Page 1

Instruction Manual

2300

SMART SITE

February 2011 Revised edition 5 2300A981-05 11-02H

Page 2

Contents

Contents

APPX

I

Introduction.................................................................................1

Safety Notes............... .. .. ... .. ................. .. ... .. ... ................ ... .. ... .. ..1

Notes on Use.. .. .. ... ................................. ... .. ... .. ................. .. ... .. ..4

Service .......................................................................................7

1

2301-20 HUMIDITY MODULE___________________ 9

1.1 Overview .......................................................................9

1.1.1 Product Overview ............................................................9

1.1.2 Major Features ................................................................9

1.1.3 Name and Function of the Parts ...................................12

1.1.4 Dimension Diagrams .................................................. ...1 3

1.1.5 Accessory and Option .................................. ..... ............13

1.2 Settings .......................................................................14

1.2.1 Setting the Module ID ....................................................14

1.3 Preparations................................................................15

1.3.1 Installing the Module .....................................................15

1.3.2 Connecting Input/Output Cables ...................................16

1

2

3

4

5

6

1.4 Others .........................................................................19

1.4.1 Alarm output ........................................ ..... .....................19

1.4.2 Insulation of Internal Circuit ...........................................21

1.5 Specifications..............................................................22

1.5.1 Basic Specifications ......................................................22

1.5.2 Function Specifications .................................................22

1.5.3 General Specifications ..................................................23

1.5.4 9764-50 HUMIDIDTY SENSOR Specifications .............24

2

2302-20 Pt MODULE_________________________ 25

2.1 Overview .....................................................................25

2.1.1 Product Overview ..........................................................25

2.1.2 Major Features ..............................................................25

2.1.3 Name and Function of the Parts ...................................28

2.1.4 Dimension Diagrams .................................................. ...2 9

2.1.5 Accessory and Option .................................. ..... ............29

2.2 Settings .......................................................................30

2.2.1 Setting the Module ID ....................................................30

7

8

9

2.3 Preparations................................................................31

2.3.1 Installing the Module .....................................................31

IDX

Page 3

II

Contents

2.3.2 Connecting Input/Output Cables ...................................31

2.4 Others......................................................................... 34

2.4.1 Alarm output .................................................................34

2.4.2 Insulation of Internal Circuit ..........................................36

2.5 Specifications ............................................................. 37

2.5.1 Basic Specifications ......................................................37

2.5.2 Function Specifications ....................... .... ..... ..... ............37

2.5.3 General Specifications ..................................................38

3

2303-20 TC MODULE ________________________39

3.1 Overview..................................................................... 39

3.1.1 Product Overview .........................................................39

3.1.2 Major Features ..............................................................39

3.1.3 Name and Function of the Parts ..................................42

3.1.4 Dimension Diagrams ....................................................43

3.1.5 Accessory and Option ...................................................43

3.2 Settings....................................................................... 44

3.2.1 Setting the Module ID ...................................................44

3.3 Preparations...............................................................45

3.3.1 Installing the Module .....................................................45

3.3.2 Connecting Input/Output Cables ...................................45

3.4 Others......................................................................... 49

3.4.1 Alarm output .................................................................49

3.4.2 Insulation of Internal Circuit ..........................................51

3.5 Specifications ............................................................. 52

3.5.1 Basic Specifications ......................................................52

3.5.2 Function Specifications ....................... .... ..... ..... ............53

3.5.3 General Specifications ..................................................53

4

2304-20 PULSE MODULE_____________________55

4.1 Overview..................................................................... 55

4.1.1 Product Overview .........................................................55

4.1.2 Major Features ..............................................................56

4.1.3 Name and Function of the Parts ..................................58

4.1.4 Dimension Diagrams ....................................................59

4.1.5 Accessory and Option ...................................................59

4.2 Settings....................................................................... 60

4.2.1 Setting the Module ID ...................................................60

4.3 Preparations...............................................................61

4.3.1 Installing the Module .....................................................61

4.3.2 Connecting Input/Output Cables ...................................61

Page 4

Contents

APPX

4.4 Others .........................................................................66

4.4.1 Examples of Voltage/Contact Output Dev ice Connection 66

4.4.2 Alarm output ........................................ ..... .....................68

4.4.3 Insulation of Internal Circuit ...........................................70

4.5 Specifications..............................................................71

4.5.1 Basic Specifications ......................................................71

4.5.2 Function Specifications .................................................72

4.5.3 General Specifications ..................................................72

5

2304-21 PULSE MODULE ____________________ 75

5.1 Overview .....................................................................75

5.1.1 Product Overview ..........................................................75

5.1.2 Major Features ..............................................................76

5.1.3 Name and Function of the Parts ...................................78

5.1.4 Dimension Diagrams .................................................. ...7 9

5.1.5 Accessory and Option .................................. ..... ............79

5.2 Settings .......................................................................80

5.2.1 Setting the Module ID ....................................................80

III

1

2

3

4

5

5.3 Preparations................................................................81

5.3.1 Installing the Module .....................................................81

5.3.2 Connecting Input/Output Cables ...................................81

5.4 Others .........................................................................85

5.4.1 Examples of Connections According to Type of Device

Coupled .........................................................................85

5.4.2 Alarm output ........................................ ..... .....................87

5.4.3 Insulation of Internal Circuit ...........................................89

5.5 Specifications..............................................................90

5.5.1 Basic Specifications ......................................................90

5.5.2 Function Specifications .................................................90

5.5.3 General Specifications ..................................................91

6

2305-20 INSTRUMENTATION MODULE _________ 93

6.1 Overview .....................................................................93

6.1.1 Product Overview ..........................................................93

6.1.2 Major Features ..............................................................94

6.1.3 Name and Function of the Parts ...................................96

6.1.4 Dimension Diagrams .................................................. ...9 7

6.1.5 Accessory and Option .................................. ..... ............97

6

7

8

9

6.2 Settings .......................................................................98

6.2.1 Setting the Module ID ....................................................98

6.3 Preparations................................................................99

IDX

Page 5

IV

Contents

6.3.1 Installing the Module .....................................................99

6.3.2 Connecting Input/Output Cables ...................................99

6.4 Others....................................................................... 102

6.4.1 Alarm Output ...............................................................102

6.4.2 Insulation of Internal Circuit ........................................104

6.5 Specifications ........................................................... 105

6.5.1 Basic Specifications ....................................................105

6.5.2 Function Specifications ....................... .... ..... ..... ..........105

6.5.3 General Specifications ................................................106

7

2306-20 MULTIFUNCTION MODULE___________107

7.1 Overview................................................................... 107

7.1.1 Product Overview .......................................................107

7.1.2 Major Features ............................................................108

7.1.3 Name and Function of the Parts ................................110

7.1.4 Dimension Diagrams ..................................................111

7.1.5 Accessory and Option .................................................111

7.2 Settings..................................................................... 112

7.2.1 Setting the Module ID .................................................112

7.3 Preparations.............................................................113

7.3.1 Installing the Module ...................................................113

7.3.2 Paste the seal to the terminal block. ...........................114

7.3.3 Connecting Input/Output Cables .................................114

7.3.4 Procedure for connecting to the terminal ....................115

7.4 Digital filter................................................................ 120

7.5 Others....................................................................... 121

7.5.1 Insulation of Internal Circuit ........................................121

7.5.2 Measurement method .................................................121

7.5.3 Pre-heating time before the start of recording ............122

7.5.4 Function to detect broken wires when using a

thermocouple .............................................................. 123

7.6 Specifications ........................................................... 124

7.6.1 Basic Specifications ....................................................124

7.6.2 Function Specifications ....................... .... ..... ..... ..........125

7.6.3 General Specifications ................................................126

8

2321-20 WAVEFORM MODULE _______________127

8.1 Overview................................................................... 127

8.1.1 Product Overview .......................................................127

8.1.2 Major Features ............................................................128

8.1.3 Name and Function of the Parts .................................130

Page 6

Contents

APPX

8.1.4 Dimension Diagrams .................................................. .132

8.1.5 Accessory and Option .................................. ..... ..........133

8.2 Settings .....................................................................133

8.3 Preparations..............................................................134

8.3.1 Installing the Module ...................................................134

8.3.2 Connect the signal input cable ....................................135

8.3.3 Connect the trigger input signal ...................................138

8.3.4 Connect the trigger output signal ... ..... ..... .... ...............139

8.4 Recording dat a..... ................. ............................... .....141

8.5 Insulation of Internal Circuit.......................................144

V

1

2

8.6 Trigger applicatio n ex am p le.............. .. ................. .. ...1 4 5

8.7 Specifications............................................................153

8.7.1 Basic Specifications ....................................................153

8.7.2 Function Specifications ...............................................154

8.7.3 General Specifications ................................................157

8.8 Disposing of the Instrument ......................................158

9

2331-20 POWER METER MODULE____________ 159

9.1 Overview ...................................................................159

9.1.1 Product Overview ........................................................159

9.1.2 Major Features ............................................................160

9.1.3 Name and Function of the Parts ..................................166

9.1.4 Dimension Diagrams .................................................. .167

9.1.5 Accessory and Option .................................. ..... ..........168

9.2 Settings .....................................................................169

9.2.1 Setting the Module ID ..................................................169

3

4

5

6

7

8

9.3 Preparations..............................................................170

9.3.1 Installing the Module ...................................................170

9.3.2 Connecting the Clamp Sensor to Module ....................171

9.3.3 Connecting the Voltage Cable to the Module ..............172

9.3.4 Connecting Alarm Output ............................................173

9.3.5 Connecting to the Measured Line ...............................174

9.4 Others .......................................................................178

9.4.1 Alarm Output .................................. ..... ..... ...................178

9.4.2 Insulation of Internal Circuit .........................................179

9.5 Specifications............................................................180

9.5.1 Basic Specifications ....................................................180

9.5.2 Function Specifications ...............................................182

9.5.3 General Specifications ................................................183

9

IDX

Page 7

VI

Contents

10

2332-20 POWER METER MODULE ____________185

10.1 Overview................................................................... 185

10.1.1 Product Overview .......................................................185

10.1.2 Major Features ............................................................186

10.1.3 Name and Function of the Parts .................................192

10.1.4 Dimension Diagrams ..................................................194

10.1.5 Accessory and Option .................................................195

10.2 Settings..................................................................... 196

10.2.1 Setting the Module ID .................................................196

10.3 Preparations.............................................................197

10.3.1 Installing the Module ...................................................197

10.3.2 Connecting the Clamp Sensor to Module ...................198

10.3.3 Connecting the Voltage Cable to the Module .............200

10.3.4 Connecting to the Measured Line ...............................201

10.4 Others....................................................................... 205

10.4.1 Alarm Assessment ......................................................205

10.4.2 Insulation of Internal Circuit ........................................205

10.5 Specifications ........................................................... 206

10.5.1 Basic Specifications ....................................................206

10.5.2 Function Specifications ..................................... .... ......208

10.5.3 General Specifications ................................................209

11

2341-20 INPUT MODULE ____________________211

11.1 Overview................................................................... 211

11.1.1 Product Overview .......................................................211

11.1.2 Major Features ............................................................211

11.1.3 Name and Function of the Parts .................................212

11.1.4 Dimension Diagrams ..................................................214

11.1.5 Accessory and Option .................................................214

11.2 Settings..................................................................... 215

11.3 Preparations.............................................................216

11.3.1 Installing the Module ...................................................216

11.3.2 Connecting Input/Output Cables .................................217

11.4 Others....................................................................... 219

11.4.1 Internal Circuit ................................................... .... ......219

11.4.2 Examples of Connections According to Type of Device

Coupled ......................................................................220

11.4.3 Insulation of Internal Circuit ........................................222

11.5 Specifications ........................................................... 223

11.5.1 Basic Specifications ....................................................223

11.5.2 Function Specifications ..................................... .... ......223

Page 8

Contents

11.5.3 General Specifications ................................................224

12 2342-20 OUTPUT MODULE _______________ 225

12.1 Overview ...................................................................225

12.1.1 Product Overview ........................................................225

12.1.2 Major Features ............................................................225

12.1.3 Name and Function of the Parts ..................................226

12.1.4 Dimension Diagrams ................................ .... ..... ..... .....227

12.1.5 Accessory and Option ............................................ .... .227

12.2 Settings .....................................................................228

VII

11

12

12.3 Preparations..............................................................229

12.3.1 Installing the Module ...................................................229

12.3.2 Connecting Input/Output Cables .................................229

12.4 Others .......................................................................231

12.4.1 Output Circuit .................................................... ..... .... .231

12.4.2 Examples of Connections According to Type of Device

Coupled .......................................................................233

12.4.3 Insulation of Internal Circuit .......................... ...............237

12.5 Specifications............................................................238

12.5.1 Basic Specifications ....................................................238

12.5.2 Function Specifications ...............................................238

12.5.3 Each Channel Output Function ...................................239

12.5.4 General Specifications ................................................239

13

2343-20 RS LINK MODULE __________________ 241

13.1 Overview ...................................................................241

13.1.1 Product Overview ........................................................241

13.1.2 Major Features ............................................................241

13.1.3 Name and Function of the Parts ..................................242

13.1.4 Dimension Diagrams ................................ .... ..... ..... .....243

13.1.5 Accessory and Option ............................................ .... .243

13

13.2 Settings .....................................................................244

13.2.1 Setting the Module ID ..................................................244

13.3 Preparations..............................................................245

13.3.1 Installing the Module ...................................................245

13.3.2 Connecting RS-232C Cable to the Module .................246

13.4 Specifications............................................................247

13.4.1 Basic Specifications ....................................................247

13.4.2 Function Specifications ...............................................247

13.4.3 General Specifications ................................................248

10

Page 9

VIII

Contents

14

2351 AIR MODULE

2352-20 WIRE MODULE ____________________ _249

14.1 Overview................................................................... 249

14.1.1 Product Overview .......................................................249

14.1.2 Major Features ............................................................250

14.1.3 Name and Function of the Parts .................................251

14.1.4 Dimension Diagrams ..................................................252

14.1.5 Accessory and Option .................................................252

14.2 Settings..................................................................... 253

14.2.1 Setting the COM ID .....................................................253

14.3 Preparations.............................................................254

14.3.1 Installing the Module ...................................................254

14.3.2 Connecting Sending/Receiving

Antenna to Module (2351 Only) ..................................255

14.3.3 How to install the antennae ........................................256

14.3.4 Connecting RS-232C Cable to Module .......................258

14.4 Specifications ........................................................... 259

14.4.1 Basic Specifications ....................................................259

14.4.2 Function Specifications ..................................... .... ......260

14.4.3 General Specifications ................................................260

14.5 Disposing of the Instrument...................................... 261

15

2353-20 LAN MODULE ______________________263

15.1 Overview................................................................... 263

15.1.1 Product Overview .......................................................263

15.1.2 Major Features ............................................................263

15.1.3 Name and Function of the Parts .................................264

15.1.4 Dimension Diagrams ..................................................265

15.1.5 Accessory and Option .................................................265

15.2 Settings..................................................................... 266

15.2.1 Setting the COM ID .....................................................266

15.3 Preparations.............................................................267

15.3.1 Installing the Module ...................................................267

15.3.2 Connecting the LAN Cable .........................................268

15.3.3 Setting the IP Address ................................................269

15.4 Specifications ........................................................... 270

15.4.1 Basic Specifications ....................................................270

15.4.2 Function Specifications ..................................... .... ......270

15.4.3 General Specifications ................................................270

15.5 Disposing of the Instrument...................................... 271

Page 10

Contents

16

2354-20 MEMORY MODULE _________________ 273

16.1 Overview ...................................................................273

16.1.1 Product Overview ........................................................273

16.1.2 Major Features ............................................................274

16.1.3 Name and Function of the Parts ..................................274

16.1.4 Dimension Diagrams ................................ .... ..... ..... .....276

16.1.5 Accessory and Option ............................................ .... .276

16.2 Settings .....................................................................277

16.2.1 Setting the COM ID .....................................................277

16.3 Preparations..............................................................278

16.3.1 Installing the Module ...................................................278

16.3.2 Connecting the LAN Cable ..........................................279

IX

16.4 Other .........................................................................280

16.4.1 For CF card ............. ............................ ..... .... ..... ..........280

16.4.2 Recording operation ....................................................283

16.4.3 Setting the IP Address ................................................285

16.5 Specifications............................................................286

16.5.1 Basic Specifications ....................................................286

16.5.2 Function Specifications................................................286

16.5.3 Data recorded Specifications ................... .... ..... ..........287

16.5.4 General Specifications ................................................287

16.6 Disposing of the Instrument ......................................288

17

2361-20 AC POWER MODULE _______________ 289

17.1 Overview ...................................................................289

17.1.1 Product Overview ........................................................289

17.1.2 Major Features ............................................................289

17.1.3 Name and Function of the Parts ..................................290

17.1.4 Dimension Diagrams ................................ .... ..... ..... .....291

17.1.5 Accessory and Option ............................................ .... .291

14

15

16

17

17.2 Preparations..............................................................292

17.2.1 Installing the Module ...................................................292

17.2.2 Connecting Power Cable .............................................293

17.3 Specifications............................................................295

17.3.1 Basic Specifications ....................................................295

17.3.2 Function Specifications ...............................................295

17.3.3 General Specifications ................................................295

Page 11

X

Contents

18

2362-20 DC POWER MODULE________________297

18.1 Overview................................................................... 297

18.1.1 Product Overview .......................................................297

18.1.2 Major Features ............................................................297

18.1.3 Name and Function of the Parts .................................298

18.1.4 Dimension Diagrams ..................................................299

18.1.5 Accessory and Option .................................................299

18.2 Preparations.............................................................300

18.2.1 Installing the Module ...................................................300

18.2.2 Connecting Power Cable ............................................301

18.3 Specifications ........................................................... 303

18.3.1 Basic Specifications ....................................................303

18.3.2 Function Specifications ..................................... .... ......303

18.3.3 General Specifications ................................................303

19

2391-01, 2391-02, 2391-03 MODULE BASE _____305

19.1 Overview................................................................... 305

19.1.1 Product Overview .......................................................305

19.1.2 Major Features ............................................................306

19.1.3 Name and Function of the Parts .................................306

19.1.4 Dimension Diagrams ..................................................308

19.1.5 Accessory and Option .................................................310

19.2 Preparations.............................................................311

19.2.1 Installing the Module ...................................................311

19.2.2 Connecting Power Supply Output Cord

(2391-01 only) .............................................................314

19.2.3 Connecting the CAN Cable .........................................315

19.3 Specifications ........................................................... 317

19.3.1 Basic Specifications ....................................................317

19.3.2 Function Specifications ..................................... .... ......318

19.3.3 General Specifications.................................................318

20

2392-01/02 MODULE BASE __________________319

20.1 Overview................................................................... 319

20.1.1 Product Overview .......................................................319

20.1.2 Major Features ............................................................319

20.1.3 Name and Function of the Parts .................................320

20.1.4 Dimension Diagrams ..................................................323

20.1.5 Accessory and Option .................................................324

20.2 Preparations.............................................................325

Page 12

Contents

APPX

20.2.1 Installing the Module ...................................................325

20.2.2 Connecting Power Supply Output Cord

(2392-01 only) .......................................... .... ..... ..... .....328

20.2.3 Connecting the CAN Cable .........................................329

XI

20.3 Specifications............................................................331

20.3.1 Basic Specifications ....................................................331

20.3.2 Function Specifications ...............................................331

20.3.3 General Specifications ................................................331

21

Maintenance and Service ___________________ 333

21.1 Cleaning....................................................................333

21.2 Servicing ...................................................................333

11

12

13

14

15

16

17

18

19

20

21

IDX

Page 13

XII

Contents

Page 14

APPX

Introduction

Thank you for purchasing the HIOKI “2300 Smart Site”. To obtain

maximum performance from the instrument, please read this manual first, and keep it handy for future reference.

When you receive the instrument, inspect it carefully to ensure that

no damage occurred during shipping. In particular, check the

accessories, panel switches, and connectors. If damage is evident,

or if it fails to operate according to the specifications, contact your

dealer or Hioki representative.

Safety Notes

This instrument is designed to comply with IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, mishandling during use could result in

injury or death, as well as damage to the instrument. Using

the instrument in a way not described in this manual may

negate the provided safety features. Be certain that you

understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or

injuries not resulting directly from instrument defects.

Introduction

1

1

1

2

2

3

3

4

4

16

5

5

6

6

This manual contains information and warnings essen tial for safe

operation of the instrument and for maintaining it in safe operating

condition. Before using it, be sure to carefully read the following

safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important

information t hat the u ser sh ou ld read be fo re u s ing the instrument.

The symbol printed on the instrument indicates that the

user should refer to a corresponding topic in the manual

(marked with the symbol) before using the relevant function.

Indicates a grounding terminal.

Indicates a protective conductor terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

7

7

8

8

9

9

10

10

11

Indicates the OFF side of the power switch.

IDX

Page 15

2

Safety Notes

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious injury

or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in seriou s injury

or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the

instrument.

Indicates advisory items related to perfo rmance

or correct operation of the instrument.

Other Symbols

Indicates the prohibited action.

❖

Indicates the reference.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg.

(reading) and dgt. (digit) values, with the following meanings:

f.s.

(maximum

display value or

scale lengt h)

rdg.

(reading or

displayed value)

dgt.

(resolution)

The maximum displayable value or scale

length. This is usually the name of the currently

selected range.

The value currently being measured and indicated on the measuring instrument.

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a "1" as the

least-significant digit.

Page 16

3

APPX

Safety Notes

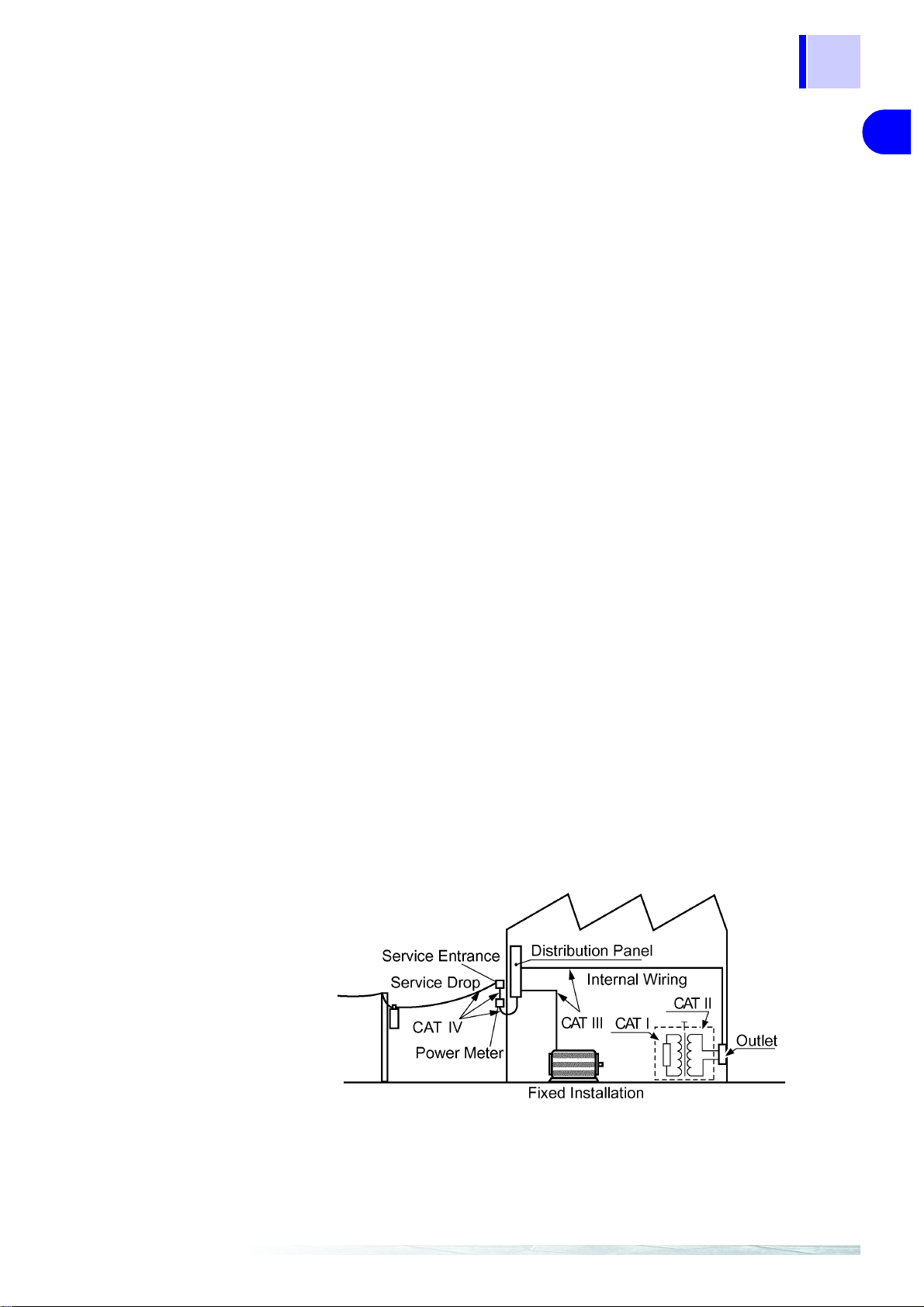

Measurement categories (Ove rvoltage categories)

Model 2301-20, 2302-20, 2303-20, 2304-20, 2304-21 and 2305-20

comply with CAT I safety requirements.

Model 2331-20 and 2332-20 comply with CAT III safety requirements.

To ensure safe operation of measurement ins truments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT I to CAT IV, and calle d measurement categories. These are defined as follows.

CAT I Secondary electrical circuits connected to an AC electrical

outlet through a transformer or similar instrument.

CAT II Primary electrical circuits in equipme nt connected to a n AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly me asuring el ectrical outle t recept acles.

CAT III Primary electrical circuits of heavy equipment (fixed installa-

tions) connected directly to the distribution panel, and feeders

from the distribution panel to outlets.

CAT I V The circui t from the service d rop to t he service e ntrance, and

to the power meter and prim ary overcur ren t protec tion inst rument (distribution panel).

1

1

2

2

3

3

4

4

16

5

5

Higher-numbered categories correspond to electrical environments

with greater momentary energy. So a measurement instrument

designed for CAT III environments can endure greater momentary

energy than a instrument designed for CAT II.

Using a measurement instrument in an environment designated

with a higher-numbered category than that for which the instrument

is rated could result in a severe accident, and must be carefully

avoided.

Never use a CAT I measuring instrument in CAT II, III, or IV environments.

The measurement categories comply with the Overvoltage Categories of the IEC60664 Standards.

6

6

7

7

8

8

9

9

10

10

11

IDX

Page 17

4

Notes on Use

Notes on Use

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Instrument Installation

Operating temperature and humidity: 0 to 50°C (32 to 122°F), 80%

RH (non-condensating)

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct

sunlight

Exposed to high

temperature

Exposed to liquids

Exposed to

high humidity or condensation

Exposed to high levels

of particulate dust

When the module is used in

a dusty environment, place it

in a dustproof case and take

measures to ensure heat

dissipation.

Do not allow the instrument to get wet, and do not take measurements with wet hands.

The instrument may be damaged.

In the presence of

corrosive or explosive

gases

Exposed to strong

electrom agnetic fields

Near electromagnetic

radiators

Subject to vibration

To avoid damage to the instrument, protect it from physical shock

when transporting and handling.

Be especially careful to avoid physical shock from dropping.

Do not obstruct the ventilation holes.

Ventilation holes for heat radiation are provided on the top and rear

panels of the instrument. Leave sufficient space around the ventilation

holes and install th e instrum ent wi th the ho les uno bstru cted. Installation

of the instrument with the ventilation holes obstructed may cause a

malfunction or fire.

When using the instrument in the case, drill ventilation holes.

Drill ventilation holes or install a ventilation fan to p revent heat buildup.

Page 18

5

APPX

Notes on Use

Only use sensors dedicated to the type of module.

To avoid damaging the ins trument, do not connec t any other sensors

than those dedicated to the instrument to its input terminals. Furth er, do

not connect any other signal sources to the terminals, as such signals

may lead to module damage due to excessive voltage or current.

1

1

Wiring

• A qualified electrician shall perform the wiring to prevent

electric shock.

• Avoid live-line electrical work to prevent electric shock and

accidents due to short-circuiting.

• Ensure that the power supply, input, and output are correctly wired according to the wiring diagram. (See the section on "Preparations" for each module.) This will prevent

fire, malfunction, and errors.

Connect the module to a power source that matches the

rating in order to prevent fire.

• Do not work on live lines. Such work may result in electric

shock or short-circuiting.

• Use cables of the proper sizes for the rated current. This

will prevent entire system errors and fire resulting from

broken wire.

• Use crimp connectors suitable for the cable sizes. This will

prevent module errors and fire due to broken wires.

• When tightening the screws, confirm that all screws are

securely tightened. A loose screw may result in module

errors, fire, or electric shock.

• Tighten the screws within the s pecified torque. Excessive

torque may damage the terminals. Inadequate torque may

result in module errors, fire, or electric shock.

2

2

3

3

4

4

16

5

5

6

6

7

7

8

8

• Ensure that the power supply module and input are OFF

until all wiring work is finished. This will prevent module

trouble and electric shock.

• Ensure that the power supply module and input are OFF

when connecting or disconnecting the module to the system. This will prevent electric shock, errors, and malfunction.

• Avoid using an unused terminal for relaying or any other

purpose to prevent electric shock, errors, and malfunction.

9

9

10

10

11

IDX

Page 19

6

Notes on Use

• If power supply noise poses a problem, use of a noise filter is

recommended.

• When the power and sig nal lines may be subject to a lightninginduced surge, install a lightning arrester between another

instrument or module connected to this module and line to protect the system.

• Avoid stepping on or pinching cables, which could damage the

cable insulation.

• Keep the cables well aw ay from heat sources, as bare conductors could be exposed if the insulation melts.

Preliminary Checks

Before using the instrument, make sure that the insulation

on the cables is undamaged and that no bare conductors are

improperly exposed. Using the product in such conditions

could cause an electric shock, so contact your dealer or

Hioki representative for repair.

To prevent an electric shock accident, confirm that the white or red portion (insulation layer) inside the cable is not exposed. If a color inside

the cable is exposed, do not use the cable.

Before using the instrument the first time, verify that it operates

normally to ensure that the no damage occurred during storage or

shipping. If you find any damage, contact your dealer or Hioki representative.

Page 20

APPX

Service

7

Service

Cleaning

To clean the instrument, wipe it gently with a soft cloth moistened

with water or mild detergent. Never use solvents such as benzene,

alcohol, acetone, ether, ketones, thinners or gasoline, as they can

deform and discolor the case.

Service

1

1

2

2

Never modify the instrument. Only Hioki service engineers

should disassemble or repair the instrument. Failure to

observe these precautions may res ult in fire, electric shock,

or injury.

• If the instrument seems to be malfunctioning, confirm that the

cables are not open circuited before contacting your dealer or

Hioki representative.

• When sending the instrument for repair, pack carefully to prevent

damage in transit. Include cushioning materia l so the instrument

cannot move within the package. Be sure to include details of the

problem. Hioki cannot be responsible for damage that occurs

during shipment.

• When transporting the module or a 2300 Smart Site, tape the

front of the module or take similar measures to avoid losing internal components.

• The instrument contains a built-in backup lithium battery, which

offers a service life of about five years. If the da te and time deviate substantially when the instrument is switched on, it is the time

to replace that battery. Contact your dealer or Hioki representative.

3

3

4

4

16

5

5

6

6

7

7

8

8

9

9

10

10

11

IDX

Page 21

8

Service

Page 22

1 2301-20 HUMIDITY MODULE

(Conceptual image)

2301-20 HUMIDITY MODULE 1

1.1 Overview

9

1

2

1.1.1 Product Overview

• The 2301-20 is a measurement module of Hioki "Smart Site"

(remote measurement system).

• This module measures and records temperature and humidity at

regular intervals.

• The 2301-20 is used with the power supply module, communications module, and module base.

Number of measurement channels

Measurement range -40.0 to 85.0°C, 0.0 to100.0%RH

3

4

5

Temperature 1 CH + Humidity 1 CH

6

7

8

1.1.2 Majo r Fe atures

The recordin g interval is selectable from 1 secon d to

60 minutes.

The maximum, minimum, and average measurements

during the recording interval can be recorded (with

sampling once a second).

The module has an alarm output terminal.

9

APPX

IDX

Page 23

10

1 2301-20 HUMIDITY MODULE

The capacitive humidity sensor for this module has

the following features relating to humidity measurement:

• Stable characteristics

• Wide measurement range

• Long service life

• Quick response

• Resistance to condensation

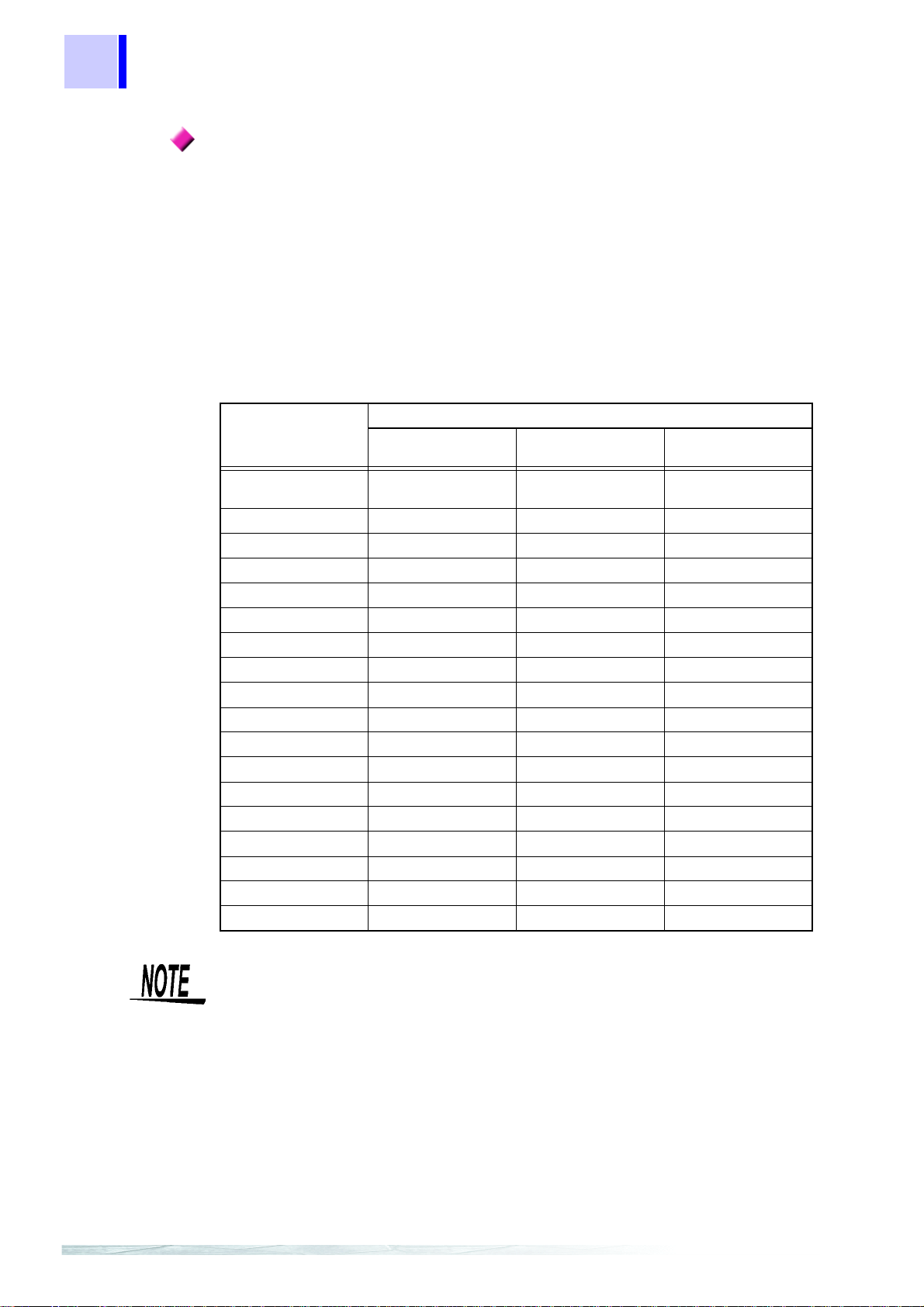

Rough Estimate of Storable Data Quantity and Time

Action at memory full: Continue recording (Endless)

Instantaneous

Quantity of

storable data

Recording Mode

MAX/MIN/AVE Instantaneous V alue

Value

26000 13000 10000

+ MAX/MIN/A VE

Recording interval

1 sec. 7.5 hours 3.5 hours 2.5 hours

2 sec. 14.5 hours 7 hours 5.5 hours

5 sec. 1.5 days 18 hours 14.5 hours

10 sec. 3 days 1.5 days 1 day

15 sec. 4.5 days 2 days 1.5 days

20 sec. 6 days 3 days 2 days

30 sec. 9 days 4.5 days 3.5 days

1 min. 18 days 9 days 7 days

2 min. 36 days 18 days 14 days

5 min. 92 days 46 days 36 days

10 min. 184 days 92 days 73 days

15 min. 277 days 138 days 110 days

20 min. 369 days 184 days 147 days

30 min. 554 days 277 days 221 days

60 min. 1109 days 554 days 443 days

When the alarm log is ON, the higher the number of alarms generated, the smaller the recording period. (A pprox. 1 of the data

per alarm)

Page 24

1 2301-20 HUMIDITY MODULE

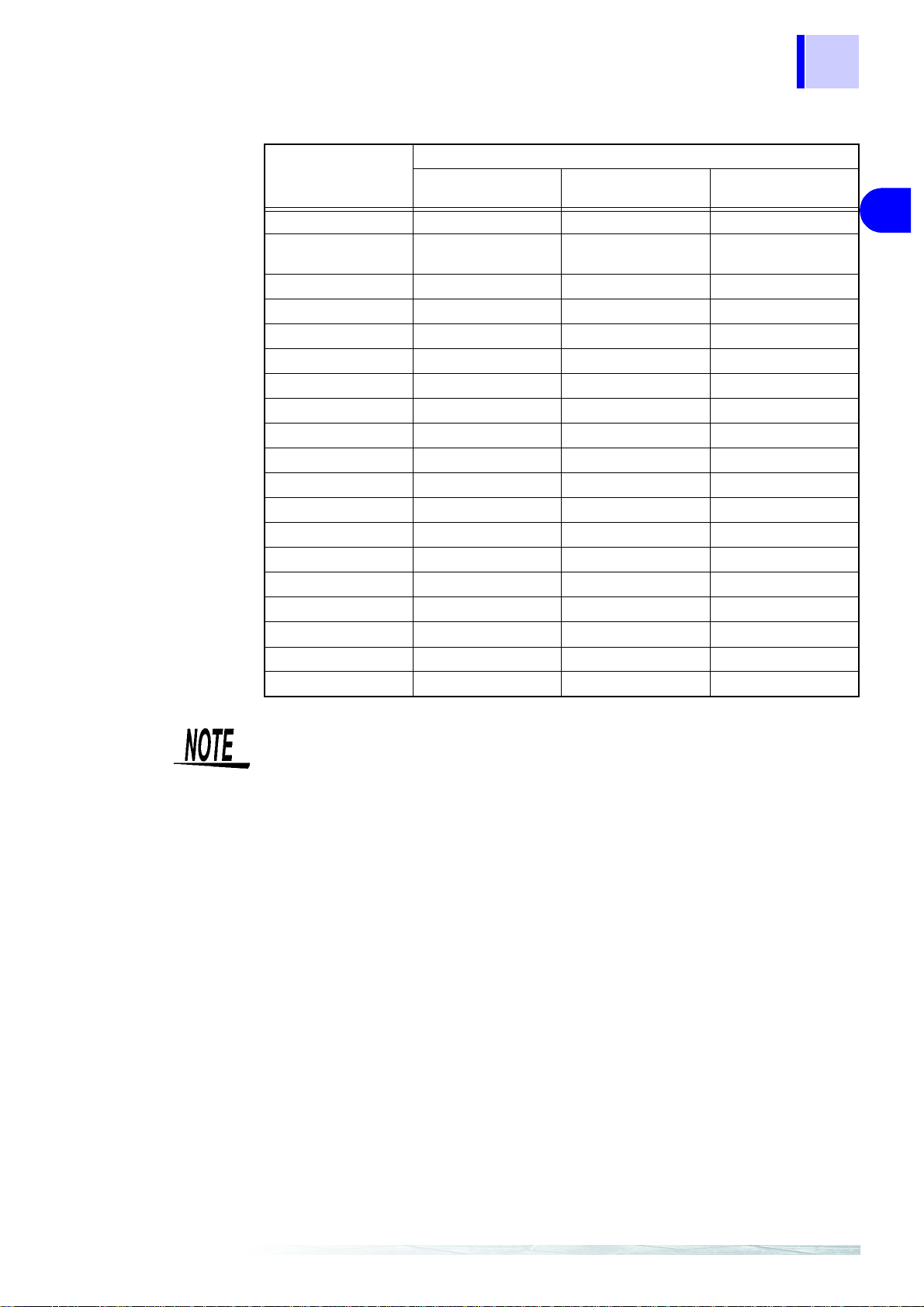

Action at memory full: Stop recording (Memory full stop)

Recording Mode

Quantity of

storable data

Instantaneous

Value

30000 15000 12000

MAX/MIN/AVE Instantaneous V alue

11

+ MAX/MIN/A VE

1

Recording interval

1 sec. 8.5 hours 4 hours 3 hours

2 sec. 17 hours 8.5 hours 6.5 hours

5 sec. 1.5 days 21 hours 17 hours

10 sec. 3.5 days 1.5 days 1.5 days

15 sec. 5 days 2.5 days 2 days

20 sec. 7 days 3.5 days 2.5 days

30 sec. 10 days 5 days 4 days

1 min. 21 days 10 days 8 days

2 min. 42 days 21 days 17 days

5 min. 106 days 53 days 42 days

10 min. 213 days 106 days 85 days

15 min. 319 days 159 days 127 days

20 min. 426 days 213 days 170 days

30 min. 639 days 319 days 255 days

60 min. 1279 days 639 days 511 days

When the alarm log is ON, the higher the number of alarms generated, the smaller the recording period. (Approx. 1 of the data

per alarm)

2

3

4

5

6

7

8

9

APPX

IDX

Page 25

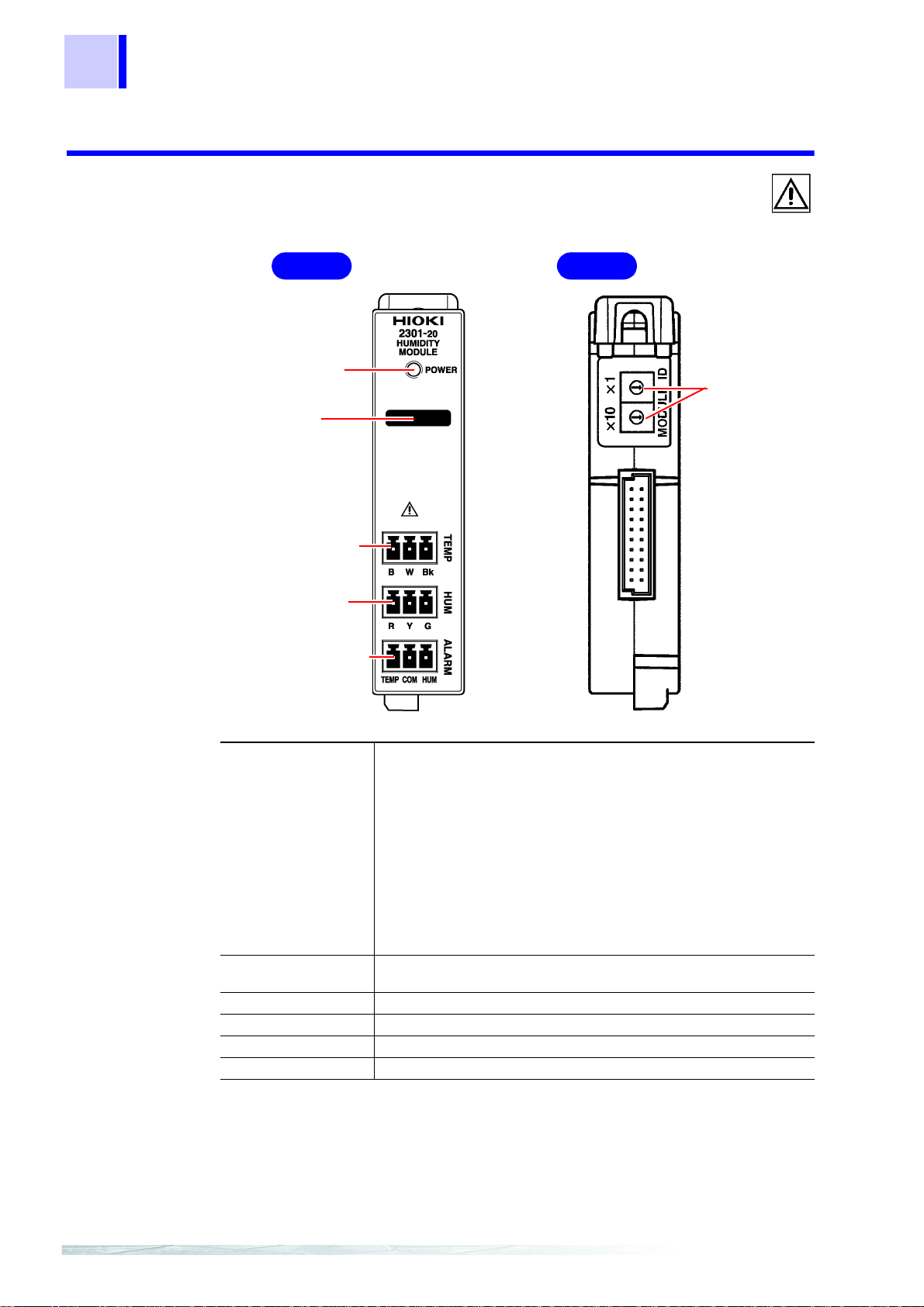

12

Front

Back

TEMP terminal

Module ID

setting dial

ALARM terminal

HUM terminal

Mark area

POWER LED

1 2301-20 HUMIDITY MODULE

1.1.3 Name and Function of the Parts

POWER LED Goes on or flashes when power is supplied to the module.

Remains on, flashe s, or chan ges to another color accordi ng to

the state of the module.

POWER LED indication

Lit in green : Data being recorded.

Flashing in green : Standing by.

Lit in yellow : Alarm output.

Flashing in yellow: Overrange detected.

Lit in red : Non-recoverable error occurred.

Flashing in red : Recoverable error occurred.

Mark area Use this area to make a note of the object to measure or the module ID.

TEMP terminal Connect the temperature sensor to this terminal.

HUM terminal Connect the humidity sensor to this terminal.

ALARM terminal Connect the alarm output cable to this terminal.

Module ID setting dial Use the dial to set the module's identification No.

Use an ink pen, since pencil lead may rub off.

*1

*2

*1: The module needs r e pai r . Co ntact your dealer or H ioki r ep res en tative .

*2: The same module ID may be used by another module.

Page 26

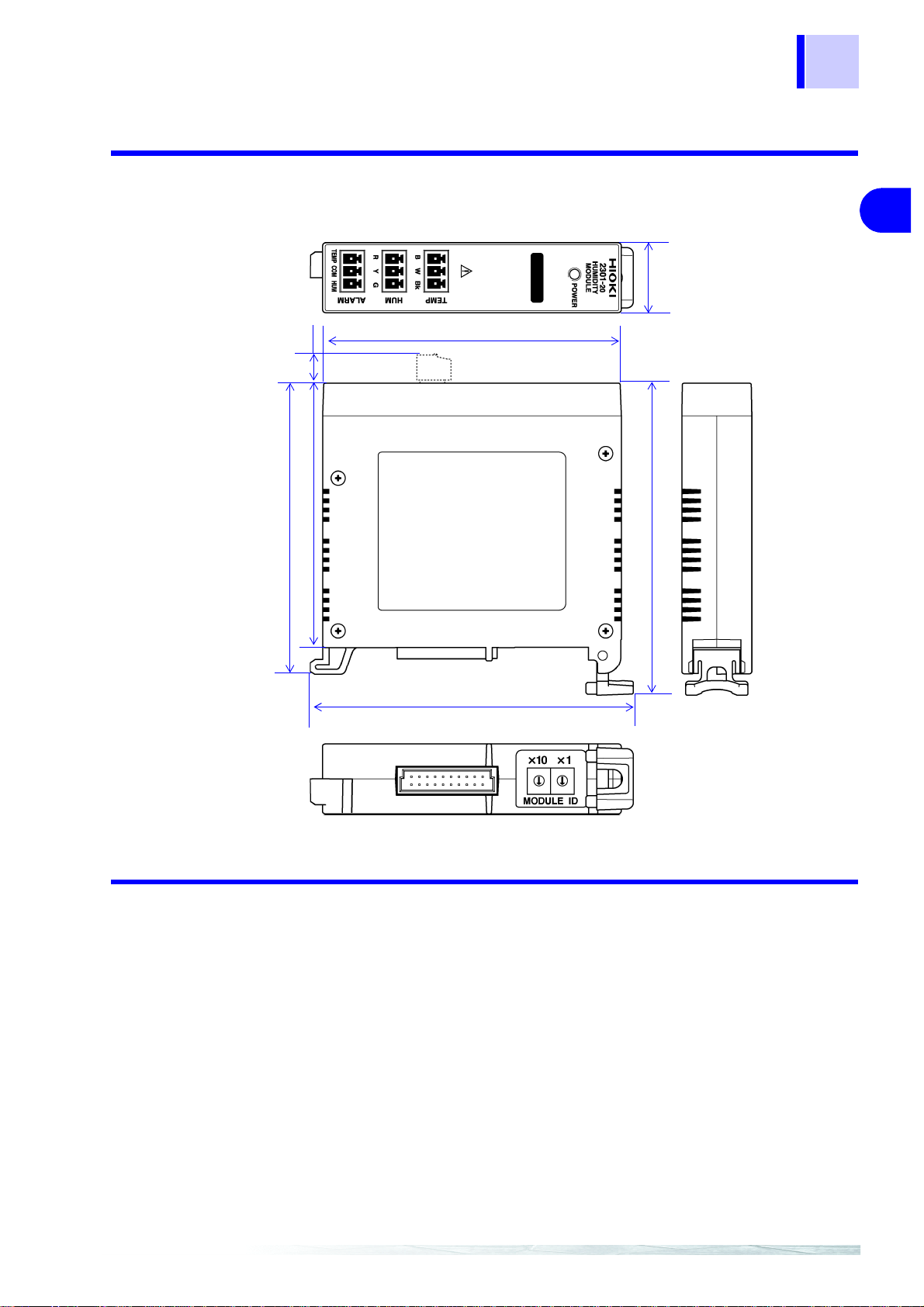

1.1.4 Dimension Diagrams

22.5±1

96±1

9.6±0.5

93.8±1

85±1

103.9±1

100.5±1

(Unit: mm)

13

1 2301-20 HUMIDITY MODULE

1

2

3

4

5

6

7

8

9

1.1.5 Accessory and Option

Accessories

Ferrite clamp ................................................................................. 1

Terminal block ............................................................................... 3

Option

9764-50 HUMIDIDTY SENSOR

APPX

IDX

Page 27

14

1 2301-20 HUMIDITY MODULE

1.2 Settings

1.2.1 Setting the Module ID

You can connect up to 63 measurement modules to one communications module.

Setting Proced u re

Use the module ID setting dial to set the ID No. of the module to a

number from 01 and to 63. (You cannot set a number other than

the above.)

• Ensure that the set ID is not used for any other module connected to the same communications module.

• The ID numbers of modules need not be consecutive.

• Setting the ID to 99, then turning on the power resets all internal settings to the defaults.

• The module ID and COM ID are not related and can be set

independently.

Page 28

1.3 Preparations

1

2

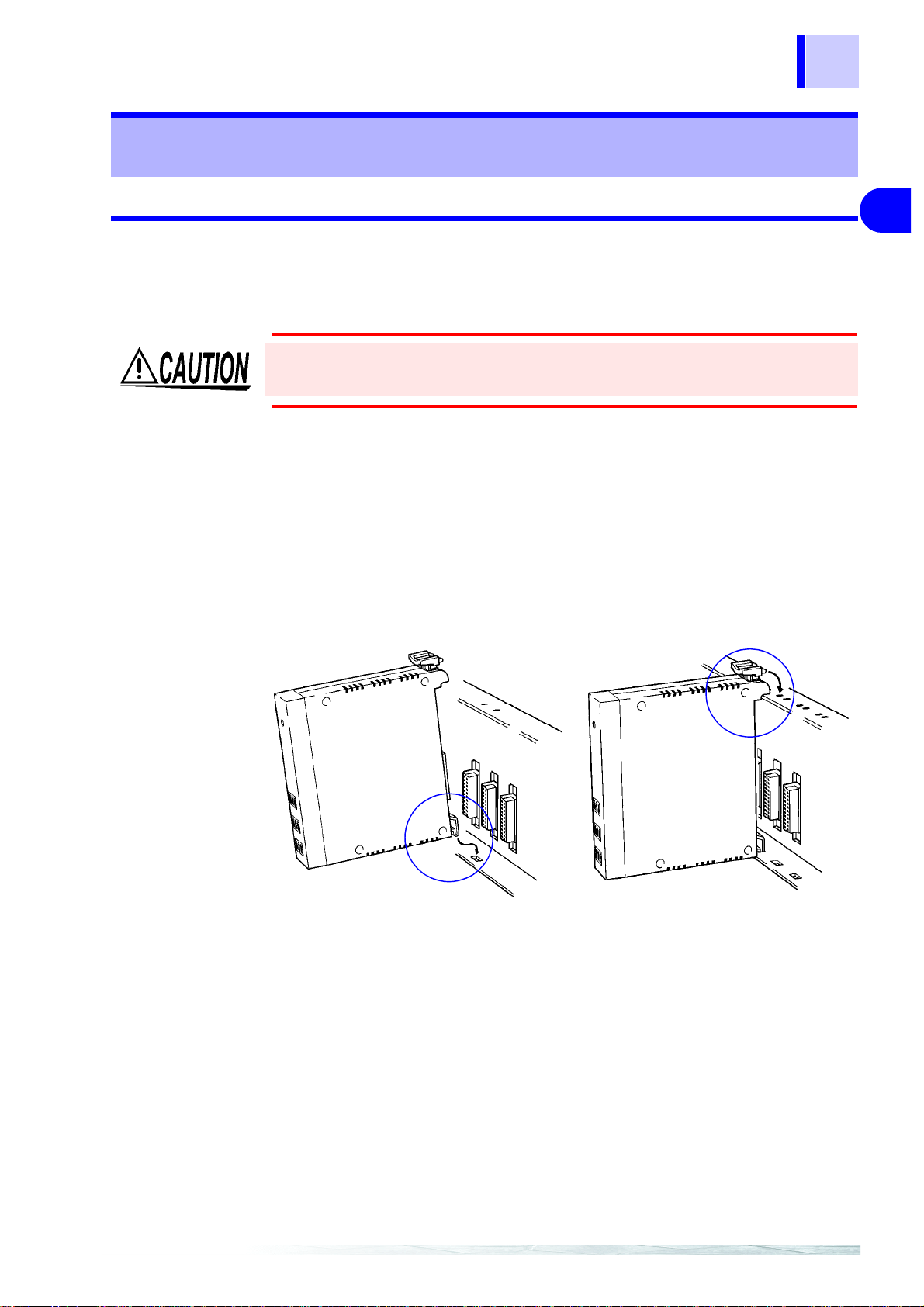

1.3.1 Installing the Module

15

1 2301-20 HUMIDITY MODULE

1

(1) Installing the Module Base

Do not mount the module base on the ceiling where it may fall off.

Fasten the module base to a DIN rail or the wall a ccording to the

procedure described in the

BASE"(P.305) or 20 "2392-01/02 MODULE BASE"(P.319) series

MODULE BASE instruction manual.

(2) Mounting a Module on the Module Base

Mount a module on the module base as shown below. Ensure that

the lever clicks.

19 "2391-01, 23 91-0 2, 239 1-03 MODU LE

2

3

4

5

6

7

8

9

APPX

IDX

Page 29

16

Blue RedBlack Green

White Yellow

Sensor cable of the 9764-50

Terminal block

TEMP terminal

HUM terminal

1 2301-20 HUMIDITY MODULE

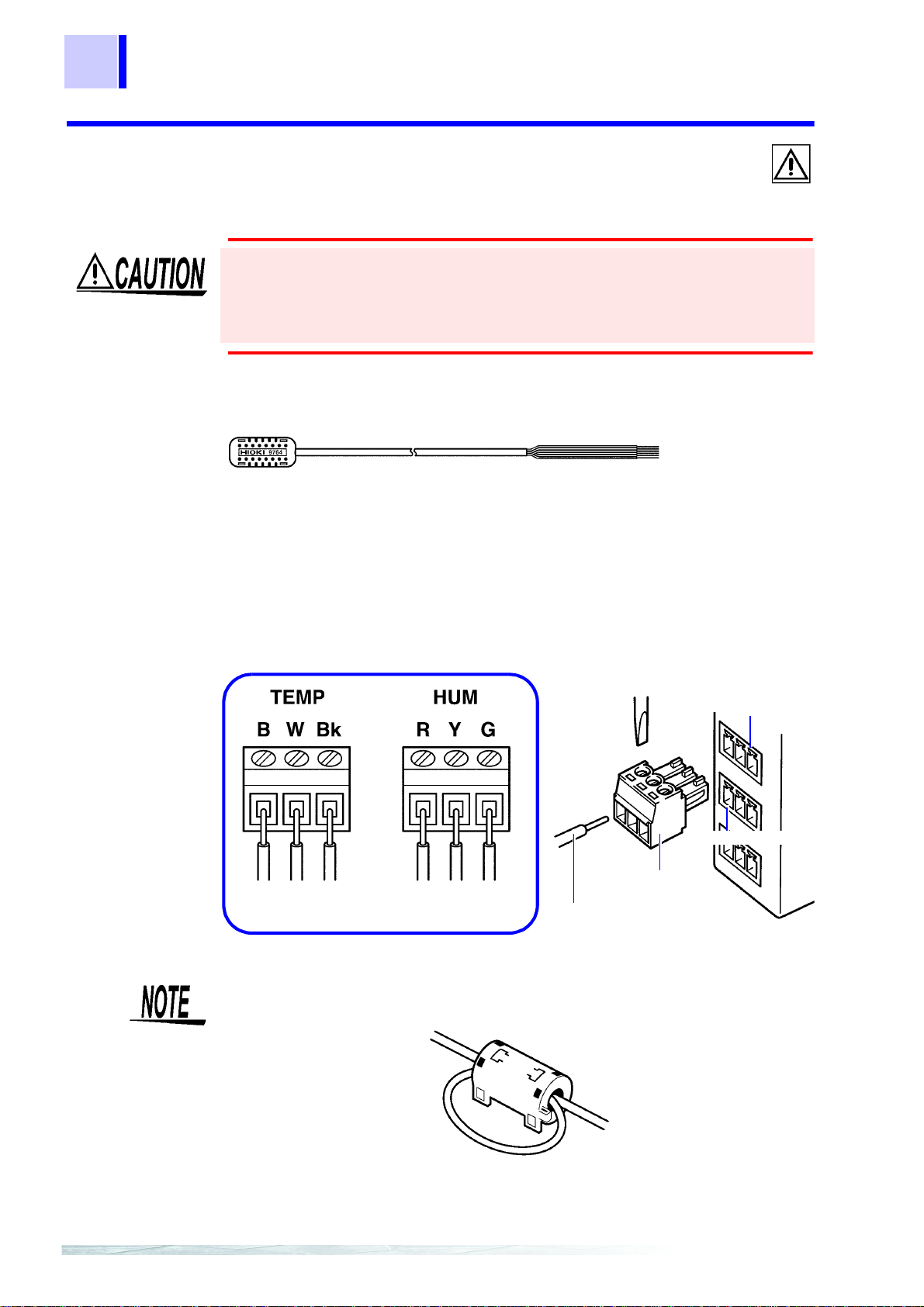

1.3.2 Connecting Input/Output Cables

(1) Connecting Sensor Cables to the Terminal Block

• The TEMP terminal and HUM terminal are not insulated from

each other. Avoid short-circuiting.

• Be sure to connect the cables to matching connectors to prevent

damage to the module or sensor.

Connect the 9764-50 HUMIDIDTY SENSOR to the module by following the procedure below.

1. Use a flat blade screwdriver to loosen the screws on the t ermi-

nal block.

2. Insert a cable into the terminal block, then tighten the screws

(at a tightening torque of 0.25 N•m).

3.

Connect the terminal block to the TEMP terminal, and HUM terminal.

• In case of external noise, wind the cable around the ferrite

clamp supplied as an accessory as shown below.

• Note that measurement may be adversely affected by external

noise or the electromagnetic environment when using a cable

longer than 3 meters.

Page 30

1 2301-20 HUMIDITY MODULE

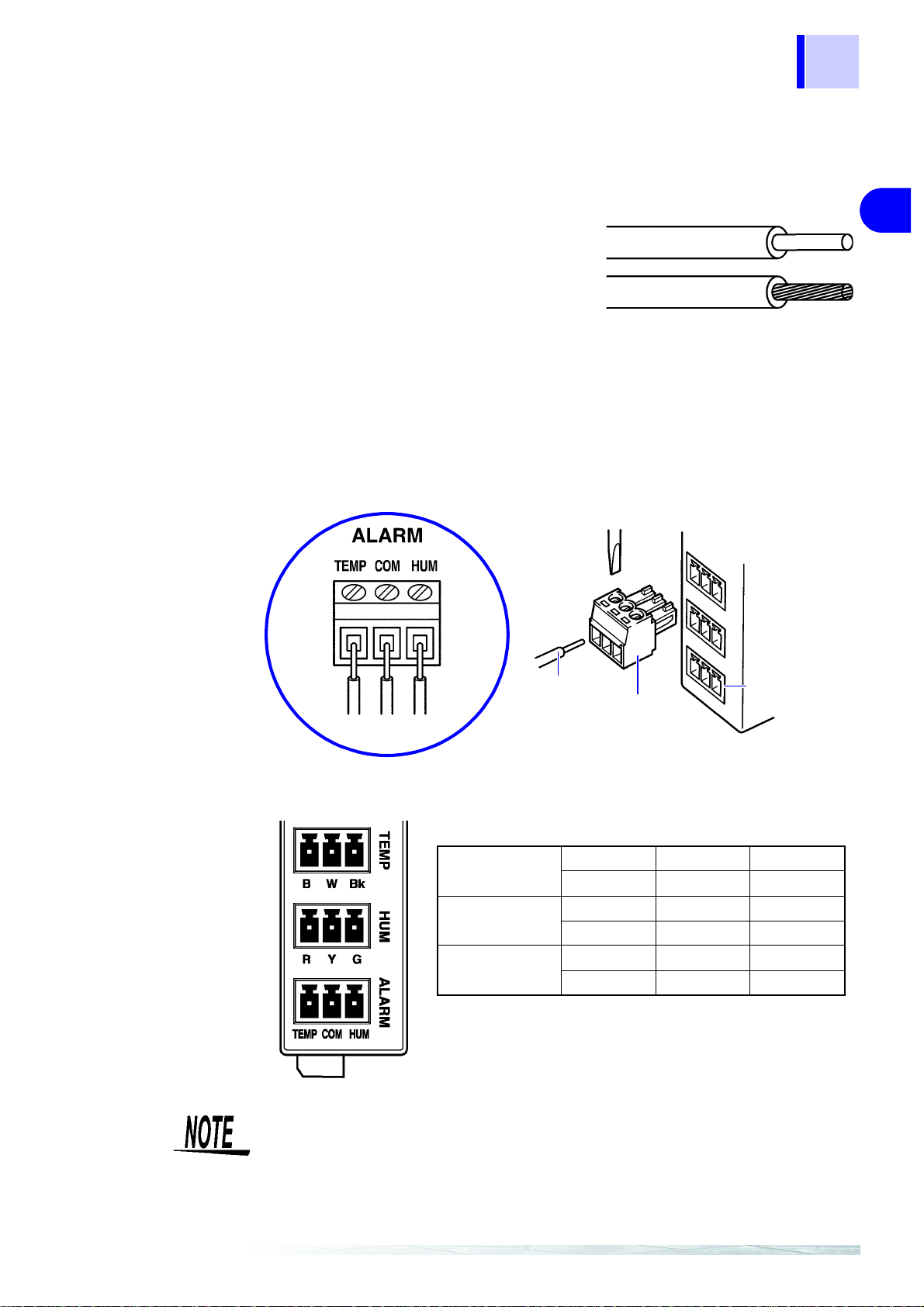

Single-wire : 0.14 to 1.5 mm

2

Stranded-wire : 0.14 to 1.5 mm

2

AWG : 26 to 16

Cable strip length : 5 mm (0.2")

Terminal block

Terminal block

Cable

ALARM

terminal

TEMP terminal

(Input)

BWBk

Blue White Black

HUM terminal

(Input)

RYG

Red Yellow Green

ALARM terminal

(output)

TEMP COM HUM

Alarm output Common Alarm output

(2) Connecting Cables to the ALARM Terminal (Alarm output)

Recommended Cable

1. Use a flat blade scre wdriver to loosen the screws on the termi-

17

1

2

nal block.

2. Insert a cable for alarm output into the terminal block, then

tighten the screws (at a tightening torque of 0.25 N•m).

3. Connect the ter minal block to the ALARM terminal.

(3) The Location of the Input/Output Cable

3

4

5

6

7

8

The TEMP and HUM terminals are used to connect the optional

9764-50 HUMIDIDTY SENSOR.

9

APPX

IDX

Page 31

18

1 2301-20 HUMIDITY MODULE

9764-50 HUMIDIDTY SENSOR

• To avoid damaging the 2301-20, only connect the 9764-50

HUMIDIDTY SENSOR to the TEMP an d HUM terminals. Moreover, do not input other signals to these terminals.

• If the sensor is used or stored outside the operatin g or storage

ranges, sensor accuracy may be adversely affected and you

may not get accurate measurements even within the one-year

guaranteed period of accuracy.

• Hioki is not liable for any problems caused by sensor use or storage outside the operating or storage ranges.

• When not using th e 9764-50 HUMIDIDTY SEN SOR, seal it in a

plastic bag and store it in a cool, dark place.

• Be careful to avoid condensation on the sensor. If condensation occurs,

you may not get accurate measurements. Condensation is likely to

occur when the sensor is subject to rapid changes in temperature.

Page 32

1.4 Others

TEMP

Photocoupler

<Internal circuit>

COM

HUM

1.4.1 Alarm output

Ensure that the input does not exceed the maximum input

voltage or current to avoid module damage, short-circuiting

and electric shock resulting from heat building.

Output method Open collector

Maximum input voltage / current 30 V, 20 mA max.

Signal logic Enabled: ON Disabled: OFF

19

1 2301-20 HUMIDITY MODULE

1

2

3

4

(1) Internal Circuit

The alarm output circuit is configured as shown below.

• Signal logic indicates the signal state in which a signal's function is enabled.

• The output transistor works as a switch between signal output

and ground in the module. When output becomes enabled, the

switch is turned on and current flows from the output signal to

COM in the module. Therefore, a relay or LED lamp can be

connected directly to the output terminal (P.20).

5

6

7

8

9

APPX

IDX

Page 33

20

<Circuit diagram>

COM

Power

Output

Limit resistor

LED

Connecting LED

Power

Relay

Diode

COM

Output

Connecting relay

TEMP

Wired-OR output

COM

HUM

Using on Wired-OR Logic

1 2301-20 HUMIDITY MODULE

• When connecting a relay or LED lamp, ensure that the relay or

• Open collector output operates on wired-OR logic by short-cir-

lamp operates at up to 30 V and 20 mA. When connecting a

relay, be sure to use a diode to absorb counter electromo tive

force.

cuiting TEMP and HUM. Moreover, it enables the signal if an

alarm occurs in either channel.

Page 34

1 2301-20 HUMIDITY MODULE

Analog

circuit

TEMP/HUM

Measurement

Input

Digital

circuit

Insulating

circuit

Module-to-

module com-

munications

circuit

CAN bus

Connector

Module base

Power

Insulation

withstand voltage

of 1.4 kVAC

Insulation

withstand voltage

of 1.4 kVAC

ALARM

Alarm output

Ground

1.4.2 Insulation of Internal Circuit

In the 2301-20, the input circuit and alarm output are insulated

from the CAN bus as shown in the block diagram below. (Withstand voltage: 1.4 kVAC, 50/60 Hz, Response current: 5 mA, 1

minute)

21

1

2

3

4

The COM terminal of the alarm output terminal is used for both

TEMP and HUM.

5

6

7

8

9

APPX

IDX

Page 35

22

Relative humidity (%RH)

Temperature (°C)

*Accuracy not guaranteed

(reference values)

1 2301-20 HUMIDITY MODULE

1.5 Specifications

1.5.1 Basic Specifications

Sensor type 9764-50 HUMIDIDTY SENSOR

Number of inputs Temperature 1 CH + Humidity 1 CH

Measurement range -40.0 to 85.0°C Resolution: 0.1°C, 0.0 to 100.0%RH Resolution: 0.1%RH

Measurement accuracy Temperature

(Display range: -10.0 to 110.0%RH)

-40.0 to -0.1°C ±1.0°C

0.0 to 35.0°C ±0.5°C

35.1 to 70.0°C ±1.0°C

70.1 to 85.0°C ±2.0°C

Humidity

Period of guaranteed

accuracy

Sampling 1 time / sec.

Input terminal 3 Input terminal block × 2

1 year

1.5.2 Function Specifications

Execute the functions from the PC application via communications.

Monitoring function

This function outputs the current measured values (instantaneous values).

Measured value recording function

Measurements are recorded at a set recording interval.

Real-time manage-

ment

Recording start Immediate start/Reserved-tim e start

Recording end Manual end/Reserved-time end

Operation when

memory is full

Recording interval 1/2/5/10/15/20/30 sec., 1/2/5/10/15/20/30/60 min.

This is automatically set from the PC application at the start of recording.

Memory full stop /Endless

Set the condition before the start of recording.

Page 36

23

1 2301-20 HUMIDITY MODULE

Recording mode • Instantaneous value

• MAX/MIN/AVE

• Instantaneous value + MAX/MIN/AVE

Total 3 modes

Set the mode before the start of recording.

Recorded data One data set contains time and temperature/humidity information (One channel each).

Data is scaled if scaling is ON.

Recording capacity 512 k bytes Flash memory

Quantity of recorded

data

Power outage

protection

Alarm judgment and recording function

Alarm judgment is made at every sampling, and the history will be recorded in flash memory if the measured

value recording function remains active.

Judgment method Criterion threshold can be set to either Hi or Lo.

Recorded data One data set contains time, generation/reversion, CH and judgment threshold.

Alarm output Alarm output × 2 CH

• Instantaneous value recording mode: 30,000 data × 2 CH

• MAX/MIN/AVE recording mode: 15,000 data × 2 CH

• Instantaneous value + MAX/MIN/AVE recording mode: 12,000 data × 2 CH

After recovering from a power outage, the instrument automatically returns to the state

held before the outage.

The instantaneous va lue at every sampli ng is judged (effecti ve in any measurem ent

mode).

Output is turned ON when an alarm (Hi or Lo) occurs.

Whether to hold the al arm output can be selecte d. The reset s witch or a c ommand

can be used to reset alarms.

1

2

3

4

5

1.5.3 General Specifications

Clock accuracy ±100 ppm (Reference value at temperature from 0 to 50°C (32 to 122

communicatio ns mod ule)

Backup Recorded data (saved in flash memory)

Data loss for up to 2 minutes before and after a power outage may occur.

Communication

interface

Maximum rated

voltage to earth

Alarm output Open collector: 30 VDC, 20 mA max.

Rated supply voltage 5 V±0.3 VDC

Maximum rated Power

Dielectric strength 1.4 kVAC Between input and alarm output, Input/Output and CAN bus (50/60 Hz,

Dimensions Approx. 22.5W × 96H × 85D mm (0.89"W × 3.78"H × 3.35"D) (excluding projections)

Mass Approx. 120 g (4.2 oz.)

Accessories Ferrite clamp............. ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ......................1

Option 9764-50 HUMIDIDTY SENSOR

Operational ranges

for temperature and

humidity

Temperature and

humidity ranges for

storage

Operating

environment

Standards applying Safety EN61010, Pollution degree 2, Measurement Category I

CAN bus

33 Vrms, 70 VDC

1.4 W

Response current 5 mA, one minutes

Terminal block.............................. ....... ...... ...... .............................................. ...... ....... .. 3

0 to 50°C (32 to 122

-10 to 50°C (14 to 122

Indoors, altitude up to 2000 m (6562-ft.)

(anticipated transient overvoltage 330 V)

EMC EN61326, CLASS A

°F)

, 80%RH or less (with no condensation)

°F)

, 80%RH or less (with no condensation)

°F)

without the

6

7

8

9

APPX

IDX

Page 37

24

1 2301-20 HUMIDITY MODULE

1.5.4 9764-50 HUMIDIDTY SENSOR Specifications

Operational ranges

for temperature and

humidity

Temperature and

humidity ranges for

storage

Response time Temperature: Approx. 100 sec., Humidity: Approx.300 sec.

Temperature sensor Thermistor

Humidity sensor High polymer film (capacitive humidity sensor)

Cord length Approx. 3 m

Dimensions Sensor, Approx. 30W × 13H × 8D mm (1.18" W × 0.51"H × 0.31"D)

Long time stability ±1%RH (5 years at 25°C (77

-40 to 85°C (-40 to 185

-40 to 85°C (-40 to 185

°F)

, 0.0 to 100.0%RH (with no condensation)

°F)

, 0.0 to 100.0%RH (with no condensation)

°F)

, 50%RH, reference value)

The 2301-20 may indicate a humidity measurement below z ero or

above 100%RH. These values indicate a change in low or high

humidity levels, and do not indicate ac tual humidity (since values

over 100% and lower than 0% are impossible).

Page 38

2 2302-20 Pt MODULE

(Conceptual image)

2302-20 Pt MODULE 2

2.1 Overview

25

1

2

2.1.1 Product Overview

• The 2302-20 is a measurement module of Hioki "Smart Site"

(remote measurement system).

• This module measures and records temperature at regular intervals.

• The 2302-20 is used with the power supply module, communications module, and module base.

Usable Temperature sensor Platinum resistance thermometer sensor

Number of measurement channels Temperature 2 CH

Measurement range -100.0 to 300.0°C

(Selectable between Pt100 and JPt100)

3

4

5

6

7

8

2.1.2 Majo r Fe atures

The recordin g interval is selectable from 1 secon d to

60 minutes.

The maximum, minimum, and average measurements

during the recording interval can be recorded (with

sampling once a second).

The module has an alarm output terminal.

Rough Estimate of Storable Data Quantity and Time.

9

APPX

IDX

Page 39

26

2 2302-20 Pt MODULE

Action at memory full: Continue recording (Endless)

Quantity of

storable data

Recording interval

1 sec. 7.5 hours 3.5 hours 2.5 hours

2 sec. 14.5 hours 7 hours 5.5 hours

5 sec. 1.5 days 18 hours 14.5 hours

10 sec. 3 days 1.5 days 1 day

15 sec. 4.5 days 2 days 1.5 days

20 sec. 6 days 3 days 2 days

30 sec. 9 days 4.5 days 3.5 days

1 min. 18 days 9 days 7 days

2 min. 36 days 18 days 14 days

5 min. 92 days 46 days 36 days

10 min. 184 days 92 days 73 days

15 min. 277 days 138 days 110 days

20 min. 369 days 184 days 147 days

30 min. 554 days 277 days 221 days

60 min. 1109 days 554 days 443 days

Recording Mode

Instantaneous

Value

26000 13000 10000

MAX/MIN/AVE Instantaneous V alue

+ MAX/MIN/A VE

When the alarm log is ON, the higher the number of alarms generated, the smaller the recording period. (A pprox. 1 of the data

per alarm)

Page 40

2 2302-20 Pt MODULE

Action at memory full: Stop recording (Memory full stop)

Recording Mode

Instantaneous

Value

Quantity of

storable data

Recording interval

1 sec. 8.5 hours 4 hours 3 hours

2 sec. 17 hours 8.5 hours 6.5 hours

5 sec. 1.5 days 21 hours 17 hours

10 sec. 3.5 days 1.5 days 1.5 days

15 sec. 5 days 2.5 days 2 days

20 sec. 7 days 3.5 days 2.5 days

30 sec. 10 days 5 days 4 days

1 min. 21 days 10 days 8 days

2 min. 42 days 21 days 17 days

5 min. 106 days 53 days 42 days

10 min. 213 days 106 days 85 days

15 min. 319 days 159 days 127 days

20 min. 426 days 213 days 170 days

30 min. 639 days 319 days 255 days

60 min. 1279 days 639 days 511 days

30000 15000 12000

MAX/MIN/AVE Instantaneous Value

27

+ MAX/MIN/A VE

1

2

3

4

5

6

When the alarm log is ON, the higher the number of alarms generated, the smaller the recording period. (Approx. 1 of the data

per alarm)

7

8

9

APPX

IDX

Page 41

28

Front

Back

CH1 terminal

Module ID

setting dial

ALARM terminal

CH2 terminal

Mark area

POWER LED

2 2302-20 Pt MODULE

2.1.3 Name and Function of the Parts

POWER LED Goes on or flashes when power is supplied to the module.

Mark area Use this area to make a note of the object to measure or the

CH1 terminal Connect the platinum resistance thermometer sensor to this

CH2 terminal Connect the platinum resistance thermometer sensor to this

ALARM terminal Connect the alarm output cable to this terminal. This terminal is

Module ID setting dial Use the dial to set the module's identification No.

Remains on, flashe s, or chan ges to another color accordi ng to

the state of the module.

POWER LED indication

Lit in green : Data being recorded.

Flashing in green : Standing by.

Lit in yellow : Alarm output.

Flashing in yellow: Overrange detected.

Lit in red : Non-recoverable error occurred.

Flashing in red: Recoverable error occurred.

module ID.

Use an ink pen, since pencil lead may rub off.

*2

*1

terminal. (Channel 1)

terminal. (Channel 2)

electrically insulated from the CH1 and CH2 terminals.

*1: The module needs r e pai r . Co ntact your dealer or H ioki r ep res en tative .

*2: The same mod ule ID may be used by a nother module .

Page 42

2.1.4 Dimension Diagrams

22.5±1

96±1

9.6±0.5

93.8±1

85±1

103.9±1

100.5±1

(Unit: mm)

29

2 2302-20 Pt MODULE

1

2

3

4

5

6

7

2.1.5 Accessory and Option

Accessories

Ferrite clamp ................................................................................. 2

Terminal block ............................................................................... 3

Option

None

8

9

APPX

IDX

Page 43

30

2 2302-20 Pt MODULE

2.2 Settings

2.2.1 Setting the Module ID

You can connect up to 63 measurement modules to one communications module.

Setting Proced u re

Use the module ID setting dial to set the ID No. of the module to a

number from 01 and to 63. (You cannot set a number other than

the above.)

• Ensure that the set ID is not used for any other module connected to the same communications module.

• The ID numbers of modules need not be consecutive.

• Setting the ID to 99, then turning on the power resets all internal settings to the defaults.

• The module ID and COM ID are not related and can be set

independently.

Page 44

2.3 Preparations

1

2

Single-wire : 0.14 to 1.5 mm

2

Stranded-wire : 0.14 to 1.5 mm

2

AWG : 26 to 16

Cable strip length : 5 mm (0.2")

2.3.1 Installing the Module

31

2 2302-20 Pt MODULE

1

(1) Installing the Module Base

Do not mount the module base on the ceiling where it may fall off.

Fasten the module base to a DIN rail or the wall a ccording to the

procedure described in the

BASE"(P.305) or 20 "2392-01/02 MODULE BASE"(P.319) series

MODULE BASE instruction manual.

(2) Mounting a Module on the Module Base

Mount a module on the module base as shown below. Ensure that

the lever clicks.

19 "2391-01, 23 91-0 2, 239 1-03 MODU LE

2

3

4

5

6

7

2.3.2 Connecting Input/Output Cables

Recommended Cable

8

9

APPX

IDX

Page 45

32

CH2 terminal

CH1 terminal

Terminal block

Terminal block

Cable

2 2302-20 Pt MODULE

(1) Connecting Cables to the CH1 and CH2 Terminals

(Temperature Sensor Signal Input)

The CH1 and CH2 terminals are not insulated from each other. Avoid

short-circuiting.

1. Use a flat blade screwdriver to loosen the screws on the t ermi-

nal block.

2. Insert a cable for input temperature sensor signal into the ter-

minal block, then tighten the screws (at a tightening torque of

0.25 N•m).

3. Connect the terminal block to the CH1 or CH2 terminal.

• The CH1 and CH2 terminals are not insulated from each other.

When measuring two measurement points having a potential

difference, use an electrically insulated sensor or another Pt

module, since measurements may be adversely affected.

• In case of external noise, wind the cable around the ferrite

clamp supplied as an accessory as shown below.

• Note that measurement may be adversely affected by external

noise or the electromagnetic environment when using a cable

longer than 3 meters.

Page 46

2 2302-20 Pt MODULE

Terminal block

Terminal block

Cable

ALARM terminal

Connect the cable for CH1 output to CH1 and COM; and

connect the cable for CH2 output to CH2 and COM.

CH1

terminal

(Input)

Left Center Right

Resistance

thermome-

ter sensor

input (A)

Resistance

thermome-

ter sensor

input (B)

Conductor

input (B)

CH2

terminal

(Input)

Left Center Right

Resistance

thermome-

ter sensor

input (A)

Resistance

thermome-

ter sensor

input (B)

Conductor

input (B)

ALARM

terminal

(output)

CH1 COM CH2

Alarm

output

Common

Alarm

output

(2) Connecting Cables to the ALARM Terminal (Alarm output)

1. Use a flat blade scre wdriver to loosen the screws on the termi-

nal block.

33

2. Insert a cable for alarm output into the terminal block, then

tighten the screws (at a tightening torque of 0.25 N•m).

3. Connect the ter minal block to the ALARM terminal.

(3) The Location of the Input/Output Cable

1

2

3

4

5

6

Temperature Sensor

Only connect the Pt100 or JPt100 sensor to the CH1 and CH2

terminals to avoid damaging the 2302-20. Moreover, do not

input other signals to these terminals.

7

8

9

APPX

IDX

Page 47

34

CH1

Photocoupler

<Internal circuit>

COM

CH2

2 2302-20 Pt MODULE

2.4 Others

2.4.1 Alarm output

(1) Output Rating

Ensure that the input does not exceed the maximum input

voltage or current to avoid module damage, short-circuiting

and electric shock resulting from heat building.

Output method Open collector

Maximum input voltage / current 30 V, 20 mA max.

Signal logic Enabled: ON Disabled: OFF

(1) Internal Circuit

The alarm output circuit is configured as shown below.

• Signal logic indicates the signal state in which a signal's function is enabled.

• The output transistor works as a switch between signal output

and ground in the module. When output becomes enabled, the

switch is turned on and current flows from the output sign al to

COM in the module. Therefore, a relay or LED lamp can be

connected directly to the output terminal (P.35).

Page 48

2 2302-20 Pt MODULE

<Circuit diagram>

COM

Power

Output

Limit resistor

LED

Connecting LED

Power

Relay

Diode

COM

Output

Connecting relay

CH1

Wired-OR output

COM

CH2

Using on Wired-OR Logic

35

1

2

3

4

• When connecting a relay or LED lamp, ensure that the relay or

lamp operates at up to 30 V and 20 mA. When connecting a

relay, be sure to use a diode to absorb counter electromotive

force.

• Open collector output operates on wired-OR logic by short-circuiting CH1 and CH2. Moreover, it enables the signal if an

alarm occurs in either channel.

5

6

7

8

9

APPX

IDX

Page 49

36

Analog

circuit

CH1/ CH2

Measurement

Input

Digital

circuit

Insulating

circuit

Module-to-

module com-

munications

circuit

CAN bus

Connector

Module base

Power

Insulation

withstand voltage

of 1.4 kVAC

Insulation

withstand voltage

of 1.4 kVAC

ALARM

Alarm output

Ground

2 2302-20 Pt MODULE

2.4.2 Insulation of Internal Circuit

The CH1 and CH2 terminals are not insulated from each other.

When connecting signals different in potential to these terminals, use

an additional measurement module or insulate the signals externally

before connection to the terminals. Th is will pr event module er rors and

malfunction.

In the 2302-20, the input circuit and alarm output are insulated

from the CAN bus as shown in the block diagram below. (Withstand voltage: 1.4 kVAC, 50/60 Hz, Response current: 5 mA, 1

minute)

The COM terminal of the alarm output terminal is u sed for both

CH1 and CH2.

Page 50

2.5 Specifications

2.5.1 Basic Specifications

37

2 2302-20 Pt MODULE

1

Sensor type Platinum resistance thermometer sensor

Number of inputs 2 CH