Page 1

Instruction Manual

3144-20

NOISE SEARCH TESTER

Aprio 2013 Revised edition 5 3144A981-05 13-04H

Page 2

Page 3

i

Contents

Contents

Introduction ...............................................................1

Inspection..................................................................1

Safety Notes .............................................................2

Operating Precautions..............................................5

Chapter 1 Overview 11

1.1 Product Overview......................................11

1.2 Features....................................................13

1.3 Names and Functions of Parts..................14

1.4 Quick Reference........................................21

Chapter 2 Measurement Preparations 25

2.1 Attaching the Strap....................................26

2.2 Installing the Batteries...............................27

2.3 Connecting the AC Adapter.......................29

2.4 Connecting the 9741 CLAMP ON

VOLTAGE SENSOR............................. .. ..30

2.4.1 Connecting the Sensor to the

Voltage Sensor Input Terminal.......30

2.4.2 Connecting the Instrument to the

Line being Measured......................32

2.5 Connecting Signals to the BNC Input

Terminal ....................................................34

2.6 Connecting to Ground...............................36

2.7 Turning the Power On/Off.........................38

2.8 Connecting the Earphone..........................40

2.9 Connecting Signals to the

Output Terminal.........................................41

Page 4

Contents

ii

Chapter 3 Setup and Measurement 43

3.1 Sample Measurement........................... .... 43

3.2 Monitoring Measurement Data [MONI] ..... 48

3.3 Recording Data [REC]............. ..................50

3.4 Deleting Memory ....................................... 53

3.5 Viewing Recorded Data [VIEW]................ 54

3.6 Setting Date and Time.............................. 55

Chapter 4 Analysis of Recorded Data 57

4.1 General.....................................................57

4.2 Installing Software Drivers ........................ 58

4.3 Installing PC Application Software............ 60

4.4 Setting the Clock ....................................... 61

4.5 Transferring Data to the PC...................... 63

4.6 Analyzing Recorded Data on the PC ........ 68

4.7 Saving Images of Waveform Windows ..... 75

4.8 Printing a Waveform Window....................76

4.9 Analyzing Saved Recorded Data with

Excel .........................................................78

4.10 Error Information.......................................79

Chapter 5 Specifications 83

5.1 Main Unit Specifications............................83

5.2 Clamp Specifications......... ... .....................90

Page 5

iii

Contents

Chapter 6 Maintenance and Service 93

6.1 Battery Replacement.................................93

6.2 Cleaning and Storage................................94

6.3 Repair and Servicing.................................94

6.4 Error Indications and Corrective Action.....95

6.5 System Mode.................................. ..........96

6.6 Instrument Disposal.................................101

Page 6

Contents

iv

Page 7

1

Introduction

Thank you for purchasing the HIOKI "Model 314420 NOISE SEARCH TESTER." To obtain maximum performance from the instrument, please

read this manual first, and keep it handy for future

reference.

Registered Trademarks:

Windows and Excel are registered trademarks of

Microsoft Corporation in the United States and/or

other countries.

Inspection

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel

switches, and connectors. If damage is evident, or if

it fails to operate according to the specifications,

contact your dealer or Hioki representative.

Confirming package contents

• 9741 CLAMP ON VOLTAGE SENSOR..........1

• Instruction Manual..........................................1

• LR6 alkaline batteries.....................................6

• 9445-02 AC ADAPTER or

9445-03 AC ADAPTER..................................1

• PC software(CD-R) ........................................1

• USB cable......................................................1

• Earphone........................................................1

• Strap...............................................................1

• Carrying case.................................................1

Introduction

Page 8

Safety Notes

2

Safety Notes

This instrument is designed to comply with

IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, mishandling during use

could result in injury or death, as well as

damage to the instrument. Using the instrument in a way not described in this manual

may negate the provided safety features.

Be certain that you understand the instructions and precautions in the manual before

use. We disclaim any responsibility for accidents or injuries not resulting directly from

instrument defects.

This manual contains information and warnings

essential for safe operation of the instrument and

for maintaining it in safe operating condition.

Before using it, be sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should

read before using the instrument.

The symbol printed on the instrument indicates that the user should refer to a correspond-

ing topic in the manual (marked with the

symbol) before using the relevant function.

Indicates a double-insulated device.(9741)

Indicates a grounding terminal.

Indicates DC (Direct Current).

Page 9

3

Safety Notes

Symbols in Use

The following symbols in this manual indicate the

relative importance of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the

instrument.

Indicates advisory items related to performance

or correct operation of the instrument.

Indicates the prohibited action.

Indicates the location of reference information.

Accuracy

We define measurement tolerances in terms of f.s.

(full scale) and rdg. (reading) with the following

meanings:

• f.s. (maximum display value or scale length)

The maximum displayable value or scale length.

This is usually the name of the currently selected

range.

• rdg. (reading, displayed or indicated value)

The value currently being measured and indicated on the measuring instrument.

Page 10

Safety Notes

4

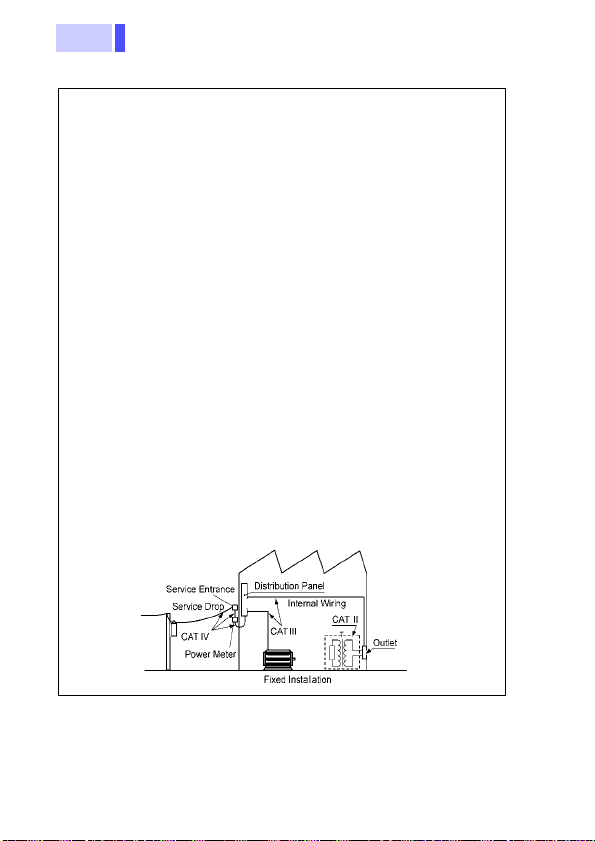

The 9741 CLAMP ON VOLTAGE SENSOR complies with

CAT III 200 V safety requirements.

To ensure safe operation of measurement instrument, IEC

61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

CAT II Primary electrical circuits in equipment connected to

an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

CAT III Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution

panel, and feeders from the distribution panel to outlets.

CAT IV The circuit from the service drop to the service en-

trance, and to the power meter and primary overcurrent protection device (distribution panel).

Using a measurement instrument in an environment designated with a higher-numbered category than that for which the instrument is rated could result in a severe accident, and must

be carefully avoided.

Use of a measurement instrument that is not CAT-rated in

CAT II to CAT IV measurement applications could result in a

severe accident, and must be carefully avoided.

Measurement categories

Page 11

5

Operating Precautions

Before Use

Installation, Operating Environment, and Handling

of the Instrument

Operating Precautions

Follow these precautions to ensure safe operation

and to obtain the full benefits of the various functions.

• Before using the instrument the first time, verify

that it operates normally to ensure that the no

damage occurred during storage or shipping. If

you find any damage, contact your dealer or

Hioki representative.

• Before using the instrument, make sure that the

insulation on the 9741 CLAMP ON VOLTAGE

SENSOR is undamaged and that no bare conductors are improperly exposed. Using the

instrument in such conditions could cause an

electric shock, so contact your dealer or Hioki

representative for repair.

• Do not allow the instrument to get wet, and

do not take measurements with wet hands.

This may cause an electric shock.

• Do not use the instrument where it may be

exposed to corrosive or combustible

gases. The instrument may be damaged or

cause an explosion.

Page 12

Operating Precautions

6

Operating Environment

Observe the following to avoid damage to

the instrument.

• Installation and Operating Environment

Between 0°C and 40°C; 80% RH or less;

indoors only.

• Do not store or use the instrument where it

could be exposed to direct sunlight, high

temperature or humidity, or condensation.

Under such conditions, the instrument may

be damaged and insulation may deteriorate so that it no longer meets specifications.

• This instrument is not designed to be

entirely water- or dust-proof. To avoid damage, do not use it in a wet or dusty environment.

• Do not use the instrument near a device

that generates a strong electromagnetic

field or electrostatic charge, as these may

cause erroneous measurements.

• To avoid damage to the instrument, protect

it from vibration or shock during transport

and handling, and be especially careful to

avoid dropping.

Page 13

7

Operating Precautions

Handling of Cables

• To avoid corrosion from battery leakage,

remove the batteries from the product if it

is to be stored for a long time.

• Adjustments and repairs should be made

only by technically qualified personnel.

• If the protective functions of the product

are damaged, either remove it from service

or mark it clearly so that others do not use

it inadvertently.

Accurate measurement may be impossible in the

presence of strong magnetic fields, such as near

transformers and high-current conductors, or in

the presence of strong electromagnetic fields such

as near radio transmitters.

• To avoid breaking the cables, do not bend or pull

them.

• Avoid stepping on or pinching cables, which

could damage the cable insulation.

Page 14

Operating Precautions

8

T erminals

• The instrument is provided with various

types of external connectors. When plugging cables into the connectors, be carefu l

not to misconnect.

• The voltage sensor input terminal of the

instrument is dedicated to the 9741

CLAMP ON VOLTAGE SENSOR. Be sure

to use the 9741 sensor specified by HIOKI.

Keep in mind that using any other type of

sensor may result in electric shock or malfunction.

• Note the following maximum input voltage

and maximum rated voltage to earth of the

BNC input terminal. If their voltages are

exceeded, this device will be damaged and

personal injury will result. Therefore, do

not perform measurement in this case.

Maximum input voltage: 5 V

PEAK

Maximum rated voltage to earth: 5 V

To protect against dirt and dust, always leave the

protective cover in place, unless using the terminals.

Page 15

9

Operating Precautions

Care and Handling of CD-R

• Always hold the disc by the edges, so as not to

make fingerprints on the disc or scratch the printing.

• Never touch the recorded side of the disc. Do not

place the disc directly on anything hard.

• Do not wet the disc with volatile alcohol or water,

as there is a possibility of the label printing disappearing.

• To write on the disc label surface, use a spiritbased felt pen. Do not use a ball-point pen or

hard-tipped pen, because there is a danger of

scratching the surface and corrupting the data.

Do not use adhesive labels.

• Do not expose the disc directly to the sun's rays,

or keep it in conditions of high temperature or

humidity, as there is a danger of warping, with

consequent loss of data.

• T o remove dirt, dust, or fingerprints from the disc,

wipe with a dry cloth, or use a CD cleaner.

Always wipe radially from the inside to the outside, and do no wipe with circular movements.

Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems

with a computer system that arises from the use

of this CD-R, or for any problem related to the

purchase of a Hioki product.

• In the interests of ongoing product developments, there may be minor discrepancies

between screen displays and the operating

instructions, and in the data conversion process.

• Hioki shall not be held liable for any problems

with a computer system that arises from the use

of this CD-R, or for any problem related to the

purchase of a Hioki product.

Page 16

Operating Precautions

10

Page 17

11

Chapter 1 Overview

Overview Chapter 1

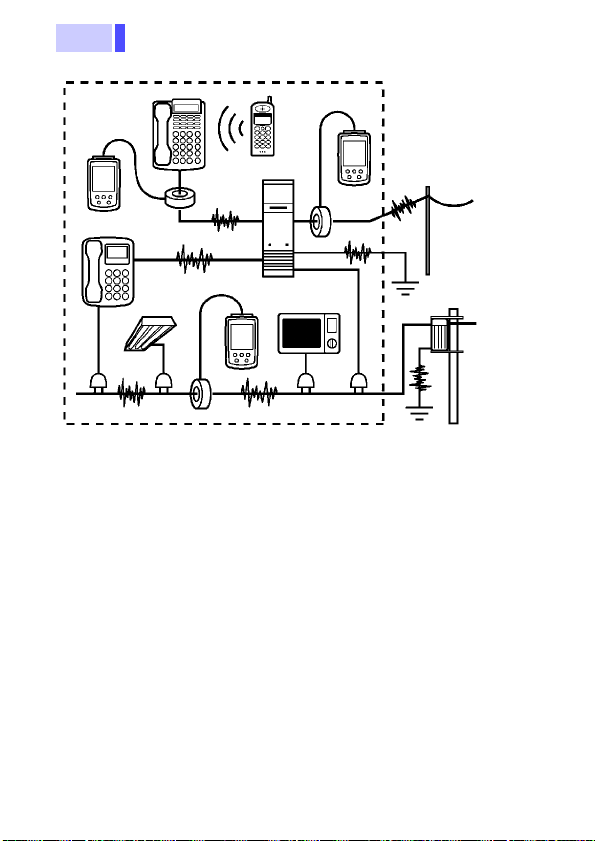

1.1 Product Overview

Noise is propagated through diverse routes such

as communication lines and power supply lines.

Many cases of trouble, including false operation

and malfunction caused by noise, are currently on

the rise. To avoid such trouble, it is essential to

identify the noise frequency bands and routes

through which noise enters, and to take appropriate corrective action.

The 3144-20 NOISE SEARCH TESTER can

search for noise frequency bands and routes of

penetration by simply clamping the 9741 CLAMP

ON VOLTAGE SENSOR to the line being measured.

Moreover, the logging function of the instrument

enables long-time monitoring. The USB interface

allows recorded data to be transferred to a PC,

displayed in graphs, and output to a printer.

Page 18

Chapter 1 Overview

12

Cell phone

Penetrates through

communication

lines

Penetrates through power

supply lines

Extension line

Lighting apparatus

Home appliances

Power supply

lines

Communication lines

Penetrates through

ground wires

Main unit

3144-20

Penetrates directly

Noise sources:

There are many noise sources, such as power

transmission lines, electric railways, inverter units,

and CB radios.

Penetration routes:

Some noise enters through communication lines,

power supply lines, and ground wires, while other

noise penetrates devices directly.

Propagation routes:

Noise is propagated through various routes,

including communication lines and power supply

lines.

The instrument can search for noise frequency

bands and penetration routes by simply attaching

the 9741 CLAMP ON VOLTAGE SENSOR.

Page 19

13

1.2 Features

Noncontact type of voltage sensor

Searches for noise in a system in operation, without affecting circuits currently in communication or

damaging cables.

Measuring frequency band range: 500 Hz

to 30 MHz

Covers a wide band ranging from noise on power

transmission lines to that of CB radios.

Noise indicated on a large-LCD level

meter

Indicates detected noise on a level meter, separately by frequency band.

PEAK HOLD function

Indicates the peak value in each frequency band

and the time measured.

Memory function for up to 64,000 items of

data

Records measurement data and measurement

times for up to 64,000 items of data.

Equipped with USB interface

Using the PC software supplied with the instrument enables the transfer of data to a PC, display

of time series data, and output to a printer.

Compatible with two different power

sources: Batteries and AC adapter

Applicable to field measurements, given its portability and long-time monitoring capability.

Handy type

A compact, lightweight noise measuring tool that

can be used just like a simple circuit-tester.

Chapter 1 Overview

Page 20

Chapter 1 Overview

14

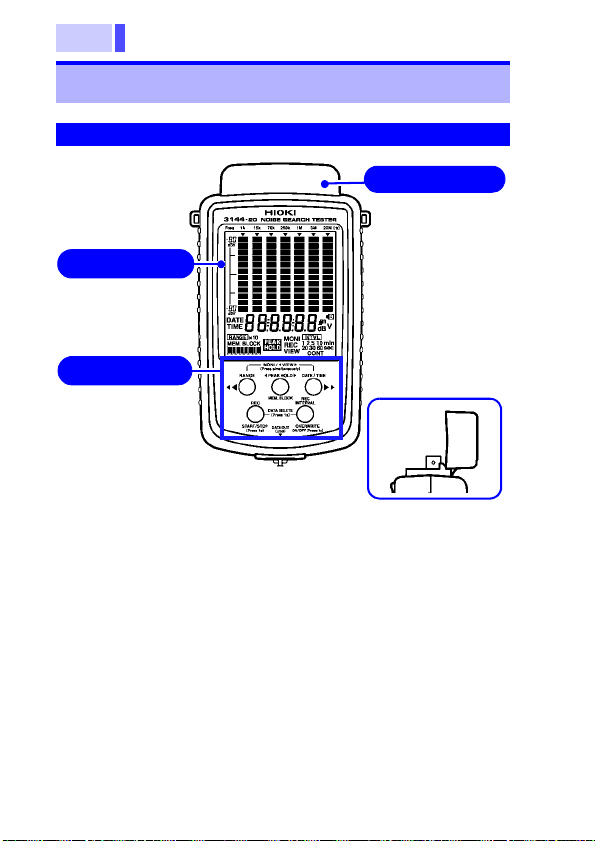

Front

page 17

Protective cover

for the voltage sensor input terminal,

BNC input terminal, and output terminal.

When not using

the instrument,

place the protective cover back in

place.

page 18

Protective cover

Operating keys

LCD display

Cover fastening method

when instrument in use

3144-20 NOISE SEARCH TESTER

1.3 Names and Functions of Parts

Page 21

15

Chapter 1 Overview

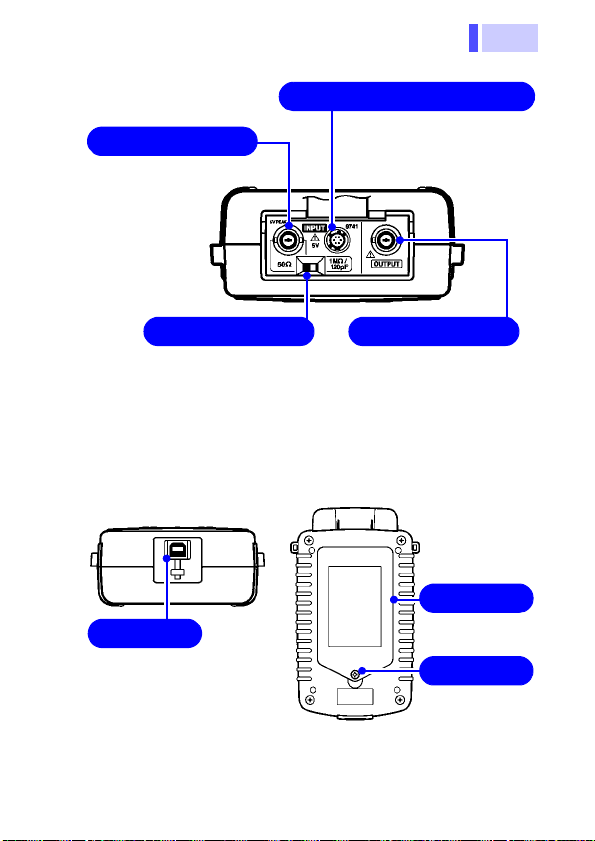

Top

Input terminal for

external signals,

excluding signals

from the 9741.

Effective when the

instrument is not

connected to the

9741.

page 34

Output terminal for waveforms applied to the voltage

sensor input terminal or

BNC input terminal.

page 41

Connect the supplied 9741

CLAMP ON VOLTAGE

SENSOR here.

page 30

Switch to select the input

impedance of the BNC input

terminal.

(50 /1 M approx. 120 pF

page 34

Voltage sensor input terminal

BNC input terminal

Output terminalSelector switch

Bottom Surface

Plug the USB cable in

this terminal.

Rear Side

USB terminal

Battery cover

Setscrew

Page 22

Chapter 1 Overview

16

Left Side

page 38

page 26

Right Side

Regulates the sound volume of the earphone.

Audible band monitoring

output terminal. Plug in the

earphone used to listen to

noise here.

page 40

Plug in the 9445-02 or 9445-03 AC

ADAPTER (supplied with the instrument) here.

Ground terminal for this instrument.

page 36

Protective cover

(when fastened)

Strap hole

POWER switch

Volume control knob

AC adapter connection terminal

Ground terminal

Earphone terminal

Page 23

17

Chapter 1 Overview

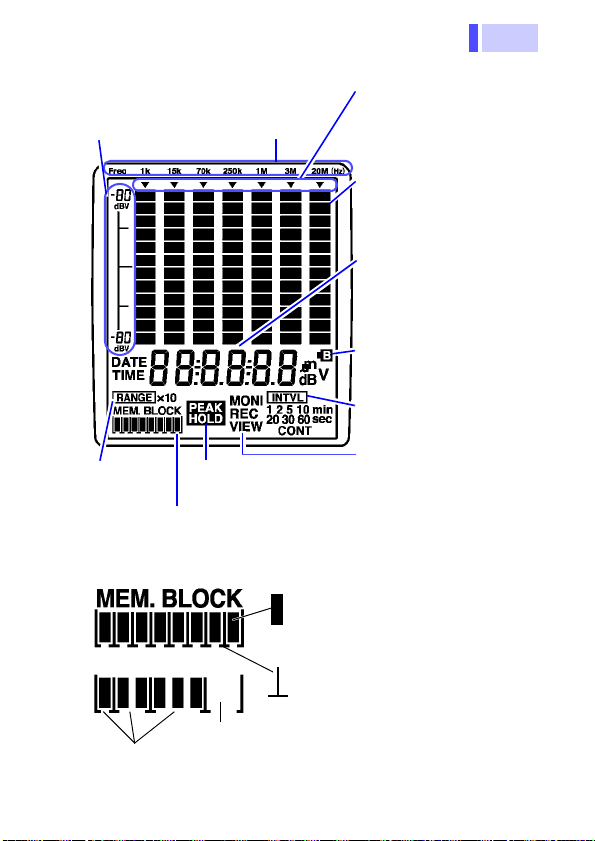

Frequency range

indication

Display Section

Scale indication

[In decibels (dBV)]

Indication of Memory Blocks

Remains on when the

PEAK HOLD function is

ON.

Indication of

measuring

range

Indicates the frequency

range at peak detection, with

the PEAK HOLD function

ON.

Level meter (indicates for

each frequency range in 12

steps).

Indicates when noise is detected.

Indicates the date and time,

with the PEAK HOLD function OFF.

Indicates the peak detection

time, with the PEAK HOLD

function ON.

Battery mark

(Lights when the supply voltage drops below 6.5 V.)

Indication of recording time

interval

MONI: Remains on during

monitoring.

REC: Remains on during

recording.

VIEW: Remains on during

display of recorded

data.

Blocks (Storage units of recorded

data)

One block can hold up to 8,000

items of data.

Indicates the delimiter of files, with

each file covering the start to the

end of a recording. A file consists

of one to eight blocks, depending

on the number of data items recorded.

Empty blocks

Blocks occupied

by files

Indication of Memory Blocks

Page 24

Chapter 1 Overview

18

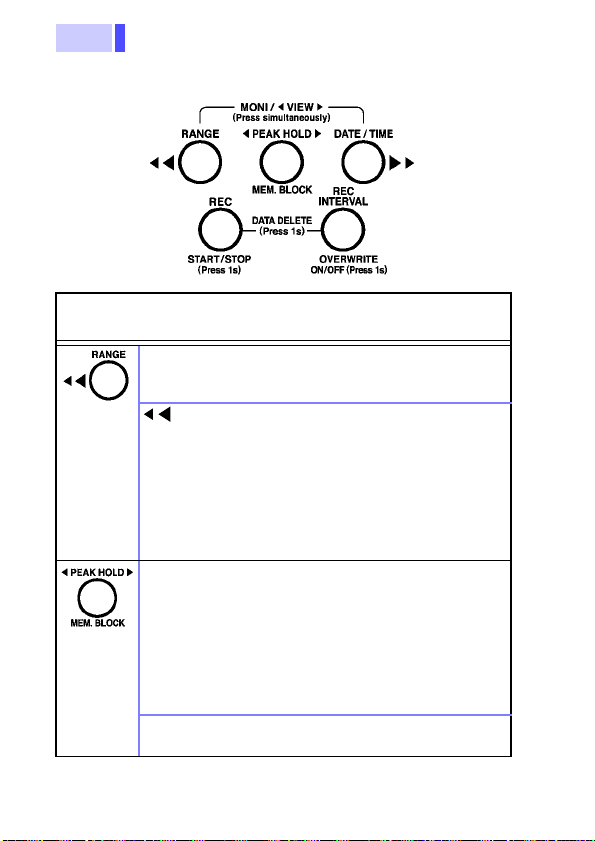

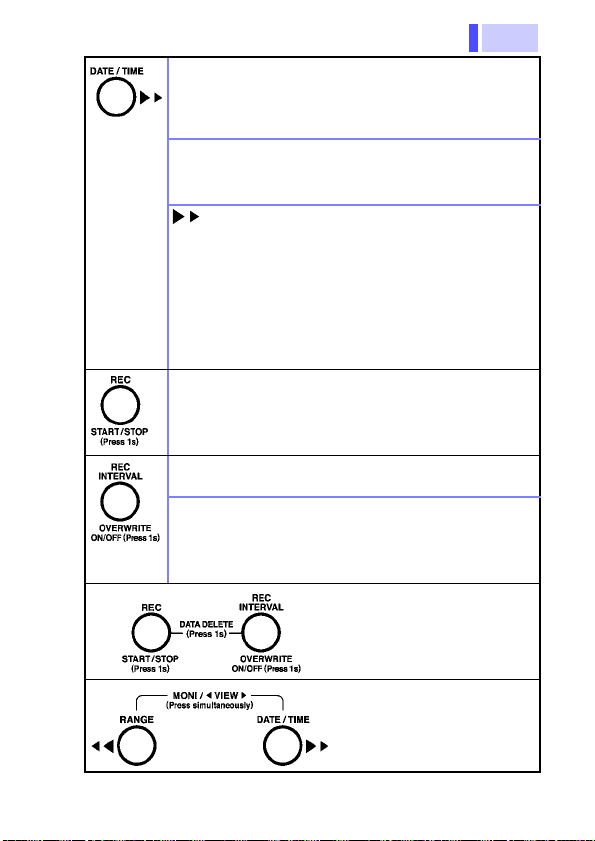

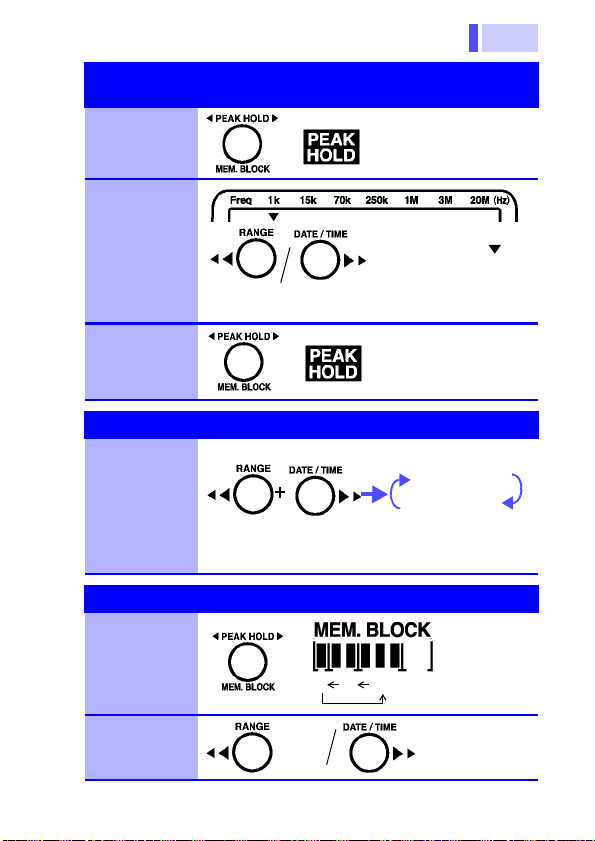

Operation Keys

Key

Press for 1 sec.

RANGE key

key

PEAK HOLD

key

MEM.BLOCK

key

(The functions of keys vary, depending on

the settings made.)

Selects the measuring range (on the

monitoring screen [MONI] with the

PEAK HOLD function OFF.)

Selects the frequency range corresponding to the peak detection time to

be indicated (with the PEAK HOLD

function ON).

Scrolls recorded data (on the data view

screen [VIEW]).

Sets the date and time (in date and

time setup). (Values DOWN)

Sets the PEAK HOLD function on and

off (on the monitoring screen [MONI] or

recording screen [REC]).

Each pressing of this key shifts flashing to the setting position in order of

Year Month Day Hour

Minute Second (in date and time

setup).

Explanation

Defines the settings of date and time.

Selects the memory block (on the data

view screen [VIEW]).

Page 25

19

DATE/TIME

key

DATE/TIME

key

Press for 1

sec.

key

REC key

Press for 1

sec.

Chapter 1 Overview

Switches the current indication to a

date or time (on the monitoring screen

[MONI] with the PEAK HOLD function

OFF).

Enables date and time setup.

Selects the frequency range corresponding to the peak detection time to

be indicated (with the PEAK HOLD

function ON).

Scrolls recorded data (on the data view

screen [VIEW]).

Sets the date and time (in date and

time setup). (Values UP)

Starts or stops recording.

(Starts on the monitoring screen [MONI]).

(Stops on the recording screen [REC]).

REC INTERVAL key

OVERWRITE ON/

OFF key

Press for 1

sec.

Sets the recording interval (on the

monitoring screen [MONI]).

Switches between Automatic Stopping

Mode and Overwrite Recording Mode

for recording (on the monitoring screen

[MONI]).

Deletes all recorded data

(on the monitoring screen

[MONI] or data view screen

[VIEW]). (When pressed for

1 sec.)

Switches between monitoring screen [MONI] and data

view screen [VIEW] (when

pressed simultaneously).

Page 26

Chapter 1 Overview

20

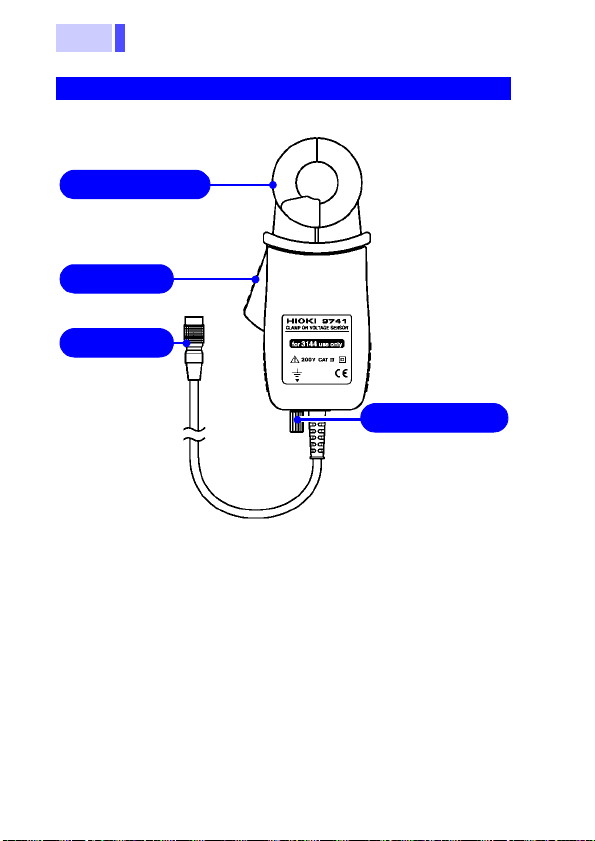

9741 CLAMP ON VOLTAGE SENSOR

Clamp section

Connector

Lever

page 36

page 30

page 32

Pressing the lever

opens the clamp

section.

Ground terminal

Page 27

21

Date indication

Time indication

DATE

TIME

To cancel: Press any key

other than the above.

Press for

1 sec.

Value setting

DOWN UP

Shifts to setting position

(Year

Month Day

Hour Minute

Second)

End of setup.

The setting position

flashes.

Set the value

at the flashing

position.

Each pressing of the

key changes the indication.

Chapter 1 Overview

1.4 Quick Reference

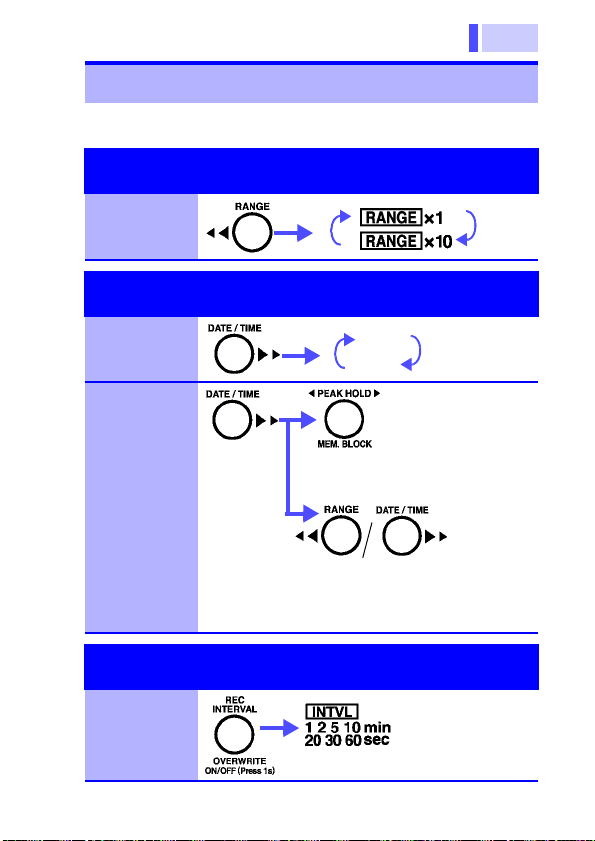

[MONI]: Monitoring screen/ [REC]: Recording screen/

[VIEW]: Data view screen

Measuring Range

(On [MONI] with the PEAK HOLD function OFF)

Switching of

range

Date and Time Indication

(On [MONI] with the PEAK HOLD function OFF)

Switching of

indication

Change of

settings

Recording Interval

(On [MONI])

Change of

settings

Page 28

Chapter 1 Overview

22

CONT

Lights.

When memory becomes full, new data is

written over old data to

continue recording.

Press for

1 sec.

remains on.)

(CONT

Goes off.

When memory becomes full, recording

stops automatically.

Press for

1 sec.

CONT

REC

MONI

Recording is started.

Recording is stopped.

Lights.

Lights.

Press for

1 sec.

Press for 1 sec simultaneously.

All recorded data is

deleted.

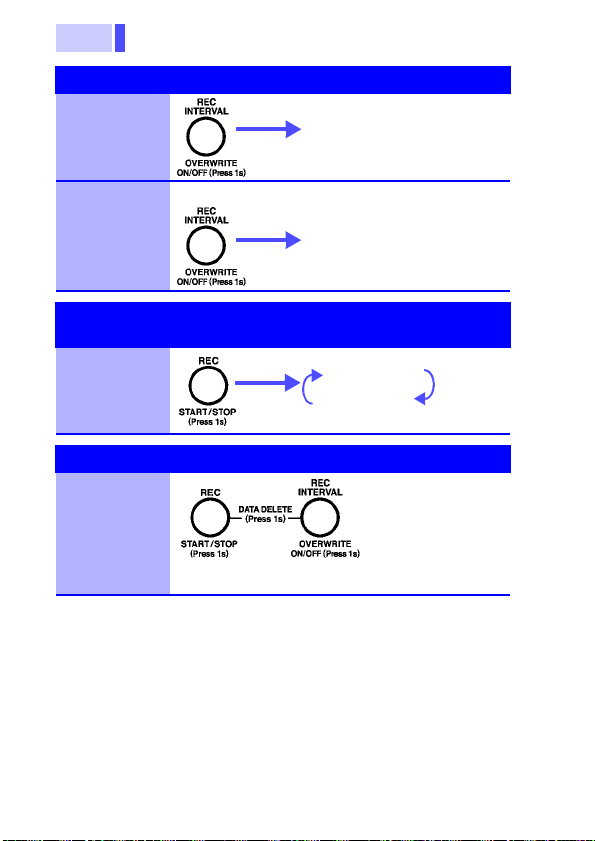

Data Saving Method (On [MONI])

Save by

overwriting

Save without

overwriting

Start and Stop of Measurement

(Start on [MONI], Stop on [REC])

Start and

stop of measurement

Data deletion (On [MONI] or [VIEW])

Deletion

(Batch dele-

tion)

Page 29

23

Chapter 1 Overview

Lights.

Shifts to

the left.

Shifts to

the right.

Indicates the peak value of

the range in which is

lighting, and the detection

time.

Goes off.

Press simultaneously

MONI

VIEW

Lights.

Lights.

Monitoring screen [MONI]

Data view screen [VIEW]

Allows monitoring recorded data.

Each pressing of the key

switches the

blocks.

123

Back

Forward

Peak Value Indication (PEAK HOLD function)

(On [MONI] or [REC])

Activating

the PEAK

HOLD function

Selecting the

frequency

range to be

indicated

(Effective only

with PEAK

HOLD ON)

Deactivating

the function

Switching of Screens

Switching

between

monitoring

screen

[MONI] and

data view

screen

[VIEW]

Viewing of Recorded Data (On [VIEW])

Selecting the

memory

block

Scrolling the

data

Page 30

Chapter 1 Overview

24

Page 31

25

Chapter 2 Measurement Preparations

Connect to the

output terminal.

page 41

Attach the strap.

page 26

1 Install the batteries.

page 27

2 Connect the AC

adapter.

page 29

3 Connect the 9741.

page 30

4 Turn on the POWER

switch.

page 38

Rear side

Attach the

earphone.

page 40

Connect to ground.

page 36

Connect the USB cable.

Connect to the BNC

input terminal.

page 34

Measurement

Preparations

Please read the "Operating Precautions" (page 5) before setting

up this instrument.

Chapter 2

Page 32

Chapter 2 Measurement Preparations

26

Tighten the strap sufficiently to prevent loosening or twisting.

3144-20

Attach the two rings of the

strap to the respective locations in the 3144-20.

2.1 Attaching the Strap

Use the strap to carry the instrument, or to hang it

up at the installation location.

Attach both ends of the strap securely to the

instrument. If insecurely attached, the instrument

may fall and be damaged when carrying.

Page 33

27

Chapter 2 Measurement Preparations

2.2 Installing the Batteries

The instrument operates on battery power or AC

through the adapter. When using the AC adapter

and batteries together, AC adapter power is

employed.

When powering the instrument using the batteries,

the operating time is as follows:

About five hours when indications are shown on

the monitoring screen [MONI]

(Ambient temperature: 23°C, reference value)

The operating time varies depending on the ambient temperature and type of batteries used.

Do not mix old and new batteries, or different

types of batteries. Also, be careful to obse rve

battery polarity during installation. Otherwise,

poor performance or damage from battery

leakage could result.

• Do not use other than the specified type of batteries (LR6 alkaline batteries). Using manganese

batteries will result in a shorter operating time

than when using alkaline batteries.

• When measurement data must be recorded, use

the AC adapter.

• The indicator appears when battery voltage

becomes low. Replace the batteries as soon as

possible.

• After use, always turn OFF the power.

• To replace the batteries, see 6.1, "Battery

Replacement" (page 93).

Page 34

Chapter 2 Measurement Preparations

28

1. Make sure that the POWER

switch of the 3144-20 is OFF

and disconnect all cables.

2. Turn over the 3144-20, then

loosen the setscrew to detach

the battery cover.

3. Install six LR6 alkaline batter-

ies in the battery compartment, and confirm the correct

polarity.

(Replace all batteries at the

same time.)

4. Put the battery cover back in

place, then tighten the screw.

3144-20

Tool required for installation:

Six LR6 alkaline batteries , Phillips-head screwdriver

Page 35

29

Chapter 2 Measurement Preparations

1. Connect the output plug of

the AC adapter to the AC

adapter connection terminal.

2. Plug the AC adapter into a

power outlet.

AC adapte

r connection terminal

Right side of the 3144-20

2.3 Connecting the AC Adapter

• Use only the supplied Model 9445-02 AC

ADAPTER or 9445-03 AC ADAPTER .

AC adapter input voltage range is 100 to

240 VAC (with ±10% stability) at 50/60 Hz.

To avoid electrical hazards and damage to

the instrument, do not apply voltage outside of this range.

• Turn the instrument off before connecting

the AC adapter to the instrument and to

AC power.

To avoid damaging the power cord, grasp the plug,

not the cord, when unplugging it from the power

outlet.

When using the AC adapter and batteries together,

AC adapter power is employed.

If AC power supply is interrupted for some reason,

the instrument will automatically switch to battery

power.

Page 36

Chapter 2 Measurement Preparations

30

2.4 Connecting the 9741 CLAMP ON VOLTAGE SENSOR

2.4.1 Connecting the Sensor to the Voltage Sensor Input Terminal

The voltage sensor input terminal of the

instrument is dedicated to the 9741 CLAMP

ON VOLTAGE SENSOR. Always use the

9741 as designated by HIOKI. Keep in mind

that connecting any other type to the terminal

could result in electric shock or malfunction.

• To prevent damage to the instrument and sensor, never connect or disconnect a sensor while

the power is on, or while the sensor is clamped

around a conductor.

• To avoid damaging the output cable, grasp the

connector, not the cable, when unplugging the

cable.

• Be careful to avoid dropping the clamps or otherwise subjecting them to mechanical shock,

which could damage the mating surfaces of the

core and adversely affect measurement.

Page 37

31

Chapter 2 Measurement Preparations

Plug in the 9741 CLAMP ON

VOLTAGE SENSOR.

Voltage sensor input

terminal

Top side of the 3144-20

Plugging in

Unplugging

Hold the upper part of the

connector to plug it in.

(The connector cannot be

inserted if held by the metallic part.)

Tip of the 9741's connector

Insert the connector by

aligning its protrusion with

the groove of the voltage

sensor input terminal.

Hold the metallic part of the

connector to unplug it.

(The connector cannot be

unplugged if held by the upper part.)

Page 38

Chapter 2 Measurement Preparations

32

2.4.2 Connecting the Instrument to the Line being Measured

The 9741 CLAMP ON VOLTAGE SENSOR

should first be plugged into the 3144-20

before being connected to the live line being

measured. To avoid short-circuiting or electric shock, observe the precautions below.

• To avoid short circuits and potentially lifethreatening hazards, never attach the

clamp to a circuit that operates at more

than 200 VAC, or over bare conductors.

• The 9741 should only be connected to th e

secondary side of a breaker, so the

breaker can prevent an accident if a short

circuit occurs. Connections should never

be made to the primary side of a breaker,

because unrestricted current flow could

cause a serious accident if a short circuit

occurs.

To avoid electric shock when measuring live

lines, wear appropriate protective gear, such

as insulated rubber gloves, boots and a

safety helmet.

To prevent damage to the instrument and sensor,

never connect or disconnect a sensor while the

power is on, or while the sensor is clamped around

a conductor.

Page 39

33

Chapter 2 Measurement Preparations

OK

Secure the conductor in the center of the clamp.

• Max. diameter of clamp: 20 mm

• Cable diameter that can be clamped:

No larger than 20 mm

Due to the principles of measurement, the detecting sensitivity of the 9741 varies with the diameter

of the cable to be measured, cable position inside

the clamp, permittivity of the cable covering, and

other factors. See the typical characteristics data

for the relationship between the diameter of cable

being measured and the sensitivity, and between

the cable position inside the clamp and the sensitivity (page 91). Especially when data must be

recorded for an extended period of time, fix the

position of the cable being measured inside the

clamp.

Page 40

Chapter 2 Measurement Preparations

34

2.5 Connecting Signals to the BNC Input Terminal

Note the following maximum input voltage

and maximum rated voltage to earth of the

BNC input terminal. If their voltages are

exceeded, this device will be damaged and

personal injury will result. Therefore, do not

perform measurement in this case.

Maximum input voltage: 5 V

PEAK

Maximum rated voltage to earth: 5 V

When disconnecting the BNC connector, be sure

to release the lock before pulling off the connector.

Forcibly pulling the connector without releasing the

lock, or pulling on the cable, can damage the connector.

To apply external signals output from a near-magnetic field probe or antenna (excluding those from

the 9741) to the instrument, connect the signals to

the BNC input terminal.

The level in each frequency band can be checked

or recorded in the same way as with the 9741.

Input to the BNC input terminal is effective when

the instrument is not connected to the 9741.

The measuring range is the same as for input from

the 9741 (0 to -50 dBV).

Page 41

35

Selector switch

Top side of the 3144-20

Insert the connector by aligning

the groove of the BNC connector with the connector guide on

the 3144-20 side.

Turn clockwise to lock.

To unplug the connector, unlock it by turning it counterclockwise, then pull it out.

Lock

BNC input terminal

connector guide

pins

BNC connector

BNC input terminal

1. Plug the BNC connector into

the BNC input terminal.

2. Use the selector switch to

select the input impedance

(50/ 1M, approx. 120 pF).

Plugging in and unplugging the BNC connector

Chapter 2 Measurement Preparations

Page 42

Chapter 2 Measurement Preparations

36

1. Loosen the screw of the 9741

ground terminal and pass the

ground wire through the earthing hole.

2. Tighten the screw to lock the

ground wire.

3. Connect the other end of the

ground wire to ground.

Required tools: Ground wire

About ground wires

Applicable wires: Solid or stranded wire 2.1 mm or less in

diameter

Connecting the 9741 CLAMP ON VOLTAGE SENSOR

to ground

Earthing hole

Ground terminal

screw

2.6 Connecting to Ground

Connect the ground terminal of the 9741 CLAMP

ON VOLTAGE SENSOR or 3144-20 NOISE

SEARCH TESTER to ground.

The noise detected when using the 9741 is that in

a common mode which exists between communication lines/power supply lines and the earth. By

connecting that terminal to ground, noise against

the earth can be detected.

Moreover, ground connection reduces the influence of the surroundings (coupling with metallic

materials in the surroundings), excluding the cable

being measured, by means of the shielding effect.

Failure to connect the instrument to ground would

make the measurement susceptible to effects from

objects other than the cable being measured, thus

making it impossible to conduct correct measurement.

Page 43

37

Chapter 2 Measurement Preparations

1. Insert the ground wire into the

earthing hole while pressing

the ground terminal of the

3144-20 with a flat-tip screwdriver.

2. Release the screwdriver to

lock the wire in place.

3. Connect the other end of the

ground wire to ground.

Required tools: Ground wire, flat-tip screwdriver

About ground wires

• Applicable wires

Solid wire: 0.4 mm (AWG26) to 1.2 mm (AWG16) in dia.

Stranded wire: 0.3 mm

2

(AWG22) to 1.25 mm2 (AWG16)

in dia.

Diameter of strand: 0.18 mm or more

• Recommended applicable tool: Flat-tip screwdriver with tip

width of 2.6 mm

Connecting the 3144-20 NOISE SEARCH TESTER

Right side of the 3144-20

Ground terminal

Earthing hole

Page 44

Chapter 2 Measurement Preparations

38

Switching the power on:

Turn on the POWER switch.

The screen will appear.

Switching the power off:

Turn off the POWER switch.

Left side of the 3144-20

2.7 Turning the Power On/Off

Before turning the instrument on, make sure

the supply voltage matches that indicated on

the its power connector. Connection to an

improper supply voltage may damage the

instrument and present an electrical hazard.

• If the battery mark ( at the upper right of the

screen) lights when power is turned on, the batteries are depleted. Replace with new ones.

2.2, "Installing the Batteries" (page 27)

6.1, "Battery Replacement" (page 93)

• The settings of the immediately preceding measurement are retained even when power is

turned off. Turning power on again restores the

immediately preceding settings. Note that any

data recording in progress at the time is stopped.

• After use, always turn OFF the power.

Page 45

39

Chapter 2 Measurement Preparations

Model indicated

Date indicated

Time indicated

Data memory checked

Monitoring screen

POWER switch turned ON

The following are indicated on the screen when

power is turned on:

The checking time for data memory varies

depending on the contents of memory.

Page 46

Chapter 2 Measurement Preparations

40

1. Plug the earphone into the

earphone terminal.

Insert the plug securely as far

as it will go.

2. Adjust the sound volume by

turning the VOLUME control

knob.

Right side of the 3144-20

Connect the earphone

here.

2.8 Connecting the Earphone

To avoid damage to the instrument, do not apply

current or voltage to Earphone terminal.

The earphone outputs a detected noise signal that

is converted into an envelope component of the

audible range.

It can be used as an aid, for example, in identifying

the type of noise signal.

Page 47

41

Chapter 2 Measurement Preparations

Connect this to the input terminal of an oscilloscope or

other measuring instrument.

Output terminal

Top side of the 3144-20

2.9 Connecting Signals to the Output Terminal

To avoid damage to the instrument, do not shortcircuit the output terminal and do not input voltage

to the output terminal.

The instrument outputs the waveform of a

detected noise signal.

This terminal can be used to check a detected signal by its waveform.

Page 48

Chapter 2 Measurement Preparations

42

Page 49

43

Chapter 3 Setup and Measurement

• Location of measurement: Indoors

• Facility being measured: ADSL circuit

• Measured object: Noise signal

• Measurement period: 8 hours

• Data storage: Saved in internal memory.

• Measuring conditions: Range x1

Recording interval: 1 min.

• 3144-20

• 9445-02 or 9445-03 AC ADAPTER

• 9741 CLAMP ON VOLTAGE SENSOR

• USB cable

• Others (PC, PC software, ground wire, tools)

Setup and

Measurement

3.1 Sample Measurement

In this sample measurement, the frequency band of a

noise signal propagated through an ADSL circuit will be

identified.

Equipment to be prepared:

Chapter 3

Page 50

Chapter 3 Setup and Measurement

44

1. Connect the AC adapter to the

instrument and to a power outlet.

2. Connect the 9741 CLAMP ON

VOLTAGE SENSOR to the voltage sensor input terminal of the

instrument.

3. Connect the ground wire to the

ground terminal of the instrument.

4. Connect the ground wire to

ground.

5. Turn on the POWER switch of

the instrument.

6. Clamp the 9741 CLAMP ON

VOLTAGE SENSOR to the ADSL

circuit.

1

2

3

3144-20

ADSL circuit

4

5

9741

6

Connecting the instrument and peripherals

1

Page 51

45

Chapter 3 Setup and Measurement

Set up the parameters according to the intended measurement.

1. Check the current time, then set the date and time.

3.6, "Setting Date and Time" (page 55)

2. Set the range to ×1.

3. Set the recording interval

to one minute.

4. Set up the recording

method.

3.3, "Recording Data

[REC]" (page 50)

Press for 1

sec.

Lights.:

Overwrite Recording Mode

Goes off.:

Automatic Stopping

Mode

Press this key for 1 sec. to start recording.

Setting up recording conditions

2

Starting data recording

3

Page 52

Chapter 3 Setup and Measurement

46

Peak Hold can be indicated, as required.

"Activation/deactivation of PEAK HOLD function"

(page 48)

Recording in progress

1. Press this key once again for 1 sec. to stop

recording.

2. Remove the 9741 CLAMP ON VOLTAGE SENSOR from

the ADSL circuit.

3. Turn off the POWER switch.

4. Disconnect the AC adapter, 9741, and ground wire from

the instrument.

Stopping data recording

4

Page 53

47

Chapter 3 Setup and Measurement

1. Connect the USB cable to the USB terminals of the instru-

ment and the PC.

2. Turn on the POWER switch of the instrument.

3. Activate the PC software supplied with the instrument.

Chapter 4, "Analysis of Recorded Data" (page 57)

Before using the instrument for this purpose for the first

time, be sure to install the application program supplied.

4.2, "Installing Software Drivers" (page 58)

4.3, "Installing PC Application Software" (page 60)

4. Transfer recorded data from the 3144-20 to the PC.

4.5, "Transferring Data to the PC" (page 63)

5. Display time-series data in waveforms and check the

noise level, peak value, peak detection time, etc., corresponding to each frequency band.

4.6, "Analyzing Recorded Data on the PC" (page 68)

The waveform data can be saved in CSV format.

4.9, "Analyzing Saved Recorded Data with Excel"

(page 78)

Moreover, the images of waveform windows can be

saved in BMP format and output to a printer.

4.7, "Saving Images of Waveform Windows" (page 75)

4.8, "Printing a Waveform Window" (page 76)

Analyzing recorded data on the PC

5

Page 54

Chapter 3 Setup and Measurement

48

3.2 Monitoring Measurement Data [MONI]

When the instrument is switched on, the monitoring screen appears (MONI lights), indicating the

voltage levels of various frequency ranges on the

level meter.

Selection of range________________________

Select the range for the input voltage.

Each pressing of the RANGE key changes the

indications of range and scale.

×1........1V range

(Scale indication: 0 to -30 dBV)

×10......0.1V range

(Scale indication: -20 to -50 dBV)

Activation/deactivation of PEAK HOLD function

When the PEAK HOLD function is currently active

(ON), the instrument shows the peak value of the

level detected in each frequency range and the

detection time.

PEAK HOLD lights: Peak hold ON

PEAK HOLD goes off: Peak hold OFF

Each pressing of the PEAK HOLD key changes

the ON/OFF setting of the PEAK HOLD function.

Page 55

49

Chapter 3 Setup and Measurement

Frequency

range

Peak value

Peak detection

time indicated

Date and time are

displayed alternately.

• The indications of peak values and the detection

times cover the time range from the start of

recording to the present time. When the PC software is used, the indications of peak values and

detection times cover all recorded data that was

downloaded to the PC. For this reason, if data

was acquired in overwrite recording mode, the

3144-20 and PC software may indicate different

peak values and detection times.

• When there are multiple peak values, the time of

the peak value detected first will be indicated.

Checking peak values and peak detection times

When PEAK HOLD is on, the frequency ranges

can be switched to check the corresponding peak

values and detection times.

Use the key or key to select the frequency range.

Page 56

Chapter 3 Setup and Measurement

50

3.3 Recording Data [REC]

Pressing the REC key on the monitoring screen

[MONI] for 1 sec. displays the recording screen

(REC lights), and the instrument starts recording

measurement data in memory at the preset interval.

Two recording modes are available. Either should

be set before recording.

• Automatic Stopping Mode

When memory becomes full (64,000 data items),

recording stops automatically.

When there are empty blocks in memory, recording can be repeatedly started and stopped to

continue measurement.

Memory Block: (page 17)

• Overwrite Recording Mode

When memory becomes full, older data is overwritten to continue measurement.

When data already exists before the start of

recording, the data must be deleted to start

recording.

Data deletion: (page 53)

• To record data, use the 9445-02 or 9445-03 AC

ADAPTER. When the instrument is operated on

batteries, all data may not be saved since the

time of continuous use depends on the service

life of batteries in use.

• Due to the principles of measurement, the

detecting sensitivity of the 9741 varies with the

diameter of the cable to be measured, cable

position inside the clamp, permittivity of the

cable covering, and other factors. See the typical characteristics data for the relationship

between the diameter of cable being measured

and the sensitivity, and between the cable position inside the clamp and the sensitivity ( page

91). Especially when data must be recorded for

an extended period of time, fix the position of

the cable being measured inside the clamp.

Page 57

51

Chapter 3 Setup and Measurement

Setup before recording ____________________

Make the following settings before starting recording (on the monitoring screen [MONI]). Once

recording gets under way, the settings cannot be

changed, except the ON/OFF setting of the peak

value indication, until the recording is stopped.

1. Set the current time and measuring con-

ditions.

• Date and time setup(page 55)

• Setup of measuring range and ON/OFF of peak

value indication (page 48)

2. Set the recording interval.

This setting cannot be changed while recording is

in progress.

Each pressing of the REC key switches the indication of recording intervals.

1/ 2/ 5/ 10/ 20/ 30 sec

1/ 2/ 5/ 10/ 20/ 30/ 60 min

The maximum recording time varies with the

recording mode selected.

"Recording Time" (page 85)

3. Set the recording mode.

Press the OVERWRITE key for 1 sec. to select the

recording mode. Each pressing of the key

switches the mode.

• When Overwrite Recording is ON (Overwrite

Recording Mode): CONT remains on.

• When Overwrite Recording is OFF (Automatic

Stopping Mode): CONT remains off.

Page 58

Chapter 3 Setup and Measurement

52

When measurement is stopped, a delimiter appears at the end of the blocks.

Start of record ing ________________________

Press the REC key for 1 sec.

The recording screen [REC] opens. (REC lights.)

The occupied state of memory is displayed on the

screen.

End of recording _________________________

Press the REC key again for 1 sec.

(REC goes off.)

The instrument stops recording and returns to the

monitoring screen [MONI].

Page 59

53

Chapter 3 Setup and Measurement

Press these keys simultaneously for 1 sec.

3.4 Deleting Memory

All recorded data is deleted. Before deleting

recorded data, download the necessary data to the

PC.

4.5, "Transferring Data to the PC" (page 63)

The following window appears:

Recorded data can be deleted through monitoring

screen [MONI] or data view screen [VIEW]. After

the data is deleted, operation returns to the monitoring screen [MONI].

• Note that, once initiated, data deletion cannot be

cancelled.

It takes up to about 30 seconds to delete data.

• Data deletion cannot be executed block by block.

Page 60

Chapter 3 Setup and Measurement

54

Back Forward

3.5 Viewing Recorded Data [VIEW]

1. Open the data view screen [VIEW].

Press the RANGE key and DATE/TIME key simultaneously on the monitoring screen [MONI] to

open the data view screen [VIEW]. (VIEW lights.)

If there is no data stored in memory, an error

(E_NULL) will be displayed. Pressing either key

returns operation to the monitoring screen [MONI].

6.4, "Error Indications and Corrective Action"

(page 95)

2. Select the memory b lo ck.

Press the MEM.BLOCK key to select the memory

block from which you wish to display data. The last

data of the block selected will be shown.

3. Select the data you want to display.

Use the key or key to scroll data

recorded in the selected memory block.

Page 61

55

Chapter 3 Setup and Measurement

3.6 Setting Date and Time

Set the current date and time on the 3144-20.

Once saved, the date and time will be stored on

the 3144-20.

When the instrument is connected to a PC through

the USB cable, the time of the PC's system clock

can also be set using the supplied PC software.

4.4, "Setting the Clock" (page 61)

1. Activate date and time setup mode.

Press the DATE/TIME key for 1 sec. on the monitoring screen [MONI] (with the PEAK HOLD function OFF).

The digits of the year flash.

2. Set the date and time.

Move the flashing digits to the position you want to

change.

Each pressing of PEAK HOLD shifts the flashing

as follows:

Year Month Day Hour Minute Second End

Change the flashing digits.

: Values DOWN

: Values UP

Page 62

Chapter 3 Setup and Measurement

56

Pressing either key shown at

left before defining the settings will cancel the settings,

and return operation to the

monitoring screen [MONI].

3. Define the setting.

Move the flashing position to second digit, then

press the PEAK HOLD key again to define the setting.

Operation returns to the monitoring screen

[MONI].

Cancellation of settings

Page 63

57

Chapter 4 Analysis of Recorded Data

Analysis of

Recorded Data

(Application Software)

4.1 General

Data recorded on the 3144-20 can be downloaded to a PC and

analyzed using the PC software supplied with the instrument.

To download data from the 3144-20, you must install the driver

and application of the PC software on the PC beforehand.

(page 58), (page 60)

Operating Environment

Compatible OSWindows 2000, XP, Vista, 7, 8

HDD capacity 10 MB or more of disk space

Interface USB Ver.1.1 or later

Composition of CD-R

Folder File Explanation

Japanese driverSetup.msi Driver Installer (Japanese)

English driverSetup.msi Driver Installer (English)

(Japanese or English; 64-bit support limited to

Windows 7 or 8)

The CPU, memory, display, and other hardware environments should conform to those

recommended by the OS.

Only one 3144-20 unit can be connected to

the PC at a time.

setup.exe PC Software Installer (Japanese)

setup.exe PC Software Installer (English)

Chapter 4

Select "Small Font" for use with the OS. Using "Large

Font" may cause irregularities in screen indications.

Page 64

Chapter 4 Analysis of Recorded Data

58

4.2 Installing Software Drivers

Perform this procedure before connecting the the

instrument to the PC with a USB cable.

If already connected, disconnect the USB cable

while you perform the procedure.

Installation Procedure_____________________

1. Log into the PC using the "administrator" account

or other account with administrative pri vileges.

2. Exit all applications runn ing on the PC before

installing the hardware drivers.

3. Execute the following software from the

included CD:

X:\English\driverSetup.msi (where X: indicates

the CD-ROM drive)

After executing driverSetup.msi, follow the

instructions on the screen to continue the

installation.

A warning message will be displayed since the

software has not been certified under the Windows

logo program. Continue the installation.

4. Once the installation is complete, t he 3144-20

will be automatically detected when the main

unit is connected to the PC with a USB cable.

If the "Found New Hardware" wizard dialog box is

displayed, select [No, not this time] under "Can

Windows connect to Windows Update to search

for software?" and select [Install the software

automatically].

Page 65

59

Chapter 4 Analysis of Recorded Data

When a 3144-20 unit with a different serial No. is

connected, the instrument may indicate that a new

device has been detected.In such case, install the

device driver by following the instructions appearing on the screen.

A warning message will be displayed since the

software has not been certified under the Windows

logo program. Continue the installation.

Uninstallation Procedure___________________

Select [Control Panel] -[Add and Remove Pro-

grams] and delete HIOKI USB Single Driver.

Page 66

Chapter 4 Analysis of Recorded Data

60

4.3 Installing PC Application Software

Installation Procedure_____________________

1. Log into the PC using the "administrator" account

or other account with administrative pri vileges.

2. Exit all applications runn ing on the PC before

installing the software.

3. Execute X:\English\setup.exe from the included

CD. (where X: indicates the CD-ROM drive).

After executing setup.exe follow the instructions on the screen to continue the installation.

A warning message will be displayed since the

software has not been certified under the Windows

logo program. Continue the installation.

4. Once the installation is complete, make all the

necessary connections and then launch the

program by selecting [Programs]-[HIOKI]-[DA TA

VIEWER for 3144]-[DATA VIEWER for 3144].

Uninstallation Procedure __________________

Select [Control Panel]-[Add and Remove Pro-

grams] and delete HIOKI DA TA VIEWER for 3144.

Page 67

61

Chapter 4 Analysis of Recorded Data

4.4 Setting the Clock

The clock of the 3144-20 can be set to the same

date and time as the PC.

1. Switch on the 3144-20 and activate "DATA

VIEWER for 3144-20."

2. Connect the 3144-20 and PC by using the USB

cable supplied with the instrument (and insert the

plugs securely).

The 3144-20 will display "USb" and all keys except

the POWER switch will be disabled.

• Only one 3144-20 unit can be connected to the

PC at a time.

• If the 3144-20 is displaying an error, the USB

cable will not be recognized even when connected to the 3144-20. Clear the error by pressing any key on the 3144-20.

• When connecting the 3144-20 and a PC by using

the USB cable, limit the cable length to less than

two meters to avoid effects of noise.

3. Select [Communication] - [Clock setting] from

the menu bar of "DATA VIEWER for 3144-20," or

left-click the mouse button on (Clock) on the

toolbar.

The clock setting window will appear.

Page 68

Chapter 4 Analysis of Recorded Data

62

4. Left-click the mouse button on [OK].

5. When the following window appears, click [OK],

disconnect the USB cable from the 3144-20 and

PC, then switch off the 3144-20.

• Dates are valid for the year 2000 and subsequent years. Data may not be handled for other

years.

• Clock setting cannot be made while the instrument is recording data.

• When data transfer is not to be made, disconnect

the USB cable from the 3144-20.

Moreover, refrain from plugging in or unplugging

the USB cable, unless absolutely necessary.

When the instrument is operated on batteries,

such action may shorten the time of continuous

battery use.

Page 69

63

Chapter 4 Analysis of Recorded Data

4.5 Transferring Data to the PC

Recorded data is transferred from the 3144-20 to a

PC. On the PC, the data can be saved in CSV format.

1. Switch on the 3144-20 and activate "DATA

VIEWER for 3144-20" on the PC.

2. Connect the 3144-20 and the PC by using the

USB cable supplied with the instrument (and insert

the plugs securely).

The procedure is the same as that for "4.4, "Setting the Clock" (page 61).

• Only one 3144-20 unit can be connected to the

PC at a time.

• Recorded data cannot be transferred while the

instrument is still recording.

• When connecting the 3144-20 and a PC by using

the USB cable, limit the cable length to less than

two meters to avoid effects of noise.

•

3. Select [Communication] - [Data transfer] from

the menu bar of "DATA VIEWER for 3144-20," or

left-click the mouse button on (Transfer) on

the toolbar to open the "3144-20 Data list" window.

Page 70

Chapter 4 Analysis of Recorded Data

64

A listing of files contained in memory of the 314420 will appear in the "3144-20 Data list" window.

Item on Screen Explanation

Transfer all

Transfer

Update list

Delete all

Close The "3144-20 Data list" window is closed.

All data recorded on the 3144-20 is transferred to the PC.

Data of the selected file is transferred to the

PC. Select the desired file by checking the

check box located to the left of the file No.

The file list of the 3144-20 is acquired again.

Execute this command when a 3144-20 unit

with a different serial No. has been reconnected while the "3144-20 Data list" window

is displayed.

All data recorded on the 3144-20 is deleted.

Keep in mind that recorded data cannot be

restored once deleted.

Page 71

65

Chapter 4 Analysis of Recorded Data

4. Transfer recorded data to the PC.

• To transfer all data:

Left-click the mouse button on [Transfer all].

All data recorded on the 3144-20 is transferred to

the PC.

• To transfer selected data:

Select the file to be transferred by checking the

check box located to the left of the file No., then

click [Transfer].

• While data transfer is in progress, do not plug in

or unplug the USB cable. Such action will hinder

normal transfer.

• It takes up to about five minutes to transfer

recorded data.

5. Left-click the mouse button on [Close] to close the

"3144-20 Data list" window.

Page 72

Chapter 4 Analysis of Recorded Data

66

6. When recorded data has been transferred to the

PC, a waveform window appears for each file

transferred.

7. Save the recorded data that has been transferred.

(page 67)

Delete any recorded data remaining on the 314420 that is no longer necessary.

(page 67)

8. Disconnect the USB cable from the 3144-20 and

PC, then switch off the 3144-20.

Page 73

67

Chapter 4 Analysis of Recorded Data

Saving the recorded data that has been

transferred ______________________________

1. Activate (display on top of other windows) the wave-

form window of the recorded data to be saved by

left-clicking the mouse button in the window.

2. Select [File] - [Save As] from the menu bar or left-

click the mouse button on (Save As) on the

toolbar.

The "Save As" window will appear.

3. Specify the file name and saving location, then left-

click the mouse button on [Save].

Execute saving on all waveform windows displayed.

The files are saved in CSV format, delimited with

commas.

Deleting data recorded on the 3144-20 _______

Delete all data recorded on the 3144-20 that is not

necessary.

1. Select [Communication] - [Data transfer] from

the menu bar of "DATA VIEWER for 3144-20," or

left-click the mouse button on (Transfer) on

the toolbar to open the "3144-20 Data list" window.

In this operation, leave the USB cable connected.

2. Left-click the mouse button on [Delete all] to

delete all data recorded on the 3144-20.

• It takes about 30 seconds to delete all data.

• Recorded data cannot be restored once deleted.

Therefore, before deleting data recorded on the

3144-20, be sure to transfer the data to the PC.

• Recorded data can also be deleted through operation on the 3144-20 only.

3.4, "Deleting Memory" (page 53)

Page 74

Chapter 4 Analysis of Recorded Data

68

4.6 Analyzing Recorded Data on the PC

Recorded data saved on a PC can be displayed in

waveforms for analysis purposes.

Displaying recorded data__________________

1. Activate "HIOKI Data Viewer for 3144-20."

2. Select [File] - [Open] from the menu bar or left-

click the mouse button on (Open) on the toolbar. The "Open file" window will appear.

3. Select the recorded data saved on th e PC, then

left-click the mouse button on [Open].

The waveform window of the recorded data will

appear.

• The operation above is not necessary when

waveform windows are currently displayed, such

as immediately after data transfer has been

made from the 3144-20 to the PC.

• Waveforms may not be shown in waveform windows that are overly reduced. In such case,

enlarge the window size.

Page 75

69

Chapter 4 Analysis of Recorded Data

1

2

3

4

67

8

9

10

5

Explanation of Windows

Waveform Wind ow________________________

1 Menu bar

2 Toolbar

3 Level (Vertical axis)

4 Date and time (Horizontal axis)

5 Display range

6 Cursor A

7 Cursor B

8 Data recorded in each frequency range

9 Horizontal axis

scroll bar

10 Vertical axis scroll

bar

"Menu" (page 71)

"Toolbar" (page 73)

Indication in dBV

Indicates the range within which waveforms are displayed among all data.

Can be moved around when dragged with

the left mouse button held down.

Can be moved around when dragged with

the left mouse button held down.

Allows movement of the waveform to display when the horizontal axis is displayed

in an enlarged size.

Allows movement of the waveform to display when the vertical axis is displayed in

an enlarged size.

Page 76

Chapter 4 Analysis of Recorded Data

70

12

4

9

3

56

78

Information Window ______________________

1

File name

2

Settings for

recording

3

Cursor position Positions (dates and times) of cursors A

4

ON/OFF of

waveform

indication

5

Waveform color Allows the waveform color of each frequen-

6

Name of frequency range

7

Peak of all data * Detection times and values of peaks among

8

Peak between

A-B*

9

Values of

cursors A and B

*: When there are multiple peak values, the time of the peak value dete ct-

ed first will be indicated.

Settings of a recording performed with the

3144-20

and B in the waveform window. The Up and

Down buttons located to the right allow corresponding cursor movement right and left.

Allows whether to display the waveform of

each frequency range in the waveform window.

cy range in the waveform window to be

changed. Select the desired color in the

"Color Setup" window by left-clicking the

mouse button, then left-click the mouse button on [OK].

all recorded data

Detection times and values of peaks of re-

corded data covered between cursors A

and B

Measurement values of each frequency

range at the positions of cursors A and B

Page 77

71

Chapter 4 Analysis of Recorded Data

Menu

File

Open Selects a file and opens a waveform window.

Close Closes the waveform window currently open.

Save As

Print

Preview Displays a sample of waveform printout.

Print Settings

Exit

Saves the recorded data currently open to another file.

Prints waveforms.

4.8, "Printing a W aveform Wind ow" (p age 76)

Used to make print settings.

4.8, "Printing a W aveform Wind ow" (p age 76)

Edit

Saves the image of a waveform window in a bit

Save Image

Copy

map.

4.7, "Saving Images of Waveform Win-

dows" (page 75)

Copies the images of a waveform window and

information window to the Clipboard. Both images can be pasted to such software as Paint

Brush or Word.

Page 78

Chapter 4 Analysis of Recorded Data

72

View

• Vertical axis: Creates an enlarged view of the

Zoom In

Zoom Out

Total View Creates a reduced view showing all the data.

Color setting

Independent-lyDisplays the waveforms of each frequency

Toolbar Allows whether to select display on the toolbar.

Status Bar

• Time axis: Creates an enlarged view of the

• Vertical axis: Creates a reduced view of the

• Time axis: Creates a red uced view of the

• 1 kHz to 20 MHz:

Allows the waveform color of each frequency

range to be changed.

• Background:

Allows the background color of the waveform

window to be changed.

•Frame:

Allows the frame color of the graph to be

changed.

• Default:

Restores all the colors above to the standard

colors.

range divided into separate frames.

Allows whether to select display of the status

bar.

vertical axis.

horizontal axis.

vertical axis.

horizontal axis.

Communication

Data transfer

Clock setting

Transfers recorded data from the 3144-20 to a

PC.

4.5, "Transferring Data to the PC" (page 63)

Sets the clock of the 3144-20 to the same time

as the PC.

4.4, "Setting the Clock" (page 61)

Page 79

73

Chapter 4 Analysis of Recorded Data

Enlarge time axis

Enlarges the time base

of a graph.

Reduce time axis

Reduces the time base

of a graph.

Total View

Displays an entire

graph.

Independently

Display a graph in a

split form.

Transfer

Transfers recorded

data from the 3144-20

to a PC.

Clock

Sets the clock of the

3144-20.

Open

Opens a file.

Save As

Saves a file.

Copy

Copies a window to the

Clipboard.

Print

Prints a file.

Enlarge vertical axis

Enlarges the vertical

axis of a graph.

Reduce vertical axis

Reduces the vertical

axis of a graph.

Toolbar

Window

New Window

Cascade

Tile

Displays another of the same waveform window.

Multiple open waveform windows are displayed

in an overlapped form.

Multiple open waveform windows are displayed

side by side.

Help

About Data Viewer

for 3144-20

Shows the version information of "DATA

VIEWER for 3144-20."

Page 80

Chapter 4 Analysis of Recorded Data

74

Popup Menu

Right-clicking the mouse button in a waveform

window displays the Popup Menu.

Copy

Zoom In

Zoom Out

Total View

Color settings

Jump

Put cursor

Performs the same function as [Edit] - [Copy] on

the menu.

Performs the same function as [View] - [Enlarge] on the menu.

Performs the same function as [View] - [Reduce] on the menu.

Performs the same function as [View] - [Total

View] on the menu.

Performs the same function as [View] - [Color

Setup] on the menu.

Moves the cursor to the selected position when

the time base is displayed in an enlarged size.

The position can be selected from: "Start" (Beginning of data), "End" (Terminal end of data),

"Cursor A," and "Cursor B."

Moves cursor A or B to the position where rightclicked on the mouse button.

Page 81

75

Chapter 4 Analysis of Recorded Data

4.7 Saving Images of Waveform Windows

The waveform windows and information windows

can be saved in bit maps.

1. Activate (display on top of the others) the wave-

form window to be saved.

2. Select [Edit] - [Save Image] - [Graph and Info.] or

[Graph only] from the menu bar.

• Graph and Info.

Saves the images of a waveform window and

information window.

• Graph Only

Saves the image of a waveform window.

The "Save As" window will appear.

3. Specify the saving location, file name, and type of

file, then left-click the mouse button on [Save].

The desired type of file can be selected from the

following:

• Full-color bit map

• Monochromatic bit map

• Gray scale bit map

If any part of an image is hidden, it may not be

saved normally. The same applies to copying to

the Clipboard.

Page 82

Chapter 4 Analysis of Recorded Data

76

4.8 Printing a Waveform Window

Waveform images of the recorded data currently

displayed can be output to the printer of a PC.

1. Make sure that the printer connected to the PC in

use is ready to print.

2. Select [File] - [Print Settings] - [Page Settin gs]

from the menu bar.

The "Page Settings" window will appear. After set-

ting the margins, if necessary, click [OK].

3. Select [File] - [Print Settings] from the menu bar,

then left-click the mouse button on the color in

which you wish to print.

Make a selection according to the printer. "Color,"

"Gray Scale," or "Monochrome" can be selected.

To check a print image beforehand, select [File] [Preview] from the menu bar.

4. Select [File] - [Print] from the menu bar or left-click

the mouse button on (Print) on the toolbar.

The "Printer Settings" window will appear.

For setting the printer, refer to the operation manual of the printer you are using.

5. Start printing by left-clicking the mouse button on

[OK].

Page 83

77

Chapter 4 Analysis of Recorded Data

• The image printed out may differ depending on

the type of printer used.

• If excessively large margins are set, printing may

be inhibited. In such case, set smaller margins.

Likewise, printing may be inhibited when a paper

size too small is selected.

Sample Printout

Page 84

Chapter 4 Analysis of Recorded Data

78

4.9 Analyzing Saved Recorded Data with Excel

The recorded data transferred to and saved on a

PC can be loaded to Excel.

• Note that data edited with Excel and saved may

not be opened with "DATA VIEWER for 3144-

20."

• If time must be indicated down to the second on

a data sheet of Excel, the cell format must be set.

• The date and time indicated at the end of the

"Time" row denote when measurement was completed.

Sample display by Excel

Page 85

79

Chapter 4 Analysis of Recorded Data

4.10Error Information

If an error occurs during data recording or file

operation, the error information is recorded on the

2nd line of recorded data that is saved on the PC.

This information can be checked when the file is

loaded to Excel or Memo Pad.

The following describes the character strings and

contents of error information.

Table of Error Indications

1.Errors arising from the 3144-20

Error Description

Stop By Battery

Low

Stop By Memory

Error

Stop By FIFO

Error

Recording was stopped due to low battery

voltage. Replace the batteries of the 3144-20

with new ones.

Recording was stopped due to frequent errors

that occurred in 3144-20 memory. The error is

related to flash memory of the 3144-20.

The 3144-20 must be repaired.

Recording was stopped due to a FIFO error

that occurred in 3144-20 memory. The error is

related to flash memory of the 3144-20.

The 3144-20 must be repaired.

Page 86

Chapter 4 Analysis of Recorded Data

80

2.Errors arising from the 3144-20 or USB

Error Description

Header Memory

Error

End Memory

Error

Data Memory

Error

USB File No.

Error

USB Start Time

Error

USB Interval

Error

USB Range

Error

USB End Time

Error

USB Data Num

Error

Error involving abnormal end due to power

outage, etc., during data recording, or error

arising from USB data reception. Check the

3144-20 and PC connections according to the

operation manuals. If this does not resolve the

problem, an error involving an abnormal end

due to a power outage, incorrect polarity of

batteries during data recording, or other similar reason may be the cause.

Error in the File No. at USB data reception.

Check the 3144-20 and PC connections according to the operation manuals.

Error in the recording start time at USB data

reception.

Check the 3144-20 and PC connections according to the operation manuals.

Error in the recording interval at USB data reception.

Check the 3144-20 and PC connections according to the operation manuals.

Error in range information at USB data reception

Check the 3144-20 and PC connections according to the operation manuals.

Error in the recording end time at USB data

reception.