Page 1

Instruction Manual

3145-20

NOISE HiLOGGER

Contains explanation and

instructions regarding the

3145-20 NOISE HiLOGGER’s

operating method and functions.

April 2013 Revised edition 5 3145A981-05 13-04H

Page 2

Page 3

Contents

Contents

i

Introduction.................................................................................1

Verifying Package Contents.......................................................2

Safety Information .................................. ... ... ..............................3

Operating Precautions................................................................5

Chapter 1 Overview__________________________ 7

1.1 Product Overview .........................................................7

1.2 Features ....................................................................... 8

1.3 Measuring Principle ......................................................9

1.3.1 Monitor Measuring and Logging Measuring ...........10

1.3.2 Merits of the Measurement Method of this

Instrument ...............................................................1 1

1.4 Names and Functions of Parts ...................................12

1.5 Display Screen ...........................................................16

1.5.1 Screen Layout .........................................................16

1.5.2 Logging Screen .......................................................17

1.5.3 Monitor Screen .......................................................20

1.5.4 Icon Summary .........................................................22

1.5.5 Submenus ...............................................................24

Chapter 2 Measurement Preparations _____25

2.1 Attaching the Strap .....................................................26

2.2 Install the Ferrite Cores ..............................................27

2.3 Connecting the AC Adapter .......................................28

2.4 Supplying Power with the Battery Pack .....................29

2.4.1 Installing the Battery Pack ......................................29

2.4.2 Charging the Battery Pack ......................................30

2.4.3 Battery Pack Life .....................................................32

2.5 Connect the CLAMP ON NOISE SENSOR ................33

2.6 Turning the Power On and Off ...................................36

2.7 Using the PC Card .....................................................37

2.7.1 Inserting the PC card ..............................................37

2.7.2 PC Card Initialization ..............................................38

2.8 Pre-Operation Inspection ......... ..................................40

1

2

3

4

5

6

7

8

9

A

Index

Page 4

ii

Contents

Chapter 3 Measurement____________________ 41

3.1 The Measurement Process ....................................... 42

3.2 Check the Current Input (Monitor Measurement) ...... 43

3.3 Record Changes Over Time (Logging Measurement) 45

3.4 "O.F." Display and "U.F." Display .............................. 50

Chapter 4 Useful Functions ________________ 51

4.1 View the Latest Logging Measurement Value or

Peak Value ................................................... ... ... ....... 52

4.2 Check Using a Bar Graph (Monitor Measurement) ... 52

4.3 View Past Waveforms (Scroll Function) .................... 53

4.3.1 Scrolling the Waveform ..........................................53

4.3.2 Auto Scrolling .........................................................54

4.4 A/B Cursor Measurement .......................................... 55

4.5 Using the Alarm Function .......................................... 56

4.5.1 Settings on the Logging Screen or the

Monitor Screen. ......................................................56

4.5.2 Setting on the Set Up Screen .................................59

4.5.3 Take the Alarm Reference Value (Monitor Screen) 65

4.6 Adding Event Marks to Waveforms ........................... 66

4.6.1 How to Add an Event Mark .....................................66

4.6.2 Searching Event Marks ..........................................67

4.7 Highlighting a Specific Band ...................................... 68

4.8 Preventing Malfunctions (Key Lock) ........... .. ... ... .. ..... 69

4.9 Saving the Display Screen to PC Card

(Screen Capture) 70

Chapter 5

Setting the Measurement Conditions ______ 71

5.1 Inputting Comments ..................................... ... .......... 72

5.1.1 Comment Input Method Details ..............................73

5.2 Setting the Input Type ............................................... 74

5.3 Setting the Range ..... ............................... ... ............... 75

5.4 Setting the Recording Interval ................................... 76

5.5 Setting the Recording Time ....................................... 77

5.6 Setting the Waveform Color ...................................... 79

Page 5

Chapter 6 Saving and Reading Data________81

6.1 Saving Data during Measurement ............ ... .. .............82

6.1.1 Select "3145 Form" .................................................82

6.1.2 Filenames ............................................................... 83

6.1.3 Save Mode ..............................................................84

6.1.4 Specify the File Save Target ...................................89

6.2 Planning to Save Text after Measurement .................90

6.3 Saving Data after Measurement .............................. ..91

6.4 Saving Settings Data ..................................................94

6.5 Reading Measurement and Settings Data .................97

6.6 File Operation .............................................................99

6.6.1 Moving between Folders .......................................100

6.6.2 Deleting Files and Folders ....................................101

6.6.3 Creating Folders ...................................................102

6.6.4 Changing File Names and Folder Names .............104

6.6.5 Changing the File Order .......................................105

6.7 Calculation Method for “3145 Form” Files ................106

6.8 Content Format for Text Format Files ......................107

Chapter 7 System Screen_________________ 109

iii

Contents

1

2

3

4

5

6

7.1 Env (Environment) Screen .................................... ...110

7.1.1 Start Key Receive Condition

(Malfunction Prevention) 110

7.1.2 Start Backup After Power Loss .............................111

7.1.3 Grid Type ..............................................................112

7.1.4 Time Format when Saving Text ............................11 3

7.1.5 External Trigger Input (Event Marker) ..................114

7.1.6 External Trigger Filter ...........................................115

7.1.7 Copy Key Function (Monitor) ................................116

7.1.8 Save Color ............................................................117

7.1.9 Backlight Saver .....................................................118

7.1.10Backlight Brightness .............................................119

7.1.11Screen Color Scheme ...........................................120

7.1.12Display Language .................................................121

7.2 Setting Screen ..........................................................122

7.2.1 Saving Settings .....................................................122

7.2.2 Loading Setting Conditions ...................................124

7.2.3 Deleting Setting Conditions ..................................125

7.2.4 Automatically Loading ...........................................126

7

8

9

A

Index

Page 6

iv

Contents

7.2.5 Auto Setup ............................................................126

7.3 Init (Initialization) Screen ......................................... 127

7.3.1 Setting the Clock ..................................................127

7.3.2 Erasing Logging Measurement Data ....................128

7.3.3 System Reset .......................................................129

7.3.4 Self-check .............................................................130

Chapter 8 Using the CD ___________________131

8.1 CD Contents ............................................................ 131

8.2 Installing the Software ............................................. 132

8.3 Running the Software ............ .................................. 133

8.4 Deleting the Application (Uninstall) ..................... .. ... 134

8.5 Opening the Instruction Manual (PDF Format) ........ 135

Chapter 9 Specifications __________________137

9.1 General Specifications ............................................. 137

9.2 Input Area Specifications .. .. ..................................... 140

9.3 Accuracy ........................ .......................... ................ 142

9.4 Function Specifications ............................ ................ 143

9.5 Application Software Specifications ......................... 146

Chapter 10 Maintenance and Service_____147

10.1 Troubleshooting ....................................................... 148

10.1.1Before Returning for Repair ..................................148

10.1.2System Reset .......................................................149

10.2 Warning Messages .................................................. 150

10.3 Cleaning .................................................................. 152

10.4 Replacing the Backup Battery ............... .. ... .. ... ... ..... 153

10.5 Removing the Battery Before Discarding the

Instrument 154

Appendix____________________________________ A1

Appendix 1 The Carrying Case ......................................................A1

Appendix 2 Trigger Terminals ........................................................A2

Appendix 2.1EXT TRIG Terminal .............................................A2

Appendix 2.2TRIG OUT Terminal .............................................A5

Appendix 3 Glossary of Terms.......................................................A7

Page 7

Introduction

Thank you for purchasing the HIOKI "Model 3145-20 NOISE HiLOGGER." To obtain maximum performance from the instrument, please

read this manual first, and keep it handy for future reference.

The following instruction manuals are included with the 3145-20 NOISE

HiLOGGER. Refer to them as they pertain to your usage of the instrument.

Manuals Contents

Measurement Guide

1

1

Introduction

Read first.

Offers an introduction to the 314520's basic measuring method for first

time users.

Instruction Manual

2

(this manual)

CD

"DATA VIEWER for

3145"

3

Instruction Manual

"Communications"

4

Instruction Manual

"Communication

Commands"

5

Instruction Manual

Use the optional Clamp on Noise Sensor for measuring current. Read

uction manual included with the Clamp on Noise Sensor and fol-

the instr

low all safety precautions.

User's License The "DATA VIEWER for 3145" software is included with the instrument.

Th

is software requires a license agreement. Please use it only after

reading and accepting the license agreement at the back of the book.

Registered

Trademarks

Windows, Microsoft Excel, and MS-DOS are registered trademarks of

Microsoft Corporation in the United States and/or other countries.

Contains explanation and instructions

rding the instrument's operating

rega

method and functions.

Contents

Contains information about PC soft-

ware which can analyze the measurement data recorded by the

instrument.

Explains the communication functions

which can be used via the LAN and

RS-232C interfaces.

Explains the commands for remote

control of the instrument via the LAN

and RS-232C interfaces.

Page 8

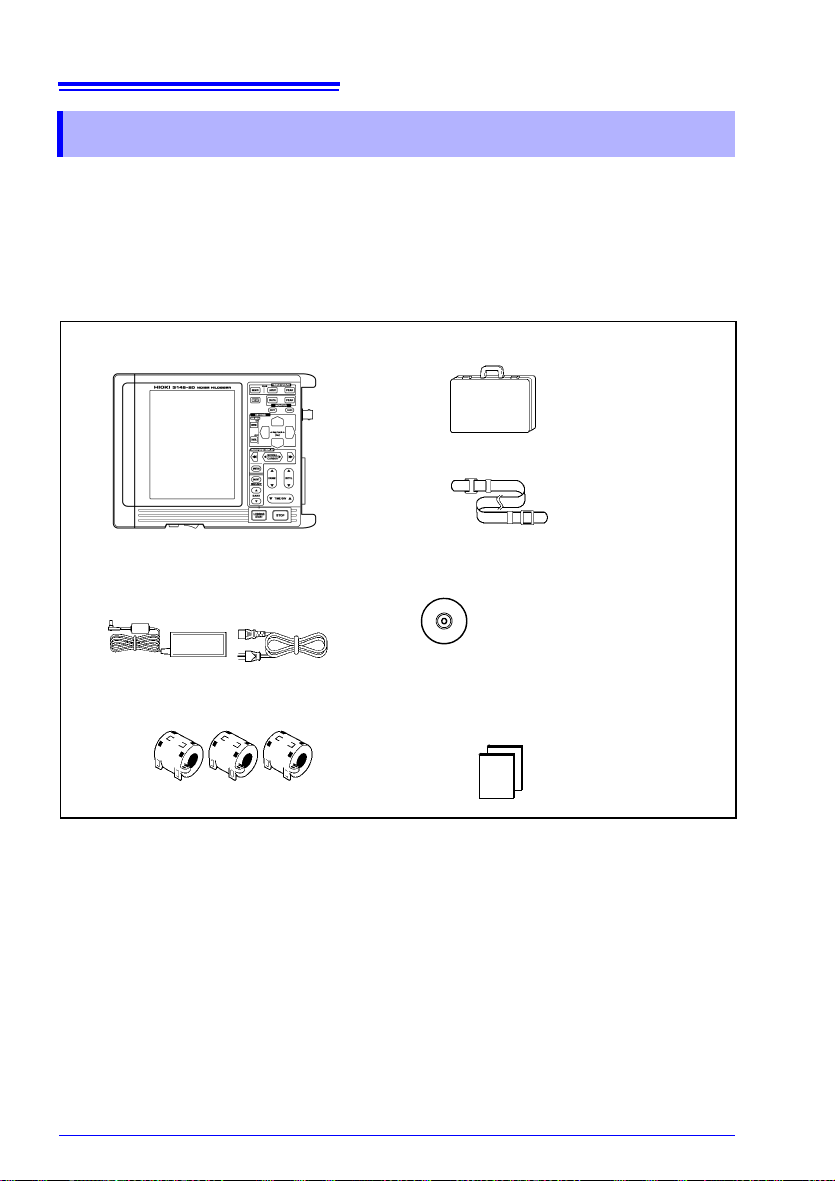

2

Carrying case........................................1

Strap......................................................1

CD (Software, Instruction Manuals)

...................................................................1

Instruction Manual (this manual)/

Measurement Guide ..................each one

• "DATA VIEWER for 3145"

Software and Instruction Manual

• "Communications”

Instruction Manual

• "Communication Commands"

Instruction Manual

Model 3145-20 NOISE HiLOGGER ......1

Accessories

Model 9418-15 AC ADAPTER..............1

Ferrite cores........................................ ..3

Verifying Package Contents

Verifying Package Contents

• When you receive the instrument, inspect it carefully to ensure that no damage occurred

during shipping. In particular, check the accessories, panel switches, and connectors. If

damage is evident, or if it fails to operate according to the specifications, contact your

dealer or Hioki representative.

• Use the original packing materials when transporting the instrument, if possible.

Please check to make sure that no items are missing from your package.

Options Model 9754 CLAMP ON NOISE SENSOR

Model 9418-15 AC ADAPTER

Model 9447 BATTERY PACK (7.2 V, 2400 mAh)

Model 9643 CHARGE STAND (For the 9447 BATTERY PACK)

Model 9612 RS-232C CABLE

(9-pin mini DIN to 9-pin Dsub, cross cable, for PC)

Model 9721 RS-232C CABLE

(9-pin mini DIN to 9-pin Dsub, straight cable, for modem)

Model 9726 PC CARD 128M

Model 9727 PC CARD 256M

Model 9728 PC CARD 512M

Model 9729 PC CARD 1G

Model 9642 LAN CABLE

Page 9

Safety Information

3

Safety Information

Notation

Symbols

Safety

This instrument is designed to comply with IEC 61010 Safety Standards, and has been thoroughly te

ment. However, mishandling during use

death, as well as damage to the instrument. Using the instrument

in a way not described in this manual may negate the provided

safety features.

Be certain that you understand the instruc

the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition.

using it, be sure to carefully read the following safety precautions.

Before

In the manual, the symbol indicates particularly important information that the user should read before using

the in

strument.

The symbol printed on the instrument indicates that

the user should refer to a corresponding topic in the man-

ual (marked with the symbol) before using the relevant

function.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

sted for safety prior to ship-

could result in injury or

tions and precautions in

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of

ns and warnings.

cautio

Indicates that incorrect operation presents an extreme

haza

rd that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a significant

haza

rd that could result in serious injury or death to the

user.

Indicates that incorrect operation presents a possibility of

injur

y to the user or damage to the instrument.

Indicates advisory items related to performance or correct

oper

ation of the instrument.

Page 10

4

Safety Information

Others

Indicates a prohibited action.

p

Indicates the location of reference information.

Indicates quick references for operation and remedies for

oubleshooting.

tr

Indicates that descriptive information is provided below.

*

Accuracy We define measurement tolerances in terms of rdg. (reading) valu e, with

the follo

wing meanings:

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring

instrument.

Measurement categories

To ensure safe operation of measurement instrument, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

CAT II

CAT III

CAT IV

Using a measurement instrument in an envi-

onment designated with a higher-numbered

r

category than that for which the instrument is

rated could result in a severe accident, and

must be carefully avoided.

Use of a measurement instrument that is not

CAT-rated in CAT II to CAT IV measurement

applications could result in a severe accident,

and must be carefully avoided.

Primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the distribution panel

panel to outlets.

The circuit from the service drop to the service entrance, and to the power

meter and primary overcurrent protection instrument (distribution panel).

, and feeders from the distribution

Page 11

5

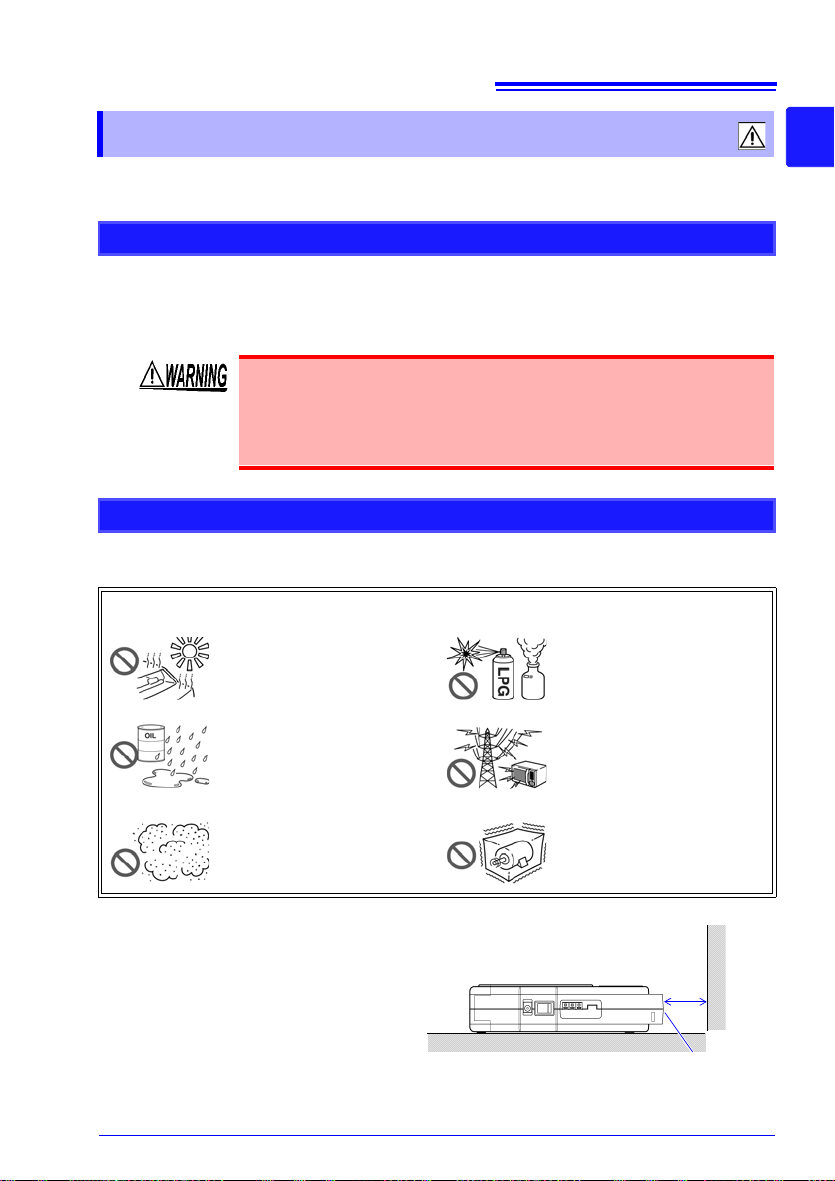

Installing the instrument

• Vents must not be obstructed.

• The instrument should be operated

only with the bottom side downwards.

• Do not place on an unstable stand or

on an incline.

10 cm or more

Ventilation holes

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary checks

Before using the instrument the first time, verify that it operates normally to ensure that the

n

o damage occurred during storage or shipping. If you find any damage, contact your

dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the

test leads is undamaged and that no bare conductors are improperly exposed. Using the instrument i

cause an electric shock, so contact your dealer or Hioki representative for repair.

Installing the instrument

Operating temperature & humidity: 0 to 40°C (32 to 104°F), 80%RH or less (non-condensating)

Operating temperature & humidity for guaranteed accuracy: 23

Avoid the following locations that could cause an accident or damage to the instrument.

n such conditions could

± 5°C (73 ± 9°F), 80%RH or less

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity

or

condensation

Exposed to high levels of

p

articulate dust

In the presence of corrosive or explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Subject to vibration

Page 12

6

Operating Precautions

Handling the instrument

To avoid electric shock, do not remove the instrument's case. The

internal components of the instrument carry high voltages and

may become very hot during operation.

To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

To avoid problems with battery operation, remove the batteries from the

instrument if it is to be stored for a long time.

Handling the CD

• Always hold the disc by the edges, so as not to make fingerprints on

the disc or scratch the printing.

• Never touch the recorded side of the disc. Do not place the disc

directly on anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not

use a ball-point pen or hard-tipped pen, because there is a danger of

scratching the surface and corrupting the data. Do not use adhesive

labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high temperature or humidity, as there is a danger of warping,

with co

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry

cloth, or use a CD cleaner. Always wipe radially from the inside to the

outside, and do no wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system

tha

t arises from the use of this CD, or for any problem related to the

purchase of a Hioki product.

nsequent loss of data.

Page 13

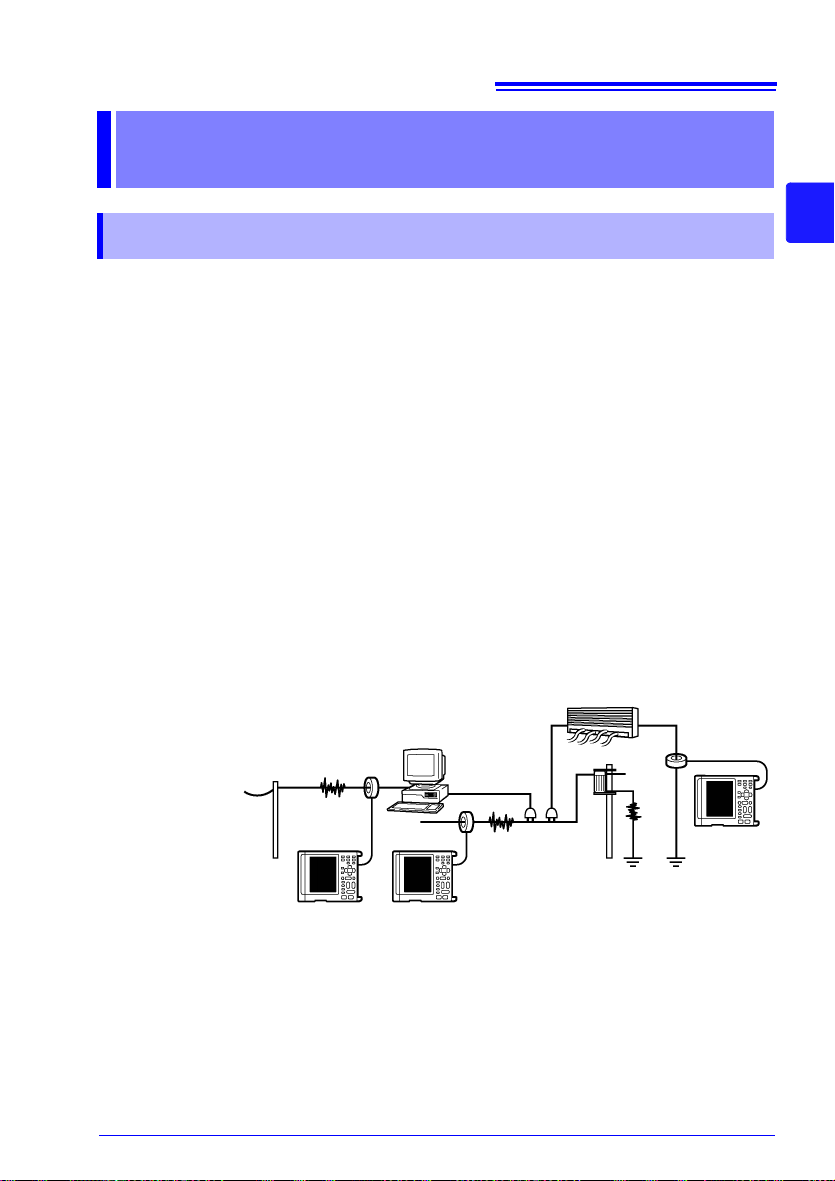

1.1 Product Overview

Communication

lines

Electrical

lines

Ground

lines

Overview Chapter 1

7

1.1 Product Overview

The 3145-20 NOISE HiLOGGER is the ideal measuring instrument for

measuring current on lines which can easily become channels for noise

penetration, such as communication lines, electric power cords and

ground lines which connect to electronic equipment.

By clamping with the 9754 CLAMP ON NOISE SENSOR the 3145-20

detects noise without touching the sample. Therefore it can perform

measurements on instruments in their normal operational state, without

worry of communication malfunction due to probe contact, or electrical

shock or electrical short circuit accidents from electrical lines. Furthermore, it can reliably detect sudden surges which may occur unexpectedly, such as thunder surges and open-close surges.

With the use of the logging function, long term or cyclic noise level fluctuations can be understood. Recorded data is shown on the instrument's

color LCD display as a chronological graph. Additionally, transferring

data to a PC and checking the chronological graph can be done using

the "DATA VIEWER for 3145" software on the included CD. This can be

useful for examining noise counter-measures after an occurance of

noise interference.

1

Chapter 1 Overview

Page 14

8

1.2 Features

1.2 Features

Simple and safe measurements

With the use of the optional Clamp on Noise Sensor, noise can be measured on

power cords, various communications lines, and ground lines without making contact or grounding.

Wide frequency range (5 kHz - 100 MHz)

The instrument is effective for detecting switching regulator noise, inverter noise,

electrostatic discharge noise, and FM broadcast wave noise.

Surge detection

The instrument detects lightning surges, power-related switching surges, and

electrostatic discharge noise.

Logging measurement function

Long-term and cyclic noise levels can be ascertained, and the times at which the

noise and interference occured can be investigated.

Alarm function and event mark function

An alarm level for alarm output can be set, and event marking can be enacted at

the time an event occurs.

Remote measuring with an HTTP server

Remote control of the instrument's settings, data acquisition and data display can

be performed using a web-based browser such as IE.

A portable, dedicated noise measurement instrument intended for onsite use

The instrument supports two types of power sources, recharchable batteries

designed for on-site use, and an AC adaptor power supply for long period observation and remote measuring. The recharchable battery can also be used as a

backup in case of power failure.

Page 15

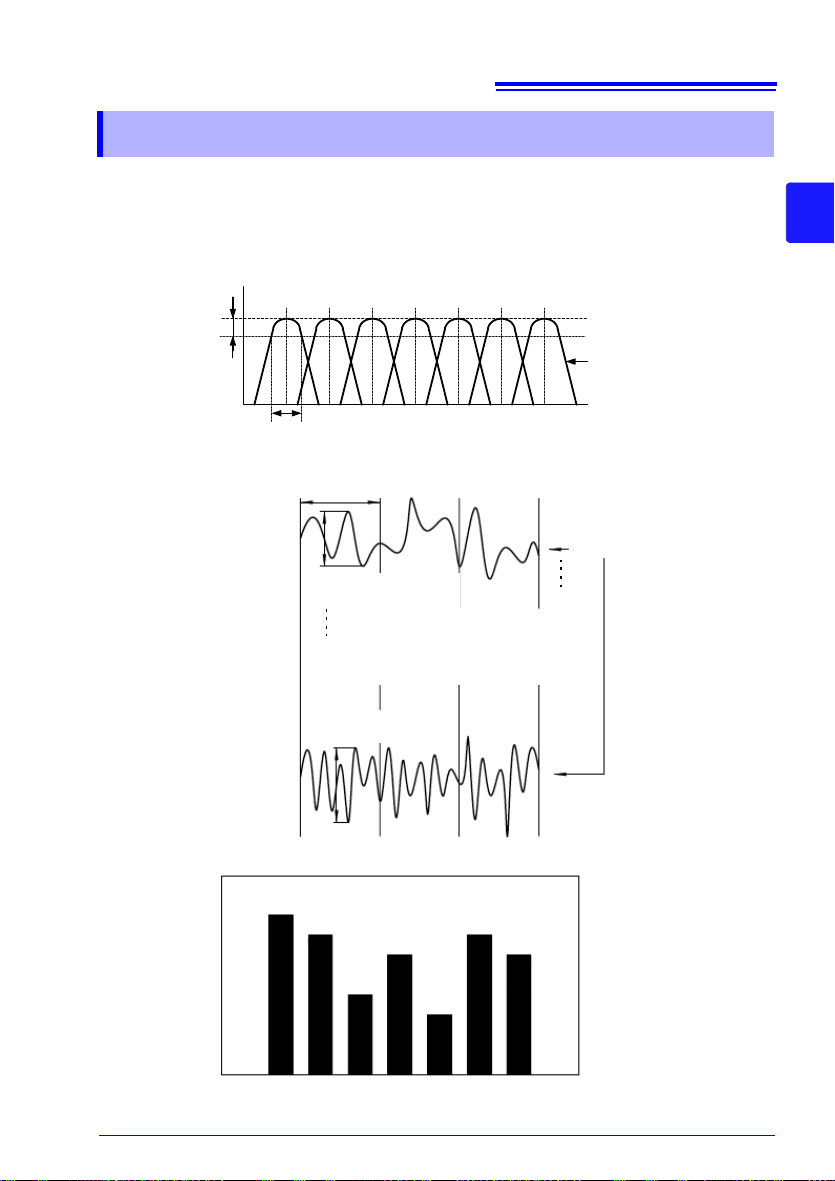

-3dB

Q=fo/B=1

15kHz 70kHz 250kHz 1MHz 5MHz 20MHz 60MHz

-40dB/dec

Center frequency f

0

Attenuation property

Frequency

Band width B

Amplification

15kHz

70kHz

250kHz

1MHz

60MHz20MHz

5MHz

f0 = 15 kHz

f

1

= 70 kHz

f

2

= 250 kHz

f

3

= 1 MHz

f

4

= 5 MHz

f

5

= 20 MHz

f

6

= 60 MHz

Sampling time

Measurement

values at each

band

Measures and displays Peak to Peak

values during sampling time at each

PBF.

Peak to Peak value

within sampling time

Peak to Peak value

within sampling time

9

1.3 Measuring Princi ple

1.3 Measuring Principle

The instrument separates input noise waves into frequency bandwidths using a seven

band-pass filter (7 frequency waves) and detects and displays peak values (Peak to Peak

values) for each respective frequency range.

1

Chapter 1 Overview

Page 16

10

The current input levels of each frequency are displayed

as a bar graph and numbers.

Noise measurement can be made easily in the tester interval.

With the logging measurement function the change over

time of the noise level of each frequency band is recorded. When and at what frequency band

noise penetrated can be easily ascertained. The time that

the interference occured and the type of noise that occured at that time can be understood.

The peak value within the manually set recording interval

segment is saved in the internal memory and displayed in

a chronological bar graph. The recording interval can be

set between 1 second and 60 seconds.

Measurement data can be saved on PC card.

Daily and weekly changes in the noise can be observed using the "DATA VIEWER for 3145" software on the included CD to conduct daily and

weekly calculation displays of the recorded data.

1.3 Measuring Principle

1.3.1 Monitor Measuring and Logging Measuring

This instrument has two measuring modes, monitor and logging.

Monitor measurement

Logging measurement

Page 17

1.3 Measuring Princi ple

Electrostatic discharge

Electric railway induction

Flourescent light

Motor for power

Arc-welding machine

Medium wave radio

Lightning surge

Switching

Neon sign

Elevator

The 3145-20 possible

measurement range

1G

100M

10M

1M

100k

10k

1k

The cause of the noise

Frequency (Hz)

Cellular phone

Television

Personal wireless radio

Banned CB wireless radio

Amateur radio

FM broadcast

Short wave radio

Inverter

Electric power induction

1.3.2 Merits of the Measurement Method of this

Instrument

11

Simultaneous noise measurement of each frequency bandwidth from 10 kHz

to 100 MHz.

Noise exists in a wide bandwidth and its frequency differs depending on

its cause. With this instrument a wide bandwidth of noise can be

checked all at once.

Peak-detection function for capturing surge events

Surge incidents of noise such as lightning surges and electrostatic discharge noise sometimes occur. Using the instrument's peak function,

incidents of surge noise can be accurately captured.

1

Chapter 1 Overview

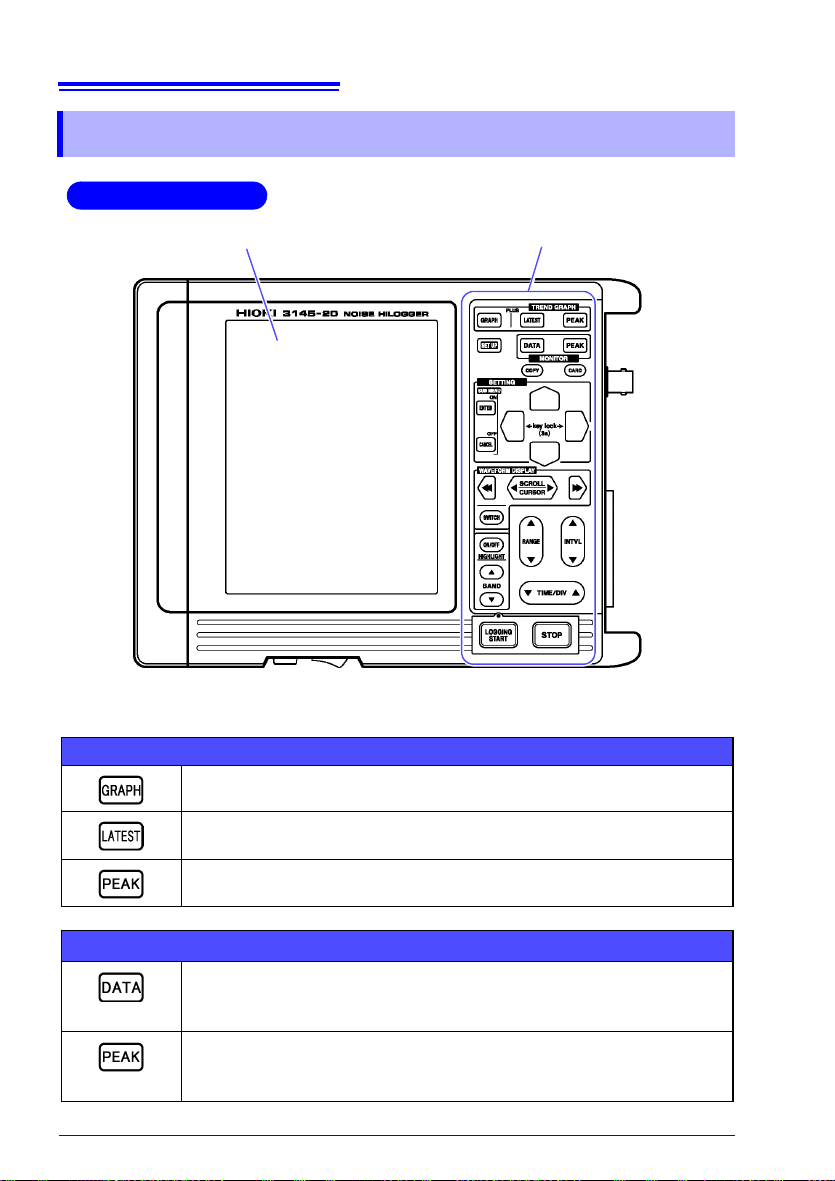

Page 18

12

Display ( p. 16)

Front Panel

Key operations

1.4 Names and Functions of Parts

1.4 Names and Functions of Parts

Key operations

Logging (time series graph)

Monitor (level meter)

Displays the waveforms on the full screen.

Displays the latest value on the left side, and the waveforms on the right

side of the screen.

Displays the peak value on the left side, and the waveforms on the right

side of the screen.

Displays the instantaneous values as a bar graph.

Displays the instantaneous values on the left side, and a bar graph on the

right side of the screen.

Displays the peak values as a bar graph.

Displays the peak values on the left side, and the bar graph on the right

side of the screen.

Page 19

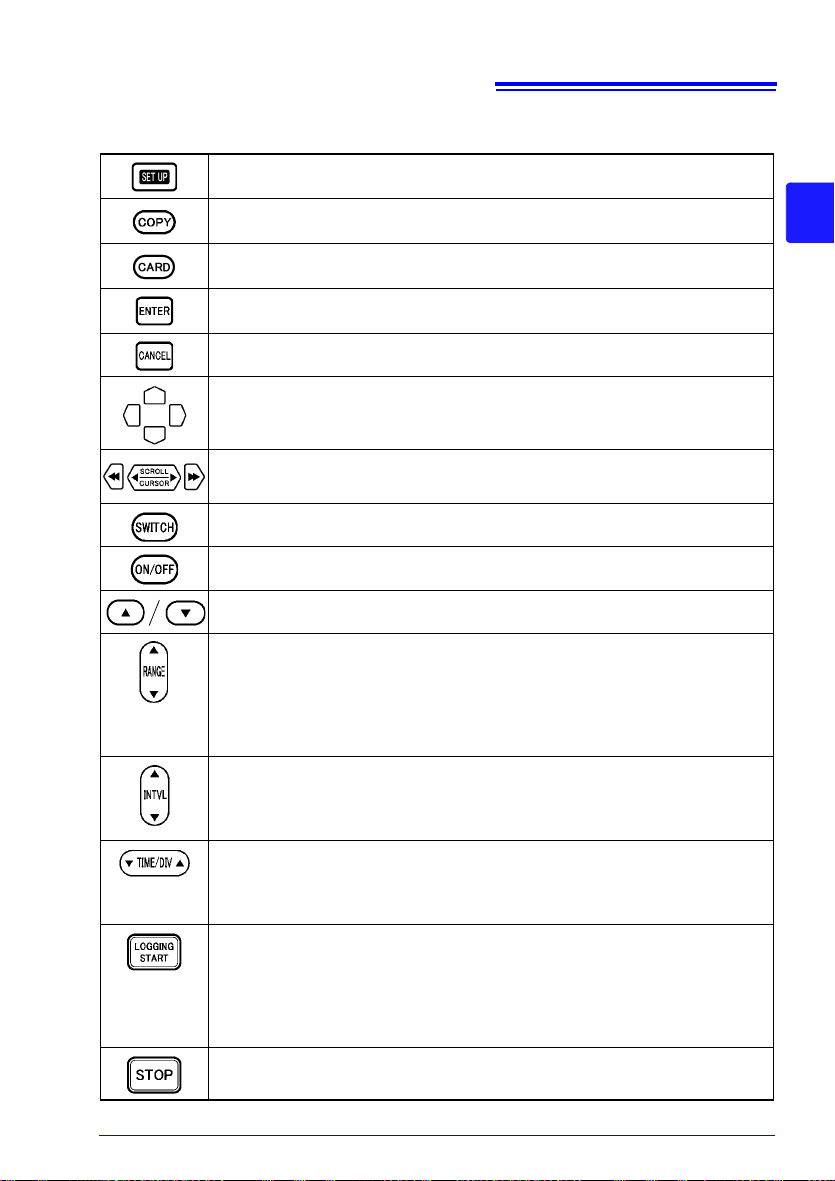

Key operations (continued)

Displays the Set up screen (the screen for setting the measurement conditions).

Saves an image of the display screen to a PC card.

Takes the alarm reference value from the measurement value.

Displays the PC card screen. Performs loading and saving of measurement

and other data.

Displays the settings contents summary. Turns off the settings contents display.

Cancels the item selected with the cursor.

Moves the cursor up, down, left and right.

Scrolls the waveform. Moves the A/B cursor.

Switches between waveform scroll and A/B cursor movement.

Highlights and displays a particular waveform during logging measurement.

Selects the band to highlight.

13

1.4 Names and Functions of Parts

1

Chapter 1 Overview

Sets the range.

When the input category is current sensor: selects between 200 mA, 2 A

and 20 A.

When the input category is voltage: selects between 10 mV, 100 mV and

1 V.

The possible measurement range differs depending on the selected range.

Sets the interval for taking data.

Select 1s, 2s, 5s,10s, 20s, 30s or 60s to suit the object to be measured.

Shortening the recording interval causes the maximum recording time to be

decreased.

Sets the logging measurement time axis (horizontal axis).

Select 2s, 5s, 10s, 20s, 30s, 1min, 2min, 5min, 10min, 20min, 30min, 1h,

2h, 5h,10h, 12h or 1d.

The time axis indicates the time of 1 mass in the horizontal axis direction.

Commences logging measurement. Adds an event marker if pressed during measurement.

(regarding the key LED display)

Green light : Performing logging measurement; backlight OFF

Flashing green light : Performing settings; backlight OFF

Red light : Performing battery charge with the power turned off.

Press twice to stop logging measurement.

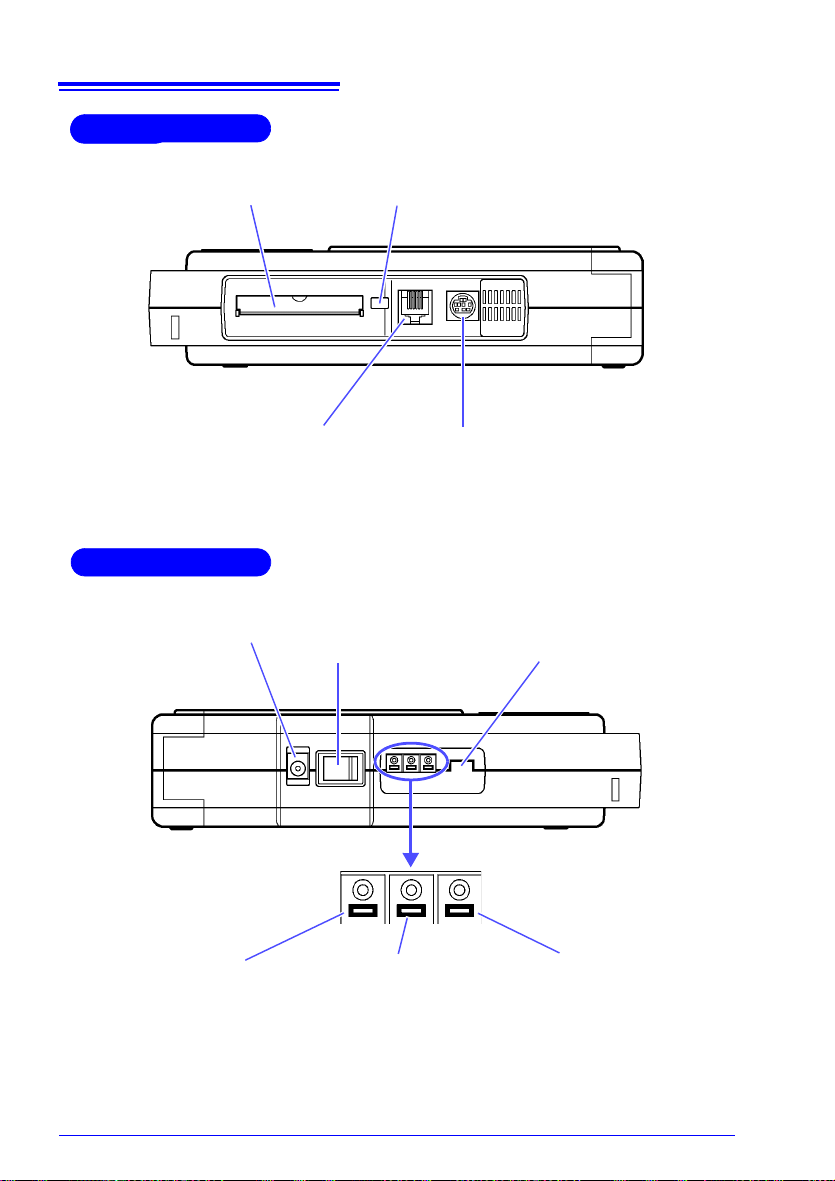

Page 20

14

Eject button

Ejects the PC card.

PC card slot

10BASE-T Ethernet connection port

Connects with a 9642 LAN CABLE.

RS-232C port

Connects with the 9612 RS-232C CABLE

(cross cable for PC use) or the 9721 RS-232C

CABLE (straight cable for modem use).

è„ ñþ

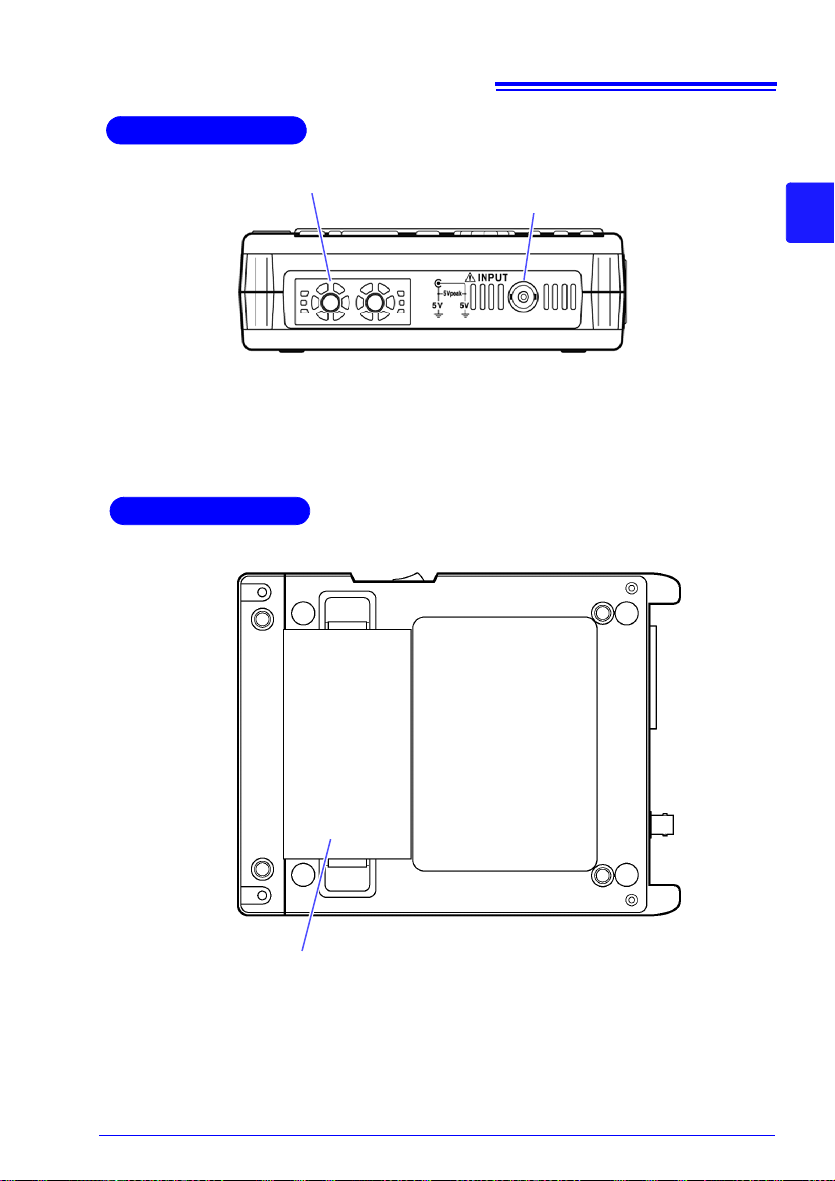

Upper Panel

Lower Panel

AC adaptor input connector

Power switch

(POWER)

Contrast adjustment control

(CONTRAST)

EXT TRIG terminal

(external trigger)

Used for entering event markers during logging measurement. (

p. A2)

TRIG OUT terminal

(trigger output)

Outputs a signal during

warning. (

p. A5)

GND terminal

Used in combination with the

trigger terminals

1.4 Names and Functions of Parts

Page 21

15

Right Panel

Input terminal

Connects with the Clamp on Noise Sensor.

Ventilation holes

Bottom Panel

Battery box

For installing the 9447 BATTERY PACK

1.4 Names and Functions of Parts

1

Chapter 1 Overview

Page 22

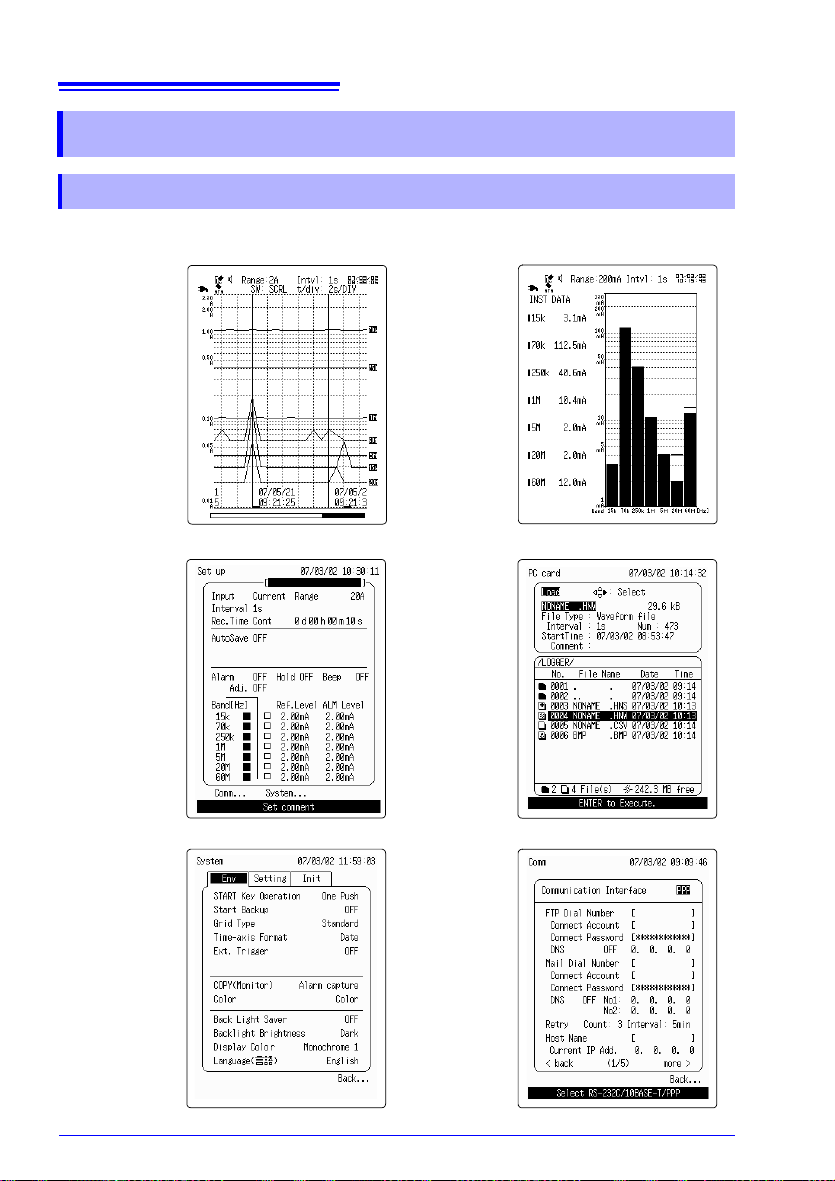

16

Logging

Screen

•Full

• Latest values

• Peak values

(Full screen

shown right)

Set up

Screen

System

Screen

•Env

• Setting

•Init

Monitor

Screen

• Instantaneous values

• Peak values

(Instantaneous

value shown

right)

PC card

Screen

Comm

Screen

1.5 Display Screen

1.5 Display Screen

1.5.1 Screen Layout

Broadly classified, the instrument has the following 6 different display screen layouts.

Page 23

17

Displays the waveforms on the full screen.

Displays the latest value on the

left side, and the waveforms on

the right side of the screen.

Displays the peak value on the left

side, and the waveforms and date

and time on the right side of the

screen.

1.5 Display Screen

1.5.2 Logging Screen

The logging screen has three display types: full screen display, latest value display, and

peak value display.

1

Chapter 1 Overview

Page 24

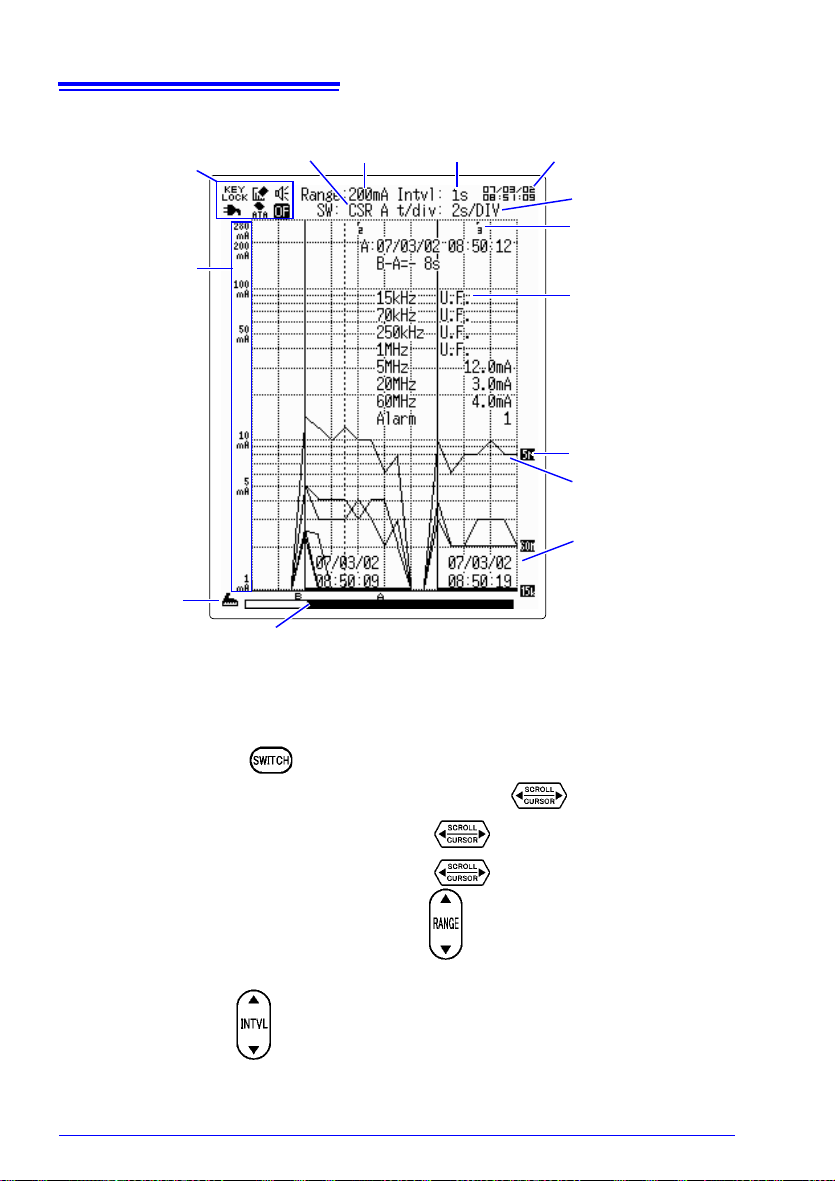

18

Range Recording interval Time

Time axis

Toggle

Icon

Gauge

Time display

Band waveform

Event mark

A/B cursor

values

Band marker

View

Icon

1.5 Display Screen

Logging screen

Icon Displays various aspects of the instrument's current state. ( p. 22)

Gauge The vertical axis of the graph (logarithmic display).

Toggle Press to toggle between the following functions:

Scroll: Scroll through the waveform using .

Cursor A: Move cursor A using .

Cursor B: Move cursor B using .

Range The measurement range. Use to set.

Recording

int

The recording interval for logging measurement.

erval

Use to set.

Page 25

19

Marker

O.F. icon

1.5 Display Screen

Time Displays the current time. Set using the System Init screen.

Time axis The period of time for 1 mass in the time access direction. Use

to set.

Event mark A mark can be added by pressing during logging measurement.

1

Chapter 1 Overview

A/B cursor

values

Band marker Indicates which waveform band is being displayed.

Individual

ban

waveform

Time display The graph's horizontal axis (measurement time) display.

Alarm

aveform

w

Overflow

(O.F.)

The read value of the measurement value.

The measurement waveforms for each individual band.

d

Toggles between time, date and time, and data number for the current

display e

play the display format changes each time is pressed.

If the alarm function is set and the measurement value exceeds the judgment value a marker appears at the bottom of the graph.

View The display position of the currently displayed waveform (the section of

wavefo

Also displays the positions of the A cursor and B cursor.

If the measurement value exceeds the measurement range, a marker

appears at the top of the graph. Also, the icon is displayed in the

upper left of the screen.

ach time the key is pressed. For example, during full screen dis-

rm being displayed relative to the full waveform).

Underflow

U.F.)

(

Underflow occurs when the measurement value is lower than the measurement range.

Page 26

20

Displays the instantaneous values on the left side, and a bar graph on the

right side of the screen.

Displays the peak value with its date and time on the left side, and a bar

graph on the right side of the screen.

1.5 Display Screen

1.5.3 Monitor Screen

The monitor screen has two display types: instantaneous value display and peak value display.

Page 27

Monitor screen

Range

Time

Icon

Peak

Alarm judgment

value

Band display

Level bar

21

1.5 Display Screen

1

Chapter 1 Overview

Alarm judg-

Band display The frequency band display.

Icon Displays various aspects of the instrument's current state. ( p. 22)

Range The measurement range. Use to set.

Time Displays the current time. Set using the System Init screen.

ment value

Level bar The current input value.

The value at which an alarm is triggered at each band when using the

alar

m function.

Peak The peak value at the time of the screen display.

Page 28

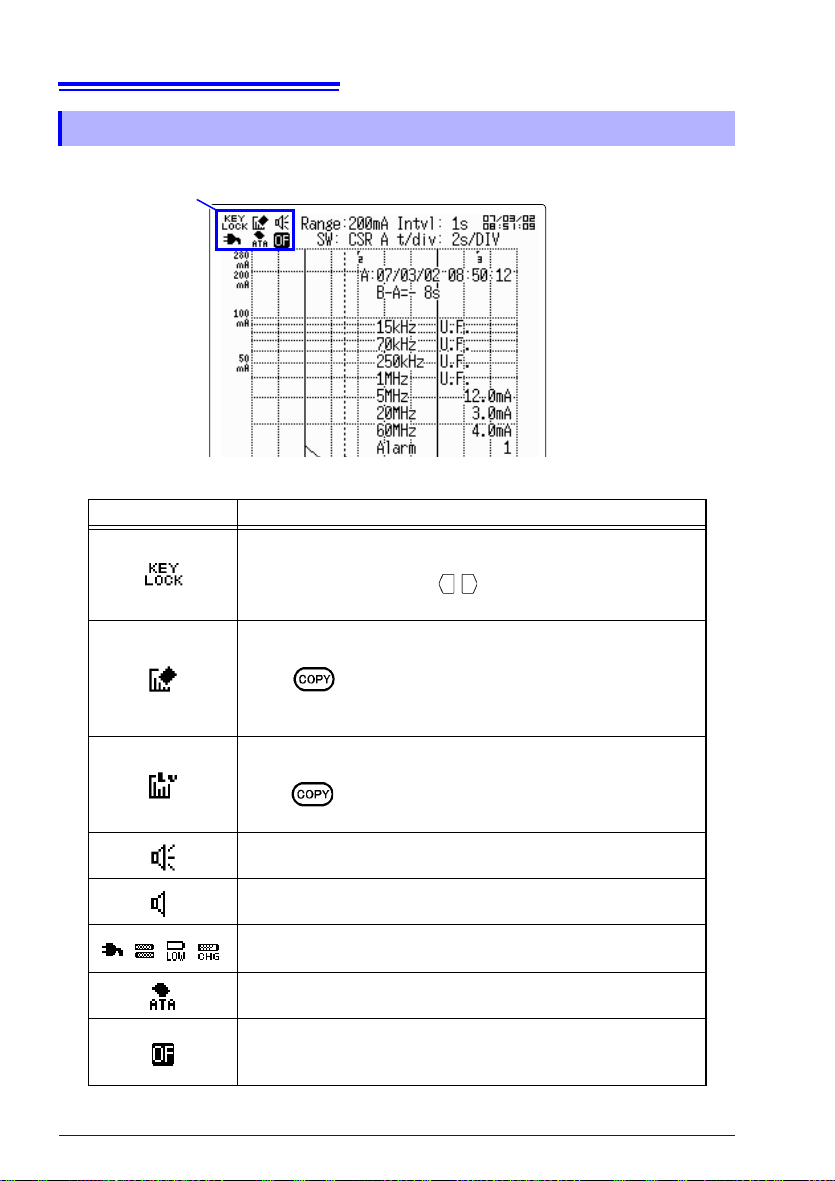

22

Icon

1.5 Display Screen

1.5.4 Icon Summary

The following icons are displayed in the upper left of the logging and monitor screens.

(Logging screen shown above)

Icons Explanations

Indicates that the instrument cannot receive commands from

the fr

ont panel keys (Key lock).

Simultaneously pressing / for 3 seconds or more will

switch between Lock and Unlock.

Indicates that the System Env screen copy key is set to

"Scree

n capture".

When is pressed the display screen is BMP saved to

the PC card.

Refer to "7.1.7 Copy Key Function (Monitor)" ( p. 116)

Indicates that the System Env screen copy key is set to "Alarm

captur

e".

When is pressed the alarm reference value is taken.

Refer to "7.1.7 Copy Key Function (Monitor)" ( p. 116)

Indicates that the instrument is in alarm state.

Indicates that the instrument is not in alarm state.

Indicates the type of power source being used.

Refer to "2.6 Turning the Power On and Off" ( p. 36)

Indicates that a PC card is set in the instrument.

Indicates that the measurement value is an overflow value.

During the logging peak value screen or the monitor peak

value scr

een the overflow display is retained.

Page 29

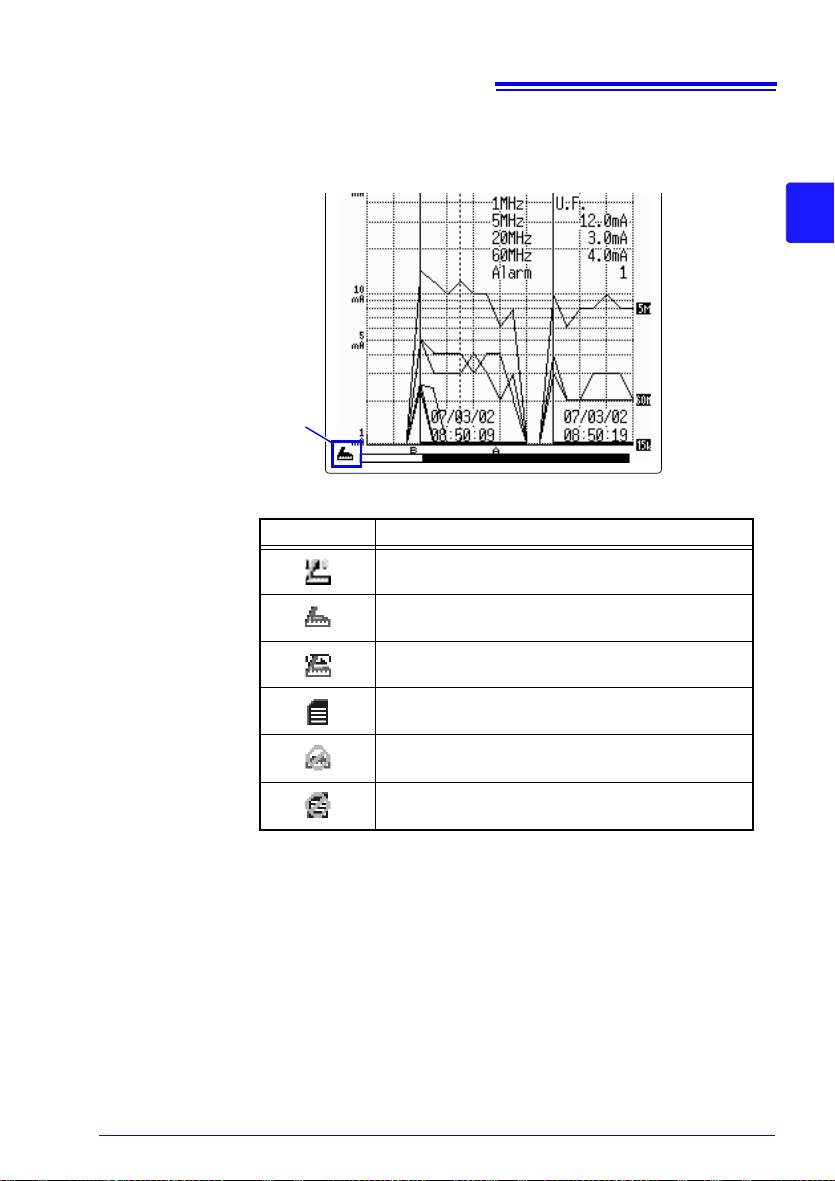

23

Icon

1.5 Display Screen

The following icons are displayed in the lower left of the display screen.

They indicate the save condition of the measurement data.

(Logging screen shown above)

Icons Explanations

Performing auto save (erase save).

Performing auto save (file full).

1

Chapter 1 Overview

Performing auto save (endless).

Text save is set.

Auto save is not possible because there is not

ficient space on the PC card.

suf

Text save is not possible because there is not suf-

ficient space on the PC card.

Page 30

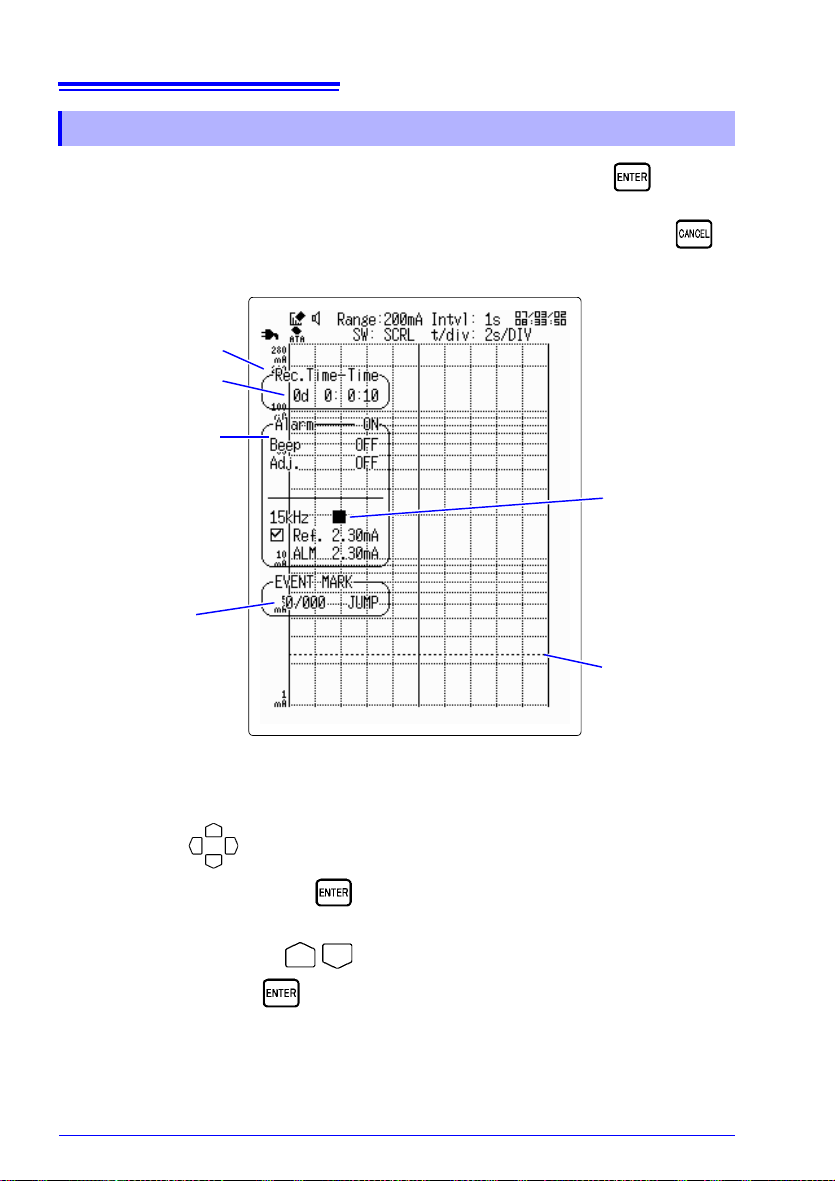

24

Recording time

Alarm function

Event mark

(logging screen)

Alarm judgment

value

Submenu

Waveform color

(Logging screen

shown here)

1.5 Display Screen

1.5.5 Submenus

From the logging display or the monitor display, press to display

the submenu.

Measurement conditions can be set right on the screen. Press to

close the submenu.

Changing the settings

1. Press the keys to move the blinking cursor to the position of the setting

to be changed, and press to open the selection window.

2. Use the up and down / keys to select the desired item in the selection

window, and press to set.

Page 31

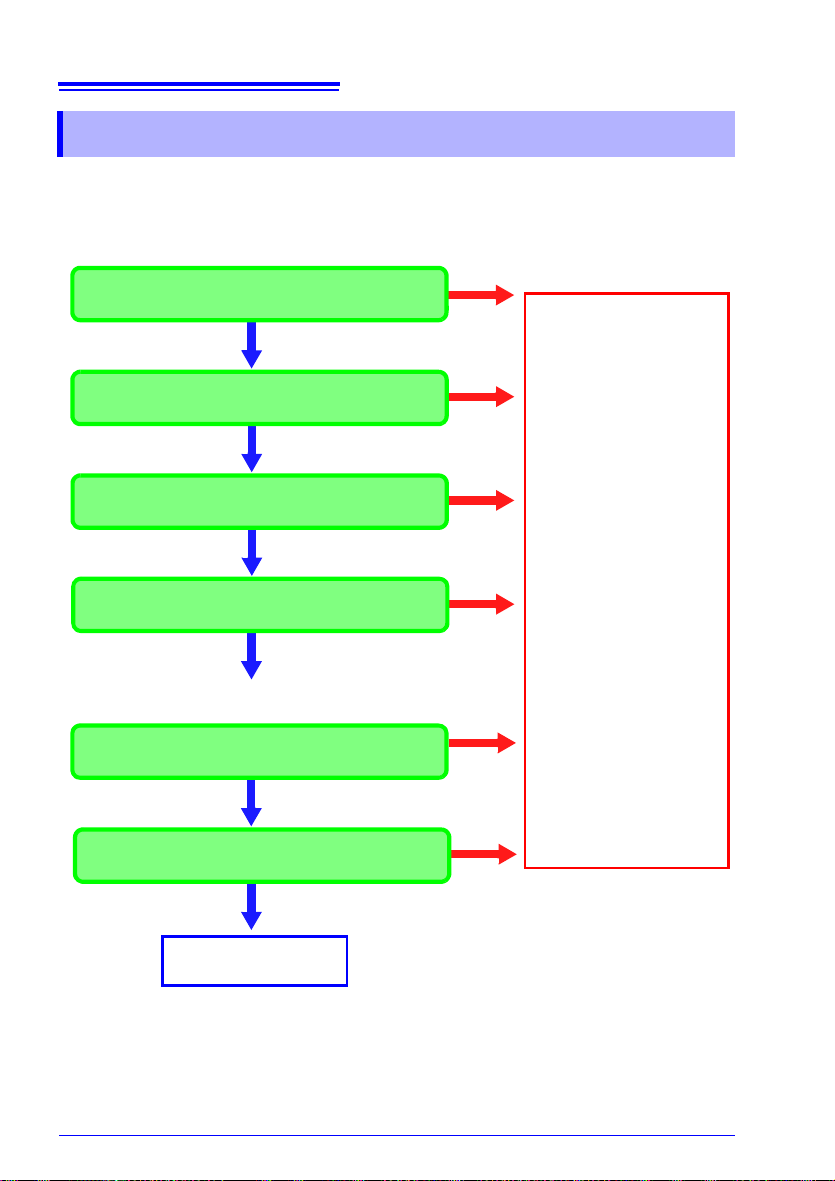

Measurement

Charge the battery pack.

Connect the Clamp on Noise Sensor.

Install the battery pack.

Connect the AC adapter to the 3145-20.

Install the strap.

Install ferrite cores onto the AC adapter,

Clamp on Noise Sensor, and LAN cables.

( p. 26)

(

p. 27)

(

p. 28)

(

p. 29)

(

p. 30)

(

p. 33)

Initialize the PC card.

Perform pre-measurement check.

Insert the PC card.

Turn on the power.

( p. 36)

(

p. 37)

(

p. 38)

(

p. 40)

(At time of

purchase)

Commence measurement.

( p. 41)

25

Preparations

The step-by-step preparations for measuring are as follows.

Chapter 2

2

Chapter 2 Measurement Preparations

Page 32

26

Attachment Point

Attachment Point

Front Panel

Stopper

Strap

Buckle

(1)

(2)

(3)

2.1 Attaching the Strap

2.1 Attaching the Strap

Attach the Strap at attachment point of the instrument.

Attach both ends of the Strap securely to the instrument. If insecurely

attached, the instrument may fall and be damaged when carrying.

1. Insert each end of the Strap through an attachment point on the instrument.

2. Thread the end of the Strap through the buckle.

3. Finally, slide the stopper over the end of the Strap.

Page 33

27

(AC adapter shown here)

Install as close as possible to

the pre-installed ferrite core.

Termination box

2.2 Install the Ferrite Cores

2.2 Install the Ferrite Cores

In order to prevent malfunctions due to external magnetic waves, install ferrite cores onto

the AC adapter, Clamp on Noise Sensor, and LAN cables.

1. Wrap the output side of the cable two times around the ferrite core.

2. Close the ferrite core until it makes a clicking sound.

• In the case of the Clamp on Noise Sensor, install the ferrite core as

close as possible to the termination box.

• In the case of the LAN cable, install the ferrite core as close as possible to the connector which connects to the 3145-20.

2

Chapter 2 Measurement Preparations

Page 34

28

Lower Panel

AC Adapter

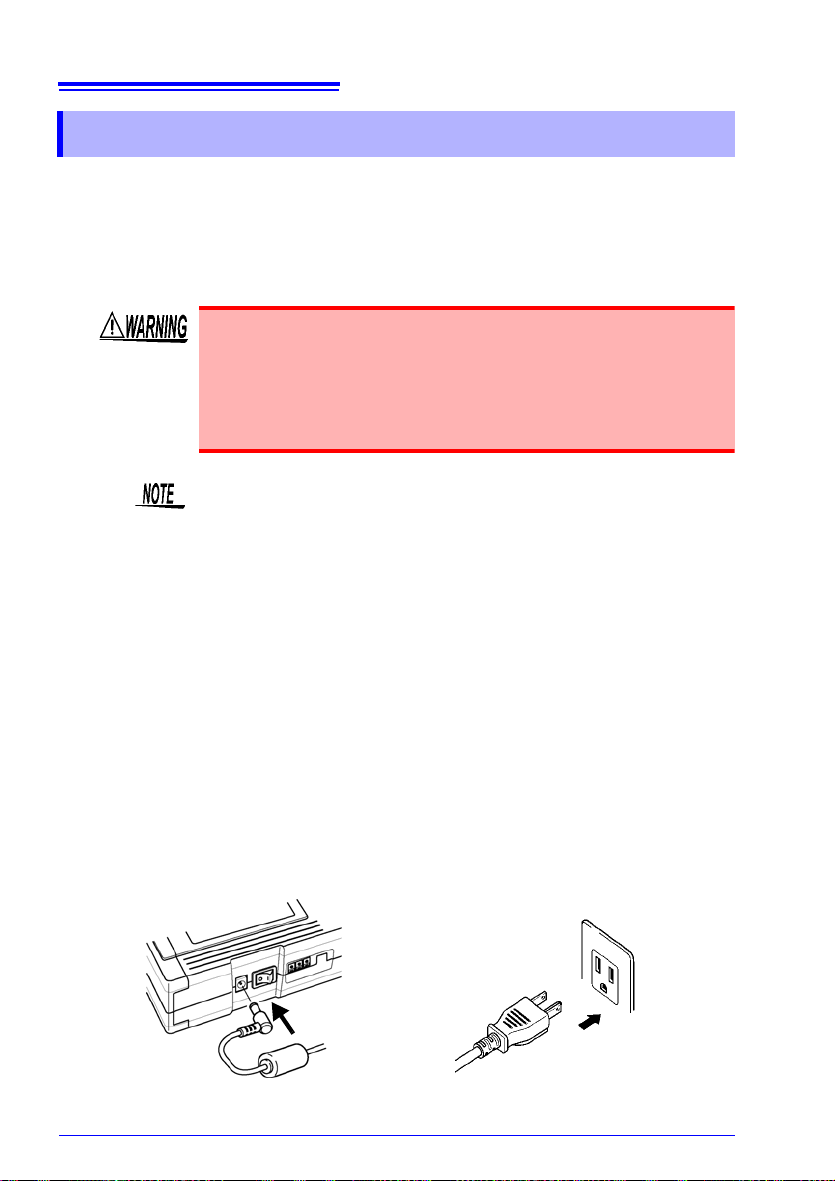

2.3 Connecting the AC Adapter

2.3 Connecting the AC Adapter

Connect the AC adapter to the 3145-20 and supply power to the instrument. The 3145-20

can receive power from two types of power sources: either AC adapter or battery pack.

When both are supplied at the same time, the AC adapter is used.

Please use the instrument with the battery pack always in place, as it is also a countermeasure in the case of power outage.

• Turn the instrument off before connecting the AC adapter to the

instrument and to AC power.

• Use only the supplied Model 9418-15 AC ADAPTER. AC adapter

input voltage range is 100 to 240 VAC (with

60 Hz. To avoid electrical hazards and damage to the instrument,

do not apply voltage outside of this range.

• Data can be retained for about ten minutes after power is interrupted

(when the Battery pack is not installed). Operation after power interruption depends on the setting for Resume Recording After Power

Loss.

Refer to "2.7.2 PC Card Initialization" ( p. 38) and "7.1.2 Start

Backup After Power Loss" ( p. 111).

• This instrument will not run erratically under a momentary power

outage lasting less than 40 ms. However, if a momentary outage

of 40 ms or more occurs, the instrument turns off temporarily, so

the power condition at the installation location should be considered beforehand. Therefore, consider the p

tions at your installation site before installing the instrument.

±10% stability) at 50/

ower supply condi-

1. Make sure the instrument is OFF.

2. Connect the AC adapter to the instrument.

3. Plug the AC adapter into the power outlet.

Page 35

29

Bottom Panel

Model 9447 BATTERY PACK

2.4 Supplying Power with the Battery Pack

2.4 Supplying Power with the Battery Pack

By using battery power to run the 3145-20 NOISE HiLOGGER, it can be used even in

places with no commercial power outlets.

The 9447 BATTERY PACK is rated for approximately 1 hour of continuous use (backlight:

bright; after approximately 2.5 hours charging the battery). When longer periods of continuous measurement are required, please prepare multiple battery packs.

The 3145-20 can also receive power from its AC adapter. When both are supplied at the

same time, the AC adapter is used. Please use the instrument with the battery pack always

in place, as it is also a counter-measure in the case of power outage.

• To avoid electric shock, turn off the power switch and disconnect

the cables before replacing the batteries.

• For battery operation, use only the HIOKI Model 9447 BATTERY

PACK. We cannot accept responsibility for accidents or damage

related to the use of any other batteries.

2.4.1 Installing the Battery Pack

At the time of purchase, the back side of the instrument is equipped with a battery box.

Remove the battery box and install the 9447 BATTERY PACK.

2

Chapter 2 Measurement Preparations

1. Turn off the power switch.

2. Remove the battery compartment.

3. Insert the 9447 BATTERY PACK until it clicks.

The battery pack is subject to self-discharge. Be sure to charge

the battery pack before initial use. (Please refer to the next page)

Page 36

30

Lower Panel

AC Adapter

Charging

Charged

2.4 Supplying Power with the Battery Pack

2.4.2 Charging the Battery Pack

The battery pack may be charged in the 3145-20 itself, or in the optional 9643 CHARGE

STAND.

Charging with the 3145-20 NOISE HiLOGGER

The 9447 BATTERY PACK can be charged whether the 3145-20's power switch is turned

ON or OFF (both during and after measurement).

1. Install the battery pack and con-

nect the AC adapter.

2. Rapid charge of the battery pack

begins.

(When the power switch is OFF)

The LED lights up red, and turns

off when rapid battery charge is completed.

(When the power switch is ON)

The mark is displayed at the top of

the screen, and the mark is disp lay ed

when rapid battery charge is completed.

3. It takes approximately 2.5 hours to

complete rapid charge.

Rapid charge alone provides approximately 70% of the battery life that full

charge provides.

After completion of rapid charge, supplementally charging for approximately 10

additional hours will bring the battery

pack to full charge.

Supplemental charging continues even after the battery pack is fully

charged to prevent the battery pack self discharging.

Page 37

2.4 Supplying Power with the Battery Pack

Charge stand

Battery Pack

AC Adapter

Charging with the optional 9643 CHARGE STAND

1. Place the battery pack in the

charge stand.

31

2. Connect the AC adapter to the

charge stand.

The LED will blink red, and then continually remain lit as rapid charge commences.

3. Rapid charge is completed in

approximately 2 hours.

The green LED lights up, and supplemental charging begins.

• The ambient temperature should be between 0 and 40 °C when charg-

ing. If charging is done outside this temperature range, the battery

rial will degrade and the battery may not be able to be sufficiently

mate

charged, or the battery life may be shortened.

• Do not use chargers made by other companies.

• If the battery pack expires and the instrument automatically shuts off,

sure to turn off the power switch. If left as is with the power switch

be

turned on for a long period of time, the battery pack may be in danger

of overdischarging.

2

Chapter 2 Measurement Preparations

• The battery pack is subject to self-discharge. If stored or otherwise not

used

for a long time, the battery pack should be discharged and then

recharged at least once every two months. Battery capacity may be

degraded if stored for a long time without charging.

Page 38

32

Low battery display

2.4 Supplying Power with the Battery Pack

2.4.3 Battery Pack Life

If the battery life is considerably short even with correct charging,

replace the battery pack with a new one. As the battery pack charge is

depleted, the low battery mark will be displayed in the upper left of

the logging screen or monitor screen. Alternatively, the following warning

is displaye

charge the battery pack.

d: "WARNING 620: Battery low.". In such cases, please

Page 39

33

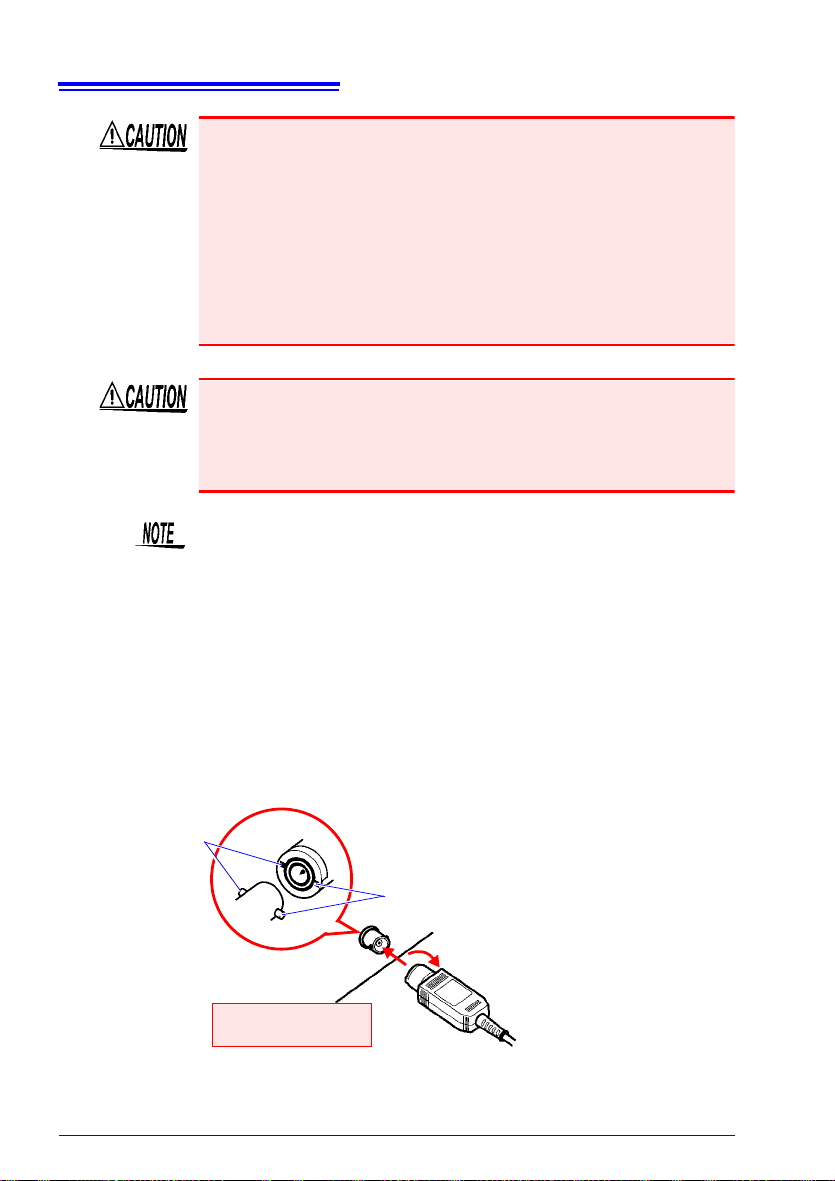

2.5 Connect the CLAMP ON NOISE SENSOR

2.5 Connect the CLAMP ON NOISE SENSOR

Connect the Clamp on Noise Sensor to the terminals of the 3145-20, and clamp the line to

be measured.

Before using, read the instruction manual included with the Clamp on Noise Sensor and follow all safety precautions.

• To avoid electric shock, do not to uch th e po r tio n be yon d t he p rotective barrier during use.

• To avoid short circuits and potentially life-threatening hazards,

never attach the clamp to a circuit that operates at more than 600

V (CAT II) / 300 V (CAT II ), or over bare conductors.

• To avoid electrical shock, be careful not to damage the insulation

of the conductor being measured.

• To avoid electrical shock, follow the precautions below to ensure

no dangerous voltage from the power of the instrument being

connected to or its other measuring terminals (those not connected to this instrument) is impressed upon the 9754 CLAMP

ON NOISE SENSOR. If dangerous voltage is impressed upon

this instrument, dangerous voltage will be generated in its BNC

connector and inner circuitry, presenting an extreme hazard.

Only connect to instruments which are constructed with double

insulation and use a protective earth.

Confirm that basic insulation which meets the measurement category, working voltage and pollution degree of the circuit being

tested, is used to isolate the other measurement terminals of the

instrument being connected to.

If you are not sure basic insulation is used between the terminals

of the measurement instrument, do not input voltage which

exceeds the Separated Extra-Low Voltage Earthed (SELV-E) level

into the other terminals of the instrument.

Observe all safety precautions of the instrument you are using.

Refer to the following standards regarding the meanings of

underlined terms.

IEC 61010-1

IEC 61010-031

IEC 61010-2-032

2

Chapter 2 Measurement Preparations

To avoid electric shock when measuring live lines, wear appropriate protective gear, such as insul

safety helmet.

ated rubber gloves, boots and a

Page 40

34

Line up

Line up

(1)

(2)

Turn until it clicks

2.5 Connect the CLAMP ON NOISE SENSOR

To avoid damaging the instrument, do not apply current that exceeds

the maximum continuous input range.

* Maximum continuous input range:

This range is based on heat that is internally generated during sine

wave

input at a prescribed frequency at room temperature. It varies

according to the frequency of the measured current. (Use the 9754

CLAMP ON NOISE SENSOR at the highest effective value within the

maximum continuous input range.) In addition to the maximum continuous input range, there is also the "maximum peak current value 15

Apeak"

product specification. This indicates an upper waveform

response limit of 15 Apeak.

• When disconnecting the BNC connector, be sure to release the lock

before pulling off the connector. Forcibly pulling the connector without

releasing the lock, or pulling on the cable, can damage the connector.

• To avoid damaging the instrument, always open the clamp by using

the

slider.

Apart from the Clamp on Noise Sensor, near magnetic field probes or

antennae may be connected in a similar fashion to the Clamp on Noise

Sensor to check and record individual band levels. Please use near

magnetic field probes or antennae which match the characteristics of

the Clamp on Noise Sensor. The measurement range, frequency char

acteristics and input impedance are as follows.

Measurement range : 1 Vp-p to 0.15 mVp-p

Frequency bandwidth : 5 kHz to 100 MHz (-3 dB bandwidth)

Input impedance : 50

-

1. Connect the BNC connector of the 9754 CLAMP ON NOISE SENSOR to the

input terminal of the instrument being connected to.

Page 41

2.5 Connect the CLAMP ON NOISE SENSOR

Current

Current direction

indicator

Make sure that the current direction indicator arrow matches the direction of current flow on the conductor being

measured.

Make sure also that the conductor is

clamped in the center of the clamp opening.

Communication

lines

Electrical

lines

Ground lines

<Connection example>

2. Pull the slider on the sensor to open the clamp.

35

3. Clamp the conductor to be measured and close the clamp.

4. Press on the slider until it clicks to lock shut.

Press the sensor slider until the "UNLOCK" message disappears and "LOCK" is displayed,

and confirm that the slider is firmly locked and the clamp securely closed.

5. When disconnecting the 9754 CLAMP ON NOISE SENSOR, pull the sensor

slider to open the clamp and remove the Clamp on Noise Sensor from the conductor being measured.

2

Chapter 2 Measurement Preparations

Page 42

36

Marks Explanations

Operating with the AC adapter.

Operating with the 9447 BATTERY

PACK.

Battery capacity is low.

Charge the battery pack.

Charging the battery pack

2.6 Turning the Power On and Off

2.6 Turning the Power On and Off

Power On

1. Turns on ( ) the POWER switch.

2. Depending on the type and condition of the power supplied to the instrument,

one of the following messages appears on the display.

3. During initial use after purchasing, set the time using the System Init screen.

Refer to "7.3.1 Setting the Clock" ( p. 127).

Power Off

1. Turns off ( ) the power switch.

2. Remove the Clamp on Noise Sensor from the conductor being measured.

3. Remove the AC adaptor plug from its electrical outlet.

• After power is turned off, the last waveform data is retained for about

10 minutes.

• When power is turned on, the instrument restores the settings used

immediately before power was turned off last (backup function).

Page 43

2.7 Using the PC Card

Some PC Cards are susceptible to static electricity. Exercise care when

using such products because static electricity could damage the PC

Card or cause malfunction of the instrument.

37

2.7 Using the PC Card

2.7.1 Inserting the PC card

When saving logging measurement data or setting conditions to a PC card, insert the PC

card into the slot at the top of the 3145-20.

Important

Use only PC Cards sold by Hioki.

Compatibility and performance are not guaranteed for PC cards made by other manufacturers. You may be unable to read from or save data to such cards.

Hioki options PC cards (includes adapter)

Model 9726 PC CARD 128M, Model 9727 PC CARD 256M,

Model 9728 PC CARD 512M, Model 9729 PC CARD 1G

PC card insertion

1. Open the cover and insert the PC card with

the arrow facing up and in the direction of

the PC card slot, as far as it will go.

Inserting a PC card upside down, backwards or in

the wrong direction may damage the instrument

2. Before using a new PC Card, it must be ini-

tialized.

2

Chapter 2 Measurement Preparations

Removing the PC card

1. Press the eject button and pull out the PC

card.

2. Always close the cover when no PC Card

is installed.

Page 44

38

2.7 Using the PC Card

2.7.2 PC Card Initialization

Initialize the PC card. All files on the PC card will be erased, and a system file resistant to

power outage will be created.

When using a PC card with the instrument, be sure to format the card

before its initial use using the instrument. When formatting in "FAT 16"

using a PC (personal computer), please note that the Power Fault Protection function will be ineffective. Furthermore, do not use the "FAT

32

" format, as doing so will result in error.

When recording for long durations, format the card before measurement, and make a backup copy of the resulting waveform files on your

PC or ot

mended that you re-format the card before measurement in order to

ob

her storage media. When re-using a PC card, it is recom-

tain maximum performance.

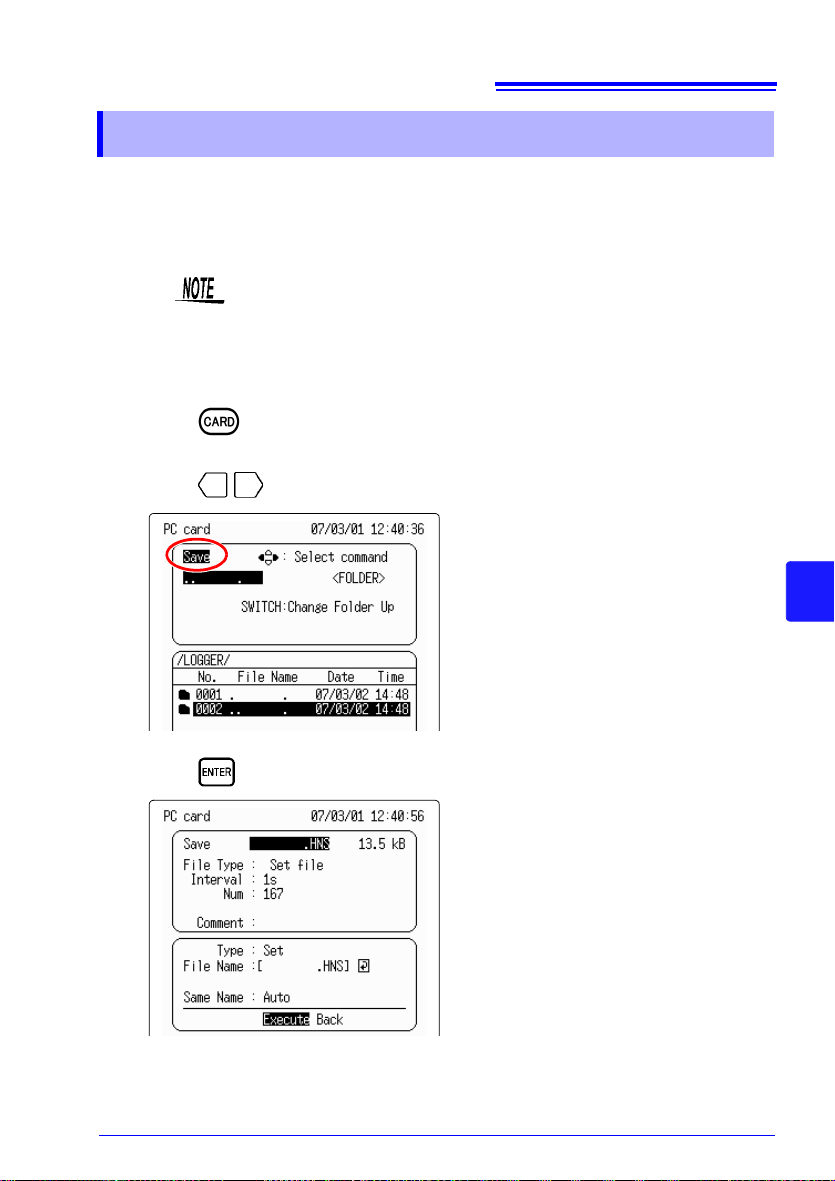

1. Press to open the PC card screen.

2. Press / to choose [Format].

3. Press to open the initialize screen.

Page 45

39

Selectable

items

Explanations

Quick

The PC Card is not tested for

bad sectors.

Entirely

The PC Card is tested for bad

sectors, which are removed

from use if possible.

When using a brand new PC

card for the first time, select

[Entirely].

2.7 Using the PC Card

4. Press to move the flashing cursor to [Method], and press to open the

contents.

2

Chapter 2 Measurement Preparations

5. Use the up and down / keys to select [Entirely], and press to set.

6. Press to move the blinking cursor to [Execute], and press to execute

initialization.

To cancel, move the blinking cursor to [Back] and press .

• If a PC card is formatted by the instrument, a /LOGGER/ directory will

be created, and when you attempt to save a file into the root directory

automatically it will be saved to this directory instead. When the saving operation begins, you will automatically be moved to the /LOGGER/ directory.

• You cannot change the name of the /LOGGER/ directory or delete the

direct

ory.

Page 46

40

Yes

No

Is the probe free from any torn insulation or

exposed metal?

Yes

Check complete

No

Model 9754 CLAMP ON NOISE SENSOR

Is the 3145-20 chassis completely free of

damage?

Discontinue use and

contact the store

where you bought

the instrument, or

your closest HIOKI

dealer or business

office.

Yes

No

Are the cables free of any torn insulation or

exposed metal?

Yes

Does the "HIOKI" logo appear on the screen

when the power is turned on?

Yes

Yes

No

No

No

Model 3145-20 NOISE HiLOGGER

Is the clamp free from any cracks or damage?

Is the logging screen or monitor screen

displayed after startup?

2.8 Pre-Operation Inspection

2.8 Pre-Operation Inspection

Before beginning measuring, check the following points.

Page 47

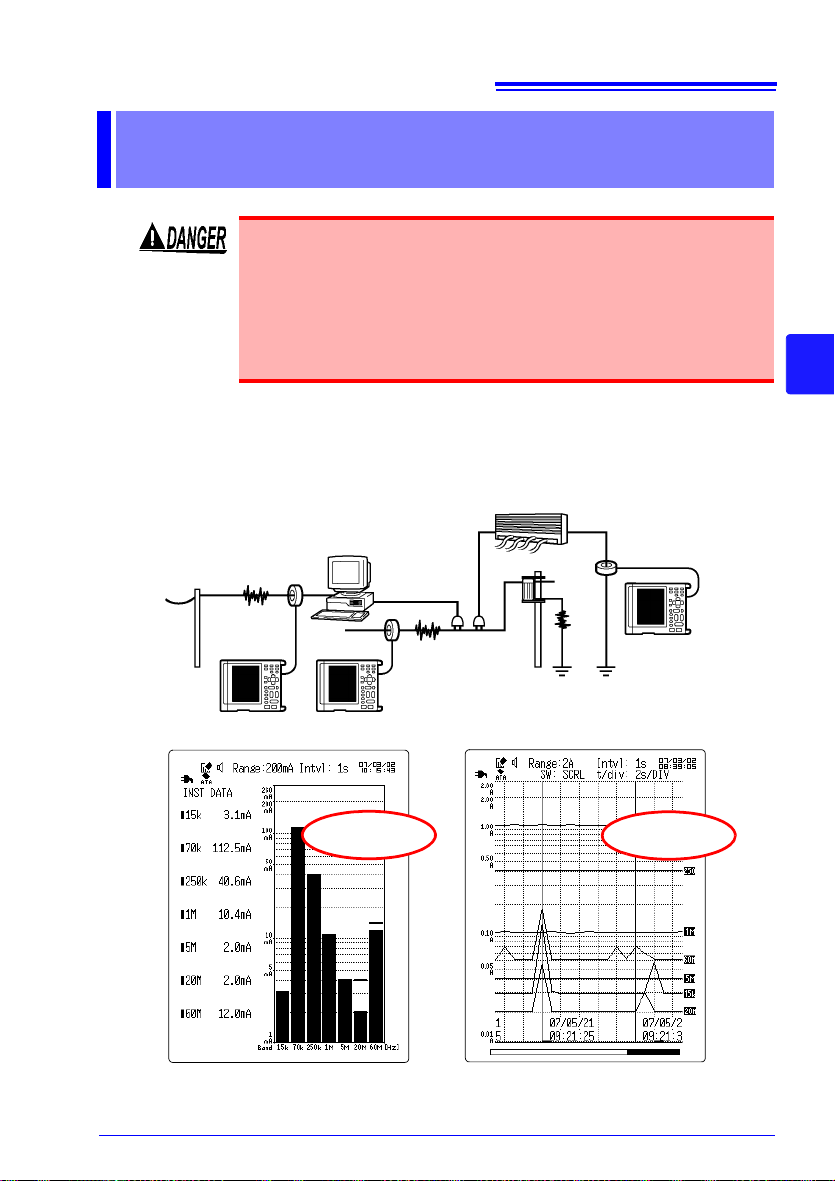

41

Communication

lines

Electrical

lines

Ground

lines

Monitor screen

Logging screen

<Connection example>

Waveform display

Bar graph display

Measurement Chapter 3

• The maximum input voltage is 5 V peak. Attempting to measure

voltage in excess of the maximum input could destroy the instrument and result in personal injury or death.

• The maximum rated voltage between input terminals and ground

is 5 V. Attempting to measure voltages exceeding 5 V with

respect to ground could damage the instrument and re sult in personal injury.

Clamp the Clamp on Noise Sensor to the place to be measured on the communication line,

power line or ground line. With monitor display, the measured values of each band * are

shown as a bar graph. With logging measurement, change of the measurem ent values over

time can be displayed and this data saved to a PC card.

3

Chapter 3 Measurement

* Band: the frequency band of the measured waveform.

Page 48

42

Begin measurement.

Complete measurement.

Set automatic save. ( p. 82)

Set the alarm function

( p. 56)

Perform monitor measurement.

Check the current input

Monitor measurement ( p. 43)

Set the time axis.

Record changes over time

Set the recording time.

( p. 77)

Set the recording interval.

Set the measurement range.

Display the logging screen.

Logging Measurement ( p. 45)

To initialize settings, refer to "7 .3. 3 Syste m

Reset" (

p. 129).

Pre-measurement preparations

( p. 25)

Set the alarm function. ( p. 56)

Set the measurement range.

Display the monitor screen.

Pre-measurement preparations

( p. 25)

Set the input type. ( p. 74)

Set the input type. ( p. 74)

3.1 The Measurement Process

3.1 The Measurement Process

Page 49

43

The instantaneous values for each band are displayed on the left side of the screen, and the level meter is displayed on the right.

The peak values for each band are displayed on

the left side of the screen, and the level meter is

displayed on the right.

The peak value during monitor measurement is

the peak value from the time of switching to monitor display until the present. When switching

from the logging screen back to the monitor

screen, the peak value will have been cleared.

The peak value is also cleared by pressing

.

3.2 Check the Current Input (Monitor Measurement)

3.2 Check the Current Input

(Monitor Measurement)

The measurement values for each individual band (15kHz, 70kHz, 250kHz, 1MHz, 5MHz,

20MHz, 60MHz) can be checked on the screen. The data cannot be saved.

1. Make preparations for measurement referring to "Chapter 2 Measurement

Preparations" ( p. 25).

2. Set the input type to [Current ] or [Voltage] on the Set up screen. ( p. 74)

3. Press to display the instantaneous values.

3

Chapter 3 Measurement

4. Press to display the peak values.

Page 50

44

Selectable ranges: 200mA, 2A, 20A

As a general reference, select 200mA for

communications, 2A for power supply and

20A for lightning surge.

When checking using voltage levels, set the

input type to "Voltage" on the Set up screen.

(

p. 74)

Set the range to 10mV, 100mV or 1V.

3.2 Check the Current Input (Monitor Measurement)

5. Press to select the range.

The noise measurement range differs depending on the current or voltage range selected. See the chart below.

Measurement object

Current

(When using the 9754)

Voltage

Measurement range

20 A

2 A

200 mA

1 V

100 mV

10 mV

Measurable noise range

28 A

to 200 mA

P-P

2.8 A

P-P

280 mA

1.4 V

P-P

140 mV

14 mV

to 20 mA

P-P

to 20 mV

P-P

to 0.2 mV

P-P

to 2 mA

to 2 mV

P-P

P-P

P-P

P-P

P-P

P-P

"O.F."

display

(Overflow display)

If the measured value exceeds the upper value of the selected range,

the numerical value on the left side of the screen will become "O.F."

"U.F."

display

Increase the range in such a case.

(Underflow display)

If the measured value is lower than the lower value of the selected

range, the numerical value on the left side of the screen will become

"U.F." Decrease the range in such a case.

To sound an alarm when the measurement value exceeds the set value:

Set the alarm function. Refer to "4.5 Using the Alarm Function" ( p. 56).

Page 51

45

Selectable ranges: 200 mA, 2 A, 20 A

As a general reference, select 200mA for

communications, 2A for power supply and

20A for lightning surge.

When checking using voltage levels, set the

input type to "Voltage" on the Set up screen.

(

p. 74)

Set the range to 10mV, 100mV or 1V.

3.3 Record Changes Over Time (Logging Measurement)

3.3 Record Changes Over Time

(Logging Measurement)

With logging measurement, the change over time of the measurement values at each band

(15kHz, 70kHz, 250kHz, 1MHz, 5MHz, 20MHz and 60MHz) can be viewed.

1. Make preparations for measurement referring to "Chapter 2 Measurement

Preparations" ( p. 25).

2. Set the input type to [Current ] or [Voltage] on the Set up screen. ( p. 74)

3. Press to display the logging full screen, and to select the range.

3

Chapter 3 Measurement

• The noise measurement range differs depending on the current or

voltage range selected. See the left chart.

• Upon starting a new logging session, previously logged and recorded

data will be automatically deleted from the internal memory. Be sure

to save any required measurement data to the PC Card before starting a new logging session.

Page 52

46

Selectable ranges:

1s, 2s, 5s, 10s, 20s, 30s, 60s

Selectable ranges:

2s, 5s, 10s, 20s, 30s, 1min, 2min,

5min, 10min, 20min, 30min,

1h, 2h, 5h, 10h, 12h, 1d

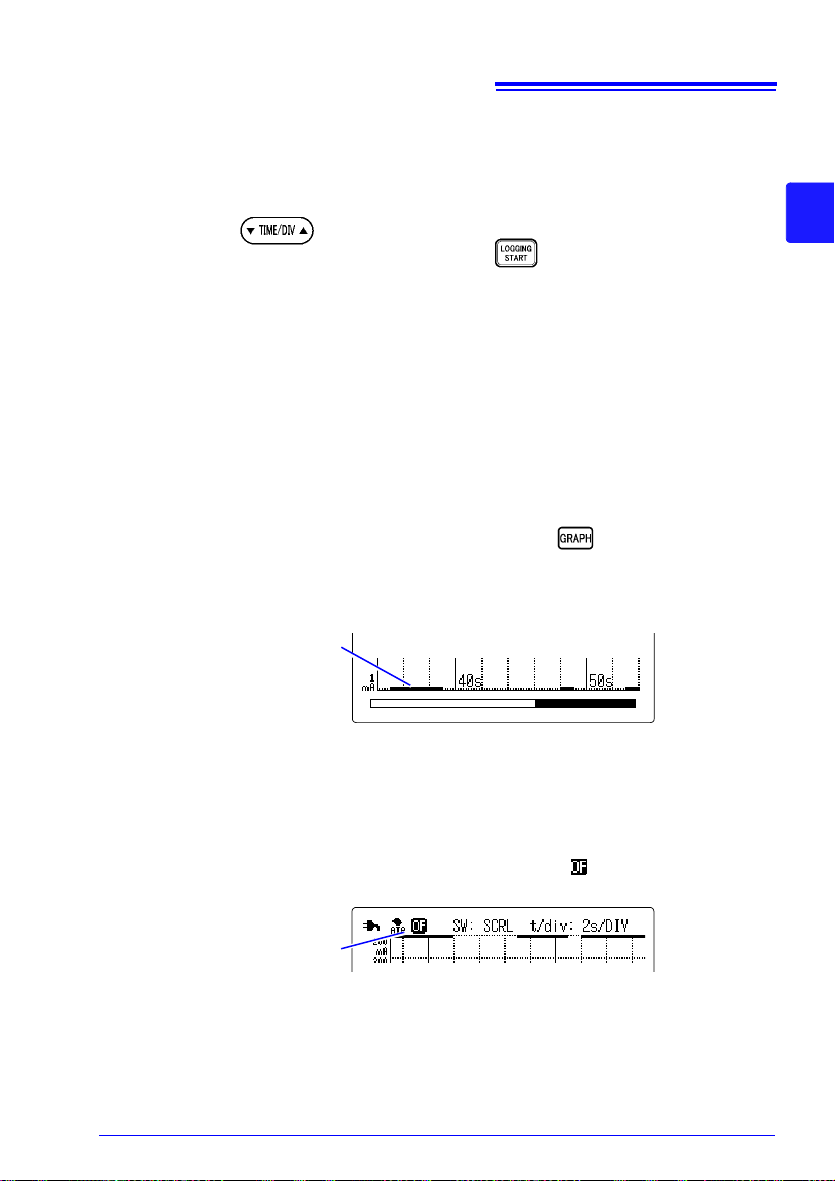

3.3 Record Changes Over Time (Logging Measurement)

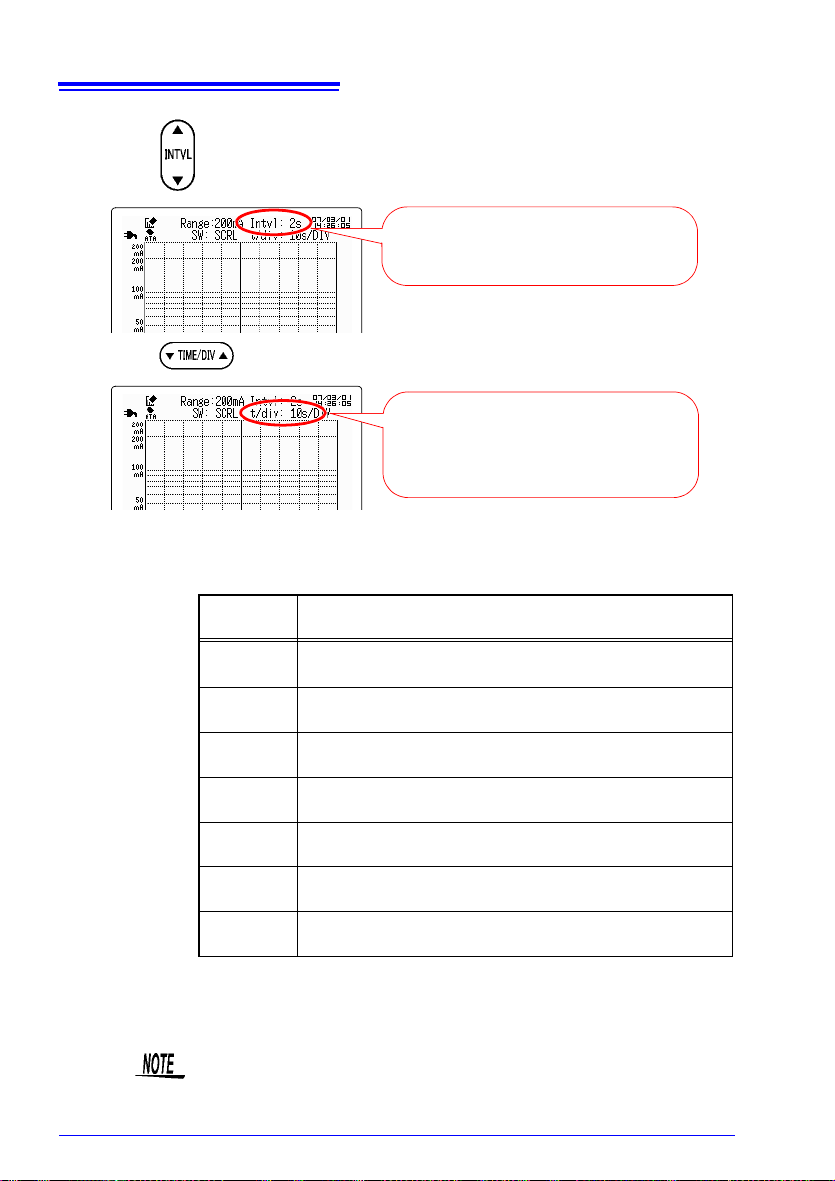

4. Press to select the recording interval.

5. Press to change the time axis.

The selectable range of the time axis differs depending on the recording

l setting. See the chart below.

interva

Recording

interval

1s

2s

5s

10s

20s

30s

60s

The range, recording interval and time axis can also be set with the Set

up scre

p. 71).

The range and recording interval cannot be changed during logging

measurement.

Possible time axis settings

2s, 5s, 10s, 20s, 30s, 1min, 2min, 5min, 10min, 20min,

30m

in, 1h, 2h, 5h, 10h, 12h, 1d

10s, 20s, 30s, 1min, 2min, 5min, 10min, 20min, 30min,

1h, 2h, 5h, 10h, 12h, 1d

10s, 20s, 30s, 1min, 2min, 5min, 10min, 20min, 30min,

1h, 2h, 5h, 10h, 12h, 1d

20s, 30s, 1min, 2min, 5min, 10min, 20min, 30min, 1h, 2h,

5h, 10

h, 12h, 1d

1min, 2min, 5min, 10min, 20min, 30min, 1h, 2h, 5h, 10h,

12h, 1

d

1min, 2min, 5min, 10min, 20min, 30min, 1h, 2h, 5h, 10h,

12h, 1

d

2min, 5min, 10min, 20min, 30min, 1h, 2h, 5h, 10h, 12h,

1d

en. Refer to "Chapter 5 Setting the Measurement Conditions" (

Page 53

47

Selectable

items

Explanations

OFF Does not save data.

3145 Form

Auto saves in binary format

readable by the instrument

and the "DATA VIEWER for

3145" software on the

included CD.

Text

Auto saves in text format

readable by personal computer spreadsheet programs.

(Cannot be read by the

3145-20)

3.3 Record Changes Over Time (Logging Measurement)

6. In order to save data to the PC card simultaneously while measuring, press

to open the Set up screen.

When using a new PC card for the first time, initialize the PC card.

7. Press to move the flashing cursor to [Auto Save] , and press to

open the selection window.

3

Chapter 3 Measurement

8. Use the up and down / keys to select [3145 Form], and press to

set.

Normally, the save mode is set to [Normal], [Full]. This setting saves a wave file for each

measurement, then stops measurement when the PC card becomes full.

To perform detailed settings, refer to "6.1.3 Save Mode" (

• By setting auto save to "Text", after completion of measurement the

• By setting auto save to OFF, data is saved in the 3145-20 internal

Setting the recording time:

Set the recording time to [Time] on the Set up screen.

Refer to "5.5 Setting the Recording Time" ( p. 77).

To sound an alarm when the measurement value exceeds the set value:

Set the alarm function. Refer to "4.5 Using the Alarm Function" ( p. 56).

data which remains in internal memory is auto-saved.

emory (32MB). Please note that when the internal memory becomes

m

full, old data is erased. Data in the internal memory can be saved to

PC card following measurement. ( p. 91)

p. 84).

( p. 90)

Page 54

48

Logging latest value display

Logging peak value display

3.3 Record Changes Over Time (Logging Measurement)

9. Press to commence logging measurement.

If auto save mode is set to [Ref. Time], when starting measurement the "Sync fixed time“

message is displayed until the recording interval synchronizes to reference time.

10.Press to view the latest value. Press to view the peak value.

If "O.F." or "U.F." is displayed on the screen, then the measurement value is outside of the

measurement range. Please change the range.

11.Press twice to stop logging measurement.

If the recording time has been specified and the recording ti me expires, then logging measurement automatically stops.

Page 55

49

3.3 Record Changes Over Time (Logging Measurement)

• If the auto save setting is OFF in the Set up screen, when commencing a new measurement after a prior measurement the recorded data

in the internal memory is erased. To retain the data, use the PC card

screen to save it to PC card. Refer to "6.3 Saving Data af ter Me asure ment" ( p. 91).

• If power is interrupted before the first data refresh, no data is stored,

and a file is created with zero bytes.

• When the recording period is set to [Cont] (Continuous) and automatic saving is set to [Text], the data remaining on the internal mem-

ory will be saved automatically.

• During automatic saving, if an abnormality occurs on the PC Card

while recording, one of the following messages appears near the bottom of the screen.

Messages Descriptions

No PC Card

PC Card has error

PC Card is full

Appears when no PC Card is installed

in the PC Card slot.

Appears when a fault occurs on the

PC Card, and when recording is not

possible.

Appears when the available space on

the PC Card reaches or falls below the

specified amount.

Be sure to stop measurement before

replacing the PC card. If the PC card

is removed during measurement the

data may be damaged.

This message does not appear when

deleting and saving files.

3

Chapter 3 Measurement

Page 56

50

3.4 "O.F." Display and "U.F." Display

3.4 "O.F." Display and "U.F." Display

If the measurement value for each frequency wave range is lower than

the selected measurement range, "U.F." (Underflow) will be displayed.

Alternatively, if the measurement value for each frequency wave range

is higher than the selected measurement range, "O.F." (Overflow) will be

displayed.

"O.F." (Overflow) display will also occur if the input value exceeds the

measu

rement range.

In the case of "O.F." display, change the range.

If overflow occurs during logging measurement, the "O.F." marker will be

displayed at the top of the graph display screen for the section where the

overflow occurred. Also, the icon is displayed in the upper left of the

screen. The icon remains displayed during the logging peak value

or the monitor peak value screen.

screen

Page 57

51

Useful Functions Chapter 4

The 3145-20 NOISE HiLOGGER has the following useful functions.

Please make use of them as necessary.

Functions Logging Monitor

"4.1 View the Latest Logging Measurement

Value or Peak Value" ( p. 52)

"4.2 Check Using a Bar Graph (Monitor Measurement)" ( p. 52)

"4.3 View Past Waveforms (Scroll Function)"

( p. 53)

"4.4 A/B Cursor Measurement" ( p. 55) Available --

"4.5 Using the Alarm Function" ( p. 56) Available Available

"4.6 Adding Event Marks to Waveforms" ( p.

66)

"4.7 Highlighting a Specific Band" ( p. 68) Available --

"4.8 Preventing Malfunctions (Key Lock)" (

p. 69)

"4.9 Saving the Display Screen to PC Card

(Screen Capture)" ( p. 70)

Available --

-- Available

Available --

Available --

Available Available

Available Available

4

Chapter 4 Useful Functions

Page 58

52

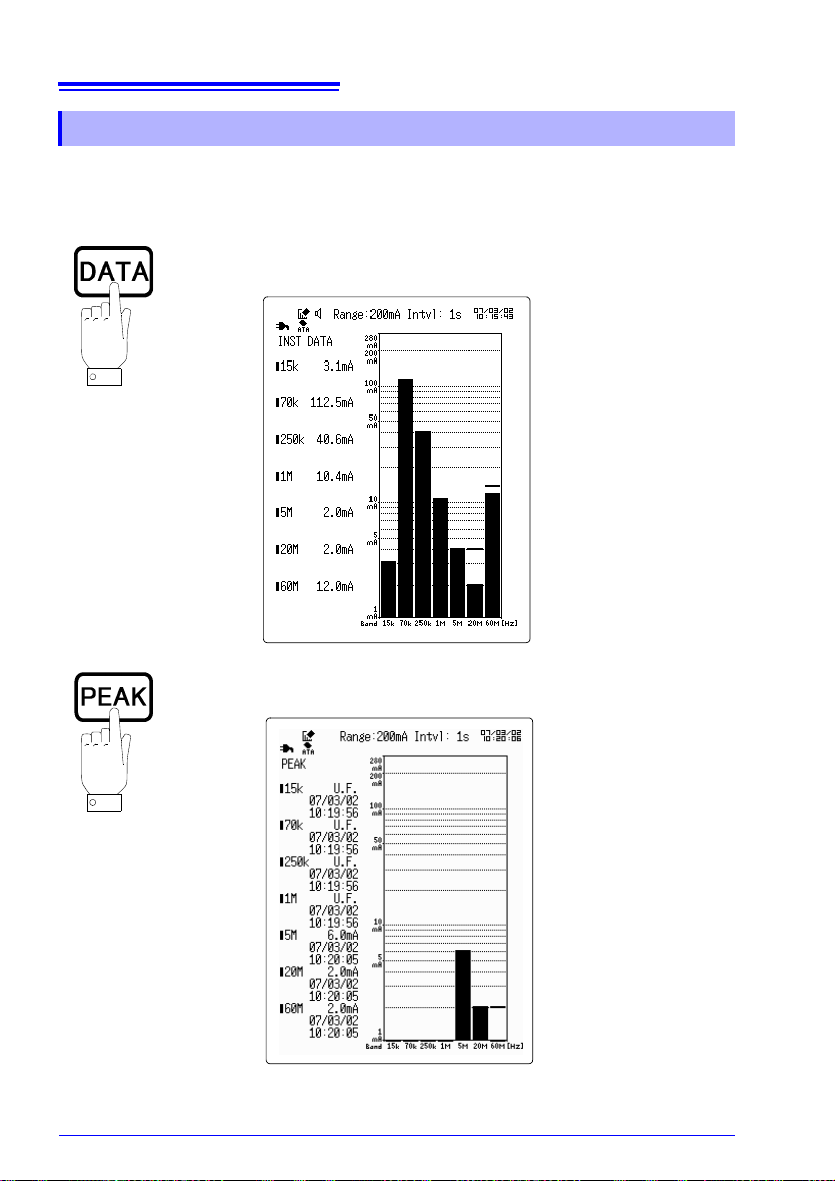

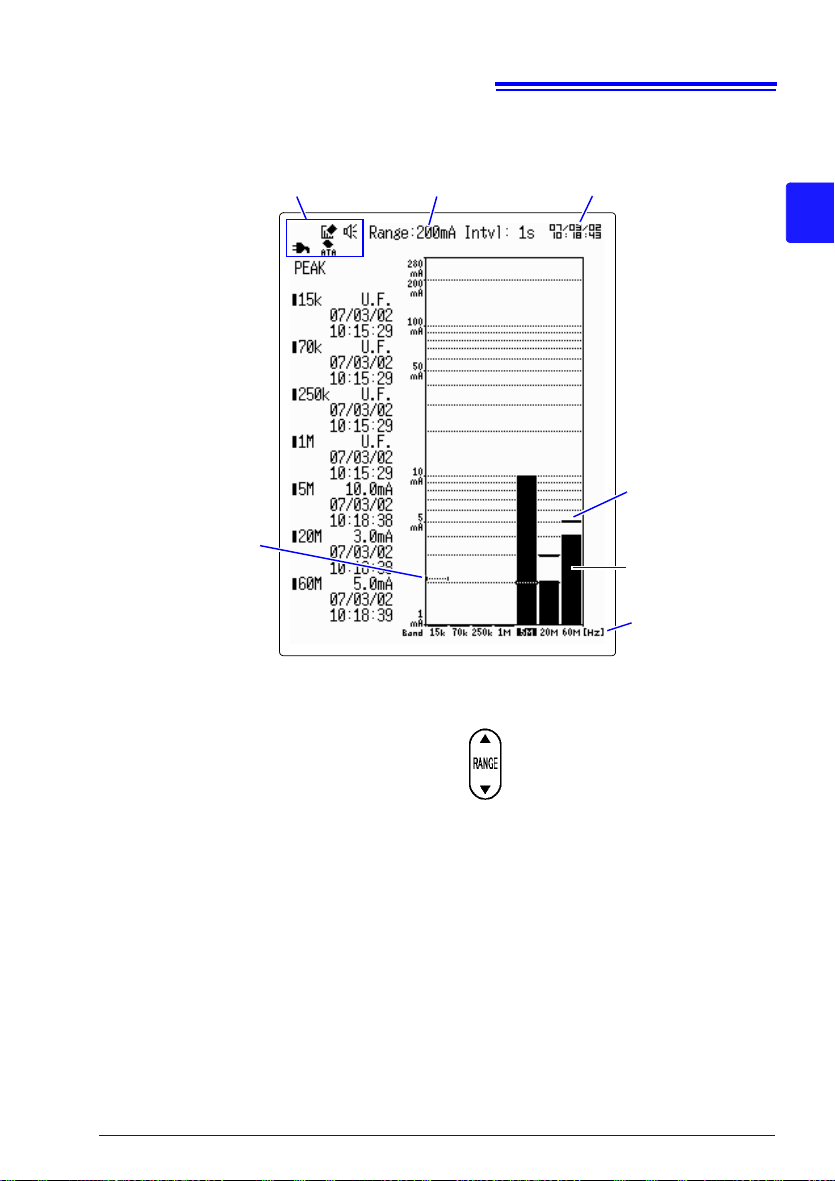

Displays the latest value on the left

side, and the waveforms on the

right side of the screen.

Displays the peak value on the left

side, and the waveforms on the right

side of the screen.

Displays the instantaneous values

on the left side, and a bar graph on

the right side of the screen .

Displays the peak values on the left

side, and the bar graph on the right

side of the screen.

4.1 View the Latest Logging Measurement Value or Peak Value

4.1 View the Latest Logging Measurement V alue

or Peak Value

4.2 Check Using a Bar Graph

(Monitor Measurement)

When saving a file there may be a delay before the graph is displayed.

You can clear the peak value during monitor measurement by pressing

. When moving to the screen other than the monitor screen, the

peak value will be cleared.

Page 59

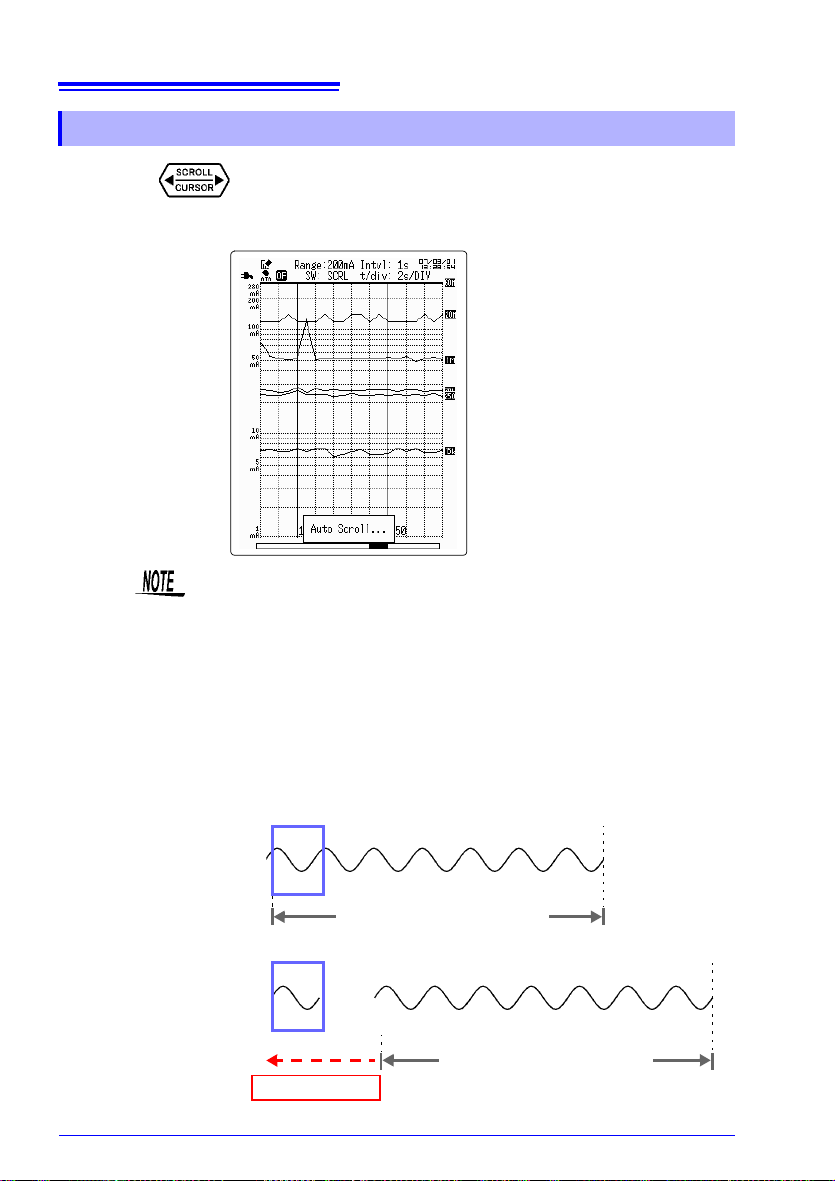

4.3 View Past Waveforms (Scroll Function)

Scroll Left

Display

Display

<Example>

4.3 View Past Waveforms (Scroll Function)

Waveforms on the Logging screen can be scrolled horizontally.

4.3.1 Scrolling the Waveform

1. Press and switch the position to [SCRL].

53

4

Chapter 4 Useful Functions

2. Press to scroll the waveform.

Scroll the waveform fast. : or

Move to the head of the data stored in instrument memory. : and

Move back to the current waveform. : and

Page 60

54

Instrument Memory

(Max. Recording Time)

Display

Erased data

Recording Data

Recording Data

Display

Instrument Memory

(Max. Recording Time)

4.3 View Past Waveforms (Scroll Function)

4.3.2 Auto Scrolling

Holding the for five seconds activates automatic waveform scrolling ("Auto

Scroll" is displayed). Press any key to cancel auto scrolling.

• During measurement auto scroll cannot be performed.

• The amount of time which can be saved (maximum recording time) in

the instrument's internal memory differs depending on the recording

interval setting, so please refer to "The relationship between recording

interval and maximum recording time"( p. 78).

• When the recording time is

when the instrument's internal memory capacity is exceeded. By

scrolling the waveform past waveforms are displayed on the display

screen, but take note that the data may not be saved in internal memory.

• When the recording time is

[Cont] (Continuous), old data is erased

[Time], old data is not overwritten.

Page 61

55

The values read by the A cursor

Full record of internal memory

Displayed waveform

A Cursor position

B Cursor position

Alarm 0

Alarm 1: The alarm state occured

4.4 A/B Cursor Measurement

4.4 A/B Cursor Measurement

Measurement data at a particular position on a waveform can be read using the A-B cursors. The A-B cursor operations are available while measuring.

For the values read by the A and B cursors, values outside the measur ement r ange are d isplayed as "O.F." or "U.F."

1. Press and switch the position to [CSR A] or [CSR B].

2. Press to move the cursor and read the measurement values.

4

Chapter 4 Useful Functions

(When the alarm function is ON)

Page 62

56

(Logging screen shown here)

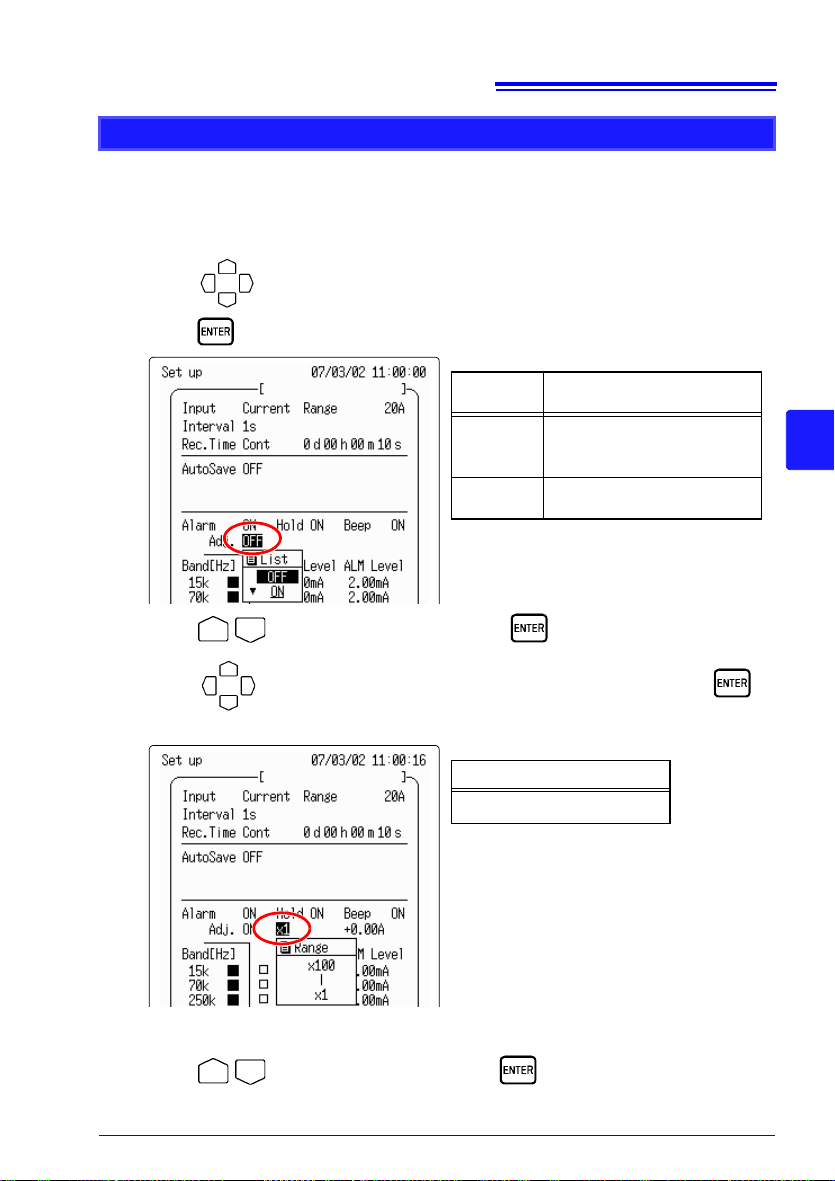

4.5 Using the Alarm Function

4.5 Using the Alarm Function

If the measurement values at each individual band exceed the alarm judgment values, the

following actions are taken as notification.

• The alarm state notification icon is displayed on the screen.

• The alarm sound sounds

• A signal is output via the TRIG OUT terminal (LOW active)

• An email is sent to computer or cellular phone (only available during logging measurement)

Refer to the "Communications" instruction manual on the included CD.

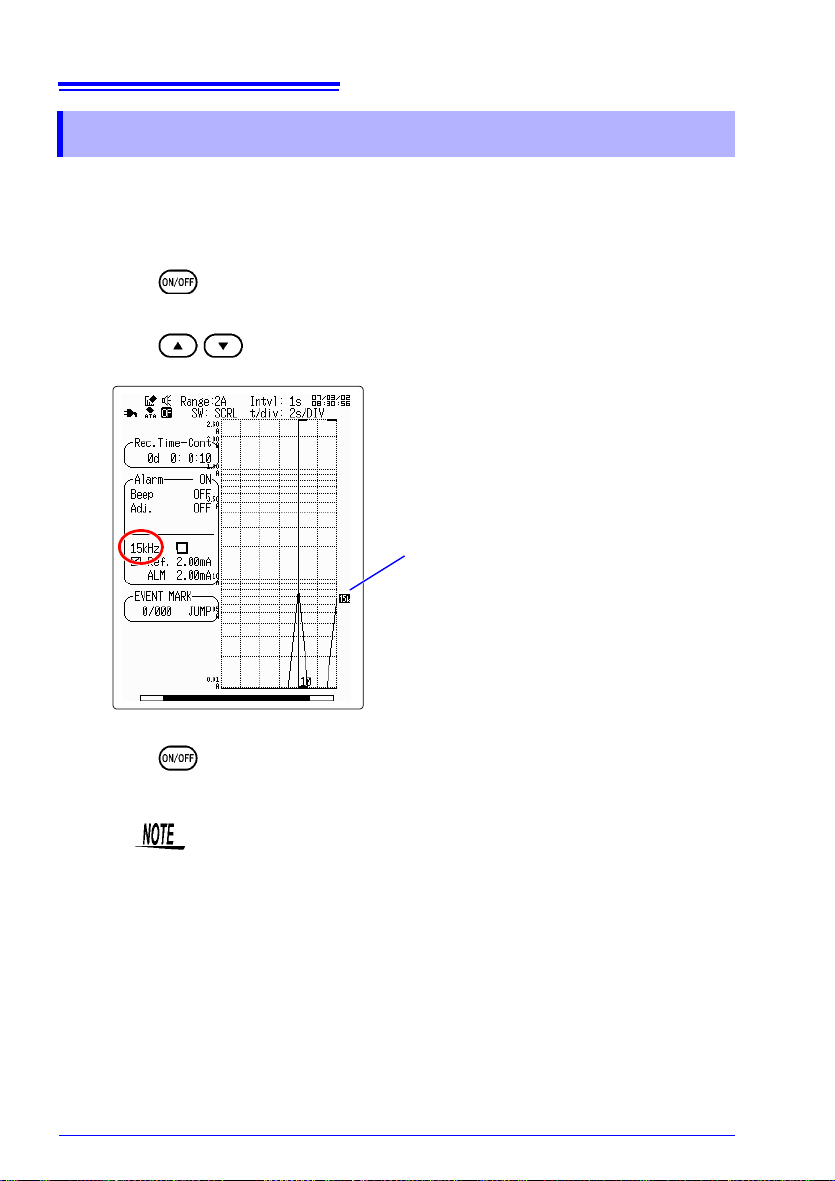

4.5.1 Settings on the Logging Screen or the Monitor Screen.

1. Press to display the submenu.

2. Press to move the blinking cursor to [Alarm], and press to open

the selection window.

3. Press / to select [ON], and press to set.

4. Press to move the blinking cursor to [Beep], and press to open the

selection window.

5. Press / to select the alarm sound as ON or OFF, then press to set.

6. Press / to select the band for which to set the alarm.

Page 63

57

The band for setting the alarm

: The instrument is not in alarm state.

: The instrument is in alarm state.

The time period when the alarm state occurred.

4.5 Using the Alarm Function

7. Press to move the blinking cursor to the reference value position, and

press to set it to ON.

8. Press to move the blinking cursor to the value position, and press to

open the selection window.

4

9. Press / to select the reference value, and to set.

If the compensation setting is OFF, then the reference value will be tre ated as the judgment

value. If the measured value exceeds the judgment value, the instrument en ters al arm state.