Page 1

3030-10

HiTESTER

Measurement value 100 V

10 Ω

Instruction Manual EN

June 2016 Revised edition 15

Printed in Japan

3030E981-15 16-06H

Warranty

Warranty malfunctions occurring under conditions of normal

use in conformity with the Instruction Manual and Product

Precautionary Markings will be repaired free of charge. This

warranty is valid for a period of three (3) years from the date of

purchase. Please contact the distributor from which you

purchased the product for further information on warranty

provisions.

Introduction

Thank you for purchasing the HIOKI 3030-10 HiTESTER. To

obtain maximum performance from the instrument, please read

this manual first, and keep it handy for future reference.

60014966B

Safety

DANGER

This instrument is designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested for safety

prior to shipment. However, mishandling during use could

result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions

and precautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting directly

from instrument defects.

Measurement categories

This instrument complies with CAT III safety requirements.

To ensure safe operation of measurement instruments, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT III to CAT IV, and called

measurement categories..

CAT II: Primary electrical circuits in equipment connected to

CAT III: Primary electrical circuits of heavy equipment (fixed

CAT IV: The circuit from the service drop to the service

Using a measurement instrument in an environment designated

with a higher-numbered category than that for which the

instrument is rated could result in a severe accident, and must

be carefully avoided.

an AC electrical outlet by a power cord (portable tools,

household appliances, etc.

CAT II covers directly measuring electrical outlet

receptacles.

installations) connected directly to the distribution

panel, and feeders from the distribution panel to

outlets.

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Use of a measurement instrument that is not CAT-rated in CAT

II to CAT IV measurement applications could result in a severe

accident, and must be carefully avoided.

This manual contains information and warnings essential for safe

operation of the instrument and for maintaining it in safe operating

condition. Before using it, be sure to carefully read the following safety

precautions.

Safety symbols

The symbol printed on the instrument indicates that the

user should refer to a corresponding topic in the manual

(marked with the

function.

In the manual, the

information that the user should read before using the

instrument.

Indicates a grounding terminal.

Indicates a double-insulated device.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

The following symbols in this manual indicate the relative importance of

cautions and warnings.

DANGER

WARNING

CAUTION

NOTE

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

instrument.

Indicates advisory items related to performance or

correct operation of the instrument.

symbol) before using the relevant

symbol indicates particularly important

Inspection

When you receive the instrument, inspect it carefully to ensure that no

damage occurred during shipping. If damage is evident, or if it fails to

operate according to the specifications, contact your dealer or Hioki

representative.

Precautions

DANGER

Observe the following precautions to avoid electric shock.

Always verify the appropriate setting of the range selector

switch before connecting the test leads. Disconnect the

test leads from the measurement object before switching

the range selector switch.

Before taking a measurement, check the position of the

range switch. Do not measure voltage outside the set

voltage range or voltage at levels in excess of the

measurement limit. Doing so may damage the instrument

or cause an accident resulting in injury or death.

Do not input voltage to the current measurement,

resistance measurement, and battery test ranges. Doing

so may damage the instrument or cause an accident

resulting in injury or death.

NOTE: The built-in fuse prevents a short-circuit in a power

line resulting from a malfunction or misuse of the

instrument. However, this built-in fuse protection is

effective for up to 250 VAC commercial power

input.

If the end of a test lead short-circuits lines with a voltage

between them, this is very dangerous and can lead to a serious

accident. E xercise great care when measuring voltage.

WARNING

To prevent electric shock, do not allow the instrument to

become wet and do not use the instrument when your

hands are wet.

CAUTION

If the protective functions of the instrument are damaged,

either remove the instrument from service or post warnings

to prevent others from using the instrument inadvertently.

Note that the instrument may be damaged if voltage or

current in excess of the measurement range is input.

Do not store or use the instrument where it will be exposed

to direct sunlight, high temperatures, high humidity, or

condensation. If exposed to such conditions, the instrument

may be damaged, the insulation may deteriorate, and the

instrument may no longer satisfy its specifications.

After use, always turn OFF the power.

NOTE

If the meter pointer is not positioned in the 0 scale value, use the zero

adjuster to adjust it correctly.

If the fuse is blown, or the test leads are damaged, any range does

not operate. To check the test leads wiring and fuse blowing, refer to

“

3. Fuse and Test Leads Continuity Check”in Battery and Fuse

Replacement.

If the meter cover becomes electrostatically charged, values may

display incorrectly because of attractive forces on the needle. In this

case, apply anti-static treatment to inhibit electrostatic charge buildup.

The efficacy of such electrostatic treatments dissipates over time, so

the treatment may need to be reapplied periodically.

Measurement Procedure

Pre-Operation Inspection

To avoid the possibility of electric shock or incorrect measurement,

check the following items before using the instrument.

WARNING

Use only the supplied Model L9207-30 TEST LEAD.

Before using the instrument, make sure that the insulation

on the test leads is undamaged and that the white or red

portion (insulation layer) inside the cable is not exposed.

Using the instrument in such conditions could cause an

electric shock, so contact your dealer or Hioki

representative for replacements.

(Model L9207-30 TEST LEAD)

For voltage measurement, short the test leads and check that 0 V is

indicated.

For resistance measurement, short the test leads and adjust the

reading to zero using the zero ohm adjuster (0 Ω ADJ knob).

Measure a test item with a known value (battery, AC supply, resistor,

etc.) to check that the instrument is functioning correctly.

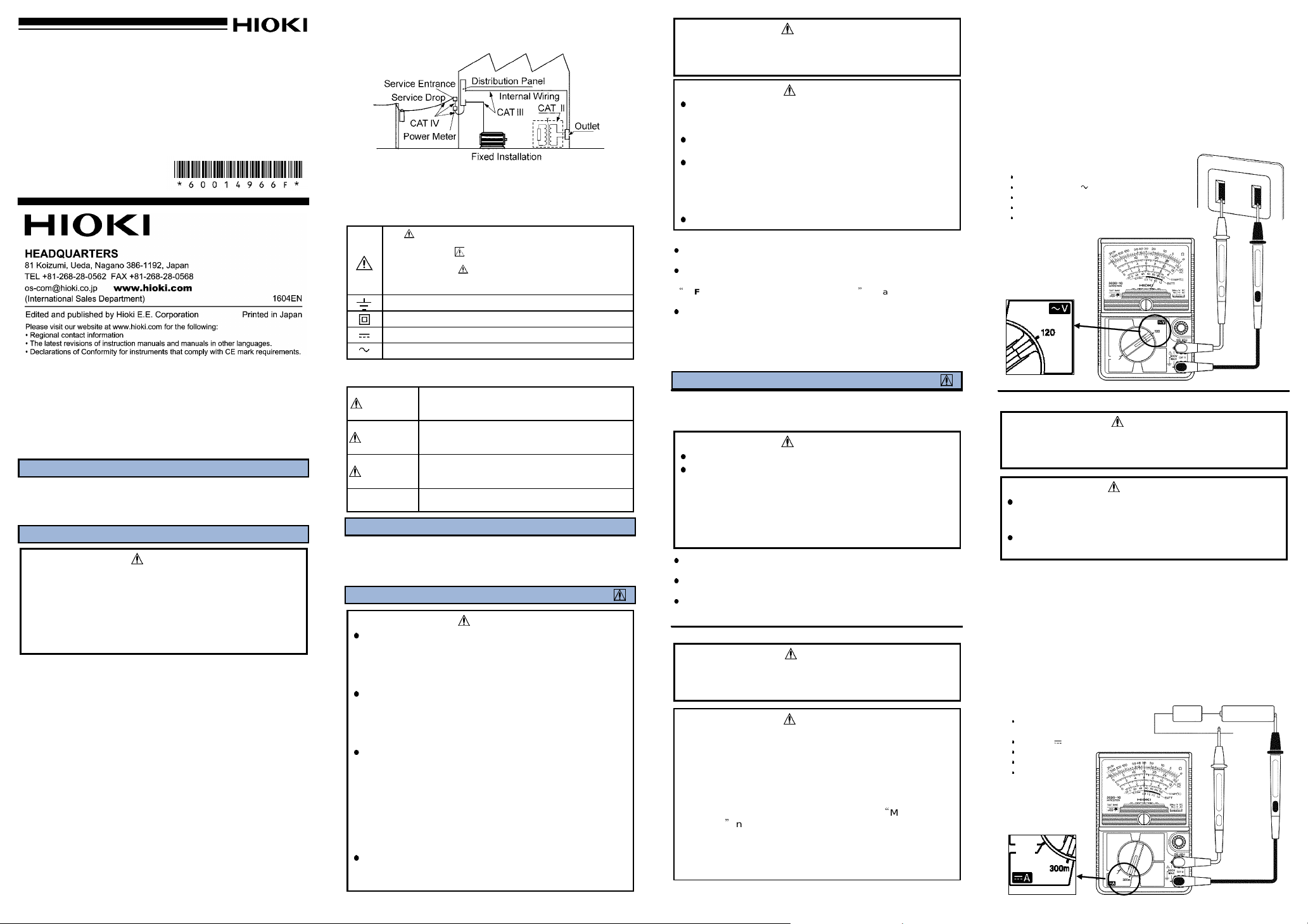

Voltage Measurement (AC, DCV)

DANGER

The maximum input voltage is 600 V DC/AC. Attempting to

measure voltage in excess of the maximum input could

destroy the instrument and result in personal injury or death.

CAUTION

Removable sleeves are attached to the metal pins at the

ends of the test leads.

To prevent a short circuit accident, be sure to use the test

leads with the sleeves attached when performing

measurements in the CAT III measurement category.

Remove the sleeves from the test leads when performing

measurements in the CAT II measurement category.

For details on measurement categories, see“Measurement

categories”in the instruction manual.

When performing measurements with the sleeves attached,

be careful to avoid damaging the sleeves. If the sleeves are

inadvertently removed during measurement, be especially

careful in handling the test leads to avoid electric shock.

1. Set the range switch to the ACV or DCV range proper for the voltage

to be measured.

NOTE

: If the voltage value is unclear, initially set the range switch to the

600 V range, and after obtaining a reading in this range, change

to the range proper for the voltage value.

2. Connect the black test lead to the - terminal, and the red one to the +

terminal.

3. Connect the test leads to the circuit to be measured in parallel, then

read the results on the AC/DC scale. When the DCV is selected, if

connecting the red test lead to the positive side, and the black one to

the negative side, then the pointer deflects normally.

NOTE

: When changing the range, disconnect the test leads from the

object to be measured.

Measurement example

The voltage measurement of the outlet

Function V

Range 120 V

Scale DC/AC 12

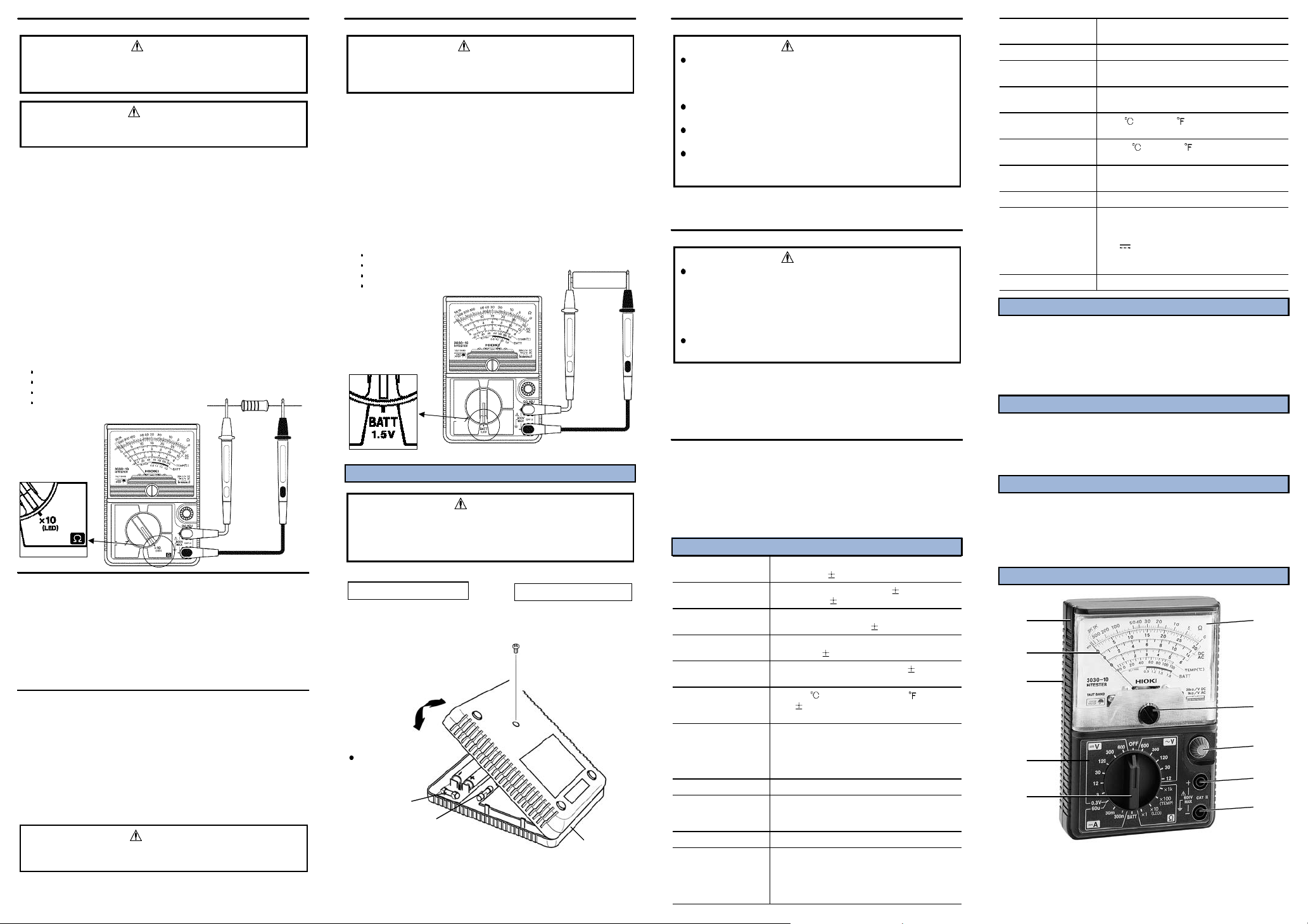

Current Measurement (DCmA, 60 μADC)

DANGER

Do not apply a voltage while a current range is selected.

Applying a voltage may result in damage to the instrument,

or a serious accident.

WARNING

To avoid electrical shock, do not use the instrument to

measure current in circuits of 250 V or greater. The

current function overload protection trips at 250 Vrms.

To prevent electrical accidents, turn the power off before

connecting the test leads and then take measurements.

1. Set the range switch to the DCmA or 60 μA range.

NOTE

: If the current value is unclear, initially set the range switch to the

300 mA DC range, and after obtaining a reading in this range,

change to the range proper for the current value.

2. Connect the black test lead to the - terminal, and the red one to the +

terminal.

3. Connect the instrument to the electrical line to be measured in series

(to the cut off line). Connect it so that current flows from the red test

lead to the black one. (If connecting it reversely, the pointer deflects

in the reverse direction.)

NOTE

: When changing the range, disconnect the test leads from the

object to be measured.

4. Read the result on the AC/DC scale.

Measurement example

The current measurement

that it flows for the load 10 Ω.

Function: A

Range: 300 mA

Scale: DC/AC 30

Measurement

value: 150 mA

+1.5V-

Page 2

Resistance Measurement (Ω )

Measurement value 5.1 kΩ

Resistance

+1.5V-

Measurement value 1.5 V

DANGER

Do not input voltage to the resistance measurement

functions. Doing so may damage the instrument or cause

an accident resulting in injury or death.

WARNING

Turn off the power and discharge the capacitors before

measuring resistance in a circuit.

1. Set the range switch to the proper Ω range.

Accurate measurement can be made by selecting a range where the

reading will be about the center of the range.

2. Connect the black test lead to the - terminal, and the red one to the +

terminal.

3. Short the test leads, and use the zero ohm adjuster (0 ΩADJ knob) to

adjust the pointer to the 0 Ω scale.

NOTE

: If the pointer cannot be adjusted to the 0 Ω scale, replace the

battery.

4. Connect the test leads to the circuit to be measured, and read the

value from the scale.

NOTE

: When changing the range, disconnect the test leads from the

object to be measured.

For resistance measurement, the indication may be unstable if

the ends of the test leads are dirty, and the contact is poor. If

the indication is unstable, increase the contact pressure, or

clean the ends of the test leads by wiping with alcohol or similar

solvent.

5. In order to obtain the true value, it is necessary to multiply the reading

shown by the factor for the range in use.

Measurement example

5.1kΩ resistance measurement

Function x10

Scale Ω

LED Check (Lighting Test)

1. Set the range switch to the Ω x 10 (LED) range.

2. Connect the test leads to both sides of the LED to be tested.

3. The LED has polarity, so unless it light in 2., try reversing the test

leads connections.

4. When it lights, the pointer deflect, however a reading has no meaning.

NOTE

: The internal battery of the Ω meter has positive polarity in the -

terminal. Therefore, it is right to connect the red (+) test lead to

the cathode side of the LED, and the black (-) one to the anode

side.

Temperature Measurement

(Use the optional 9021-01 THERMISTOR TEMPERATURE

PROBE.)

1. Set the range switch to the Ω function, R x 10 (TEMP) range.

2. Connect the two black plugs of the three plugs of the temperature

probe to the + and - terminals.

3. Use the zero ohm adjuster (0 Ω ADJ knob) to adjust the pointer to the

0 Ω scale.

4. After 0 Ω adjustment, change the plug in the + terminal to the red

plug.

5. Connect the temperature probe tip to the measurement place, and

read the value from the temperature scale.

CAUTION

Be careful to avoid touching the removed plug with any

other objects.

REFERENCE

The time for indication and measured temperature vary

depending on the condition of heat conduction to the

probe.

Battery test (BATT 1.5 V)

DANGER

Do not apply a over-voltage while a BATT 1.5 V range is

selected. Applying a over-voltage may result in damage to

the instrument, or a serious accident.

1. Set the range switch to the BATT 1.5 V range.

2. Connect the black test lead to the - terminal, and the red one to the +

terminal.

3. Connect the test leads to both sides of the battery to be measured

(the red test lead to the positive side and the black one to the

negative side), and read the measurement value.

Removed a battery from a set as much as possible, and measure it

alone.

REFERENCE

Measurement example

1.5V battery deterioration examination

Function BATT

Scale BATT

This measures the voltage with a 150 mA (load resister

10 Ω) current in order to measure the battery when it is

being used.

When this is compared with measurement in the 3 V

DC range (no-load voltage value), the lower voltage

value is indicated for the more consumed battery.

Battery and Fuse Replacement

WARNING

To avoid electric shock when replacing the batteries and

fuse, first disconnect the test leads from the object to be

measured. Also, after replacing the batteries, fuse, always

replace the case before using the instrument.

Removing the case back

1. Remove the fixing

screw.

2. Remove the case

back from the upper

part.

3. Replace the

batteries and fuse.

Insert the batteries

with the polarity

correct as per the

battery indication

FUSE

Spare fuse

A good one should always

Attaching the case back

3. Fasten the

fixing screw.

2. Attach the

upper part.

1. Fit the nail

on the edge

of the lower

part.

1. Battery Replacement

WARNING

Do not mix old and new batteries, or different types of

batteries. Also, be careful to observe battery polarity

during installation. Otherwise, poor performance or

damage from battery leakage could result.

Battery may explode if mistreated. Do not short-circuit,

recharge, disassemble or dispose of in fire.

Handle and dispose of batteries in accordance with local

regulations.

To avoid corrosion from battery leakage, remove the

batteries from the instrument if it is to be stored for a long

time.

1. Remove the case back.

2. Replace the batteries with new ones.

3. Attach the case back.

2. Fuse Replacement

WARNING

Only use fuses of the specified type that is rated for the

specified current and voltage. Using a fuse that does not

meet the specifications, especially of large current

capacity (including a short circuit of the copper wire) may

not cause the shut-off function to operate, and result in

burning, a short circuit, or injury or death.

Fuse specification: F0.5 AH/250 V, with non-arcing

protection, 20 mm x 5 mm dia.

1. Remove the case back.

2. Replace the fuse with a new one.

NOTE

: A spare fuse is provided inside the instrument as shown.

Be sure to supply a new spare fuse if the spare fuse is used to

replace a blown fuse.

3. Attach the case back.

3. Fuse and Test Leads Continuity Check

1. Connect the black test lead to the - terminal, and the red one to the +

terminal.

2. Set the range switch to the Ω x 1 k range, and short the test leads.

3. If the pointer deflects, the fuse and test leads conduct (are not blown

and damaged).

If the pointer does not deflect, the test leads may be damaged.

Check again after replacing the fuse.

Specifications (*mark: shared range)

DCV *0.3/3/12/30/120/300/600 V, 20 kΩ/V (0.3

ACV 12/30/120/300/600 V, 9 kΩ/V, 2.5% of f.s.

DCA *60 μA, 30/300 mA, internal voltage drop

Ω

BATT 0.9 to 1.8 V, load resistance 10Ω, 6% of f.s.

Temperature scale -20 to 150 (standard), -20 to 300 (for USA

Protective system Short circuit protection of power line by fuse

Meter Internally magnetized taut band

Fuse F0.5 AH/250 V, 20 mm x 5 mm dia. (non-

Drop proof One meter to concrete

Standards applying Safety EN 61010

V:16.7 kΩ/V),

reading (12 V:

(nominal value) 300 mV,

0to3kΩ, central scale 30 Ω, R x 1/R x 10/R x

100/R x 1 k,

reading

only),

9021-01 THERMISTOR TEMPERATURE PROBE)

(up to 250 VAC commercial power input)

NOTE: This system is not for protecting the instrument

Overload protection of meter device by diode

arcing type),

Internal resistance Approx. 0.866 Ω

EMC EN 61326

2.5% of f.s. reading

4%)

3% of f.s. reading

3% of scale length

3% of scale length (with the optional

from damage but for securing safety.

Measurement Category III

(anticipated transient overvoltage 6000

V), Pollution Degree 2

Power supply Rated power voltage 1.5 VDC x 2,

Maximum rated power 0.36 VA

Location for Use Altitude up to 2000 m, Altitude up to 6562 feet,

Dimensions and mass Approx.95W x 141H x 39D mm, Approx.280 g

Operating temperature

and humidity

Storage temperature

and humidity

Period of guaranteed

accuracy

Maximum input voltage 600 VAC/DC

Accessories L9207-30 TEST LEAD

Optional accessory 9021-01 THERMISTOR TEMPERATUR E PROBE

R6P manganese battery x 2

indoors

Approx.3.74"W x 5.55"H x 1.54"D, Approx.9.9 oz.

0to40 , 32 to 104 , 80% RH max.

-10 to 50 , 14 to 122 , 80% RH max.

1 year

Spare fuse (F0.5 AH/250 V, 20 mm x 5 mm

dia., non-arcing type)

R6P (

1.5 V) manganese battery (2)

Instruction Manual

9390 CARRYING CASE

Handling of carrying case

When the instrument is used or stored with the cover of the carrying

case incompletely closed, the cover can be deformed depending on

ambient temperature. This may cause that the cover cannot be closed.

Close the cover completely to prevent it from being deformed. To close

the cover completely, press the cover vertically, engaging the edge of the

cover with that of the lower case.

Maintenance

Gently wipe dirt from the surface of the instrument with a soft cloth

moistened with a small amount of water or mild detergent.

Do not try to clean the instrument using cleaners containing organic

solvents such as benzine, alcohol, acetone, ether, ketones, thinners, or

gasoline. They may cause discoloration or damage.

Service

If the instrument is not functioning properly, check the batteries, the test

leads wiring, and fuse blowing. If a problem is found, contact your dealer

or HIOKI representative. Pack the instrument carefully so that it will not

be damaged during transport, and write a detailed description of the

problem. HIOKI cannot bear any responsibility for damage that occurs

during shipment.

Part Names

1.

2.

3.

4.

5.

Meter Nomenclature

1. Panel 2. Pointer 3. Case back 4. Face plate

5. Range selector switch 6. Scale plate 7. Zero adjuster

8. Zero ohm adjuster 9. Positive (+) terminal

10. Negative (-) terminal

6.

7.

8.

9.

10.

Loading...

Loading...