Page 1

Hioki 3154 Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/analyzers/hioki/digital-m-ohm-hitesters/3154

Page 2

DIGITAL MΩ HiTESTER

INSTRUCTION MANUAL

3154

Page 3

Page 4

Contents

Introduction i

Inspection ii

Safety Notes iii

Notes on Use vii

Chapter 1 Outline 1

1.1 Product Introduction 1

1.2 Features

1

1.3 Controls and Functions

3

1.3.1 Displays 3

1.3.2 Front Panel

4

1.3.3 Rear Panel

5

Chapter 2 Preparation for Testing 7

2.1 Connecting Power Cord 8

2.2 Powering On and Off the Unit

9

2.3 Connecting Cord and Probes

(9257, 9289, 9294)

10

2.4 Using Handle

11

2.5 Connecting to Equipment to be tested

12

Chapter 3Setting Basic Testing Conditions 13

3.1 Setting Test voltage 14

3.2 Setting and Verifying Comparator

15

3.2.1 Setting Lower Limit Value 15

3.2.2 Setting and Verifying Test mode

17

3.3 Setting and Verifying Resistance Range 18

3.4 Setting and Verifying Timer

19

3.4.1 Setting and Verifying Test Duration 19

3.4.2 Setting and Verifying Delay Time

21

3.4.3 Determining Delay Time

23

Page 5

3.5 Setting Sampling Rate 25

3.6 Example Test Condition Setting

26

Chapter 4 Testing 29

4.1 Test Flow 30

4.2 Start Testing

31

4.3 During Testing (TEST status)

32

4.4 Measurement Value Display

33

4.5 Completing Testing

34

4.6 Automatic Discharge

35

4.7 Testing with 9299 SWITCHED PROBE

36

4.7.1 Connecting 9299 SWITCHED PROBE 37

4.7.2 Setting 9299 SWITCHED PROBE

38

Chapter 5 Other Functions 39

5.1 Setting and Verifying Beep Sound 40

5.1.1 Setting Judgment Beep Sound 40

5.1.2 Setting Beep Sound During Key Press

41

5.2 Saving and Loading Test Conditions 42

5.2.1 Saving Test Conditions 42

5.2.2 Loading Test Conditions

44

5.3 Key Lock Function 45

5.4 System Reset

46

Chapter 6 External Interface 47

6.1 Controlling 3154 with External I/O 47

6.1.1 Terminal Connector Board/Signal Wires 48

6.1.2 Electric Specifications

50

6.1.3 Connecting External I/O Terminal

52

6.1.4 External I/O Terminal Circuit

54

6.1.5 Settings to be selected with VOLT 0 to 2

signals

55

6.1.6 Setting TEST Signal OFF Timing

57

6.1.7 Timing Chart

59

6.1.8 Output Signal Connection Example

61

6.1.9 Input Signal Connection Example

62

Page 6

6.2 Analog Outputting 63

6.2.1 Connecting the 9094 OUTPUT CORD 63

6.2.2 Analog Output

64

6.2.3 Setting Analog Output

65

6.3 Outputting to Printer 66

6.3.1 Connecting Printer 70

6.3.2 Printing Example

71

Chapter 7 RS-232C Interface 73

7.1 Controlling from Personal Computer 74

7.1.1 Preparing for Data Transfer 75

7.1.2 Communication

77

7.1.3 Command Format

78

7.1.4 Numeric Format Chart

82

7.1.5 Command Reference

83

7.2 Sending Measurement Data to PC 97

Chapter 8 Specifications 101

8.1 General Specifications 101

8.2 Measurement Part Specifications

103

8.3 Dimensions

109

8.4 Options and specifications

110

Chapter 9 Maintenance and Service 113

9.1 Maintenance and Inspection 113

9.2 Trouble shooting

114

Page 7

Page 8

i

_____________________________________________________________________

Introduction

______________________________________________________________

Introduction

Thank you for purchasing the HIOKI "3154 DIGITAL MΩ

HiTESTER." To obtain maximum performance from the

product, please read this manual first, and keep it handy for

future reference.

Changes to Specifications

Changes are made to software version 1.10.

Software version appears following the model name (3154)

after start up.

・Measurement range is expanded up to 4000 MΩ with

test voltage at 500 V.

・Analog output voltage is changed from 4 V to 2 V when

2000 MΩ is displayed with test voltage at 500 V.

・Outputs 4 V output with analog output at each resistance

range maximum value.

・Wider key entry selections to set lower limit values.

・Saved test conditions can be loaded using external I/O

VOLT 0 to 2 signals.

・External I/O TEST signal OFF timing setting display

appears as "tEStSIGnAL".

・The following four RS-232C commands are added;

:VOLTage:SIGNaL

:VOLTage:SIGNaL?

:AOUT:RANGe

:AOUT:RANGe?

Page 9

ii

_____________________________________________________________________

Inspection

______________________________________________________________

NOTE

TEST PROBES are not included. Please purchase separately

according to your needs.

Inspection

When you receive the product, inspect it carefully to ensure

that no damage occurred during shipping. In particular,

check the accessories, panel switches, and connectors. If

damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Accessories

Verify that following standard accessories are complete.

Instruction Manual

1

Grounded three-core power cord

1

Shipment of the unit

Use the original packing materials when reshipping the

product, if possible.

Warranty

HIOKI cannot be responsible for losses caused either

directly or indirectly by the use of the 3154 with other

equipment, or if ownership is transferred to a third party.

Page 10

iii

_____________________________________________________________________

Safety Notes

______________________________________________________________

WARNING

This product is designed to conform to IEC 61010

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling during

use could result in injury or death, as well as damage

to the product. Be certain that you understand the

instructions and precautions in the manual before use.

We disclaim any responsibility for accidents or injuries

not resulting directly from product defects.

Safety Symbols

The symbol printed on the product indicates that the

user should refer to a corresponding topic in the

manual (marked with the

symbol) before using the

relevant function.

In the manual, the symbol indicates particularly

important information that the user should read before

using the product.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates that dangerous voltage may be present at

this terminal.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

SafetyNotes

This manual contains information and warnings essential

for safe operation of the product and for maintaining it in

safe operating condition. Before using the product, be sure

to carefully read the following safety notes.

Page 11

iv

_____________________________________________________________________

Safety Notes

______________________________________________________________

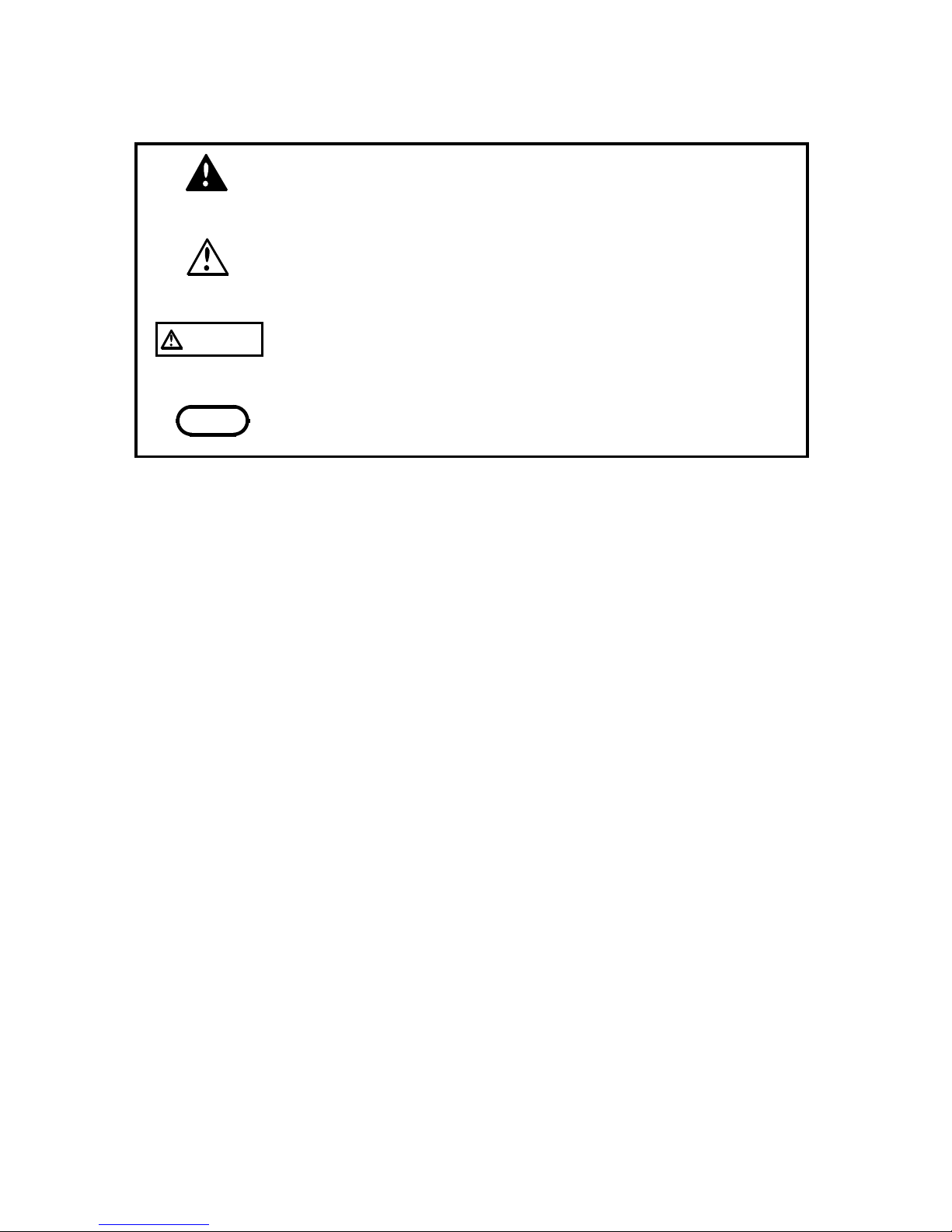

DANGER

Indicates that incorrect operation presents an extreme

hazard that could result in serious injury or death to

the user.

W

ARNING

Indicates that incorrect operation presents a

significant hazard that could result in serious injury or

death to the user.

CAUTION

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

product.

NOTE

Advisory items related to performance or correct

operation of the product.

The following symbols in this manual indicate the relative

importance of cautions and warnings.

Page 12

v

_____________________________________________________________________

Safety Notes

______________________________________________________________

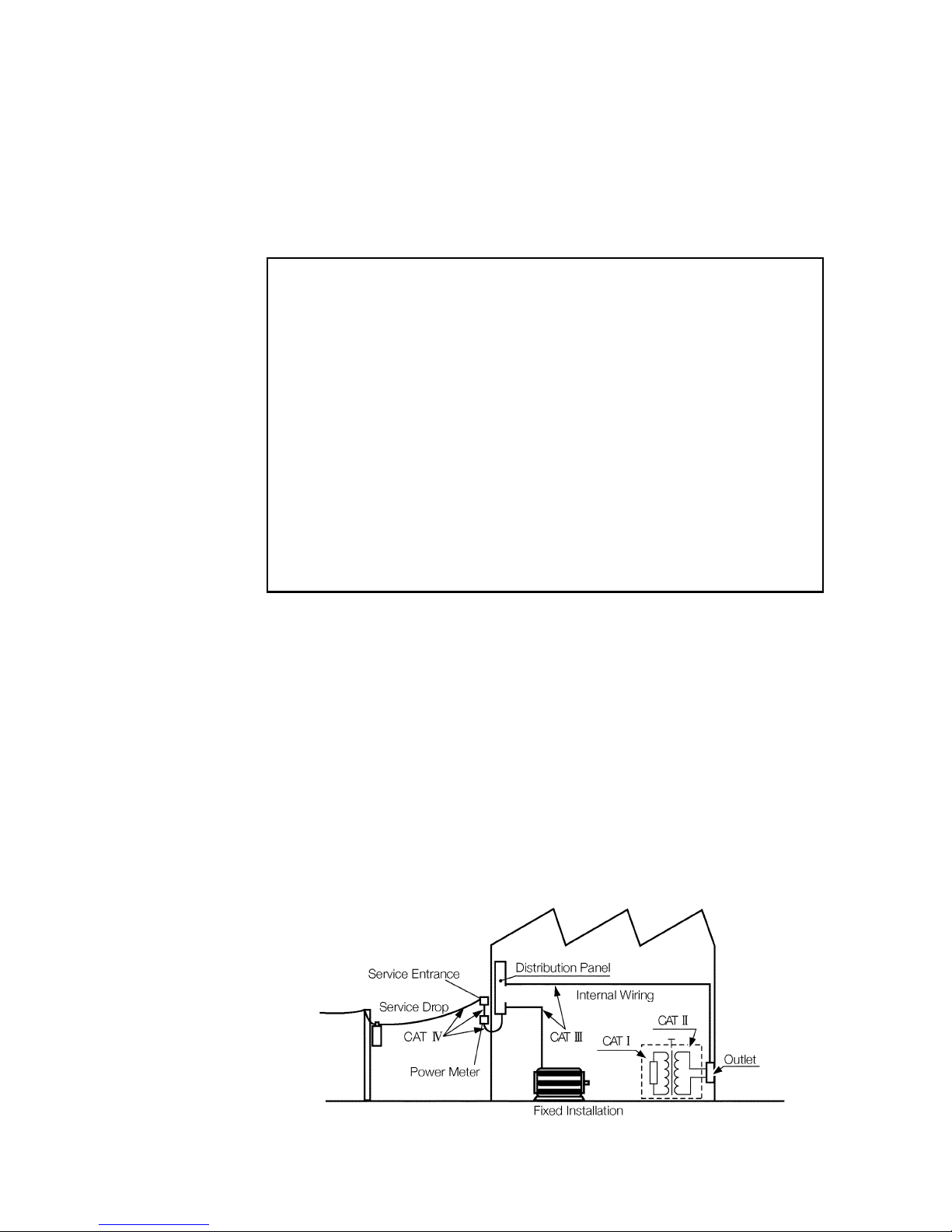

CAT I

Secondary electrical circuits connected to an AC

electrical outlet through a transformer or similar

device.

CAT II

Primary electrical circuits in equipment connected

to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT III

Primary electrical circuits of heavy equipment

(fixed installations) connected directly to the

distribution panel, and feeders from the distribution

panel to outlets.

CAT IV

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Measurement categories (Overvoltage categories)

This product complies with CAT I safety requirements.

To ensure safe operation of measurement product, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT I to CAT IV, and called

measurement categories. These are defined as follows.

Higher-numbered categories correspond to electrical

environments with greater momentary energy. So a

measurement device designed for CAT III environments can

endure greater momentary energy than a device designed for

CAT II. Using a measurement product in an environment

designated with a higher-numbered category than that for

which the product is rated could result in a severe accident,

and must be carefully avoided.

Never use a CAT I measuring product in CAT II, III, or IV

environments. The measurement categories comply with the

Overvoltage Categories of the IEC60664 Standards.

Page 13

vi

_____________________________________________________________________

Safety Notes

______________________________________________________________

f.s.

(maximum display value or scale length)

The maximum displayable value or the full length of the

scale.

This is usually the maximum value of the currently

selected range.

rdg.

(reading or displayed value)

The value currently being measured and indicated on the

measuring product.

dgt.

(resolution)

The smallest displayable unit on a digital measuring

product, i.e., the input value that causes the digital

display to show a "1".

Accuracy

We define measurement tolerances in terms of f.s. (full

scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

Page 14

vii

_____________________________________________________________________

Notes on Use

______________________________________________________________

DANGE

R

To avoid electric shock, do not remove the product's

case. The internal components of the product carry

high voltages and may become very hot during

operation.

WARNING

Before using the product, make sure that the insulation

on the test probes is undamaged and that no bare

conductors are improperly exposed. Using the product

under such conditions could result in electrocution.

Replace the test probes specified by Hioki .

Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged or cause an explosion.

Do not use the product where it may be exposed to

corrosive or combustible gases. The product may be

damaged or cause an explosion.

Notes on Use

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

Page 15

viii

_____________________________________________________________________

Notes on Use

______________________________________________________________

CAUTION

This product is not designed to be entirely water- or dustproof. To avoid damage, do not use it in a wet or dusty

environment.

This product should be installed and operated indoors only,

between 0 and 40

80% RH or less. Do not use the unit

in direct sunlight, dusty conditions, or in the presence of

corrosive gases.

Do not store or use the product where it could be exposed

to direct sunlight, high temperature or humidity, or

condensation. Under such conditions, the product may be

damaged and insulation may deteriorate so that it no longer

meets specifications.

Do not use the product near a device that generates a

strong electromagnetic field or electrostatic charge, as

these may cause erroneous measurements.

To avoid damage to the product, protect it from vibration or

shock during transport and handling, and be especially

careful to avoid dropping.

To avoid electrocution, turn off the power to all devices

before pluggingor unplugging any of the interface

connectors. Be sure to connect properly to avoid shortcircuit.

Because external I/O INT.GND terminal, RS-232C

connector frame, ground terminal and analog output GND

terminal are grounded, all equipment connected with GND

terminals are grounded. Use caution when handling. If the

equipment has an electric potential against the earth, a

short-circuit accident may occur.

Page 16

1

_____________________________________________________________________

Outline

______________________________________________________________

Chapter 1

Outline

1.1 Product Introduction

1.2 Features

HIOKI 3154 DIGITAL MΩ HiTESTER performs insulation

resistance testing on components and equipment using

direct current voltage. Comparator and timer functions

facilitate easy and accurate insulation resistance testing.

Equipped with six selectable test voltages and external I/O,

RS-232C interface and analog output terminal, HIOKI 3154

DIGITAL MΩ HiTESTER proves its efficiency and

versatility from laboratory to production and inspection line

testing.

(1) Easy Testing in accordance with safety standards

Select from six test voltages from 25 V to 1000 V.

Pass/Fail judgment function comparing measured value

by setting lower limit value and timer function support

wide variety of insulation resistance testing according to

safety standards.

(2) Easy-to-read display

High definition LED display

Page 17

2

_____________________________________________________________________

Outline

______________________________________________________________

(3) Saves Setting Conditions

Saves up to ten testing conditions including lower limit

value to quickly change conditions for various

standards.

Also restarts with values saved at power shutdown when

power is turned on.

(4) External Interface

External I/O outputs signals according to 3154 status

and inputs start/stop signals. Additional test conditions

can be selected.

Records extended insulation resistance fluctuations

using analog output.

(5) Equipped with RS-232C Interface

Use personal computer for automated testing and

recording test results. Optional 9442 PRINTER

provides measurement data printing.

(6) Optional Push Switch Probe

9299 SWITCHED PROBE enables efficient manual

testing.

(7) Automatic Discharge Function

Automatically discharges any charge buildup in

measured object after testing.

TEST lamp blinking during discharge indicates

discharge status.

Protects equipment from possible damage during

successive insulation resistance testing.

Page 18

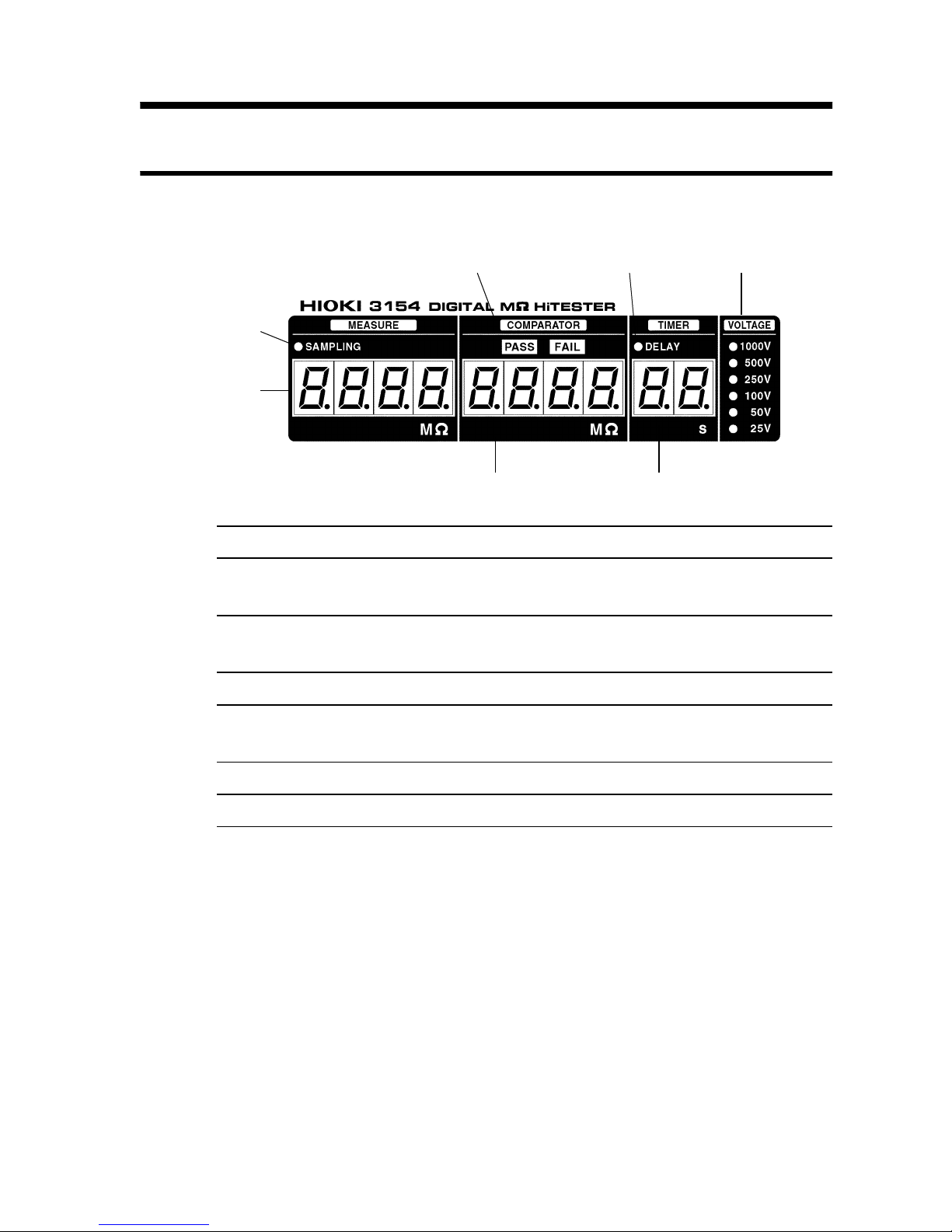

3

_____________________________________________________________________

Outline

______________________________________________________________

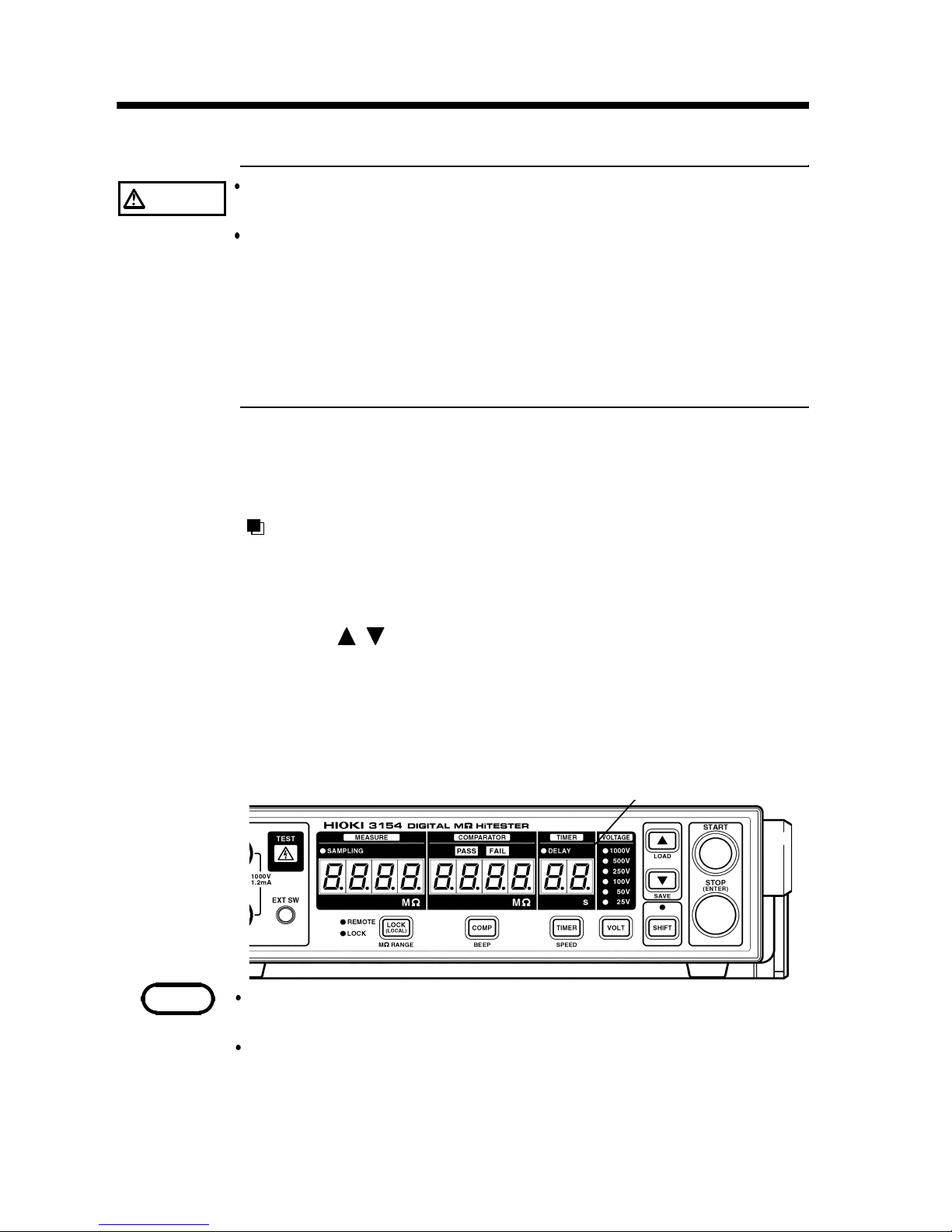

1

2

4

3

6

5 7

1. Sampling lamp Blinks during resistance measurement.

2. Measurement value

display

Displays measured resistance value.

3. Judgment result

display lamp

Displays comparator PASS/FAIL results.

4. Lower limit display Displays comparator lower limit value.

5. DELAY lamp (Delay

time setting lamp)

On when delay time is set.

6. Timer display Displays test duration or delay time.

7. Test voltage display Displays test voltage.

1.3 Controls and Functions

1.3.1 Displays

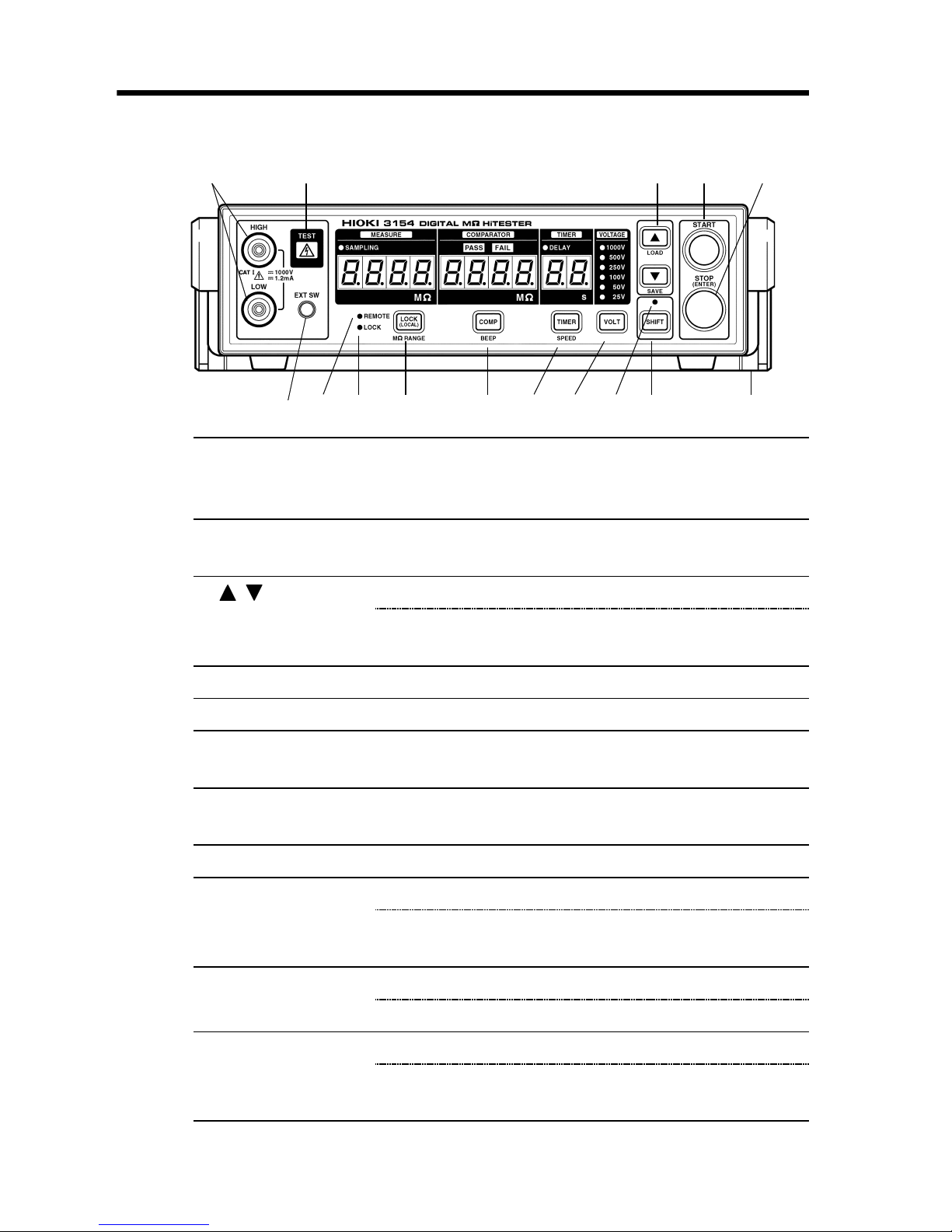

Page 19

4

_____________________________________________________________________

Outline

______________________________________________________________

1

6 7 8 9 10 11

2 543

13 1412 15

1. Measurement

terminals

Connect test probes. High voltage occurs

between terminals continuously electrically

connected to rear panel measurement terminals.

2. TEST lamp Turns on during testing. Blinks during

discharging buildup in tested object.

3. / key Press to change settings.

LOAD/SAVE

key

Press SHIFT key - LOAD/SAVE key to save and

load setting conditions.

4. START key Press to start testing.

5. STOP key Press to terminate testing or to confirm settings.

6. EXT.SW

terminal

Switch signal terminal for optional 9299

SWITCHED PROBE.

7. REMOTE lamp Turns on when communicating with personal

computer via RS-232C.

8. LOCK lamp Turns on when key lock is engaged.

9. LOCK key Press to engage or disengage key lock.

MΩ RANGE

key

Press SHIFT key - MΩ RANGE key to change to

and from auto range/manual range.

10. COMP key Press to set comparator.

BEEP key Press SHIFT key - BEEP key to set beep sound.

11. TIMER key Press to set test duration and delay time.

SPEED key Press SHIFT key - SPEED key to set

measurement speed.

1.3.2 Front Panel

Page 20

5

_____________________________________________________________________

Outline

______________________________________________________________

12. VOLT key PRESS to set test voltage.

13. SHIFT lamp Turns on when SHIFT key is pressed.

14. SHIFT key Press to engage shift.

When SHIFT key is pressed, shift is engaged and

SHIFT lamp turns on. Press again to disengage

shift.

When shift is engaged, functions displayed in

blue below keys become valid.

15. Handle/Stand Adjust handle to use as a stand.

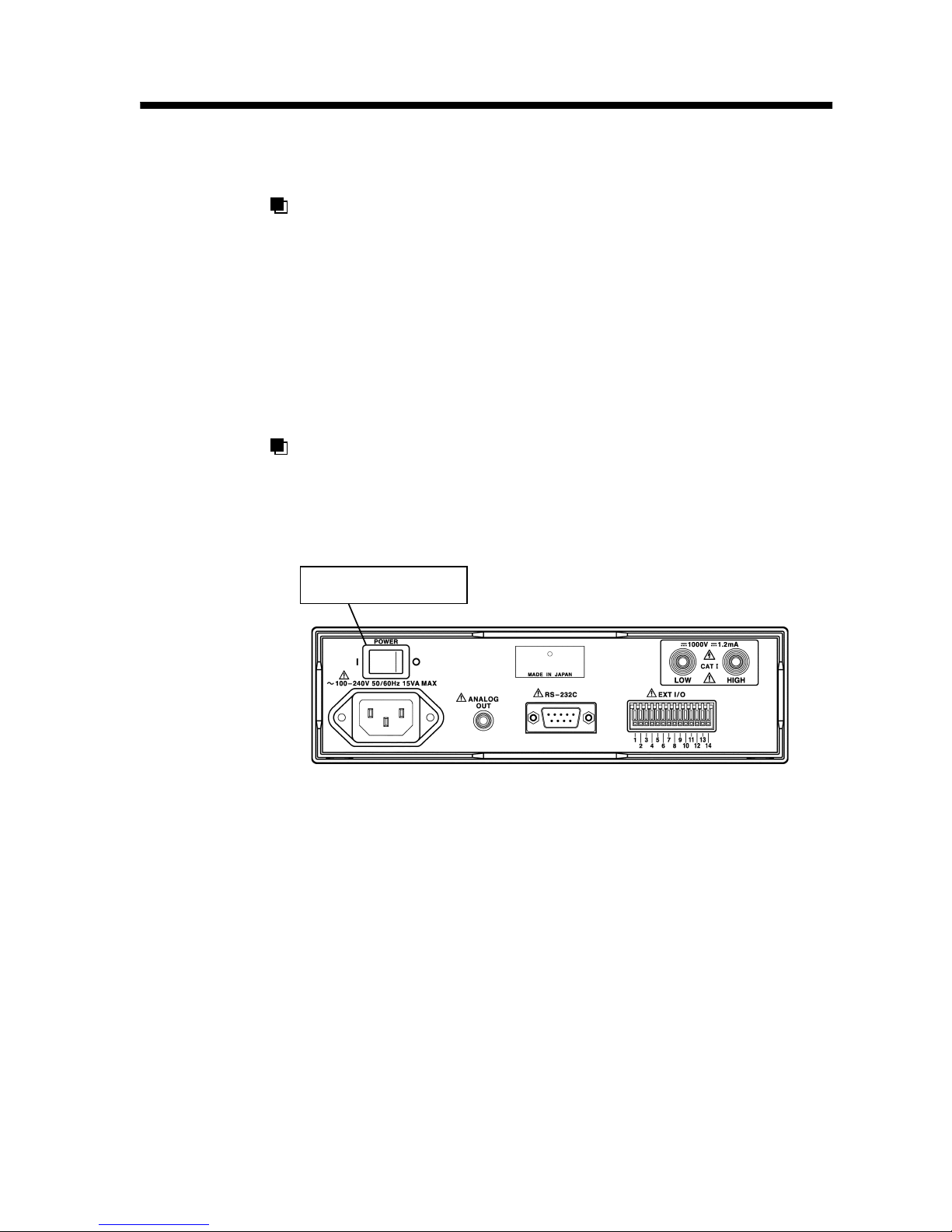

21 3 4 5 6

1. Power supply

connector

Terminal to connect power cord. (Internal fuse

type)

2. POWER switch Turns power ON/OFF.

3. Analog output

terminal

Converts measured resistance value and

outputs voltage.

Use to connect 9094 OUTPUT CORD.

4. RS-232C terminal Use to connect RS-232C for remote operation

or optional 9442 PRINTER.

5. External I/O

terminals

Outputs 3154 status and inputs start/stop and

test voltage switching signals.

6. Rear

measurement

terminals

Connect test probes. High voltage occurs

between terminals. Continuously electrically

connected to front panel measurement

terminals.

1.3.3 Rear Panel

Page 21

6

_____________________________________________________________________

Outline

______________________________________________________________

Page 22

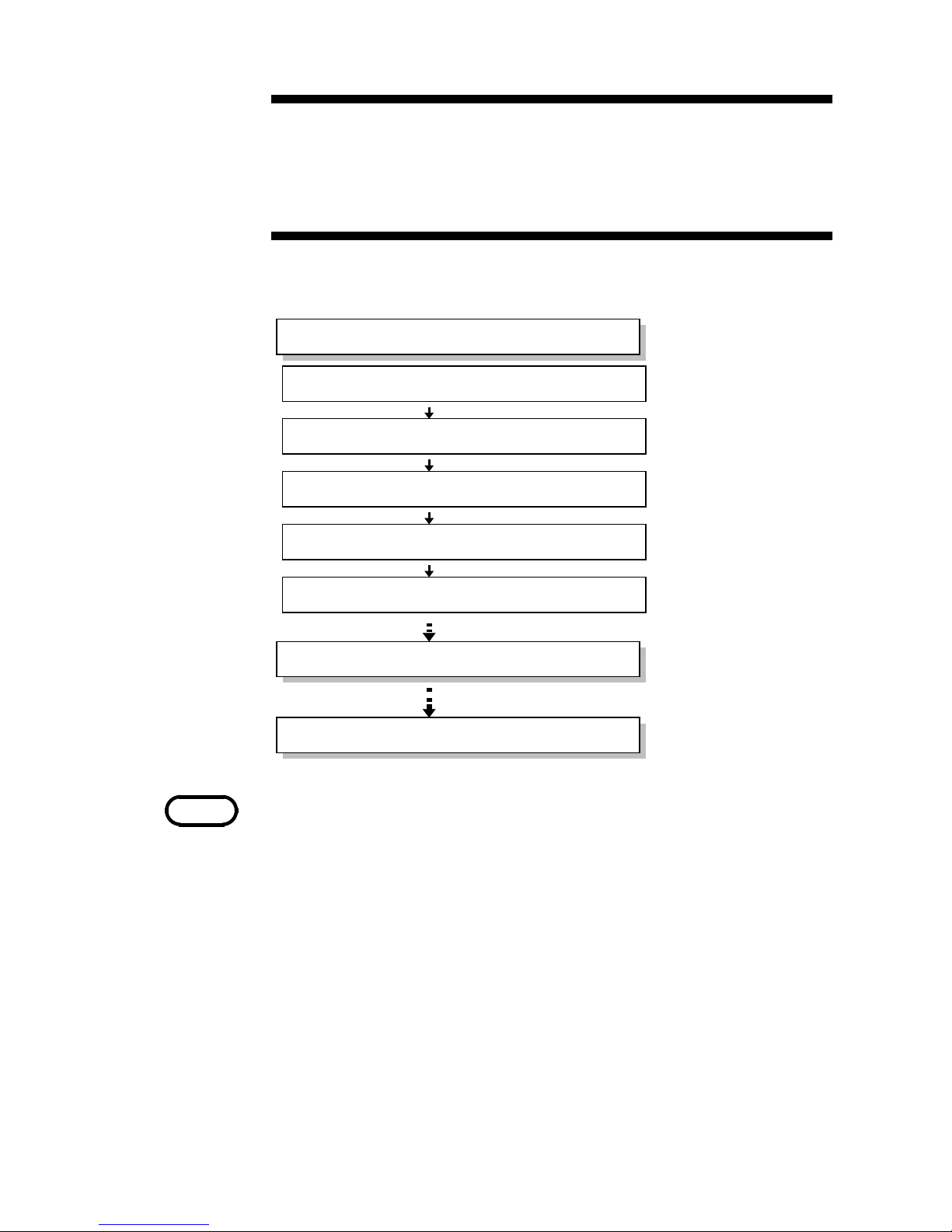

7

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

Connecting Cord and Probes

Using Handle

Connecting to Equipment to be tested

Connecting Power Cord

Powering On and Off the Unit

See 2.1.

Preparation for Testing

Testing

Setting Basic Testing Conditions

See 2.2.

See 2.3.

See 2.4.

See 2.5.

See Chapter 3.

See Chapter 4.

NOTE

See 4.7 Testing with SWITCHED PROBE to conduct

measurement using 9299 SWITCHED PROBE.

Chapter 2

Preparation for Testing

Before testing preparation, read each note carefully.

Page 23

8

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

WARNING

The unit is constructed so as to be connected to a

ground line via a three-core power cord that is supplied

with the unit.

To avoid electric shock and ensure safe operation,

connect the power cable to a grounded (3-contact)

outlet.

Before turning the product on, make sure the source

voltage matches that indicated on the product's power

connector. Connection to an improper supply voltage

may damage the product and present an electrical

hazard.

To avoid damaging the pow er cord, grasp the plug, not

the cord, when unplugging the cord from the power

outlet.

(example)

Insert the plug into

the outlet

2.1 Connecting Power Cord

Connecting Power Cord

(1) Verify that the 3154 POWER switch is OFF ( O ).

(2) Connect power cord supplied with the 3154 to power

supply connector located in the back.

(3) Connect power cord plug to grounded dual polarity

power outlet.

Page 24

9

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

POWER switch

2.2 Powering On and Off the Unit

Powering On

(1) Turn POWER switch ON ( I ) on the rear panel.

(2) All displays light up displaying product name and

software version.

(3) Returns to normal READY status for use with settings

saved prior to turning power off.

For stable measurement readings, allow thirty minutes

or more to warm up after turning power on.

Powering Off

Turn POWER switch OFF (O) on the rear panel. Settings

are saved when turning power off.

Page 25

10

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

WARNING

To avoid the risk of electric shock, be sure to press the

3154 STOP key and confirm that the TEST lamp is off

before connecting/disconnecting probes. Do not keep

power on equipment to be tested when connecting

probes.

Before using the product, make sure that the insulation

on the test probes is undamaged and that no bare

conductors are improperly exposed. Using the product

under such conditions could result in electrocution.

Replace the test specified by Hioki .

CAUTION

For safety reasons, only use the optional CONNECTION

CORD, 9257 and TEST PROBEs, 9289 or 9294, provided

with the unit for measurement.

To avoid damaging the probes, do not bend or pull the probes.

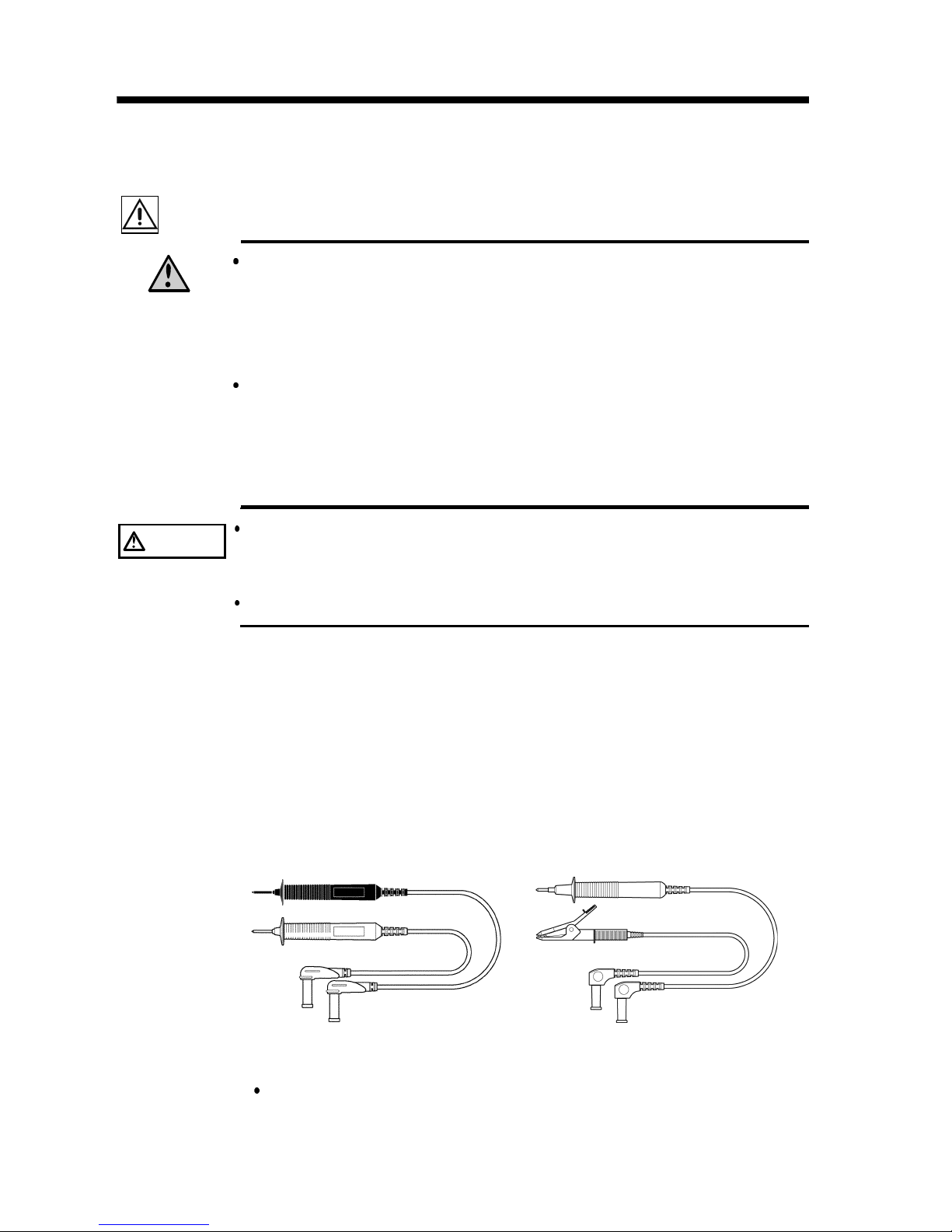

9289 TEST PROBE 9294 TEST PROBE

2.3 Connecting Cord and Probes

(9257, 9289, 9294)

Although measurement terminals are both located in the front

and rear panels, both cannot be used at the same time. Leave

one side disconnected.

The 9257, 9289 and 9294 come with protective caps. Take the

caps off before connecting to 3154.

Connect black probe to LOW terminal and red probe to HIGH

terminal. Tightly insert probes all the way into the terminals.

See 8.4 Options and specifications, about the 9257

CONNECTION CORD.

Page 26

11

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

CAUTION

When using the handle as a stand for the device, do not

press down too hard on the device as this can damage the

handle.

When interface cable, etc. is connected to the rear panel,

keep the unit flat to avoid damaging the cable.

When setting the unit to show display upward, tilt it

carefully to avoid damaging power cord by excessive

stress.

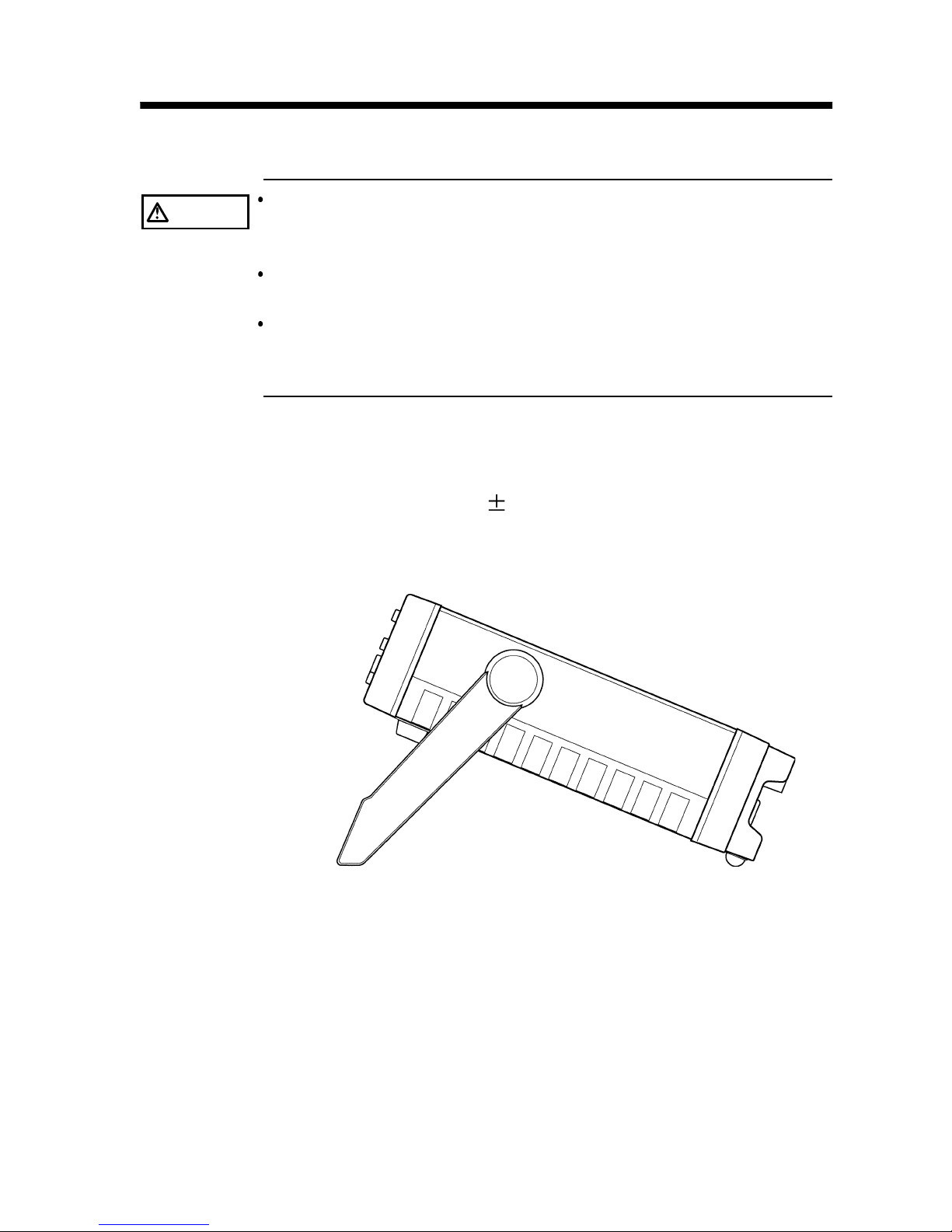

2.4 Using Handle

Handle can be used as stand. Pull out the side, turn and

press in the handle.

Handle turns each 22.5

.

When setting flat, turn the handle over the unit.

Page 27

12

_____________________________________________________________________

Preparation for Testing

______________________________________________________________

WARNING

Observe the follow ing precautions to avoid electric

shock.

To avoid the risk of electric shock, turn power off on

equipment to be tested.

Before and after testing, do not touch equipment to be

tested and probe tip when TEST lamp is on or blinking.

Afte r testing is complete, confirm that the 3154 TEST

lamp is off before disconnecting probe from equipment

to be tested.

CAUTION

When connecting probe to equipment to be tested under

TEST status, verify the voltage occurred on the display

before connecting. Improper voltage may damage

equipment to be tested.

NOTE

When 3154 is in READY status, approximately a voltage

greater than +10 V volts in equipment to be tested initiates

TEST lamp, and blinks after connecting probe.

When connecting the LOW side of the measurement terminal

with the earth, there is a possibility that a measurement value

smaller than the actual value may be displayed. As such,

when conduction an insulation test with the earth, be sure to

ground the measurement object, and connect the HIGH side of

the terminal with the earth.

2.5 Connecting to Equipment to be tested

Connect probe to equipment to be tested.

Page 28

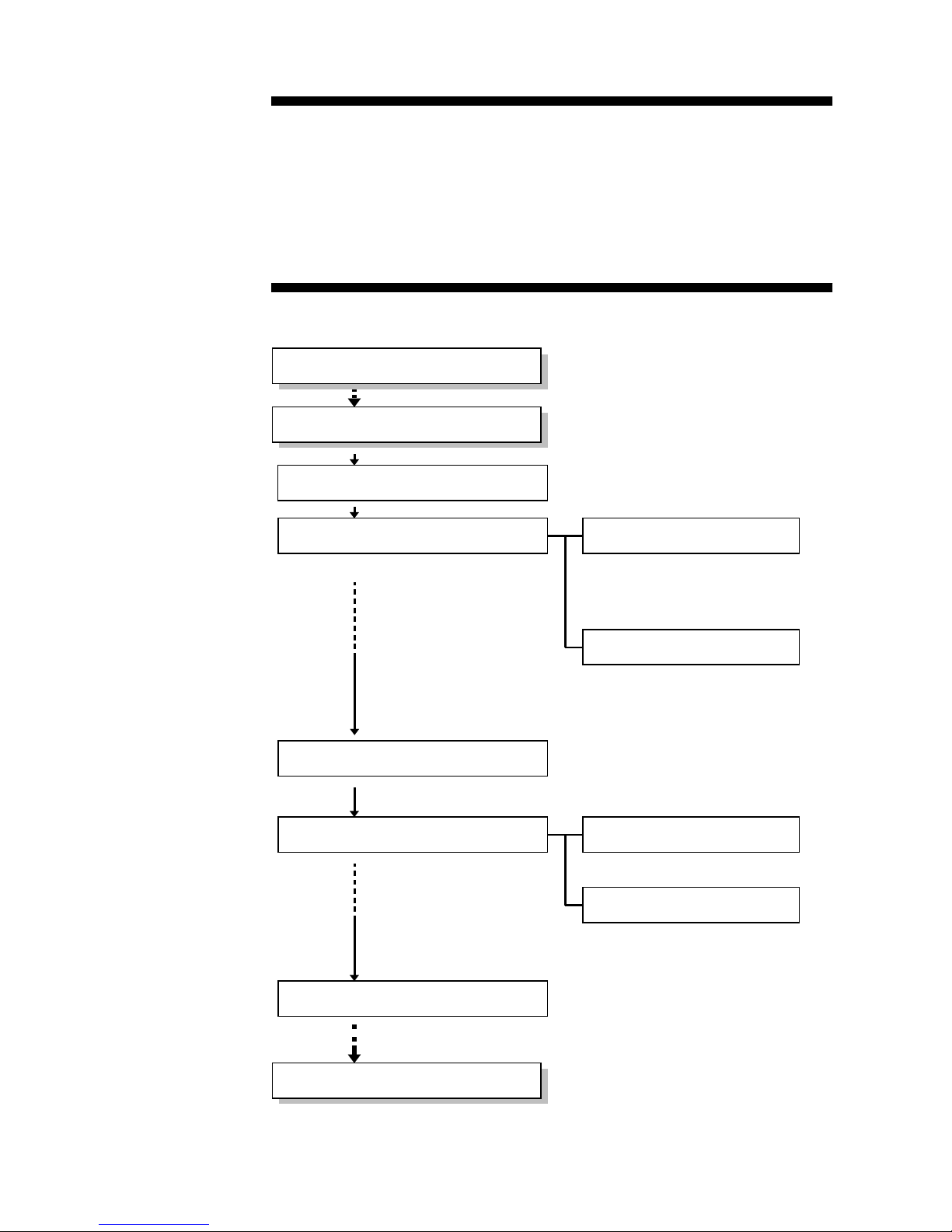

13

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Setting comparator

Setting timer

Setting lower limit value

Setting test mode

Setting test duration

Setting delay time

・See Chapter 2

Pre

p

aration for Testing.

・

When using PASS/FAIL

judgment, set lower limit

value. See 3.2.1.

・

When using PASS/FAIL

judgment, set test mode.

See 3.2.2.

・

Set test duration. See 3.4.1

・

Set delaytime. See 3.4.2.

・See Cha

p

ter 4 Testing.

Setting test voltage

・

Select from 25 V to 1000 V.

See 3.1.

Setting resistance range

・

Set either manual range

(4 types) or auto range.

See 3.3.

Setting sampling rate

・

Set FAST or SLOW.

See 3.5.

Preparation for testing

Setting testing conditions

Start testing

Chapter 3

Setting Basic Testing

Conditions

The below shows setting items and procedures.

Page 29

14

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

CAUTION

Setting at improper voltage may damage equipment to be

tested.

Test voltage can be set by external I/O. In this case, the

3154 test voltage display lamp stays on displaying previous

voltage until testing starts after setting voltage from external

I/O. Do not start the test simply by confirming the voltage

display lamp, as unexpected voltage may be generated.

Start the test only after you have confirmed the test voltage

setting of the external I/O.

Test voltage indicator lamp

NOTE

During READY status, TEST status, test voltage can be verified

by blinking test voltage indicator lamp.

When selecting test voltage with external I/O, test voltage

cannot be set by key press. Set all external I/O VOLT0 to

VOLT2 to LOW or HIGH (not necessary to connect) use key

press for setting.

3.1 Setting Test voltage

Set and select test voltage from 25 V to 1000 V. To set

comparator at each voltage, selecting another voltage

automatically changes lower limit value.

Setting test voltage

(1) When READY status (with TEST lamp off or blinking),

press VOLT key to initiate test voltage display lamp to

blink. (Setting)

(2) Press

/ key to select test voltage to start and test

voltage indicator lamp starts blinking.

(3) Press STOP key or VOLT key to complete setting with

test voltage indicator lamp no longer blinking but on

and returns to READY status.

Page 30

15

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

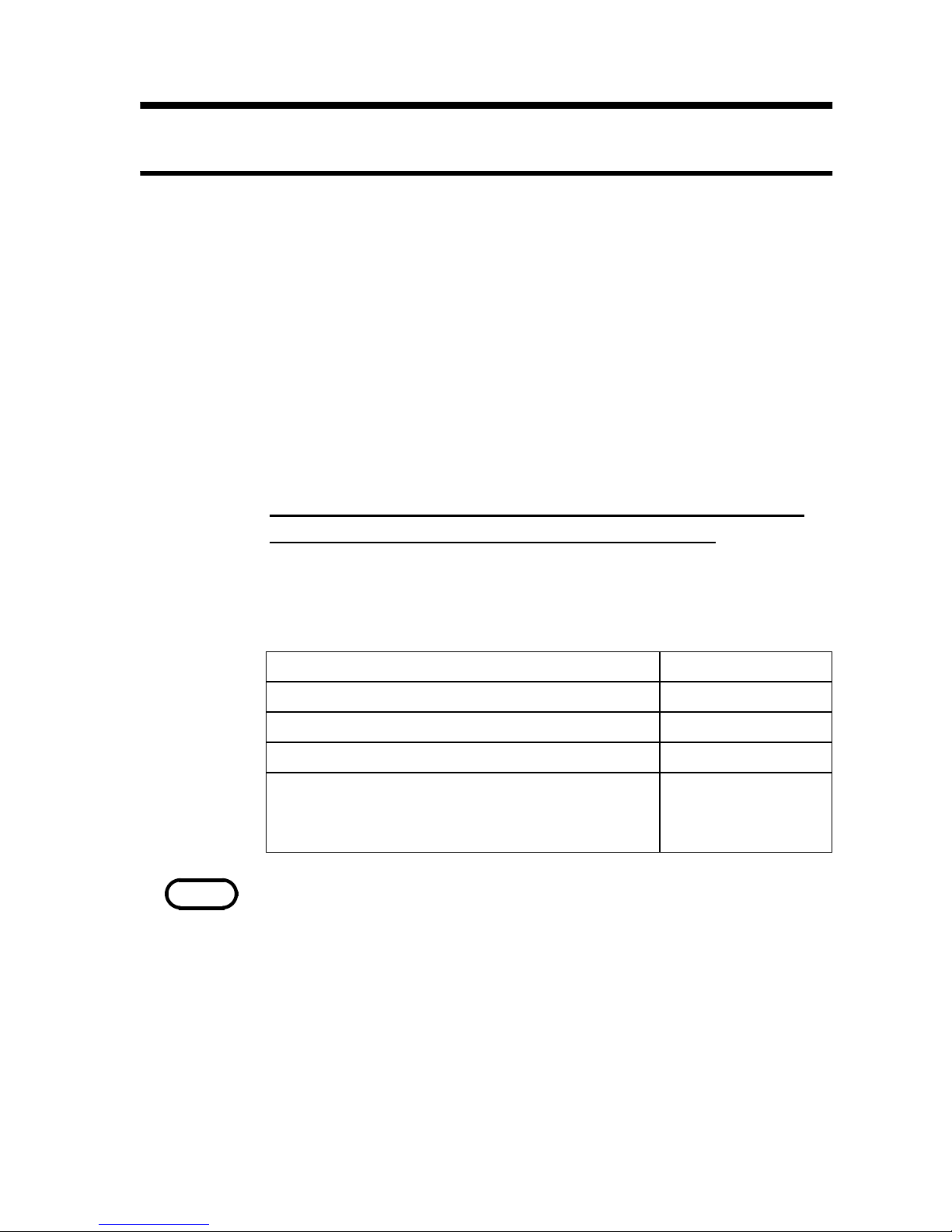

Lower limit value(MΩ) Resistance range

0.1/0.2/0.3/0.4/0.5/0.6/0.7/0.8/0.9/1/2 2MΩ

2/3/4/5/6/7/8/9/10/20 20 MΩ

20/30/40/50/60/70/80/90/100/200 200 MΩ

200/300/400/500/600/700/800/900/1000/2000

/3000/4000 (Limited to test voltage 500 V,

1000 V for 3000/4000)

2000 MΩ

(4000 MΩ range for

500 V, 1000 V)

NOTE

RS-232C Interface provides an option to set lower limit value at

any value within the measurement range in addition to the

displayed selection. Once designated lower limit value is

switched to another by key press, use RS-232C Interface to reset

at designated lower limit value.

3.2 Setting and Verifying Comparator

3.2.1 Setting Lower Limit Value

When comparator is set, set lower limit value and test

mode. Execute PASS/FAIL judgment by comparing value

set as lower limit value and measurement value.

Lower limit value determines resistance range for setting

(manual range). See the chart below for possible

combination of lower limit value and resistance range for

setting.

When auto range is selected for resistance range, lower

limit value is not limited at any value.

Improper combination of lower limit value and resistance

range results in incorrect PASS/FAIL judgment.

See 3.3 Setting and Verifying Resistance Range to set

resistance range.

Lower limit value chart

Page 31

16

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Setting Lower Limit Value

(1) During READY status, press COMP key and lower

limit value indicator starts blinking.

(2) Press

/ key to select and display lower limit. (Unit

is[MΩ

]

)

"----" appears when comparator is not set.

(3) Press either STOP key or COMP key to confirm lower

limit value.

Display automatically returns to test mode setting

display. Continue with test mode setting. See 3.2.2.

Not Setting Lower Limit Value

(Not Setting Comparator)

(1) During READY status, press COMP key and

comparator lower limit value indicator starts blinking.

(2) Press both

key and key at the same time to

display "----" blinking or press either

/ key several

times to display "----" blinking.

(3) Press STOP key or COMP key.

(4) Returns not to test mode setting status but to READY

status. Lower limit value indicator displays "----".

Page 32

17

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

NOTE

Set test mode adjusted to test voltage.

When lower limit value is set at "----"(not using comparator),

test mode setting is not available.

Ready status does not display test mode.

3.2.2 Setting and Verifying Test mode

Setting Test mode

(1) After selecting lower limit value (other than "----") at

lower limit value setting status, test mode setting status

automatically appears by pressing either STOP key or

COMP key.

Which ever display previously set, FAIL StOP or

Continue starts blinking.

(2) Press

/ key to switch FAIL StOP/ContinuE.

FAIL STOP mode: FAIL judgment stops testing.

CONTINUE mode: FAIL judgment does not interfere

with testing.

(Testing stops by STOP key press

or by time set by timer.)

(3) Press STOP key or COMP key to confirm selected

mode.

After determining selected mode, automatically returns

to READY status and displays selected lower resistance

value.

Confirming Test mode

When lower limit value (excluding "----") is set, follow the

instructions below to confirm test mode.

(1) Press COMP key twice when READY status. Confirm

that designated test mode display starts blinking.

(2) After confirming, press COMP key to return to READY

status.

Page 33

18

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

A

UtO

3.3 Setting and Verifying Resistance

Range

Resistance range comes with four types of manual range, 2

MΩ,20MΩ, 200 MΩ, 2000 MΩ(4000 MΩ at 500/1000

V) and auto range.

Auto range may require some time before measurement

value is displayed because range has to shift immediately

after testing starts. Set resistance range to manual range

according to measuring object to eliminate time to

display.

Setting Resistance Range

(1) Press SHIFT key, then LOCK key when READY status.

Display as shown below appears and lower limit value

indicator blinks and displays one of the following

"AUtO", "2", "20", "200", "2000". ("4000" at 500/1000

V)

(2) Each

/ key press switches blinking display.

(3) When desired resistance range is displayed, press STOP

key or LOCK key to confirm. After determining, returns

to READY status.

When manual range is selected and measurement value is

over 2000 count, "O.F." (Over flow) is displayed.

When measurement value is less than 190 count,

"U.F." (Under flow) is displayed.

Confirming Resistance Range

(1) Press SHIFT key, then LOCK key when READY status

to display selected resistance range blinking.

(2) After confirming, press STOP key or LOCK key to

return to READY status.

Page 34

19

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

3.4 Setting and Verifying Timer

3.4.1 Setting and Verifying Test Duration

Test duration is the time to apply voltage, measure

resistance and perform PASS/FAIL judgment.

Same Test duration setting is applicable at any test voltage.

When setting at auto range, if the test time is set at a short

time period, there is a possibility that test may finish

without displaying a measurement value because of a range

shift. To prevent this from occurring, please set a test time

longer than 2 seconds (for 25 V or 50 V, 1.5 seconds)

when setting at auto range.

Setting Test duration

(1) During READY status, press TIMER key and timer

indicator starts blinking.

(2) Press

/ key to display desired test duration at timer

indicator.

Hold

/ key down to speed up adjustment of timer

control. (units in [seconds], setting range: 0.5 s to 99 s)

"--" is displayed when test duration is not set.

(3) Press STOP key or TIMER key to confirm test duration.

Indicator automatically switches and displays delay time

setting status and timer display and DELAY lamp start

blinking. To set delay time, see 3.4.2.

Page 35

20

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

When Not Setting Test duration

(1) During READY status, press TIMER key. When timer

indicator is blinking, press both

key and key at

the same time to display "--" blinking or hold down

either

key or key to display "--" blinking.

(2) When "--" is blinking, press STOP key or TIMER key.

(3) After setting delay time, returns to READY status. Timer

indicator displays "--" .

In this case, testing is performed with no time limit.

Page 36

21

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

DELAY lam

p

3.4.2 Setting and Verifying Delay Time

Delay time is used to set test duration lock out time for

timer function and PASS/FAIL judgment by comparator

immediately after testing starts and voltage is applied.

Measurement value is displayed.

Same delay time setting is applicable at any test voltage.

For details, read 3.4.3 Determining Delay time.

Setting Delay Time

(1) During test duration setting status, press STOP key or

TIMER key to automatically change and display delay

time settings display.

Timer display and DELAY lamp start blinking.

(2) Press

/ key to display desired delay time on timer

indicator.

Hold

/ key down to speed up adjustment of timer

control. (units in [seconds], setting range: 0.1 s to 99 s)

(3) Press STOP key or TIMER key to confirm delay time.

After determining, automatically returns to READY

status and DELAY lamp is turned on.

Timer indicator displays selected test duration.

When Not Setting Delay Time

(1) During delay time setting status, press both

key and

key at the same time to display "--" blinking or hold

down either

key or key to display "--" blinking.

(2) When "--" is blinking, press STOP key or TIMER key.

(3) Returns to READY status. In this case, testing is

performed as 0 second delay time.

Page 37

22

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Confirming Delay Time

During READY status, delay time is not displayed. Follow

the direction below to confirm delay time.

(1) During READY status, press TIMER key twice.

Selected delay time is displayed with DELAY lamp

blinking. When delay time is not set, "--" is displayed

with DELAY lamp blinking.

(2) After confirming, press TIMER key to return to

READY status.

Page 38

23

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

TEST lam

p

Time

r

Resistance

measurement

Comparator

Test voltage

App

rox. 0.3 s

Confirmed test duration

Dischargetime

Approx.

10 V

Time

OFF ON

OFF

START STOP

Blinkin

g

OFF

Test duration timer ON

OFF

OFF

OFF

PASS/FAIL judgment

Measuring・Displayin

g

OFF

OFF

3.4.3 Determining Delay Time

When equipment to be tested contains capacitance,

measurement value is low due to current charging

capacitance immediately after test voltage is applied

resulting in FAIL judgment by comparator. To avoid

incorrect FAIL judgment, set delay time.

While charging capacitance, time is required for applied

voltage to reach test voltage standard value. Because test

duration countdown begins after time elapses when

confirmed as delay time, it provides an option for a test

with test duration excluding charging time (during low

voltage).

Determine delay time by examining measurement value

fluctuation after start of testing and applied voltage rising

waveform (observed with optional tester).

Without Delay Time

Page 39

24

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Confirmed

dela

y

time

TEST lam

p

Time

r

Resistance

measurement

Comparator

Test voltage

App

rox. 0.3 s

Confirmed test

duration

Dischargetime

Approx.

10 V

Time

OFF ON

OFF

START STOP

Blinkin

g

OFF

Delay time

timer ON

Test duration

timer ON

OFF

OFF

OFF

PASS/FAIL

judgment

Measurin

g

・

Displayin

g

OFF

OFF

Voltagegraduallyrises chargingcapacitance.

With Delay Time

Page 40

25

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

FAST

SLOW

3.5 Setting Sampling Rate

Choose from two sampling rates, FAST or SLOW.

Sampling resistance and displaying value with FAST is ten

times per second and with SLOW one time per second.

When measurement value fluctuates, select SLOW for

effective reading.

During TEST status, SAMPLING lamp blinking rate alter

according to sampling rate. To confirm selected sampling

rate check the lamp blinking rate.

Setting Sampling Rate

(1) During READY status, press SHIFT key and then

TIMER key.

Display appears as shown below to display sampling

rate FAST or SLOW blinking.

(2) Press

/ key to switch blinking display.

(3) When selected sampling rate is displayed, press STOP

key or TIMER key to confirm. After confirming,

returns to READY status.

Page 41

26

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Test voltage

500 V

Lower limit value

1MΩ

Test duration

5s

Test mode

FAIL STOP

Delay time

ON

Judgment beep sound

END(see 5.1.1)

3.6 Example Test Condition Setting

The example shows READY status setting display after

setting is complete before START key is pressed.

Measurement value display decimal position may differ

case by case.

When returning to READY status without changing

previous setting condition, the last measurement value and

PASS/FAIL judgment result are displayed again.

(1) When testing with comparator and timer and judging

PASS/FAIL with beep sound, set as instructed below.

Test mode, delay time and beep sound setting are not

displayed during READY status.

Start testing with above settings. While timer is ON, FAIL

judgment stops test followed by an approximately two

second continuous beep sound. When test duration timer

ends, short beep sound repeats three times.

When FAIL STOP mode is set, completing test duration

with timer indicates PASS judgment.

Single continuous beep sound indicates FAIL and repeating

beep indicates PASS judgment.

Page 42

27

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Test voltage

500 V

Lower limit value

No limit

Test duration

OFF

Test mode −−−

Delay time

OFF

(2) Exclusively for insulation resistance measurement, set as

instructed below.

Page 43

28

_____________________________________________________________________

Setting Basic Testing Conditions

______________________________________________________________

Page 44

29

_____________________________________________________________________

Testing

______________________________________________________________

NOTE

See 4.7 Testing with 9299 SWITCHED PROBE to conduct

measurement using 9299 SWITCHED PROBE.

Chapter 4

Testing

HIOKI 3154 DIGITAL MΩ HiTESTER is equipped with

READY status, setting status and TEST status.

(1) READY status

Stands ready for testing. TEST lamp is either OFF or

blinking during READY status.

(2) Setting status

Sets various test settings. Each setting display blinks

during setting status.

(3) TEST status

To test with voltage between measurement terminals.

TEST lamp is ON during TEST status.

Page 45

30

_____________________________________________________________________

Testing

______________________________________________________________

・During READY status, press START key to start testing.

・Switches to TEST status and TEST lamp is ON.

ON

OFF

Delaytime

CONTINUE mode

Lower limit

value

OFF

FAIL

judgment

OFF

ON

ON

Test mode

Designated Test

duration passes.

FAIL STOP

mode

Test

duration

OFF

Press STOP

key.

・Returns to READY status.

Continues to display measurement value and judgment result

(when lower limit value is set).

・For safety, discharge charge buildup in tested equipment.

During discharge, TEST lamp blinks.

1. Resistance measurement 2. Delay time countdown

1. Resistance measurement 2. PASS/FAIL judgment

3. Test duration countdown

Ends testing.

ON

4.1 Test Flow

Simple test flow chart

Page 46

31

_____________________________________________________________________

Testing

______________________________________________________________

WARNING

To avoid the risk of electric shock,c do not touch

equipment to be tested, probe tips and measurement

terminals when TEST lamp is on or blinking.

Do not touch equipment to be tested, probe tips and

measurement terminals immediately after testing. High

voltage charge may result in electric shock.

To avoid the risk of electric shock, After testing,

proceed with discharge function to discharge charge in

tested equipment. (See 4.6.)

START key

NOTE

To start and end testing, in addition to keys, 3154 DIGITAL

MΩ HiTESTER is equipped with external I/O, RS-232C and

probes with switch. Different ways can be used to start and to

end testing.

Check and see if test probes are securely connected before

testing.

When external I/O STOP signal is set to LOW, testing does not

start.

4.2 Start Testing

During READY status, press START key to start testing in

TEST status with TEST lamp ON.

Page 47

32

_____________________________________________________________________

Testing

______________________________________________________________

NOTE

Approximately 0.3 s is required after pressing START key to

start resistance measurement and delay time countdown.

See 4.4 to display measurement value.

4.3 During Testing (TEST status)

When switching to TEST status, the 3154 applies test

voltage to equipment to be tested.

1. When delay time is set, starts resistance measurement

and delay time countdown.

For details, see 3.4.3 Determining Delay time.

(1) Starts resistance measurement and displays

measurement value. (unit: MΩ)

(2) During delay time countdown, DELAY lamp blinks.

After completing delay time countdown, DELAY

lamp goes OFF.

2. After passing delay time (or without setting delay time),

starts resistance measurement, PASS/FAIL judgment and

test duration countdown.

(1) Starts resistance measurement and displays

measurement value. (unit: MΩ)

(2) Following resistance measurement, performs

PASS/FAIL judgment by comparator.

When measurement value < lower limit value, FAIL

lamp turns ON.

When measurement value

lower limit value, PASS

lamp turns ON.

See 5.1.1 to set beep sound for judgment.

When lower limit value is not set, lower limit value

indicator displays "----" without PASS/FAIL

judgment.

(3) Timer indicator indicates test duration countdown.

When test duration is not set, indicator displays "--".

Page 48

33

_____________________________________________________________________

Testing

______________________________________________________________

4.4 Measurement Value Display

Tips for measurement value display

When resistance range is set to auto range, range shifts

immediately after testing starts and only decimal point moves

and measurement value is not displayed on measurement

value display. To eliminate time for decimal point to move,

switch resistance range to manual range. (See 3.3 for setting.)

When using the test duration timer at auto range, testing will

finish without displaying a measurement value during a range

shift if the set time set has past. Please set the test duration

timer longer than 2 seconds (for 25 V or 50 V, 1.5 seconds)

when setting at auto range.

When set at auto range, measurement value fluctuates

betweentworesistanceranges. Inthiscaseswitchresistance

range to manual range. (See 3.3 for setting.)

Display "O.F." indicates overflow. In auto range, "O.F." is

displayed when going over measurement range maximum

value and in manual range when over each range maximum

value.

Display "U.F." indicates underflow. In manual range,

excluding 2 MΩ range, "U.F." is displayed when going below

190 dgt. Does not display in auto range.

Insulation resistance is known to be unstable. This is not a

difficulty although measurement values may not be consistent

depending on the equipment to be tested.

When measurement values fluctuate and are unable to read,

set sampling rate to SLOW. (See 3.5)

Larger capacitance in equipment to be tested tends to result in

a wider range of measurement value fluctuations. See "Limit

determined by capacitance contained in equipment to be

measured" in Chapter 8.

Page 49

34

_____________________________________________________________________

Testing

______________________________________________________________

WARNING

To avoid the risk of electric shock, disconnect probe

from tested object after TEST lamp is turned off after

testing is complete.

4.5 Completing Testing

(1) After ending testing by one of three following ways,

returns to READY status.

Press STOP key to stop testing.

Designated testing time passes and stops testing.

When test mode is set at FAIL STOP mode, FAIL

judgment stops testing.

(2) After returning to READY status, previously displayed

measurement value and judgment result display lamp at

testing completion continue to display.

(3) TEST lamp may not turn off and continue to blink after

testing is complete indicating discharging any charge

buildup in tested object and the 3154.

Proceed with discharge by following instruction in 4.6

Automatic Discharge.

(4) After TEST lamp is turned off, remove probes from

tested equipment.

Page 50

35

_____________________________________________________________________

Testing

______________________________________________________________

NOTE

Safe to set and verify test condition setting or press START key

to restart testing while TEST lamp is still blinking.

When the 3154 power supply is turned OFF, discharge

resistance is approximately 12 MΩ .

4.6 Automatic Discharge

When insulation resistance test is performed on equipment

to be tested containing capacitance, test voltage load is

charged during testing which may result in electric shock.

Use automatic discharge function to discharge buildup

charge through the 3154 internal circuit.

After testing, follow the instructions below to discharge.

(1) End testing without removing both test probes from

tested equipment.

(2) The 3154 internal discharge resistance unit enables

automatic discharge of the buildup charge in the tested

equipment.

(3) During discharge, TEST lamp blinks.

(4) When voltage goes below approximately 10 V, TEST

lamp turns off.

Internal discharge resistance is approximately 2 MΩ .

Larger amount of capacitance requires longer discharge

time.

Page 51

36

_____________________________________________________________________

Testing

______________________________________________________________

1

3

2

1. Push switch

Functions as external switch for the

3154 START key and STOP key.

2. Switching signal lead plug

Connects to the 3154 EXT SW

terminal.

3. Measurement plug

Connect to the 3154 measurement

terminal.

NOTE

The same operations are applicable in both TEST status and

READY status.

9299 SWITCHED PROBE can be used as an ordinary probe

when switch signal lead plug is not connected to EXT SW

terminal.

When external I/O STOP signal is set to LOW or the 3154

STOP key is pressed, testing cannot be initiated.

4.7 Testing with 9299 SWITCHED PROBE

Optional 9299 SWITCHED PROBE permits control starting

and stopping 3154 operation while probe is held in hand.

Before testing, set push switch probe mode to either trigger

mode or continue mode. (See 4.7.2 to set mode.) The

3154 initial setting is set to continue mode.

(1) Continue Mode

Only when pressing ON switch, continues TEST status.

During READY status, press switch to start testing.

Release switch to terminate testing.

(2) Trigger Mode

Press switch to start testing. TEST status continues

even after releasing switch. Press switch to terminate

testing in TEST status.

Page 52

37

_____________________________________________________________________

Testing

______________________________________________________________

WARNING

Inserting switch signal lead plug into terminal may turn

TEST lamp on causing high voltage to occur in

measurement terminal and probe tip. To avoid the risk

of electric shock, before connecting switch signal lead

plug to 3154, make sure to disconnect test probe from

measurement terminal.

Do not press switch on probe when connecting and

disconnecting probe. Unintentional generation of high

voltage may result in electric shock and/or equipment

damage.

4.7.1 Connecting 9299 SWITCHED PROBE

9299 SWITCHED PROBE requires another test probe. Use

either 9257 CONNECTION CORD, 9289 or 9294 TEST

PROBEs.

Follow these steps carefully to connect probe.

(1) Connect 9299 switch signal lead plug to EXT SW terminal.

Insert plug securely so that plug metal tip is not exposed at

all.

When TEST lamp is on after inserting plug, press switch on

9299 or press 3154 STOP key to turn TEST lamp off.

(2) After confirming TEST lamp is turned off, connect 9299

measurement plug to front panel HIGH or LOW

measurement terminal.

(3) Connect connection cord (9257) or another test probe (9289

or 9294) to the other front panel measurement terminal.

(4) When 3154 is in READY status, press switch on 9299 and

verify that 3154 TEST lamp is turned on.

When disconnecting 9299 from the 3154, disconnect test

probe first and signal lead last.

Page 53

38

_____________________________________________________________________

Testing

______________________________________________________________

Trigger mode

Continue mode

4.7.2 Setting 9299 SWITCHED PROBE

Select either continue mode (cont) or trigger mode (trig) to

set 9299 SWITCHED PROBE.

Operation Setting

(1) During READY status, press SHIFT key then press and

hold VOLT key for approximately two seconds or

longer to display "SPECIAL".

(2) Press ▲/▼ key to display "9299 ProbE".

(3) Press STOP key and "9299 Cont" or "9299 triG" appear

blinking to show display to select and set Push Switch

probe mode setting. (Display "9299" does not blink.)

(4) Press

/ key to switch blinking display with "Cont"

or "triG".

(5) Display blinking "Cont" to switch to continue mode and

"triG" to trigger mode and press STOP key. After

pressing STOP key, probe operation mode is confirmed

and returns to READY status.

Page 54

39

_____________________________________________________________________

Other Functions

______________________________________________________________

Key Lock Function

System Reset

Setting Judgment BeepSetting and Verifying Beep

Sound

Saving and Loading Test

Conditions

・

See 5.1.1.

Setting Beep Sound During

Key Press

Saving Test Conditions

Loading Test Conditions

・

See 5.1.2.

・

See 5.2.1.

・

See 5.2.2.

・

See 5.3.

・

See 5.4.

Chapter 5

Other Functions

3154 is equipped with the following functions.

Page 55

40

_____________________________________________________________________

Other Functions

______________________________________________________________

5.1 Setting and Verifying Beep Sound

5.1.1 Setting Judgment Beep Sound

When PASS/FAIL judgment is performed with comparator

and timer, select beep sound from following four options.

PASS : Beeps for PASS judgment.

FAIL : Beeps for FAIL judgment.

End : Beeps when test duration timer ends.

OFF : No beep sound.

Setting Judgment Beep Sound

(1) During READY status, press SHIFT key and then

COMP key.

Display appears blinking to indicate selected beep

sound option. (Example below shows when beep sound

is OFF.)

(2) Each

/ key press switches blinking displays

"PASS", "FAIL", "End", "OFF" to indicate options.

(3) Press either STOP key or COMP key to confirm the

option. After confirming, automatically returns to

READY status.

Verifying Judgment Beep Sound

(1) During READY status, press SHIFT key and then

COMP key. Verify that selected beep sound option

indicator is blinking.

(2) After verifying, press either STOP key or COMP key

and returns to READY status.

Page 56

41

_____________________________________________________________________

Other Functions

______________________________________________________________

BeepOFF

BeepON

5.1.2 Setting Beep Sound During Key Press

Select from beep sound options to set beep ON or OFF

during key press.

Setting Beep Sound ON or OFF.

(1) During READY status, press SHIFT key then press and

hold VOLT key for approximately two seconds or

longer to display "SPECIAL".

(2) Press ▲/▼ key to display "KEY bEEP".

(3) Press STOP key and "bEEP ON" or "bEEP OFF"

appears blinking to select and set beep sound during

key press. (Display "bEEP" does not blink.)

(4) Each

/ key press switches blinking displays "ON"

and "OFF".

(5) Select blinking indicator "ON" to set beep sound on and

"OFF" to set off and press STOP key to confirm option.

After confirming, automatically returns to READY

status.

Page 57

42

_____________________________________________________________________

Other Functions

______________________________________________________________

5.2 Saving and Loading Test Conditions

5.2.1 Saving Test Conditions

All 3154 configured test conditions, up to ten settings can

be saved in internal memory excluding the following four

conditions.

Special Conditions

9299 SWITCHED PROBE operation mode

Changing RS-232C Interface options (personal

computer/printer)

Beep sound setting during key press

External I/O TEST signal OFF timing setting

Settings to be selected with external I/O VOLT 0 - 2

signals

Analog output setting

Read saved memory by operation instructed in 5.2.2

Loading Test Conditions.

Page 58

43

_____________________________________________________________________

Other Functions

______________________________________________________________

Saving Test Conditions

(1) During READY status, press SHIFT key and then

key. Following indicator appears displaying a number

blinking to display save setting. The number identifies

test condition setting to be saved.

When save setting display appears, the number

displayed is determined as described below.

Displays the smallest number available if not all ten

numbers are used.

Displays number 10 if all ten numbers are already in

use to identify and save settings.

(2) Press

/ key to select desired number from option 1

to 10 to save settings. (When a saved option is

selected, overwrites previous test condition settings.)

(3) Press STOP key. Display "SAVE NO." blinks

approximately two seconds or returns to READY status

completing saving test conditions.

To return to READY status without saving test

conditions, press any key except STOP key and

/

key.

Page 59

44

_____________________________________________________________________

Other Functions

______________________________________________________________

NOTE

When loading with test voltage setting signal input through

external I/O, following loaded conditions; test voltage, lower

limit value and test mode become invalid defaulting to external

I/O setting even after pressing START key.

When no condition setting is saved, loading display shows "--"

in stead of number. In this case pressing

/ key does not

switch displays.

5.2.2 Loading Test Conditions

Saved test conditions can be loaded from internal memory.

Loading saved test conditions

(1) During READY status, press SHIFT key and then

key. Following indicator appears displaying a number

blinking. The number identifies saved test condition

setting.

(2) Press

/ key to select option to load. Does not

display numbers not in use.

(3) Press STOP key. Display "LOAD No." appears blinking

approximately two seconds and returns to READY

status completing loading test condition.

To return to READY status without loading test

conditions, press any key except STOP key and

/

key.

(4) Each indicator displays loaded conditions.

Page 60

45

_____________________________________________________________________

Other Functions

______________________________________________________________

LOCK lam

p

LOCK ke

y

5.3 Key Lock Function

Execute key lock to disable front panel key switch

operations excluding START key, STOP key and 9299

SWITCHED PROBE switching operations.

Executing Key Lock

During READY status, press and hold LOCK key for

approximately two seconds or longer.

When key lock status, LOCK lamp on the left of LOCK

key is on.

Disengaging Key Lock

During READY status, press and hold LOCK key for

approximately 2 s or longer.

Page 61

46

_____________________________________________________________________

Other Functions

______________________________________________________________

Test voltage 25 V

Lower limit value OFF (displays [----])

Test mode Continue mode

Test duration OFF (displays [--])

Delay time OFF (displays [--])

Resistance range Auto range

Judgment beep sound FAIL

Sampling rate FAST

Push switch probe mode Continue mode

Beep sound during key press ON

Connection with RS-232C PC

External I/O TEST signal OFF timing SLOW

External I/O VOLT 0 to 2 signals VOLT

Analog output setting FULL RANGE

5.4 System Reset

System reset is used to set all test conditions back to initial

factory settings. All saved test conditions are cleared by

system reset.

Executing system reset

(1) During READY status, press SHIFT key then press and

hold VOLT key for approximately two seconds or

longer to display "SPECIAL".

(2) Press ▲/▼ key several times to display "rESEt".

(3) Press STOP key and all indicators are turned on. After

displaying "Product name" and "Software version",

returns to READY status completing system reset.

Factory Settings

Page 62

47

_____________________________________________________________________

External Interface

______________________________________________________________

Chapter 6

External Interface

6.1 Controlling 3154 with External I/O

External I/O terminal connector board is located in the back

and enables signal input for START

STOP test voltage

control and signal output for 3154 status (TEST status,

etc.)

comparator judgment results.

All signal leads are isolated through a photocoupler from

other parts. (Not isolated between signal leads)

Use external power supply (5 to 30 VDC).

Internal power supply 5 V and GND are output by external

I/O terminal enabling simple external I/O functions. Use

caution because external I/O, RS-232C connector and

analog output terminal are not isolated.

Page 63

48

_____________________________________________________________________

External Interface

______________________________________________________________

Pin number IN/OUT Signal name

1, 2 OUT INT.GND

3 IN EXT.COM

4 OUT FAIL

5 OUT PASS

6 OUT TEST

7 IN VOLT2

8 IN VOLT1

9 IN VOLT0

10 IN STOP

11 IN START

12 IN EXT.DCV

13, 14 OUT INT.DCV

114

START Set signal to LOW to enable same function as

pressing 3154 START key. To perform start up

edge detection, it requires more than 60 ms when

set to LOW. Locking on LOW does not release

continuous START signal input. In this case STOP

signal is accepted for input.

STOP Set signal to LOW to enable same function as

pressing 3154 STOP key. To perform start up edge

detection, it requires more than 60 ms when set to

LOW. Locking on LOW does not accept "all test

start" for input.

VOLT0,VOLT1,

VOLT2

Combination of these signals enables selection from

six test voltages (including comparator) options or

from seven saved test condition options. See 6.1.5.

TEST During TEST status, selects LOW. Set with options

either to wait until after discharging charge in tested

equipment after completing test or not to wait and

returns to HIGH. See 6.1.6.

PASS Selects LOW when comparator gives PASS

judgment.

FAIL Selects LOW when comparator gives FAIL judgment.

EXT.DCV Terminal to supply power from external equipment.

Power supply voltage range is 5 to 30 VDC.

Supplies power also by connecting with INT.DCV

terminal.

6.1.1 Terminal Connector Board/Signal Wires

Page 64

49

_____________________________________________________________________

External Interface

______________________________________________________________

EXT.COM Terminal to connect to external equipment GND.

Also connects with INT.GND terminal.

INT.DCV

、

INT.GND

Outputs 3154 internal power supply (5 VDC) and

internal GND. Use to enable simple external I/O

functions. Not isolated.

GND terminal is connected with power supply cord

ground lead.

NOTE

Beep sound can be set to ON/OFF during START and STOP

signal input. Same setting applies and performs same operation

as beep sound during key press.

To avoid starting test by mistake, hold STOP signal LOW and

set it back to HIGH right before setting START signal to LOW.

In this case, be sure to set STOP signal to HIGH at least 1 ms

before START signal is to set to LOW.

Page 65

50

_____________________________________________________________________

External Interface

______________________________________________________________

Input signal

Active LOW input

Maximum applied voltage

Voltage of EXT.DCV terminal

HIGH level

Voltage of EXT.DCV terminal or open

LOW level

0.3 VDC or less

Output signal

Open corrector output

Maximum load voltage

DC+30 V

(when not using EXT.DCV terminal)

Maximum output current

60 mADC/1 signal (when LOW level)

Output voltage

5 VDC

Maximum load current

100 mADC

6.1.2 Electric Specifications

Input signal specifications

(Applied signal names: START, STOP, VOLT0, VOLT1,

VOLT2)

Output signal specifications

(Applied signal names: PASS, FAIL, TEST)

EXT.DCV terminal maximum input voltage: 30 VDC input

to EXT.COM terminal

Internal power supply output

(between INT.DCV and INT.GND terminals)

Output signal is a photocoupler open corrector output.

3154 is internally connected to EXT.DCV terminal at 4.7

kΩ pull up resistance.

Page 66

51

_____________________________________________________________________

External Interface

______________________________________________________________

External

DC power

supply

Output voltage

High level

Low level

Output current

10 mA

Output current

40 mA

Output current

60 mA max.

5V 5V 0.9 V 1.1 V 1.2 V

12 V 12 V 0.9 V 1.1 V 1.2 V

24 V 24 V 0.9 V 1.1 V 1.2 V

When Not Using EXT.DCV Terminal

When connecting and loading directory to output terminal

without using EXT.DCV terminal, refer to the chart below

for external DC power supply to be connected for another

direct loading and output signal voltage, output current.

Page 67

52

_____________________________________________________________________

External Interface

______________________________________________________________

CAUTION

In order to avoid risk of damaging the unit, do not input

excessive voltage or current above standard to external I/O

terminal. See "6.1.2 Electric Specifications" to set standard

voltage and current.

5 VDC is output between internal DC power

supply(INT.DCV) and INT.GND. Maximum current is 100

mA. To prevent product damage, do not connect to

external circuit consuming more than 100 mA.

Power supply voltage to external DC power supply

(EXT.DCV, EXT.COM terminals) is 5 to 30 VDC.

To prevent product damage, do not apply voltage over 30

VDC. In order to activate circuit, connect power supply

with at least 50 mA output capacity.

In order to avoid risk of electric shock, turn equipment

power supply OFF before connecting and disconnecting

wires to terminal board. Carefully handle wiring and see

that no wire is disconnected and exposing conducting

elements including the unit body etc.

To prevent product and equipment damage, when using

relay, be sure to install back electromotive force absorption

diode.

Do not short circuit terminals other than designated

terminals. Internal short circuit may occur when sheathing

is exposed beyond standard length.

6.1.3 Connecting External I/O Terminal

Page 68

53

_____________________________________________________________________

External Interface

______________________________________________________________

Recommended

wire

Single strand

0.65 mm dia (AWG#22)

Multi-strand

0.32 mm

2

(AWG#22)

Usable limits Single strand

0.32 to 0.65 mm dia. (AWG #28 to #22)

Multi-strand

0.08 to 0.32 mm

2

(AWG #28 to #22)

Standard insulation stripping length 10 mm

Button pressing tool Blade screwdriver

(tip width 2.6 mm)

(1) Push the tab with a flatblade screwdriver or similar.

(2) While keeping the tab depressed, insert a stripped wire

into the connector opening.

(3) Release the tab to lock the wire.

Page 69

54

_____________________________________________________________________

External Interface

______________________________________________________________

CAUTION

Signal wire insulation is used to cut down interference

between signals. Be sure to apply protective grounding to

external equipment to be connected to avoid risk of

damaging insulation.

Maximum photocoupler low level output current is 60 mA.

When more than 60 mA current is required, current

amplifier transistor circuit and other external power supply

devices must be connected externally.

Terminal board pin number

11

10

9

8

7

6

5

4

12

13

14

2

1

3

Connected to power cord ground lead

4.7 kΩ(1/4W)

External powe

r

supply (COM)

EXT.COM

Internal powe

r

supply (5 V)

INT.DCV

Externalpowe

r

supply

(5 V to 30 V)

EXT.DCV

Internal powe

r

supply

(5 V) (GND)

INT.GND

*

:Connect when using internal DC power supply (5 V).

*

*

START

STOP

VOLT0

VOLT1

VOLT2

TEST

PASS

FAIL

External I/O terminal circuit

shematic diagram shown below.

6.1.4 External I/O Terminal Circuit

Page 70

55

_____________________________________________________________________

External Interface

______________________________________________________________

Test voltage

Signal

25 V 50 V 100 V 250 V 500 V 1000 V Invalid

VOLT0 L H L H L H L H

VOLT1 H L L H H L L H

VOLT2 H H H L L L L H

Test condition

Signal

No.1 No.2 No.3 No.4 No.5 No.6 No.7 Invalid

VOLT0 L H L H L H L H

VOLT1 H L L H H L L H

VOLT2 H H H L L L L H

6.1.5 Settings to be selected with VOLT 0 to 2

signals

External I/O VOLT 0 to 2 signals allow the following two

selections to be selected. At factory setting, test voltage and

comparator (VOLT) are selected.

(1) Selecting test voltage and comparator (VOLT)

Select test voltage (including comparator) according the

chart below.

"H" stands for HIGH, "L" for LOW.

(2) Loading saved test conditions (LOAd)

Select from saved test conditions No.1 through No. 7

according to the chart below. To select from saved test

conditions, see 5.2.1.

"H" stands for HIGH, "L" for LOW.

Page 71

56

_____________________________________________________________________

External Interface

______________________________________________________________

Setting content with VOLT 0 to 2 signals

(1) During READY status, press SHIFT key and press and

hold VOLT key approximately two seconds or longer to

display "SPECIAL".

(2) Press▲/▼key to display "VOLt SIGnAL"

(3) Press STOP key to display either "VOLt VOLt" or

"VOLt LOAd" blinking and display appears to set

content settable with VOLT 0 to 2 signals. ("VOLt"

does not blink.)

(4) Press