────────

Notes on Use

Page 8

v

────────────────────────────────────────────────────

・

CAUTION

Before using the product, make sure that the insulation on the

probes(9296 or 9297) is undamaged and that no bare conductors are

improperly exposed. Using the product in such conditions could cause an

electric shock, so contact your dealer or Hioki representative for repair.

・

For safety reasons, only use the optional 9296 or 9297 probe for

measurement.

・

This product should be installed and operated indoors only, between 0

and 40

・

Do not store or use the product where it could be exposed to direct

and 90%RH max.

sunlight, high temperature or humidity, or condensation. Under such

conditions, the product may be damaged and insulation may deteriorate

so that it no longer meets specifications.

・

To avoid electrocution, turn off the power to all devices before plugging or

unplugging any of the interface connectors.

・

To avoid damaging the output cable, grasp the connector, not the cable,

when unplugging the cable from the product.

・

To avoid damaging probes (especially where the leads connect to the

probes), do not kink or pull on the leads.

・

Keep in mind that, in some cases, conductors to be measured may be

hot.

・

Avoid obstructing the ventilation holes on the sides of the 3157, as it could

overheat and be damaged, or cause a fire.

・

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

・

Do not insert a board other than optional interface boards into the

Interface slot. The unit software or calibration data may be lost.

・

In the event that the equipment malfunctions in any manner during use,

turn off the power immediately, and contact your dealer or HIOKI

representative.

・

NOTE

Do not use the product near a device that generates a strong electromagnetic field

or electrostatic charge, as these may cause erroneous measurements.

・

This product may cause interference if used in residential areas. Such use

must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

────────────────────────────────────────────────────

Notes on Use

Page 9

vi

────────────────────────────────────────────────────

Contents and Indications of this Manual

Chapter 1: Overview

Describes an overview, features, and the names and functions of the

parts of the unit.

Chapter 2: Testing Arrangements

Describes particulars of testing arrangements.

Chapter 3: Testing Method

Describes procedures for setting, testing, and test results judgement.

Chapter 4: Optional Functions

Describes procedures for setting optional functions.

Chapter 5: Saving/loading Preset Values

Describes procedure for saving and loading test values.

Chapter 6: External I/O

Describes use of the external I/O.

Chapter 7: Maintenance, Inspection and Ultimate Disposal

Covers the maintenance and inspection, fuse replacement, and ultimate

disposal.

Chapter 8: Specifications

Contains the unit specifications such as the general specifications,

measurement accuracy, etc. of the unit.

Appendix:

Covers the options of the unit and standards.

Indications in the Instruction Manual

Indicates that settings can be made for optional functions.For more information, see

Chapter 4, "Optional Functions."

In this Instruction Manual, the flashing area of the screen is represented in reverse

mode.

In this figure, for example, the current value of 25.0 A flashes.

────────────────────────────────────────────────────

Contents and Indications of this Manual

Page 10

1

────────────────────────────────────────────────────

Chapter 1

Overview

1.1 Product Introduction

The HIOKI "3157 AC GROUNDING HiTESTER" is designed for protection circuit

testing of a wide range of electrical equipment, including industrial machinery,

medical equipment, and measuring instruments.

Using a constant current system, the HIOKI 3157 provides stable output current.

The unit is capable of accurate four-terminal measurement. The comparator

function, timer function, and screening function permit simple testing, conforming

to technical standards and regulations.

────────────────────────────────────────────────────

1.1 Product Introduction

Page 11

2

────────────────────────────────────────────────────

1.2 Features of the 3157

(1) Simple testing procedures conforming to technical standards

This unit incorporates a constant current method to provide stable output current.

Voltage drop is measured with four terminals. The 3157 is also equipped with a

function timer and a screening function, using maximum and minimum values,

allowing straightforward testing in conformance with applicable technical standards.

(2) Test data counting function

This function enables test point counting for measured objects that have large

numbers of test points.

(3) Soft-start function

By constantly monitoring current fluctuations, this function checks that the probe is

connected to the measured object. The function also prevents sparking when the

probe is connected to a test point after measurement begins.

(4) Compact and lightweight

With a compact lightweight design, the unit is highly portable and well-suited to

maintenance measurement.

(5) Fluorescent indicator

The large, easy-to-read fluorescent display permits quick checking of the testing

state and result.

(6) Probe

The 3157 is equipped with an alligator-clip probe (the 9296 CURRENT

PROBE) and a switching probe (the 9297 CURRENT APPLY PROBE).

To improve testing efficiency, the push switch on the switching probe

starts testing and inactivates result-checking mode.

(7) Saving testing set values

This unit is provided with a function for saving the set values used in a test,

allowing quick switching between different testing set values to meet a variety of

standards and regulations. Up to 20 values may be saved.

(8) Interface

By using the optional 9593-02 RS-232C and 9518-02 GP-IB INTERFACE boards,

the user can perform automatic testing and save the test results by means of a PC.

Test results can be printed on the optional 9442 PRINTER. Connecting with the

optional 3155 LEAK CURRENT HiTESTER enables testing and the test results can

be saved and printed together with the 3155 leakage current test results.

(9) External I/O

The external I/O terminal generates signals according to the state of the 3157.

It can be used to feed signals for the start and stop key.

────────────────────────────────────────────────────

1.2 Features of the 3157

Page 12

3

────────────────────────────────────────────────────

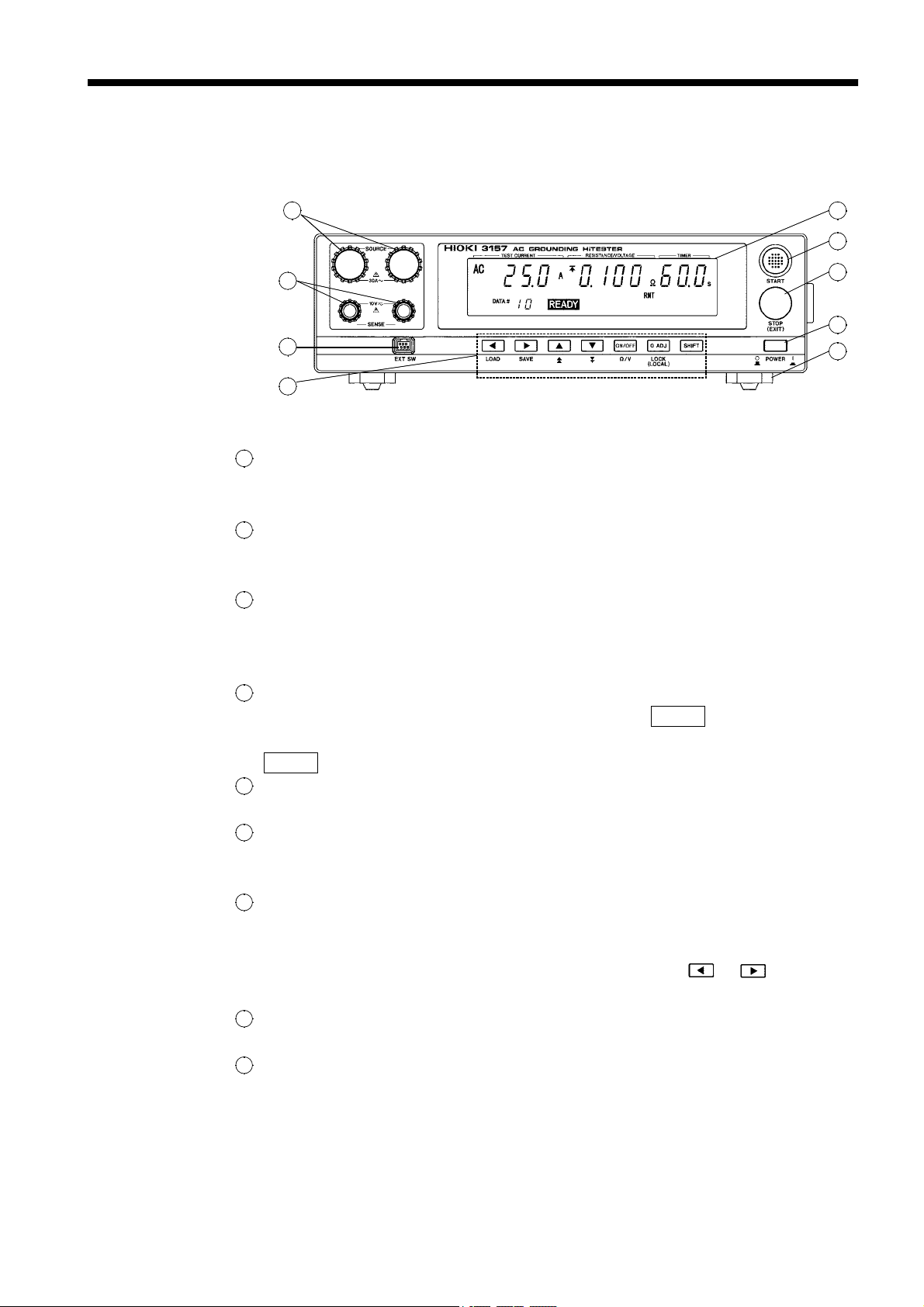

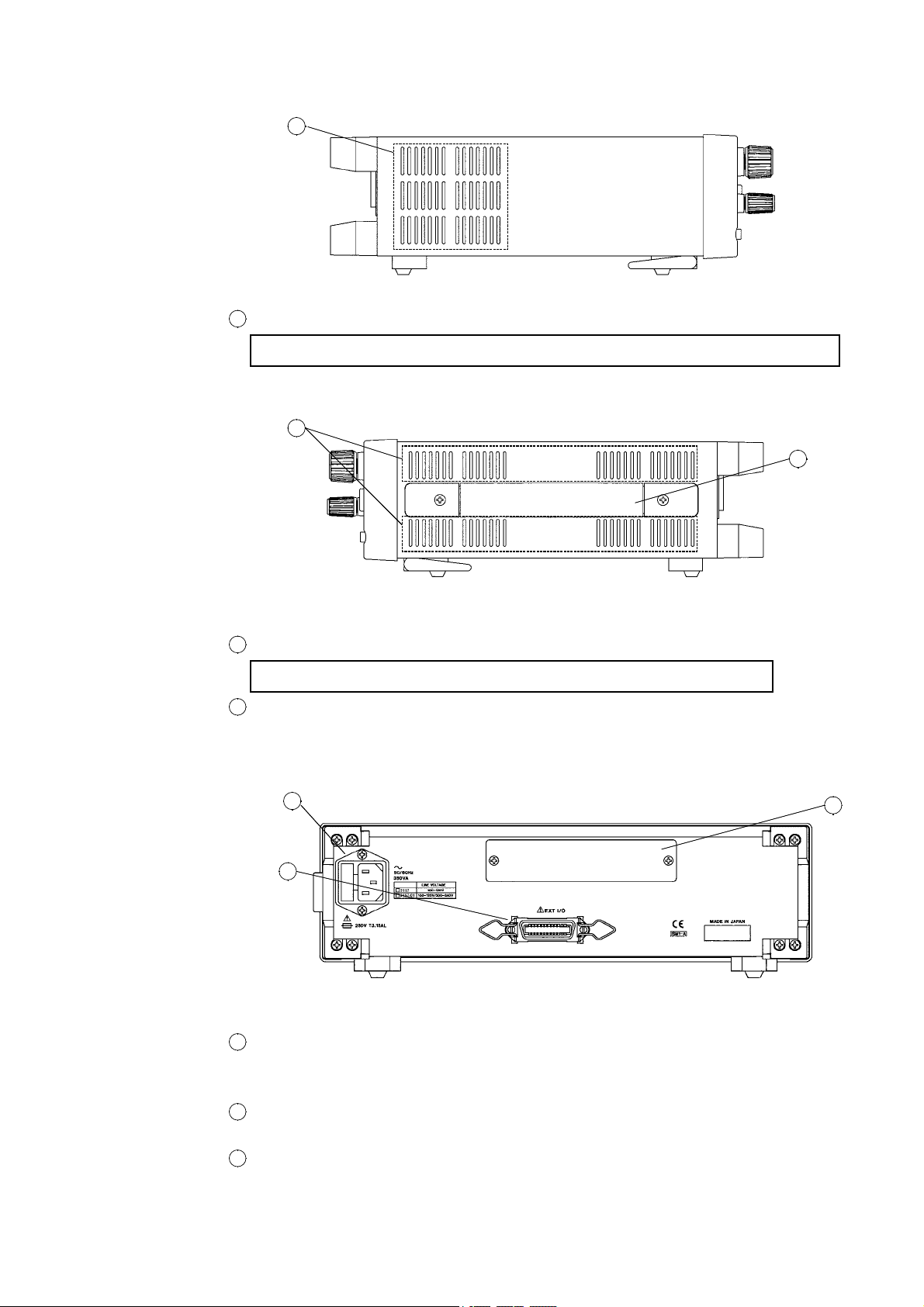

1.3 Names and Functions of Parts

Front panel

1

5

6

2

3

4

1

Current output terminal

Providing current during a test, this terminal serves as the SOURCE terminal for

four-terminal measurement.

2

Voltage measurement terminal

Used to measure voltage. This terminal serves as the SENSE terminal for

four-terminal measurement.

3

External switch terminal

Used for the switch signal line connected to the switching probe (the 9297

CURRENT APPLY PROBE), the 9613 REMOTE CONTROL BOX(SINGLE) or

the 9614 REMOTE CONTROL BOX(DUAL).

4

Rubber keys

The seven rubber keys include six function keys and a

SHIFT

key.

The six function keys offer a variety of settings, used in combination with the

SHIFT

5

Fluorescent indicator

key.

Displays various kinds of information, such as test state and results.

6

START key

Used to start a test. On starting a test with a preset value, the unit enters TEST

mode. The test starts whether or not the flashing cursor is displayed.

7

STOP key

・

Used to perform forcible ending of a test.

・

Pressing the STOP key when the flashing cursor is displayed causes it to

disappear. To display the flashing cursor again, press the

or key. The

cursor appears, displaying the preset current value.

8

Main power switch

Powers the 3157 on or off.

9

Stand

The 3157 can be tilted up by using this stand.

7

8

9

────────────────────────────────────────────────────

1.3 Names and Functions of Parts

Page 13

4

────────────────────────────────────────────────────

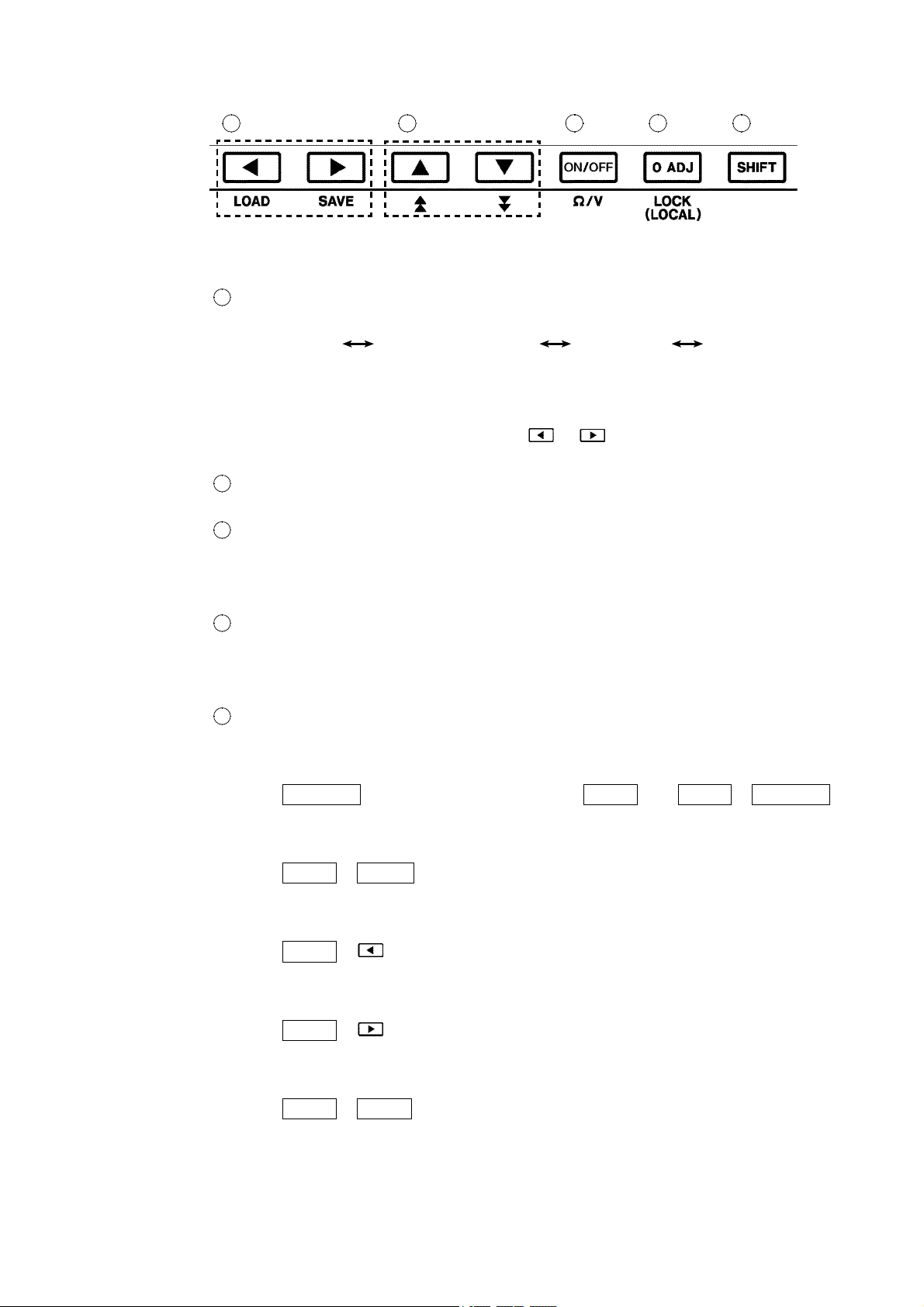

Rubber keys (in READY state)

1 2 3 4 5

1

Left/Right cursor key

Moves the flashing cursor. The switching range is preset before shipment: Preset

current value

Frequency.

The key can be set to shift to the minimum test value and the test data count, when

these values are set with the optional functions.

To display the flashing cursor, press the

displaying the preset current value.

2

Up/Down cursor key

Changes the position at which the flashing cursor appears.

3

ON/OFF (Ω/V) key

Switches on/off the set value for the position of the flashing cursor.

However, this key can't perform the switching on/off of the preset current value. If

turned off, the set value is not used in testing.

4

Zero Adjustment key

Use this key to perform zero adjustment within the effective range of adjustment.

The zero adjustment function is active when the 0ADJ lamp is lit.

For zero adjustment procedure, see Section 3.4, "Zero Adjustment Function."

5

SHIFT key

Used in combination with other keys.

Maximum Test Value Testing time Output

or key. The cursor appears,

(1) Switching between voltage and resistance indicators

Press

ON/OFF

(Ω/V) while holding down the

SHIFT

key (

(Ω/V)) to switch between voltage and resistance indicators.

(2) Setting the key lock

Press

SHIFT

+

0ADJ

(LOCK) key to activate key-lock mode.

For more information, see Section 3.5, "Key-lock Function."

(3) Displaying the Preset-data loading screen

Press

SHIFT

+ to display the Preset-data loading screen.

For more information, see Chapter 5, "Saving/loading Preset Values."

(4) Displaying the Preset-data saving screen

Press

SHIFT

+ to display the Preset-data saving screen.

For more information, see Chapter 5, "Saving/loading Preset Values."

(5) Displaying the Optional function setting screen

Press

SHIFT

+

STOP

to display the Optional function setting screen.

For more information, see Chapter 4, "Optional Functions."

SHIFT

+

ON/OFF

────────────────────────────────────────────────────

1.3 Names and Functions of Parts

Page 14

5

────────────────────────────────────────────────────

Left side view

1

1

Air outlet

Never touch the air outlet. The air outlet is provided with an internal cooling fan.

Right side view

1

2

Rear panel

1

Air inlet

Never touch the air inlet. Air for cooling is drawn through this opening.

2

Handle

This is used for transporting the 3157.

1

2

1

Power inlet

Connect the grounded three-core power cord supplied here. Integrated with a fuse

holder.

2

External I/O terminal

For output of 3157 state and input of start and stop signals.

3

Interface slot

Expansion slot for installation of the optional 9593-02 RS-232C INTERFACER or

9518-02 GP-IB INTERFASE board.

3

────────────────────────────────────────────────────

1.3 Names and Functions of Parts

Page 15

6

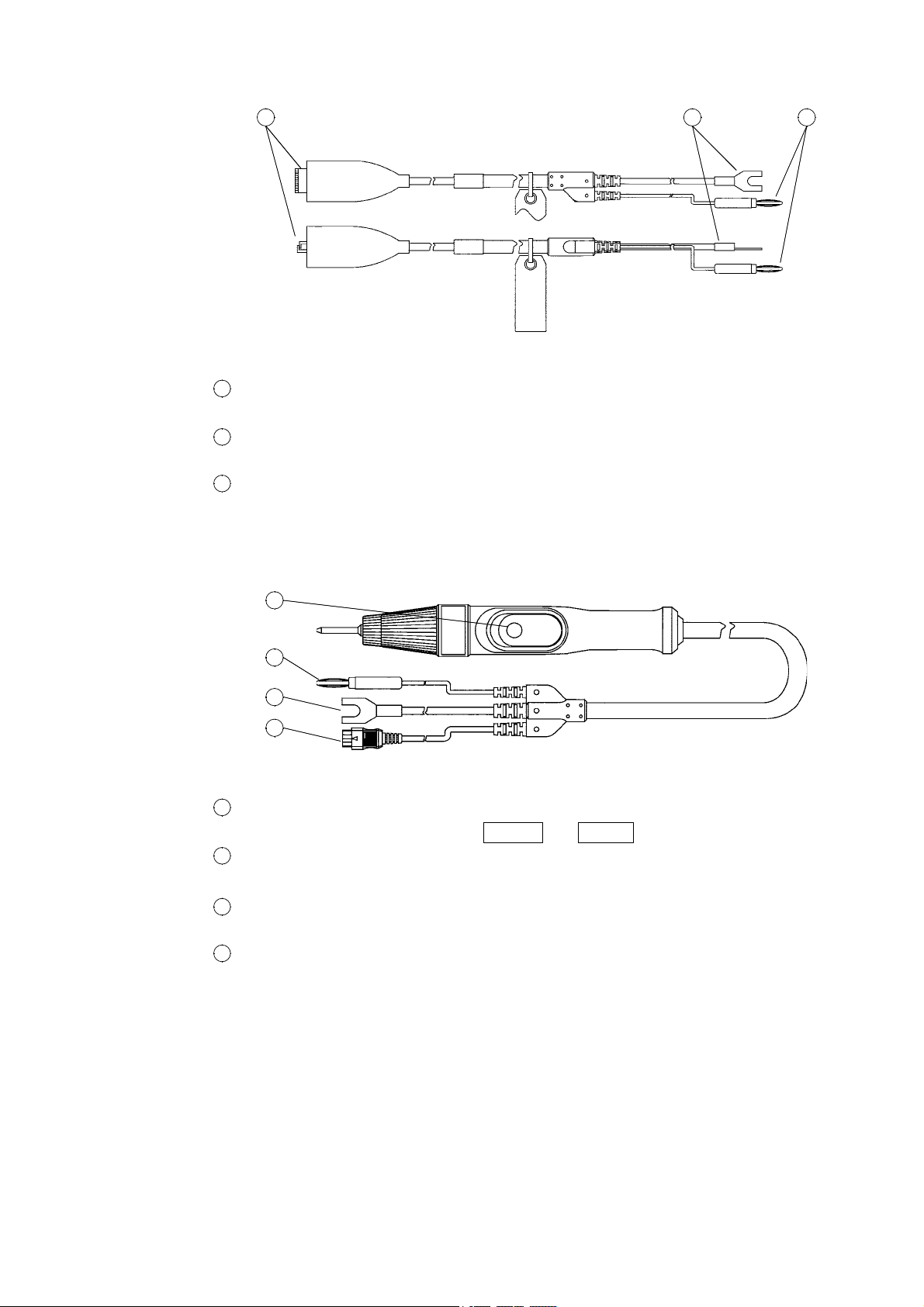

────────────────────────────────────────────────────

9296 CURRENT PROBE

1 2 3

1

Alligator clip

Clipped to the measured object.

2

Current output plug

Connected to the unit's current output terminal.

3

Banana-type voltage measurement plug

Connected to the unit's voltage measurement terminal.

9297 CURRENT APPLY PROBE

1

2

3

4

1

Push switch

External switch equivalent for the

2

Banana-type voltage measurement plug

Connected to the unit's voltage measurement terminal.

Current output plug

3

Connected to the unit's current output terminal.

Switch signal line plug

4

Connected to the unit's controller terminal.

START

and

STOP

keys.

────────────────────────────────────────────────────

1.3 Names and Functions of Parts

Page 16

7

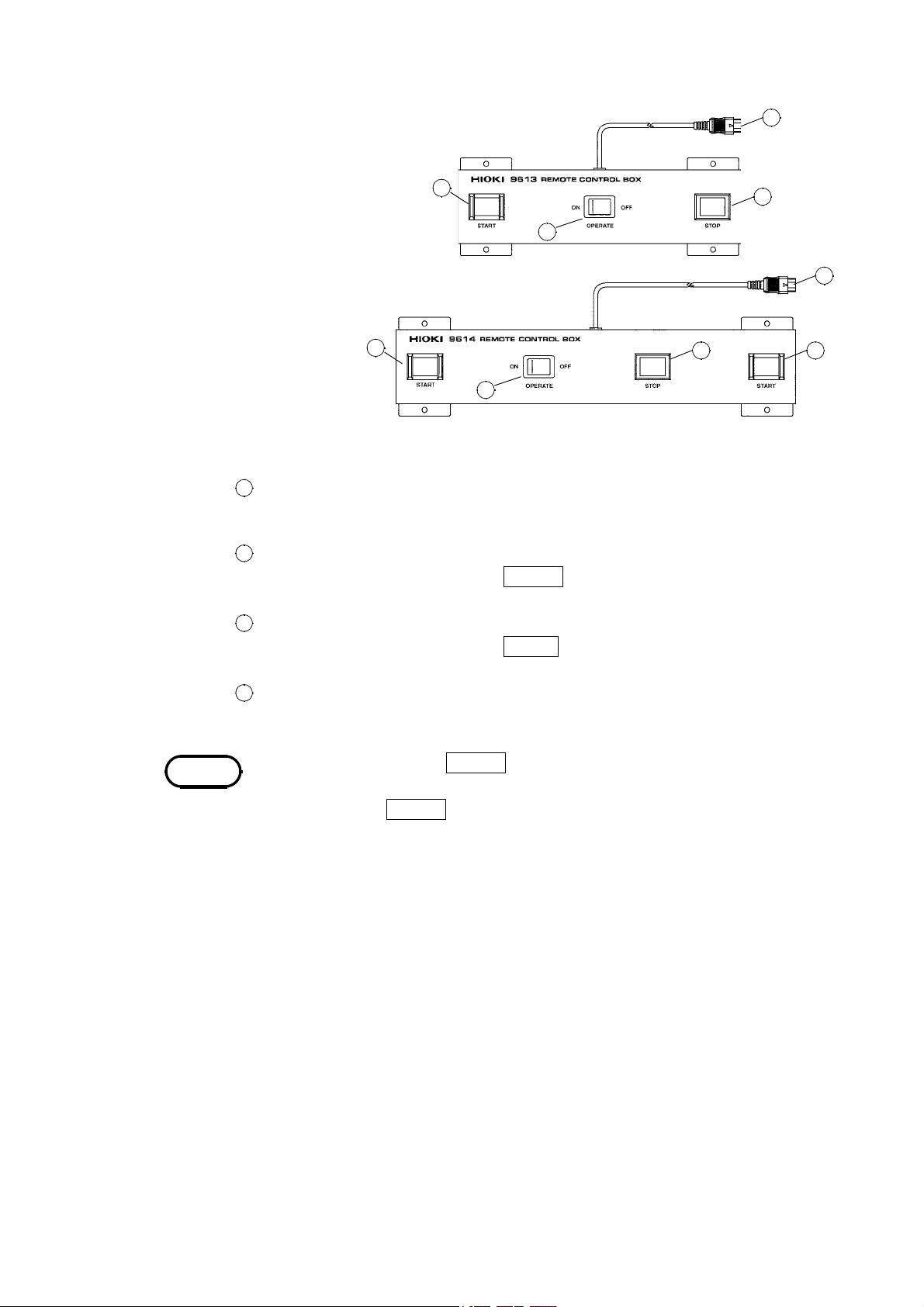

────────────────────────────────────────────────────

REMOTE CONTROL BOX

9613 REMOTE CONTROL BOX (SINGLE)

2

1

4

3

9614 REMOTE CONTROL BOX (DUAL)

OPERATE switch

1

2

1

3 2

Used to enable remote-control operation. When this switch is ON, the START and

STOP keys for remote control are active.

2

START key

Works in the same manner as the

START

key on the unit. With the 9614 dual

remote-control box, the two START switches must be pressed.

3

STOP key

Works in the same manner as the

STOP

key on the unit. The STOP key is ON

during a test or when a voltage is being output.

4

Switch signal line plug

Connect to the external switch terminal on the unit.

4

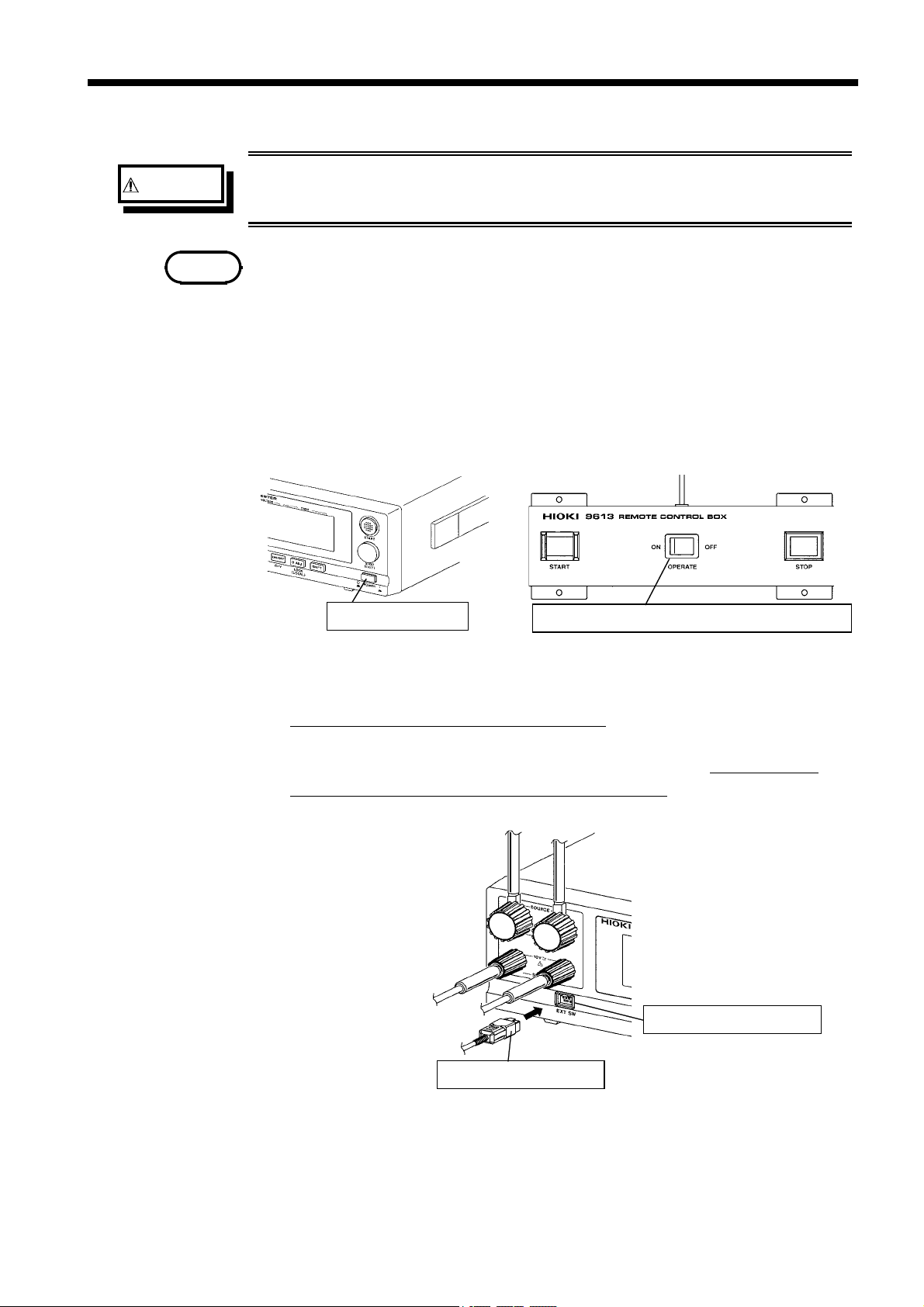

NOTE

Priority for control of the

START

key is in the following order: the external switch,

the external I/O, and the front panel of the unit. Connecting the switch signal line

plug disables the

START

key on the front panel of the unit and the start signal for

the external I/O.

────────────────────────────────────────────────────

1.3 Names and Functions of Parts

Page 17

9

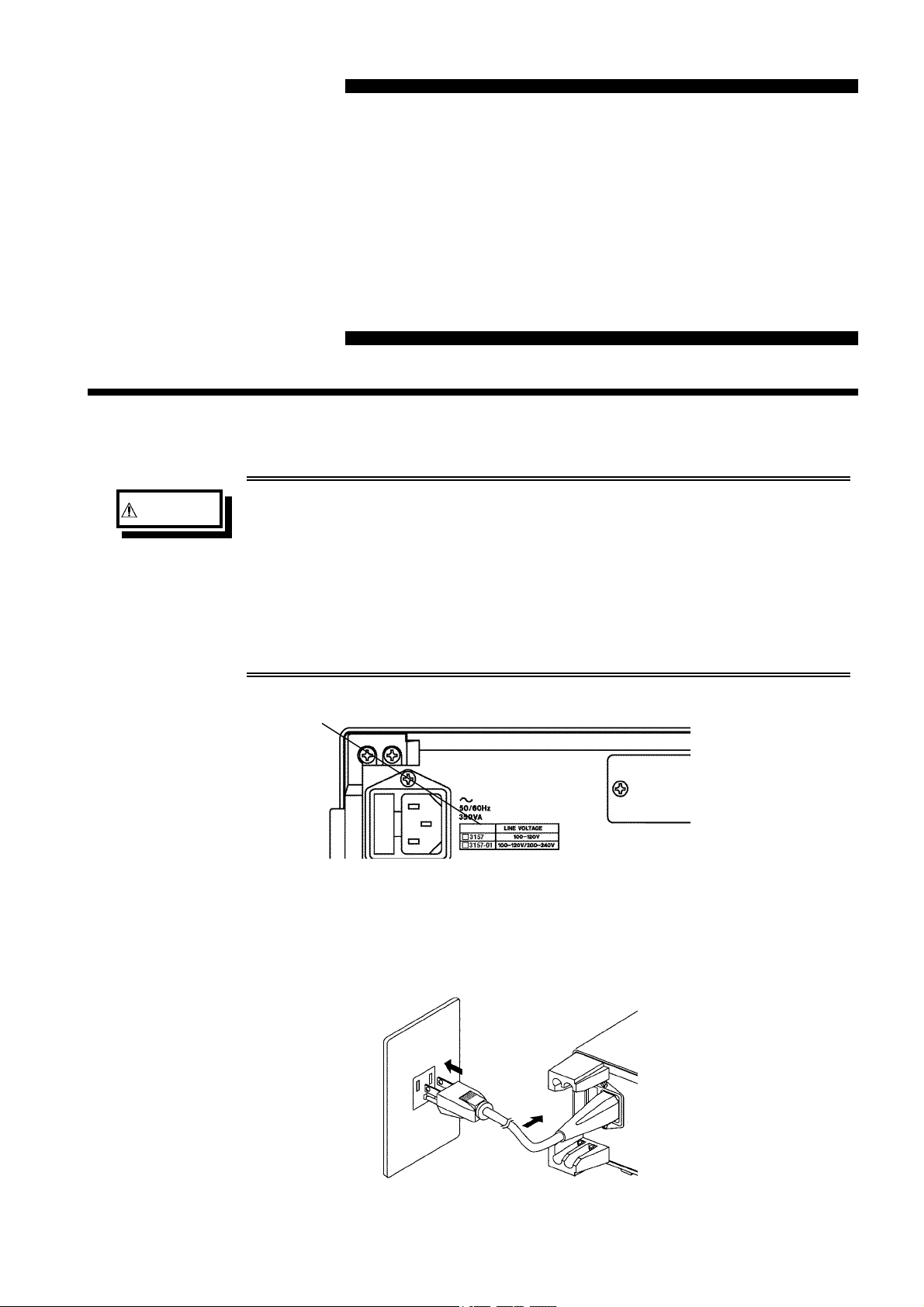

────────────────────────────────────────────────────

Chapter 2

Testing Arrangements

2.1 Power Cord Connection

WARNING

The 3157 and the 3157-01 use different rated power voltages. Before

turning the product on, make sure the source voltage matches that

indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

To avoid electric shock and ensure safe operation, connect the

power cable to a grounded (3-contact) outlet.

Supply voltage indicated on the rear panel

(1) Be sure that the main power switch is turned to OFF.

(2) Connect the grounded three-core power cord provided to the power inlet on the back

of the unit.

(3) Insert the plug into the grounded outlet.

────────────────────────────────────────────────────

2.1 Power Cord Connection

Page 18

10

────────────────────────────────────────────────────

2.2 Powering on and off the Unit

WARNING

NOTE

Before turning the product on, make sure the source voltage matches

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

・

Allow 10 minutes warming up after powering on.

・

To use the external controller, the external I/O terminal, and the interface, you

must connect them before startup. Only devices or peripherals connected before

startup are activated. Connection following startup may lead to operational or

equipment failure.

For connection procedures, see Section 2.3, "Probe Connection" for the external

controller, Chapter 6, "External I/O" for the external I/O terminal, and the

instruction manual accompanying the interface for each interface.

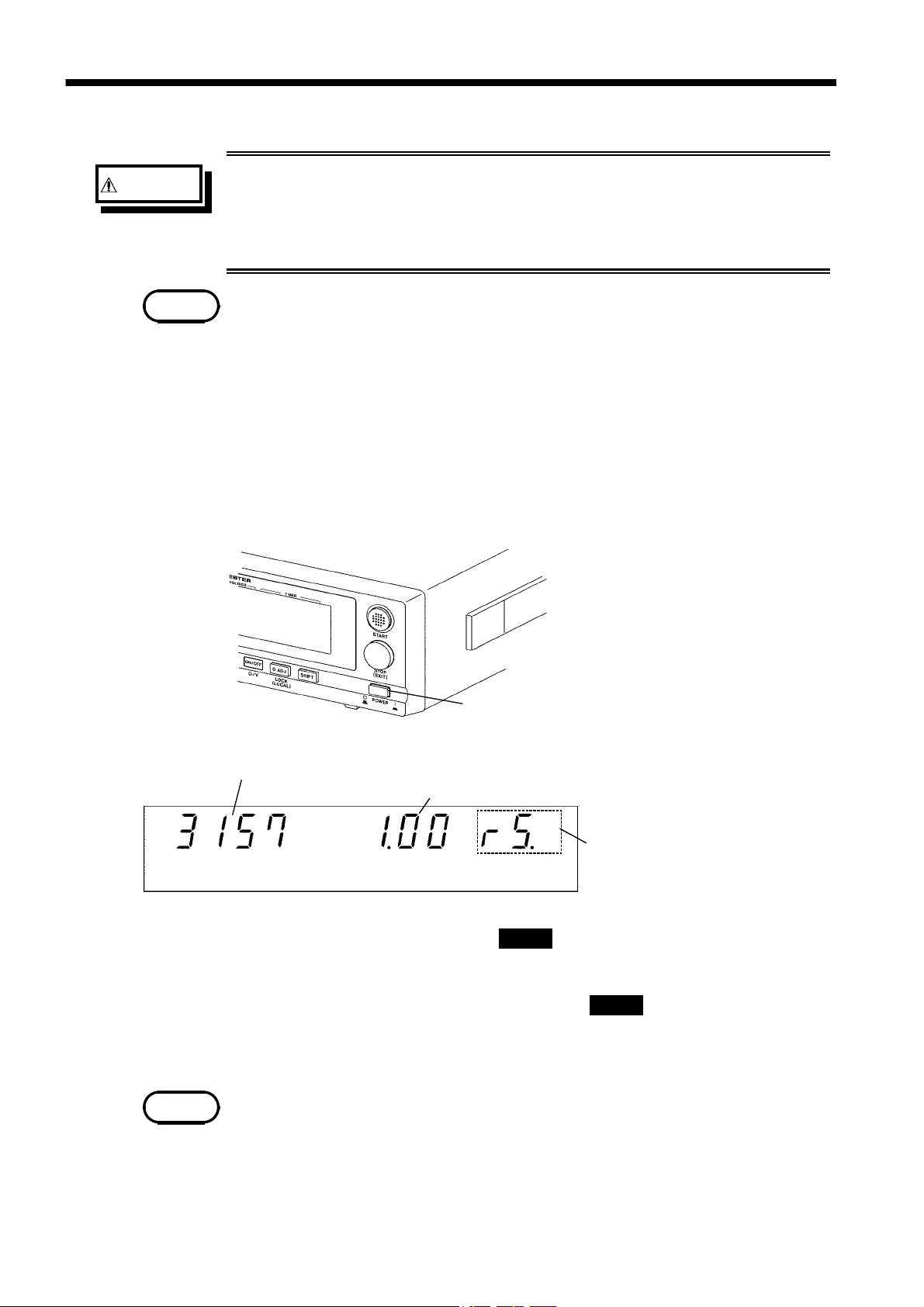

Powering on the unit

(1) Turn the main power switch to ON(l).

(2) The model name and version number are displayed as below:

The model name is displayed.

(3) The unit enters READY state five seconds after startup.

Key operation is disabled unless the

Powering off the unit

After the testing has finished, being sure that the

the main power switch on the back of the unit to OFF.

Note that the unit may be damaged if the main power switch is turned to OFF while

the unit is outputting current.

NOTE

The current settings are all preserved when the unit is next turned on. If there has

been a power failure or other malfunction of the power supply, the settings in effect

at the time the malfunction occurred are preserved.

Main power switch

The version number is displayed.

"Version 1.00" is displayed.

READY

lamp is lit.

Indicates active interfaces.

G.01: 9518-02 GP-IB INTERFACE

rS: 9593-02 RS-232C INTERFACE

rS.P: 9442 PRINTER

READY

lamp is turned on, turn

────────────────────────────────────────────────────

2.2 Powering on and off the Unit

Page 19

11

────────────────────────────────────────────────────

2.3 Probe Connection

WARNING

To avoid shock and short circuits, turn off all power before

connecting probes.

To avoid electrical accidents, confirm that all connections are secure.

The increased resistance of loose connections can lead to

overheating and fire.

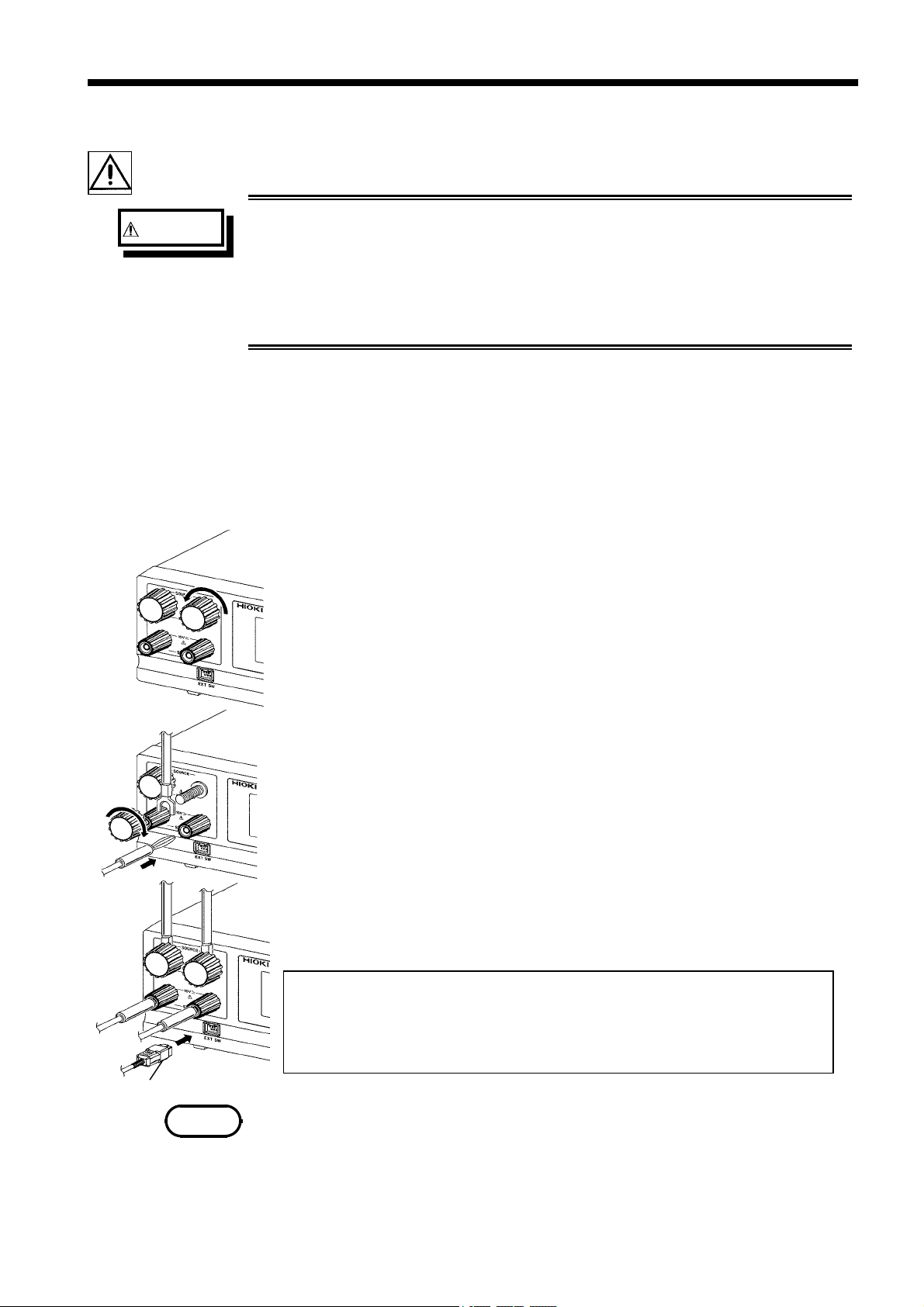

The 9296 CURRENT PROBE (with alligator clip) and 9297 CURRENT APPLY

PROBE are available as optional probes. Connect two sets of the 9296 or a single

combined set of 9296 and 9297.

You can use a custom-built probe. If you do use a custom-built probe, make sure

the wire/cable used for it has sufficient current capacity (AWG 12/cross-sectional

2

area 3.5 mm

min.)

(1) Rotate the current output terminal counter-clockwise to open.

(2) Connect the current output plug as shown in the figure on the left.

(3) Rotate the current output terminal clockwise to close.

(4) Insert the banana-type voltage measurement plug into the voltage

measurement terminal.

(5) With the 9296 CURRENT PROBE, be sure to connect the probe to the other

terminals using the same procedure.

To use the 9297 CURRENT APPLY PROBE, insert the switch signal line

plug into the external switch terminal.

To use the push switch on the 9297 CURRENT APPLY PROBE, use the

・

current output terminal and the voltage measurement terminal on the right,

as shown in the figure.

Make sure the switch signal line plug is correctly oriented. If the plug is

・

dislocated during testing, the unit will enter READY state.

Switch signal line plug

・

NOTE

To activate the push switch, connect the switch signal line plug to the external

switch terminal before startup. For more information on the push switch, see

Section 4.9, "Momentary OUT."

・

The 9297 CURRENT APPLY PROBE can be used unless it is connected to the

external switch terminal. In this case, the push switch cannot be used.

────────────────────────────────────────────────────

2.3 Probe Connection

Page 20

12

────────────────────────────────────────────────────

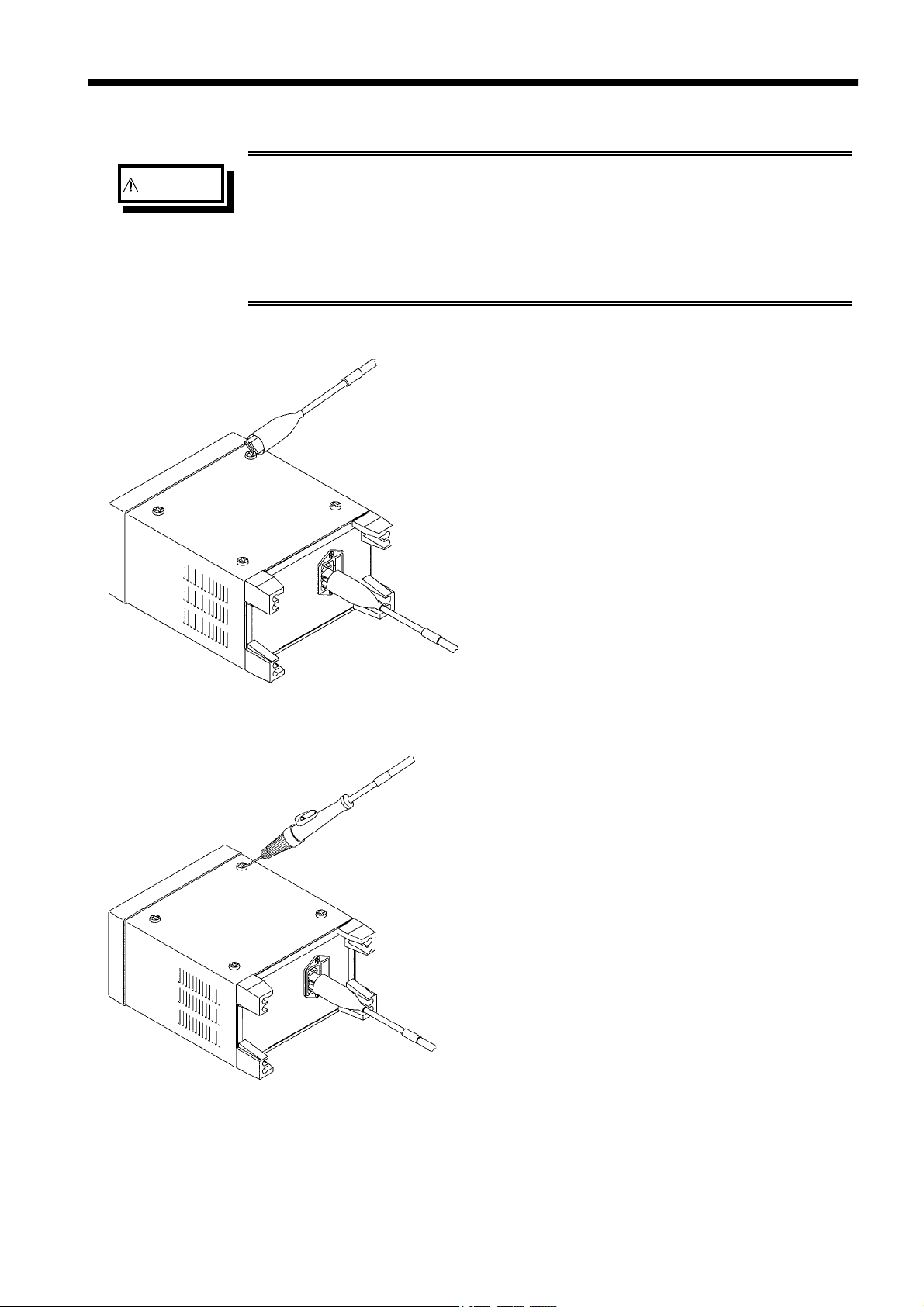

2.4 Short Bar Connection

WARNING

To avoid shock and short circuits, turn off all power before

connecting probes.

To avoid electrical accidents, confirm that all connections are secure.

The increased resistance of loose connections can lead to

overheating and fire.

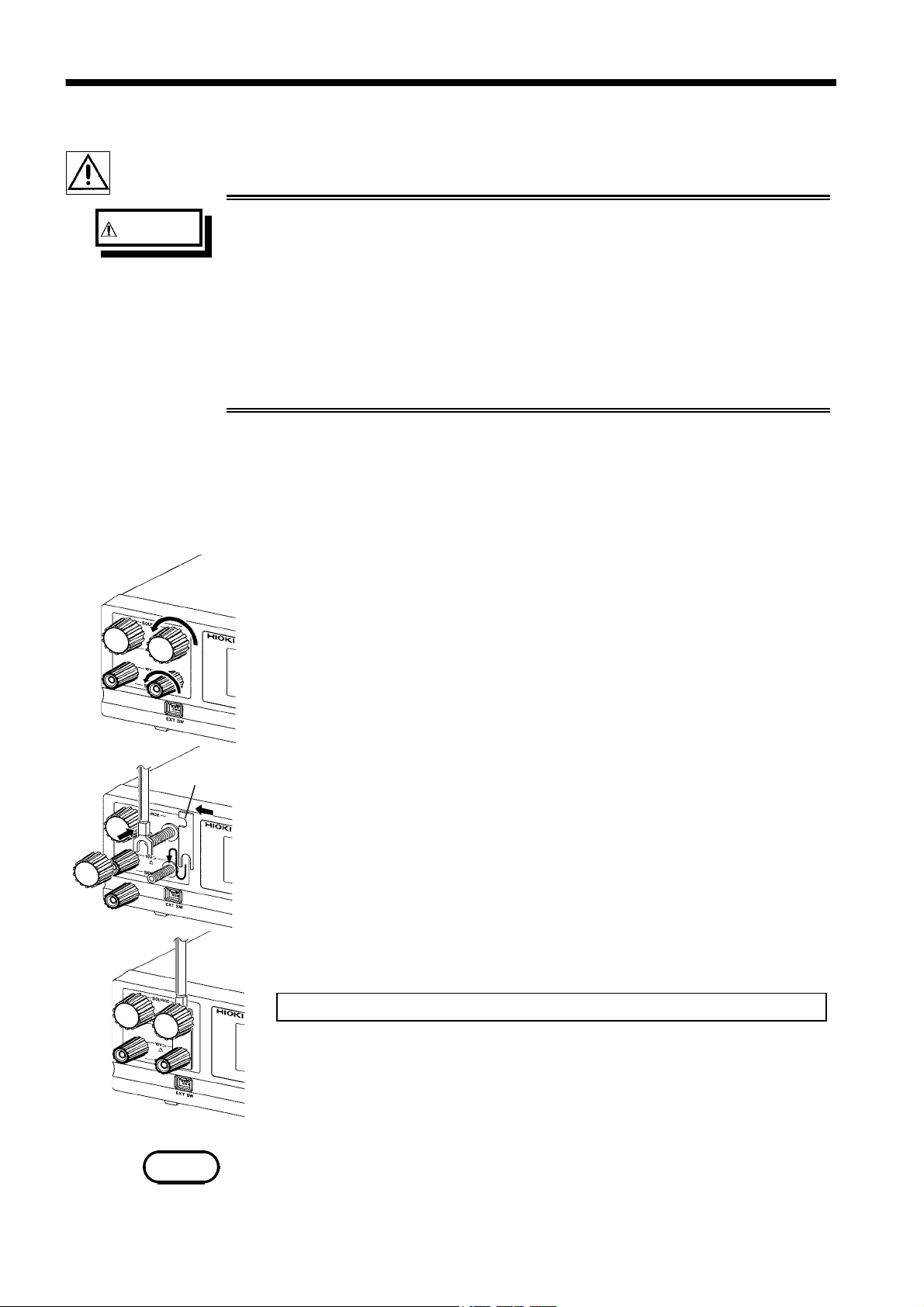

In a test using two terminals, be sure to use the current output

terminal. Use of the voltage measurement terminal may lead to the

terminal overheating, resulting in burns or equipment damage.

When connecting a probe incompatible with four-terminal measurement, or when

measuring with two terminals, connect the short bar between the voltage measurement

terminal (the SENSE terminal) and the current output terminal (the SOURCE

terminal). Connect to both the voltage measurement terminal and the current output

terminal. In this case, be sure to connect the probe to the current output terminal.

Short bar

(1) Rotate the current output terminal and the voltage measurement terminal

counter-clockwise to open.

(2) Connect the probe and short bar as shown in the figure on the left.

(3) Rotate the current output terminal and the voltage measurement terminal

clockwise to close. Be sure to connect the other terminals using the same

procedure.

In a test using two terminals, be sure to use the current output terminal.

*The figure on the left shows how to connect the probe and the shortbar to the

terminals on the right. The shortbar can be connected to the terminals on the

left in the same manner.

NOTE

Measurement with two terminals will be affected by a voltage drop in the probe,

leading to inaccurate results. Before beginning a test, perform zero adjustment (see

Section 3.4, Zero Adjustment Function).

────────────────────────────────────────────────────

2.4 Short Bar Connection

Page 21

13

────────────────────────────────────────────────────

2.5 Connecting the REMOTE CONTROL BOX

WARNING

NOTE

To avoid shock and short circuits, turn off all power before connecting

probes.

To prevent malfunctions, do not remove the remote-control box following startup.

Before removing it, be sure to turn OFF the power.

Connection of the remote-control box (9613/9614) enables start/stop operations to

be performed easily.

(1) Make sure the Main Power switch and OPERATE switch on the remote-control

box are OFF.

Main power switch

OPERATE switch on the remote-control box

(2) Insert the switch signal line plug into the external switch terminal.

Check the direction of the switch signal line.

(3) Turn ON the OPERATE switch of the remote-control box. The OPERATE

switch can be turned ON/OFF even following startup.

External switch terminal

Switch signal line plug

────────────────────────────────────────────────────

2.5 Connecting the REMOTE CONTROL BOX

Page 22

14

────────────────────────────────────────────────────

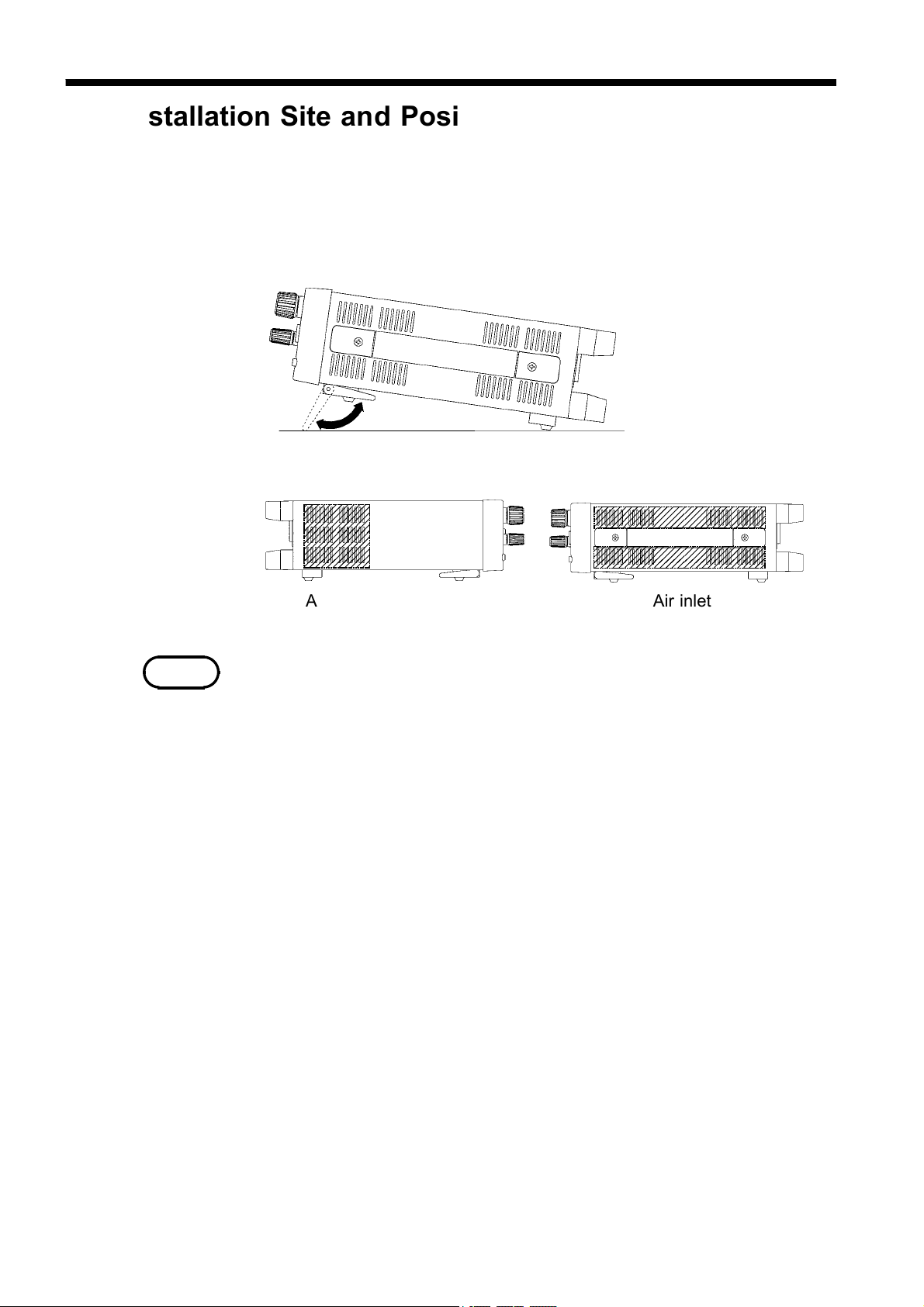

2.6 Installation Site and Position

Place on a stable, flat surface, using the four-footed stand. Orienting the unit

vertically will block its air outlet, greatly increasing the risk of overheating. In

positioning the unit, make sure the air inlet and outlet are kept open.

Stand

Left side view Right side view

NOTE

Air inletAir outlet

・

Do not insert the foreign objects into the air inlet or outlet.

・

Do not apply strong downward pressure with the stand extended. Damage to the

stand will result.

・

Magnetic fields generated by the unit may affect CRT displays. During testing,

keep the current probe away from such subjects.

────────────────────────────────────────────────────

2.6 Installation Site and Position

Page 23

15

────────────────────────────────────────────────────

2.7 Connection to the Measured Object

WARNING

To avoid burns, never touch the output current terminal, probe tip, or

contact point while testing (i.e., in TEST state).

Take particular care to avoid touching the tip of the current

application probe, which may be quite hot when operating, due to its

small surface area.

(1) Connecting using two 9296 units

Connect one 9296 to the protection ground terminal

on the measured object.

Connect the other 9296 to the test point. Connect

the probe firmly to prevent disconnection during

testing.

During current output, take care to ensure that

adjacent probes do not touch, as this may result in a

short-circuit.

(2) Connecting using a single combined set of

9296 and 9297

Connect the 9296 to the protection ground terminal

on the measured object.

Connect the 9297 to the test point. Connect the

probe firmly to prevent disconnection during testing.

During current output, take care to ensure that

adjacent probes do not touch, as this may result in a

short-circuit.

────────────────────────────────────────────────────

2.7 Connection to the Measured Object

Page 24

16

)

)

)

)

)

)

AB(

)

)

)

)

)

)

)

)

AB(

)

)

)

────────────────────────────────────────────────────

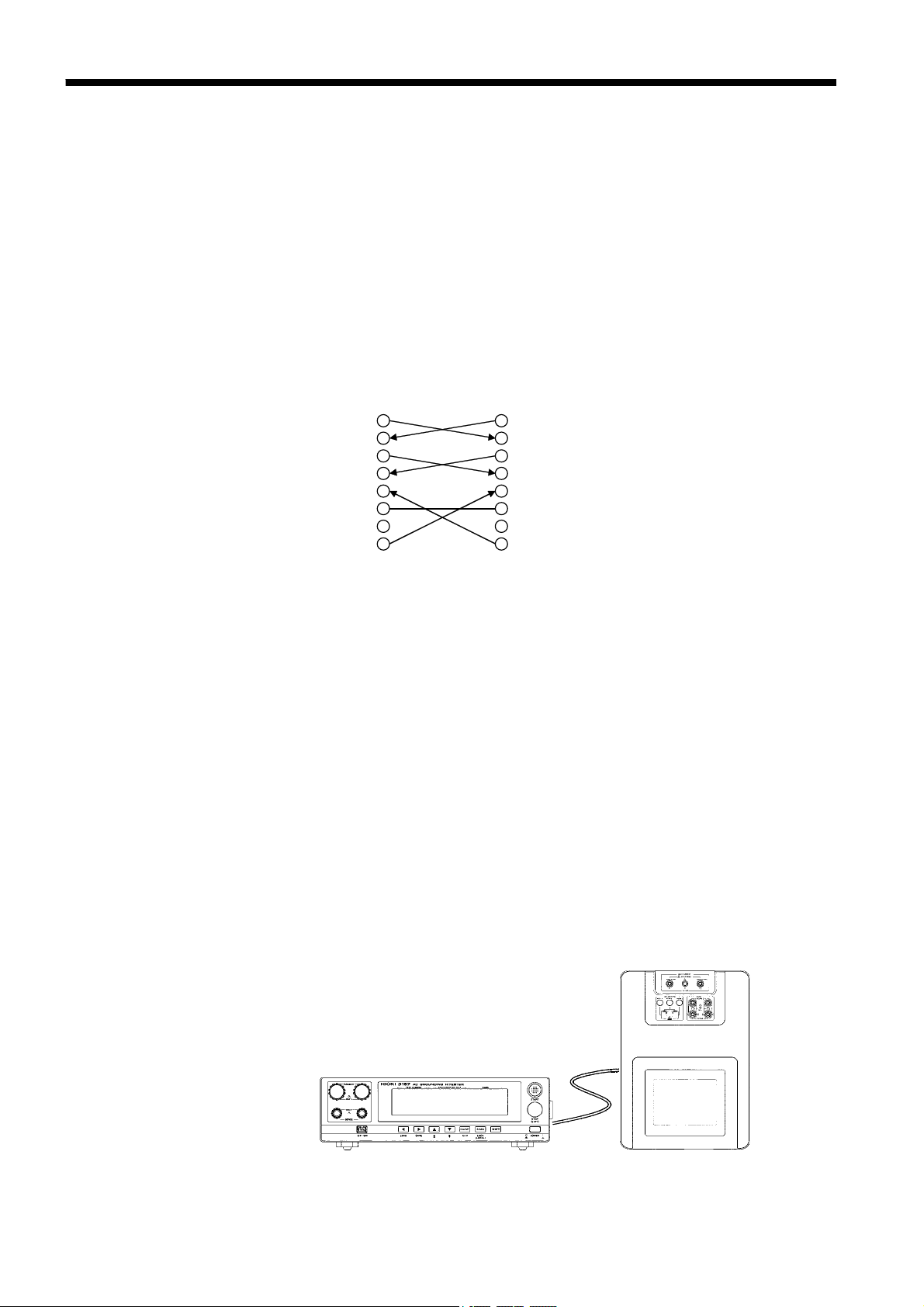

2.8 Connection to the 3155 LEAK CURRENT HiTESTER

Attaching optional 9593-02 RS-232C INTERFACE to 3157 enables testing when

connected with 3155.

3155 sends command to 3157 to start testing and receives test results when the

3157 testing is complete. The test results can be saved and printed together with

the 3155 leakage current test results.

For usage for the 3155, see 3155 (-01) Instruction Manual.

When connecting 3155 with 3157 (9593-02), use connection cable as specified

below.

3157(9593-02

GND

2

3

4

5

6

7

8

20

BA(TxD

BB(RxD

CA(RTS

CB(CTS

CC(DSR

CF(DCD

CD(DTR

3155

3

BA(TxD

2

BB(RxD

7 CA(RTS

CB(CTS

8

CC(DSR

6

GND

5

CF(DCD

1

CD(DTR

4

Specification: D-subminiature 25-pin male to D-subminiature 9-pin female

connectors, with "crossed" data connections

Settings

(1) Leave power OFF for both 3155 and 3157 while connecting each RS-232C

connector with the RS-232C cable.

(2) Turn the power ON for both 3155 and 3157.

(3) Set up 3157 test settings. Measurement does not start unless the following

conditions are met.

1. Test settings

・

Unit of the maximum and minimum test values: Resistance

・

Test time: ON

・

Maximumtestvalue:ON

When the optional minimum test value setting function is ON.

・

Minimumtestvalue:OFF

2. Optional function setting

Endless timer function: Not set

────────────────────────────────────────────────────

2.8 Connection to the 3155 LEAK CURRENT HiTESTER

Page 25

17

e

────────────────────────────────────────────────────

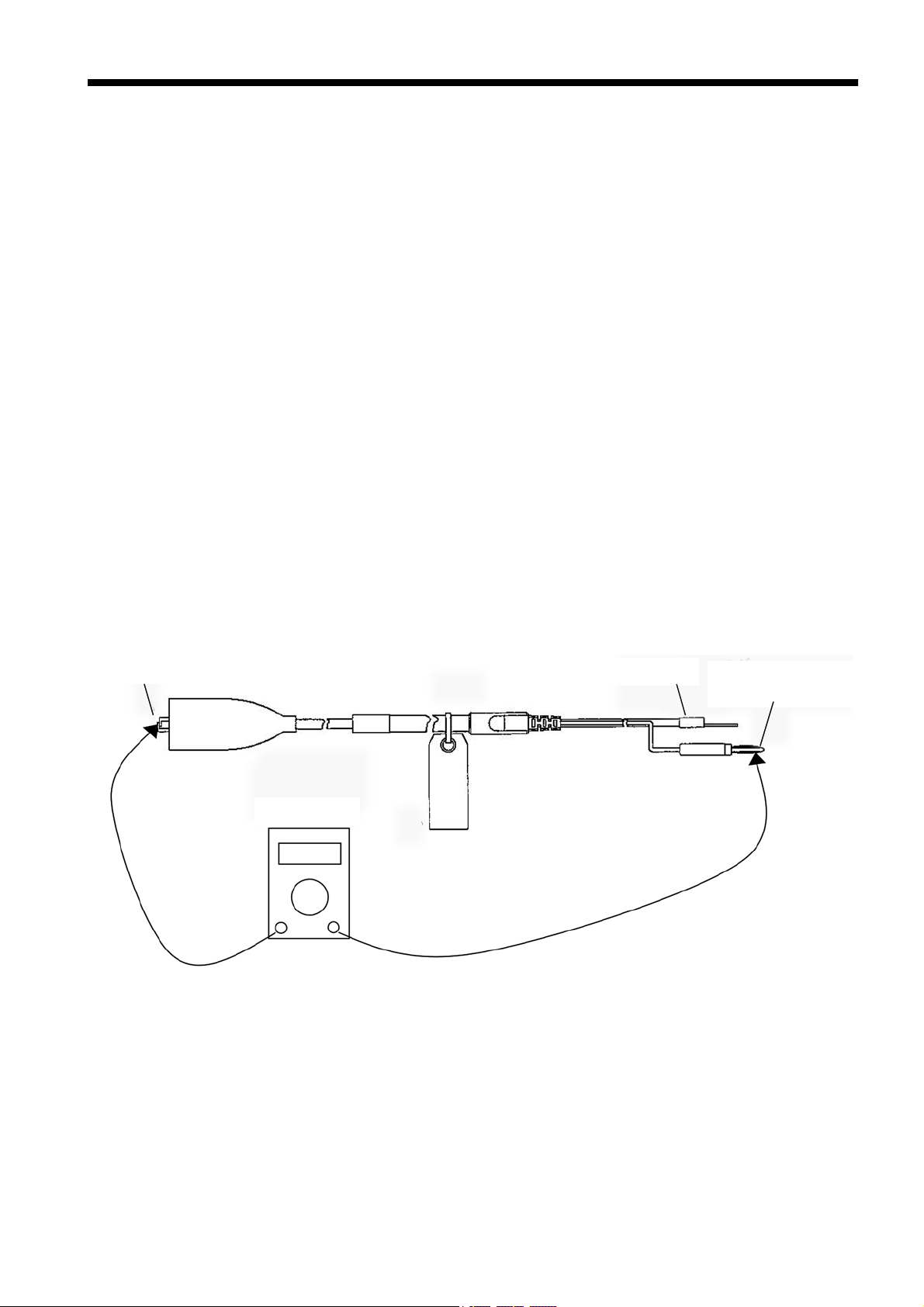

2.9 Pre-operation Inspection

By using the optional two sets of the 9296 CURRENT PROBEs or using each of

the 9296 and the 9297 CURRENT APPLY PROBE, the user can perform fourterminal measurement. In this case, the damage on the cable connecting to the

voltage measurement terminal (the SENSE terminal) will affect the measurement

values.

The 3157 cannot detect the open circuit of this voltage measurement cable when

performing four-terminal measurement. So, please follow the pre-operation

inspection below.

Prepare the follows.

・

9296 CURRENT PROBE or 9297 CURRENT APPLY PROBE

・

Resistance measuring device (e.g. tester)

For the 9296, measure the resistance between the alligator clip and the banana-type

voltage measurement plug. For the 9297, measure the resistance between the tip of

the probe and the banana-type voltage measurement plug.

Perform measurement on the two PROBEs to be used for four-terminal

measurement and make sure the resistance values to be under 1Ω and the wires are

not broken.

(The sketch below shows for the 9296 CURRENT PROBE.)

Alligator clip

Tester or etc.

Current output plug

Banana-type voltag

measurement plug

────────────────────────────────────────────────────

2.9 Pre-operation Inspection

Page 26

19

────────────────────────────────────────────────────

Chapter 3

Testing Method

This chapter describes the procedural flow for testing, making settings, and proper

testing procedure.

Read Chapter 2, "Testing Arrangements" and make the necessary arrangements for

testing.

Press

Setting the optional functions allows testing under various conditions.

For more information, see Chapter 4, "Optional Functions."

SHIFT

+

STOP

to display the Optional function setting screen.

────────────────────────────────────────────────────

Page 27

20

────────────────────────────────────────────────────

3.1 Procedural Flow for Testing and Setting Parameters

The 3157 is in one of four states:

READY state

The unit is ready for starting a test. The READY lamp is turned on.

To enter TEST state, press the

Setting in READY state

Setting other functions

START

Setting the output current value

Setting the maximum value

Setting the testing time

Setting the minimum value

Setting the output current

frequency or changing the

test count value

Performing zero adjustment

Setting the key-lock function

key while in READY state.

Settings can't be made if the endless timer is set at

"1: Set."

The minimum value can be set if the minimum

test value is set at "1: Set."

The output current frequency can be set only if

the test count value is set at"0: Not set."

Otherwise, setting and display of the test

count value are enabled.

Setting the optional functions allows testing under various conditions.

Press

────────────────────────────────────────────────────

3.1 Procedural Flow for Testing and Setting Parameters

SHIFT

Setting optional functions

+

STOP

to display the Optional Function Setting screen.

Switching the output current

frequency

PASS/FAIL hold function

Hold function

Setting the minimum test value

Endless timer function

Test data count

Setting the buzzer

Changing currents in TEST state

Momentary OUT

Test mode

Printer output

Page 28

21

────────────────────────────────────────────────────

TEST state

This state indicates that a test is underway. The TEST lamp is turned on. The current preset in the

READY state is output.

The current output value, a decrease in voltage, and resistance are measured and displayed.

The measured values are compared against the comparator values preset in the READY state.

If the measured value deviate from the comparator value, the unit enters FAIL state and halts

measurement.

If the preset testing time completes without the measured value deviating from the comparator value, the

unit enters PASS state.

Key operation in

the TEST status

Changing output

current values

Forced ending

The output current value can be made changeable by

pressing the

"1: Changeable" in TEST status.

Press the STOP key.

and keys if the current is set to

PASS state

PASS indicates that the measured object passed the test set in READY state. The

on. The PASS state screen is displayed for about 1 second before switching to READY state.

Enabling the PASS hold function in the optional settings makes it possible to retain the PASS state. To

check the test results, enable the PASS/FAIL hold function.

To switch the display between resistance and voltage, press

SHIFT

+

ON/OFF

state (see Section 4.2, "PASS/FAIL Hold Function").

PASS

lamp is turned

(Ω/V) while in PASS

FAIL state

FAIL indicates that the measured object failed the test set in READY state. Both the

lamps light when the measured value exceeds the maximum test value. Both

FAIL

and

FAIL

LOWER

and

UPPER

lamps

light when the measured value drops below the minimum test value. The FAIL state screen is displayed

for about 1 second before switching to READY state.

Enabling the FAIL hold function in the optional settings makes it possible to retain the

FAIL state. To check the test results, enable the PASS/FAIL hold function.

To switch the display between resistance and voltage, press

SHIFT

+

ON/OFF

(Ω/V) while

in FAIL state (see Section 4.2, "PASS/FAIL Hold Function").

────────────────────────────────────────────────────

3.1 Procedural Flow for Testing and Setting Parameters

Page 29

22

────────────────────────────────────────────────────

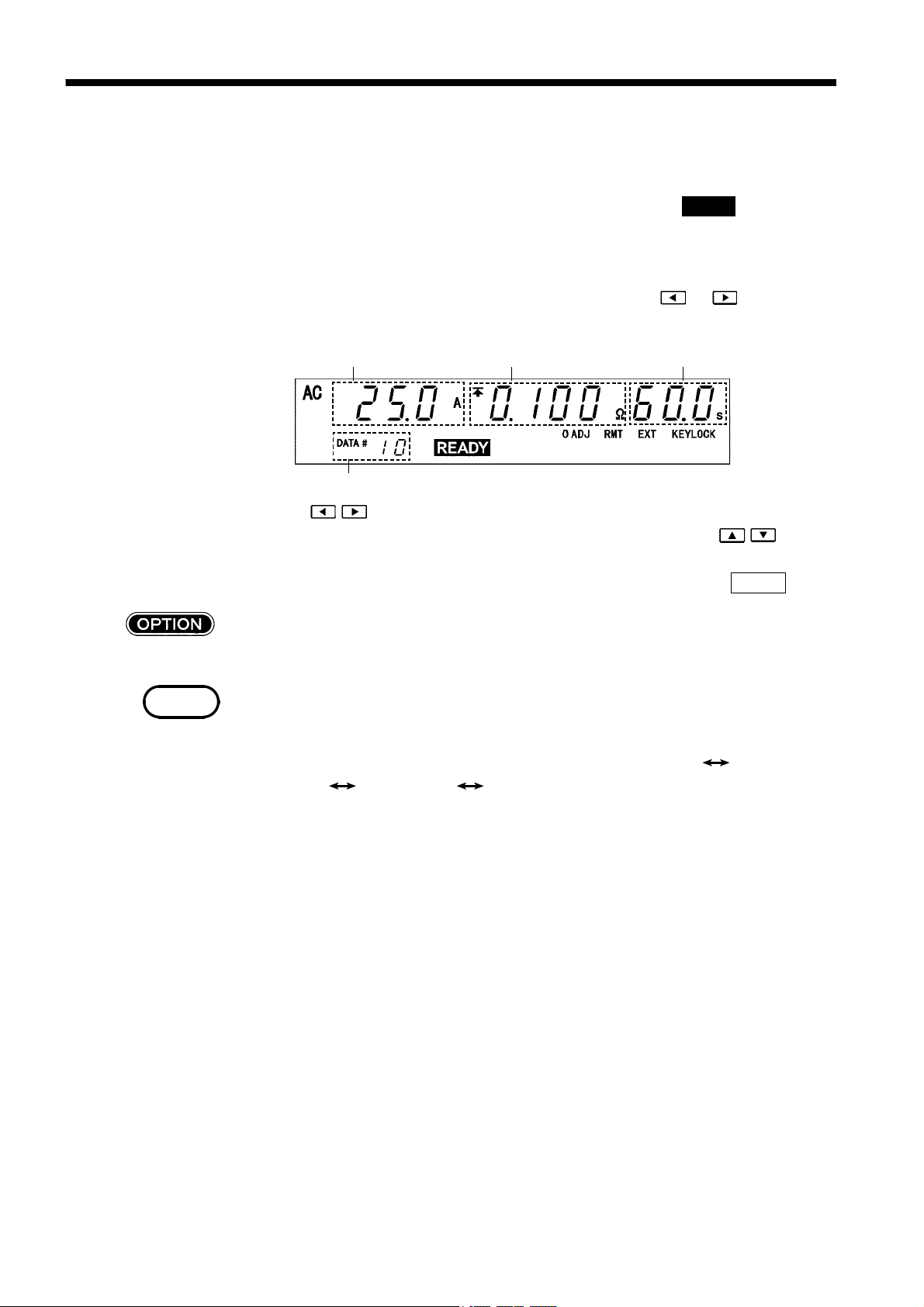

3.2 Making Testing Arrangements (in READY State)

Make testing arrangements in READY state, including test parameter settings, keylocking, and zero adjustment. Saving and loading for setting data and the setting of

optional functions are made following the READY state. The READY lamp remains

lit to indicate READY state.

Starting and completing settings

Display the flashing cursor to change set values. Press the

display the flashing cursor with the output current value.

or key to

NOTE

Output current value

Output current frequency or test data count

Press the

/ keys to move the flashing cursor through different settings when

Maximum (minimum) test value

it is lit till the cursor reaches the value to be re-set. Then, press the

Testing time

/ keys to

change the settings.

To erase the flashing cursor, or when settings are complete, press the

STOP

key.

The set values can be printed using the printer output function (see Section4.11).

・

The value range that can be set on the flashing cursor depends on the minimum

test value, the state of the endless timer, and the test data count value on optional

settings.

The range set at the factory is as follows: Output current value

test value

・

If STOP signal (key, external I/O, communication) is input, you cannot perform

Testing time Output frequency.

Maximum

the test even though the READY lights.

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

Page 30

23

────────────────────────────────────────────────────

3.2.1 Setting Output Current Values

(1) If no flashing cursor is displayed in the READY state, press either the key or

the

key to display the cursor while the output current value is lit.

(2) Change output current values using the

/ keys. The value changes in 0.1 A

increments.

To change the value by 1.0 A, press

SHIFT

+ / keys.

The output current value can be set from 3.0 A to 31.0 A.

(3) When settings are complete, press the

STOP

key.

The output current can be changed using the current changeability in TEST

State (see Section 4.8).

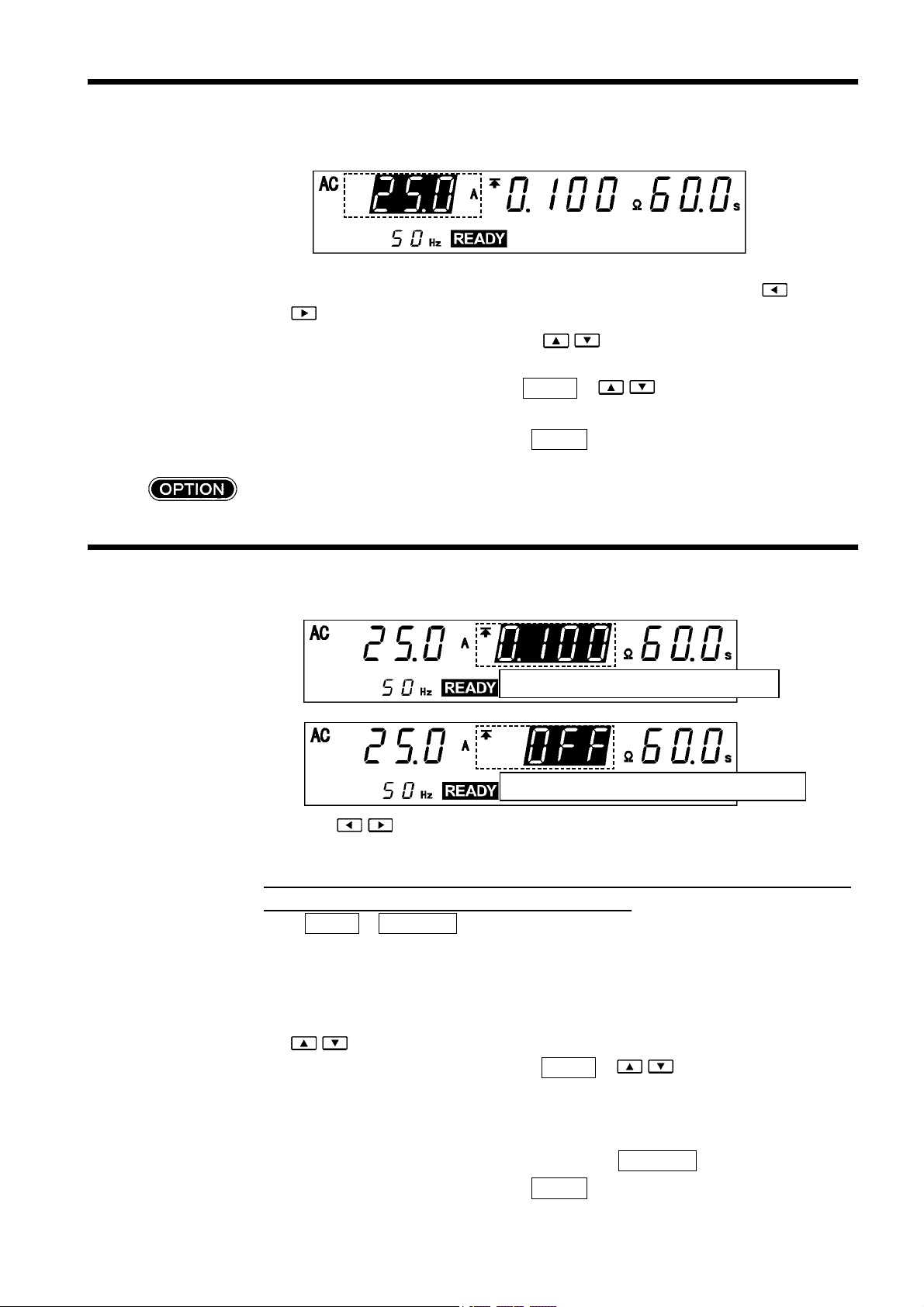

3.2.2 Setting the Maximum (Minimum) Test Value

The maximum resistance is displayed.

The maximum resistance is not displayed.

(1) Using the

/ keys, move the flashing cursor to the maximum test value.

(2) Switching between resistance and voltage indicators

The maximum test value can be set for both resistance and voltage. If both are set,

only the one displayed in READY state is activated.

Press

SHIFT

+

ON/OFF

(Ω/V) to switch between resistance and voltage

indicators. (This key operation is valid no matter where the flashing cursor is

located.)

(3) Setting the maximum test value

After selecting between the resistance and the voltage, set the maximum value using

the

To change the value by 0.010 Ω,press

/ keys.

SHIFT

+ / keys (0.10 V when the

voltage is displayed).

Resistance may be set from 0.000 Ω to 2.000 Ω, while voltage may be set from

0.00 V to 6.00 V.

If no maximum test value is required, turn off the

(4) When settings are complete, press the

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

STOP

ON/OFF

key.

key.

Page 31

24

────────────────────────────────────────────────────

The minimum test value can be set using the minimum test value setting

function (see Section 4.4).

Once a minimum test value is set, both minimum and maximum values are

provided for resistance or voltage.

To set a minimum test value, activate the optional minimum test value setting

function.

The minimum resistance is displayed.

To set a minimum test value, do the same as when setting a maximum test value.

The minimum test value must be smaller than the maximum test value. Otherwise,

key is pressed.

NOTE

a test will not start when the

・

Four values may be set - the maximum and minimum test values for resistance

START

and maximum and minimum test values for voltage. However, the reference

value for testing is expressed in the unit displayed in TEST state. That is,

screening is conducted using the reference resistance when resistance is displayed,

and reference voltage when voltage is displayed.

・

A combination of resistance and voltage values (such as a maximum resistance

value and a minimum voltage value) can't be tested.

3.2.3 Setting the Testing Time

(1) Using the

(2) Set the testing time using the

With time set at 0.5 s to 99.9 s, the time changes in 0.1 s increments (1 s

increments when the set time scale is 100 s to 999 s).

With time set at 0.5 s to 99.9 s, press

s increments (10 s increments when the set time scale is 100 s to 999 s).

Settings may be made along a scale ranging from 0.5 s to 999 s (in gradations of

0.1 s for the range 0.5 s to 99.9 s and 1 s for the range 100 s to 999 s).

If no testing time is required, turn off the

/ keys, move the flashing cursor to the testing time.

/ keys.

SHIFT

The testing time is not displayed.

+ / . The time changes in 1.0

ON/OFF

key.

(3) When settings are complete, press the

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

STOP

key.

Page 32

25

────────────────────────────────────────────────────

The endless timer function allows continuous testing regardless of the

testing time set (see Section 4.5).

NOTE

The test automatically stops after the lapse of 999 s while the testing time setting

can be disabled by using the

ON/OFF

key.

3.2.4 Setting the Output Current Frequency (in READY State)

If the optional test data count function is activated, the output current frequency is

not displayed in READY state. To display or modify the output current frequency

in READY state, change the setting for the test data count to "0: Not set."

(1) Using the

(2) Change the output current frequency (50/60 Hz) using the

(3) When settings are complete, press the

The frequency can also be changed using the output current frequency

switching function (see Section 4.1).

/ keys, move the flashing cursor to the testing time.

/ keys.

STOP

key.

NOTE

Changing the frequency in READY state automatically changes the contents of the

optional output current frequency switching function.

3.2.5 Setting the Test Data Count (in READY State)

The number of test data may be changed in the READY state.

For the test data count setting, see Section 4.6, "Test Data Count Function."

NOTE

(1) Using the

(2) Change the test data count using the

(3) When settings are complete, press the

If you make settings for the test data count, output frequency cannot be changed in

the READY state. To change output frequency, use the optional function setting

screen.

/ keys, move the flashing cursor to the test data count.

/ keys.

STOP

key.

────────────────────────────────────────────────────

3.2 Making Testing Arrangements (in READY State)

Page 33

26

────────────────────────────────────────────────────

3.3 Initial Settings for Optional Functions

Press

SHIFT

+

STOP

while in READY state to display the Optional function

setting screen.

Setting the optional functions allows testing under various conditions.

Settings can be made for the following eleven optional functions. One number is

assigned to each function. Settings are made by changing the number by using the

/ keys.

For more information on the settings, see Chapter 4, "Optional Functions."

1 2 3 4 5 6 7 8 9 10 11

The optional functions of the 3157 are factory-preset to the following settings:

Setting item Initial setting

1

Switching the output current

frequency

PASS/FAIL HOLD function

2

HOLD function

3

Setting the minimum test value

4

Endless timer function

5

Test data count

6

Setting the buzzer

7

Changing currents in TEST state

8

Momentary OUT

9

Test mode

10

Setting the printer output

11

0:50Hz

0: PASS not held, FAIL held

0: Not held

0: Not set

0: Not set

0: Not set

0: ON at screening, ON at error

0: Not changeable

0: Not set

0: Soft start mode

0: Not used

NOTE

・

To reset the system, turn on power while pressing the

SHIFT

key. Once the

system is reset, settings for the optional functions and the recorded parameters

will return to their default values (factory-preset values). For more information,

see Section 7.5, "Resetting the System."

・

If STOP signal (key, external I/O, communication) is input, you cannot perform

the test even though the READY lights.

────────────────────────────────────────────────────

3.3 Initial Settings for Optional Functions

Page 34

27

────────────────────────────────────────────────────

3.4 Zero Adjustment Function

Measurements may be affected by a voltage drop in the probe. Zero adjustment is

necessary for accurate measurement, especially when measuring with two terminals

using the short bar. The 0ADJ lamp is lit while the zero adjustment function is

active. Following zero adjustment, the probe's voltage drop is accounted for in

returning measurement data. Note that the zero adjustment function is automatically

disabled if the output current value is changed or when setting data is loaded.

Zero adjustment procedure

(1) Confirm that the unit is in READY state, then short-circuit the probe.

(2) Set an output current value. The value set must be the same as the one used in the

test.

(3) Press the

0ADJ

executed.

Note that a preset current is output during zero adjustment.

Zero adjustment is completed in about 3 seconds. On completion, the unit enters

READY state, and the 0ADJ lamp lights.

key; 0ADJ lamp starts flashing and then zero adjustment is

NOTE

Zero adjustment active

Zero adjustment completed

Zero adjustment is possible within a range equivalent to a resistance between 0.000

Ω and 0.100 Ω, on either the voltage or resistance indicator. If the measured value

falls outside this range, either the resistance value or the voltage value will blink,

and the unit will enter READY state.

Canceling zero adjustments

To disable zero adjustment function, press the

0ADJ

key while it is active. When

the zero adjustment function is inactivated, the 0ADJ lamp goes out, indicating that

the function is inactive. This function is automatically inactivated when the output

current value is changed or when setting data is loaded.

・

The zero adjustment function will not be inactivated, even if you change the

output current by selecting "1: Changeable" on the optional "Current

Changeability in TEST State." Note that if the zero adjustment function is active,

changing the output current value may produce inaccurate results.

・

Current outputs will soft-start during zero adjustment, regardless of the setting for

"Test mode" on the optional function (see Section 4.10.1, "Soft Start Mode").

────────────────────────────────────────────────────

3.4 Zero Adjustment Function

Page 35

28

────────────────────────────────────────────────────

3.5 Key-lock Function

This function is used to keep lock the current set values. It inactivates all keys

except the

START

key,

STOP

KEYLOCK lamp is lit while the key-lock function is active.

Setting and inactivating the key-lock function

To activate the key-lock function, press

To inactivate the key-lock function, press

active.

key, and the resistance/voltage switch. The

Key-lock indicator

SHIFT

SHIFT

+

0ADJ

+

0ADJ

.

while the function is

NOTE

NOTE

Even when the key-lock function is activated, the external switch and the start and

stop signals on the external I/O terminal remain active.

How to inactivate key-lock function in REMOTE state

Once interface communication starts in REMOTE state (the RMT lamp lights), all

keys except the

STOP

To inactivate the REMOTE state, press

key are inactivated.

SHIFT

Remote indicator

+

0ADJ

(LOCK).

Even in REMOTE state, the external switch and the start and stop signals on the

external I/O terminal remain active.

────────────────────────────────────────────────────

3.5 Key-lock Function

Page 36

29

────────────────────────────────────────────────────

3.6 Examples of Settings

Output current value set: 25.0 A, Maximum test value: 0.100 Ω, Testing time:

1minute.

Assume that "0: not set" is selected for "Minimum test value setting," "Timer

setting," and "Test data count" on the optional functions.

The following provides an example of changing set values.

Values currently set

Values to be set

Output current value 30.0 A Output current value 25.0 A

Maximum test value 0.050 Ω Maximum test value 0.100 Ω

Testing time 10.0 s Testing time 60.0 s

(1) Setting output current values

Using the

/ keys, move the flashing cursor to the output current value.

Using the / keys, set "Output current value" to 25.0 A.

To change the value by 1.0 A, press

In this example, press the

key five times while holding down the

SHIFT

+ / keys.

SHIFT

set the output current value to 25.0 A.

key to

(2) Setting the maximum test value

Using the

key, move the flashing cursor to the maximum test value.

In this example, "Maximum test value" is preset to the resistance value.

Using the

To change the value by 0.010 Ω,press

/ keys, set "Maximum test value" to 0.100 Ω.

SHIFT

+ / keys (0.10 V when the

voltage is displayed).

In this example, press the

key five times while holding down the

SHIFT

key to

set the maximum test value to 0.100 Ω.

────────────────────────────────────────────────────

3.6 Examples of Settings

Page 37

30

────────────────────────────────────────────────────

When the voltage indicator is displayed, or to set in a voltage value, first switch to

the resistance indicator, then set the maximum and minimum test values.

Press

SHIFT

+

ON/OFF

(Ω/V) to switch between resistance and voltage

indicators.

(3) Setting the testing time

Using the

key, move the flashing cursor to the testing time.

Using the / keys, set "Testing time" to 60.0 s.

To change the time by 1.0 s, press

SHIFT

+ / keys.

NOTE

The new parameters following setting are shown below:

Output current value 25.0 A

Maximum test value 0.100 Ω

Testing time 60.0 s

Press the

START

key while in this state. The unit enters TEST state to begin

testing.

Press the

STOP

key to finalize the test parameters. The flashing cursor

disappears.

Press the

or key to restore the flashing cursor and allow the test parameters

to be changed.

Even if "Minimum test value setting" on the optional function is active, you can get

the same results obtained in the example above by moving the flashing cursor to the

minimum test value and turning it off with the

ON/OFF

key.

Output current value: 25.0 A, Maximum test value: 0.100 Ω, Minimum test value:

OFF, Testing time: 60.0 s.

────────────────────────────────────────────────────

3.6 Examples of Settings

Page 38

31

────────────────────────────────────────────────────

3.7 Starting a Test

WARNING

NOTE

To avoid electrical accidents, confirm that all connections are secure.

The increased resistance of loose connections can lead to

overheating and fire.

To avoid burns, never touch the output current terminal, probe tip, or

contact point while testing (i.e., in TEST state).

Take particular care to avoid touching the tip of the current

application probe, which may be quite hot when operating, due to its

small surface area.

・

The soft start mode is active only with a load 0.200 Ω or less. If the load

exceeds this value, the state of connection of the probe is not known, and a test

cannot be started. In this case, set the test mode to normal mode.

・

Priority for control of the

START

key is in the following order: the external

switch, the external I/O, and the front panel of the unit. Connecting the switch

signal line plug disables the

START

key on the front panel of the unit and the

start signal for the external I/O.

Normally, the 9296 CURRENT PROBE should be connected to the protection ground

terminal on the equipment being tested. Connect the probe securely, so that it's not

easily dislodged. During current output, take care to ensure that adjacent probes do

not touch, as this may result in a short-circuit. In most cases, the 9297 CURRENT

APPLY PROBE is connected to a test point on the equipment being tested.

Starting a test

The test start procedure varies according to the test mode setting. The unit is

initially set to Soft start mode. For more information, see Section 4.10, "Setting the

Test Mode."

Depending on the output current value and the state of the test object, it will generally

takes about 2 seconds to output the set current. After a while, the output current

value equals the set current value

1 A, and the test screening function activates.

(1) Set the appropriate parameters in the READY state.

(2) Press the

START

key to start the test. If the probe is detached from the measured

object, the test will not start, and the unit will enter the stand-by state (as indicated

by a blinking

TEST

lamp). If this state continues for more than 30 seconds, the

unit returns to the READY state. The test begins when the probe is connected to

the measured object.

(3) The TEST lamp lights when the unit enters TEST state. While the TEST lamp is lit,

be careful not to cause electrical shock by touching the terminal or other parts

through which the current is passing.

(4) If the probe is detached from the measured object during testing, the FAIL lamp

lights together with the UPPER and the LOWER lamps, and the unit enters FAIL

state.

(5) To end the test normally, the probe must contact the measured object throughout the

test.

────────────────────────────────────────────────────

3.7 Starting a Test

Page 39

32

────────────────────────────────────────────────────

Forcible ending of a test

To perform forcible ending of a test, press the

STOP

key. This stops current

output, and the unit enters READY state. No screening operation is performed.

The value at which to forcibly end the test can be held using the hold function

(see Section 4.3).

Failure to start a test

The following cases may make prevent starting a test. In case of failure, check the

settings and reset parameters, if necessary.

(1) The maximum test value is lower than the minimum test value:

After the minimum test value flickers, the unit returns to the READY state. Reset

the maximum or minimum test values.

(2) The output current value is lower than the output current set value:

・

The probe can be disconnected from the tested equipment.

Never attempt to reconnect the probe before the unit returns to READY state.

Sparks may be given off. Before reconnecting, make sure the unit has returned to

READY state.

・

The load resistance may exceed the output capacity of this unit.

In this case, the

FAIL

lamp lights together with the

UPPER

and the

LOWER

lamps, and the unit enters FAIL state.

────────────────────────────────────────────────────

3.7 Starting a Test

Page 40

33

────────────────────────────────────────────────────

Measurement range

Load resistance

1.8

1.5

1.0

0.5

0

Measurement range

0

10 20 30

Open terminal voltage 6 V line

Maximum output power 130 VA line

At an output of 6 A,

6 (V) / 6 (A) = 1.0 (Ω)

from the 6 V line

At an output of 25 A,

130 (VA) / 25

2(A2

) = 0.208 (Ω)

from the 130 VA line

Output current (A)

────────────────────────────────────────────────────

3.7 Starting a Test

Page 41

34

────────────────────────────────────────────────────

3.8 Testing (in TEST State)

TEST state indicates that the unit is performing a test. Be careful not to cause

electrical shock by touching the terminal or other parts though which the current

(the value of which has been set in READY state) is passing.

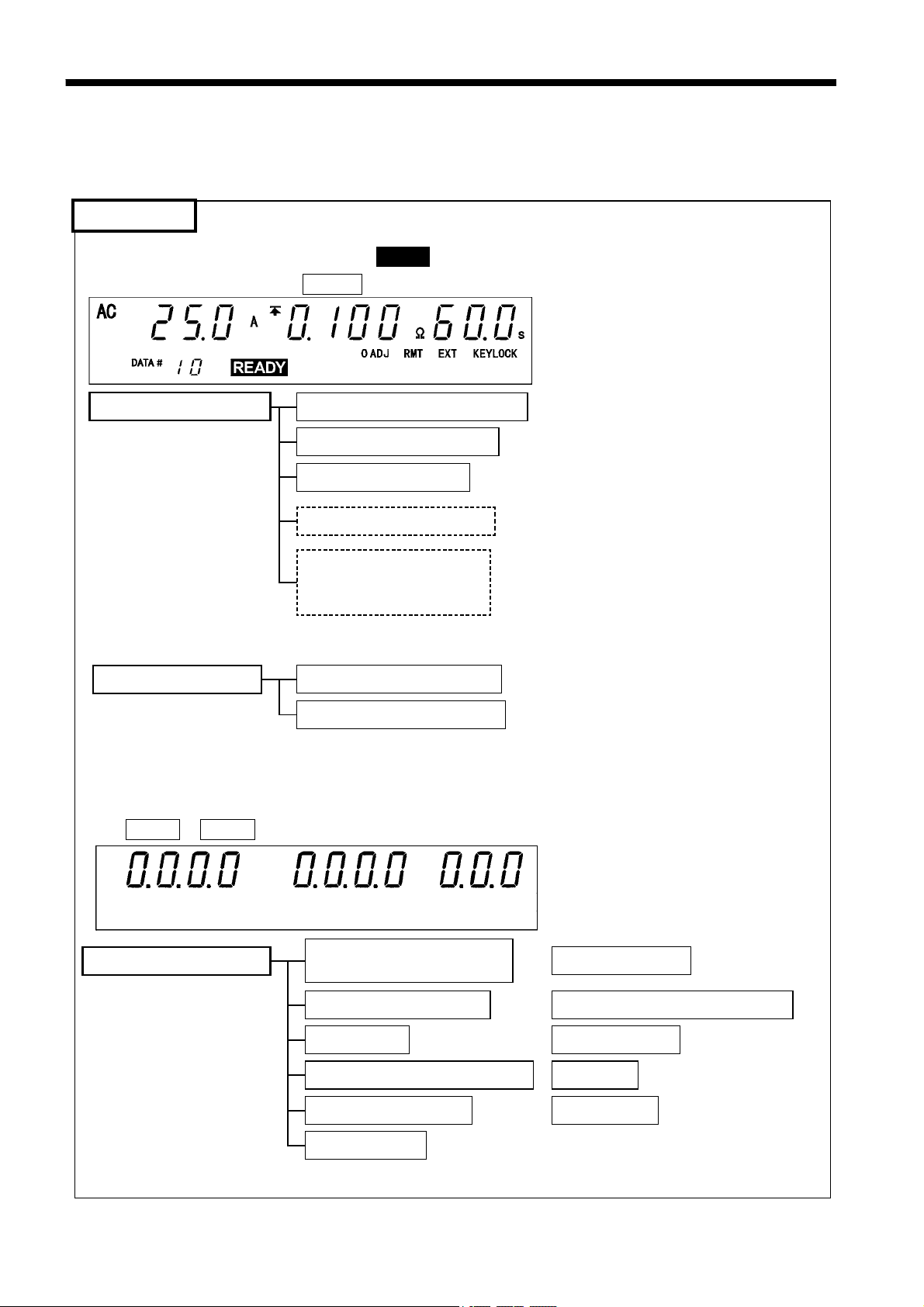

31 2 4

5 6

1

Measured current value

Indicates the current value being output.

The output current can be changed using the current changeability in TEST

State (see Section 4.8).

2

Maximum value icon and minimum value icon

The symbol

appears when the maximum test value is set, and the symbol

appears when the minimum value is set.

Measured voltage value and measured resistance value

3

The measured voltage value is displayed if the voltage indicator is selected and the

measured resistance value is displayed if the resistance indicator is selected. Press

SHIFT

+

ON/OFF

(Ω/V) to switch between resistance and voltage indicators.

Only the indicators are switched. The maximum and minimum test values are not

changed.

Testing time elapsed

4

When the testing time is set, countdown starts from the time set, and is displayed.

When the testing time is set to OFF, the time elapsed after the start of the test is

displayed. Once elapsed testing time reaches 999 s, the unit completes the test and

returns to READY state. If either the maximum or minimum test value has been

set, the unit enters PASS state.

The endless timer function allows continuous testing regardless of the

testing time set (see Section 4.5).

5

Data count indicator

Lights when the optional test data count function is set to "1: Set."

Test data count (output current frequency)

6

5

Displays test data when the data count indicator described in

above is lit or the

output frequency.

────────────────────────────────────────────────────

3.8 Testing (in TEST State)

Page 42

35

────────────────────────────────────────────────────

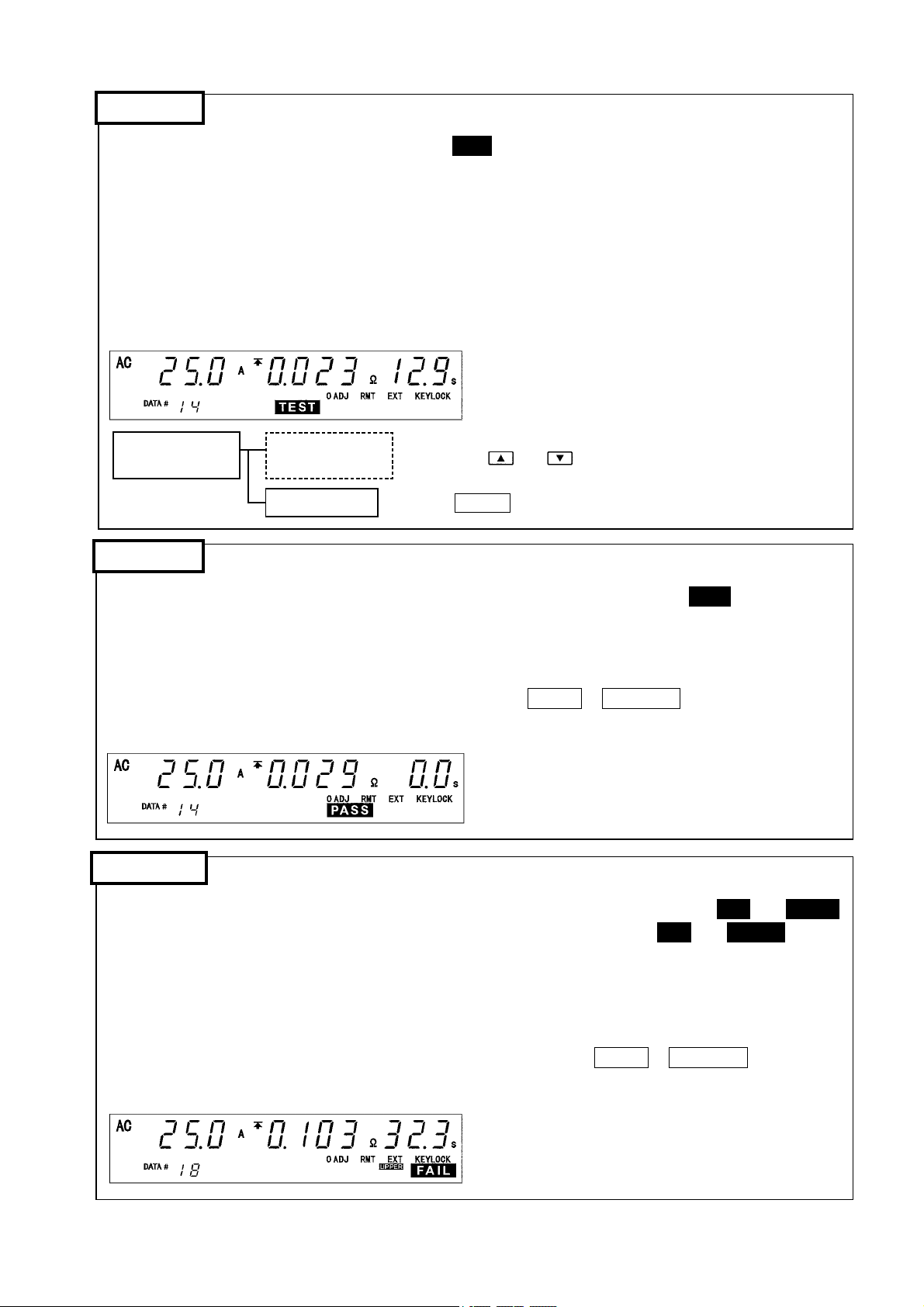

3.9 Screening (in PASS State)

The unit enters PASS state when either the maximum or minimum test value is set,

and when the test is completed. The

displaying the value established at the end of the testing period. The PASS state

screen is displayed for about 0.5 second before the unit resumes READY state.

The PASS state is held using the PASS/FAIL HOLD function (see Section 4.2).

The test data count can be displayed using the test data count function (see Section

4.6).

The test result can be printed using the printer output function (see Section 4.11).

1 42 3

PASS

lamp lights while in PASS state,

5 6

1

Measured current value at the end of a test

Displays the current value being output at the end of the test.

2

Maximum value icon and minimum value icon

The symbol

appears when the maximum test value is set, and the symbol

appears when the minimum value is set.

Measured voltage value and measured resistance value at the end of a test

3

The measured voltage value is displayed if the voltage indicator is selected and the

measured resistance value is displayed if the resistance indicator is selected. Press

SHIFT

4

Test completion time

+

ON/OFF

(Ω/V) to switch between resistance and voltage indicators.

Displays the time in which the test has been completed. In PASS state, "0.0s"is

displayed.

Test data count indicator

5

Lights when the optional test data count function is set to "1: Set."

6

Test data count (output current frequency)

5

Displays test data when the data count indicator described in

above is lit or the

output frequency.

────────────────────────────────────────────────────

3.9 Screening (in PASS State)

Page 43

36

────────────────────────────────────────────────────

3.10 Screening (in FAIL State)

The unit enters FAIL state if the measured value deviates from the maximum (or

minimum) test value set.

The FAIL state indicates the time at which the measured value deviated from the

maximum (or minimum) value. The FAIL lamp lights together with the UPPER or

LOWER

the

lamp while in FAIL state (together with the

lamps if the set current cannot be output).

The FAIL state screen is displayed for about 1 second before the unit resumes

READY state.

The FAIL state is held using the PASS/FAIL HOLD function (see Section 4.2).

The test data count can be displayed using the test data count function (see Section

4.6).

The test result can be printed using the printer output function (see Section 4.11).

UPPER

and the

LOWER

4

5 6

1

Measured current value at the end of a test

31 2

Displays the current value being output at the end of the test.

Maximum value icon and minimum value icon

2

The symbol

appears when the maximum test value is set, and the symbol

appears when the minimum value is set.

Measured voltage value and measured resistance value at the end of a test

3

The measured voltage value is displayed if the voltage indicator is selected and the

measured resistance value is displayed if the resistance indicator is selected. Press

SHIFT

Test completion time

4

+

ON/OFF

(Ω/V) to switch between resistance and voltage indicators.

If the testing time is set in FAIL state, the testing time elapsed displays the set

testing time remaining.

When the testing time is set to OFF, the elapsed time is displayed.

Test data count indicator

5

Lights when the optional test data count function is set to "1: Set."

Test data count (output current frequency)

6

5

Displays test data when the data count indicator described in

above is lit or the

output frequency.

────────────────────────────────────────────────────

3.10 Screening (in FAIL State)

Page 44

37

────────────────────────────────────────────────────

Chapter 4

Optional Functions

Setting the optional functions allows testing under various conditions.

Settings can be made for the following eleven optional functions. One number is

assigned to each function. Settings are made by changing the number by moving

the cursor key.

Since improper settings can produce inaccurate results, this chapter explains the

correct way to make settings. Please read it carefully.

Entering the Optional function setting screen

Press

setting screen.

SHIFT

+

STOP

while in READY state to display the Optional function

1 2 3 4 5 6 7 8 9 10 11

Setting optional functions

Use the

Use the

To complete the optional settings, press

READY state.

Press the

state without finalizing settings.

/ keys to move the flashing cursor to the target function.

/ keys to set a value at the flashing cursor location.

SHIFT

STOP

key to abort the setting process. The unit reverts to the READY

+

STOP

. The unit reverts to the

────────────────────────────────────────────────────

Page 45

38

────────────────────────────────────────────────────

The following describes the numbers corresponding to the functions. For additional

information, see Section APPINDIX 2, "Table of Optional Functions."

1

Switching the output current frequency

Switches output current frequencies (50 Hz or 60 Hz).

When the test data count is at "0: Not set," the frequency is displayed in the

READY state.

Selection

2

PASS/FAIL hold function

0: 50 Hz, 1:60Hz

This function retains PASS and FAIL states to help verify the value screened

in the test.

Selection

0: PASS not held, FAIL held

1: PASS held, FAIL held

2: PASS not held, FAIL not held

3: PASS held, FAIL not held

3

Hold function

When the hold function is set in the following cases, the current state is

retained:

・

Following selection of only the test time, some time has elapsed without

setting the maximum or minimum test value.

・

Press the

Selection

4

Setting minimum test value

STOP

0: Not held, 1: Held

key to cancel the test in progress.

The minimum test value can be set as a test parameter.

Selection

5

Endless timer function

0: Not set, 1:Set

If this function is not selected, the test ends after 999 s, after which the test

time is set to OFF in the READY state. Select this function to continue until

it returns a FAIL state, or until you press the

Selection

6

Test data count function

0: Not set, 1:Set

STOP

key.

The test data count function can be preset.

This function counts the number of tests, and is used when testing a large

number of points for a single measured object.

Selection

0: Not set, 1:Set

────────────────────────────────────────────────────

Page 46

39

────────────────────────────────────────────────────

7

Buzzer setting

The buzzer ON/OFF may be set in the PASS, FAIL, error state, and other

states.

Selection

0: ON at screening, ON at error

1: OFF at screening, OFF at error

2: OFF at screening, ON at error

3: ON at screening, OFF at error

8

Changing the current value in TEST state

In TEST state, the current value can be changed during output by pressing the

/ keys.

Selection

9

Momentary OUT

0: Not changeable, 1: Changeable

The momentary OUT function allows current output only while the

key is held down. Once this function is set, working with the 9297

CURRENT APPLY PROBE requires different procedures.

Selection

0: Not set (Trigger operation),

1: Set (Momentary OUT operation)

10

Test mode

Soft start mode, normal mode and continuous test mode can be set.

For more information, see Section 4.10, "Test mode."

START

Selection

11

Printer output

0: Soft start mode, 1: Normal mode, 2: Continuous test mode

You can print test parameters and results with the optional 9442 PRINTER.

This printer offers the following two print modes.

Selection

0: Not used (Initial setting)

1: Automatically print for PASS/FAIL screening.

2: Print selectively when the PASS/FAIL state is held.

────────────────────────────────────────────────────

Page 47

40

────────────────────────────────────────────────────

4.1 Switching the Output Current Frequency

Changes the output current frequency. When the optional test data count function

is set to "1: Not set," the output current frequency set in the READY state is

displayed and can be changed. If you change the frequency in the READY state,

the output current frequency can be changed automatically in the optional function

setting screen.

Setting procedure

NOTE

(1) Press

SHIFT

+

STOP

while in READY state to display the Optional function

setting screen.

(2) Use the