SKID STEER LOADER VERSAPLOW

MODELS 4208, 4210

OPERATOR’S MANUAL

DO NOT USE OR OPERATE THIS EQUIPMENT UNTIL THIS MANUAL

HAS BEEN READ AND THOROUGHLY UNDERSTOOD

PART NUMBER 27000355

Table of Contents 1

TABLE OF CONTENTS

27000355 9/19 MANUALS/27000355

TO THE PURCHASER .................................................................................................................. 2

SAFETY ......................................................................................................................................... 3

OPERATING PROCEDURES .................................................................................................... 4-8

MAINTENANCE ....................................................................................................................... 9-10

TROUBLE SHOOTING ................................................................................................................11

VERSAPLOW ASSEMBLY ..................................................................................................... 12-15

SPECIFICATIONS ....................................................................................................................... 16

WIRING DIAGRAM ..................................................................................................................... 17

HYDRAULIC DIAGRAMS ............................................................................................................ 18

ELECTRICAL PIN LAYOUT ........................................................................................................ 19

WARRANTY ................................................................................................................................ 21

2 To The Purchaser

TO THE PURCHASER

This product is designed and manufactured to

give years of dependable service when properly

maintained and used for the purpose for which

it is intended. Never allow anyone to operate

this equipment until they fully understand the

complete contents of this manual. It is the

responsibility of owners who do not operate this

equipment to ensure the operator is properly

instructed and understands the contents of this

manual. It is also the owner’s responsibility to

ensure that anyone operating this equipment is

mentally and physically capable of so doing.

Important information is contained in this

manual to help ensure safe and efficient

operation.

If you have any questions about this manual, or

the equipment discussed herein, contact your

snowplow dealer.

TAKE NOTE! THIS SAFETY ALERT

SYMBOL FOUND THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR

ATTENTION TO INSTRUCTIONS INVOLVING

YOUR PERSONAL SAFETY AND THE SAFETY

OF OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR

DEATH.

All references to Left or Right are defined as

viewing the plow from the cab of the machine.

This Operator’s Manual is shipped with this

equipment. Contact your dealer for additional

copies.

Always obtain original factory service parts.

Substitute parts could adversely affect

equipment performance and warranty.

Check that your dealer has forwarded the delivery

report form along with the plow identification

number because it helps maintain maximum

service and warranty benefits. This does not put

you on any mailing list, and information thereon

is not available to others.

Your plow’s identification number plate is at

location (1) in the following illustration.

THIS SYMBOL MEANS:

- ATTENTION!

- BECOME ALERT!

- YOUR SAFETY IS INVOLVED!

SAFETY SIGNAL WORDS:

DANGER: Indicates an imminently hazardous

situation that, if not avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous

situation that, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation that, if not avoided, may result in minor or

moderate injury, or damage to components.

NOTE: Addresses safety practices not related to

personal safety.

DWG NO. 7602

Record the following information for later

reference when obtaining service parts:

Purchase Date

Purchaser’s Name

Dealer’s Name

Machine I.D. No.

SAFETY

Safety 3

This is a safety alert symbol. It alerts

an operator to information concerning

personal safety. Always observe

and heed these symbols and instructions,

otherwise death or serious injury can result.

Operator safety is a principle concern in

equipment design and distribution. However,

many accidents occur because a few seconds

of thought, and a more careful approach

to handling, were ignored. Accidents can

be avoided by knowing and following the

precautions cited in this manual.

GENERAL SAFETY

1. Read this manual thoroughly. Make sure

the operator understands it and knows

how to operate this equipment safely. This

equipment can kill or injure an untrained or

careless operator and bystanders. If you

sell this equipment, ensure the new owner

acknowledges receipt of this manual.

BEFORE OPERATION

1. Discipline yourself to visually check for

worn, damaged or cracked parts before

starting use. Replace these with genuine

factory service parts.

2. Escaping hydraulic oil under pressure can

penetrate the skin, causing serious injury.

Do not use your hand to check for leaks.

Use a piece of paper or cardboard to ! nd

suspected leaks. Tighten all connections

before pressurizing hydraulic lines. If " uid is

injected into the skin, get medical attention

immediately to prevent serious infection.

3. Check all controls and operating functions

of the machine in a safe area before starting

to work.

DURING OPERATION

2. This manual Does Not instruct the operation

or maintenance of the skid steer loader.

Obtain training on control and function

of the skid steer loader from your loader

dealer.

3. This plow is intended for plowing snow

only. Plowing gravel, rocks, etc., or using

the plow for any purpose other than plowing

snow could result in harm to the operator

or bystanders or cause damage to the plow

and will void the warranty.

4. Do not attempt to handle or service this

equipment, or direct others to do the same,

unless you know how to do it safely and

have the proper tools for the job.

5. Do not service or otherwise handle a plow

in the raised position unless it is securely

blocked against unexpected falling.

6. Keep hands, feet, hair, and clothing away

from moving parts.

1. Always wear the seat belt and lower the

seat bar, if equipped, when operating the

loader.

2. Make sure all controls are in the neutral

position before starting the loader.

3. Ensure everyone is clear of the machine,

especially away from blind areas of the

operator, before actuating hydraulics or

operating this equipment.

4. Do not plow snow at excessively high

speeds.

5. Avoid hitting objects that will damage your

plow.

6. Set the brakes and stop the loader’s engine

before adjusting or servicing your plow.

AFTER OPERATION

7. Do not alter the equipment to the extent of

compromising safety or performance.

1. Park the plow on a solid, level surface.

4 Operating Procedures

OPERATING PROCEDURES

IMPORTANT: To prevent damage to

snowplow components, skid steer

loaders with a “High Flow/Low Flow”

hydraulic system must be operated in the

Low Flow setting when the plow is attached.

ATTACHING PLOW

Mount the plow on the skid steer loader by

driving the loader into the mount frame, then

set the brakes and relieve hydraulic pressure

before exiting the cab. Secure the plow frame

to the loader as instructed in the loader

manual. Make sure all latches are fully locked

in place to prevent the plow from detaching.

Clean quick couplers of dirt before making

hydraulic connections. Make sure quick

couplers are fully engaged. If quick couplers

do not fully engage, check that the couplers

are the same size and type. Check also to see

that hydraulic pressure has been relieved.

See your loader or attachment dealer for

coupler information.

When using a 7 or 14 pin harness that operates

the plow through the base machines internal

controls operators need to push and hold the

joystick button speci! c to each manufacturer

which will activate a solenoid valve.

Rotate the box ends (forward or backward) by

pushing and holding the appropriate joystick

button speci! c to each machine while directing

oil through the auxiliary ports. Reverse rotation

by pushing and holding the appropriate joystick

button speci! c to each machine while reversing

the oil " ow direction through the auxiliary ports.

Clean electrical connections then check that

the pins and receptacles are aligned before

plugging the connector on the plow into the

connector on the loader.

Test the angling and rotating box end functions

in a safe area before using the plow.

CONTROLLING PLOW FUNCTIONS

Raise and lower the plow by operating the

loader arms as you would for any other

attachment. Avoid tipping the mount plate

forward to apply down pressure on the plow.

Angle the plow left and right by directing oil

through the auxiliary hydraulic ports on the

skid steer loader. Reverse oil flow to angle

the blade the opposite direction.

Release the hydraulic flow controller to hold

the blade at an angle position between full

left or full right. If the plow angles opposite

from what is expected, switch couplers on the

two feed hoses that connect to the loader.

DWG NO. 7603

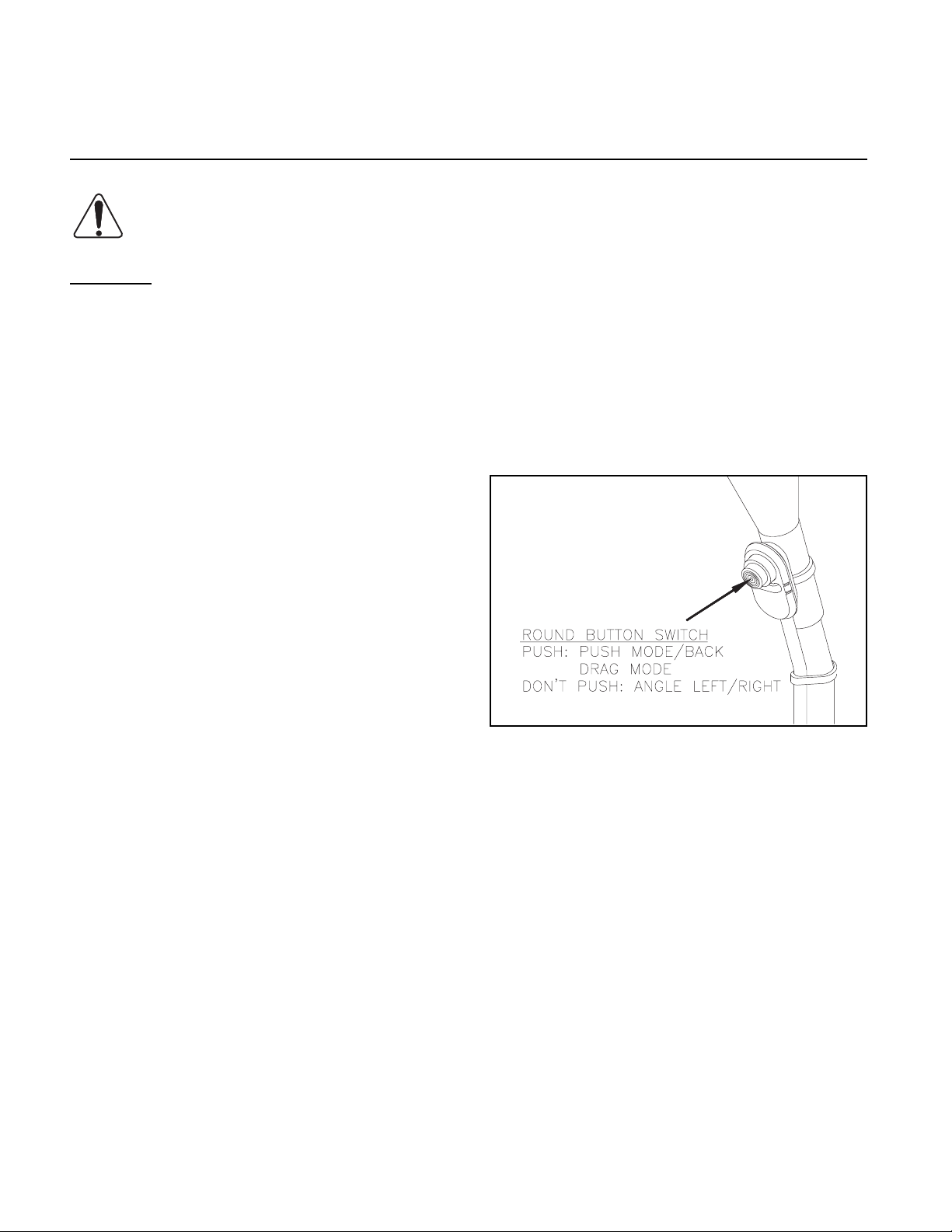

When using a Fox universal controller rotate

box ends rearward by pushing and holding the

round button switch while directing oil to the

auxiliary ports on the skid steer loader putting

the plow in back drag mode.

Rotate box ends forward by pushing and holding

the round button switch while reversing the oil

flow direction to the auxiliary hydraulic ports on

the loader to put plow in push mode.

To hold box ends at an intermediate position

between full forward or full back, release

hydraulic flow controller, then release round

button switch.

Box ends will move more freely if rotating box

end functions are done with plow in raised

position to avoid resistance from ground.

TRANSPORTING PLOW

Raise plow to a position where it does not block

your view forward. Transport plow with hydraulic

flow off or in neutral to prevent accidental

lowering of plow. Never adjust blade position

while driving.

PLOWING SNOW

WARNING: Always wear seat belt

and lower seat bar, if equipped, when

plowing snow. Sudden contact with a

hidden object can result in serious personal

injury.

Inspect areas to be plowed before snowfall for

potential hazards, and mark obstructions with

stakes that will be seen when snow covers the

ground. Identify any emergency equipment and

utility outlets that may need to be cleared in the

event of a storm. Prepare a plan beforehand for

clearing snow from tight or enclosed areas and

locate sites for stacking snow.

Operating Procedures 5

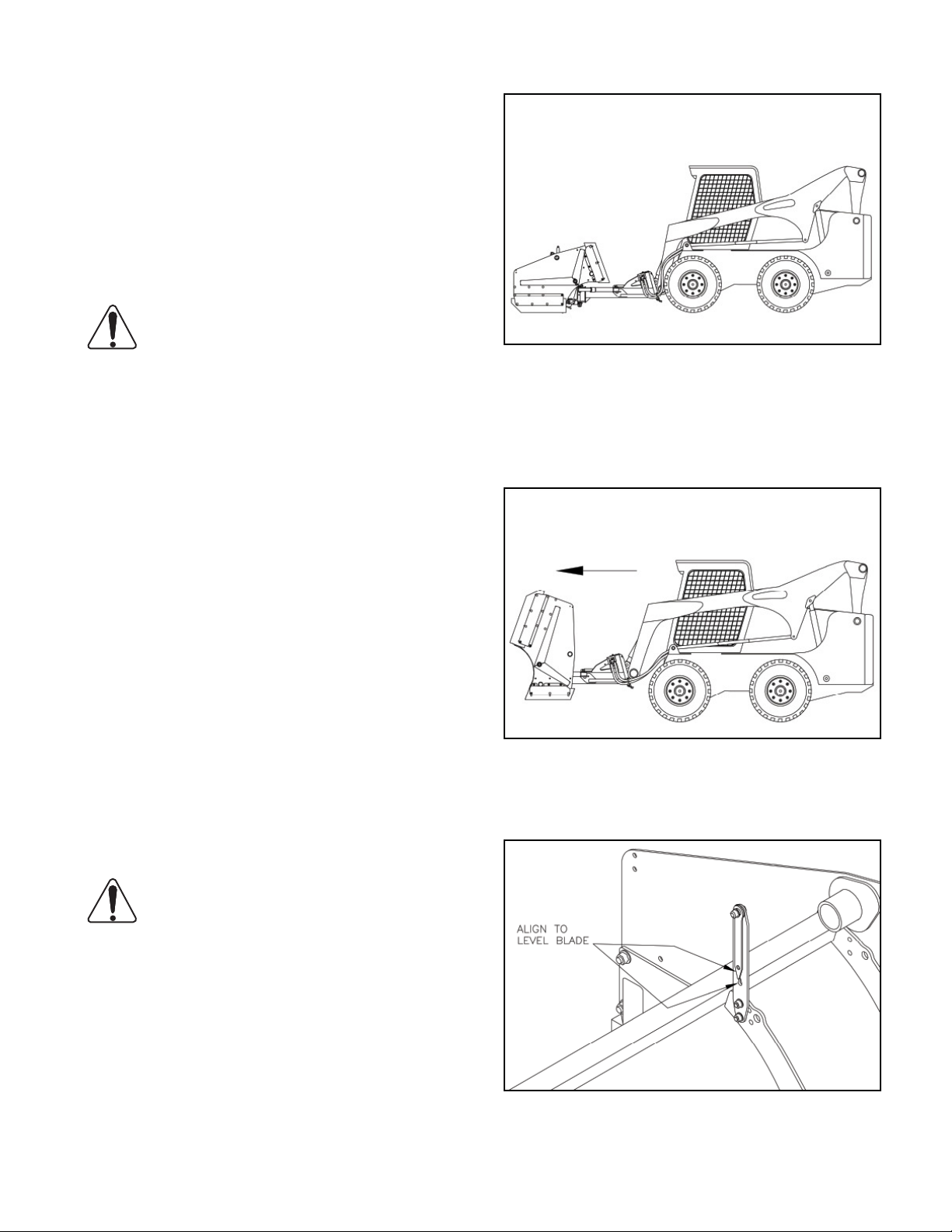

DWG NO. 7742

To back drag snow away from a parking stall or

building, lift plow up off of ground and straighten

plow across loader. Rotate box ends all the way

rearward.

Set the loader lift arms into the float mode so

the plow can follow the contour of the ground

and clean up low areas while plowing snow.

Always plow snow as it is accumulating. Wet

snow may weigh about 12 pounds per cubic

foot. The weight of snow being pushed by your

plow may increase to several tons.

Allowing snow depth to grow to unmanageable

levels can cause difficult removal problems and

can be costly in terms of wear on equipment.

WARNING: Serious personal injury

can result from plowing at excessive

speeds, as well as costly damage to

equipment and property, if an obstruction is

encountered while plowing. Do not exceed

10 mph while plowing.

DWG NO. 7743

Slowly drive into area to be cleaned out lower

cutting edge to ground.

DWG NO. 7744

Tilt plow blade to align level indicators.

6 Operating Procedures

DWG NO. 7745

Slowly back drag snow away from parking stall

or building to an open area.

DWG NO. 7742

After back dragging successive passes to

accumulate a pile of snow. Rotate box ends all

the way forward. Verify leveling bars are plumb

and adjust loader mount plate angle as needed.

Push and stack snow in a clear area away from

the path of vehicle travel.

DWG NO. 7608

Clear large lots by angling blade and creating a

single path. Push snow to outer edges of lot by

taking successive passes with blade angled.

DWG NO. 7747

Plow box ends can be rotated slightly rearward

allowing operator to clean curbs easier in plow

angled position. Rotate sides so lowest point

is higher than curb. Partially rotated sides

also help contain large amounts of snow while

windrowing large parking lots.

When plowing very deep snow, it may be

necessary to raise blade and shear off layers

of snow until a working area is cleared. Work

small areas in multiple passes to push snow to

outer edges.

Generally, 6 inch snow accumulation can be

plowed with the entire blade width; 9 inch snow

accumulation with 3/4 of the blade width; 12

inch snow accumulation with 1/2 of the blade

width. Local conditions will determine how much

work can be done before stalling or losing tire

traction.

HITCH OPTIONS

There are (2) hitch options for the VersaPlow,

fixed and floating.

DWG NO. 7748

The fixed hitch is recommended for rear wheel

and (4) wheel drive vehicles including skid

steers, Toolcats, etc.

Operating Procedures 7

DWG NO. 7750

This hitch is recommended for front wheel drive

and some 4 wheel drive vehicles where slight

down pressure on plow can cause operators to

have a difficult time steering and getting traction

during snowplowing. Another advantage is

cutting edges last longer with reduced down

pressure on them.

DWG NO. 7749

The other option is a floating hitch which has a

floating upper link to allow the plow to ride on

the contour of the ground. This option makes it

more difficult to put down pressure on plow.

8 Operating Procedures

ADJUSTING OUTER CUTTING EDGES

Periodically after finishing snowplowing check

height of box end urethane cutting edges in

both push and back drag mode with respect to

main cutting edge. It is recommended to have

the box end cutting edges 1/4” higher than the

main cutting edge. If the box end edges are

higher than 1/4” off the ground or are lifting the

main cutting edge off the ground, the box end or

main cutting edges need to be adjusted.

REMOVING PLOW

Park the plow on a solid level surface with the

blade straight across the loader.

Lower the blade to the ground, relieve hydraulic

pressure and set the brakes on the loader.

Uncouple the hydraulic feed lines from the

loader and unplug the electrical connector.

Replace any dust caps at this time.

Unlatch the attachment mechanism at the front

of the loader then slowly drive the loader back

away from the plow.

DWG NO. 7746

Using a 1/4” thick block of wood or other

shimming material, loosen box end cutting edge

bolts and raise plow slightly if necessary, and

insert 1/4” shim blocks under box end urethane

cutting edges. Lower main plow cutting edge to

the ground, with plow edge on ground and 1/4”

shims under box wing cutting edges.

Tighten 1/2” carriage bolts until metal on outside

plates slightly deforms into slots of cutting

edges. This will prevent cutting edges from

sliding up or down during operation.

Perform similar procedure to check back drag

cutting edge heights. Adjust as needed and

again tighten hardware so outside plates slightly

deform to hold urethane cutting edge in place.

Maintenance 9

Section 9

MAINTENANCE

WARNING: Do not service or otherwise

handle a plow in the raised position

unless it is securely blocked against

unexpected falling.

Dependable snowplow operation is the result of

following good maintenance procedures. Inspect

your plow frequently to ensure that all parts are

working smoothly, and develop a schedule for

maintenance at required intervals.

GENERAL

Wash salt and dirt off the plow before storage.

Do not power wash hydraulic cylinders, as high

pressure can damage seals and cause cylinder

failure. Touch-up any chips or scratches in the paint

and apply a light coating of grease to extended

cylinder rods to prevent corrosion.

MECHANICAL COMPONENTS

TITLE

GRADE 5 TYPE B & F LOCK NUT TORQUES

Size Ft-lbs. N-m

5/16” 13-18 17-25

3/8” 23-33 31-44

1/2” 58-82 79-112

5/8” 117-165 158-223

GRADE 5 BOLT TORQUES*

Size Ft-lbs. N-m

1/4” 8-12 11-16

3/8” 29-41 39-56

1/2” 73-103 99-140

5/8” 146-206 198-279

*Applications without lock nuts.

Loose bolts can cause hole elongation and

part failure resulting in dangerous operating

conditions and equipment breakdown.

Prior to the operation of a new snowplow, or

one which has been stored, inspect all hardware

and verify proper torque on all bolts and nuts

in accordance with the recommended torque

speci! cations.

Check all hardware periodically during operation

and keep tightened to speci! ed torques. Replace

worn bolts and lock nuts with grade 5 bolts and

equivalent type B or type F lock nuts. Type B

lock nuts are plain hex; type F lock nuts are

" anged hex.

Inspect wear of cutting edges before every

plowing season and frequently throughout the

season. Adjust or replace cutting edges before

wear reaches the main plow blade.

10 Maintenance

ELECTRICAL MAINTENANCE

Periodically check all electrical connections for

proper • t and remove any contamination, that

may be present.

To prevent contamination, always place dust caps

on connectors when not in use. This is particularly

important when the plow is being stored. The

use of dielectric grease is recommended to

reduce corrosion of the contacts and to make

connecting and disconnecting easier.

Before each season check loader battery and

electrical system for proper operation. A weak

battery, dirty terminals, or faulty charging system

may cause improper operation.

LUBRICATION

Periodically throughout the year between

snowfalls, grease all pivot points on plow as

shown in diagrams. Look for grease decals to

help with zerk locations.

DWG NO. 7751

DWG NO. 7752

Trouble Shooting 11

Section 11

TROUBLE SHOOTING

GENERAL

1. Check to see that the plow and loader are

wired correctly with clean, tight connections

at the battery. Check for proper voltage.

2. Check that hydraulic quick couplers are

fully engaged and electrical connection is

tight at the front of the loader.

PROBLEM

1. Hydraulic cylinder does

not function or functions

slowly when hydraulics are

activated.

A. Weak or defective loader

B. Oil level low.

C. Hydraulic connection leak.

D. Solenoid valve not opening

TITLE

POSSIBLE CAUSE

battery.

properly.

3. Check the hydraulic oil level in the skid

steer loader.

4. Check for external leakage at cylinders,

hoses and valve manifold.

REMEDY

A. Charge or replace battery.

B. Add oil (do not over! ll).

C. Tighten or redo connection.

D. Replace valve.

2. Plow angles opposite

expected direction.

3. Oil leaks from cylinder(s).

4. Angling cylinders relieve

too easily or too dif! cultly

while plowing.

5. Plow does not clean-up

snow from low areas.

6. Battery goes dead with

power on the loader.

7. Hydraulic quick couplers

don’t connect.

A. Feed hoses reversed.

A. Loose packing.

B. Defective cylinder.

A. Relief pressure set too low

or too high.

A. Loader arms not in " oat

mode.

A. Short in wiring.

A. Wrong size or type of

couplers.

A. Switch quick couplers on

feed hoses.

A. Tighten packing nut 1/8

turn.

B. Repack or replace cylinder.

A. Have relief pressure

adjusted by skidsteer

dealer.

A. Loader arms should be in

" oat mode.

A Locate and repair.

A. Verify matching couplers.

B. Oil pressure in loader lines.

B. Relieve hydraulic pressure

in loader.

12 VersaPlow Assembly

12 Section

VERSAPLOW ASSEMBLY

GENERAL INFORMATION

WARNING: To prevent personal injury

or death, be certain to keep clear of any

parts that may drop when removing

bundling straps, wires or brackets. Support

heavy sections with hoist or blocks before

removing wires or straps.

Be certain that hydraulic hoses and electrical

wires are safely routed and allow full motion of

moving parts. Secure loose hoses and wires

with plastic tie straps.

PLOW ASSEMBLY

1. Lift moldboard assembly by hooking to

inner ribs and bring to a clear level area.

TITLE

Insert main pivot pin so formed lip is pointing

rearward. Slide the washer onto the bottom

of the pin, then secure the assembly with

the slotted nut and cotter pin. Tighten the

nut so the assembly is secure, but pivots

freely.

DWG NO. 7753

2. Remove shipping brackets and shipping

stop brackets from outside ribs if supplied

with moldboard assembly.

3. Stabilize moldboard assembly using blocks

or secure on lifting mechamism. Move the

hitch frame to the back of the moldboard

and align pivot pin bushings.

DWG NO. 7754

Pin rod ends between lugs on the moldboard

with 3/4 inch x 3 1/4 inch clevis pin and

cotter pins from the parts box.

4. Install two straight hydraulic adapters from

the parts box into both ports of the rollover

cylinder.

DWG NO. 7755

Tighten two 90° Flare/Swivel nut adapter

onto straight ! tings, directed as shown.

5. When installing a Versa Plow with the

ocillating/fl oating hitch option on a loader

with with taller snow tires, remove and

reinstall two rear push frame bolts through

the upper set of holes to allow more

downward travel of the blade.

Floating Hitch Height Adjustment DWG NO. 7756

VersaPlow Assembly 13

Oscillating Hitch Hose Routing DWG NO. 7758

Tie hoses together and route along the

frame, as shown. Ensure hoses have

adequate length for cylinder extension/

retraction, and will not be pinched in rotating

stop plates before securing to the frame

with plastic tie straps.

6. Refer to the appropriate drawing below

for hose routing along the different hitch

frames.

Fixed Hitch Hose Routing DWG NO. 7757

Route hydraulic supply and return hoses

through U-Bolts on the mount plate up to

couplers on the loader. Tie hoses where

they will not drag on the ground or get

caught in loader tires.

7. Assemble hose ends to rollover cylinder as

follows:

- Port C3 to rotation cylinder rod end.

- Port C4 to rotation cylinder fi xed end.

DWG NO. 6694

Refer to labels on hose ends to ensure

hoses are connected correctly.

14 VersaPlow Assembly

8. Attach two leveling bars onto the ribs using

provided 5/16 hardware.

DWG NO. 7759

Verify top bar rotates freely on bushing after assembly.

QUICK COUPLERS

IMPORTANT: Damage to the wiring

harness will occur if adequate cable

length is not provided to allow for

full motion of the loader arms. Use plastic

tie straps to secure the wiring harness to

the loader arm immediately adjacent to the

loader arm pivot point.

Refer to drawing number 7627. Fasten the

square connector next to the hydraulic quick

couplers. Route the cable along the skid-steer

arm to the pivot point of the arm and secure with

the supplied plastic tie straps. It is especially

important to leave adequate cable at the pivot

point to allow for arm movement.

Next, the switch cable needs to be routed into

the cab. Attach the switch to the control arm

using a plastic tie strap as shown in drawing

number 4284.

Select and install hydraulic quick couplers

and adapter ! ttings on VersaPlow feed lines

according to the size and type (i.e. " at face or

poppet style) of couplers on customers machine.

Hoses supplied on VersaPlow have 9/16-18

JIC female swivel ends for 9/16-18 JIC male

adapters.

UNIVERSAL CONTROLLER

ELECTRICAL WIRING

Identify the electrical control cable purchased

with the snowplow. It has a square 4-pin

weather pack connector on the ! rst end, two ring

terminals on the second end, and a single push

button switch on the third end.

DWG NO. 4284

Route the third length of the cable to the battery.

Connect the red fused wire ring terminal to the

positive post of the battery and the black wire

ring terminal to the negative post of the battery.

Ensure all wires are away from hot or moving

parts, and secured with plastic ties to prevent

damage.

DWG NO. 7627

The wiring on the plow comes preinstalled. The

connectors to the solenoids should be ! rmly

seated. The connectors are interchangeable, as

both solenoids are activated at the same time

when the push button switch is pressed.

VersaPlow Assembly 15

Refer to Operating Procedures section for

attaching and operating the plow. Test that all

functions are working properly and that cabling

is not being stretched or pinched.

14 PIN OR 7 PIN ELECTRICAL HARNESS

Locate 7 or 14 pin wiring harness purchased with

plow. Insert 4 pin plug into mating connection

from plow. Electrical wiring from plow is inside

sleeve of hydraulic hose, and connector is

located near hydraulic couplers from plow. Insert

14 or 7 pin connectors into machines mating

connector.

ADJUSTING OUTER CUTTING EDGES

Check height of box end urethane cutting edges

in both push and back drag mode with respect

to main cutting edge. Box end cutting edges

should be 1/4” higher than the main cutting

edge. If the box end edges are more than 1/4”

off the ground or are lower than the main cutting

edge adjust the cutting edges, as follows.

DWG NO. 7629

Refer to loader operator’s manual for list of

functions on proper attachment control.

In some cases 14 pin plug layout needs to be

modi! ed for speci! c machines. Refer to table on

page 19 for pin layout.

If pin layout needs to be modi! ed refer to

instruction sheet with 14 pin harness for

instructions to change pin layout. Refer to

loaders wiring diagram on pin layout.

DWG NO. 7746

Using a 1/4” thick block of wood or other

shimming material, loosen box end cutting edge

bolts and raise plow slightly if necessary, then

insert 1/4” shim blocks under box end urethane

cutting edges. Lower main plow cutting edge to

the ground, with plow edge on ground and 1/4”

shims under box wing cutting edges.

Tighten 1/2” carriage bolts until metal on outside

plates slightly deforms into slots of cutting

edges. This will prevent cutting edges from

sliding up or down during operation.

Perform similar procedure to check back drag

cutting edge heights. Adjust as needed and

again tighten hardware so outside plates slightly

deform to hold urethane cutting edge in place.

16 Section

16 Specifications

SPECIFICATIONS

Models 4108 4208 4110 4210

Blade Width 8’ 8’ 10’ 10’

Overall Width 8’ 8” 8’ 8” 10’ 8” 10’ 8”

Blade Height 30 1/2” 30 1/2” 30 1/2” 30 1/2”

Weight

(Moldboard & Wings Only)

Weight

Fixed Hitch

807 lbs. 938 lbs. 911 lbs. 1,075 lbs.

TITLE

311 lbs.

Weight

Floating Hitch

Cutting Edge

Feed Hose Ends 9/16-18 JIC Female Swivel

Wiring Harness Fuse 10 AMP

1 1/2” x 8”

Polyurethane

1/2” x 6”

Steel

474 lbs.

1 1/2” x 8”

Polyurethane

1/2” x 6”

Steel

Wiring Diagram 17

Section 17

UNIVERSAL CONTROLLER WIRING DIAGRAM

TITLE

DWG NO. 4286

18 Hydraulic Diagrams

DWG NO. 7618

Electrical Pin Layout 19

Skid Steer Electronic Pin Layout

Pin A B C D

Bobcat 14 Pin LH L/R (-) Gnd LH Center L LH Center R

Case 14 Pin N/A (-) Gnd Button 2 LH Handle Dn Button 2 LH Handle Up

Cat 14 Pin LH Trigger Aux 7 (-) Gnd C-Control Aux 5 C+ Control - Aux 6

JCB/Volvo 14 Pin N/A (-) Gnd C-SW FWD C-SW BWD

John Deere (-) Gnd N/A Right Down Left Down

Kubota 14 Pin

SVL75/90/95 Standard

Kubota Extended 14 Pin

Add-On Kit

New - NH 14 Pin N/A (-) Gnd LH #3 - Dn LH #3 - Up

Old - NH 14 Pin N/A (-) Gnd SW3 MOM Dn SW MOM Up

Takeuchi N/A (-) Gnd SW1 Up R Joy/L Up SW 1 Dn R Joy/L Down

Yanmer N/A (-) Gnd SW1 Up SW 1 Dn

Mustang N/A (-) Gnd SW1 Up SW 1 Dn

Gehl SW 4 (-) Gnd SW1 Up SW 1 Dn

Terex (-) Gnd LH-SW Dn LH - Right LH - Left

Wacker 14 Pin N/A (-) Gnd LH Center L LH Center R

N/A (-) Gnd LH Switch RH Switch

N/A (-) Gnd Button #1 Button #2

20 Notes

NOTES:

Warranty 21

HINIKER WARRANTY

SKID STEER SNOWPLOW LIMITED WARRANTY

The only warranty Hiniker gives and the only warranty that any Hiniker dealer is authorized to give on behalf

of Hiniker is as follows: (NO EMPLOYEE OR REPRESENTATIVE IS AUTHORIZED TO CHANGE THIS

WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY.)

Hiniker warrants to the original purchaser of a Hiniker snowplow that Hiniker will repair or replace any

defects in material and workmanship that occur within one year from date of retail delivery.

Hiniker’s obligation and liability under this warranty is expressly limited to repairing or replacing, at Hiniker’s

option, at an authorized Hiniker dealer location, the defective parts at no charge to the original purchase.

Hiniker MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED AND MAKES NO WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR ANY PARTICULAR PURPOSE.

HINIKER’S OBLIGATION UNDER THIS WARRANTY SHALL NOT INCLUDE ANY TRANSPORTATION

CHARGES TO OR FROM THE AUTHORIZED HINIKER DEALER LOCATION OR ANY LIABILITY FOR

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGE OR DAMAGES OF ANY KIND FOR LOST

PROFITS OR DELAY. If requested by Hiniker, products or parts for which a warranty claim is made are to

be returned freight prepaid to our factory. Any improper use, operation beyond rated capacity, substitution

of parts not approved by Hiniker, or any alteration or repair in such manner as in our judgment affects the

product materially and adversely shall void this warranty.

Hiniker reserves the right to make improvements or changes to any of it’s products without notice. Such

improvements or changes shall not trigger any obligation by Hiniker to update, modify or change any

products previously sold by Hiniker.

Hiniker does not warrant the following:

1. Used products.

2. Any product that has been repaired, modi! ed or altered in a way not approved by Hiniker.

3. Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure

to follow Operators Manual Instructions, misuse, lack of proper protection during storage, or accident.

4. Parts replacement and service necessitated by normal wear or maintenance including, but not

limited to, cutting edges, hoses, and hardware.

5. Paint ! nish damage caused by normal wear.

Hiniker does not assume any liability for any damage to a vehicle resulting from the attachment or use of a

Hiniker snowplow. Attachment of a Hiniker snowplow to a vehicle is at the risk of the purchaser.

It is the responsibility of the original snowplow purchaser to verify the original date of purchase.

A DELIVERY REPORT FORM must be ! lled out and received by Hiniker with 30 days of retail delivery at

the address below to initiate the warranty coverage.

HINIKER COMPANY

58766 240th St.

MANKATO, MN 56002

PHONE (507) 625-6621 -- FAX (507) 625-5883

www.hiniker.com

Loading...

Loading...