Hioki 3153 Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

3153

Instruction Manual

AUTOMATIC INSULATION/

WITHSTANDING HiTESTER

Mar. 2017 Revised edition 15

3153A981-15 17-03H

EN

Contents

Introduction i

Inspection i

Safety Notes ii

Notes on Use v

Chapter Summary vi

Chapter 1 Overview 1

1.1 Product Introduction 1

1.2 Names and Functions of Parts

1.2.1 Front panel 3

1.2.2 Rubber keys 4

1.2.3 Rear panel 5

1.2.4 9615 H.V. TEST LEAD 6

1.2.5 REMOTE CONTROL BOX 7

1.3 External Dimensions 8

Chapter 2 Testing Arrangements 9

2.1 Connecting the Protective Ground Terminal 9

2.2 Wearing rubber gloves

2.3 Connecting the External I/O Connector

2.4 Power Cord Connection

2.5 Powering On and Off the Unit

2.6 Connecting the 9615 H.V. TEST LEAD

2.7 Connecting the REMOTE CONTROL BOX

2.8 Installation of the Unit

10

10

11

12

14

15

16

3

3153A981-15

2.9 Connection to the Measured Equipment

2.10 Startup Inspection

17

18

Chapter 3 Withstand Voltage ModeTesting Method 19

3.1 Withstand Voltage Mode Display 20

3.2 Displaying the "READY" State

3.2.1 Key-lock Function 23

3.3 "SETTING" State 24

3.3.1 Setting the Test Voltage Value 25

3.3.2 Setting the Upper (Lower) Limit Value 26

3.3.3 Setting the Test Time 27

3.3.4 Setting of the Ramp Timer 28

22

3.3.5 Setting the Type of Test Voltage 29

3.3.6 Examples of Settings 30

3.4 Starting a Test 34

3.4.1 Executing a Test 34

3.4.2 Screening in "TEST" State 36

3.5 "PASS" or "FAIL" Determination 37

3.5.1 "PASS" State 37

3.5.2 Screening in "PASS" State 38

3.5.3 "FAIL" State 39

3.5.4 Screening in "FAIL" State 41

3.6 Automatic Discharge Function 42

Chapter 4 Insulation Resistance Mode Testing Method 43

4.1 Insulation Resistance Mode Display 44

4.2 Displaying the "READY" State

4.2.1 Key-lock Function 47

46

4.3 "SETTING" State 48

4.3.1 Setting the Test Voltage Value 49

4.3.2 Setting the Lower (Upper) Limit Value 50

4.3.3 Setting the Test Time 52

4.3.4 Setting the Delay Time 53

4.3.5 Examples of Settings 54

4.4 Starting a Test 57

4.4.1 Executing a Test 58

4.4.2 Screening in "TEST" State 59

4.5 "PASS" or "FAIL" Determination 60

4.5.1 "PASS" State 60

4.5.2 Screening in "PASS" State 62

4.5.3 "FAIL" State 63

4.5.4 Screening in "FAIL" State 65

4.6 Automatic Discharge Function 66

Chapter 5 Auto Test Mode Testing Method 67

5.1 Auto Test Mode Display 68

5.2 Displaying the "READY" State

5.2.1 Key-lock Function 71

5.3 "SETTING" State 72

5.4 Starting a Test

5.4.1 Executing a Test 74

5.4.2 Screening in "TEST" State 75

5.5 PASS or FAIL Determination 76

70

73

5.5.1 "PASS" State 76

5.5.2 Screening in "PASS" State 78

5.5.3 "FAIL" State 79

5.5.4 Screening in "FAIL" State 81

5.6 Automatic Discharge Function 82

Chapter 6 Program Mode Testing Method 83

6.1 Program Mode Display 84

6.2 Displaying the "READY" State

6.2.1 Key-lock Function 87

86

6.3 Program Setting State 88

6.3.1 Examples of Settings 91

6.4 Program-File Loading 96

6.5 Starting a Test

6.5.1 Executing a Test 98

6.5.2 Screening in "TEST" State 99

97

6.6 PASS or FAIL Determination 100

6.6.1 "PASS" State 100

6.6.2 Screening in "PASS" State 101

6.6.3 "FAIL" State 102

6.6.4 Screening in "FAIL" State 104

6.7 Automatic Discharge Function 105

Chapter 7 Optional Functions 107

7.1 PASS Hold Function 110

7.2 FAIL Hold Function

7.3 Hold Function

7.4 Momentary Out

7.5 Double Action

7.6 FAIL Mode

7.7 Interface Command "START"

7.8 Inter-lock Function

7.9 Setting of an Output-Voltage Restricting Value

7.10 Insulation Resistance Test Measurement Range

7.11 Insulation Resistance Test Termination Mode Settings

7.12 Setting for Screening during the Ramp-Up Time

7.13 PC Interface

7.14 START Protection Function

7.15 TEST-Signal Output

7.16 Example of Optional Functions Use

111

112

114

115

116

117

118

119

120

121

123

124

125

126

127

Chapter 8 Saving/loading Preset Values 129

8.1 Saving Preset Values 129

8.1.1 Procedure for Saving Data 129

8.1.2 Example of Saving 132

8.2 Loading Preset Values 134

8.2.1 Procedure for Loading Data 134

8.2.2 Example of Loading 137

Chapter 9 External Interface 139

9.1 External I/O Terminal 139

9.1.1 Signal Line 140

9.1.2 Example of Input Signal Connection 142

9.1.3 Example of Output Signal Connection 144

9.1.4 Inter-lock Function 146

9.1.5 Selecting a Program Test File 147

9.1.6 Timing Chart of External I/O Terminal 149

9.2 Buzzer 154

Chapter 10 PC Interface 155

10.1 RS-232C Interface 156

10.1.1 Specifications 156

10.1.2 Preparing for Data Transfer 157

10.1.3 RS-232C Command Transfer Methods 159

10.2 Command Table 164

10.3 RS-232C Command Reference

10.3.1 Common Command Messages 168

10.3.2 Specific Command Messages 171

10.4 Response Formats 201

10.5 GP-IB Interface

10.5.1 Specifications 203

10.5.2 Preparing for Data Transfer 203

10.6 GP-IB Command Transfer Methods 205

10.7 GP-IB Commands

10.8 GP-IB Command Reference

167

203

211

212

10.8.1 Command Reference 212

10.8.2 Specific Command Messages 216

Chapter 11 Specifications 219

11.1 Basic Specifications 219

11.1.1 Withstand Voltage test portion 219

11.1.2 Insulation resistance test portion 221

11.1.3 Timer Section 222

11.1.4 Interface 223

11.1.5 Program Function 224

11.1.6 Other Functions 225

11.2 General Specifications 226

Chapter 12 Maintenance and Inspection 227

12.1 Maintenance and Service 227

12.2 Fuse Replacement

12.3 Troubleshooting

12.4 Displaying Errors

12.5 Removing the Lithium Battery

12.6 Resetting the System

229

230

231

232

233

Appendix APPENDIX 1

Appendix 1 9613 REMOTE CONTROL BOX (SINGLE)

Appendix 2 9614 REMOTE CONTROL BOX (DUAL)

Appendix 3 9615 H.V. TEST LEAD (Standard Accessory)

Appendix 4 Insulation Resistance Mode measurement range

APPENDIX 1

APPENDIX 2

APPENDIX 3

APPENDIX 4

INDEX INDEX 1

_____________________________________________________________________________________________

p

i

Introduction

Thank you for purchasing the HIOKI 3153 AUTOMATIC INSULATION/

WITHSTANDING HiTESTER. To obtain maximum performance from the

product, please read this manual first, and keep it handy for future reference.

Inspection

When you receive the product, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the connectors. If damage is

evident, or if it fails to operate according to the specifications, contact your

dealer or Hioki representative.

NOTE

Accessories

Verify that the following standard accessories are complete.

Instruction Manual 1

Spare fuse (built into the power inlet) 1

Grounded three-core power cord 1

9615 H.V. TEST LEAD (High voltage and return side ) 1

Shipment of the unit

Use the original packing materials when reshipping the product, if possible.

Warranty

HIOKI cannot be responsible for losses caused either directly or indirectly by

the use of the 3153 with other equipment, or if ownership is transferred to a

third party.

Before using the product, make sure that the insulation on the leads is undamaged

and that no bare conductors are improperly exposed. Using the product in such

conditions could cause an electric shock, so contact your dealer or Hioki

resentative for repair.

re

______________________________________________________________________________________________

ii

_____________________________________________________________________________________________

Safety Notes

This product is designed to conform to IEC 61010 Safety Standards, and

WARNING

has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as

damage to the product. Be certain that you understand the instructions

and precautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting directly from

product defects.

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before

using the product, be sure to carefully read the following safety notes.

Safety Symbols

The symbol printed on the product indicates that the user should

refer to a corresponding topic in the manual (marked with the

symbol) before using the relevant function.

In the manual, the symbol indicates particularly important

information that the user should read before using the product.

Indicates that dangerous voltage may be present at this terminal.

Indicates a fuse.

Indicates AC (Alternating Current).

Indicates both DC (Direct Current) and AC (Alternating Current).

Indicates a protective conductor terminal.

Indicates a grounding terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of

cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that

DANGER

WARNING

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

CAUTION

NOTE

______________________________________________________________________________________________

Indicates that incorrect operation presents a possibility of injury to

the user or damage to the product.

Advisory items related to performance or correct operation of the

product.

_____________________________________________________________________________________________

iii

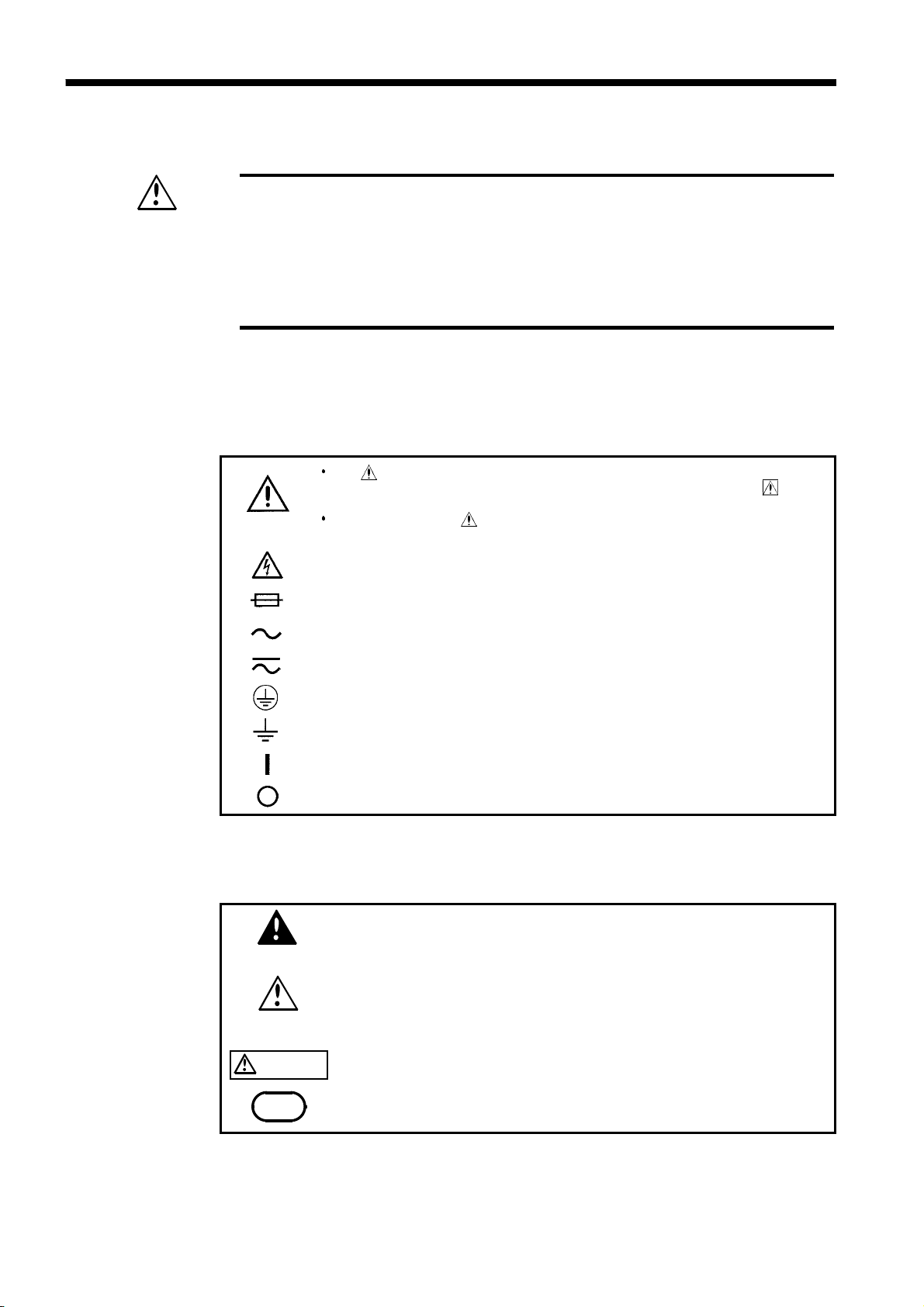

Measurement categories

To ensure safe operation of measurement products, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT II to

CAT IV, and called measurement categories.

CAT II

CAT III

CAT IV

Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet

receptacles.

Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distribution panel to

outlets.

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Using a measurement product in an environment designated with a highernumbered category than that for which the product is rated could result in a

severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT

IV measurement applications could result in a severe accident, and must be

carefully avoided.

______________________________________________________________________________________________

iv

_____________________________________________________________________________________________

Accuracy

The specifications in this manual include figures for "measurement accuracy"

when referring to digital measuring instruments, and for "measurement

tolerance" when referring to analog instruments.

f.s.

rdg.

dgt.

(maximum display or scale value, or length of scale)

Signifies the maximum display (scale) value or the length of the scale

(in cases where the scale consists of unequal increments or where the

maximum value cannot be defined).

In general, this is the range value (the value written on the range

selector or equivalent) currently in use.

(displayed or indicated value)

This signifies the value actually being measured, i.e., the value that is

currently indicated or displayed by the measuring instrument.

(resolution)

Signifies the smallest display unit on a digital measuring instrument,

i.e., the value displayed when the last digit on the digital display is

"1".

______________________________________________________________________________________________

_____________________________________________________________________________________________

v

Notes on Use

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

To avoid electric shock, do not remove the product's case. The internal

DANGER

WARNING

components of the product carry high voltages and may become very

hot during operation.

The vinyl shield on the 9615 H.V. TEST LEAD alligator clip is not high

voltage insulated. Do not touch when high voltage is applied.

To avoid electric shock, do not allow the product to get wet, and do not

use it when your hands are wet.

To avoid electric shock, be sure to connect the protective ground

terminal to a grounded conductor.

To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3-contact

(two-conductor + ground) outlet.

Before turning the product on, make sure the source voltage matches

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

Replace the fuse only with one of the specified characteristics and

voltage and current ratings. Using a non-specified fuse or shorting the

fuse holder may cause a life-threatening hazard.

Fuse type: 250VT10AL (100-120 V), 250VT5AL (200-240 V)

To avoid electric shock when measuring live lines, wear appropriate

protective gear, such as insulated rubber gloves, boots and a safety helmet.

CAUTION

NOTE

To avoid electrocution, turn off the power to all devices before plugging or

unplugging any of the interface connectors.

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging the cord from the power outlet.

To avoid damaging H.V. TEST LEAD, do not kink or pull on the leads.

For safety reasons, when taking measurements, only use the 9615 H.V.

TEST LEAD provided with the product.

To avoid damage to the product, protect it from vibration or shock during

transport and handling, and be especially careful to avoid dropping.

Failure to observe the following precaution may result in bodily injury.

This instrument weighs approximately 18kg. When lifting or moving the

unit, it is strongly recommended that two capable persons hold the

instrument at both ends of the bottom to prevent drop or damage.

The instrument is heavy. When transporting it, follow your company's

workplace safety standards to assure safety (for example, by wearing non-

slip gloves and protective footwear).

To avoid electric shock, do not exceed the lower of the ratings shown on the

instrument and test leads.

Do not use the product near a device that generates a strong electromagnetic field or

electrostatic charge, as these may cause erroneous measurements.

This product may cause interference if used in residential areas. Such use

must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

______________________________________________________________________________________________

vi

_____________________________________________________________________________________________

Chapter Summary

Chapter 1 Overview

Describes an overview, features, and the names and functions of the parts of

the product.

Chapter 2 Testing Arrangements

Describes particulars of testing arrangements.

Chapter 3 Withstand Voltage Mode Testing Method

Describes the procedures for setting the withstand-voltage mode testing,

testing method, and test decisions.

Chapter 4 Insulation Resistance Mode Testing Method

Describes the procedures for setting the insulation-resistance mode testing,

testing method, and test decisions.

Chapter 5 Auto Test Mode Testing Method

Describes the procedures for setting the auto test mode testing, testing

method, and test decisions.

Chapter 6 Program Mode Testing Method

Describes the procedures for setting the program mode testing, testing

method, and test decisions.

Chapter 7 Optional Functions

Describes procedures for setting optional functions.

Chapter 8 Saving/Loading Preset Values

Describes procedure for saving and loading test values.

Chapter 9 External Interface

Describes use of the external I/O, and buzzer.

Chapter 10 PC Interface

Describes communication procedures and commands for an RS-232C/GP-IB

interface.

Chapter 11 Specifications

Contains the unit specifications such as the general specifications,

measurement accuracy, etc. of the unit.

Chapter 12 Maintenance and Inspection

Covers the maintenance and inspection, fuse replacement, ultimate disposal,

and system reset.

Appendix

Covers the options of the unit.

______________________________________________________________________________________________

_____________________________________________________________________________________________

1

Chapter 1

1

2

1.1 Product Introduction

(1) Easy testing conforming to standards

With the unit insulation-resistance and withstand-voltage tests based on a

wide variety of standards can be performed. Accurate test results can be

obtained by comparative screening functions that use upper- and lower-limit

values, timer functions, and ramp up/down timer functions that control testvoltage increases/decreases.

(2) Automatic insulation-resistance testing and withstand-voltage

testing

The Continuous Test mode allows consecutive insulation-resistance and

withstand-voltage tests to be performed.

Overview

3

4

5

6

7

8

9

(3) Fluorescent indicator

The large, easy-to-read fluorescent display permits quick checking of the

testing state and result.

(4) Analog Voltage Measurement

The voltage is digitally displayed on the fluorescent indicator. This value can

also be checked on the analog voltmeter.

(5) Saving testing set values (Memory function)

This unit is provided with a function for saving the set values used in a test,

allowing quick switching between different testing set values to meet a

variety of standards and regulations. Up to 10 values may be saved for each

test mode (withstand-voltage mode or insulation-resistance mode). The

values immediately prior to a power shutdown are saved in the unit, and the

unit restarts with these settings the next time.

10

11

12

13

14

A

______________________________________________________________________________________________

1.1 Product Introduction

2

_____________________________________________________________________________________________

(6) REMOTE CONTROL BOX

The 9613 REMOTE CONTROL BOX (single-hand) or the 9614 REMOTE

CONTROL BOX (dual-hand) can be connected to the external switch

terminal to perform 3153 start/stop control.

(7) External I/O

The external I/O terminal generates signals according to the state of the

3153. It can be used to feed signals for the

START

and

STOP

key.

(8) RS-232C/GP-IB interface as a standard feature

Automatic testing and saving of the test results are possible with the use of a

computer.

(9) Program test

Withstand-voltage and insulation-resistance tests under various conditions

can be conducted successively at your option. Through the use of a 3930

HIGH VOLTAGE SCANNER, many test points can be tested at one time.

Up to 32 files can be created, with each file containing up to 50 steps.

(10) Switching-power-supply method

The adoption of the PWM switching power supply allows the unit to output

any preset voltage. The test voltage is not affected by fluctuations in the

power-supply voltage of this unit.

______________________________________________________________________________________________

1.1 Product Introduction

_____________________________________________________________________________________________

3

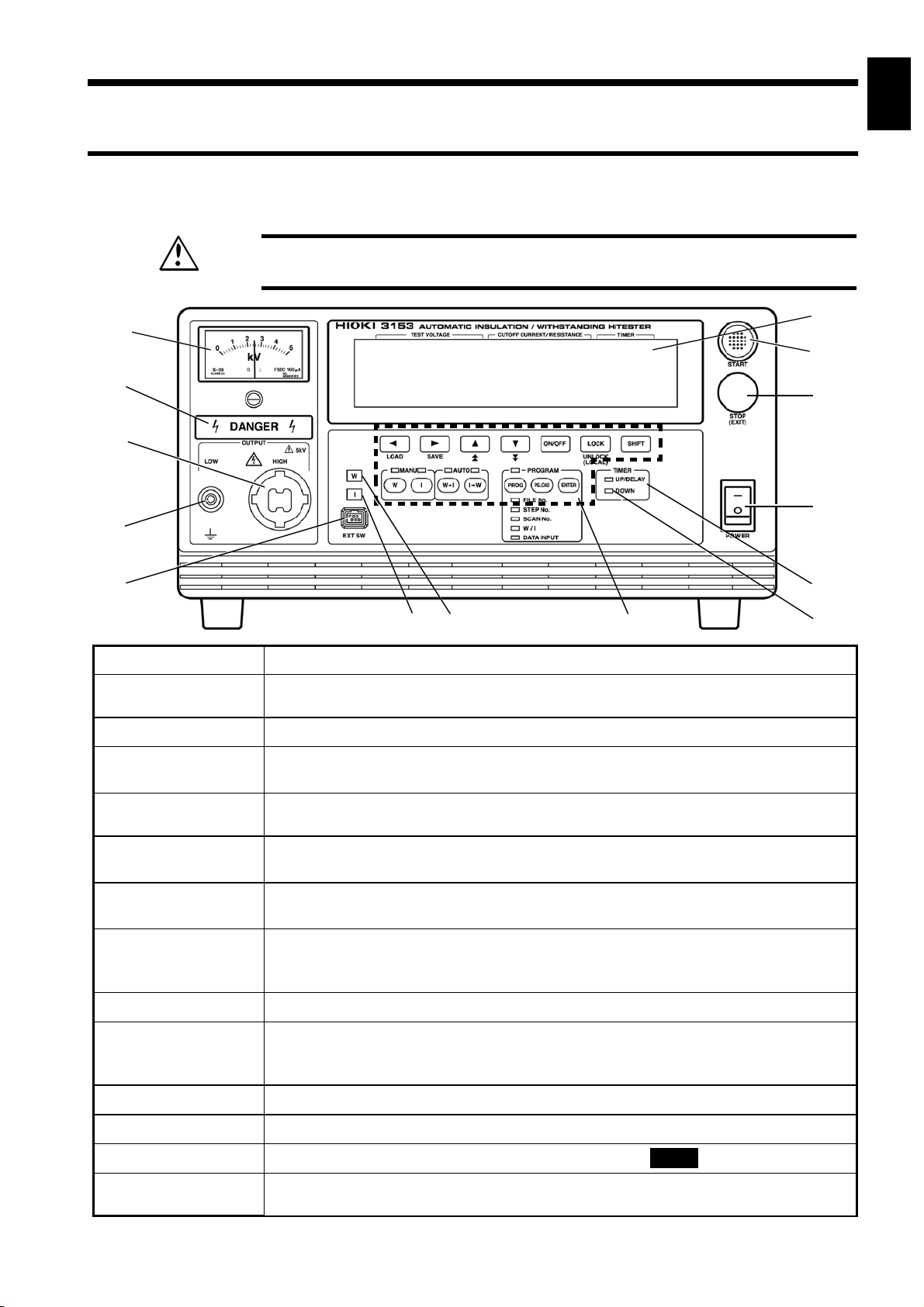

1.2 Names and Functions of Parts

1

1.2.1 Front panel

To prevent electric shock, when the

WARNING

1

2

3

4

5

HIGH or LOW terminals, H.V. TEST LEAD, or the tested object.

2

DANGER

lamp is lit, never touch the

14

13

12

3

4

5

6

11

7

10

6

7

8

9

8

1 Analog voltmeter

2

DANGER lamp

3 HIGH terminal

4 LOW terminal

5 External switch

terminal

6 I lamp

7 W lamp

8 Rubber keys

9 DOWN lamp

10 UP/DELAY

lamp

11 Main power switch

Indicates output-voltage value.

This lamp lights to warn that voltage is present between the terminals during

testing.

The HIGH terminal is a high-voltage terminal for voltage outputs.

The LOW terminal is a low-voltage terminal for voltage outputs. It has the same

electric potential as the unit body.

Used for the switch signal line plug for the REMOTE CONTROL BOX.

This lamp lights when insulation-resistance mode is selected and during

insulation-resistance testing.

This lamp lights when withstand-voltage mode is selected and during withstandvoltage testing.

The 14 rubber keys include 13 function keys and a

The six function keys offer a variety of settings, used in combination with the

SHIFT

This lamp lights during ramp-down from withstand-voltage testing.

This lamp lights during ramp-up to withstand-voltage testing and during

insulation-resistance testing delays. (However, it does not light during time testing

when insulation-resistance test termination mode is set to 0 [initial setting].)

Powers the 3153 product on or off.

key.

SHIFT

key.

9

10

11

12

13

14

12 STOP key

13 START key

14 VFD (vacuum

fluorescent display)

______________________________________________________________________________________________

Normally used to terminate a test.

Used to start a test. This key functions only when the

Displays various information, such as the test state and test results.

READY

1.2 Names and Functions of Parts

lamp is lit.

A

4

_____________________________________________________________________________________________

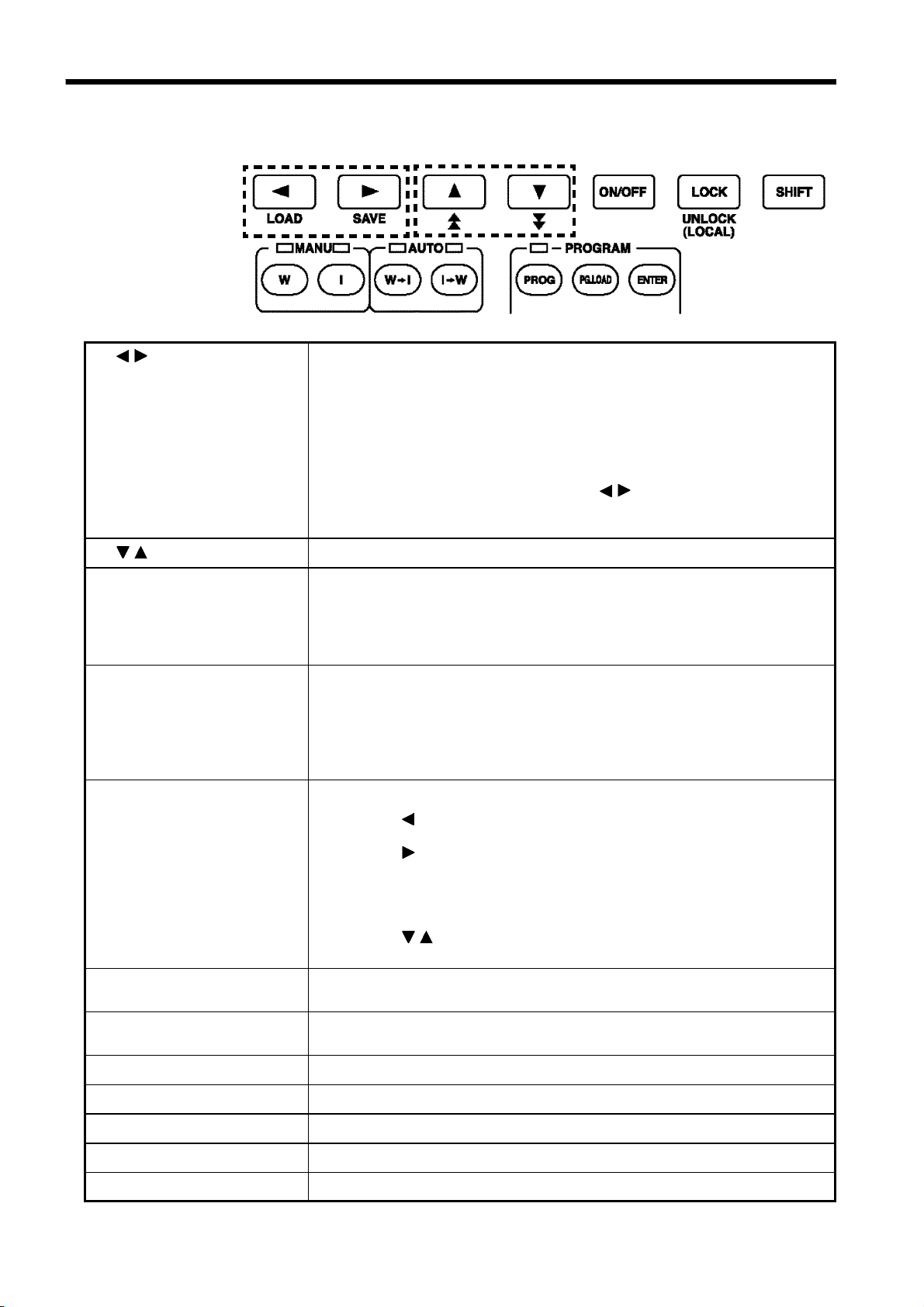

1.2.2 Rubber keys

1

/

2

/

3

ON/OFF key

key

key

1

6

7

8 9

2

10 11 12

3

4

Moves the flashing cursor.

The switching range is preset before shipment:

Withstand-voltage test:

Test-voltage value ⇔ Upper-limit value ⇔ Lower-limit value ⇔

Test time ⇔ Ramp-up time ⇔ Ramp-down time ⇔ Test-voltage type

Insulation-resistance test:

Test-voltage value ⇔ Lower-limit value ⇔ Upper-limit value ⇔

Test time ⇔ Delay time

To display the flashing cursor, press the

keys. The cursor appears,

/

displaying the preset comparative voltage value or test-voltage value.

(withstand-voltage test and insulation-resistance test)

Changes the position at which the flashing cursor appears.

Switches on/off the set value for the position of the flashing cursor. If

turned off, the set value is not used in testing.

However, the following key can't perform the switching on/off:

Withstand-voltage test: Test-voltage type, Test voltage, Upper-limit value

Insulation-resistance test: Test voltage, Lower-limit value

5

4

LOCK key

(LOCAL key)

5

SHIFT key

6

W key

(withstand-voltage test)

7

I key

(insulation-resistance test)

8

W→I key

9

I→W key

10

PROG key

Used to lock the keys.

When pressed, the

STOP

key, and Key Lock Cancel key (

LOCK

key disables all keys except the

LOCK+SHIFT

key). See the

START

key,

"Key-lock Function" section. (Chapter 3 to 6)

In the remote state, this key functions as a

LOCAL

key. It cancels the

remote state.

Used in combination with other keys.

①

SHIFT

+ key

Displaying the Preset-data loading screen. (See Chapter 8)

②

SHIFT

+ key

Displaying the Preset-data saving screen. (See Chapter 8)

③

SHIFT+UNLOCK

key

Disabling the key lock function. Cancels the key lock. When GP-IB is

used for communication, go to LOCAL state.

④

SHIFT

+

key

/

Changing the increment size of setting values.

Performs withstand-voltage tests and settings. (See Chapter 3)

Performs insulation-resistance tests and settings. (See Chapter 4)

Tests for withstand-voltage, then insulation-resistance. (See Chapter 5)

Tests for insulation-resistance, then withstand-voltage. (See Chapter 5)

Creates or edits program tests or their files. (See Chapter 6)

11

PG.LOAD key

12

ENTER key

______________________________________________________________________________________________

1.2 Names and Functions of Parts

Used to load program data. (See Chapter 6)

Used to create or edit program test files. (See Chapter 6)

_____________________________________________________________________________________________

5

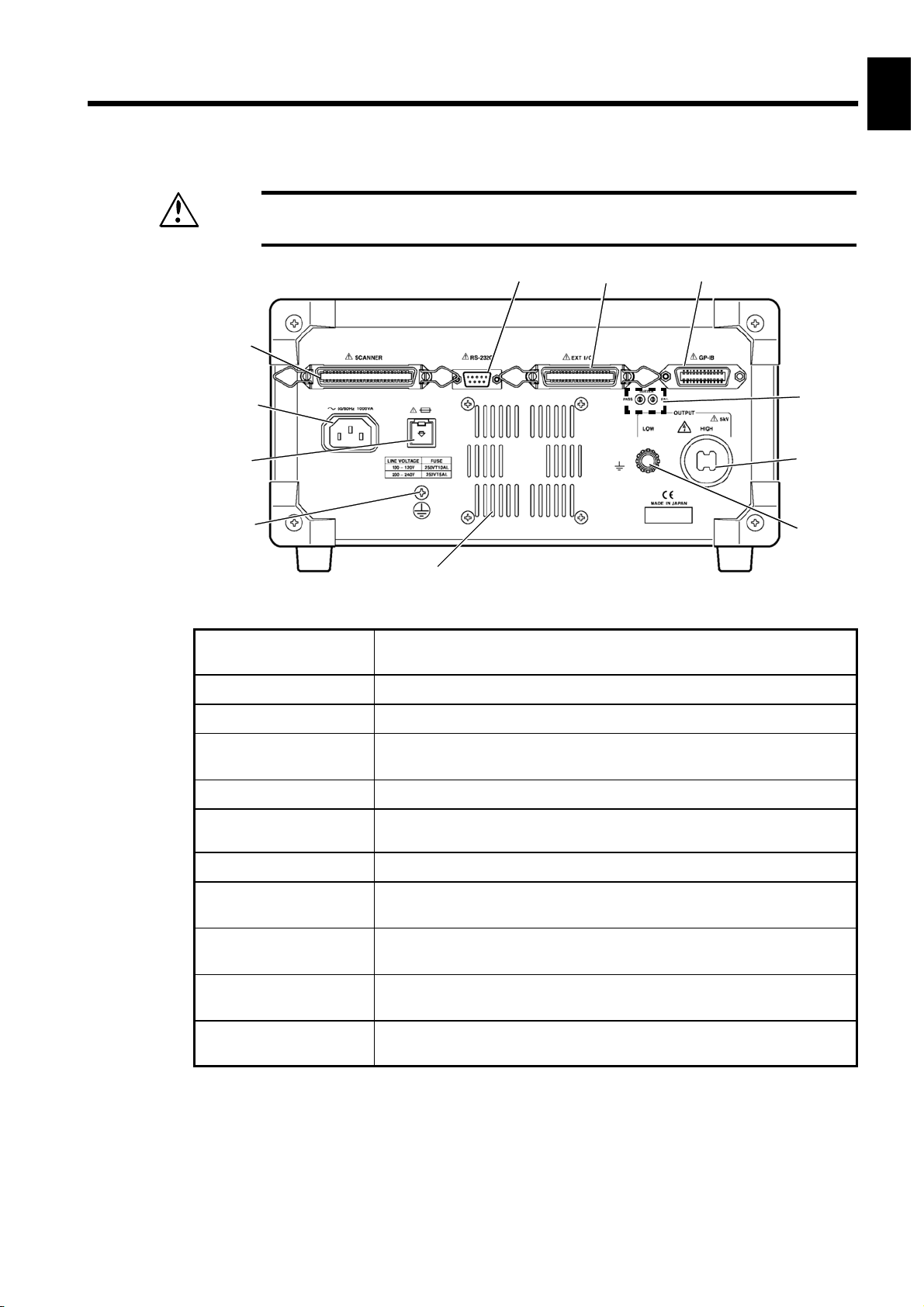

1.2.3 Rear panel

1

2

WARNING

1 Scanner connection

To prevent electric shock, when the

HIGH or LOW terminals, H.V. TEST LEAD, or the tested object.

1

2

3

4

11

terminal

Terminal for connecting the optional 3930 HIGH VOLTAGE

SCANNER. Do not connect any scanner other than the 3930.

DANGER

5 6 7

lamp is lit, never touch the

10

8

9

3

4

5

6

7

8

2 Power inlet

3 Fuse holder

4 Protective ground

terminal

5 RS-232C terminal

6 External I/O

terminal

7 GP-IB terminal

8 HIGH terminal

9 LOW terminal

10 Buzzer adjustment

knob

11 Vent holes

Connect the grounded three-core power cord supplied here.

Contains a power fuse.

Used to earth a protective ground wire. Be sure to make grounding

connections before starting a test.

Used for remote control with RS-232C.

For output of 3153 state and input of start and stop signals.

Used for remote control with GP-IB.

A high-voltage terminal for voltage output. Connected to the

HIGH terminal on the front panel.

A low-voltage terminal for voltage output. Contains the same

electrical potential as this units casing.

Used for buzzer sound adjustment. Two knobs are provided: one

for PASS screening and one for FAIL screening.

Holes for cooling the inside of the unit. Both sides of the unit also

have vent holes.

9

10

11

12

13

14

______________________________________________________________________________________________

1.2 Names and Functions of Parts

A

6

_____________________________________________________________________________________________

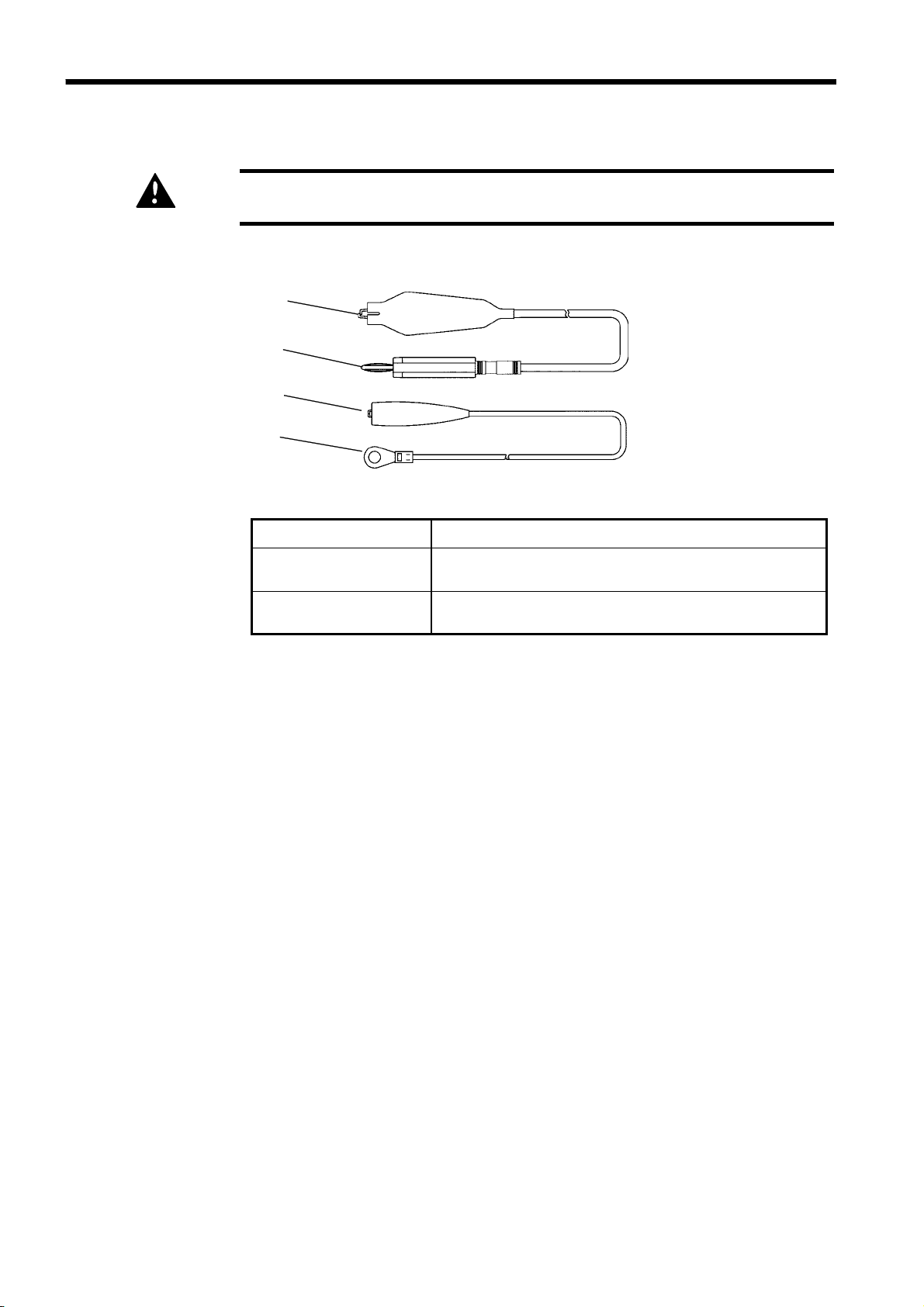

1.2.4 9615 H.V. TEST LEAD

The vinyl shield on the 9615 H.V. TEST LEAD alligator clip is not high

DANGER

voltage insulated. Do not touch when high voltage is applied.

1

High-voltage side (red)

2

1

Low-voltage side (black)

3

1 Alligator clip

2 High-voltage output

plug

3 Low-voltage output

plug

Connect to a test point on the tested object.

Connect to the HIGH terminal on the unit.

Connect to the LOW terminal on the unit.

______________________________________________________________________________________________

1.2 Names and Functions of Parts

_____________________________________________________________________________________________

7

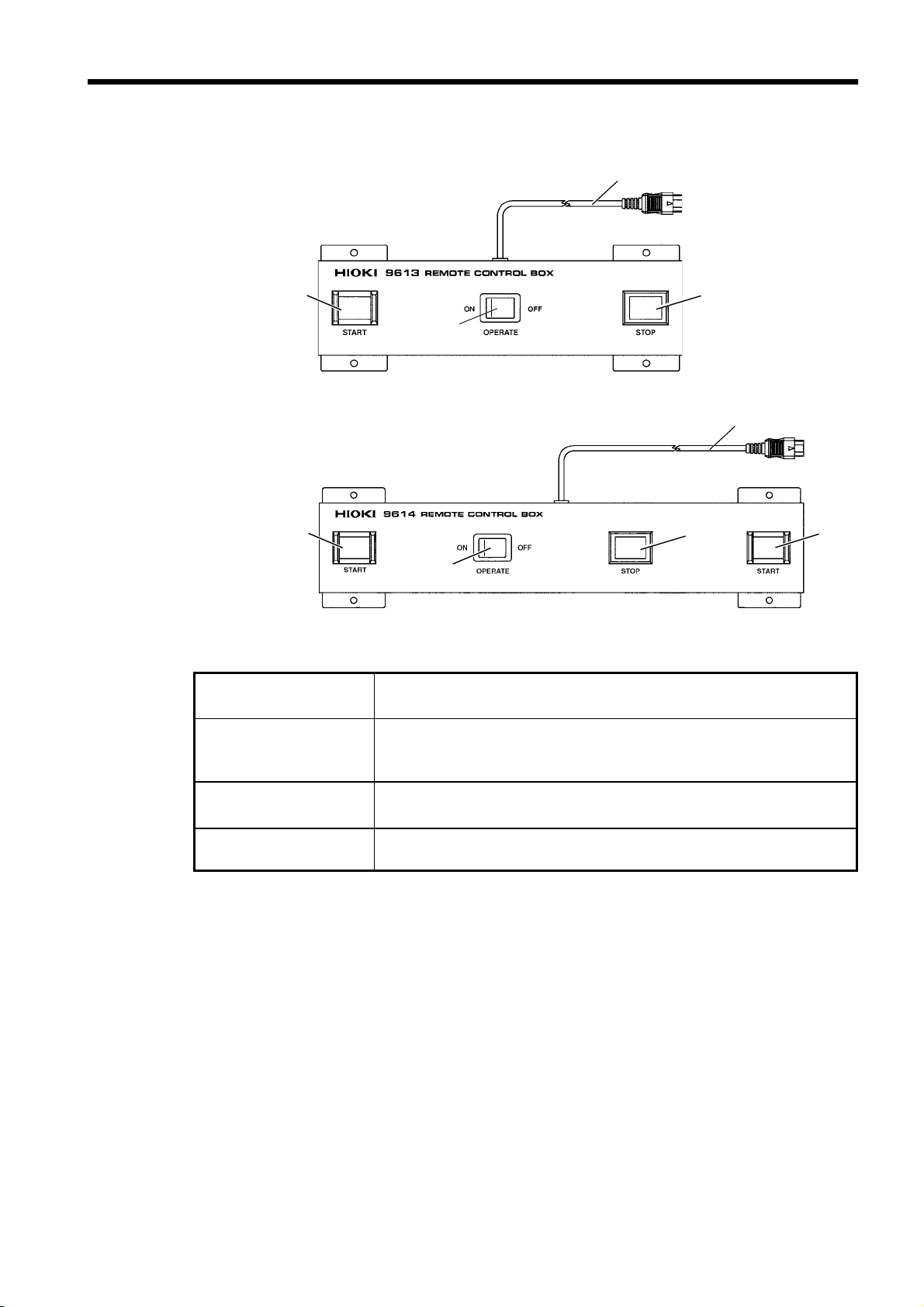

1.2.5 REMOTE CONTROL BOX

9613 REMOTE CONTROL BOX (SINGLE)

2

1

9614 REMOTE CONTROL BOX (DUAL)

2

1

4

3

4

3

2

1 OPERATE switch

2 START key

3 STOP key

4 Switch signal-line

plug

Used to enable remote-control operation. When this switch is ON,

the

START

Works in the same manner as the

the 9614 REMOTE CONTROL BOX (dual-hand), the two

and

STOP

keys for remote control are active.

START

key on the unit. With

START

switches must be pressed.

Works in the same manner as the

STOP

key is ON during a test or when a voltage is being output.

STOP

key on the unit. The

Connect to the external switch terminal on the unit.

______________________________________________________________________________________________

1.2 Names and Functions of Parts

8

_____________________________________________________________________________________________

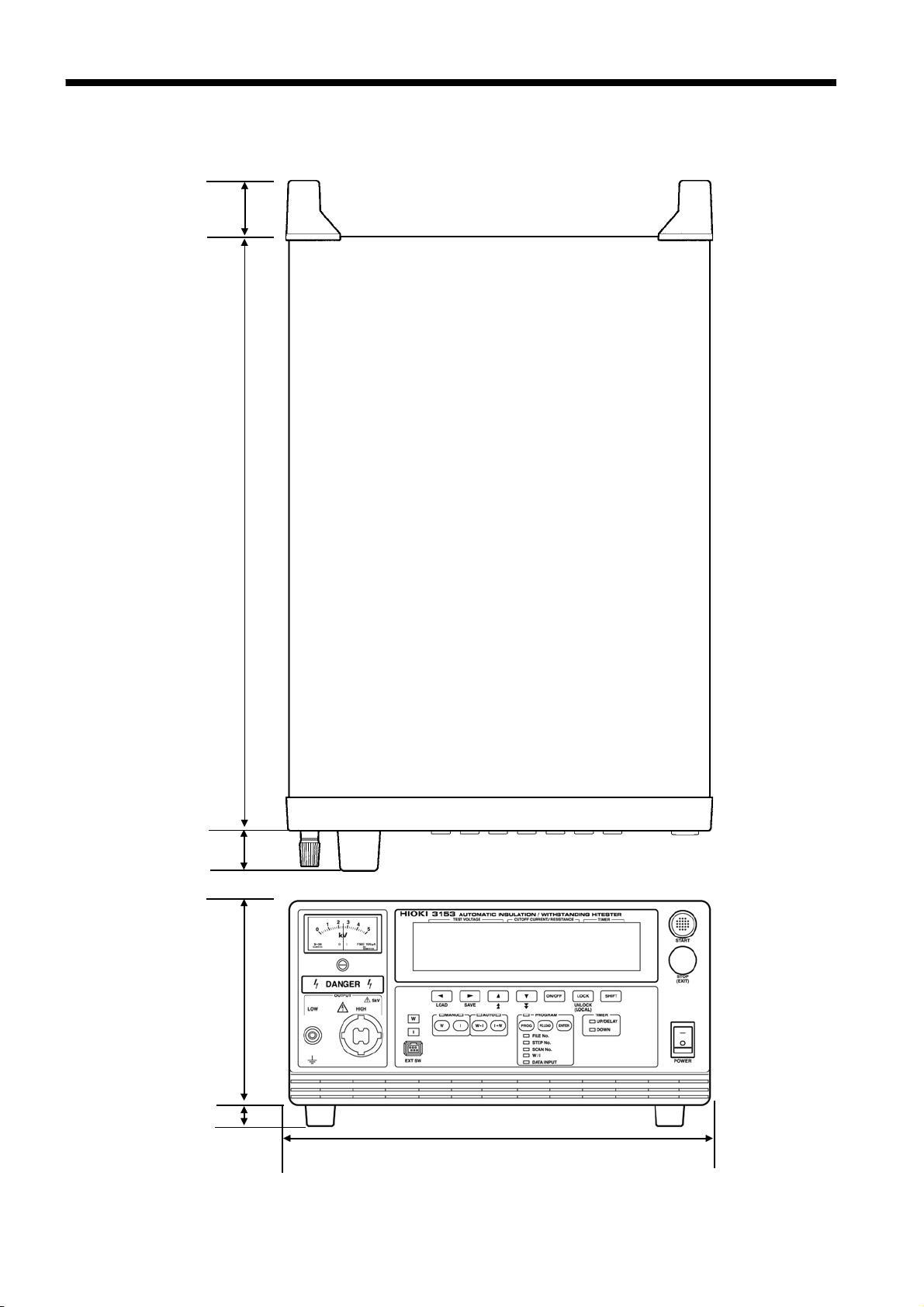

1.3 External Dimensions

m

m

1

±

2

4

m

m

2

±

0

8

4

m

m

1

±

0

3

m

m

2

±

5

5

1

m

m

1

±

6

1

320±2 mm

______________________________________________________________________________________________

1.3 External Dimensions

_____________________________________________________________________________________________

9

Chapter 2

1

2

Testing Arrangements

2.1 Connecting the Protective Ground Terminal

To avoid electric shock, be sure to connect the protective ground

WARNING

terminal to a grounded conductor.

To avoid electric shock, connect the protective ground terminal to a

grounded conductor before making any other connections.

1. Using a Phillips-head screwdriver, remove the protective ground terminal

from the rear of the unit.

2. Connect an electric wire with a sufficient current capacity to the

protective ground terminal, and secure the wire using a Phillips-head

screwdriver.

3

4

5

6

7

8

9

NOTE

3. Ground the other end of the wire.

10

11

12

13

14

A

If the ground-type double-pole power cord that is supplied with the unit is used, the

unit is automatically grounded.

______________________________________________________________________________________________

2.1 Connecting the Protective Ground Terminal

10

(

)

_____________________________________________________________________________________________

2.2 Wearing rubber gloves

To avoid any life-threatening electric shock accidents, ensure that the

DANGER

following rules are observed.

The AC Withstanding HiTester is a dangerous product which

・

discharges high voltages. To prevent getting electrocuted, always

wear high-voltage protective rubber gloves when carrying out any

operation.

Be careful when using the product and ensure that you do not touch

・

this product, any tested object that is connected or any H.V. Test

Lead, etc.

1. To avoid electrocution, always wear high-voltage protective rubber gloves

when using this product.

2. Contact your dealer or Hioki representative to help you look for high-

voltage protective rubber gloves.

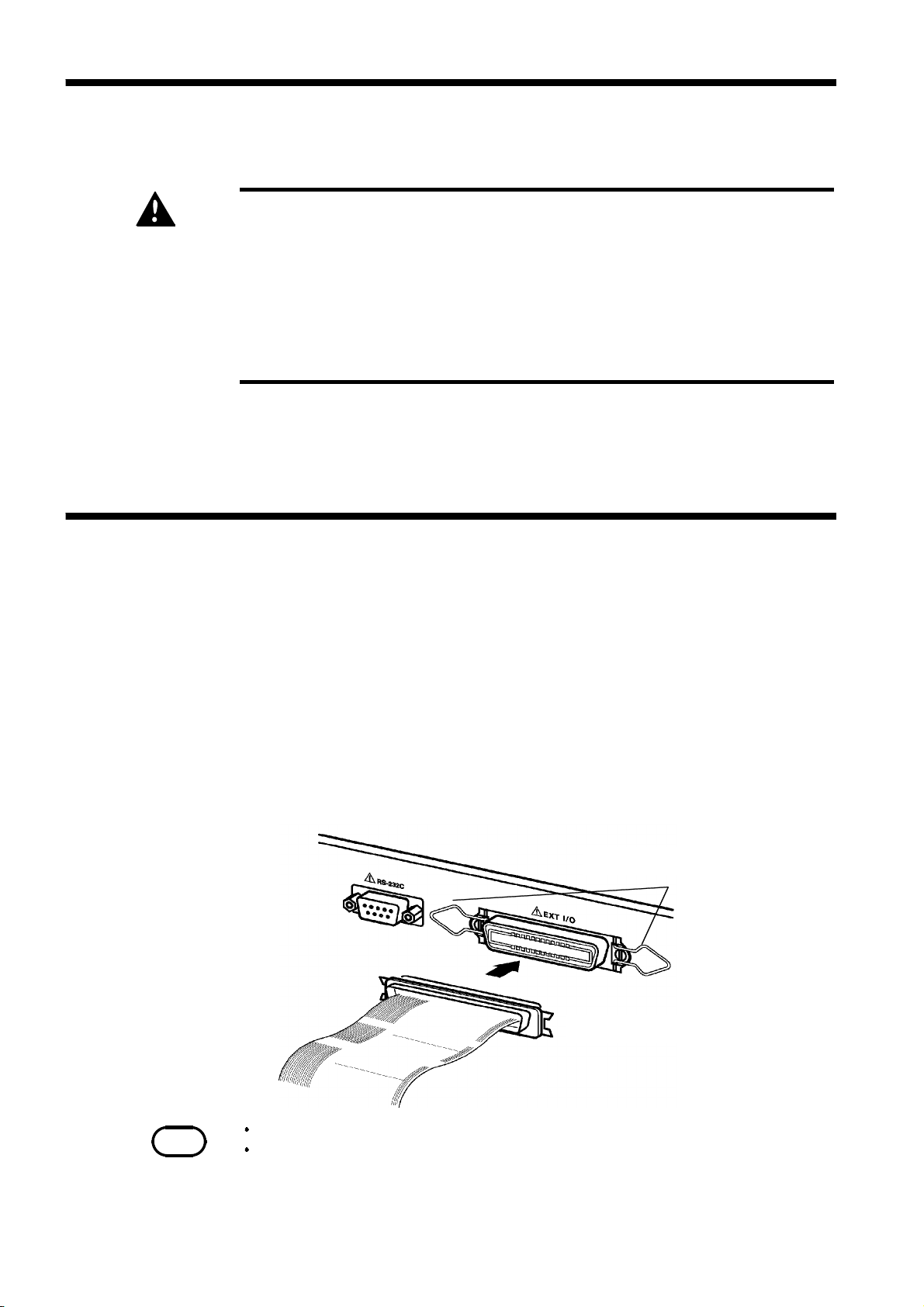

2.3 Connecting the External I/O Connector

Connect the external I/O connector before turning on the power. If the

external I/O connector is installed or removed following startup, malfunction

may result.

1. Insert the external I/O connector into the external I/O terminal.

2. Secure the external I/O connector using the hooks of the external I/O

terminal.

Hook of the external I/O terminal

External I/O connector

NOTE

______________________________________________________________________________________________

2.3 Connecting the External I/O Connector

For the specifications of the external I/O connector, see Section 9.1.

If the optional "Interlock" function is set to "1: Set," set Pin 10 of the external I/O

terminal to "LOW level" before starting a test. "

"LOW level" is set.

See Section 9.1.4

Err 000

" will be indicated until

_____________________________________________________________________________________________

11

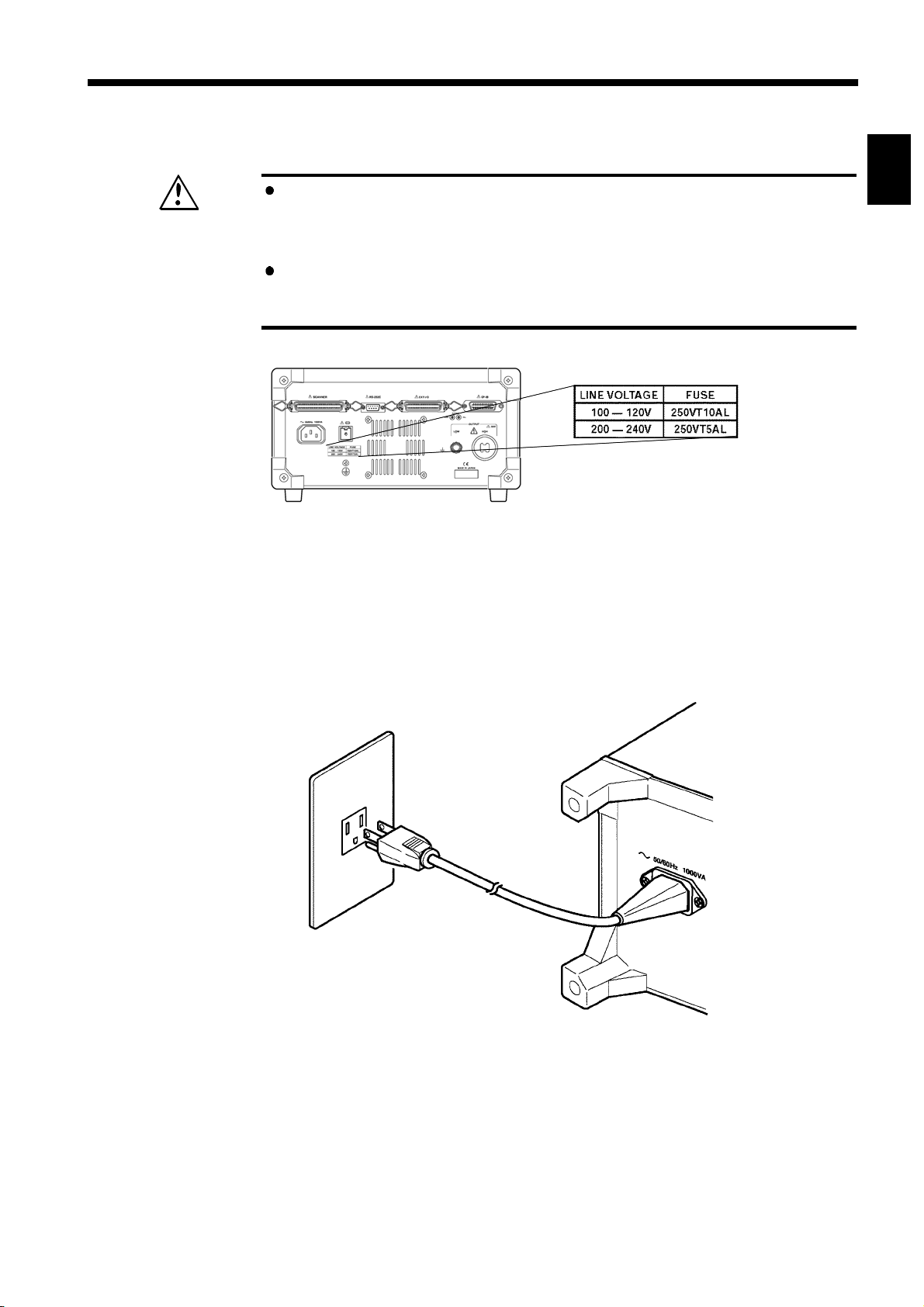

2.4 Power Cord Connection

Before turning the product on, make sure the source voltage matches

WARNING

that indicated on the product's power connector. Connection to an

improper supply voltage may damage the product and present an

electrical hazard.

To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3contact (two-conductor + ground) outlet.

Supply voltage indicated on the rear panel

1

2

3

4

5

6

1. Be sure that the main power switch is turned to OFF.

2. Connect the grounded three-core power cord provided to the power inlet

on the back of the unit.

3. Insert the plug into the grounded outlet.

3

2

7

8

9

10

11

12

______________________________________________________________________________________________

2.4 Power Cord Connection

13

14

A

12

p

_____________________________________________________________________________________________

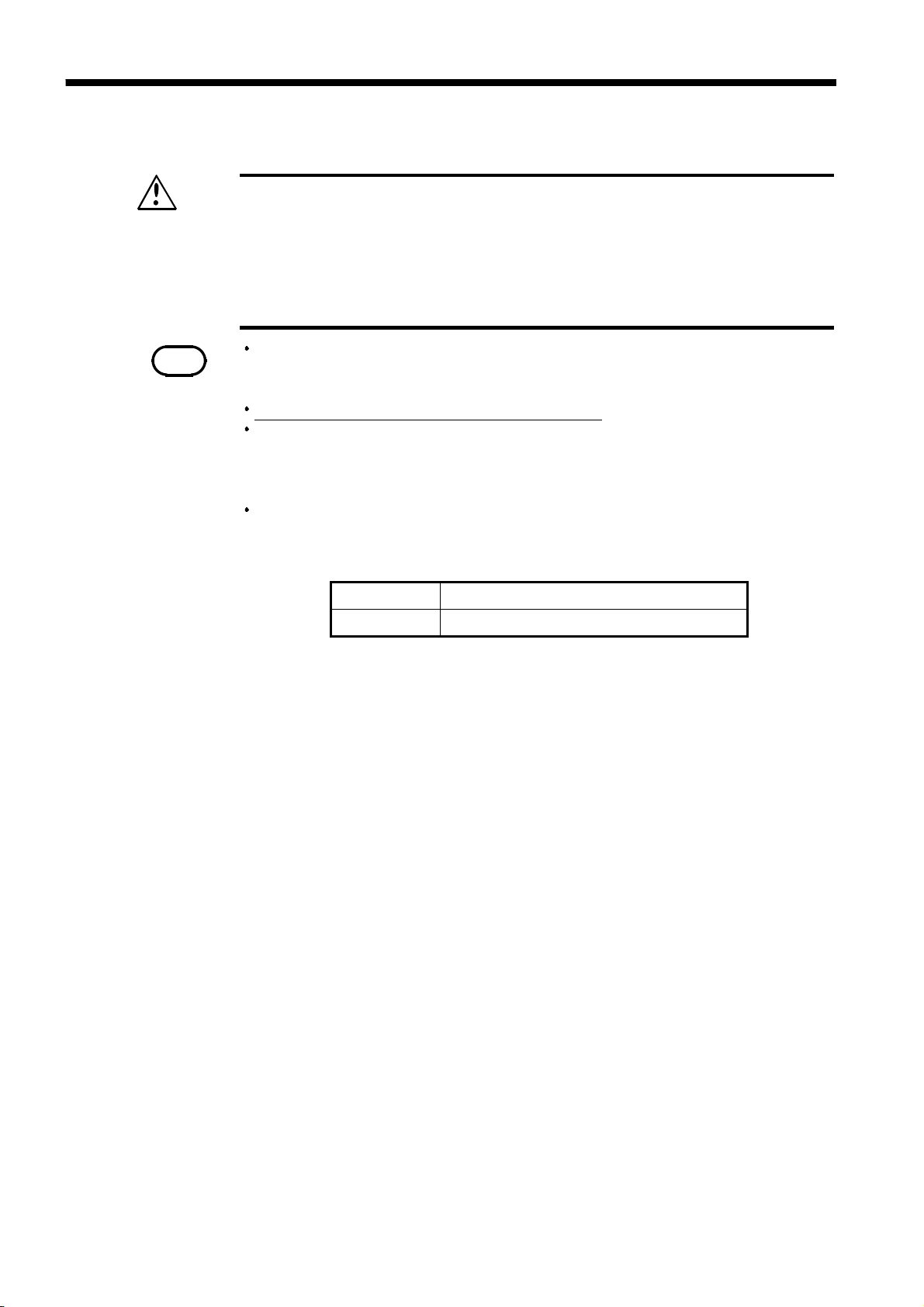

2.5 Powering On and Off the Unit

Before turning on the power, make sure that the voltage of the power

WARNING

supply being used matches the supply voltage indicated on the rear

panel of the unit. If an attempt is made to use an improper supply

voltage, there is danger of damage to this unit and of life-threatening

risk to the operator. Apply a voltage within the acceptable powervoltage range. Otherwise, damage to the unit or electrical accidents

may result.

NOTE

The settings immediately prior to power shutdown are saved. The unit restarts

with these settings, even following a power interruption. When settings are

modified, however they are only saved after running a test.

Allow 10 minutes warming up after powering on.

The REMOTE CONTROL BOX, external I/O device, RS-232C interface, and GPIB interface are active only when they are connected prior to startup. If these

devices are connected after the power is turned on, the protective function may be

activated, thus causing a malfunction.

A filter circuit is provided in the first stage of the power supply. Therefore, power

(apparent power) is consumed even when the main power switch is turned OFF,

rovided that the unit is connected to an outlet.

2

50 Hz (Effective voltage)

60 Hz (Effective voltage)

x 1.4 x 10-3(VA)

2

x 1.7 x 10-3(VA)

______________________________________________________________________________________________

2.5 Powering On and Off the Unit

_____________________________________________________________________________________________

13

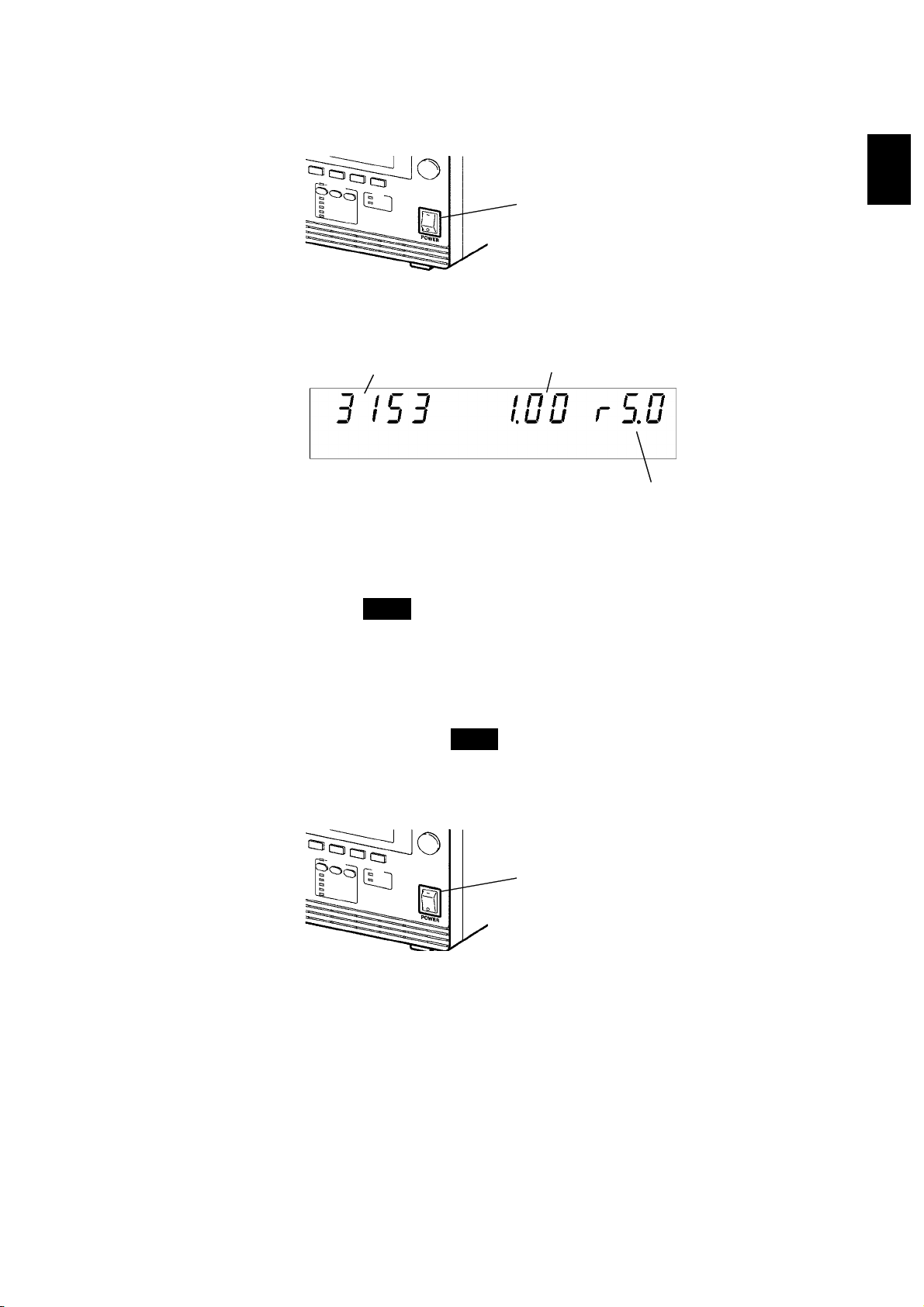

(1) Powering on the unit

1. Turn the main power switch to ON

2. The model name and version number are displayed as below:

Software version

Model name

"Version 1.00" is displayed.

(l)

.

Main power switch

Interface

"RS-232C 9600 bps" is displayed.

"rS.0" :RS-232C 9600 bps

"rS.1" :RS-232C 19200 bps

"G.XX" :GP-IB address XX

1

2

3

4

5

6

7

3. When the

mode), the keys are ready for operation. (See Section 7.5)

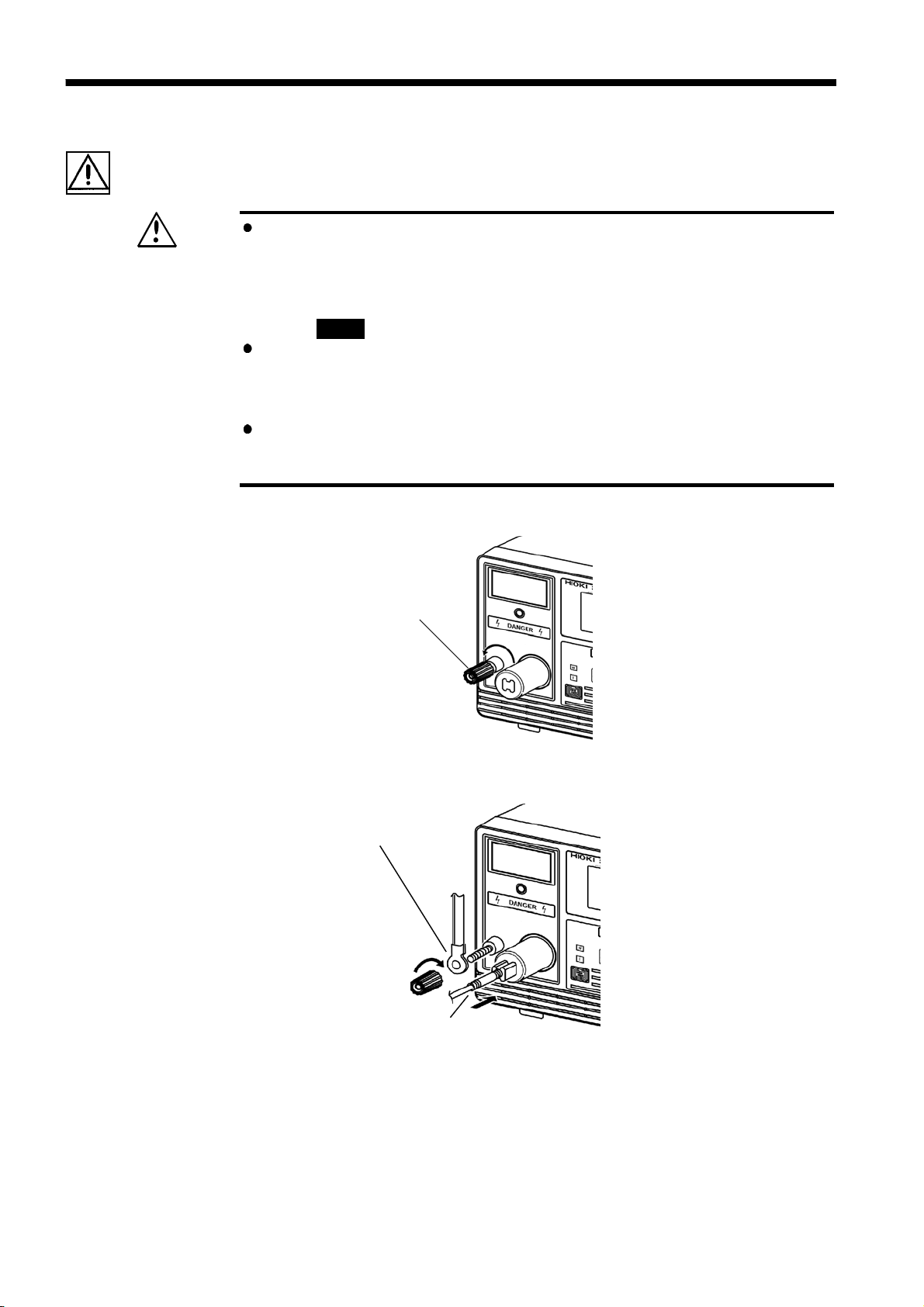

(2) Powering off the unit

1. Following a test, make sure the analog voltmeter is at 0 kV, the

lamp is OFF, and the

2. Turn OFF the Main Power switch.

READY

lamp is lit (it does not light up in the Double Action

READY

lamp is lit.

Main power switch

8

9

DANGER

10

11

12

13

______________________________________________________________________________________________

2.5 Powering On and Off the Unit

14

A

14

_____________________________________________________________________________________________

2.6 Connecting the 9615 H.V. TEST LEAD

To prevent electrical shock, turn off the power unit, make sure that

WARNING

there is no high voltage being applied to the output, confirm the

following 3 items, and connect the 9615 H.V. TEST LEAD.

(1) The analog voltmeter reads 0 kV.

(2) The

(3) The

Before connecting the 9615 H.V. TEST LEAD, be sure to check its

insulation for tearing and metal exposure.Using the product in such

conditions could cause an electric shock, so contact your dealer or

Hioki representative for repair.

To avoid electric shock, make sure the 9615 H.V. TEST LEAD is

securely connected before starting a test, as a loose test lead can

cause a hazard when a voltage is output.

DANGER

READY

lamp is OFF.

lamp is lit (it is off in the Double Action mode).

1. Remove the LOW terminal by turning it counterclockwise.

Low terminal

2. As shown in the figure, insert the plug on the H.V. TEST LEAD (low

voltage side).

Plug on the H.V. TEST LEAD

(low voltage side)

3. Secure the LOW terminal by turning it clockwise.

4. Connect the plug on the H.V. TEST LEAD (high voltage side) to the

HIGH terminal.

______________________________________________________________________________________________

2.6 Connecting the 9615 H.V. TEST LEAD

_____________________________________________________________________________________________

15

2.7 Connecting the REMOTE CONTROL BOX

To prevent electrical shock, turn off the power unit, make sure that

WARNING

there is no high voltage being applied to the output, confirm the

following 3 items, and connect the 9615 H.V. TEST LEAD.

(1) The analog voltmeter reads 0 kV.

(2) The

(3) The

DANGER

READY

lamp is OFF.

lamp is lit (it is off in the Double Action mode).

To prevent malfunctions, do not remove the REMOTE CONTROL BOX

following startup. Before removing it, be sure to turn OFF the power.

To avoid electric shock, when using the REMOTE CONTROL BOX,

provide safety measures to keep the output-voltage terminal, tested

object, and H.V. TEST LEAD out of contact with one another when

they are in the TEST state.

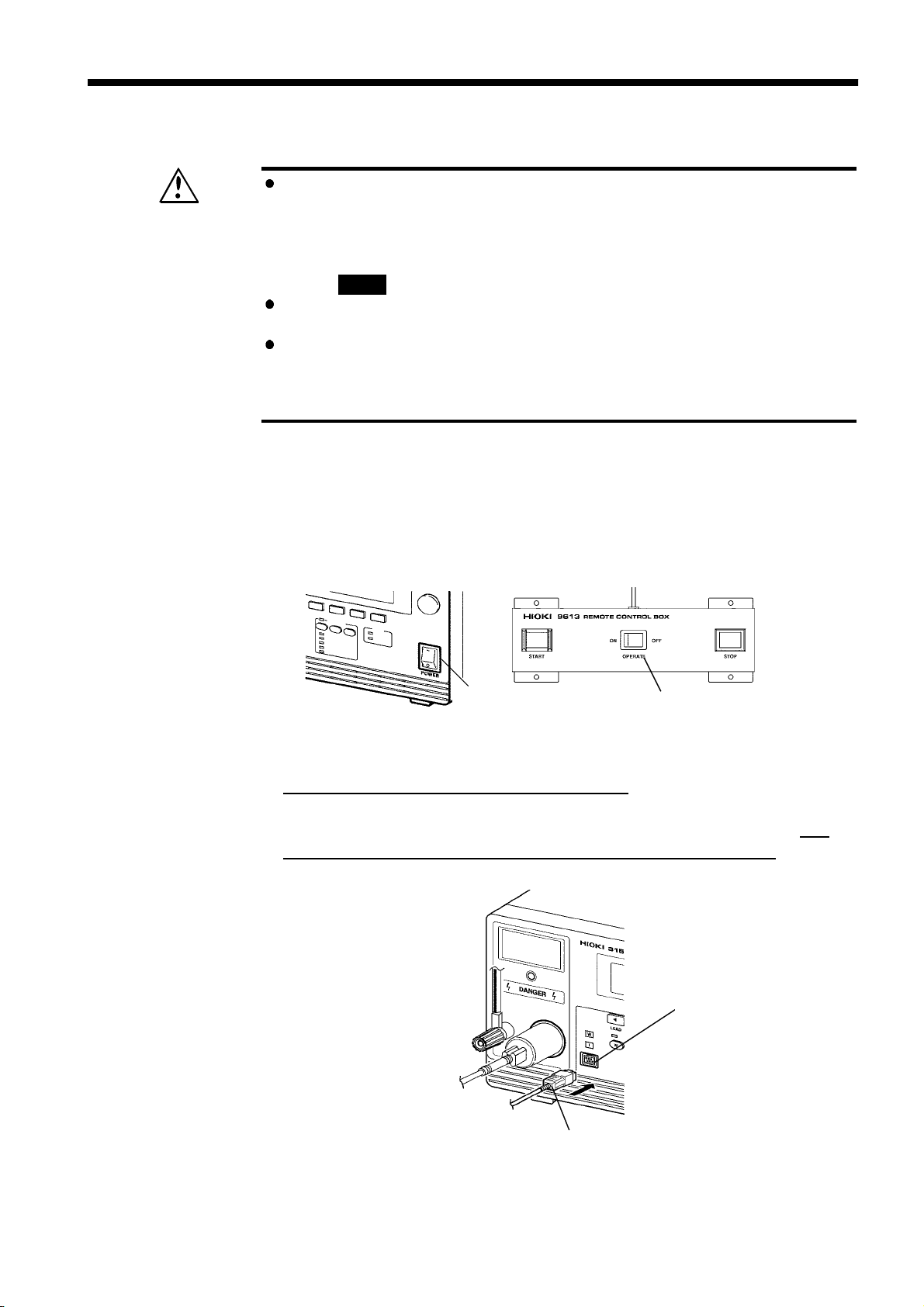

Connection of the REMOTE CONTROL BOX (9613/9614) enables start/stop

operations to be performed easily.

1. Make sure the Main Power switch and OPERATE switch on the

REMOTE CONTROL BOX are OFF.

Main power switch

OPERATE switch on the

REMOTE CONTROL BOX

2. Insert the switch signal-line plug into the external switch terminal.

Check the direction of the switch signal line.

3. Turn ON the

OPERATE

switch can be turned ON/OFF even following startup.

OPERATE

switch of the REMOTE CONTROL BOX. The

External switch terminal

Switch signal-line plug

______________________________________________________________________________________________

2.7 Connecting the REMOTE CONTROL BOX

16

,

_____________________________________________________________________________________________

2.8 Installation of the Unit

Temperature: 0 to 40

℃

Humidity: 80% RH or less (no condensation)

Avoid the following locations:

・

Subject to direct sunlight.

・

Subject to high levels of dust, steam, or corrosive gases (Avoid using the

equipment in an environment containing corrosive gases (e.g., H2S, SO2,

NI2,andCI2) or substances that generate harmful gasses (e.g., organic

silicones, cyanides, and formalins)).

・

Subject to vibrations.

・

In the vicinity of equipment generating strong electromagnetic fields.

NOTE

The noise generated by this unit may affect equipment located around the unit.

Install the unit in such a way that the vent holes on both sides and at the rear of

the unit are not blocked

so that the unit can function normally.

______________________________________________________________________________________________

2.8 Installation of the Unit

_____________________________________________________________________________________________

p

17

2.9 Connection to the Measured Equipment

Observe the following precautions to avoid electric shock.

DANGER

Make sure that no high voltage is being applied to the output, confirm

the following items, and connect the H.V. TEST LEAD.

(1) The analog voltmeter reads 0 kV.

(2) The

(3) The

In the TEST state, never touch the output-voltage terminal, H.V. TEST

LEAD, or tested object.

Even following a test, there may be a residual voltage at the output

terminal. Therefore, before touching the output-voltage terminal, H.V.

TEST LEAD, or tested object, make sure that no high voltage is being

applied between the output terminals.

DANGER

READY

lamp is OFF.

lamp is lit (it is off in the Double Action mode).

NOTE

1. Make sure the analog voltmeter is at 0 kV and the

2. Make sure the unit is in the READY state with the

DANGER

READY

lamp is OFF.

lamp ON (it is

OFF in the Double Action mode).

3. Connect the LOW terminal probe to the tested object. Fasten the probe

securely to prevent it from loosening during a test.

4. Following the procedure described above, connect the HIGH terminal

probe to the tested object.

Note that taking measurements or routing cables in a humid location may cause

errors in insulation-resistance tests.

If the HIGH and LOW voltage output terminals short-circuit or a dielectric

breakdown occurs in the tested object during the test, noise will be generated and

such noise may lead to a malfunction of this unit or of a nearby electronic device.

If this problem occurs, connect a ferrite core or a resistor to the H. V. TEST

LEAD (high voltage side).

When using a resistor, choose one appropriate for the power rating and withstand

voltage. Also, be alert to any drop in test voltage.

Beware of electric shock when connecting the resistor.

Do not the test lead and the EXT/IO cable arranged closely to each other.

Doing so may lead to a malfunction of the external control due to a noise.

Additionally, if the test lead touches to other metallic parts, it may cause an

increase in leakage current.

Prevent the test lead from coming into contact with other parts as much as

ossible.

______________________________________________________________________________________________

2.9 Connection to the Measured Equipment

Loading...

Loading...