Page 1

INSTRUCTION MANUAL

3155-01

LEAK CURRENT HiTESTER

Page 2

Page 3

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use iii

Contents of this Manual viii

Chapter 1 Overview 1

1.1 Product Introduction 1

1.2 Features of the 3155 2

1.3 Measuring Mode of the 3155 4

1.4 Leakage Measurement Types 5

1.5 Standards Regarding Leakage Current 6

Chapter 2 Names and Functions of Parts 7

Chapter 3 Options

3.1 Measurement Networks 13

3.1.1 9497 NETWORK B (for the Medical Electrical Equipment)

3.1.2 9498 NETWORK C (for IEC/TR 60990)

3.1.3 9499 NETWORK D (Universal)

3.2 9196 APPLY UNIT 18

3.2.1 9196 APPLY UNIT

3.2.2 Names and Functions of the Parts

of the 9196 APPLY UNIT

3.2.3 9196 APPLY UNIT Operation

3.2.4 9196 APPLY UNIT Specifications

3.3 9388 CARRYING CASE (with Casters) 24

13

13

14

16

18

19

21

23

Chapter 4 Preparations for Measurement 25

4.1 Installing the Measurement Network 26

4.2 Power Cord Connection 27

4.3 Powering on and off the Unit 28

4.4 Loading Recording Paper 30

Page 4

Chapter 5 Medical Electrical Equipment Measurement

Network B Installed

31

5.1 Leakage Current Measurement Types and

Their Allowable Values for Medical Electrical Equipment 31

5.2 Screens (ME Equipment) 34

5.2.1 Initial Screen (ME Equipment)

5.2.2 Equipment Set-up Screen (ME Equipment)

5.2.3 Measuring Mode Screen (ME Equipment)

5.2.4 System Screen (ME Equipment)

5.2.5 Flow of Screens for Basic Operations (for ME Equipment)

35

35

37

38

40

5.3 Earth Leakage Current Measurement Mode (ME Equipment) 41

5.3.1 Earth Leakage Current Measurement Mode

5.3.2 Connecting Equipment for Earth Leakage Current

Measurement (ME Equipment)

5.3.3 Zero Adjustment (Earth Leakage Current)

5.3.4 Basic Settings for Earth Leakage Current Measurement

(ME Equipment)

41

42

44

45

5.3.5 Earth Leakage Current Measurement Screen

(ME Equipment)

46

5.4 Enclosure Leakage Current Measurement Mode

(ME Equipment) 48

5.4.1 Enclosure Leakage Current Measurement Mode

5.4.2 Connecting Equipment for Enclosure Leakage Current

Measurement (ME Equipment)

5.4.3 Basic Settings for Enclosure Leakage Current

Measurement (ME Equipment)

5.4.4 Enclosure Leakage Current Measurement Screen

(ME Equipment)

48

50

54

55

5.5 Patient Leakage Current Measurement Mode 57

5.5.1 Patient Leakage Current

5.5.2 Connecting Equipment for Patient Leakage Current

Measurement 59

5.5.3 Basic Settings for Patient Leakage Current

Measurement Mode 57

Measurement 61

5.5.4 Patient Leakage Current

Measurement Screen 62

Page 5

5.6 Patient Leakage Current Measurement Mode 64

5.6.1 Patient Leakage Current

5.6.2 Connecting Equipment for Patient Leakage Current

Measurement 65

5.6.3 Basic Settings for Patient Leakage Current

Measurement 67

5.6.4 Patient Leakage Current

Measurement Mode 64

Measurement Screen 68

5.7 Patient Leakage Current Measurement Mode 70

5.7.1 Patient Leakage Current

5.7.2 Connecting Equipment for Patient Leakage Current

Measurement 71

5.7.3 Zero Adjustment (ME Equipment - Patient Leakage

Current

5.7.4 Basic Settings for Patient Leakage Current

Measurement 74

5.7.5 Patient Leakage Current

) 73

Measurement Mode 70

Measurement Screen 75

5.8 Patient Auxiliary Current Measurement Mode 77

5.8.1 Patient Auxiliary Current Measurement Mode

5.8.2 Connecting Equipment for Patient Auxiliary Current

Measurement

5.8.3 Basic Settings for Patient Auxiliary Current Measurement

5.8.4 Patient Auxiliary Current Measurement Screen

77

79

81

82

5.9 Low Resistance Measurement Mode (ME Equipment) 84

5.9.1 Low Resistance Measurement Mode

5.9.2 Connecting Equipment for Low Resistance Measurement

(ME Equipment)

5.9.3 Basic Settings for Low Resistance Measurement

(ME Equipment)

5.9.4 Low Resistance Measurement Screen (ME Equipment)

84

85

88

89

5.10 Condition Set-up Window Setting (ME Equipment) 91

5.10.1 Allowable Value Setting (For Leakage Current

Measurement)

5.10.2 Allowable Value Setting (For Low Resistance

91

Measurement)

5.10.3 Automatic Measurement Setting (ME Equipment)

5.10.4 Measurement Current Setting (ME Equipment)

5.10.5 Printing out the Maximum Values (ME Equipment)

5.10.6 Saving the Maximum Values (ME Equipment)

5.10.7 Low Resistance Measurement with 3157

93

95

99

100

101

103

Page 6

5.11 System Screen (ME Equipment) 105

5.11.1 System Screen

5.11.2 Saved Data Reference Screen (ME Equipment)

5.11.3 Initialization Screen

5.11.4 Allowable Value Judgment Set-up Screen

5.11.5 Beep Sound Set-up Screen

5.11.6 Communications Set-up Screen

5.11.7 Printer Set-up Screen

5.11.8 Time and Date Set-up Screen

5.11.9 Self-test Screen

5.11.10 Language Set-up Screen

Chapter 6 Ordinary Electrical Equipment Measurement

Network C Installed

6.1 Measurement Network C 116

6.1.1 Leakage Current Measurement Types and Their

Allowable Values for Ordinary Electrical Equipment

105

106

110

111

111

112

112

113

113

114

115

117

6.2 Screens (for IEC/TR 60990) 118

6.2.1 Initial Screen (for IEC/TR 60990)

6.2.2 "Equipment Set-up" Screen (for IEC/TR 60990)

6.2.3 Measuring Mode Screen (for IEC/TR 60990)

6.2.4 System Screen (for IEC/TR 60990)

6.2.5 Flow of Screens for Basic Operations (for IEC/TR 60990)

118

119

121

122

124

6.3 Enclosure Leakage Current Measurement Mode

(for IEC/TR 60990) 125

6.3.1 Measurement Accompanying IEC 60950 (1991-10) +

am4 (1996-07)

6.3.2 Connecting Equipment for Measurement Accompanying

IEC 60950 (1991-10) + am4 (1996-07)

6.3.3 Zero Adjustment (for IEC/TR 60990 - Enclosure Leakage

Current)

6.3.4 Measurement Accompanying IEC 61010-1 (1990-09) +

am1 (1992-09) + am2 (1995-07)

126

128

131

132

6.3.5 Connecting Equipment for Measurement Accompanying

IEC 61010-1 (1990-09) + am1 (1992-09) + am2 (1995-07)

6.3.6 Basic Settings for Enclosure Leakage Current

Measurement (for IEC/TR 60990)

6.3.7 Enclosure Leakage Current Measurement Screen

(for IEC/TR 60990)

133

135

136

Page 7

6.4 Earth Leakage Current Measurement Mode

(for IEC/TR 60990)

6.4.1 Earth Leakage Current Measurement Mode

6.4.2 Connecting Equipment for Earth Leakage Current

139

139

Measurement (for IEC/TR 60990)

6.4.3 Zero Adjustment (Earth Leakage Current)

6.4.4 Basic Settings for Earth Leakage Current Measurement

(for IEC/TR 60990)

6.4.5 Earth Leakage Current Measurement Screen

(for IEC/TR 60990)

140

141

142

143

6.5 Low Resistance Measurement Mode (for IEC/TR 60990) 146

6.5.1 Low Resistance Measurement Mode

6.5.2 Connecting Equipment for Low Resistance Measurement

(for IEC/TR 60990)

6.5.3 Basic Settings for Low Resistance Measurement

6.5.4 Low Resistance Measurement Screen

146

147

149

150

6.6 Condition Set-up Window Setting (for IEC/TR 60990) 152

6.6.1 Allowable Value Setting (For Leakage Current

Measurement)

6.6.2 Allowable Value Setting (For Low Resistance

152

Measurement)

6.6.3 Automatic Measurement Setting (for IEC/TR 60990)

6.6.4 Measurement Current Setting (for IEC/TR 60990)

6.6.5 Printing out the Maximum Values (for IEC/TR 60990)

6.6.6 Saving the Maximum Values (for IEC/TR 60990)

6.6.7 Low Resistance Measurement with 3157

154

156

160

161

162

163

6.7 System Screen (for IEC/TR 60990) 165

6.7.1 System Screen

6.7.2 Saved Data Reference Screen (for IEC/TR 60990)

6.7.3 Initialization Screen

6.7.4 Allowable Value Judgment Set-up Screen

6.7.5 Beep Sound Set-up Screen

6.7.6 Communications Set-up Screen

6.7.7 Printer Set-up Screen

6.7.8 Time and Date Set-up Screen

6.7.9 Self-test Screen

165

166

170

171

171

172

172

173

173

6.7.10 Language Set-up Screen

174

Page 8

Chapter 7 Ordinary Electrical Equipment Measurement

Network D Installed

175

7.1 Measurement Network D 176

7.2 Screens (Universal) 177

7.2.1 Initial Screen (Universal)

7.2.2 "Equipment Set-up" Screen (Universal)

7.2.3 Measuring Mode Screen (Universal)

7.2.4 System Screen (Universal)

7.2.5 Flow of Screens for Basic Operations (Universal)

178

178

180

181

183

7.3 Enclosure Leakage Current Measurement Mode (Universal) 184

7.3.1 Enclosure Leakage Current Measurement Mode

7.3.2 Leakage Current Measurement with the Universal

Measurement Network

7.3.3 Connecting Equipment for Leakage Current Measurement

7.3.4 Zero Adjustment (Universal - Enclosure Leakage Current)

7.3.5 Basic Settings for Enclosure Leakage Current

Measurement (Universal)

184

185

186

188

189

7.3.6 Enclosure Leakage Current Measurement Screen

(Universal)

190

7.4 Earth Leakage Current Measurement Mode (Universal) 193

7.4.1 Earth Leakage Current Measurement Mode

7.4.2 Connecting Equipment for Earth Leakage Current

Measurement (Universal)

7.4.3 Zero Adjustment (Earth Leakage Current)

7.4.4 Basic Settings for Earth Leakage Current Measurement

(Universal)

7.4.5 Earth Leakage Current Measurement Screen (Universal)

193

194

195

196

197

7.5 Low Resistance Measurement Mode (Universal) 200

7.5.1 Low Resistance Measurement Mode

7.5.2 Connecting Equipment for Low Resistance Measurement

(Universal)

7.5.3 Basic Settings for Low Resistance Measurement

7.5.4 Low Resistance Measurement Screen

200

201

203

204

7.6 Condition Set-up Window Setting (Universal) 206

7.6.1 Allowable Value Setting (For Leakage Current

Measurement)

7.6.2 Allowable Value Setting (For Low Resistance

Measurement)

206

208

Page 9

7.6.3 Automatic Measurement Setting (Universal) 210

7.6.4 Measurement Current Setting (Universal)

7.6.5 Printing out the Maximum Values (Universal)

7.6.6 Saving the Maximum Values (Universal)

7.6.7 Low Resistance Measurement with 3157

214

215

216

217

7.7 System Screen (Universal) 219

7.7.1 System Screen

7.7.2 Saved Data Reference Screen (Universal)

7.7.3 Initialization Screen

7.7.4 Allowable Value Judgment Set-up Screen

7.7.5 Beep Sound Set-up Screen

7.7.6 Communications Set-up Screen

7.7.7 Printer Set-up Screen

7.7.8 Time and Date Set-up Screen

7.7.9 Self-test Screen

7.7.10 Language Set-up Screen

219

220

224

225

225

226

226

227

227

228

Chapter 8 Command Reference 229

8.1 Overview 229

8.2 Specifications 229

8.3 Names of Parts 230

8.4 Connecting Method 231

8.5 Operation 233

8.5.1 Communication Conditions Setting

8.5.2 Communication Methods by the RS-232C

8.5.3 Message Format

8.5.4 Headers

8.5.5 Data Formats

8.5.6 Delimiters

8.5.7 Separators

8.5.8 Abbreviating Messages with Compound Headers

8.5.9 Output Queue

8.5.10 Input Buffer

233

234

235

236

237

238

238

239

240

240

8.5.11 Error Register

241

8.6 Command Summary 242

8.7 Initialization Items 244

Page 10

8.8 Command Reference 245

8.8.1 Format of Command Explanations 245

8.9.2 Commands 246

8.9 Reading in All the Saved Data 285

8.10 Sample Programs 286

8.11 Troubleshooting 293

Chapter 9 Specifications 295

9.1 General Specifications 295

9.2 Measuring Mode Specifications 297

9.2.1 Leakage Current Measurement

9.2.2 Low Resistance Measurement

9.2.3 Monitor Function

297

298

298

9.3 Accuracy Tables 299

Chapter 10 Maintenance and Servicing 303

10.1 Maintenance and Inspection 303

10.2 Fuse Replacement 304

10.2.1 Replacement of the 3155 Power Source Fuse

10.2.2 Replacement of the Measurement Network Fuse

10.2.3 Replacement of the 9196 APPLY UNIT Power Source

Fuse

10.3 Troubleshooting 307

10.4 System Reset 308

10.4.1 Resetting the system

10.4.2 Default Settings

304

305

306

308

309

10.5 Ultimate Disposal 312

10.6 External Dimensions 314

Page 11

Appendices 315

Appendix 1 Error Messages 316

Appendix 2 Leakage Current Measurement 317

Appendix 2.1 IEC 60601-1 (1988-12) + am1 (1991-11) +

am2 (1995-03)

2.1.1 Earth Leakage Current

2.1.2 Enclosure Leakage Current

2.1.3 Patient Leakage Current

2.1.4 Patient Leakage Current

2.1.5 Patient Leakage Current

2.1.6 Patient Auxiliary Current

Appendix 2.2 IEC 60950 (1991-10) + am4 (1996-07)

319

320

321

Appendix 3 Standards for Leakage Current and Current

Measurements

Appendix 3.1 When the 9497 NETWORK B is installed

3.1.1 Medical Electrical Equipment Part 1: General

Requirements of Safety (IEC 60601-1 (1988-12) + am1

(1991-11) + am2 (1995-03))

Appendix 3.2 When the 9498 NETWORK C is Installed

3.2.1 Methods of Measurement of Touch-current and

317

317

318

322

323

327

327

327

328

Protective Conductor Current (IEC/TR 60990 (1990-06))

3.2.2 Safety of Information Technology Equipment (IEC 60950

(1991-10) + am4 (1996-07))

3.2.3 IEC 61010-1 (1990-09) + am1 (1992-09) +

am2 (1995-07)

328

330

332

Appendix 4 Glossary (Extracted from IEC 60601-1(1988-12)

+ am1 (1991-11) + am2 (1995-03)) 333

Appendix 5 Assembling the Supplied Power Plug 336

Page 12

Page 13

────────────────────────────────────────────────────

I

I

ntroduction

Thank you for purchasing this HIOKI "3155 LEAK CURRENT HiTESTER." To

get the maximum performance from the unit, please read this manual first,

and keep this at hand.

nspection

When the unit is delivered, check and make sure that it has not been

damaged in transit. If the unit is damaged, or fails to operate according to the

specifications, contact your dealer or HIOKI representative.

Checking the main unit and accessories

Main unit

"3155 LEAK CURRENT HiTESTER"

i

NOTE

Accessories

Verify that the following standard accessories are complete.

(1) Grounded three-core power cord

(2) 9170 TEST LEADS

(3) Instruction Manual

(4) 9195 ENCLOSURE PROBE

(5) Spare fuse 3155 (120 V): 250 V T0.5 AL

3155 (200/240 V): 250 V T0.25 AL

3155-01: 250 V T0.2 AL

(6) 9233 RECORDING PAPER (1 roll)

(7) 9399 CARRYING CASE (for accessories)

(8) Alligator clips (red and black)

(9) Outlet power plug (3155 (200/240 V), 3155-01)

(10) Voltage selector key (3155-01 only) 2

The NETWORKS (9497 to 9499), 9461 PIN- TYPE LEADS, 9287 CLIP-TYPE

LEADS, and 9196 APPLY UNIT are not included. Please purchase separately

according to your needs.

Shipment of the unit

If reshipping the unit, preferably use the original packing.

Warranty

HIOKI cannot be responsible for losses caused either directly or indirectly by

the use of the 3155 with other equipment, or if ownership is transferred to a

third party.

────────────────────────────────────────────────────

Introduction

Page 14

ii

R

t

R

G

t

N

S

────────────────────────────────────────────────────

afety Notes

DANGE

This Instruction Manual provides information and warnings essential for operating this

equipment in a safe manner and for maintaining it in safe operating condition. Before using

this equipment, be sure to carefully read the following safety notes.

This equipment is designed according to IEC 61010-1 Safety Standards,

and has been tested for safety prior to shipment. During high voltage

measurement, incorrect measurement procedures could result in injury or

death, as well as damage to the equipment. Please read this manual

carefully and be sure that you understand its contents before using the

equipment. The manufacturer disclaims all responsibility for any acciden

or injury except that resulting due to defect in its product.

Safety symbols

・This symbol is affixed to locations on the equipment where the

operator should consult corresponding topics in this manual

(which are also marked with the

functions of the equipment.

・In the manual, this mark indicates explanations which it is

particularly important that the user read before using the

equipment.

symbol) before using relevant

Indicates a fuse.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols are used in this Instruction Manual to indicate the relative importance

of cautions and warnings.

DANGE

WARNIN

Indicates that incorrect operation presents extreme danger of accident

resulting in death or serious injury to the user.

Indicates that incorrect operation presents significant danger of acciden

resulting in death or serious injury to the user.

CAUTIO

NOTE

────────────────────────────────────────────────────

Safety Notes

Indicates that incorrect operation presents possibility of injury to the

user or damage to the equipment.

Denotes items of advice related to performance of the equipment or to

its correct operation.

Page 15

iii

G

N

N

────────────────────────────────────────────────────

otes on Use

In order to ensure safe operation and to obtain maximum performance from

the unit, observe the cautions listed below.

Before measurement

WARNIN

Before turning on the power, make sure that the voltage of the power

supply being used matches the supply voltage indicated on the rear

panel of the unit. (3155: specified at order, 3155-01: set by the voltage

selector)

If an attempt is made to use an improper supply voltage, there is danger

of damage to this unit and of life-threatening risk to the operator.

The unit is constructed so as to be connected to a ground line via a

three-core power cord that is supplied with the unit. In order to avoid

electric shock, connect the unit to a properly grounded (3-pin) outlet

using the power cord provided.

Before using the unit, make sure that the sheathing on the leads /

probes is not damaged and that no bare wire is exposed. If there is

damage, using the unit could cause electric shock. Replace the lead /

probe with the specified 9195 or 9170, or optional 9461 or 9287.

To avoid the danger of electric shock, never operate the unit with a

measurement network removed.

Do not swithc the voltage selector when the power is turned on.

CAUTIO

NOTE

Do not press hard upon the touch screen, or operate it using a hard object or

one with a sharp end. Doing so could scratch or damage the screen or the

soft keys.

・Of the three optional Measurement Networks (9497, 9498 and 9499), one

must be installed with the 3155 or no measurements can be made. If the

power to the 3155 is turned on without having installed one of the networks,

the message ’Measurement Network not installed.’ will appear on the LCD.

In which case, please install a measurement network as described in Section

4.1, "Installing the Measurement Network."

・Because the current consumption monitor is AC coupled, errors occur when

measuring an AC current which includes a DC offset. (Example: half-wave

rectified current)

────────────────────────────────────────────────────

Notes on Use

Page 16

iv

N

G

────────────────────────────────────────────────────

Connection

CAUTIO

・In order to avoid electric shock, turn off the power to all devices before

plugging in or unplugging the measurement network or RS-232C connector.

・When unplugging the power cord from the power receptacle or from the unit,

grasp the plug, not the cord, in order to avoid damaging the cable.

・To avoid damaging the leads or probes, do not bend or pull the leads or

probes.

・Use caution when taking measurements in circuits where the power line are

hot.

・For safety reasons, only use the 9195 or 9170 probe / test lead provided with

the unit, or the optional 9461 or 9287 for measurement.

・The changing of the function when replacing the test terminals requires

disconnection of the test leads from the equipment being measured and then

the disconnection of the test leads from the terminals.

・To avoid damage to the unit, do not short the output terminal and do not

input voltage to the output terminal.

・Use the unit near the power receptacle.

During measurement

WARNIN

The 9196 APPLY UNIT used in the measurement of enclosure leakage

current, patient leakage current

and patient leakage current

continuously outputs voltage while the voltage application button is

being pressed. Care is required to avoid accidents caused by electrical

shock.

The leakage current measurement terminals, the resistance

measurement terminals and the RS-232C connector are not insulated.

Handle these items carefully in order to avoid electric shock or a short

circuit accident.

If the end of a lead or a probe short-circuits lines with a voltage between

them, this is very dangerous and can lead to a serious accident.

Exercise great care when measuring voltages.

In the event that the equipment malfunctions in any manner during use,

turn off the power immediately, and contact your dealer or HIOKI

representative.

────────────────────────────────────────────────────

Notes on Use

Page 17

v

Monitor lamps

R

N

G

────────────────────────────────────────────────────

Input

DANGE

NOTE

When the power to the 3155 is turned on, if the

MON2 and MON3 lamps are illuminated, an

accurate measurement can be obtained. (The unit

can also be wired so that MON1 and MON2

illuminate.)

For details, refer to Section 4.3, "Powering on and

off the Unit."

To avoid electric shock and damage to the unit, do not input a voltage

exceeding the permissible common mode voltage to the leakage current

measurement terminals. The permissible common mode voltage is 250 V

(DC+AC peak). (In the 50 μA range, 20 V (DC+AC peak))

CAUTIO

Replacement

WARNIN

When the power is turned off, do not apply voltage or current to the leakage

current measurement terminals or resistance measurement terminals. Doing

so may damage the unit.

Only use fuses of the specified type that is rated for the specified

current and voltage. Using a fuse that does not meet the specifications

or shorting the fuse holder may cause an accident that might result in

injury or death.

(120 V: 250 V T0.5 AL, 200/240 V: 250 V T0.25 AL 20 mm × 5 mm dia.

(3155))

(110 to 120/200/240 V: 250 V T0.2 AL 20 mm × 5 mm dia. (3155-01))

When replacing the fuse and measurement network, always power off

the unit.

────────────────────────────────────────────────────

Notes on Use

Page 18

vi

G

────────────────────────────────────────────────────

Operating environment

WARNIN

NOTE

To prevent electric shock, do not allow the unit to become wet and do

not use the unit when your hands are wet.

The interior of the 3155 contains some components which are subject to

high voltage, and therefore dangerous. Absolutely do not remove the

cover panel. In particular, be careful of the 9196 APPLY UNIT, which is

subject to high voltage.

To avoid damage to the unit, do not subject the equipment to vibrations

or shocks during transport or handling. Be especially careful to avoid

dropping the equipment.

The unit should always be operated indoors in a range from 5℃ to 40℃

and 35% to 80% rh. Do not use the unit in direct sunlight, dusty

conditions, or in the presence of corrosive gases.

Do not use the unit near any device which generates strong

electromagnetic radiation or near a static electrical charge, as these may

cause errors.

・Accurate measurement may be impossible in locations subject to strong

external magnetic fields, such as transformers and high-current conductors,

or in locations subject to strong external electric fields, such as radio

transmission equipment.

・Do not use the 3155 in operating rooms, ICUs, CCUs or other areas where

an isolated electrical supply is used. To do so will result in inaccurate

readings.

────────────────────────────────────────────────────

Notes on Use

Page 19

vii

────────────────────────────────────────────────────

Printer and recording paper

Printer

・Using the printer in a high-temperature or high-humidity environment

should be avoided at all costs. This can seriously reduce the printer life.

・Because the thermal printing head is subject to high temperatures during

printing, do not touch the head itself or its support sections either during or

directly after printing. Care is also necessary when replacing the paper or

during maintenance. For paper replacement, refer to Section 4.4, "Loading

Recording Paper."

・Because the motor is subject to high temperature during operation, do not

touch it either during or directly after printing.

・To prevent the motor from being overheated, do not press the feed switch

continuously for more than 3 minutes.

Recording paper

・This unit uses a thermal printer. The recording paper supplied has

characteristics finely tuned for use with the printer.

Using recording paper of a different specification may not only result in

impaired printing quality, but even prevent the printer from operating.

Always use the HIOKI specified product.

・If light reaches the paper over a long period, the paper will discolor. Do not

unwrap rolls of paper until you are ready to use them.

・The recording paper uses a thermochemical reaction. Note the following

points:

・To avoid discoloration, do not leave recording paper in direct sunlight.

Store at not more than 40℃ and 90% rh.

・To keep definitive data, make photocopies of the recordings.

・If the thermal paper absorbs an organic solvent such as alcohols or

ketones it may no longer develop properly, and recorded information may

fade. Soft PVC film and transparent contact adhesive tape contain such

solvents, so avoid using them with recordings.

・Avoid interleaving the thermal recordings with damp diazo copies.

────────────────────────────────────────────────────

Notes on Use

Page 20

viii

C

────────────────────────────────────────────────────

ontents of this Manual

The operating methods of the 3155 LEAK CURRENT HiTESTER will vary

depending upon the type of measurement network used. The various

operating methods for each type of measurement network are shown in

Chapters 5 to 7. Although there is some repetition between chapters, to

ensure safe operation please read thoroughly the chapter pertaining to the

measurement network you use.

Chapter 1: Overview

Gives an overview and features of the unit.

Chapter 2: Names of Functions of Parts

Describes the names and functions of the parts of the unit.

Chapter 3: Options

Describes the options (measurement networks and application

units) of the unit.

Chapter 4: Preparations for Measurement

Describes the installation and preparatory work.

Chapter 5: Medical Electrical Equipment Measurement

(9497 NETWORK B installed)

Describes the medical electrical equipment measurement.

Chapter 6: Ordinary Electrical Equipment Measurement (for IEC/TR 60990)

(9498 NETWORK C installed)

Describes the ordinary electrical equipment measurement (for

IEC/TR 60990).

Chapter 7: Ordinary Electrical Equipment Measurement (Universal)

(9499 NETWORK D installed)

Describes the ordinary electrical equipment measurement

(universal).

Chapter 8: Command Reference

Describes the RS-232C communications and their operation

examples.

Chapter 9: Specifications

Contains the unit specifications such as the general specifications,

measurement ranges, accuracy, etc. of the unit.

Chapter 10: Maintenance and Servicing

Covers the maintenance and servicing.

Appendices: Covers the error messages, leakage current measurement,

standards and glossary.

────────────────────────────────────────────────────

Contents of this Manual

Page 21

1

1

w

1

────────────────────────────────────────────────────

Chapter

1

2

.1 Product Introduction

The HIOKI 3155 LEAK CURRENT HiTESTER is a leakage current

measuring instrument for use in testing electrical equipment used in a wide

variety of applications from computers to medical care. Not only does it

conform to all standards for testing medical electrical equipment, but also to

laws and standards applicable to equipment for non-medical care as well.

By using one of three (optional) measurement networks that simulate the

human body, measurements that conform to a variety of laws and standards

for electrical equipment can be made.

Once the measurement network for the equipment to be measured is attached,

a measurement screen conforming to the applicable requirements is displayed.

By using the ’touch keys’ on the screen, measurements are easily made. (For

patient leakage current

current, the 9196 APPLY UNIT is necessary.)

To ensure safety in the use of electrical equipment, a wide variety of tests for

characteristics such as insulation resistance, earth resistance, leakage current,

etc., need be made. The 3155 is designed to be used in leakage current testing

in a variety of fields.

Overvie

, patient leakage current and enclosure leakage

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

1.1 Product Introduction

Page 22

2

1

────────────────────────────────────────────────────

Used by:

Manufacturers of medical electrical equipment For formal inspections and pre-shipping inspections

Sales agents of medical electrical equipment For inspection and maintenance

Personnel performing repairs on medical electrical

equipment

Clinical engineering technologists at hospital For inspection and maintenance

Clinical engineering technologists training schools For educational purposes

Electrical contractors qualified to install operating

rooms, ICUs and CCUs

Public agencies For formal inspections

Manufacturers of electrical equipment For formal and pre-shipping inspections

Users of electrical equipment For inspection and maintenance

Electrical contractors For inspection and maintenance

Electrical repair technicians For inspection and maintenance

Manufacturers of electrical components For formal and pre-shipping inspections

Manufacturers of electric generators For formal and pre-shipping inspections

For inspection and maintenance

For inspections of insulated transformers

.2 Features of the 3155

(1) Measurement networks that conform to a variety of laws and standards

In order to perform a variety of tests that conform to the various laws and

standards applicable to leakage current testing, it is necessary to utilize a

measurement network that simulates the human body when making

measurements. Different measurement networks conform to different laws

and standards:

9497 NETWORK B: IEC 60601-1

9498 NETWORK C: IEC/TR 60990

9499 NETWORK D: IEC 60065, IEC 60335-1, UL

These measurement networks can also be used to perform tests that conform

to a variety of other standards as well. For details, refer to Section 3.1,

"Measurement Networks."

(2) Superior operability

All operations are performed via the display screen touch panel. The

operational keys are displayed on the screen for interactive operation.

(3) Measuring mode

Once a measurement network has been attached to the back of the 3155 unit

and the power is turned on, the measuring modes available in that network

are displayed on the screen.

Earth leakge current Enclosure leakage current

Patient leakage current Patient leakage current

Patient leakage current Patient auxiliary current

Low resistance measurement

────────────────────────────────────────────────────

1.2 Features of the 3155

Page 23

3

────────────────────────────────────────────────────

(4) Leakage current measurement

The user can select a measuring mode from the ones available in the

measurement network. The configuration of the instrument will also effect

which modes are available. The necessary modes are displayed from

(5) Low resistance measurement

Low resistance measurement of a protective earth conductor is performed at a

current of 25 AAC or DC as prescribed in all standards. The 3155 is equipped

with a DC 4-terminal method measurement (at 100 mADC max.) function for

easy measurement. Measurement is also possible using RS-232C interfacing

with the 3157 AC GROUNDING HiTESTER (max. 31A AC, conforming to

various standards), available separately.

(6) Interface

An RS-232C interface is standard equipment to allow for easy transfer of

measurement data to a computer.

(7) Built-in printer

The built-in thermal serial printer allows for easy printout of saved data.

(8) Monitor function

Equipped with a line voltage and current consumption monitor.

(9) Voltage selector (3155-01 only)

The equipment with the power voltages of 110 to 240 V can be measured with

a single unit.

to .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

1.2 Features of the 3155

Page 24

4

s

t

g

h

t

d

t

r

t

t

t

t)

1

────────────────────────────────────────────────────

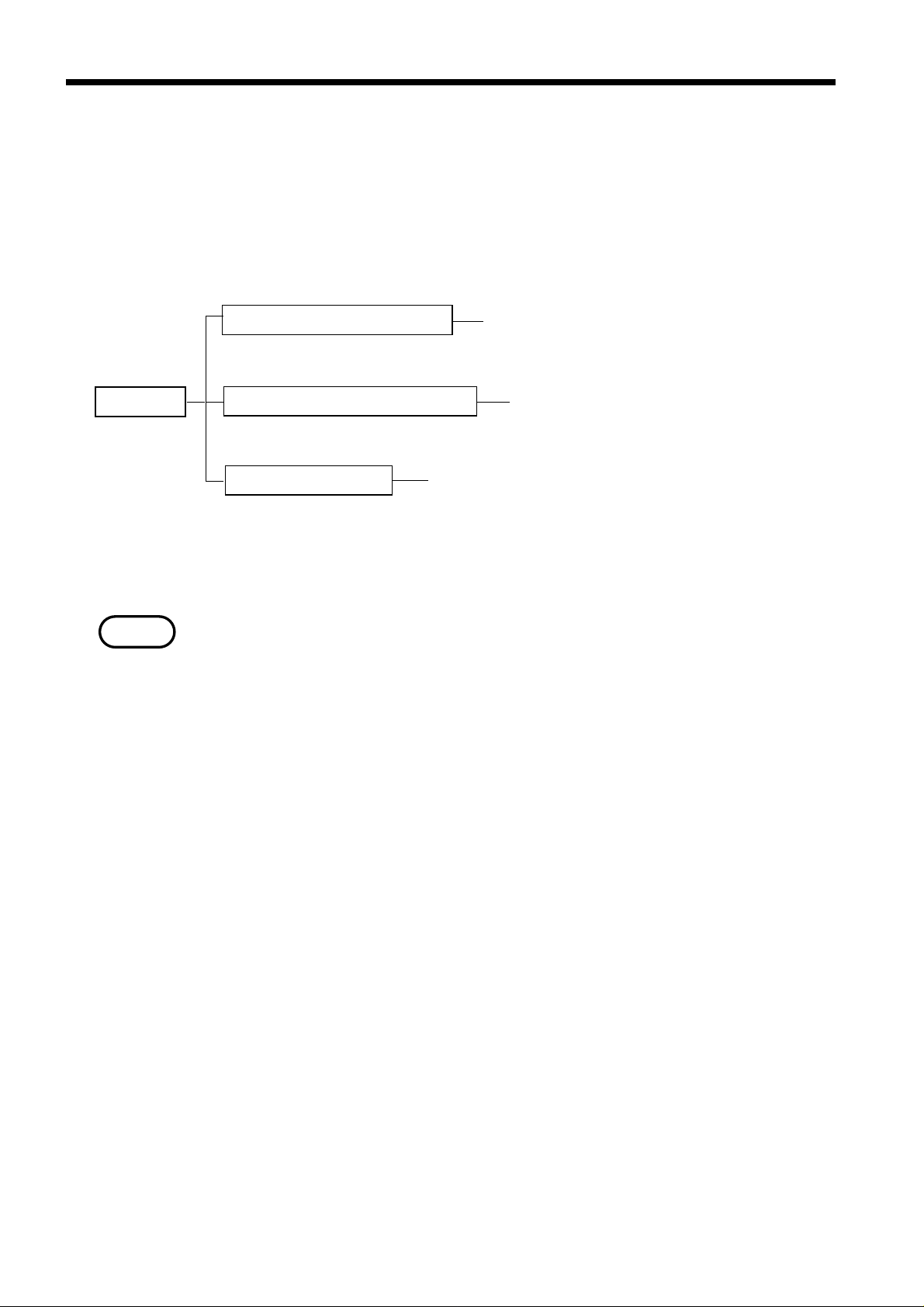

.3 Measuring Mode of the 3155

The 3155 has been designed with the idea in mind that leakage current

testing is the most important of all tests for electrical safety. In particular, for

medical electrical equipment, leakage current has the greatest potential for

harming human beings, and is therefore strictly regulated even with regard to

single fault conditions. Through the use of measurement networks B, C and

D, the 3155 can perform leakage current testing for all types of electrical

equipment from ordinary electrical equipment to medical electrical equipment.

For details, refer to Section 3.1, "Measurement Networks."

NOTE

Measurement network type

9497 NETWORK B

9498 NETWORK C

9499 NETWORK D

Earth leakage current Enclosure leakage current

Patient leakage current Patient leakage current

Patient leakage current Patient auxiliary current

Low resistance measurement

Earth leakage current Enclosure leakage current

Low resistance measurement

Earth leakage current Enclosure leakage current

Low resistance measurement

Setting for normal condition or single fault conditions is possible. The polarity

Available measuring modes

of the power source can also be set.

The voltage input from the power inlet is directly output to the auxiliary

outlet for the equipment to be measured.

When testing with the 110% power voltage, input it to the power inlet.

Leakage current route of the medical electrical equipment (ME equipmen

Faulty ME equipmen

Faulty ME equipmen

Signal input an

Medical outle

Eart

output parts

3-P plu

Protective earth conducto

Earth leakage curren

Enclosure leakage curren

ME equipmen

Patient leakage current

Patient leakage current

Patient leakage current

For details, refer to Appendix 2, "Leakage Current Measurement."

────────────────────────────────────────────────────

1.3 Measuring Mode of the 3155

Page 25

5

)

)

)

)

n

n

e

e

e

r

y

d

n

n

h

n

n

n

n

e

e

e

n

e

e

r

y

1

────────────────────────────────────────────────────

.4 Leakage Measurement Types

1

2

Earth leakage current

(ordinary electrical equipment or

medical electrical equipment)

A current between the protective eart

terminal and the earth is measured.

Enclosure leakage current

(ordinary electrical equipment or

medical electrical equipment)

Currents between the enclosure an

the earth, and between parts of the

enclosure are measured.

Patient leakage current

(medical electrical equipment

A current is measured betwee

the applied and the earth.

Normal condition

Single fault condition

Normal conditio

Single fault condition

Normal conditio

Single fault conditio

Interruption of on

supply conductor

Interruption of on

supply conductor

Interruption of a protectiv

earth conductor

A voltage equivalent to 110% of

the maximum rated voltage is

applied between the signal input o

output part which is not protectivel

earthed and the earth

(medical electrical equipment only)

Interruption of on

supply conductor

Interruption of a protectiv

earth conductor

3

4

5

6

7

8

Patient leakage current

(medical electrical equipment

A current is measured betwee

the applied part and the earth.

Patient leakage current

(medical electrical equipment

A current is measured betwee

the F-type applied part and the

faulty equipment.

Patient auxiliary current

(medical electrical equipment

A current is measured betwee

parts of the applied part.

NOTE

・Measurements including the combined single fault conditions is not possible.

・The optional 9196 APPLY UNIT is required to apply a voltage equivalent to

110% of the maximum rated voltage.

Single fault condition

Single fault condition

Normal conditio

Single fault conditio

A voltage equivalent to 110% of

the maximum rated voltage is

applied between the signal input o

output part which is not protectivel

earthed and the earth

(medical electrical equipment only)

A voltage equivalent to 110%

of the maximum rated voltag

is applied between the F-type

applied part and the earth.

Interruption of on

supply conductor

Interruption of a protectiv

earth conductor

9

10

11

12

13

14

A

────────────────────────────────────────────────────

1.4 Leakage Measurement Types

Page 26

6

s

t

t

)

t

)

)

1

────────────────────────────────────────────────────

.5 Standards Regarding Leakage Current

The measurement network you use will vary depending upon the standards to

which you must conform.

There are instances where testing for leakage current is required by standard

to be included in formal testing, or in ownership transfer testing as well.

Standard

NOTE

Medical electrical equipmen

Electrical measuring instrumen

Electrical equipmen

The standards above are subject to amendment. For details, refer to each

standard.

IEC 60950 (1991-10) + am4 (1996-07),

IEC/TR 60990 (1990-06),

IEC 60065 (1998-07),

IEC 60335-1 (1991-06) + am1 (1994-11

IEC 60601-1 (1988-12) + am1 (1991-11

+ am2 (1995-03)

IEC 61010-1 (1990-09) + am1 (1992-09

+ am2 (1995-07)

────────────────────────────────────────────────────

1.5 Standards Regarding Leakage Current

Page 27

7

2

of

ts

────────────────────────────────────────────────────

Chapter

1

2

Names and Functions

Par

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

Page 28

8

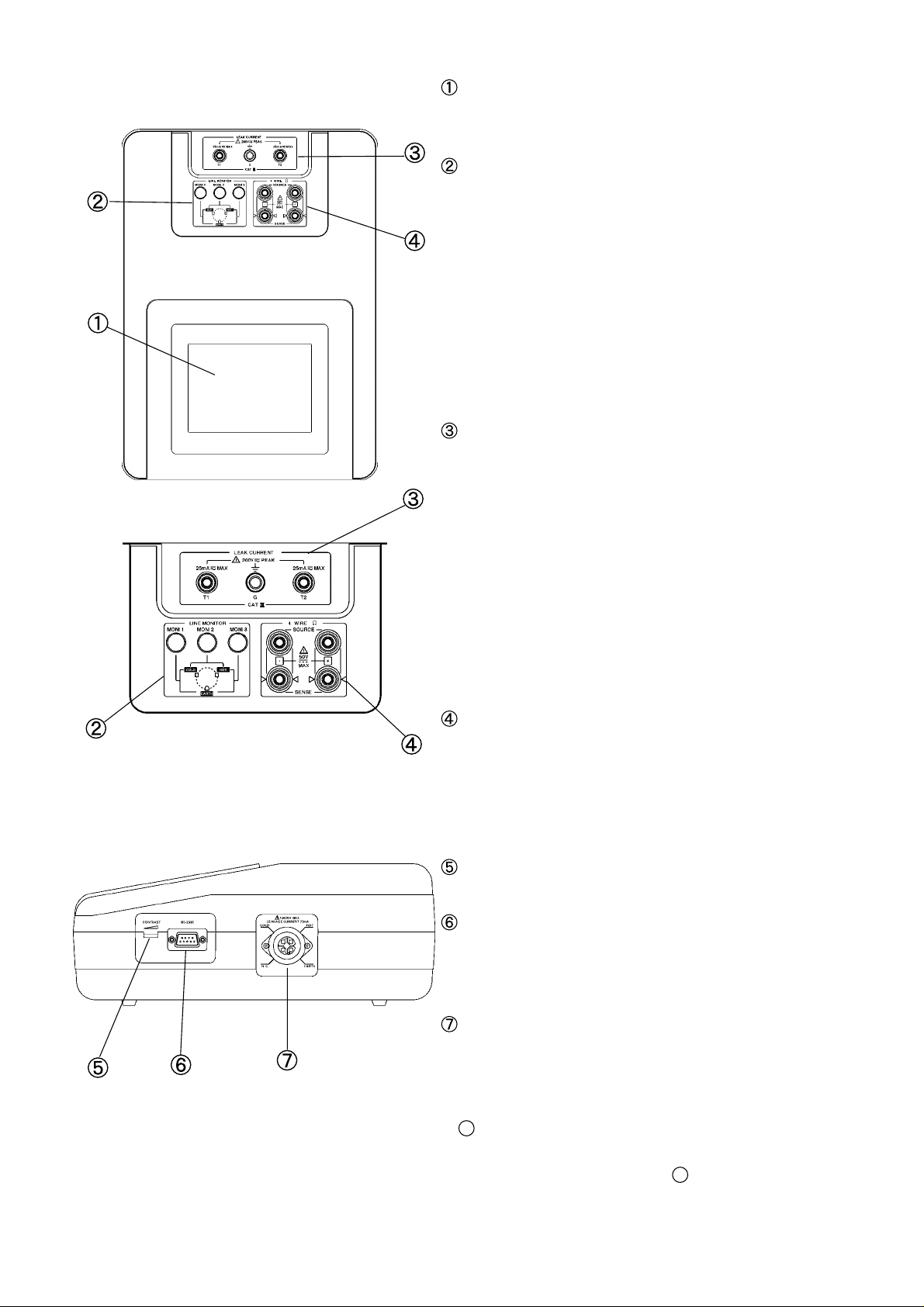

Enlarged diagram of the terminal section

3

3

────────────────────────────────────────────────────

Top view

Liquid crystal display

This 5-inch display includes a touch panel

which performs the role of the input keys.

Monitor lamps

The condition of elements such as the power

line ground are indicated by these monitor

lamps.

When the power to the 3155 is turned on, if

the MON2 and MON3 lamps are illuminated,

an accurate measurement can be obtained.

(The unit can also be wired so that MON1 and

MON2 illuminate.)

For details, refer to Section 4.3, " Powering on

and off the Unit."

Leakage current measurement terminals

There are three terminals available.

G: G terminal (connects to the earth terminal

of the equipment to be measured)

T1: Leakage current measurement terminal T1

(Location of connection to the equipment

to be measured varies with the measuring

mode.)

T2: Leakage current measurement terminal T2

(Location of connection to the equipment

to be measured varies with the measuring

mode.)

Right side view

Resistance measurement terminals

There are four terminals available.

SOURCE(+), SENSE(+), SENSE(-), SOURCE(-)

The SOURCE banana plug of the 9461 or 9287

is to be connected to SOURCE, and the

SENSE to SENSE.

Contrast adjustment knob

Use this knob to adjust the screen contrast.

RS-232C connector (Dsub 9 pin male)

Connect a RS-232C cable here to communicate

with an external controller such as a

computer.

Auxiliary power socket (for the equipment to be

measured)

(earthed 3-pin socket - 1500 VA max.)

Plug the equipment to be measured in here.

Outputs the voltage input from the power inlet

1

directly.

When testing with the 110% power voltage,

input it to the power inlet

1

.

Use the supplied power plug for connection.

────────────────────────────────────────────────────

Page 29

9

101312

11

3155

101413

11

3155-01

Voltage selector key

1

2

3

4

────────────────────────────────────────────────────

Left side view

Front view

Internal printer

Prints out the measurement results etc.

Handle

This is used for transporting the 3155.

1

2

3

4

5

6

Rear view

Main power switch

Powers the 3155 on(|)or off(○).

(With the 3155-01, includes the function of the

auxiliary power outlet circuit breaker.)

1

Fuse holder

Insert the proper fuse here, as indicated on

the label.

1

Auxiliary power outlet circuit breaker (3155 only)

In the event that the current to the auxiliary

power outlet

will trip.

ON(|): Current is being supplied to the

auxiliary power outlet.

OFF(○): Current is not being supplied to

the auxiliary power outlet.

1

Power inlet

Connect the grounded three-core power cord

supplied here.

exceeds 1500 VA, this breaker

7

8

9

10

11

12

13

────────────────────────────────────────────────────

1

Voltage selector key (3155-01 only)

Insert the supplied voltage selector key into

the keyhole of the voltage selector, and select

the power voltage by setting it to the required

power voltage.

For details, refer to Section 4.2, " Power Cord

Connection."

14

A

Page 30

10

15

5

────────────────────────────────────────────────────

Auxiliary power outlet circuit breaker

The unit uses the medium-speed breaker for the rush current of the

equipment to be measured.

Refer to the following table for breaking characteristics.

Bottom view

1

Measurement network socket

Use this socket to attach the measurement

network that conforms to your needs.

The following measurement networks are

available:

a. 9497 NETWORK B: Medical electrical

equipment

b. 9498 NETWORK C: IEC/TR 60990

c. 9499 NETWORK D: IEC 60065, IEC 60335-1,

UL

NOTE

For measurement networks, refer to Section 3.1,

"Measurement Networks," and for installation,

Section 4.1, "Installing the Measurement

Network."

────────────────────────────────────────────────────

Page 31

11

161718

19

r

To the auxiliary

power socket

Changing the power

source polarity

interruption of a protective

earth conductor

interruption of one

supply conductor

From the power

inlet

H (L)

C (N)

GGC (N)

H (L)

6

7

8

9

────────────────────────────────────────────────────

Interior of the built-in printe

Inside the changeover box

A changeover box is built into the 3155.

It is built between the power inlet and the auxiliary power socket.

It outputs changing the power source polarity and the condition. So the power

source polarity (normal or reverse polarity) can be changed easily, and the

single fault condition (interruption of one supply conductor or interruption of a

protective earth conductor) can be set easily.

1

Printer cover

1

Recording paper holder

1

Paper feed

1

Feed switch

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

Page 32

12

Outlet

T1T2G

Auxiliary power outlet

Measurement

network

Protective earth

terminal

3155

Outlet

T1T2G

Auxiliary power outlet

Measurement

network

Protective earth

terminal

3155

Outlet

T1

T2

G

Auxiliary power outlet

Measurement

network

Protective earth

terminal

3155

────────────────────────────────────────────────────

Connections of G, T1 and T2

(1) In the earth leakage current measurement mode

G and the earth electrode of the auxiliary power outlet are connected to one

side of the measurement network.

The other side of the measurement network is connected through the

protective earth terminal and its conductor to the ground.

(2) In the enclosure leakage current mode (contact condition: between the enclosure

and the earth) and patient leakage current

measurement modes

T2 is connected to one side of the measurement network.

The other side of the measurement network is connected through the

protective earth terminal and its conductor to the ground.

(Class , equipment) and

G and the earth electrode of the auxiliary power outlet are connected through

the protective earth terminal and its conductor to the ground.

(3) In the enclosure leakage current mode (contact condition: between parts of the

enclosure (when the 9497 is installed) and between the enclosure and the power

line (when the 9498 or 9499 is installed)), patient leakage current

(Internally

powered equipment) measurement modes, patient leakage current

measurement mode and patient auxiliary current measurement modes

T2 is connected to one side of the measurement network.

T1 is connected to the other side of the measurement network.

G and the earth electrode of the auxiliary power outlet are connected through

the protective earth terminal and its conductor to the ground.

────────────────────────────────────────────────────

Page 33

13

3

V

1

0.1%

10 kΩ±0.1%

0.015 μF

1%

V

s

d

3

s

3

────────────────────────────────────────────────────

Chapter

1

2

.1 Measurement Networks

Please choose one of the three measurement networks that simulate the

human body to perform measurements conforming to standards for electrical

equipment to be tested.

The measurement networks cannot be used separately, but must always be

installed on the 3155.

For the installation procedure, refer to Section 4.1, "Installing the

Measurement Network," and for the fuse replacement, Section 10.2.2,

"Replacement of the Measurement Network Fuse."

Option

3

4

5

6

7

8

.1.1 9497 NETWORK B (for the Medical Electrical Equipment)

This measurement network is for the medical electrical equipment.

Measurement network B conforms to the following standard:

Medical electrical equipment Part 1: General requirements of safety (IEC

60601-1 (1988-12) + am1 (1991-11) + am2 (1995-03))

By installing on the 3155 and making the appropriate settings from the

screen, a configuration with a network with frequency characteristics for ON,

and a network with only 1 kΩ of uninduced resistance for OFF is established.

kΩ

±

±

1kΩ±0.1%

Network with frequency characteristic

(ON)

Network with only 1 kΩ of uninduce

resistance (OFF)

9

10

11

12

13

14

A

────────────────────────────────────────────────────

3.1 Measurement Networks

Page 34

14

3

V

1.5 kΩ

0.1%

0.22 μF

1%

500 Ω

0.1%

0.0062μF

1%

20 kΩ

0.1%

0.0091μF

1%

10kΩ±0.1%

V

V

0.022μF

1%

0

μF

1%

1

Ω

0.1%

500 Ω

0.1%

1.5 kΩ

0.1%

0.22 μF

1%

500 Ω

0.1%

10 kΩ±0.1%

)

)

)

────────────────────────────────────────────────────

Specifications

Standard Medical electrical equipment Part 1: General requirements ofsafety (IEC 60601-1

(1988-12) + am1 (1991-11) + am2 (1995-03))

Measuring circuit

Basic measuring element 1 kΩ, frequency characteristics ±0.5% (DC to 1 MHz)

configuration

Low pass filter function (1MΩ load with input protection fuse shorted)

Filter configuration (ON setting): RC filter (10 kΩ+15 nF)

Cutoff frequency, fc (at -3 dB): 1061 Hz±16 Hz

Passband attenuation: 0 dB±2% (at 100 Hz)

Attenuation: -20 log (f/fc) ±1dB (10 kHz≦f≦1 MHz)

Filter setting: On/off switch (off: 1 kΩ only)

Approved tolerances

±0.1% for resistance, ±1% for capacitor

for element

Fuse 250 V T0.032 AL 20 mm×5 mm dia.

Dimensions and mass 140W × 35H × 29D mm(5.51"W × 1.38"H × 1.14"D), approx. 70 g(2.5 oz.)

Accessories Instruction Manual, spare fuse

.1.2 9498 NETWORK C (for IEC/TR 60990)

This measurement network conforms to IEC/TR 60990.

Measurement network C conforms to the following standard:

Methods of measurement of touch-current and protective conductor current

(IEC/TR 60990 (1990-06))

By installing on the 3155 and making the appropriate settings from the

screen, a configuration with a body impedance network for OFF, a perception

and reaction network for ON1, and a let-go network for ON2 is established.

.5 k

±

.22

±

±

Body impedance network (OFF

±

±

±

±

±

±

Let-go network (ON2

±

±

±

±

Perception and reaction network (ON1

────────────────────────────────────────────────────

3.1 Measurement Networks

Page 35

15

────────────────────────────────────────────────────

Installation of measurement network C will enable leakage current testing

that conforms to the following standards:

・Safety requirements for electrical equipment for measurement, control, and

laboratory use Part 1: General requirements (IEC 61010-1 (1990-09) + am1

(1992-09) + am2 (1995-07))

・Safety of information technology equipment (IEC 60950 (1991-10) + am4

(1996-07))

・Audio, video and similar electronic apparatus - Safety requirements (IEC

60065 (1998-07))

・Applicable UL standards:(Examples:UL1419, UL3101-1, UL3111-1, etc.)

Specifications

Standard Methods of measurement of touch-current and protective conductor current

(IEC/TR 60990 (1990-06))

Measuring circuit

configuration

Filter configuration and

characteristics

Basic measuring element 1.5 kΩ+500 Ω

(1MΩ load with input protection fuse shorted)

OFF setting: High pass filter

Cutoff frequency (at -3 dB): 1805 Hz±27 Hz

Passband attenuation: 0 dB±2% (at 100 kHz)

Low-frequency attenuation: -12 dB±0.3 dB (at 100 Hz)

ON1 setting: (perception) 10 kΩ+22 nF

Passband attenuation: -12 dB±0.3 dB (at 100 Hz)

High-frequency attenuation: -42.8 dB±1 dB (at 100 kHz)

ON2 setting: (let-go) 10 kΩ+(20 kΩ+6.2 nF)//9.1 nF

Passband attenuation: -12 dB±0.3 dB (at 100 Hz)

High-frequency attenuation: -35.1 dB±1 dB (at 100 kHz)

1

2

3

4

5

6

7

8

Approved tolerances

for element

Fuse 250 V T0.032 AL 20 mm×5 mm dia.

Dimensions and mass 140W × 35 H × 29D mm(5.51"W × 1.38"H × 1.14"D), approx. 90 g(3.2 oz.)

Accessories Instruction Manual, spare fuse

±0.1% for resistance, ±1% for capacitor

9

10

11

12

13

14

────────────────────────────────────────────────────

3.1 Measurement Networks

A

Page 36

16

3

V

1. kΩ

0.1%

V

0.15 μF

2%

1.5 kΩ

0.1%

V

2kΩ

0.1%

Network of 2 kΩ (2 kΩ)

Network of 1 kΩ (1 kΩ)

Network of 1.5 kΩ and 0.15 μF (1.5 kΩ)

────────────────────────────────────────────────────

.1.3 9499 NETWORK D (Universal)

This is a universal measurement network.

Measurement network D conforms to the following standards:

Safety of household and similar electrical appliances - Part 1: General

requirements (IEC 60335-1 (1991-06) + am1 (1994-11))

Applicable UL standards:

By installing on the 3155 and making the appropriate settings from the

screen, a configuration with a network of 1 kΩ for 1 kΩ, a network of 1.5 kΩ

and 0.15 μF for 1.5 kΩ, and a network of 2 kΩ for 2 kΩ is established.

±

±

±

±

In addition, there are many applicable standards.

Specifications

Standard Safety of household and similar electrical appliances - Part 1:

General requirements (IEC 60335-1 (1991-06) + am1 (1994-11))

Applicable UL standards: (Examples: UL471, UL1310, UL1437, UL1492, etc.)

Measuring circuit

configuration/accuracy

Filter configuration and

characteristics

Approved tolerances

for element

Fuse 250 V T0.032 AL 20 mm×5 mm dia.

Dimensions and mass 140W × 35 H × 29D mm(5.51"W × 1.38"H × 1.14"D), approx. 80 g(2.8 oz.)

Accessories Instruction Manual, spare fuse

(a) Network of 1 kΩ

Impedance: 1 kΩ±0.5% (DC to 1 MHz)

(b) Network of 1.5 kΩ and 0.15 μF

Impedance: Theoretical value±0.5% (DC≦f≦400 Hz)

Theoretical value±(2%+1Ω) (400 Hz<f≦1 MHz)

Cutoff frequency (at -3 dB): 707 Hz±15 Hz

(c) Network of 2 kΩ

Impedance: 2 kΩ±0.5% (DC to 1 MHz)

(1MΩ load with input protection fuse shorted)

OFF setting: High pass filter

Cutoff frequency (at -3 dB): 1805 Hz±27 Hz

Passband attenuation: 0 dB±2% (at 100 kHz)

Low-frequency attenuation: -12 dB±0.3 dB (at 100 Hz)

ON1 setting: (perception) 10 kΩ+22 nF

Passband attenuation: -12 dB±0.3 dB (at 100 Hz)

High-frequency attenuation: -42.8 dB±1 dB (at 100 kHz)

ON2 setting: (let-go) 10 kΩ+(20 kΩ+6.2 nF)//9.1 nF

Passband attenuation: -12 dB±0.3 dB (at 100 Hz)

High-frequency attenuation: -35.1 dB±1 dB (at 100 kHz)

±0.1% for resistance, ±2% for capacitor

────────────────────────────────────────────────────

3.1 Measurement Networks

Page 37

17

T

)

────────────────────────────────────────────────────

ypical frequency response graphs of measurement networks

9497 NETWORK B

9498 NETWORK C

1

2

3

4

5

6

7

9499 NETWORK D

Impedance vs input frequency (1.5 kΩ//0.15 μF

8

9

10

11

12

13

────────────────────────────────────────────────────

3.1 Measurement Networks

14

A

Page 38

18

3

3

────────────────────────────────────────────────────

.2 9196 APPLY UNIT

.2.1 9196 APPLY UNIT

The 9196 APPLY UNIT is an instrument which outputs 110% of the input

power voltage.

Also, it has a function to break the circuit to prevent damage to the equipment

to be measured and electric shock to the user if an output current exceeding

6 mA.

Combined with the 3155 LEAK CURRENT HiTESTER, it is used to test

leakage current in medical electrical equipment. Leakage current from

medical electrical equipment has the greatest potential for harming human

beings, and is therefore strictly regulated even with regard to single fault

conditions. The following 6 types of testing for leakage current in medical

electrical equipment are available.

Earth leakage current Enclosure leakage current

Patient leakage current Patient leakage current

Patient leakage current Patient auxiliary current

The 9196 is used in testing for types

, , and .

NOTE

For the fuse replacement, refer to Section 10.2.3, "Replacement of the 9196

APPLY UNIT Power Source Fuse."

────────────────────────────────────────────────────

3.2 9196 APPLY UNIT

Page 39

19

3

────────────────────────────────────────────────────

.2.2 Names and Functions of the Parts of the 9196 APPLY

UNIT

Front view

1

2

3

4

5

6

Main power switch (POWER)

Powers the 9196 on and off.

Main power monitor (POWER MONI): Clear monitor lamp

The status of the main power is shown by this monitor lamp.

If illuminated, the power is ON.

If not illuminated, the power is OFF.

Polarity toggle switch (POLARITY)

This switch is used to toggle the polarity of the voltage output from the

voltage application probe. (in respect to the voltage input from the power inlet)

NORMAL: Polarity conforms with that of the voltage input from the power

inlet.

REVERSE: Polarity does not conform with that of the voltage input from the

power inlet.

Type toggle switch (TYPE)

Changes per the type of applied part of the equipment to be measured to

which voltage is applied.

B/BF: No protective resistance connected to the output point of the voltage

application probe.

CF: Protective resistance (10 kΩ) connected to the output point of the voltage

application probe in series.

Main power switch indication: |:ON ○: OFF

7

8

9

10

11

12

13

14

NOTE

────────────────────────────────────────────────────

When the type toggle switch of the 9196 APPLY UNIT is set to CF, there is a

10 kΩ protective resistance connected to the output point of the voltage

application probe in series. If the leakage current is large, the current flowing

from the output point will be subject to a reduction in voltage due to the

protective resistance, thereby reducing the actual output voltage.

3.2 9196 APPLY UNIT

A

Page 40

20

n

────────────────────────────────────────────────────

Voltage application probe connection terminal (OUTPUT)

Connect the 9190 VOLTAGE APPLY PROBE.

Output monitor (OUTPUT MONI): Red monitor lamp

The condition of the output to the voltage application probe is shown by this

monitor lamp.

If illuminated, the output is ON. (The voltage application button to the voltage

application probe is being held down.)

If not illuminated, the output is OFF.

Handle

Rear view

Fuse

Use the HIOKI specified fuse. (250 V T0.25 AL 20 mm×5 mm dia.)

Power inlet

The rated power voltage of the 9196 is 100 to 240 VAC (45 to 400 Hz), and the

maximum rated power is 25 VA.

Connect a grounded three-core power cord that is supplied with the unit.

Function earth terminal

If the protective ground terminal cannot be connected to the ground via a

grounded three-core power cord supplied, connect the function earth terminal

to the ground.

9190 VOLTAGE APPLY PROBE

Voltage application butto

────────────────────────────────────────────────────

3.2 9196 APPLY UNIT

Page 41

21

3

G

N

────────────────────────────────────────────────────

.2.3 9196 APPLY UNIT Operation

WARNIN

Before turning on the power, make sure that the voltage of the power

supply being used matches the supply voltage indicated on the rear

panel of the unit. (100 to 240 VAC)

The unit has no protective ground terminal, and is connected to a

ground line via a three-core power cord that is supplied with the unit.

In order to prevent electric shock, always connect the unit to a properly

grounded power outlet using the power cord provided.

The voltage application probe continuously outputs voltage while the

voltage application button is being pressed. While it is outputting, or

any time that the voltage application button is being pressed

intentionally, a dangerous amount voltage is present is at the tip of the

probe. To avoid electrical shock, do not touch either the device under

test or the probe tip.

Before using the unit, make sure that the sheathing on the probes is not

damaged and that no bare wire is exposed. If there is damage, using

the unit could cause electric shock. Replace the probe with the

specified 9190.

To prevent electric shock, do not allow the unit to become wet and do

not use the unit when your hands are wet.

CAUTIO

NOTE

・To avoid damaging the probes, do not bend or pull the probes.

・Do not store or use the unit where it will be exposed to direct sunlight, high

temperatures, high humidity, or condensation. If exposed to such conditions,

the unit may be damaged, the insulation may deteriorate, and the unit may

no longer satisfy its specifications.

・When unplugging the power cord from the power receptacle or from the unit,

grasp the plug, not the cord, in order to avoid damaging the cable.

・Use the unit near the power outlet.

・The 9196 is only able to operate to its full capability after it has been

properly grounded. Always use the power cord (grounded three-core power

cord) that is supplied with the unit to ground the unit.

・If operating the voltage application button to the 9190 VOLTAGE APPLY

PROBE quickly, the main power of the 9196 may be turned off.

(1) Be sure that the main power switch is turned to OFF.

(2) Being sure that the power source is of the correct voltage, connect the

grounded three-core power cord provided to the power inlet on the back of the

9196.

────────────────────────────────────────────────────

3.2 9196 APPLY UNIT

Page 42

22

────────────────────────────────────────────────────

(3) Insert the plug into the outlet. The cord is automatically grounded.

(4) Attach the 9190 VOLTAGE APPLY PROBE.

Attach the 9190 VOLTAGE APPLY PROBE provided to the connecting

terminal on the front of the 9196.

(5) Turning the power on and off.

1. Turning the power on

Set the main power switch on the front of the unit to ON.

Verify that the main power monitor lamp is illuminated when the switch is set

to ON.

2. Turning the power off

Set the main power switch on the front of the unit to OFF.

(6) Applying voltage

1. Make the appropriate settings based on the type and voltage polarity of the

equipment to be measured.

Set the type based on the type of applied part of the equipment to be

measured.

B/BF: No protective resistance connected to the output point of the voltage

application probe.

CF: Protective resistance (10 kΩ) connected to the output point of the voltage

application probe in series.

Set the voltage polarity.

NORMAL: Polarity conforms with that of the voltage input from the power

inlet.

REVERSE: Polarity does not conform with that of the voltage input from the

power inlet.

2. Apply the voltage

If the 3155 LEAK CURRENT Hi TESTER and the equipment to be measured

are ready, touch the tip of the 9190 VOLTAGE APPLY PROBE to the contact

point. After verifying that there is no danger of electrical shock, press the

voltage application button to the 9190 VOLTAGE APPLY PROBE with your

finger. If the red output monitor lamp is illuminated while pressing the

voltage application button, the voltage is being output.

3. Cease application of voltage

Release your finger from the voltage application button.

────────────────────────────────────────────────────

3.2 9196 APPLY UNIT

Page 43

23

3

────────────────────────────────────────────────────

.2.4 9196 APPLY UNIT Specifications

General specifications

Output function Alternating current (AC V)

Output indication Red monitor lamp

Power indication Clear monitor lamp

Type toggle Toggle switch (B/BF, CF)

Polarity toggle Toggle switch (NORMAL /REVERSE)

Output configuration Voltage application probe (9190) connector receptacle

Additional functions Output control function (power cutoff)

Output only when the voltage application button to the 9190 is being pressed.

Dimensions 125W × 75H × 230D mm(4.92"W × 2.95"H × 9.06"D) (excluding projections)

Mass Approx. 2.5 kg(88.2 oz.) (excluding accessories)

Accessories Grounded three-core power cord

Instruction Manual

9190 VOLTAGE APPLY PROBE

Fuse 250 V T0.25 AL 20 mm × 5 mm dia.

Electric characteristics

Rated power voltage 100 to 240 VAC

(Voltage fluctuations of 10% from the rated supply voltage are taken into account.)

Rated power frequency45 to 400 Hz

Maximum rated power 25 VA

Insulation resistance 500 VDC, 100 MΩ min. between power supply and frame

Dielectric strength 2.3 kVAC sin (50/60 Hz), 1 minute between power supply and frame

Output breaking

current

Output voltage 110% voltage of the input supply voltage (VAC)

Accuracy ±(1.0% rdg.+1 V)

6 mAAC typical

B/BF range: In a load current of 5 mA or less

CF range: In a load current of 50 μA or less

Environmental conditions

Operating temperature

and humidity range

Storage temperature

and humidity range

5to40℃(40 to 104。F), 35 to 95% rh (no condensation)

-10 to 50℃(14 to 122。F), 35 to 95% rh (no condensation)

Accuracy assurance 23±5℃(73±41。F), 35 to 80% rh (no condensation)

Operating place Indoors, max. 2000 m(6562 feet) height

Standards applying EMC EN55011:1991

EN50082-1:1992

EN61000-3-2:1995

EN61000-3-3:1995

Safety EN61010-1:1993+A.2:1995 Pollution Degree 2,

Overvoltage Category (anticipated transient overvoltage 2500 V)

────────────────────────────────────────────────────

3.2 9196 APPLY UNIT

Page 44

24

Velcro tape

9399 CARRYING CASE

(for accessories)

9196 APPLY UNIT and accessories

such as the power cord

Instruction manual

3

────────────────────────────────────────────────────

.3 9388 CARRYING CASE (with Casters)

The 9388 CARRYING CASE (with casters) is made for storage and transport

of the 3155. In addition to the 3155, it accommodates accessories, including

the optional 9196 APPLY UNIT

Storage of the 3155

In the carrying case, the 3155 is immobilized with Velcro tape.

Accessories such as the power cord and optional 9196 APPLY UNIT are

housed in a covered case.

If necessary, cushioning material may be added to the case to provide extra

protection.

When storing the 9399 CARRYING CASE (for accessories), position it so that

the end with the metal fixtures is oriented toward the top cover of the case.

Manuals and other documents can be stored in the top cover.

────────────────────────────────────────────────────

3.3 9388 CARRYING CASE (with Casters)

Page 45

25

4

r

nt

────────────────────────────────────────────────────

Chapter

1

2

Preparations fo

Measureme

3

4

5

6

7

8

9

10

11

12

13

14

A

────────────────────────────────────────────────────

Page 46

26

k

t

s

4

────────────────────────────────────────────────────

.1 Installing the Measurement Network

(1) Be sure that both the 3155 and the equipment to be measured are powered off.

Be sure that the power cord, probe, leads etc. are not connected to the 3155.

(2) Attach one of the three optional measurement networks (9497, 9498 and

9499). Hold the measurement network by the two knobs, and insert into the

slotted connector on the 3155. After inserting firmly in place, attach the two

screws.

NOTE

・After turning on the power, a measurement network is checked.

1. In the event that a measurement network is not installed, or has not been

installed properly, the message ’Measurement Network not installed.’ will

appear on the liquid crystal display screen.

2. In the event that a fuse of a measurement network is not installed, or is

blown, the message ’Measurement Network Fuse blown.’ will appear on

the liquid crystal display screen.

This message may also appear when the signal is being input to the

leakage current measurement terminal T1. Check with nothing

connected to the leakage current measurement terminal T1.

For the fuse replacement, refer to Section, 10.2.2, "Replacement of the

Measurement Network Fuse."

・The type of measurement network currently installed on the 3155 can be

verified by opening the ’Measurement Network Filter Set-up Window,’

where one of the following messages is displayed:

9497 NETWORK B: Measurement network filter for ME

9498 NETWORK C: Measurement network filter for IEC 60990

9499 NETWORK D: Universal measurement network filter

Knob

Slo

────────────────────────────────────────────────────

4.1 Installing the Measurement Network

Measurement networ

Page 47

27

G

N

t

)

4

────────────────────────────────────────────────────

.2 Power Cord Connection

1

2

WARNIN

CAUTIO

Versions of the 3155 that operate on 120 V, 200 V and 240 V of the

supply voltage are available. The 3155-01 operates on 110 to 120 V, 200

V and 240 V with the voltage selector.

Before turning on the power, make sure that the voltage of the power

supply being used matches the supply voltage indicated on the rear

panel of the unit. The maximum rated power of the 3155 is 30 VA.

The protective ground terminal of the unit is connected to a ground line

via a three-core power cord that is supplied with the unit.

In order to prevent electric shock, always connect the unit to a properly

grounded power outlet using the power cord provided.

・To prevent an error, always remove the key and keep it after setting the

power supply voltage. (3155-01 only)

・When changing the supply voltage, always turn off the power and disconnect

the power cord before beginning. (3155-01 only)

・This unit is provided with a grounded three-core power cord that is suitable

for use with power supply conditions in the country or region in which the uni

is sold. When using this unit in any other country or region, be sure to

obtain a grounded three-core power cord which is suitable for use with the

power supply conditions in that area.

3

4

5

6

7

8

NOTE

The 3155 is a leakage current measuring instrument, and thererfore is only

able to operate to its full capability after it has been properly grounded.

Always use the power cord (grounded three-core power cord) that is supplied

with the unit to ground the unit.

(1) Be sure that the main power switch is turned

to OFF.

(2) Set the power voltage with the voltage selector.

(3155-01 only)

Insert the supplied voltage selector key into the

keyhole of the voltage selector, and select the

(3155

power voltage by setting it to the required

power voltage. (110 to 120/200/240 V)

Voltage selector key (2 supplied)

(3) Being sure that the power source is of the

correct voltage, connect the grounded three-core

power cord provided to the power inlet on the

back of the unit.

(4) Insert the plug into the outlet. The cord is

automatically grounded.

9

10

11

12

13

14

A

────────────────────────────────────────────────────

4.2 Power Cord Connection

Page 48

28

G

Main power switch

4

N

────────────────────────────────────────────────────

.3 Powering on and off the Unit

WARNIN

CAUTIO

NOTE

Before turning on the power, make sure that the voltage of the power

supply being used matches the supply voltage indicated on the rear

panel of the unit.

(3155: Specify when ordering, 3155-01: Set with the voltage selector)

If an attempt is made to use an improper supply voltage, there is danger

of damage to this unit and of life-threatening risk to the operator.

Before turning main power switch ON, turn the power OFF or unplug power

cord of the equipment to be measured.